Method for constructing damage structure finite element model based on actually measured pitting corrosion data

A finite element and pitting technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as unrealizable, high cost of pitting damage, etc., and achieve a more universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

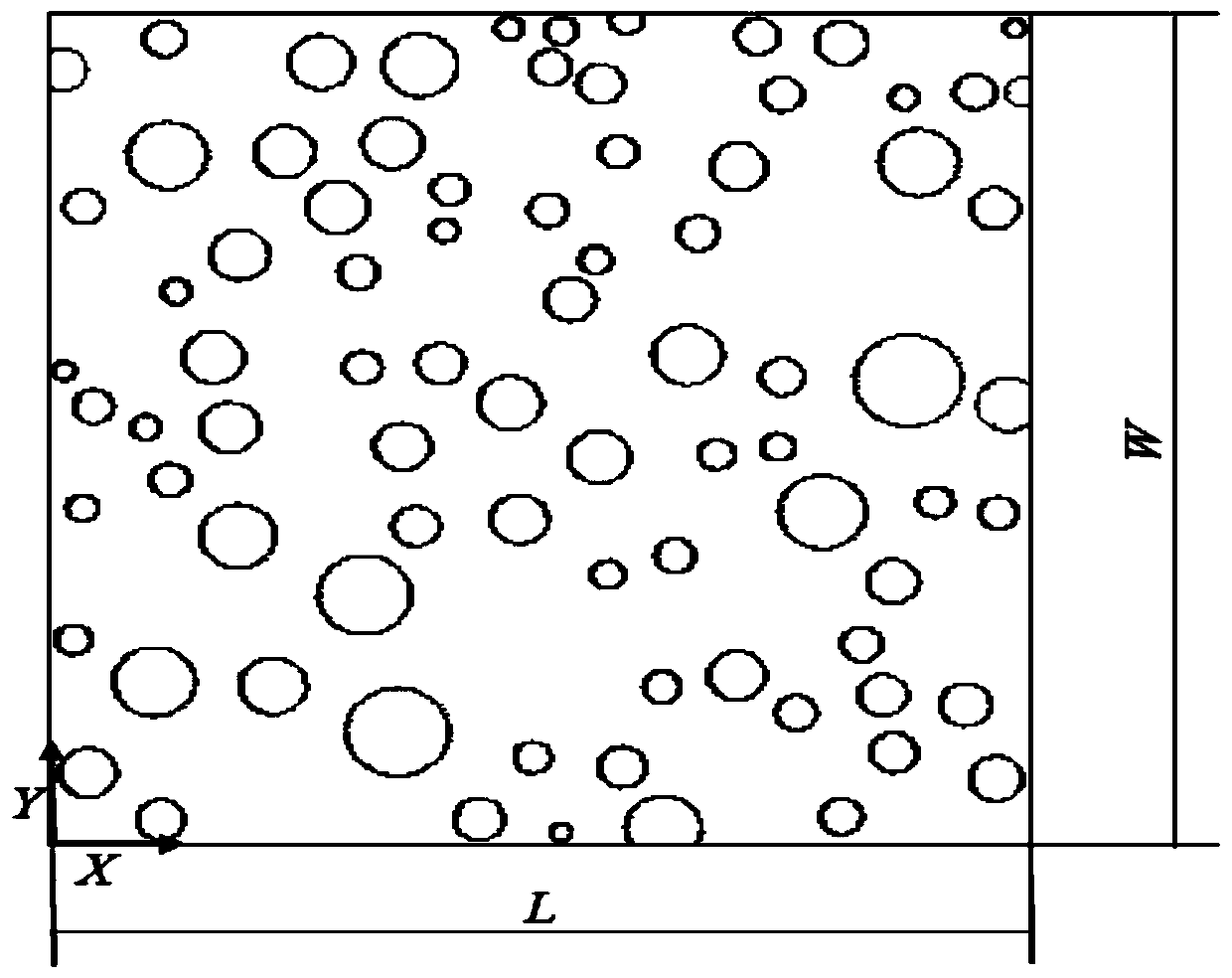

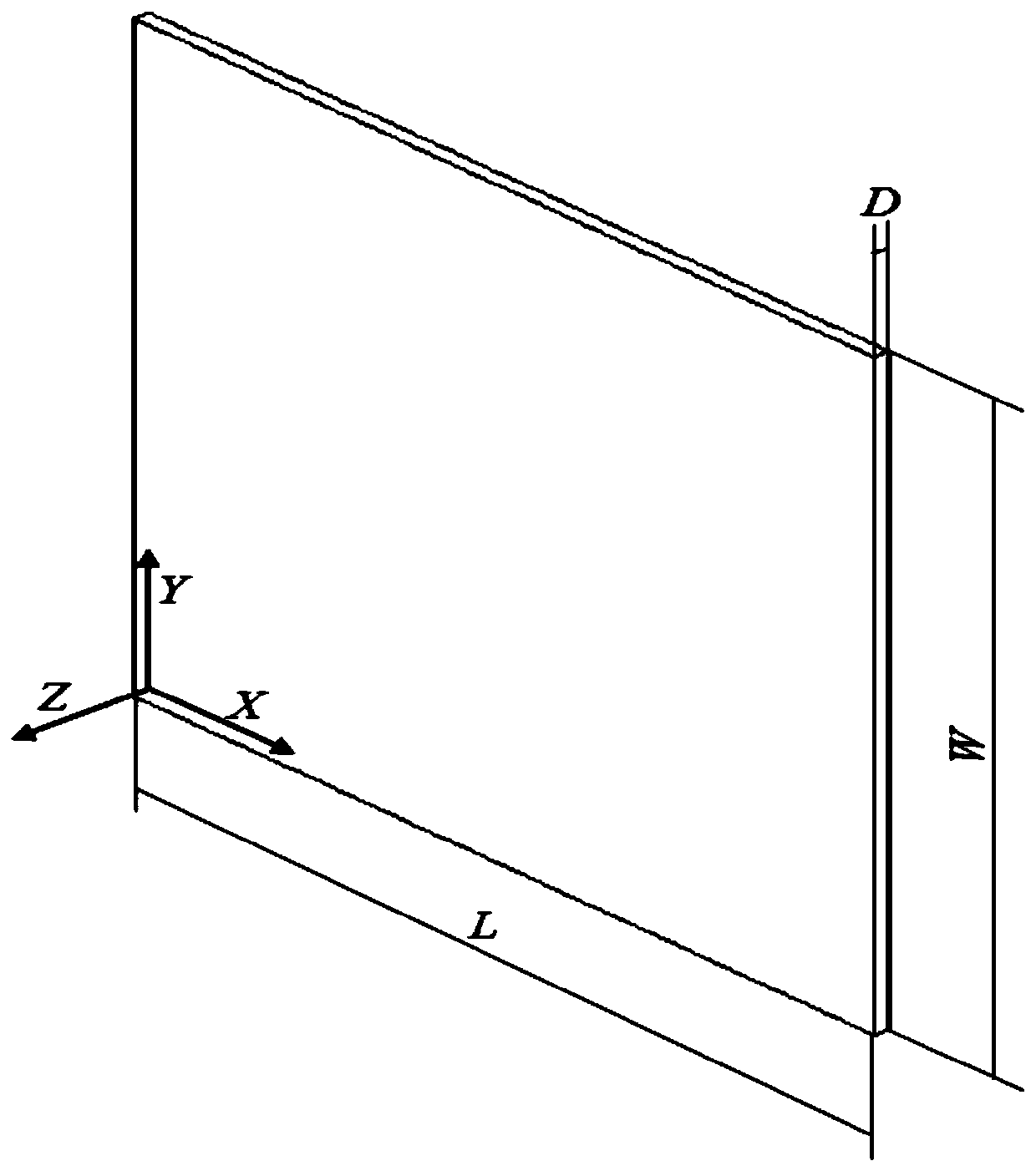

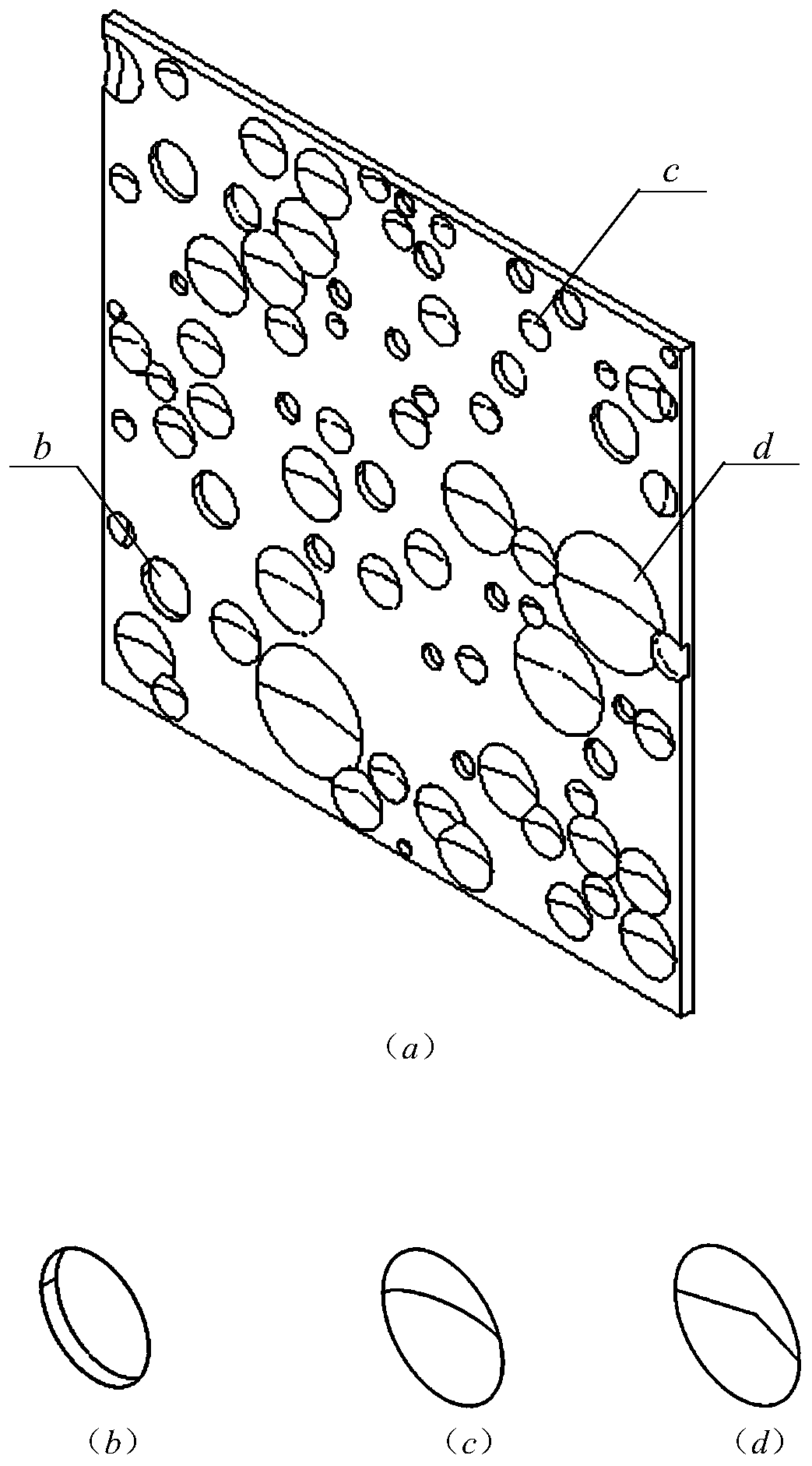

[0044] Below in conjunction with the accompanying drawings, a simple pitting damaged flat plate is taken as an example, and the finite element software adopts ANSYS to further describe the present invention in detail.

[0045] A method for constructing a finite element model of a damaged structure based on measured pitting data, specifically comprising the following steps:

[0046] Step 1: According to the measured number of pits 82, the average pit radius of 20.1mm, the average pit depth of 9.62mm, the maximum and minimum radius of 44.03mm and 8.64mm, and the maximum and minimum depth of 10.77mm and 6.66mm, Generate a set of depth data conforming to random normal distribution in EXCEL (with 9.62mm as the mean, 0.5 as the standard deviation, the function used: NORMINV(RAND(), 9.62, 0.5)), the specific generation method is as follows:

[0047] (1) Generate the random depth d of the nth (n starts from 1) point pit i (i=n).

[0048] (2) Judgment d i Whether it is greater than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com