Patents

Literature

53results about How to "Improve paint adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

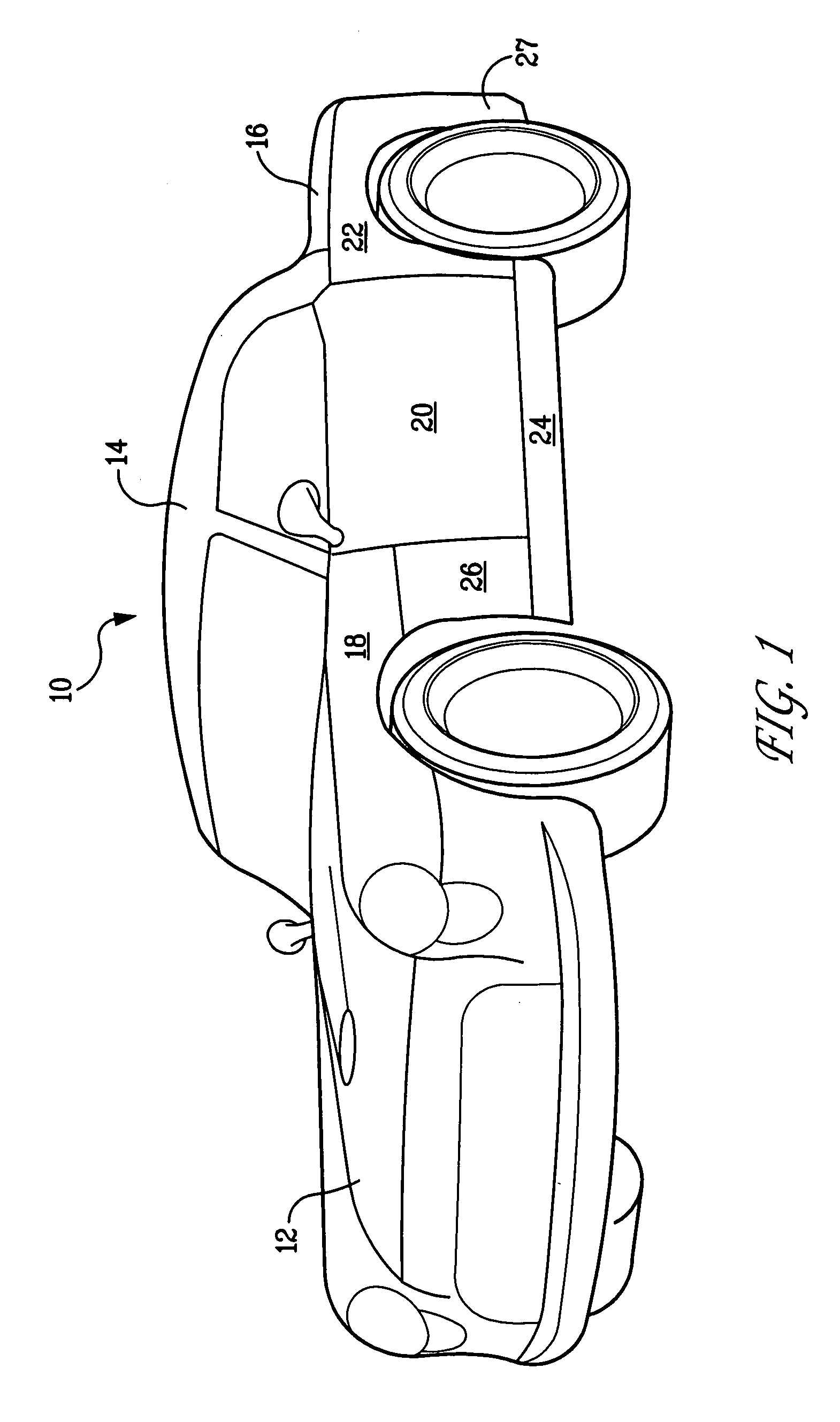

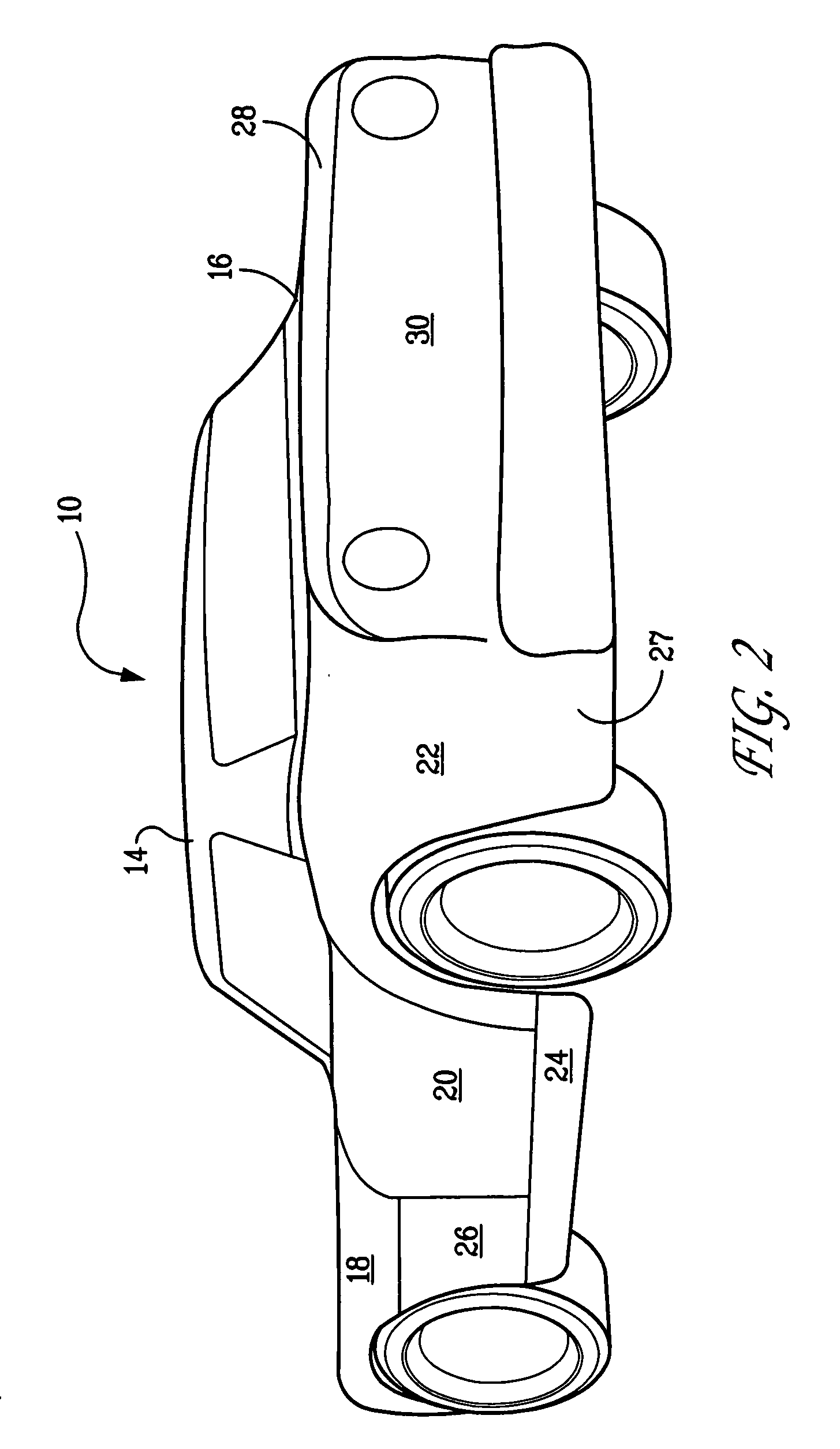

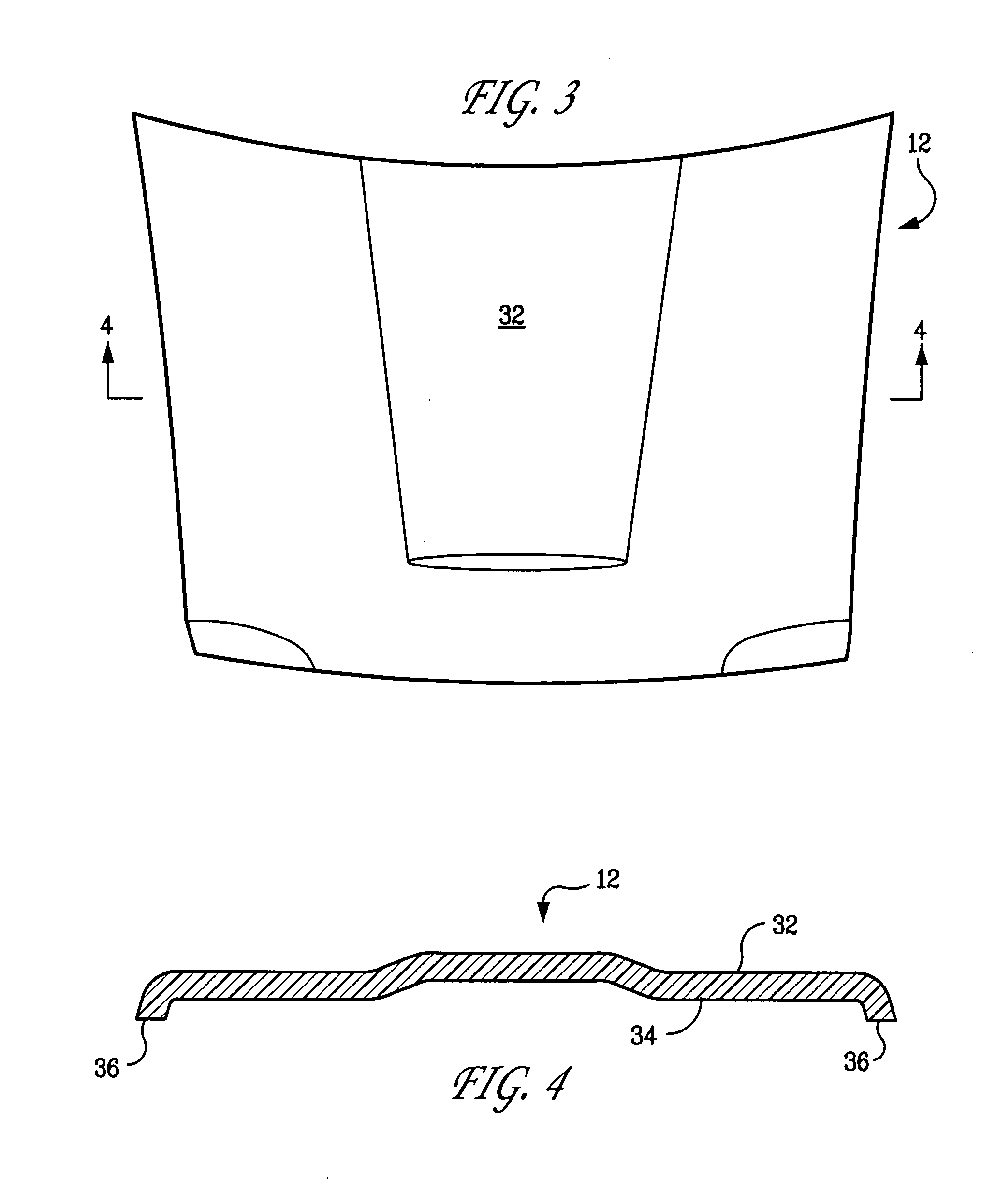

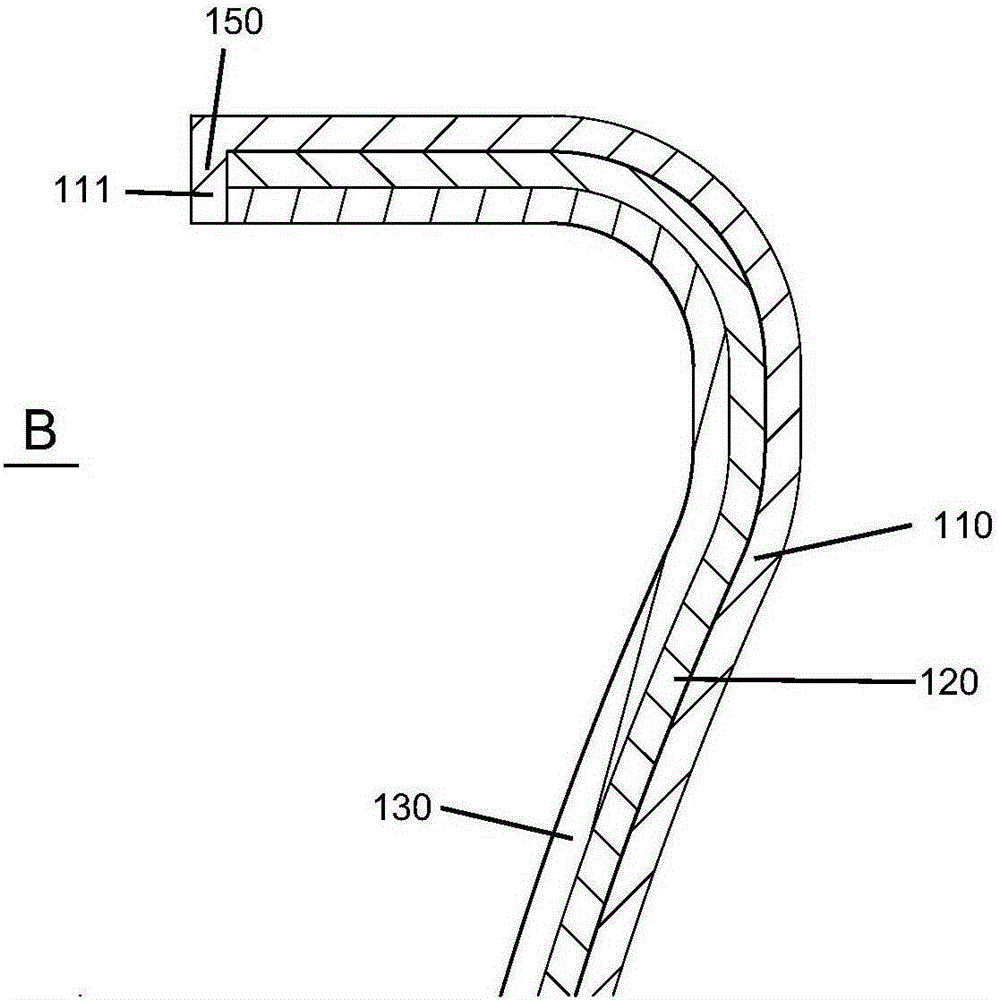

Paint system and method of painting fiber reinforced polypropylene composite components

InactiveUS20060263529A1Improve paint adhesionImprove fuel resistancePretreated surfacesCoatingsFibre reinforcementFiber-reinforced composite

A method of painting a fiber reinforced composite vehicle component, the fiber reinforced composite vehicle component molded from a composition comprising a polypropylene based resin, an organic fiber and an inorganic filler, the component having at least a first surface. The method includes the steps of lowering the surface tension of the first surface of the fiber reinforced composite vehicle component, applying a base coat paint to the first surface of the fiber reinforced composite vehicle component and applying a clear coat paint to the first surface of the fiber reinforced composite vehicle component. A paint system and a process for producing a painted fiber reinforced polypropylene composite vehicle component are also provided.

Owner:LUSTIGER ARNOLD +1

UV-curable, non-chlorinated adhesion promoters

InactiveUS7388039B2Increase heightGood solvent resistanceCosmetic preparationsSurgical adhesivesWater dispersiblePolyolefin

Modified polyolefins are produced by reacting a functionalized polyolefin with one or more ethylenically unsaturated compounds having a functional group reactive with the functional group on the polyolefin. These modified polyolefins may then polymerize in the presence of a photoinitiator upon exposure to ultraviolet radiation and also have the capability of copolymerizing in the presence of a photoinitiator with other ethylenically unsaturated crosslinking agents upon exposure to ultraviolet radiation. These modified polyolefins may also contain pendant carboxyl groups, which have the propensity to form hydrophilic salts with amines, and therefore may be rendered water-dispersible. The modified polyolefins of the present invention significantly improve the adhesion of paints, inks, and adhesives to various plastic and metal substrates.

Owner:EASTMAN CHEM CO

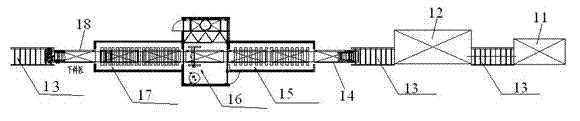

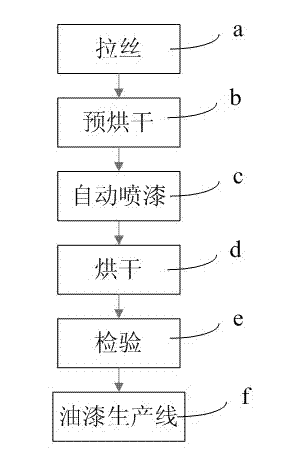

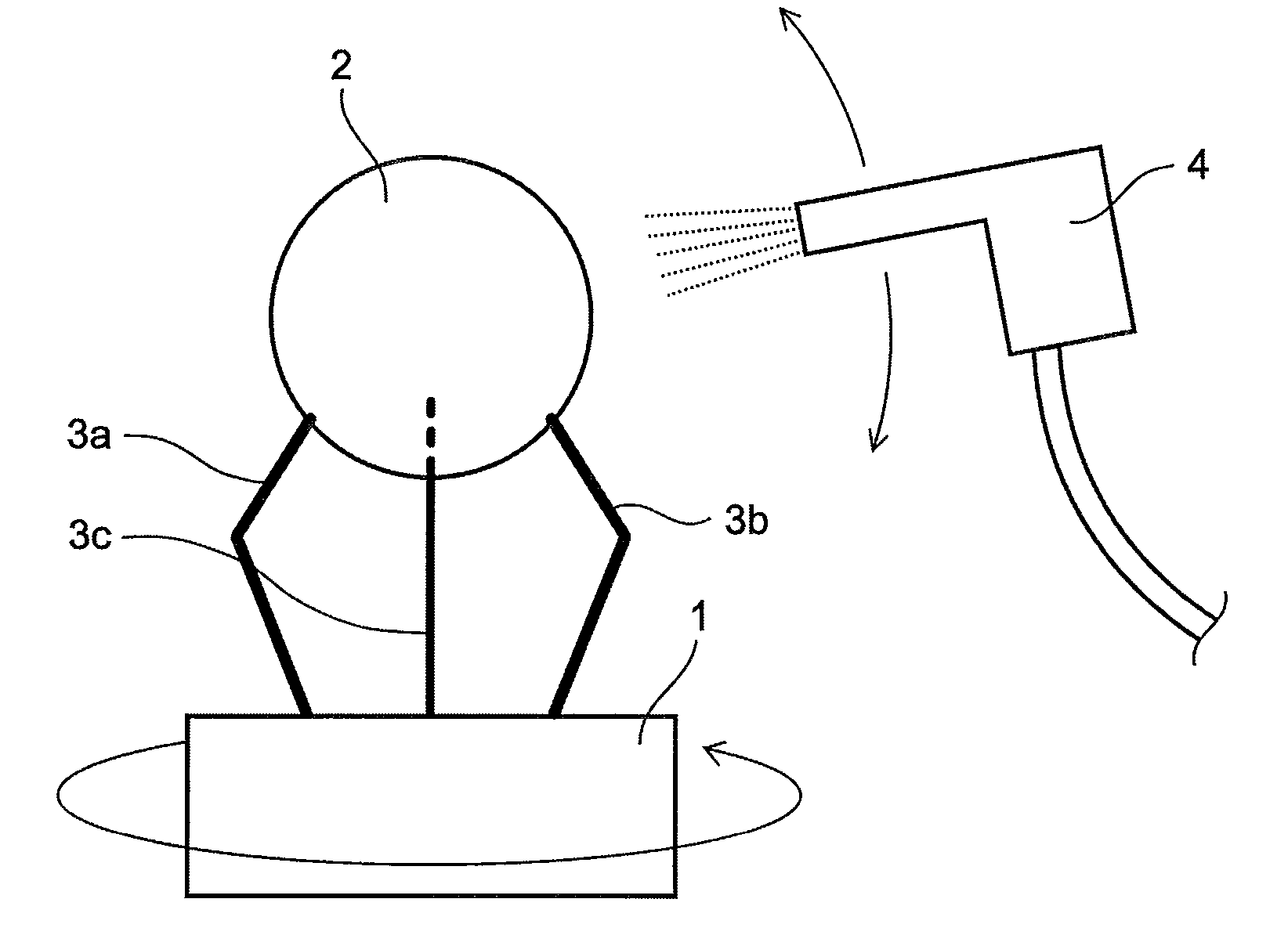

Metal surface treatment device and metal surface treatment method

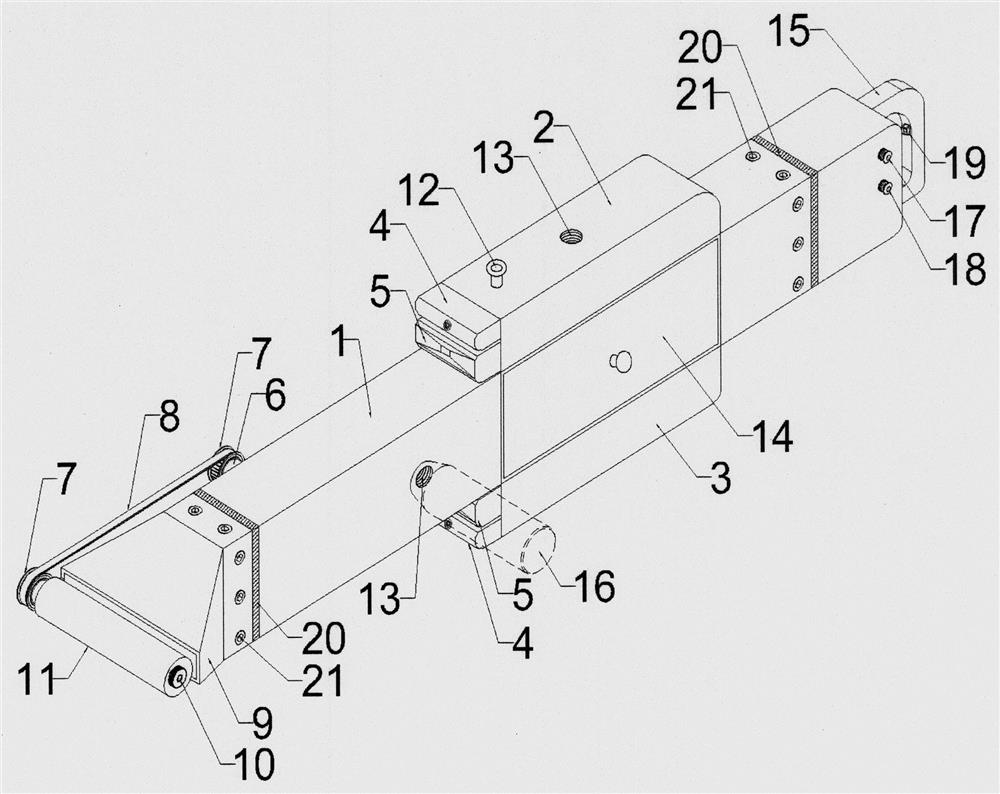

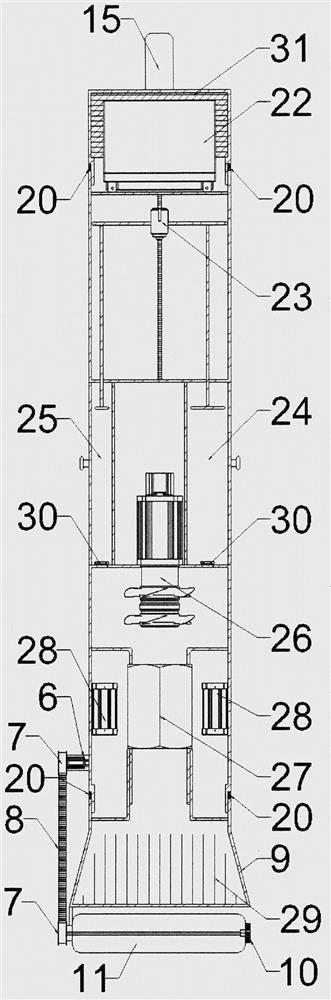

ActiveCN102847651AImprove paint adhesionImprove anti-corrosion performanceElectrophoretic coatingsSpecial surfacesEngineeringEnergy consumption

The invention provides a metal surface treatment device which comprises a drawing machine bench, a predrying device, a coating device, and a drying device which are orderly disposed, and also comprises a transmission system used for workpiece transmission between the devices. In addition, the invention also provides a metal surface treatment method, which greatly reduces the energy consumption, provides metal parts with very good anticorrosion effect, and elegant appearance.

Owner:WUXI AOMEI MACHINERY

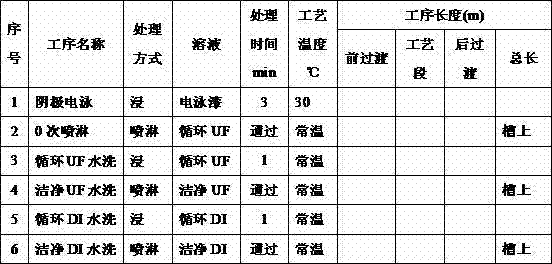

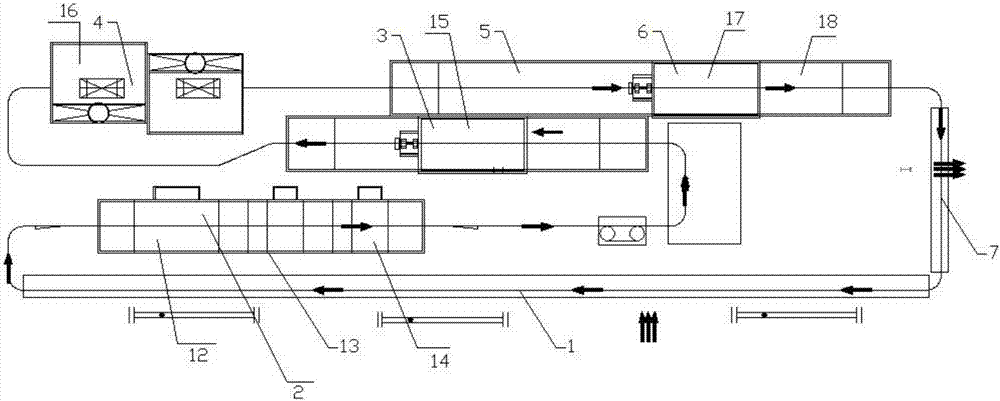

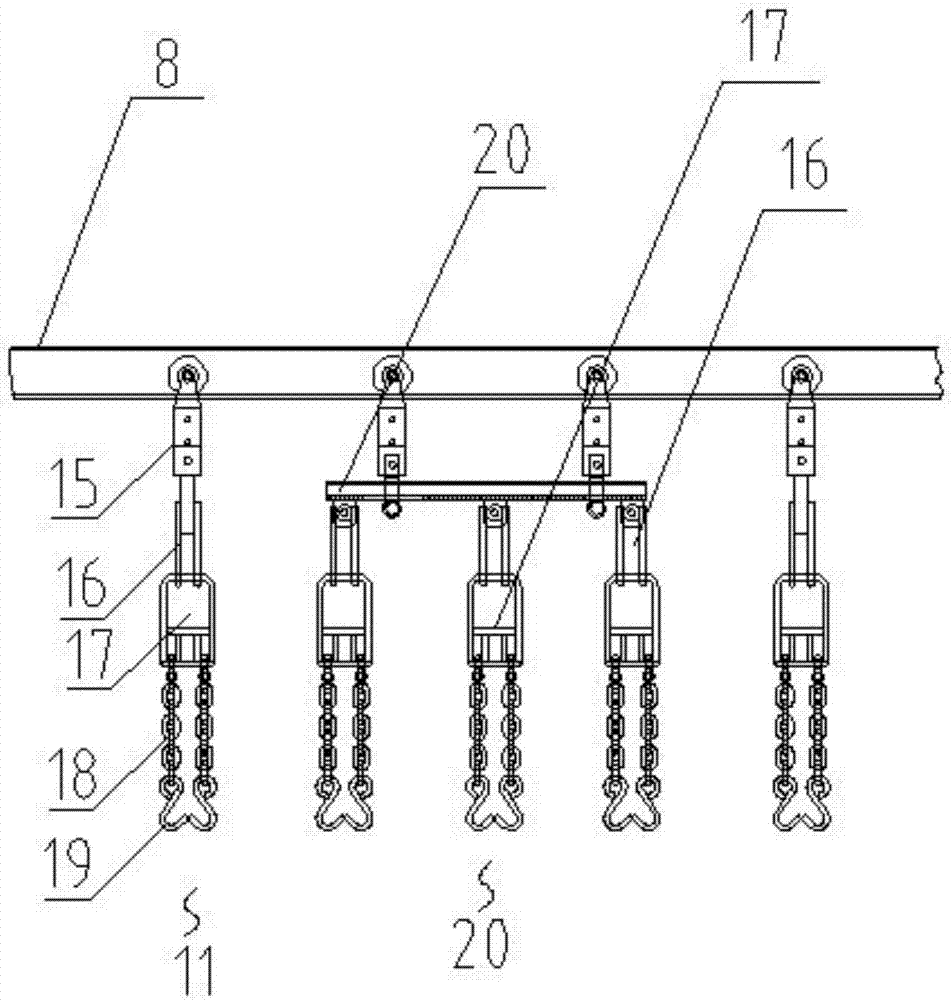

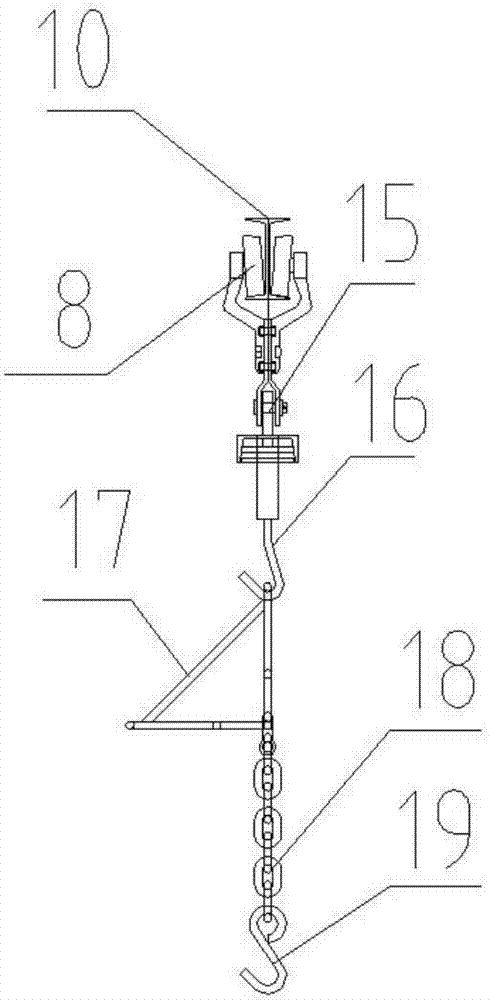

Agricultural equipment gearbox coating line and coating method thereof

ActiveCN107138335AEfficient removalReduce pollutionSpraying apparatusPretreated surfacesAgricultural engineeringElectric machinery

The invention discloses an agricultural equipment gearbox coating line which comprises a line feeding area, a washing area, a drying area, a paint spraying area, a levelling area, a finishing coat drying area, a line discharging area, a rail, a coating assembly line chain, a plurality of lifting appliance assemblies and a drive motor, wherein the line feeding area, the washing area, the drying area, the paint spraying area, the levelling area, the finishing coat drying area and the line discharging area are sequentially connected; the rail is fixedly arranged at the top of the entire agricultural equipment gearbox coating line; the coating assembly line chain is connected with the drive motor; the coating assembly line chain is connected with the rail; driven by the drive motor, the coating assembly line chain moves along the rail; the lifting appliance assemblies are fixed on the coating assembly line chain; and gearboxes are lifted through the lifting appliance assemblies at the line feeding area. The agricultural equipment gearbox coating line is reasonable in structure, light and convenient to operate, excellent in coating effect and high in paint adhesive force, and the agricultural equipment gearbox coating line and a coating method thereof can meet the using requirements.

Owner:山东卫禾传动股份有限公司

Process and seal coat for improving paint adhesion

ActiveUS20120152754A1Improve paint adhesionEnhancing surface coating characteristicGroup 4/14 element organic compoundsAntifouling/underwater paintsZinc phosphatePolyvinyl alcohol

Aqueous compositions useful as pretreatments prior to painting and to reduce the formation of rust in the uncoated condition consist essentially of water, an organo-functional silane, a compound of a Group IV-B element, and optionally a polyvinyl alcohol, stabilizing agents, wetting agents, thickeners, and biocides, and have an alkaline pH>7. A process for treating a metal surface includes contacting the surface with such an aqueous composition. The compositions and processes were found to have further benefits in comparison to the zinc phosphate metal pretreatment thought to be the standard in the industry. Preferably, the pH of the compositions is alkaline, which has been found to improve the efficacy of a silane as a surface treatment to improve uniformity of paint adhesion. By operating in the alkaline pH range, it was found that flash rusting and / or blush rust were significantly reduced.

Owner:BULK CHEM

Water base adhesion promotor for polypropylene and method for coating to polypropylene materials using the promotor

InactiveUS6447844B1Improve wettabilityImprove adhesionPretreated surfacesCoatingsWater basedChloride

The water base adhesion promotos for polypropylene comprises:a grafted polypropylene chloride, which includes a polypropylene chloride moiety and a maleic anhydride moiety as bonded thereto, and which has a chlorine content of 15~25 weight % and a maleic anhydride moiety content of 1~5 weight %;an amine-neutralized water-soluble resin;a wettability-improving agent; andwater;and is characterized by having:a combination ratio of 25~90 weight % as of the grafted polypropylene chloride to the total of the grafted polypopylene chloride and the amine-neutralized water-soluble resin;a combination ratio of 2.5~6.0 weight % as of the wettability-improving agent to the entirety of the promotor; anda solid content of 2~10 weight % of the entirety of the promotor. The method for coating to polypropylene materials comprises:a pretreatment step in which the polypropylene material is beforehand cleaned and then the above water base adhesion promotor is applied, and then dried; anda coating step in which a paint is coated to the material after the pretreatment step.

Owner:HONDA MOTOR CO LTD

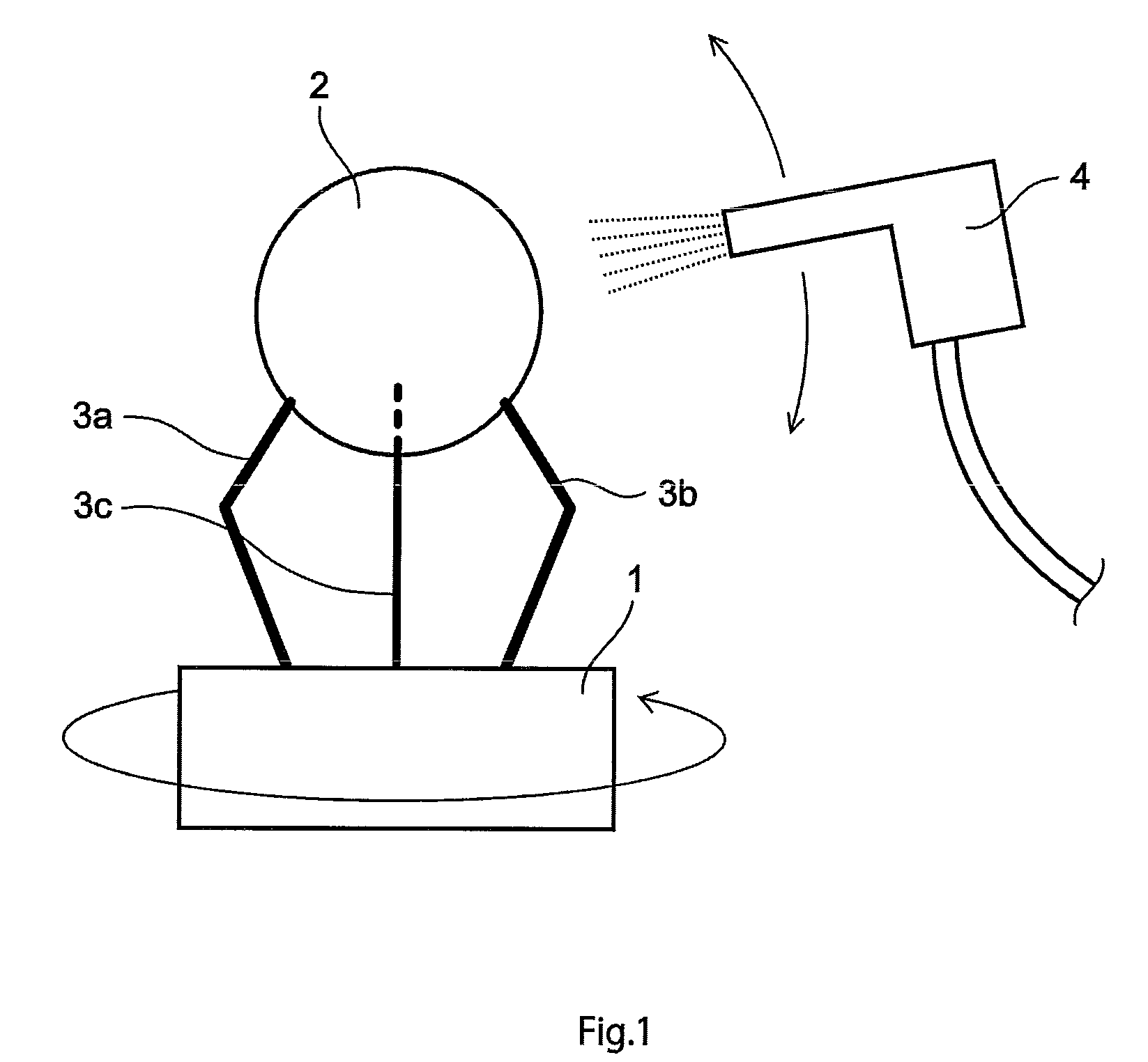

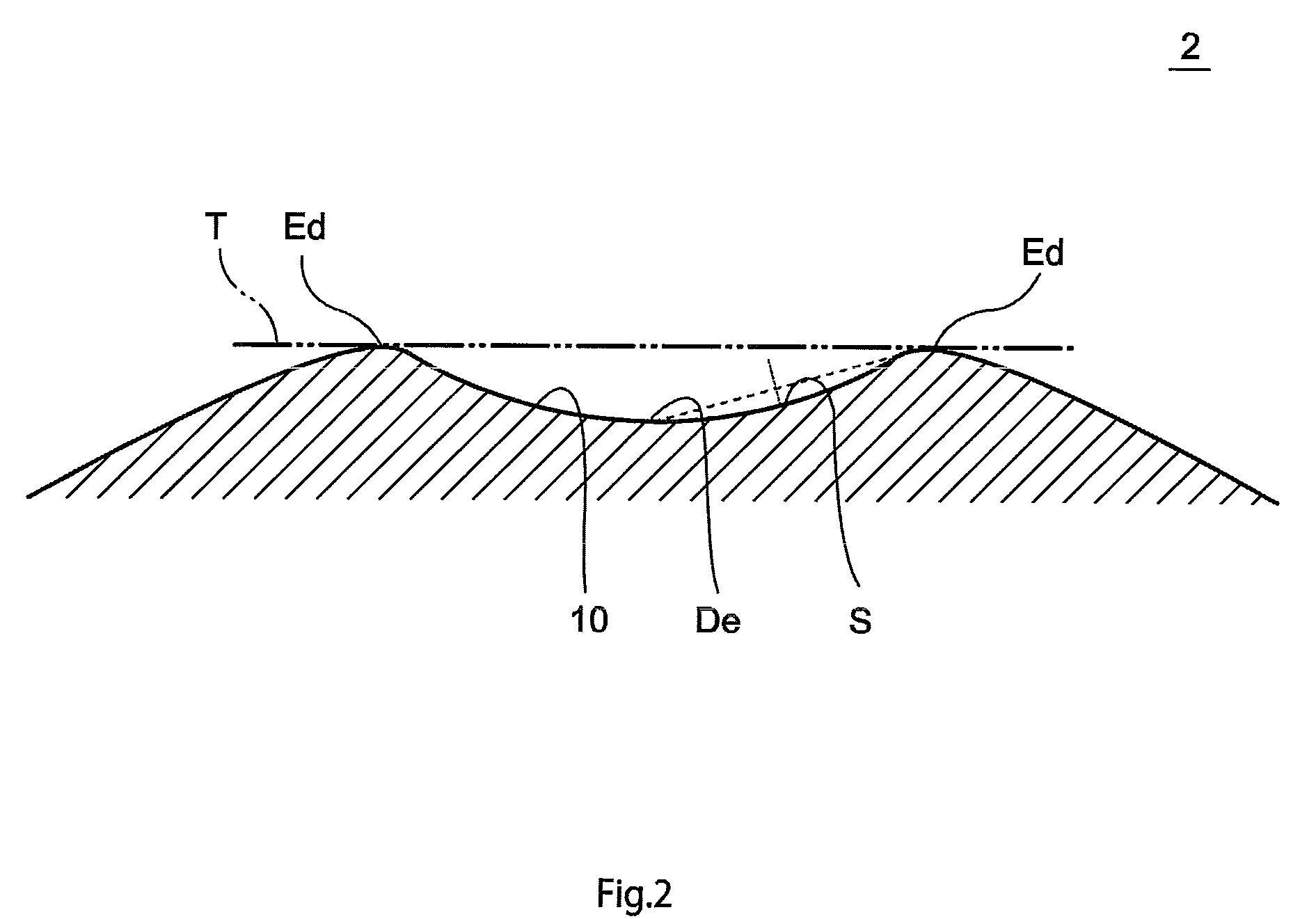

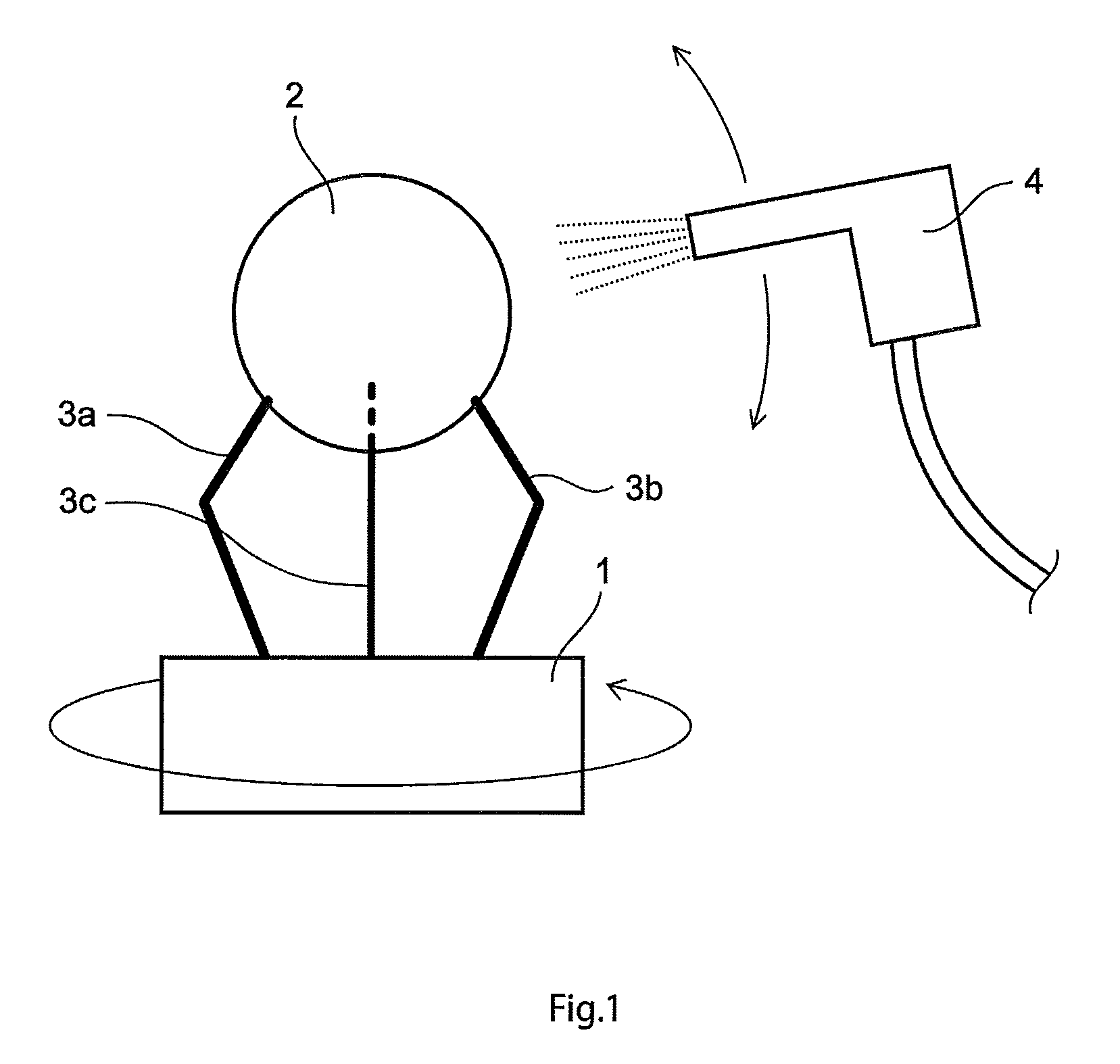

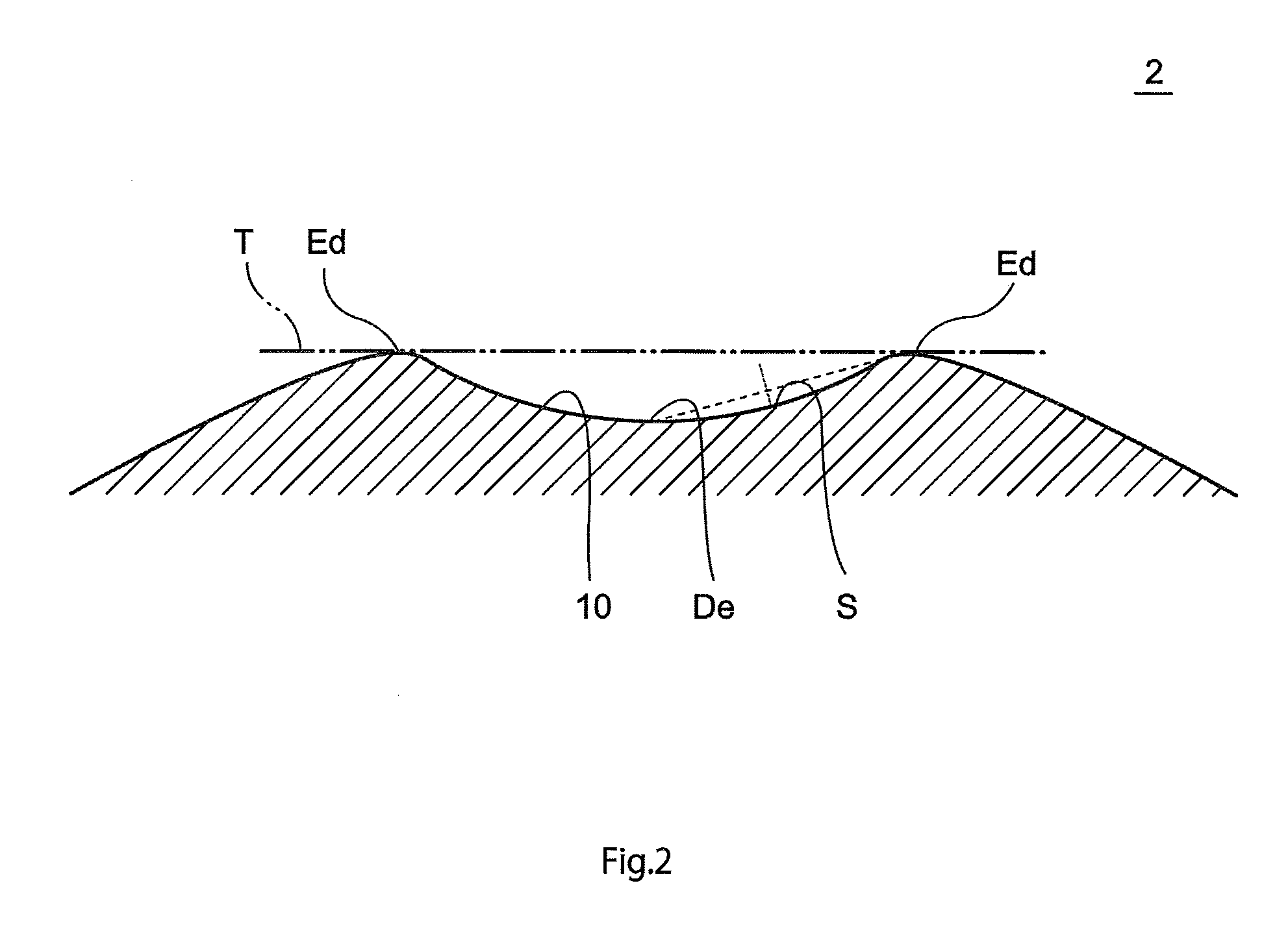

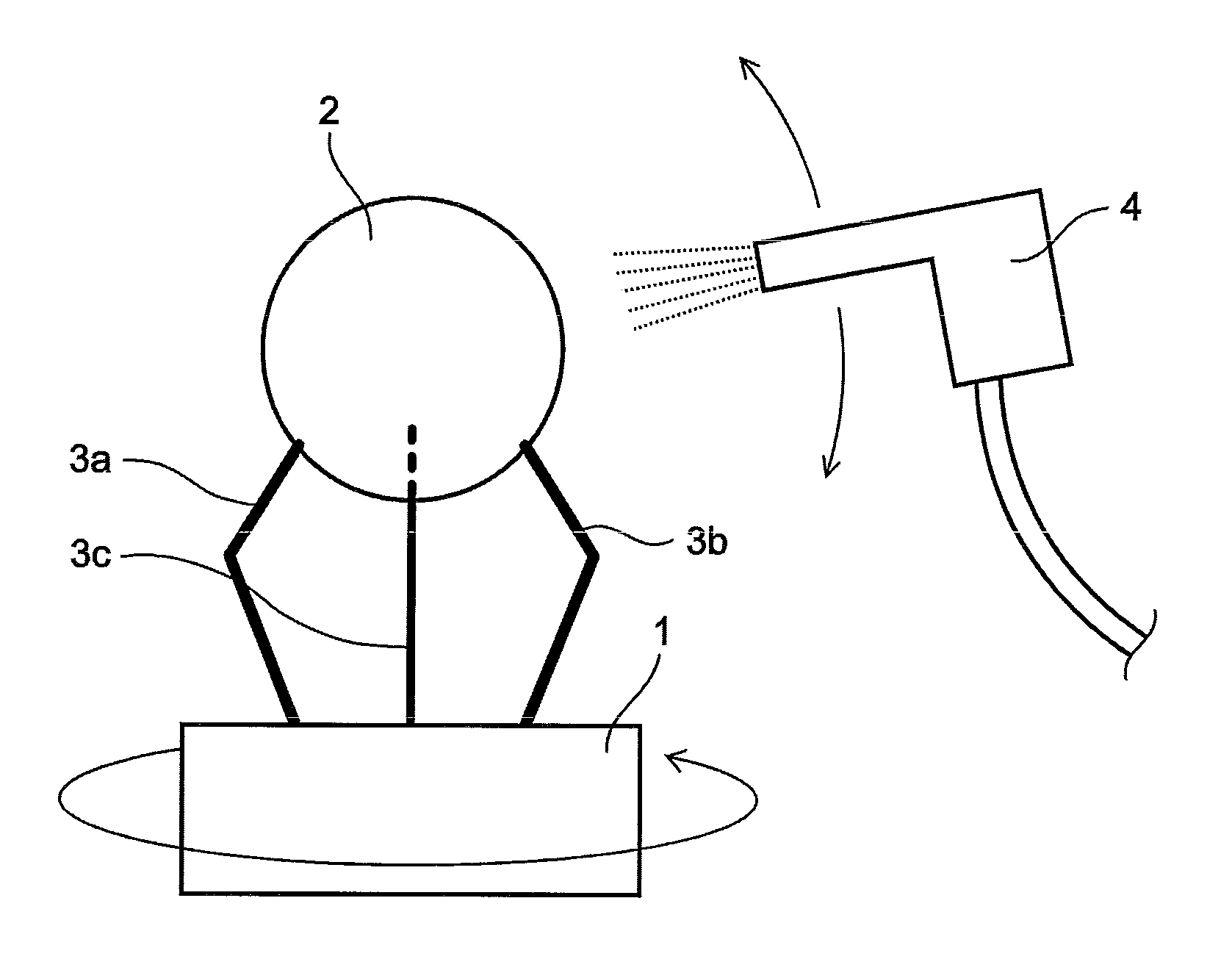

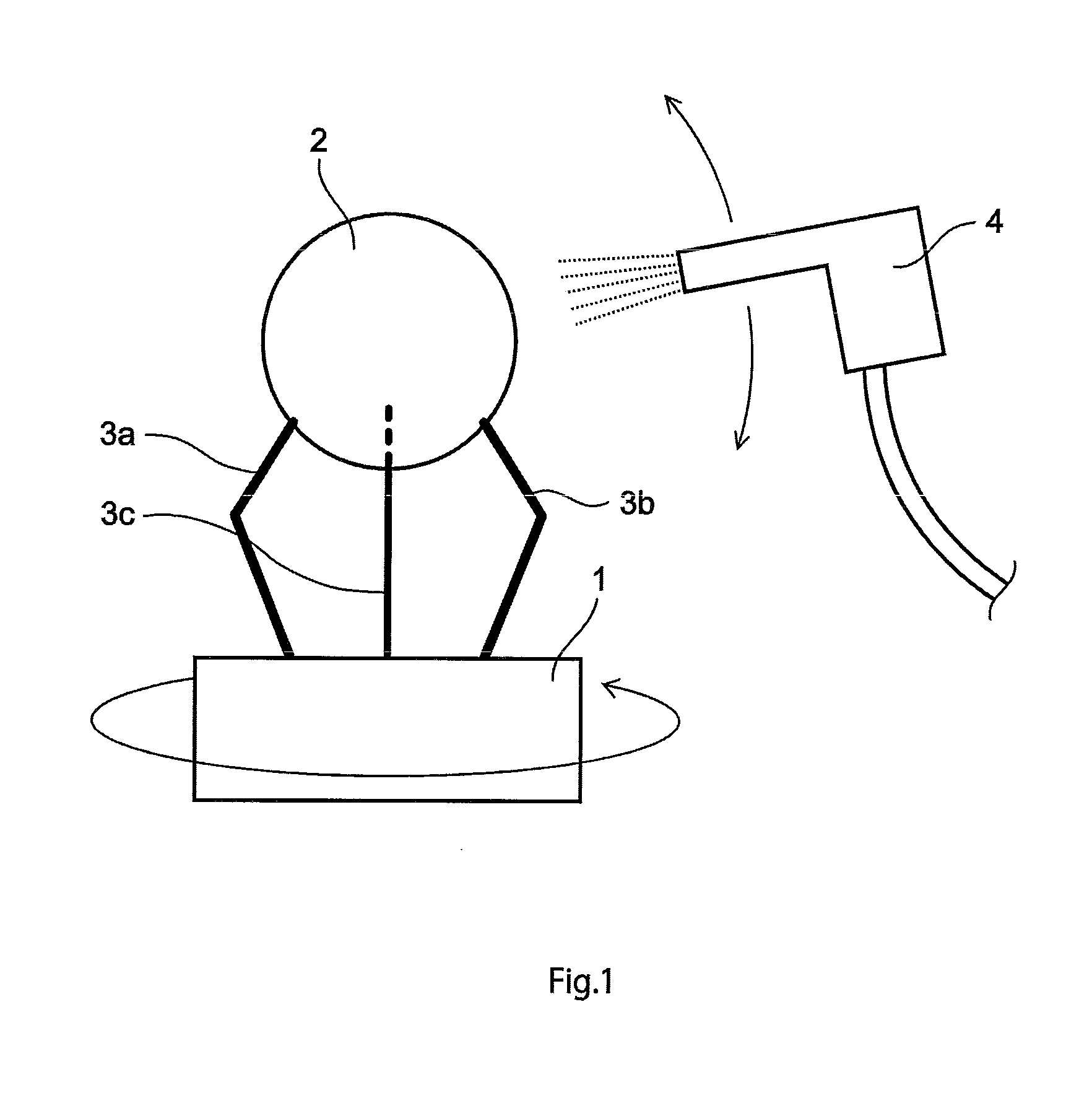

Painted golf ball and method for producing the same

InactiveUS8137753B2Excellent in gloss and evenness of paint film thicknessImproving the gloss of the paint filmPretreated surfacesLiquid/solution decomposition chemical coatingPolymer sciencePolyol

Owner:SUMITOMO RUBBER IND LTD

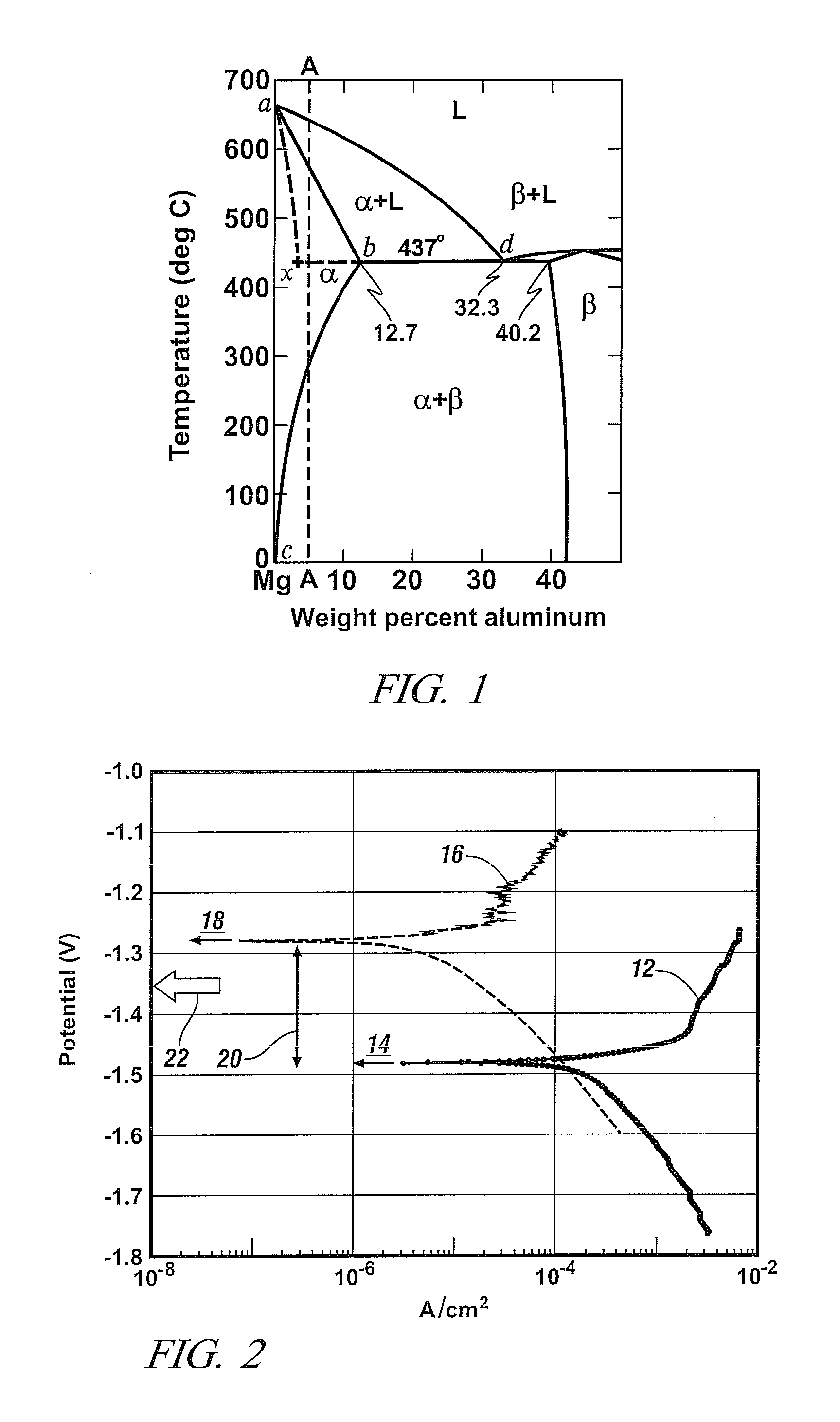

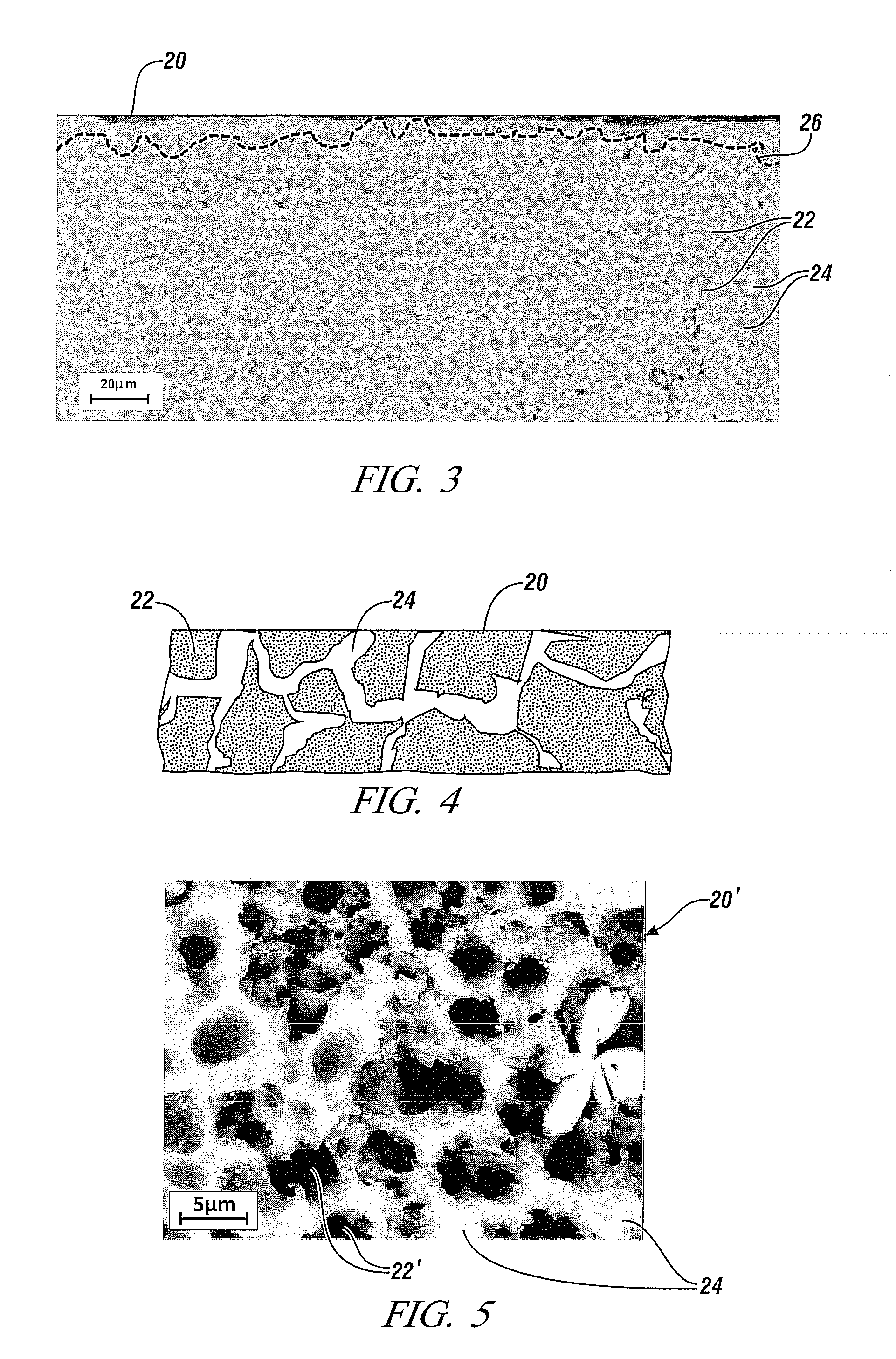

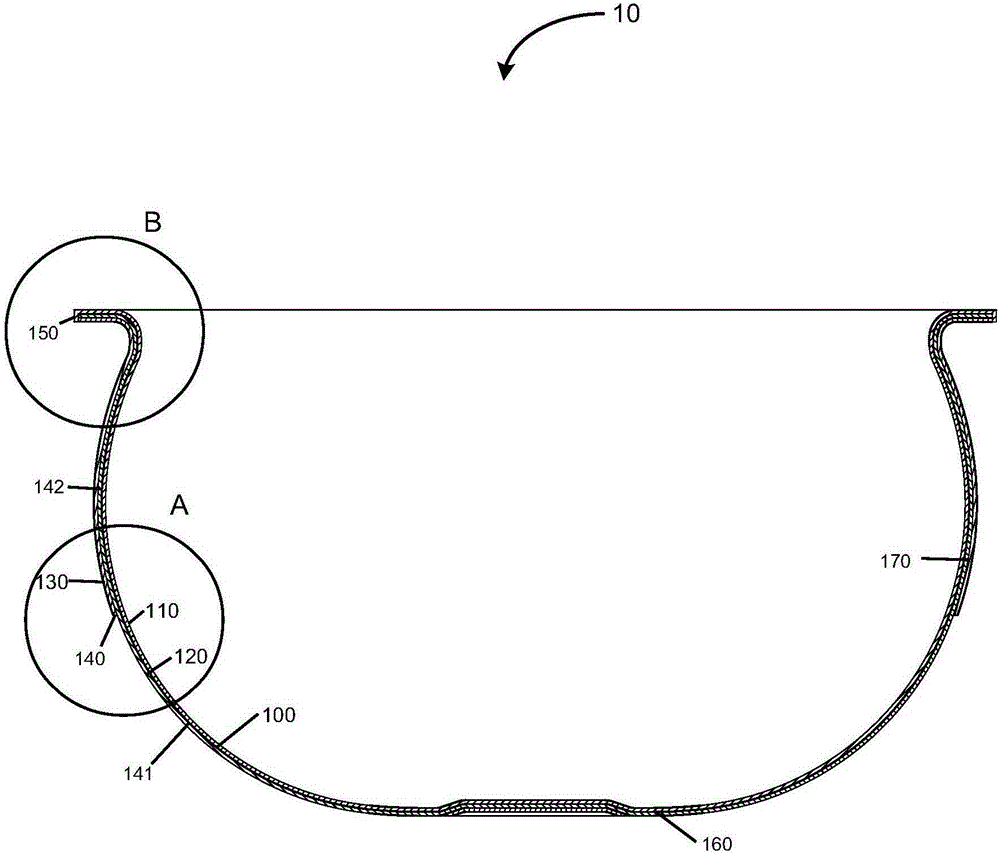

Surface treatment of magnesium alloy castings for corrosion protection

ActiveUS20120152409A1Improve corrosion resistanceImprove anti-corrosion performanceAnodisationMolten spray coatingCorrosion behaviorCorrosion resistant

A method is disclosed for improving the corrosion behavior of cast magnesium alloy articles in which the magnesium alloy comprises an average composition of more than about 5 per cent by weight of aluminum. A microstructure with regions of varying aluminum content is developed during solidification. The microstructure comprises magnesium-rich grains generally surrounded by an aluminum-enriched phase on the boundaries between adjacent grains The magnesium-rich grain interiors are then selectively chemically or electrochemically attacked to leave a more corrosion resistant aluminum-enriched surface on the articles. The corrosion resistance of the articles may be further enhanced by one or more of anodizing, aluminizing or painting the corrosion-resistant aluminum-enriched surface.

Owner:GM GLOBAL TECH OPERATIONS LLC

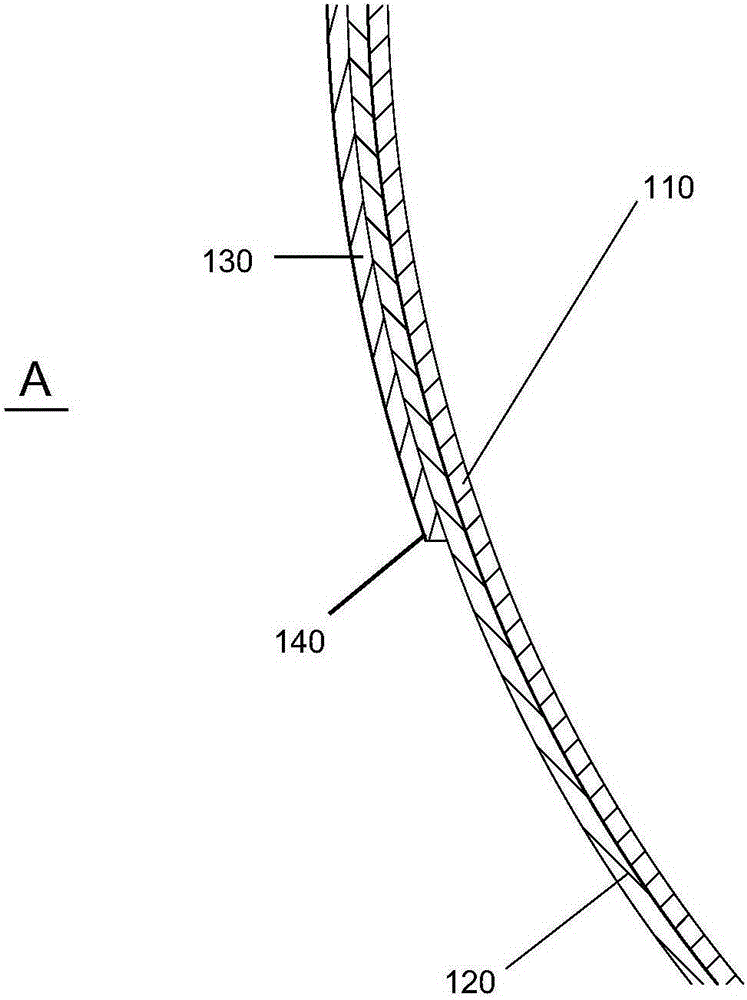

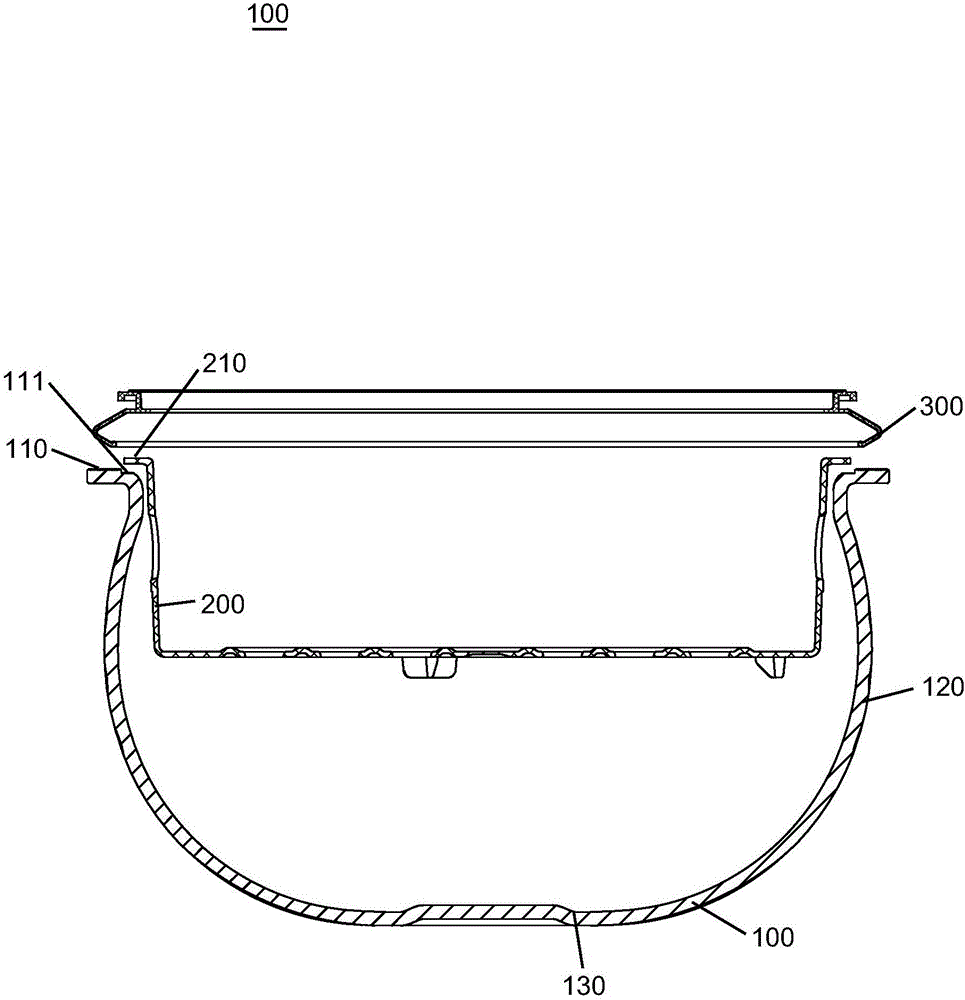

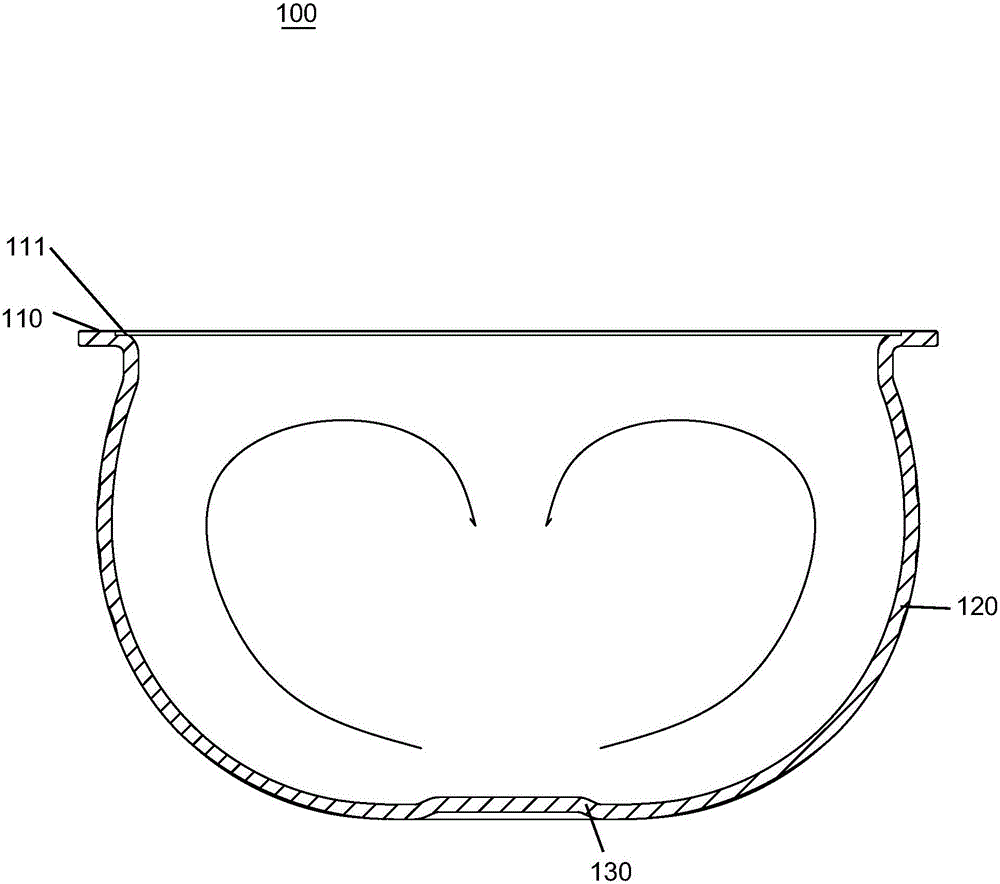

Inner pot for rice cooker, rice cooker and method for manufacturing inner pot

PendingCN106466126ANice appearanceFacilitate the processing of different effectsCooking-vessel materialsMetal layered productsEngineeringCooker

The invention provides an inner pot for a rice cooker, a rice cooker and a method for manufacturing the inner pot. The inner pot for the rice cooker comprises a pot wall, wherein an opening is formed on the top of the pot wall; the pot wall comprises a heat conductive layer arranged on the inner layer and a magnetic conductive layer arranged on the outer side of the heat conductive layer; a step part is formed on the lower part of the outer appearance of the pot wall, wherein the step part is formed along the height direction of the inner pot; and the small size portion of the step part is lower than the big size part of the step part. The inner pot of the rice cooker forms the step portion on the outer appearance of the pot wall, which provides convenience to performing processing of different effects on different portions of the outer surface of the pot wall in a later period.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

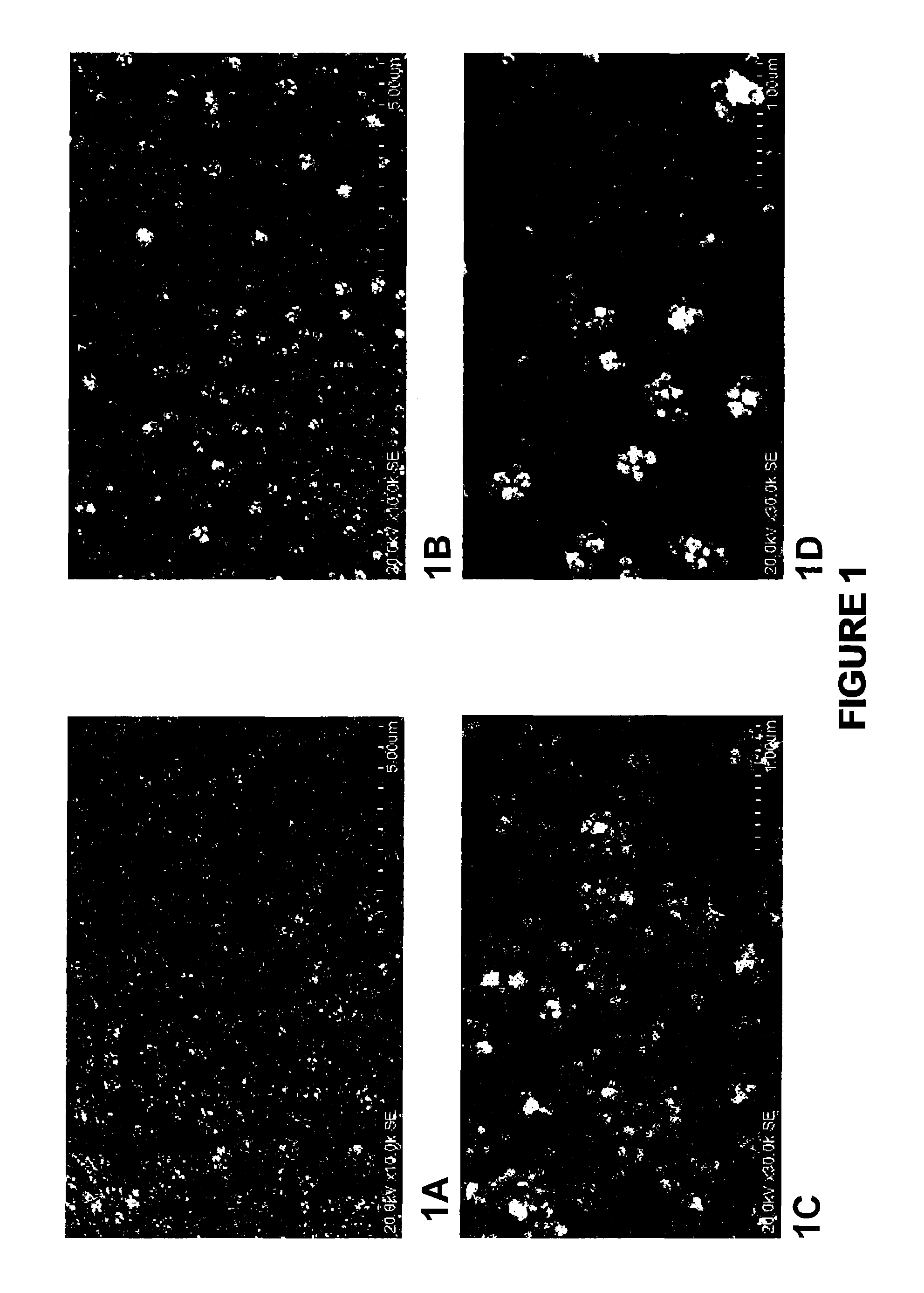

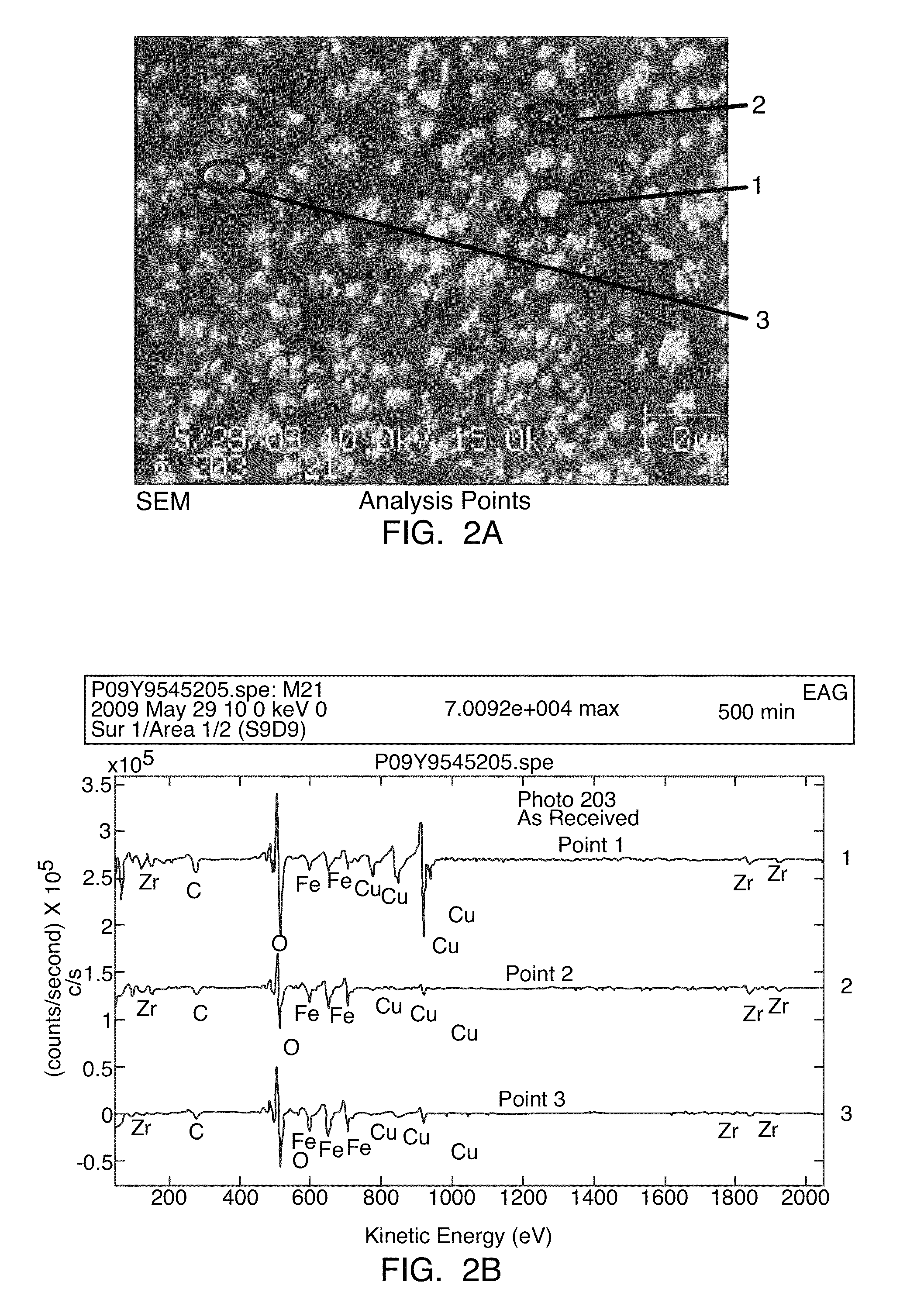

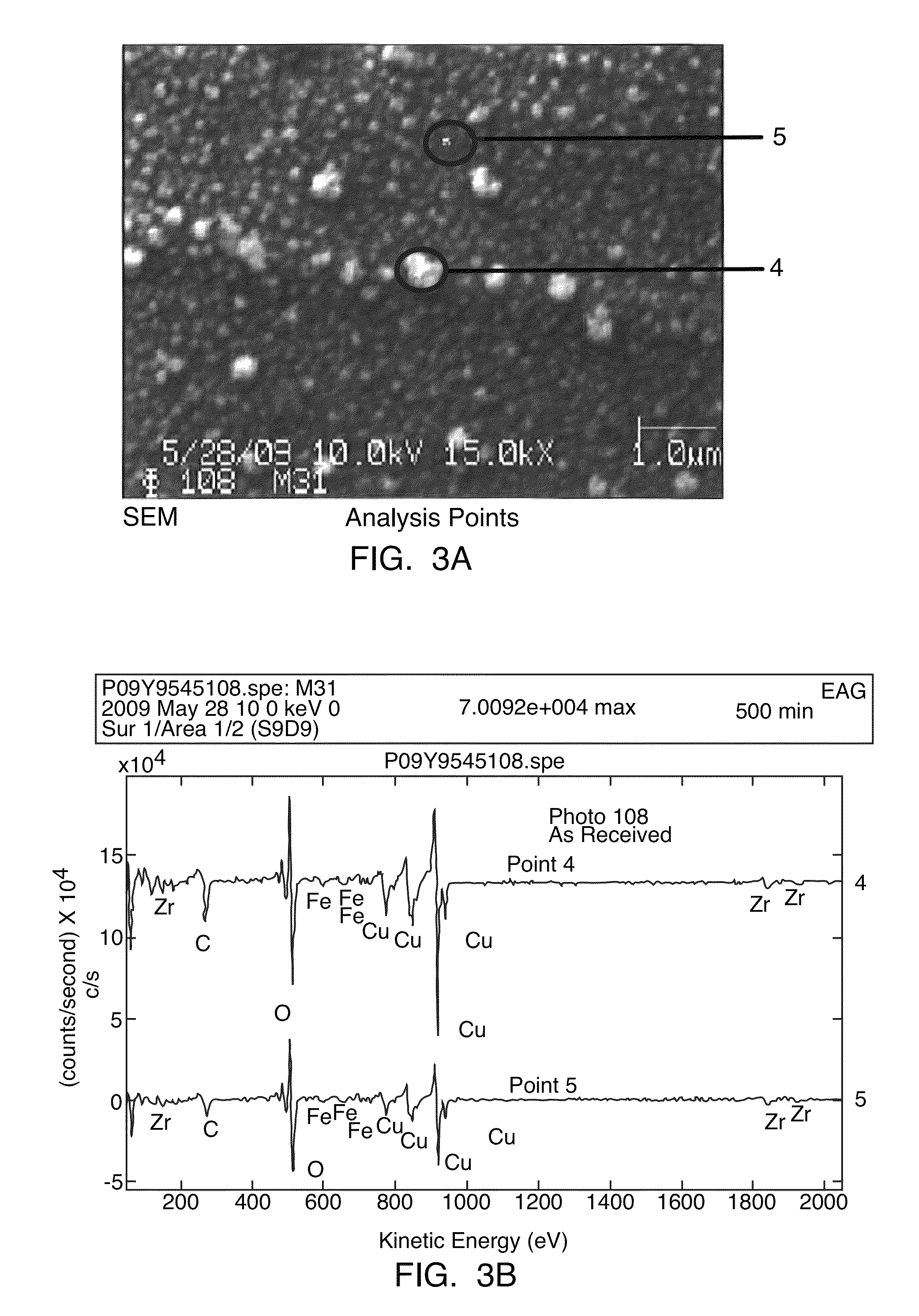

Metal pretreatment composition containing zirconium, copper, and metal chelating agents and related coatings on metal substrates

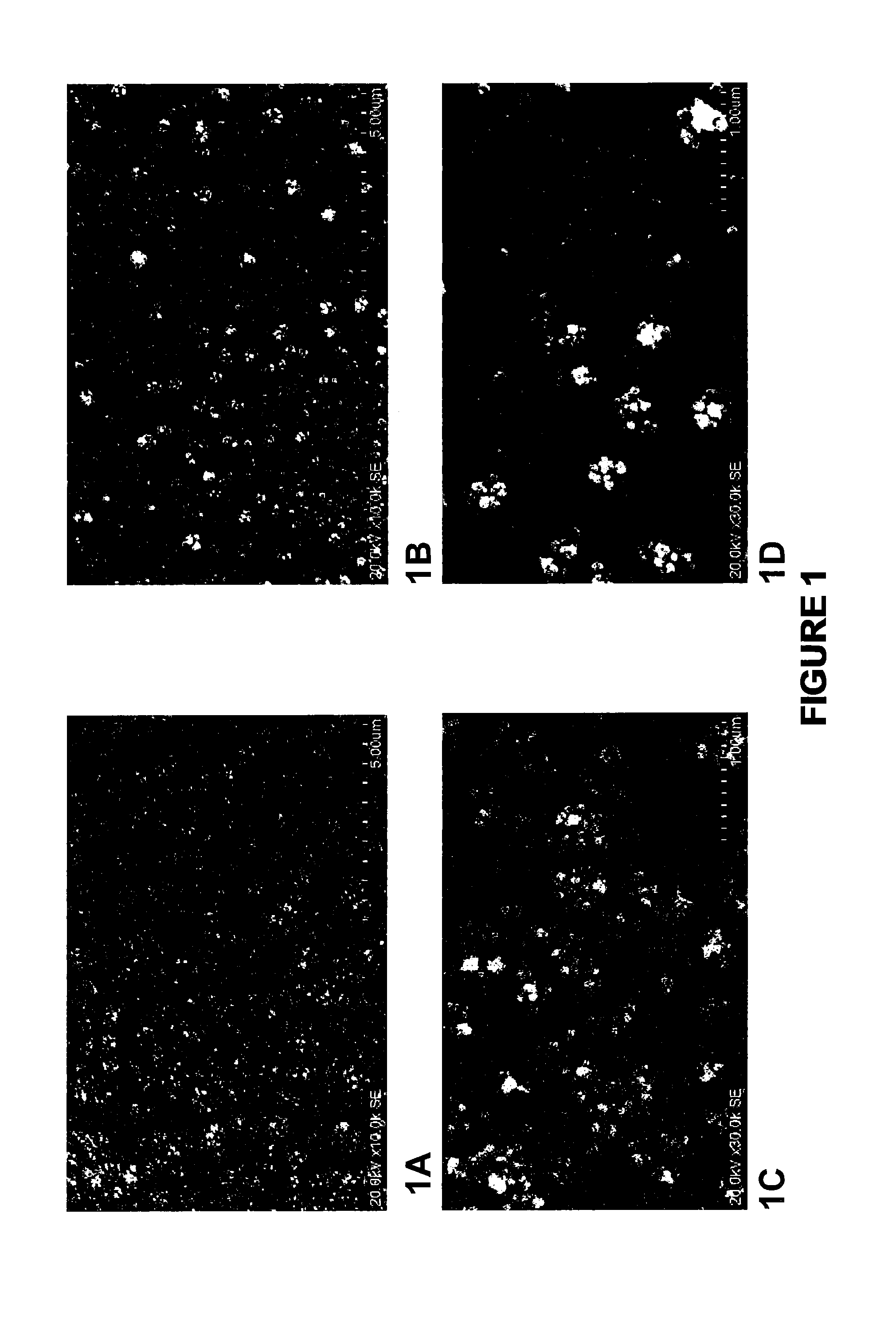

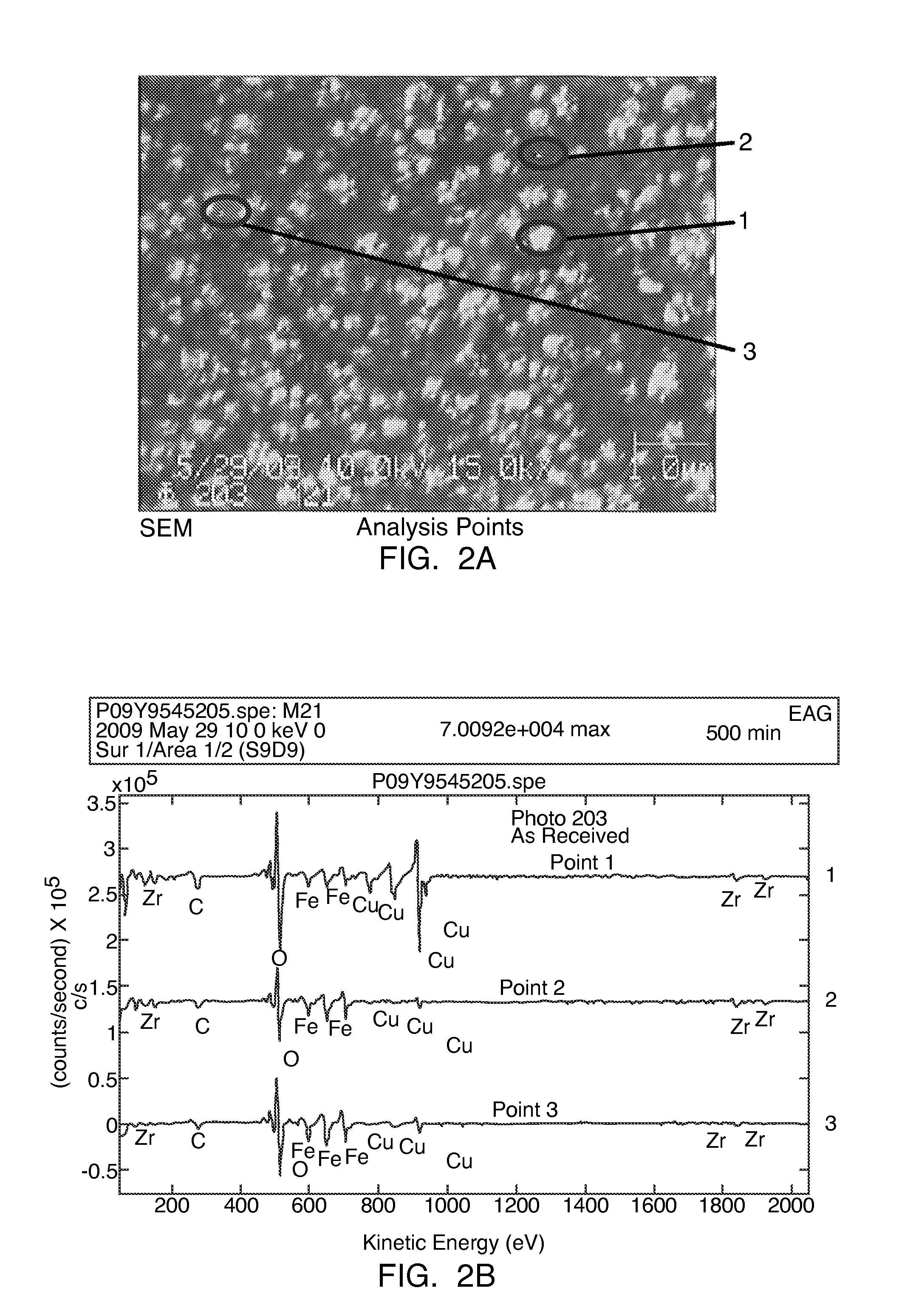

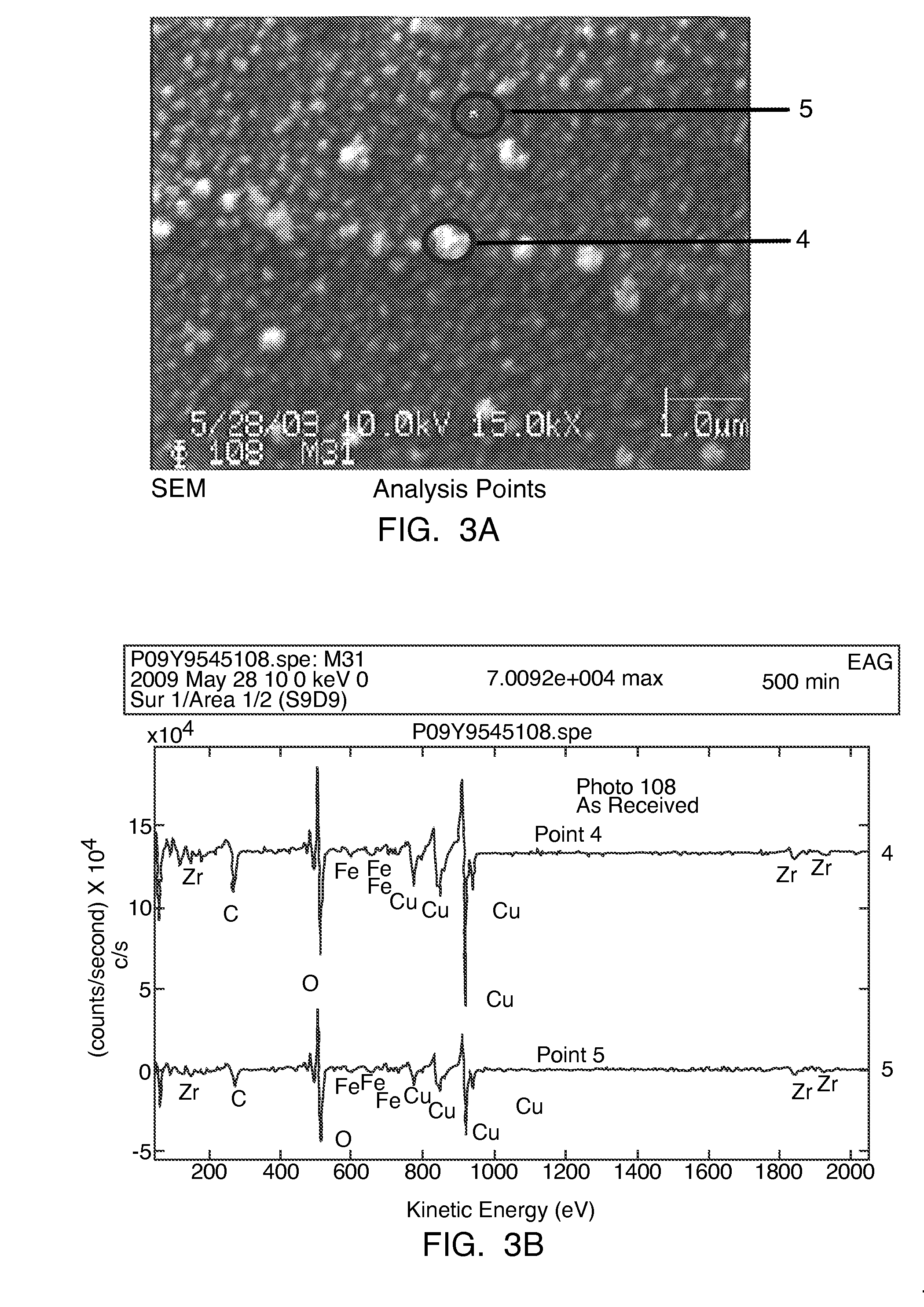

ActiveUS9284460B2Reduce resistanceLong application periodConductive materialPretreated surfacesCopperPre treatment

Disclosed is a zirconium-based metal pretreatment coating composition that includes a metal chelator that chelates copper in the metal pretreatment coating composition and thereby improves adhesion of paints to a metal substrate coated with the pretreatment coating composition. The pretreatment coating composition has a longer pot life than one without the metal chelator and therefore can accommodate a wide latitude of application times. The chelating agent is present in a sufficient amount to ensure that in the deposited pretreatment coating on the metal substrate the average total atomic % of copper to atomic % of zirconium is equal to or less than 1.1. The pretreatment coating composition is useful for treating a variety of metal substrates.

Owner:HENKEL KGAA

Metal pretreatment composition containing zirconium, copper, and metal chelating agents and related coatings on metal substrates

ActiveUS20130266819A1Long application periodReduce resistanceConductive materialPretreated surfacesCopperPre treatment

Disclosed is a zirconium-based metal pretreatment coating composition that includes a metal chelator that chelates copper in the metal pretreatment coating composition and thereby improves adhesion of paints to a metal substrate coated with the pretreatment coating composition. The pretreatment coating composition has a longer pot life than one without the metal chelator and therefore can accommodate a wide latitude of application times. The chelating agent is present in a sufficient amount to ensure that in the deposited pretreatment coating on the metal substrate the average total atomic % of copper to atomic % of zirconium is equal to or less than 1.1. The pretreatment coating composition is useful for treating a variety of metal substrates.

Owner:HENKEL KGAA

Curing type polyurethane aqueous golf ball paint and painted golf ball using the same

ActiveUS20110105247A1Imparting surface glossNo thickness unevennessPolyurea/polyurethane coatingsGolf ballsPolyolBoiling point

An object of the present invention is to provide a golf ball which is excellent in the gloss and the evenness of the paint film and a golf ball aqueous paint therefor. The golf ball of the present invention has a paint film which is formed from a curing type polyurethane aqueous golf ball paint, comprising (A) an aqueous polyol composition and (B) an aqueous polyisocyanate, wherein (A) the aqueous polyol composition contains (a-1) an aqueous acrylic polyol, (a-2) an aqueous urethane polyol and (a-3) an aqueous polyurethane resin; a molar ratio (NCO / OH) of an isocyanate group of (B) the aqueous polyisocyanate to a hydroxyl group of (A) the aqueous polyol composition ranges from 1.25 to 2.50; and a content of a high boiling point solvent having a boiling point of 150° C. or more in the aqueous golf ball paint is more than 0 mass % and 10 mass % or less.

Owner:SUMITOMO RUBBER IND LTD

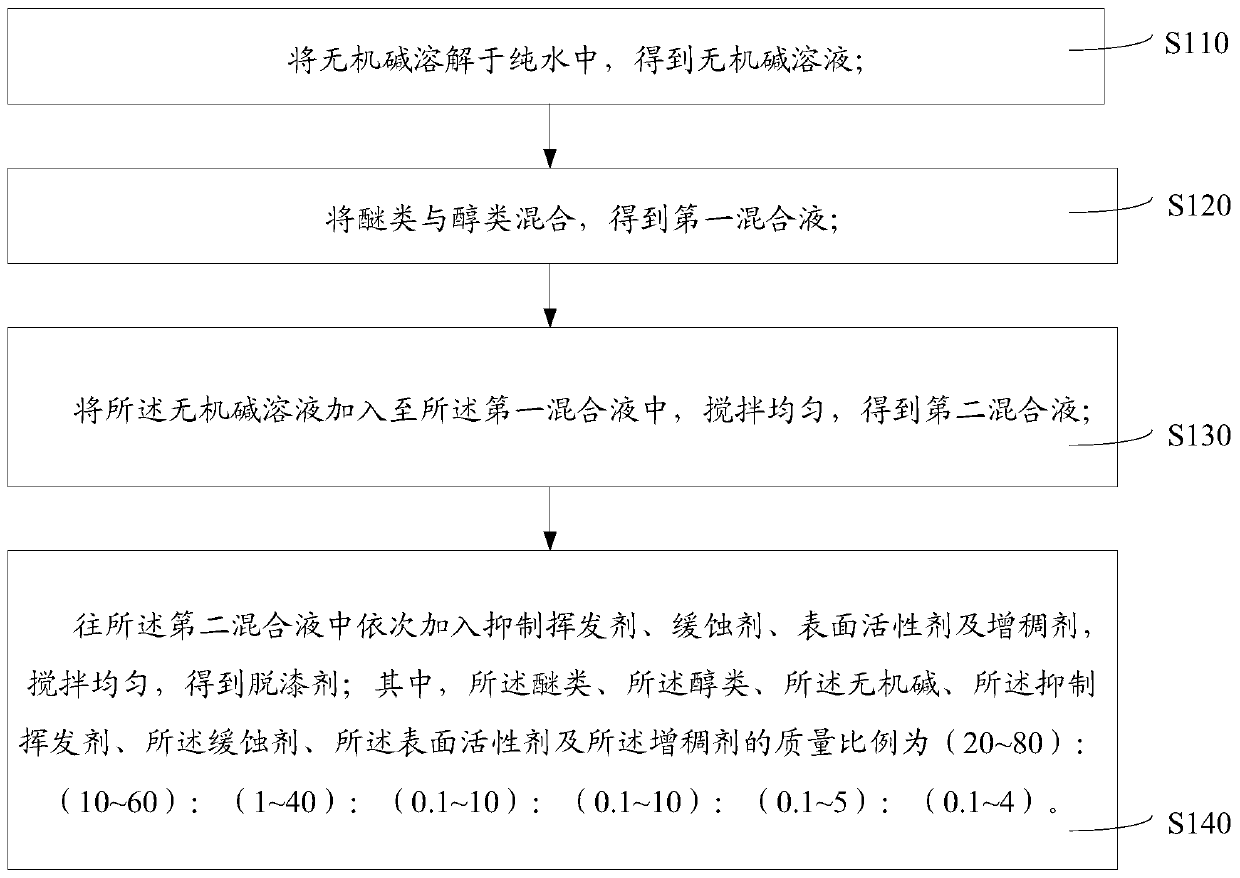

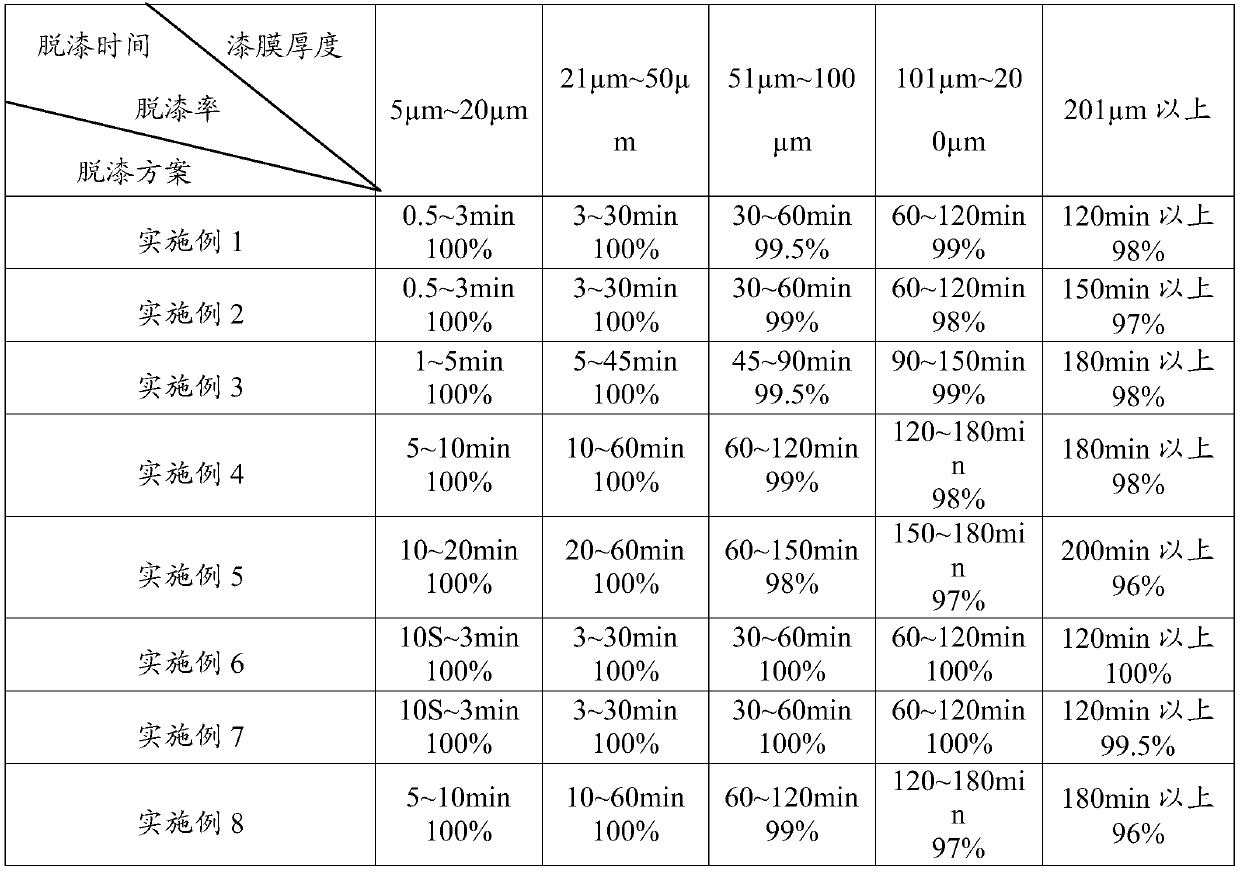

Paint remover and preparation method thereof, and paint removing method

InactiveCN111334115AAvoid over corrosionEfficient removalChemical paints/ink removersPolymer scienceActive agent

The invention relates to the field of paint removers, and discloses a paint remover and a preparation method thereof, and a paint removing method. The paint remover is prepared from the following components in parts by mass: 20 to 80 parts of ether, 10 to 60 parts of alcohol, 1 to 40 parts of inorganic alkali, 0.1 to 10 parts of a volatile inhibitor, 0.1 to 10 parts of a corrosion inhibitor, 0.1 to 5 parts of a surfactant and 0.1 to 4 parts of a thickening agent. The preparation method of the paint remover comprises the following steps: mixing the inorganic alkali, the ether, the alcohol, thevolatile inhibitor, the corrosion inhibitor, the surfactant and the thickening agent, and uniformly stirring to obtain the paint remover. According to the invention, the paint remover is low in toxicity, environmentally friendly, high in paint removing speed and good in paint removing effect, can avoid corrosion on metal base materials, improve the rust resistance of iron materials, improve the painting adhesive force of iron materials and effectively remove phenolic aldehyde paint films, alkyd paint films, nitro paint films, polyurethane paint films, epoxy resin paint films, water-based paintfilms and electrostatic powder paint films.

Owner:广东东明新材科技有限公司

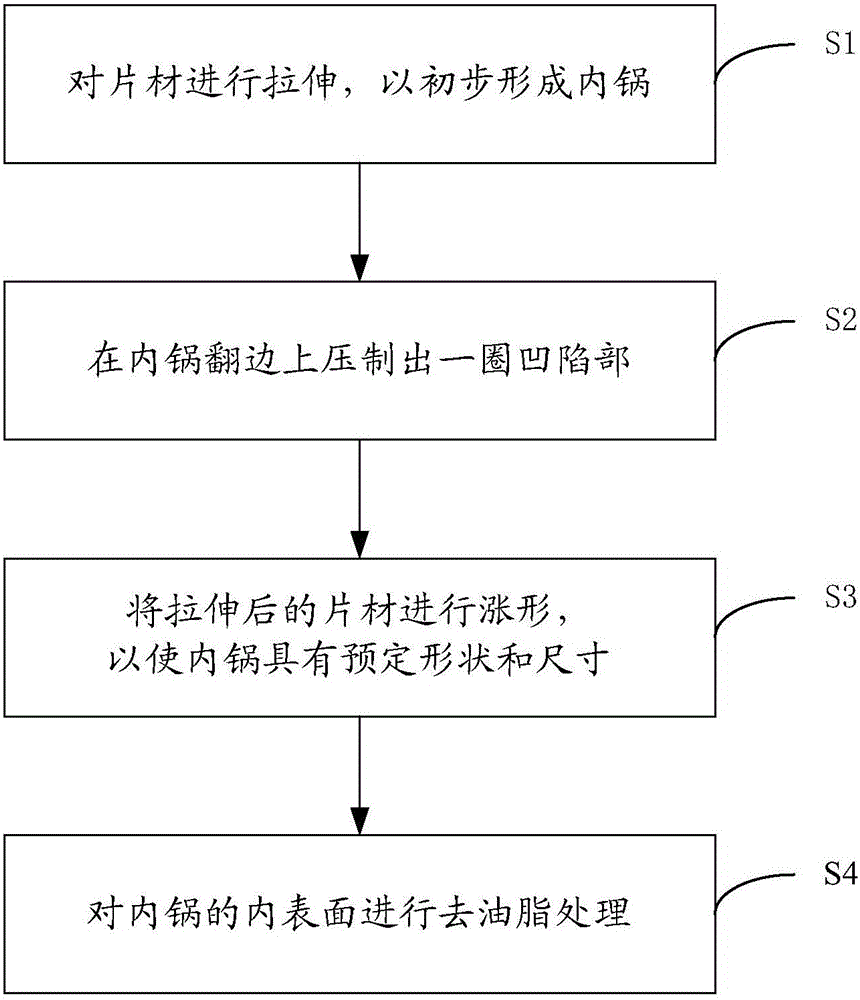

Manufacturing method of inner pot

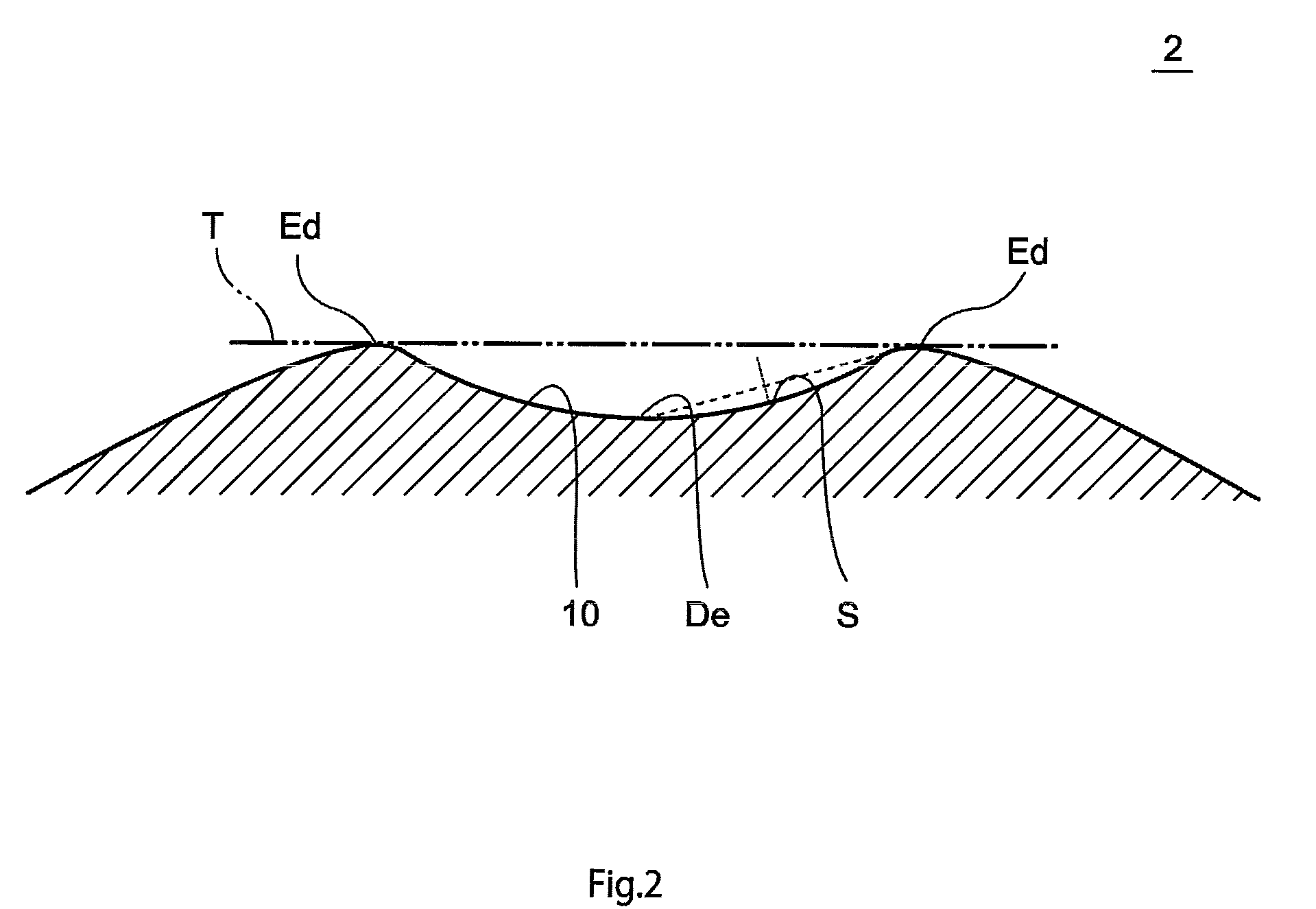

ActiveCN107432663AImprove paint adhesionEasy to operateSteam cooking vesselsHollow articlesEngineeringFlange

The invention discloses a manufacturing method of an inner pot. The inner pot is used for a cooking utensil. The cooking utensil comprises a steam layer. The top of the steam layer is provided with a steam layer flange. The manufacturing method comprises the following steps: performing stretch forming on a sheet material used for manufacturing the inner pot in order to primarily form the inner pot comprising a side wall and a bottom wall connected to the side wall, wherein the top of the side wall comprises an annular inner pot flange which outwardly extends; pressing a recessed part on the inner pot flange, wherein the recessed part is suitable for placing the steam layer flange and configured in the manner that the steam layer is fixed in a horizontal direction. The inner pot enables the cooking utensil to have a better sealing effect.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

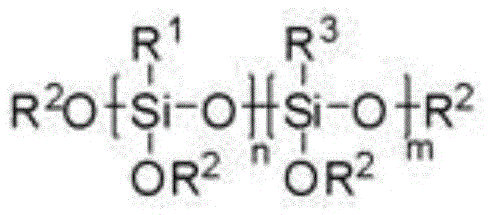

Water dispersible silanes as corrosion-protection coatings and paint primers for metal pretreatment

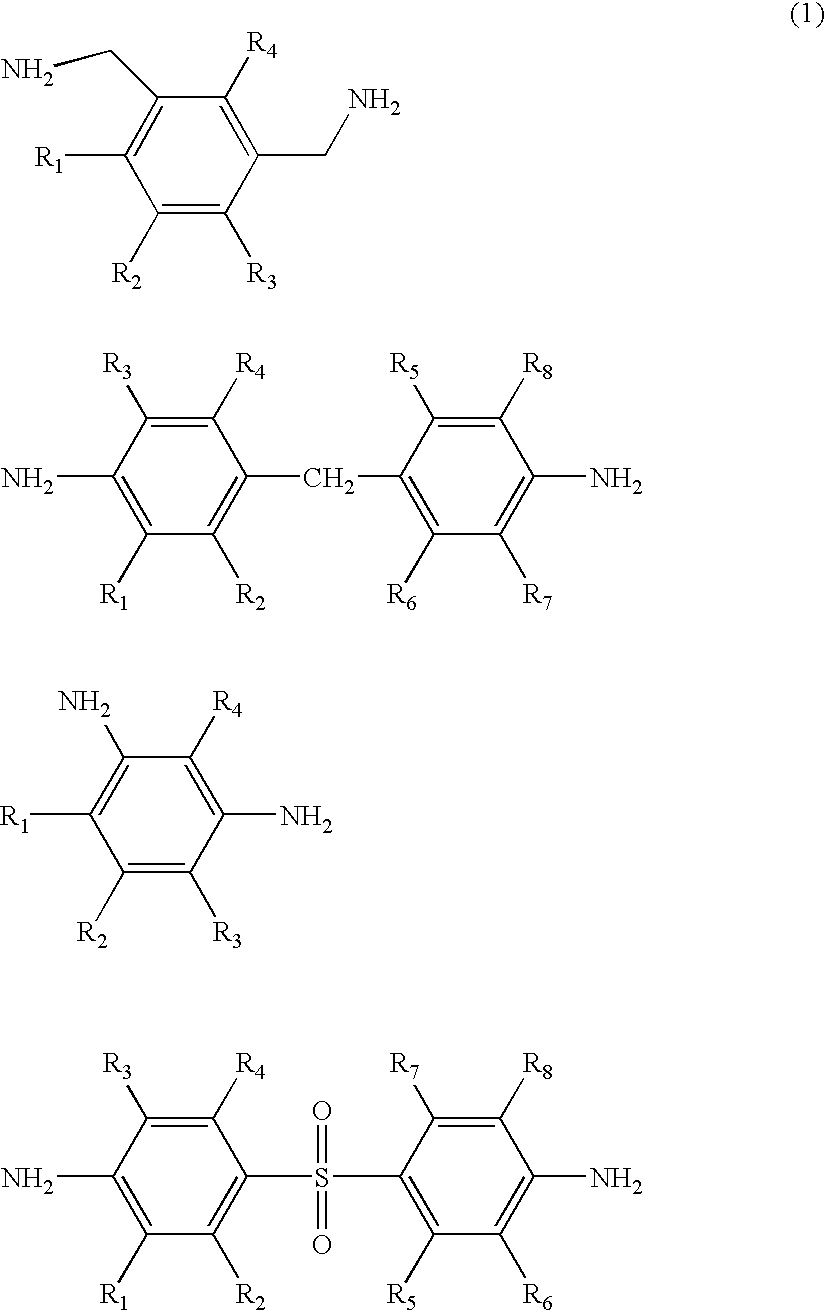

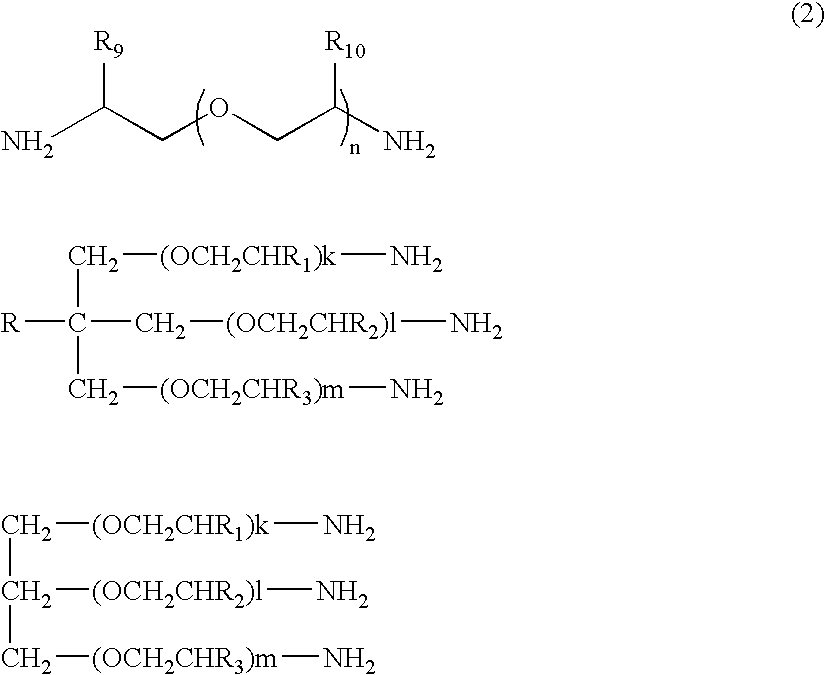

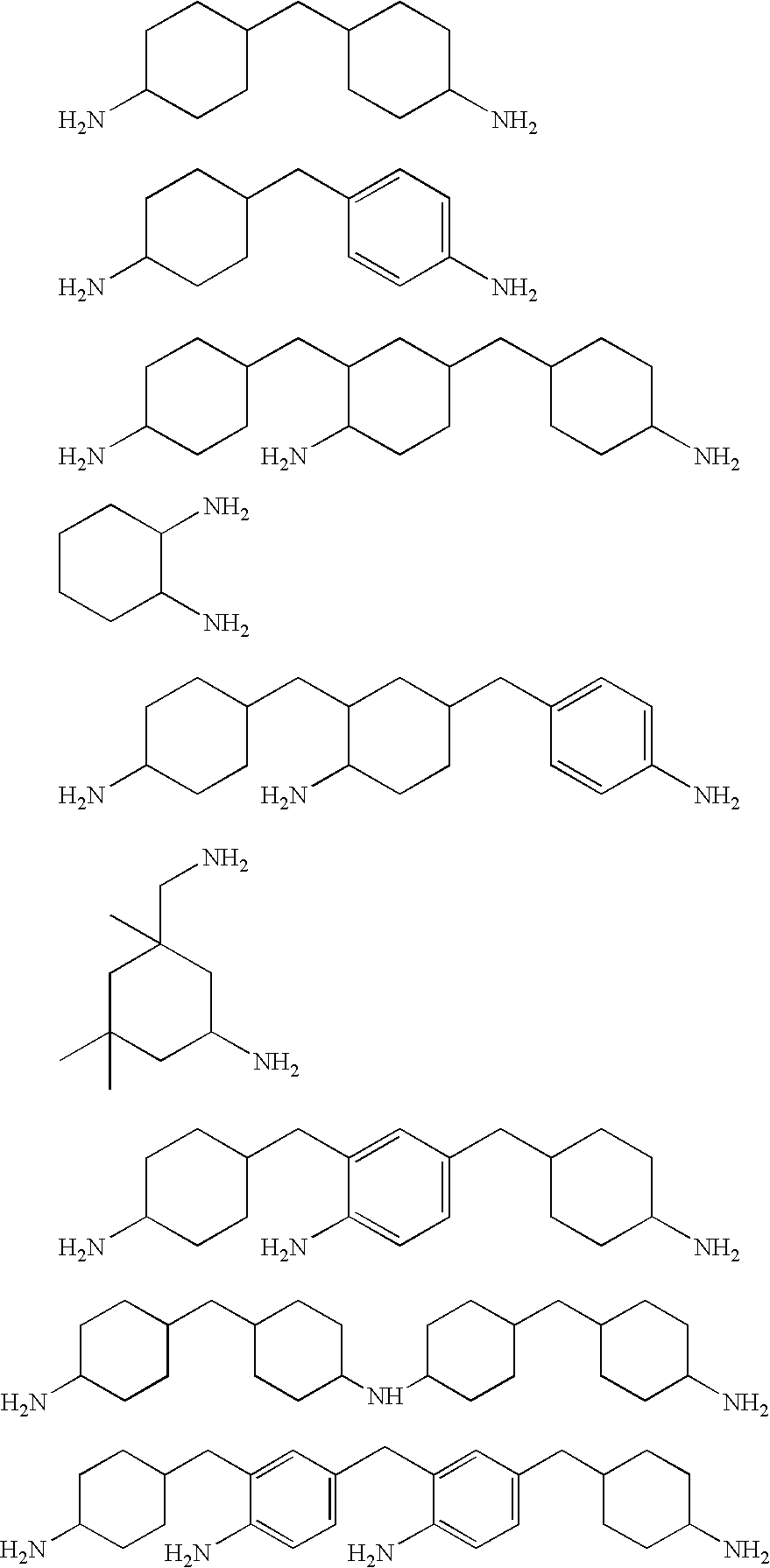

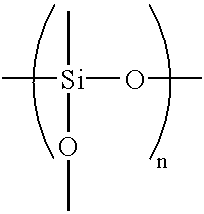

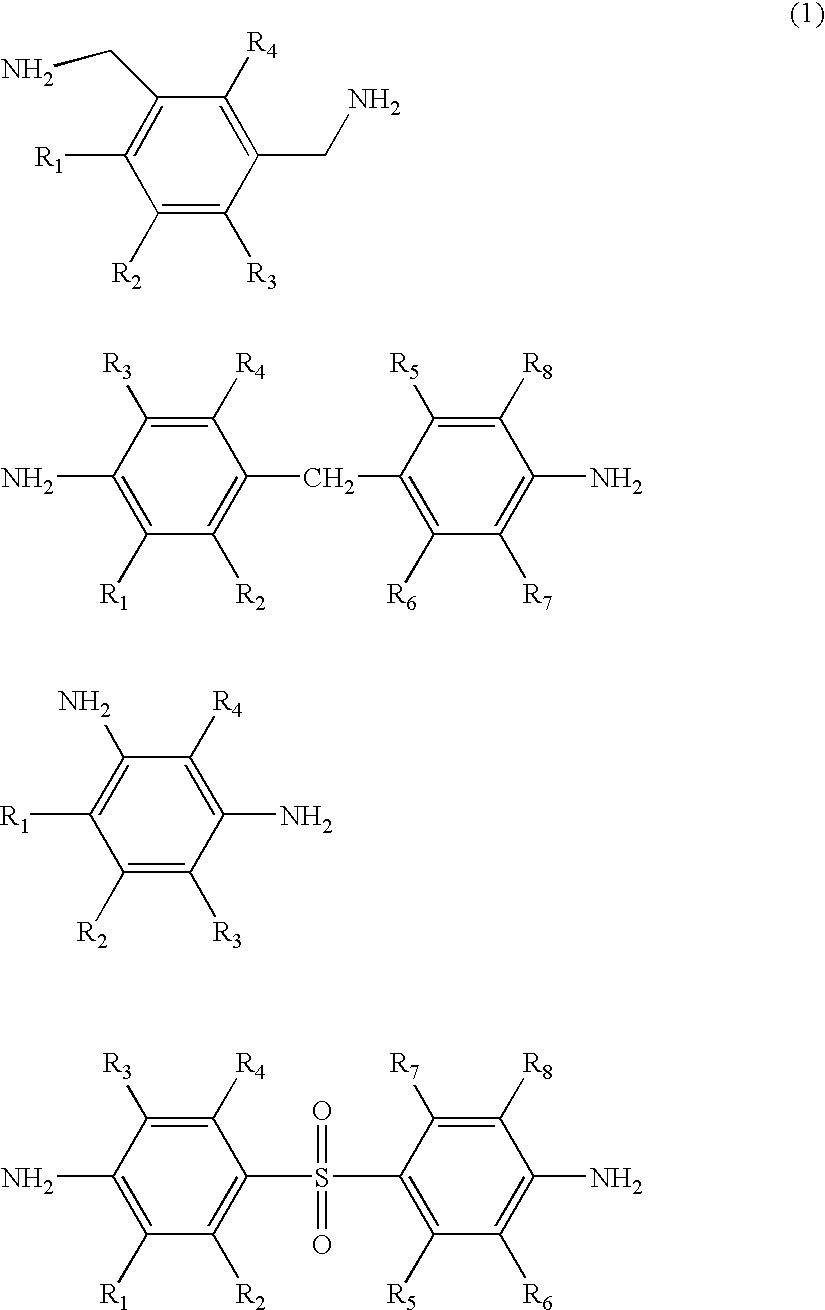

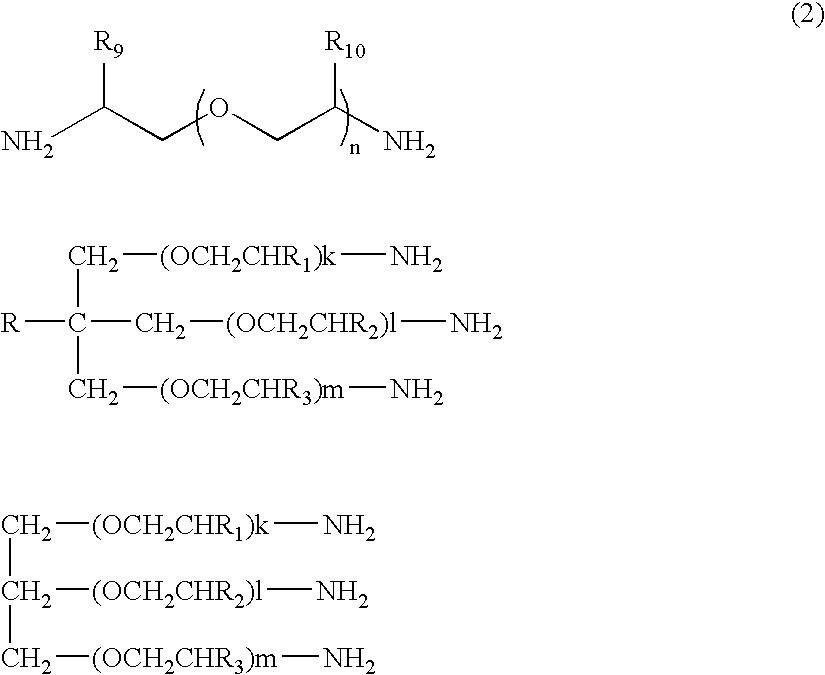

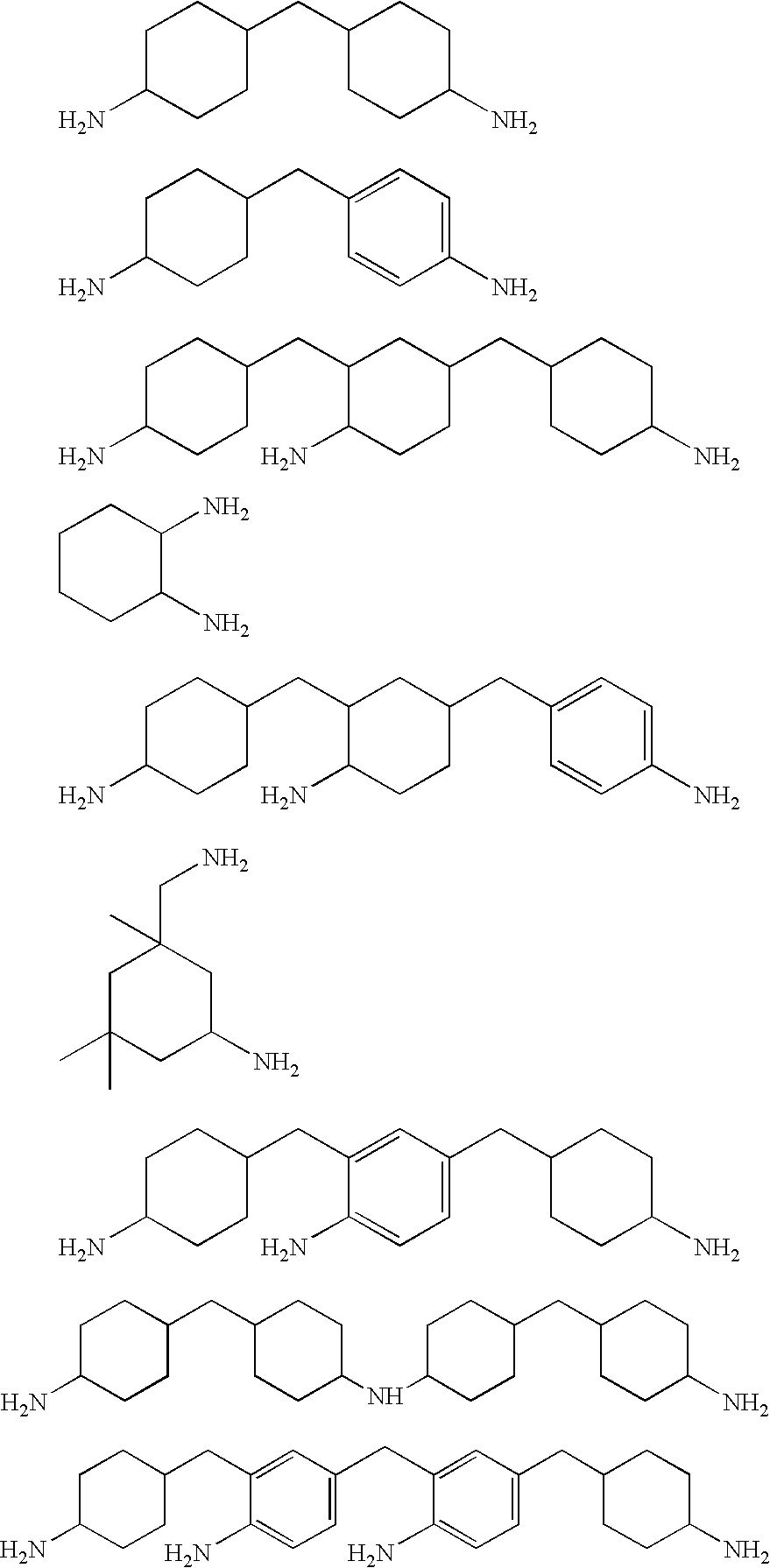

ActiveUS20070166467A1Improve paint adhesionAvoid poor resultsGroup 4/14 element organic compoundsFibre treatmentWater dispersibleSilanes

A method of applying to a metal surface a composition and drying the surface for crosslinking, which composition comprises a dispersion in the solvent of a compound comprising the reaction product of (1) a polyamine in which a plurality of amine groups are bonded to at least one radical comprising alkylene or arylene groups that separate the polyamine nitrogen atoms by at least four intermediate atoms in a chain, and (2) a silane which carries a plurality of silicon-bonded hydrolysable groups, and a silicon-bonded organic group that is covalently reactive with and which bonds with an amine group, to provide a reaction product molecule which comprises an average of at least about 2.5 of said silane groups per molecule. Some of these materials show superior advantage as a paint primer and some provide excellent corrosion resistance.

Owner:ECOLAB USA INC

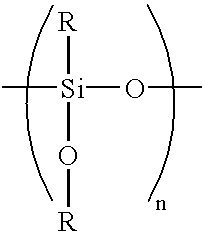

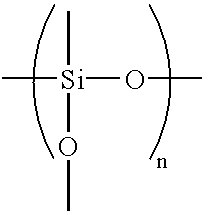

Surface treated steel sheet

InactiveUS6537674B1Improve corrosion resistanceImprove paint adhesionLiquid surface applicatorsOther chemical processesZinc phosphateCoated surface

The coated steel sheet is a zinc-based plated steel sheet which has a zinc phosphate-based coating containing magnesium thereon and a silicone resin coating containing a functional group which reacts with an organic substance on the surface of the zinc phosphate-based coating. The coated steel sheet has superior perforative corrosion resistance, paint adhesion, electrodesposition paintability, press formability, and weldability without using chromium and therefore is useful as an anti-corrosive steel sheet for automobile bodies.

Owner:KAWASAKI STEEL CORP

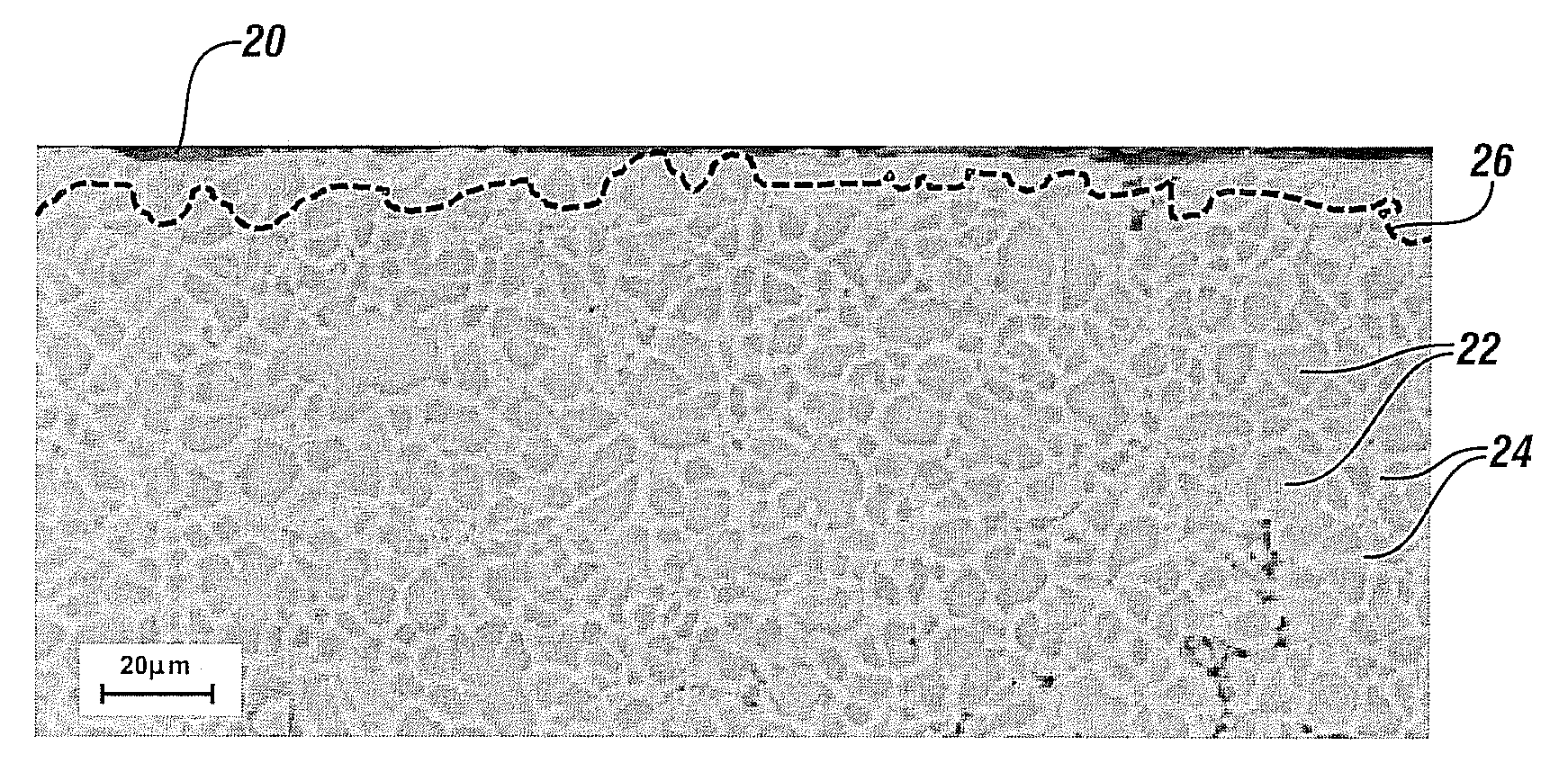

Process for the coating of metallic surfaces, coating composition, and coatings produced in such a way

InactiveUS9695322B2Improve paint adhesionImprove adhesionLamination ancillary operationsLaminationOligomerPhotoinitiator

A process for coating a metallic surface of a metallic substrate comprising applying, an organic, anionically, cationically or radically curable anticorrosive composition, to the metallic surface, wherein said anticorrosive composition is a dispersion or solution containing at least two components that are at least partially anionically, cationically or radically curable, wherein at least one monofunctional monomer or monofunctional oligomer is present, a photoinitiator, and first organic corrosion inhibitor.

Owner:GROS GEORG +2

Painted golf ball and method for producing the same

InactiveUS20100144468A1Excellent in gloss and evenness of paint film thicknessImproving the gloss of the paint filmPretreated surfacesLiquid/solution decomposition chemical coatingPolyolEngineering

An object of the present invention is to provide a painted golf ball which is excellent in the gloss and the evenness of the paint thickness as well as the adhesion of the paint film to the golf ball body. The method for producing the golf ball of the present invention comprises applying a two-component curing type urethane-based aqueous paint including an aqueous polyol composition (A) and an aqueous polyisocyanate (B) to a golf ball body in a specific method, wherein (A) the aqueous polyol composition contains (a-1) an aqueous acrylic polyol, (a-2) an aqueous urethane polyol and (a-3) an aqueous urethane resin.

Owner:SUMITOMO RUBBER IND LTD

Water dispersible silanes as corrosion-protection coatings and paint primers for metal pretreatment

ActiveUS7862862B2Improve paint adhesionAvoid poor resultsGroup 4/14 element organic compoundsFibre treatmentWater dispersibleSilanes

A method of applying to a metal surface a composition and drying the surface for crosslinking, which composition comprises a dispersion in the solvent of a compound comprising the reaction product of (1) a polyamine in which a plurality of amine groups are bonded to at least one radical comprising alkylene or arylene groups that separate the polyamine nitrogen atoms by at least four intermediate atoms in a chain, and (2) a silane which carries a plurality of silicon-bonded hydrolysable groups, and a silicon-bonded organic group that is covalently reactive with and which bonds with an amine group, to provide a reaction product molecule which comprises an average of at least about 2.5 of said silane groups per molecule. Some of these materials show superior advantage as a paint primer and some provide excellent corrosion resistance.

Owner:ECOLAB USA INC

Method for treatment of chemically passivated galvanized surfaces to improve paint adhesion

InactiveUS8309177B2Minimize changesImprove paint adhesionPretreated surfacesMetallic material coating processesPolymethacrylic AcidsCorrosion

A method of treating a zinc-galvanized metal surface, which has been chemically passivated, the treatment providing increased resistance to corrosion and improved adherence to a subsequently applied organic coating comprising contacting a chromium passivated, zinc-galvanized metal surface with a coating solution bath comprising from about 1 to about 10 parts per thousand, based on fluorine content, of an inorganic acid or ion that contains fluorine; at least 0.5 parts per thousand, based on transition metal cation content, of an oxide and / or a salt of nickel; and optionally, from about 0 to about 3.0 grams per liter of a polymer selected from the group consisting of polyacrylic acid, polymethacrylic acid, and C1 to C8 alkanol esters thereof; wherein the pH of the solution is from about 2.0 to 3.6 and the temperature of the solution is at least 60° C.; and thereafter sealing the treated surface.

Owner:HENKEL KGAA

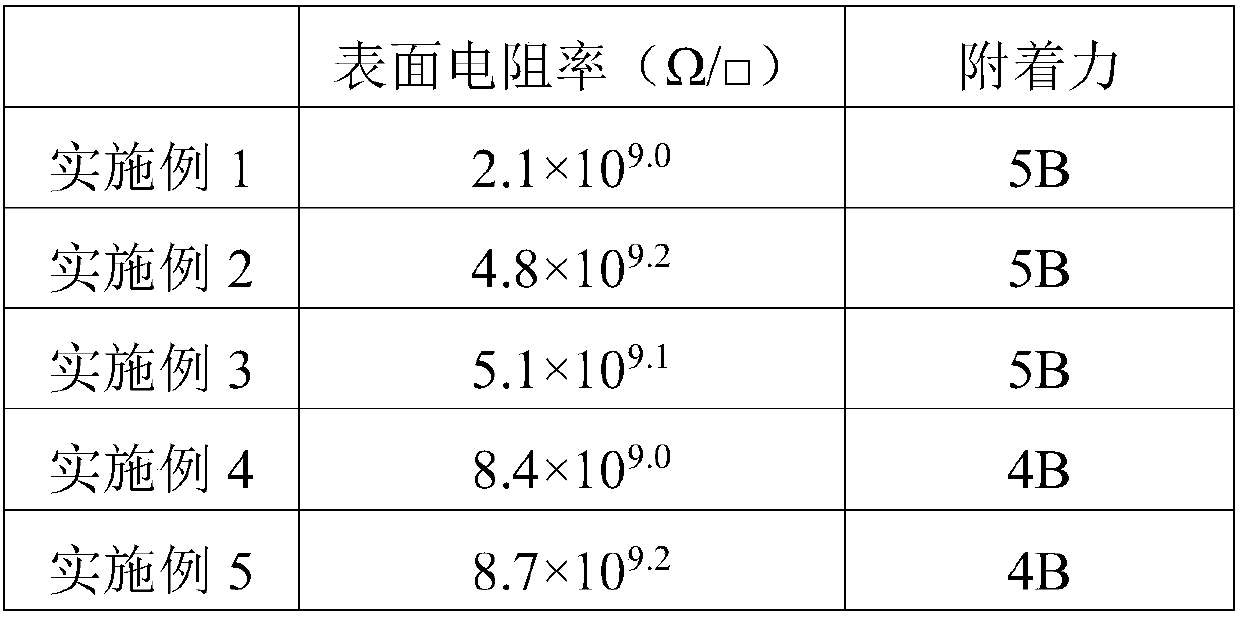

Preparation method of conductive coating composition

InactiveCN107793864AExtended service lifeAvoid skin peelingMagnetic paintsPolyurea/polyurethane coatingsOrganic solventConductive coating

The invention relates to the technical field of coatings, in particular to a preparation method of a conductive coating composition. The preparation method comprises the following steps of: (1) preparing magnetic modified cellulose; (2) dispersing ferromagnetic metal powder into an organic solvent, performing ultrasonic treatment for 30-60min, adding glass powder under a stirring condition, uniformly stirring the mixture, adding the magnetically modified cellulose in the step (1), and continuously performing ultrasonic treatment for 1-2h to obtain a mixture; and (3) blow-drying the mixture ofthe step (2) to a solid content of 91-95% by using compressed air, then transferring the mixture to a kneader for kneading, and adjusting the solid content to 85-90% by using a solvent. The preparation method of the conductive coating composition provided by the invention has the advantages that the final conductive coating is a paste, a precipitation phenomenon of a traditional fluid conductive coating does not occur in a storage process, and the leakage problem does not need to be worried in a transportation process, so that the use of the conductive coating is facilitated.

Owner:汪涛

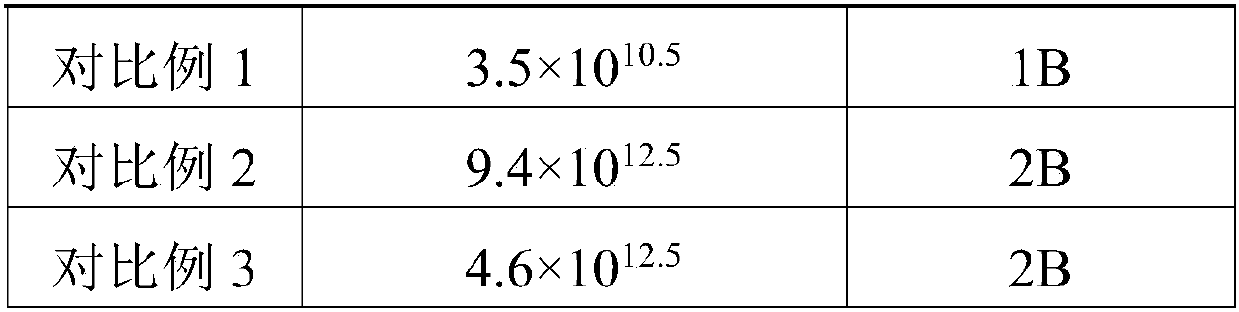

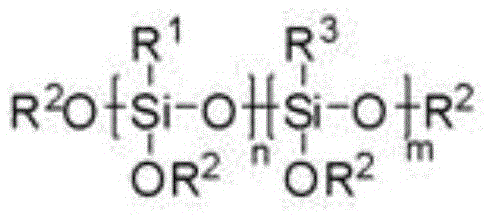

Modified polypropylene material for electric vehicle

InactiveCN105623095AExcellent resistance to flying stone impactImprove scratch resistanceElastomerPolymer science

The invention provides a modified polypropylene material for an electric vehicle and a preparing method of the modified polypropylene material.Raw materials including, by weight, 100-120 parts of polypropylene, 15-30 parts of metallocene polyolefin elastomer, 3-6 parts of glass fibers, 5-15 parts of a modified nanometer filling material, 8-14 parts of ethylene bis stearamide, 0.5-0.9 part of chlorinated polyethylene and 0.2-0.6 part of an antioxidant are weighed, wherein the modified nanometer filling material is obtained by modifying a nanometer filling material with alkyl alkoxyl siloxane, the nanometer filling material is prepared by mixing mica, silicon carbide and boron nitride at 5:1:1 by weight, and the weight ratio of the nanometer filling material to alkyl alkoxyl siloxane is 89:1.According to the modified polypropylene material for the electric vehicle and the preparing method of the modified polypropylene material, on the basis that the original performance of a polypropylene material is ensured, the flying stone impact resistance and scratch resistance of the modified polypropylene material are improved the surface tension and the paint adhesive force of the modified polypropylene material are improved, and the modified polypropylene material is especially suitable for serving as materials for accessories of the electric vehicle.

Owner:ZHEJIANG YULONG TECH DEV

Adhesion promoter composition

ActiveUS8076414B2Improve paint adhesionLess timePretreated surfacesPolyester coatingsAcrylic resinAromatic solvents

A composition for improving the adhesion of a paint to a surface, wherein the composition comprises an unsaturated polyester, a modified acrylic resin, a polymerization inhibitor, an aromatic solvent and either divinylbenzene, isopropenyl-2-methyl benzyl isocyanate or an acrylic monomer.

Owner:W M BARR

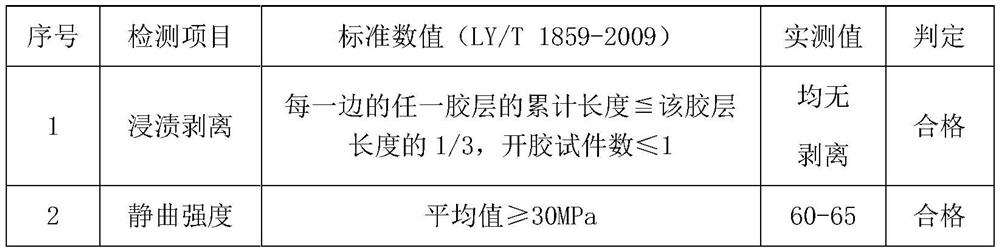

Archaized solid wood composite floor and production process thereof

PendingCN111749425ANo pollution in the processSave resourcesNatural patternsWood veneer joiningSolid woodAdhesive

The invention belongs to the technical field of building materials, and relates to an archaized solid wood floor, in particular to an archaized solid wood composite floor. A crisscross multilayer board base material layer is taken as a main body, the surface of the multilayer board base material layer is coated with adhesive to form a bonding layer, a surface layer is attached, a special archaizedprocessing layer is further arranged on the surface layer, and the uppermost layer is a UV paint layer. The special archaized layer is located between the surface layer and the surface UV paint layer, the thickness of the special archaized layer is between 0.1 mm and 1 mm, and the special archaized layer comprises a hand scraping archaized layer, a wire drawing process layer, a sawtooth grain treatment layer, a color coating process layer, a sand mark treatment layer and a color wiping treatment layer from top to bottom. The present invention also discloses a production process. According tothe archaized solid wood composite floor, the natural texture and the natural color of the wood are retained, the production process is simple, no distortion is lost in the texture pattern, the floorhas good visual characteristics through post-processing, and has relatively high paint adhesion and the like, and the physical and mechanical properties of the produced archaized floor meet the requirements of various indexes.

Owner:圣象地板(句容)有限公司

Process and seal coat for improving paint adhesion

ActiveUS9073083B2Improve paint adhesionEnhancing surface coating characteristicGroup 4/14 element organic compoundsAntifouling/underwater paintsZinc phosphateSilanes

Aqueous compositions useful as pretreatments prior to painting and to reduce the formation of rust in the uncoated condition consist essentially of water, an organo-functional silane, a compound of a Group IV-B element, and optionally a polyvinyl alcohol, stabilizing agents, wetting agents, thickeners, and biocides, and have an alkaline pH>7. A process for treating a metal surface includes contacting the surface with such an aqueous composition. The compositions and processes were found to have further benefits in comparison to the zinc phosphate metal pretreatment thought to be the standard in the industry. Preferably, the pH of the compositions is alkaline, which has been found to improve the efficacy of a silane as a surface treatment to improve uniformity of paint adhesion. By operating in the alkaline pH range, it was found that flash rusting and / or blush rust were significantly reduced.

Owner:BULK CHEM

One-piece golf ball

InactiveUS7026381B2Improve flight performanceIncrease repulsionGroup 5/15 element organic compoundsGolf ballsEngineeringGolf Ball

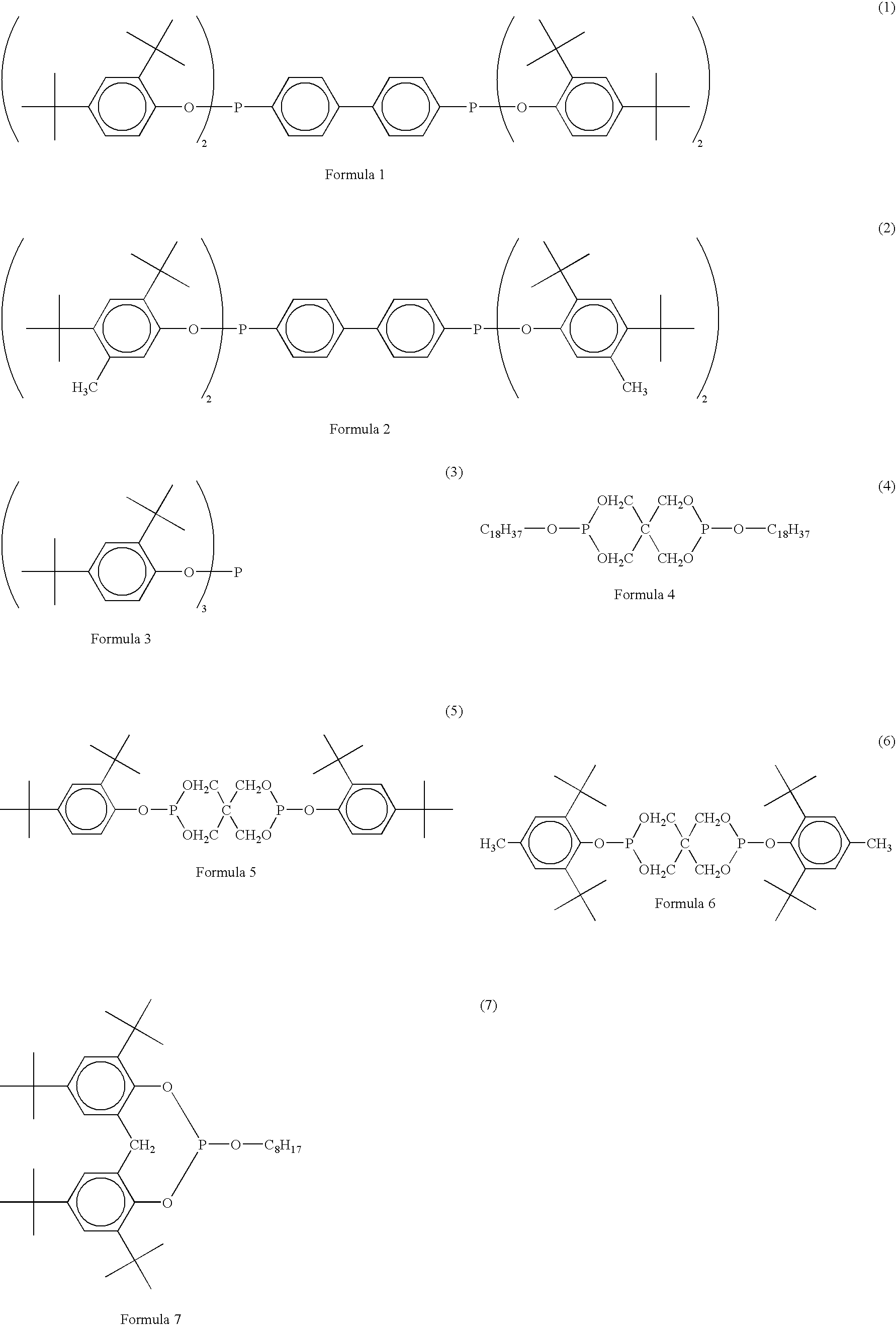

The object of the present invention is to provide a one-piece golf ball having an improved repulsion and coloring-resistance, and showing a good adhesion to the paint film. The one-piece golf ball of the present invention comprises a golf ball body formed by vulcanizing a rubber composition and a paint film covering the golf ball body, wherein the rubber composition contains 0.05 to 10 parts by mass of a phosphorus stabilizer with respect to 100 parts by mass of the rubber component.

Owner:DUNLOP SPORTS CO LTD

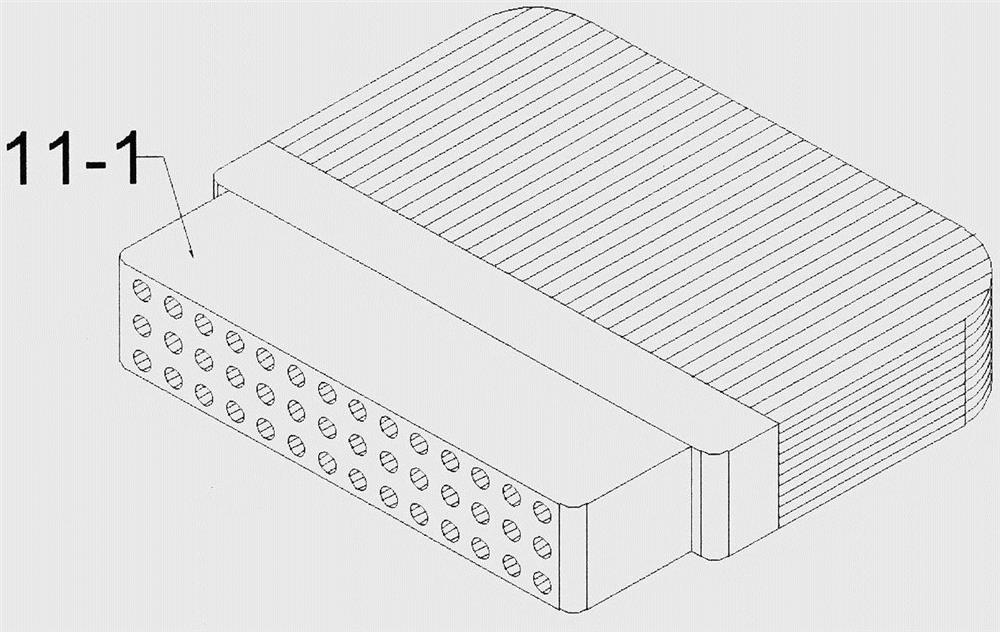

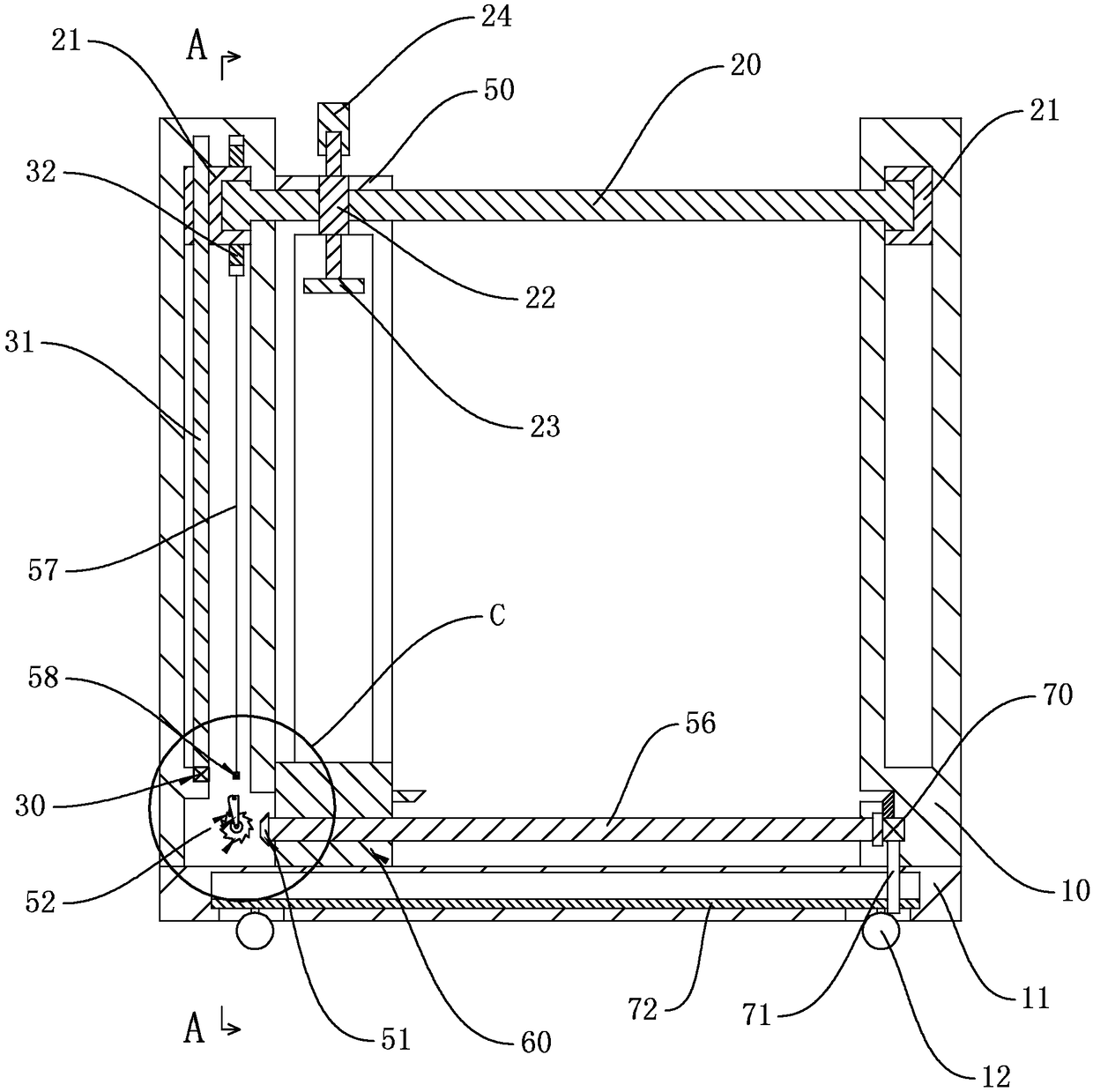

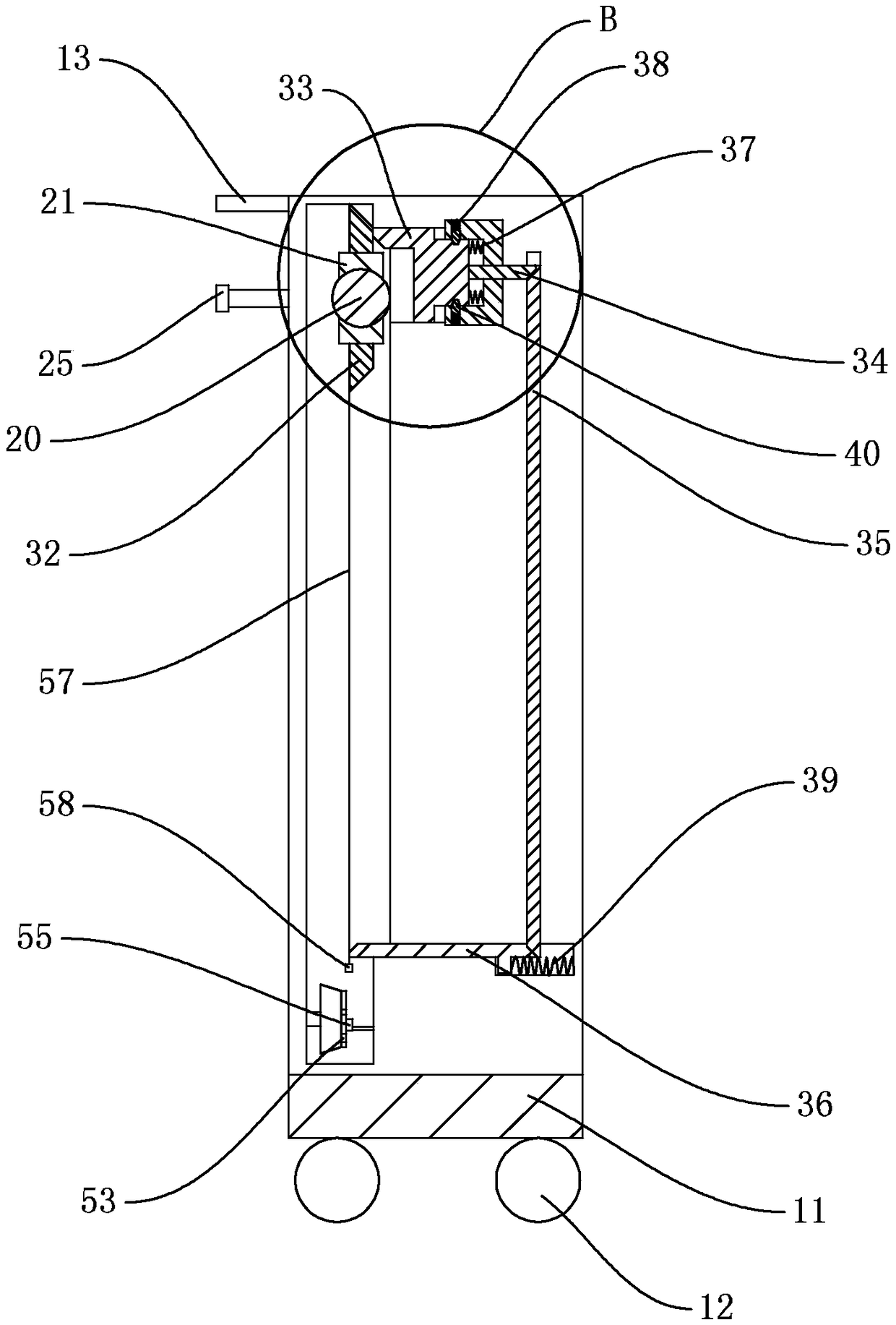

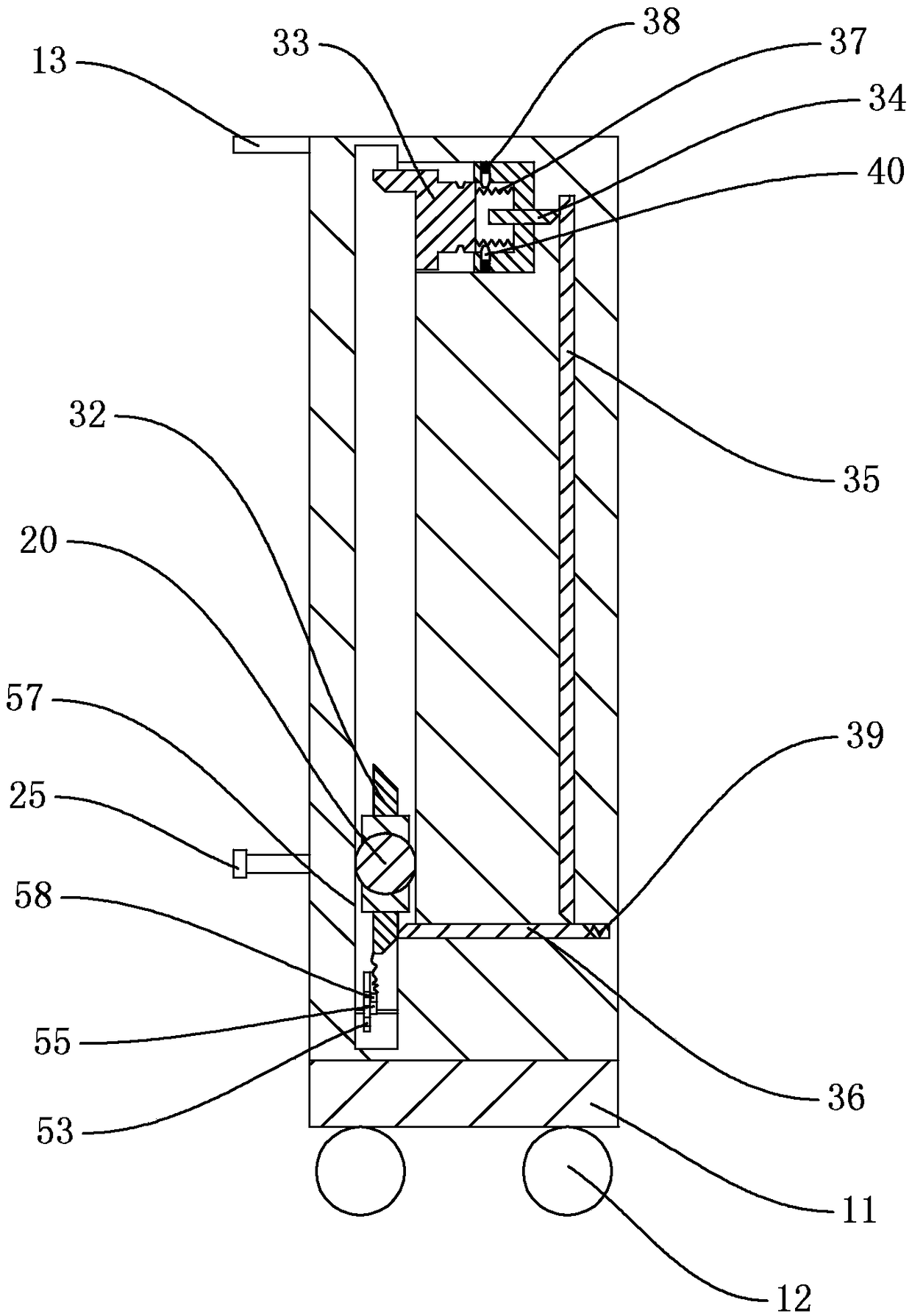

Underwater painting device

PendingCN111774261AReduce volumeEasy to operateLiquid surface applicatorsCoatingsMicroorganismUnderwater

The invention relates to the technical field of coating and painting, in particular to an underwater painting device. The underwater painting device comprises an external mechanism and an internal mechanism; the device is small in size, convenient to operate and capable of conducting painting underwater, and is provided with a material A stock bin and a material B stock bin independent from the material A stock bin, and a material A and a material B are proportionally supplied and mixed easily and practically; a material pushing mechanism adopts a motor to push the materials for feeding, and the feeding speed can be controlled manually and automatically; a roller brush driver is driven by the motor, a cog belt is connected with a roller brush driving gear to transmit a roller brush, a vibration device is arranged, operation is effortless, painting adhesion is improved, and according to different environments, a roller brush fixing device and a hairbrush special for roller brush replacement can be disassembled for usage. According to the underwater painting device, the problems that ocean equipment and ships are subjected to corrosion and microorganism parasitism because of being soaked into seawater, usage of the underwater equipment and the route speed of structure strength of ships are influenced, the underwater equipment and the ships need painting treatment and cannot leavethe water surface, and the cost for painting by leaving the water surface is too high are solved.

Owner:刘家超

Process and composition for passivating metal surfaces

InactiveUS20200340122A1Improve corrosion resistanceImprove paint adhesionMetallic material coating processesZinc phosphateSilanes

Aqueous compositions useful as a passivation treatment prior to painting to reduce corrosion. The compositions includes water, a trivalent chromium salt with the formula Cr(HxPO4)3, where x is 1.5 or 2, a polymer system having a plurality of carboxylic functional groups, an organo-functional silane, and an organopolyphosphonic acid. A process for treating a metal surface includes contacting the surface with such aqueous compositions. The compositions and the processes provide benefits in comparison to the zinc phosphate metal pretreatment thought to be the standard in the industry.

Owner:BULK CHEM

Metallic lacquer solid wood composite floor production process and floor thereof

PendingCN114102782ARich and full colorWith metallic lusterWood veneer joiningFlooring insulationsSolid woodLacquer

The invention belongs to the technical field of building materials, and relates to a metal paint solid wood composite floor production process which comprises the following steps: veneering, hot-pressing and curing, cutting, forming, antique treatment, coating of primer and finish paint with metal paint UV (ultraviolet) paint, and packaging of a finished product. The metallic paint UV paint coating comprises a metallic paint coloring coating, an adhesive force primer coating, an anti-cracking adhesion increasing coating, a hardening primer coating, a metallic paint finish coating and the like; the invention further discloses the metal paint solid wood composite floor manufactured according to the technology. After the surface of the wood floor is coated with the metal finish paint in a roller coating mode and physical mixing, the wood floor has metallic luster, strong three-dimensional sense of the paint surface, smooth hand feeling and good visual effect and touch feeling. The metal paint floor is rich and full in color and luster and has the metal low-light texture. And meanwhile, the metallic paint has excellent color fixation, pollution resistance and wear resistance, so that the floor can be bright for a long time and is beautiful as new.

Owner:圣象地板(句容)有限公司

Automatic integrated wall-surface painting machine

ActiveCN109083370AImprove paint adhesionAvoid the need to climbBuilding constructionsEngineeringMoisture

The invention discloses an automatic integrated wall-surface painting machine, and belongs to the field of painting devices. The automatic integrated wall-surface painting machine comprises a support,a painting device and a power device, wherein the painting device comprises a rotating shaft, sliding blocks arranged at the two ends of the rotating shaft, a sleeve, a roller brush, a paint brush and a cleaning brush, the sleeve, the roller brush, the paint brush and the cleaning brush are coaxially arranged on the rotating shaft, the roller brush, the paint brush and the cleaning brush are circumferentially and fixedly arranged on the sleeve, and the sliding blocks can slide up and down and are arranged on the support; the power device comprises a motor and a reciprocating threaded rod which is in driving connection with the motor, an internal thread matched with the reciprocating threaded rod is formed in any sliding block, and the reciprocating threaded rod is used for driving the sliding blocks to reciprocate up and down. The automatic integrated wall-surface painting machine has the advantages that through the cleaning brush, moisture of the wall surface can be absorbed while the wall surface can be cleaned, the wall surface is dry, the adhesive force of paint is improved, the rotating shaft is driven by the motor to move up and down, automatic cleaning and painting are achieved accordingly, and it is avoided that a worker needs to climb high during manual painting.

Owner:聊城鸿嘉网络技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com