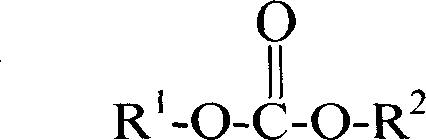

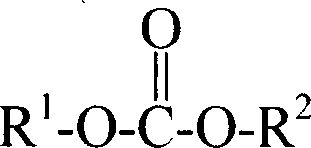

Application of alkyl carbonate as industrial solvent

A dialkyl carbonate, industrial technology, applied in the application field of alkyl carbonate, can solve problems such as no literature report, and achieve the effects of wide use, environmental friendliness and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Application of tert-butyl methyl carbonate, n-butyl methyl carbonate and ethylene glycol methyl ether methyl carbonate in polyurethane paint thinner (PU thinner). The composition of various thinners is shown in Table 2.

[0030] Table 2

[0031] Typical polyurethane thinner

[0032] C1 and C2 thinners were prepared according to the ratio of A1: B: thinner = 1:1:0.8 to prepare polyurethane varnishes and spray them on tinplate sheets and polyurethane base plates for performance testing. The results are shown in Table 3:

[0033] table 3

[0034]

[0035] It can be seen from Table 3 that the properties of the paint formulated with C2 thinner in the application example are completely qualified and can completely replace the typical C1 thinner.

Embodiment 2

[0037] Application of tert-butyl methyl carbonate, n-butyl methyl carbonate and ethylene glycol methyl ether methyl carbonate in nitro (NC) lacquer thinner (NC thinner). The composition of various thinners is shown in Table 4.

[0038] Table 4

[0039] Typical NC paint thinner

[0040] Two kinds of NC thinners C3 and C4 were prepared according to the ratio of A2: Thinner = 1:1 to prepare NC varnishes and spray them on the tinplate sheet and polyurethane base plate for performance testing. The results are shown in Table 5:

[0041] table 5

[0042]

[0043] It can be seen from Table 5 that: Application example C4 is used as NC thinner for NC paint, and all performances are qualified. C4 can completely replace C3 typical NC thinner.

Embodiment 3

[0045] Application of tert-butyl methyl carbonate, n-butyl methyl carbonate and ethylene glycol methyl ether methyl carbonate in amino (AC) stoving varnish thinner. The composition of various thinners is shown in Table 6.

[0046] Table 6

[0047] Typical AC paint thinner

C5 formula

In this example AC baking paint thinner

C6 formula

AC baking varnish

A3 formula

Raw material name W / %

Xylene 30

Butanol 10

dimethyl nylon acid

60

ester

Total 100

Raw material name W / %

n-Butyl methyl carbonate 30

Butanol 10

Ethylene glycol methyl ether methyl carbonate 60

Total 100

Raw material name W / %

saturated polyester tree

70

fat

Amino lacquer

20

fat

40% PTSA 2

dimethyl nylon acid

4

ester

Butanol 3

Leveling agent 0.5

Defoamer 0.5

Total 100 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com