Mixed soft segment type polyurethane damping material and preparation method thereof

A damping material, polyurethane technology, applied in the field of polyurethane elastomer material preparation, can solve the complicated preparation process and other problems, achieve simple process, increase glass transition temperature, and improve the effect of damping factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

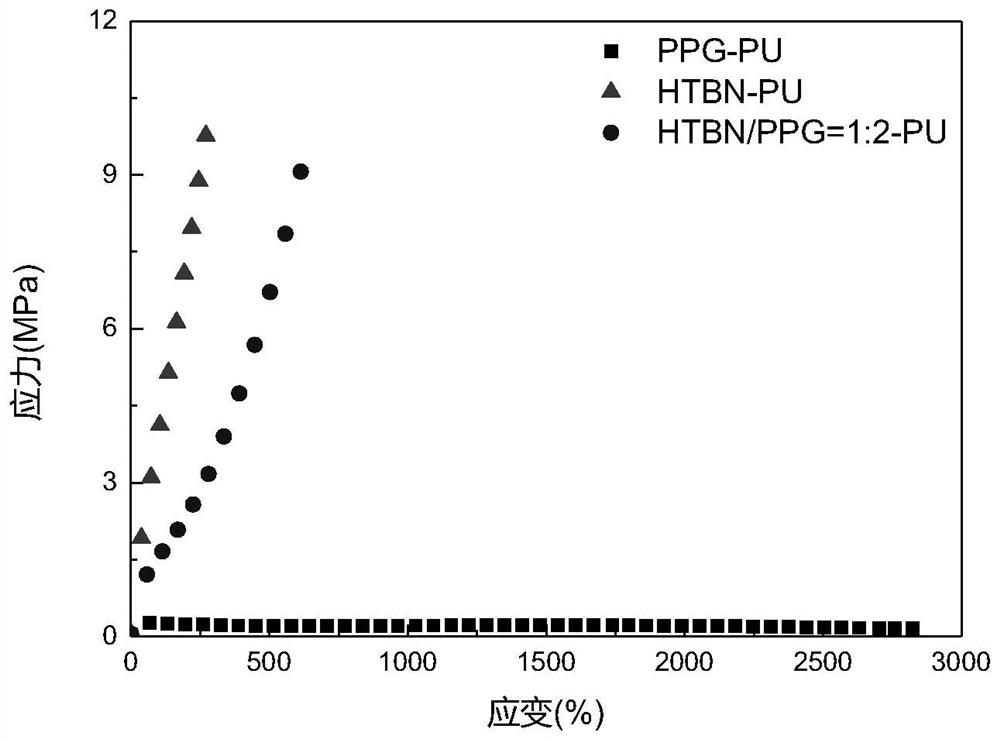

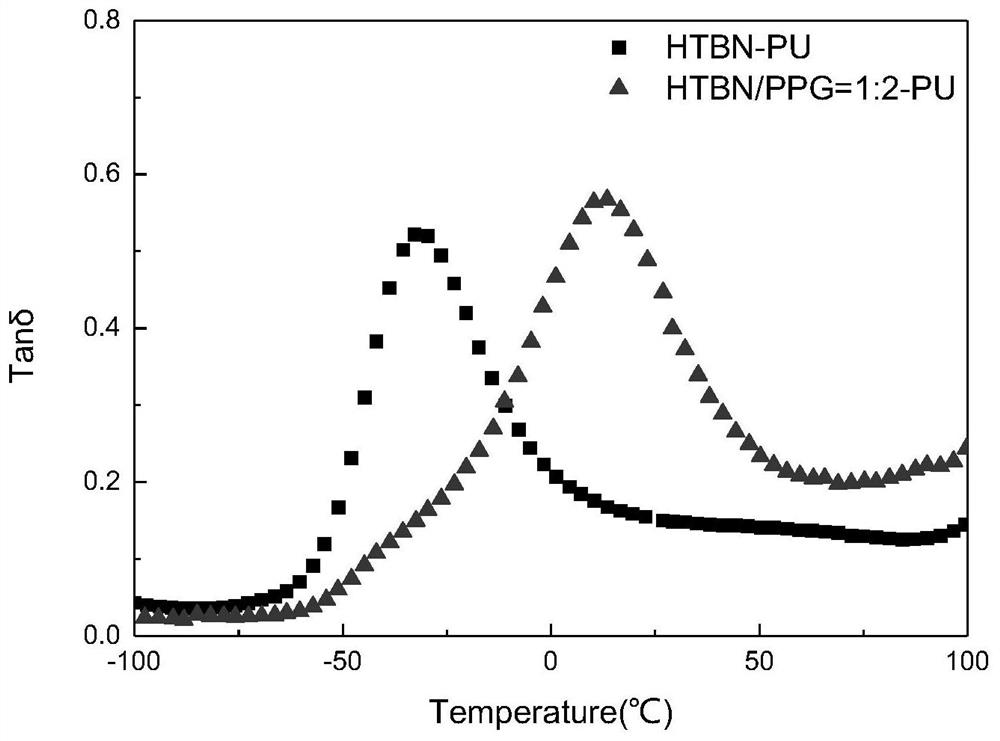

[0043] Add 23.80g of hydroxyl-terminated polybutadiene-acrylonitrile copolymer (HTBN, hydroxyl value 0.6305, molecular weight about 3500) and 30.03g polypropylene glycol (PPG, molecular weight 2000) into a four-necked flask, at 110°C, Vacuumize at 80r / min to remove water for 2h, cool down to 60°C, add 16.62g of toluene-2,4-diisocyanate (TDI-100) under nitrogen atmosphere, stabilize for half an hour, then raise the temperature to 75°C, stir at 240r / min for 3h , lower the temperature to 60°C and add 6.49g of 1,4-butanediol to stabilize for 10min, raise the temperature to 75°C for 2h, and finally put it in a vacuum oven at 100°C for 12h to prepare a mixed soft segment polyurethane damping material. The hardness, tensile strength, Young's modulus, loss factor and damping temperature range of the obtained damping material are listed in Table 1.

Embodiment 2

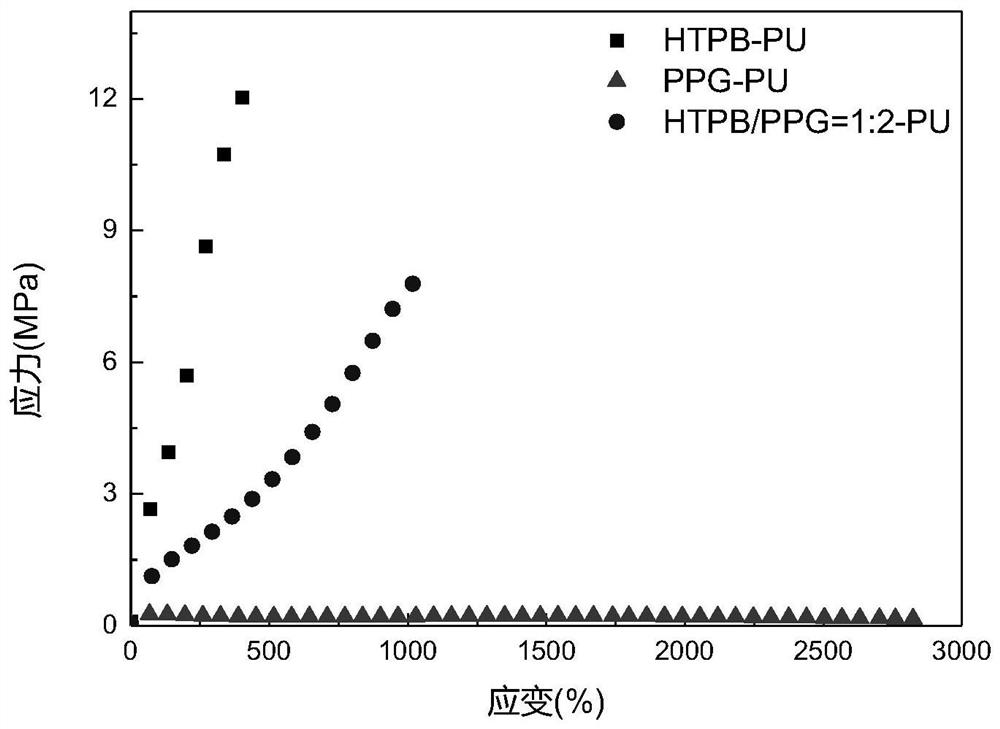

[0045] Add 19.66g of hydroxyl-terminated polybutadiene (HTPB, hydroxyl value 0.7644, molecular weight about 4500) and 17.48g polypropylene glycol (molecular weight: 2000) into a four-necked flask, vacuumize at 110°C and 80r / min. Water for 2 hours, cool down to 60°C, add 11.34g toluene-2,4-diisocyanate (TDI-100) under nitrogen atmosphere, stabilize for half an hour, then raise the temperature to 75°C, stir at 240r / min for 3h, cool down to 60°C, add 4.58 g 1,4-butanediol was stabilized for 10 minutes, heated to 75°C for 2 hours, and finally placed in a vacuum oven at 100°C for 12 hours to prepare a mixed soft-segment polyurethane damping material. The hardness, tensile strength, Young's modulus, loss factor and damping temperature range of the obtained damping material are listed in Table 1.

Embodiment 3

[0047] Add 15.92g of hydroxyl-terminated polybutadiene (HTPB, hydroxyl value 0.7644, molecular weight about 4500) and 21.22g polypropylene glycol (molecular weight: 2000) into a four-necked flask, and vacuumize at 110°C and 80r / min. Water for 2 hours, cool down to 60°C, add 11.39g of toluene-2,4-diisocyanate (TDI-100) under nitrogen atmosphere, stabilize for half an hour, then raise the temperature to 75°C, stir at 240r / min for 3h, cool down to 60°C, add 4.53 g 1,4-butanediol was stabilized for 10 minutes, heated to 75°C for 2 hours, and finally placed in a vacuum oven at 100°C for 12 hours to prepare a mixed soft-segment polyurethane damping material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com