Patents

Literature

53results about How to "Improve galvanizing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

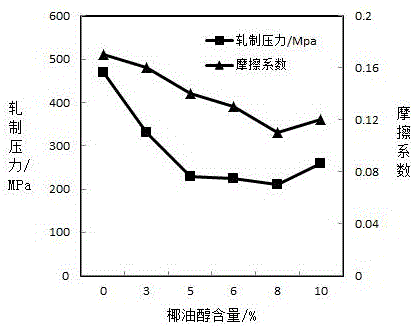

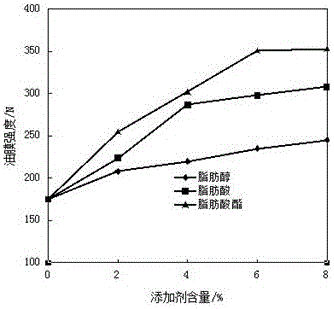

Strip steel cold rolling emulsified oil containing boric acid ester and preparation method thereof

InactiveCN105733785AModerate viscosityIncrease relative volatilityLubricant compositionSurface finishSocial benefits

The invention relates to a strip steel cold rolling emulsified oil and a preparation method thereof.The strip steel cold rolling emulsified oil is prepared from 10%-40% of a component A, 15%-45% of a component B, 5%-20% of a component C, 3%-10% of a component D, 2%-8% of a component E, 2%-8% of a component F, 1.8%-7% of a component G and 1.5%-6% of other auxiliaries H.The cold rolling emulsified oil is appropriate in viscosity, good in volatility and moderate in saponification value; the emulsion particle size is moderate after the cold rolling emulsified oil is dissolved in water, so that rolled strip steel is good in surface finish and free of residues, which plays a key role in improving the galvanization quality of strip steel in a subsequent process; the rolling liquid is long in service life, low in cost and capable of prolonging the service life of rollers and reducing product cost; besides, the preparation method is simple and easy to apply and popularize on a large scale, so that good economic benefits and social benefits are brought.

Owner:TIANJIN JINHAILI GREASE CO LTD

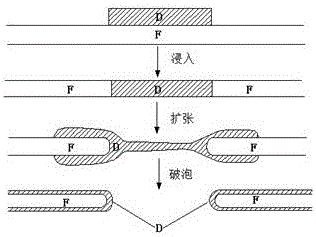

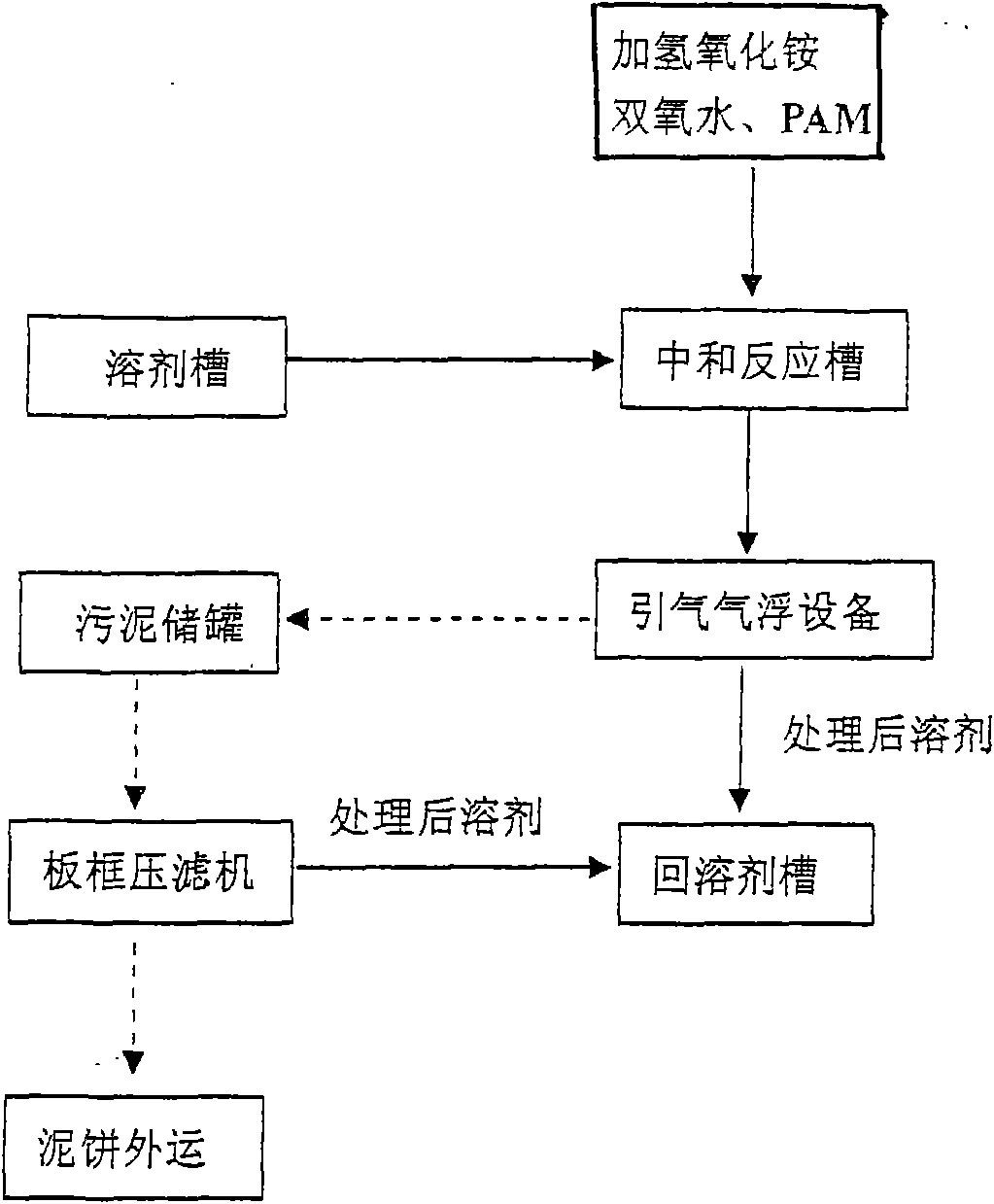

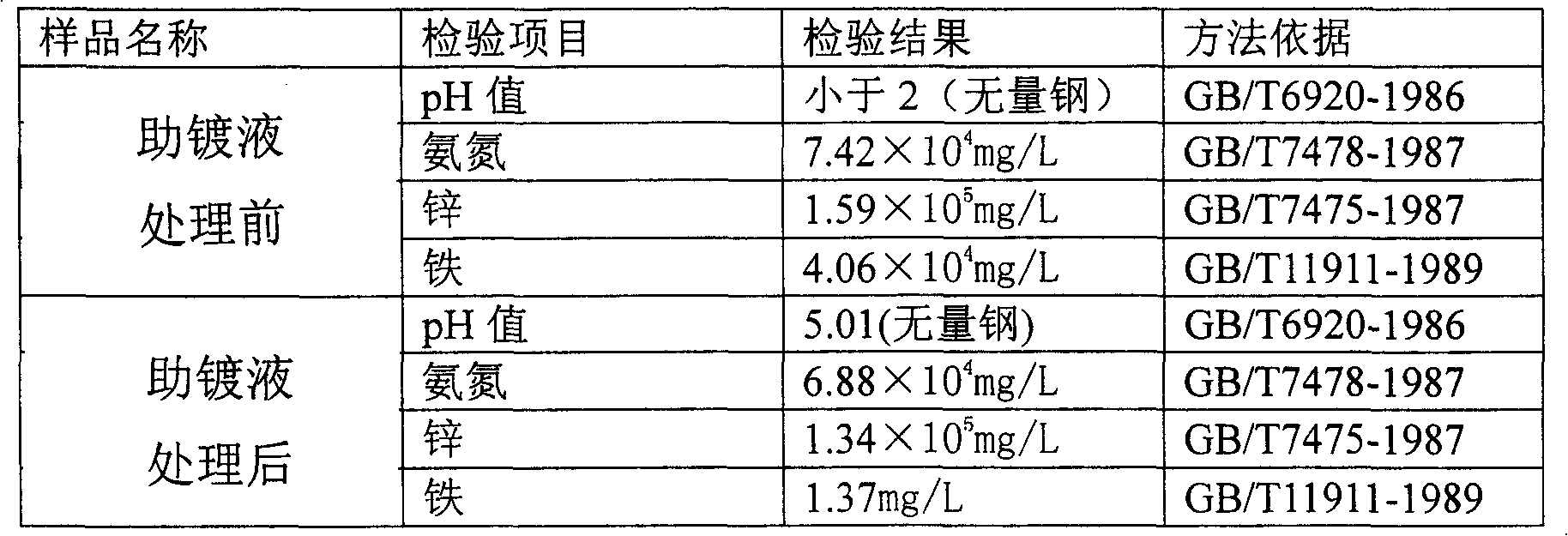

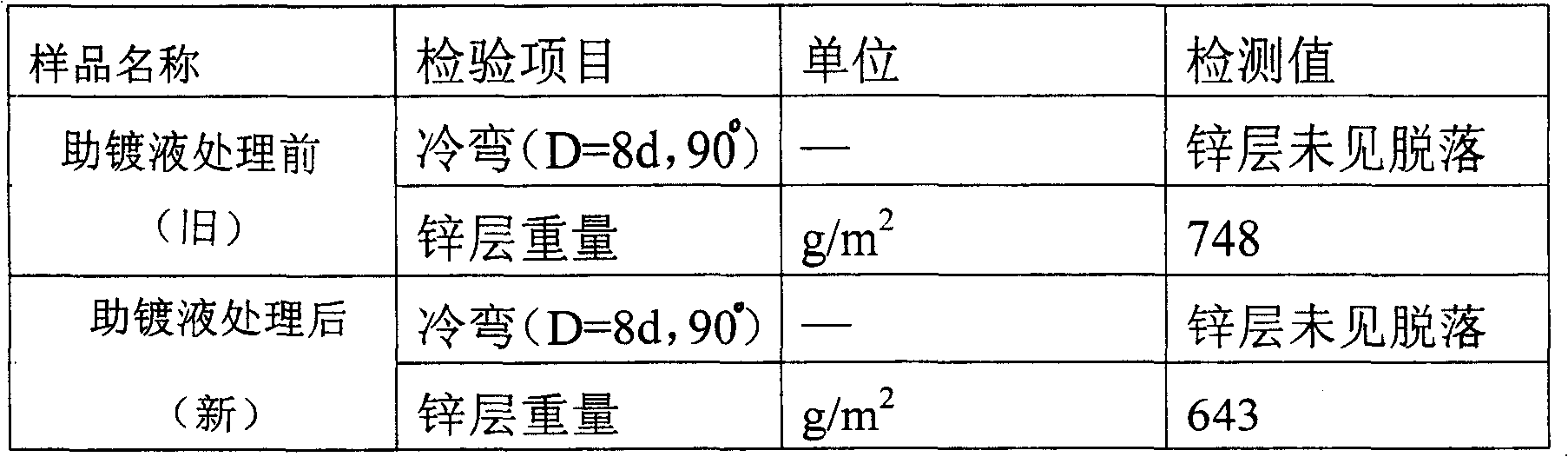

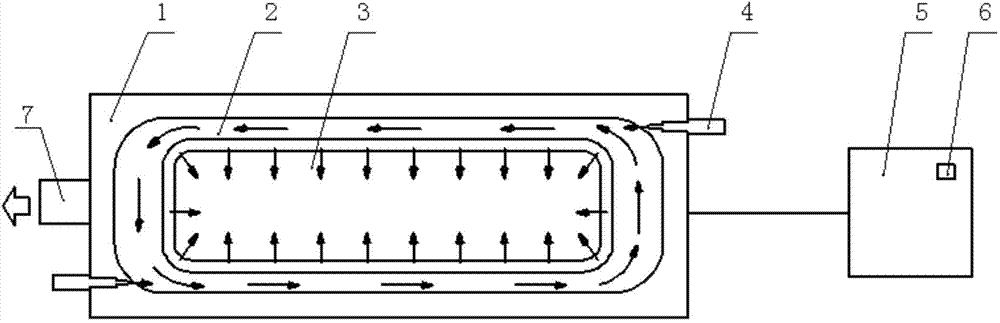

On-line circulation process for hot galvanizing process quickening liquid

The invention relates to an on-line circulation process for hot galvanizing process quickening liquid, which is carried out according to the following steps: (1) after a solvent is introduced into a neutralization reaction tank, an ammonium hydroxide solution is added, the pH value of the solvent is regulated to 5.0-5.5, and then, hydrogen peroxide is added to convert ferrous iron into ferric iron; (2) polyacrylamide is added to the solvent according to the proportion of 0.05-0.1 percent; (3) the water which flows out of the neutralization reaction tank is introduced into air-entraining air floating equipment to be separated, the chemical sludge generated by air floating enters a sludge storing pot, and the clear solution directly returns to the solvent tank; and (4) the chemical sludge in the sludge storing pot is dehydrated through a plate and frame filter press, the dehydrated sludge residues (iron hydroxide) are used as other industrial raw materials, and the filtered solution returns to the solvent tank. The invention has the advantages of simple and easy whole processes, saves a large amount of energy resources, has no environment pollution, improves the galvanizing quality and saves the galvanizing cost.

Owner:张永金

Hot dip galvanizing Al rare earth alloy for steel and iron member hot dip galvanizing and its ingot type and method

ActiveCN101086047AAvoid uneven compositionAvoid burnsHot-dipping/immersion processesSymmetrical earsRare earth

The invention relates to a zinc alloy for steel component galvanizing, the ingot shape and the method. The comprised component and weight proportion are as follows: 0.008%-0.012%(wt)Al,0.006%-0.01%(wt)RE, the rest is zinc and unavoidable impurities. The ingot shape is'T'cuboid with two symmetrical ear-warps, the bottom of cuboid is plane, ear-warps are equipped with hoisting holes, and the four sides are inclined plane which is narrow-end-up shape. It is characterized by direct fusion of said alloy to zinc bath, simple utilization, stable and homogeneous Al and rare earth content in zinc alloy, improved coating brightness and zinc flowability, decreased coating thickness, and saved zinc plating cost. The proper zinc alloy ingot shape and weight meets the demand of zinc addition for large-capacity galvanizing equipment, and it is convenient for hoisting and cross transportation, specific surface area is small, which is suitable for multi-layer stacking storage.

Owner:湖南株冶环保科技有限公司

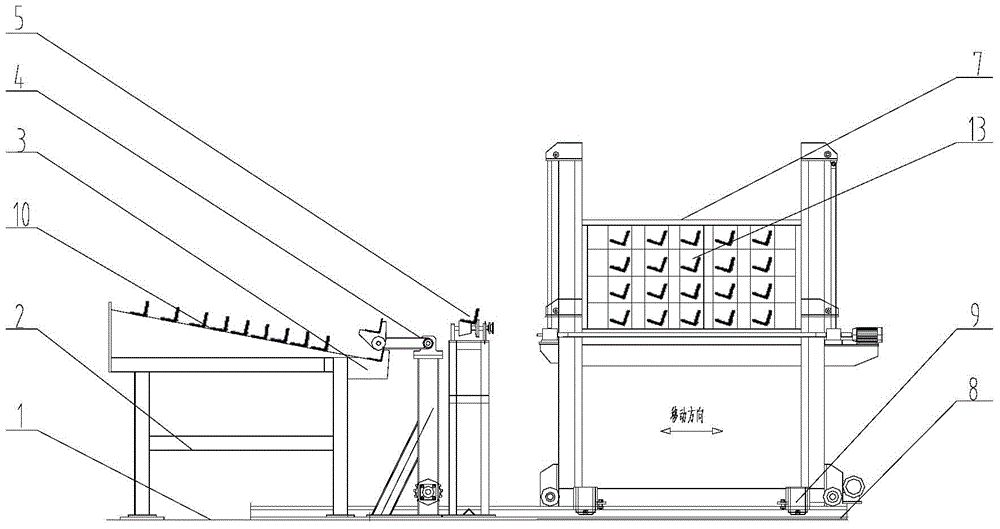

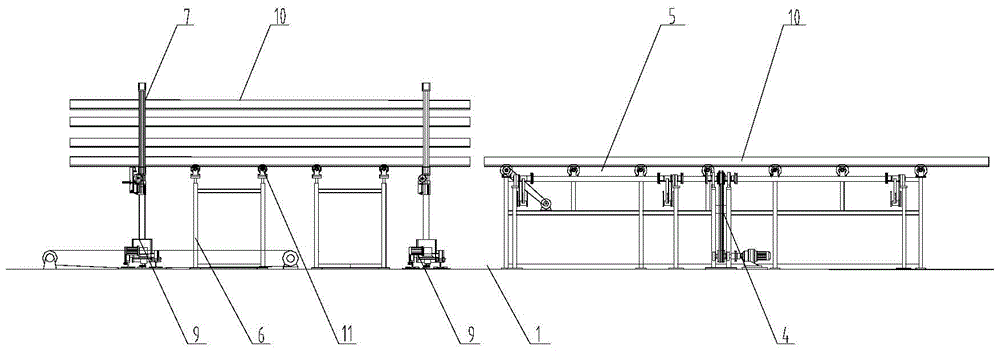

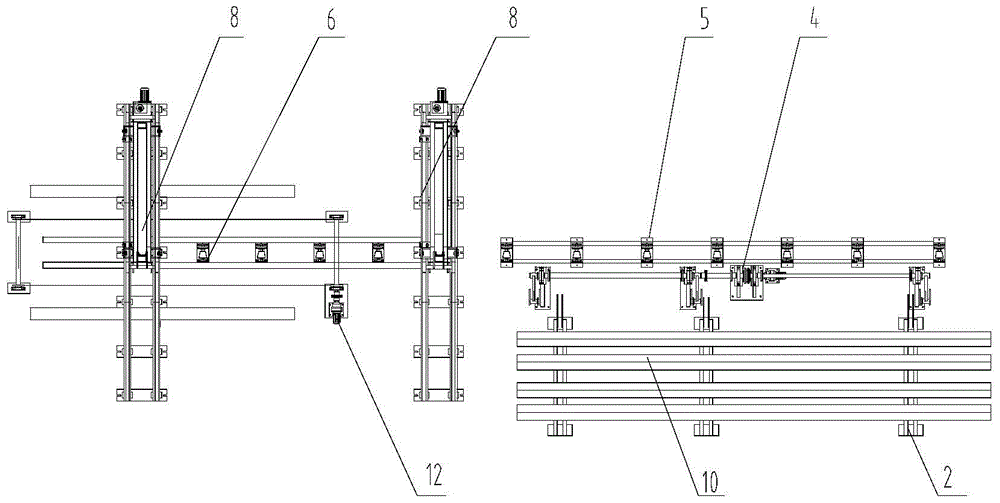

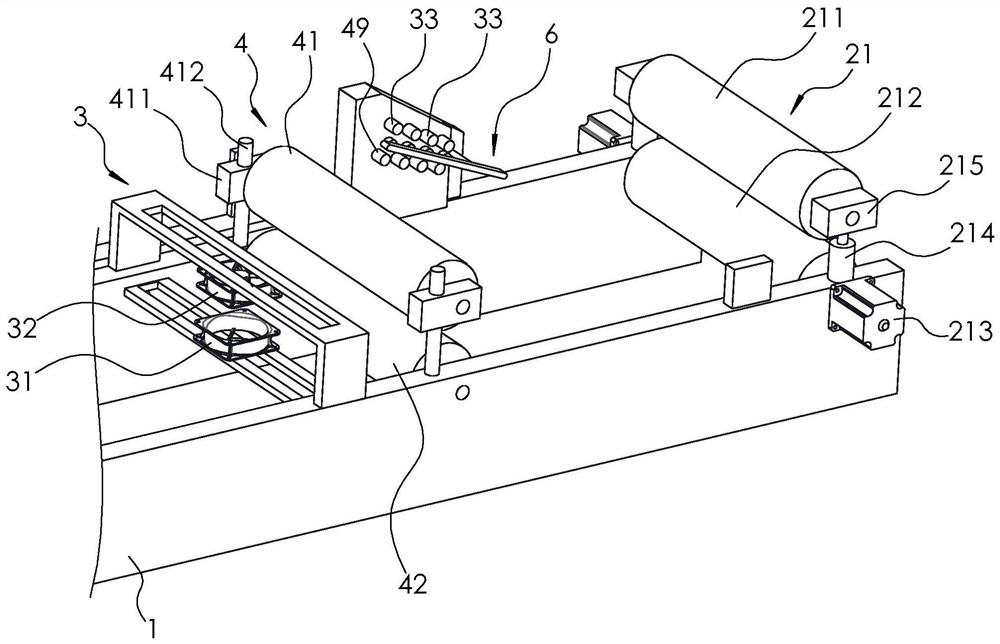

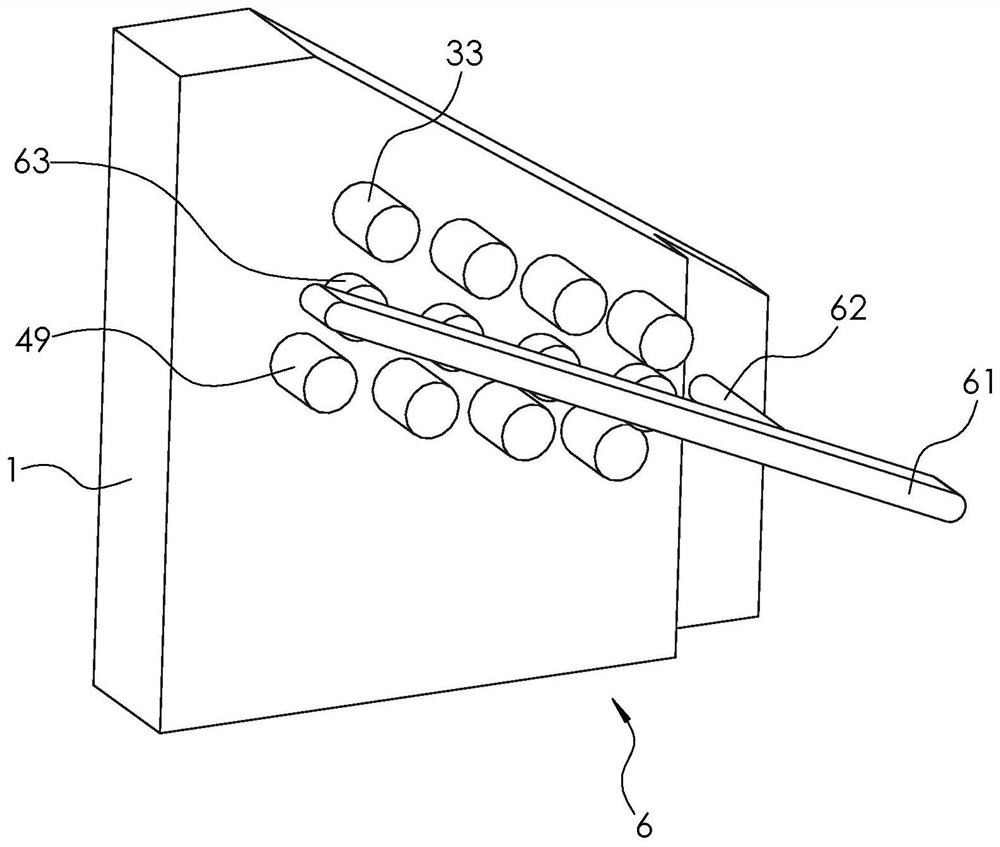

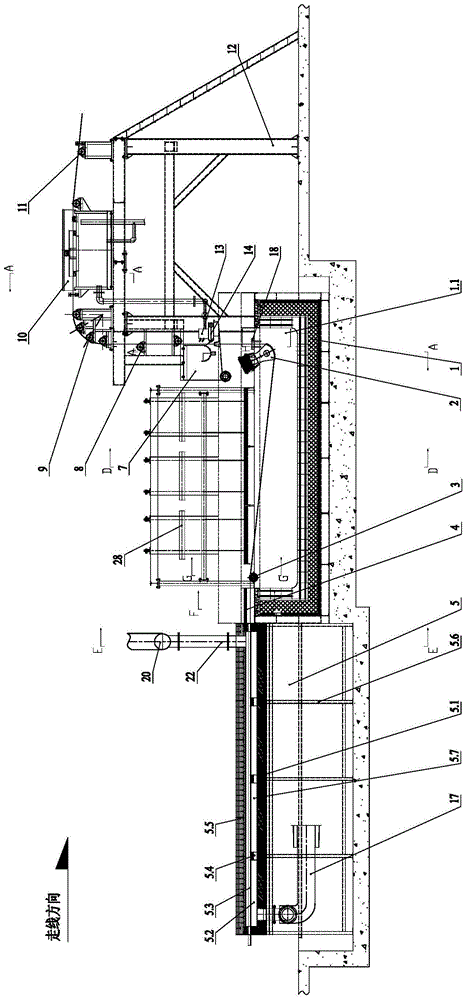

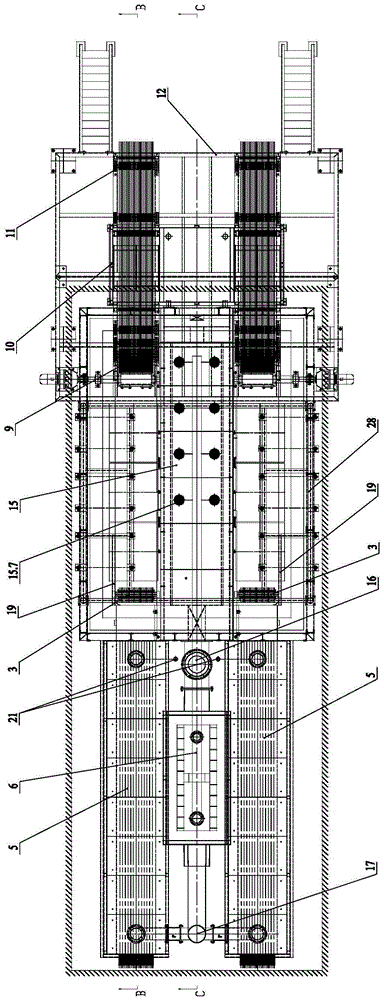

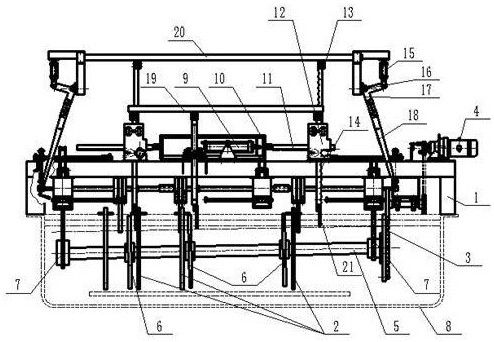

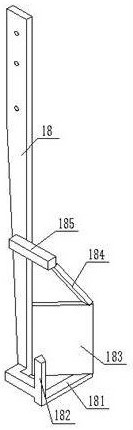

Angle steel galvanized numerical control threading and hanging device and threading and hanging process

ActiveCN104711501BNo manual deliveryImprove delivery efficiencyHot-dipping/immersion processesNumerical controlUltimate tensile strength

The invention relates to an auxiliary device for angle steel galvanization, in particular to a numerical control penetrating and hanging line device for angle steel galvanization and a penetrating and hanging process. The numerical control penetrating and hanging line device comprises a worktable, a material storage rack, an angle steel positioning seat, a material turnover device, a feeding roller way, a material-passing roller way, a material-penetrating comb, a movable guide rail and a comb clamping lifting traveling trolley, wherein the material turnover device is mounted between the angle steel positioning seat and the feeding roller way and can easily turn over and convey galvanized angle steel falling into the angle steel positioning seat to the preset feeding roller way, so that seamless connection of the angle steel and feeding and conveying processes is realized and the conveying efficiency and the conveying quality of the galvanized angle steel are improved. Angle steel feeding, conveying and penetrating-hanging processes are integrated on the same equipment, so that the occupied site space is small, the crane occupation time is short, and the safety coefficient is high; the whole penetrating and hanging operation does not need human assistance, and the galvanized angle steel is controlled through the numerical control device to realize the steps, so that the labor intensity of penetrating and hanging is greatly reduced and the penetrating and hanging efficiency is improved.

Owner:QINGDAO EAST STEEL TOWER

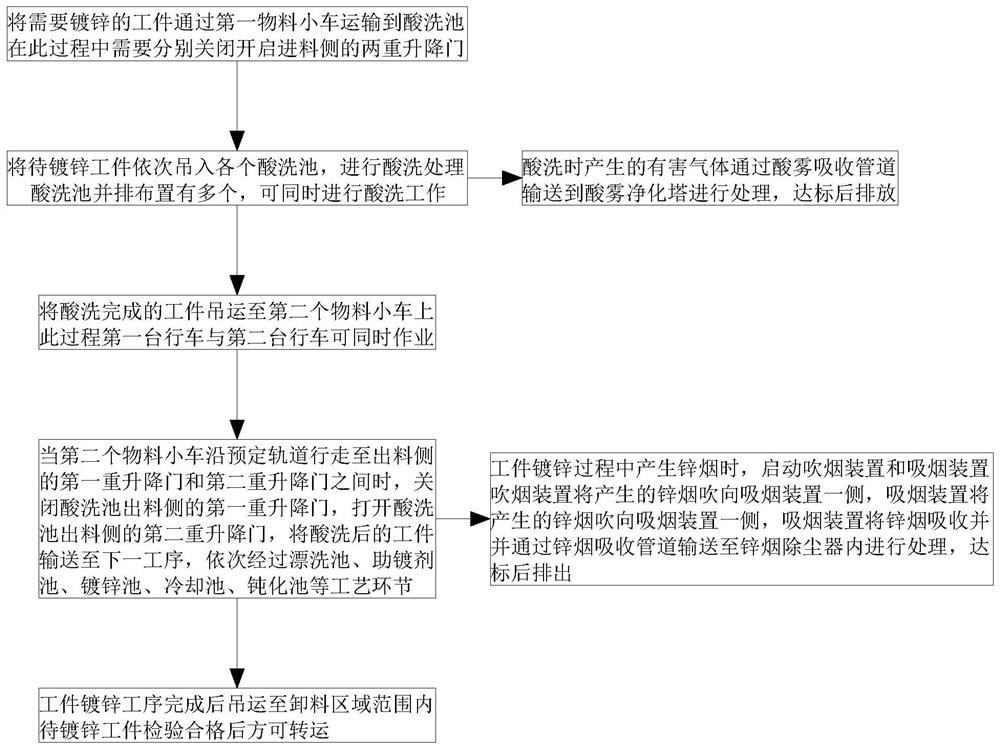

Environment-friendly sealed hot galvanizing method

PendingCN111778465AImprove galvanizing qualityIncrease productivityHot-dipping/immersion processesAcid washingWorking environment

The invention discloses an environment-friendly sealed hot galvanizing method, comprising the following steps: process preparation: providing multiple acid washing tools, rinsing pools, plating assistant agent pools, galvanizing pools, cooling pools, passivation pools and an unloading area in a closed steel structure in sequence from left to right; and providing dual doors on feed sides and discharge sides of the acid washing pools. The environment-friendly sealed hot galvanizing method improves the production efficiency of galvanized workpieces, improves the workpiece galvanizing quality, relieves the labor intensity of operators, achieves excellent tightness, prevents workers from directly contacting the working environment of strong acid mist, eliminates the injury of human bodies by harmful chemical gas such as acid gas and smoke, can convert the harmful chemical gas generated by hot galvanizing for qualified emission, improves the enterprise competitiveness, and solves the problems of pollution of ecological environment and body injury of operators by the acid gas and the smoke generated in the hot galvanizing process of metal products.

Owner:增立钢管结构(江门)有限公司

Production process of galvanized steel coil

ActiveCN111560576AGood degreasing effectImprove galvanizing qualityHot-dipping/immersion processesIron powderAir knife

The invention relates to a production process of a galvanized steel coil. The production process comprises the following steps that S1, a cold rolled hard steel coil is subjected to uncoiling, head and tail cutting and welding in sequence; S2, degreasing fluid is prepared, the steel coil treated in the step S1 is soaked into the degreasing fluid, brushed by a brushing roller, dried by hot air andtreated by an entry looper; S3, the steel coil obtained in the step S1 is annealed; S4, the annealed steel coil is placed into a zinc pot to be soaked for 4-5s, and is purged by an air knife, cooled,dried by hot air and finished in sequence to obtain the galvanized steel coil; S5, the galvanized steel coil is heated and taken out, a suction pipe is used for sucking passivating fluid to drop the fluid to the surface of the galvanized steel coil, and drying is carried out; S6, the steel coil treated in the step S5 is subjected to fingerprint resistant coating treatment, passes through an exit looper and is coated with oil; and S7, the steel coil obtained in the step S6 is cut, coiled, uncoiled and packaged. The production process of the galvanized steel coil can effectively remove pollutants such as dust and iron powder firmly stuck to the surface of the steel coil, and is beneficial to improving the quality of the galvanized steel coil, thereby prolonging the service life of the galvanized steel coil.

Owner:ZHEJIANG SOUTHEAST METAL SHEET

Preparation method of flexible zinc-air battery taking waste cloth as matrix

InactiveCN110943267AAvoid wastingPrevent leakageFuel and primary cellsFuel and secondary cellsCarbon filmPotassium hydroxide

The invention provides a preparation method of a flexible zinc-air battery taking waste cloth as a matrix. The method comprises the following steps: cobalt hydroxide is electrodeposited on a carbon film and subjected to heat treatment to form cobaltosic oxide serving as a positive electrode, zinc is plated on a chemical copper plating waste fabric to serve as a negative electrode, colloid of PVA and potassium hydroxide serves as a diaphragm and an electrolyte, then plastic packaging is conducted through a plastic film, and the flexible battery is obtained. Compared with the prior art, the invention has the following beneficial effects: 1, colloid of PVA and potassium hydroxide is used as a diaphragm and an electrolyte, and a liquid electrolyte is not used, so that liquid leakage can be effectively prevented, the colloid can be tightly attached to the rough surface of the carbon cloth positive electrode, and the conductive efficiency is improved; 2, a special alkaline galvanizing solution galvanizing formula is used for electrogalvanizing, so that the galvanizing quality is greatly improved; 3, the negative electrode raw material is waste fabric, so that waste of wastes can be avoided, and an environment-friendly effect is achieved.

Owner:福建省建瓯第一中学

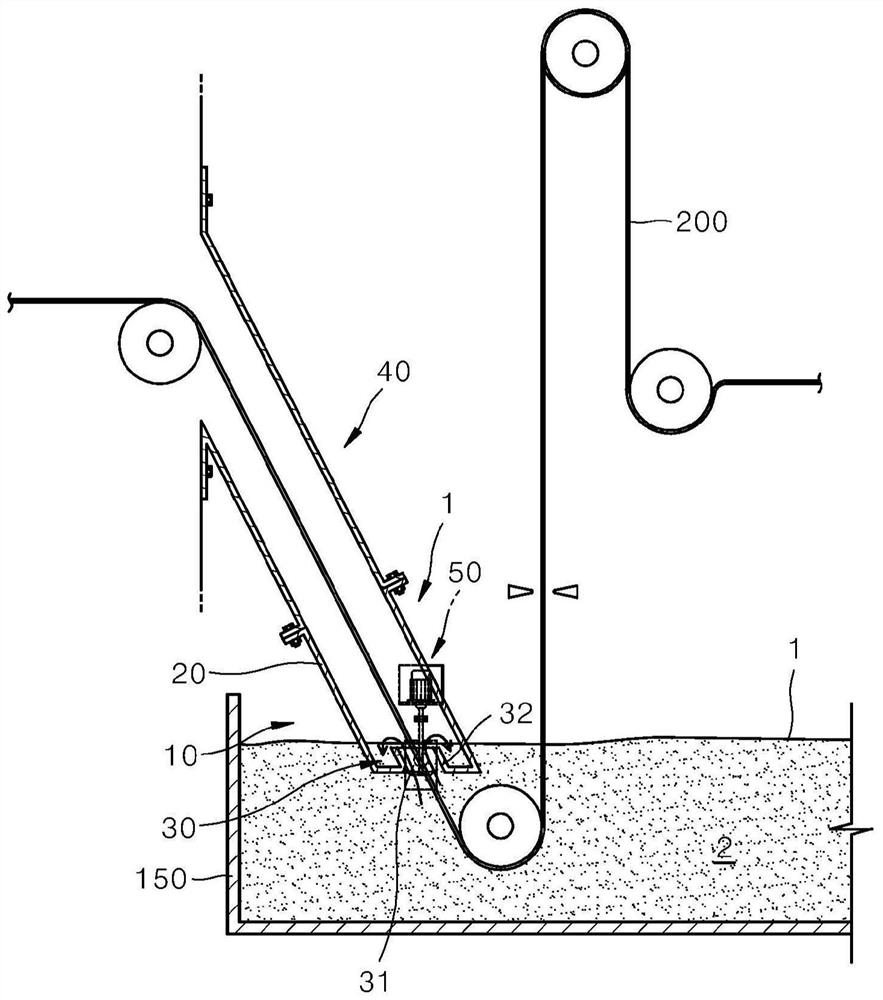

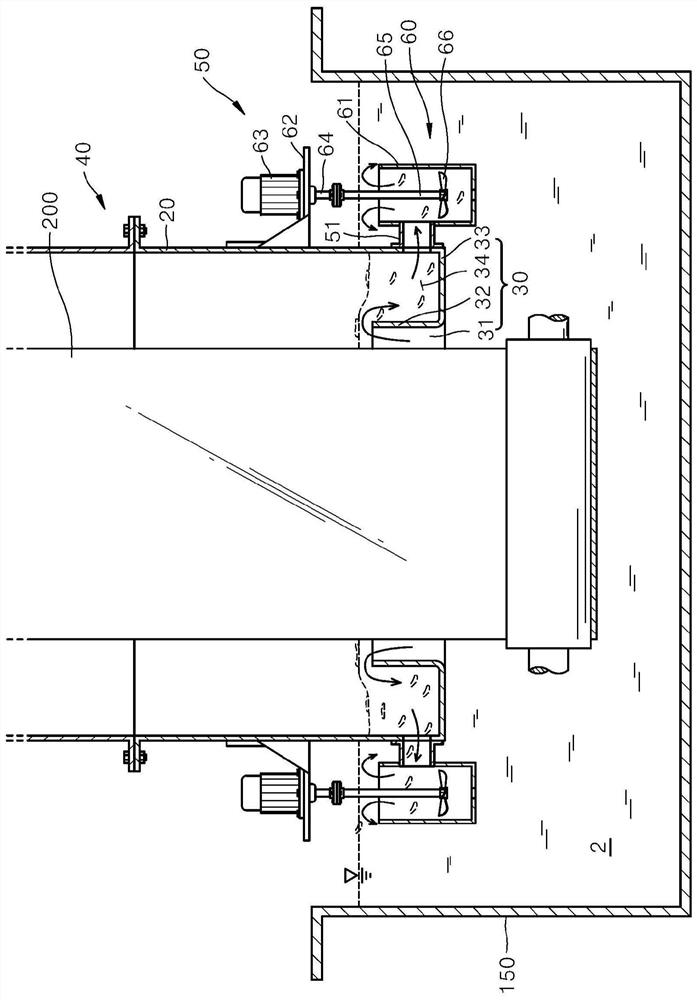

Device for removing foreign material from molten metal surface in steel sheet hot-dip galvanizing process

PendingCN113767184AAvoid recontaminationImprove galvanizing qualityHot-dipping/immersion processesFatty/oily/floating substances removal devicesMaterials scienceMolten metal

A device for removing foreign material from a molten metal surface in a steel sheet hot-dip galvanizing process, of the present invention, comprises: a snorkel part of which the end portion is submerged under the molten metal surface of a hot-dip galvanizing bath so as to encompass a steel sheet inserted into the hot-dip galvanizing bath, in order to prevent the oxidization thereof; a snout including a dam unit having a dam forming part which encompasses the steel sheet from the end portion of the snorkel part so as to be spaced a predetermined gap from same, and which allows a molten galvanizing solution inside the hot-dip galvanizing bath to flow over toward the inner peripheral surface of the snorkel part so as to prevent the foreign material that falls onto the molten metal surface inside the snorkel part from attaching to the steel sheet; and a molten zinc discharge unit which is provided inside the snorkel part so as to pump, toward the molten metal surface inside the hot-dip galvanizing bath, the molten galvanizing solution having flowed over the dam forming part of the damp unit, thereby preventing the foreign material included in the molten galvanizing solution, having flowed over the dam forming part, from mixing into the molten galvanizing solution inside the hot-dip galvanizing bath and re-polluting the molten galvanizing solution or flowing into the snorkel part again.

Owner:株式会社斯戴普安津

Galvanizing technology for combination intensity of galvanizing layer and base material

InactiveCN104762579APrevents defects that are easy to fall offGuaranteed adhesionHot-dipping/immersion processesSulfurTetramine

The invention discloses a galvanizing technology for combination intensity of a galvanizing layer and a base material, which is used for anticorrosion processing of surface of a photovoltaic flat rack. The technology comprises the steps of cleaning, drying, galvanizing and cooling in order, and the cleaning step comprises the steps of degreasing, examining, pickling and washing in order, pickling temperature scope is between 30-35 DEG C, a pickle containing hydrogen chloride, hexamethylene tetramine and a corrosion inhibitor is used for cleaning the photovoltaic flat rack; the corrosion inhibitor contains a nitrogen compound-containing corrosion inhibitor and a sulfur compound-containing corrosion inhibitor; an assistant leaching step is provided between the drying step and galvanizing step, the assistant leaching is characterized in that the photovoltaic flat rack is immersed into a plating auxiliary for 5-8 minutes, the temperature of the plating auxiliary is between 50-57 DEG C, the plating auxiliary contains zinc chloride and ammonium chloride, the mass ratio of zinc chloride to ammonium chloride is between 1 and 4 to 1 and 10, and the plating auxiliary also contains glycerin. According to the invention, the technology route is simple, and the galvanizing layer bonding strength is good.

Owner:CHENGDU ZHENZHONG ELECTRIC

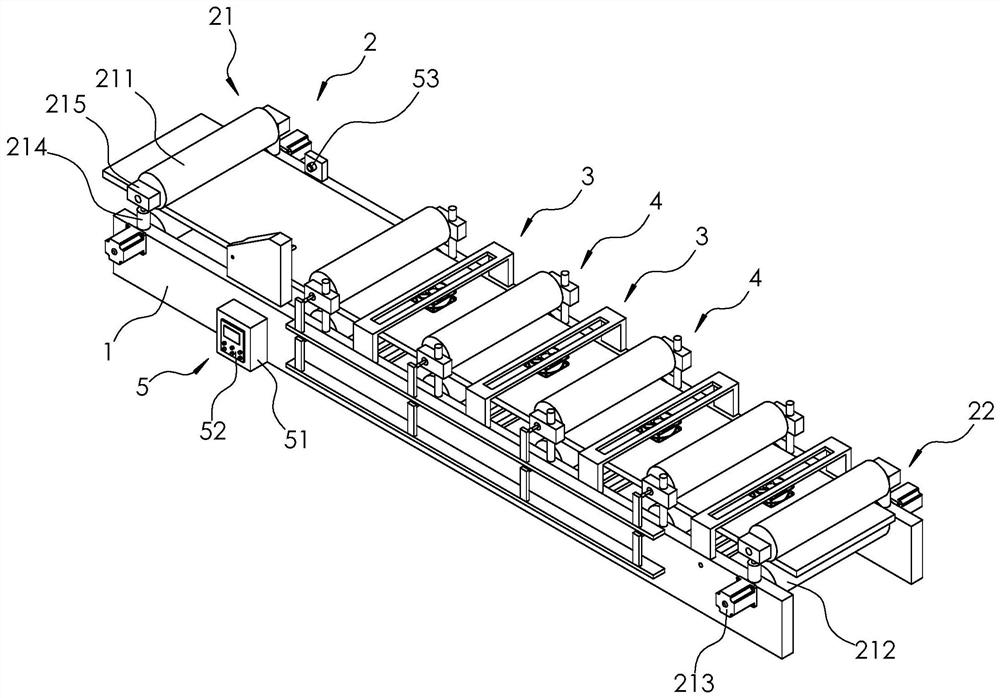

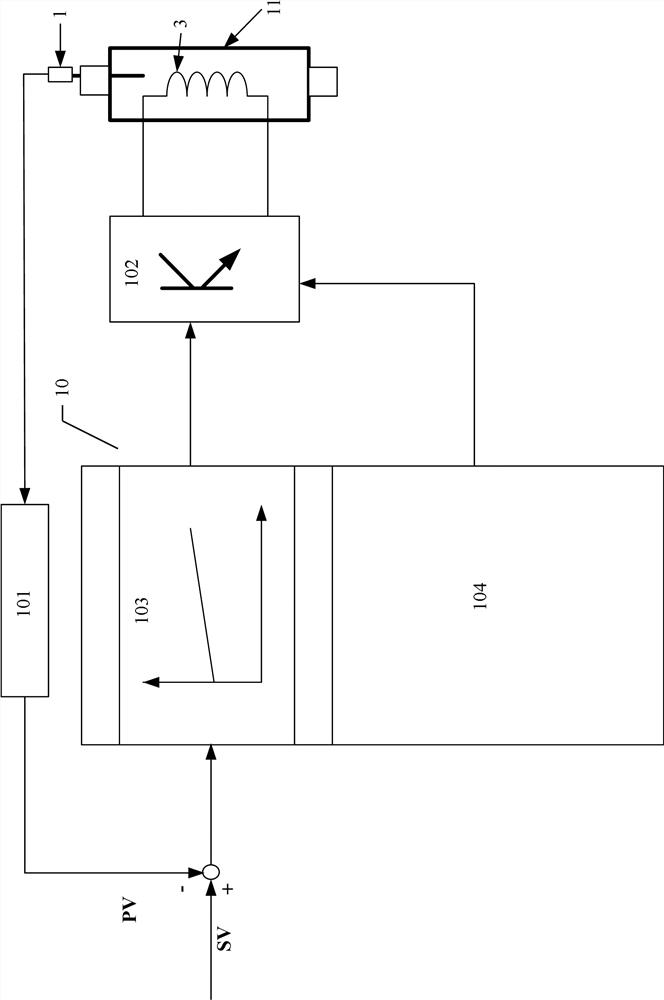

Control device for pot-entering temperature of strip steel in hot-galvanizing annealing furnace

ActiveCN113088852AImprove efficiencyImprove galvanizing qualityHot-dipping/immersion processesProcess efficiency improvementTemperature controlEngineering

The invention relates to the technical field of strip steel machining, and especially relates to a control device for a pot-entering temperature of strip steel in a hot-galvanizing annealing furnace. The control device for the pot-entering temperature of the strip steel in the hot-galvanizing annealing furnace comprises a support, wherein a conveying mechanism used for conveying the strip steel, an air blowing mechanism used for blowing air to the strip steel, a heating mechanism used for heating the strip steel, a power supply mechanism used for supplying power and an electricity conducting mechanism used for conducting electricity are arranged on the support; the electricity conducting mechanism comprises a rotating rod rotationally connected to the support through a horizontal shaft, one end of the rotating rod is placed on the upper surface of the strip steel, and an electricity conducting head is arranged at the other end of the rotating rod and connected to the power supply mechanism through a conducting wire; a first receiving head which is abutted against the electricity conducting head when the electricity conducting head overturns downwards is arranged on the air blowing mechanism; and a second receiving head which is abutted against electricity conducting head when the electricity conducting head overturns upwards is arranged on the heating mechanism. According to the invention, the galvanizing quality of the strip steel can be improved.

Owner:浙江航峰铁塔有限公司

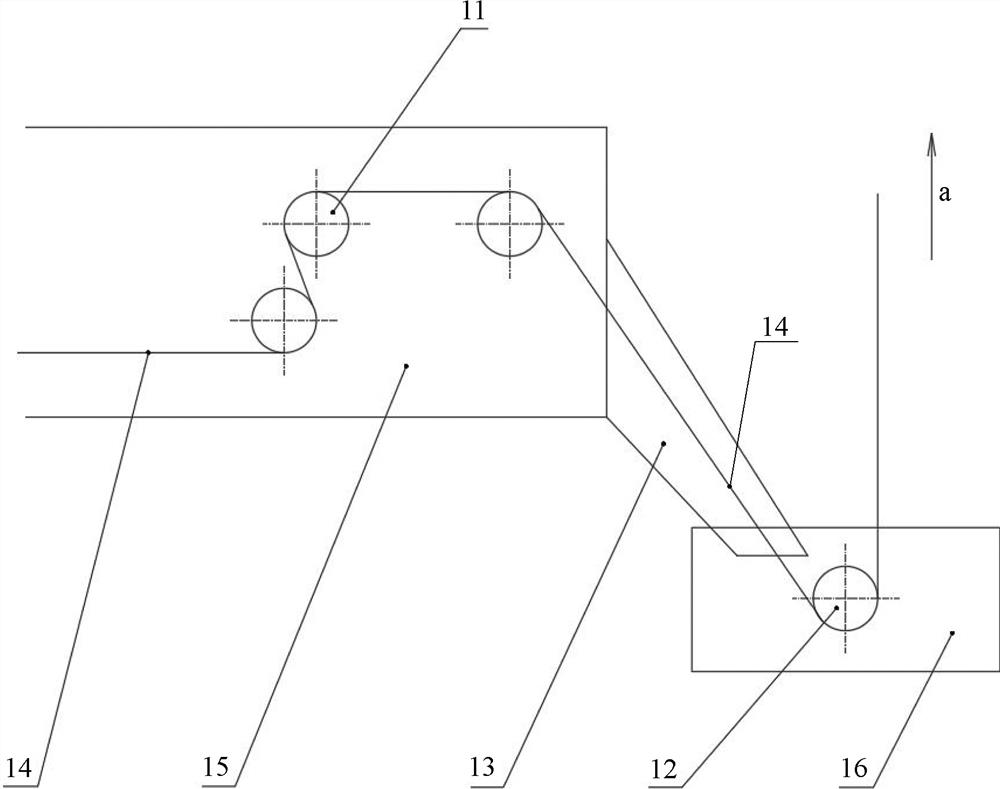

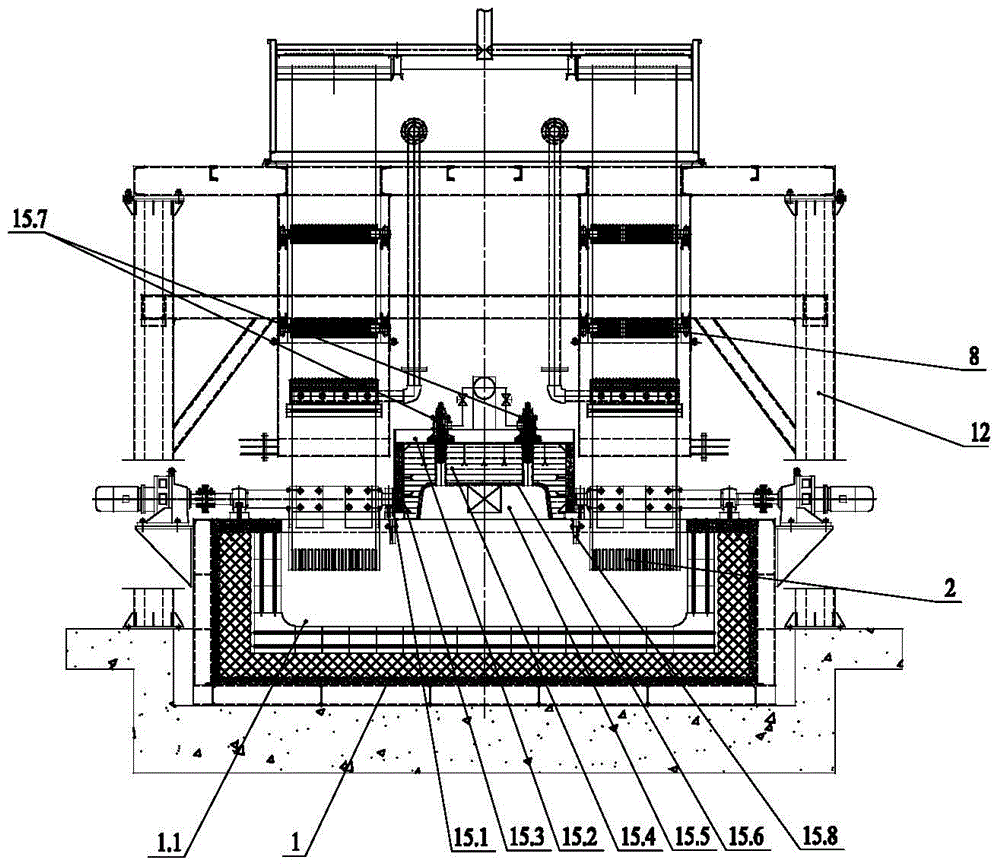

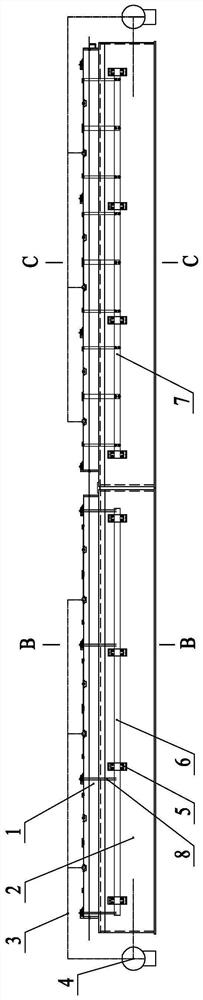

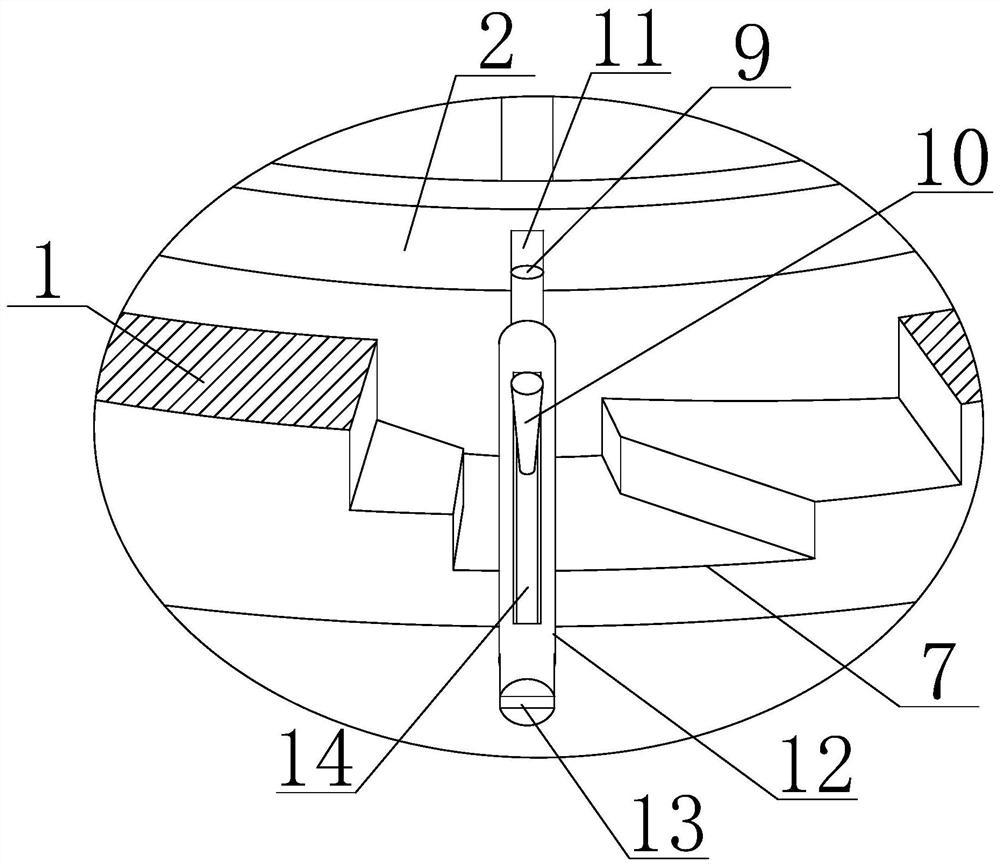

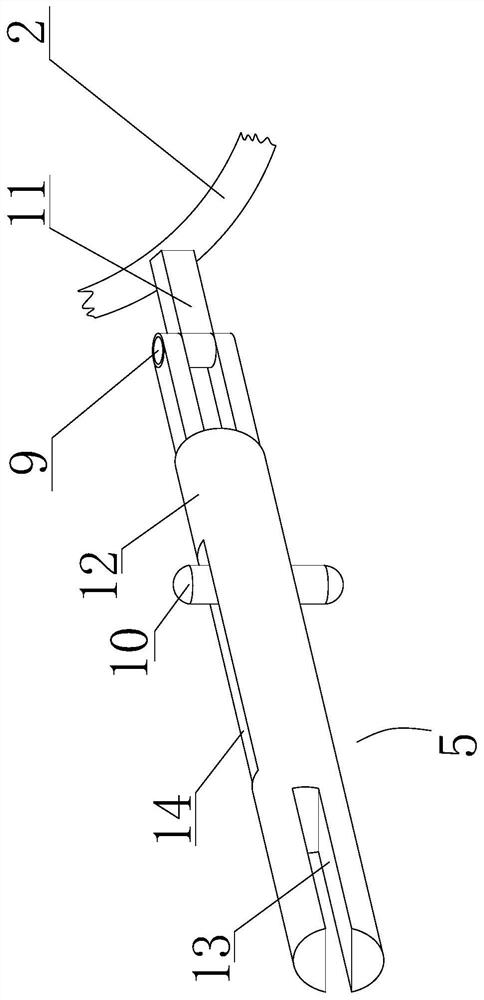

Device for controlling temperature uniformity of strip steel before entering zinc pot and using method of device

InactiveCN113122698AAchieving temperature uniformityUniform temperature controlHot-dipping/immersion processesFurnace typesMolten stateSafety control

The invention relates to the field of a hot dipping process which uses molten zinc or cadmium or an alloy coating material based on the molten zinc or cadmium and does not influence the shape, in particular to a device for controlling temperature uniformity of strip steel before entering a zinc pot and a using method of the device. The device for controlling the temperature uniformity of the strip steel before entering the zinc pot comprises a heating roller (11), a sink roller (12), a furnace nose (13), the strip steel (14), a heat treatment furnace (15) and the zinc pot (16), and is characterized in that the heating roller (11) comprises a temperature thermocouple (1), a thermocouple compensation lead wire (2), an induction heating body (3), a bearing (4), a slip ring (5), a mandrel (6), a roller body (7), a driving shaft (8), a middle shaft sleeve (9) and a temperature control device (10). The using method of the device for controlling the temperature uniformity of the strip steel before entering the zinc pot is characterized by comprising the following steps of (1) measuring, (2) calculating, (3) adjusting, and (4) safety control. By means of the device and method, the temperature control is made uniform.

Owner:BAOSTEEL ENG & TECH GRP +1

Hot galvanizing device and process for metal part production

ActiveCN113355623AEnsure personal safetyImprove work efficiencyHot-dipping/immersion processesMechanical engineeringMaterials science

The invention discloses a hot galvanizing device for metal part production. The hot galvanizing device comprises a box body, a transmission mechanism arranged on one side of the box body and a clamping mechanism arranged on the outer surface of the transmission mechanism; and the box body comprises an auxiliary mechanism arranged at the upper end of the box body and a linkage mechanism arranged on the outer surface of the box body. Through mutual adsorption between an electromagnetic disc B and an electromagnetic disc A, a clamping plate is connected to a moving block, then through stretching and retracting of an electric push rod, a moving block is moved, full galvanizing of metal parts is achieved, and the galvanizing quality is improved. The invention further discloses a process of the hot galvanizing device for producing metal parts, when the clamping mechanism moves to an arc groove, the whole galvanization process is completed through receiving of a receiving assembly, so that the whole process is automatic, workers do not need to be close to the box body, the personal safety of the workers is guaranteed, and meanwhile the working efficiency is improved.

Owner:深圳市金源康实业有限公司

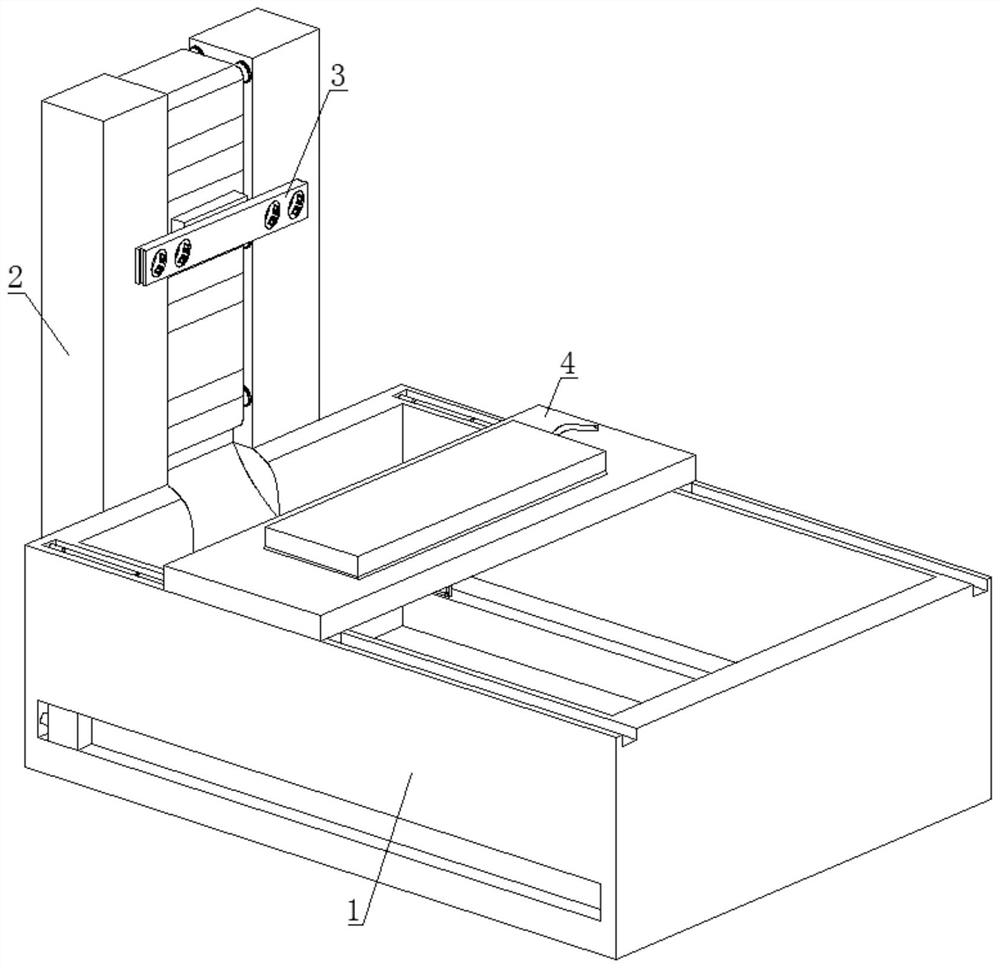

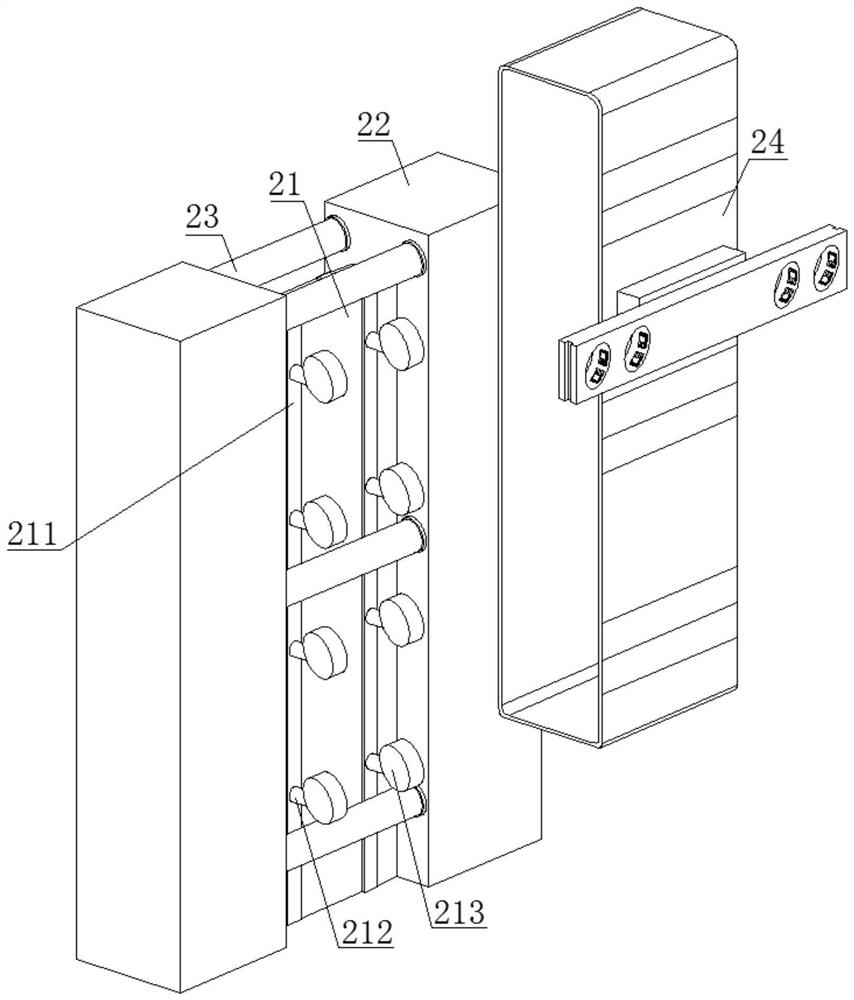

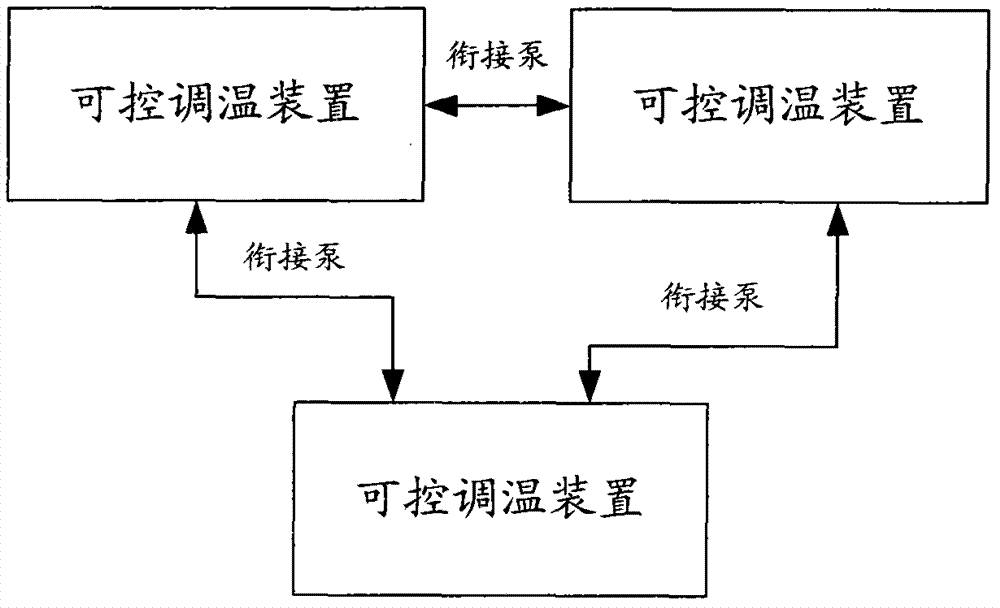

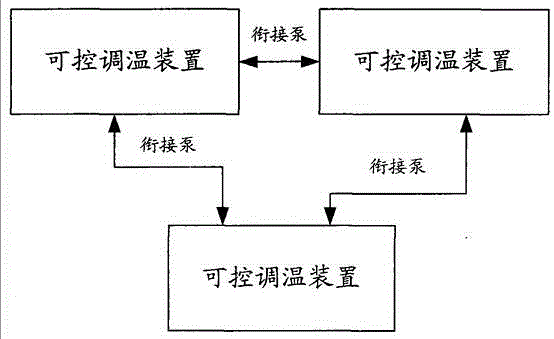

Device for hot-dip galvanizing process

InactiveCN103361589AReduce wasteImprove galvanizing qualityHot-dipping/immersion processesEngineeringTower

The invention is applicable to the technical field of galvanizing and provides a device for a hot-dip galvanizing process. The device comprises at least one controllable temperature adjusting device; the controllable temperature adjusting devices are connected two by two through an engaging pump. The device adopts the three controllable temperature adjusting devices. According to the hot-dip galvanizing device disclosed by the embodiment of the invention, technology improvement and technological innovation are carried out aiming at a hot-dip galvanizing technology of an iron tower component, the galvanizing quality is improved, the waste of materials is reduced and the production cost is reduced.

Owner:YUNNAN DONGDIAN LINE MATERIAL

Photovoltaic plate frame corrosion resistance treatment method

InactiveCN104831205AImprove galvanizing qualityImprove mechanical propertiesHot-dipping/immersion processesWater basedAcid washing

The present invention discloses a photovoltaic plate frame corrosion resistance treatment method, which is used for surface corrosion resistance treatment on a photovoltaic plate frame and sequentially comprises washing, drying, hot zinc plating, and cooling, wherein the washing step sequentially comprises degreasing, inspection, acid washing, and water washing, the degreasing step is adopting a water-based metal degreaser to carry out an oil removing treatment on the photovoltaic plate frame surface, the hot zinc plating step comprises heating a zinc liquid to a temperature of 455-480 DEG C, placing the photovoltaic plate frame into the zinc liquid, maintaining for 1-1.5 min, and taking out, the zinc liquid contains 0.07-0.1% by mass of aluminum, and the leaching assisting step is set between the drying step and the hot zinc plating step. According to the present invention, the process route is simple, and the photovoltaic plate frame surface corrosion resistance quality is easily achieved.

Owner:SICHUAN HEDING ENVIRONMENTAL PROTECTION ENG

Anti-friction processing process for connection face after galvanization of steel structure

ActiveCN109440040AQuality improvementGood atmospheric corrosion resistanceHot-dipping/immersion processesSuperimposed coating processZincGalvanization

The invention relates to an anti-friction processing process for a connection face after galvanization of a steel structure. The process comprises the steps of galvanization processing, preparation ofanti-friction processing agents, polishing of a connection beam and a connection board of the galvanized steel structure, and transverse brushing and longitudinal brushing of the steel portion needing to be brushed. A zinc layer on the surface of the steel is not damaged, and the friction coefficient is increased at the same time.

Owner:宜兴大平杆塔制造有限公司

Anticorrosion processing method used for surface of metal member

InactiveCN104762581AImprove liquidityImprove mechanical propertiesHot-dipping/immersion processesSurface layerChloride

The invention discloses an anticorrosion processing method used for surface of a metal member, which is used for anticorrosion processing of surface of a photovoltaic flat rack. The anticorrosion processing method comprises the steps of cleaning, drying, galvanizing and cooling in order, and the cleaning step comprises the steps of degreasing, examining, pickling and washing in order, the drying and galvanizing steps also comprise an assistant leaching step, the assistant leaching step is characterized in that the photovoltaic flat rack is immersed into a plating auxiliary for 5-8 minutes, the temperature of the plating auxiliary is between 50-57 DEG C, the plating auxiliary contains zinc chloride and ammonium chloride, the mass ratio of zinc chloride to ammonium chloride is between 1 and 4 to 1 and 10, and the plating auxiliary also contains glycerin. According to the invention, the technology route is simple, and the method is benefit for obtaining smoother galvanizing layer surface layer and more uniform galvanizing layer composition.

Owner:CHENGDU ZHENZHONG ELECTRIC

Medium solvent plating assisting method for galvanizing process

InactiveCN105734475AImprove galvanizing qualityReduce the formation of zinc drossHot-dipping/immersion processesSolventChemistry

The invention discloses a medium solvent plating assisting method for a galvanizing process. The medium solvent plating assisting method for the galvanizing process is characterized by including the technological requirements that (1) according to the composition of a plating assistant agent, the content of zinc chloride and ammonium chloride in the plating assistant agent is 260-300 g / L, the ratio of the sum of the zinc chloride and the ammonium chloride to ammonium and the ratio of the sum of the zinc chloride and the ammonium chloride to zinc are 1.2 and 1.4 correspondingly, and 2-3 g / L of a nonionic surface active agent is added into plating assistant liquid; (2) the PH value of the plating assistant liquid is controlled to be 4-5; and (3) the temperature of the plating assistant liquid is controlled to be 60-80 DEG C. According to the medium solvent plating assisting method for the galvanizing process, the steel surface can be activated, a steel wire is prevented from being oxidized in air in the time period from a plating assistant bath to a zinc pot, the galvanizing quality is improved, the quantity of generated zinc residues is reduced, and accordingly the production cost is reduced.

Owner:CHONGQING JINSHENG MACHINERY PARTS MFG CO LTD

High-speed pulse flame zinc-plating device

InactiveCN104513940AEvenly heatedExtended service lifeHot-dipping/immersion processesCombustorSpray nozzle

The invention relates to a high-speed pulse flame zinc-plating device. The device includes a rectangular-structured furnace body, a furnace chamber and a zinc pot. The furnace chamber is installed in the rectangular-structured furnace body. The zinc pot is arranged in the furnace chamber. Two combustors are respectively arranged at two diagonal positions of the bottom end of the furnace body. Nozzles of the combustors are aligned to the furnace body for jetting flame. A flue is installed at one side of the furnace chamber. By means of installation of the combustors respectively arranged at two diagonal positions of the bottom end of the furnace body, temperature in the furnace chamber can be rapidly increased. The device allows heating to be uniform and is low in energy consumption so that the zinc pot can be uniformly heated and meanwhile service life of the zinc pot is increased greatly. By means of a control cabinet, the temperature in the furnace chamber can be accurately controlled, thereby improving zinc-plating quality. The device is simple in structure, is scientific and reasonable in design and can effectively save energy. In addition, the zinc pot can be heated uniformly, so that the zinc pot is greatly improved in the service life and the device is reduced in maintenance cost.

Owner:TIANJIN LIQUAN METAL PROD

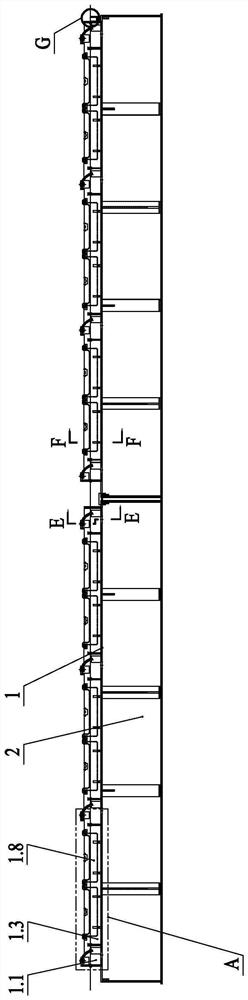

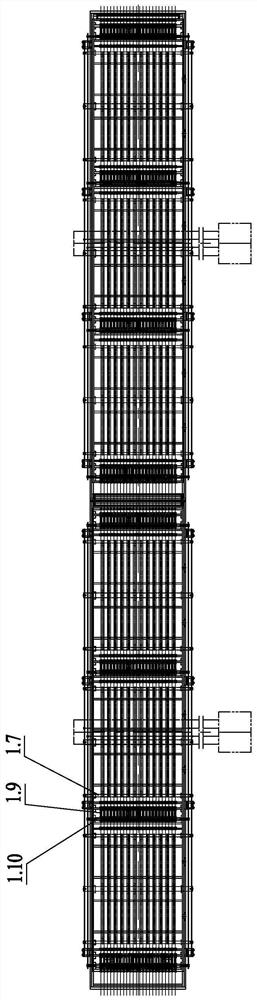

Preheating type upper heating steel wire galvanizing furnace

ActiveCN104404422BShorten the lengthIncrease productivityHot-dipping/immersion processesAir preheaterBoiler furnace

The invention relates to a preheating-type upwardly-heating steel wire zinc-plating furnace. The preheating-type upwardly-heating steel wire zinc-plating furnace comprises a zinc furnace, a zinc pot and a water-cooled wire guiding mechanism, wherein a wire shouldering roller is arranged above the zinc pot and at the position close to the front end of the zinc furnace; a press roll is arranged above the zinc pot and at the position close to the back end of the zinc furnace; the preheating-type upwardly-heating steel wire zinc-plating furnace is characterized in that a zinc pot upwardly-heating device is arranged above the zinc furnace; a steel wire preheating system is arranged in front of the zinc furnace; the steel wire preheating system comprises steel wire preheating box furnaces, an air preheater device and the zinc pot upwardly-heating device; two steel wire preheating box furnaces are symmetrically arranged left and right; the air preheater device is arranged between the two steel wire preheating box furnaces; a flue gas inlet of the air preheater device is communicated with the front end of a flame path of the zinc pot upwardly-heating device through a first flue gas heat-preserving connection pipeline; a flue gas outlet of the air preheater device is communicated with flue gas inlets of preheating flame paths of the steel wire preheating box furnaces through a second flue gas heat-preserving connection pipeline. The preheating-type upwardly-heating steel wire zinc-plating furnace can prolong the service life of the zinc pot, save energy and effectively improve the zinc-plating quality and the zinc-plating speed.

Owner:WUXI XINKE METALLURGICAL EQUIP

Waste heat utilization device for hot-dip galvanized strip steel production

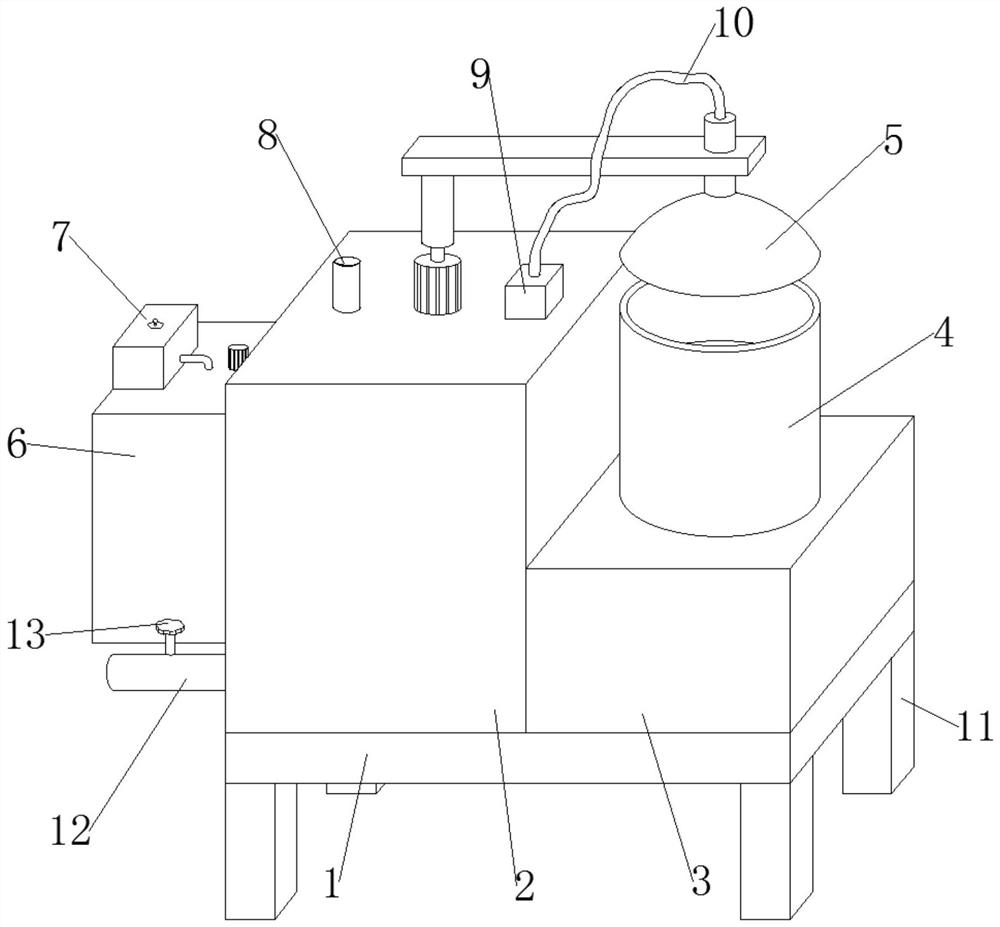

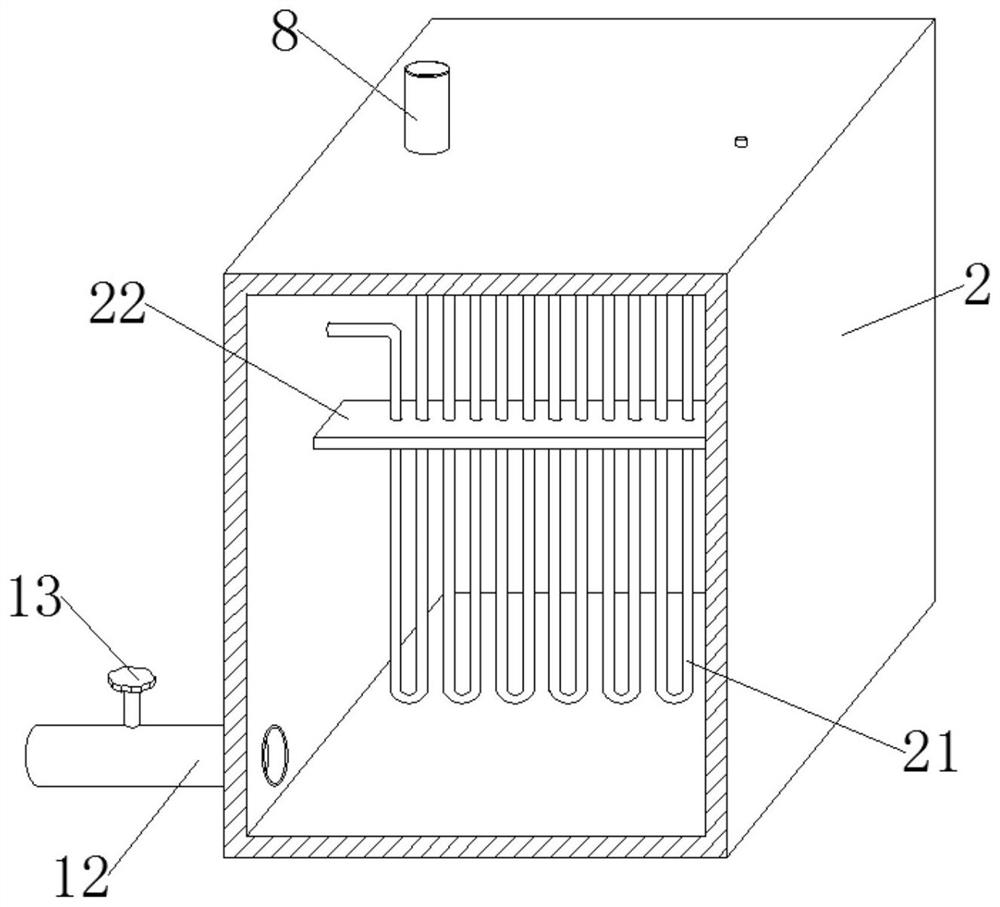

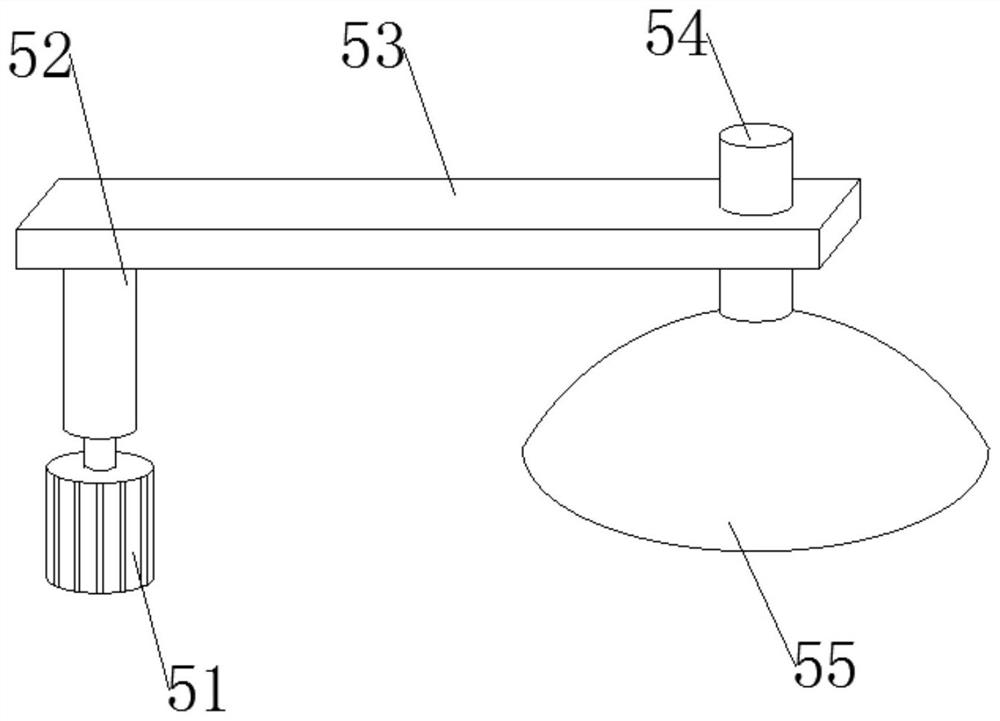

ActiveCN112251698AIncrease the suction areaDoes not affect pick and placeHot-dipping/immersion processesIncreasing energy efficiencyFlue gasProcess engineering

The invention discloses a waste heat utilization device for hot-dip galvanized strip steel production. The waste heat utilization device comprises a base, a heat exchange box is fixedly connected to the left portion of the upper end of the base, a heating base is fixedly connected to the right portion of the upper end of the base, a galvanizing pot is fixedly connected to the middle of the upper end of the heating base in penetrating and inserting manners, and an air suction device is fixedly connected to the middle of the upper end of the heat exchange box; a water inlet pipe is fixedly connected to the left portion of the upper end of the heat exchange box in penetrating and inserting manners, an exhaust fan is fixedly connected to the right portion of the upper end of the heat exchangebox, an air suction pipe is fixedly connected to the middle of the upper end of the exhaust fan in penetrating and inserting manners, a treatment box is fixedly connected to the middle of the left endof the heat exchange box, and a purification device is movably connected to the upper end of the treatment box in penetrating and inserting manners; and a water outlet pipe is fixedly connected to the lower portion of the left end of the heat exchange box in penetrating and inserting manners. According to the waste heat utilization device for hot galvanizing strip steel production, hot flue gas generated by hot galvanizing can be collected, the utilization efficiency of heat energy is improved, the flue gas can be prevented from polluting the environment, and the waste heat utilization deviceis suitable for being widely applied.

Owner:河北海洪新材料有限公司

Hot-dipped galvanized aluminum alloy containing Mg and Ca for fishery steel wire under marine environment

InactiveCN108441699AExcellent volatility resistanceImprove oxidation resistanceHot-dipping/immersion processesDip-coatingCorrosion

The invention discloses a hot-dipped galvanized aluminum alloy containing Mg and Ca for a fishery steel wire under the marine environment. The hot-dipped galvanized aluminum alloy comprises the ingredients of, in percentage by weight, 0.3-0.5% of Ca, 2.0-4.0% of Mg, 0.3-0.5% of Ti, 1.0-3.0% of Sn, 30.0-42.0% of Al, 0.5-0.8% of Cr and the balance zinc. The hot-dipped galvanized aluminum alloy for the marine fishery steel wire can be used at the temperature of 420-480 DEG C, and better corrosion resistance is achieved compared with a traditional hot-dipped coating. The hot-dipped galvanized aluminum alloy has great significance to prolonging of the service life of the marine fishery steel wire.

Owner:GUANGZHOU YUZHI TECH CO LTD

A hot-dip galvanizing process

ActiveCN107513681BFast coolingReduce water consumptionHot-dipping/immersion processesWarm waterEnergy consumption

The invention discloses a hot-dip galvanizing technology. The hot-dip galvanizing technology comprises the following steps of1 oil removing, specifically, a workpiece is poured into a mixed solution of 10-12g / L sodium carbonate and 12-15g / L sodium hydroxide, and the solution temperature is 90-100 DEG C until the workpiece is completely infiltrated; 2, pickling, specifically, the workpiece is put into a sulfuric acid solution of concentration of 15-20%, pickling is conducted for 5-10min, antifog and corrosion inhibitor is added in the solution, the pickling temperature is 30-50 DEG C, and washing by using clear water is conducted for 2-3 min after pickling is completed; and 3, the workpiece is washed by using warm water with the 50-60 DEG C. The hot-dip galvanizing technology is high in cooling speed of a cooling process, small in water consumption and low in energy consumption, adopts chrome-free passivation, and is environmentally friendly.

Owner:TONGXIANG TIESHENG LINE EQUIP

Small-space guardrail hot galvanizing device

InactiveCN112850085ASolving Space ConstraintsAchieve transferHot-dipping/immersion processesConveyor partsGear wheelElectric machinery

The invention relates to a small-space guardrail hot galvanizing device, and belongs to the field of automatic galvanizing. The small-space guardrail hot galvanizing device comprises a zinc pot and a main machine, wherein the main machine comprises a main machine frame; two lifting hooks are arranged at the two ends of the bottom of the main machine frame; a main shaft is hung on the two lifting hooks; a plurality of disc chucks are arranged on the main shaft; the main shaft can rotate on the lifting hooks; the disc chucks are matched with a charging basket in a rotating mode so that a guardrail plate can be transferred from one side of the zinc pot to the other side of the zinc pot; a gear pair is arranged on one side of the main machine frame; a driving motor is arranged at one end of the upper portion of the main machine frame; the driving motor drives the main shaft to rotate through the gear pair; a linkage mechanism is arranged on the main machine frame and comprises a driving air cylinder and a pressing-down and lifting linkage device; a pressing-down device and a lifting device are arranged on the pressing-down and lifting linkage device; the pressing-down device is arranged on the rear side of the main machine frame; the lifting device is arranged on the front side of the main machine frame; the driving air cylinder drives the pressing-down device and the lifting device to ascend and descend through the pressing-down and lifting linkage device; and the lifting direction of the pressing-down device is opposite to that of the lifting device.

Owner:刘佃福

Galvanizing tank for steel wire

ActiveCN108441910BAvoid introducingImprove galvanizing qualityTanksElectrodesElectrogalvanizationElectrical conductor

Owner:WUXI XINKE METALLURGICAL EQUIP

Anti-friction treatment process of joint surface of steel structure after galvanizing

ActiveCN109440040BQuality improvementGood atmospheric corrosion resistanceHot-dipping/immersion processesSuperimposed coating processZincJoint surface

Owner:宜兴大平杆塔制造有限公司

Device for automated process of iron tower galvanization

InactiveCN105908114AReduce wasteImprove galvanizing qualityHot-dipping/immersion processesProcess engineeringTower

The invention applies to the technical field of galvanization, and provides a device for an automated process of iron tower galvanization. The device comprises at least one controllable temperature regulator; every two controllable temperature regulators are mutually connected through a connecting pump; and in general, three controllable temperature regulators can be adopted for the device. The device provided by the embodiment of the invention is a technological improvement and a technical innovation in the hot-dip galvanization technology for an iron tower component. By adoption of the device, the galvanization quality is improved, and the material waste and the production cost are reduced.

Owner:ANHUI HONGYUAN IRON TOWER

Hanging tool for galvanizing

PendingCN112342600AGuaranteed uniformityImprove galvanizing qualityCellsStructural engineeringMechanical engineering

Owner:王倩倩

Iron wire zinc plating device

PendingCN109652751AImprove wiping effectImprove galvanizing qualityHot-dipping/immersion processesZincMechanical engineering

The invention discloses an iron wire zinc plating device. The iron wire zinc plating device comprises a solution box with an opening at the upper end, wherein a supporting plate is fixedly arranged atone end of the top of the solution box, a hollow sleeve is fixedly connected to the bottom surface of the supporting plate downwards, a charcoal powder feeding hole and an iron wire outlet are formedin the surface, provided with the sleeve, of the supporting plate in a penetrating mode, a cover plate is hinged to the end, not provided with the supporting plate, of the solution box, the end, close to the supporting plate, of the cover plate is hinged to a flow blocking plate through an opening and closing mechanism, an iron wire inlet is formed in the cover plate, a first sink wheel and a second sink wheel are further arranged in the solution box, the second sink wheel is arranged corresponding to the iron wire outlet, the cover plate is downwards provided with a stirring mechanism, the solution box is connected with a zinc liquid supplementing mechanism, and a drying mechanism and a wire coiling mechanism are further arranged on one side of the solution box. The device has the advantages of being good in plastering effect, high in zinc plating quality and simple in structure.

Owner:重庆佰鸿机械设备有限公司

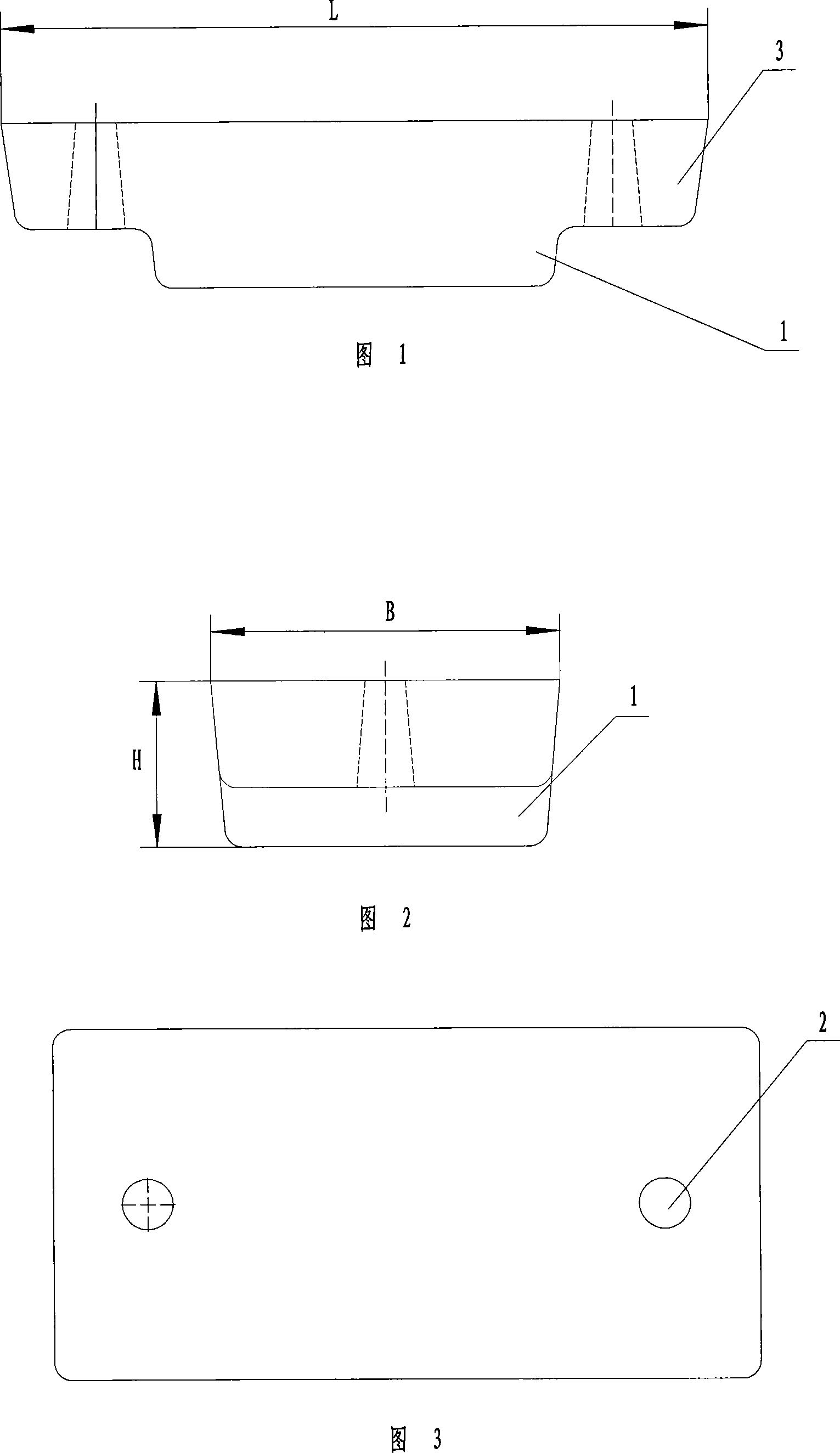

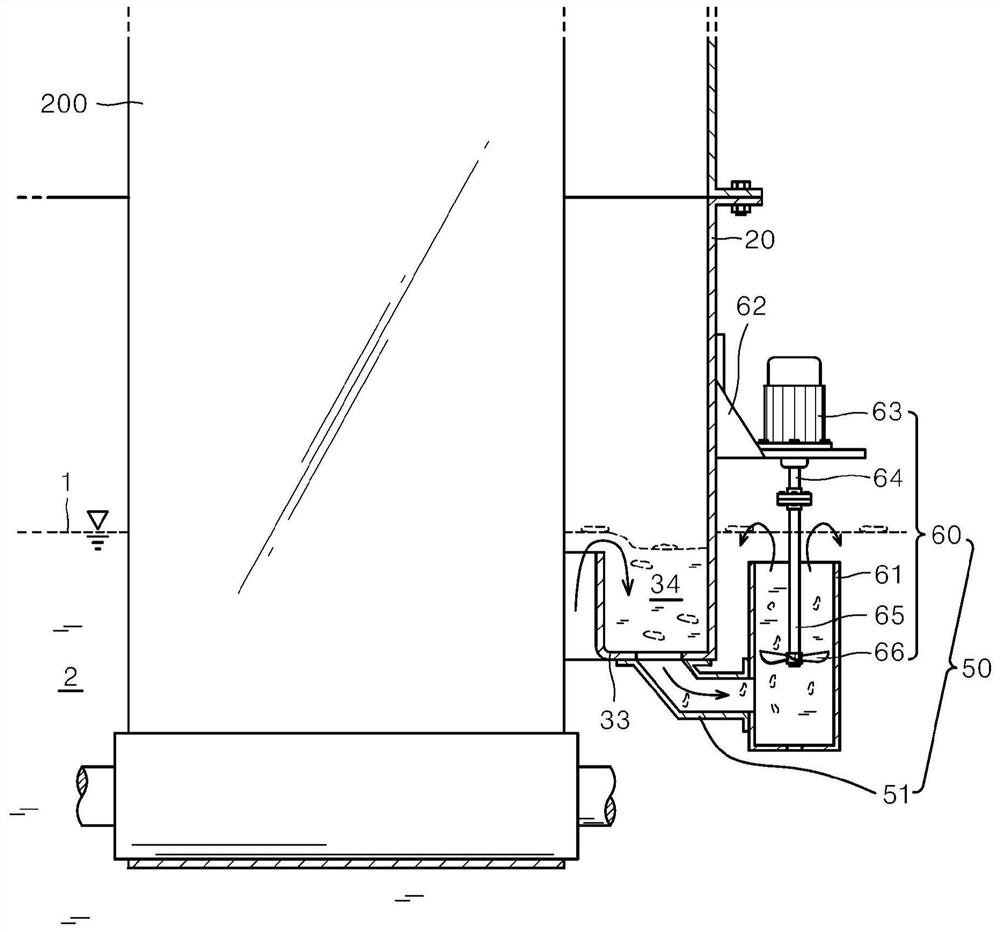

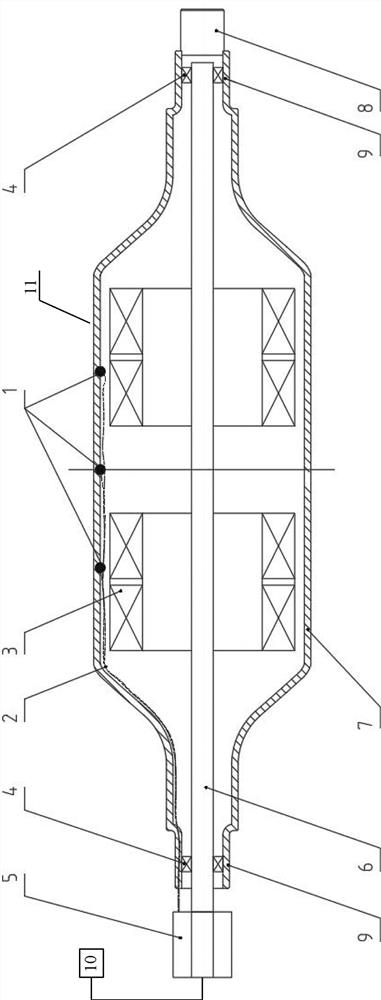

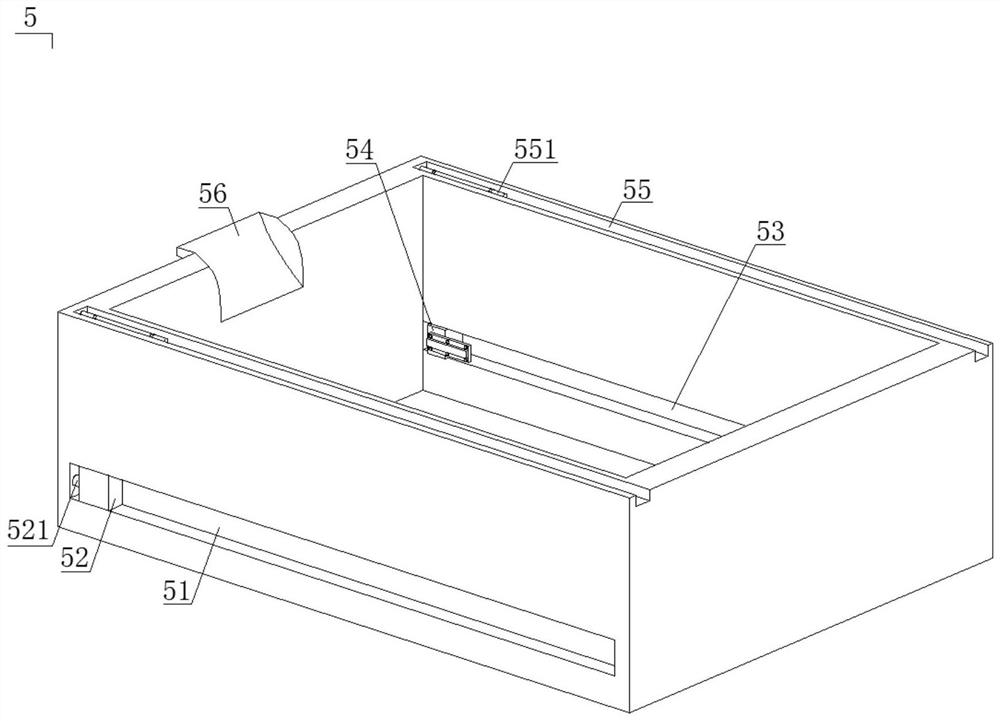

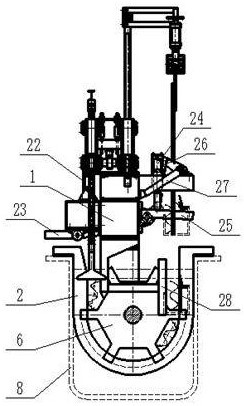

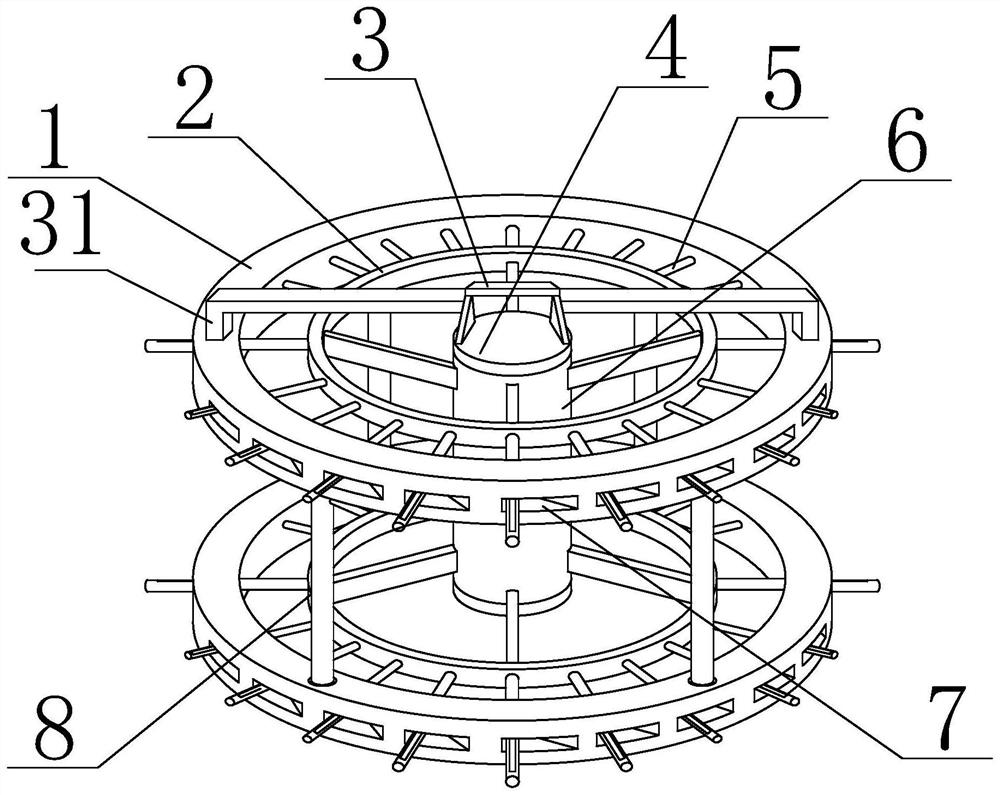

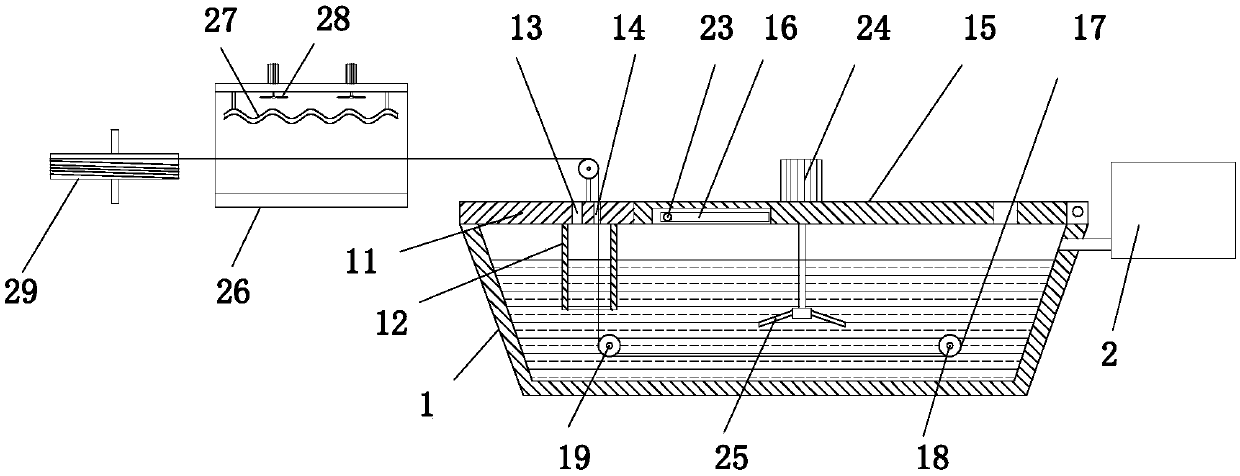

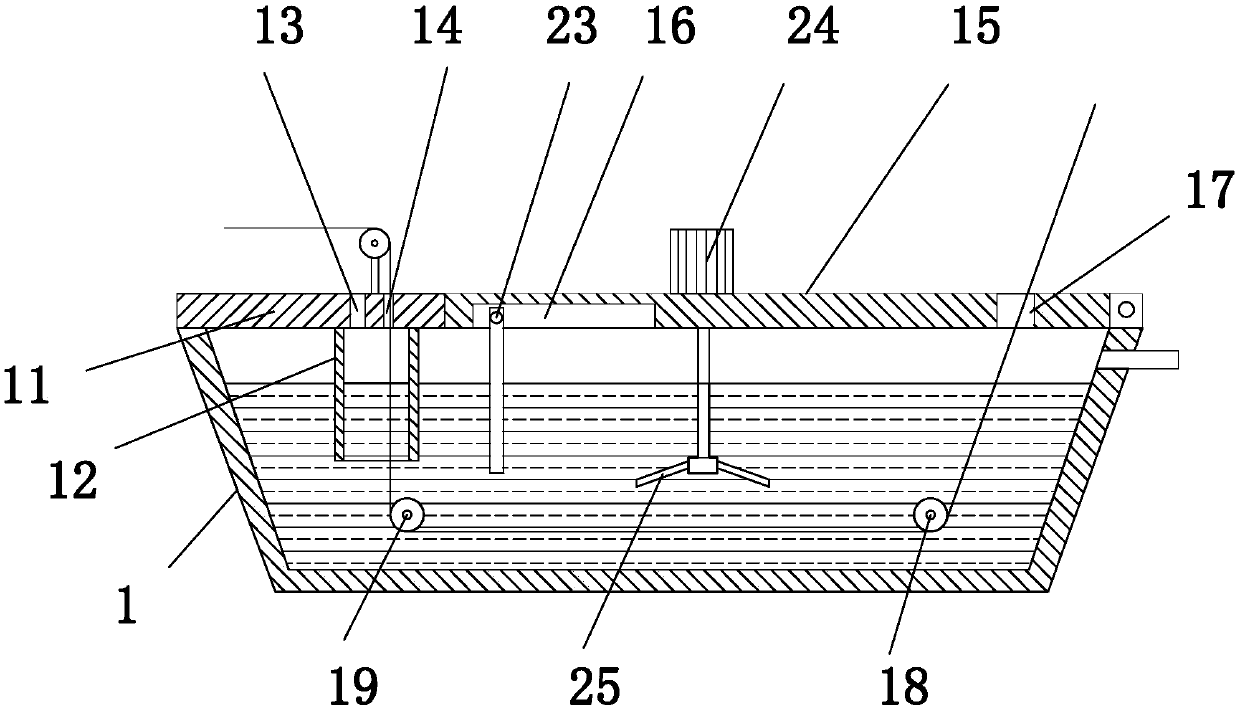

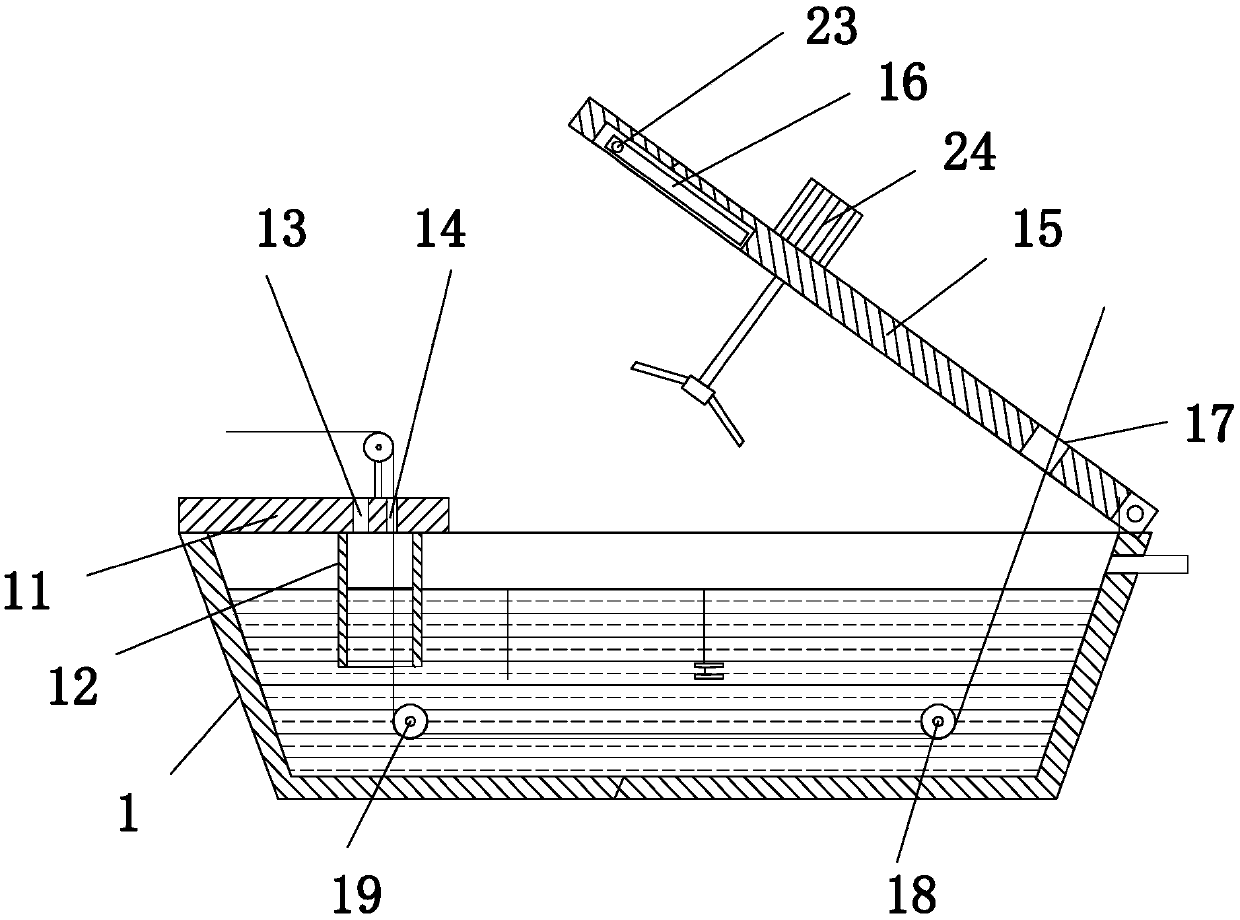

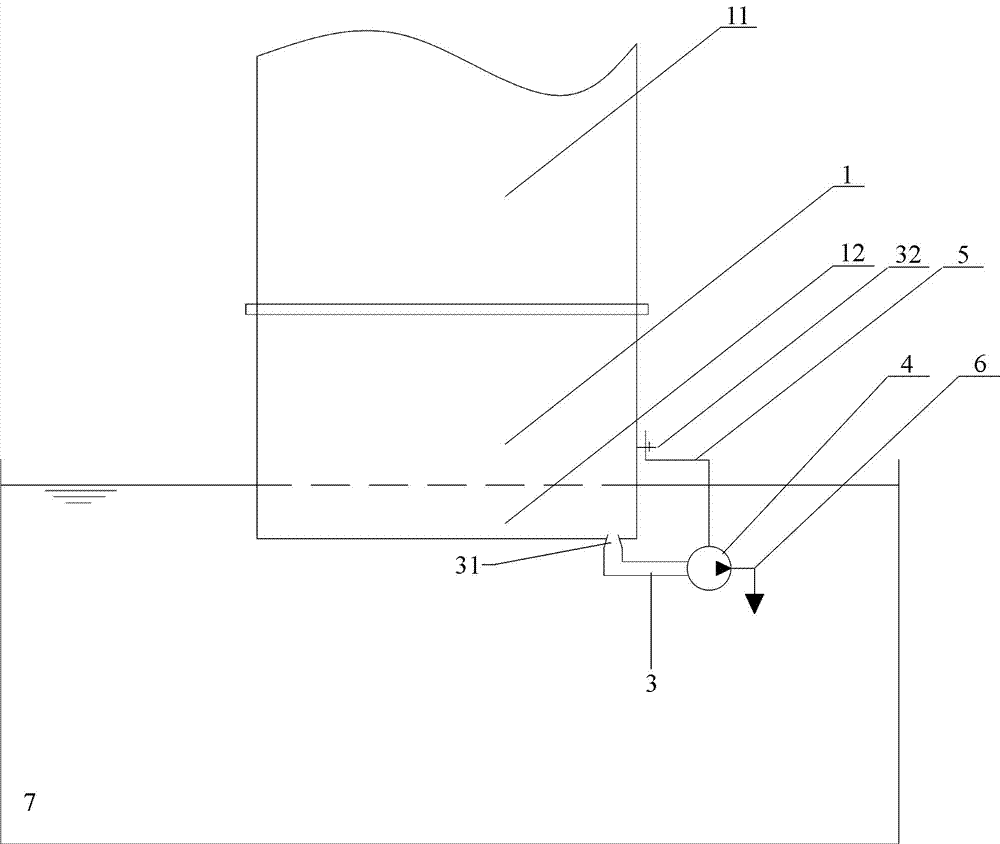

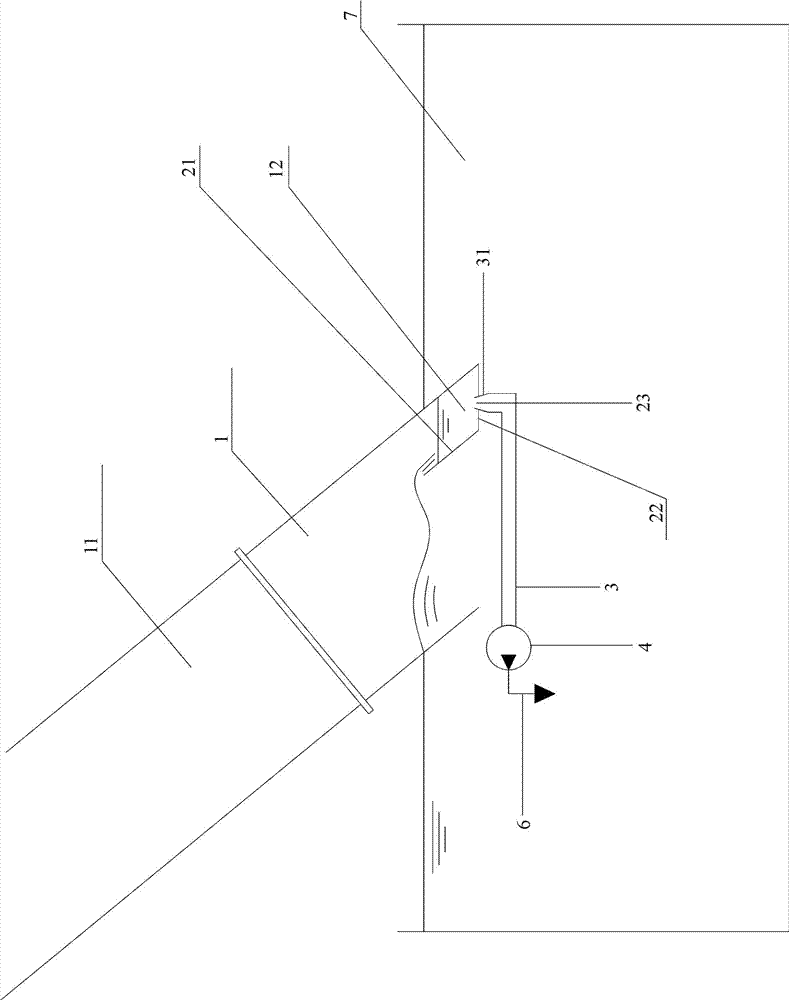

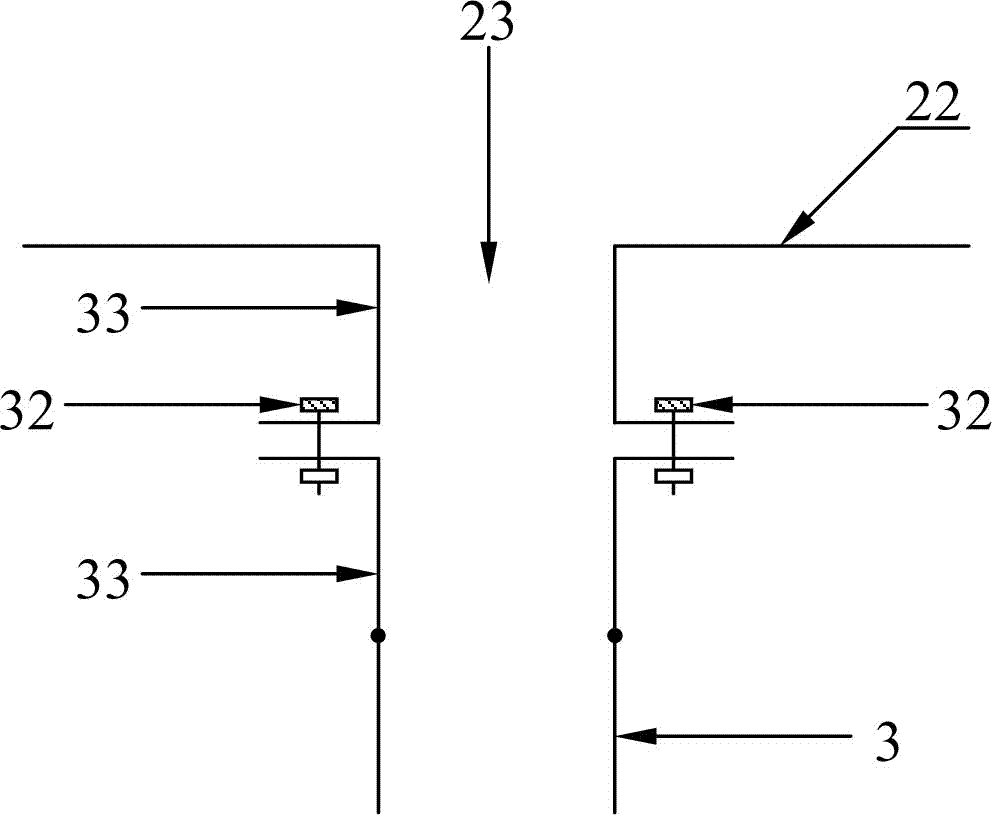

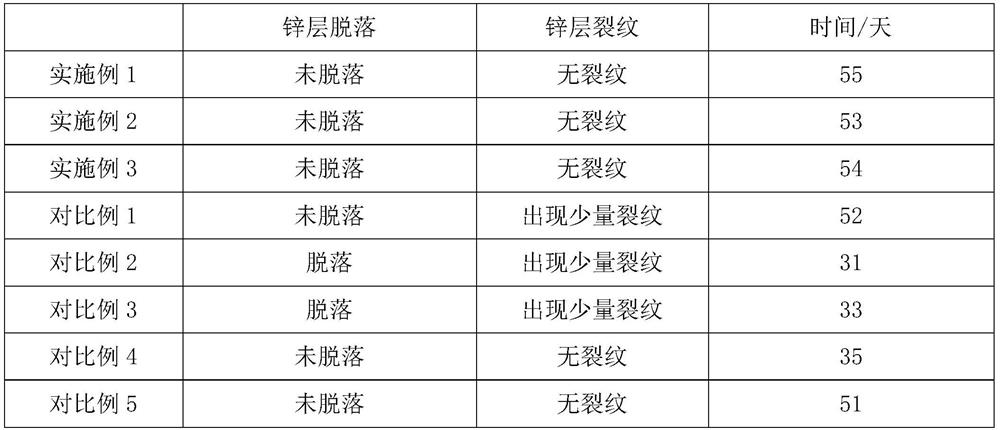

Furnace nose for hot-dip galvanizing with detachable slag discharge pipe and method of use thereof

The invention relates to the field of hot-dip galvanizing alloy technology and the equipment used therefor, in particular to a furnace nose for hot-dip galvanizing with a detachable slag discharge pipe and its use method. A furnace nose with a detachable slag discharge pipe for hot-dip galvanizing, comprising a furnace nose body (1), characterized in that it also includes a partition (21), a bottom plate (22), a slag discharge pipe (3), zinc Liquid suction pump (4), support (5) and liquid zinc discharge pipe (6), the lower half of the inner cavity of the furnace nose body (1) is provided with a partition (21), and the support (5) is detachable It is fixed on the bottom of the outer wall of the furnace nose body (1). A method for using a furnace nose with a detachable slag discharge pipe for hot-dip galvanizing, which is characterized in that: it is implemented in sequence as follows: A. When the furnace nose is in operation, insert the lower part of the furnace nose body (1) into the zinc pot ( 7) Under the zinc liquid surface; B. When the furnace nose moves laterally, release the detachable fixation respectively. The invention has good slag discharge effect, high galvanizing quality, convenient disassembly and assembly, and strong adaptability.

Owner:SHANGHAI DONGXIN METALLURGY TECH ENG

A kind of production process of galvanized steel coil

ActiveCN111560576BGood degreasing effectImprove galvanizing qualityHot-dipping/immersion processesIron powderAir knife

The invention relates to a production process of a galvanized steel coil, comprising the following steps: S1, successively uncoiling the cold-rolled hard steel coil, cutting the head and tail, and welding; S2, preparing a degreasing solution, and sequentially disposing the steel coil processed by S1 Immersion in degreasing solution, brushing with rollers, drying with hot air, and treatment with an inlet looper; S3, annealing the steel coil obtained in S1; S4, putting the annealed steel coil into a zinc pot, soaking for 4-5s, and then blowing through an air knife in turn Sweep, cool, dry with hot air, and smooth to obtain a galvanized steel coil; S5, heat the galvanized steel coil, take it out, suck passivation droplets on the surface of the galvanized steel coil with a straw, and dry it; S6, after processing S5 The steel coil obtained in S6 is treated with anti-fingerprint coating, and oiled after being exported through the looper; S7, the steel coil obtained in S6 is slit, coiled, uncoiled, and packaged. The production process of the galvanized steel coil in the present invention can effectively remove pollutants such as dust and iron powder firmly adhered to the surface of the steel coil, which is beneficial to improve the quality of the galvanized steel coil, thereby prolonging the galvanized steel coil. The service life of the roll.

Owner:ZHEJIANG SOUTHEAST METAL SHEET

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com