Electronic sealed metal casing powder injecting forming binder formula

A powder injection molding and metal shell technology, applied in the field of binders, can solve the problems of easy phase separation, difficulty in degreasing, low strength of blanks, etc., and achieve the effect of good rheology and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

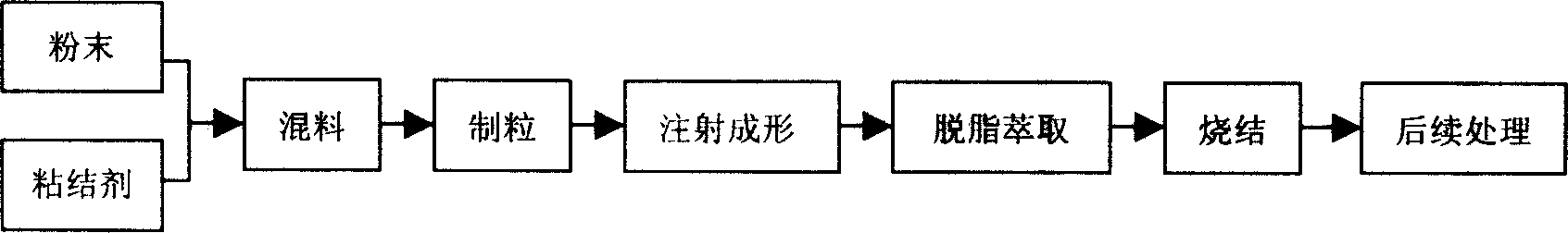

Method used

Image

Examples

Embodiment Construction

[0020] Material category

[0021] All the raw materials are common grade chemical materials, which are available in various chemical reagent stores. MP-22 is the abbreviation of synthetic wax, produced by American Micro Powders, Inc, 580white Plains Road Tarrysown, NY10591 and other companies. It can be seen from the examples in the table that the binder system is a multi-component system, that is, it is composed of a low melting point component with good fluidity and a high molecular polymer component. The role of the low molecular weight is to make the metal powder and binder mixed feed material have good flow properties and lower low molecular weight to successfully complete the injection molding process and obtain the desired shape of the injection blank. The more typical substance is paraffin. Paraffin wax has low melting point, good wettability, short molecular chain, low viscosity, and smaller volume change when decomposed than other polymers, and paraffin wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com