Patents

Literature

2098results about How to "Improve vibration resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

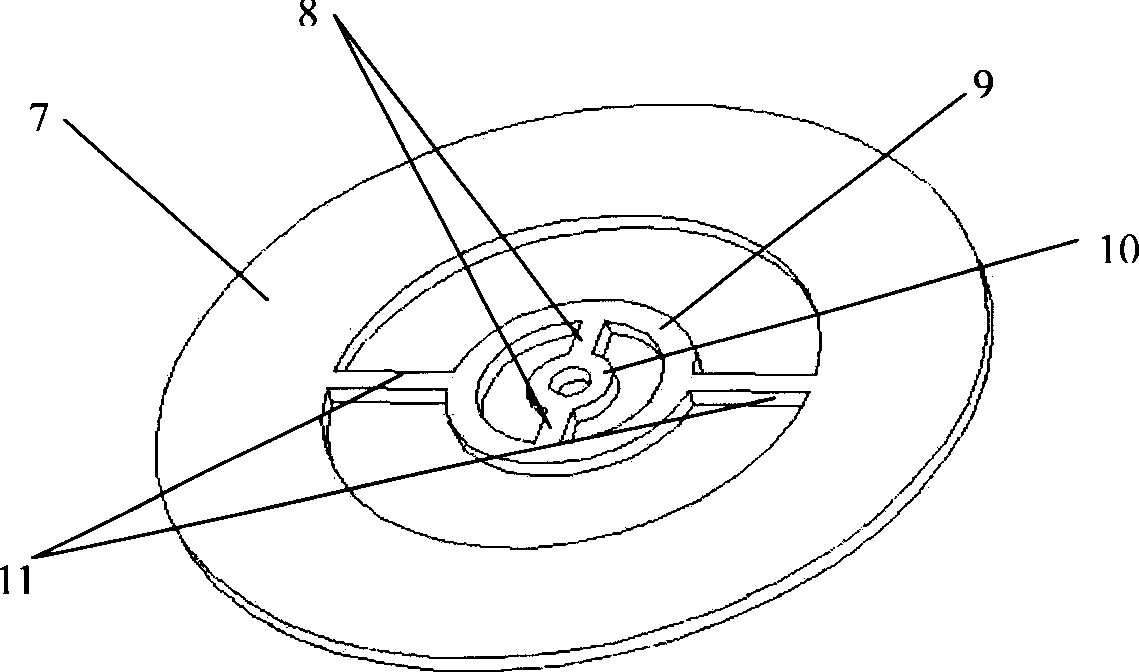

Fastener

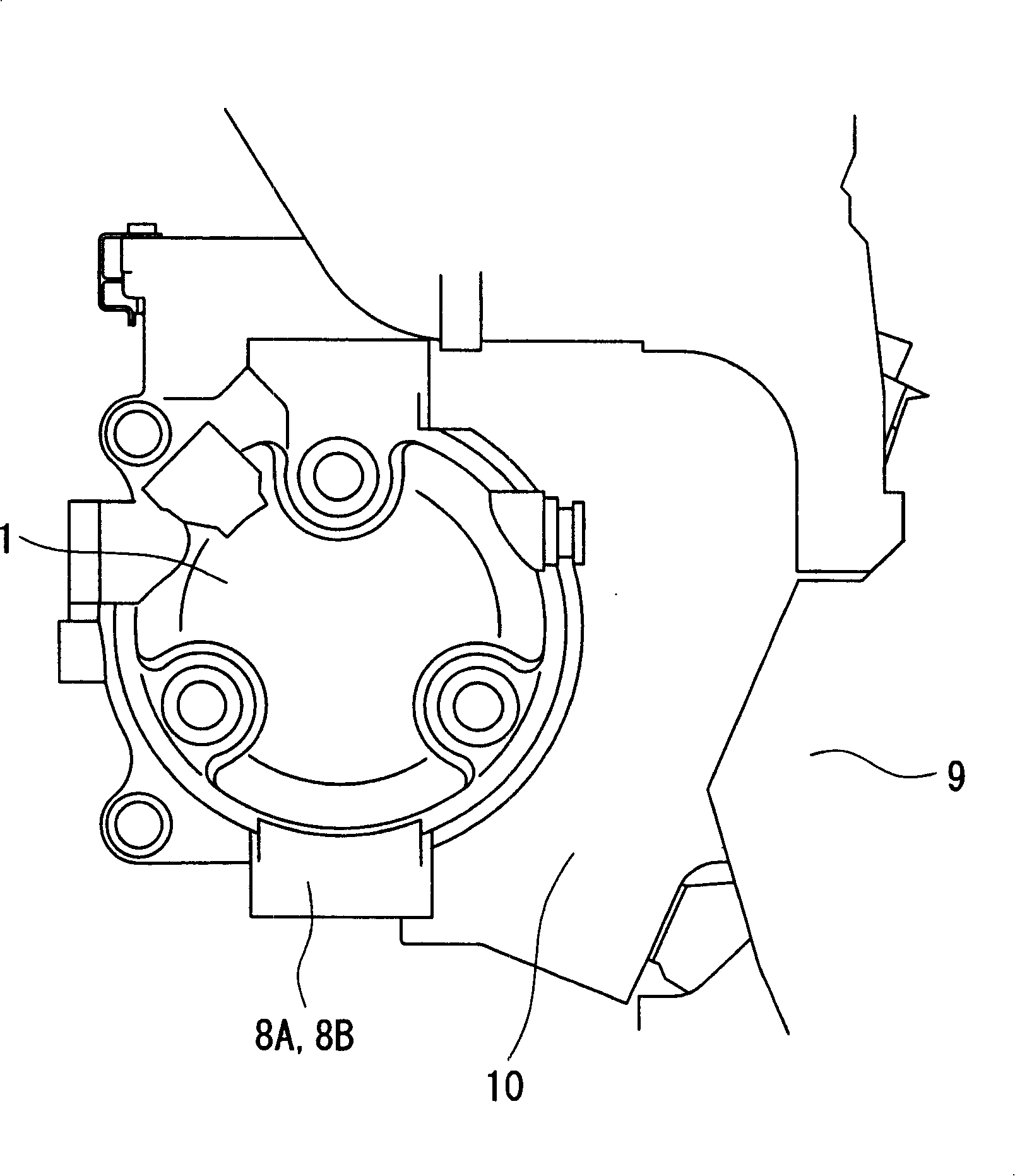

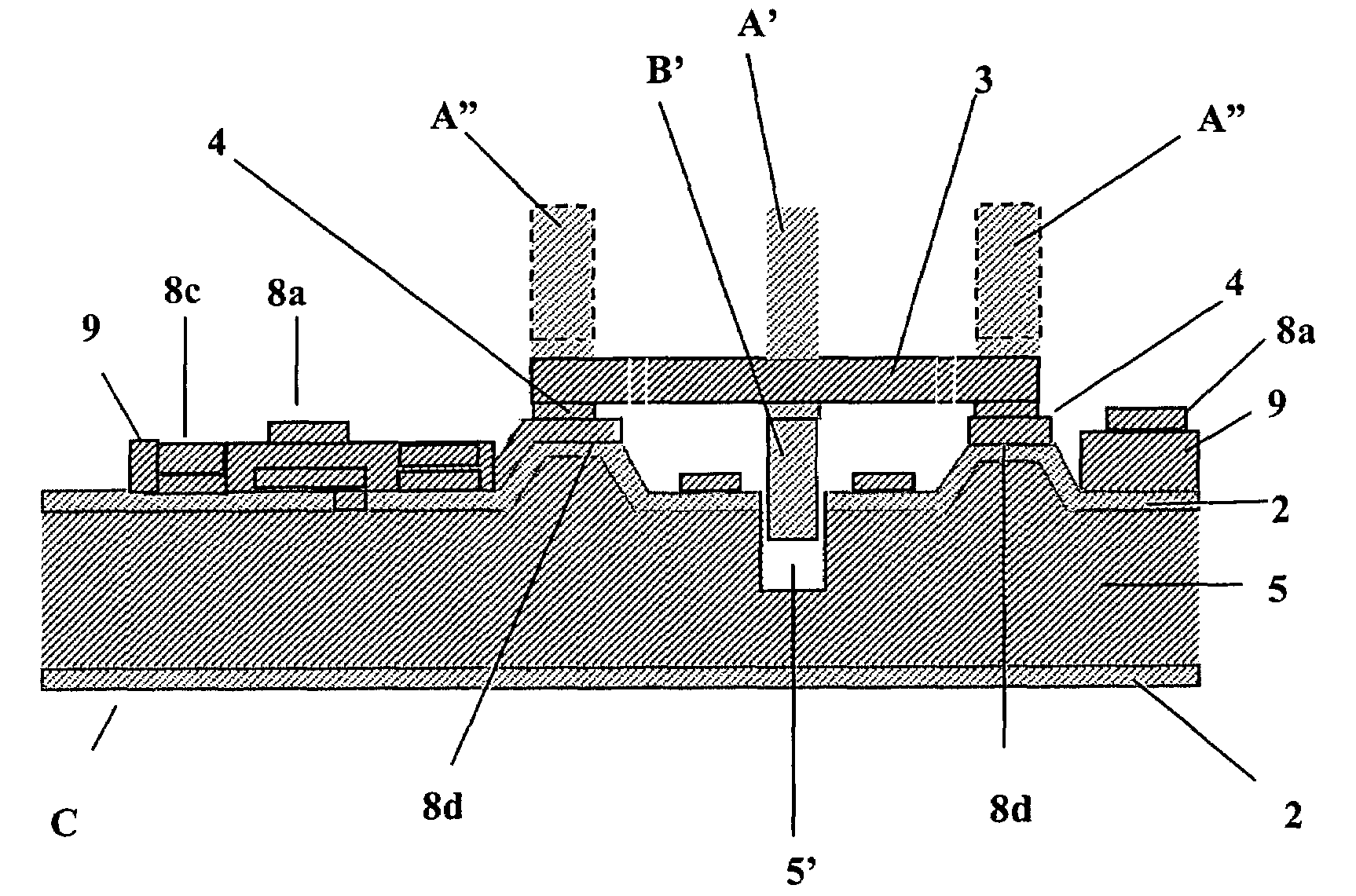

InactiveUS20050123372A1Avoid serious impactImprove vibration resistanceRivetsNutsFastenerEngineering

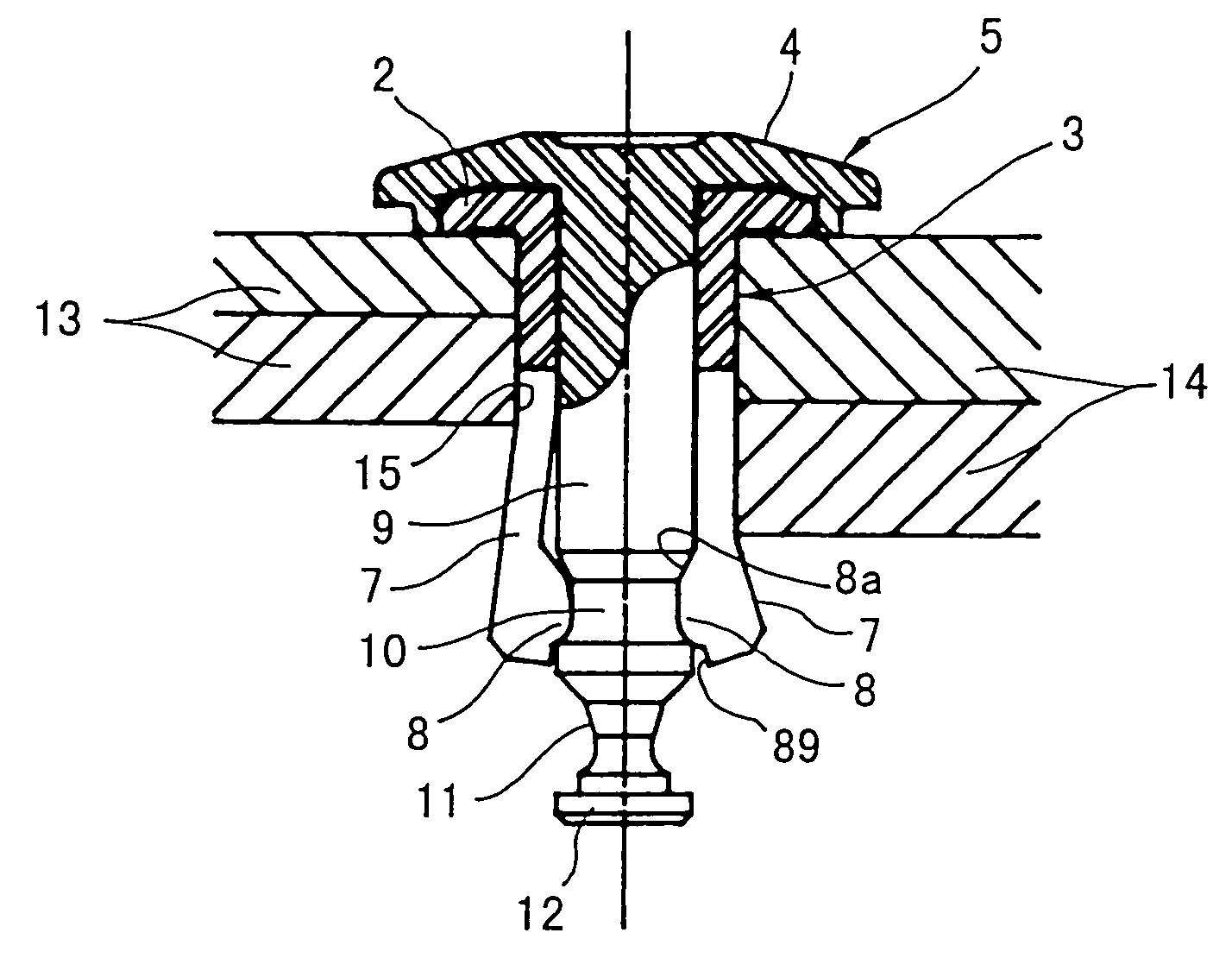

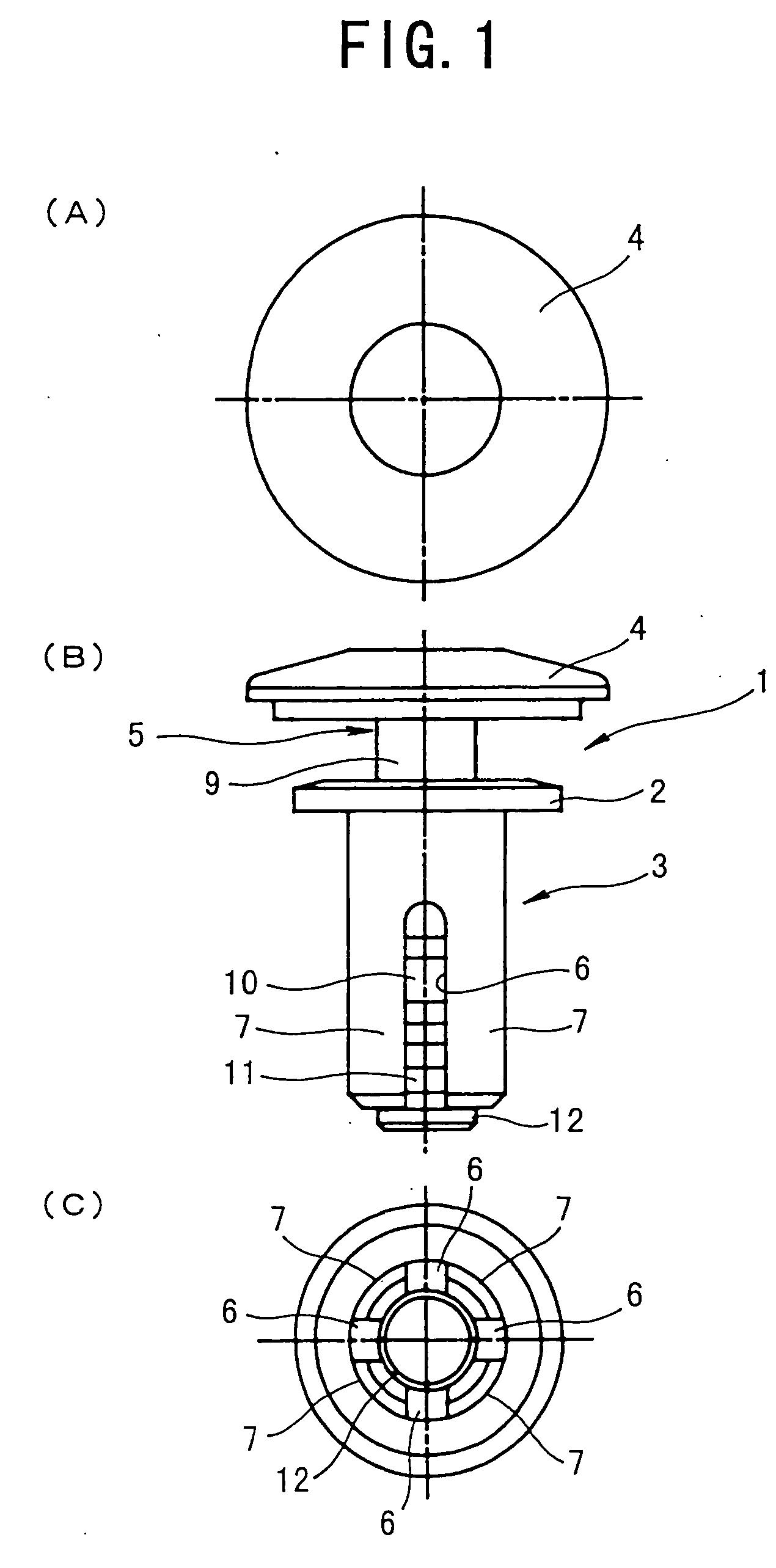

A fastener in which a sleeve 3 and a plug 4 are put into concavo-convex engagement both before and after execution to exert an effect of preventing separation between the two and an effect of preventing loosening therebetween after execution and which can be released by a single action during disassembling. Before execution, the sleeve 3 and the plug 4 press fitted therein are positioned by concavo-convex engagement between a fitting protrusion 8 on the inner periphery of an expanding portion 7 and a neck portion 11 of the plug 4. After execution, the fitting protrusion 8 on the inner periphery of the expanding portion 7 as expanded put into concavo-convex engagement with a neck portion 10 of the plug 4 again, thereby exerting an effect of stopping loosening between the two with respect to vibration, etc. During disassembling, a striking force is given to an end of the plug 4 to release the expanded state by a single action, allowing immediate pulling-away of the fastener 1.

Owner:ZEN KENCHIKU SEKKEI JIMUSHO TOKIOTOKYO

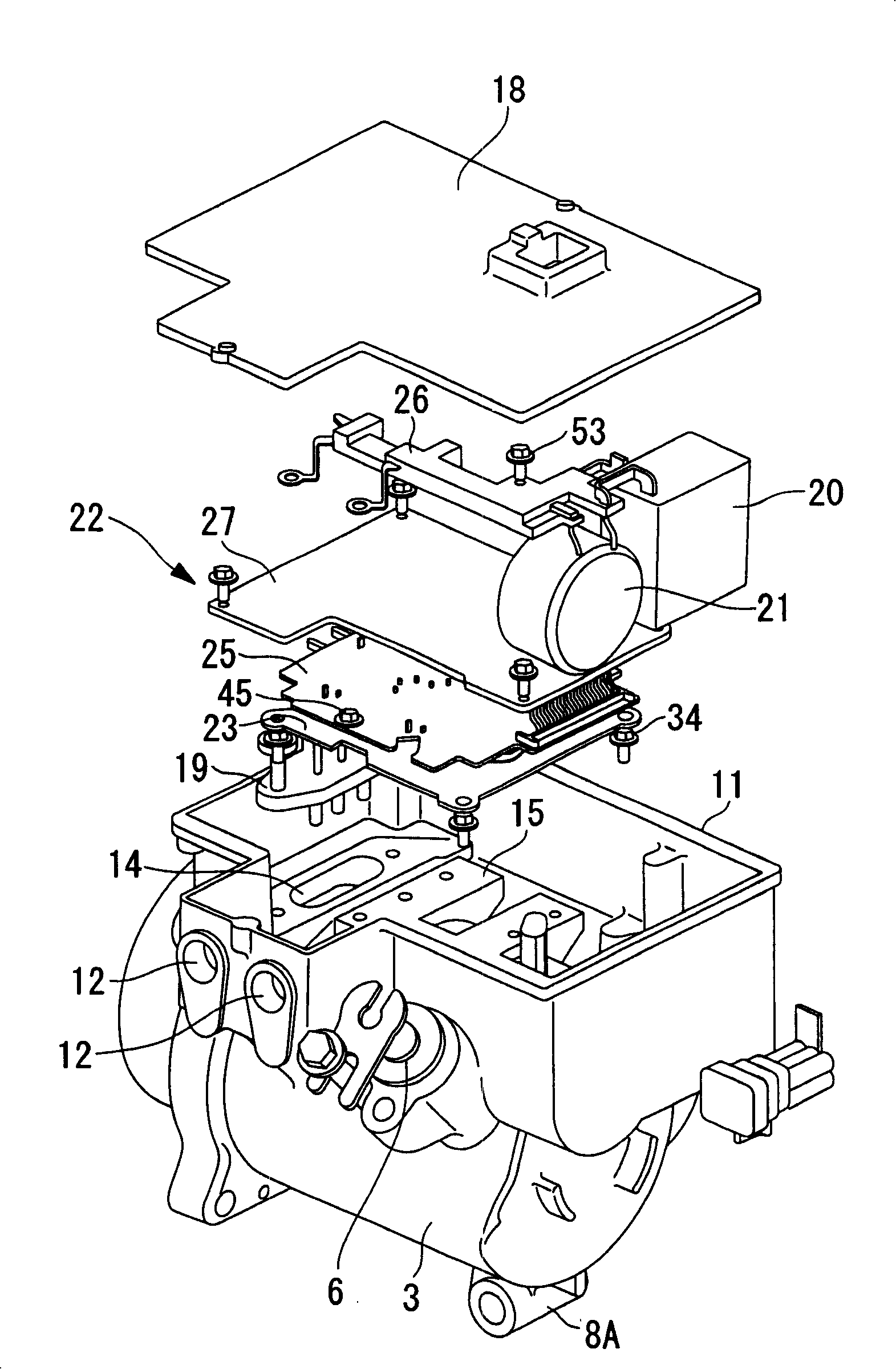

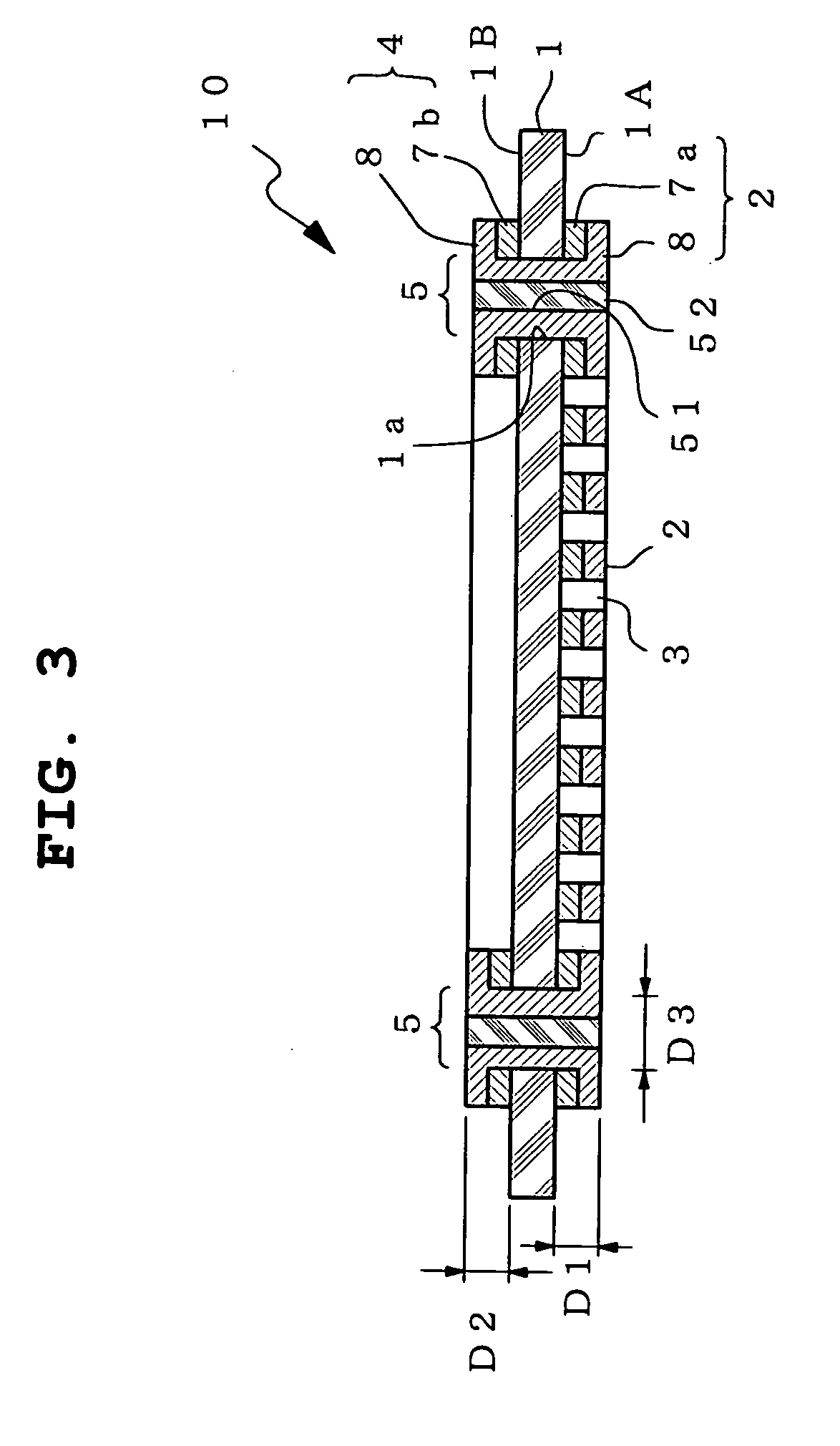

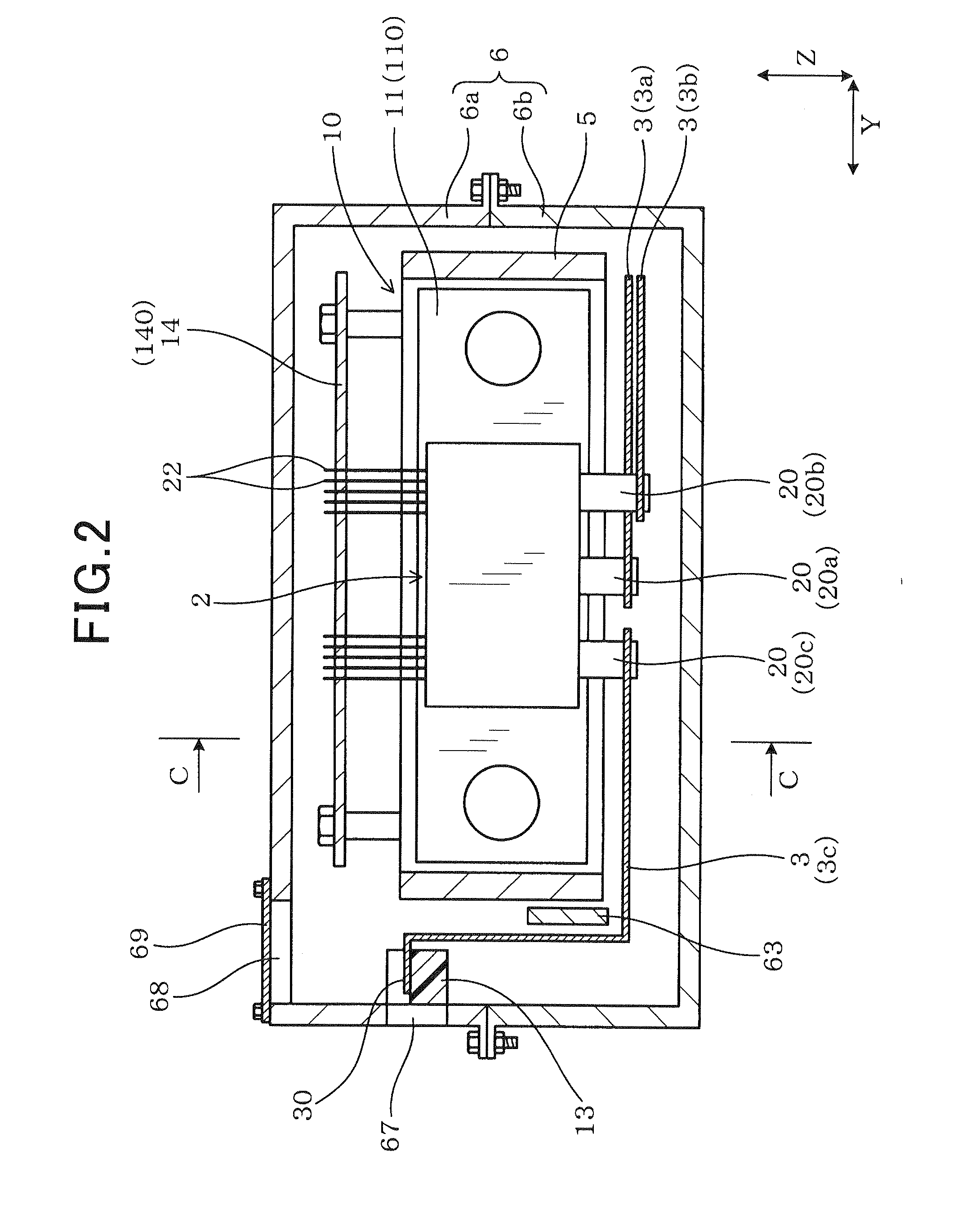

Inverter-integrated electric compressor

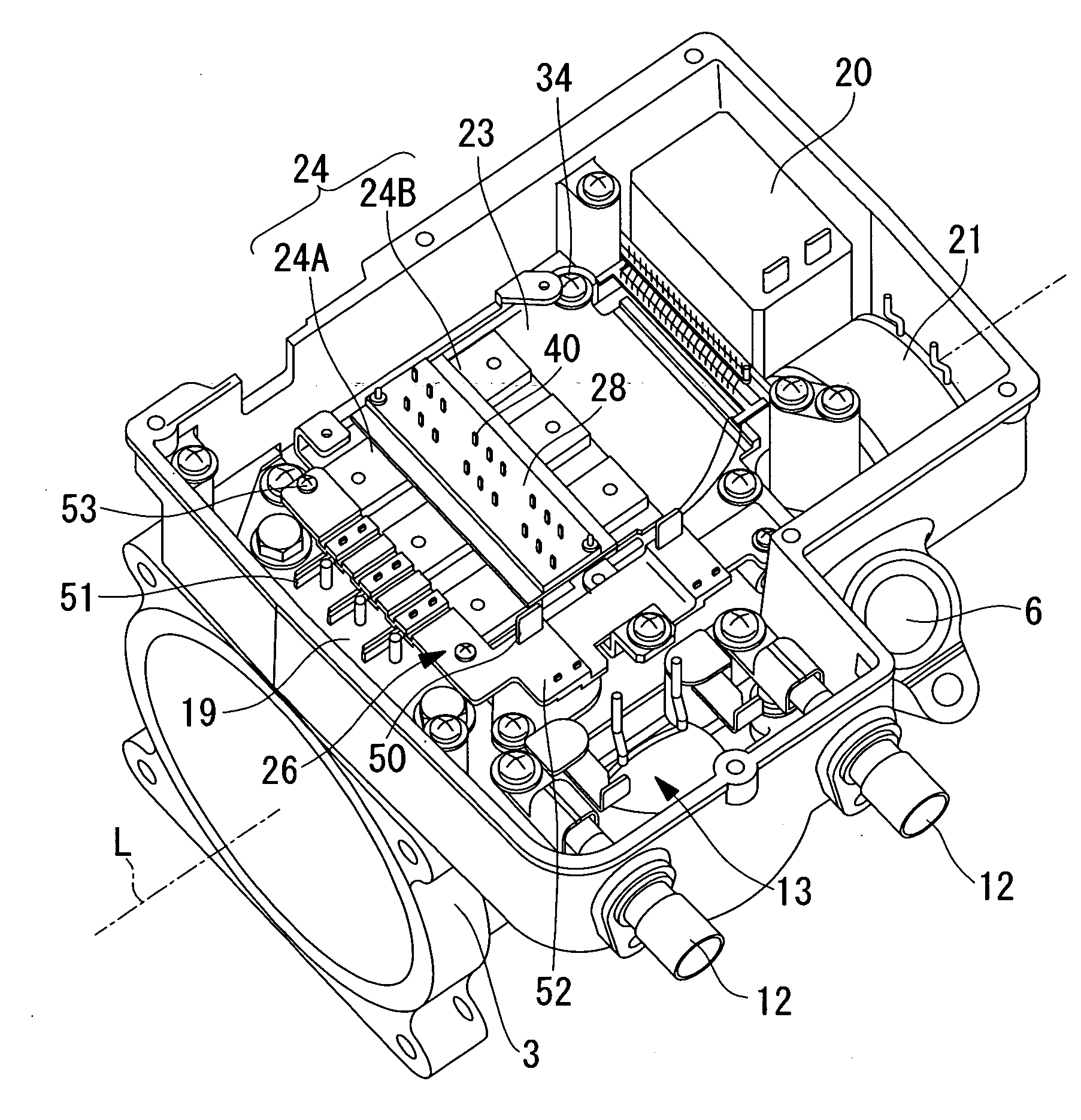

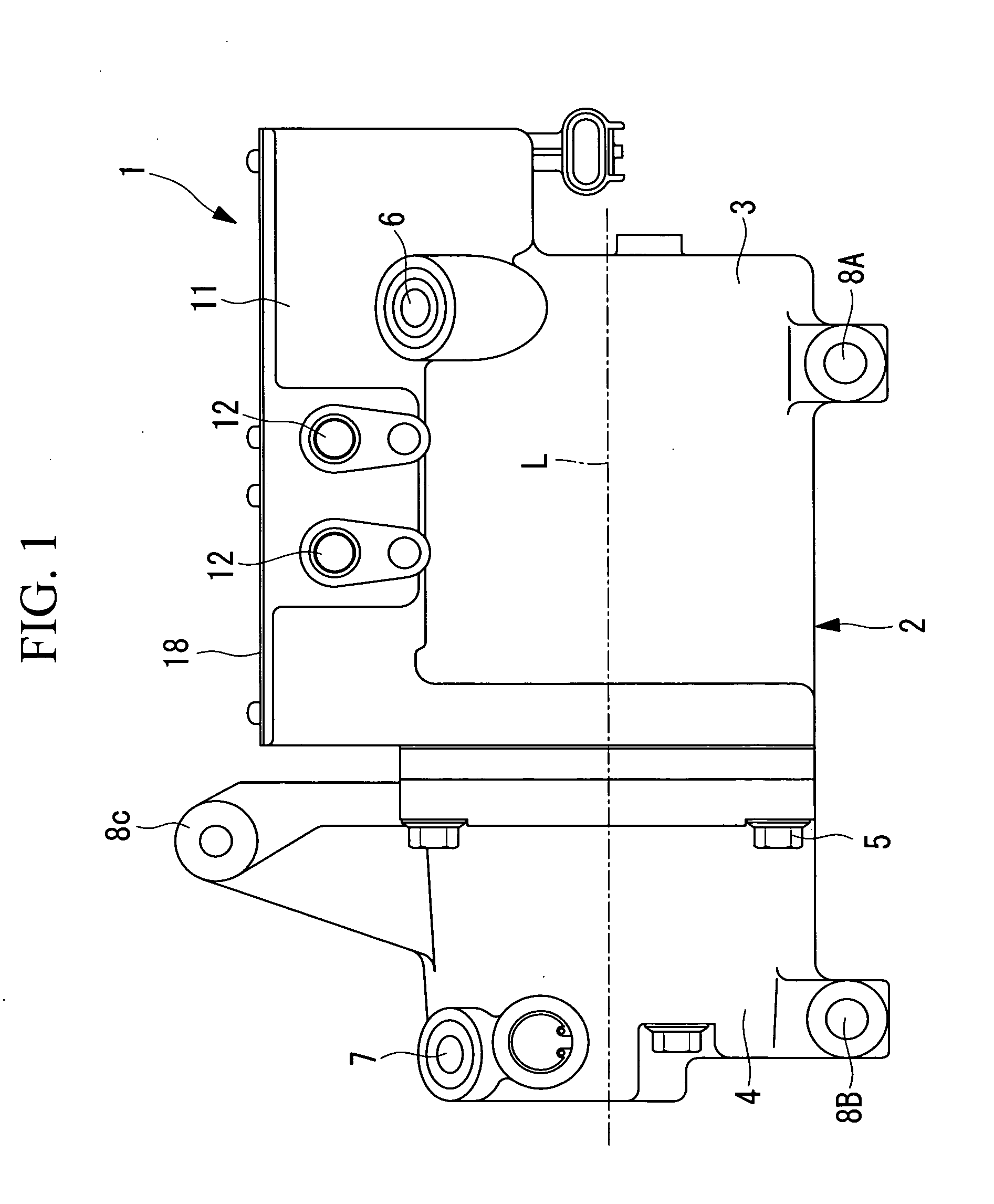

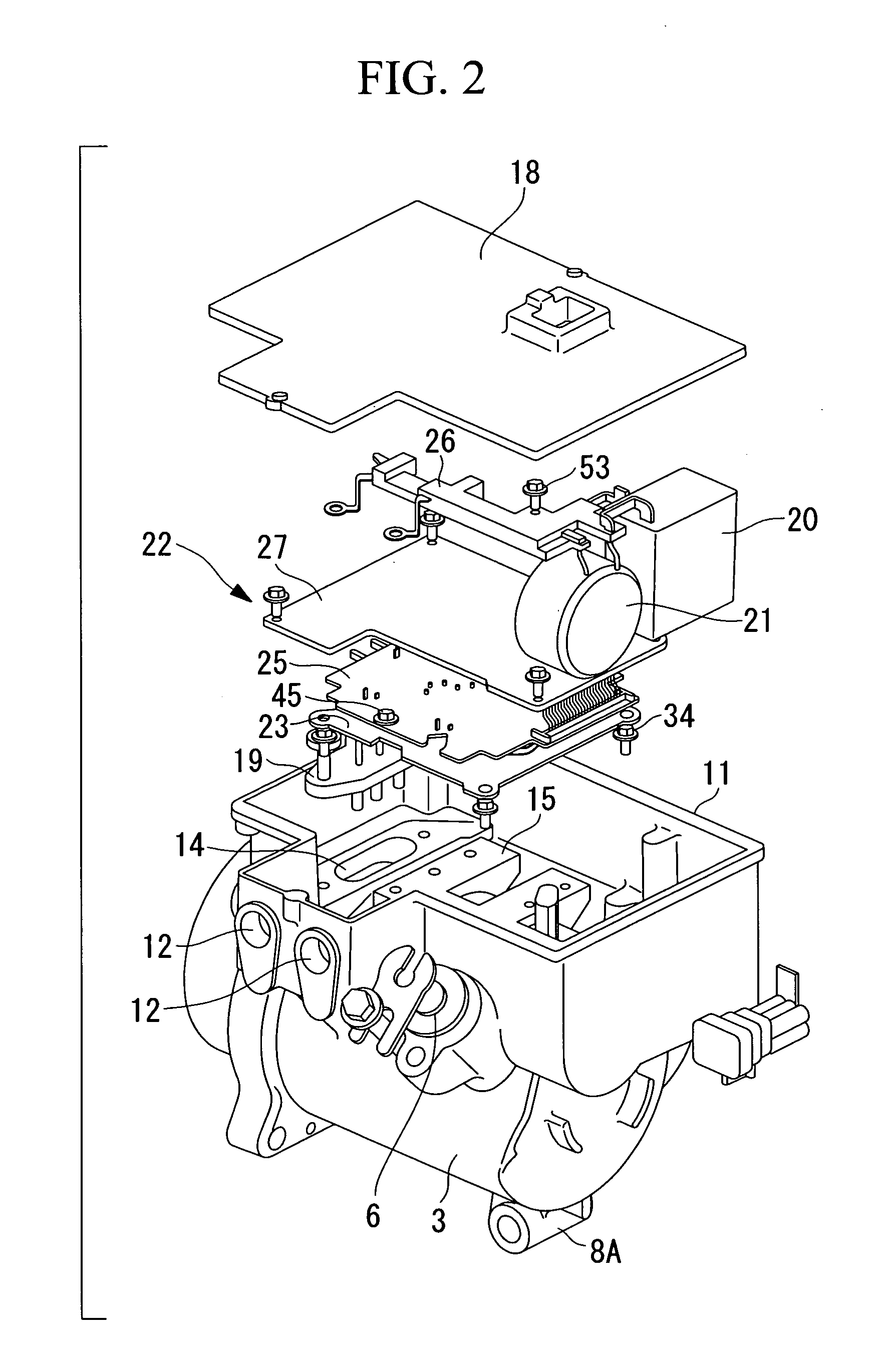

InactiveCN101187364AImprove rigidityImprove vibration resistancePositive displacement pump componentsSemiconductor/solid-state device detailsMotor shaftPower inverter

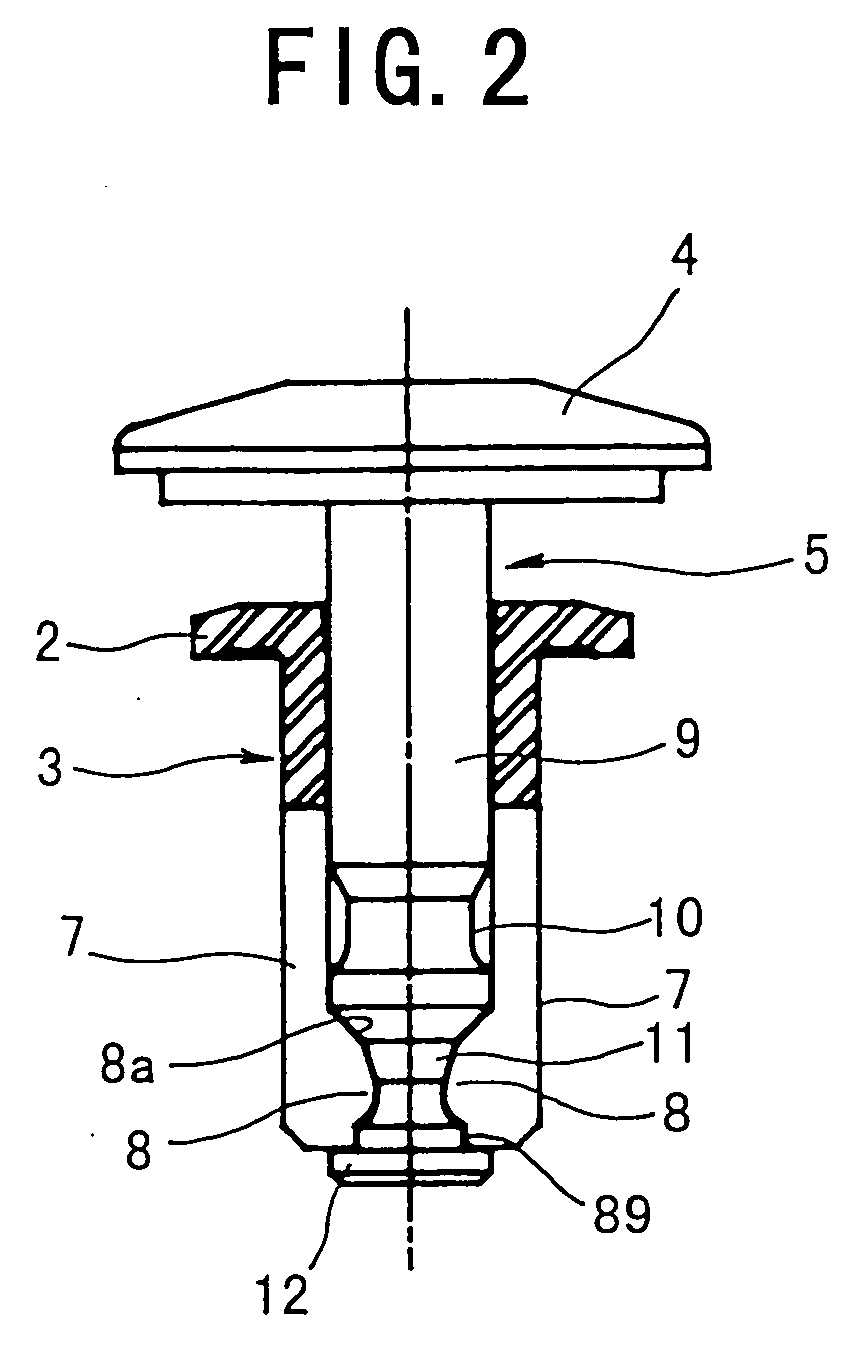

An inverter-integrated electric compressor enhances vibration resistance of an inverter apparatus integrated with a housing without degrading cooling performance, reduction in weight, or the ease of assembly of the inverter apparatus. An inverter-integrated electric compressor 1 has an inverter apparatus 22 integrated with an inverter storage box 11 of a housing 3 . The inverter apparatus 22 includes a metal plate 23 secured in an inverter storage box 11 ; a plurality of power semiconductor switching elements 24 mounted on the metal plate 23 ; a power substrate 25 on which a power-related control circuit for operating the power semiconductor switching elements 24 is mounted; and a busbar assembly 26 formed by integrating a plurality of busbars with an insulator. The metal plate 23 includesa protrusion 33 extending in a width direction perpendicular to a motor shaft direction L of an electric motor.

Owner:MITSUBISHI HEAVY IND LTD

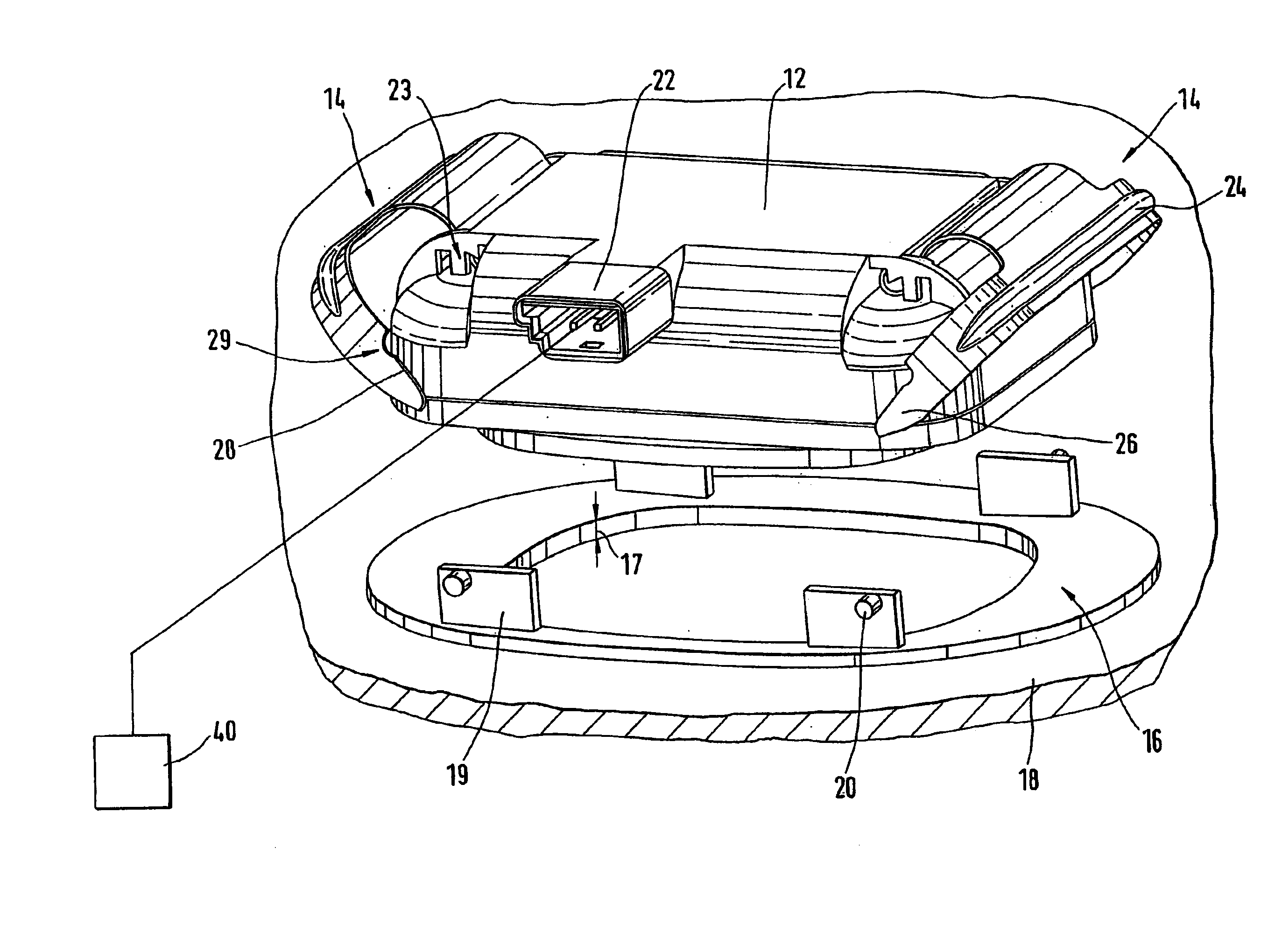

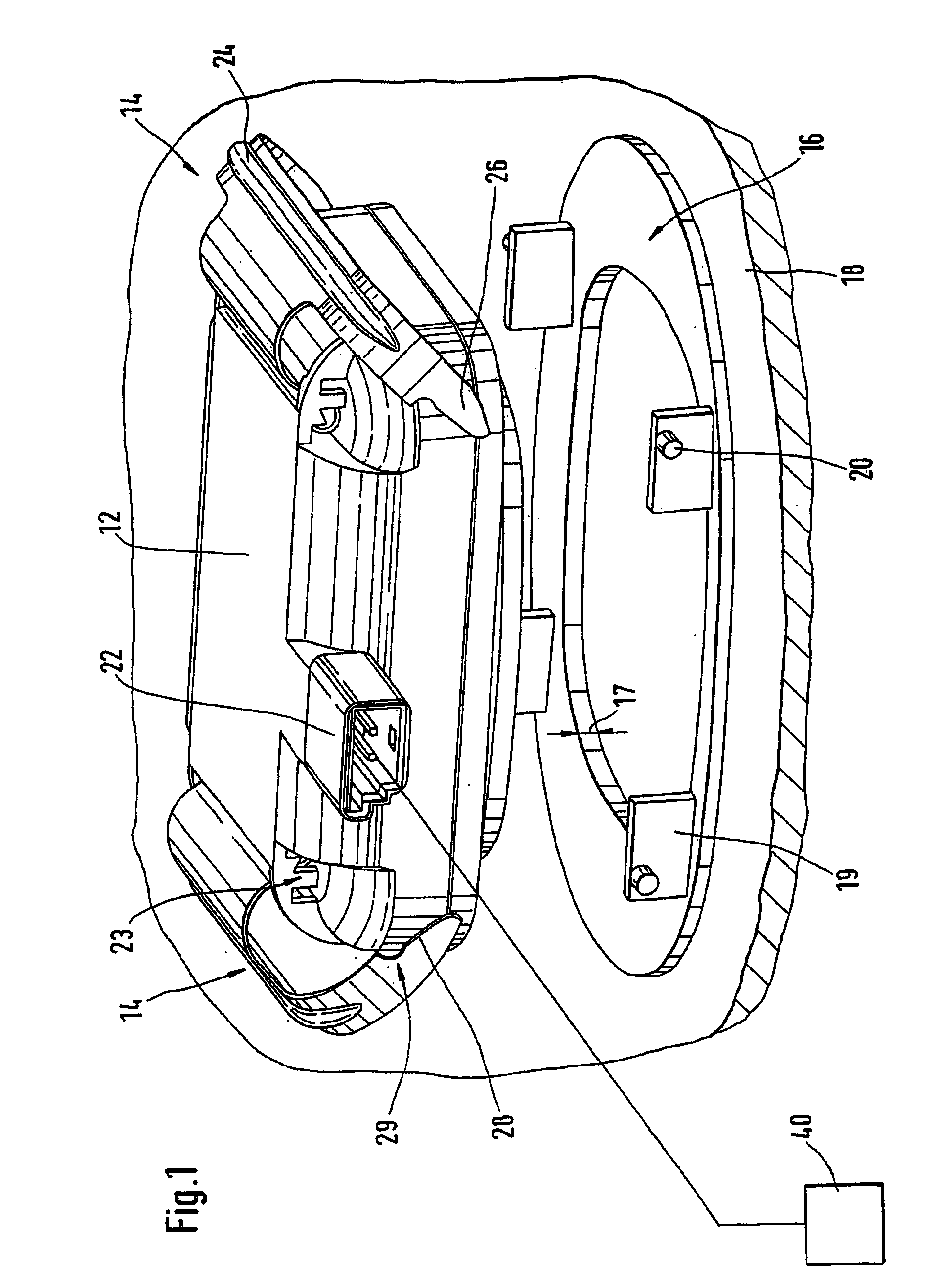

Sensor for optically detecting foreign bodies particularly raindrops on a glass pane

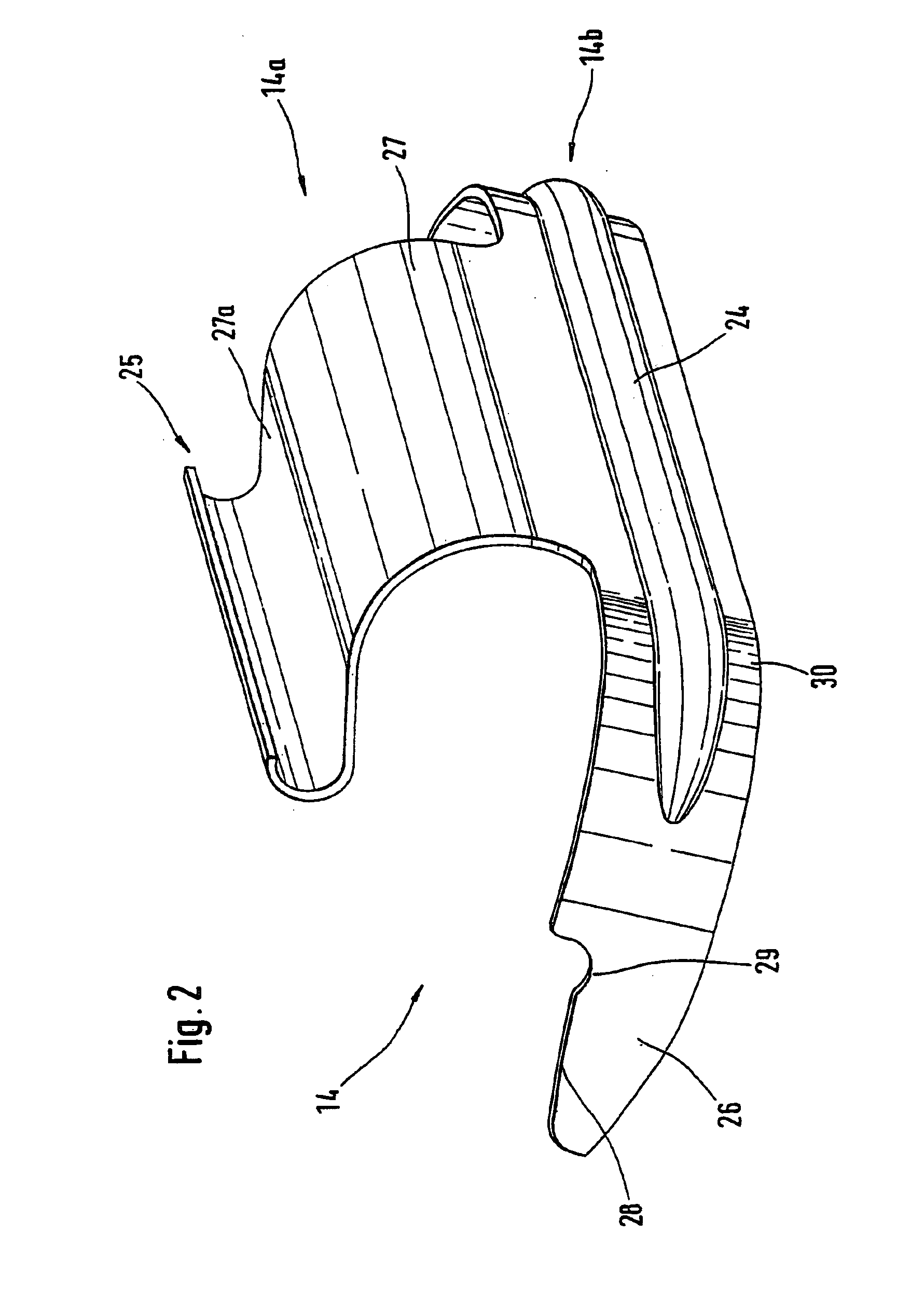

InactiveUS6894619B1Great contact forceExact fitRadiation pyrometryMotor/generator/converter stoppersMobile vehicleEngineering

A sensor for optical detection of foreign bodies, in particular raindrops, on a window, in particular on the windshield of a motor vehicle, having a sensor element that is coupled to the inside of the window and having a fastening device, which is glued to the window, wherein the housing part has a fastening part pivotably attached to it, which can be brought into engagement with the fastening device by the clamping tension.

Owner:ROBERT BOSCH GMBH

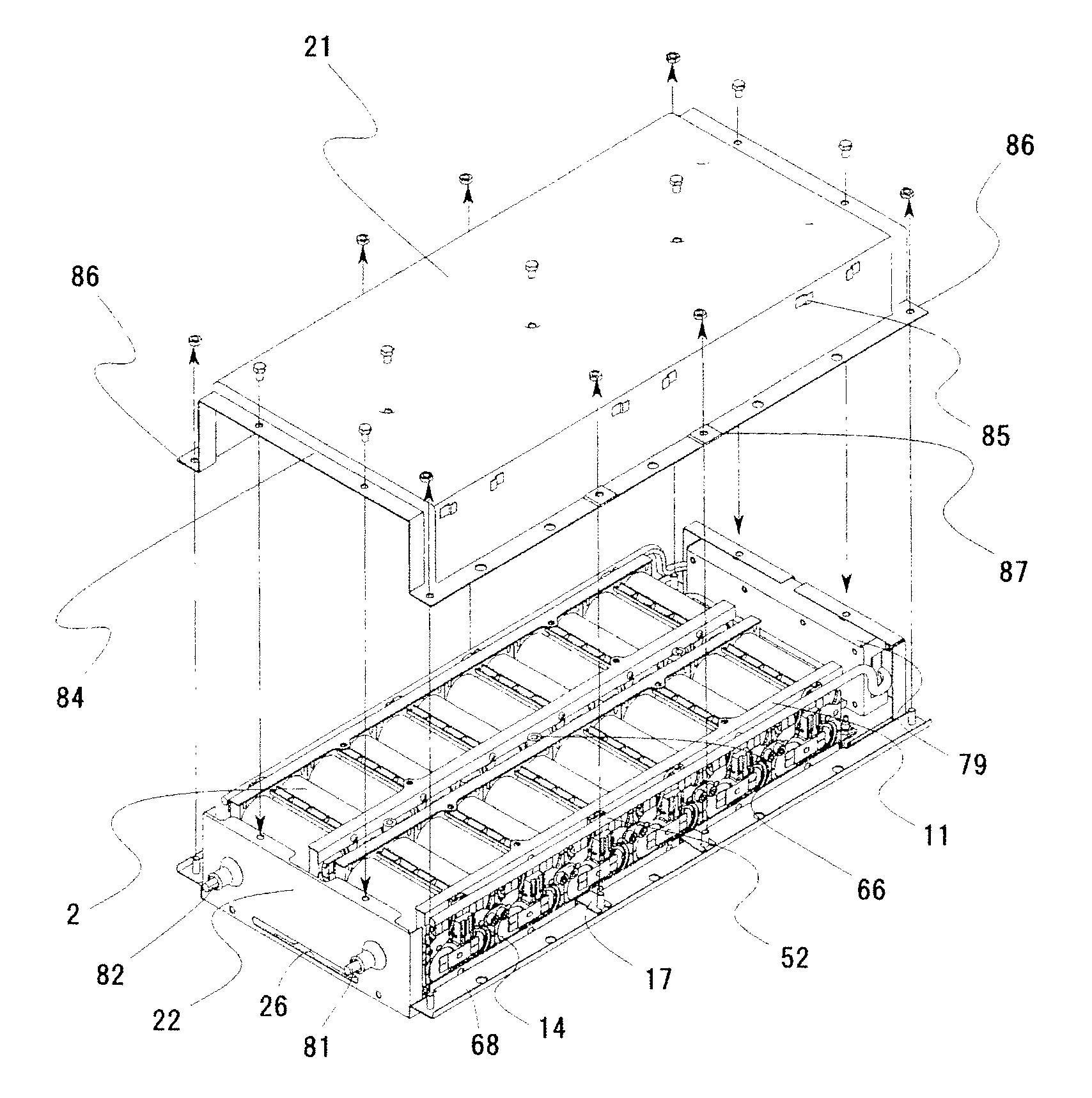

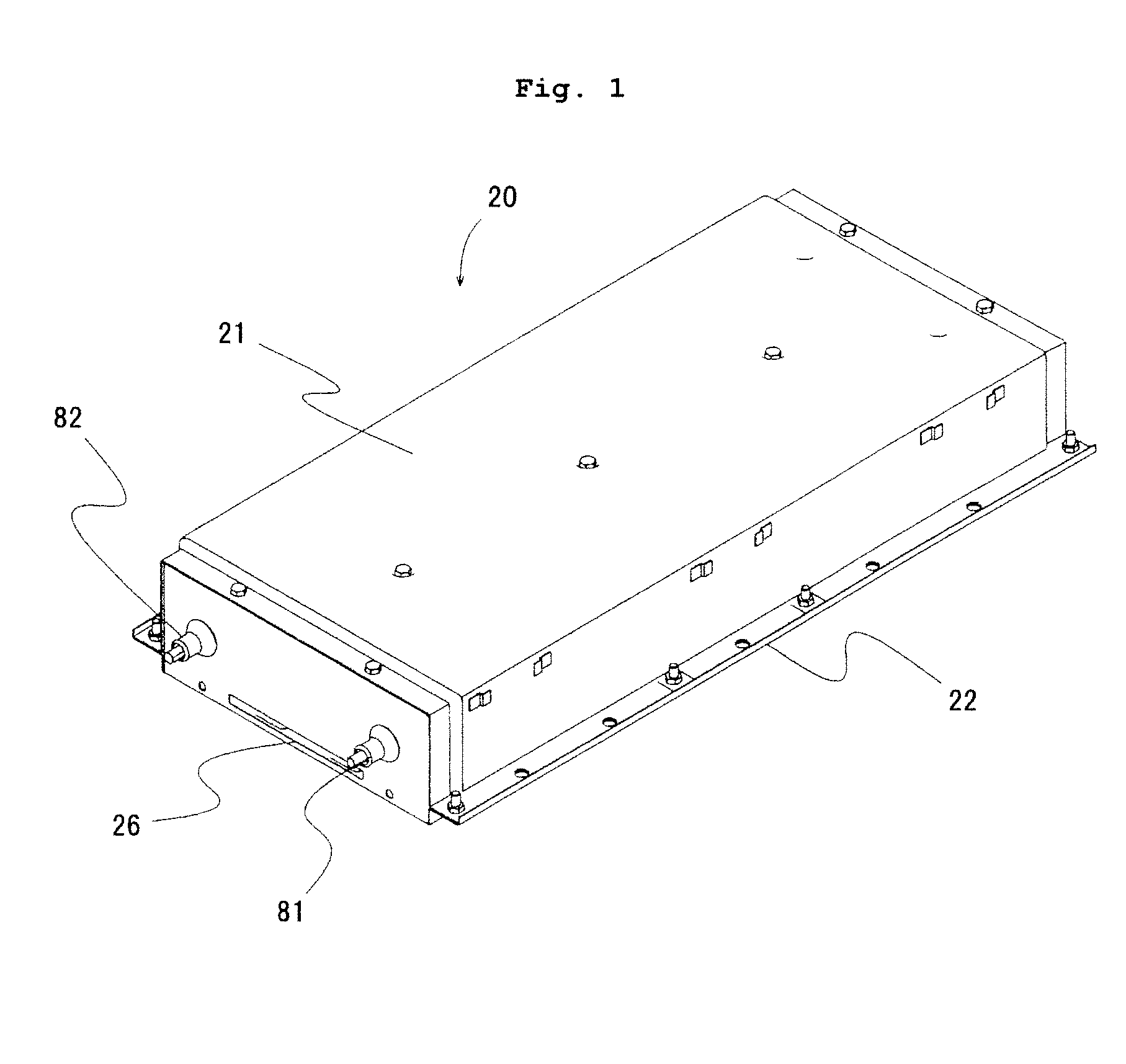

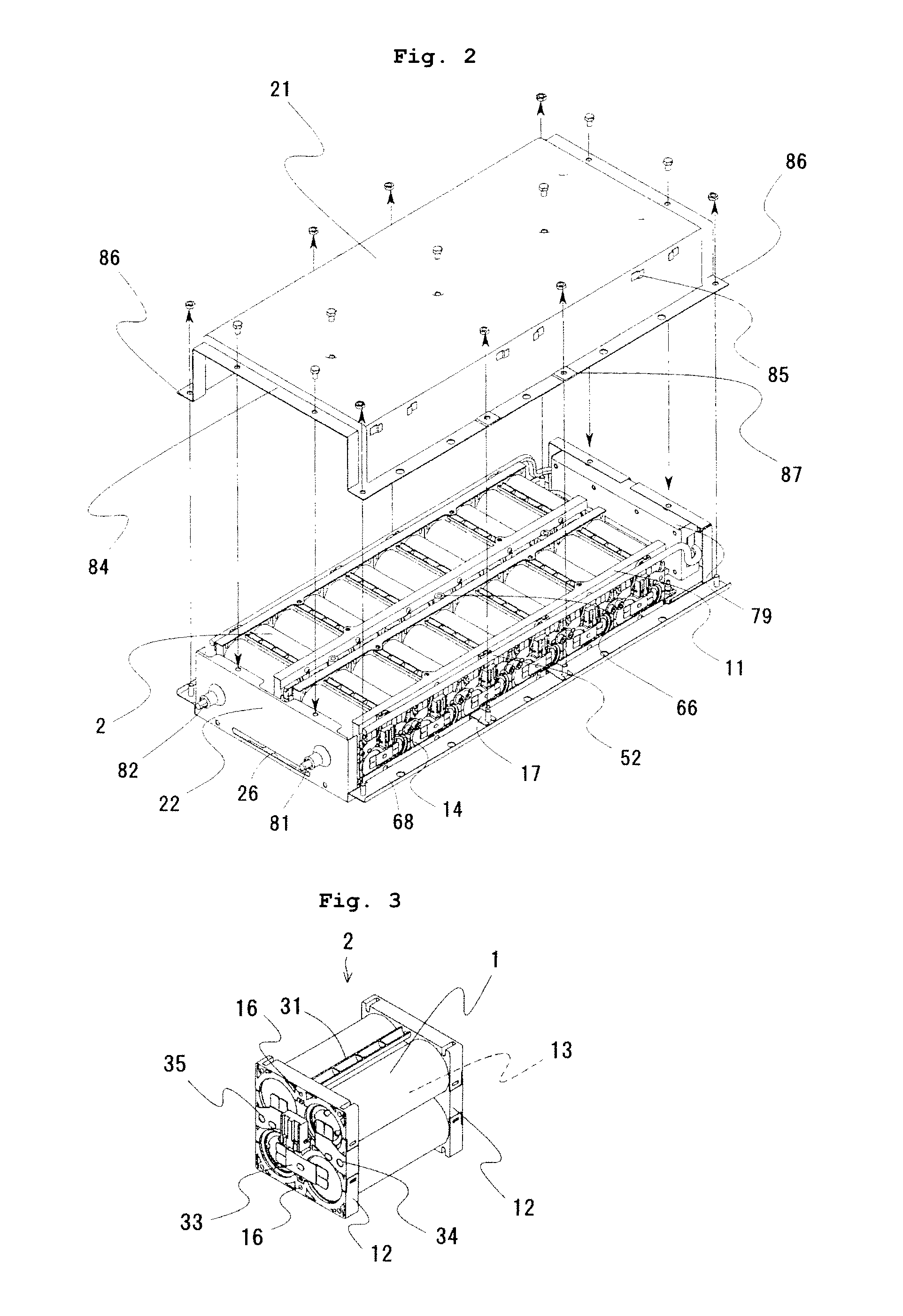

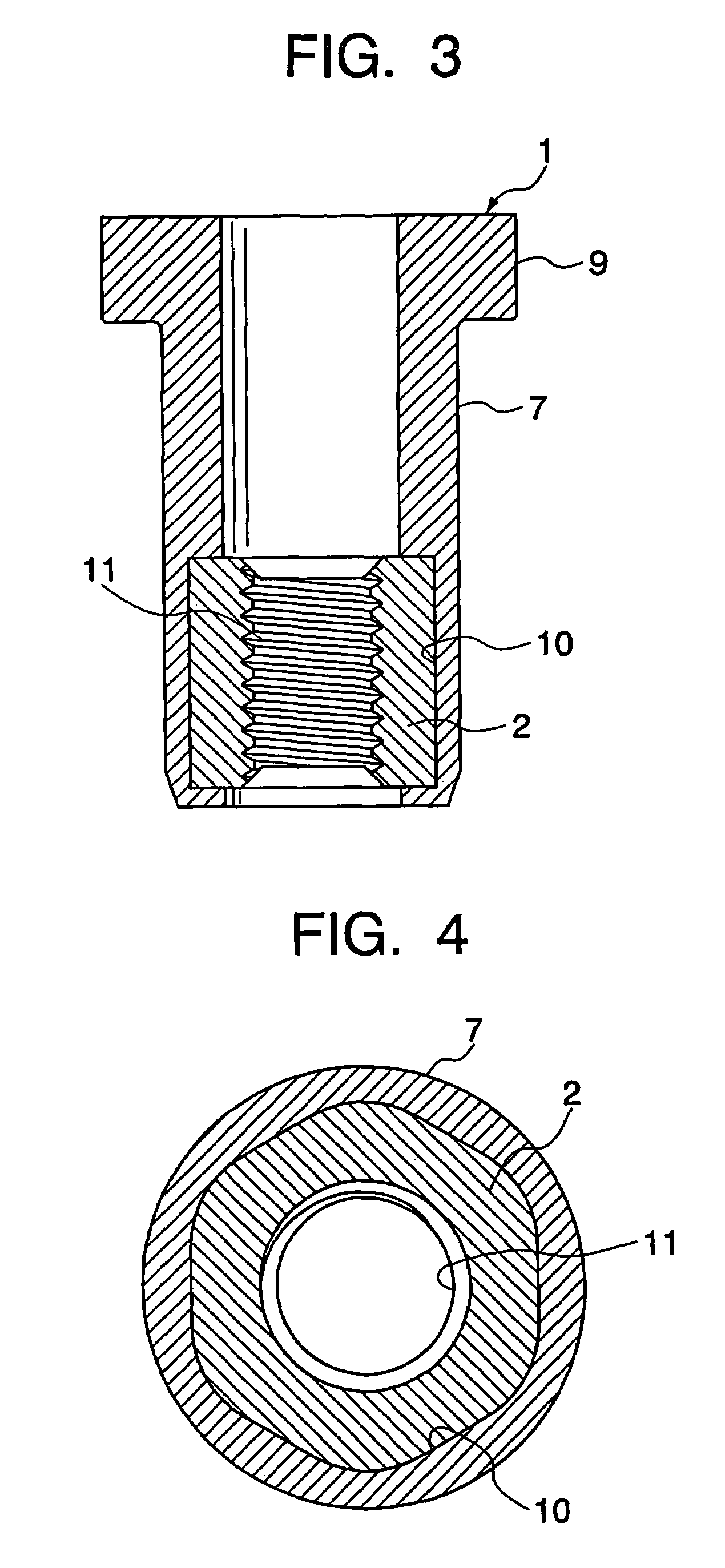

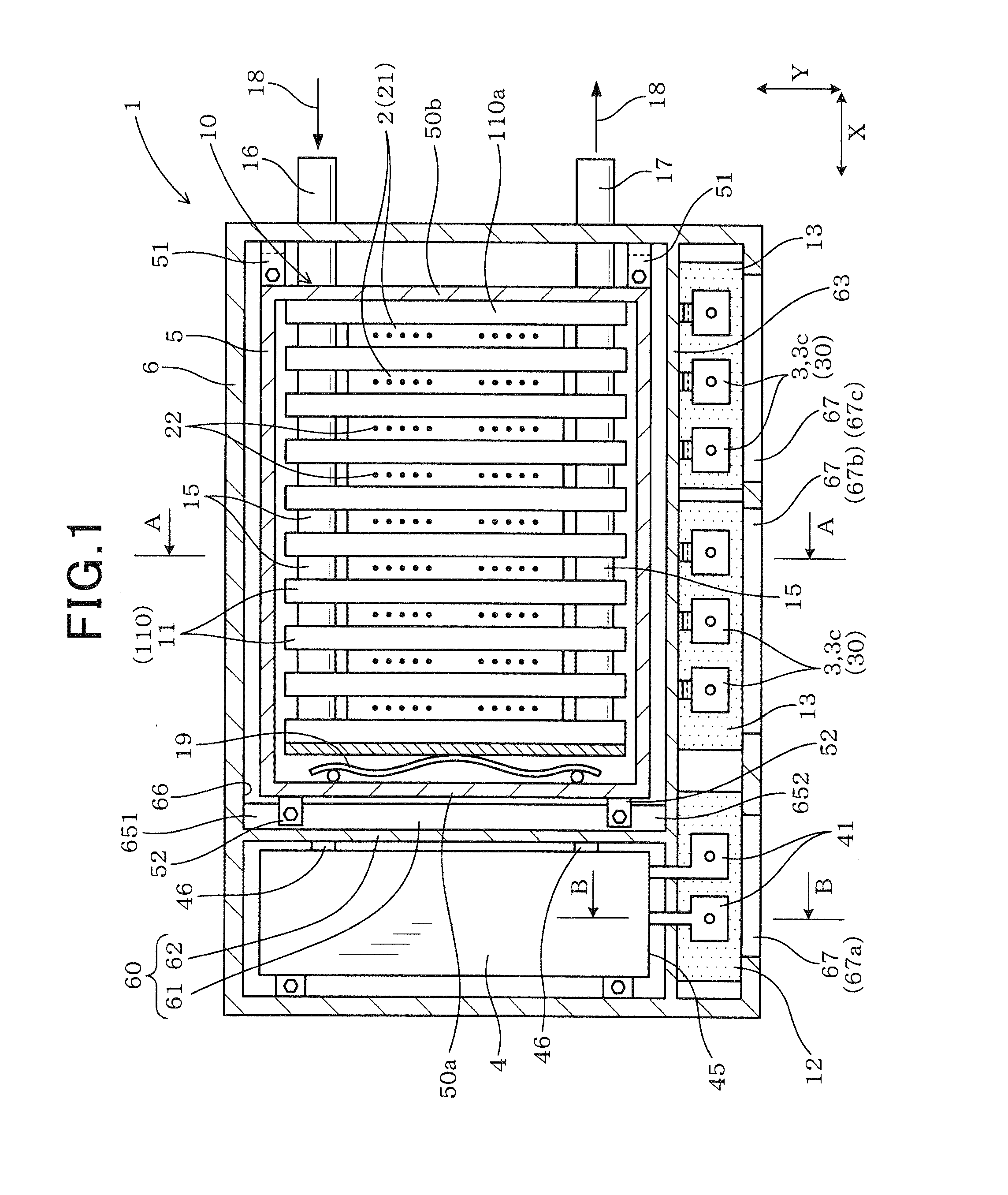

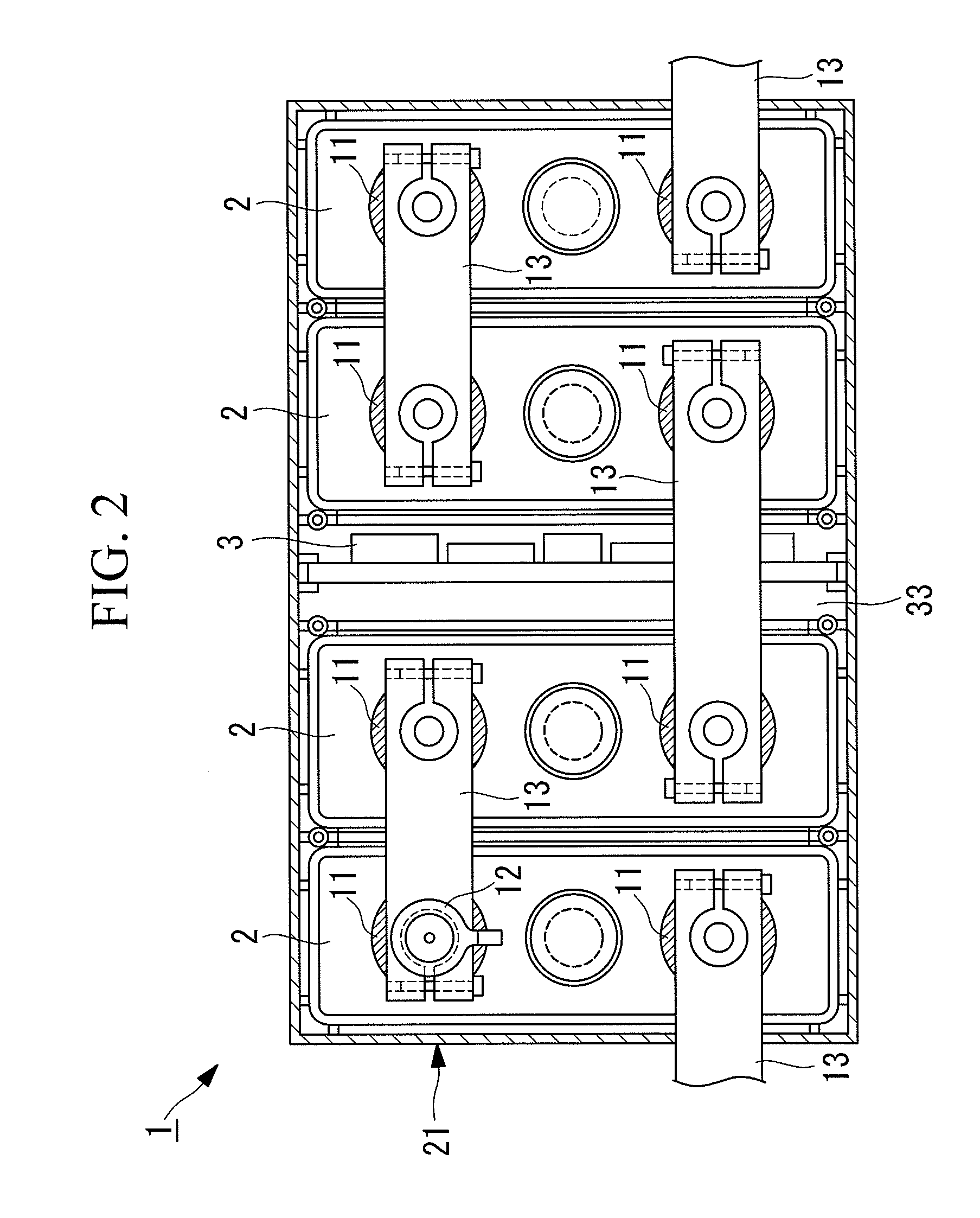

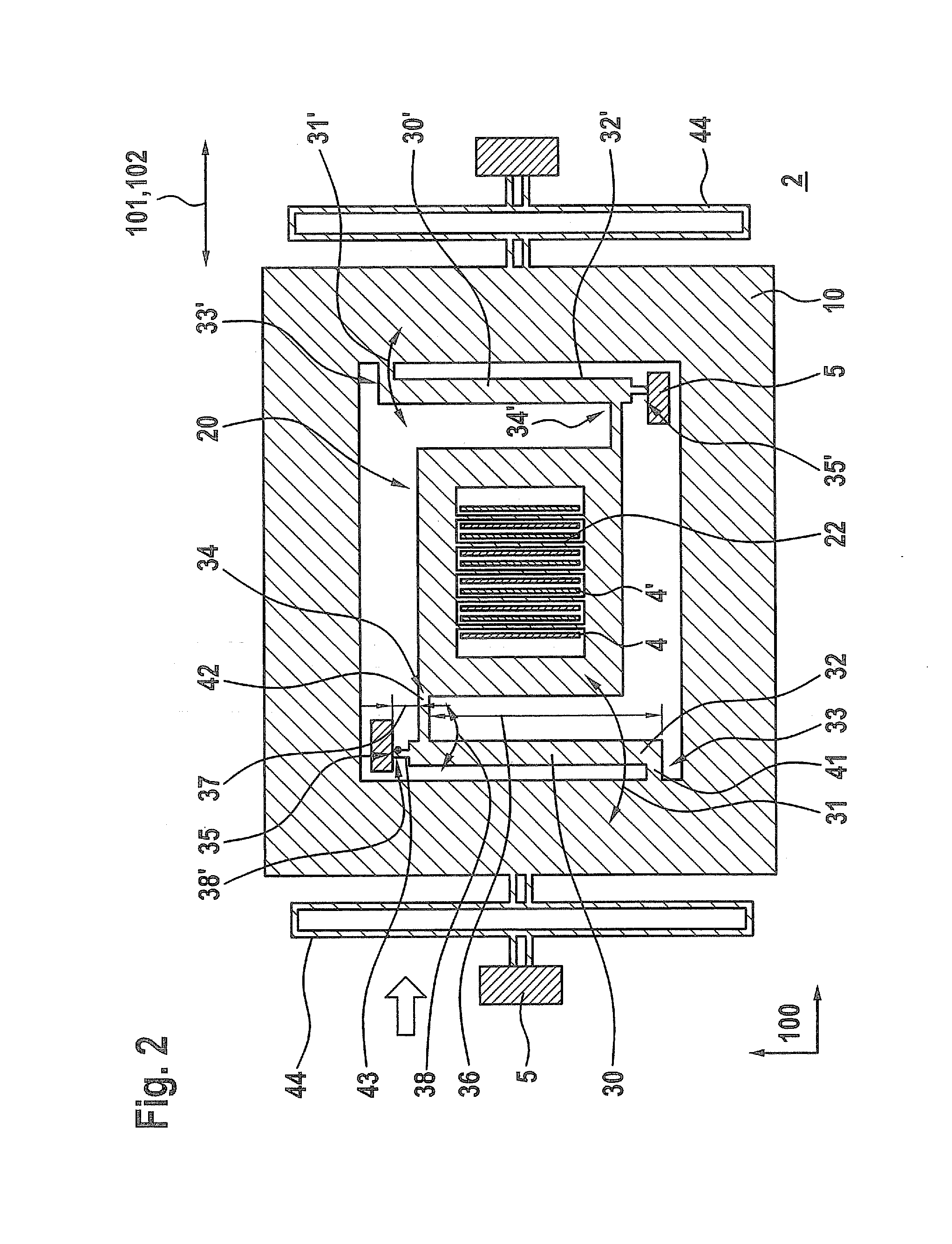

Secondary battery module

InactiveUS20080057393A1Improve vibration resistanceImprove the immunityPrimary cell to battery groupingSecondary cellsEngineeringStress change

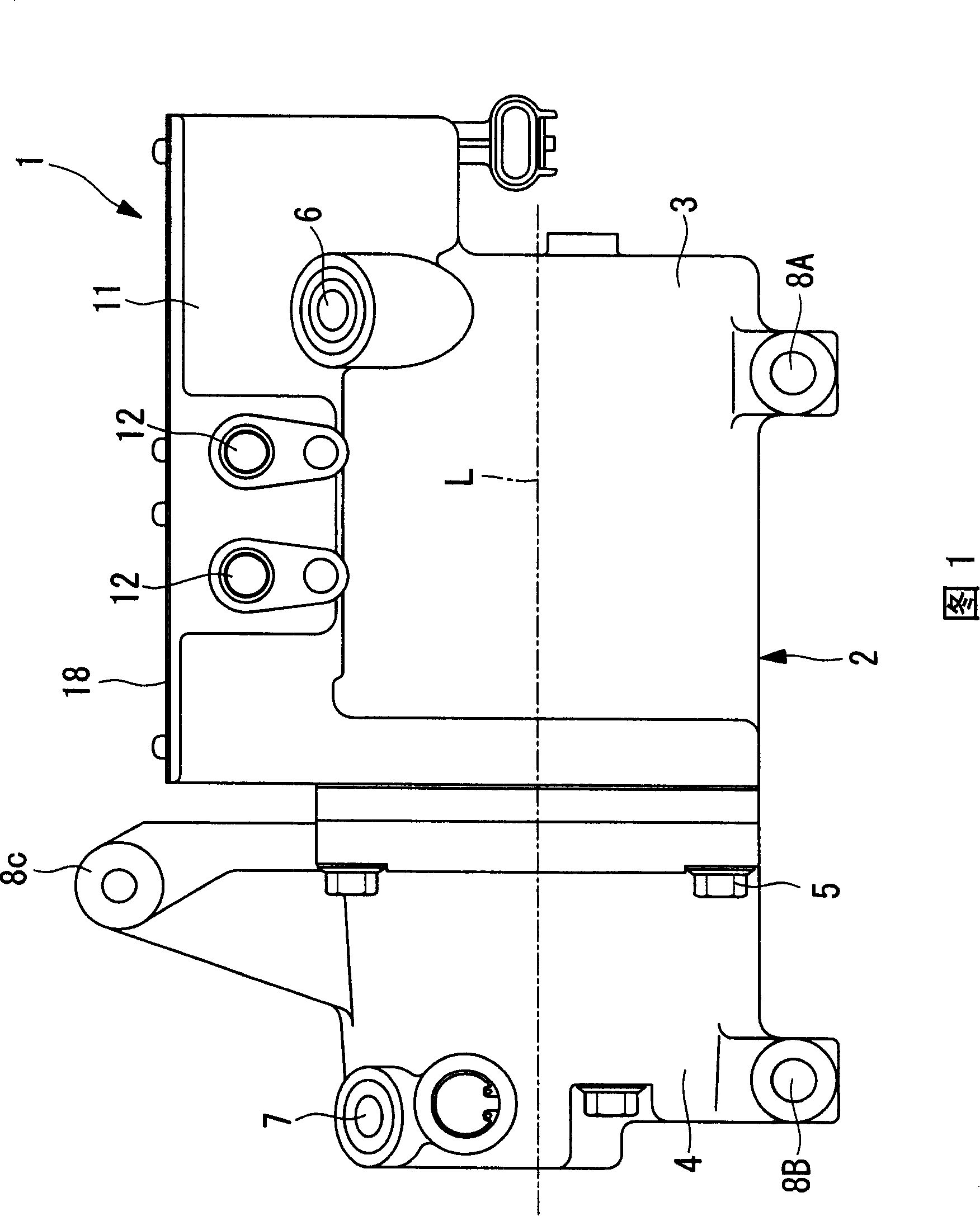

The present invention provides a secondary battery module which is excellent in vibration resistance. A battery module 20 has assembled battery blocks 11 each constituted by screw-fixing the assembled batteries 2 to the block bases 3, 4 supporting a lower portion thereof and the two block reinforcing plates 5 supporting an upper portion thereof, the six assembled batteries 2 are sandwiched by and fixed firmly to the block bases 3, 4 and the block reinforcing plates 5. The assembled batteries 2 do not move freely even if vibration is added to the battery module 20. Because the elastic sheet 9 is laid between the block bases 3, 4 and the assembled batteries 2, since a space derived due to variance in size accuracy of frames 12 which hold and fix the unit cells 11 and derived due to variance in size accuracy of the block bases 3, 4 can be removed, and vibration resistance can be enhanced. To thermal stress change caused due to combination of different materials, influence thereof can be reduced by laying the elastic sheet 9.

Owner:HITACHI AUTOMOTIVE SYST LTD

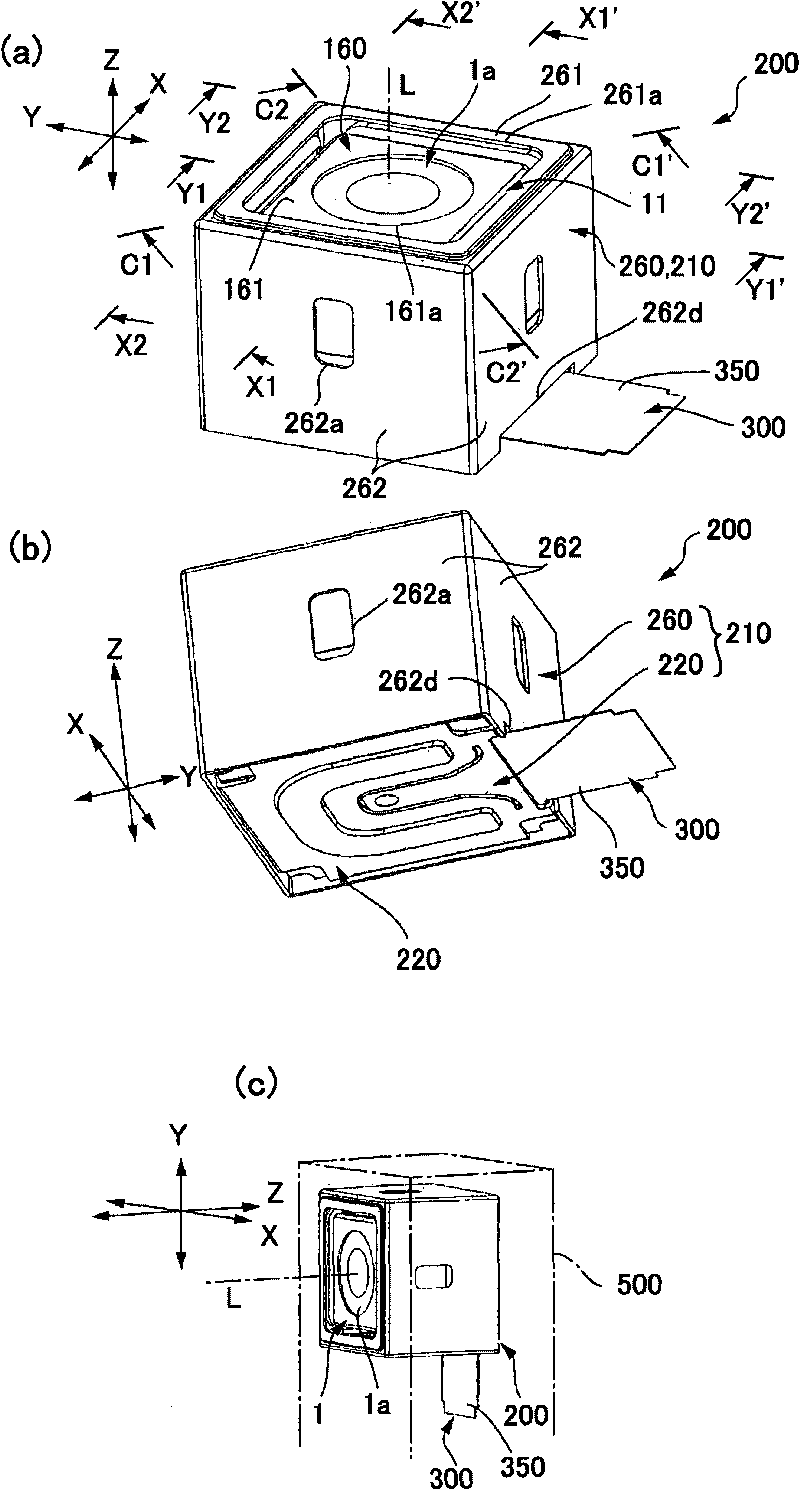

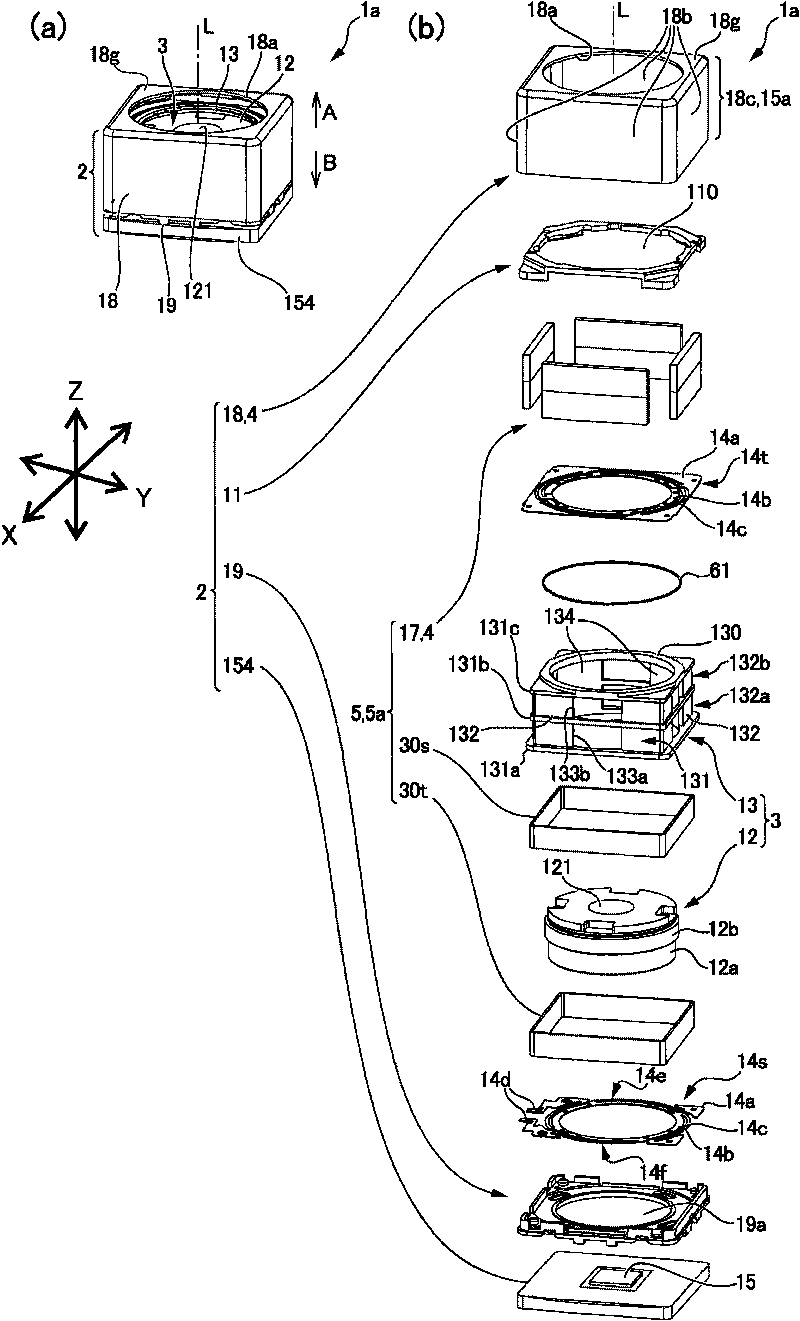

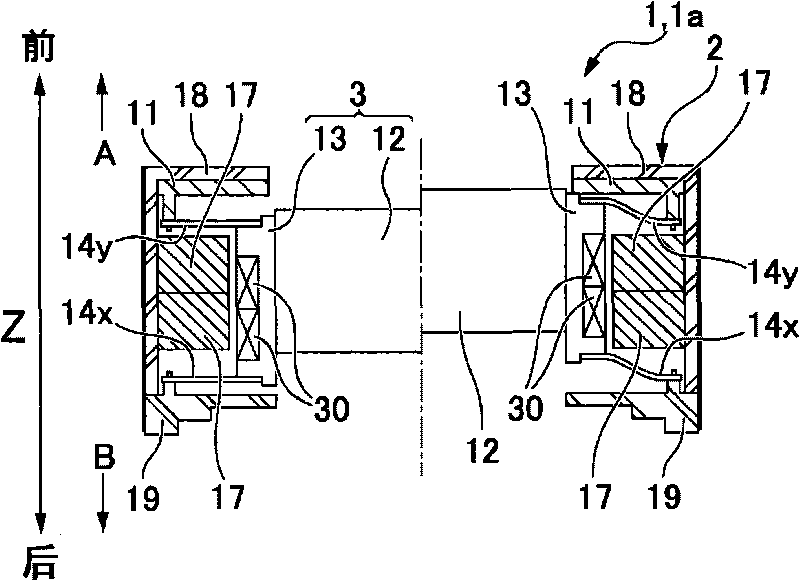

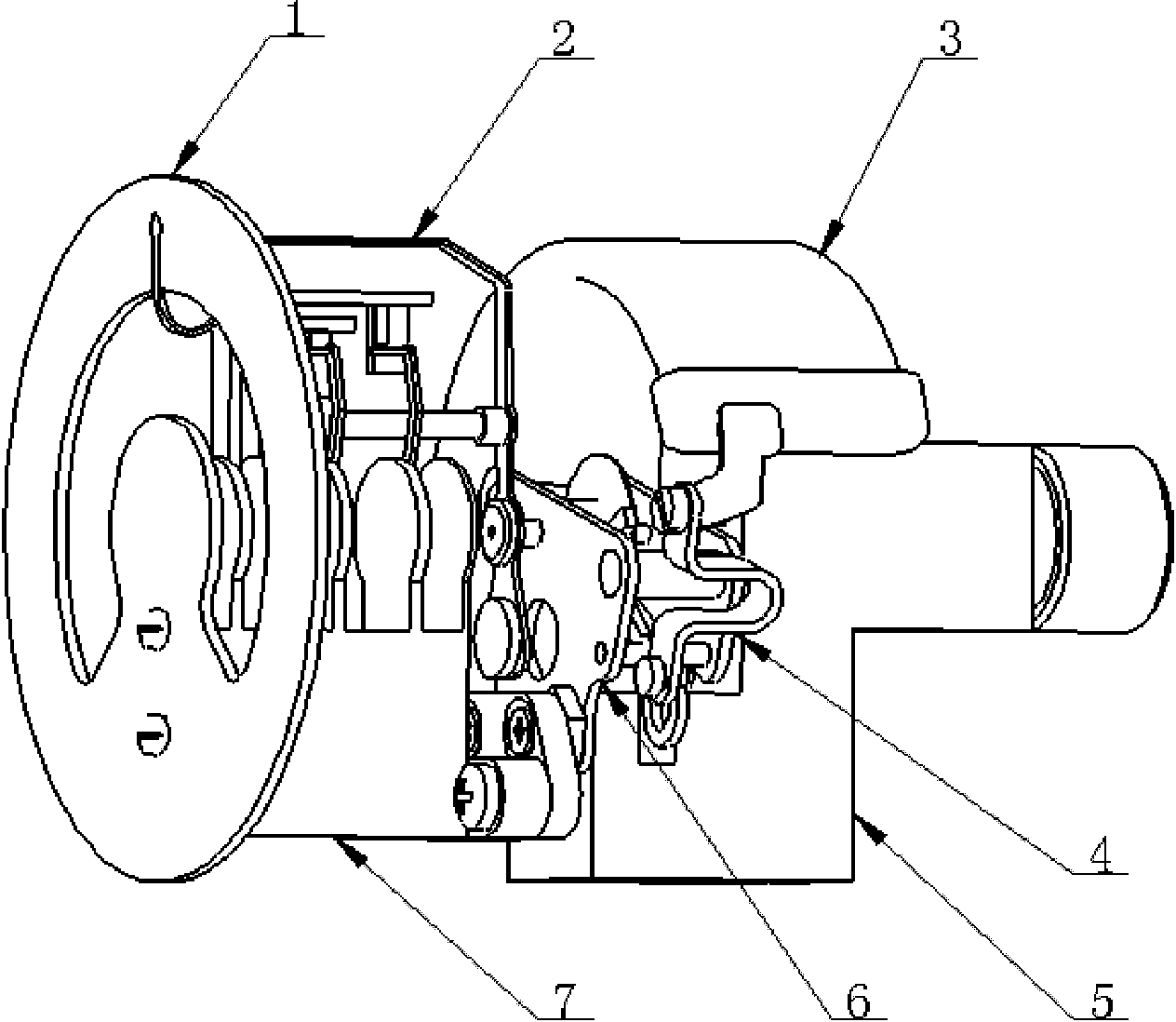

Optical unit with shake correcting function

The present invention may advantageously provide an optical unit with shake correcting function in which shake of a movable module is corrected with a small torque and a quick response without mechanically connecting the fixed body and the movable module through a drive mechanism. An optical unit with shake correcting function may include a movable module having a lens, a fixed body supporting the movable module, a shake detection sensor for detecting shake of the movable module, and at least one pair of magnetic drive mechanism for shake correction which is structured on both sides of the movable module so that the movable module is swung with respect to the fixed body on the basis of detection result of the shake detection sensor to correct the shake of the movable module. The magnetic drive mechanism for shake correction is disposed so that a shake correction magnet is held by the fixed body and a shake correction coil is held by the movable module.

Owner:NIDEC SANKYO CORP

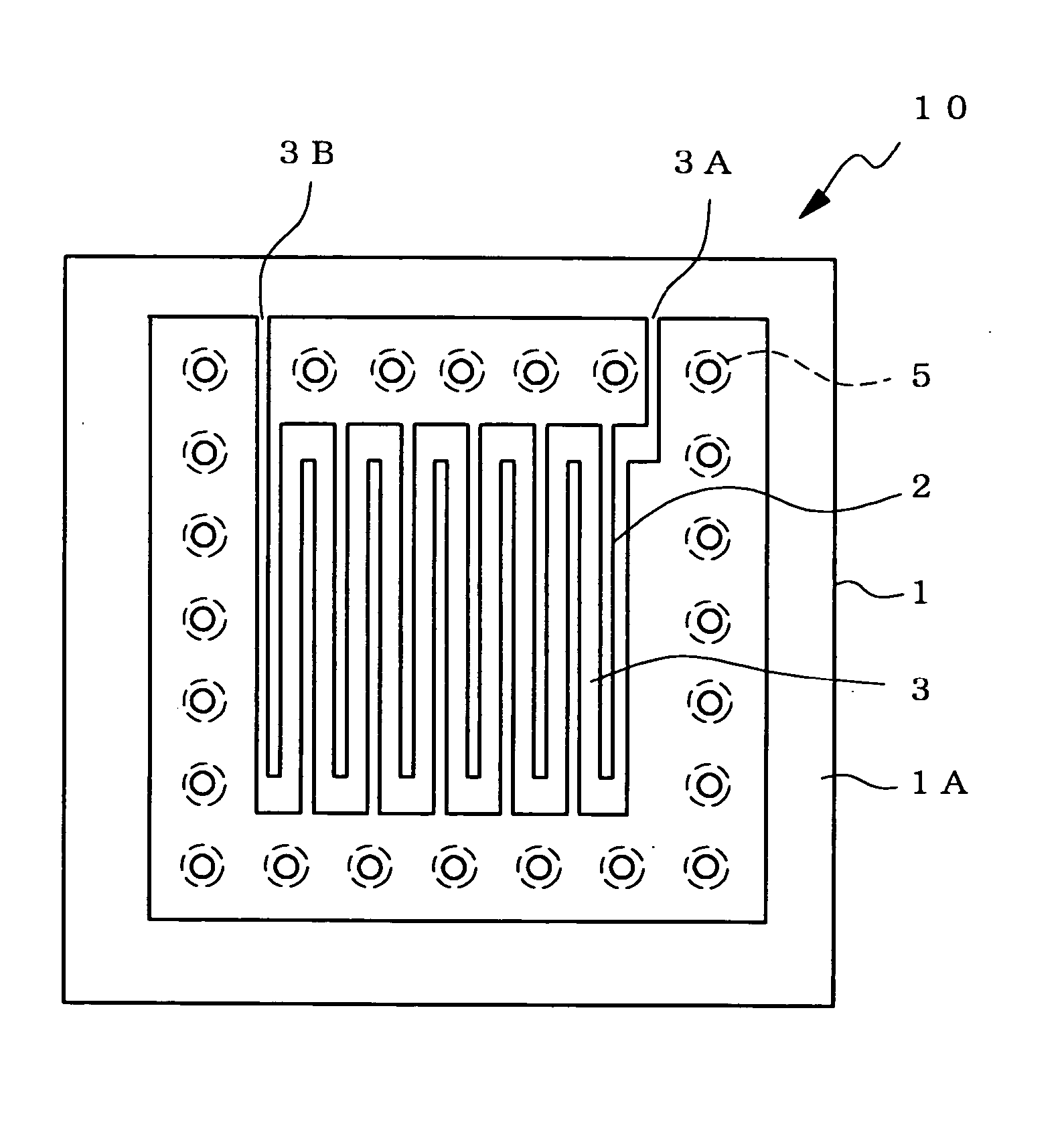

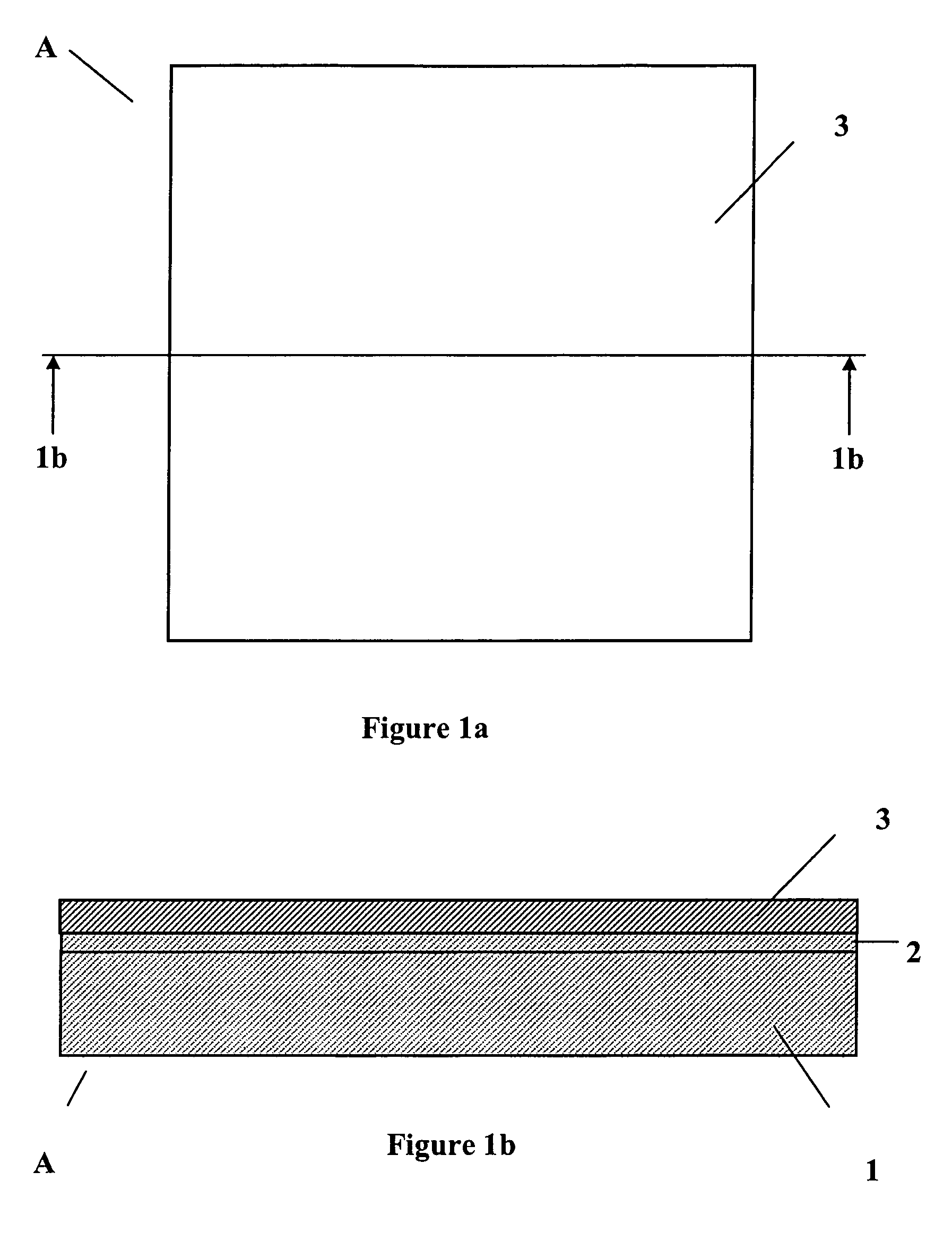

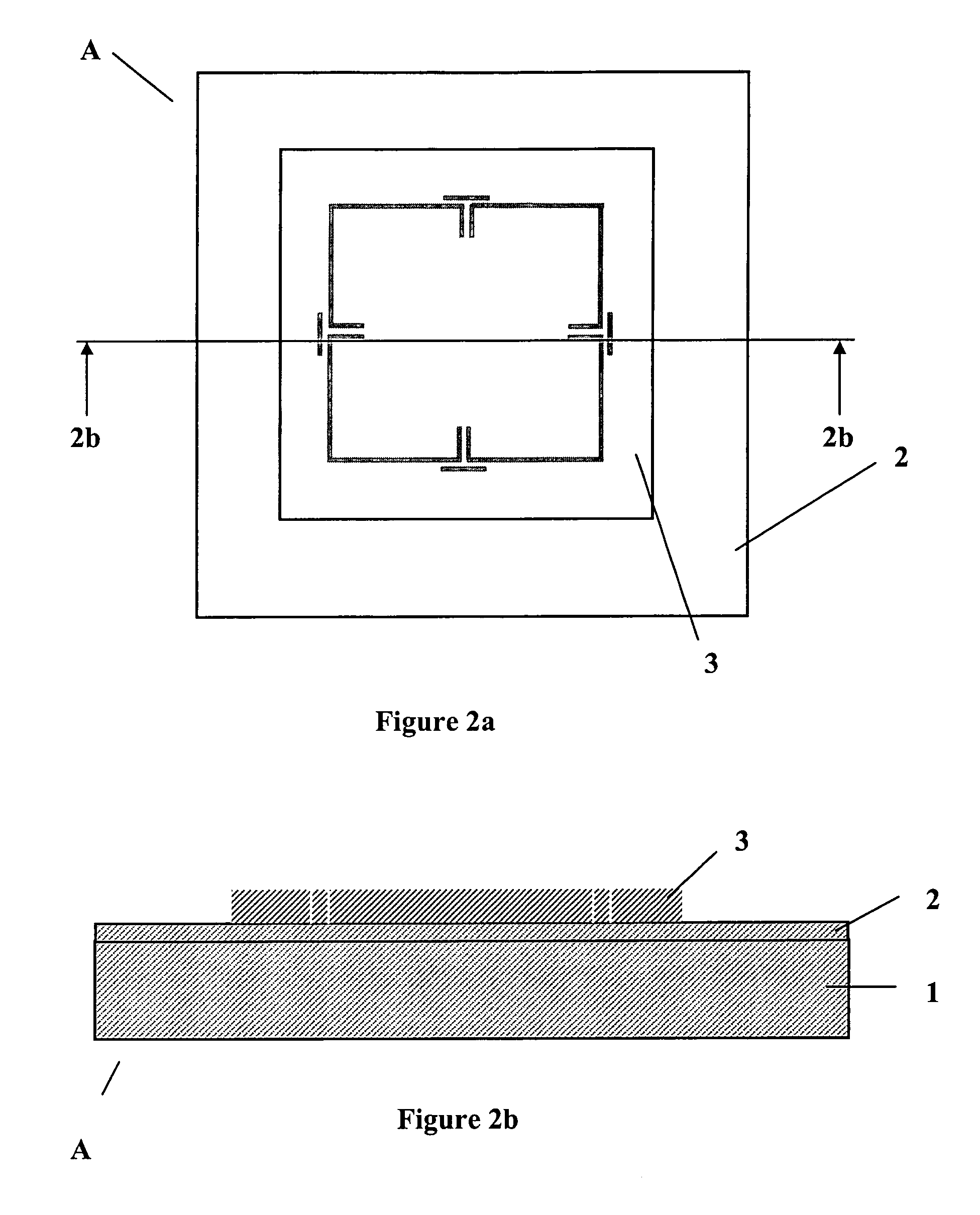

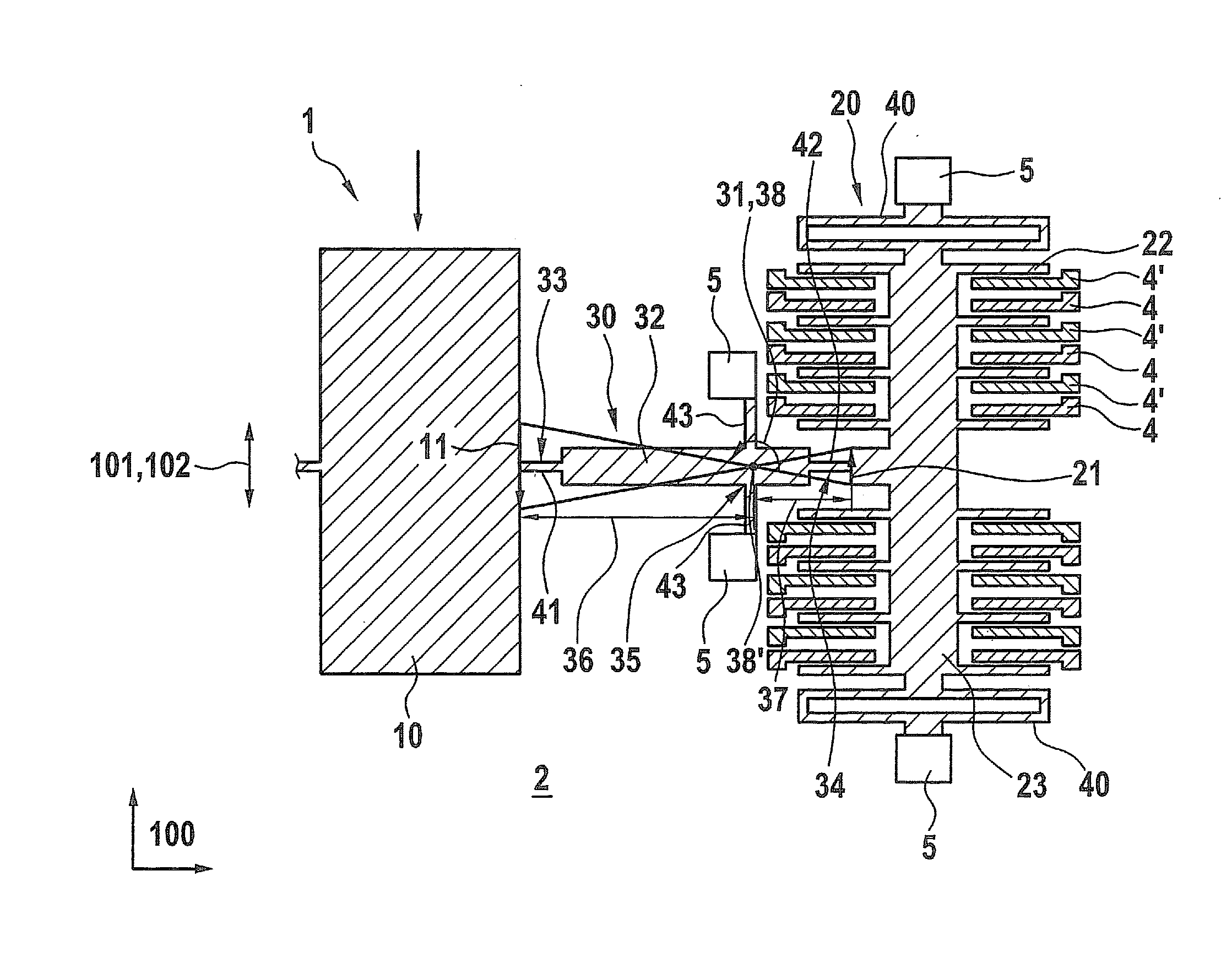

Separator for fuel cell and fuel cell using the same

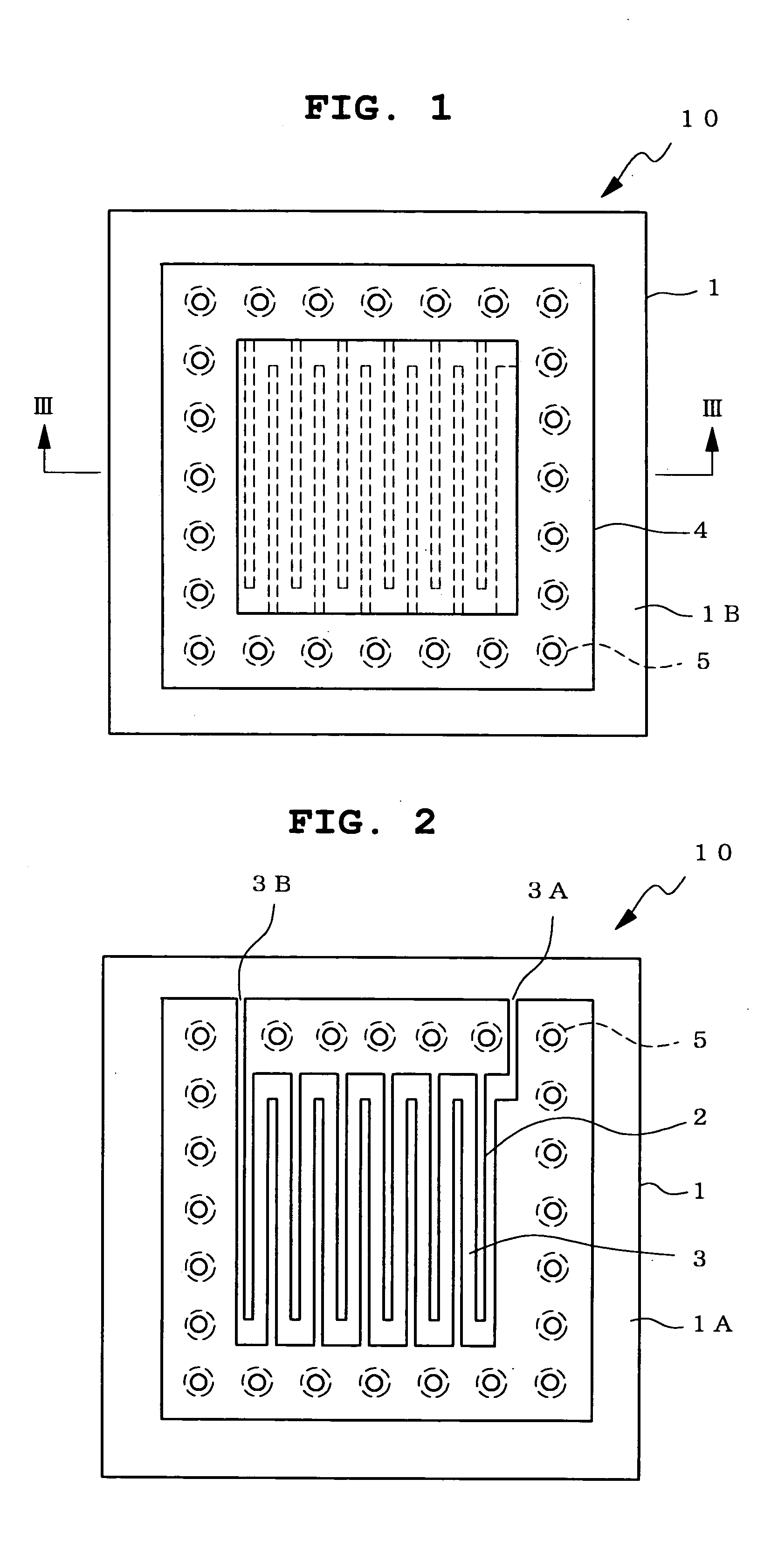

InactiveUS20050026028A1Simple processMaintain strengthFuel cells groupingFuel cell auxillariesFuel cellsElectrical conductor

The present invention provides, as a separator for fuel cell which is lightweight, can be easily made thin, and which has superior corrosion resistance and shape stability, a fuel cell 100 containing a separator for fuel cell 10, wherein a conductor pattern 2 is formed on one principal plane 1A of an insulation layer 1 to form a groove for a gas flow path 3 sectioned by the conductor pattern 2 on this principal plane, a conductor terminal 4 is formed on the other principal plane 1B of the insulation layer 1, and this conductor terminal 4 and the conductor pattern 2 are electrically connected by a via hole 5 penetrating the insulation layer 1, and a membrane electrode assembly (complex having an electrolyte membrane and an electrode (fuel electrode, oxygen electrode) laminated thereon) 14 having the separator for fuel cell disposed on both surfaces.

Owner:NITTO DENKO CORP

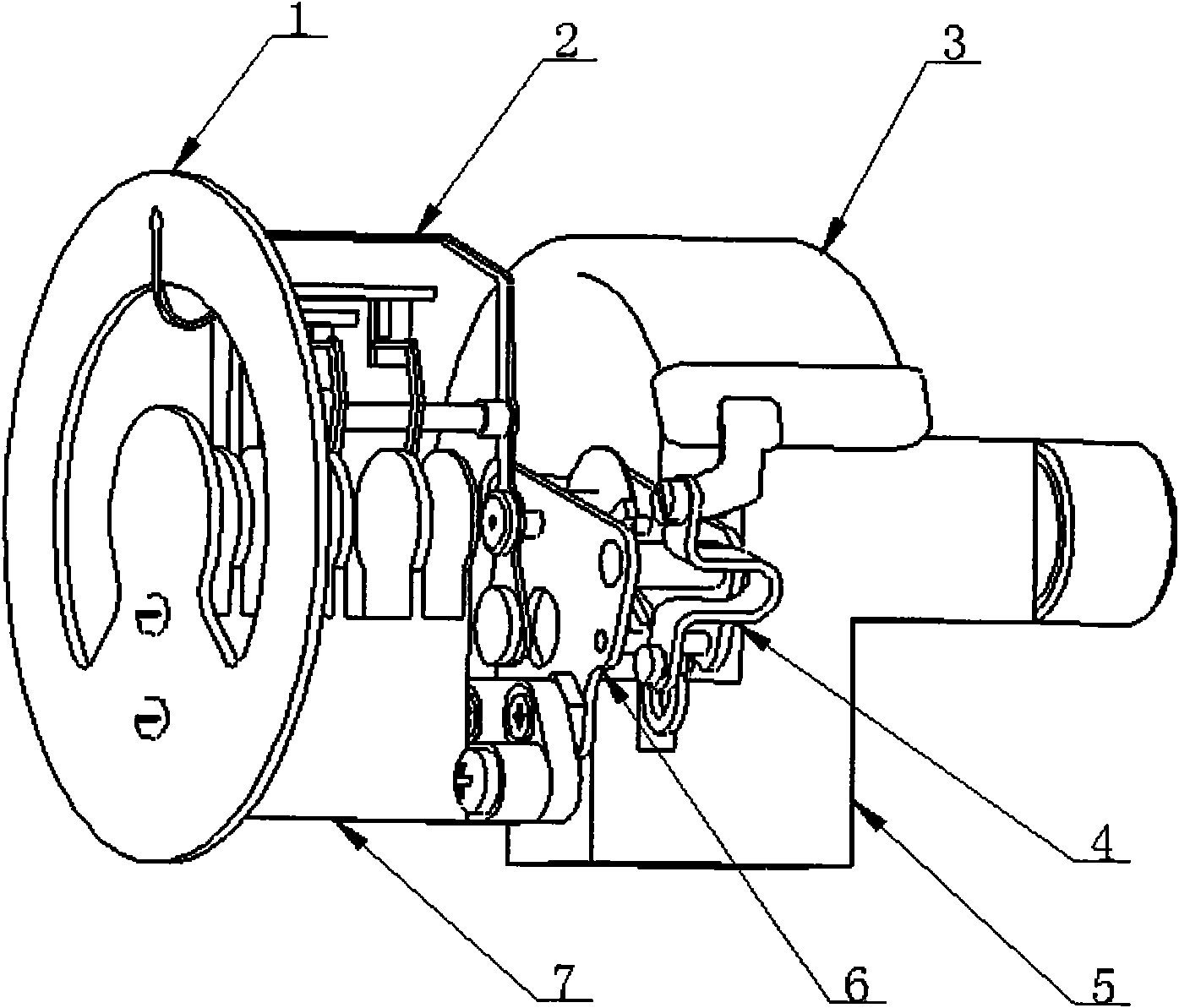

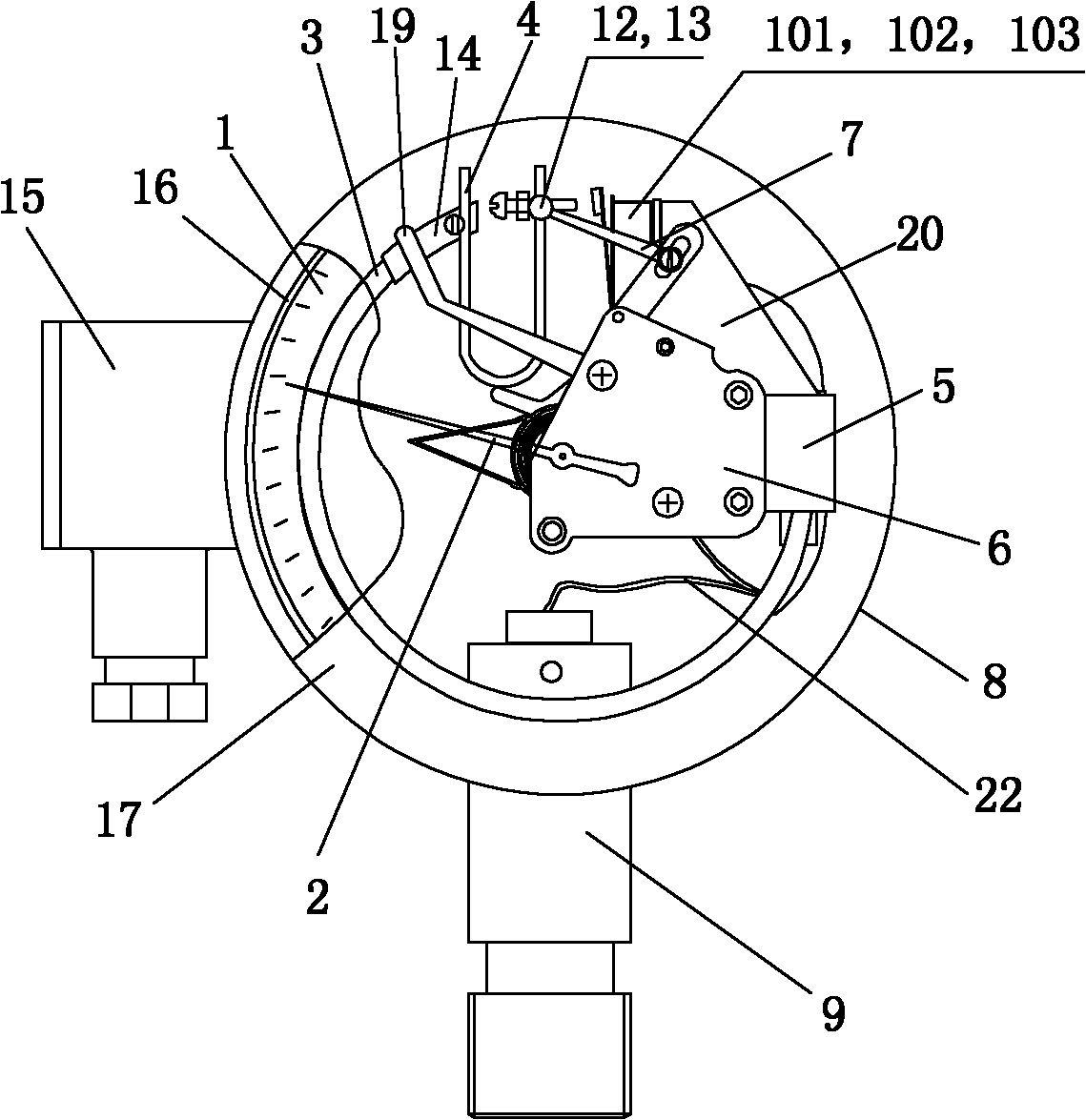

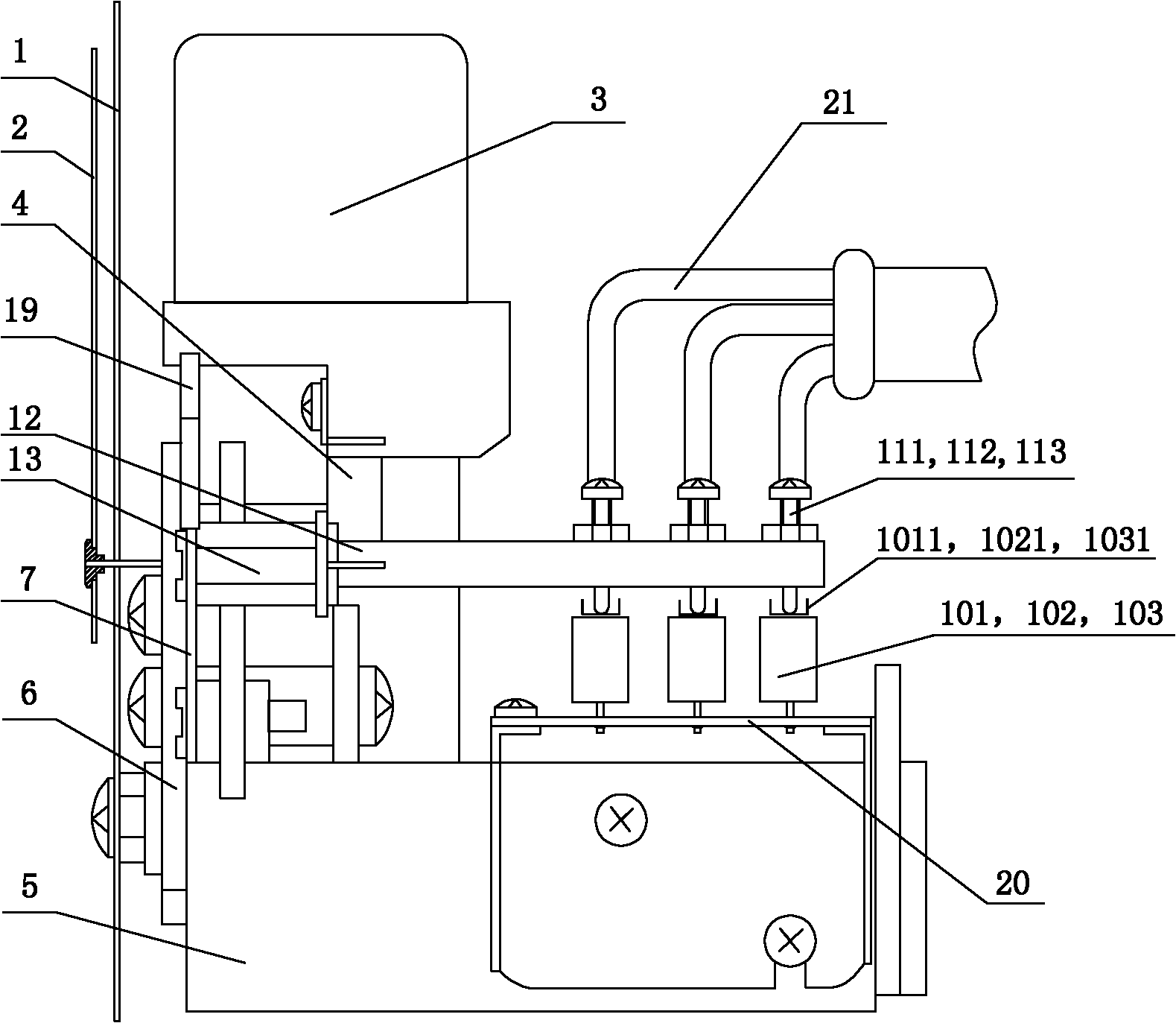

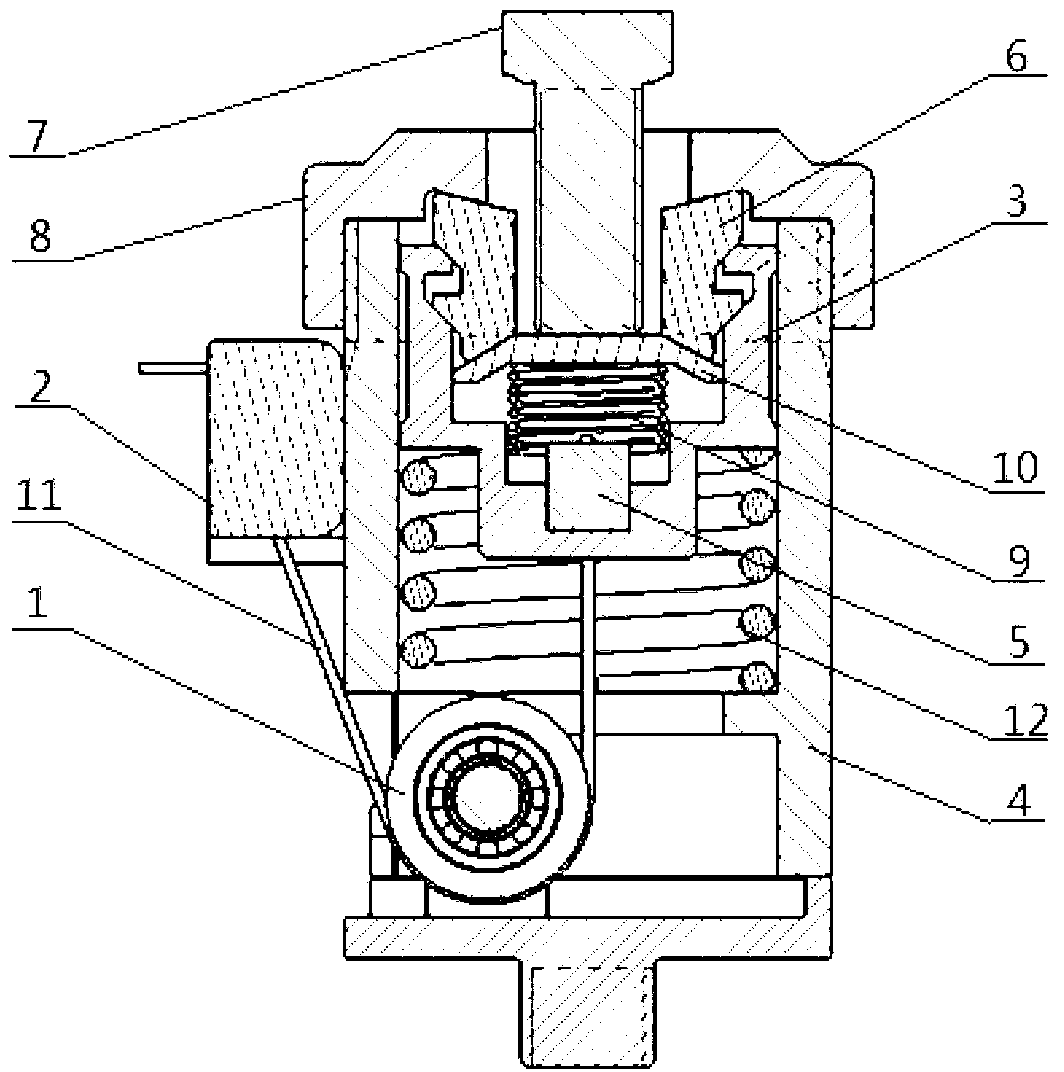

Sulfur hexafluoride gas density relay

InactiveCN102013357AImprove vibration resistanceImprove electrical performanceElectric switchesSulfur hexafluorideEngineering

The invention relates to a sulfur hexafluoride SF6 gas density relay with low pressure. In the structure of the density relay, a control part and a display part are separately designed, the control part comprises a Bourden tube, a temperature compensation element and a joint operating arm; the display part also comprises a Bourden tube and a temperature compensation element; the two Bourden tubes are welded on a base, the other ends of the Bourden tubes are connected with an end sea, the end seat is connected with one end of each temperature compensation element, and the other ends of the temperature compensation elements are connected with the joint operating arm or a clock mechanism. Therefore, the display part and the control part are not mutually influenced when working, and the display precision and the display range of the display part are not limited, and the electric property and the service life of the relay are greatly improved.

Owner:SHANGHAI ROYE ELECTRIC SCI & TECH

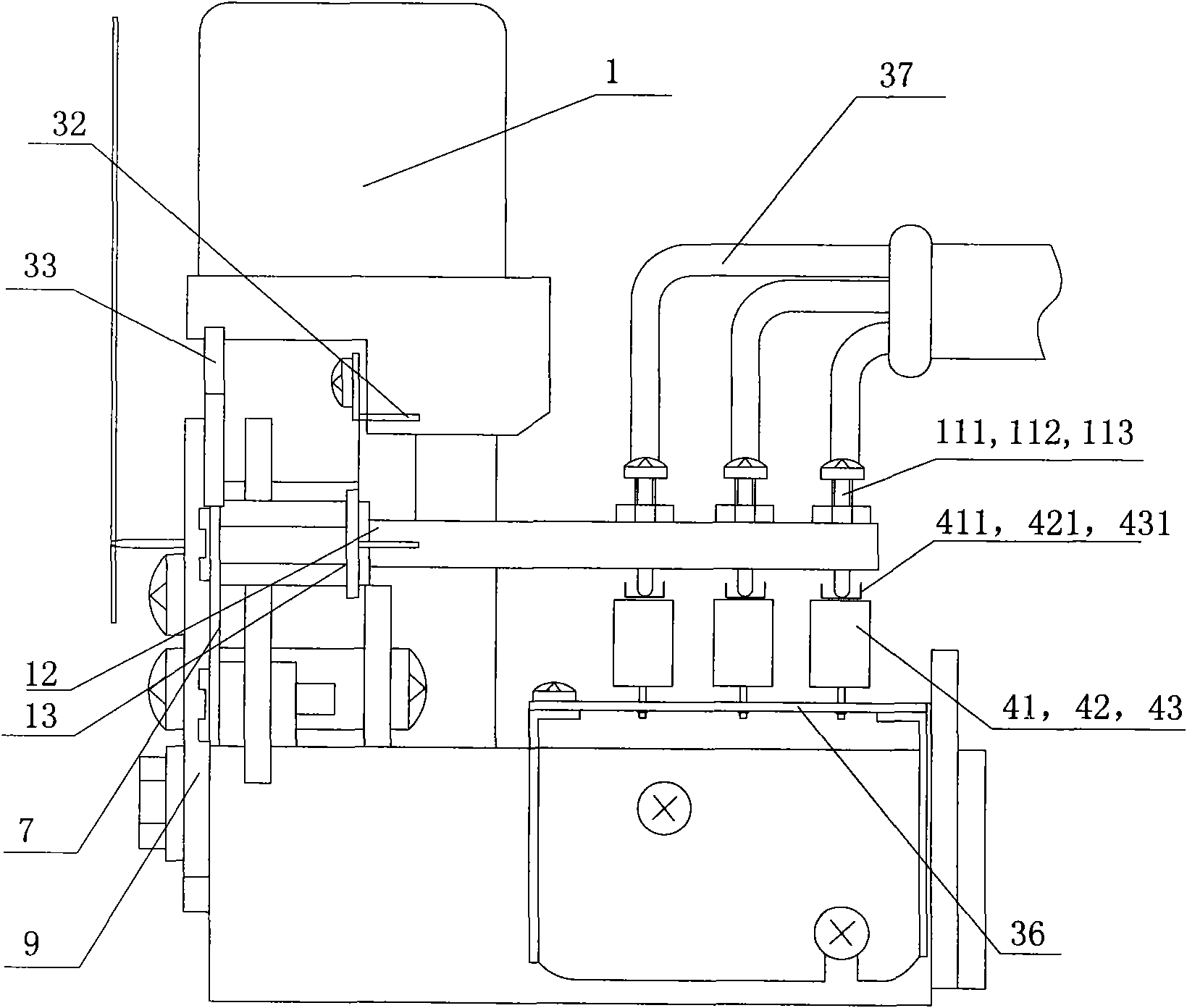

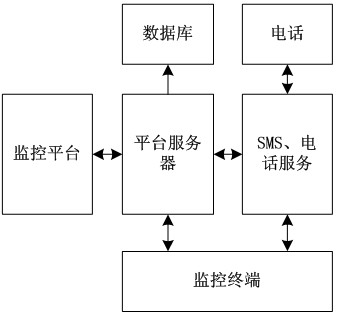

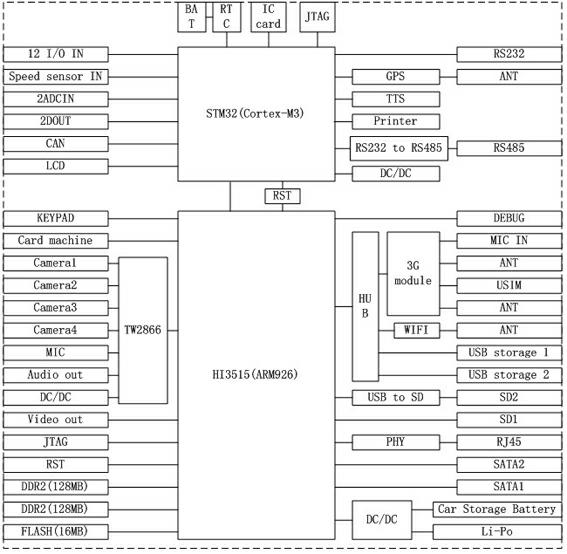

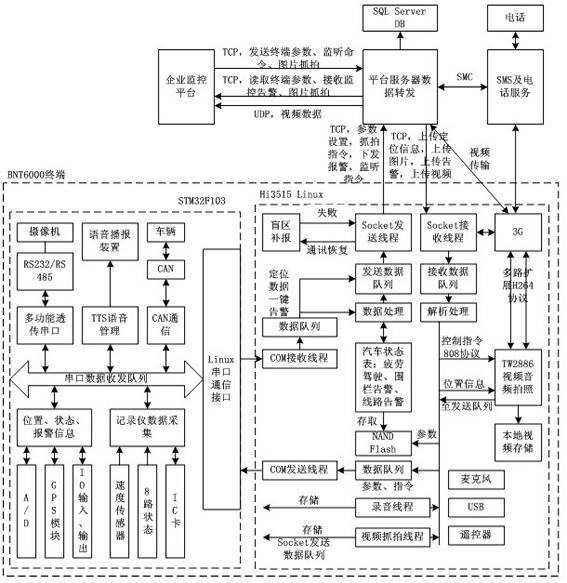

Beidou satellite monitoring safe driving system based on 3G network

InactiveCN102651173AImprove securitySubstantial market returnsRoad vehicles traffic controlVideo monitoringThird generation

The invention discloses a Beidou satellite monitoring safe driving system based on a 3G (third generation) network. The Beidou satellite monitoring safe driving system comprises a platform server positioned in a monitoring center and a monitoring terminal at a vehicle end, wherein the monitoring terminal is connected with the platform server through a network communication system; a monitoring platform, a database, SMS (short message service) and telephone service are operated on the platform server; and the monitoring terminal comprises a housing and a mechanism circuit arranged in the housing. According to the Beidou satellite monitoring safe driving system disclosed by the invention, under the concept of an inter-vehicle network, three major functions, namely positioning by a Beidou vehicle-mounted satellite, 3G wireless video monitoring and vehicle driving recording are firstly integrated, double-CPU (central processing unit) real-time processing, a DSP (digital signal processing) algorithm, an optimization transceiving queue scheduling algorithm, a double-code stream, a special file system, identity comparison identification and other technologies are integrated, video signals collected by a video camera are compressed, encoded and then converted to a compressed code stream, and real-time transmission is realized through the 3G network.

Owner:CHENGDU YIMENG HENGXIN TECH

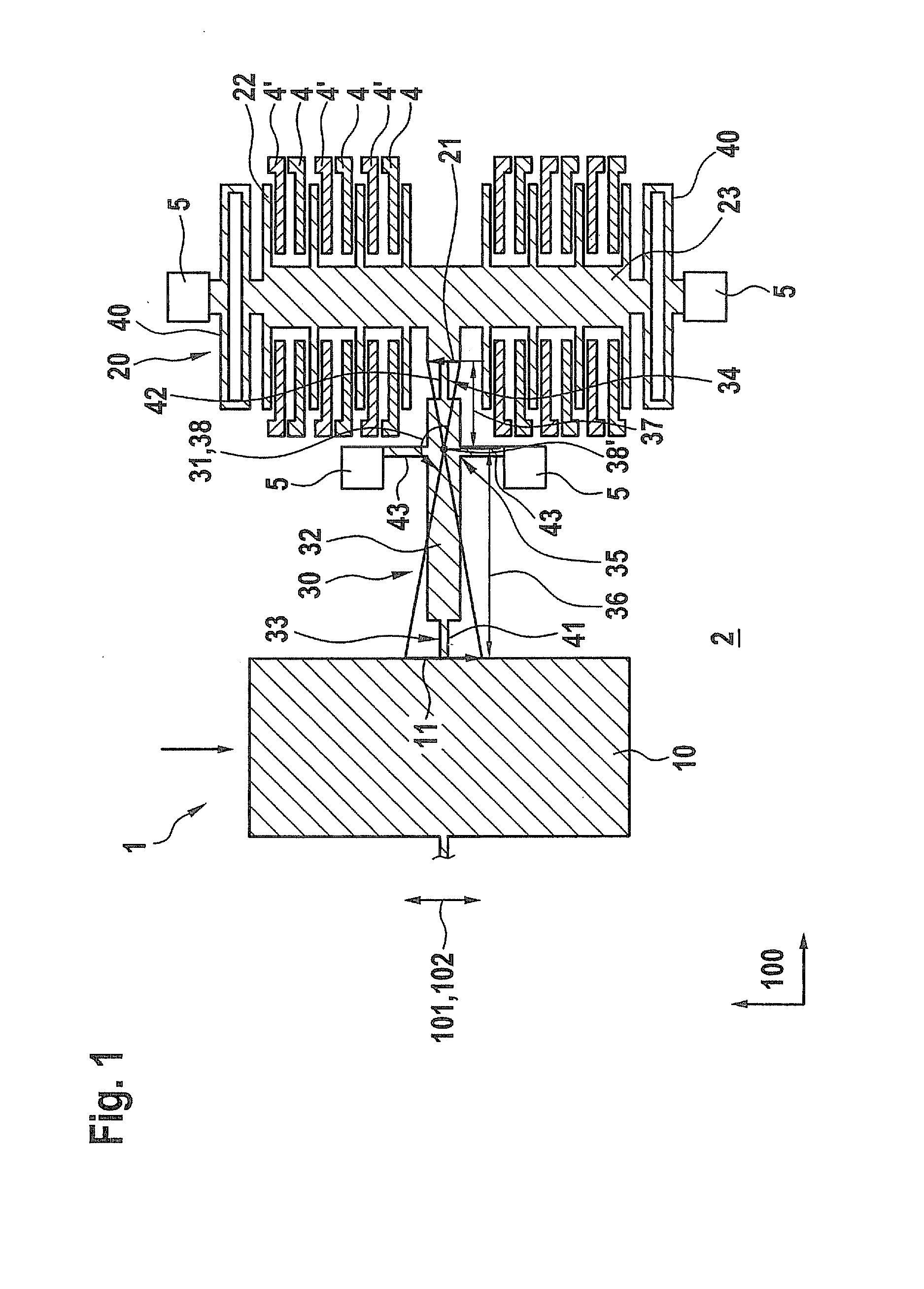

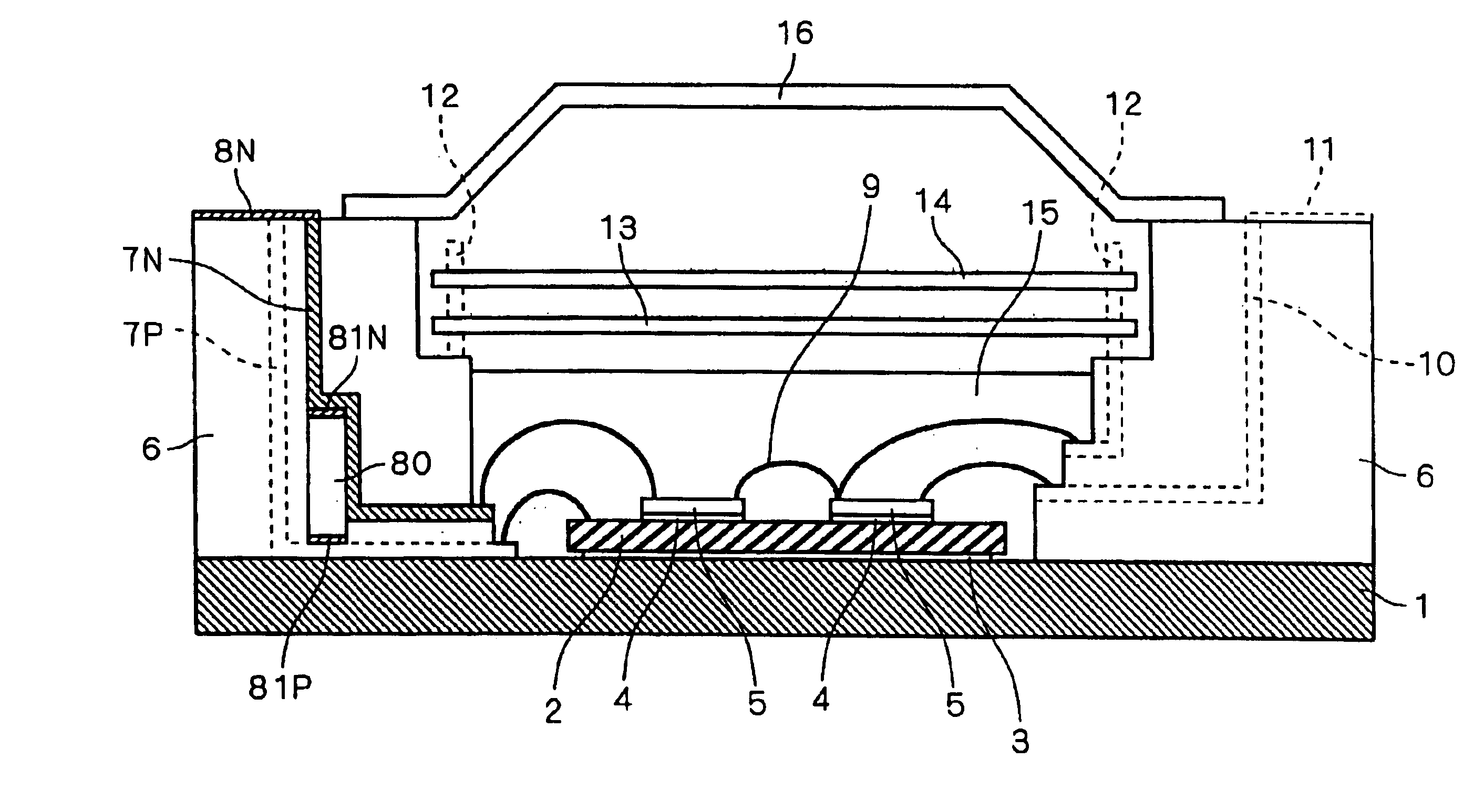

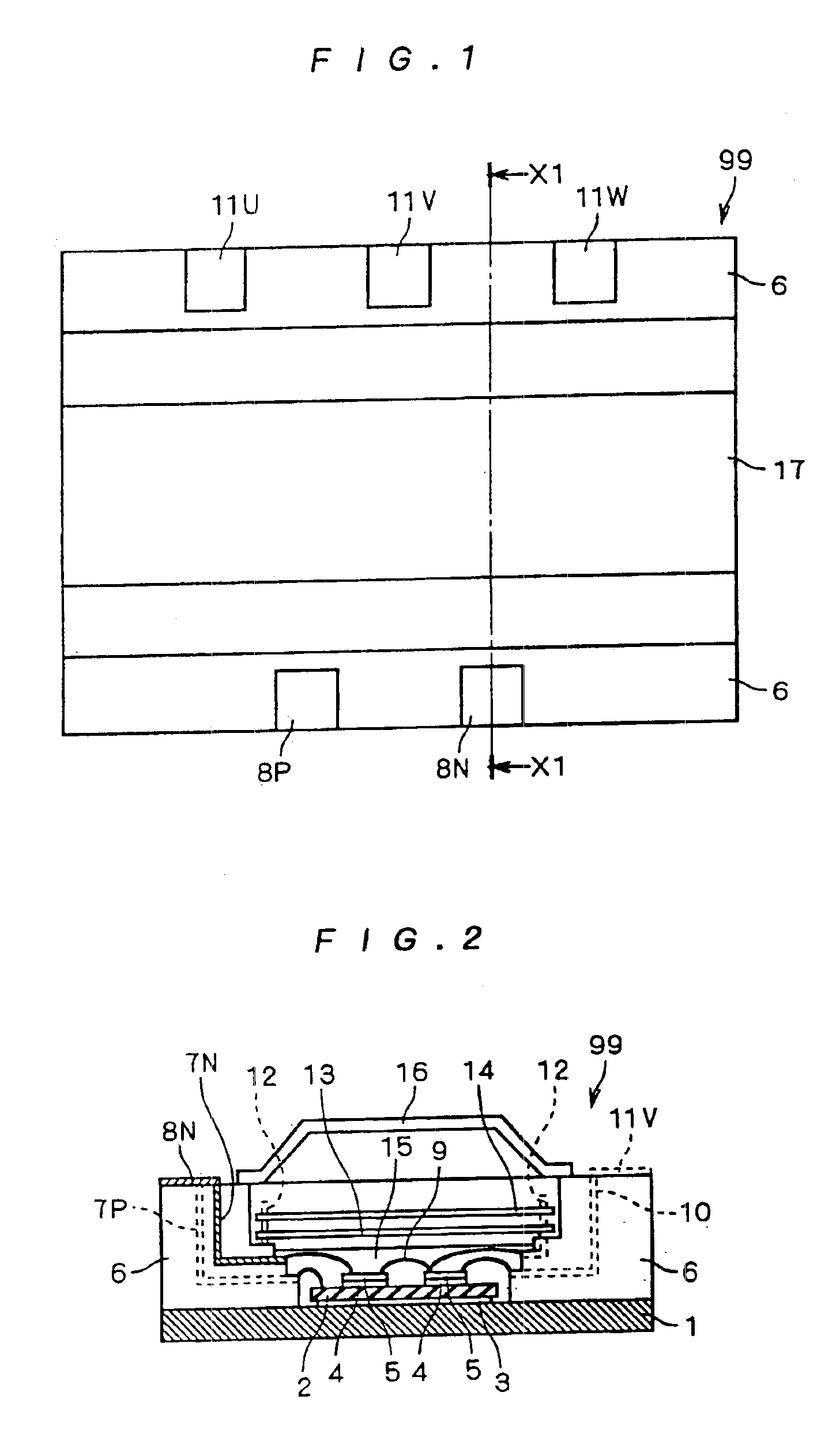

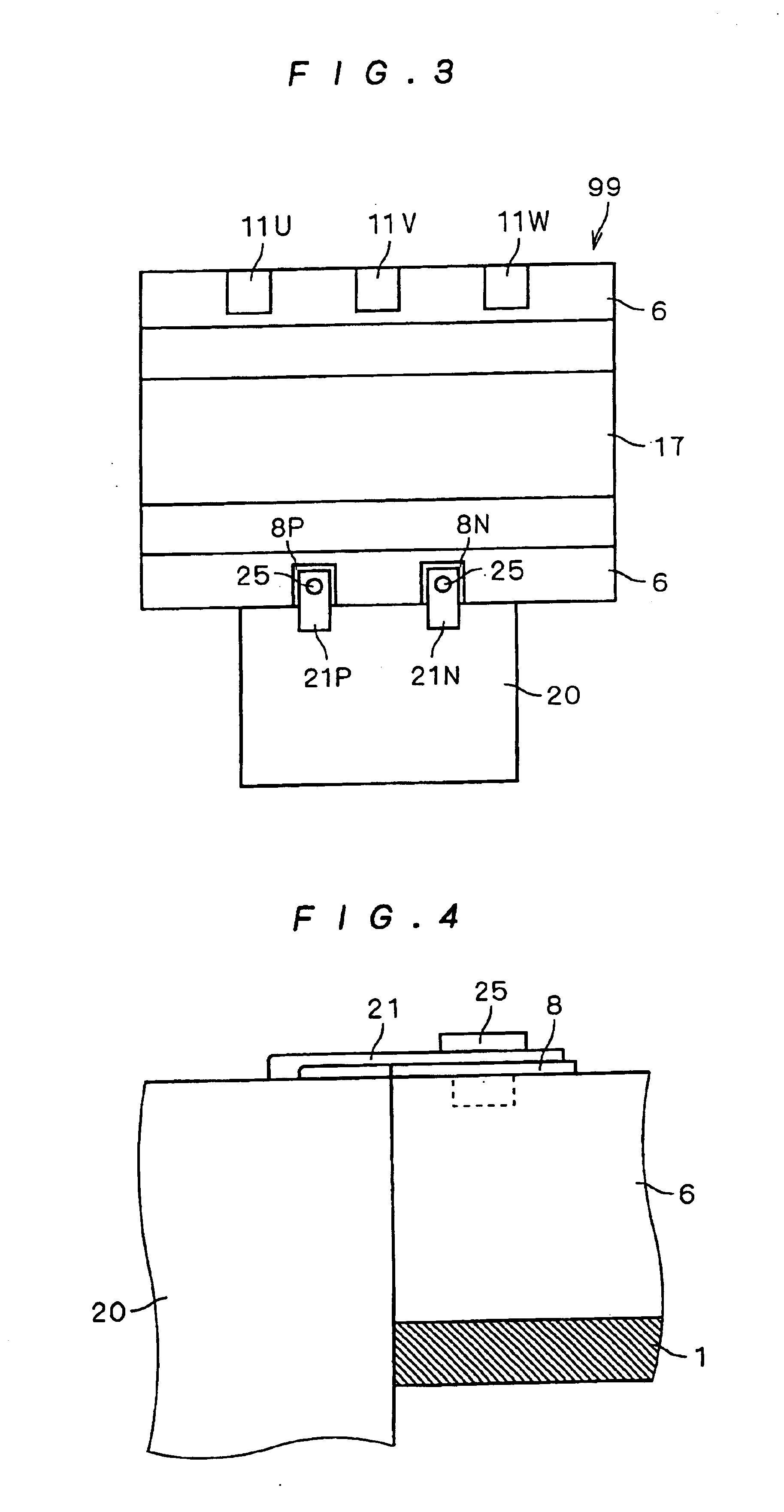

Integrated-inverter electric compressor

ActiveUS20080205107A1Easy to assembleImprove vibration resistanceLine/current collector detailsPrinted circuit board receptaclesPower semiconductor deviceEngineering

An object is to provide an integrated-inverter electric compressor that can enhance assembly and vibration resistance of power semiconductor switching devices and control substrates thereof constituting the inverter device. The integrated-inverter electric compressor, in which an inverter device is installed in an inverter container provided on an outer circumference of a housing, includes a plurality of IGBTs constituting the inverter device and a guide member having a plurality of guide holes for passing terminals of the IGBTs provided between the control substrate and the IGBTs. The guide member is provided with at least one first positioning pin, fitted in positioning holes provided in a mounting surface of the IGBT, in one side surface facing the IGBT, and at least one second positioning pin, fitted in positioning holes provided in the control substrate, in another side surface facing the control substrate.

Owner:MITSUBISHI HEAVY IND LTD

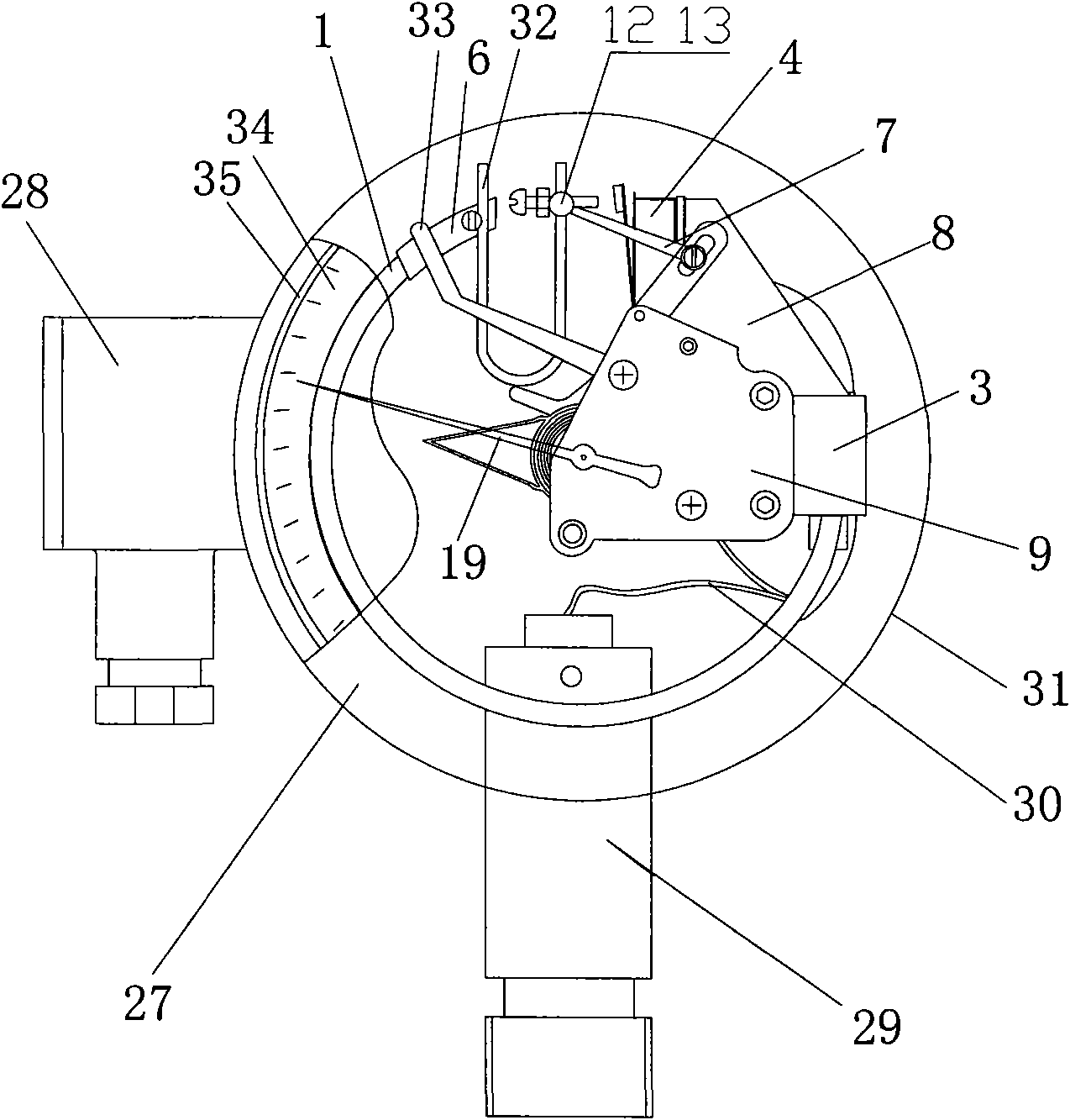

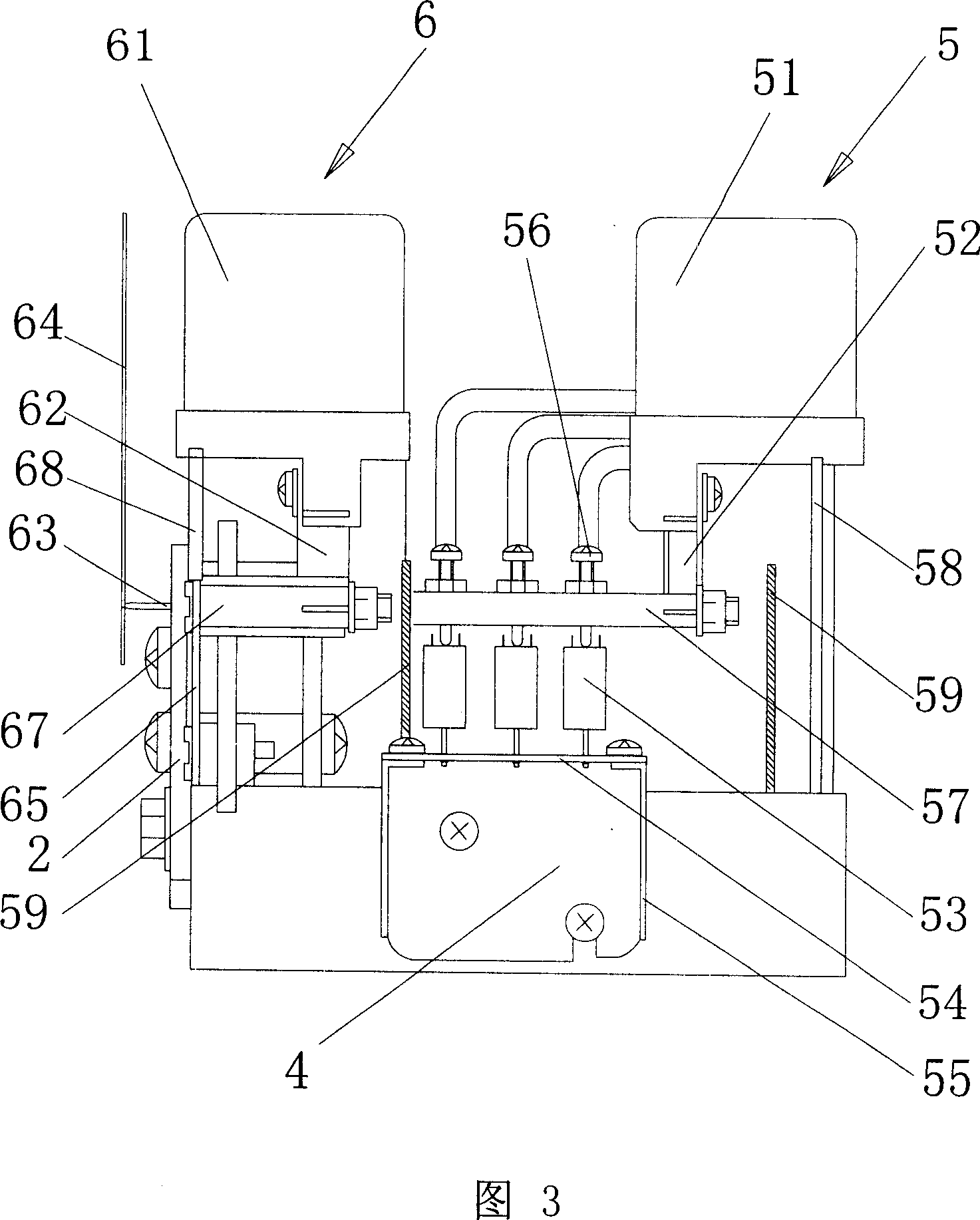

Sulfur hexafluoride gas density relay

InactiveCN101847544AOvercome the defect of only showing the zoom-in functionHigh precisionHigh-tension/heavy-dress switchesSignal generatorSulfur hexafluoride

The invention discloses a sulfur hexafluoride gas density relay, which comprises a shell, a base, an end base, a bourdon tube, a temperature compensating element, and a plurality of micro switches serving as signal generators of the gas density relay, wherein one end of the bourdon tube is connected to the base, while the other end is connected with one end of the temperature compensating element by the end base; the micro switches are arranged on the base or in the shell, and are provided with connection point operating handles; the gas density relay further comprises a displacement magnification mechanism, wherein the displacement magnification mechanism has an initial end which is connected with the other end of the temperature compensating element, and an amplifying end which drives the connection point operating handles of the micro switches to connect or disconnect connection points on the micro switches; and when a gas density value changes, the bourdon tube and the temperature compensating element displace, and the displacement is magnified by the displacement magnification mechanism and then transmitted to the micro switches to make the micro switches send corresponding signals. As a result, the function of the density relay is completed.

Owner:SHANGHAI ROYE ELECTRIC SCI & TECH

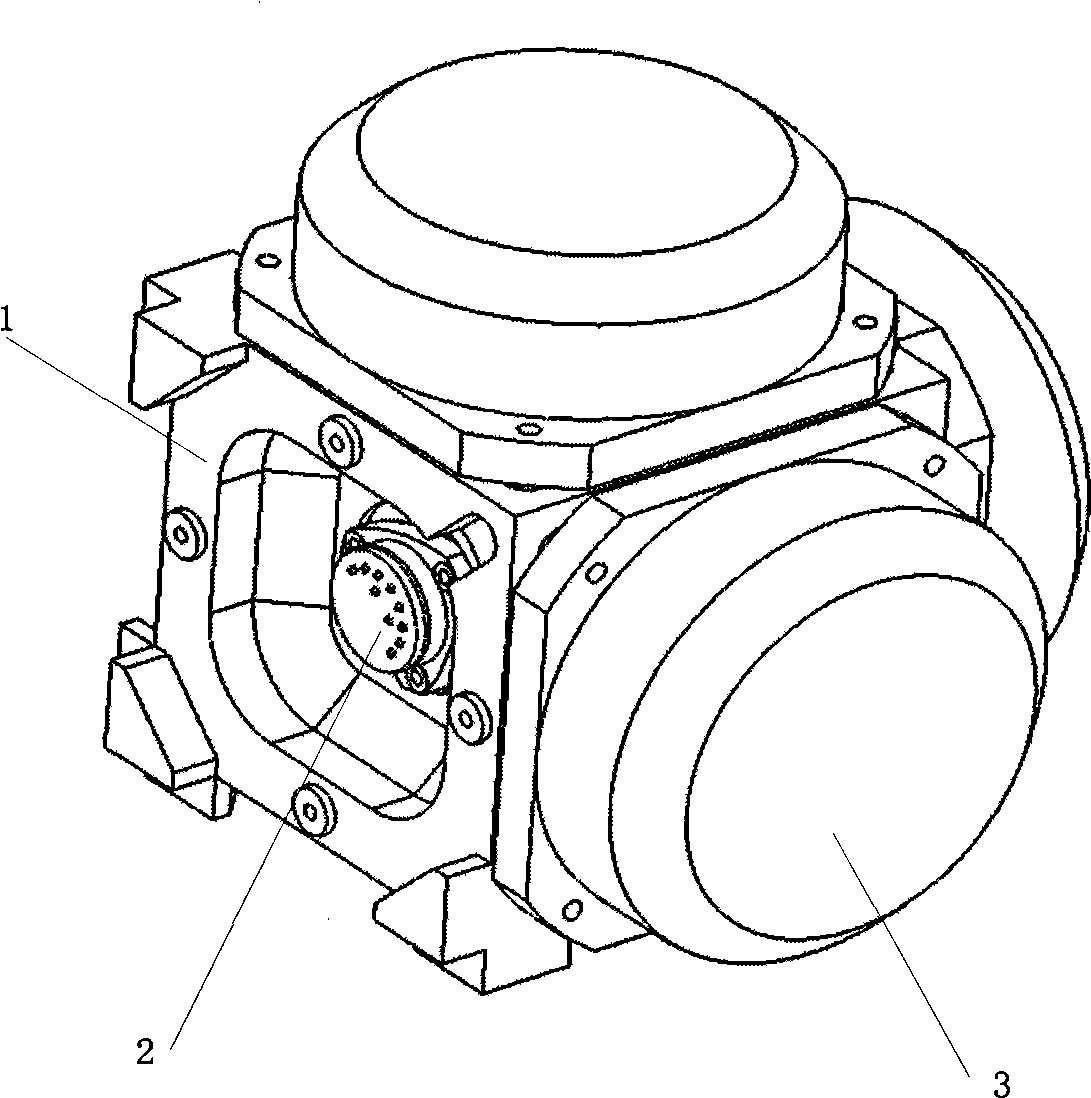

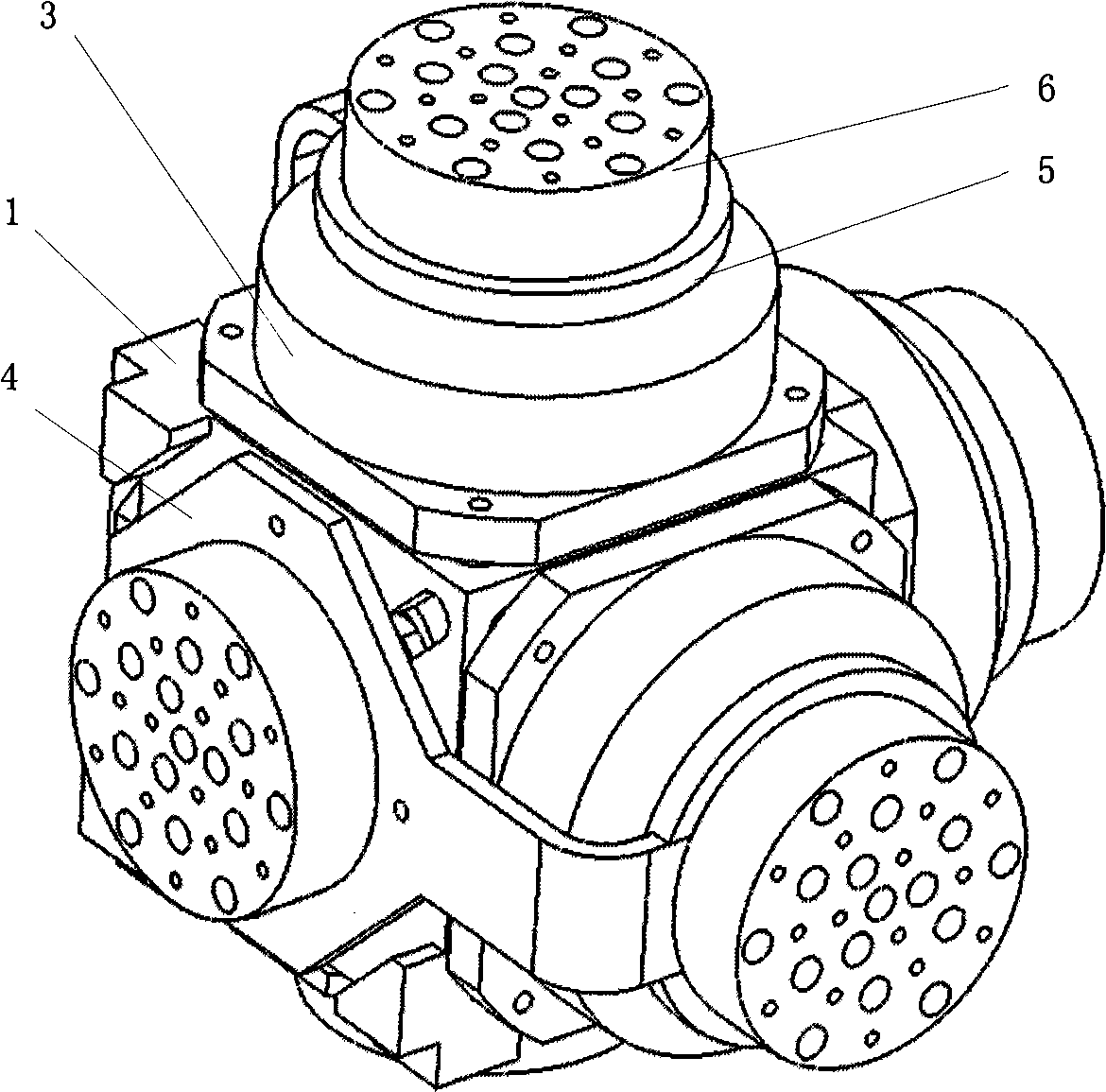

Inertia measurement device for deep-sea inertia navigation

InactiveCN101532840AHigh precisionReduce the impact of measurement accuracyNavigation by speed/acceleration measurementsAccelerometerMeasurement device

The invention relates to an inertia measurement device for deep-sea inertia navigation, which consists of six accelerometers, three gyros, a sensor bracket, a damping material, damping internal and external brackets and a mounting surface. The accelerometers and the gyros are arranged at the regular hexahedral sensor bracket. The damping internal bracket is fixed at the sensor bracket, the damping material is fixed at the damping internal bracket, the internal bracket is connected with the external bracket through the damping material and finally connected to the mounting surface, and the mounting surface is provided with a positioning surface for positioning at initial alignment. The measurement device is used for measuring the inertia of the deep-sea inertia navigation, and has the advantages of high precision and good damping property.

Owner:ZHEJIANG UNIV

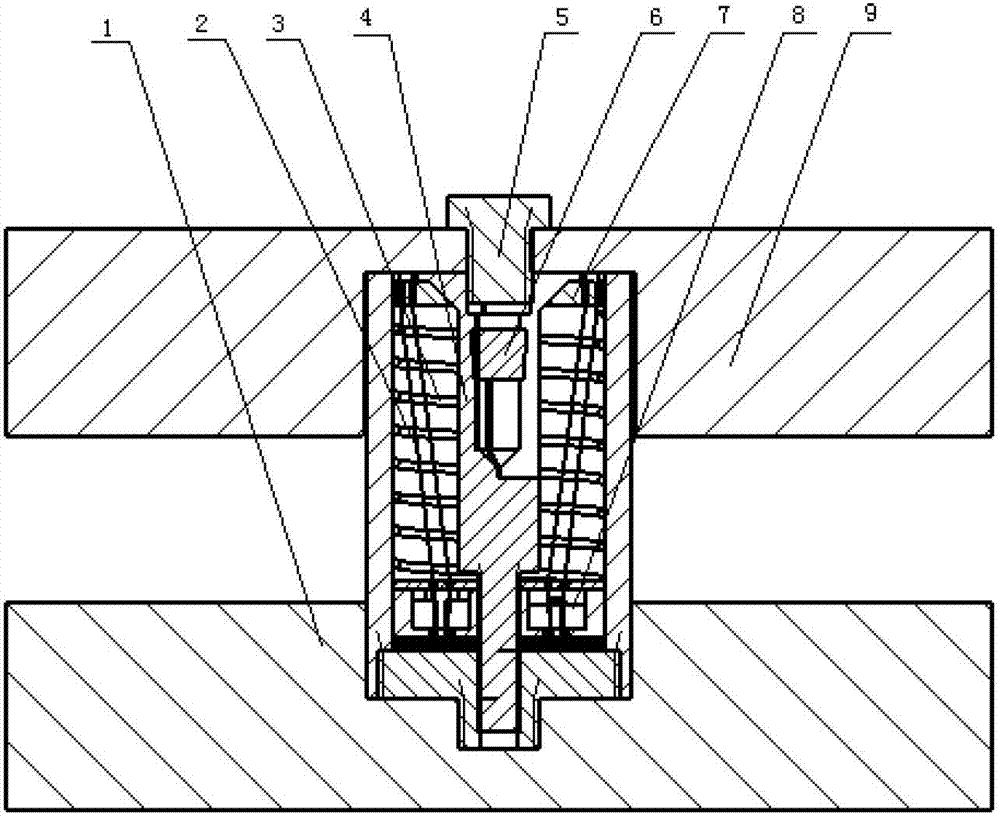

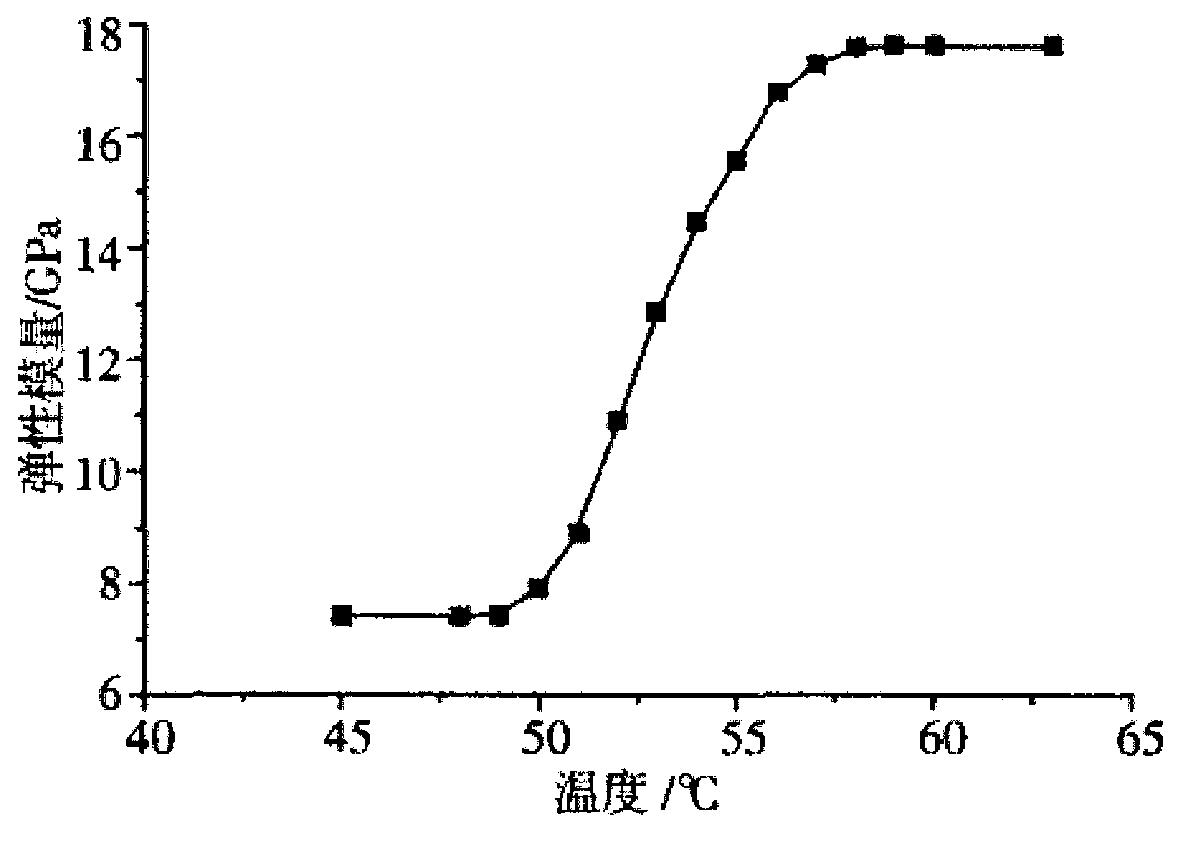

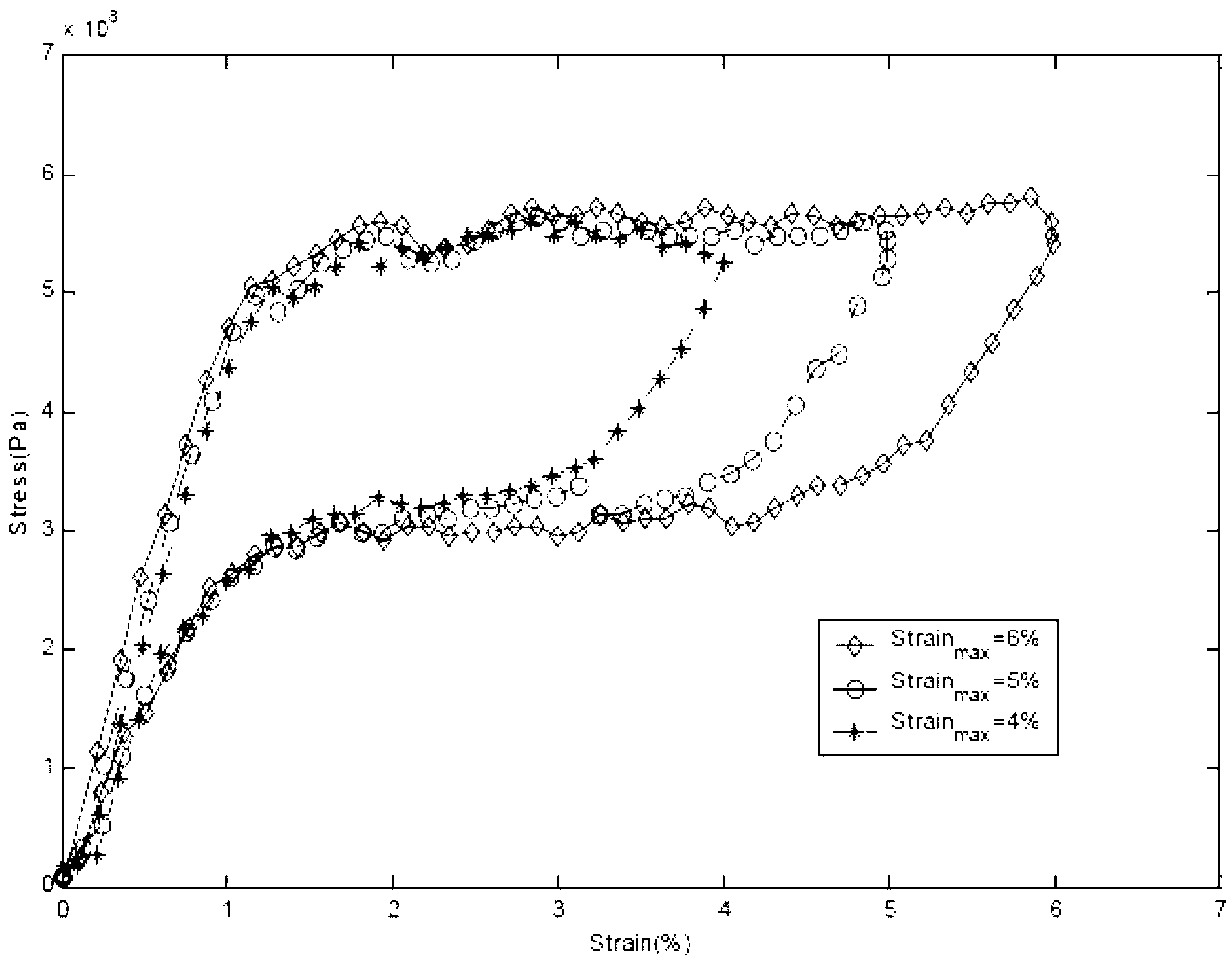

Fuse SMA (shape memory alloy) wire space connecting and disconnecting mechanism

InactiveCN102788537AUnlock completelyImprove reliabilitySelf-propelled projectilesLoad resistancePower flow

The invention provides a fuse SMA (shape memory alloy) wire space connecting and disconnecting mechanism which is provided with a split nut, a tightening spring of the split nut and a release device of the tightening spring, wherein the release device of the tightening spring is two SMA wires, one end of the first SMA wire is connected with the upper end of the tightening spring of the split nut, the other end of the first SMA wire is connected with the upper end of an outer housing, and is tensioned under the action of the tightening spring, one end of the second SMA wire is connected with the other lower end of the tightening spring of the split nut, and the other end of the second SMA wire is connected with the lower end of the outer housing, and is tensioned under the action of the tightening spring. When the two SMA wires are heated by high current, a huge recovery stress is generated caused by the phase change in the two SMA wires, the fracture strength of the material can be reduced caused by high temperature, the two SMA wires are fractured under the combined action of the huge recovery stress and the reduced fracture strength, the restriction on the tightening spring can be released, the two SMA wires are backup mutually, the redundancy design can be realized, and the very high reliability can be guaranteed; and the connecting and disconnecting mechanism is thorough in unlocking, high in reliability, and good in vibration resistance and impact load resistance.

Owner:BEIHANG UNIV

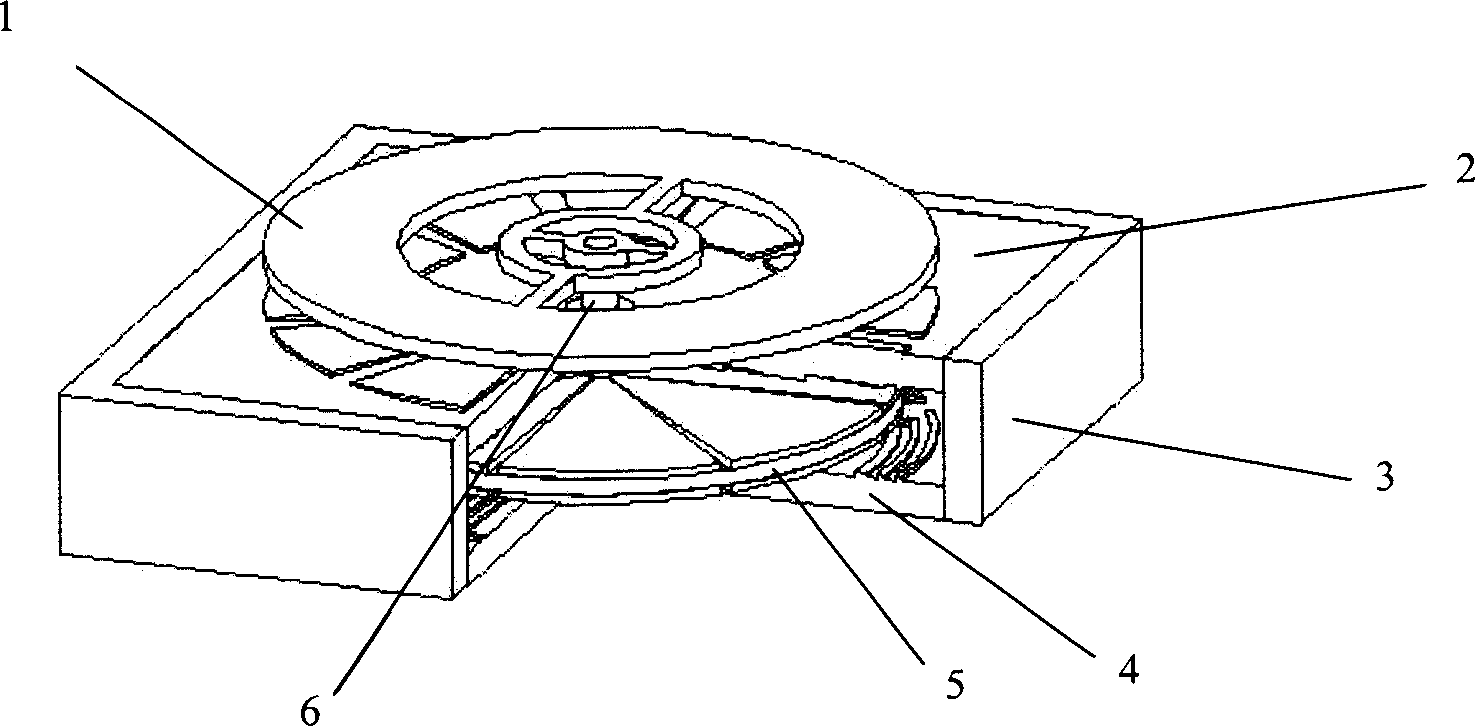

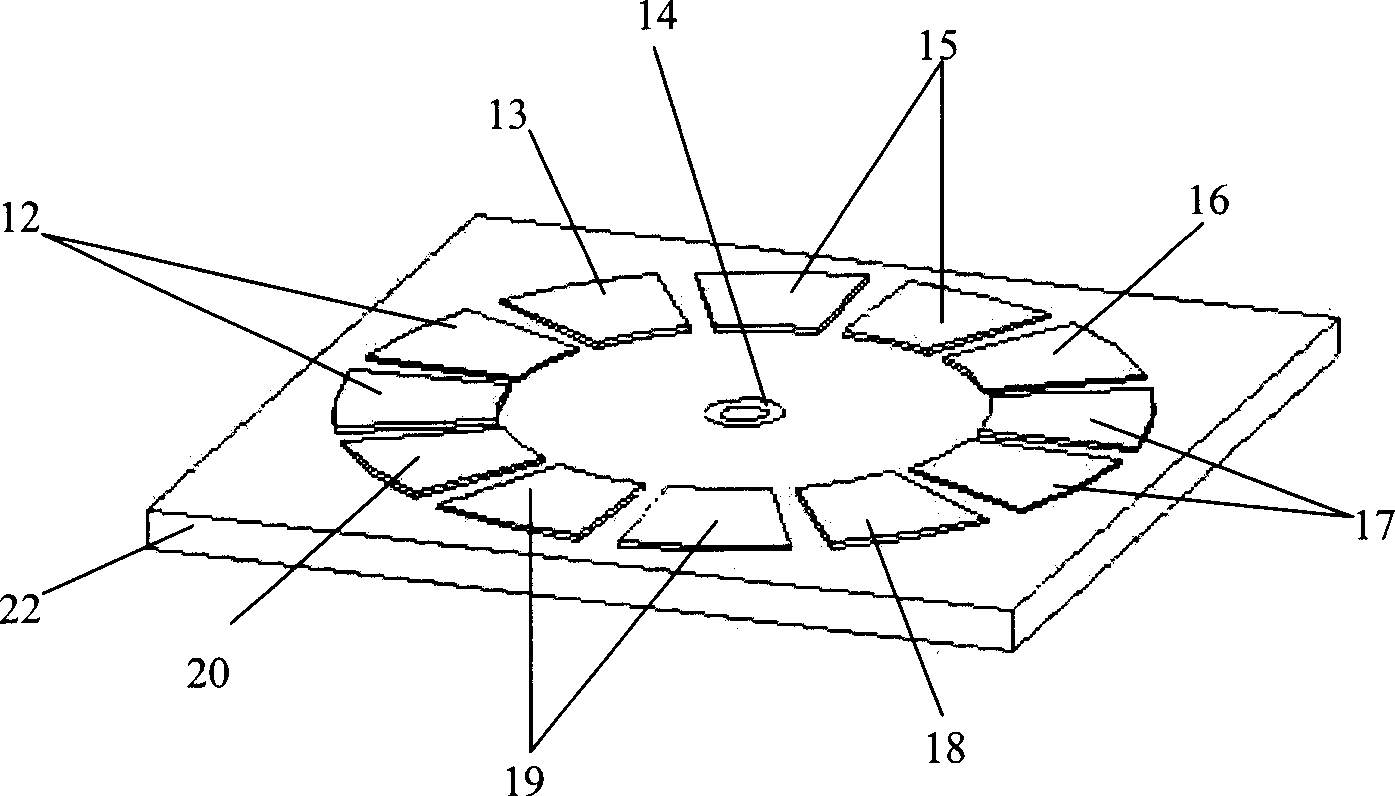

Integrated all-Si capacitive microgyro with vertical differential sense and control and process for preparing an integrated all-Si capacitive microgyro with vertical differential sense

InactiveUS7232700B1Improve vibration resistanceImprove immunityAcceleration measurement using interia forcesSemiconductor/solid-state device manufacturingCapacitanceGyroscope

The present invention relates to a method of manufacturing a cloverleaf microgyroscope containing an integrated post comprising: attaching a post wafer to a resonator wafer, forming a bottom post from the post wafer being attached to the resonator wafer, attaching the resonator wafer to a base wafer, wherein the bottom post fits into a post hole in the base wafer, forming a top post from the resonator wafer, wherein the bottom and top post are formed symmetrically around the same axis, preparing a cap with backside metallization, and attaching a cap wafer on top of the base wafer. The present invention relates further to a gyroscope containing an integrated post with on or off-chip electronics.

Owner:HRL LAB

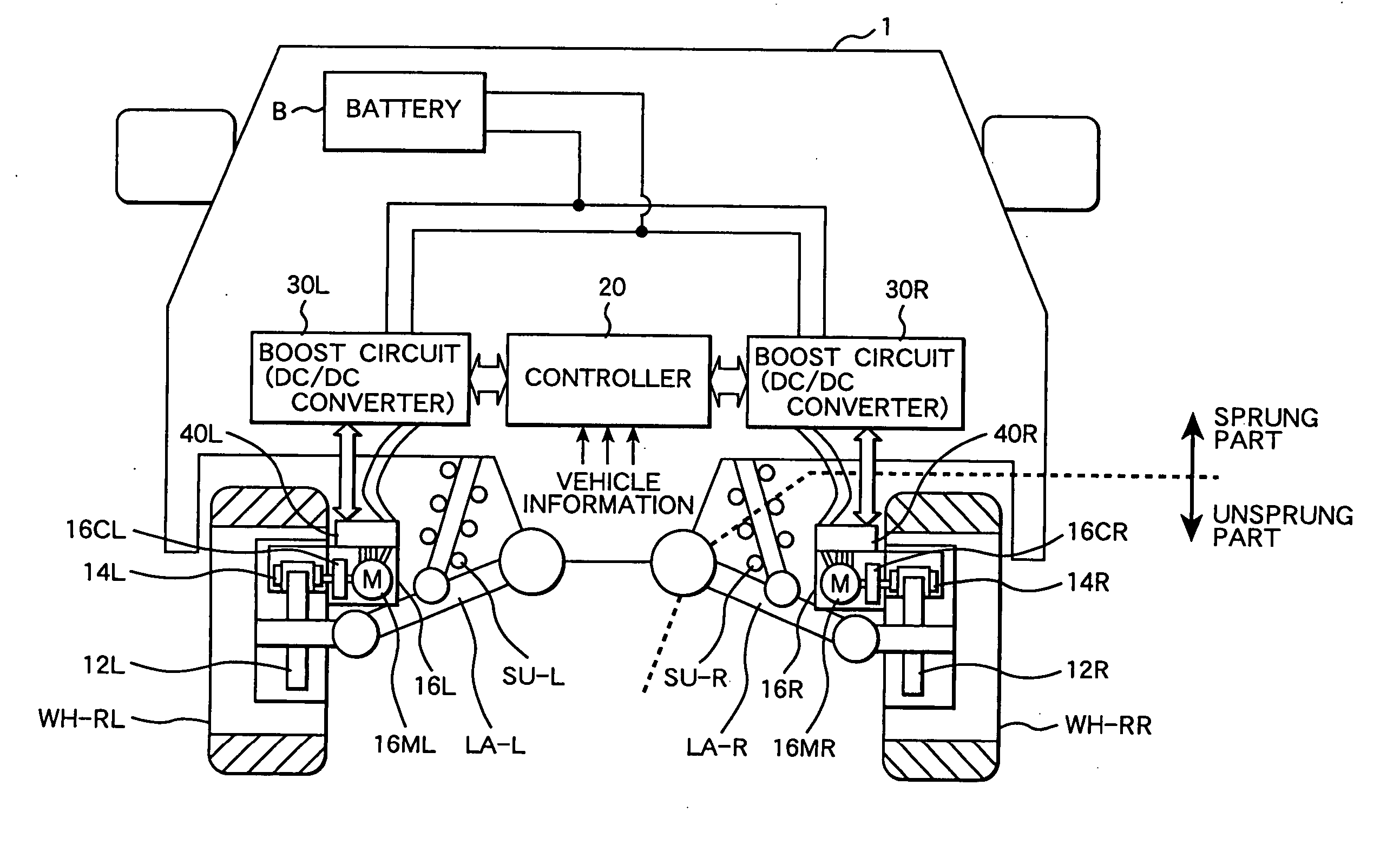

Motor system for vehicle

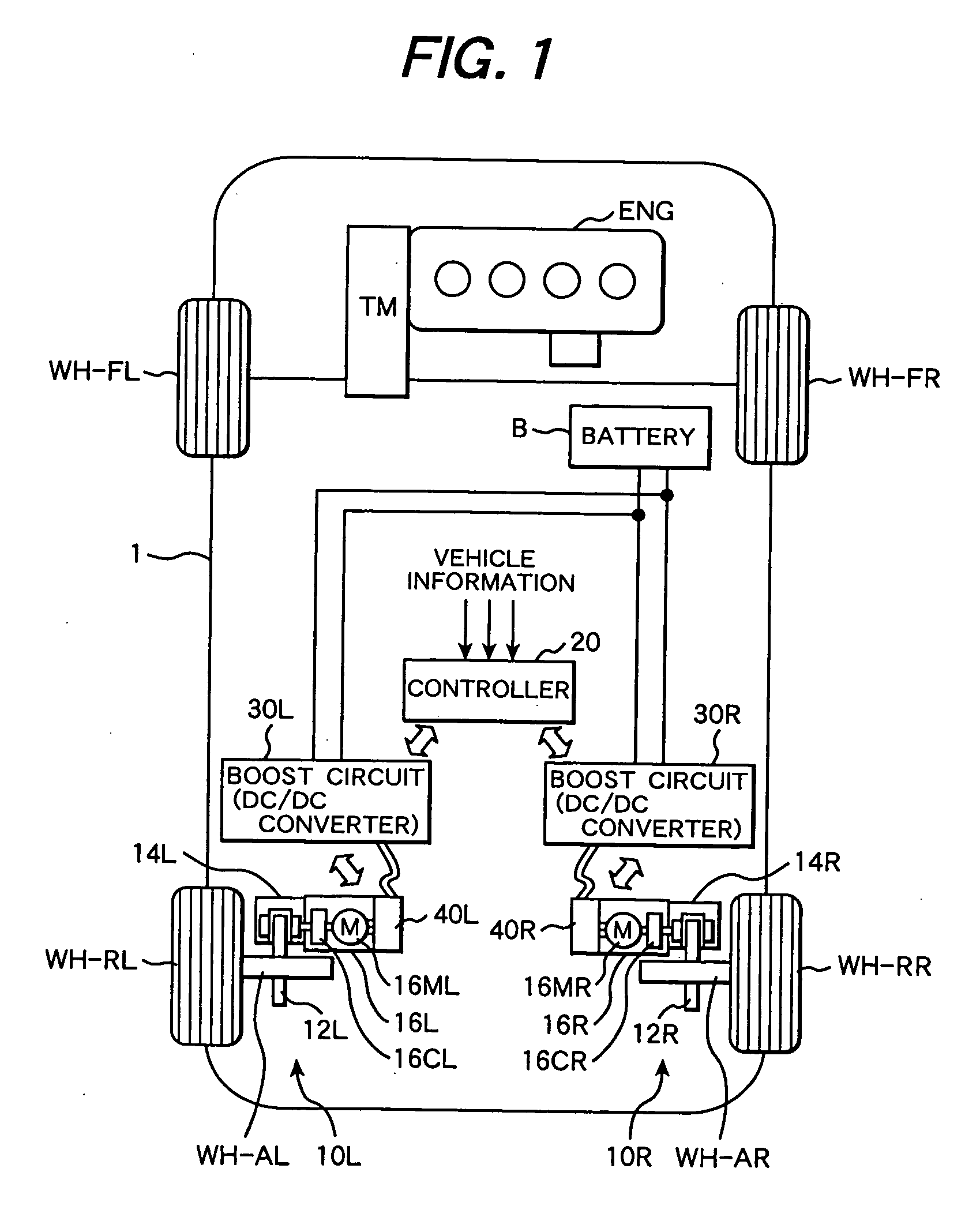

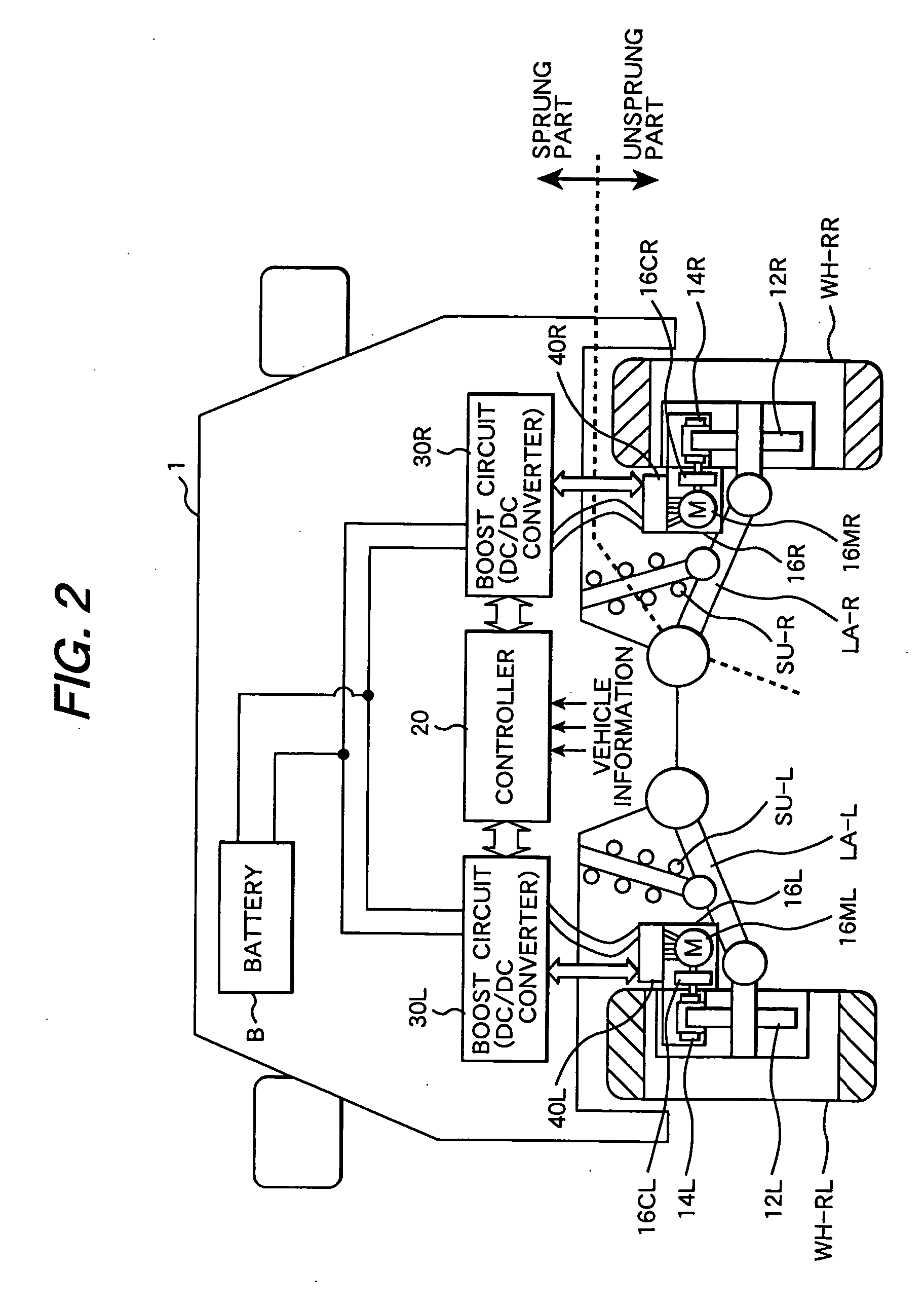

InactiveUS20060180365A1Improve the immunityUnsprung load can be reducedElectric devicesElectric propulsion mountingSynchronous motorEngineering

Motors are disposed in an unsprung part of the vehicle with reference to a suspension. Drive circuits which rectangular-wave drive the motors are disposed in the unsprung part. Voltage control circuits which control voltage supplied from a battery to the drive circuits are disposed in the sprung part of the vehicle with reference to the suspension. The motors are three-phase synchronous motors.

Owner:HITACHI LTD

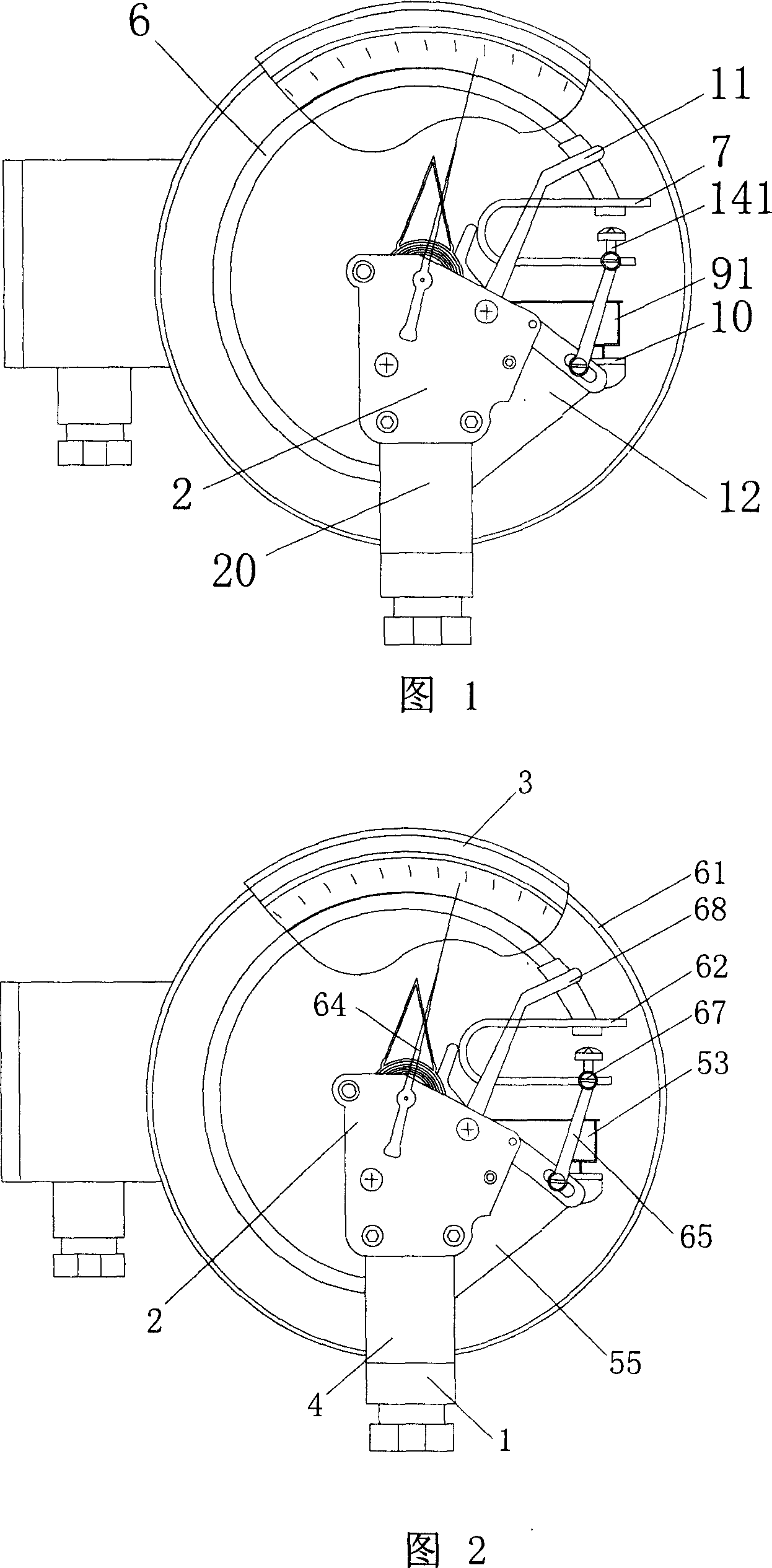

Shakeproof type sulfur hexafluoride gas density relay

ActiveCN1971795AImprove vibration resistanceCompensatory accuracyElectric switchesEngineeringSulfur hexafluoride

This invention discloses one anti-vibartion sulfur hexafluoride gas intensity relay, which comprises the following structure: the control part and display part are designed separately; the control part comprises c shape tube, temperature compensation slice, beam, the display part comprises c shape tube, temperature compensation slice, beam and two c shape tubes on the basic socket with other end connected to compensation slice and with other end connected to beam.

Owner:SHANGHAI ROYE ELECTRICAL CO LTD

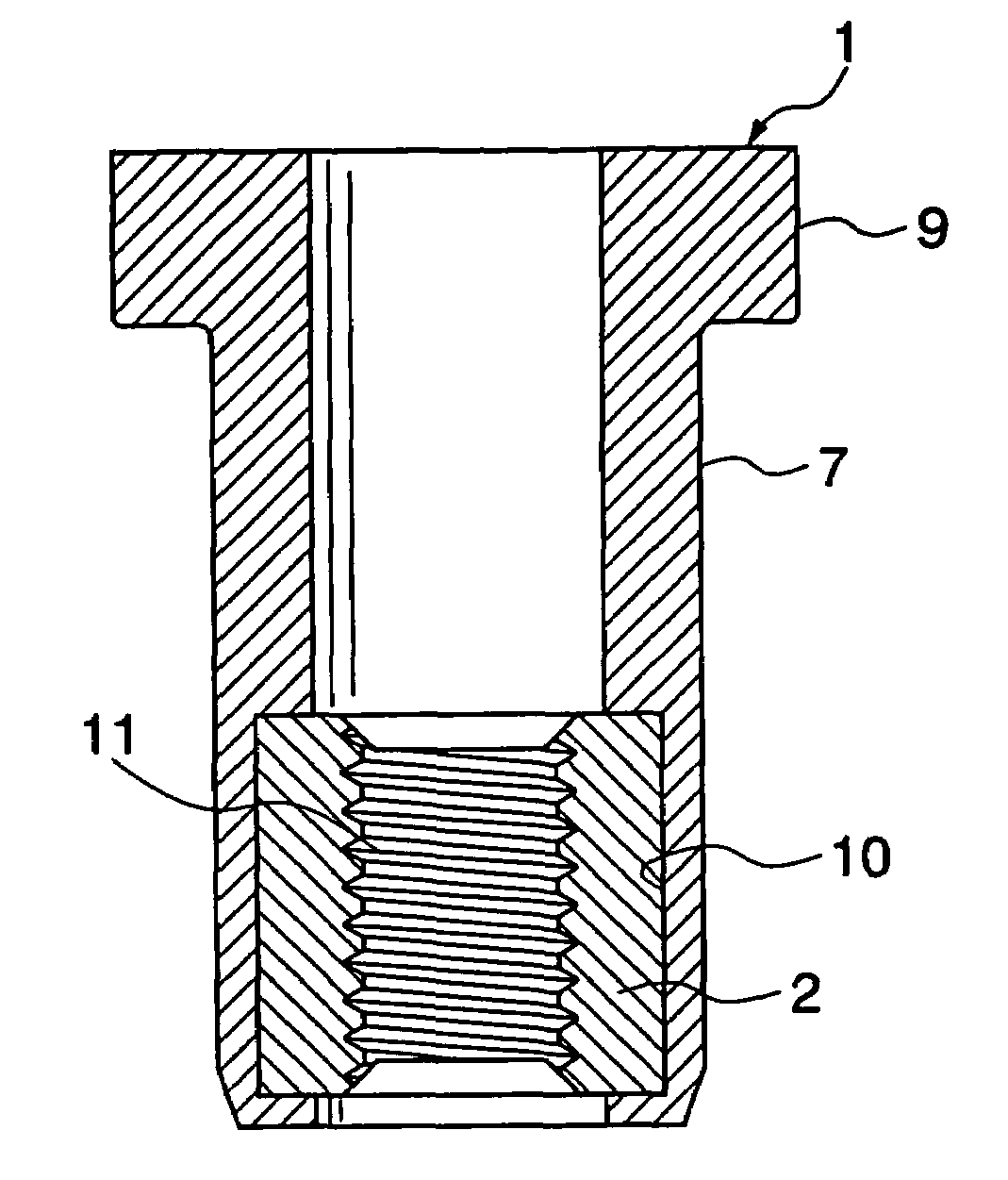

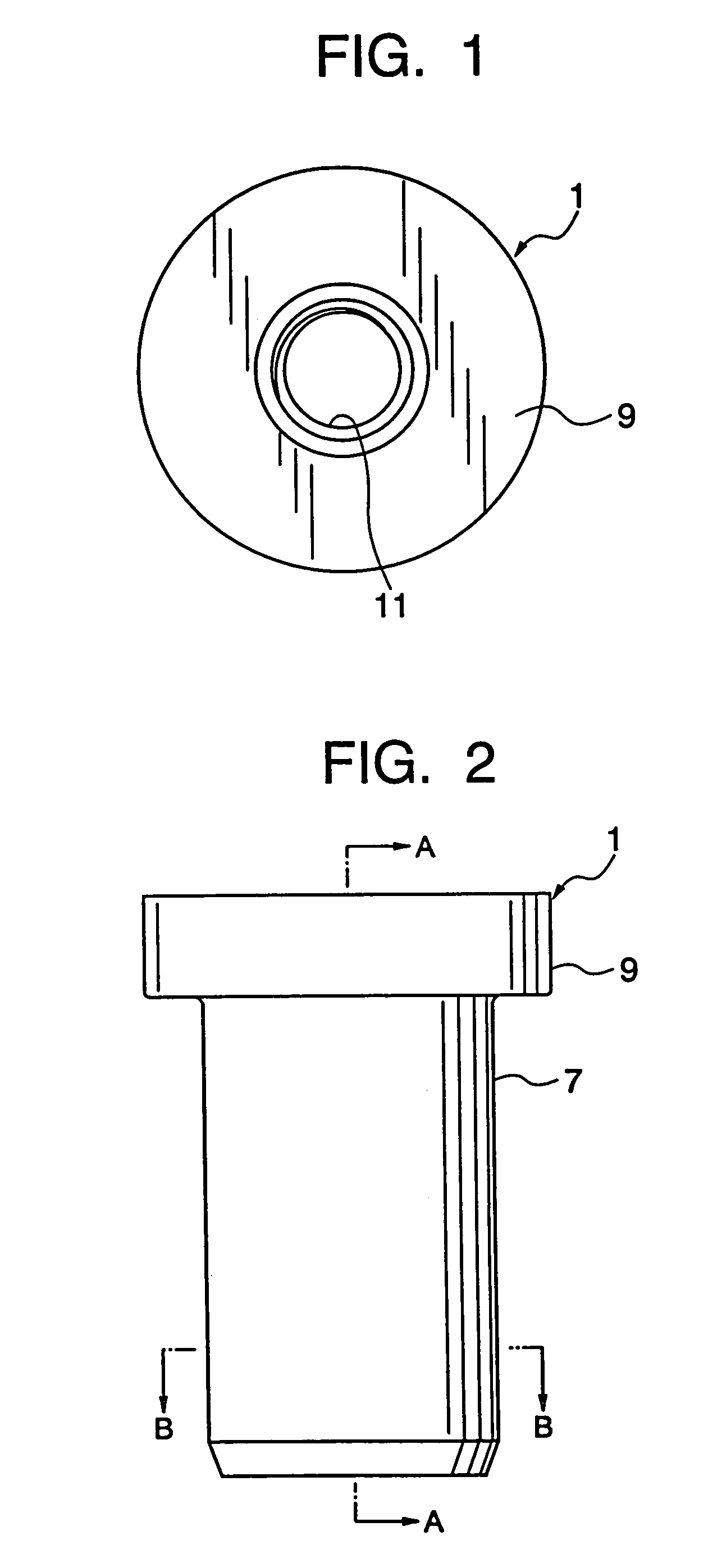

Elastic fastener

An elastic fastener 1 comprises a hollow tubular portion 7, an internally threaded portion 2 provided at one of the ends of the tubular portion 7, and a flange 9 formed at the other end of the tubular portion 7. The tubular portion 7 and the flange 9 are integrally formed of an elastomeric material, such as a styrene-based elastomer, a polyamide-based elastomer and a polyester-based elastomer. The internally threaded portion 2 is formed of a rigid resin material such as a polycarbonate resin. The internally threaded portion 2 is integrally fixed to the tubular portion 7 in a hole of the tubular portion.

Owner:NEWFREY

Power converter permitted to be reduced in size and manufactured at decreased cost

ActiveUS20130058068A1Ensures stability in installationImprove vibration resistanceCircuit arrangements on support structuresManufacturing cost reductionCapacitor

A power converter equipped with a semiconductor stack made up of semiconductor modules, bus bars coupled to power terminals of the semiconductor modules, a capacitor, and an input terminal table. The capacitor is disposed in alignment with a first direction in which the semiconductor modules are stacked. The capacitor has a first end and a second end opposed to the first end in a second direction in which the power terminals extend from the semiconductor modules. The first end faces in the second direction. The input terminal table is located near the second end of the capacitor. This structure permits the power converter to be reduced in size and produced at a decreased cost.

Owner:DENSO CORP

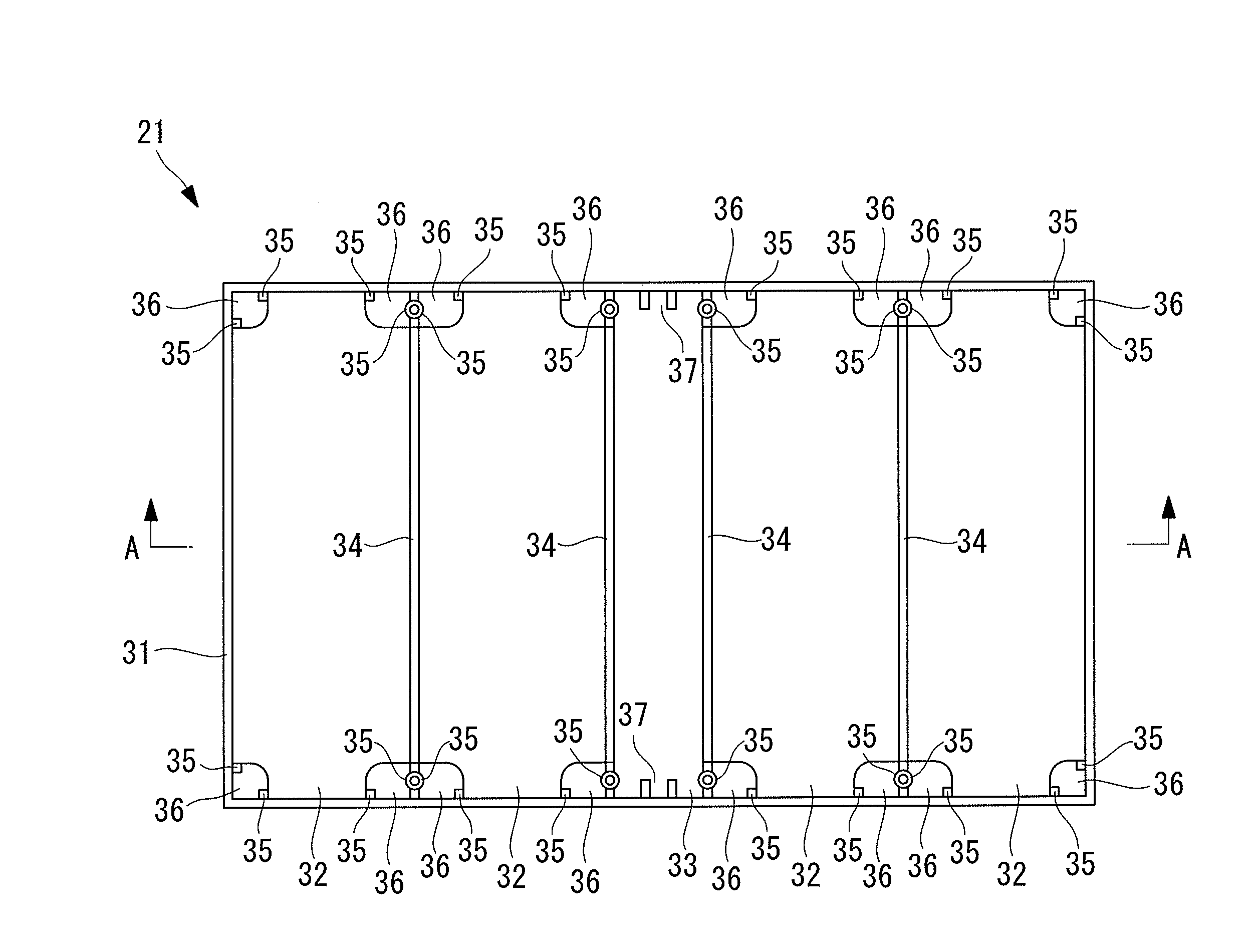

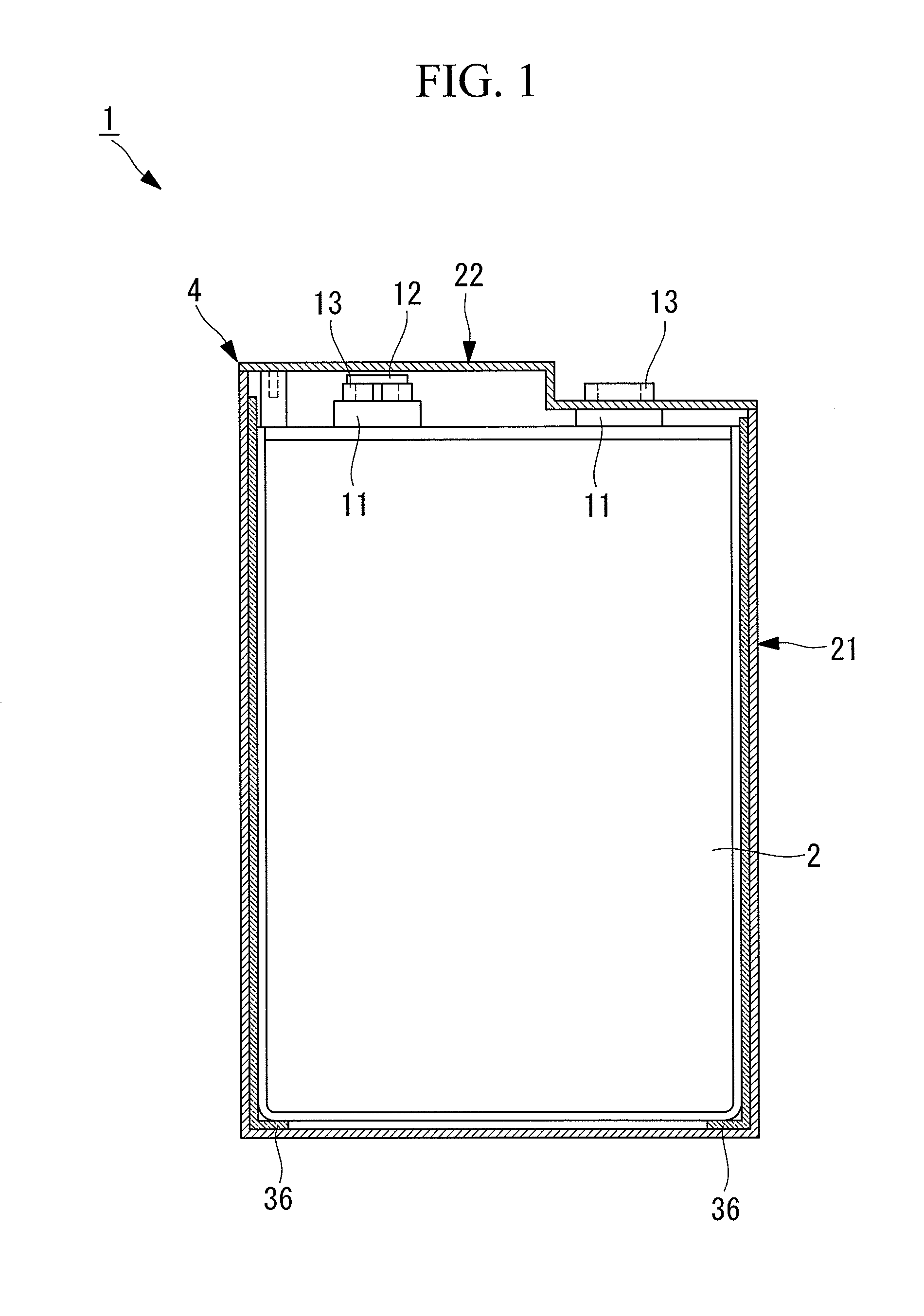

Cell container and battery

InactiveUS20100196749A1Improve vibration resistanceImprove seismic performanceLarge-sized flat cells/batteriesFinal product manufactureShock resistanceEngineering

Disclosed is a cell container offering improved vibration resistance and improved shock resistance as well as maintaining the battery performance and ensuring the reliability. Specifically disclosed is a cell container comprising: an insulative case (31) in which a plurality of unit cells are placed side by side; insulative wall portions (34) for partitioning between the plurality of unit cells; and support projections (35) projecting from at least either one of the case (31) or the wall portions (34) toward the unit cells to support the unit cells.

Owner:KYUSHU ELECTRIC POWER CO INC +1

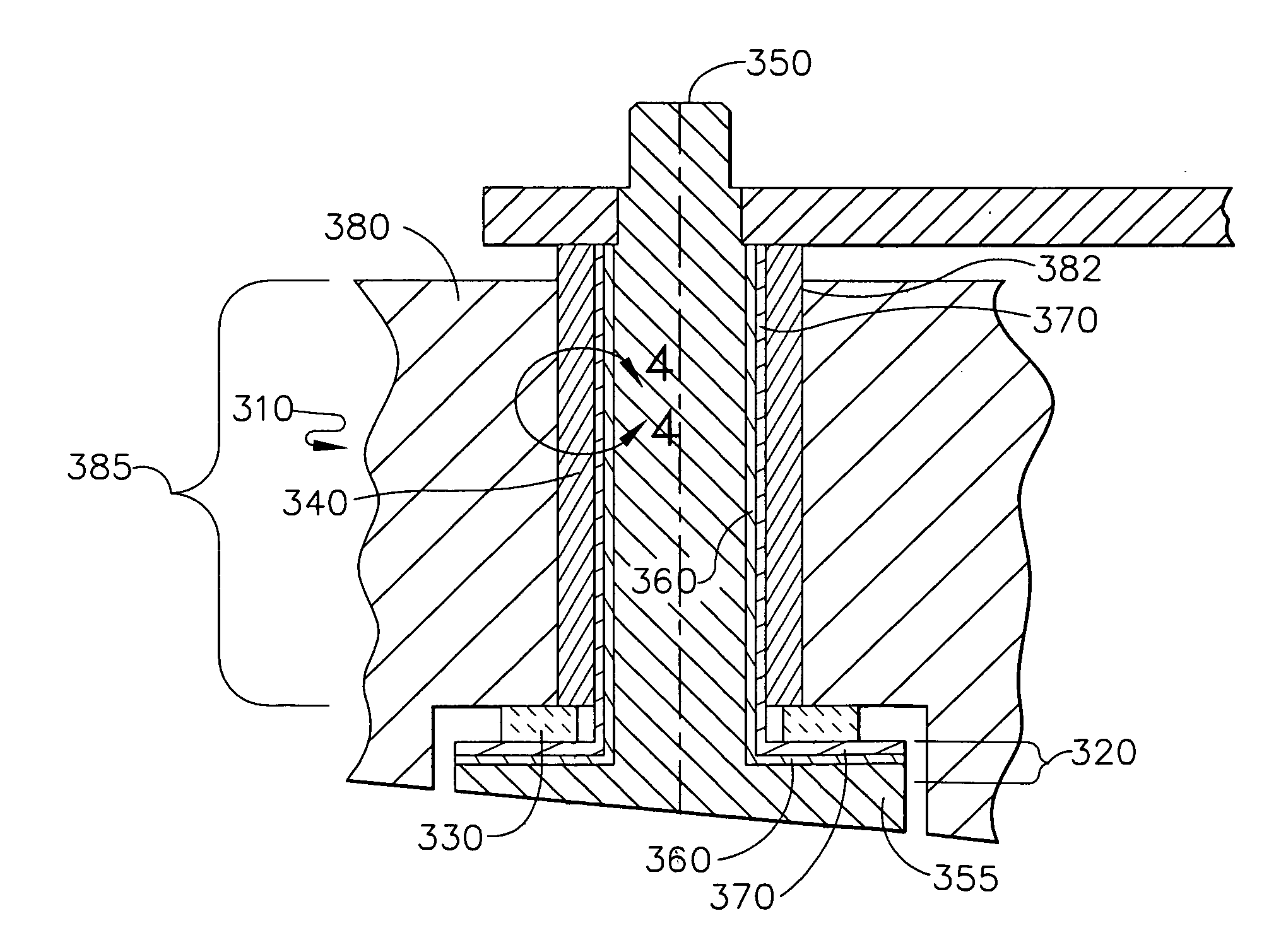

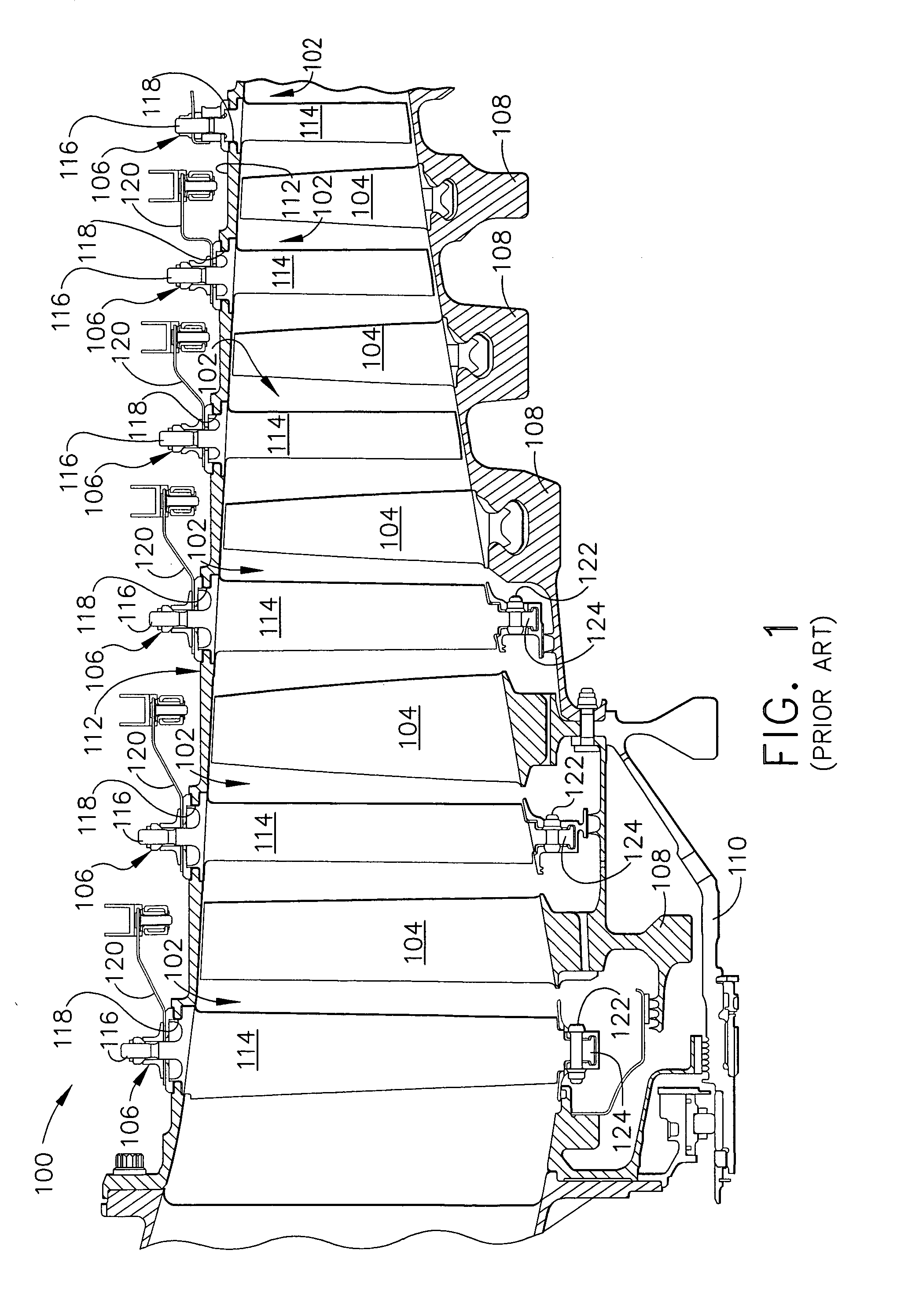

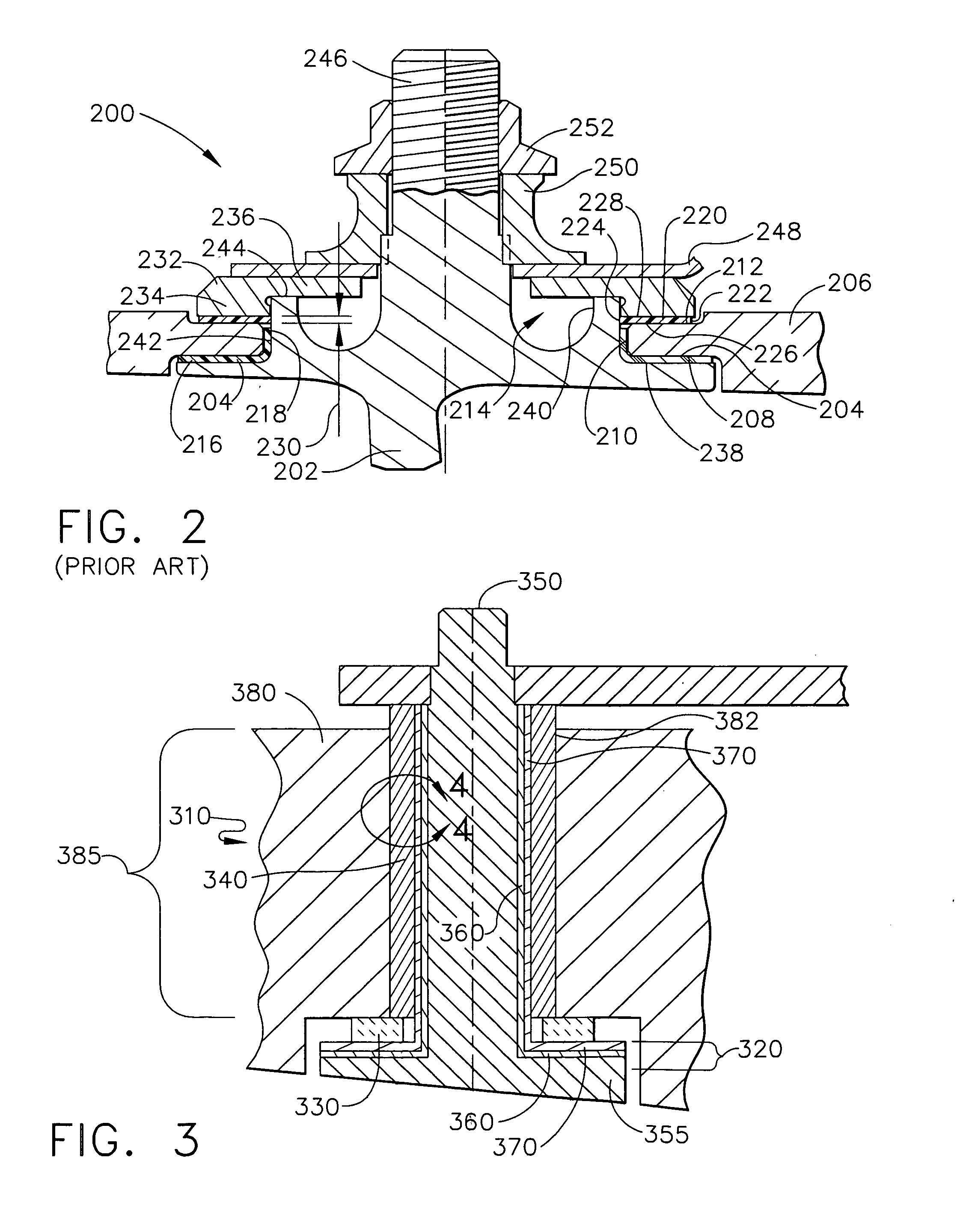

High temperature ceramic lubricant

InactiveUS20060029494A1Reduce wearImprove vibration resistanceMolten spray coatingWind motor controlMetallurgyTurbine

A gas turbine engine component having opposed surfaces in frictional contact with each other. An antifriction coating is disposed on one or more of the opposed surfaces. The antifriction coating includes a binder and a friction modifier. The weight ratio of the friction modifier to binder in the antifriction coating is greater than or equal to about 1:1.

Owner:GENERAL ELECTRIC CO

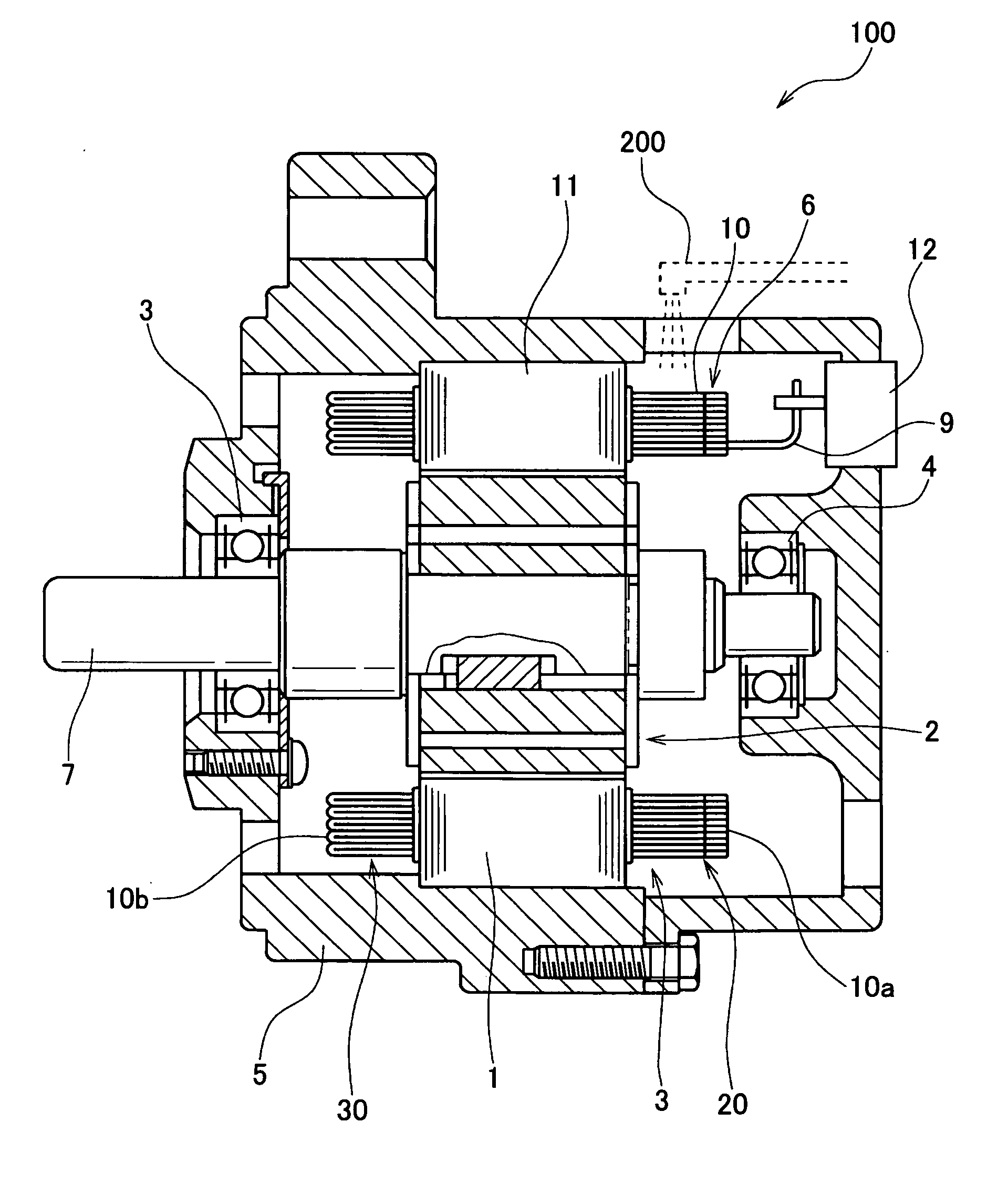

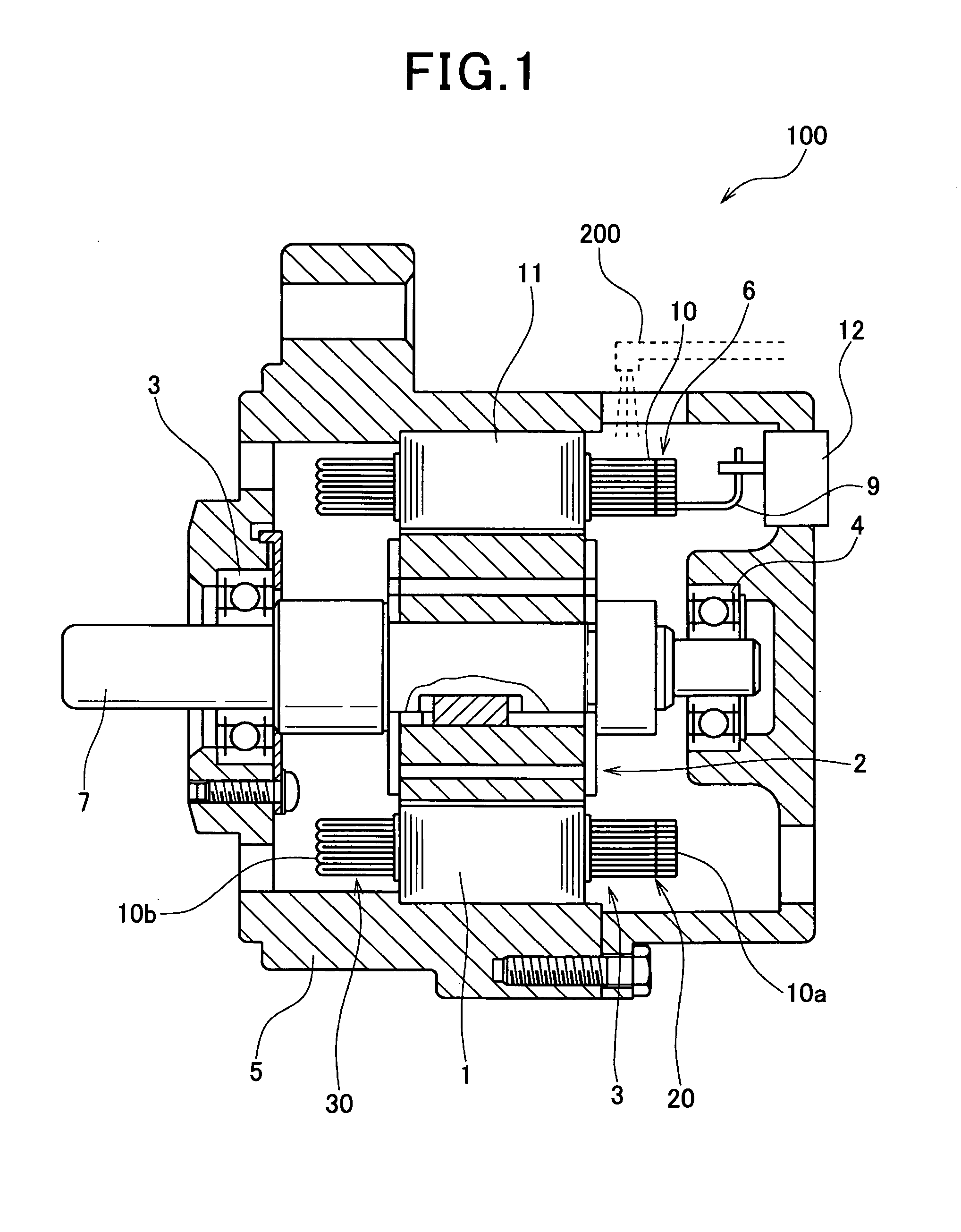

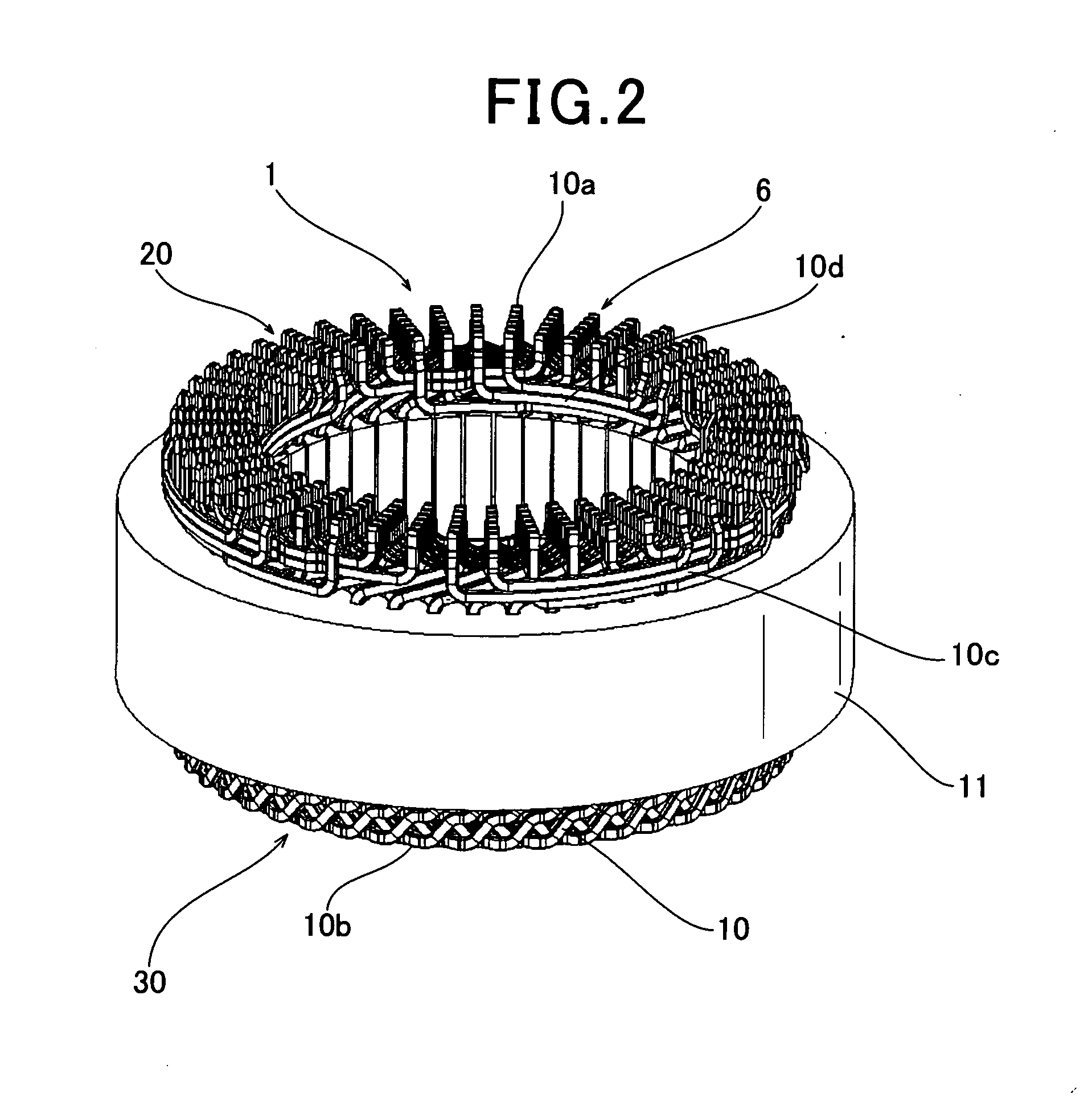

Electric rotating machine

ActiveUS20120161569A1Improve vibration resistanceSynchronous machinesAsynchronous induction motorsElectric machineMagnetic poles

The stator of the electric rotating machine includes a stator winding constituted of a plurality of U-shaped conductor segments each including a turn portion and two straight portions, the U-shaped conductor segments being connected in series by welding at welded portions formed in ends of the straight portions, and a stator core formed with slots, the straight portions of each U-shaped conductor segment being accommodated in corresponding two of the slots. The welded side slot pitch as an interval of the corresponding two of the slots on the side opposite to the turn portions is narrower than the N-S magnetic pole pitch of the rotor. The stator winding includes overlapped wire wrapping sections each constituted of the U-shaped conductor segments accommodated in the corresponding two of the slots, and crossover wires disposed on the side of the welded portions for connecting the overlapped wire wrapping sections.

Owner:DENSO CORP

Acceleration sensor and method for operating an acceleration sensor

ActiveUS20140083190A1Great robustnessGreat precisionAcceleration measurement using interia forcesPhysicsClassical mechanics

An acceleration sensor has a substrate, a seismic mass and a detection unit. The seismic mass is configured to be deflected based on an external acceleration acting on the acceleration sensor, the deflection being in the form of a deflection motion with respect to the substrate along a deflection direction. The detection unit is configured to be deflected for the detection of a deflection of the seismic mass, the detection being in the form of a detection motion with respect to the substrate along a detection direction. The detection unit is connected to the seismic mass in such a way that the amplitude of the deflection motion along the deflection direction is greater than the amplitude of the detection motion along the detection direction.

Owner:ROBERT BOSCH GMBH

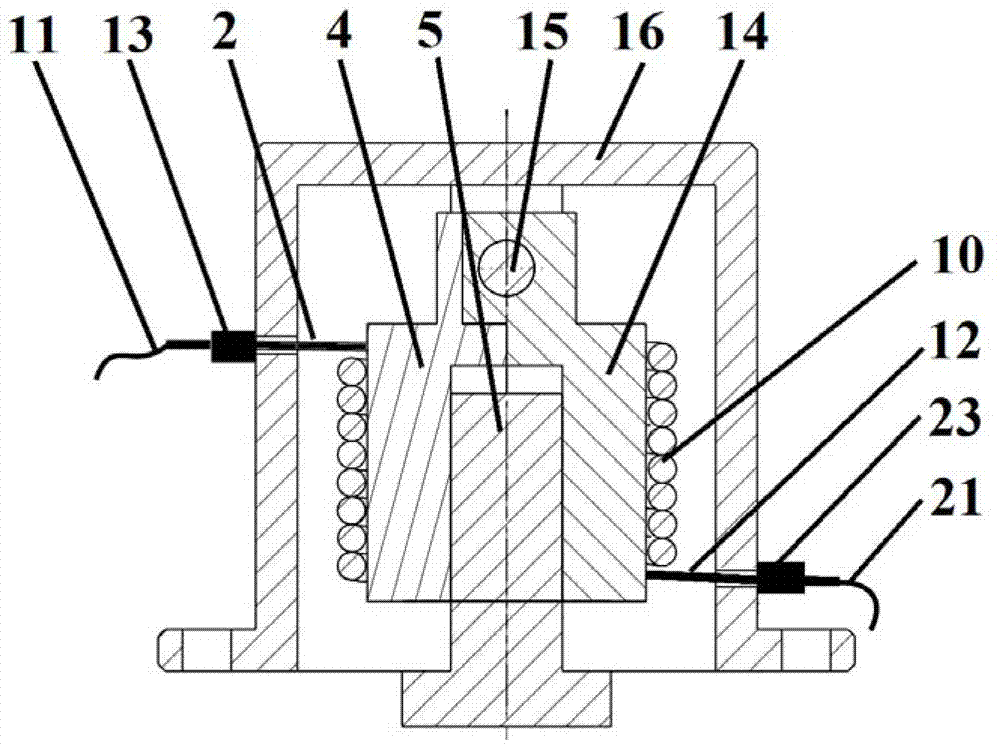

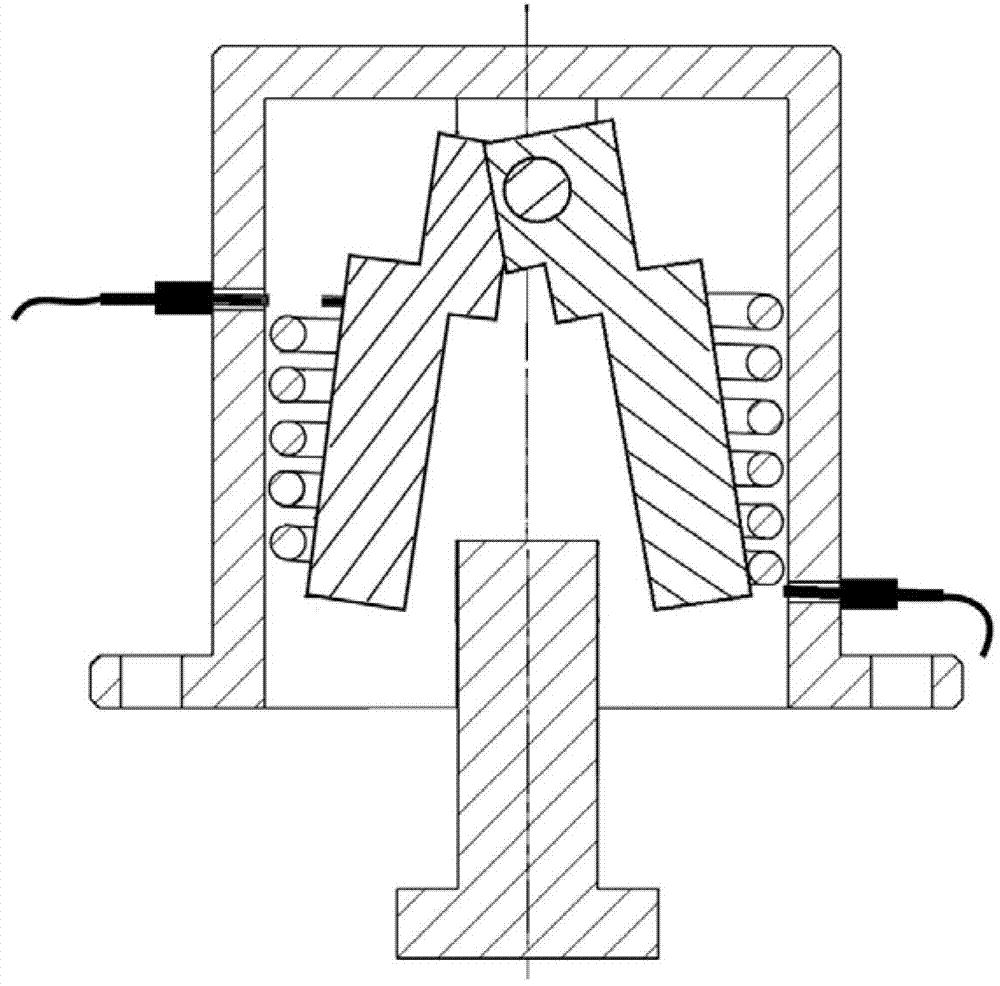

Flexible microgyrorotor and electromagnetic drive and dynamic tune

InactiveCN1712894AWith dynamic tuningAvoid the influence of fixed axisRotary gyroscopesStatorEngineering

A micro-gyroscope of flexible rotor tuned by electromagnetic driving force is prepared by setting top rotor and bottom rotor at top and bottom of shell, setting one jewel bearing at center hole of top rotor, setting another at center hole of bottom rotor, placing shaft on both bearings and driving rotor on shaft between top and bottom rotors, setting gyroscope rotor on shaft above top rotor. The prepared micro-gyroscope can be used as orientational gyroscope.

Owner:SHANGHAI JIAO TONG UNIV

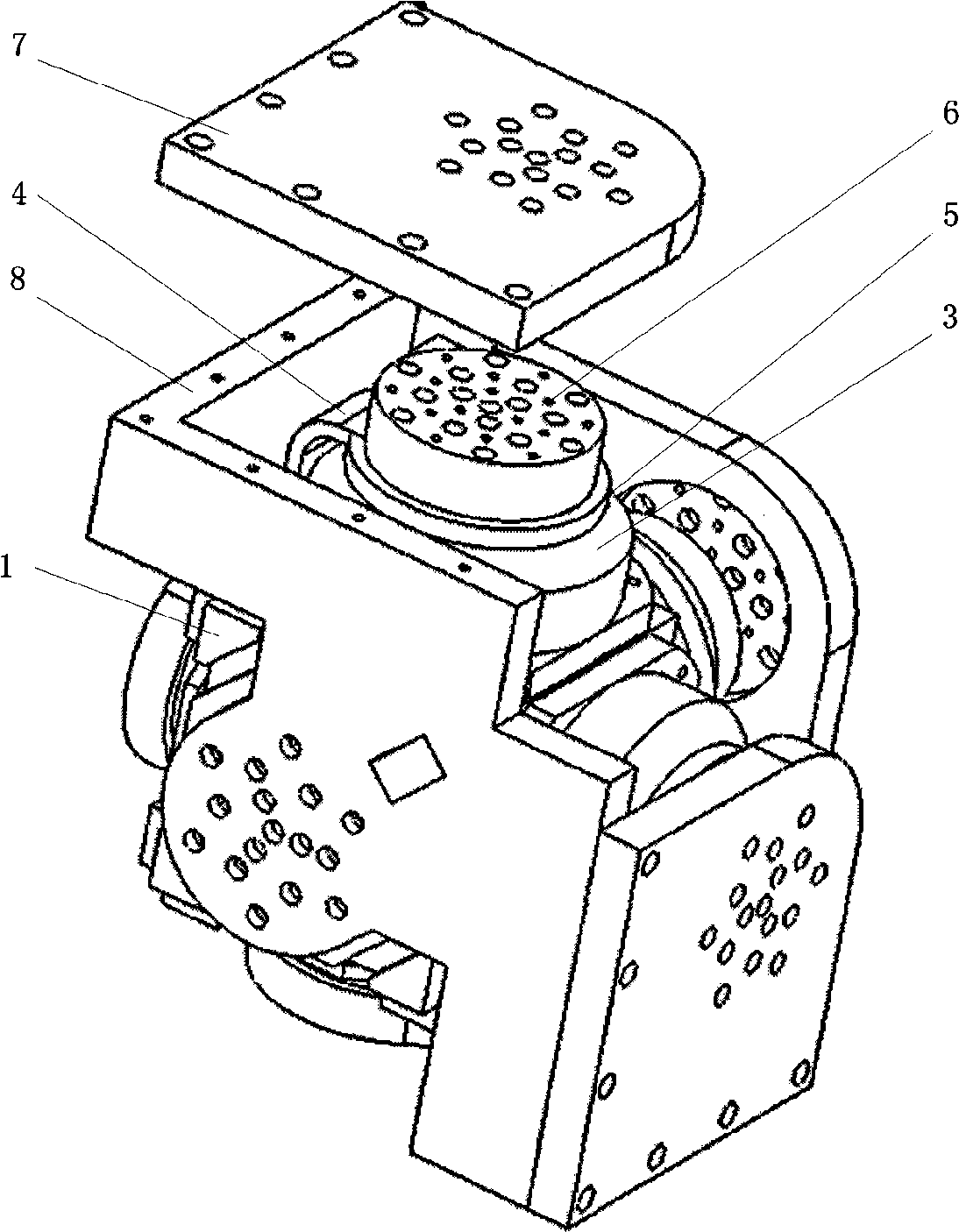

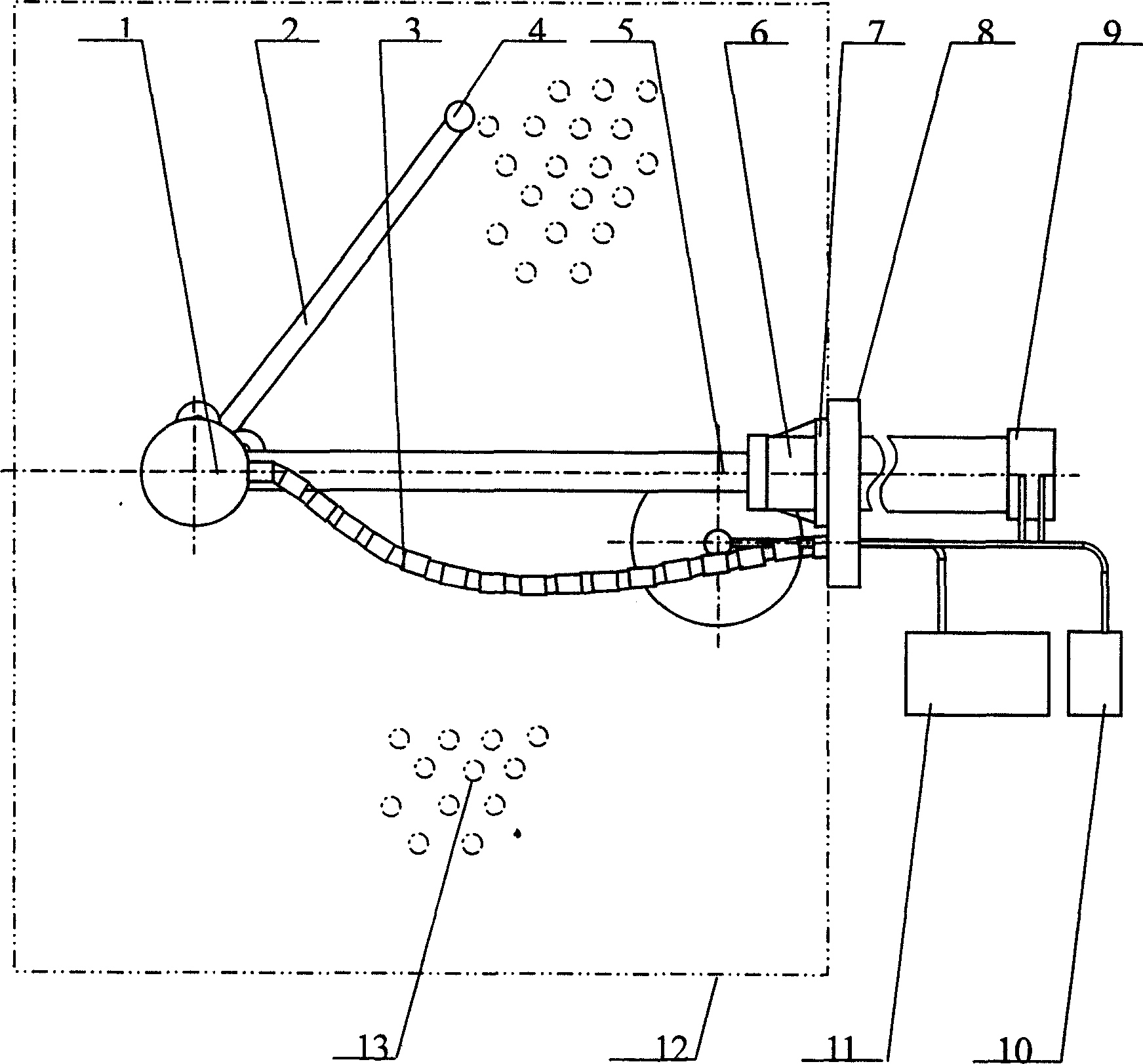

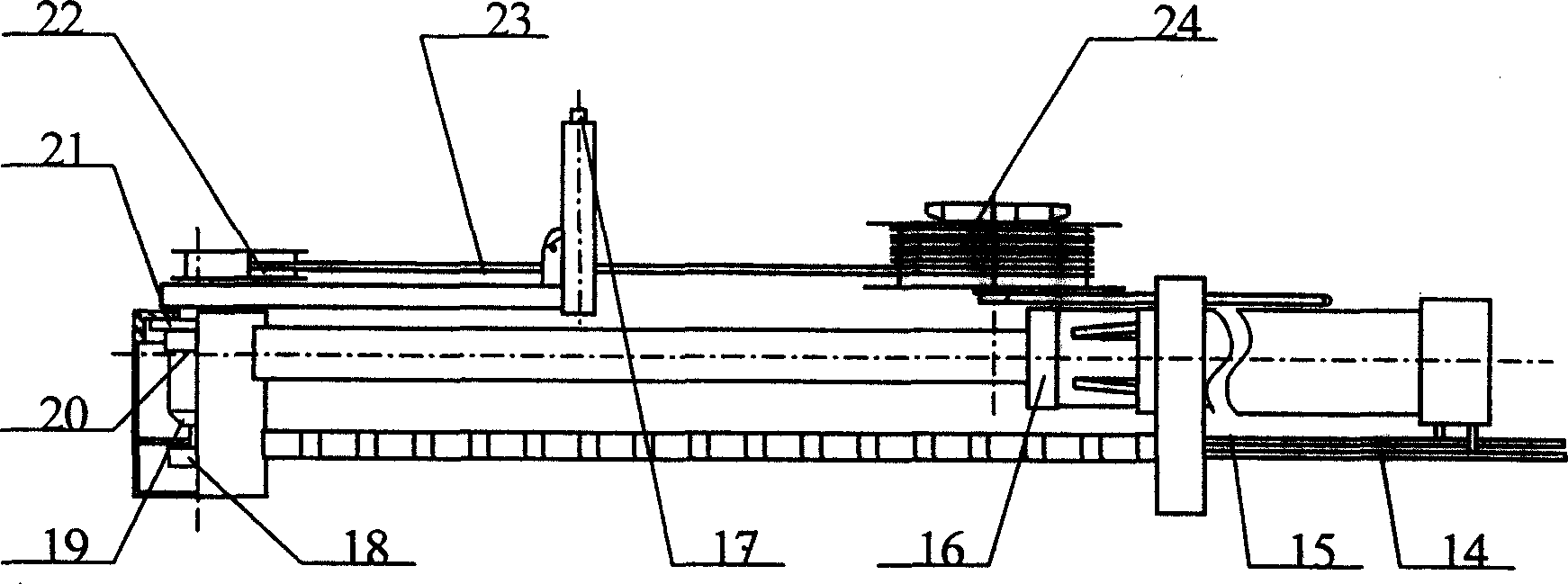

Robot technology of on-line cleaning power plant steam condenser using high pressure water jet

InactiveCN1664486AImprove operational efficiencyMaximize coverage areaRotary device cleaningNon-rotary device cleaningDevice formHigh pressure water

The invention relates to an electric power plant condenser high pressure water shooting flow online washing robot technology that cleans the electric power plant condenser by high pressure water shooting flow. Setting the mechanism arm locating device and high pressure soft tube into the condenser by using the combination method and install structure of locating mechanism arm orientation device formed by extending mechanism arm and rotating mechanism arm, high pressure soft tube manage device, and high pressure spray head control device, locates the spray head on the rotating mechanism arm by computer control system, sends to the inner of the condenser copper pipe, and cleans the dirt in the inner of the condenser copper pipe by high pressure water shooting flow. The generating set needs not stop while cleaning. The invention has advantage of simple structure, no pollution and high reliability.

Owner:CHINA UNIV OF MINING & TECH

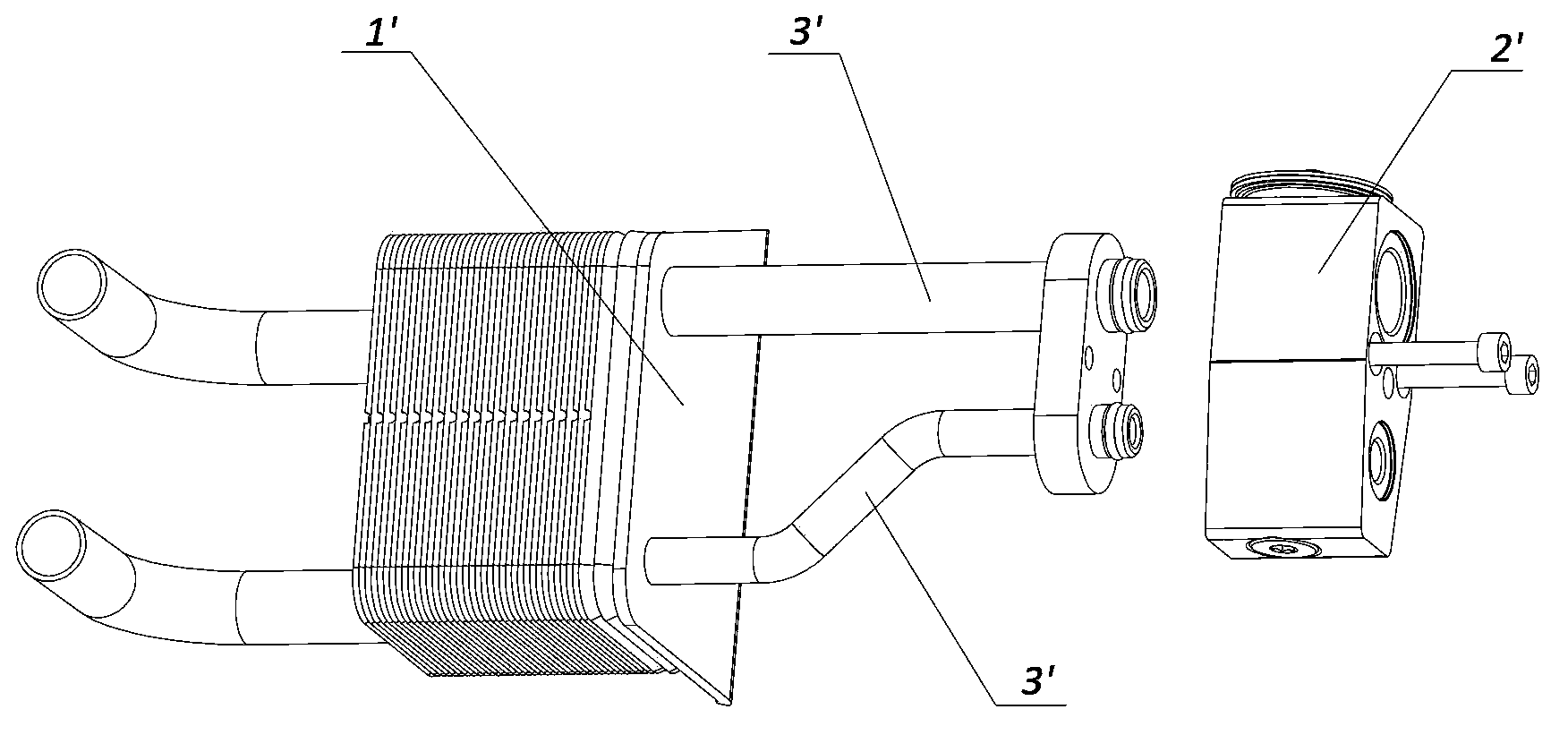

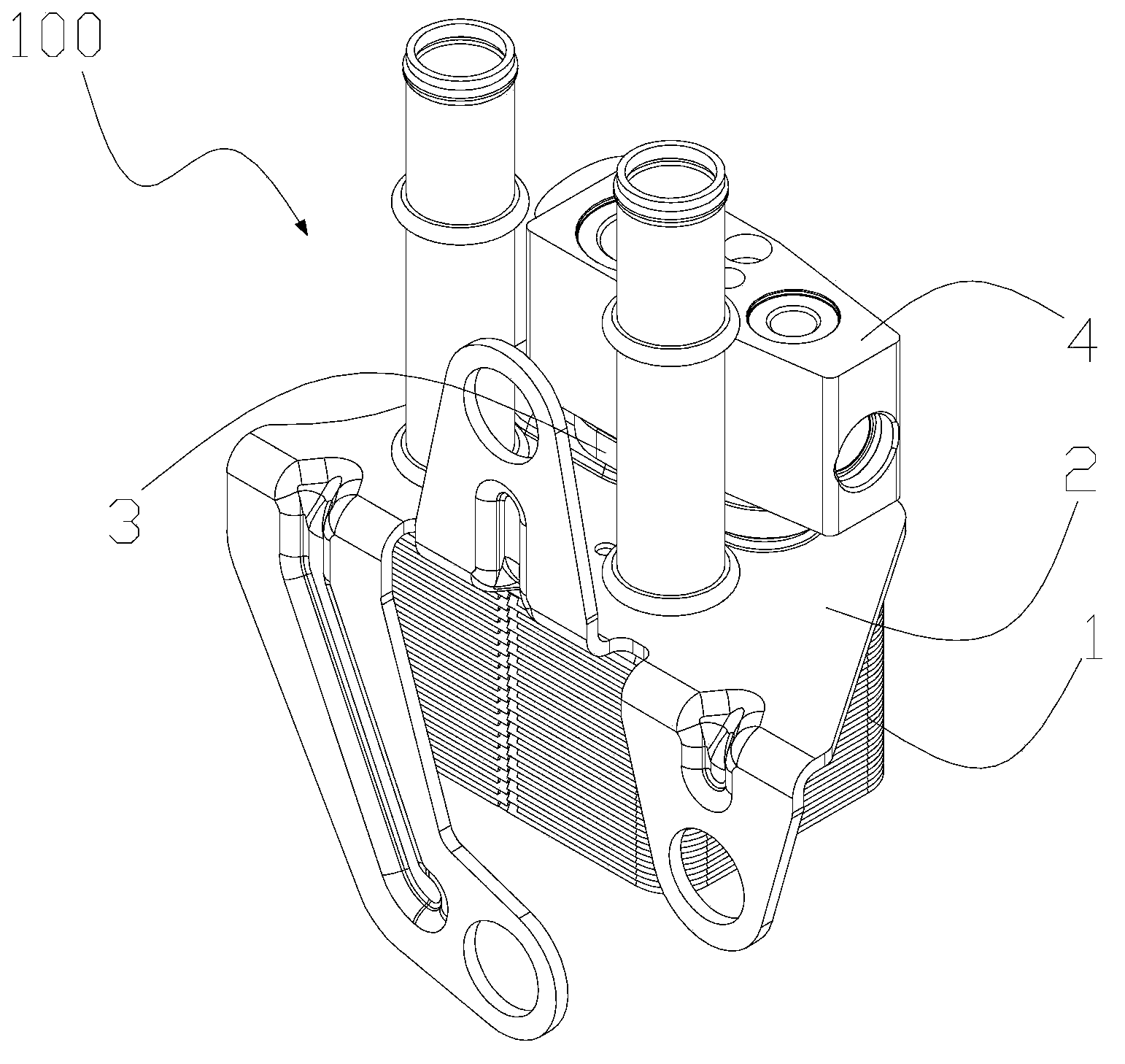

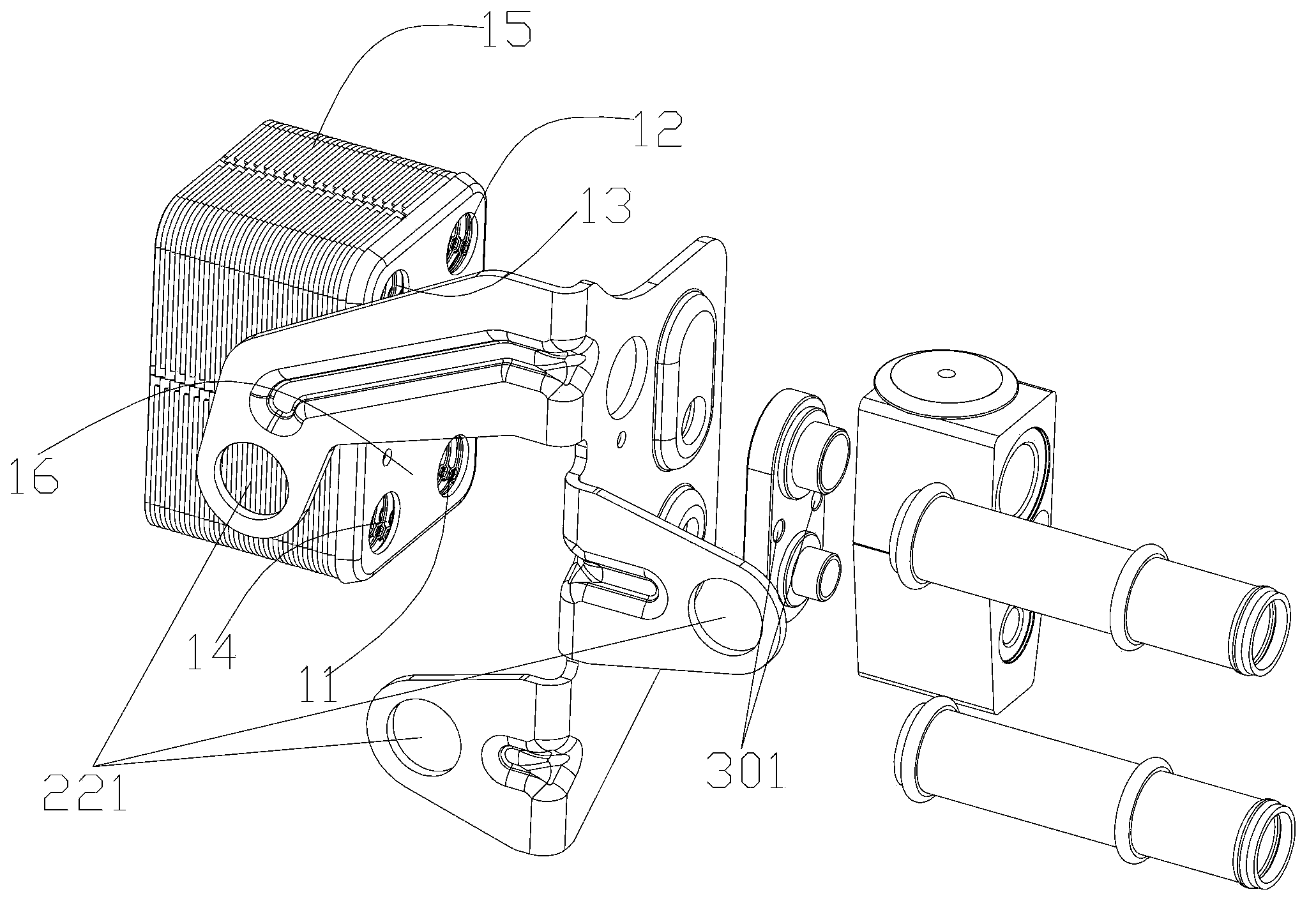

Heat exchanger integrated assembly

ActiveCN104296422AReduce volumeSimple connection structureMechanical apparatusEvaporators/condensersSoftware engineeringRefrigeration

The invention provides a heat exchanger integrated assembly. The heat exchanger integrated assembly comprises a heat exchanger, an adaptation connecting device and an installation supporting frame used for fixing the integrated assembly, wherein one end of the adaptation connecting device is fixed to a matching part, and an outwards protruding third pipeline and an outwards protruding fourth pipeline are arranged at the other end of the adaptation connecting device; the installation supporting frame comprises an installation part bent at an included angle with the matching part, the installation part comprises at least two installation plates, at least one installation plate is located on the side, opposite to the side where the other installation plate is located, of the matching part, or the installation part comprises one installation plate and at least two connecting parts, and the gap between at least two adjacent connecting parts is larger than the gap between other adjacent connecting parts. Each installation plate is provided with a plurality of installation holes, and the installation holes are completely exposed outside the heat exchanger and the adaptation connecting device in the installation direction penetrating through the installation holes. The heat exchanger integrated assembly is simple in structure, good in refrigeration effect, high in stability of the installation supporting frame and high in vibration strength.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

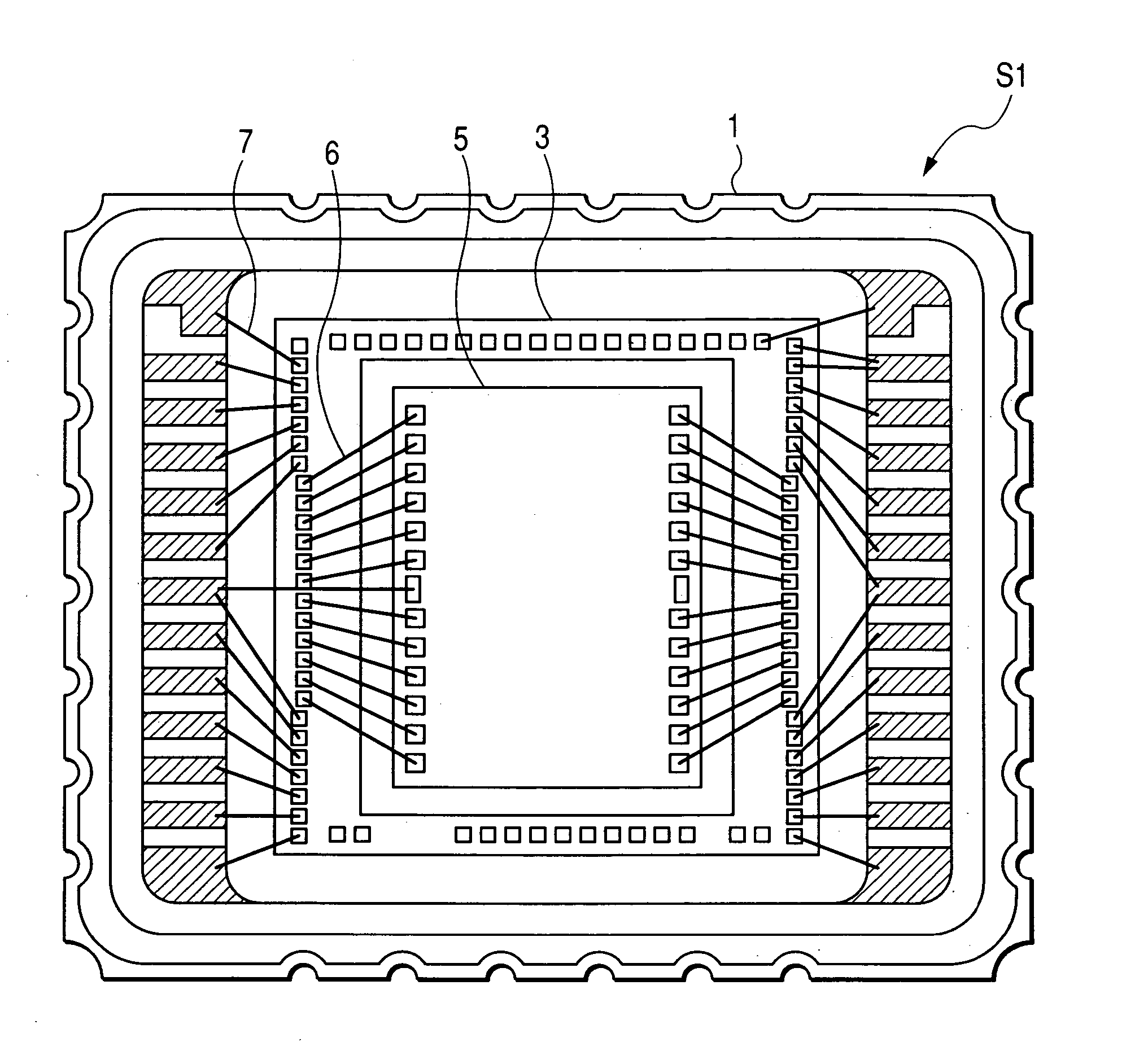

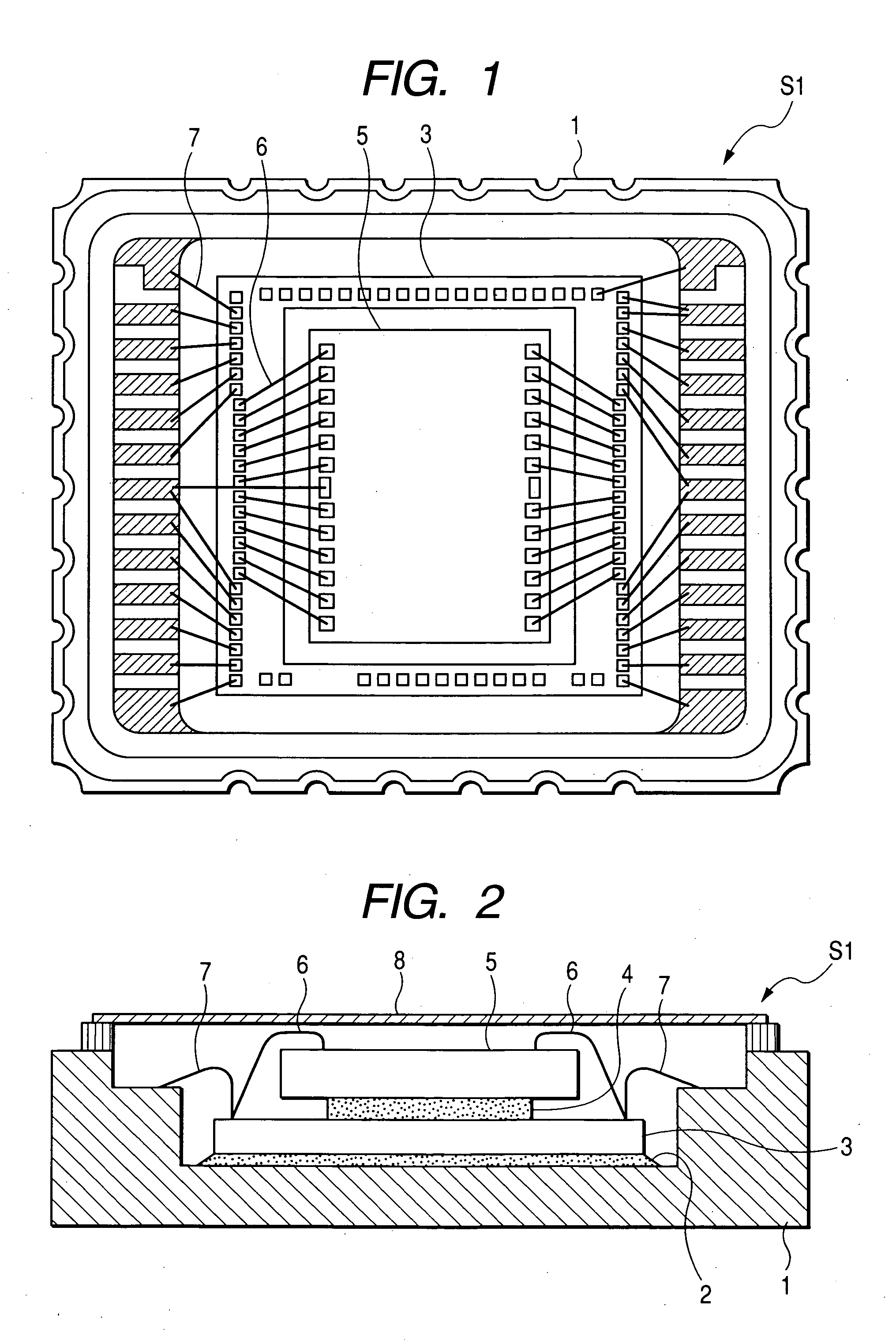

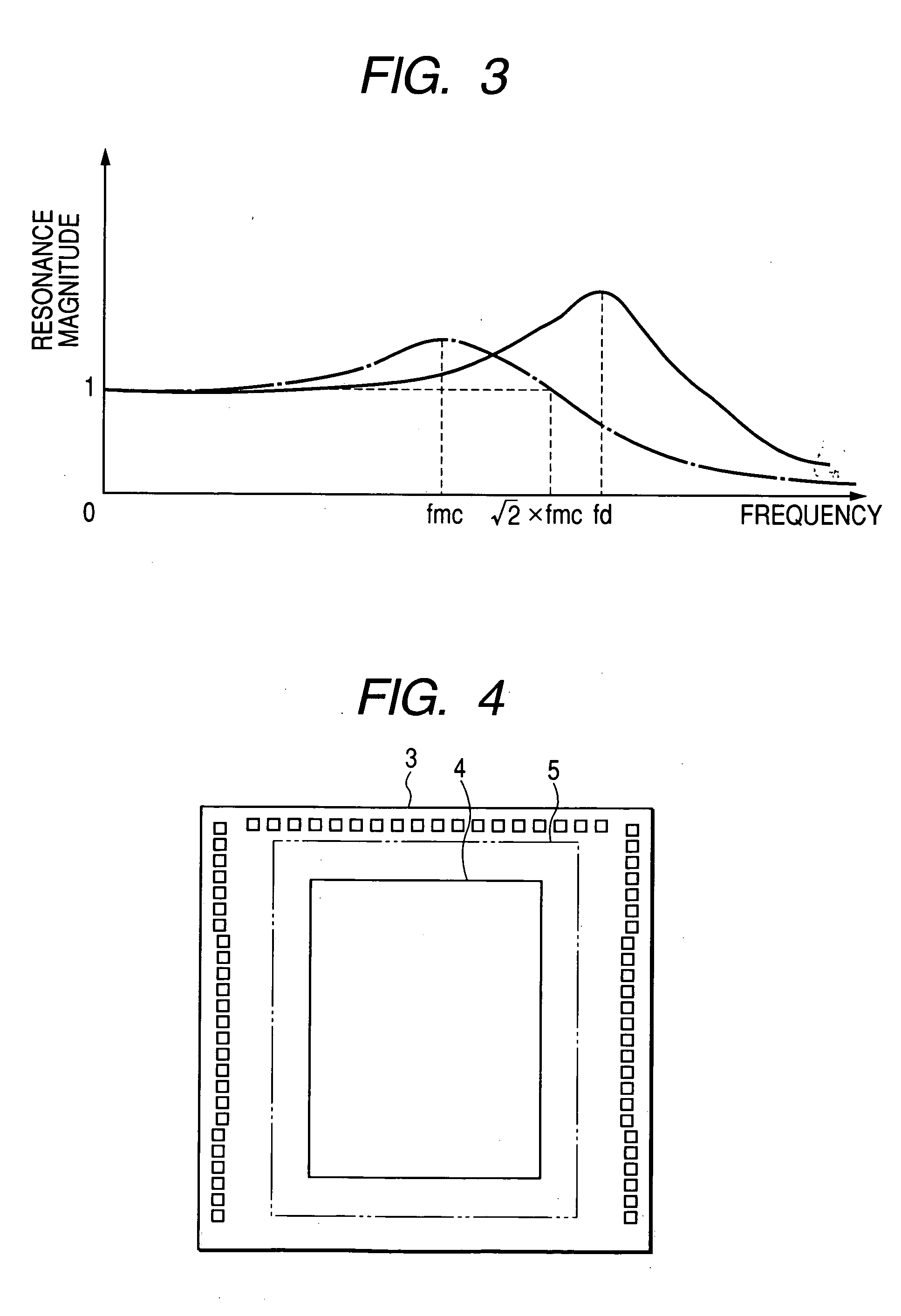

Vibration-type angular rate sensor

InactiveUS20050257615A1Secure vibration-proof propertyImprove seismic performanceAcceleration measurement using interia forcesSolid-state devicesResonanceAngular rate sensor

An angular rate sensor includes a sensor chip having an oscillator vibrating at a predetermined frequency and detecting an angular velocity applied to this oscillator around a predetermined rotation axis. A circuit chip, laminated with the sensor chip, has a circuit formed on a surface thereof to detect the angular velocity based on a signal obtained from the sensor chip. The sensor chip and the circuit chip are bonded with an adhesive film. A resonance frequency of the sensor chip is smaller than (½)1 / 2 times a driving frequency of the oscillator in a condition that adjustment is applied to at least one of configuration or elastic coefficient of the adhesive film.

Owner:DENSO CORP

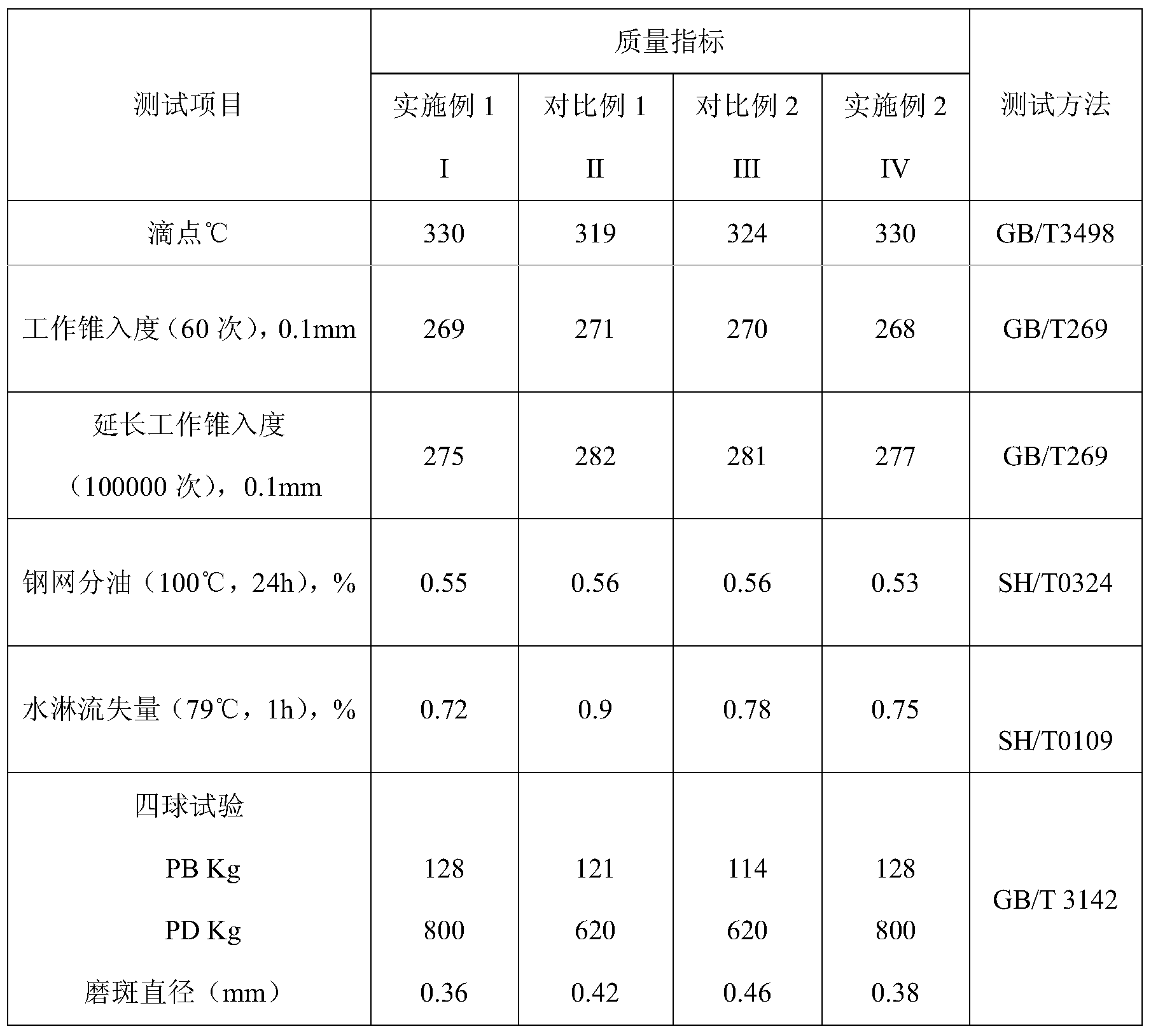

Lubricating grease composition for heavy-loading roller press bearing and preparation method thereof

ActiveCN103275798AGood extreme pressure and anti-wear propertiesImprove the lubrication effectLubricant compositionLithiumAntioxidant

The invention provides a lubricating grease composition for a heavy-loading roller press bearing and a preparation method thereof. The composition has prominent extreme-pressure anti-wear property, lubricating property and water resistance. The lubricating grease composition contains the following ingredients: (a) complex lithium and calcium-based lubricating grease, (b) a tackifier, (c) an oiliness additive, (d) an extreme-pressure anti-wear agent, (e) an antioxidant and (f) a graphite additive.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

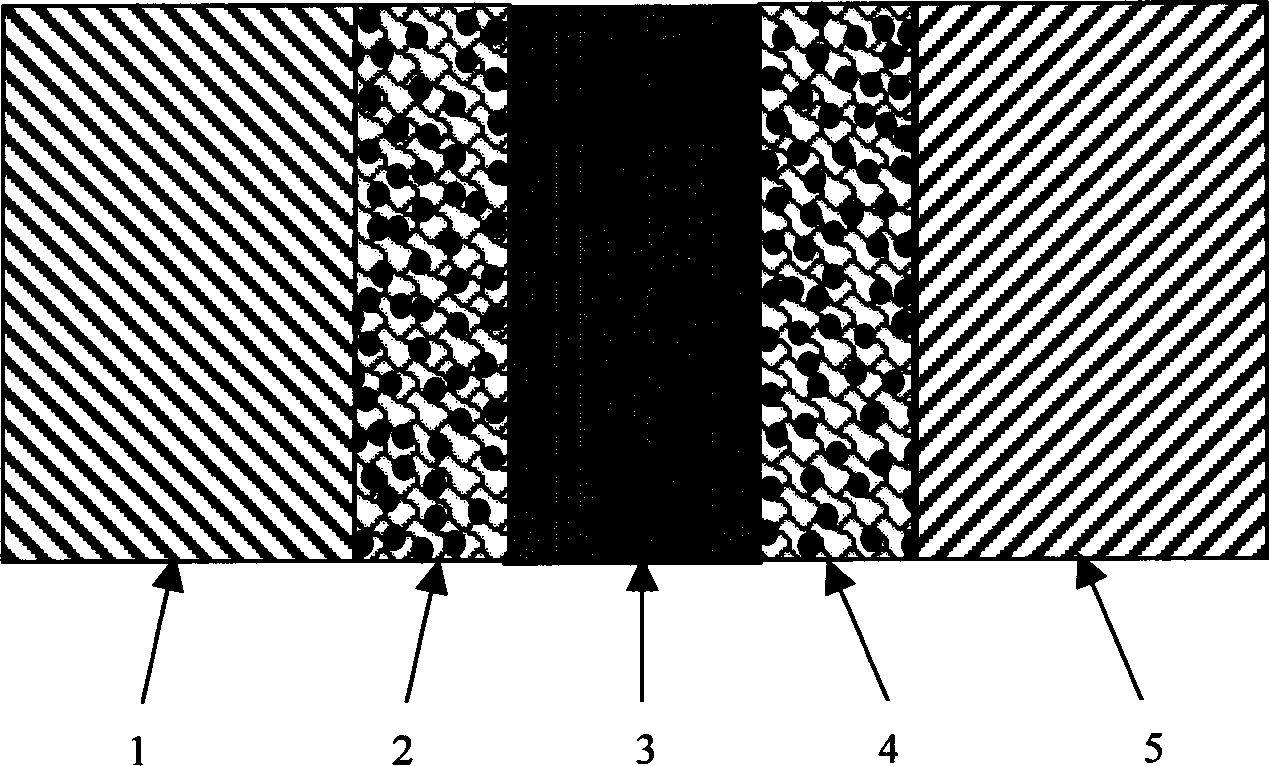

Membrane electrode for proton exchange membrane fuel cell and producing method thereof

InactiveCN1773755AImprove interface bonding performanceImprove stabilityCell electrodesFiberElectrical conductor

A film electrode used on proton exchange film fuel cell consists of five layers as middle layer of total F proton exchange film, two external layers of catalytic layers and two layers of diffusion layers outside of two external layers. Its preparing method includes embedding nanofibre proton conductor network in catalytic layer, preparing a layer of nanofibre proton conductor multiple film on total F proton exchange film surface by static spinning technique, coating ink containing catalyst in proton conductor fibre, drying and heat rolling to obtain film electrode containing nanofibre proton conductor network in catalytic layer.

Owner:SHANGHAI JIAO TONG UNIV

Colloidal electrolyte of lead acid batteries

InactiveCN101291002AInhibition of hydrationPrevent severe crackingLead-acid accumulatorsPhosphoric acidSilicon dioxide

The invention discloses a lead-acid accumulator colloid electrolyte. The lead-acid accumulator colloid electrolyte comprises the following compositions in percentage by mass: 30 to 45 percent of sulphuric acid, 4 to 12 percent of nanometer silicon dioxide, 0.05 to 0.5 percent of macromolecular stabilizing agent, 0.1 to 0.5 percent of superfine glass fibre, 0.1 to 0.5 percent of boric acid, 0.1 to 1 percent of phosphoric acid, 0.3 to 2.5 percent of sodium sulfate and 50 to 57 percent of water. The electrolyte is added with the macromolecular stabilizing agent and the hydrophilic superfine glass fibre and sets up a strong network structure with the sulphuric acid and water molecules; the macromolecular stabilizing agent effectively prevents the delamination of various compositions and the hydration of the colloid electrolyte; the superfine glass fibre in the colloid electrolyte forms a reinforcing rib of the colloid electrolyte, effectively prevents the colloid electrolyte from seriously crazing, strengthens the tensile strength and vibration resistance performance of the colloid and has the strong liquid absorption capacity which improves the diffusing and transmitting speed of the electrolyte. The lead-acid accumulator colloid electrolyte improves the charging and receiving capacity, thereby increasing the cycle life of an accumulator.

Owner:CHAOWEI POWER CO LTD

Shape memory alloy (SMA) group rolling rod type large load releasing mechanism

InactiveCN103231813AStrong impact resistanceLarge release loadCosmonautic component separationShape-memory alloyShock resistance

The invention provides a shape memory alloy (SMA) group rolling rod type large load releasing mechanism. A segmented nut of the mechanism is firmly hooped by a hooping cylinder through rolling rods, simultaneously the upper end face and the lower end face of the segmented nut are respectively matched with an end cover and a separating ejector block, so that the segmented nut is a total nut and cannot move vertically. Groove are arranged on the segmented nut, so that when separation is needed, and the hooping cylinder moves downwards to drive the rolling rods to roll downwards and properly enter the grooves of the segmented nut when moving to a certain position, so that the segmented nut can obtain radial displacement. When releasing is finished, the hooping cylinder moves upwards under the effect of an SMA reset spring and simultaneously push the rolling rods out from the grooves, and the segmented nut draws close toward the inside to form an integral thread, so that repeated using function of the mechanism can be achieved, the segmented nut is fit with the separating ejector block through a conical surface, and the separating ejector block is matched with the hooping cylinder through two end faces. The shape memory alloy (SMA) group rolling rod type large load releasing mechanism is strong in shock resistance, releases large load and has the redundancy design and high reliability.

Owner:BEIHANG UNIV +1

Power module

InactiveUS6900986B2Shorten wiring pathReduce circuit inductanceAc-dc conversion without reversalConversion constructional detailsPower semiconductor deviceElectricity

A power module includes a first substrate with a power semiconductor device mounted thereon, a second substrate with a control circuit for controlling the power semiconductor device formed thereon, a smoothing capacitor electrically connected to the power semiconductor device for smoothing a voltage to be externally supplied to the power semiconductor device, and a case including a case frame and a case lid. The case has an interior in which the first substrate, the second substrate and the smoothing capacitor are disposed, and the smoothing capacitor is disposed in contact with a side surface of the case frame.

Owner:MITSUBISHI ELECTRIC CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com