A kind of production process of galvanized steel coil

A production process and technology of galvanized steel, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve problems such as galvanized layer peeling off, extend service life, enhance corrosion resistance, and inhibit dissolution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

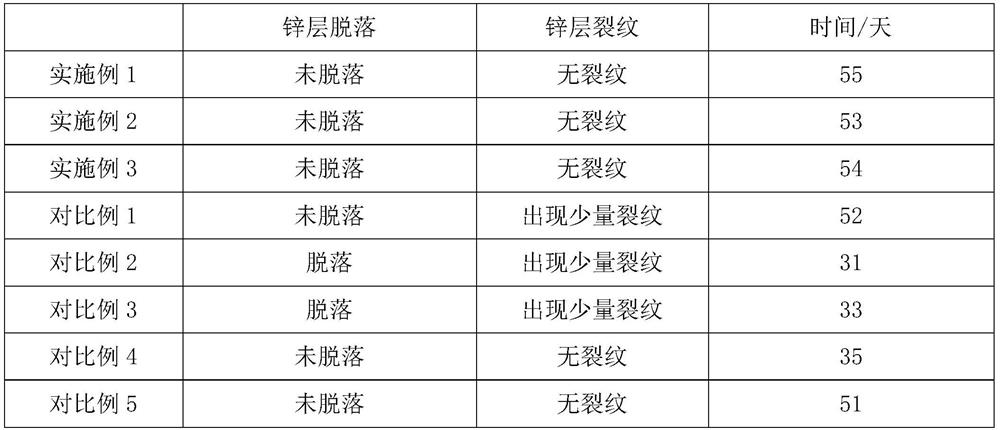

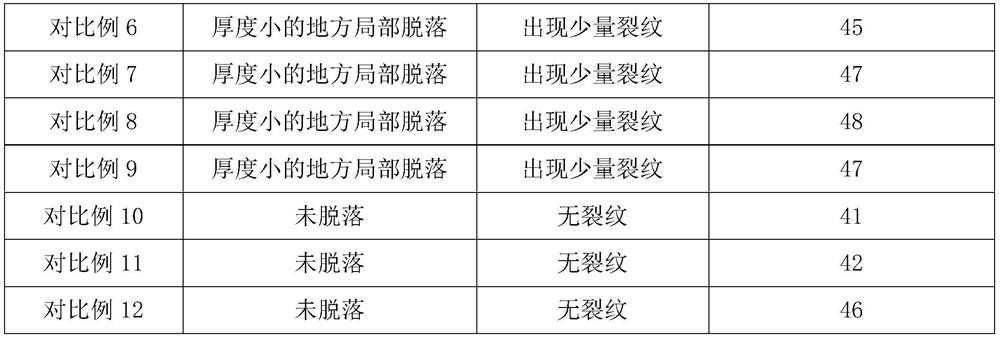

Examples

Embodiment 1

[0037] A production process of a galvanized steel coil, the production process of the galvanized steel coil comprises the following steps:

[0038] S1, take a cold-rolled hard steel coil with a thickness of 0.6mm, its chemical composition and content are shown in Table 1, after being uncoiled by an uncoiler in turn, cut the head and cut the tail, and weld by an automatic seam welder;

[0039] S2, weigh 200g of sodium hyaluronate and 1350g of deionized water in proportion, add them into a glass container, stir at room temperature to completely dissolve the sodium hyaluronate, adjust the pH of the solution to 5.5, then add 25g of gallium chloride, 200g of Sodium silicate and 50g of sodium stearate were stirred at room temperature for 4 hours at a speed of 625r / min to obtain a degreasing solution, and then the cold-rolled hard steel coils treated by S1 were immersed in the degreasing solution in turn, washed with a brush roller, Hot air drying, passing through the inlet looper to...

Embodiment 2

[0046] A production process of a galvanized steel coil, the production process of the galvanized steel coil comprises the following steps:

[0047] S1, take a cold-rolled hard steel coil with a thickness of 0.4mm, its chemical composition and content are shown in Table 1, after being uncoiled by an uncoiler in turn, cut the head and cut the tail, and welded by an automatic seam welder;

[0048] S2, weigh 150g sodium hyaluronate and 1300g deionized water in proportion, add them into a glass container, stir at room temperature to completely dissolve the sodium hyaluronate, adjust the pH of the solution to 5, then add 20g gallium chloride, 150g Sodium silicate and 30 g of sodium stearate were stirred at room temperature for 3 hours at a speed of 600 r / min to obtain a degreasing solution, and then the cold-rolled hard steel coils treated by S1 were immersed in the degreasing solution in turn, and washed with a brush roller. Hot air drying, passing through the inlet looper to obtai...

Embodiment 3

[0055] A production process of a galvanized steel coil, the production process of the galvanized steel coil comprises the following steps:

[0056] S1, take a cold-rolled hard steel coil with a thickness of 0.8mm, its chemical composition and content are shown in Table 1, after being uncoiled by an uncoiler in turn, cut the head and cut the tail, and weld by an automatic seam welder;

[0057] S2, weigh 250g sodium hyaluronate and 1400g deionized water in proportion, add them into a glass container, stir at room temperature to completely dissolve the sodium hyaluronate, adjust the pH of the solution to 6, then add 30g gallium chloride, 250g Sodium silicate and 70 g of sodium stearate were stirred at room temperature for 5 hours at a speed of 650 r / min to obtain a degreasing solution, and then the cold-rolled hard steel coils treated by S1 were immersed in the degreasing solution in turn, and washed with a brush roller. Hot air drying, passing through the inlet looper to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com