Paint remover and preparation method thereof, and paint removing method

A paint remover and volatile agent technology, applied in the field of paint remover and its preparation, can solve the problem that the surface of the metal substrate loses the metallic texture, bright and bright color, the paint stripping efficiency and speed are not ideal, and the bonding strength with the metal substrate is not enough. High problems, to achieve the effect of improving the adhesion of iron paint, good paint stripping efficiency, and improving anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

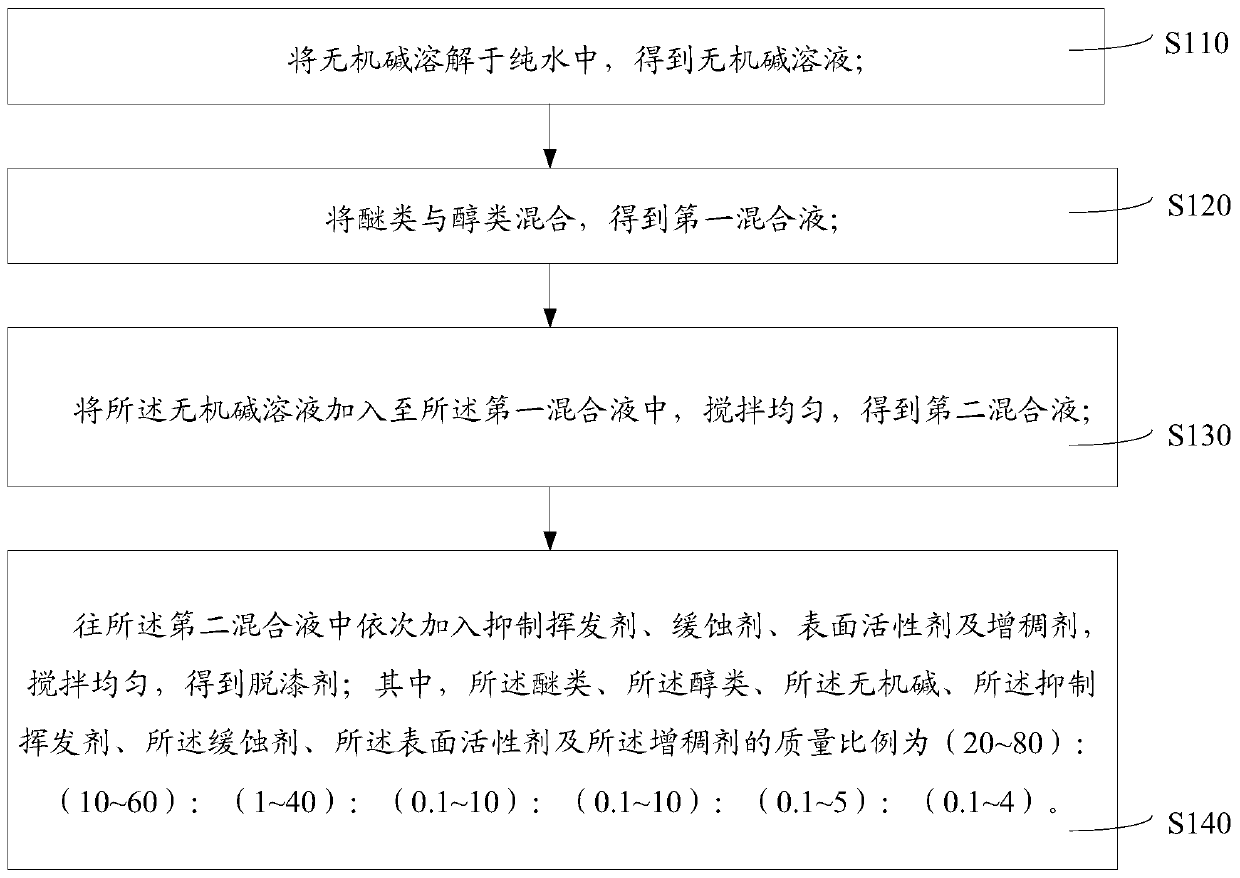

Method used

Image

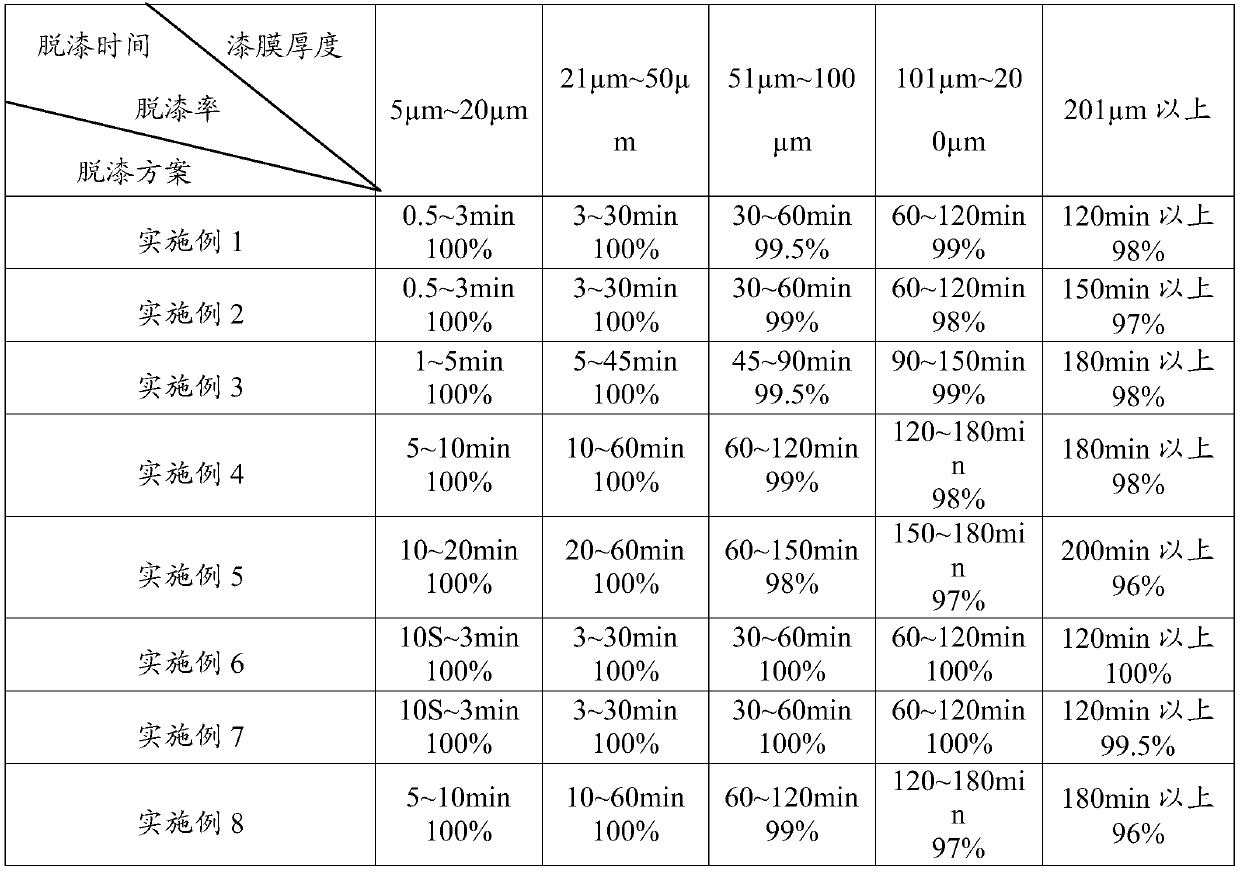

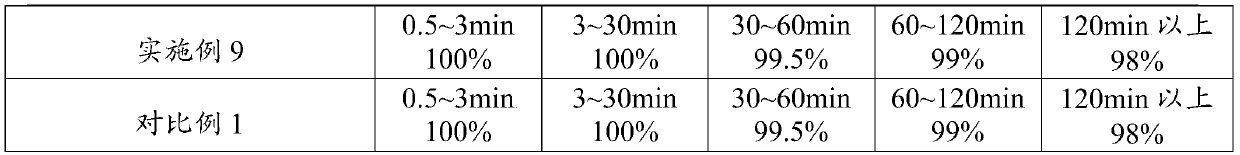

Examples

Embodiment approach

[0029] One embodiment, a paint remover, comprising the following components in parts by mass: 20-80 parts of ethers, 10-60 parts of alcohols, 1-40 parts of inorganic bases, 0.1-10 parts of volatile inhibitors, 0.1-10 parts of etchant, 0.1-5 parts of surfactant and 0.1-4 parts of thickener. As another example, the paint remover further includes pure water, and the mass fraction of the pure water is 1-10 parts. In this way, the paint remover of the present invention selects ethers as the main solvent to replace the commonly used halogenated hydrocarbons such as dichloromethane, uses alcohols as a cosolvent, and an inorganic base as an activator, supplemented by a volatile agent that inhibits the volatilization of the main solvent and inhibits corrosion. The agent avoids over-corrosion of the metal substrate, the surfactant increases the permeability of the main solvent to the metal substrate, and the thickener increases the adhesion between the main solvent and the metal substra...

Embodiment 1

[0055] Dissolve 30g of potassium hydroxide and 20g of sodium hydroxide in 50g of pure water to obtain an inorganic alkali solution; mix 450g of methylene dimethyl ether, 200g of ethylene glycol ether, 100g of ethanol and 140g of methanol to obtain the first mixed solution; the inorganic alkali solution is added to the first mixed solution, stirred evenly to obtain the second mixed solution; 10g liquid paraffin, 1.5g benzotriazole, 1g SP80 surfactant and 2g of hydroxypropyl methylcellulose were stirred evenly to obtain a paint remover.

Embodiment 2

[0057] Dissolve 20g of potassium hydroxide and 30g of sodium hydroxide in 50g of pure water to obtain an inorganic alkali solution; mix 450g of methylene dimethyl ether, 200g of ethylene glycol monobutyl ether, 100g of ethanol and 140g of methanol to obtain the second A mixed solution: adding the inorganic alkali solution to the first mixed solution, stirring evenly to obtain a second mixed solution; adding 10 g of liquid paraffin and 1.5 g of benzotriazole to the second mixed solution in sequence , 1g SP80 surfactant and 2g hydroxypropyl methylcellulose, stirred evenly to obtain a paint remover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com