Pollution-free, high-efficiency and long-distance pipe installing and cleaning method

A pipeline installation and long-distance technology, applied in cleaning methods and appliances, chemical instruments and methods, cleaning hollow objects, etc., can solve problems such as inability to adapt to long-distance flammable and explosive gas pipelines, and achieve obvious social benefits and economic benefits Benefit, good effect, good degreasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

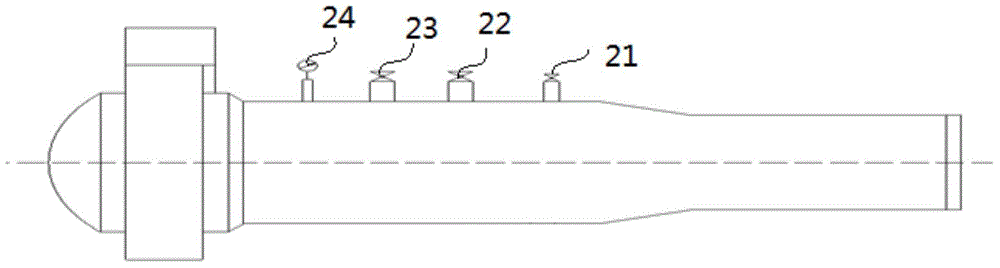

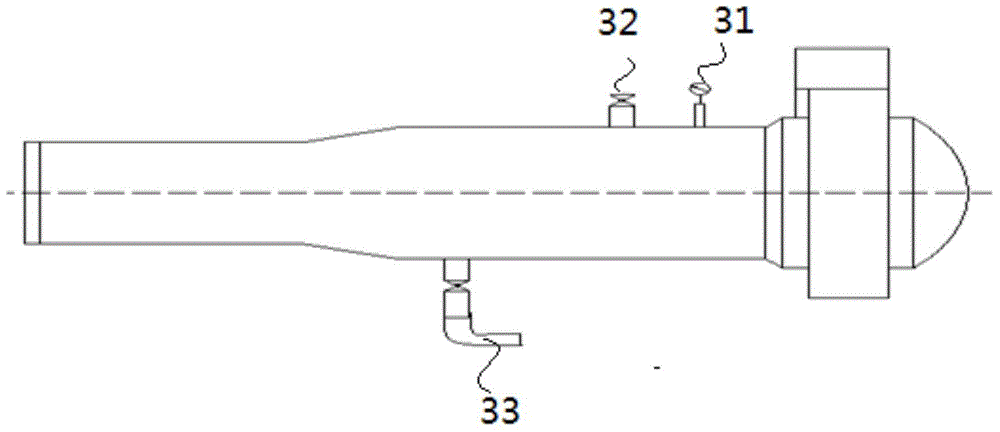

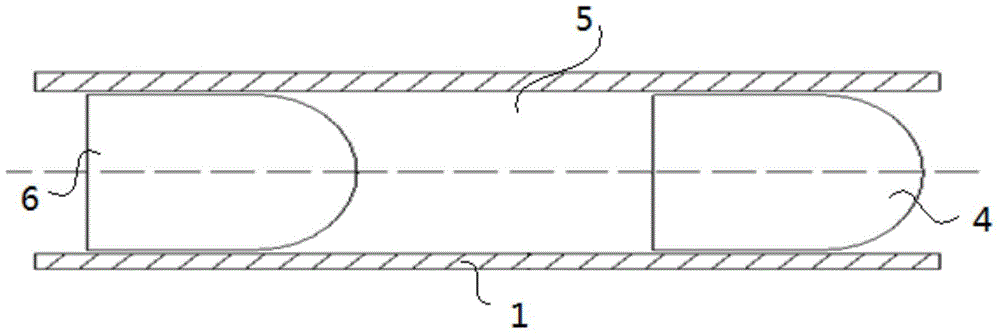

[0050] As shown in the figure, a pollution-free and high-efficiency long-distance pipeline installation and cleaning method of the present invention, the device includes a ball sending device, a ball collecting device, a pipe cleaner, a passivator and a degreasing agent, and the ball sending device and the ball collecting device use It is installed on the two ends of the pipeline 1 to be cleaned, and is used to send the pig and recover the pig; the ball serving device includes a section of the first temporary pipe, and one end of the first temporary pipe is connected to one end of the pipeline 1 to be cleaned. The other end of the above-mentioned first temporary pipe is provided with a blind plate, which can be closed / opened, and the upper part of the first temporary pipe is sequentially installed with a first vent valve 21, a liquid injection valve 22, an air source valve 23 and a first pressure gauge from the inside to the outside. 24 (eg figure 1 As shown), the air compress...

Embodiment 2

[0072] In this embodiment, the long-distance pipeline cleaning method is basically the same as in Example 1, the difference being that the formula of the passivating agent is represented by mass fraction as 2% sodium nitrite, 0.5% trisodium phosphate, and 97.5% water; If oil pollution is serious, the amount of degreasing agent needs to be increased appropriately. The formula is expressed in terms of mass fraction: sodium tripolyphosphate 3.5%, sodium carbonate 2%, sodium hydroxide 1.5%, sodium borate 0.4%, ethylenediaminetetraacetic acid di Sodium 0.2%, sodium oleate 0.1%, sodium lauryl sulfate 0.1%, alkylphenol polyoxyethylene ether 0.1%, water 92.1%. The passivating agent and degreasing agent of the present invention are all water-based degreasing agents, and the subsequent environmental protection treatment is simple and environmentally friendly, and the formula of the degreasing agent makes the degreasing effect of the degreasing agent efficient, which not only ensures the ...

Embodiment 3

[0074] In this embodiment, the long-distance pipeline cleaning method is basically the same as in Example 1, except that the formula of the passivating agent is represented by mass fraction as sodium nitrite 3%, trisodium phosphate 1%, and water 96%; The formula is expressed in mass fraction as sodium tripolyphosphate 3.0%, sodium carbonate 1.5%, sodium hydroxide 1.0%, sodium borate 0.3%, edetate disodium 0.1%, sodium oleate 0.08%, lauryl sulfate Sodium 0.08%, Alkylphenol Ethoxylate 0.07%, Water 93.87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com