Production method of GRC component with stone-like effect

A production method and component technology, applied in the production field of GRC components, can solve the problems of strict requirements for imitating stone texture of GRC mother, increase labor costs and material costs, and extremely high requirements for workers' skills, so as to achieve high stone imitation effect and improve enterprise economy. Benefits and social benefits, high-efficiency effects

Pending Publication Date: 2022-06-10

CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If the traditional GRC decorative component processing technology is used to achieve the imitation stone effect, its disadvantages are that the requirements for the imitation stone texture of the GRC master mold are more stringent, and the requirements for the workers' skills are extremely high, and the production of silicone molds is generally used, which invisibly increases Labor cost and material cost, the construction period becomes longer

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0027] In order to dedust, prevent environmental pollution, in step B, a water spray dust removal device is set at the nozzle of the sandblasting machine.

[0036] The present invention is defined in the appended claims. But based on this, those of ordinary skill in the art can do

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

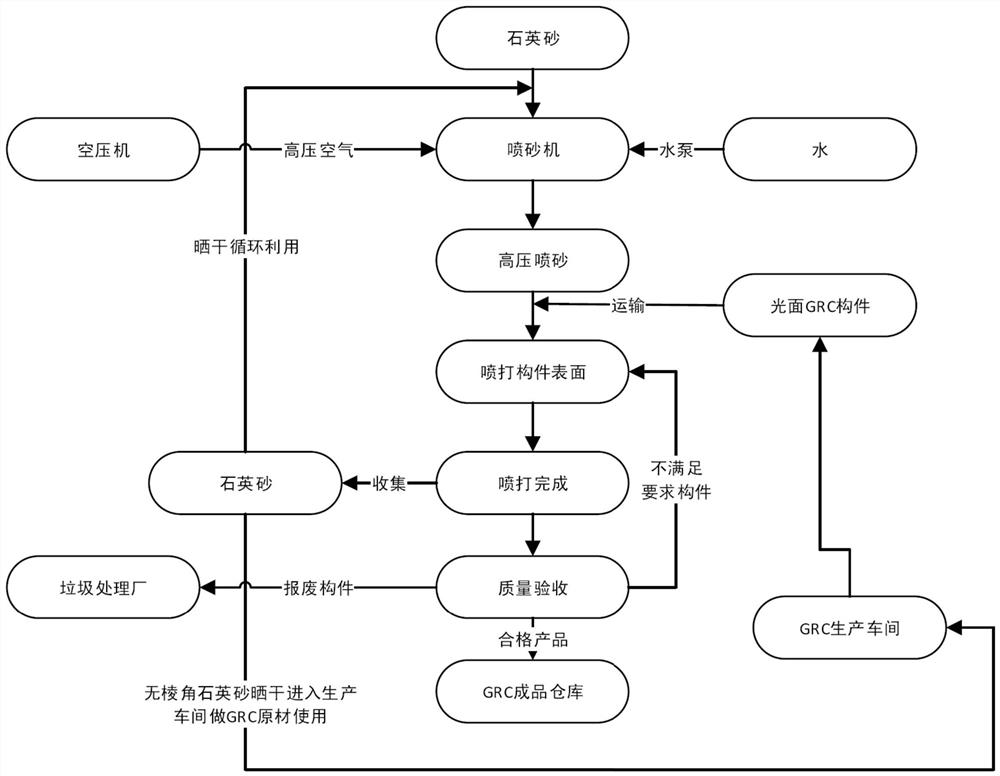

The invention relates to a production method of a GRC component with a stone-like effect. The production method comprises the following steps: A, producing a glazed GRC component by using a mold; the member is regularly maintained after being demolded, the maintenance time is not less than 7 days, and the strength is ensured to reach 80% of the design strength; and B, quartz sand is sprayed out through a sand blasting machine, the smooth GRC component is impacted, the surface of the GRC component is subjected to skin damage, natural non-quality damage is caused, and a stone-like effect surface layer is formed. According to the production method of the GRC component with the stone-like effect, on the basis of ensuring the product quality and perfectly presenting the overall stone-like effect, the construction period can be greatly shortened, the cost can be saved, and the problems of environmental protection and the like can be avoided.

Description

A kind of production method of GRC component with imitating stone effect technical field The invention belongs to technical field of building construction, particularly a kind of production method of the GRC component of imitation stone effect. Background technique With the social development of human beings, the progress of human civilization, the architectural aesthetic requirements of buildings are continuously enhanced to meet the People's needs for personalized buildings, many theme parks use GRC decorative components to themed outer packaging of structural buildings, Imitation stone buildings are on the rise. In actual construction, we are faced with many technical problems, such as ensuring the quality and effect of construction. How to save cost, reduce construction period and protect the environment under the premise. If the traditional GRC decorative component processing technology is used to The disadvantage of realizing the stone imitation effect is tha...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B24C1/00B24C5/04B24C9/00

CPCB24C1/00B24C5/04B24C9/003

Inventor 武龙河柴彬张树燕常亮高旺孙天宇侯志超夏盼何飞

Owner CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com