Patents

Literature

42results about How to "High damping factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wide-temperature-domain high-damping environment-friendly damping material for electronic product and preparation method thereof

The invention relates to a wide-temperature-domain high-damping environment-friendly damping material for an electronic product and a preparation method thereof. The damping material is prepared from the following components in percentage by mass: 40-48% of butyl rubber, 4.2-5% of dioctyl sebacate, 16-19% of brominated p-tert-octyl phenolic resin, 0.3-0.6% of an anti-aging agent, 10-25% of carbon black, 2.0-2.5% of zinc oxide, 0.6-0.8% of stearic acid and 12-15% of an antioxidant. The damping material has good damping vibration reduction performance and good mechanical property in a relatively wide temperature range, and has wide application temperature range, high damping factor and good environmental protection performance, conforms to the requirements of European Union environmental directive ROHS, meets the needs in using various electronic equipment, can be popularized to the vibration control and noise control of the instruments and electronic systems on airplanes, ships and vehicles, and has broad application prospect.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

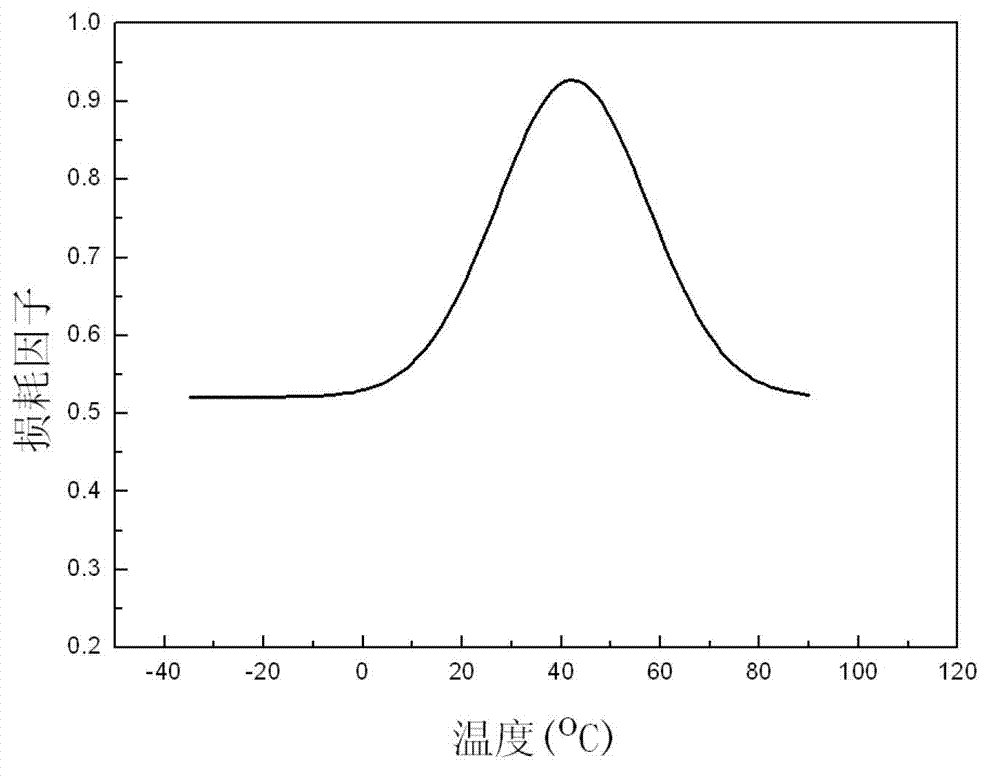

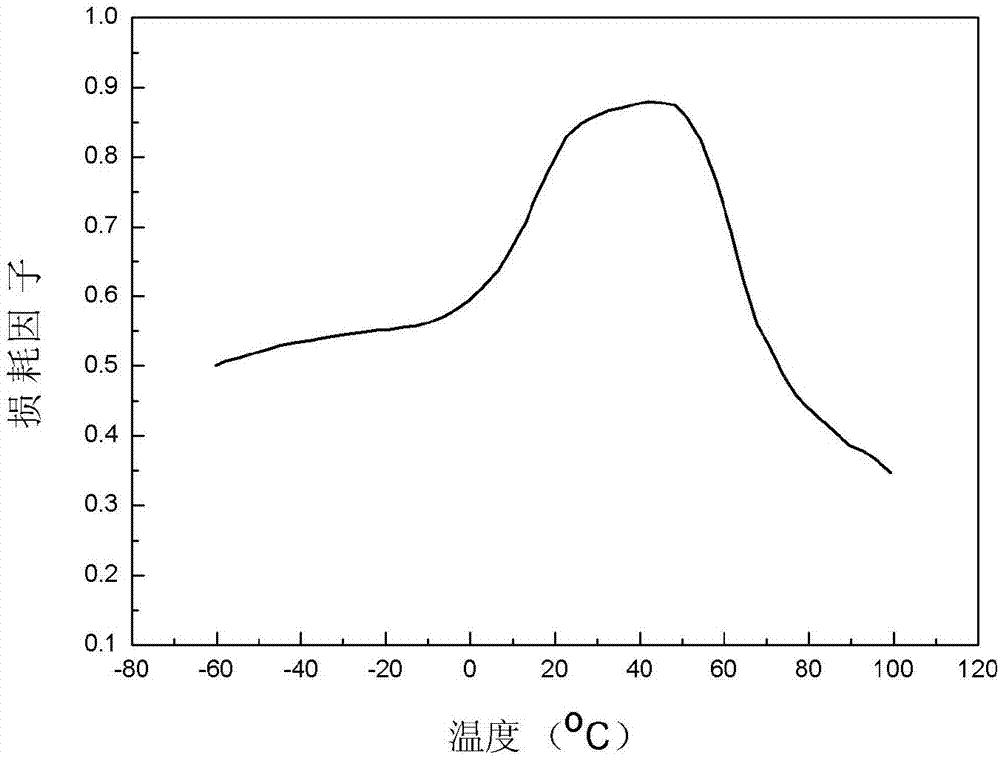

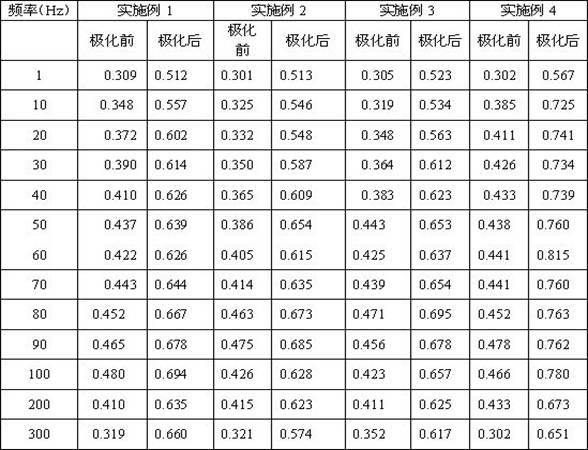

Low-frequency high-damping rubber-based piezoelectric composite material and preparation method thereof

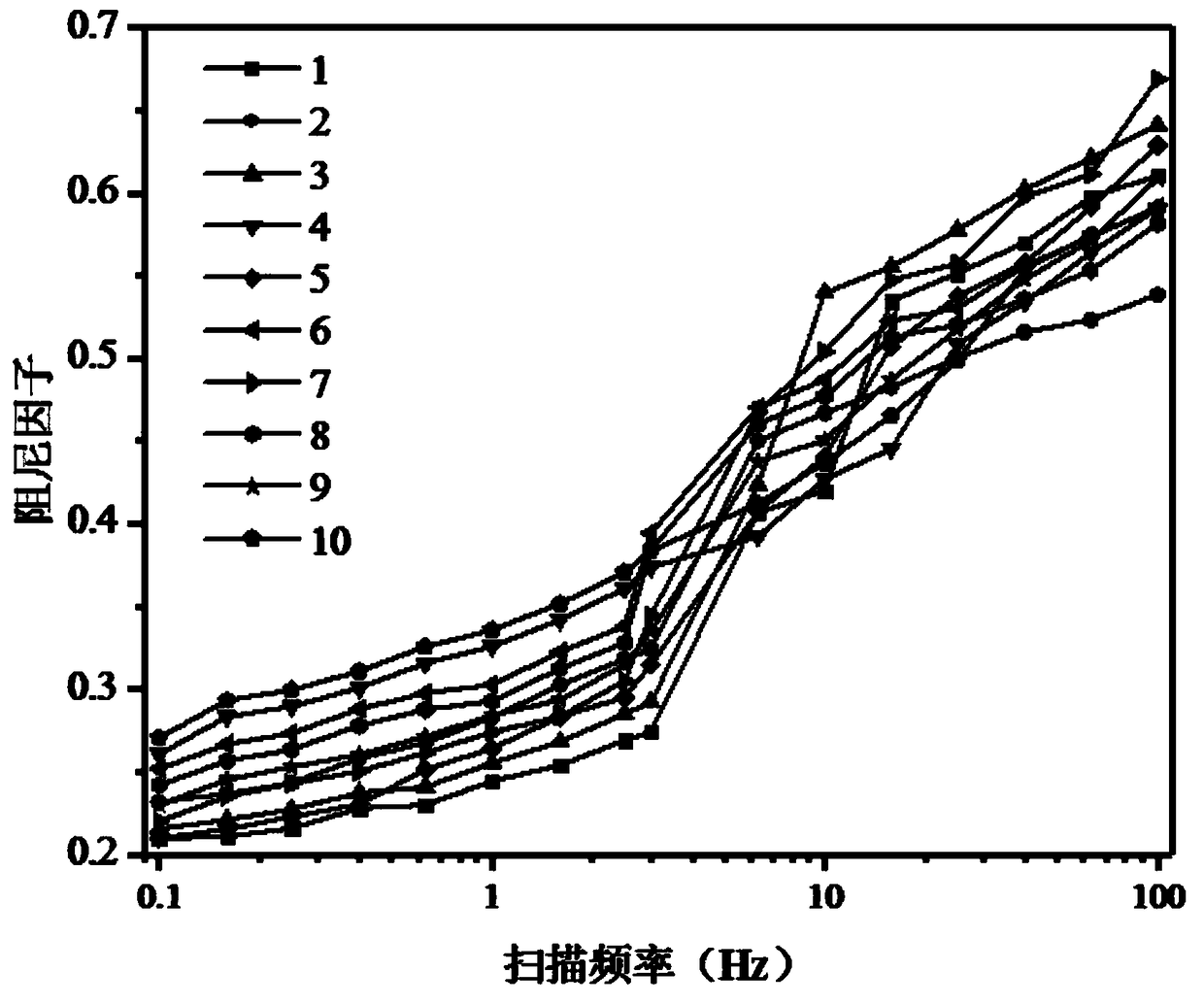

ActiveCN102585387AHigh damping factorSignificant piezoelectric synergistic effectElectricityDamping factor

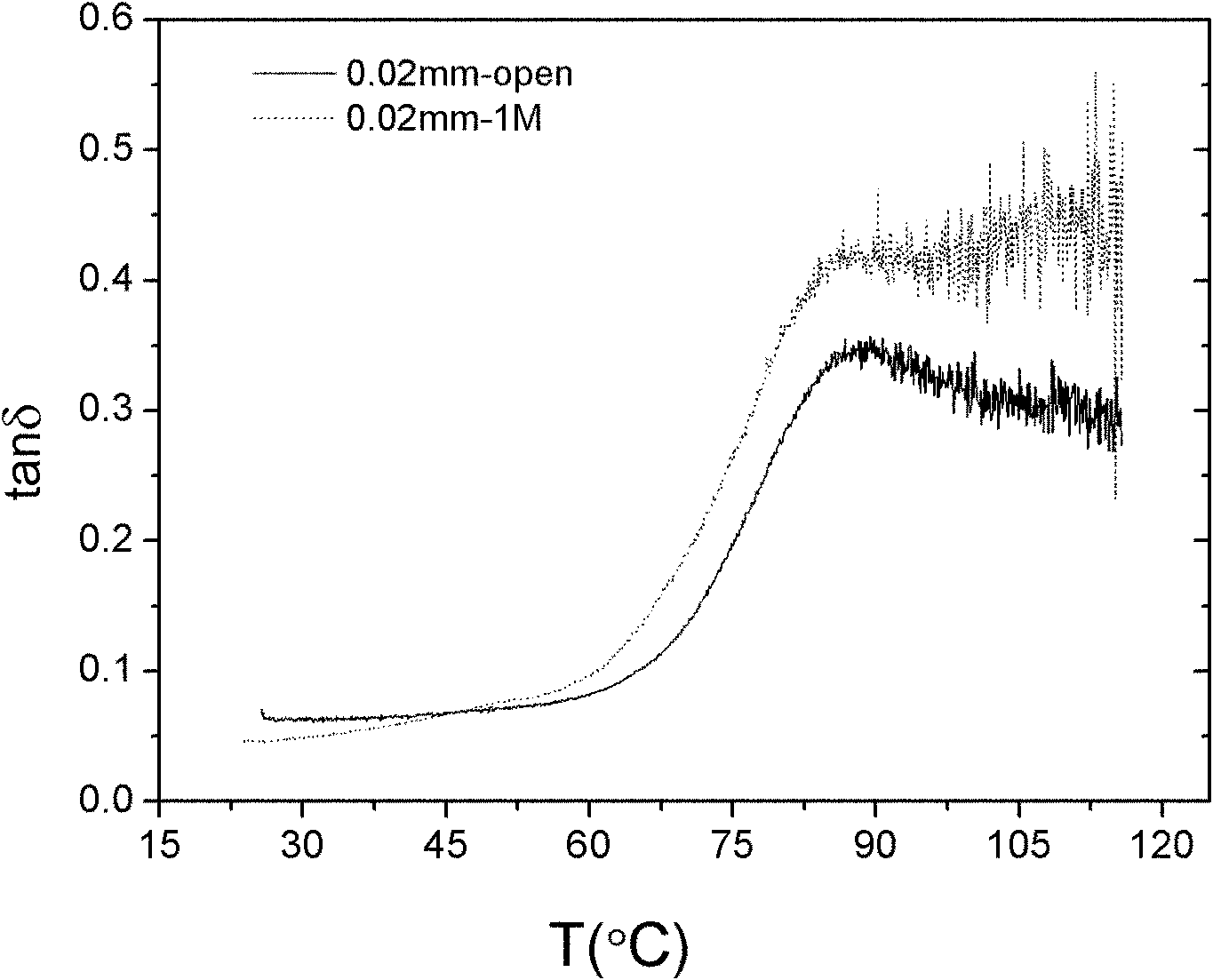

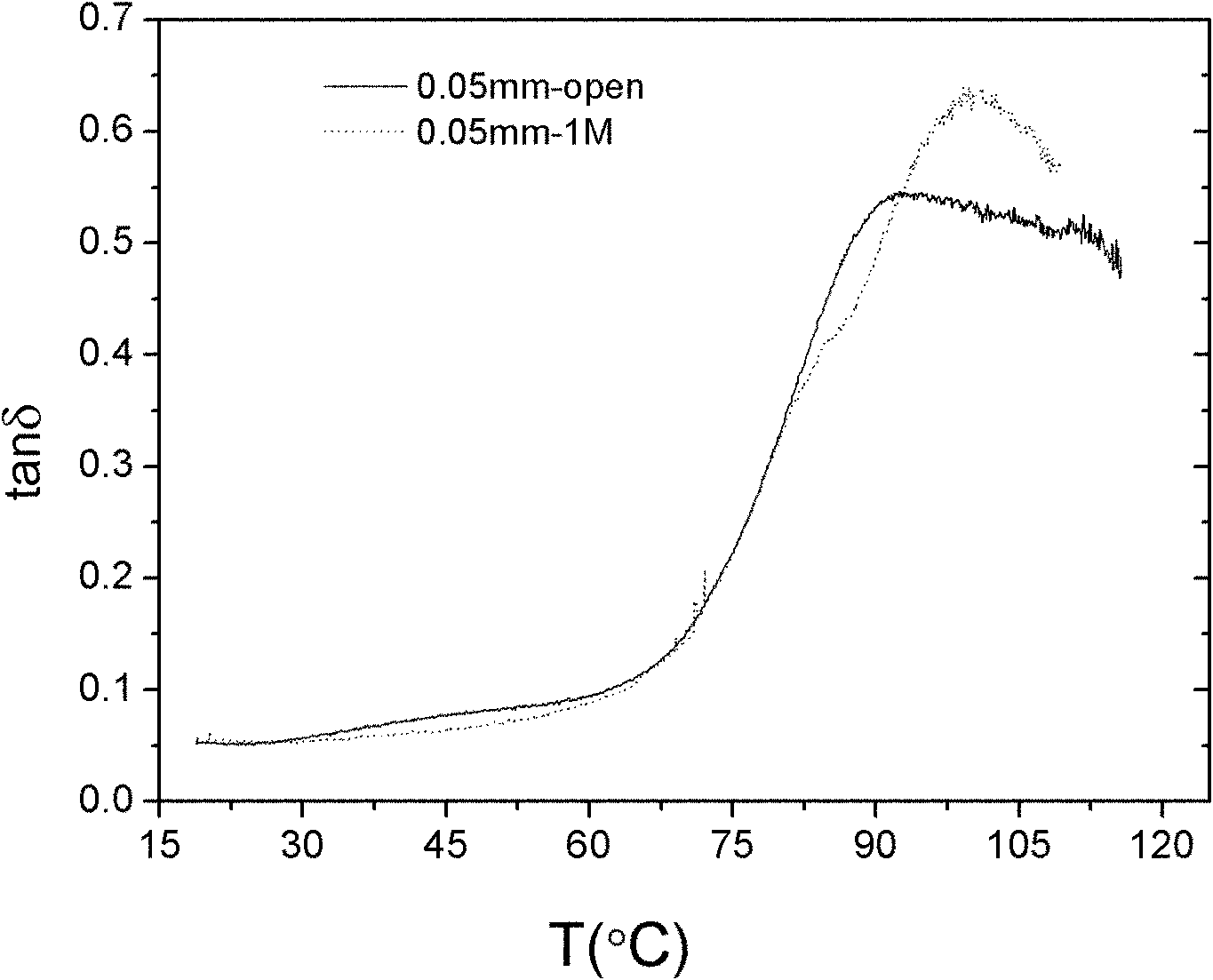

The invention discloses a low-frequency high-damping rubber-based piezoelectric composite material and a preparation method thereof. The composite material is a complex formed by mixing a rubber base material consisting of 100 parts of non-diene rubber, 1.0 to 1.5 parts of vulcanizing agent and 4.0 to 5.0 parts of vulcanizing accelerator, 100 to 500 parts of piezoelectric ceramic powder, 0.1 to 0.5 part of conductive carbon black and 0.5 to 5.0 parts of coupling agent, vulcanizing, polarizing and the like. A novel damping material which has a high damping factor (tan delta is more than or equal to 0.3) at low frequency (1 to 300Hz) can be obtained, an obvious piezoelectric synergistic effect is achieved, and the damping factor (tan delta is more than or equal to 0.2) of the polarized material is obviously improved compared with that of the unpolarized material.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

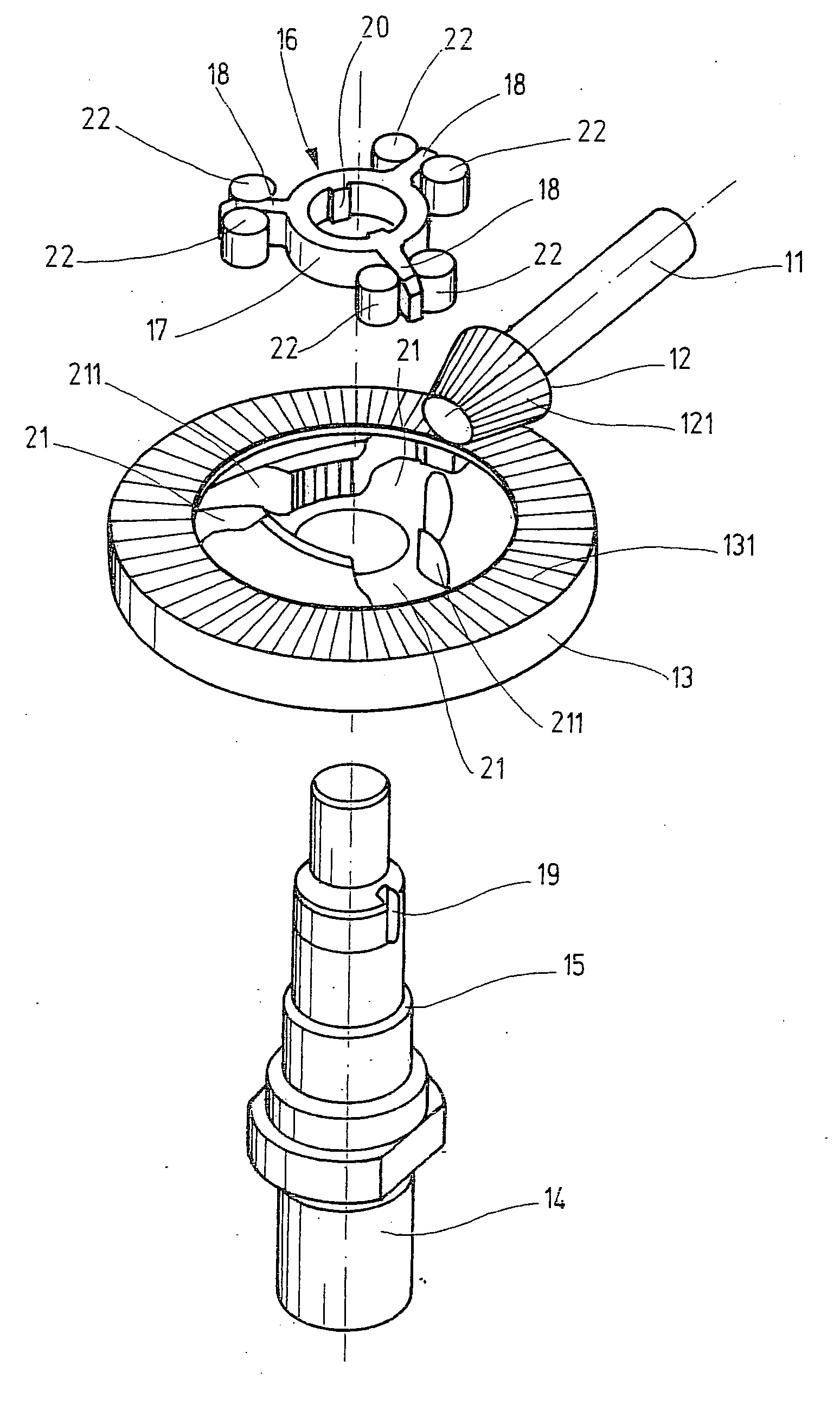

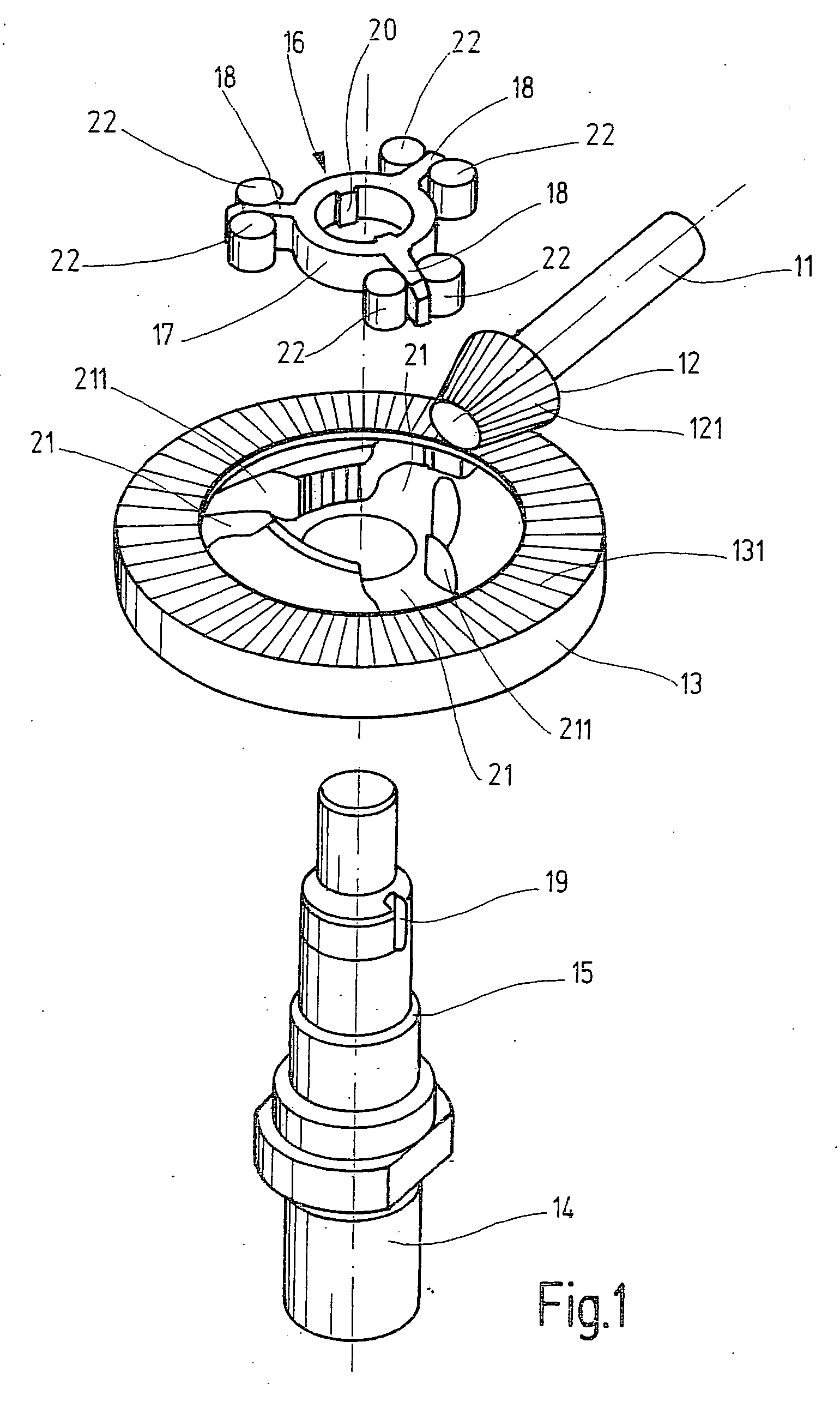

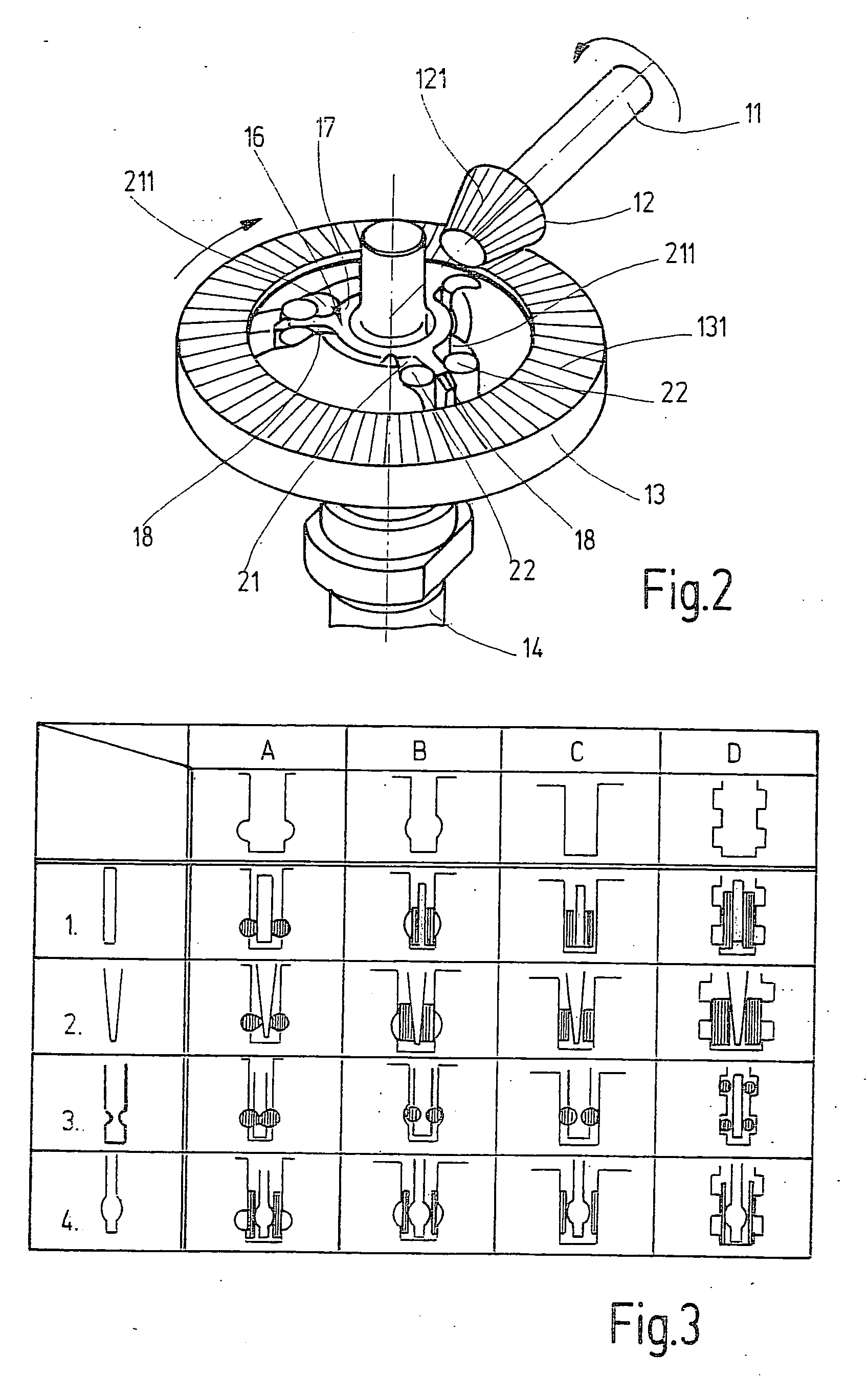

Gearset, in particular for electric hand machine tools

InactiveUS20060191365A1Highly smooth runningEasy to useGear vibration/noise dampingPortable liftingGear wheelDrive shaft

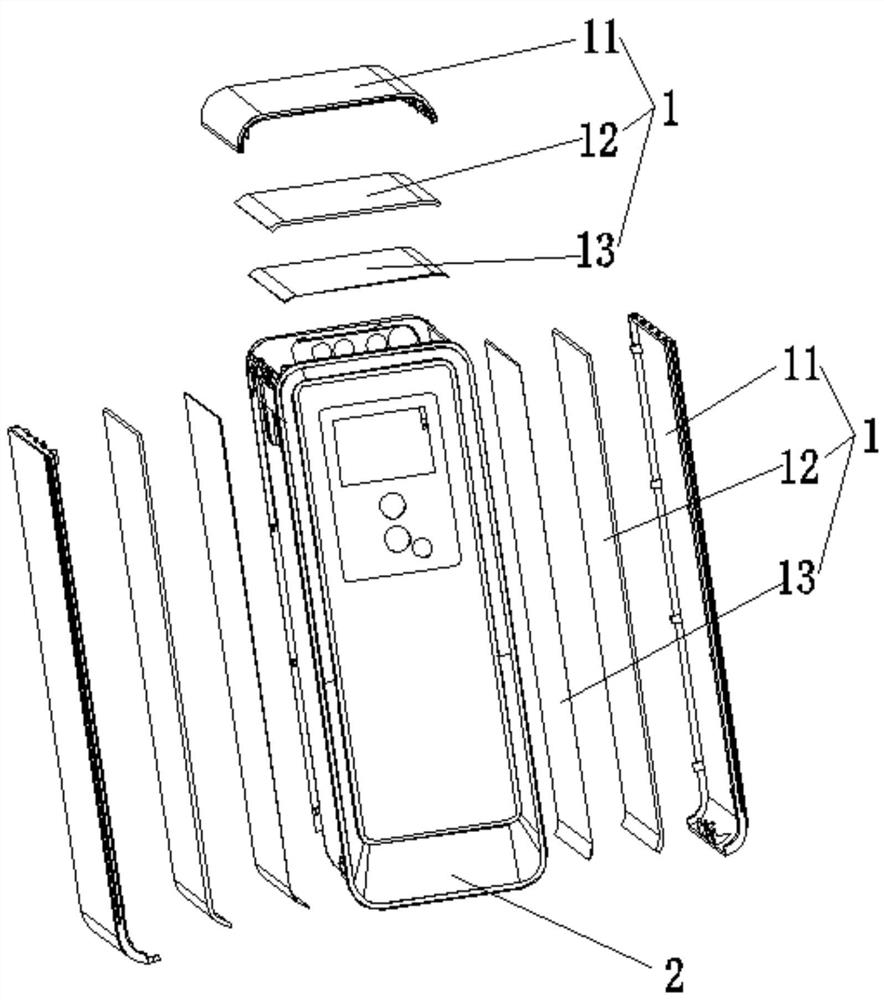

A gear mechanism, in particular for hand power tools, is disclosed which has a driving gear wheel (12), seated on a drive shaft (11) in the manner fixed against relative rotation, and a driven gear wheel (13), meshing with the driving gear wheel and driving a driven shaft (14). To attain high running smoothness of the gear mechanism and a longer service life by reducing the mechanical load on the gearing upon startup and in load peaks that occur during operation, spring-elastic damping elements (22) are located between the driven gear wheel (13) and the driven shaft (14) (FIG. 2).

Owner:ROBERT BOSCH GMBH

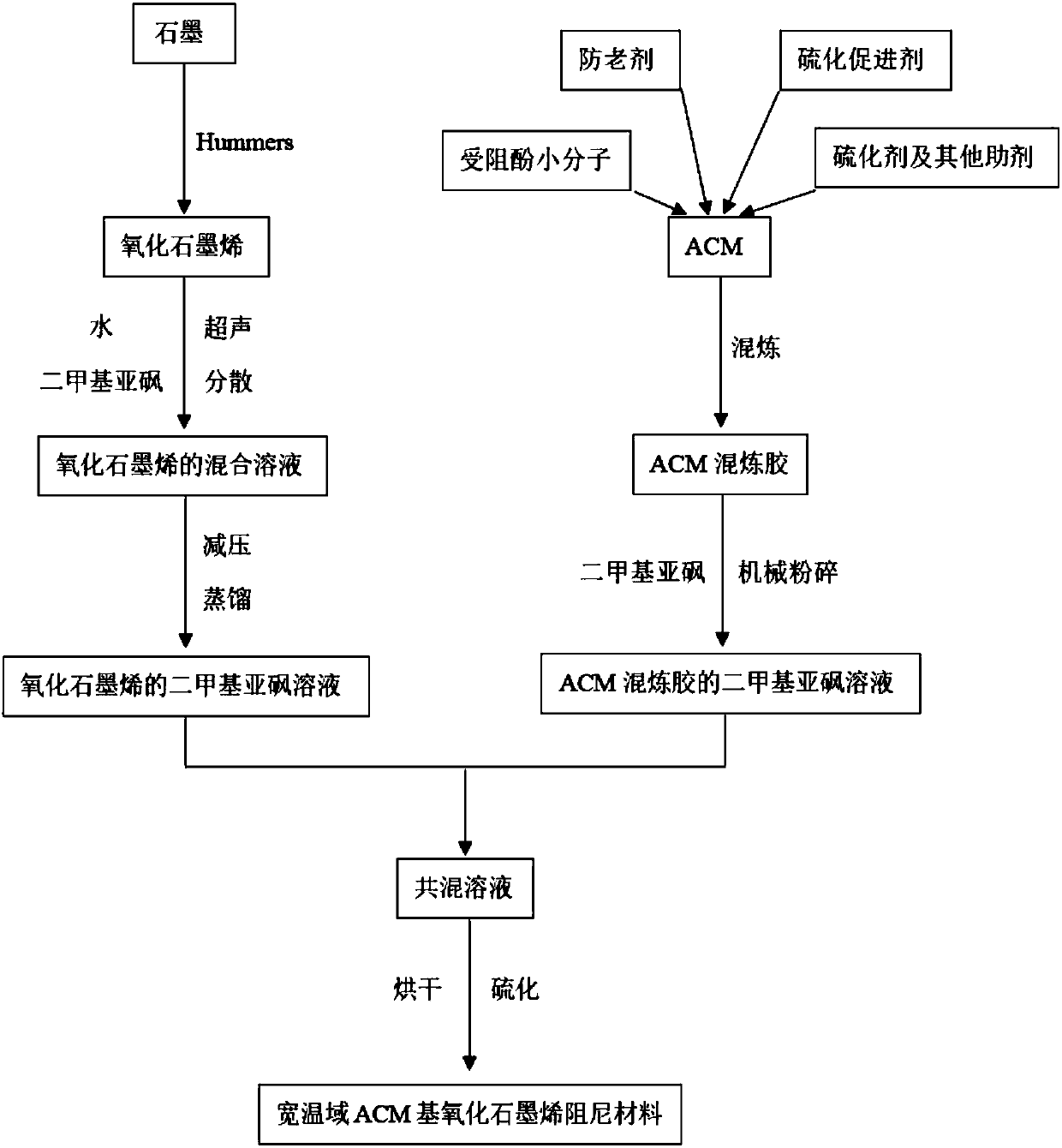

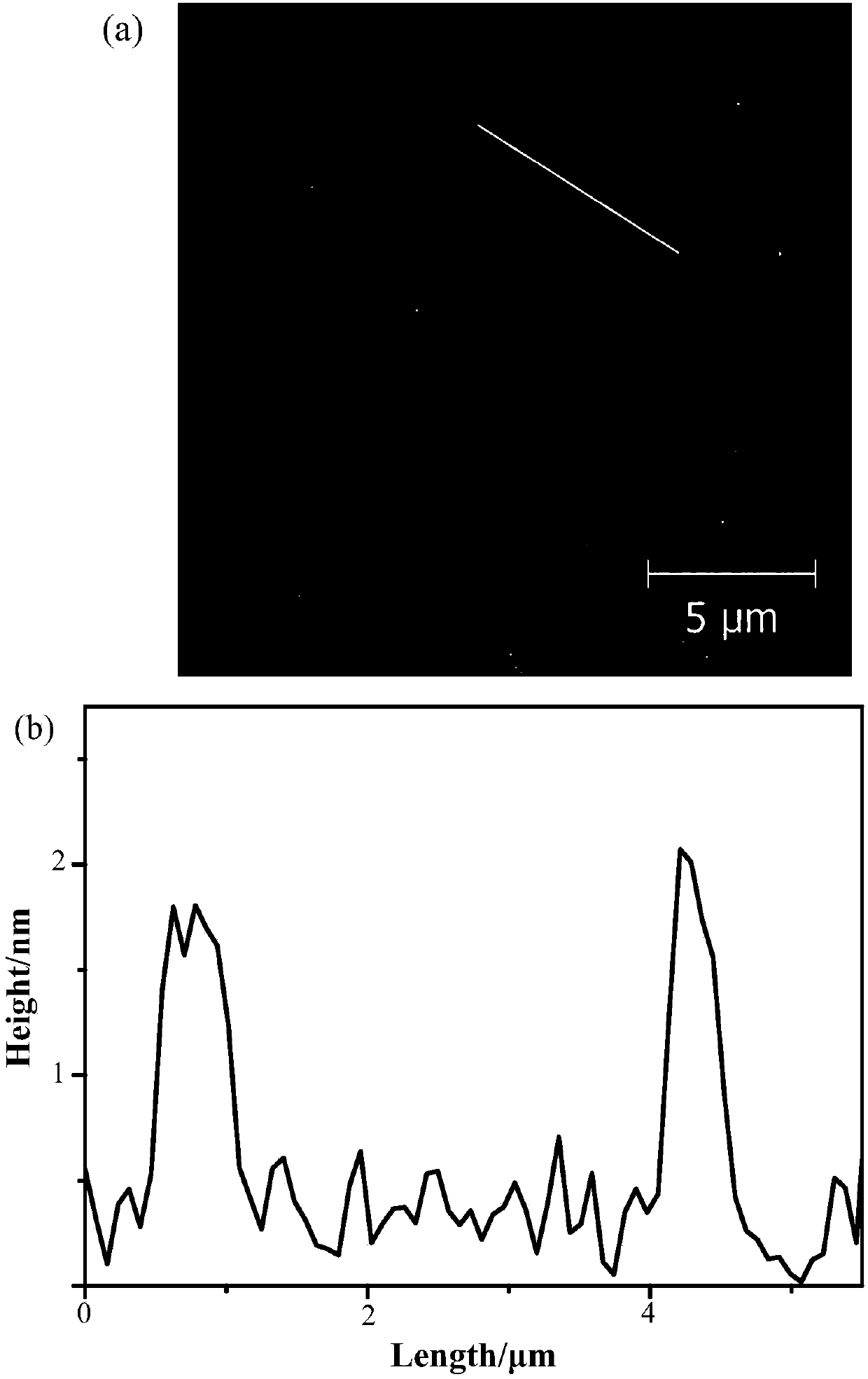

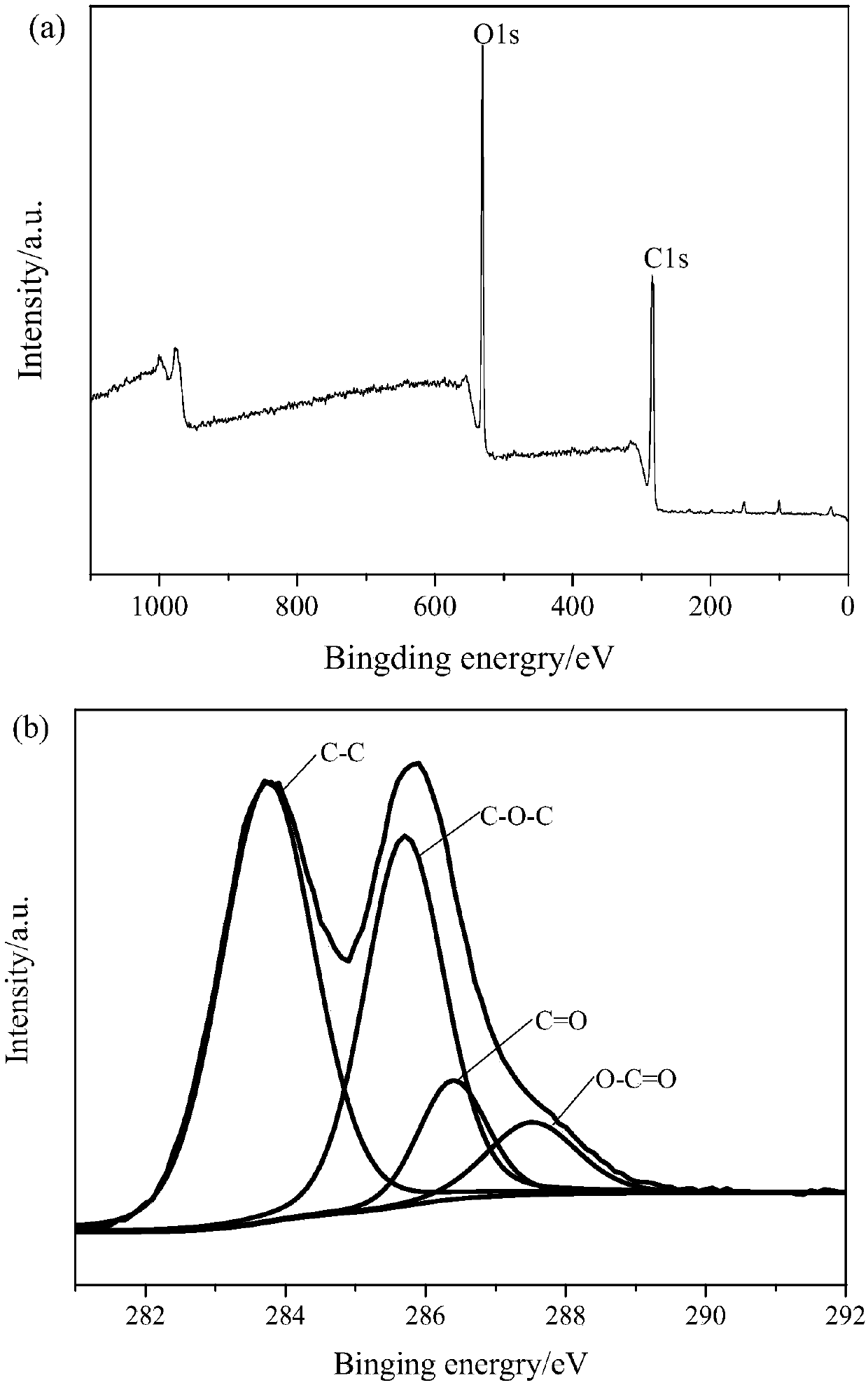

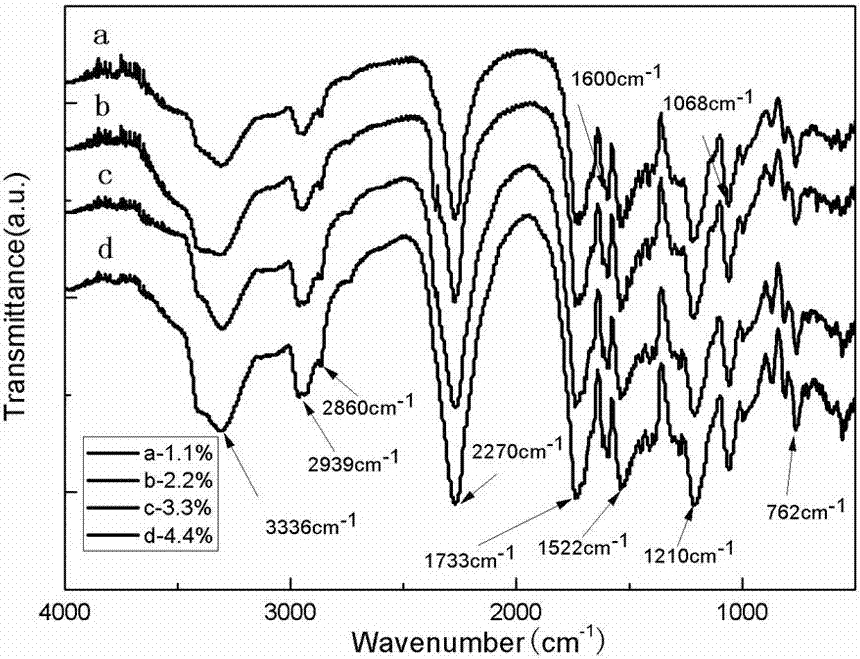

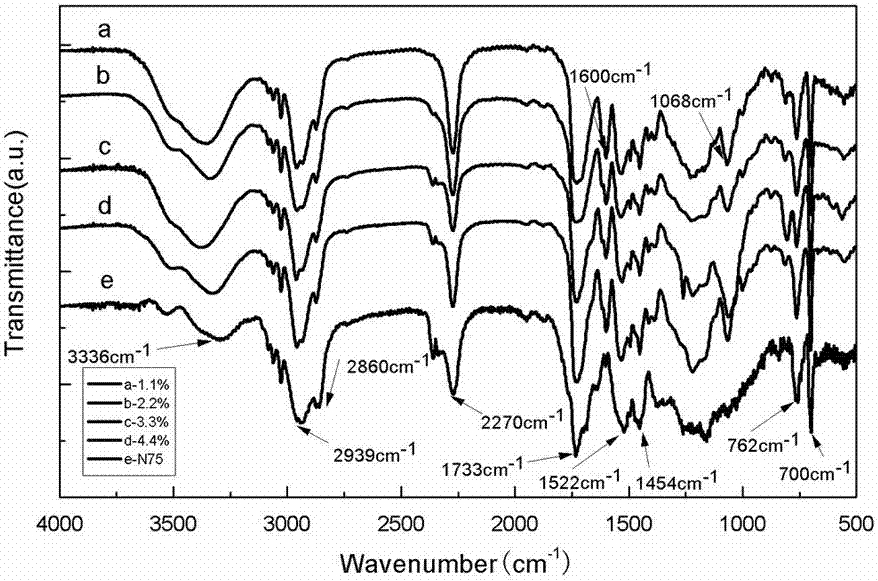

Wide temperature range acrylate rubber based graphene oxide damping material and preparation method thereof

The invention discloses a wide temperature range acrylate rubber (ACM) based graphene oxide damping material and a preparation method thereof. The method comprises the steps of: adjusting the dosage of oxidant to prepare of a graphene oxide dispersion liquid with certain size and a lot of polar groups on the surface; using mechanical blending method to blend ACM with hindered phenol small molecules, a curing agent and other compounding agents, then performing mixing with graphene oxide by solvent blending method, and conducting drying and vulcanizing so as to obtain the wide temperature rangeACM based damping rubber containing graphene oxide. According to the invention, graphene oxide with a lot of polar groups on the surface, hindered phenol small molecules and ACM are utilized to form astrong hydrogen bond, at the same time, the barrier properties of graphene oxide are utilized to greatly improve the effective damping temperature range of the ACM based graphene oxide damping material (with tan delta being greater than or equal to 0.3) and the damping properties after aging.

Owner:NANJING UNIV OF SCI & TECH

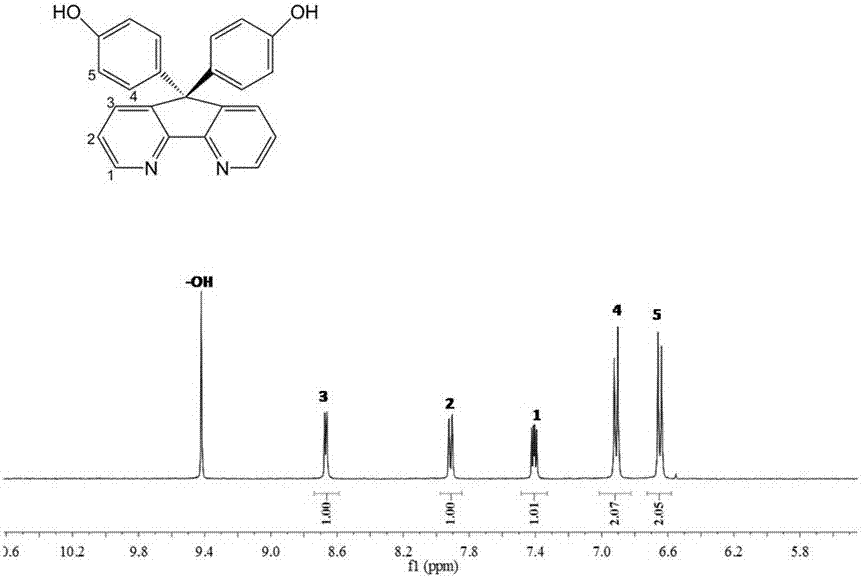

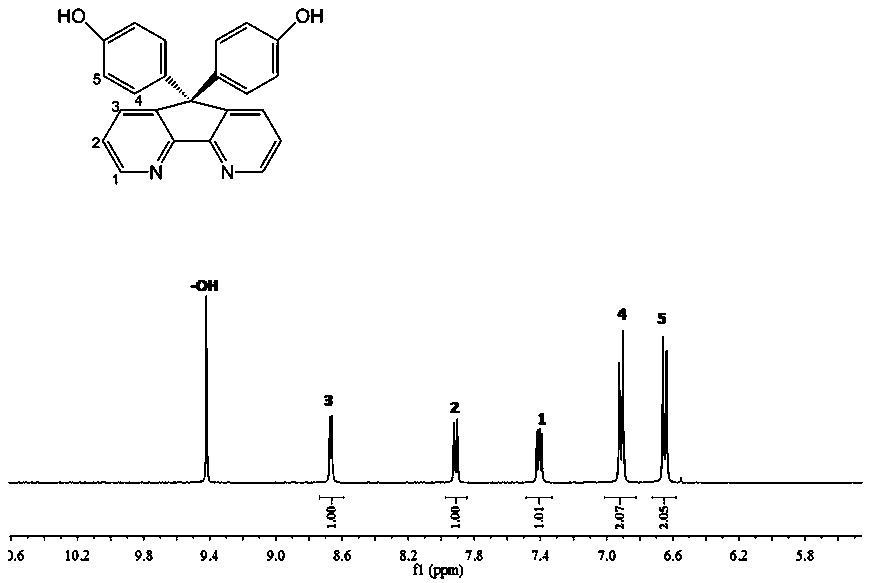

Preparation method of curing agent for high temperature damping polyurethane

ActiveCN107383304AImprove high temperature stabilityImproved high temperature damping performanceDamping factorSide chain

The invention discloses a preparation method of a curing agent for high temperature damping polyurethane. The dinitrogen bisfluorene in the structure comprises a special large spatial configuration; the spatial configuration, as a side chain of a polymer, can strengthen the friction steric hindrance between molecular chains, meanwhile, the fused heterocycle structure containing pyridine and the like is utilized to improve the proportion of a rigid segment of polyurethane, so that the damping performance of a polyurethane material in the high temperature environment and the stability of the damping performance are improved. The prepared curing agent is applied to the curing of a polyurethane resin, compared with the traditional curing agent, the curing agent increases the glass transition temperature of the polyurethane material and the damping factor at the medium-high temperature, expands the damping temperature range of the material, and improves the damping performance of the material in the medium-high temperature environment.

Owner:FUZHOU UNIV

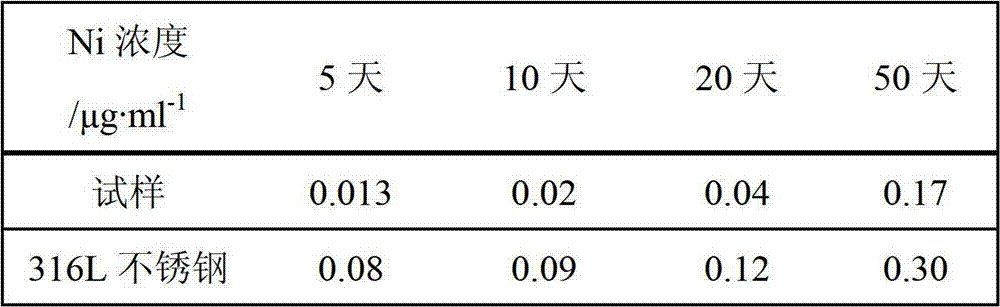

Nickel titanium memory alloy/polyurethane compound damping panel and preparation method thereof

InactiveCN102896836AHigh strengthHigh hardnessLamination ancillary operationsLaminationSurface layerTitanium

The invention provides a nickel titanium memory alloy / polyurethane compound damping panel and a preparation method thereof and relates to a compound damping panel and the preparation method thereof. The invention aims to solve the technical problems that the present surface layer is a 316L stainless steel compound steel panel, the tensile strength is low, the corrosion resistance is inferior and the present compound damping material has inferior damping effect. The preparation method according to the invention comprises the following steps: placing a nickel titanium memory alloy panel and a polyurethane panel into a hot press, and then pressing for 5-20min under the conditions of 185-195 DEG C temperature and 40-50N pressure, and taking out and cooling in air. The tensile strength of the compound damping panel provided by the invention is 600-800MPa; the precipitation volume of nickel ions in Nacl solution is 0.17ug / ml; the tensile strength is high; the corrosion resistance is excellent; a damping loss factor can reach 0.2; the vibration-reducing and noise-reducing effects are good; and the compound damping panel can be widely applied to passenger cars, trains, ships and buildings.

Owner:HARBIN ENG UNIV

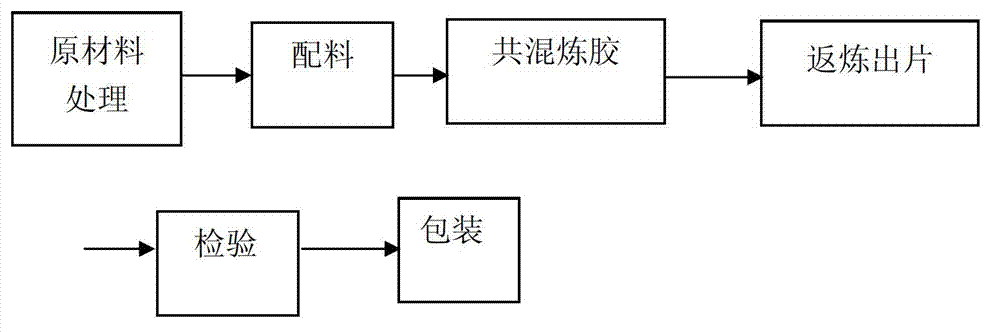

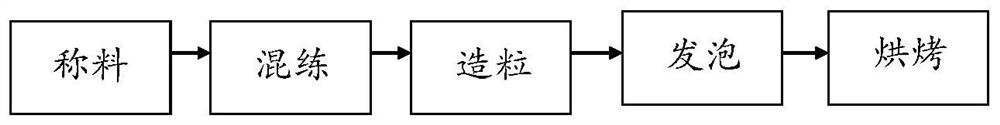

Preparation method of wide-temperature-range and high-damping rubber and plastic blended foam material

InactiveCN103951921AHalogen Free Flame RetardancyWide damping temperature rangePolymer scienceVulcanization

The invention discloses a preparation method of a wide-temperature-range and high-damping rubber and plastic blended foam material. The preparation method comprises the following steps of carrying out first-stage mixing by using an internal mixer, adding polylactic acid firstly, then, adding ethylene-polyvinyl acetate rubber and white carbon black, and mixing; carrying out second-stage mixing by using a two-roll mixing mill, sequentially adding zinc oxide, stearic acid, a foaming agent and a vulcanizing agent BIPB into a first-stage rubber compound at normal temperature, thinning and batching off to prepare a rubber compound a; standing the rubber compound a for 8-16h, then, molding, vulcanizing and foaming by using a plate vulcanizing machine to prepare a wide-temperature-range and high-damping blended material with uniform foam holes. The preparation method has the beneficial effects of effectively widening the damping temperature range and increasing damping factors; and in addition, the material prepared by using the preparation method disclosed by the invention is uniform in foam holes, smooth in surface, attractive in appearance and excellent in mechanical performance.

Owner:QINGDAO UNIV OF SCI & TECH

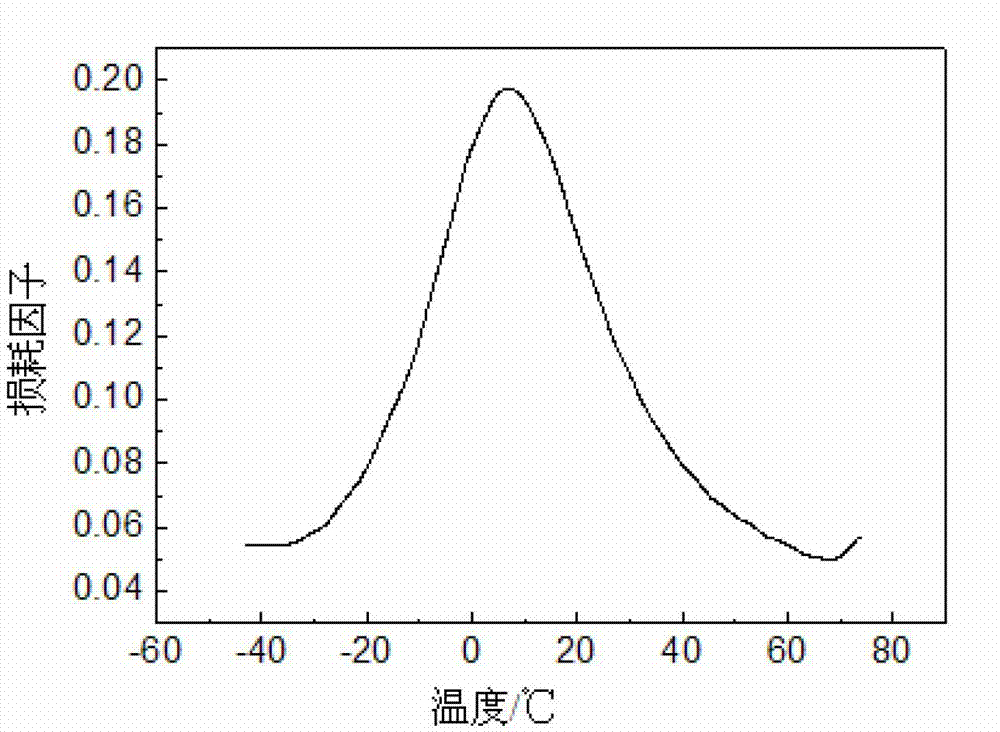

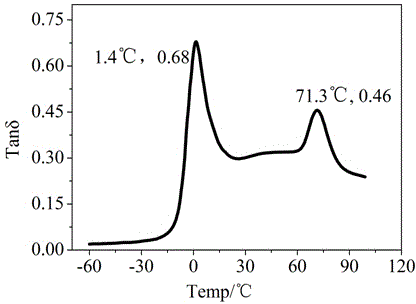

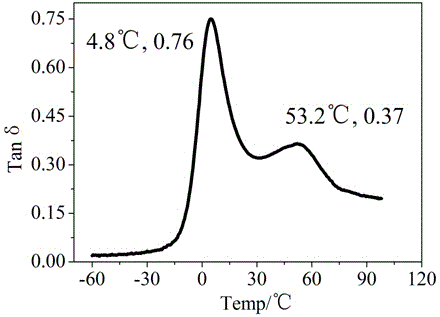

Ether-linkage-containing polyester type polyurethane damping material and preparation method thereof

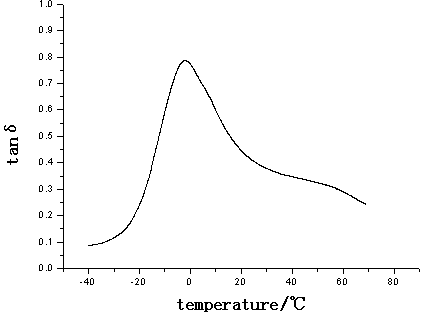

The invention discloses an ether-linkage-containing polyester type polyurethane damping material, wherein the molecular main chain of the ether-linkage-containing polyester type polyurethane damping material comprises a structure, in the structure, dimethyl, propoxy and methyl propoxy are connected, dimethyl, propoxy and methyl propoxy share a carbon, the molecular structure chart of the ether-linkage-containing polyester type polyurethane damping material is as follows (see the specification), wherein P=0 or 1, m is a value between 0 and 50, and n is a value between 1 and 50. The damping material has higher damping consumption factors, the temperature corresponding to tan Deltamax is about 0 DEG C, and the damping material is suitable for being used in cold areas.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

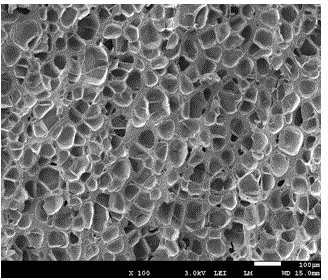

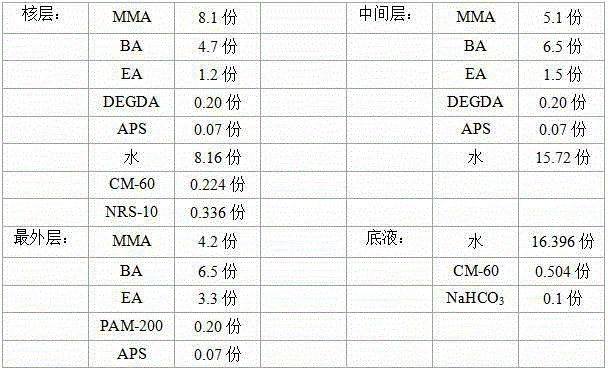

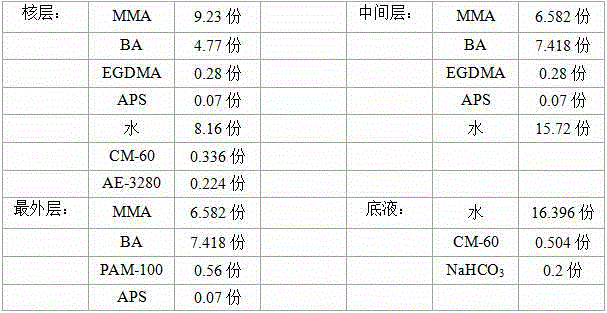

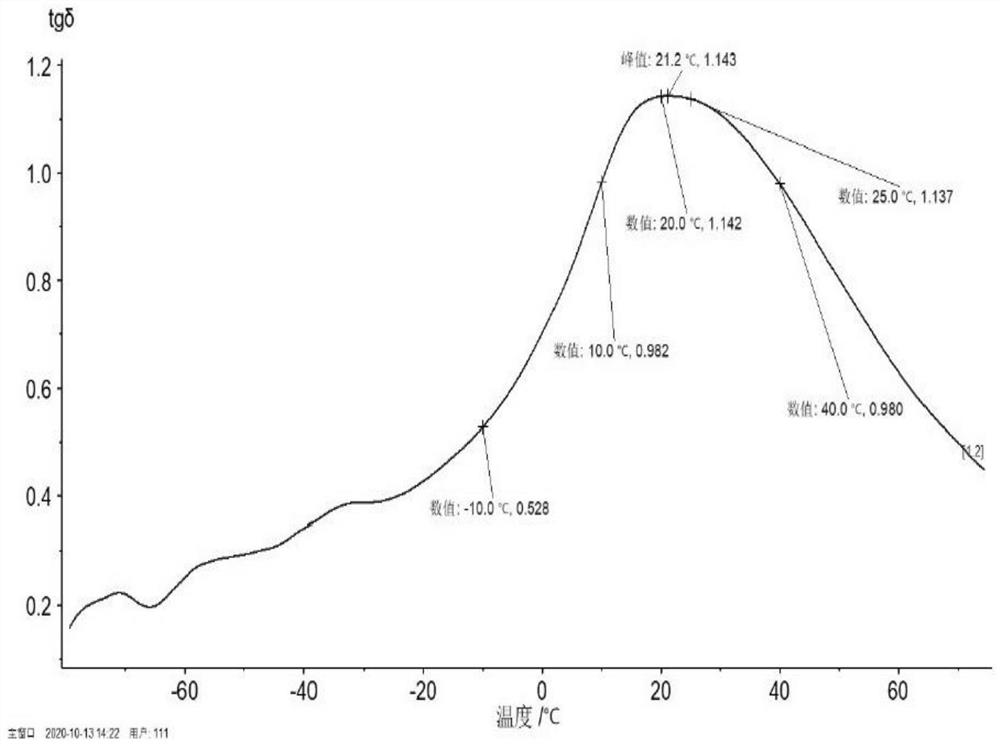

Interpenetrating network emulsion having high adhesive force to metal substrate material and synthetic method of interpenetrating network latex

The invention discloses an interpenetrating network emulsion having high adhesive force to a metal substrate material and a synthetic method of the interpenetrating network emulsion. The interpenetrating network emulsion is an interpenetrating network polymer with a core shell structure, and has a solid content of 30-45%; the core of the interpenetrating network polymer with the core shell structure is formed by virtue of polymerization between a nuclear layer monomer and a crosslinking monomer under the action of an initiator; and the shell of the interpenetrating network polymer with the core shell structure is formed by virtue of polymerization between a shell layer monomer and a phosphate functional monomer under the action of an initiator. The emulsion synthesized by the method disclosed by the invention has the following advantages: (1) the adhesive force to the metal substrate material is good; (2) the damping factor is high and can reach a maximum value of 1.3; and (3) the emulsion has a core shell structure of an interpenetrating network.

Owner:SHANGHAI UNIV

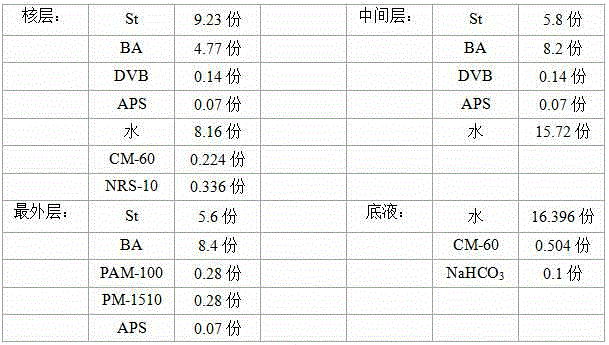

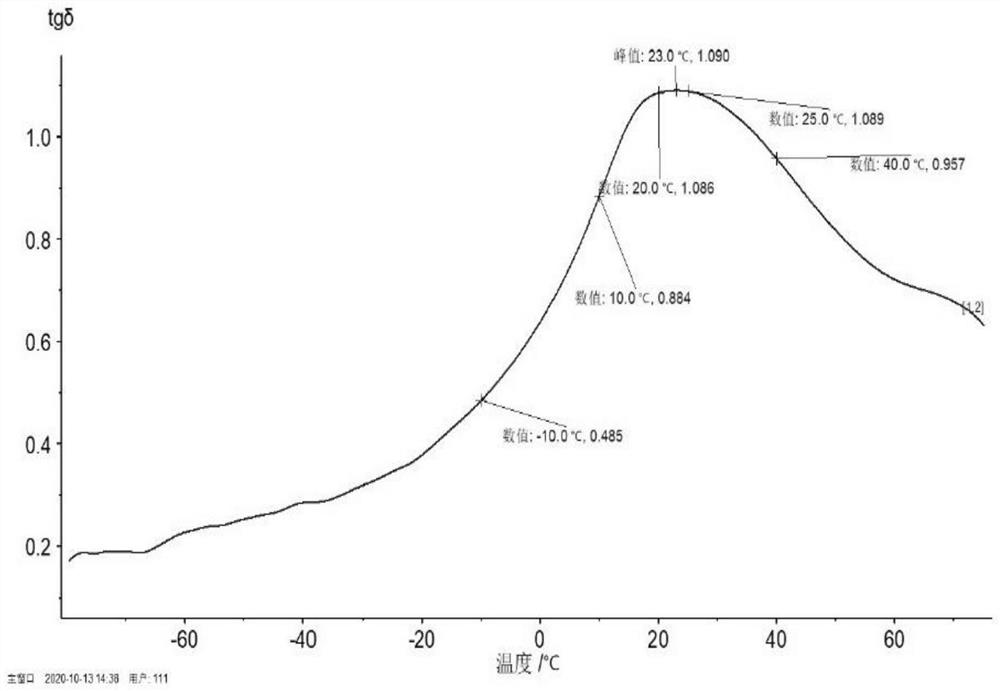

Three-layer core-shell structure interpenetrating network emulsion having high adhesion force to metal substrate and synthesis method of emulsion

The invention relates to a three-layer core-shell structure interpenetrating network emulsion having high adhesion force to metal substrate and a synthesis method of the emulsion. The content of a solid in the three-layer core-shell structure interpenetrating network emulsion is 30-45%; the core of the three-layer core-shell structure interpenetrating network polymer is prepared by polymerizing a core layer monomer and a cross-linking monomer in the presence of an initiator; an interlayer of the three-layer core-shell structure interpenetrating network polymer is prepared by polymerizing an interlayer monomer and a cross-linking monomer in the presence of an initiator; and the outer layer shell of the three-layer core-shell structure interpenetrating network polymer is prepared by polymerizing an outer layer shell monomer and phosphate ester monomer in the presence of an initiator. The emulsion has the advantages of good adhesion force to the metal substrate, wide effective damping temperature range (tan sigma is greater than 0.3), high damping factor of which the maximum value reaches 1.2 and good film-forming property.

Owner:SHANGHAI UNIV

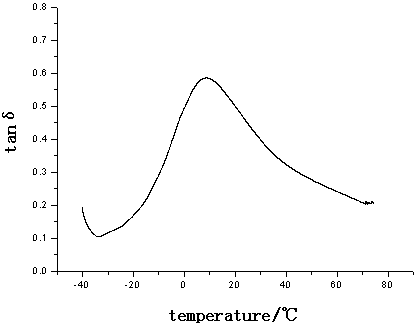

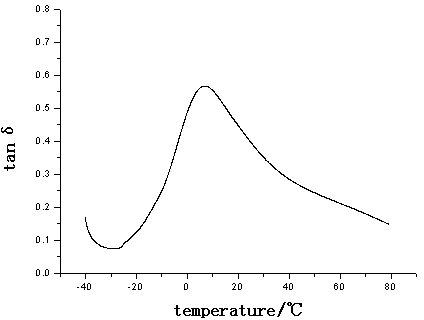

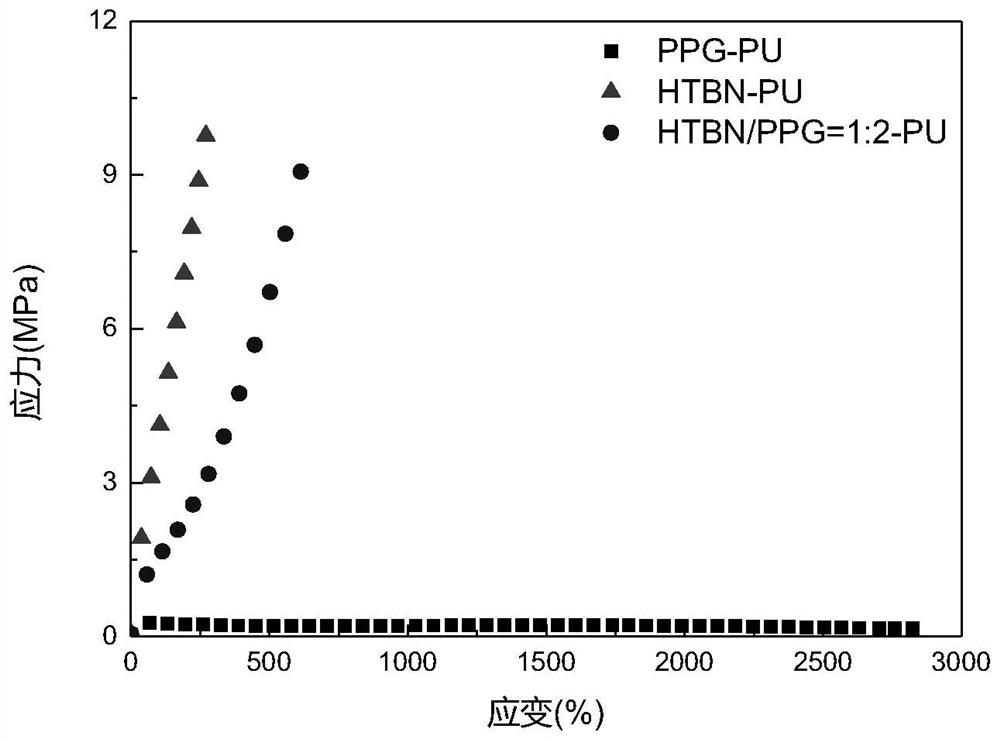

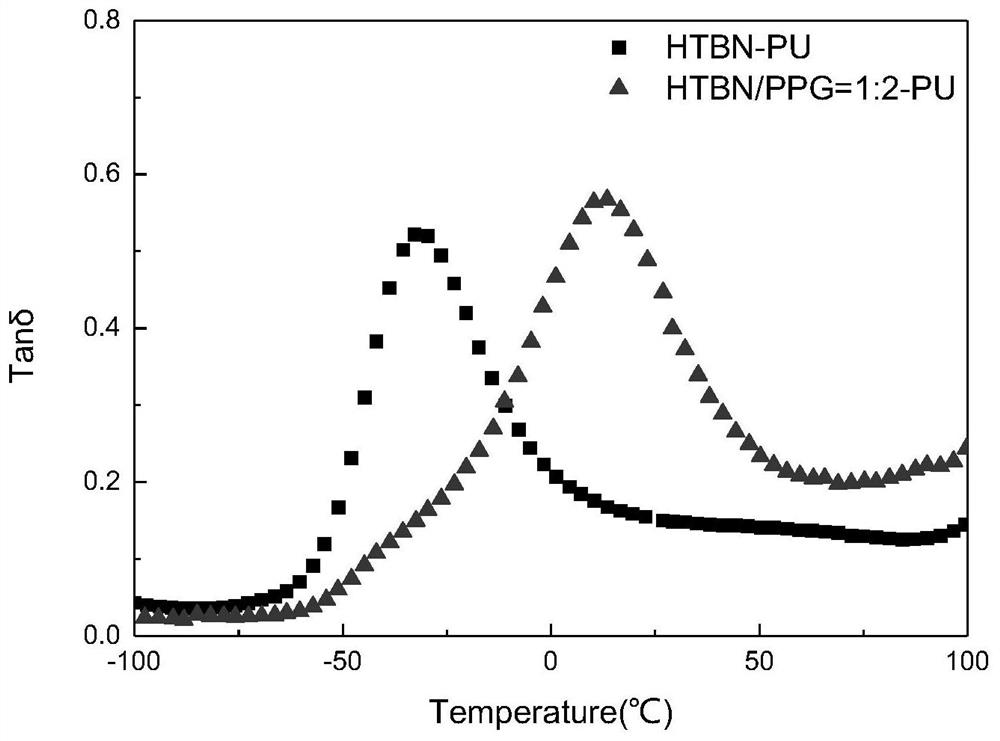

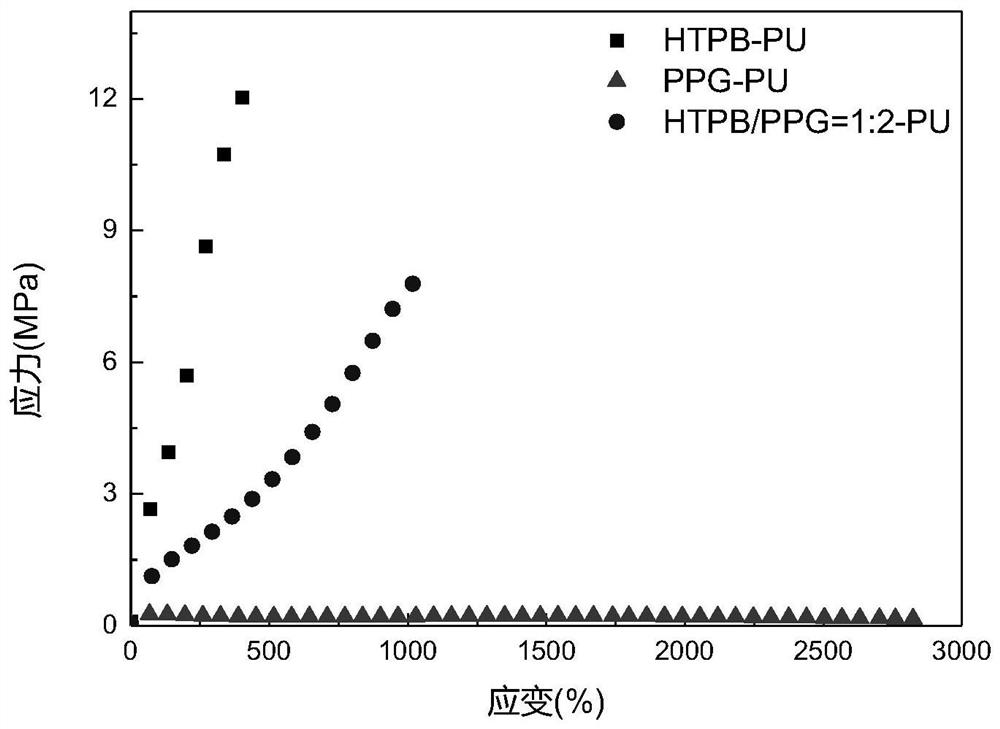

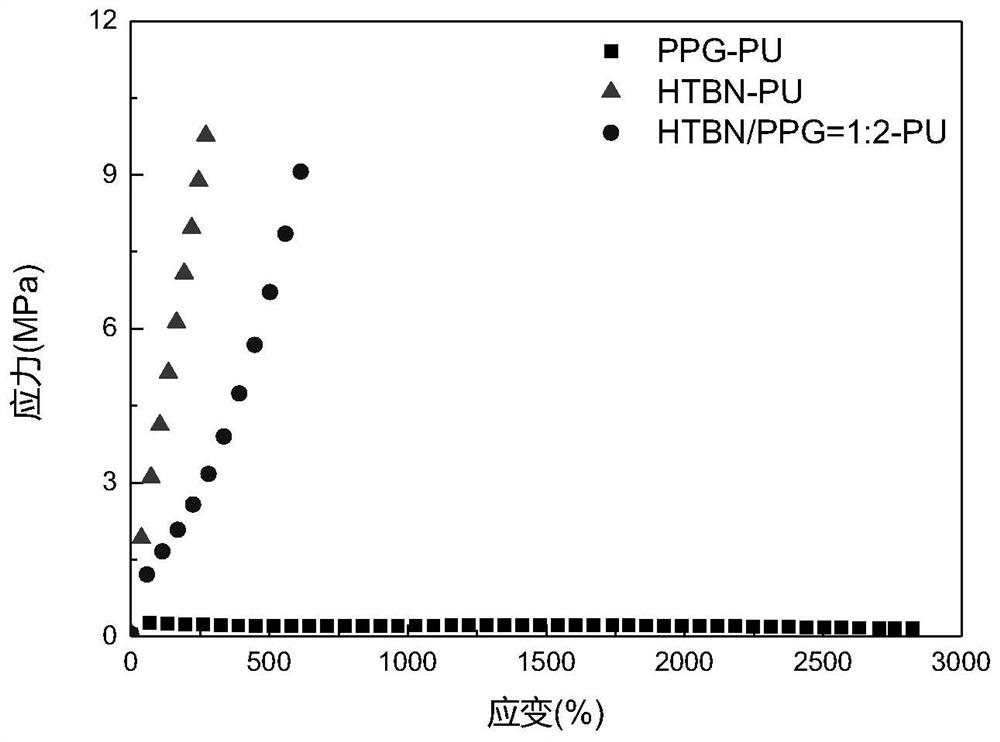

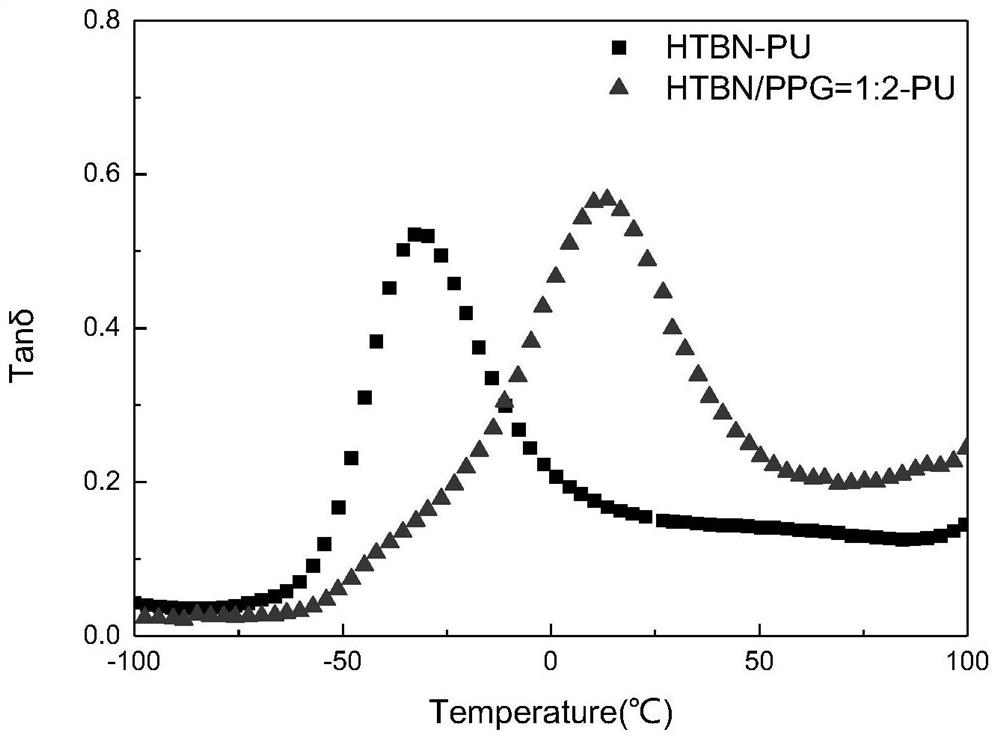

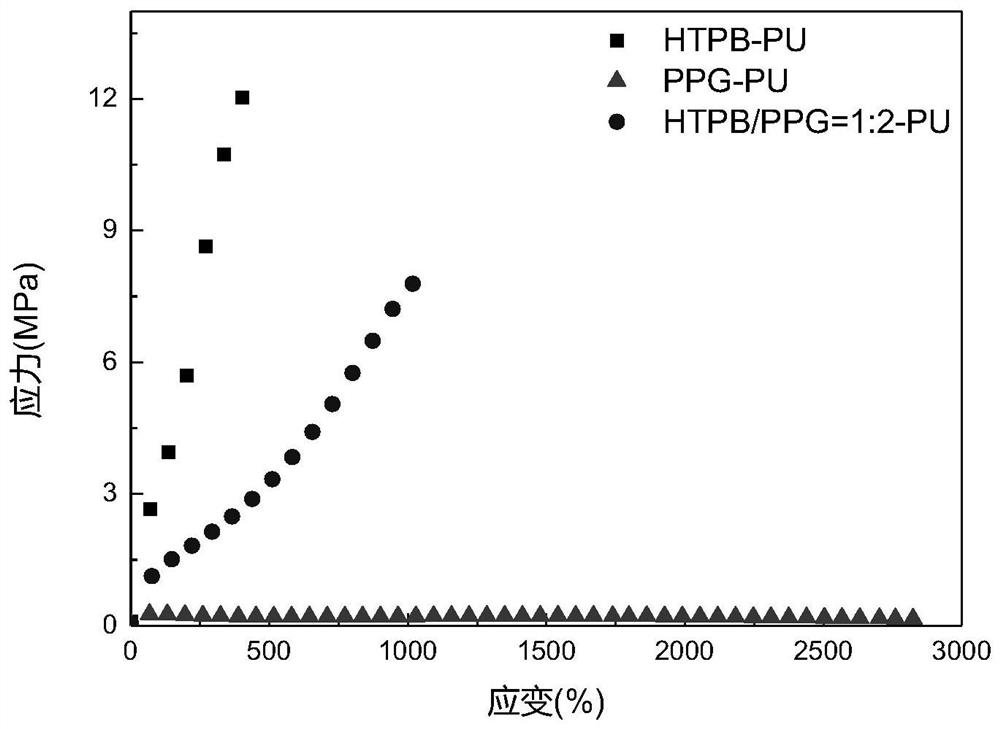

Mixed soft segment type polyurethane damping material and preparation method thereof

The invention provides a mixed soft segment type polyurethane damping material and a preparation method thereof. The soft segment of the polyurethane damping material comprises olefin oligomer dihydric alcohol and polyether dihydric alcohol. The preparation method comprises the following steps of uniformly mixing olefin oligomer dihydric alcohol and polyether dihydric alcohol, and carrying out a prepolymerization reaction with diisocyanate to obtain a biisocyanate-terminated prepolymer, and adding a chain extender into the obtained biisocyanate-terminated prepolymer, and carrying out a chain extension reaction to obtain the polyurethane damping material. The polyurethane damping material disclosed by the invention has excellent properties of two soft segments, the damping temperature rangeis improved compared with that of a single soft segment, and the polyurethane damping material has better hydrolysis resistance; meanwhile, the preparation method is simple, high in repeatability andbeneficial to industrial production.

Owner:BEIJING UNIV OF CHEM TECH

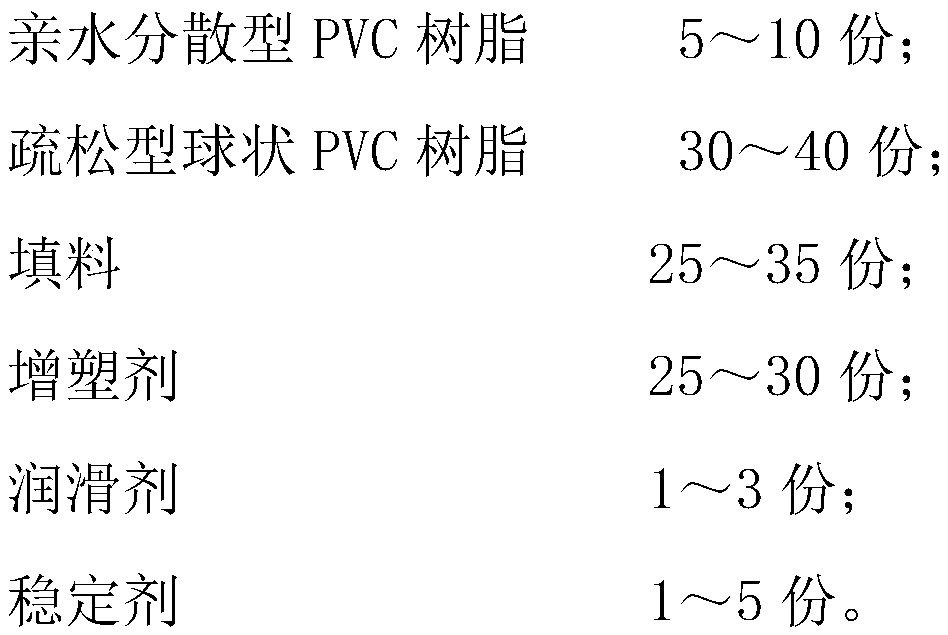

Damping composition containing hydrophilic dispersing type PVC resin and preparation method of damping composition

The invention discloses a damping composition containing hydrophilic dispersing type PVC resin. The damping composition containing the hydrophilic dispersing type PVC resin comprises the following components: the hydrophilic dispersing type PVC resin, loose type spherical PVC resin, filler, a plasticizer, a lubricating agent and a stabilizing agent. According to the damping composition, the loosetype spherical PVC resin is used as a matrix, and by the hydrophilic dispersing type PVC resin, a coating can be waterborne. The damping composition is in low VOC type, and has the advantages of environmental protection, mechanical spraying capability, good properties such as mechanical property and damping property and the like.

Owner:HUBEI UNIV

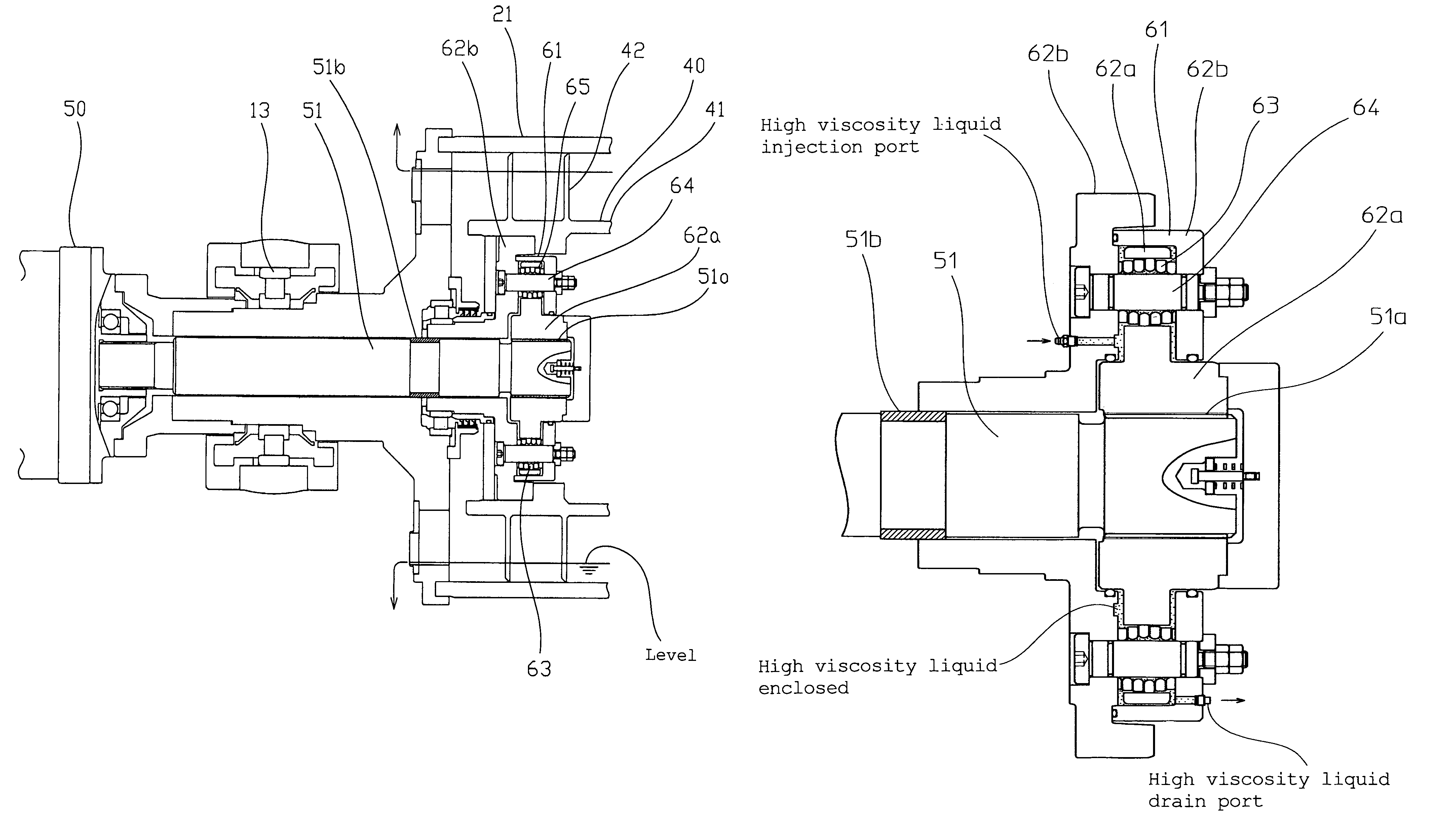

Decanter type centrifugal separator with torque transmission mechanism

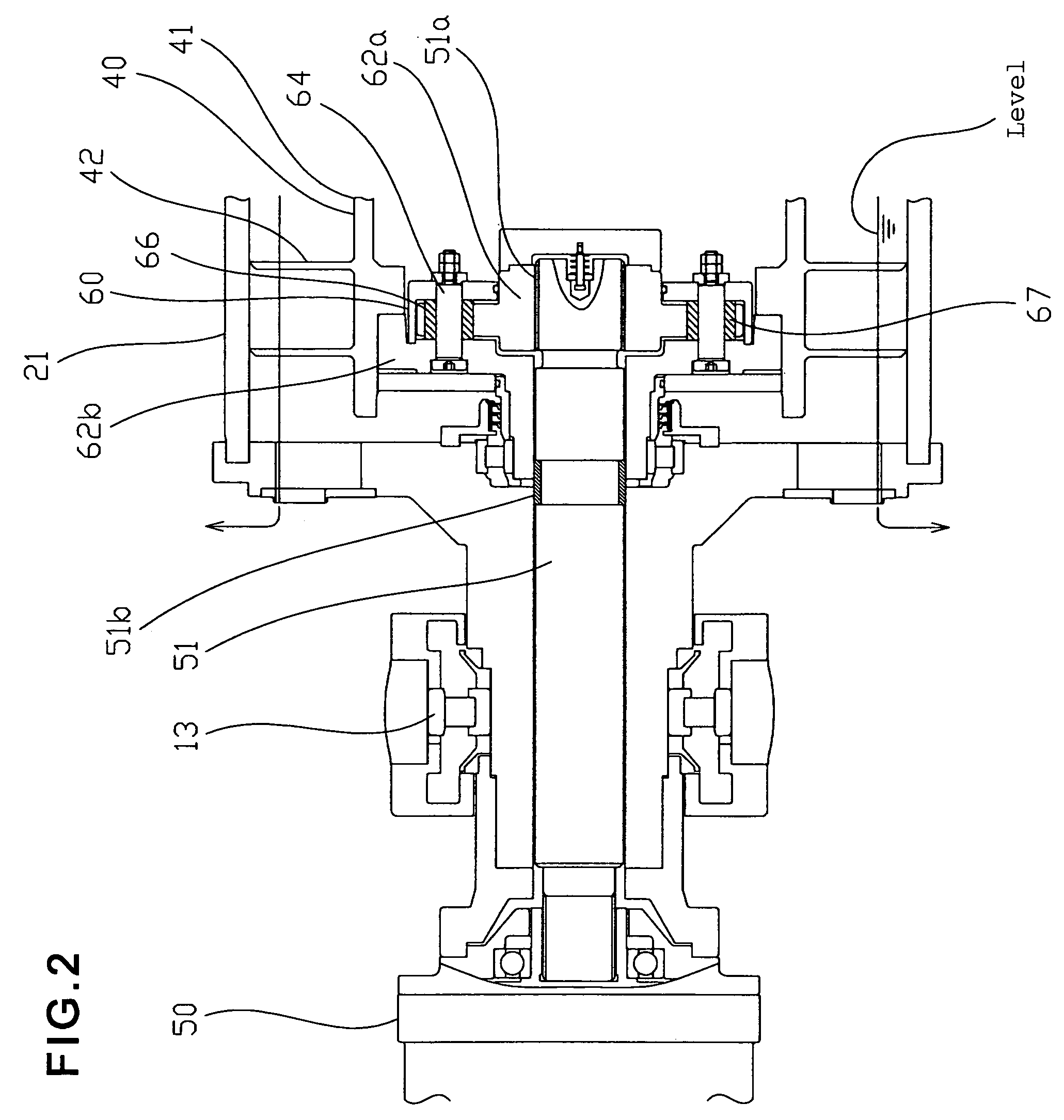

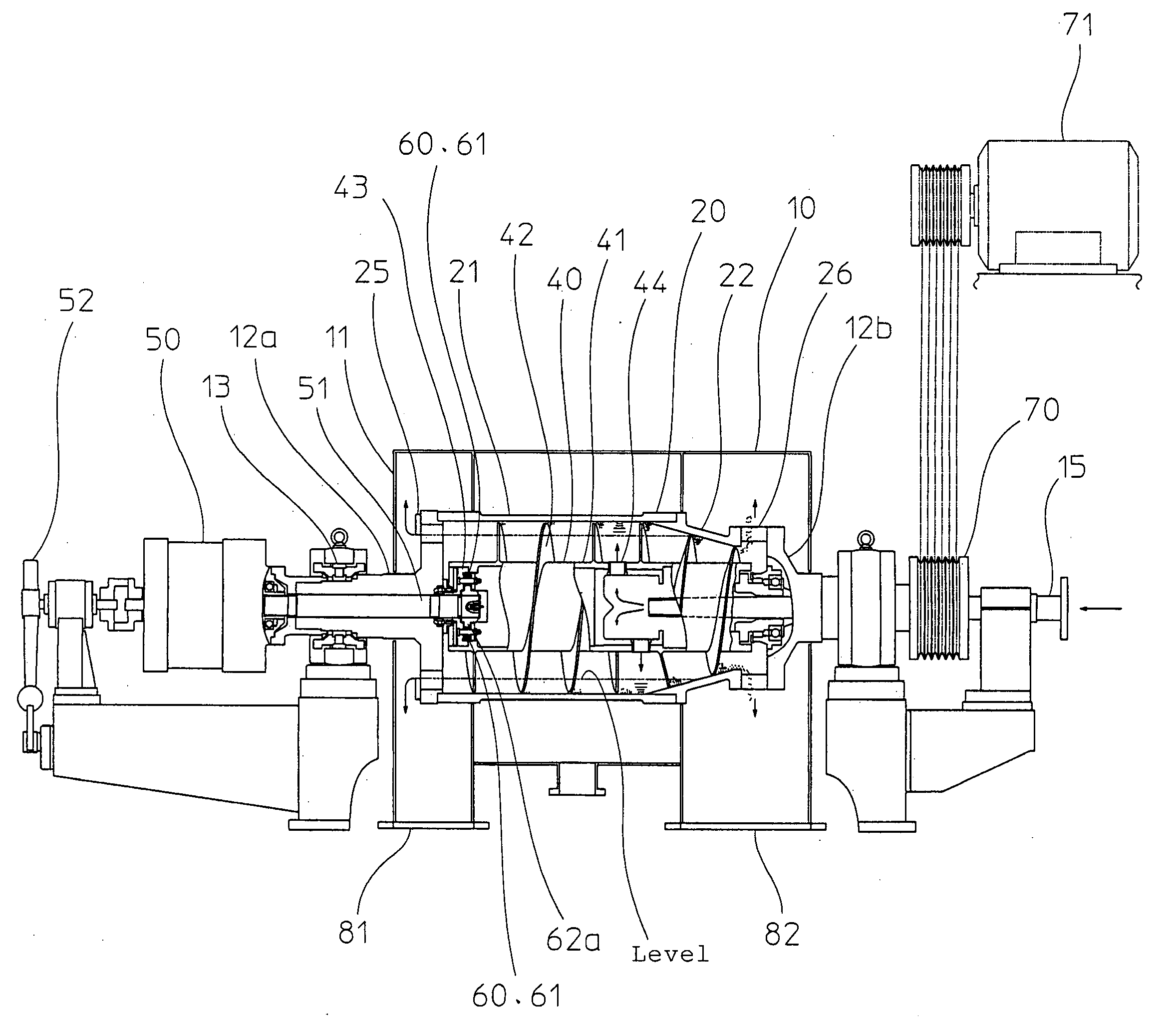

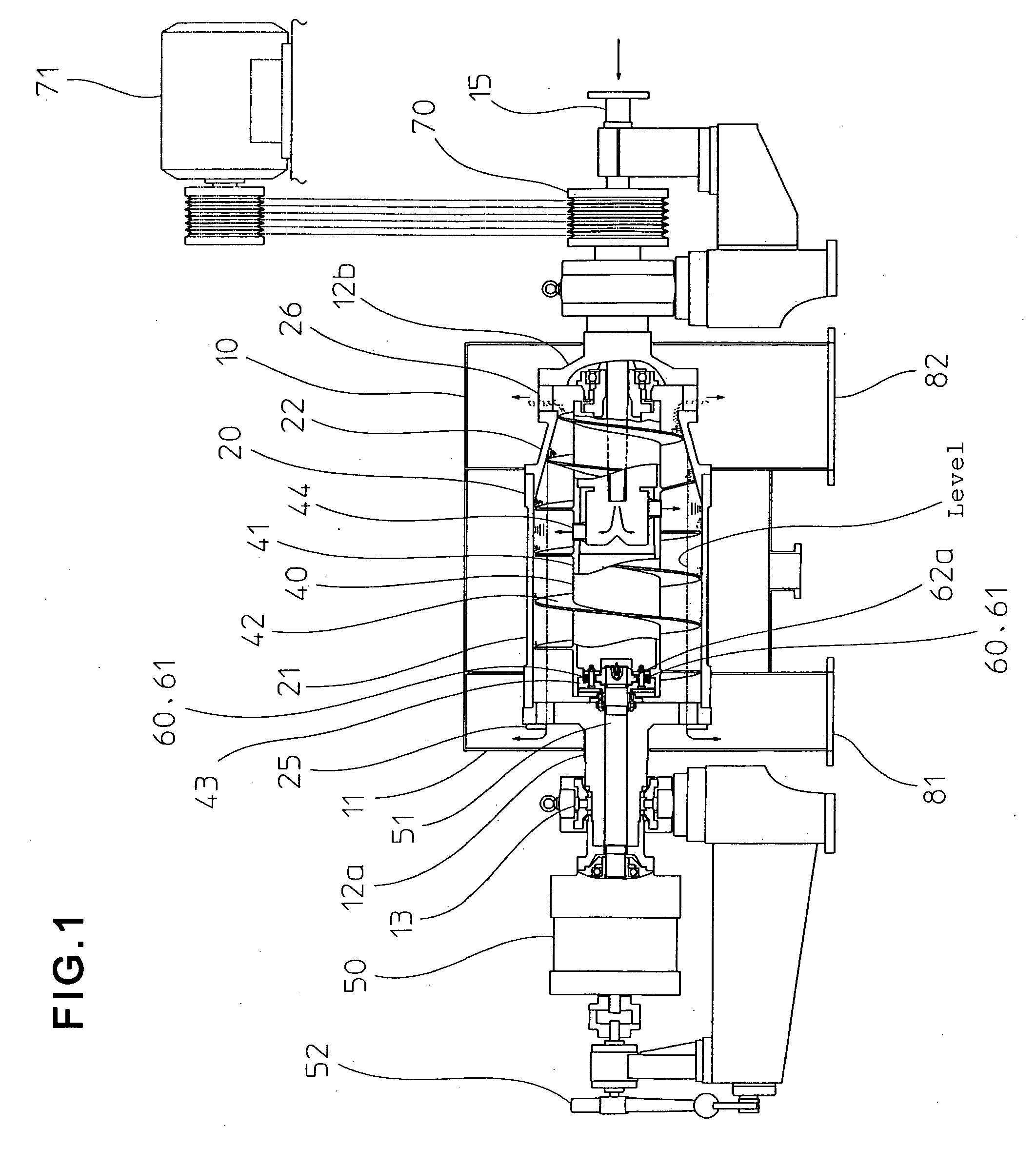

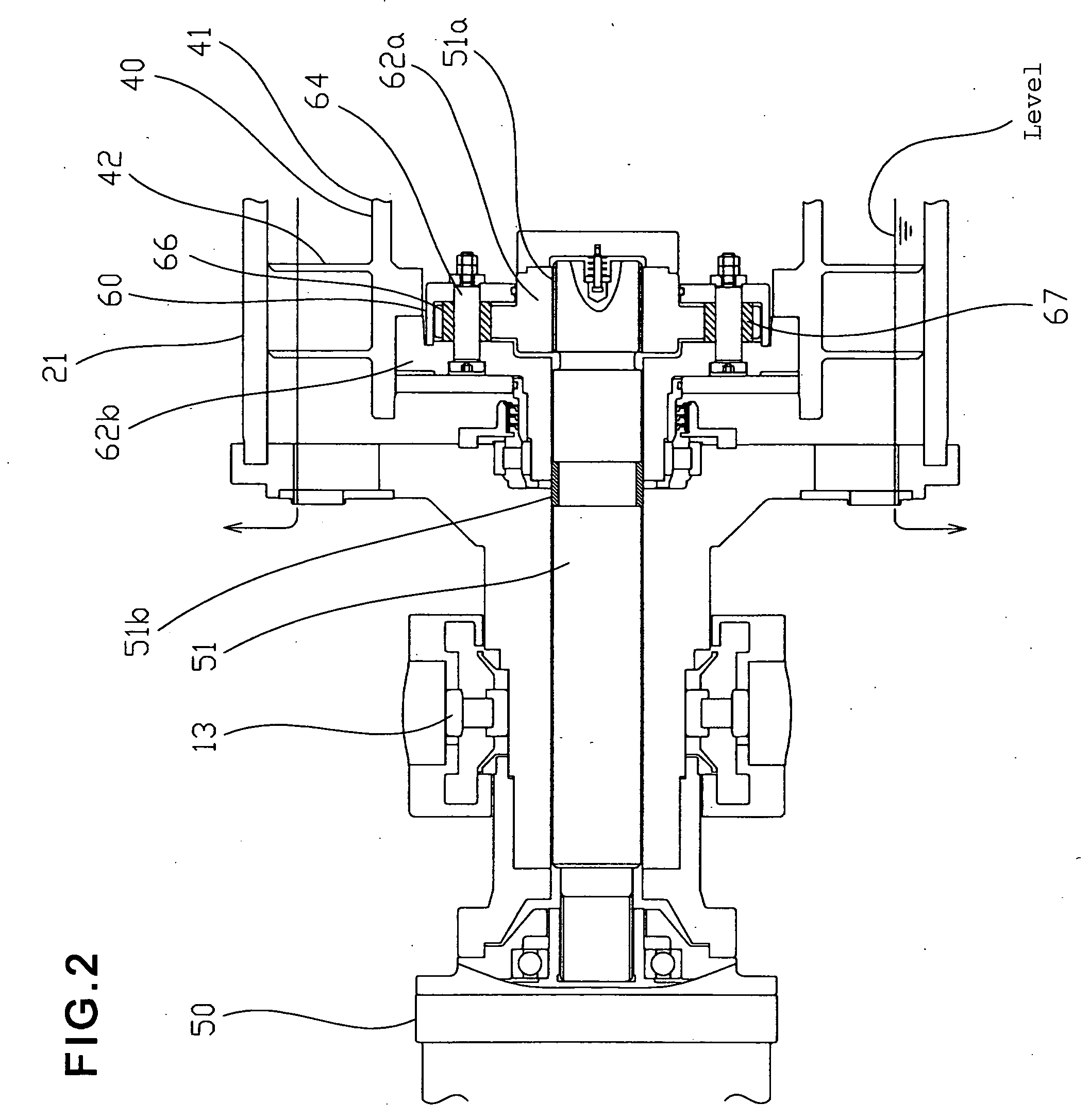

ActiveUS7670276B2Reduce absorptionReduce impactRotary centrifugesTorque transmissionTorsional vibration

A decanter type centrifugal separator includes a torque transmission mechanism with enhanced effect of absorbing a torsional vibration. The decanter type centrifugal separator (10) includes a bowl (20); a screw conveyor (40) disposed in the bowl (20); a processed liquid feed portion (15); a separated liquid discharge port (81); a solid discharge port (82); a drive portion (71); and a differential gear unit (50) for generating a difference in speeds between the bowl (20) and the screw conveyor (40). A torque transmission mechanism (60, 61) includes an elastic damping member (67) for absorbing the torsional vibration of the screw conveyor (40).

Owner:TOMOE ENGINEERING CO LTD

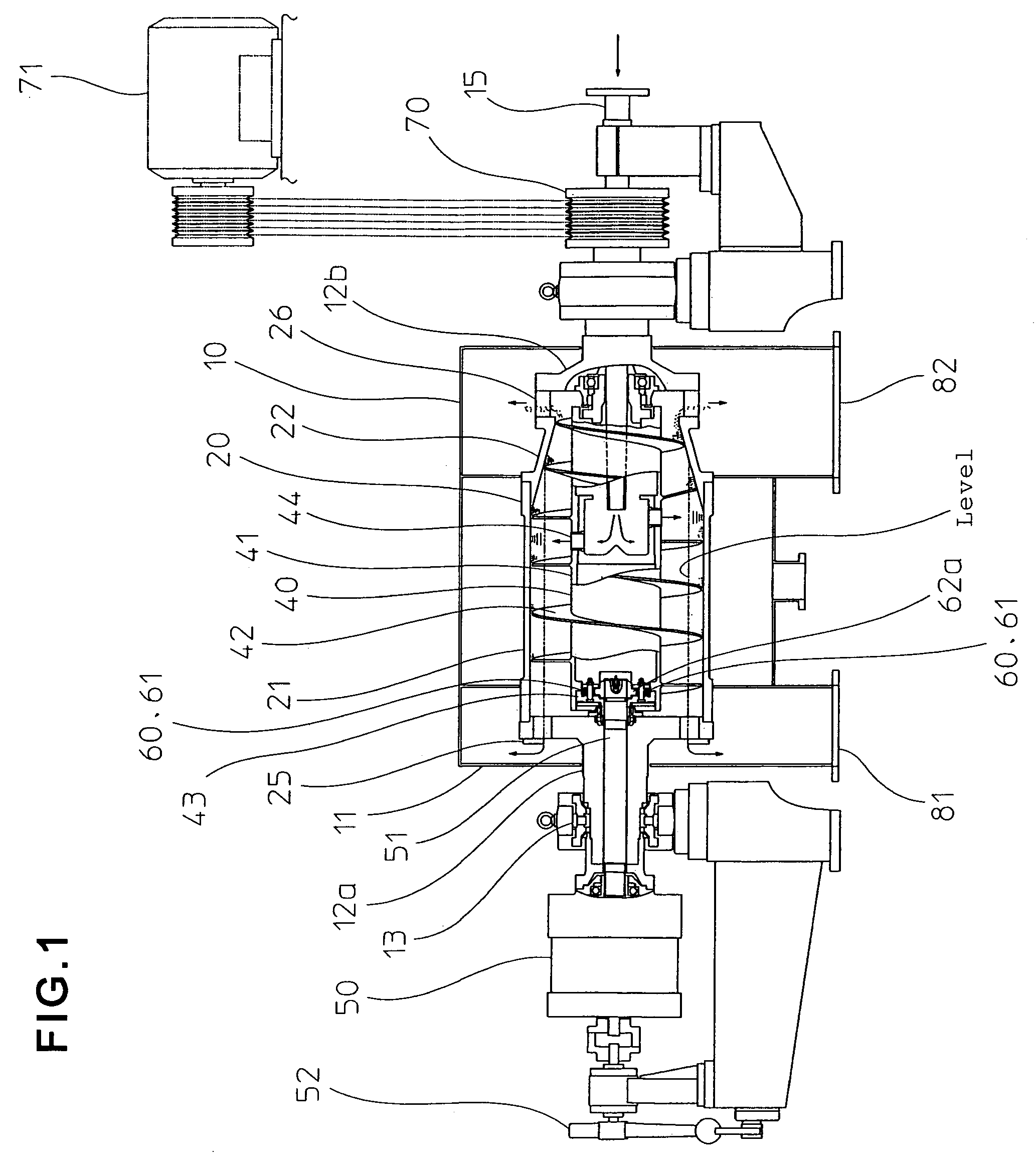

Decanter type centrifugal separator

ActiveUS20090233781A1Increase degree of dampingHigh viscosityRotary centrifugesSelf excitedDrive shaft

A decanter type centrifugal separator includes a torque transmission mechanism with enhanced effect of absorbing a torsional vibration. The decanter type centrifugal separator (10) includes a bowl (20) having a cylindrical part (21), a conical part (22), a separated liquid discharge dam part (25), and a dewatered solid discharge port (26); a screw conveyor (40) disposed in the bowl (20) for axially conveying sedimentation solid, and arranged to be coaxial with the bowl (20) to be rotatable at a speed different from that of the bowl (20); a processed liquid feed means (15); a separated liquid discharge port (81); a solid discharge port (82); a drive means (71); and a differential gear unit (50) for generating a difference in speeds between the bowl (20) and the screw conveyor (40). A torque transmission mechanism (60, 61) includes an elastic damping member (67) for receiving a drive force transmission load on a torque transmission surface (66) of a joint flange part (62a, 62b) formed in a joint part (43) of a drive transmission shaft (51) as a source of torsional vibration generation on a side of the screw conveyor (40) between the differential gear unit (50) and the screw conveyor (40) in order to provide flexibility in a direction of rotation and an effect of damping the torsional self-excited vibration in small angles in forward and backward directions generated during transmission of drive force, thereby absorbing the torsional self-excited vibration of the screw conveyor (40) generated during conveyance of treatment substances due to a minute difference in speeds between the bowl (20) and the screw conveyor (40).

Owner:TOMOE ENGINEERING CO LTD

Preparation method of damping material

ActiveCN105568429ASimple preparation stepsWide temperature rangeArtificial filament chemical after-treatmentDamping factorSlurry

The invention discloses a preparation method of a damping material, and belongs to the technical field of preparation of damping materials. The method comprises the following steps: collecting maple slurry and mixing the maple slurry with a spider web; dewatering with concentrated sulfuric acid, and removing impurities to obtain a carbide; stewing the carbide and adding an organic matter in the stewing process; when a jelly is formed, taking out the jelly and spinning while hot; and washing a filament through a potassium permanganate solution, a nitric acid solution, a hydrogen peroxide solution and clean water in sequence, and then carrying out spinning, charring and irradiation to obtain the damping material. The preparation method has the beneficial effects that the preparation steps are simple; the obtained product is wide in temperature range of -60 DEG C to 220 DEG C; the damping factor is high; and the damping and vibration-reducing performance is good.

Owner:广州联洪合成材料有限公司

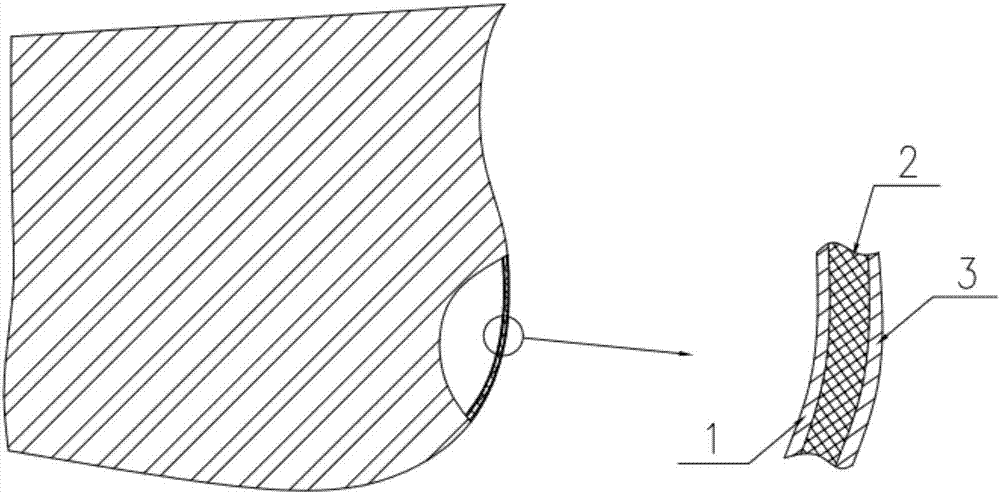

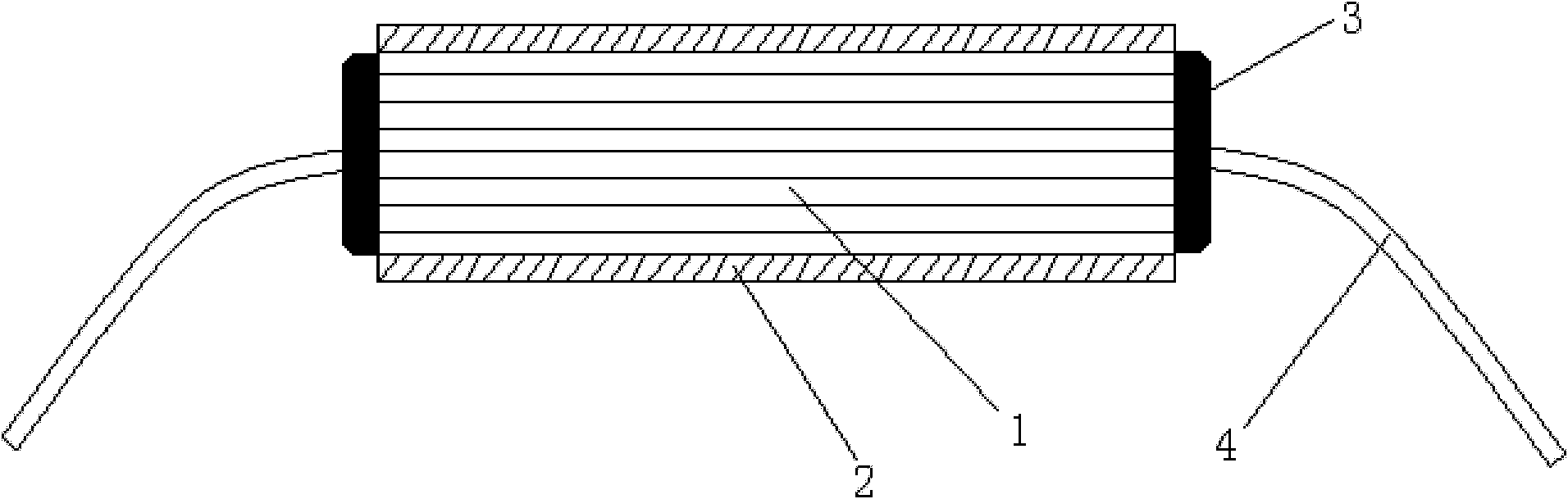

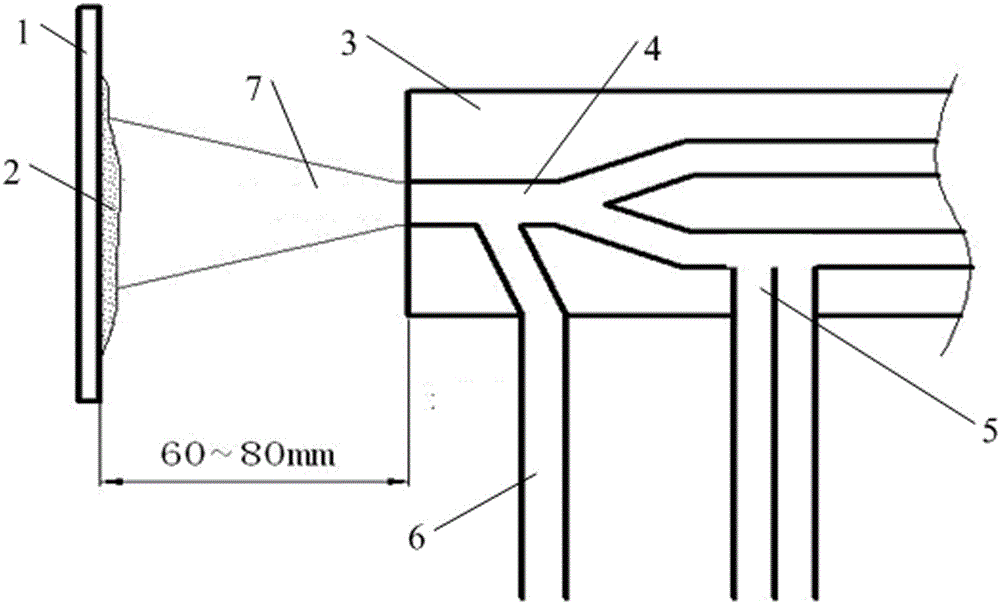

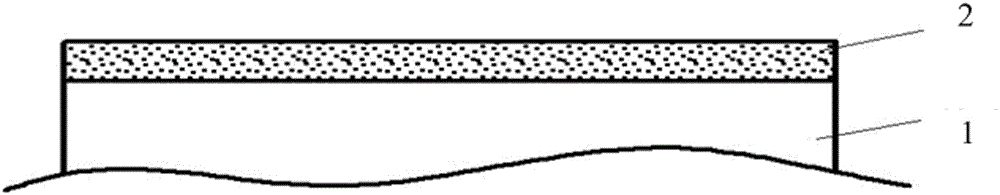

Sandwich type acoustic window structure of ship dome

PendingCN107128032AReduce vibrationSelf noise reductionSynthetic resin layered productsVessel partsDamping factorAlloy

The invention provides a sandwich type acoustic window structure form of a ship dome. A main body is of a sandwich structure and comprises an inner constraint surface layer, an outer constraint surface layer and a sandwich, wherein the material of the constraint surface layers is a fiber enhanced resin-based composite material or a titanium alloy; the material of a core layer is a viscoelastic material; the constraint surface layers are tightly stuck with the core layer. According to the sandwich type acoustic transmission window structure form provided by the invention, requirements of the structure in the aspects of strength and acoustic characteristics are comprehensively considered; after the structure strength is met, the sandwich type acoustic window structure form has good sound transmission performance, small insertion loss, great damping factors and high specific strength; self noise generated under the excitation of surface turbulent fluctuation are reduced so that signal interference, caused by flow noises, on a sonar antenna is reduced.

Owner:哈尔滨工程大学船舶装备科技有限公司

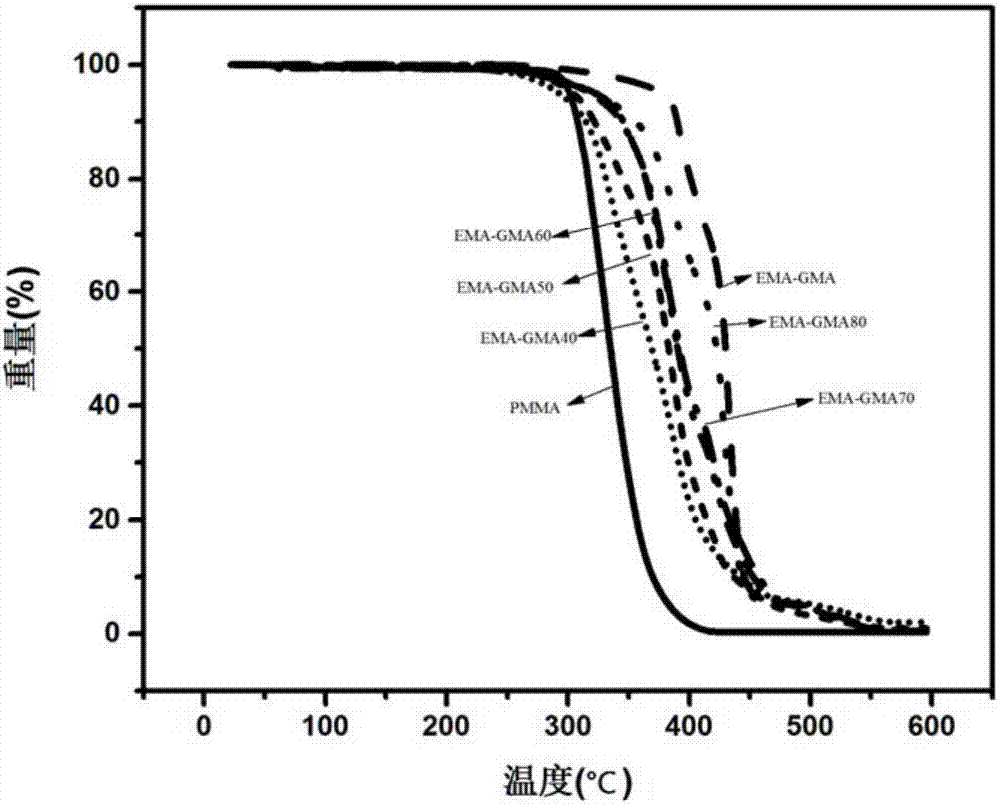

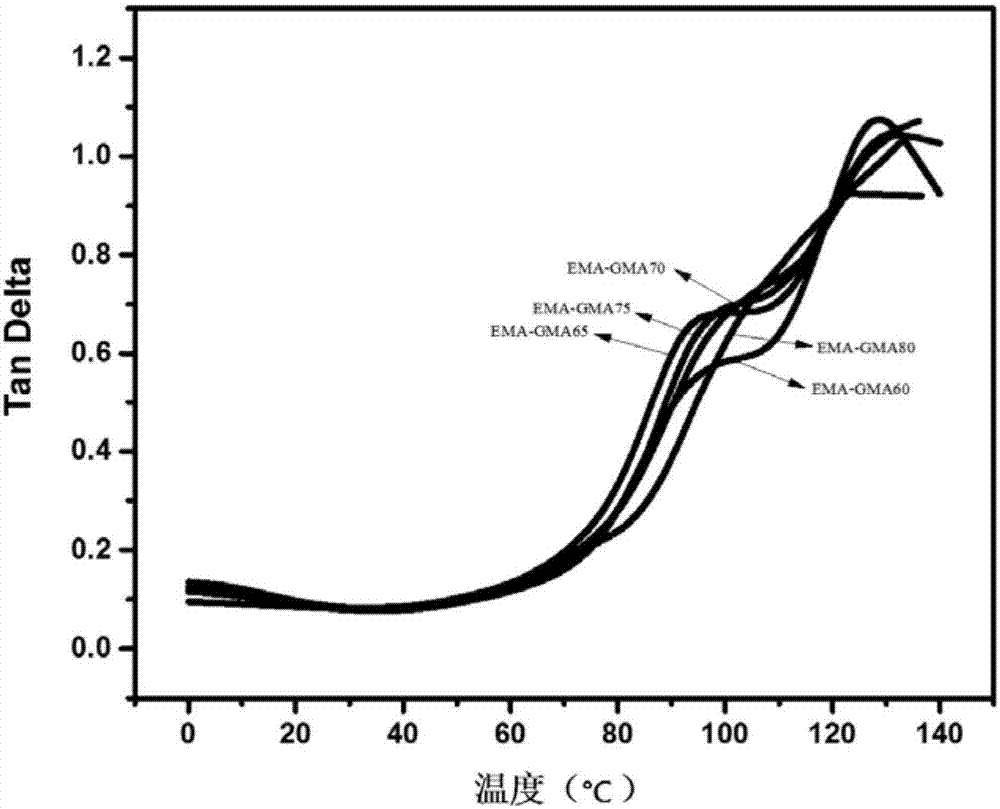

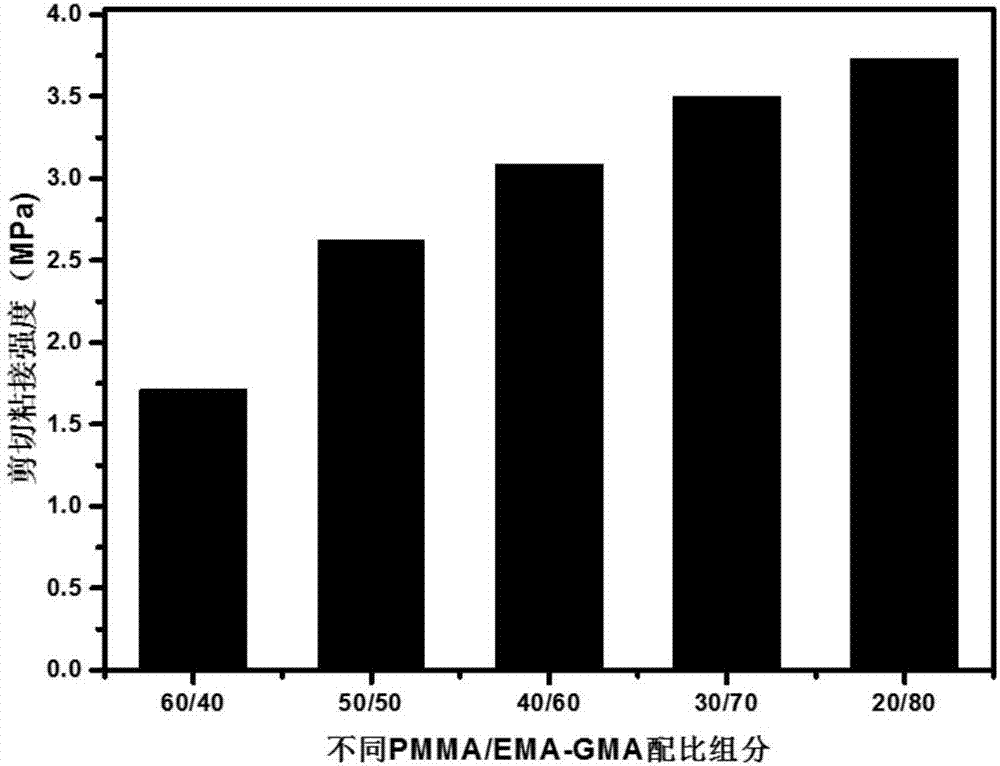

High-temperature resistant high-performance damping adhesive and preparation method thereof

InactiveCN106957624AHigh Shear Peel StrengthHigh damping factorFilm/foil adhesivesEster polymer adhesivesDamping factorGlycidyl methacrylate

The invention discloses a high-temperature resistant high-performance damping adhesive. Polymethyl methacrylate and an ethylene-methyl acrylate-glycidyl methacrylate random terpolymer are melted and mixed evenly by adopting a conventional melting and mixing mode, or an obtained blend is pressed at a high temperature through a conventional method to obtain a damping adhesive film. The decomposition temperature of the obtained damping adhesive is greater than 300 DEG C and the film is clamped between two steel plates and is pressed at high temperature and high pressure to prepare a constrained damping steel plate; and the damping factor Tandelta is greater than 0.3 and the shear and peel strength is greater than 3MPa at 75-140 DEG C. The obtained damping adhesive is high-temperature resistant, and also has excellent properties such as a large damping factor, a wide effective damping temperature range, good adhesion and high shear and peel strength; meanwhile, the problems that a solvent is needed in preparation of a traditional adhesive and secondary solidification is needed in use are solved; and the high-temperature resistant high-performance damping adhesive is especially suitable for bonding of an automotive damping steel plate.

Owner:SICHUAN UNIV

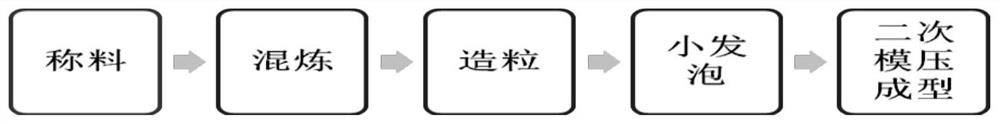

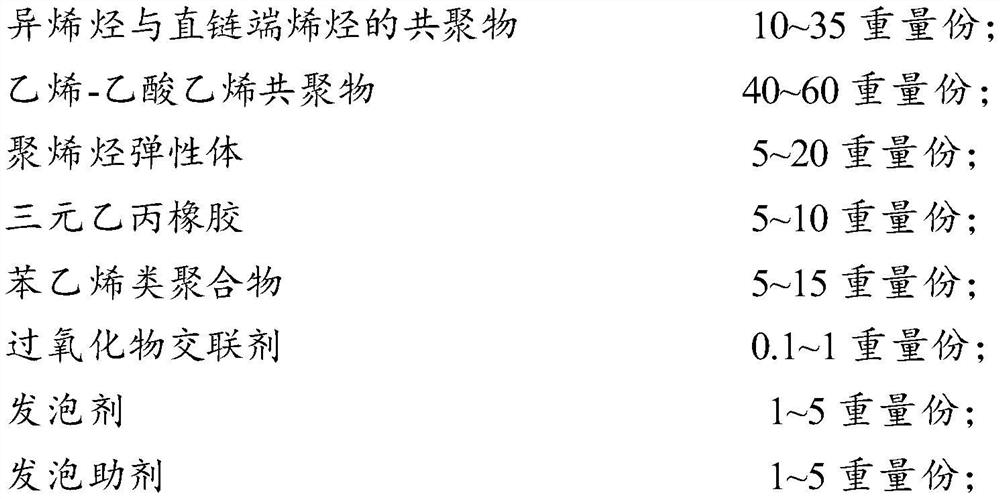

Super-absorption high-resilience foaming material as well as preparation method and application thereof

The invention provides a super-absorption high-resilience foaming material which is formed by a foaming composition, wherein the foaming composition comprises 10-35 parts by weight of a copolymer of isoolefin and linear-chain-end olefin; 40-60 parts by weight of an ethylene-vinyl acetate copolymer; 5-20 parts by weight of a polyolefin elastomer; 5-10 parts by weight of ethylene propylene diene monomer; 5-15 parts by weight of a styrene polymer; 0.1 to 1 part by weight of a peroxide cross-linking agent; 1-5 parts by weight of a foaming agent; and 1-5 parts by weight of a foaming aid; wherein the carbon atom number of the isoolefin is 5-8; and the number of carbon atoms of the straight-chain end olefin is 2-4. Compared with the prior art, after a copolymer of a stress absorption polymer isoolefin and a straight chain end olefin with relatively large steric hindrance and a high-elastic polymer are blended and foamed, the high-elastic damping material which has excellent stress absorbability, stress relaxation and damping effects at room temperature is obtained, wherein the rebound rate of the foaming material is kept to be greater than 50%.

Owner:ANTA CHINA

1-3 composite piezoelectric fiber/polymer composite damping material and preparation method thereof

InactiveCN102163689AEasy to test impedance characteristicsHigh damping factorPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionDamping factorFiber

The invention relates to a 1-3 composite PZT (piezoelectric) fiber / polymer composite damping material and a preparation method thereof, belonging to the field of composite materials. The composite damping material comprises a plurality of PZT fibers polarized along the length direction and a polymer layer coated outside the PZT fibers, and two ends of each PZT fiber are connected with an externalresistor via electrodes led out of the two ends; and the resistance of external resistor is determined according to the formula (I). The PZT property can be obtained by adopting the polarization method along the length direction of the PZT fibers, the external matching resistor is connected in the way of leading out the electrodes via organic conductive silver paste, under the condition that the damping property of the composite damping material is matched with external impedance, the damping factor can be improved by 0.1; under the condition of increasing the applied force, the damping factor can be improved; the greater the storage modulus difference between an organic matter matrix and the PZT fibers is, the more obvious the damping effect is; and the composite damping material can be used as a vibration-damping and noise-reducing material to be applied in the fields of trains, vehicles and the like.

Owner:TONGJI UNIV

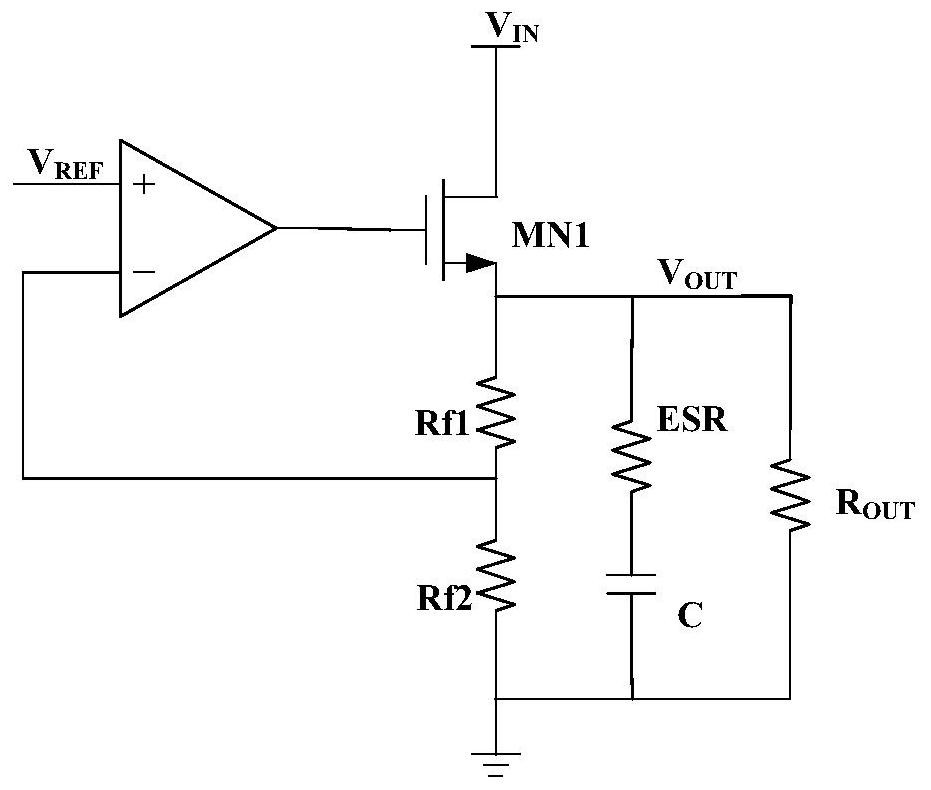

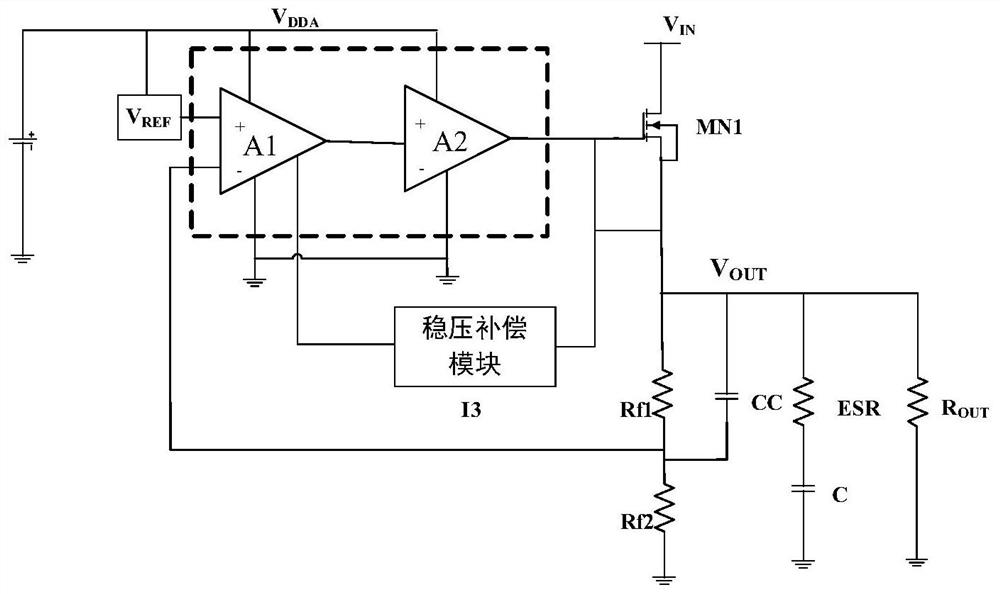

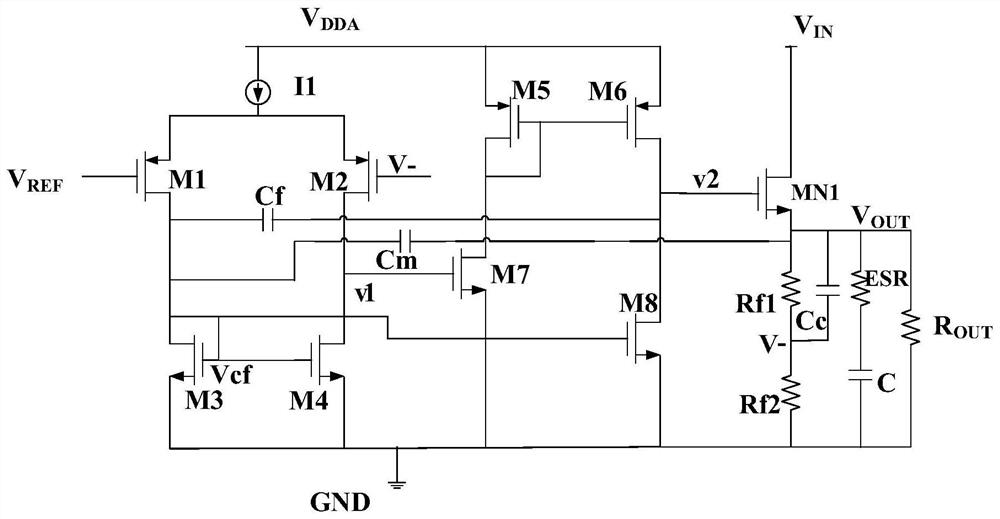

Low dropout linear regulator circuit

ActiveCN111665895BGuaranteed stabilityGuaranteed performance gainElectric variable regulationLinear regulatorCapacitance

The present invention provides a low-dropout linear voltage regulator circuit, comprising: a first power transistor with a first source, a first drain and a first gate, the first drain is connected to a voltage input terminal, the The first source is connected to the voltage output terminal; the multi-stage amplifier has a first-stage amplifier and a second-stage amplifier, the second-stage amplifier is the rear stage of the first-stage amplifier, and the output end of the second-stage amplifier connected to the first gate; the voltage stabilization compensation module includes a first compensation capacitor and a second compensation capacitor, the first end of the first compensation capacitor is connected to the first node of the first stage amplifier, the The second end of the first compensation capacitor is connected to the first gate, the first end of the second compensation capacitor is connected to the first node of the first-stage amplifier, and the second end of the second compensation capacitor connected to the first source.

Owner:JLQ TECH CO LTD

A kind of hybrid soft segment type polyurethane damping material and preparation method thereof

The invention provides a mixed soft segment polyurethane damping material and a preparation method thereof. The soft segment of the polyurethane damping material includes olefin oligomer diol and polyether diol. The preparation method includes uniformly mixing olefin oligomer diol and polyether diol, and then prepolymerizing with diisocyanate to obtain a diisocyanate-capped prepolymer; A chain extender is added to the prepolymer at the end, and the polyurethane damping material is obtained through chain extension reaction. The polyurethane damping material of the present invention has both the excellent properties of the two soft segments, and the damping temperature range is improved compared with a single soft segment, and has better hydrolysis resistance; at the same time, the preparation method is simple and repeatable, which is beneficial to industrial production .

Owner:BEIJING UNIV OF CHEM TECH

A kind of preparation method of curing agent for medium and high temperature damping polyurethane

ActiveCN107383304BImprove high temperature stabilityImproved high temperature damping performanceDamping factorSide chain

The invention discloses a preparation method of a curing agent for high temperature damping polyurethane. The dinitrogen bisfluorene in the structure comprises a special large spatial configuration; the spatial configuration, as a side chain of a polymer, can strengthen the friction steric hindrance between molecular chains, meanwhile, the fused heterocycle structure containing pyridine and the like is utilized to improve the proportion of a rigid segment of polyurethane, so that the damping performance of a polyurethane material in the high temperature environment and the stability of the damping performance are improved. The prepared curing agent is applied to the curing of a polyurethane resin, compared with the traditional curing agent, the curing agent increases the glass transition temperature of the polyurethane material and the damping factor at the medium-high temperature, expands the damping temperature range of the material, and improves the damping performance of the material in the medium-high temperature environment.

Owner:FUZHOU UNIV

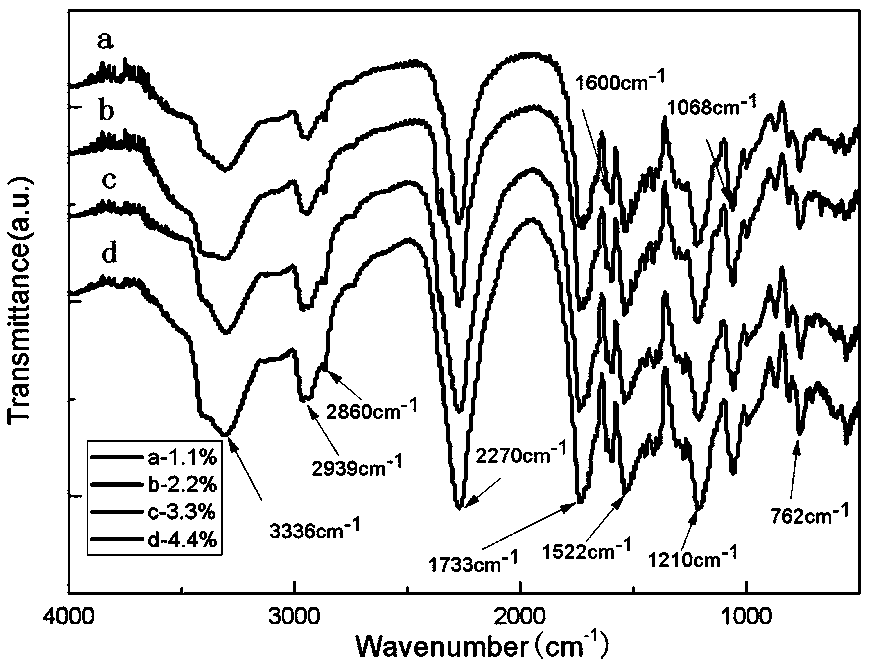

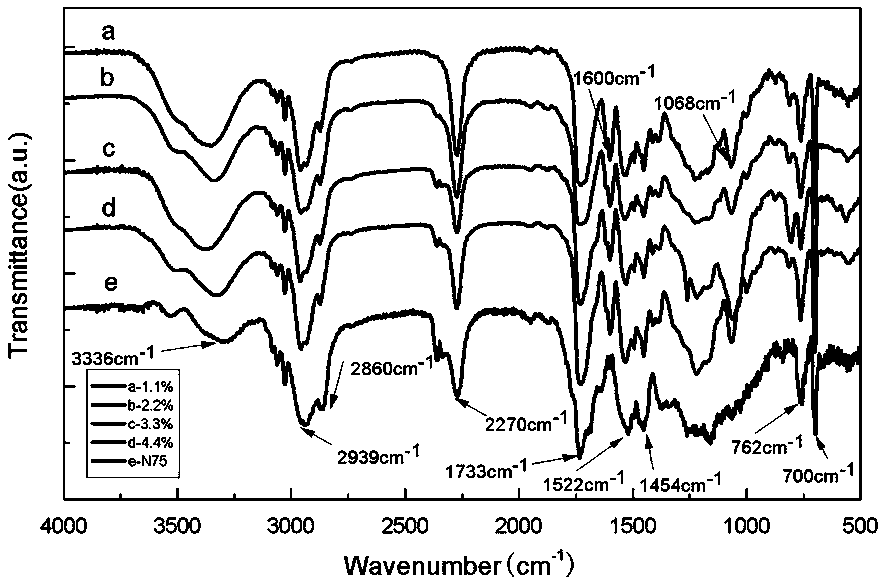

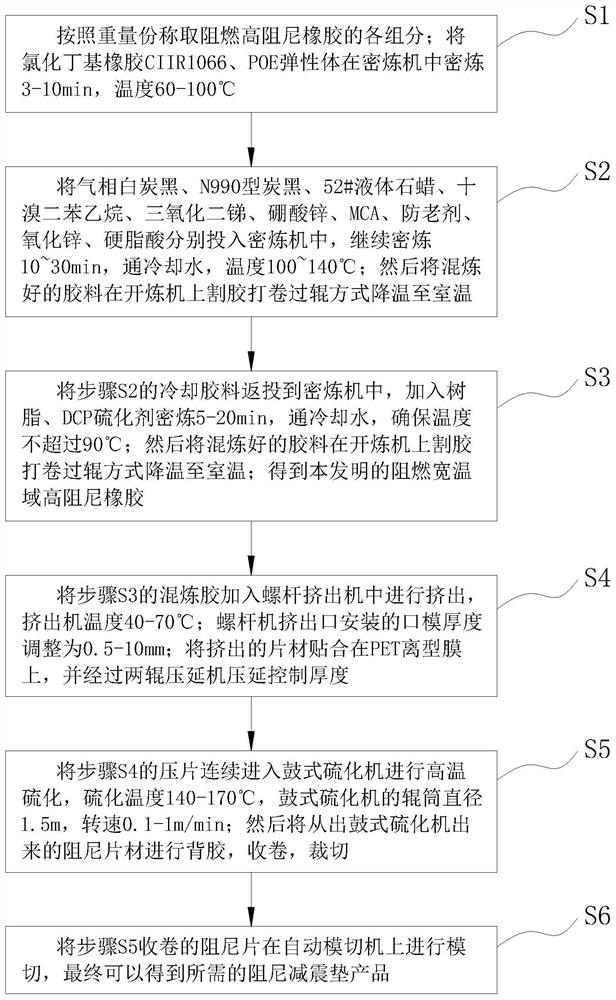

Flame-retardant high-damping rubber and preparation method of damping shock pad of flame-retardant high-damping rubber

The invention is suitable for the technical field of damping materials, and provides flame-retardant high-damping rubber and a preparation method of a damping shock pad thereof. Chlorinated butyl rubber CIIR1066, a POE elastomer, white carbon black, N990 type carbon black, 52 # liquid paraffin, decabromodiphenyl ethane, antimony trioxide, zinc borate, MCA, an anti-aging agent 1076, an anti-aging agent 2246, zinc oxide, stearic acid, resin and a DCP vulcanizing agent are adopted as ingredients to prepare the flame-retardant high-damping rubber. Through optimization design of components and contents thereof of the damping material, a rubber composition the flame retardance of which can reach UL94-V0 level, and which has a wide temperature range and high damping performance can be obtained. The damping material is wide in use temperature range, high in damping factor, good in flame retardance and aging resistance and good in mechanical property.

Owner:SHENZHEN LEPUTAI TECH CO LTD

A method for preparing a ceramic damping coating on the surface of a thin shell member of a rotating machine

ActiveCN103572192BImprove bindingWide temperature range for dampingMolten spray coatingThin shellsHydrogen

A method for preparing ceramic damping coating on the surface of thin shell components of rotating machinery, which belongs to the field of material technology and is carried out according to the following steps: (1) Mix MgO and Al2O3 by ball milling to make mixed powder, screen the parts with 60 to 80 mesh, and dry and remove them moisture to make ceramic coating material; install it into the powder feeding device of the atmospheric plasma spraying machine; (2) Use the rotating mechanical thin shell component as the base body to remove oil stains and impurities and place it on the workbench of the atmospheric plasma spraying machine; (3) Start the atmospheric plasma spraying machine, pass argon and hydrogen into the spray gun, turn on the power of the atmospheric plasma spraying machine, and generate plasma; (4) Feed powder through the powder feeding device and start spraying, and spray on the substrate Forms a ceramic damping coating. The invention is suitable for improving the damping capacity of thin-shell components of rotating machinery, improving the dynamic characteristics of parts, and reducing the possibility of vibration damage and failure.

Owner:NORTHEASTERN UNIV LIAONING

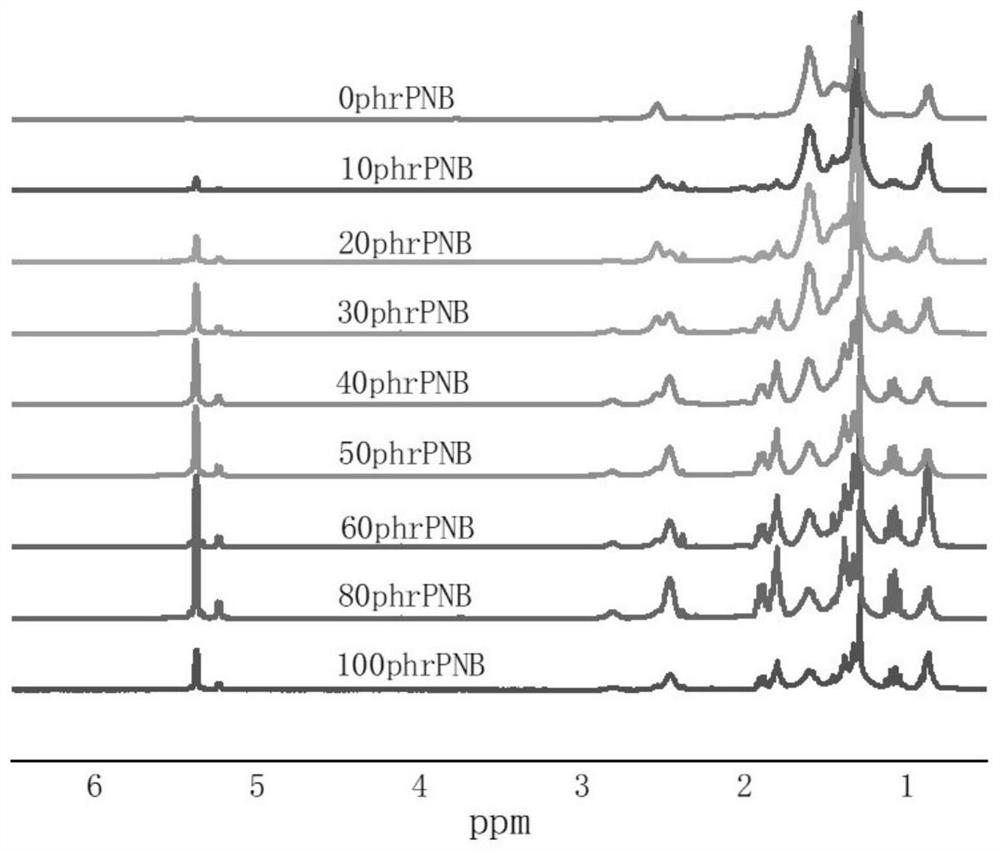

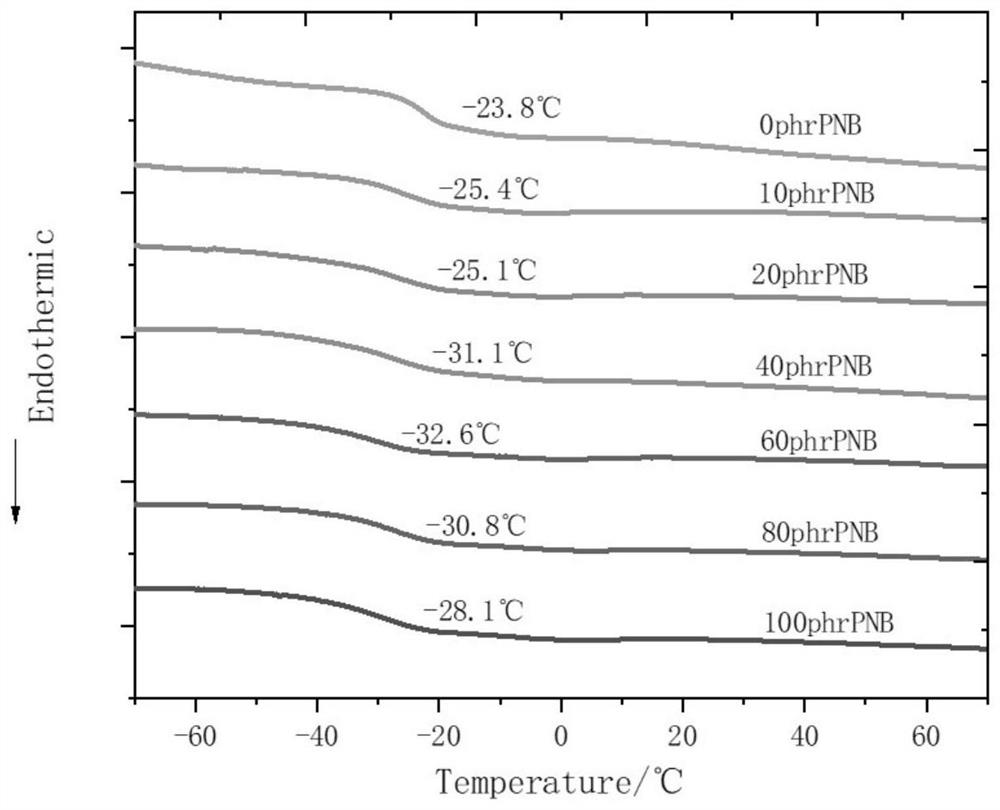

A kind of modified hydrogenated nitrile rubber material and its preparation method and application

The invention belongs to the technical field of rubber, and in particular relates to a modified hydrogenated nitrile rubber material with the characteristics of low temperature resistance and high damping, as well as its preparation method and application. The modified hydrogenated nitrile butadiene rubber material is prepared from HNBR / PNB block copolymer as a raw material; the HNBR / PNB block copolymer uses norbornene monomer as a modifying agent, through olefin metathesis reaction to NBR Or modified by HNBR. The resulting block copolymer has both the performance characteristics of HNBR and PNB, not only maintaining the basic properties of hydrogenated nitrile rubber, but also using polynorbornene to absorb a large amount of plasticizing oil, and then obtaining an improved low temperature resistant performance. permanent hydrogenated nitrile rubber material. At the same time, the damping performance of the obtained modified HNBR material is also significantly improved due to the cyclic structure of polynorbornene.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of polyurethane elastomer for steel rail energy consumption piece, polyurethane elastomer and energy consumption part

PendingCN113831492AExtended service lifeFast curing timeRailway tracksPolyurethane elastomerPolymer science

The invention provides a preparation method of a polyurethane elastomer for a steel rail energy dissipation piece, the polyurethane elastomer and the energy dissipation piece. The method comprises the following steps: preparing a component A, namely, reacting 20-30 parts by weight of MDI-50 with 80-90 parts by weight of polyether polyol to form a polyurethane prepolymer; preparing a component B, namely, uniformly mixing 130-160 parts by weight of polyether polyol, 90-120 parts by weight of a first filler, 0.5-1.2 parts by weight of a chain extender and a proper amount of an additive, and then performing vacuum dehydration at 100-120 DEG C until the moisture is less than 0.05% to obtain the component B; and adding the component B into the component A which is heated to 40-50 DEG C, uniformly conducting stirring, and conducting vulcanizing at 20-60 DEG C for multiple days to obtain the polyurethane elastomer.

Owner:BEIJING JIUZHOUYIGUI SHOCK & VIBRATION ISOLATION

A kind of preparation method of damping material

ActiveCN105568429BSimple preparation stepsWide temperature rangeArtificial filament chemical after-treatmentDamping factorSlurry

Owner:广州联洪合成材料有限公司

A kind of high damping, low luster nylon 6/abs alloy material and preparation method thereof

The present invention relates to high-damping, low-gloss nylon 6 / ABS alloy material and a preparation method thereof. The high-damping, low-gloss nylon 6 / ABS alloy material is made of a raw material composition, and the raw material composition includes: PA6 resin 40~ 50 parts by weight, ABS resin 1 20~25 parts by weight, ABS resin 2 15~25 parts by weight, polyolefin elastomer 2~5 parts by weight, maleic anhydride grafted polyolefin elastomer 1~5 parts by weight, compatibilizer 4-8 parts by weight, 0.2-0.6 parts by weight of antioxidant, 0.2-0.6 parts by weight of lubricant, the particle size of the ABS resin 1 is 500-1000 nm, and the particle size of the ABS resin 2 is 100-300 nm. The PA6 / ABS alloy material prepared by the invention has high damping coefficient and excellent noise reduction effect; it also has ultra-low gloss, is non-toxic and environment-friendly, and is beneficial to material recovery; it fills a gap in the market and has extremely high added value.

Owner:重庆会通科技有限公司

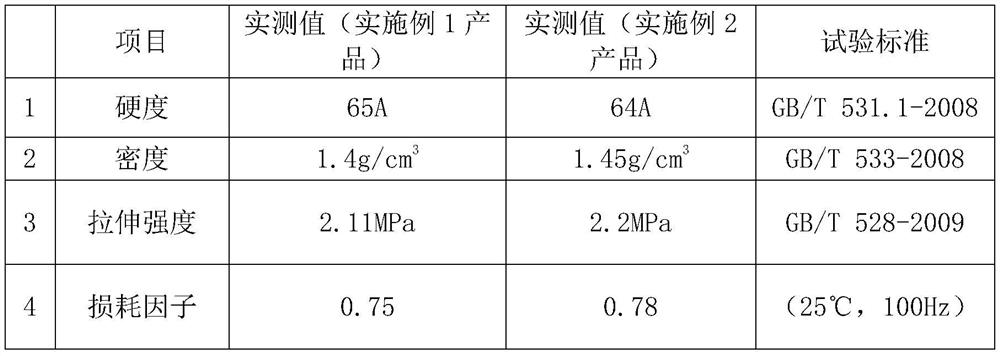

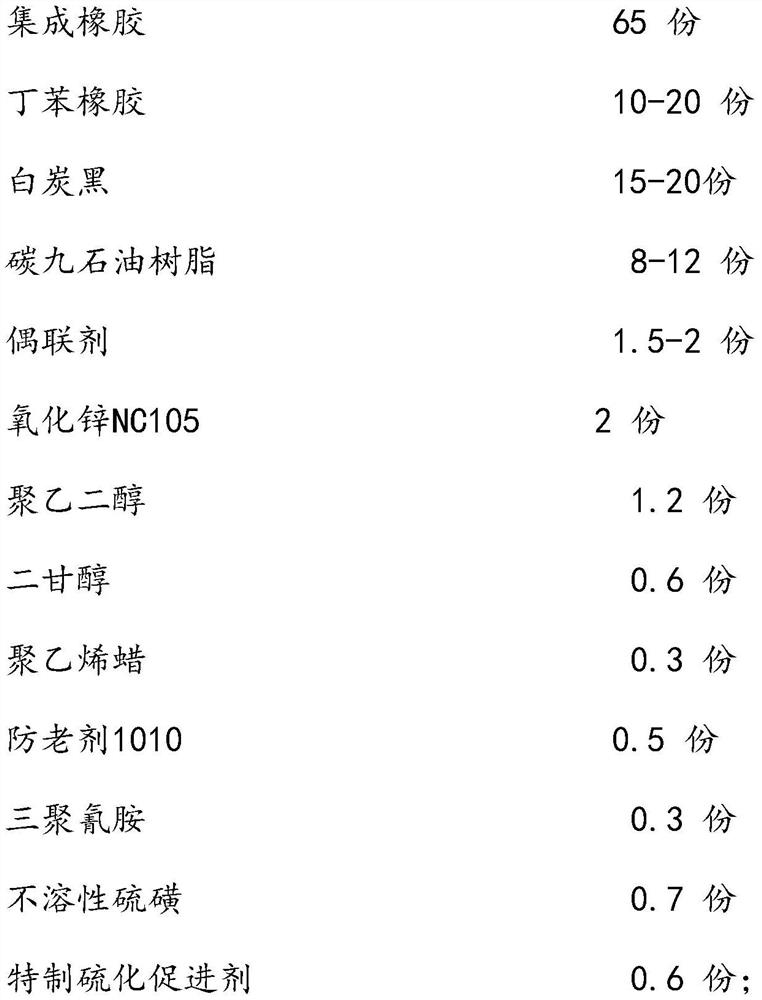

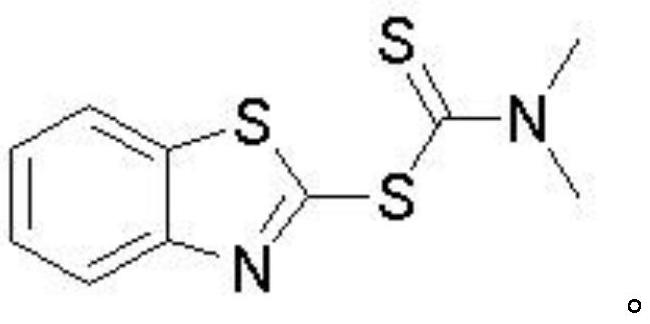

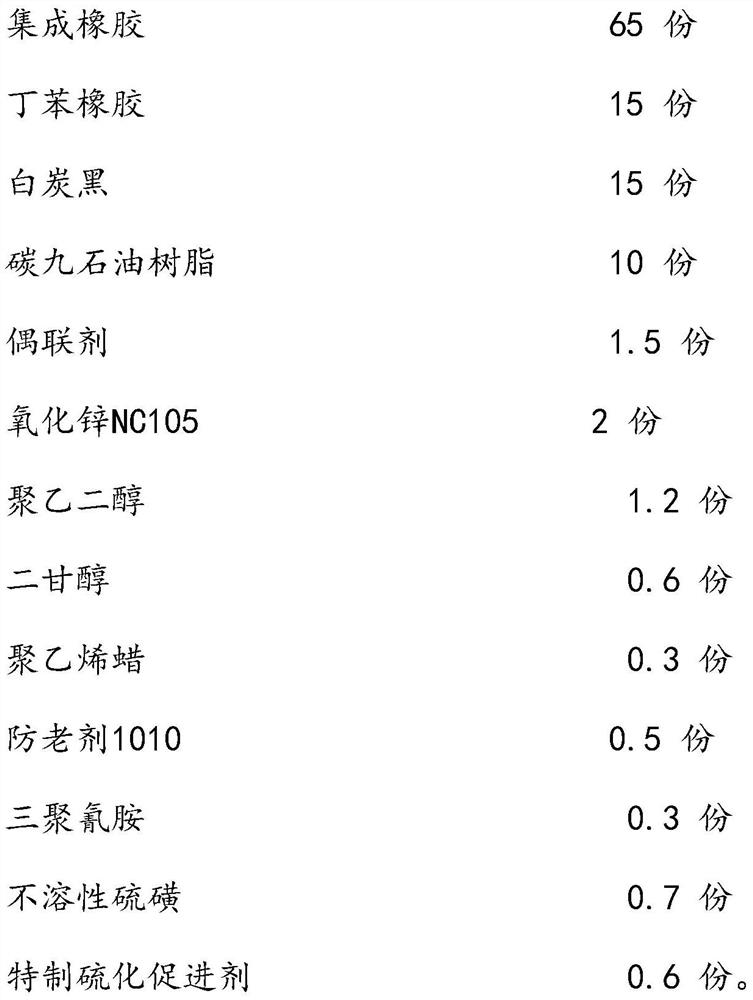

A method of acid -resistant alkali -resistant rubber shoe soles and preparation methods

The invention relates to a rubber sole, and provides an acid and alkali-resistant rubber sole and a preparation method thereof. The acid and alkali-resistant rubber sole has good acid and alkali resistance and meets the performance requirements of safety shoes; the acid and alkali resistance The rubber sole is composed of the following raw materials: integrated rubber, styrene-butadiene rubber, white carbon black, carbon nine petroleum resin, coupling agent, zinc oxide NC105, polyethylene glycol, diethylene glycol, polyethylene wax, anti-aging agent 1010, melamine, Insoluble sulfur and special vulcanization accelerator.

Owner:MAOTAI FUJIAN SOLES CO LTD

Sound insulation material, manufacturing method thereof and water purifier

PendingCN114479214AEvenly distributedIncrease crosslink densityTreatment involving filtrationFiltration separationStearic acidAccelerant

The invention relates to the technical field of environmental protection, in particular to a sound insulation material, a manufacturing method thereof and a water purifier. The sound insulation material is prepared from 100 parts of butyronitrile, 1 to 2 parts of modified graphene oxide, 1 to 2 parts of zinc oxide, 1 to 2 parts of stearic acid, 10 to 20 parts of accelerant and 1.2 to 2.4 parts of sulfur, the microstructure of the modified graphene oxide is of a sheet structure, and the modified graphene oxide is uniformly distributed in the sound insulation material to form a network architecture in the sound insulation material. The manufacturing method of the sound insulation material is used for producing the sound insulation material. The water purifier at least comprises the sound insulation material. On one hand, the modified graphene oxide can be well dispersed in a matrix of nitrile rubber, so that the overall crosslinking density of the composite material is improved; on the other hand, the graphene oxide constructs a perfect filler network, the internal friction resistance is increased to a great extent, the loss factor is increased, and the shock absorption and noise reduction effects of the sound insulation material are remarkable through the combined action of the graphene oxide and the loss factor.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com