Acid-resistant and alkali-resistant waterborne damping coating with wide temperature range and high damping capacity and method for preparing same

A technology of damping coatings and wide temperature range, which is applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of acid and alkali resistance, wide damping temperature range and high damping factor, etc. Wide temperature range, strong acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

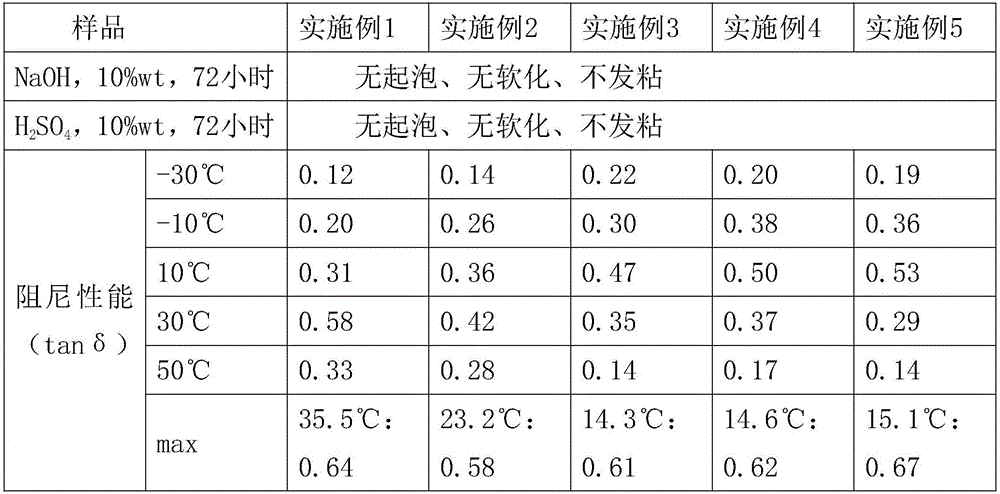

Examples

Embodiment 1

[0030] Weigh each component raw material according to the following composition formula:

[0031] Water-based emulsion (90% core-shell structure styrene-acrylic emulsion, 10% silicone-modified acrylate emulsion) 45 parts; mica 15 parts, talc powder 5 parts; phosphorus nitrogen-based halogen-free flame retardant 18 parts; polypropylene 0.6 parts of fiber; 2 parts of alcohol ester twelve; 0.8 parts of acrylic acid homopolymer sodium salt dispersant; 1 part of general water-based defoamer; 2 parts of glycol antifreeze; 5 doses.

[0032] The preparation method of the above-mentioned water-based damping coating with acid and alkali resistance, wide temperature range and high damping is as follows:

[0033] (1) Add the water-based emulsion into the container for medium-low speed dispersion and stirring for blending until uniform;

[0034] (2) Add dispersant, defoamer (half), and fiber to the dispersed emulsion in turn, then adjust the dispersion speed to high speed, and then add f...

Embodiment 2

[0037] Weigh each component raw material according to the following composition formula:

[0038] Water-based emulsion (70% styrene-acrylic emulsion with core-shell structure, 30% silicone-modified acrylate emulsion) 45 parts; 10 parts of mica, 10 parts of graphite powder, 5 parts of talcum powder; 10 parts of aluminum hydroxide; polypropylene 1 part of fiber; 1 part of alcohol ester twelve; 1.2 parts of general-purpose dispersant for water-based paint; 0.8 parts of mineral oil defoamer; 3 parts of low-carbon alcohol antifreeze; 1 part of acrylic thickener, hydroxymethyl fiber 1 part of prime; 8 parts of multifunctional additives.

[0039] The preparation method of the above-mentioned water-based damping coating with acid and alkali resistance, wide temperature range and high damping is as follows:

[0040] (1) Add the water-based emulsion into the container for medium-low speed dispersion and stirring for blending until uniform;

[0041] (2) Add dispersant, defoamer (half),...

Embodiment 3

[0044] Weigh each component raw material according to the following composition formula:

[0045] 45 parts of water-based emulsion (50% styrene-acrylic emulsion with core-shell structure, 50% silicone-modified acrylate emulsion); 15 parts of mica, 10 parts of graphite powder, 10 parts of barium sulfate; 10 parts of ammonium polyphosphate, hydrogen 10 parts of magnesium oxide; 1 part of polypropylene fiber, 1 part of basalt fiber; 1.5 parts of polycarboxylate sodium salt dispersant; 1.5 parts of mineral oil defoamer; 3 parts of polyurethane thickener; 3 parts of multifunctional additives.

[0046] The preparation method of the above-mentioned water-based damping coating with acid and alkali resistance, wide temperature range and high damping is as follows:

[0047] (1) Add the water-based emulsion into the container for medium-low speed dispersion and stirring for blending until uniform;

[0048] (2) Add dispersant, defoamer (half), and fiber to the dispersed emulsion in sequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com