Patents

Literature

42results about How to "Any shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

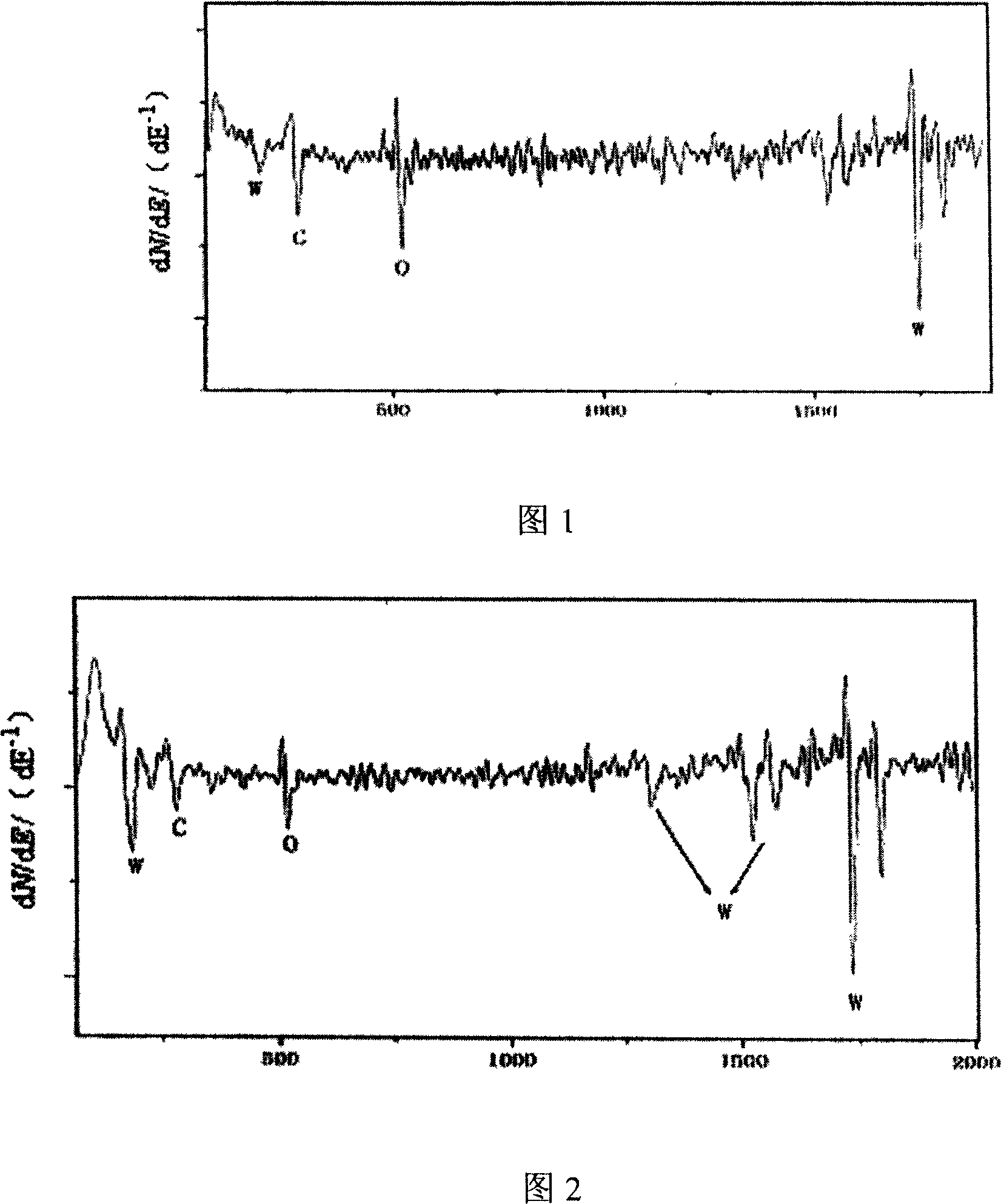

Process for preparing high-purity compact profile tungsten products

InactiveCN1962935AHigh purityHigh densityChemical vapor deposition coatingPowder metallurgyThin walled

The invention discloses a preparing method of high-purity compact tungsten product in the difficult dissolving manufacturing domain, which is characterized by the following: adopting copper to make the emulating bulk of tungsten product; cleaning the copper emulating bulk through organic solvent; drying to place in the reacting chamber; adopting WF6 and high-purity H2 as sediment reacting gas; sedimenting under normal pressure at 400-800 Deg C; setting the allocating rate of reacting gas at 1-5g / min WF6 corresponding to 1L / min H2; controlling the sedimenting speed V about 0.5-2mm / h; closing gas after sedimenting; aerating H2 continuously to cool to indoor temperature; fetching; cutting; polishing; dissolving through nitrate or heating to fuse the allotype emulating bulk.

Owner:BEIJING UNIV OF TECH

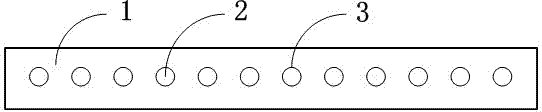

Aluminum substrate used for packaging LED (Light Emitting Diode)

InactiveCN102779922AHigh temperature resistantImprove adhesionSemiconductor devicesEpoxyAluminum substrate

The invention relates to an aluminum substrate used for packaging an LED (Light Emitting Diode). The aluminum substrate comprises a common aluminium plate and a mirror plane plate which are laminated under high temperature. Through holes used for mounting LEDs are evenly arranged on the common aluminium plate which comprises, from top to bottom, a line layer, an insulated layer and a substrate. The insulated layer is made of epoxy resin, and alumina, carborundum, silicon dioxide and aluminum nitride which are nanoscale additives; the average particle size of the nanoscale additives is 40nm; and the purity of the nanoscale additives is above 99%. By adopting the aluminum substrate, a single chip or a plurality of chips can be packaged without being notched or polished and the substrate can be in any shape. The aluminum substrate has a flexible structure in application, is simple and practical, good in heat dissipation, simplified in process and high in light emitting efficiency.

Owner:HANGZHOU DIANZI UNIV

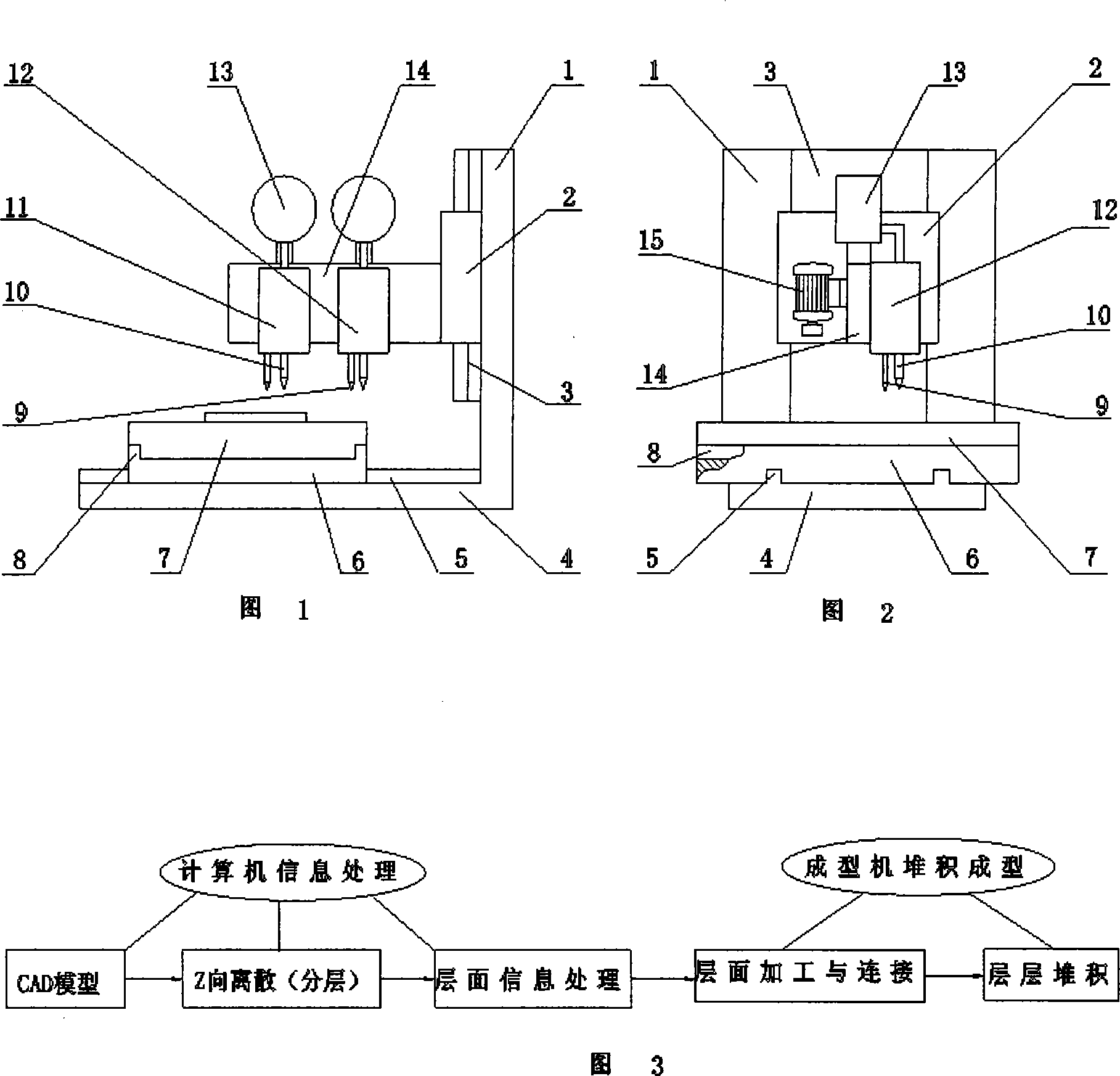

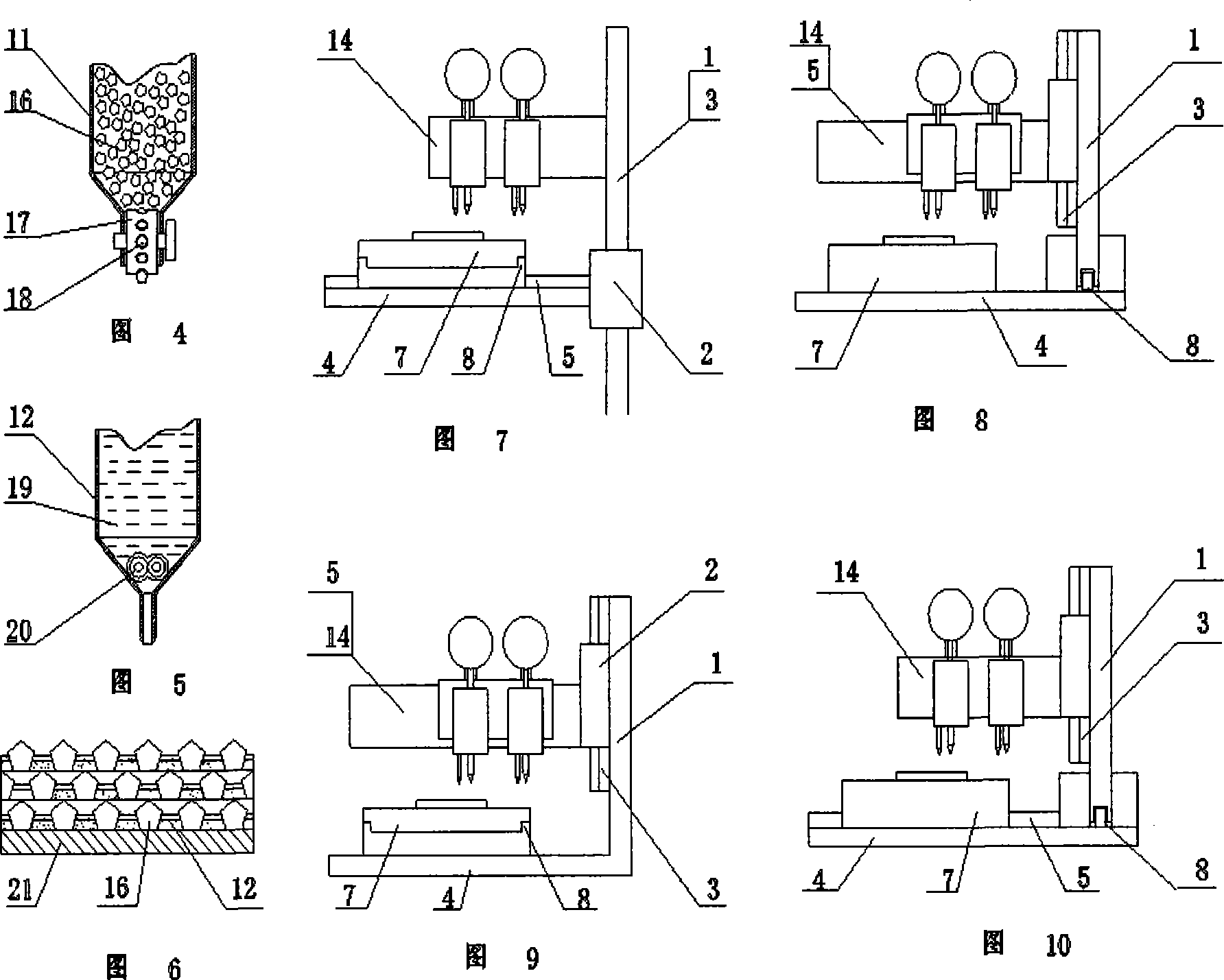

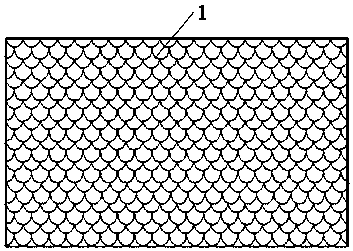

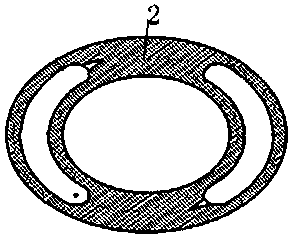

Digital control manufacturing device for abrasive wheel

InactiveCN101186031AAccurate locationHigh technical contentGrinding devicesMechanical equipmentDigital manufacturing

The invention relates to a mechanical equipment, namely a grinding wheel layered digital manufacturing device. The invention is characterized in that the device consists of a mechanical part and a computer control part. The mechanical part consists of a platform 7 used for bearing a work piece, an operation part and a slide way used for movement of the platform 7 or the operation part, etc. The operation part comprises a raw material box used for feeding raw materials to the platform 7 and a laser generator 13 used for sintering and forming the raw materials. When in work, various technical parameters are transmitted into the computer control system ahead, and then under the control of a computer program, the grinding wheel raw materials are layered and put on the platform and are sintered into shape by a laser. The granule position of the grinding material of the grinding wheel manufactured by the device is accurate, and the protruding height can be controlled. The scraps-containing room is proper and the solidified strength is enough, and the later finishing can be avoided and the shape can be randomly selected. The manufacturing cost is low and the service life is long. The grinding heat loss can be largely reduced by the device and the device can meet high processing accuracy and high manufacturing efficiency requirement. The invention provides suitable equipment for realizing the digital manufacturing of the grinding wheel.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Cotton straw-enhanced plastic-wood product and preparation method thereof

The invention provides a cotton straw-enhanced plastic-wood product which comprises the following components: 30-50 parts of short fiber wood materials, 10-30 parts of cotton straw long fibers, 25-45 parts of waste recycled plastics, 1-4 parts of lubricants, 0.2-1 parts of stabilizers, 1-2 parts of coupling agents, and 1-5 parts of other additives, wherein the other additives comprises one or more than one of an ultraviolet absorber, an antioxidant, a flame retardant, a colorant, and a compatilizer. The preparation method of the cotton straw-enhanced plastic-wood product comprises the following steps of: short fiber wood material treatment, cotton straw long fiber preparation and treatment, material mixing, granulation, and extrusion molding. The method enhances the mechanical properties of the plastic-wood product by reasonably preparing the cotton straw long fibers, and adding the cotton straw long fibers into the plastic-wood product. The plastic-wood product of the invention is green and environment-friendly, has no limitation of shape, and has wide applications and low cost.

Owner:湖南格林美资源利用有限公司 +1

Composite function liquid wound dressing and its use

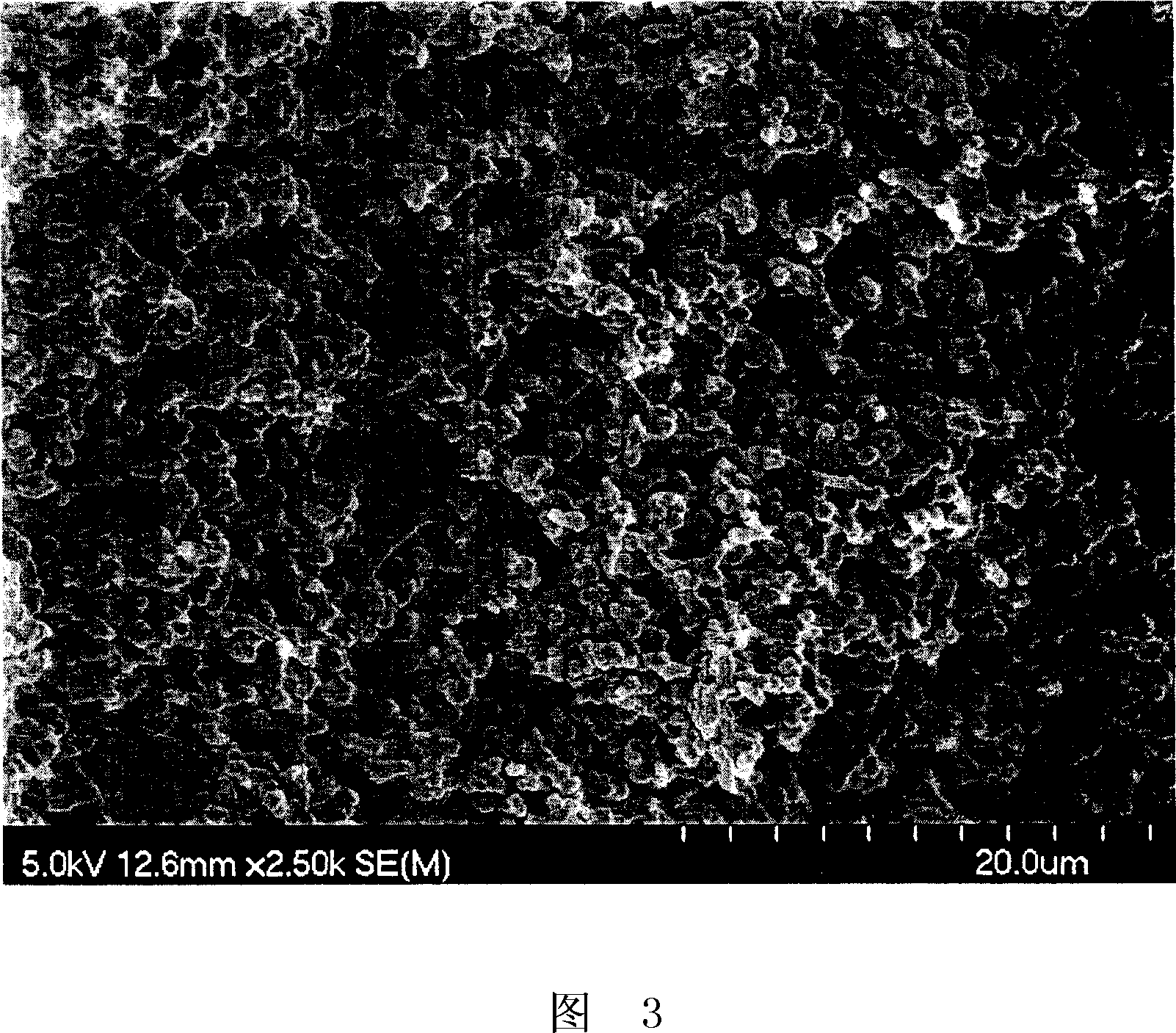

A multifunctional liquid dressing for cleaning wound, fast haemostasis and filing, preventing infection and promoting healing is a liquid sol composed of the superfine inorganic superfine particles (0.01-20%) and the liquid medium (80-99.9%) consisting of water and disinfectant.

Owner:邢宪生

3D printing and manufacturing method for surface microstructure of friction pair

ActiveCN107931605AIncreasing the thicknessImprove wear resistanceAdditive manufacturing apparatusIncreasing energy efficiencyNumerical controlEngineering

The invention provides a 3D printing and manufacturing method for a surface microstructure of a friction pair. The method comprises the steps of treating the surface of the friction pair of a elementto be machined by using a computer numerical control (CNC) grinding machine, and drawing a 3D model of the surface microstructure of the required friction pair through computer 3D CAD software; makingapproximate treatment to the 3D model from a small triangle to obtain an approximate model; dividing the approximate model into sheets of a series of thicknesses in the height direction, and extracting and processing contour information to generate CNC programs; then, inputting the CNC programs into a manipulator control device, and fixing the element to be machined to a workbench through a clamping device; and applying metal powder to the surface of the element to be machined for a certain thickness, and driving a laser device by the manipulator control device for performing laser sinteringfor the element to be machined according to a predetermined path, so that the surface microstructure of the required friction pair is formed, and the abrasion resistance and friction resistance of thefriction surface are improved effectively.

Owner:TAIYUAN UNIV OF TECH

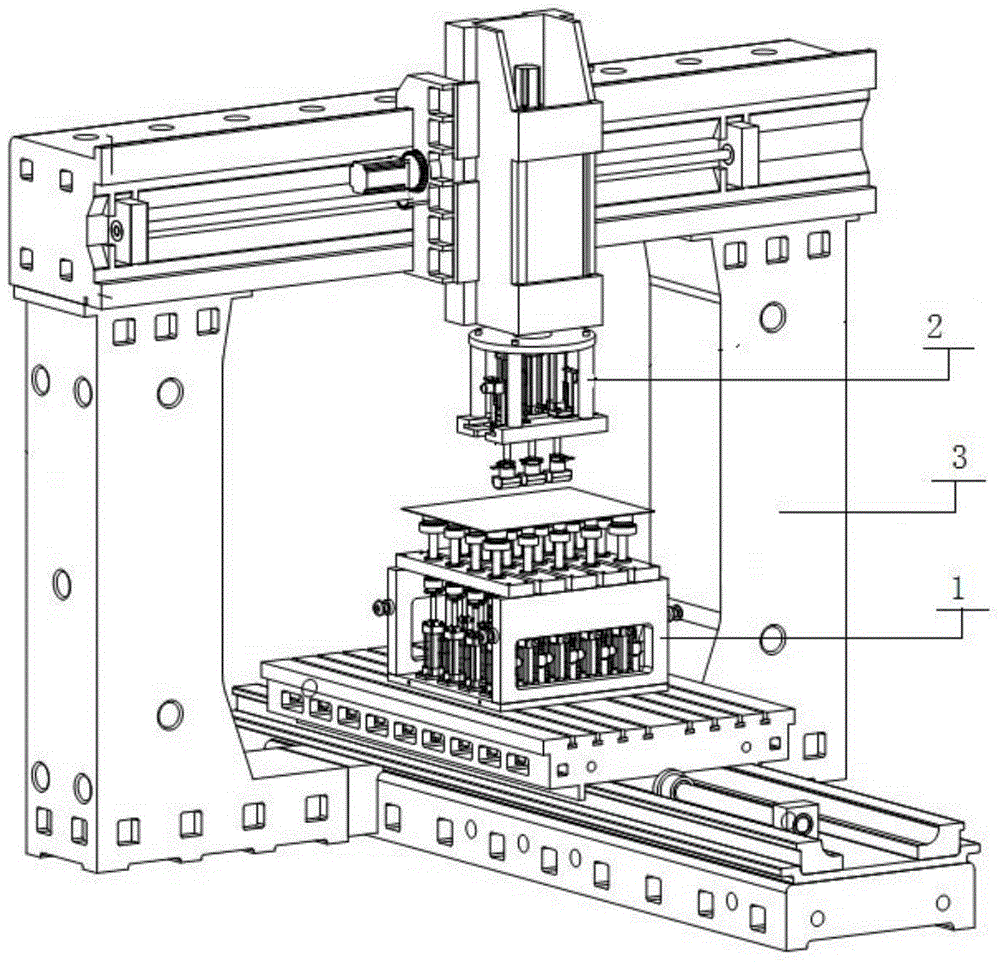

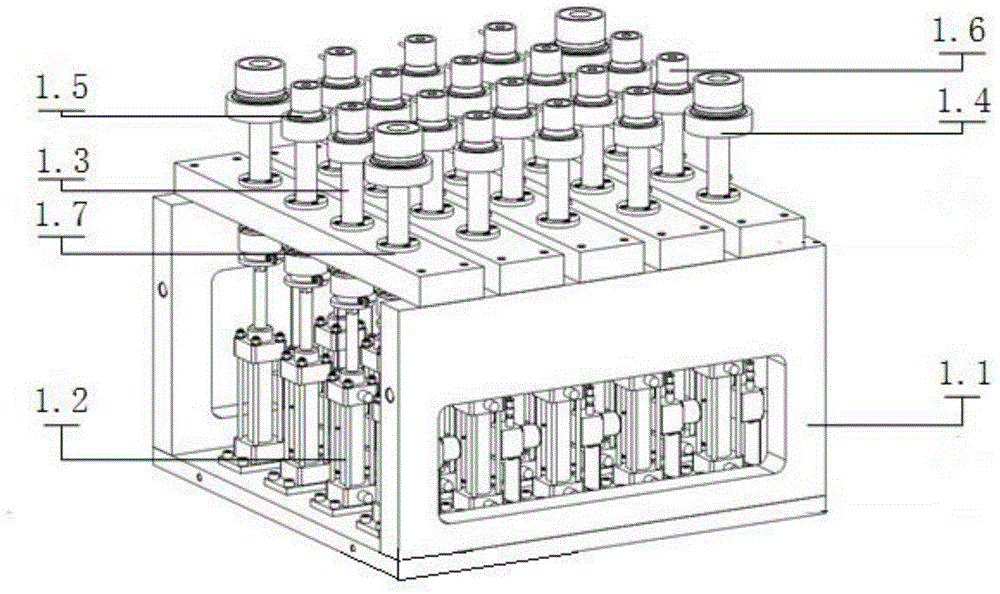

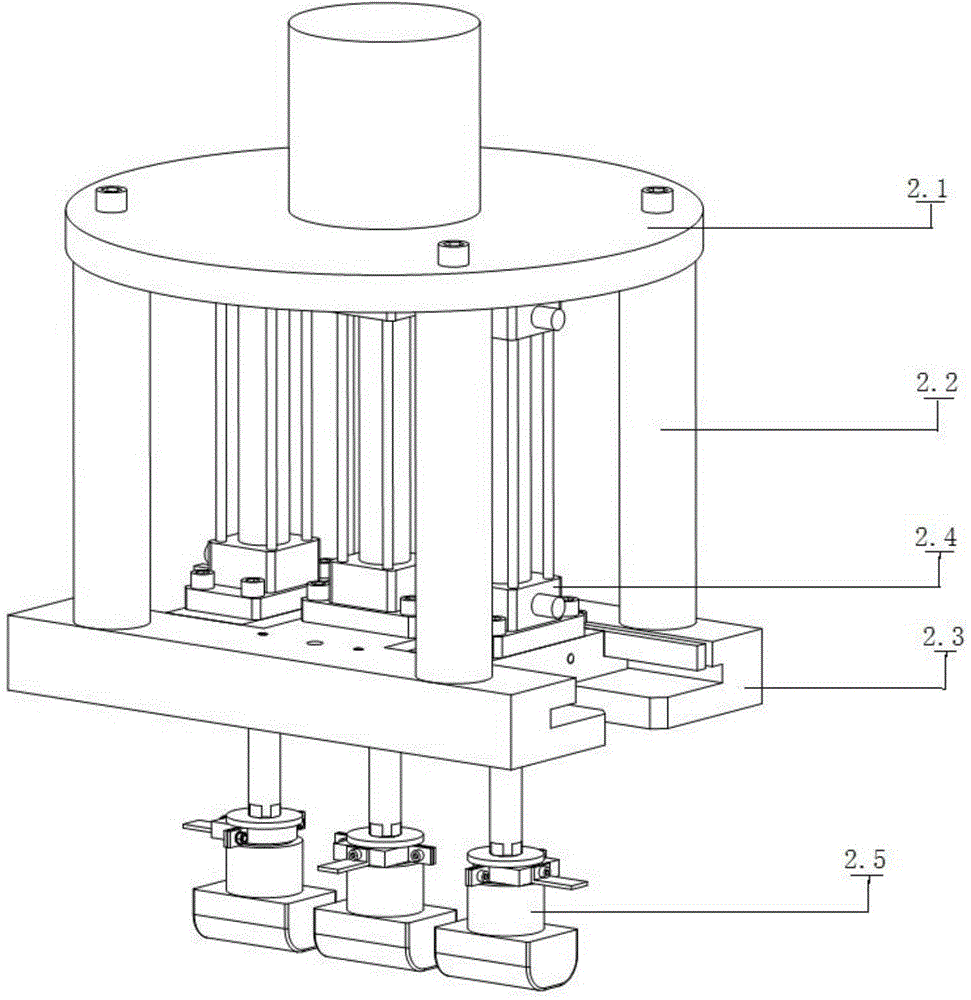

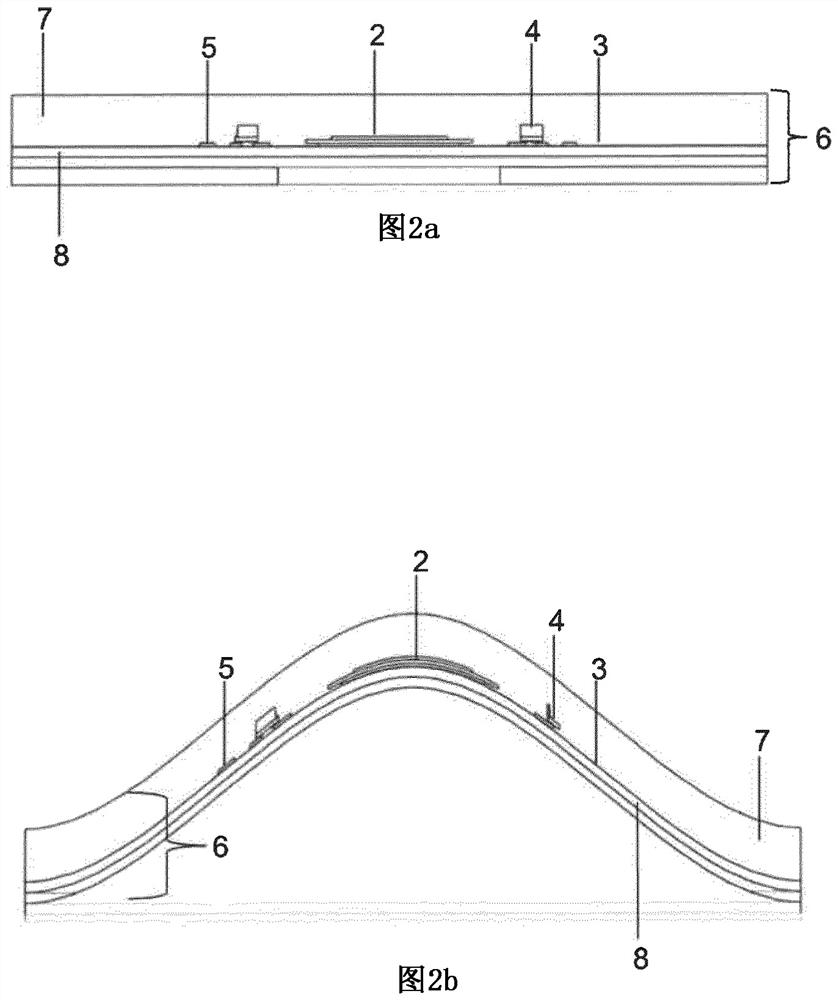

Flexible complex curved-plate machining equipment

ActiveCN104607517AAny shapeEasy to fixShaping toolsMetal-working feeding devicesHydraulic cylinderPlate pressure

The invention relates to the field of mechanical machining equipment, in particular to flexible complex curved-plate machining equipment which comprises a support pillar capable of being adjusted up and down, a bending plate pressure head and a flexible complex curved-plate machining equipment body. The flexible complex curved-plate machining equipment is characterized in that a base with an upper layer and a lower layer is arranged, a hydraulic cylinder is fixed on the lower layer of the base, the upper portion of the hydraulic cylinder penetrates the upper layer of the base to be connected with a push bar, a universal ball joint holder is fixed at the top end of the push bar, a universal ball joint is arranged on the universal ball joint holder, an electromagnetic chuck is fixed at the upper portion of the universal ball joint, side posts are fixed under a fixing frame, parallel rails are fixed at lower ends of the side posts, moving blocks are arranged on the parallel rails, lower portions of the moving blocks are fixed to stamping tool heads, and the flexible complex curved-plate machining equipment body is composed of the support pillar and the bending plate pressure head which are mounted on a machine tool. The flexible complex curved-plate machining equipment has the advantages that large plate workpieces with complex curved surfaces can be produced. Dies are not needed in the whole machining process by a gradual plate bending technology, flexibility in machining is high, and the flexible complex curved-plate machining equipment is especially suitable for the plate workpieces of small batch and double curvature.

Owner:TAIAN HUALU METALFORMING MACHINE TOOL

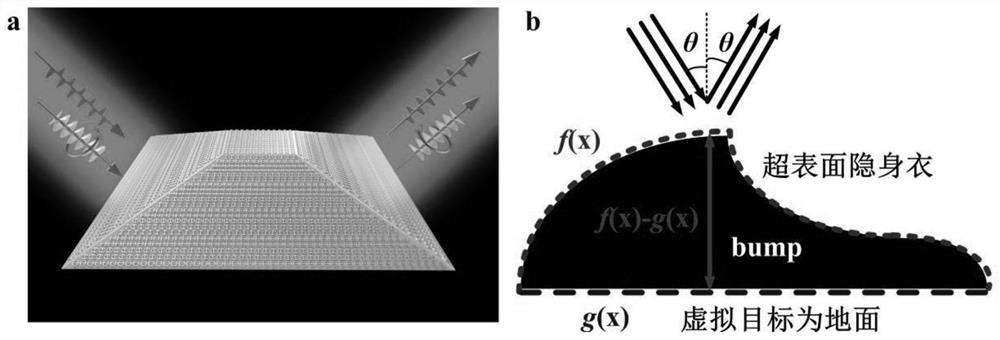

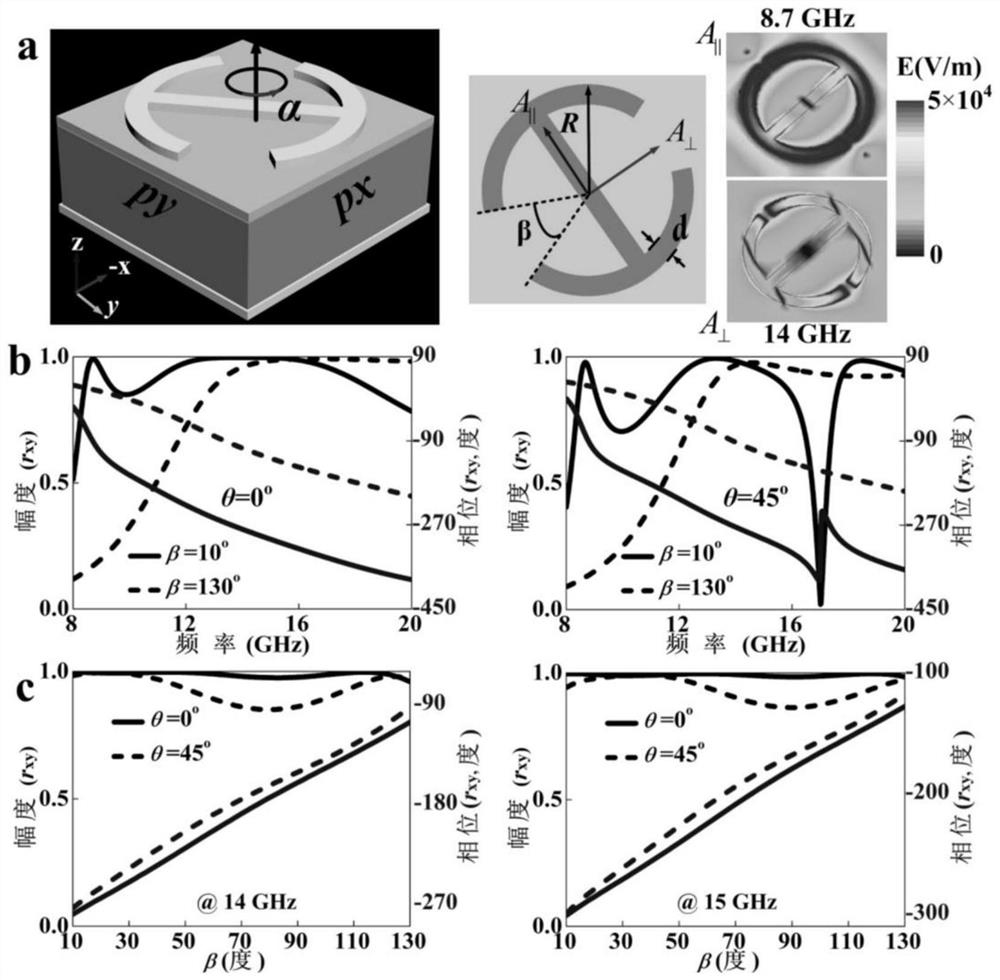

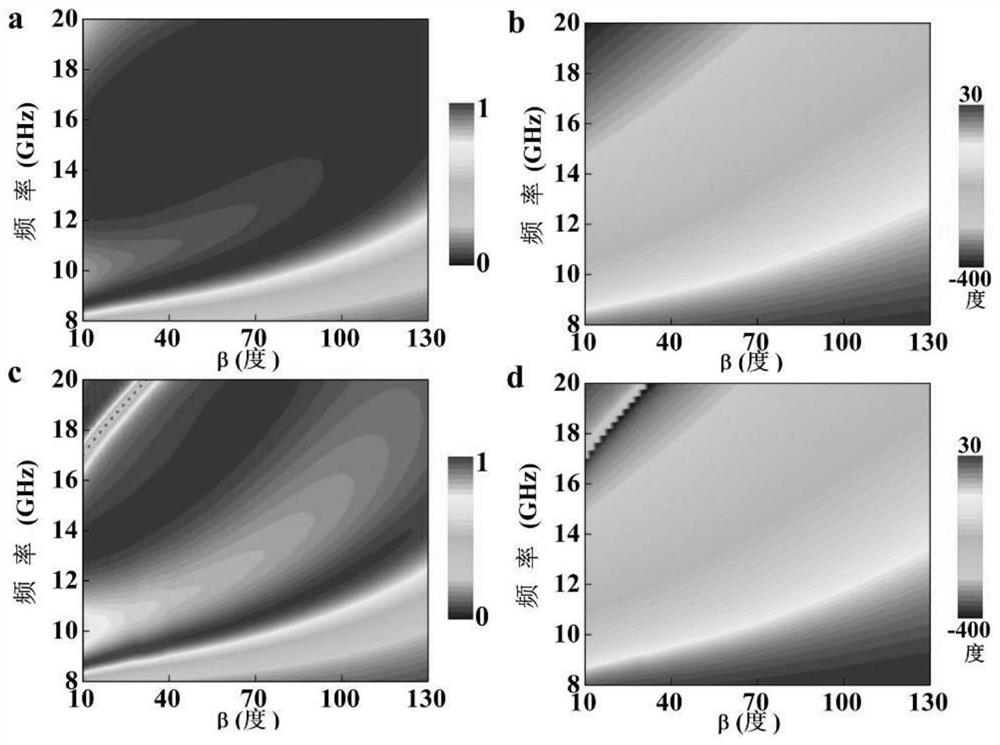

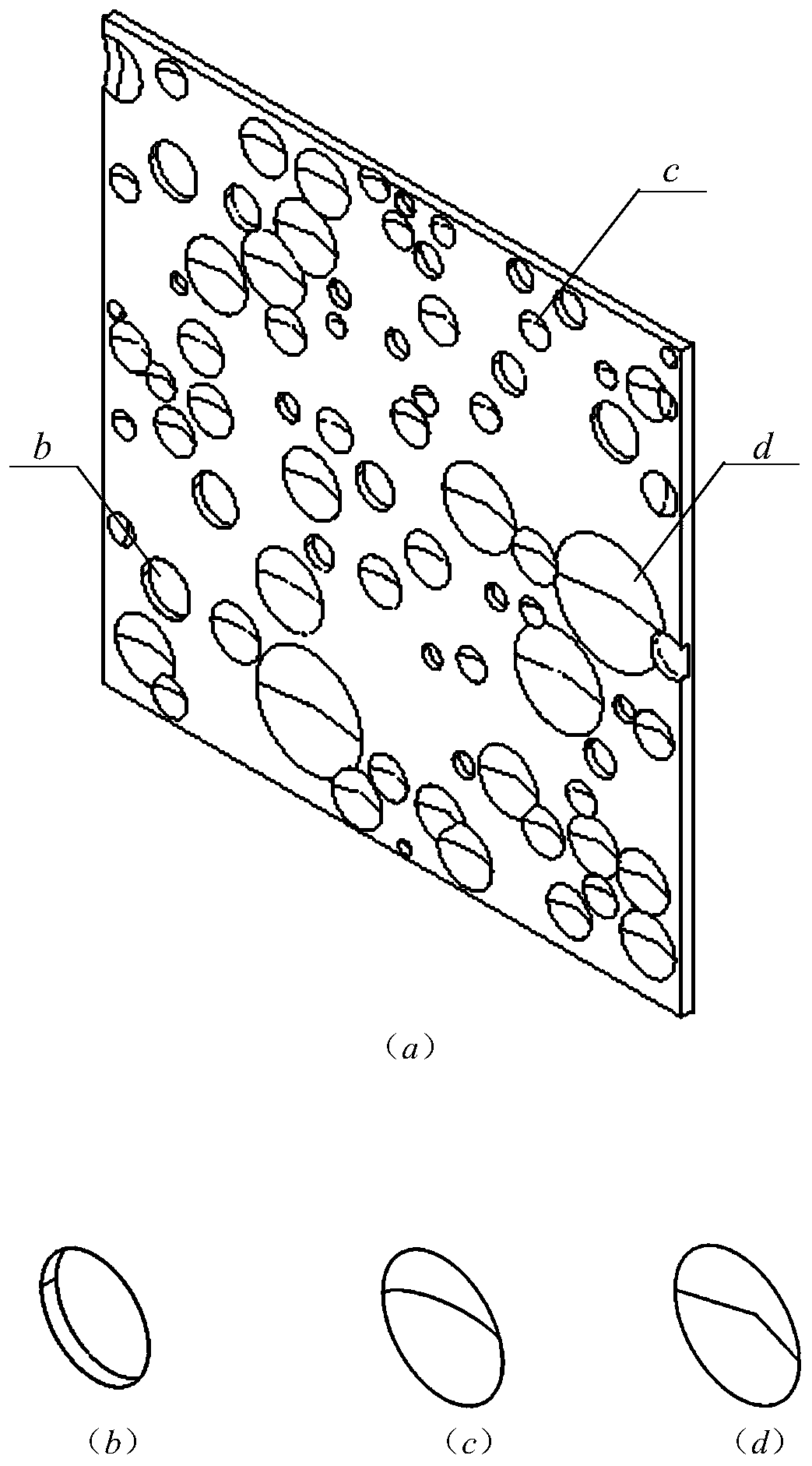

Full-polarization super-surface carpet stealth garment and design method thereof

ActiveCN111834753AArbitrary polarizationSuperior Electromagnetic Stealth PerformanceGeometric CADDesign optimisation/simulationDielectric plateElliptical polarization

The invention belongs to the technical field of metasurface stealth, and particularly relates to fully-polarized metasurface carpet stealth garment based on a geometrical phase and a transmission phase and a design method of the fully-polarized metasurface carpet stealth garment. The carpet stealth garment is of any three-dimensional structure and is formed by splicing a plurality of planar metasurfaces. Each planar metasurface is formed by periodically extending a plurality of metasurface units; each metasurface unit comprises an upper-layer flexible dielectric plate, middle-layer engineeringresin and a lower-layer flexible dielectric plate, wherein one side of the upper-layer flexible dielectric plate comprises a metal arc electric resonator, the other side of the upper-layer flexible dielectric plate is fully corroded, and one side of the lower-layer flexible dielectric plate is fully metal while the other side is fully corroded; structural parameters and azimuth angles of the arcelectric resonator are changed along with different unit positions, and the arc electric resonator is designed through a full-polarization metasurface carpet stealth garment method. The carpet stealthgarment shows excellent electromagnetic stealth performance under the excitation of linearly polarized waves, circularly polarized waves or elliptically polarized waves with different polarization angles, and has the advantages of arbitrary polarization, arbitrary shape, excellent stealth characteristic, easiness in assembly and the like.

Owner:AIR FORCE UNIV PLA

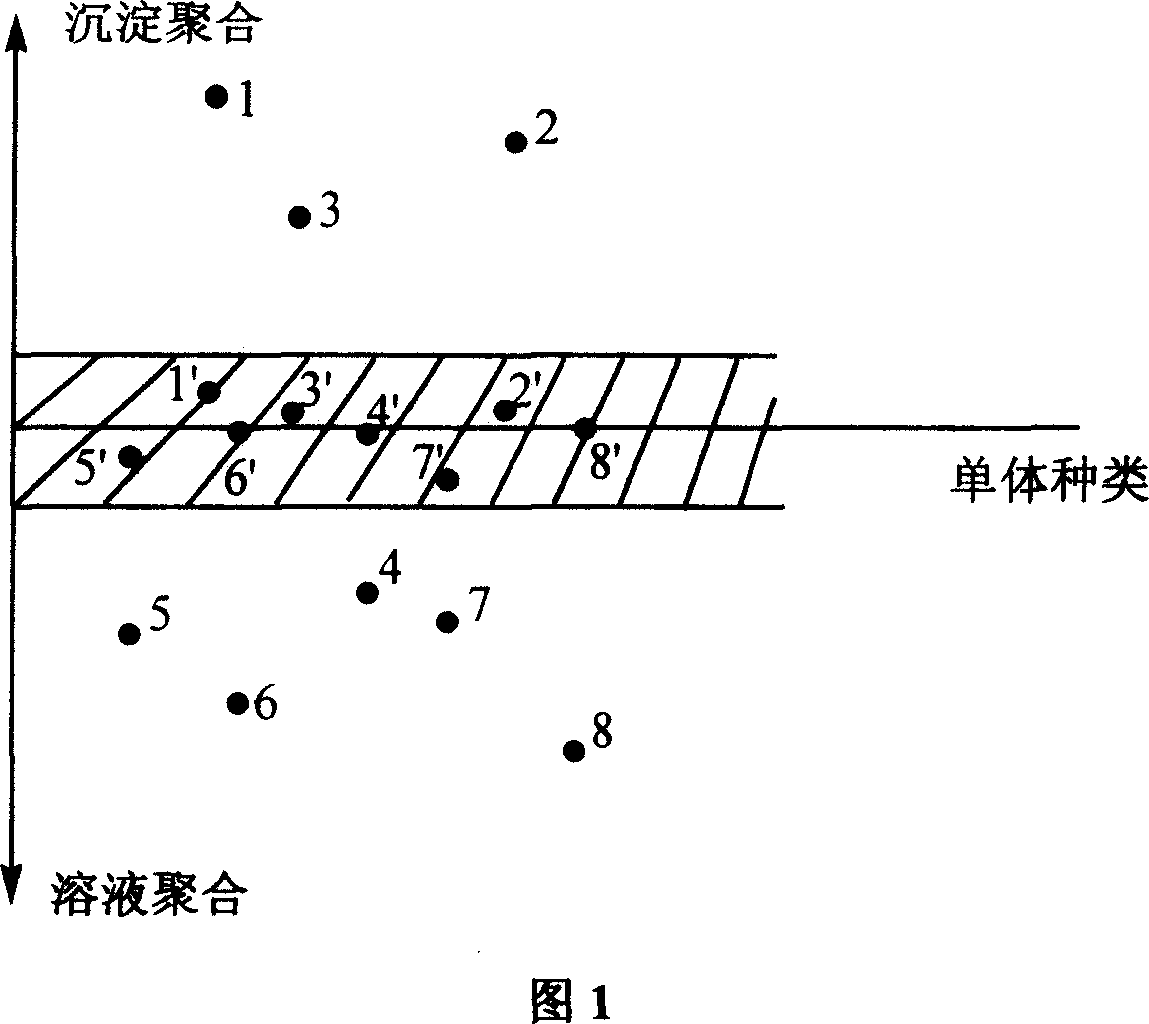

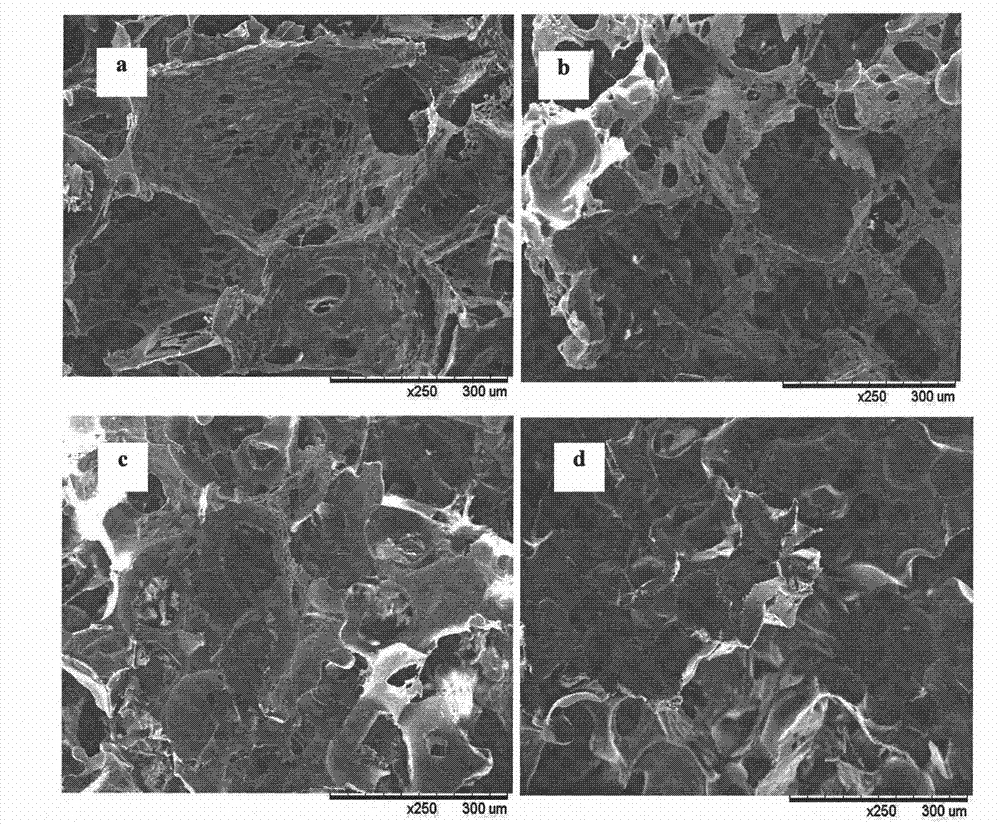

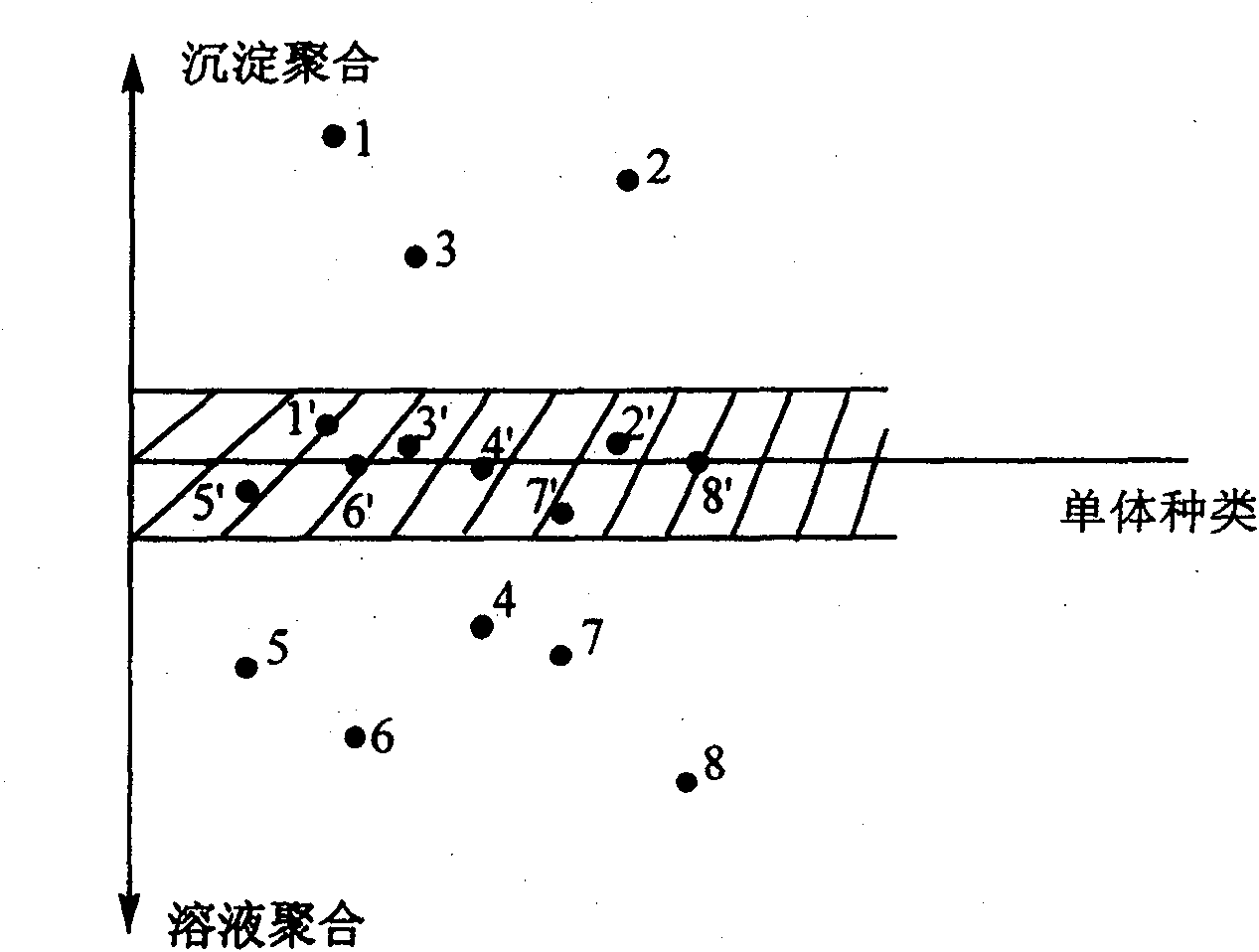

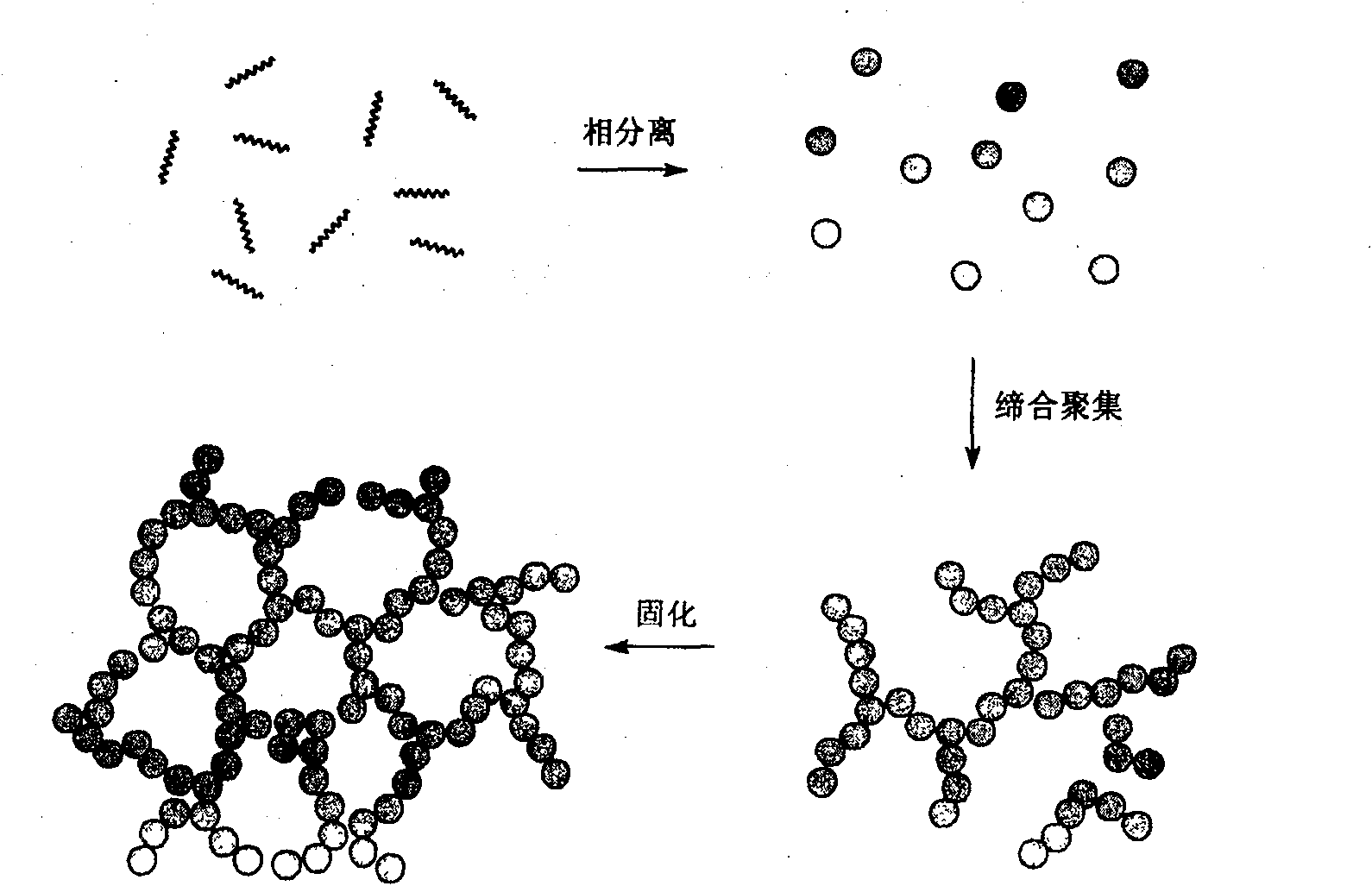

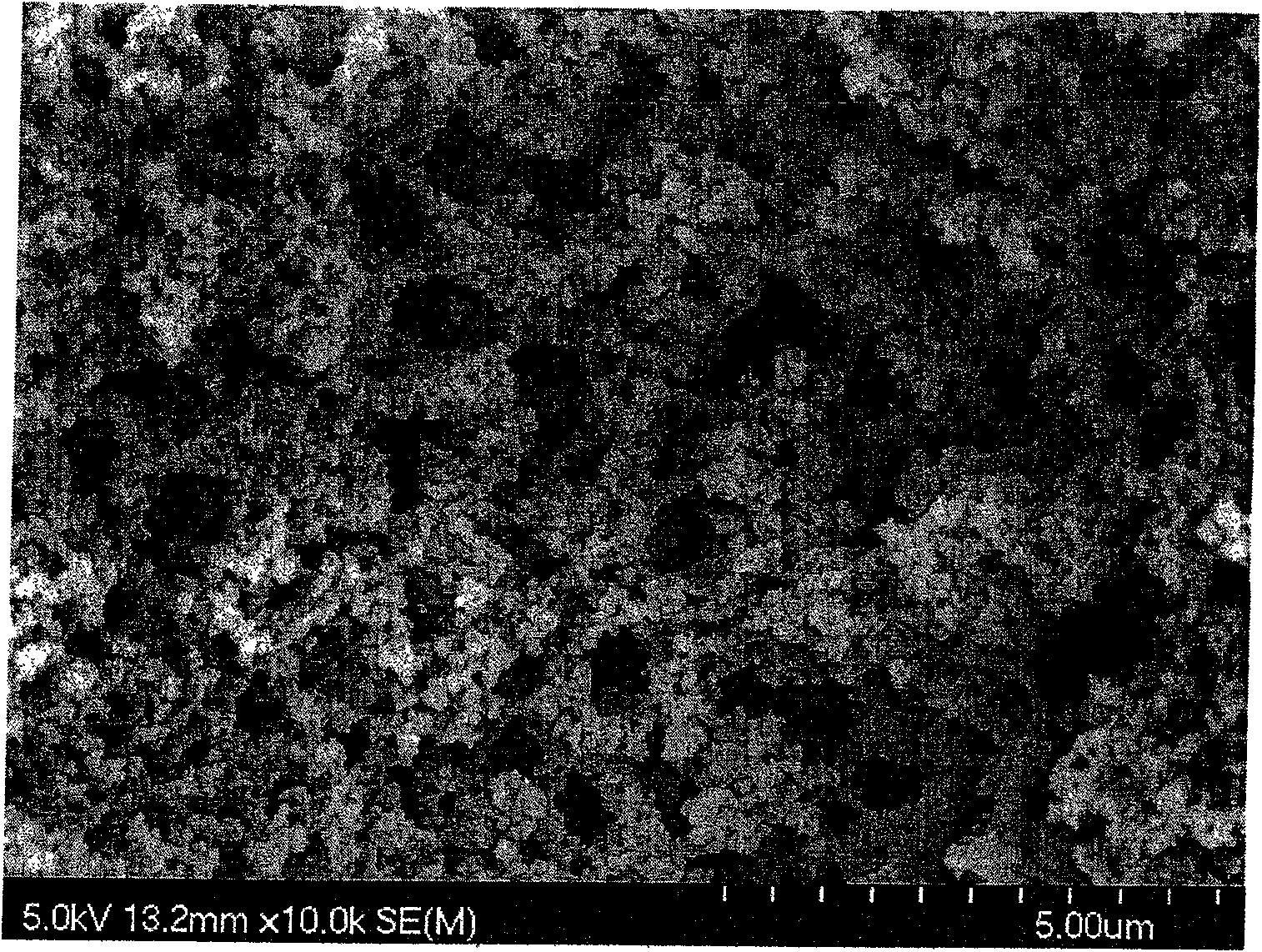

Method of preparing line type polyolefin cellular material

InactiveCN101033272ASimple preparation and molding technologyAny shapePolymer scienceFunctional monomer

This invention relates to a preparation method of linear polyolefin porous materials. Polymerization monomer uses olefin monomers, such as acrylic, styrene, acrylonitrile, vinyl acetate and functional monomer, to solve in a mixed solvent based on PEG or compatible with the appropriate solvent (or precipitation), and conduct free radical polymerization under organic initiators of azo and peroxide, appropriate temperature and atmosphere, but it is different from solution or precipitation polymerization, which has characteristics of phase separation promoted by polymerization, at last, it solidifies to be block and removes PEG, being the linear polyolefin porous materials. This material is an entirety, and has open and connective holes which average size is the degree of nanometer to micrometer, and which structure size can be controlled by PEG and mixed media.

Owner:NINGBO UNIV

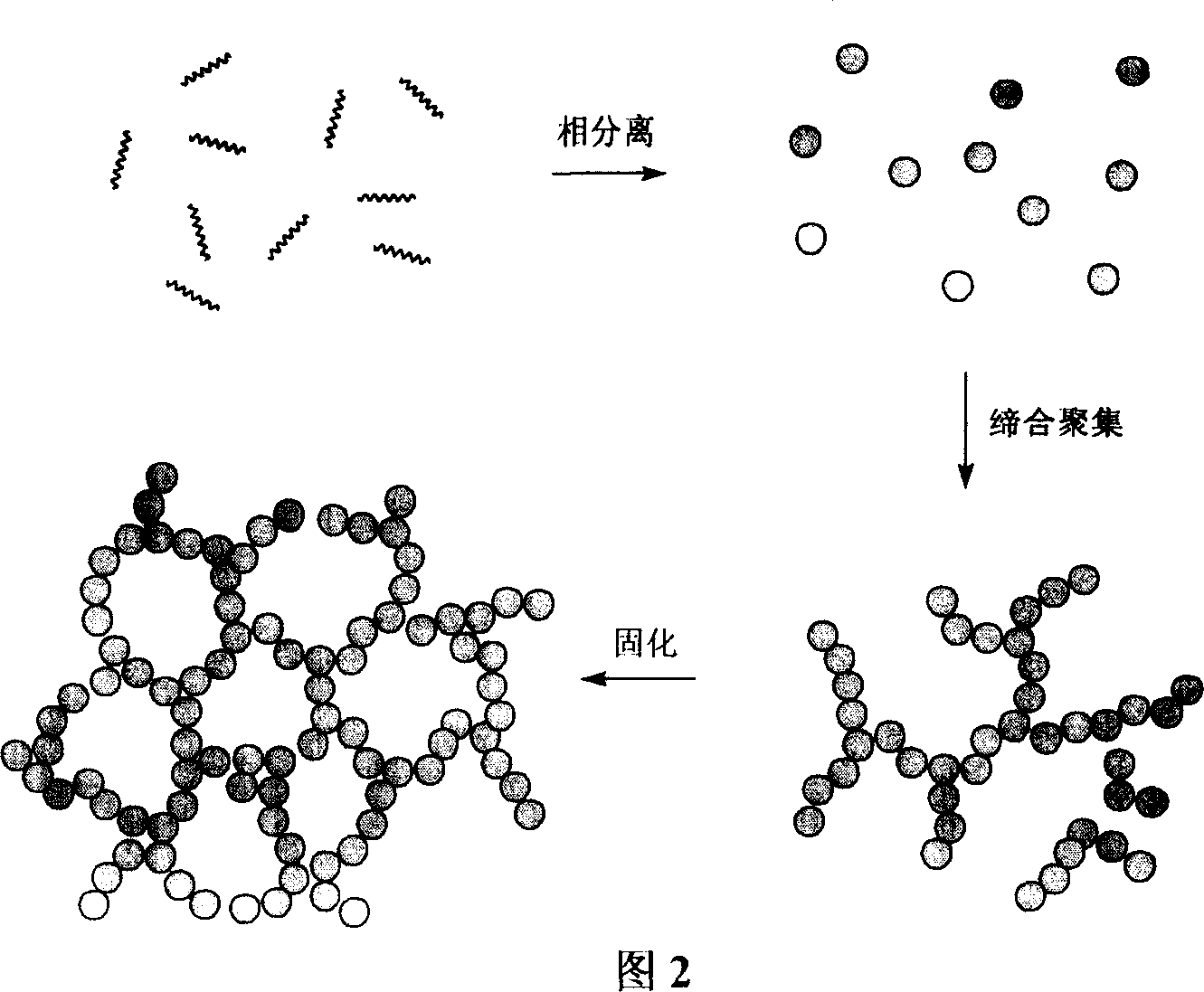

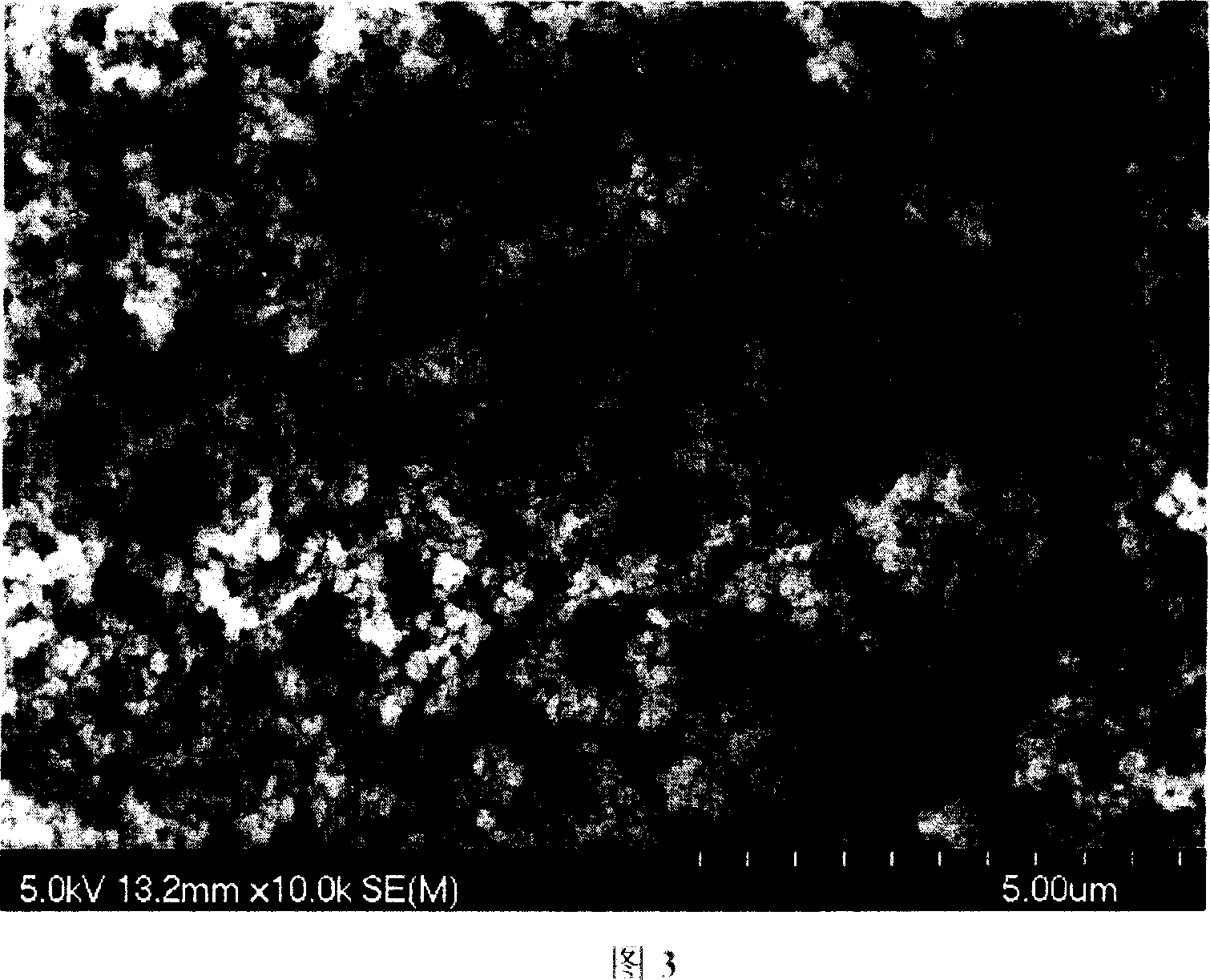

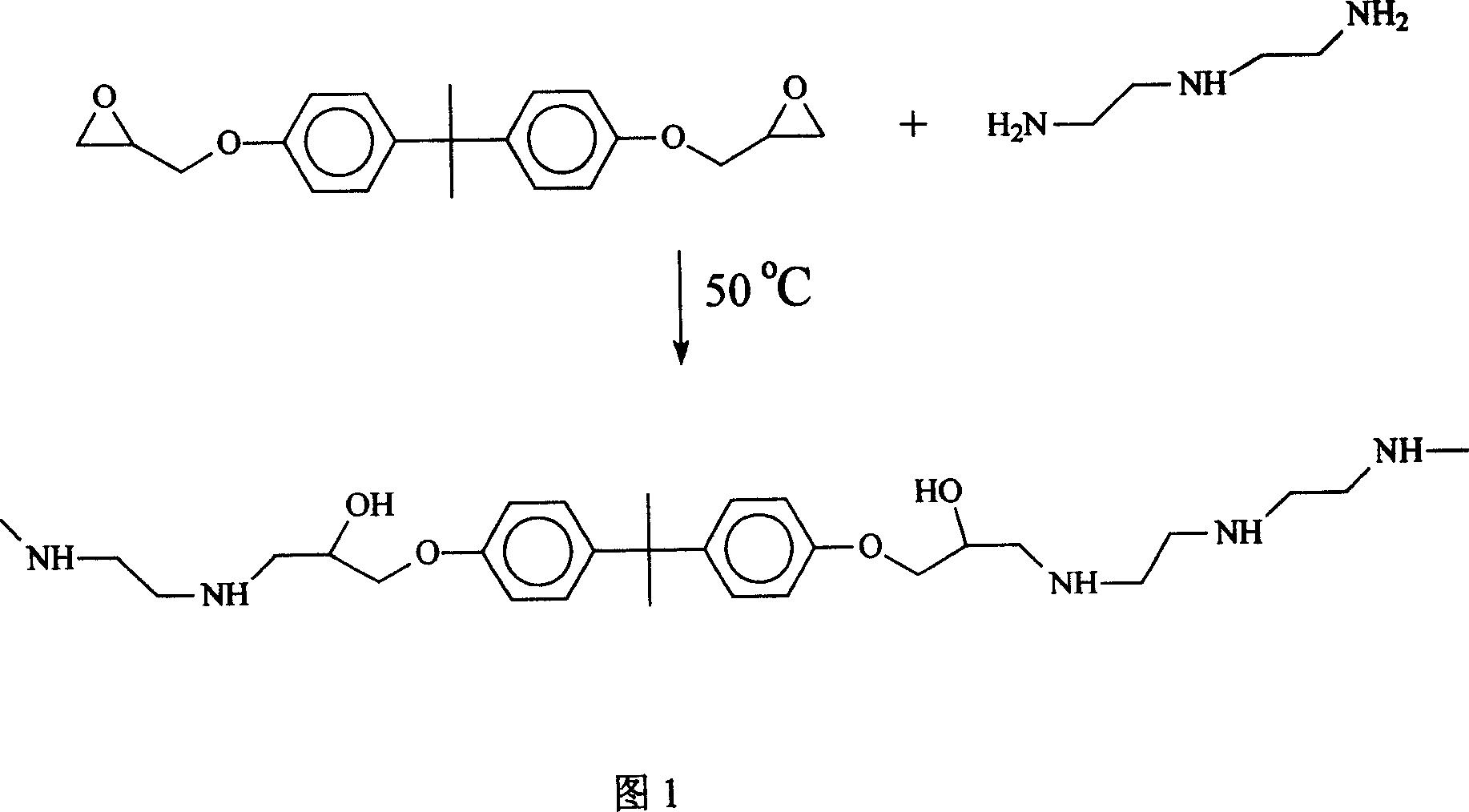

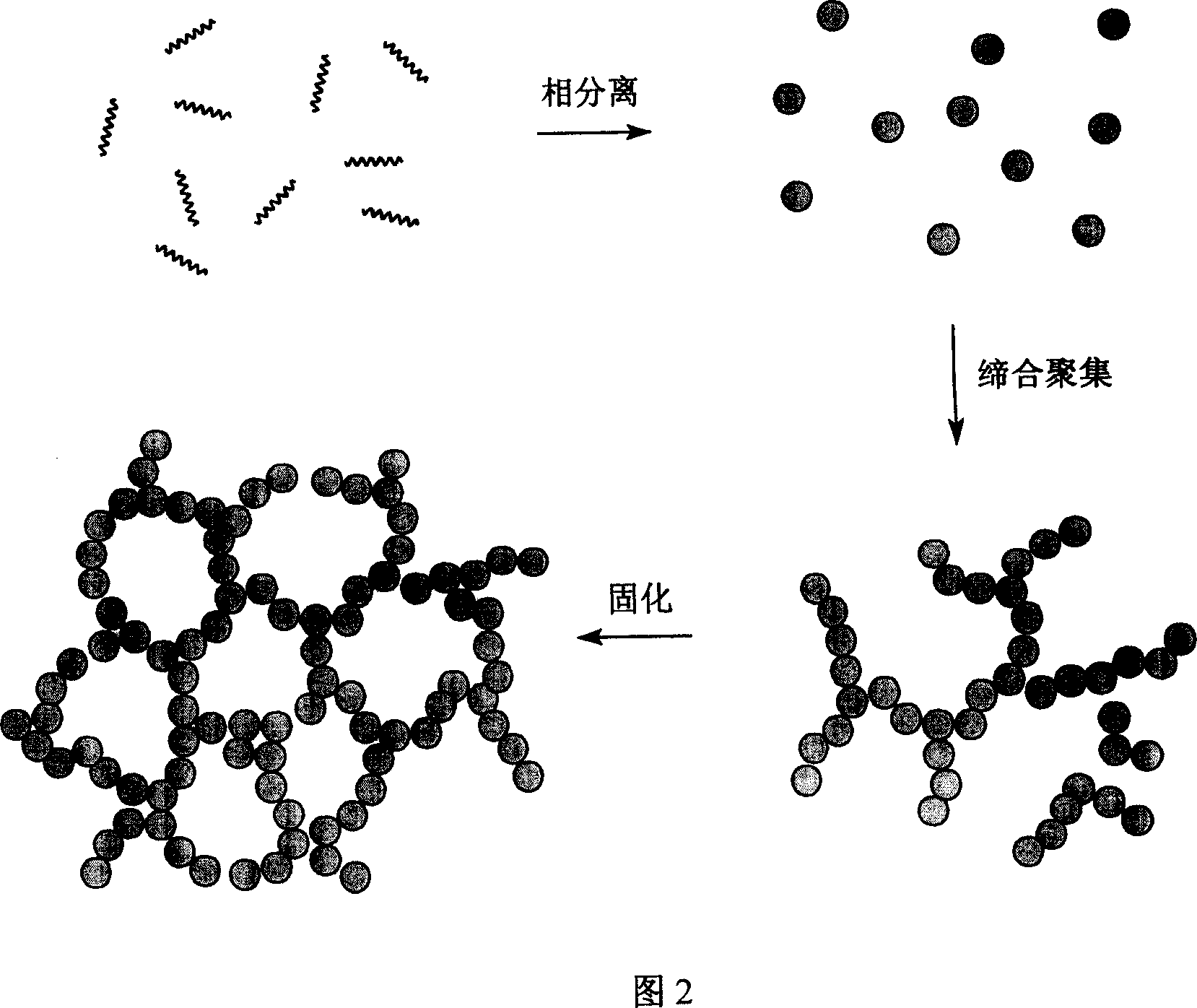

Preparation method of epoxy resin base micron to nano grade pore gelatin

This invention involves a preparation method for epoxy resin-based gel with micron to nanometer holes. The said method includes dissolving epoxy resin and amines such as diethylene triamine and triethylene tetramine in a certain weight in the polyethylene glycol solution, polymerizing to form a white gel, curing, and removing polyethylene glycol to obtain gel with micro / nano-holes. The whole preparation process is environmental-friendly. The gel can be prepared in arbitrary shape with uniform pore size distribution and adjustable size. The gel has strong hydrophilicity and resistance to acid, alkaline and solvent. There are large amounts of reaction functional groups, which can functionalized channels through chemical modification. The gel can be widely applied to separation, filtration, adsorption, and chelation in equipment analysis, water treatment and biomedical industries, such as microfiltration membrane and smart membrane, heavy metals removal, the stationary phase of chromatography column, enzyme immobilization, cell culture, drug sustained-release, chemical sensors, etc.

Owner:NINGBO UNIV

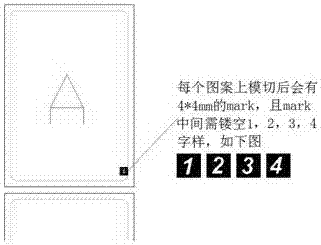

Single ticket different pattern identification sorting work flow

InactiveCN107067067ARealize sortingLow costRecord carriers used with machinesWork flowIndustrial engineering

Provided is a single ticket different pattern identification sorting work flow, belonging to the technical field of electronic label manufacturing. The work flow includes performing ticket material printing (printing the identification Mark without increasing the technological cost), performing the attached die cutting, performing the Mark identification by a sensor, sorting the different printed patterns, performing classified packaging according to the sorted different printing patterns by the personnel (meanwhile, according to the Mark at the special position, simply determining whether the printed patterns are correctly sorted). The work flow is suitable for the withdrawn ticket sorting and placing direction identification of the printed single tickets and tags, and by setting the special position of the identification Mark, the problem of inconsistent sorting and withdrawn direction of the single tickets can be solved.

Owner:ARIZON RFID TECH YANGZHOU

Preparation method of graphene composite film with conducting circuit on surface

ActiveCN107301892AImprove bindingImprove flexibilityConductive layers on insulating-supportsCompound aComposite film

The invention provides a preparation method of a graphene composite film with a conducting circuit on a surface. The preparation method comprises the following steps: firstly forming a conducting circuit on the surface of a first substrate to obtain the substrate material; compounding a layer or multi-layer graphene film on the surface with the conducting circuit of the substrate material obtained in above-mentioned step, and then combining a second substrate on the surface of the graphene film to obtain an intermediate product; finally removing the first substrate of the above-mentioned intermediate product by using the chemical etching method to obtain the graphene composite film with the conducting circuit. A high-conducting patter can be formed on the graphene film surface by using the preparation method disclosed by the invention, and the shape of the formed high-conducting pattern is random, especially, the binding force between the conducting circuit and the graphene film is good, and the high-conducting pattern has the good flexibility. Meanwhile, the preparation method provided by the invention is not only simple and practicable in process procedure, but also can match with the process procedure of the graphene film, and is suitable for the large-scale industrial application.

Owner:宁波柔碳电子科技有限公司

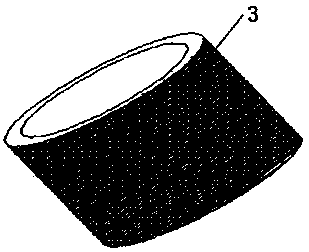

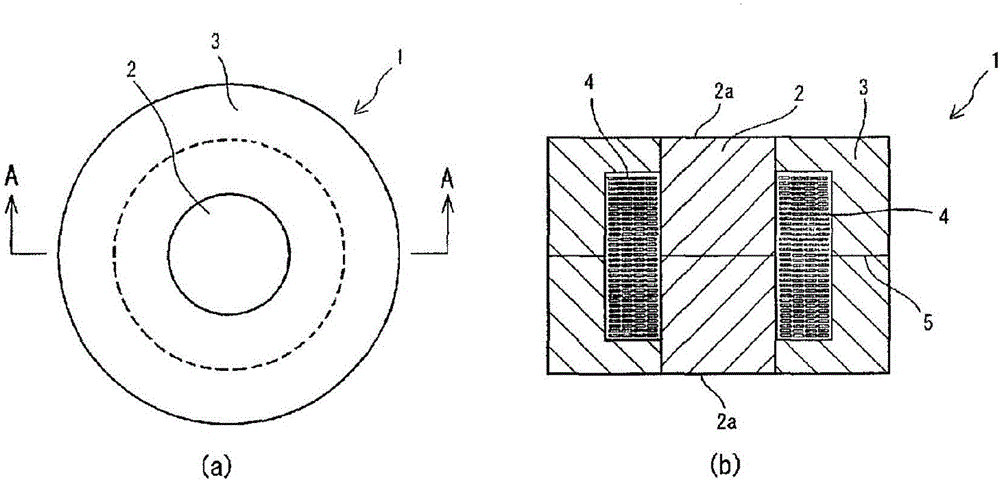

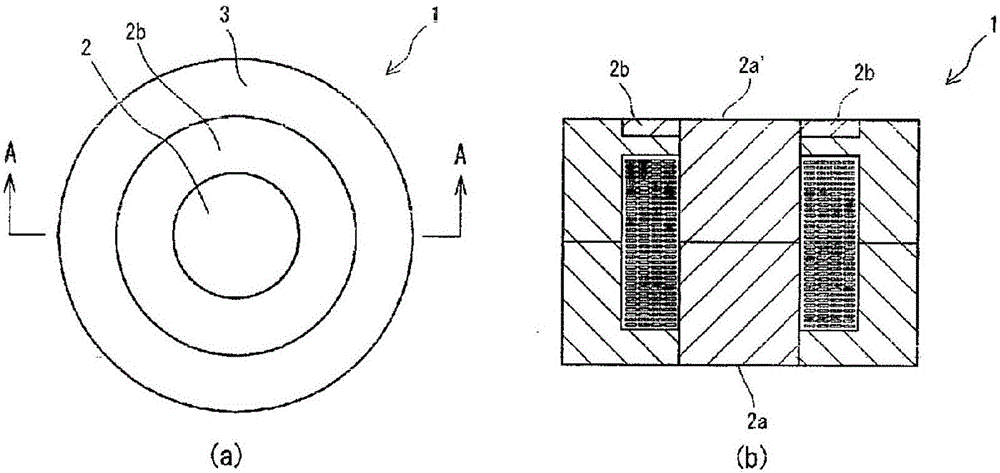

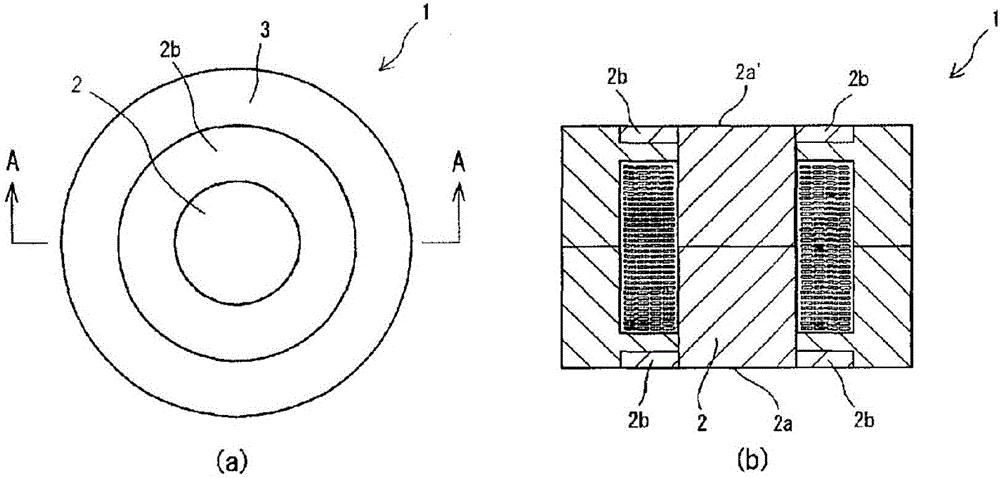

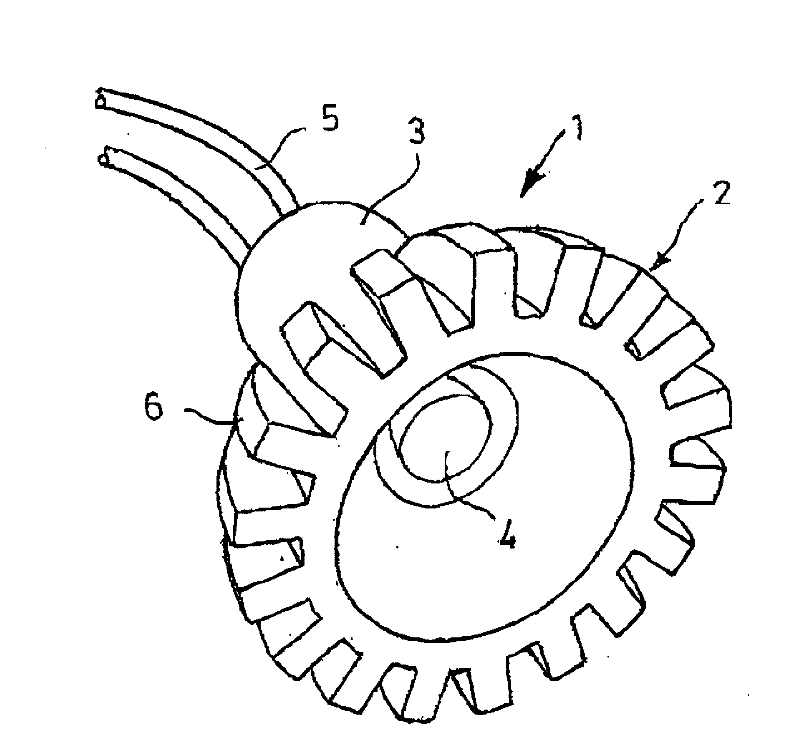

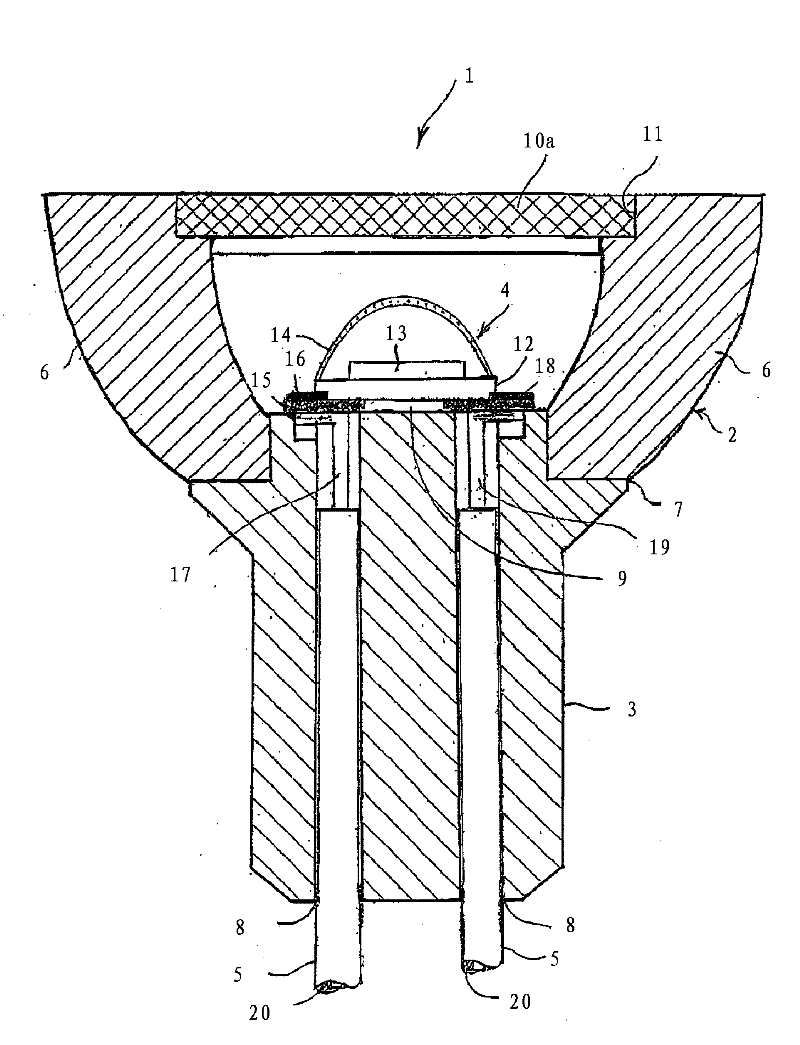

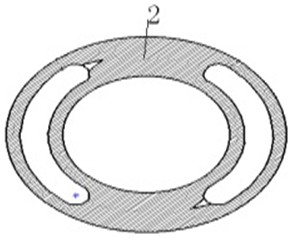

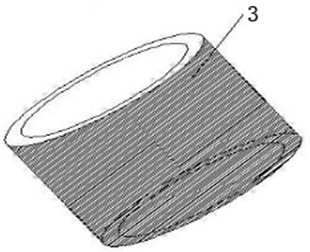

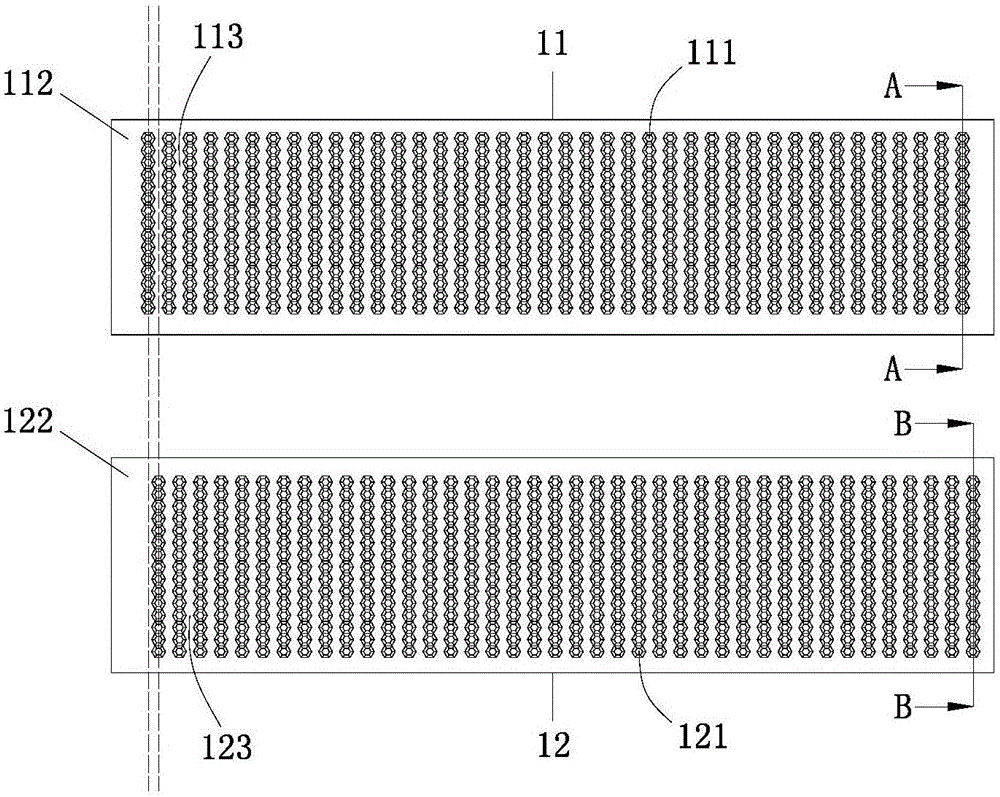

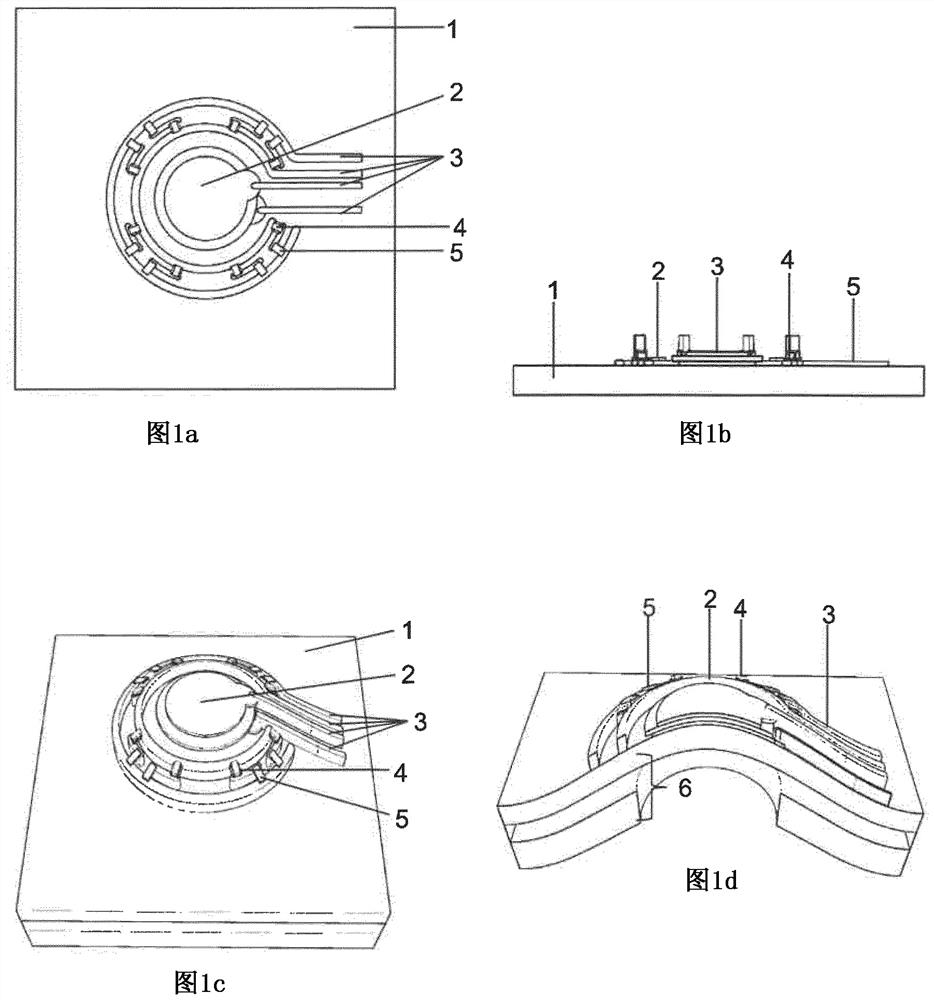

Magnetic element

ActiveCN106104718ASuppress feverAny shapeTransformers/inductances magnetic coresMagnetic materialsProduction rateMagnetic flux

Provided is a magnetic element which exhibits excellent producibility and suppresses heat generation caused by iron loss. A magnetic element provided with a magnetic body though which magnetic flux produced by a coil (4) passes, wherein: this magnetic body is a joined body obtained by joining magnetic bodies to one another which are bisected in the axial direction of the coil; a section exhibiting high heat generation caused by iron loss or a section exhibiting poor heat-dissipation properties constitutes a compression-molded magnetic body (2), while a section other than this compression-molded magnetic body constitutes an injection-molded magnetic body (3); and the compression-molded magnetic body and the injection-molded magnetic body are joined to one another. Furthermore, the compression-molded magnetic body is exposed on the surface of the magnetic body.

Owner:NTN CORP

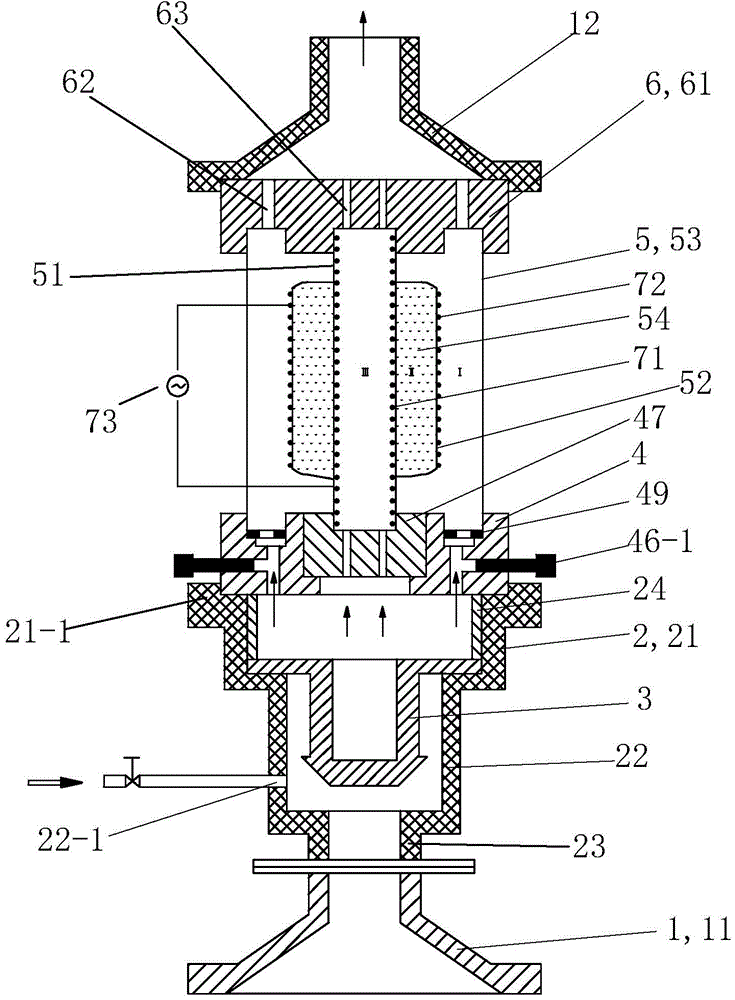

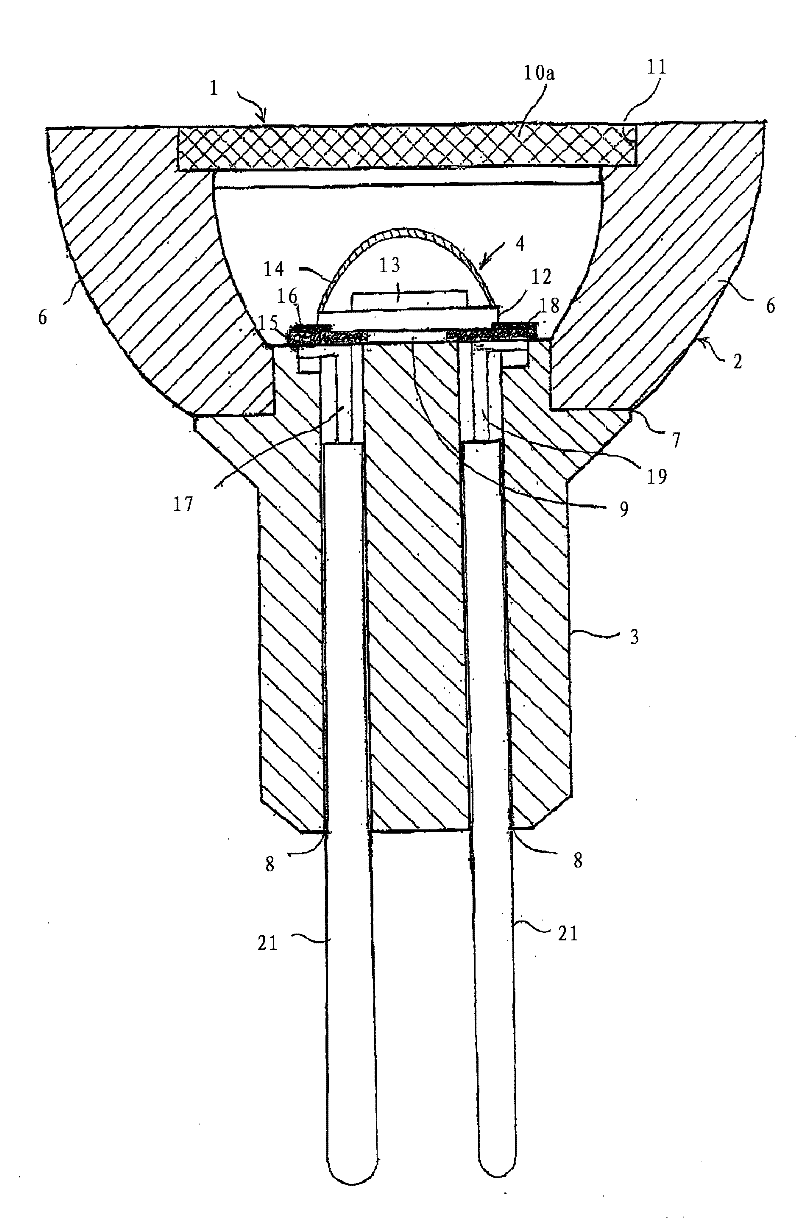

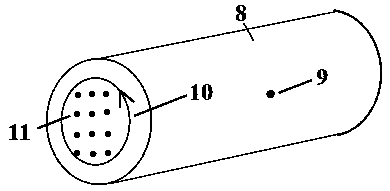

Device for photocatalytically degrading exhaust gas by electrodeless excimer lamp

ActiveCN104474885AChange luminous intensityChange luminous efficiencyDispersed particle separationCoaxial lineEngineering

The invention discloses a device for photocatalytically degrading exhaust gas by an electrodeless excimer lamp. A used reactor comprises three quartz medium layers, an inner electrode, an outer electrode and a high-voltage power supply. The three quartz medium layers comprise a first quartz tube, a second quartz tube and a third quartz tube which are coaxial and are sequentially arranged from inside to outside; the internal cavity of the first quartz tube is a reaction region III; a closed annular cavity is formed between the second quartz tube and the first quartz tube and serves as a gas filled region II; a reaction region I is formed between the third quartz tube and the second quartz tube. During the photocatalytic degradation of the exhaust gas, gas of the gas filled region II is excited to generate excimer UV light which radiates towards the direction of the reaction region I and the direction of the reaction region III, and the exhaust gas to be degraded fully passes through the reaction region I or reaction region III or enters the reaction region I and the reaction region III in a divided-flow manner and is degraded under the action of excimer ultraviolet radiation.

Owner:江苏龙环环境科技有限公司

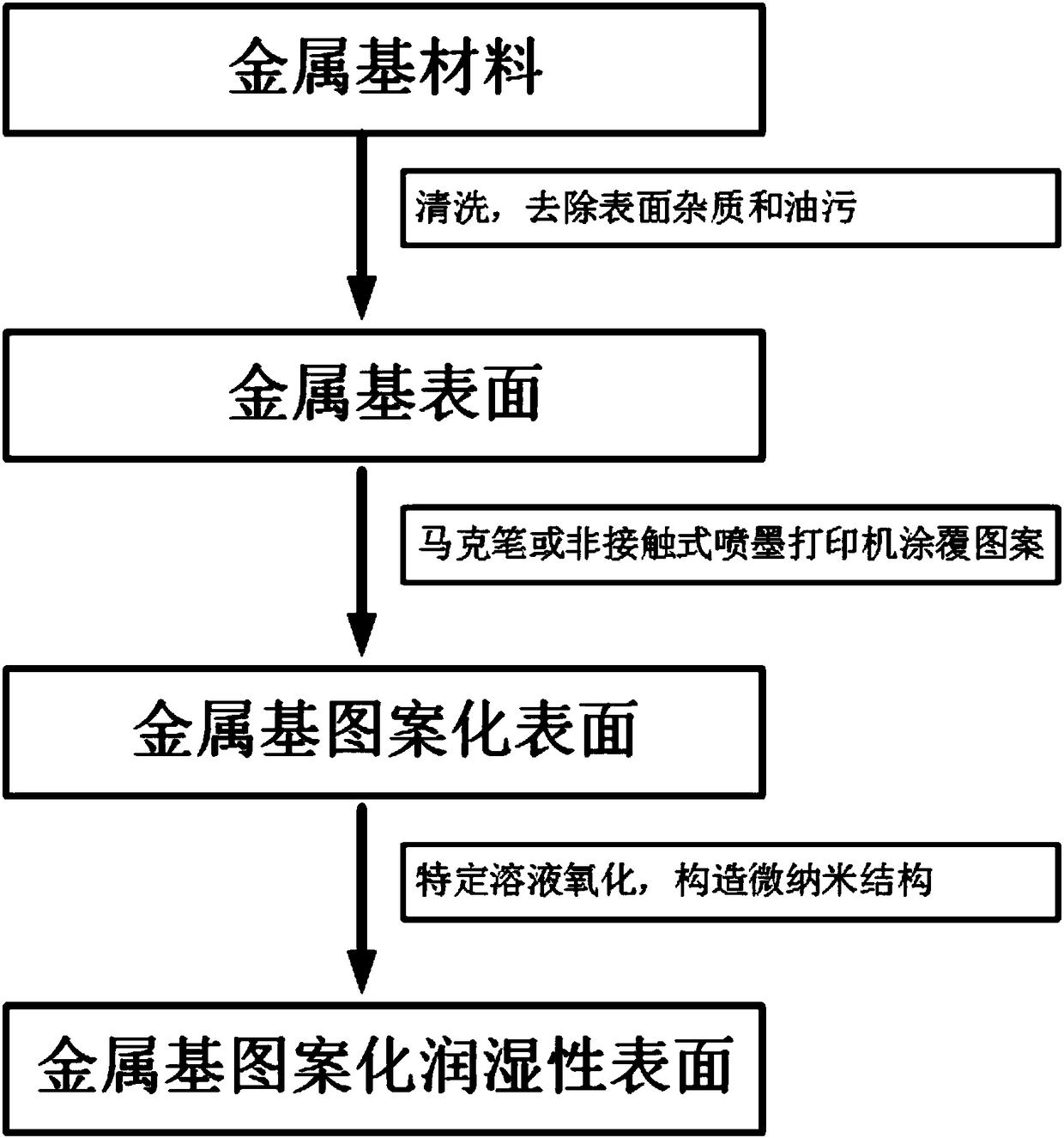

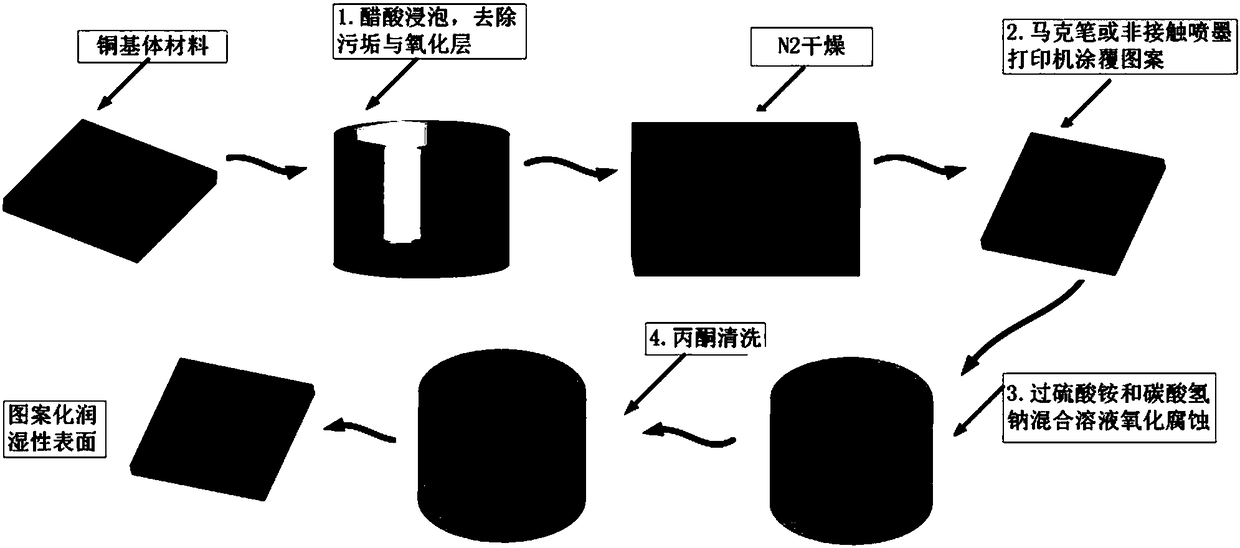

Patterned wetting surface processing method

The invention provides a patterned wetting surface processing method and belongs to the technical field of metal surface treatment and modification. The method is characterized by adopting a mark penor a non-contact ink-jet printer for coating a required ink mark pattern on a metal matrix, and producing a micro-nano structure through oxidation of metal and a specific solution so as to construct apatterned wetting surface. The method comprises the steps of pretreating the surface of the metal matrix so as to remove dirt and an oxidation layer, adopting the mark pen or the non-contact ink-jetprinter for coating the required ink mark pattern, and carrying out selective oxidation corrosion to construct the micro-nano structure. According to the patterned wetting surface processing method provided by the invention, a device and a process are simple, convenient, low in cost and better in controllability, and are applicable to various metals and alloys thereof; wetting patterns in any shape can be obtained through coating by the mark pen or the non-contact ink-jet printer; the wetting patterning of any curved-surface matrix can be realized; and the preparation of the surface with the wetting patterns in any size can be realized.

Owner:DALIAN UNIV OF TECH

Method for producing virgin walnut oil by utilizing juglans sigillata

ActiveCN108865423AAny diameterAny shapeFatty-oils/fats refiningFatty-oils/fats productionJuglans sigillataWalnut Nut

The invention discloses a method for producing virgin walnut oil by utilizing juglans sigillata. The method comprises the following steps: removing rotten fruits and diseased fruits of the juglans sigillata; after immersing with clean water, washing through a spraying type brush roller washing machine; drying walnuts through hot air at low temperature by adopting a gradient interval manner; separating shells and kernels by applying a rice polishing mill; separating to obtain kernel powder with a few of walnut kernels; covering the walnut kernel powder with oil cloth and conveying into a hydraulic oil press for pressing; then conveying meal into a spiral oil press and further pressing to obtain light yellow walnut oil; carrying out secondary filtering through a self-heating type plate-and-frame filtering machine, so as to obtain high-quality walnut oil. The method disclosed by the invention has the advantages of low production equipment cost, high efficiency and strong applicability; the oil residual rate of the meal is lower than 5 percent and the prepared walnut oil has a light yellow color and a rich walnut aroma; the acid value of the walnut oil is less than 0.8mg / g, and the content of copper, iron, arsenic, lead, aflatoxin B1, benzo(a) pyrene and the like is in a range required by national standards, so that the method is applicable to industrial production.

Owner:贵州省核桃研究所

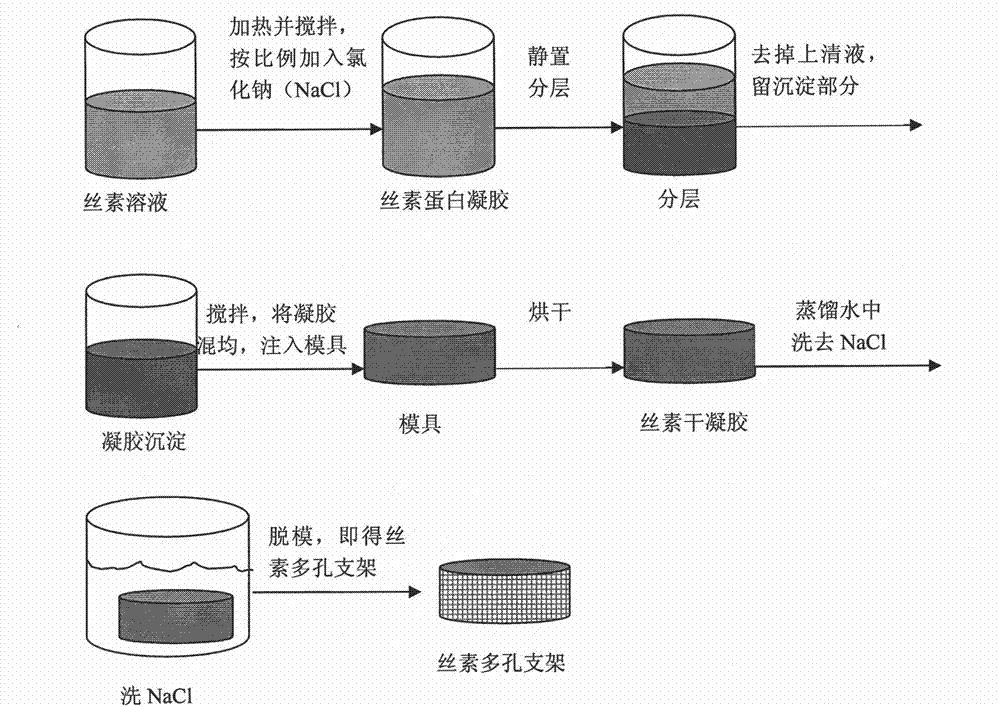

Method for preparing three-dimensional silk fibroin porous scaffold material

The invention discloses a method for preparing three-dimensional silk fibroin porous scaffold material, and relates to the field of biomaterial, in particular to the field of tissue engineering scaffolds. The method comprises: putting silk fibroin water solution with the volume concentration of 2-50wt% into a container, and adding sodium chloride into the silk fibroin water solution at 20-80 DEG C under continuous stirring, wherein the ratio between the mass (unit: gram) of sodium chloride granules and the volume (unit: ml) of silk fibroin solution is 1-20:1; after gelatinating, standing and precipitating the silk fibroin solution, taking out the precipitate to be continuously stirred and evenly mixed; then, putting the precipitate into a mould with the needed shape to be dried; finally, washing off the sodium chloride in the scaffold by distilled water, and obtaining the silk fibroin porous scaffold material having three-dimensional porous structure. No organic solvent is used in the method, the method is simple and efficient, and the prepared silk fibroin porous scaffold has controllable porosity factor and pore size, highly communicated pore structure as well as degradability.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

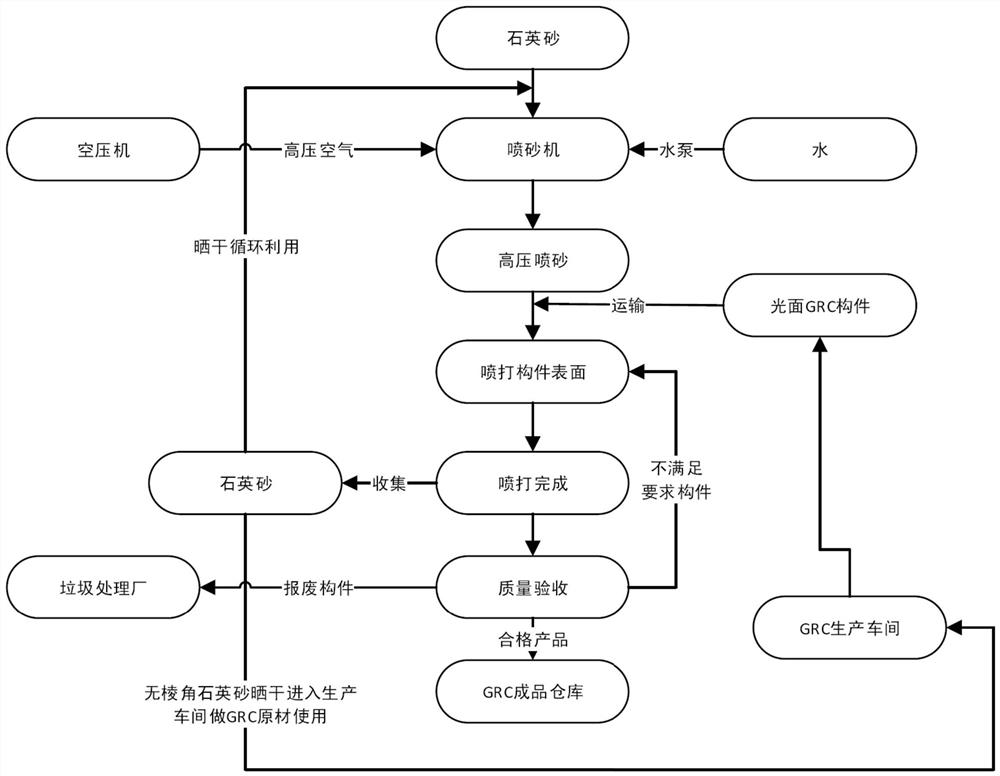

Production method of GRC component with stone-like effect

PendingCN114603488ALow costShorten the construction periodBlast gunsAbrasive machine appurtenancesSkin damageProcess engineering

The invention relates to a production method of a GRC component with a stone-like effect. The production method comprises the following steps: A, producing a glazed GRC component by using a mold; the member is regularly maintained after being demolded, the maintenance time is not less than 7 days, and the strength is ensured to reach 80% of the design strength; and B, quartz sand is sprayed out through a sand blasting machine, the smooth GRC component is impacted, the surface of the GRC component is subjected to skin damage, natural non-quality damage is caused, and a stone-like effect surface layer is formed. According to the production method of the GRC component with the stone-like effect, on the basis of ensuring the product quality and perfectly presenting the overall stone-like effect, the construction period can be greatly shortened, the cost can be saved, and the problems of environmental protection and the like can be avoided.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

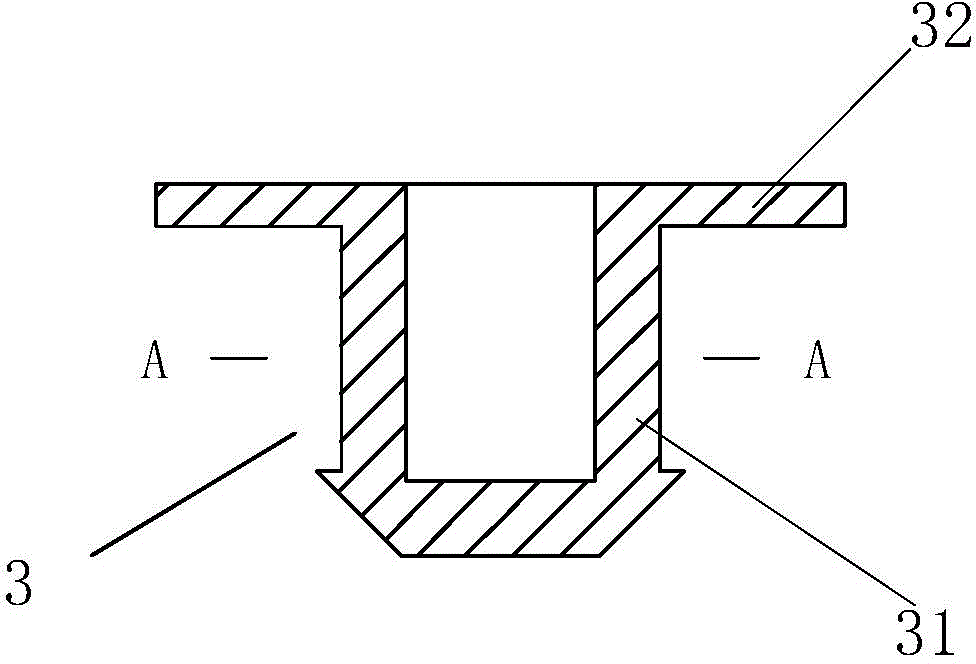

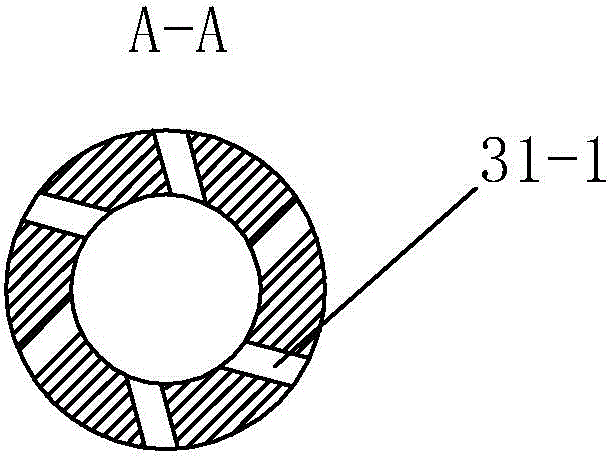

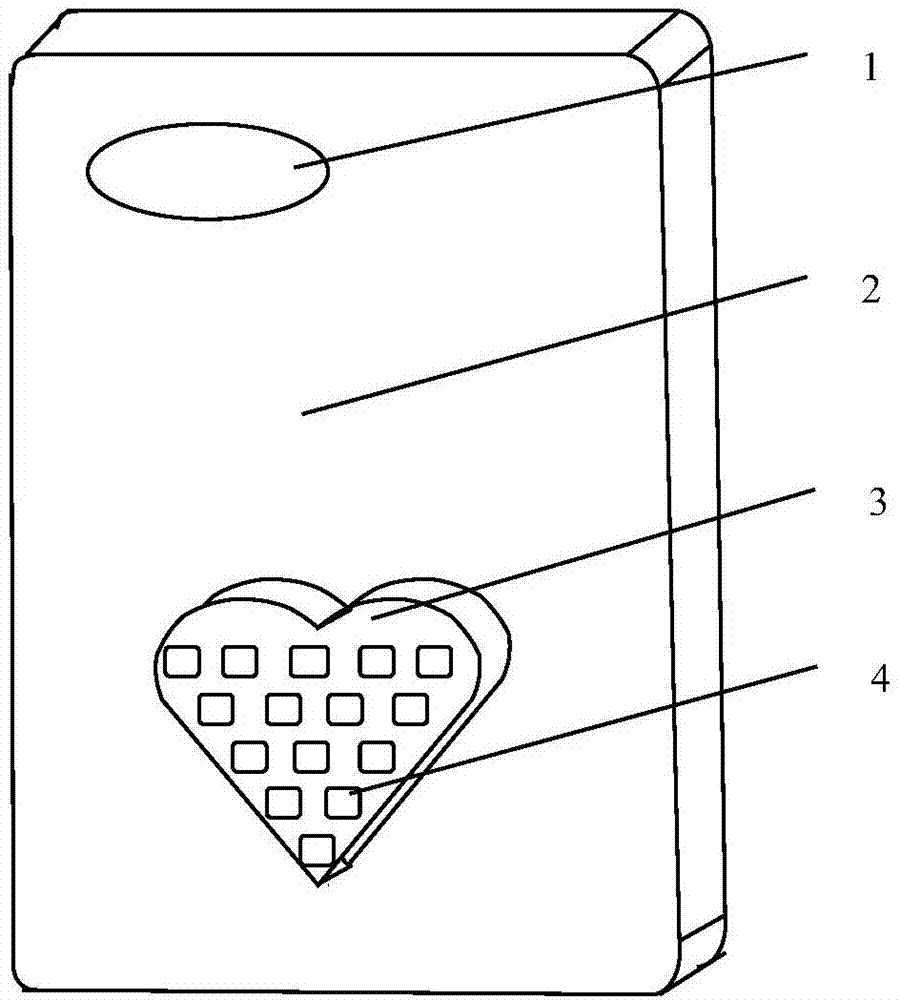

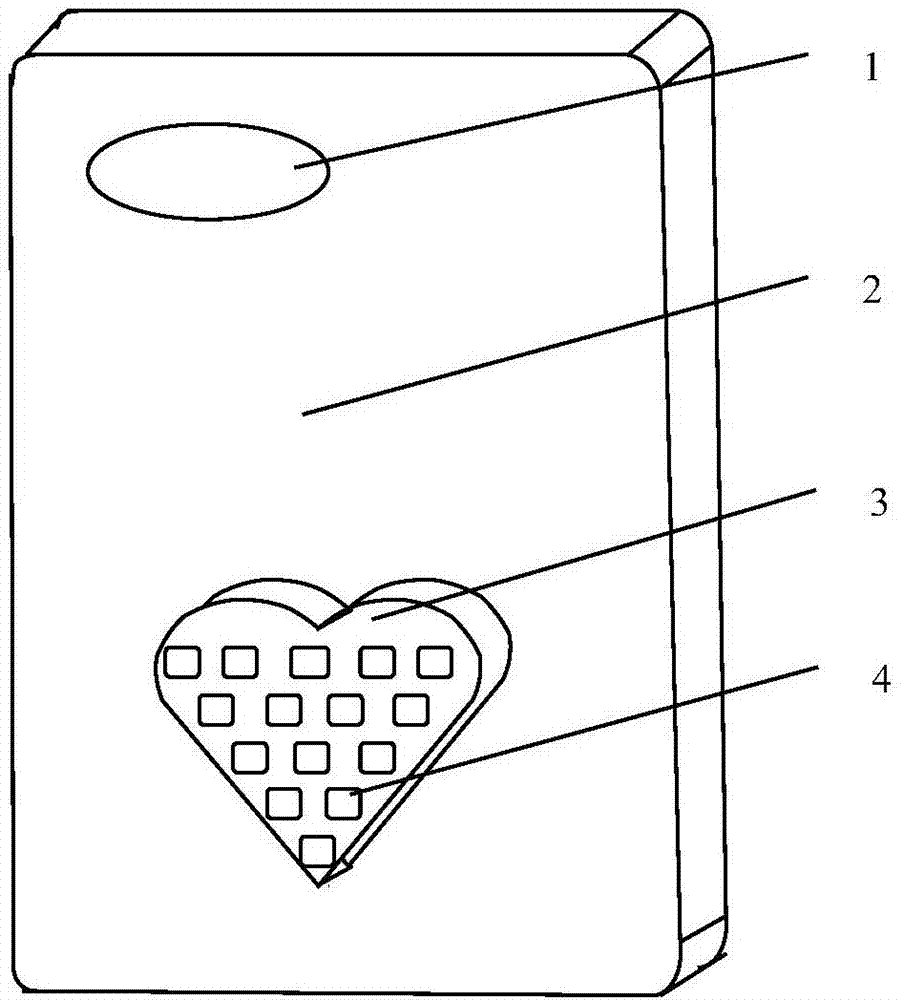

Lamp with at least one light-emitting diode

InactiveCN102216678AAny shapeFavorable structural formPoint-like light sourceElectric circuit arrangementsEngineeringLight-emitting diode

With consideration to energy savings, conventional illumination elements are being replaced by LEDs to an increasing degree. However, the higher the increase in light output, the higher the increase in losses due to radiated heat. To optimally dissipate the incident heat, it is proposed that in a lamp (1, 30) comprising at least one LED (Light Emitting Diode) (4, 34) as a illumination means, comprising a lamp body with a shield (2, 32, 32a) surrounding the LED and a socket (3, 33, 61) holding the LED, the lamp body of the lamp (1, 30) should be made entirely of a ceramic material.

Owner:CERAMTEC

Mobile phone casing

PendingCN107968870AAny sizeAny shapeTelephone set constructionsTablet computerWearable Electronic Device

The invention discloses a mobile phone casing, relates to the field of mobile phone casings, and relates to the field of casings of iPad Pro flat computers, mobile computer devices and wearable electronic devices. A hollow convex part is arranged on the outer surface of the mobile phone casing. The convex part is provided with more than one vent hole, or the convex part contacts the back of a mobile phone, and the vent hole is arranged in the casing surface of the back, which is corresponding to the vent hole, of the mobile phone casing. The size of the vent hole is not limited, and the shapeof the vent hole is arbitrary. The size and the number of the convex part are not limited, and the shape is arbitrary. The convex part becomes a partial accommodating cavity. An aroma article can be placed in the cavity. The mobile phone casing sleeves the mobile phone. The aroma is emitted from the vent hole, which refreshes people. The individual need of people is met.

Owner:王勇

3D printing manufacturing method for surface micro-texture of friction pair

ActiveCN107931605BIncreasing the thicknessImprove wear resistanceAdditive manufacturing apparatusIncreasing energy efficiencyRobot handCnc grinding

A 3D printing manufacturing method for the micro-texture of the surface of the friction pair, the method is to use a numerical control grinding machine to process the surface of the friction pair of the component to be processed, and draw the three-dimensional model of the micro-texture of the surface of the friction pair required by computer three-dimensional CAD software, The three-dimensional model is approximated by small triangles to obtain an approximate model; the approximate model is divided into a series of thin slices along the height direction, the contour information is extracted and processed, and the NC program is generated; then the NC program is imported into the robot control device and the clamping device Fix the component to be processed on the workbench, spread a certain thickness of metal powder on the surface of the component to be processed, and the laser device is driven by the manipulator control device to perform laser sintering on the component to be processed according to the predetermined trajectory to form the required micro-texture on the surface of the friction pair. Effectively improve the wear resistance and anti-friction performance of the friction surface.

Owner:TAIYUAN UNIV OF TECH

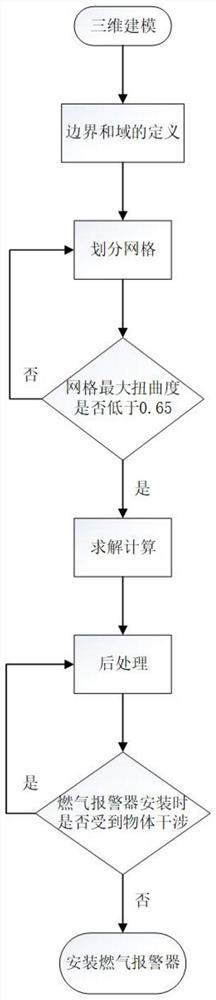

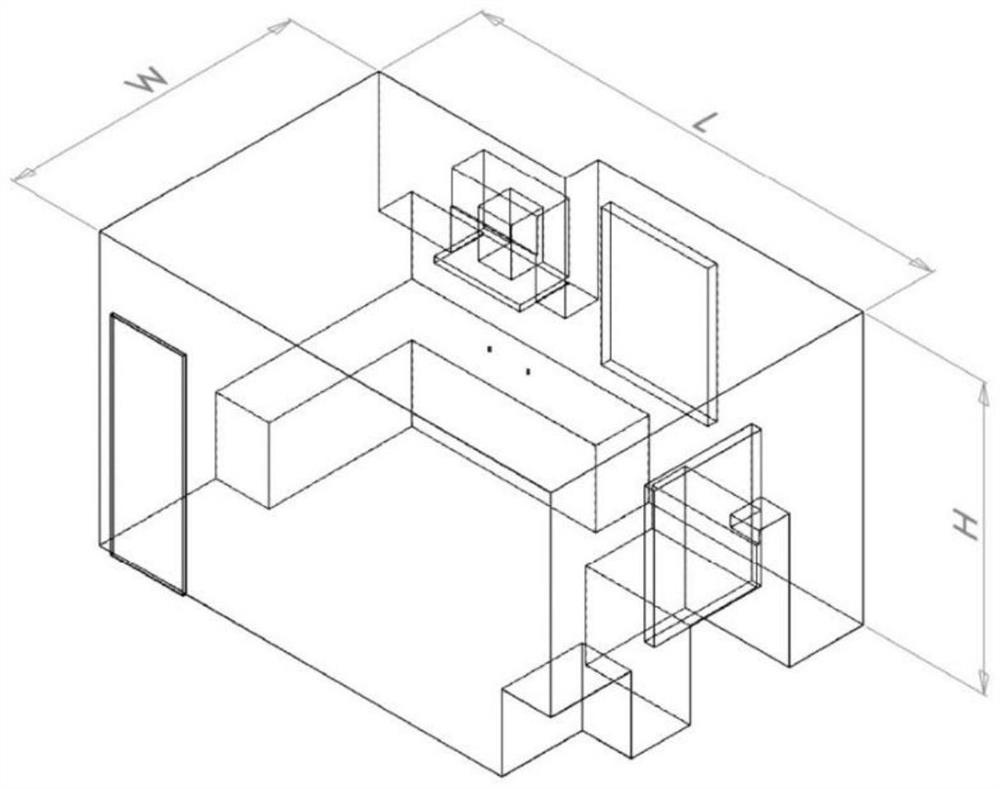

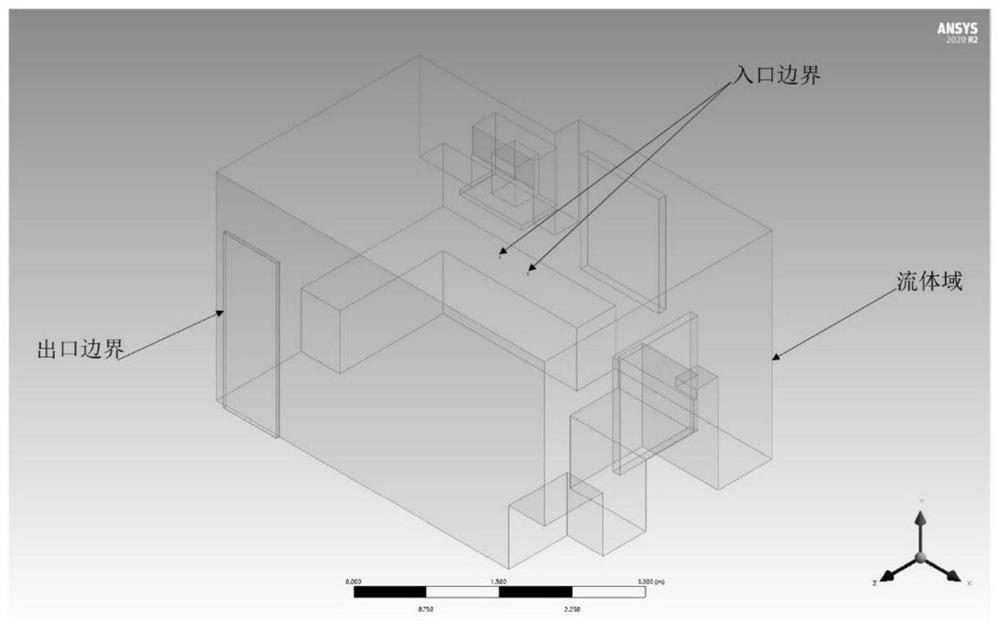

Method for confirming optimal installation position of gas alarm in kitchen based on CFD (Computational Fluid Dynamics)

PendingCN114841094AAny shapeUnlimited volumeGeometric CADDesign optimisation/simulationProcess engineeringDimensional modeling

The invention belongs to the field of natural gas leakage detection, and relates to a method for determining the optimal installation position of a gas alarm in a kitchen based on CFD. The method specifically comprises the following steps: 1, three-dimensional modeling; 2, defining a boundary and a domain of the model; 3, dividing grids; 4, solving and calculating; 5, post-treatment; and sixthly, a gas alarm is installed. According to the invention, the CFD technology is utilized to simulate the leakage of natural gas in a natural gas stove in a closed kitchen at the maximum rate, and the coordinate point at which the volume fraction of methane reaches the alarm set value of a gas alarm first in the installation area meeting the current industrial standard on the peripheral wall and ceiling is obtained; and the point is the optimal mounting position of the gas alarm in the kitchen. According to the invention, the blank of the current industrial standard of the installation area of the gas alarm is filled, and the alarm time of the gas alarm is shortest when the natural gas is accidentally leaked in the kitchen, so that effective measures can be taken in time to prevent leakage, and the accident risk is greatly reduced.

Owner:CHINA JILIANG UNIV

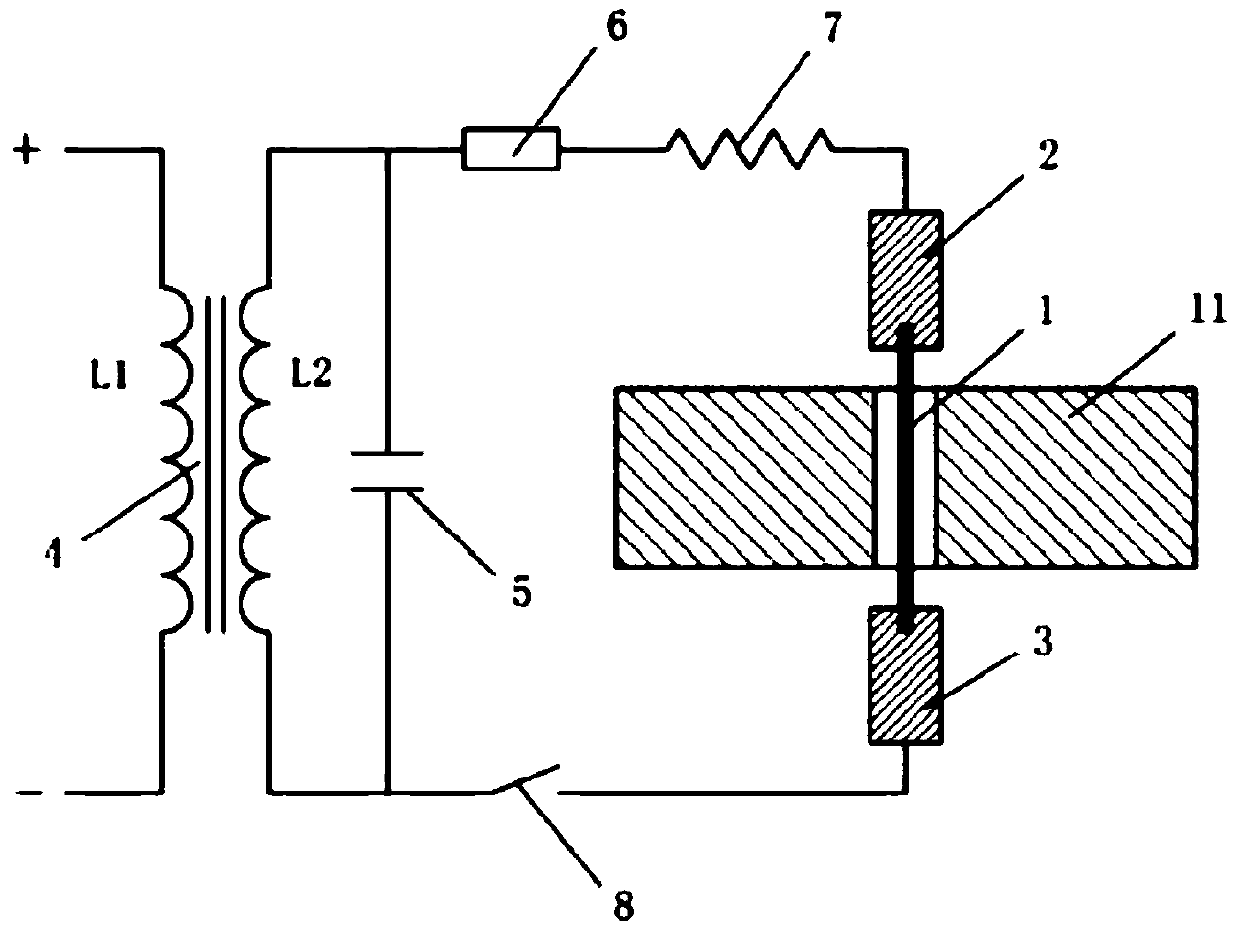

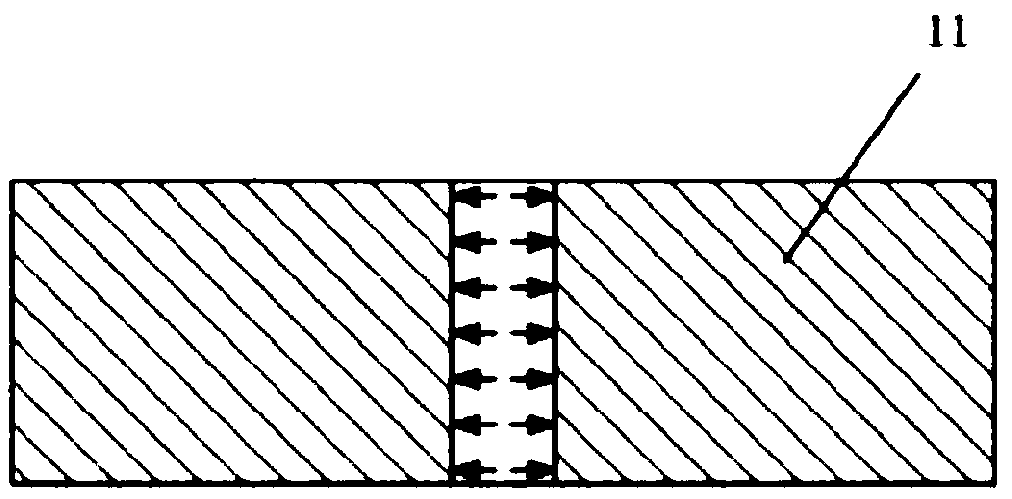

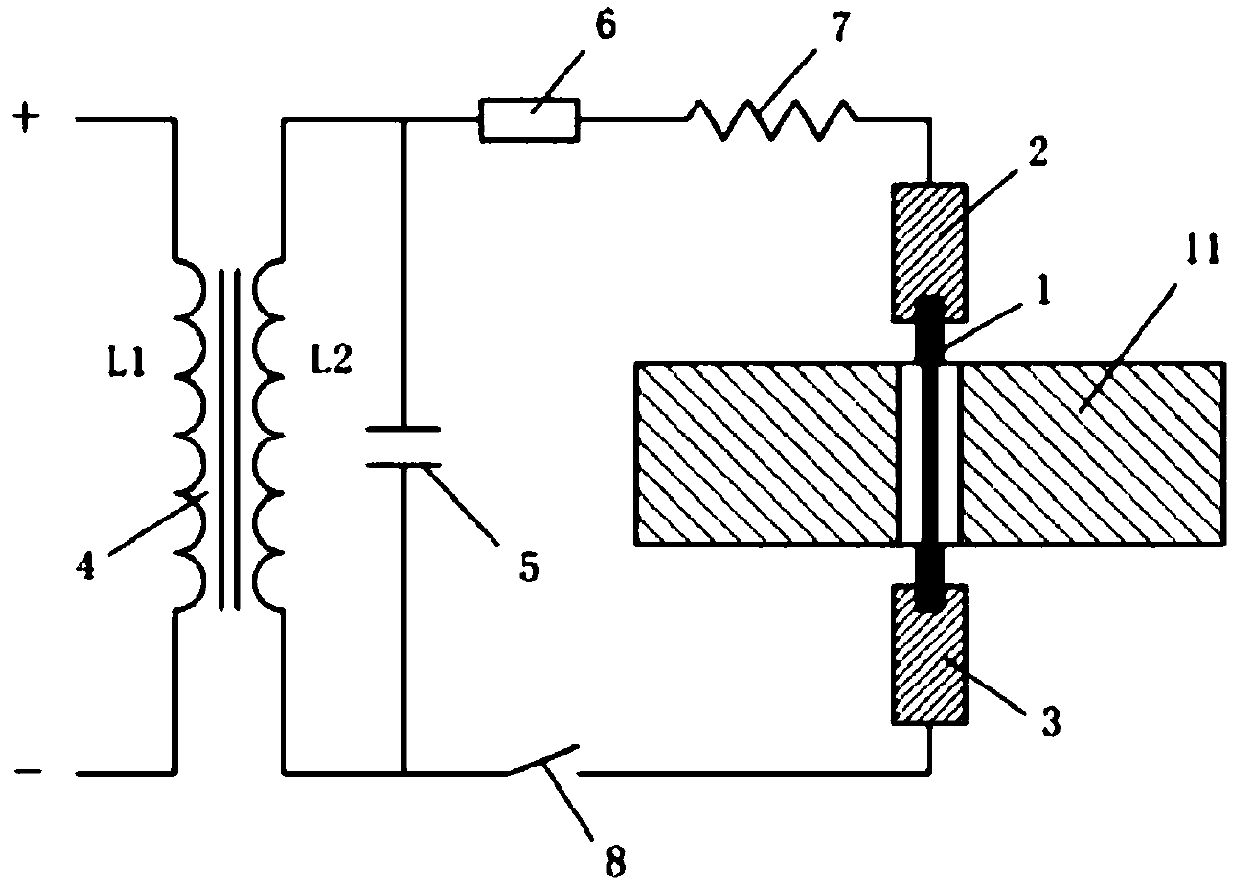

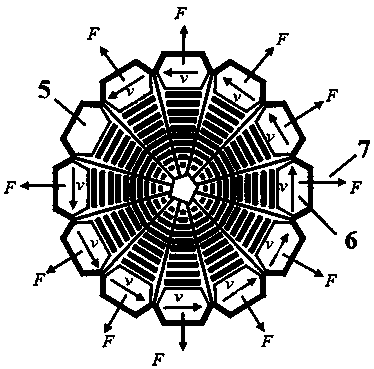

A small hole inner wall strengthening device and method

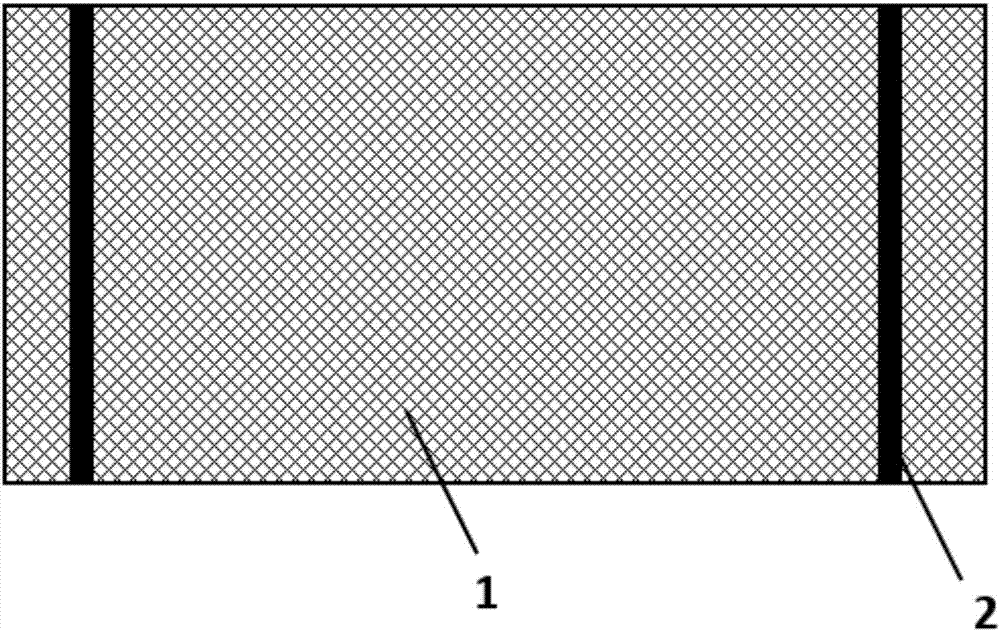

ActiveCN107460280BEvenly distributedAvoid damageMolten spray coatingVacuum evaporation coatingMetallurgySmall hole

The invention discloses a small hole inner wall strengthening device and method. The small hole inner wall strengthening device comprises a metal load (1), a first electrode (2), a second electrode (3) and a metal gasifying circuit. The metal load (1) is arranged through a hole of a part (11) with the hole; the first electrode (2) and the second electrode (3) are separately connected to two ends of the metal load (1); the metal gasifying circuit is connected to the first electrode (2) and the second electrode (3); the metal gasifying circuit, the first electrode (2), the second electrode (3) and the metal load (1) form a circuit loop; and the metal load (1) is gasified when the metal gasifying circuit discharges. The small hole inner wall strengthening device is good in strengthening effect, simple in structure and small in energy of required equipment.

Owner:CENT SOUTH UNIV

Method of preparing line type polyolefin cellular material

InactiveCN100572402CSimple preparation and molding technologyAny shapePolymer scienceFunctional monomer

Owner:NINGBO UNIV

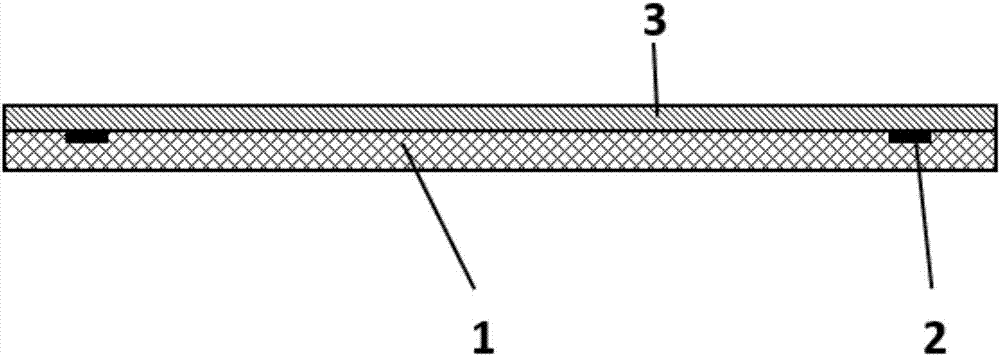

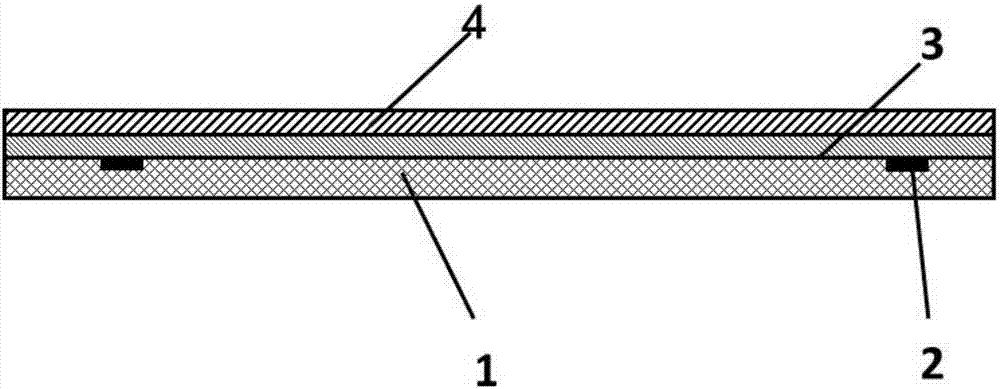

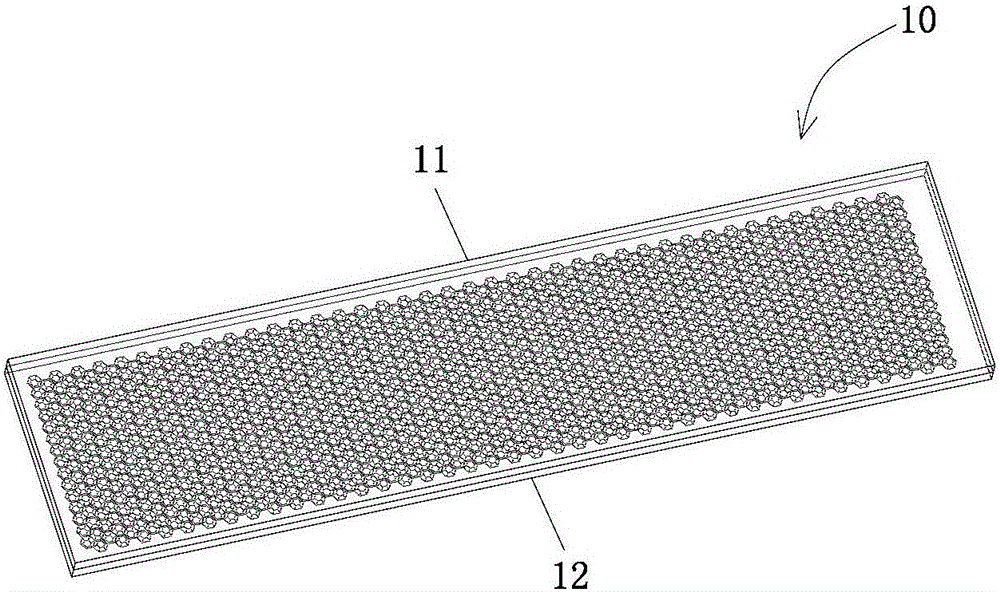

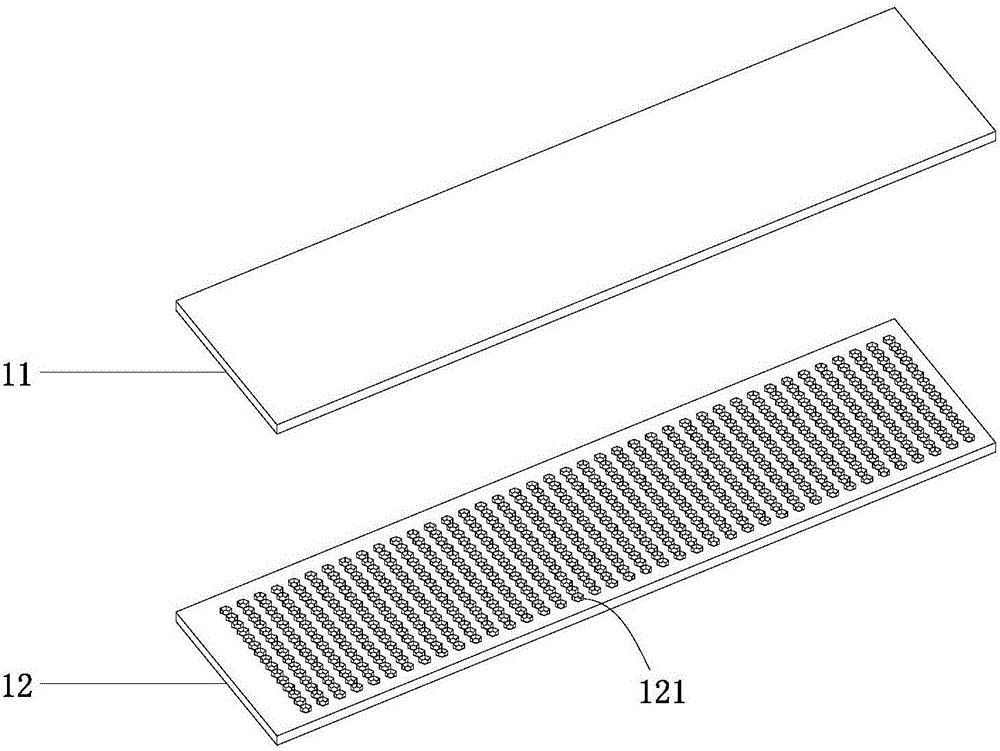

Light evening sheet and LCD module using same

ActiveCN106802514AReduce energy lossSimple processingPlanar/plate-like light guidesNon-linear opticsHigh transmittanceEngineering

Owner:FORYOU GENERAL ELECTRONICS

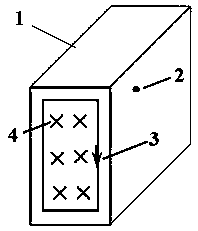

Method for inducing nodular cast iron to synthesize graphene in situ

The invention discloses a method for inducing nodular cast iron to synthesize graphene in situ, wherein the method is applied to the technical field of material modification. The method comprises thesteps that a power source is applied to a nodular cast iron base material, so that electrons moving freely are changed into current carriers moving in an oriented manner, and a circumferential currentmoving around the base material is formed; the magnitude or direction of the circumferential current is changed so that a magnetic field which perpendicularly penetrates the surface of the nodular cast iron base material can be excited; and a carbon atom sheet layer of spheroidal graphite in the nodular cast iron base material is subjected to the effect of the Ampere force pointing to the outer surface of the base material, the carbon atom sheet layer peels, and the graphene is synthesized in situ. According to the method, the internal structure that the spheroidal graphite carbon atom sheetlayer in the nodular cast iron base material is distributed in the radial direction in a layered manner is fully utilized, and the graphene is synthesized in situ based on the effects of the electricfield and the magnetic field; the process is controllable; integrity of the surface of the base body is effectively guaranteed; and performance of a nodular cast iron component is improved at the sametime through in-situ synthesis of the graphene.

Owner:JIANGSU UNIV

Curved functional film structure and method for producing same

PendingCN113423598AIncrease the areaHigh sensitivity3D rigid printed circuitsDashboard fitting arrangementsThermoformingEngineering

The present invention relates to a functional film structure and to a method for producing same. The functional film structure has a sensor key arranged on a film substrate and can be brought into a three-dimensional shape by thermal shaping processes, such as for example vacuum deep drawing or high-pressure forming. The functional film structure is preferably flexible and has preferably transparent and illuminated regions.

Owner:约阿内研究有限责任公司 +2

A method for producing virgin walnut oil by using cotton-stuffed walnuts

ActiveCN108865423BAny diameterAny shapeFatty-oils/fats refiningFatty-oils/fats productionWalnut NutProcess engineering

The invention discloses a method for producing virgin walnut oil by using cotton-padded walnuts. The cotton-padded walnuts are removed from mildew and rotten fruit, soaked in clean water and cleaned by a spray brush roller cleaning machine; the walnut nuts are dried by gradient intermittent low-temperature hot air. ; Use a rice mill to separate the shell and kernel, and obtain kernel powder with a little walnut shell after separation; use oil cloth to wrap the walnut kernel powder and send it to the hydraulic oil press for pressing, and then enter the screw oil press for further pressing to obtain light yellow. Walnut oil; secondary filtration through a self-heating plate and frame filter to obtain high-quality walnut oil. The production equipment of the invention has low cost, high efficiency, strong applicability, and the residual oil rate of the cake is less than 5%. , arsenic, lead, aflatoxin B 1 , benzo (a) pyrene, etc. are within the scope of the national standard, suitable for industrial production.

Owner:贵州省核桃研究所

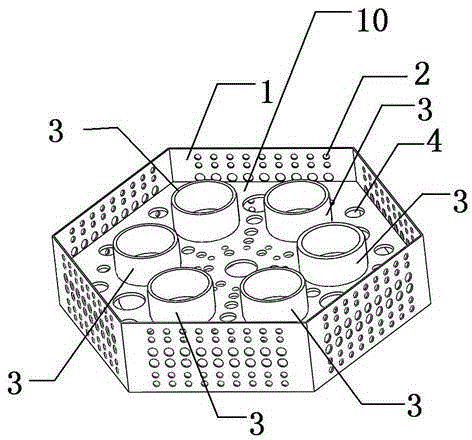

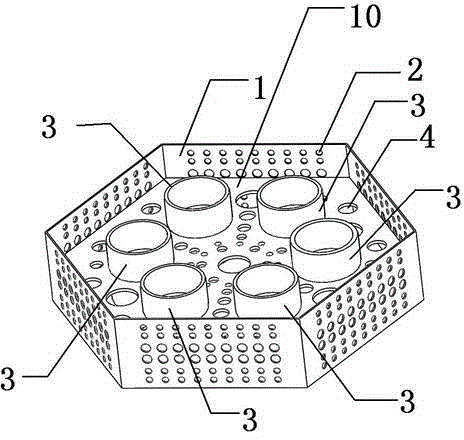

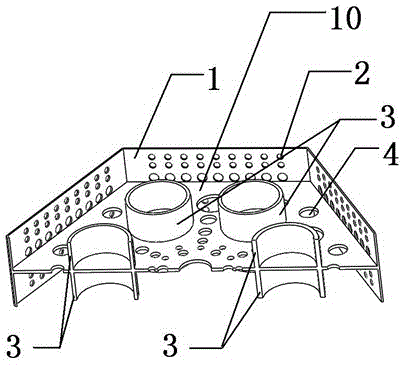

Biological landscape floating island carrier for environmental protection

ActiveCN103864219BEasy to assembleImprove firmnessBiological water/sewage treatmentEngineeringSmall hole

The invention relates to a biological landscape floating island carrier for environmental protection. The carrier is characterized by consisting of one or more plant baskets which are orthohexagonal, wherein the bottom of each basket is located at the middle section of the plant basket, one or more then floating barrel which take the bottom of each basket as a bottom is arranged on each of two sides of the bottom of the basket, many small holes are formed in a non-floating-barrel area at the bottom of each basket, and many small holes are formed in the side walls of the baskets. The floating barrels on two sides of each basket can be lower than the edge of the basket and also can be higher than the edge of the basket. The top of each floating barrel can be sealed or not sealed. The plant baskets are combined and connected by using independent connecting elements or by connection structures designed on the plant baskets. Compared with the prior art, the carrier provided by the invention has the advantages of low cost, convenience in assembly and long service life.

Owner:重庆水生网生态农业发展有限公司

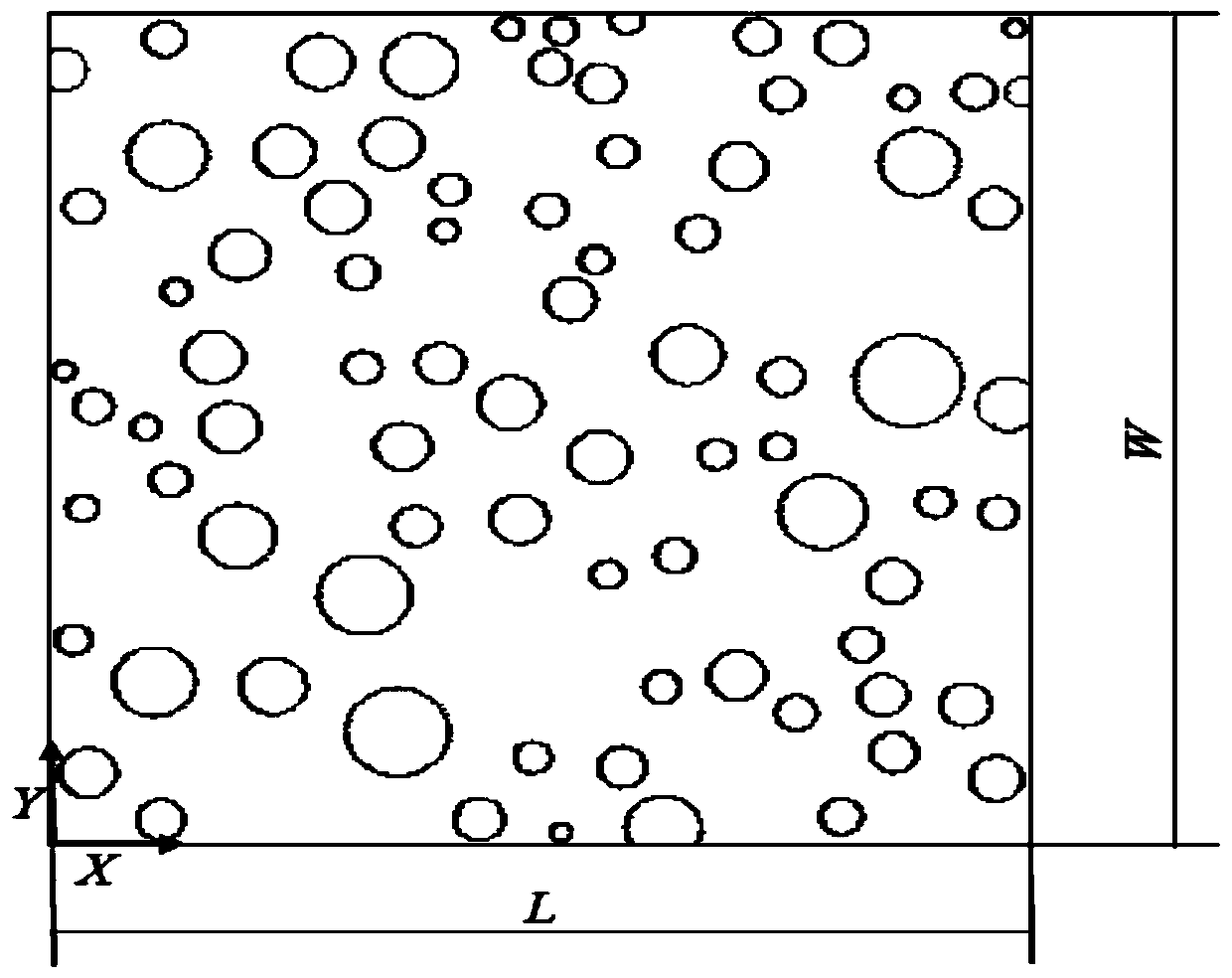

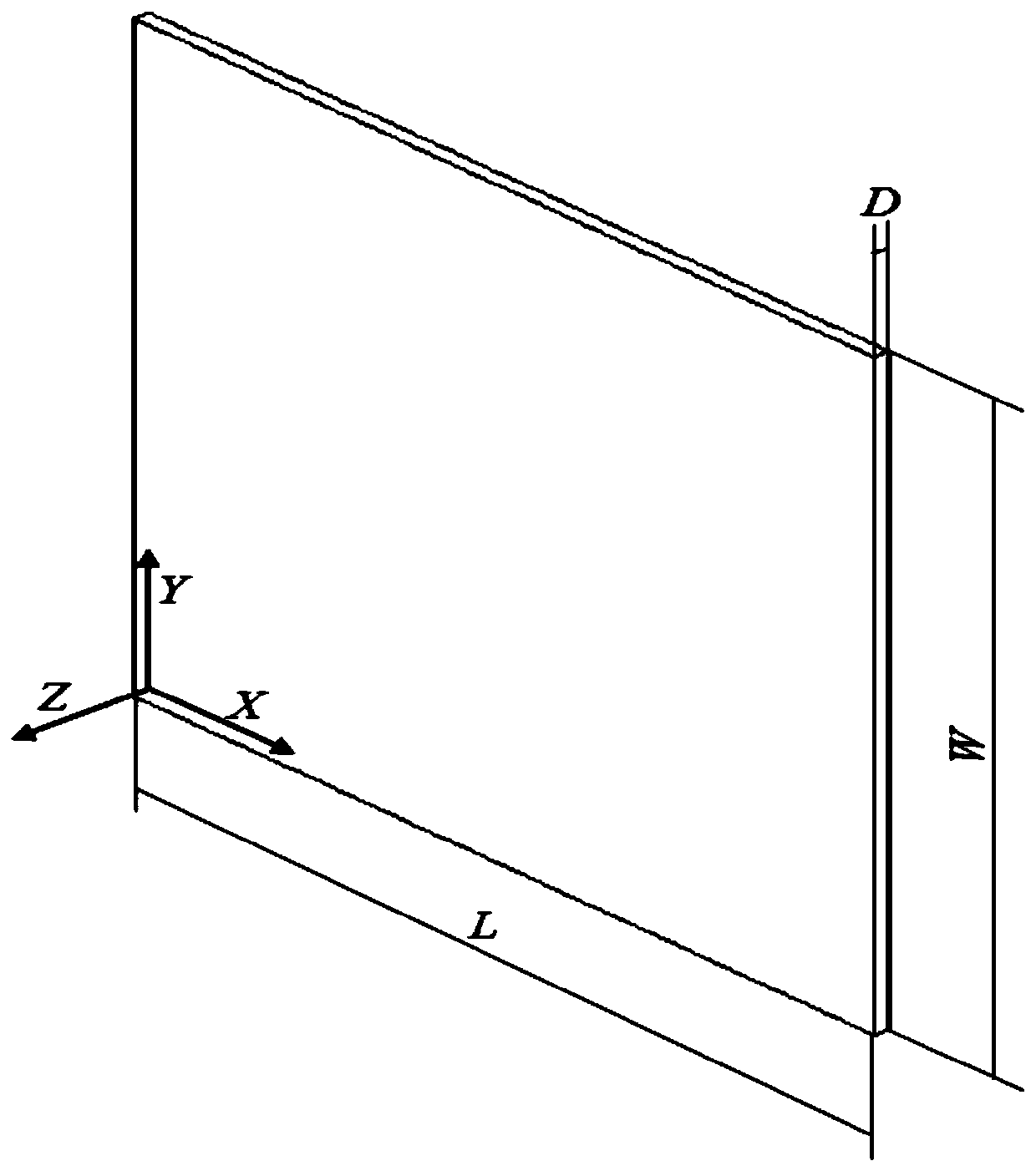

Method for constructing damage structure finite element model based on actually measured pitting corrosion data

ActiveCN110334394AUniversalAuthenticDesign optimisation/simulationSpecial data processing applicationsElement modelElement analysis

The invention discloses a method for constructing a damage structure finite element model based on actually measured pitting corrosion data. The method is suitable for various structures such as a flat plate and a cylindrical shell. The method comprises the following steps: firstly, generating a group of pseudo-random cylindrical pitting pits conforming to actual measurement statistical characteristics by utilizing a random number method according to pitting statistical data, and randomly endowing the cylindrical pitting pits with random numbers representing shapes; secondly, establishing a geometric model of the structure, and arranging a pitting corrosion pit; before the pitting pits are arranged, changing the shapes of the pitting pits according to the shape random numbers; then, carrying out Boolean operation on the pitting corrosion pit model and the structure geometric model, and constructing a random pitting corrosion geometric form in the structure geometric model; and finally,performing finite element mesh generation to obtain a finite element model of the damaged structure. The invention provides a method for simulating random pitting corrosion in a random pitting corrosion damage structure, which constructs a finite element analysis model of the structure based on statistical data of actually measured pitting corrosion, and the method can be used for accurately evaluating the structural performance.

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com