Treatment process before plating environment-friendly copper alloy

A treatment process, copper alloy technology, applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of heat source, high energy consumption, increase of product production cost, etc., and achieve the effect of avoiding over corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

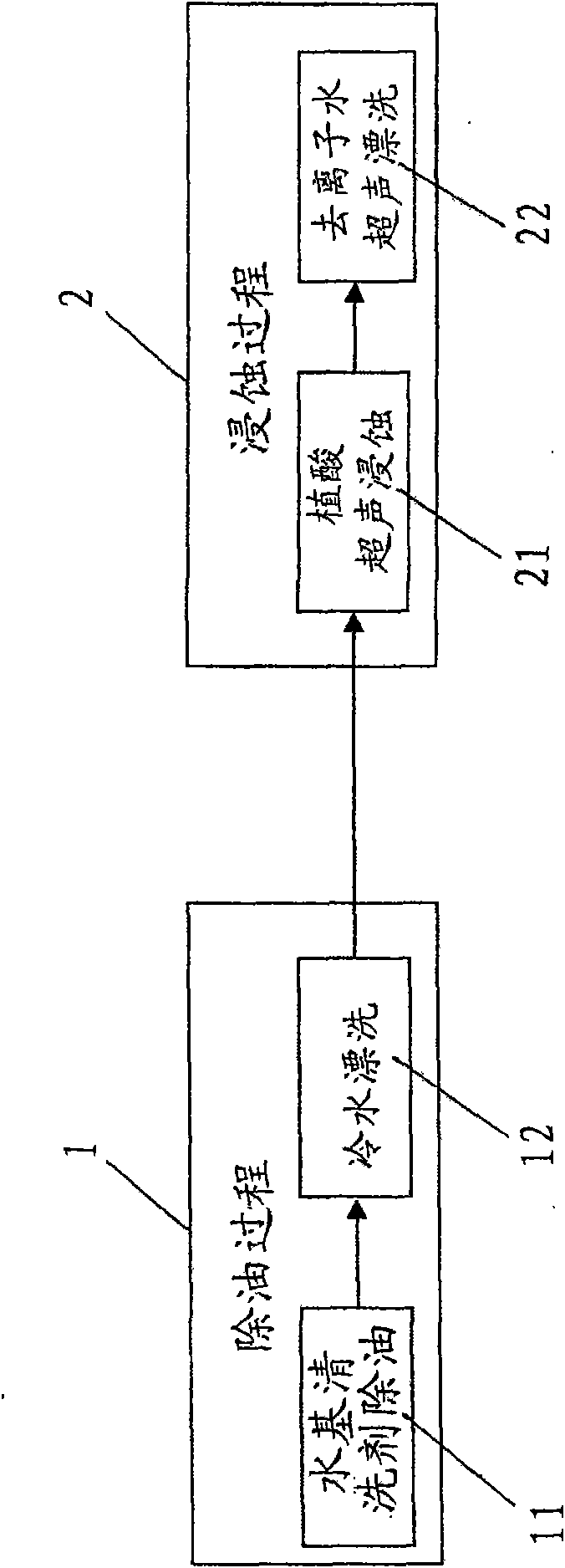

[0032] like figure 1 As shown, an environment-friendly copper alloy pre-plating process includes a degreasing process 1 and an etching process 2, wherein the degreasing process 1 is composed of water-based cleaning agent degreasing 11 and cold water rinsing 12, and the etching process 2 is composed of plant Composed of acid ultrasonic etching 21 and deionized water ultrasonic rinsing 22 . Specifically, it includes the following four steps:

[0033] (i) Water-based cleaning agent for degreasing

[0034] Degreasing liquid: water-based cleaning agent (commercially available), pH=8~10

[0035] Degreasing temperature: 0~35℃

[0036] Degreasing time: 20-30 minutes

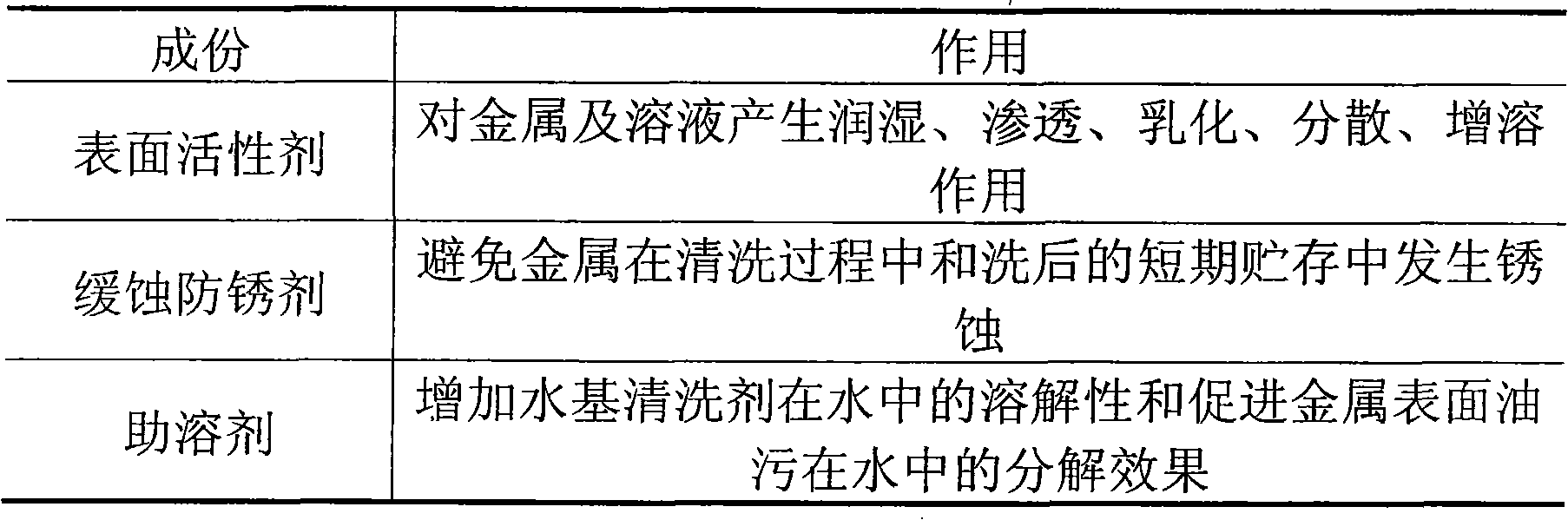

[0037] The oil-removing water-based cleaning agent is composed of a variety of surfactants, anti-rust agents, oil-stain dispersants and co-solvents that are harmless to the human body and the environment.

[0038] The composition and function of water-based cleaning agent are shown in Table 1

[0039] Table 1

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com