A method for preparing a ceramic damping coating on the surface of a thin shell member of a rotating machine

A technology of rotating machinery and damping coating, applied in the field of materials, can solve problems such as reducing the vibration stress of the blade, and achieve the effect of improving the damping capacity, reducing the vibration level, and the damping applicable temperature range is wide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

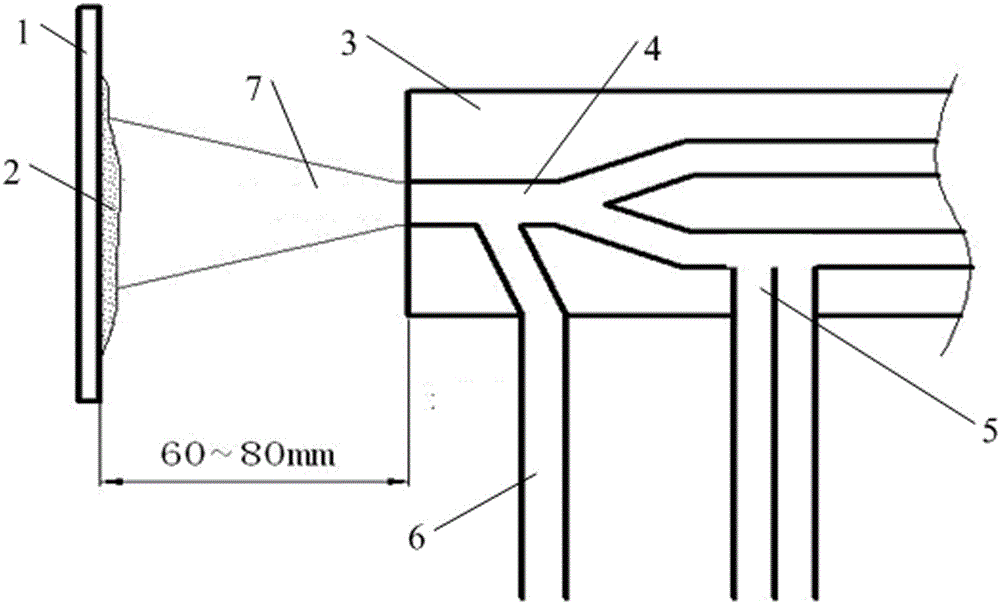

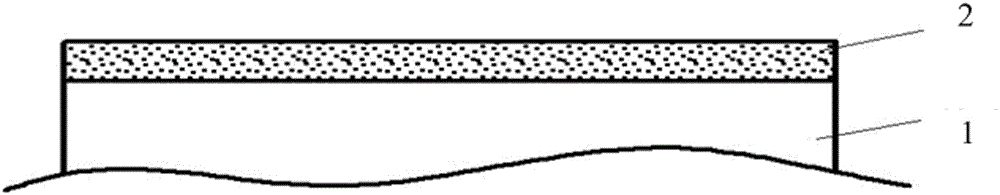

[0023] MgO and Al 2 o 3 MgO:Al by weight ratio 2 o 3 =1:2 mixing, ball milling to make mixed powder, screening out the part with a particle size of 60~80 mesh, drying to remove moisture, and making ceramic coating material; then put it into the powder feeding device of the atmospheric plasma spraying machine;

[0024] Use the rotating mechanical thin shell member as the substrate to remove the oil and impurities on the surface of the substrate, and then place it on the workbench of the atmospheric plasma spraying machine;

[0025] Start the atmospheric plasma spraying machine, feed argon and hydrogen into the spray gun of the atmospheric plasma spraying machine, control the flow rate of the argon gas to 40scm, and the flow rate of the hydrogen gas to 12.5scm. After the flow rate is stable, turn on the power supply of the atmospheric plasma spraying machine to generate glow Plasma, adjust the power to 35kw;

[0026] Turn on the powder feeding device to spray the ceramic coa...

Embodiment 2

[0028] MgO and Al 2 o 3 MgO:Al by weight ratio 2 o 3 = 1:3 mixing, ball milling to make mixed powder, screen out the part with a particle size of 60~80 mesh, then dry to remove water, and make ceramic coating material; then put it into the powder feeding device of the atmospheric plasma spraying machine;

[0029] Use the rotating mechanical thin shell member as the substrate to remove the oil and impurities on the surface of the substrate, and then place it on the workbench of the atmospheric plasma spraying machine;

[0030] Start the atmospheric plasma spraying machine, feed argon and hydrogen into the spray gun of the atmospheric plasma spraying machine, control the flow rate of the argon gas to 41scm, and the flow rate of the hydrogen gas to 13scm. After the flow rate is stable, turn on the power of the atmospheric plasma spraying machine to generate plasma. Body, adjust the power to 40kw;

[0031] Turn on the powder feeding device to spray the ceramic coating material...

Embodiment 3

[0033] MgO and Al 2 o 3 MgO:Al by weight ratio 2 o 3 = 1:4 mixing, ball milling to make mixed powder, screen out the part with a particle size of 60~80 mesh, then dry to remove water, and make ceramic coating material; then put it into the powder feeding device of the atmospheric plasma spraying machine;

[0034] Use the rotating mechanical thin shell member as the substrate to remove the oil and impurities on the surface of the substrate, and then place it on the workbench of the atmospheric plasma spraying machine;

[0035] Start the atmospheric plasma spraying machine, feed argon and hydrogen into the spray gun of the atmospheric plasma spraying machine, control the flow rate of the argon gas to 42scm, and the flow rate of the hydrogen gas to 13.5scm. After the flow rate is stable, turn on the power supply of the atmospheric plasma spraying machine to generate glow Plasma, adjust the power to 45kw;

[0036] Turn on the powder feeding device to spray the ceramic coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com