Patents

Literature

426 results about "Proton conductor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

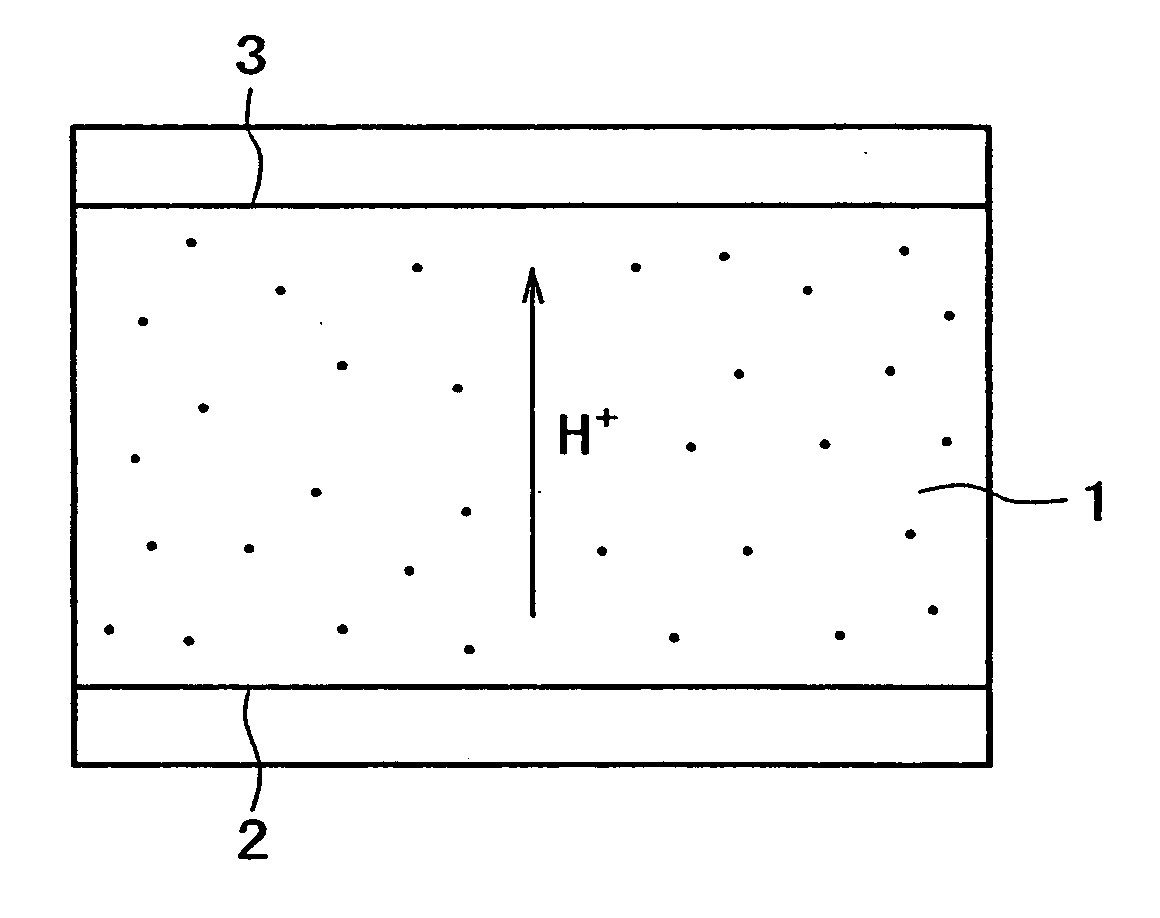

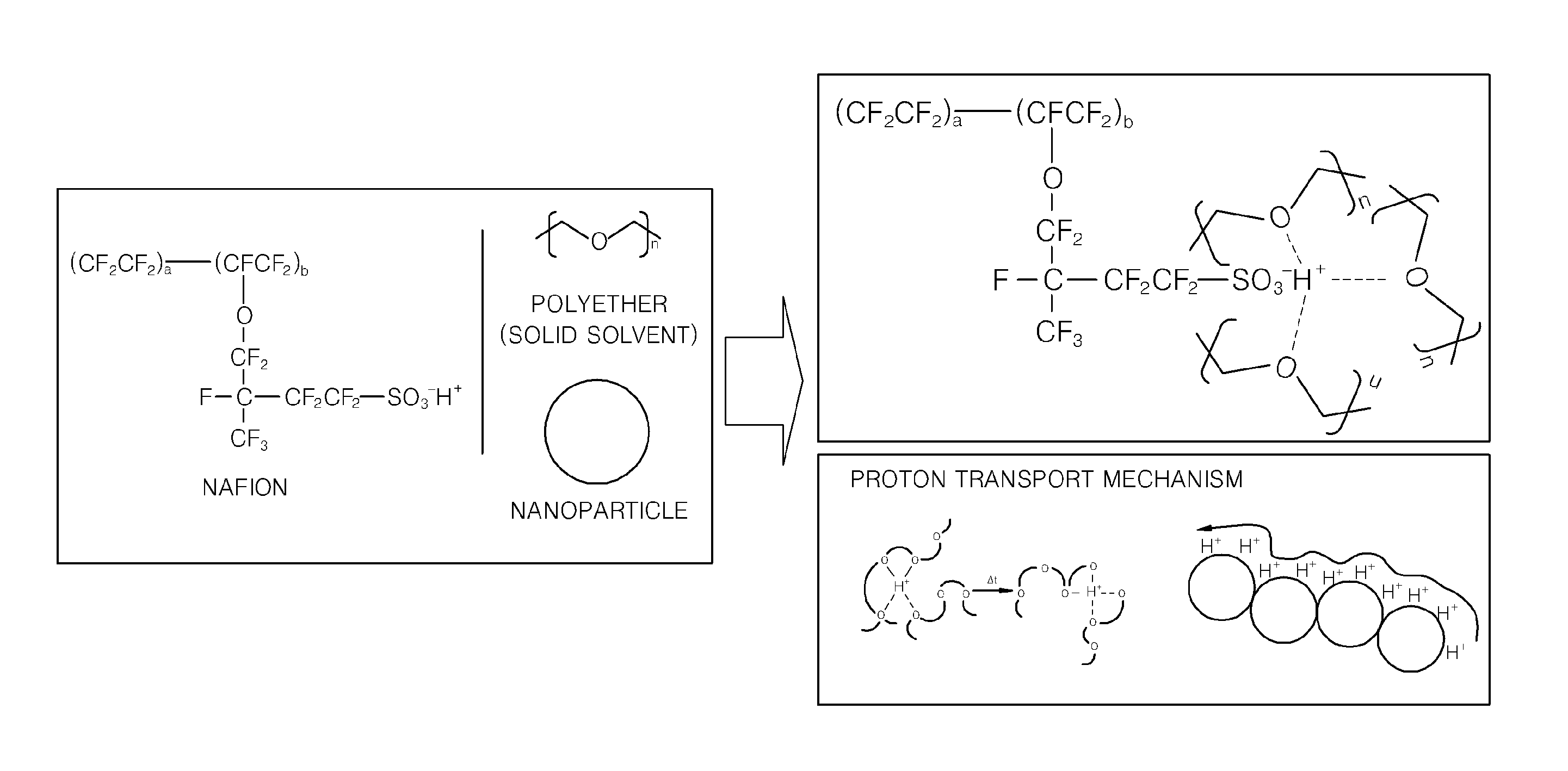

A proton conductor is an electrolyte, typically a solid electrolyte, in which H⁺ are the primary charge carriers.

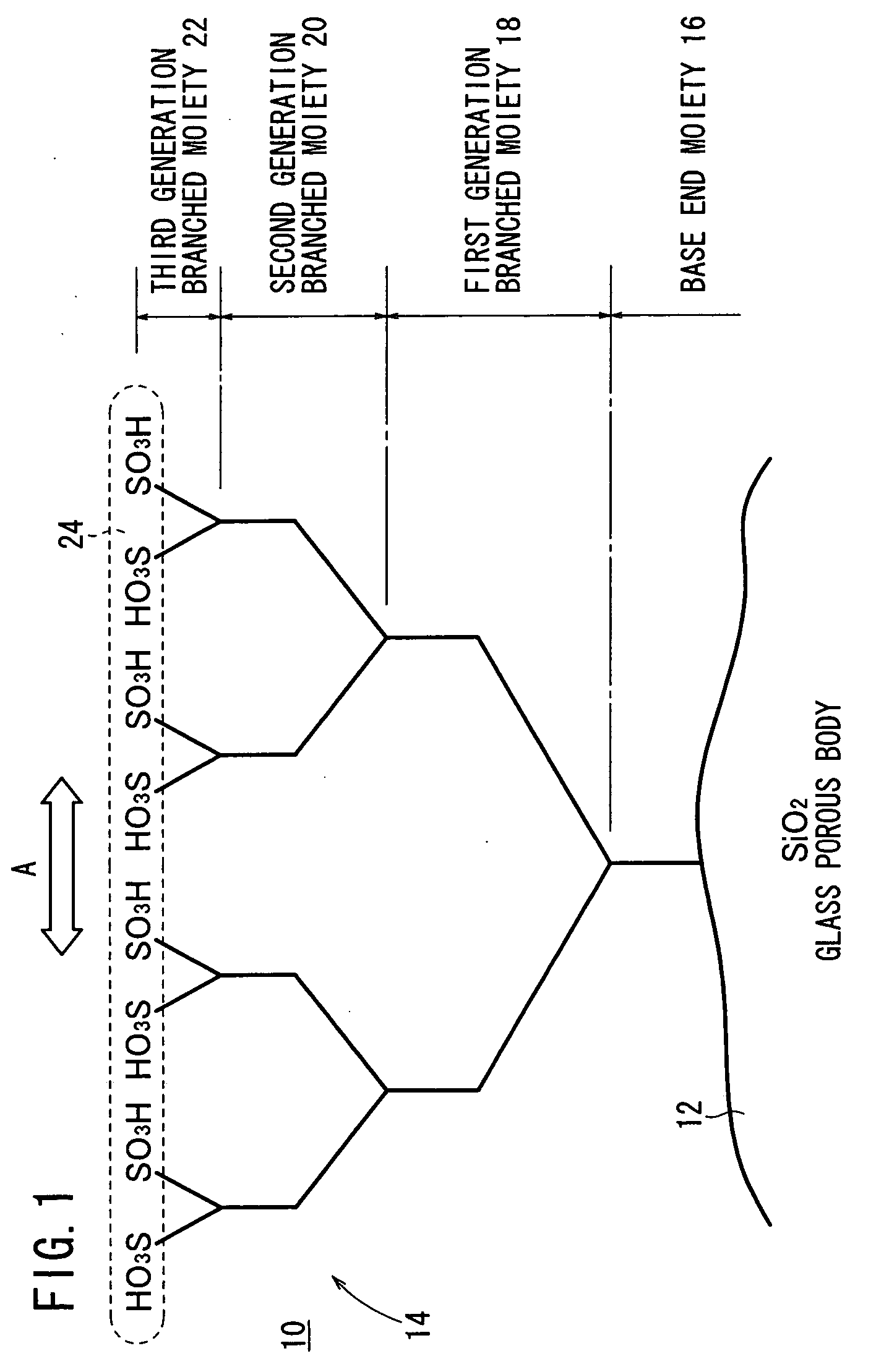

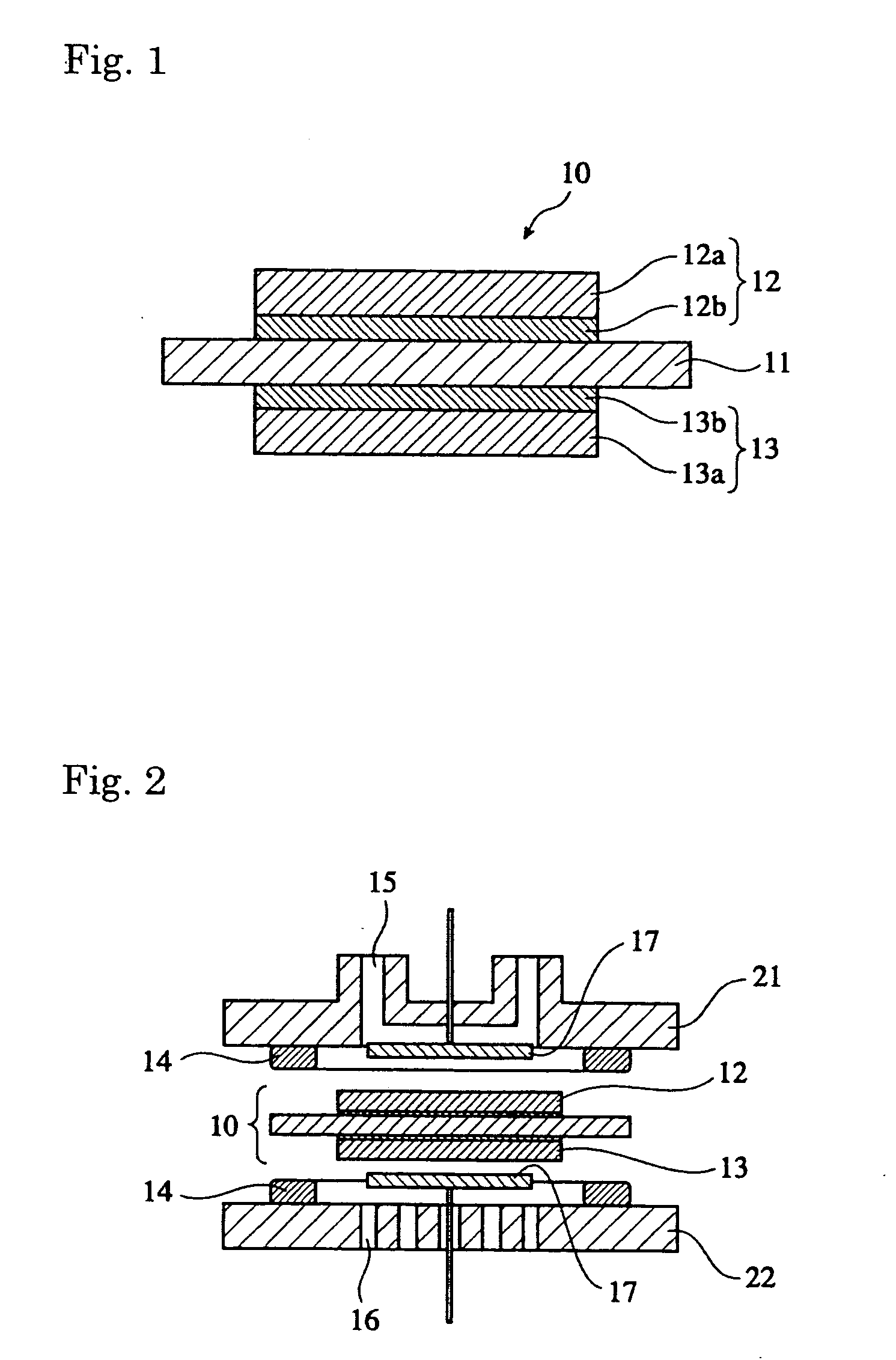

Proton conductor and method for producing the same

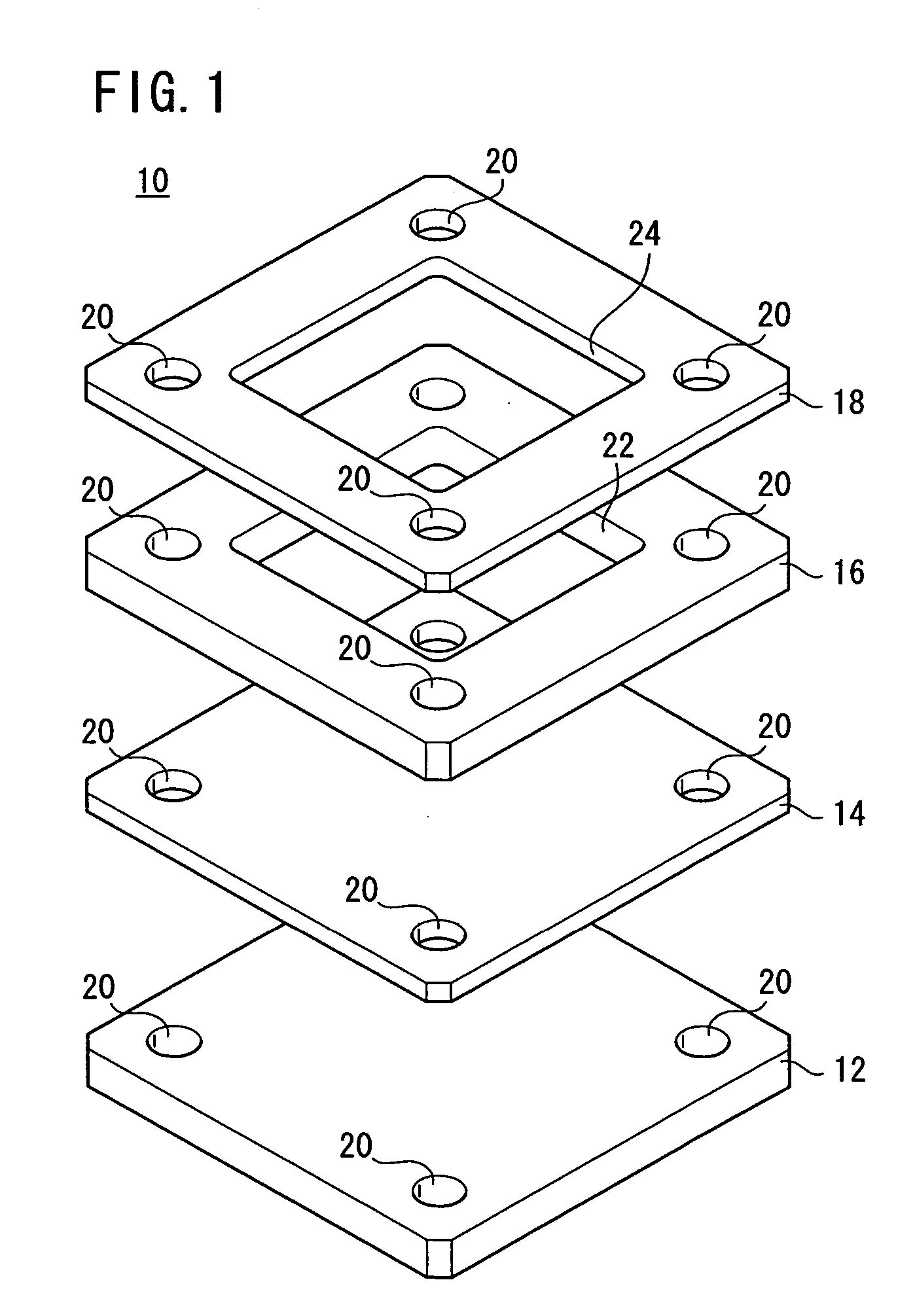

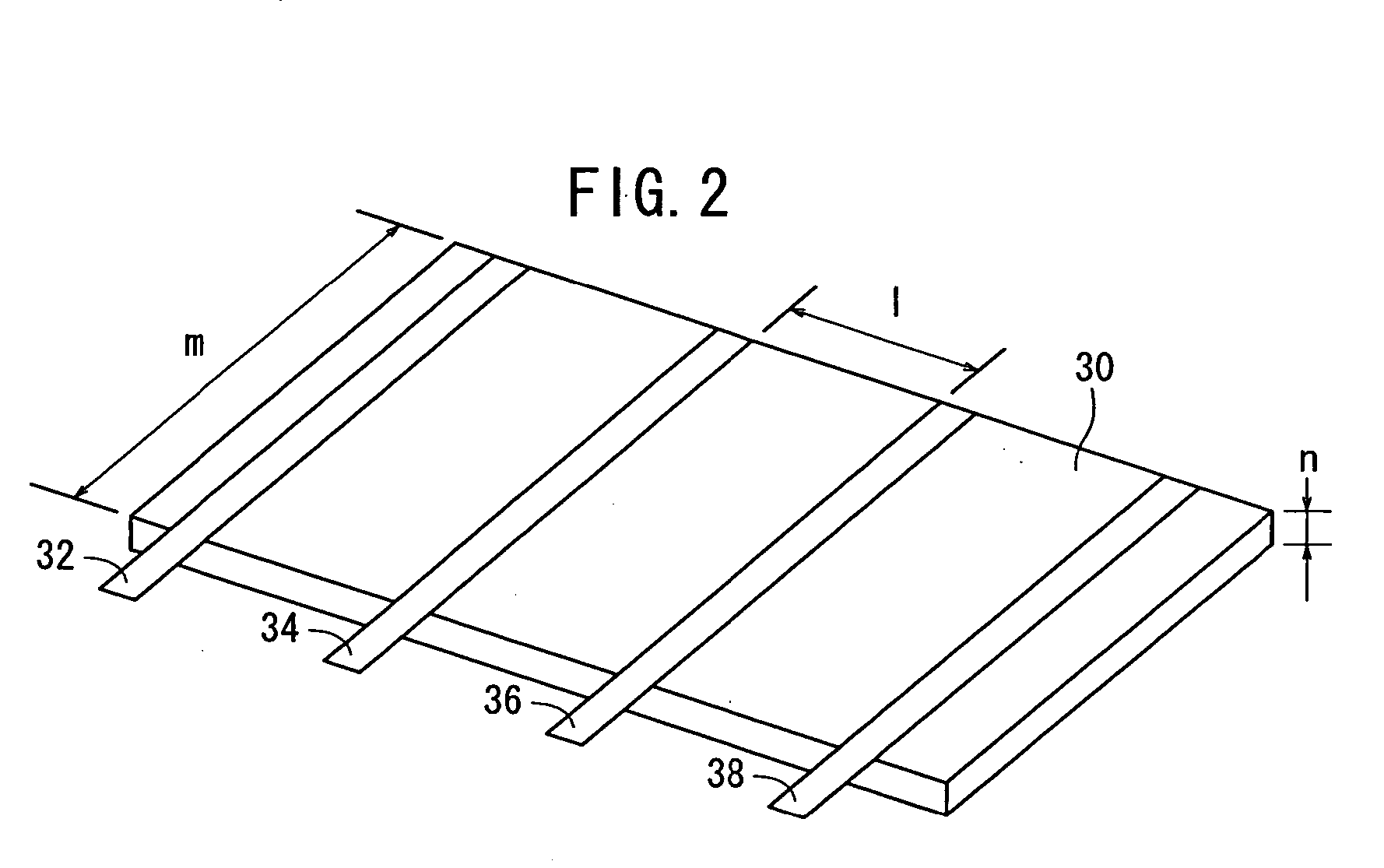

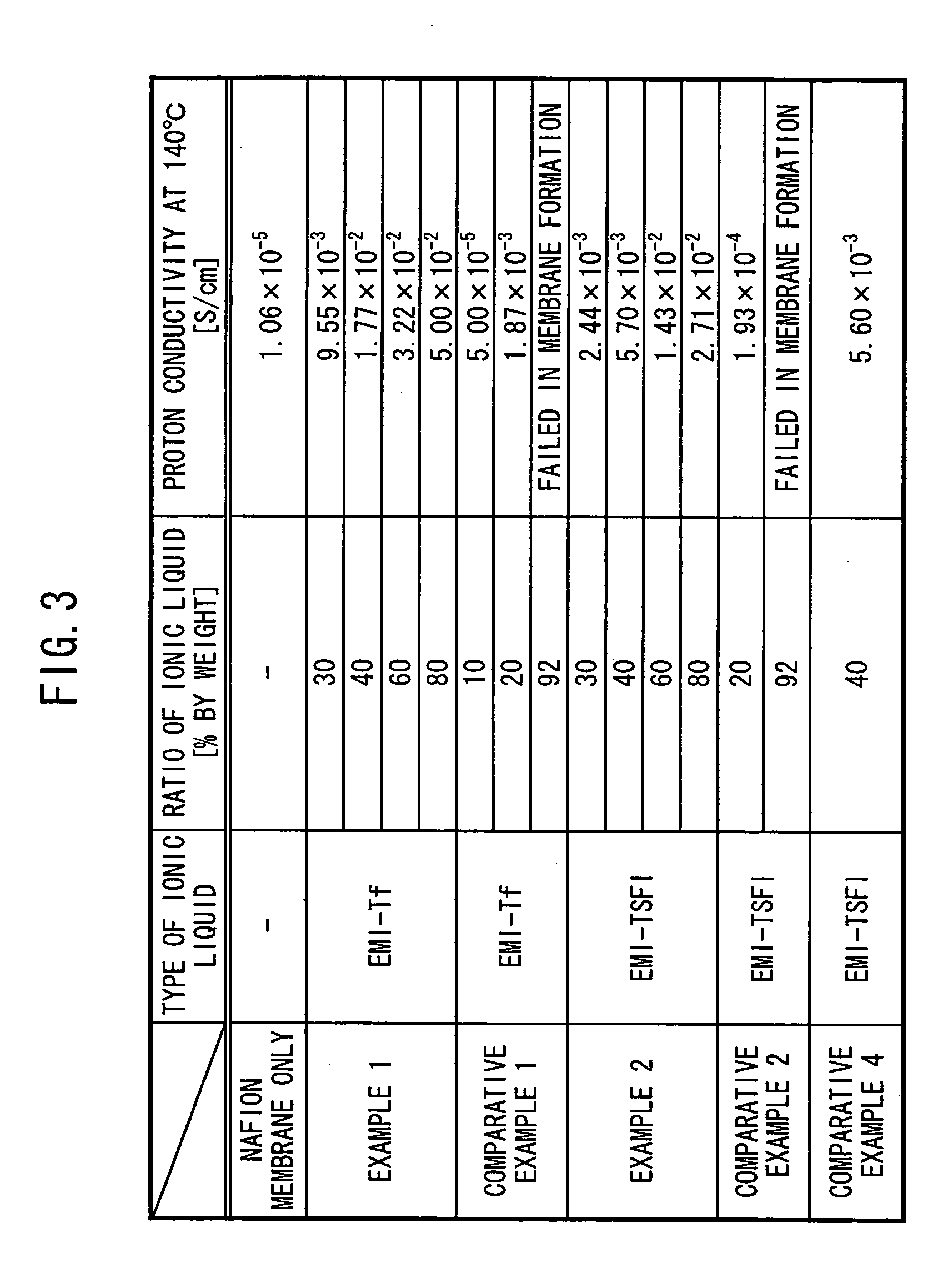

InactiveUS20050106440A1Improve featuresExcellent in its ability to retain a large amount of ionic liquidElectrolyte holding meansSolid electrolytesPolymer scienceO-Phosphoric Acid

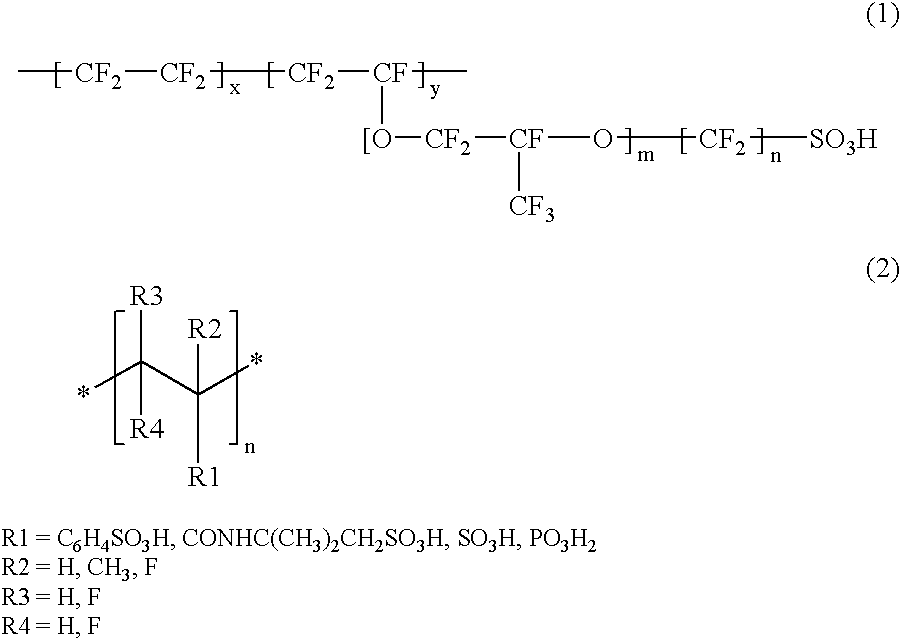

An acidic group-containing solid polymer, having an acidic group such as a sulfonic acid group, a phosphoric acid group, and / or a phosphonic acid group, is dissolved in an organic solvent other than methanol. An ionic liquid is added to the solution to prepare a casting liquid. The casting liquid is subjected to casting in a cavity formed by an opening of a frame and a sheet member, each of which is composed of PTFE (fluorine-containing polymer material). Thereafter, the solvent is removed to yeild a proton conductor membrane.

Owner:HONDA MOTOR CO LTD

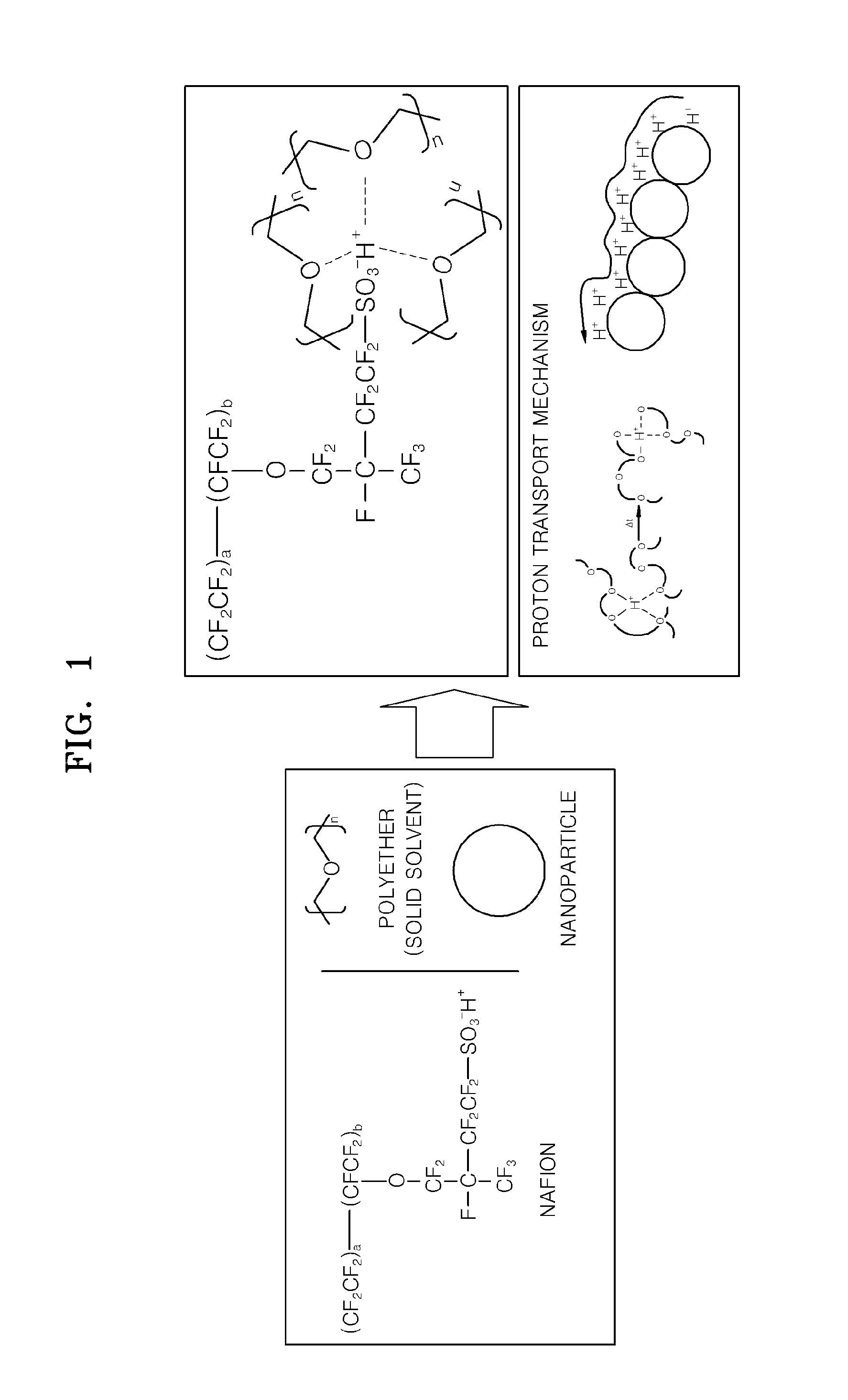

Binder composition for fuel cell, membrane-electrode assembly for fuel cell, and method for preparing the membrane-electrode assembly

InactiveUS20070020507A1Improve bindingImprove proton conductivityMaterial nanotechnologyElectrode manufacturing processesBenzoxazoleProton conductor

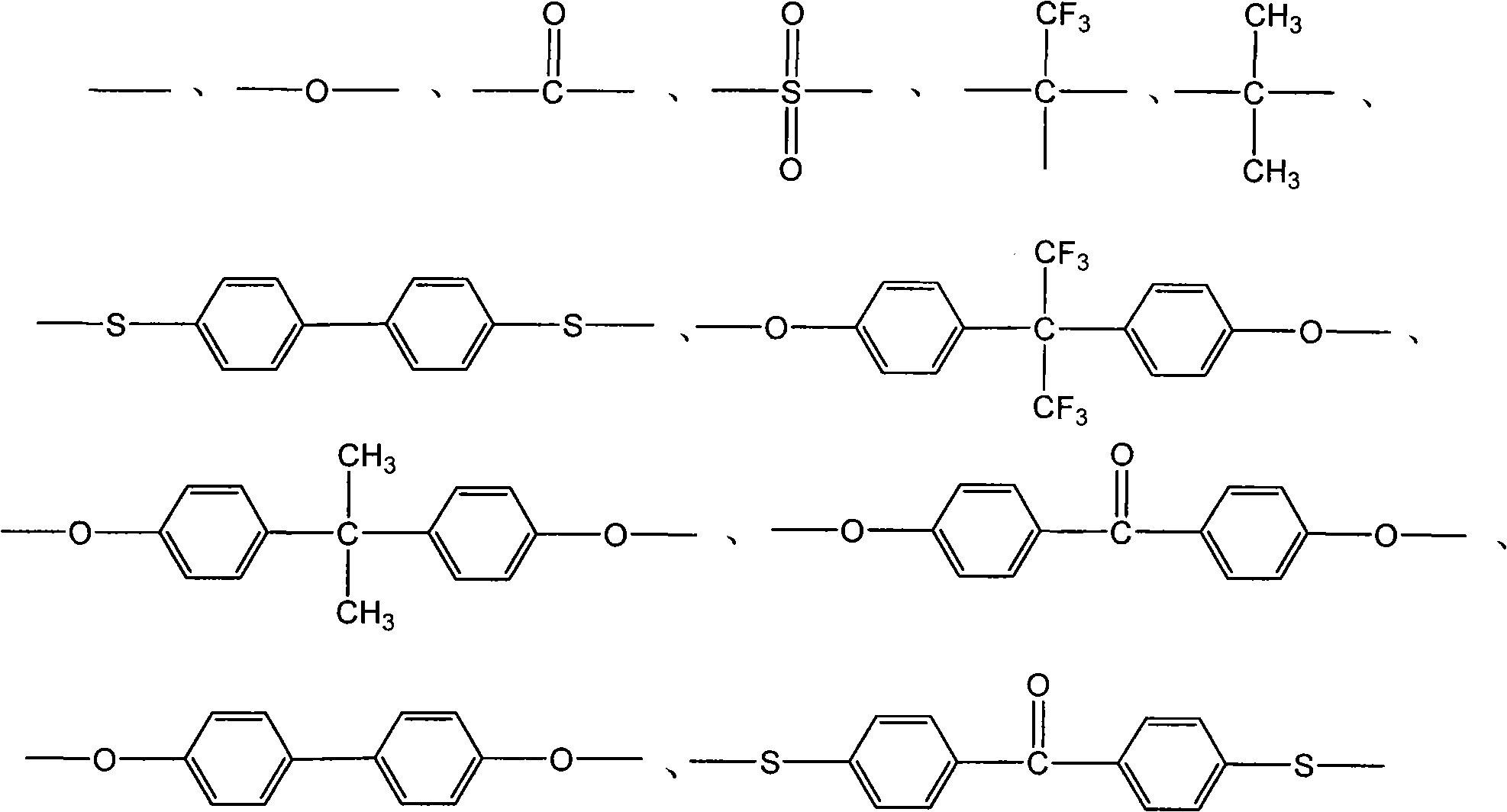

The present invention relates to a binder composition for a fuel cell including a proton conductor and one or more binders selected from the group consisting of poly[2,2′-(m-phenylene)-5,5′-bibenzimidazole] (PBI), poly[2,5-benzimidazole] (ABPBI), polybenzoxazole (PBO), and polybenzothiazole (PBT).

Owner:SAMSUNG SDI CO LTD

Proton conductor

InactiveUS20050197467A1Easy to evaporateExcellent proton conductionSolid electrolytesConductive materialSimple Organic CompoundsElectrical conductor

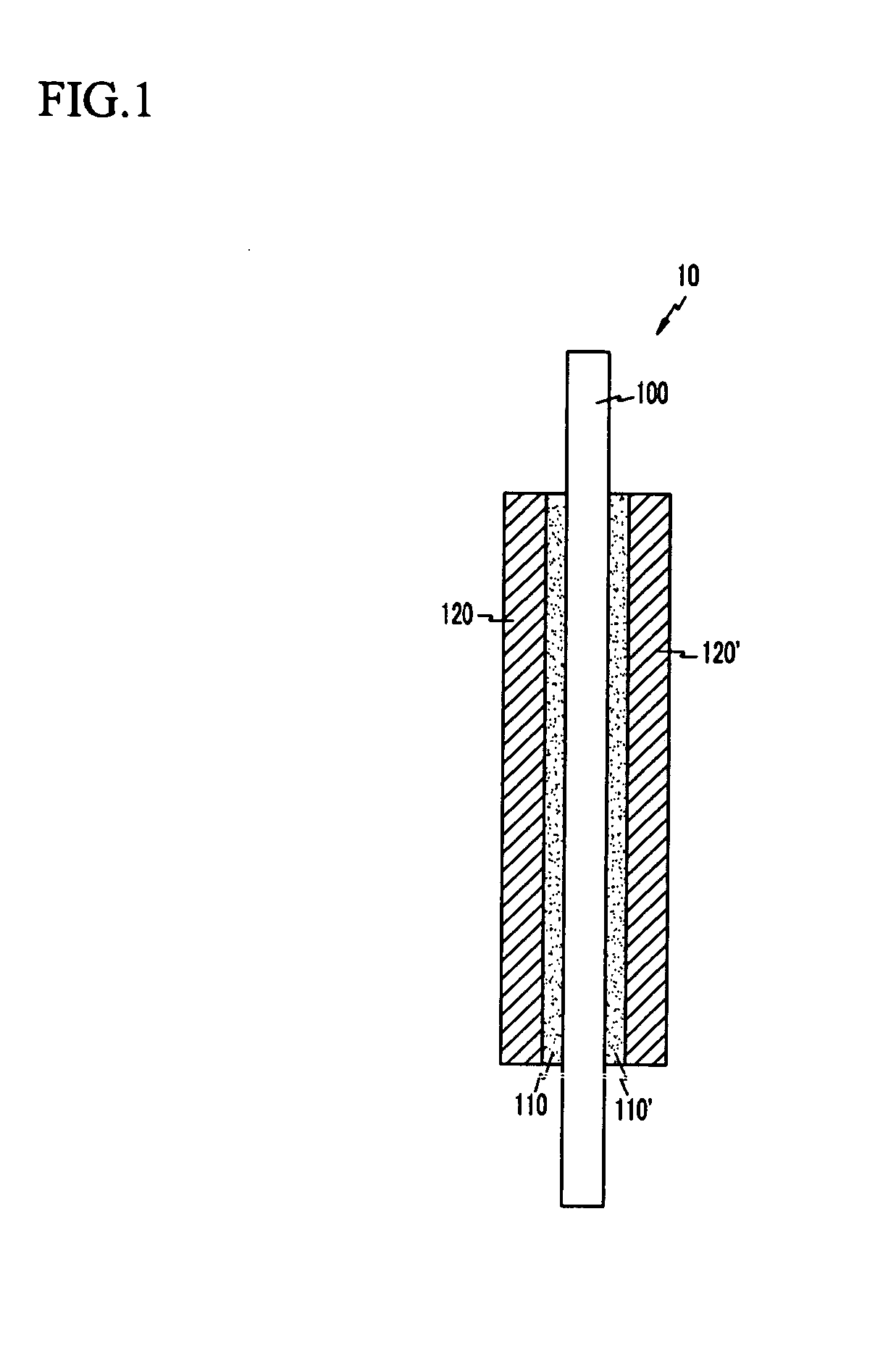

An acidic group-containing polymer which has an acidic group such as sulfonic acid group, phosphoric acid group, and phosphonic acid group, and a proton acceptor which has a boiling point at 1 atmosphere higher than 100° C. and which functions as a medium for conducting proton dissociated from the acidic group are retained in pores of a porous member. Preferred examples of the proton acceptor include a salt structure composed of an anion and a cation derived from a basic organic compound, a basic organic compound, and a dissociation-facilitating polymer which facilitates dissociation of proton. Any one of the acidic group-containing polymer and the proton acceptor may be retained first, or both may be retained simultaneously.

Owner:HONDA MOTOR CO LTD

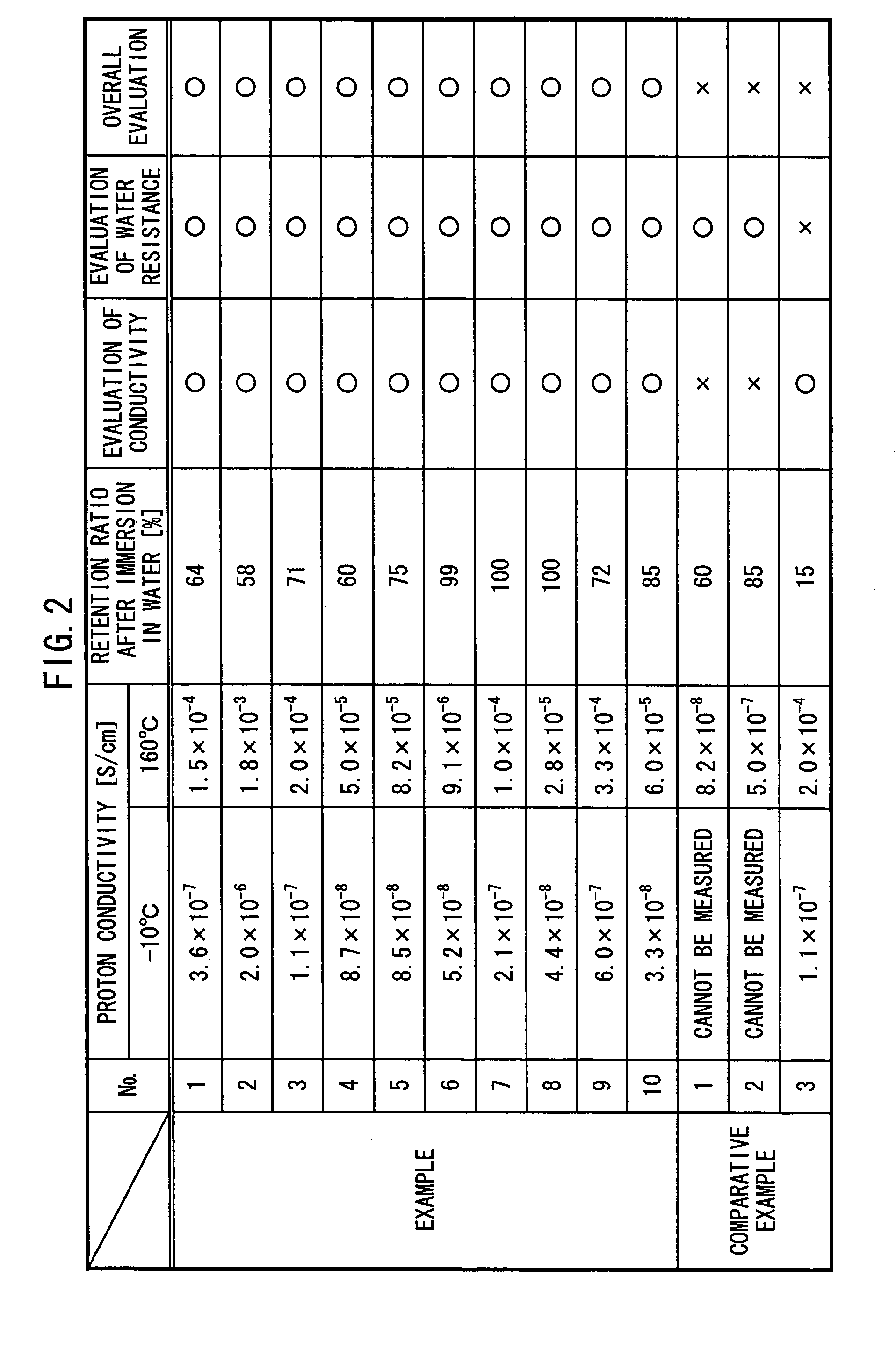

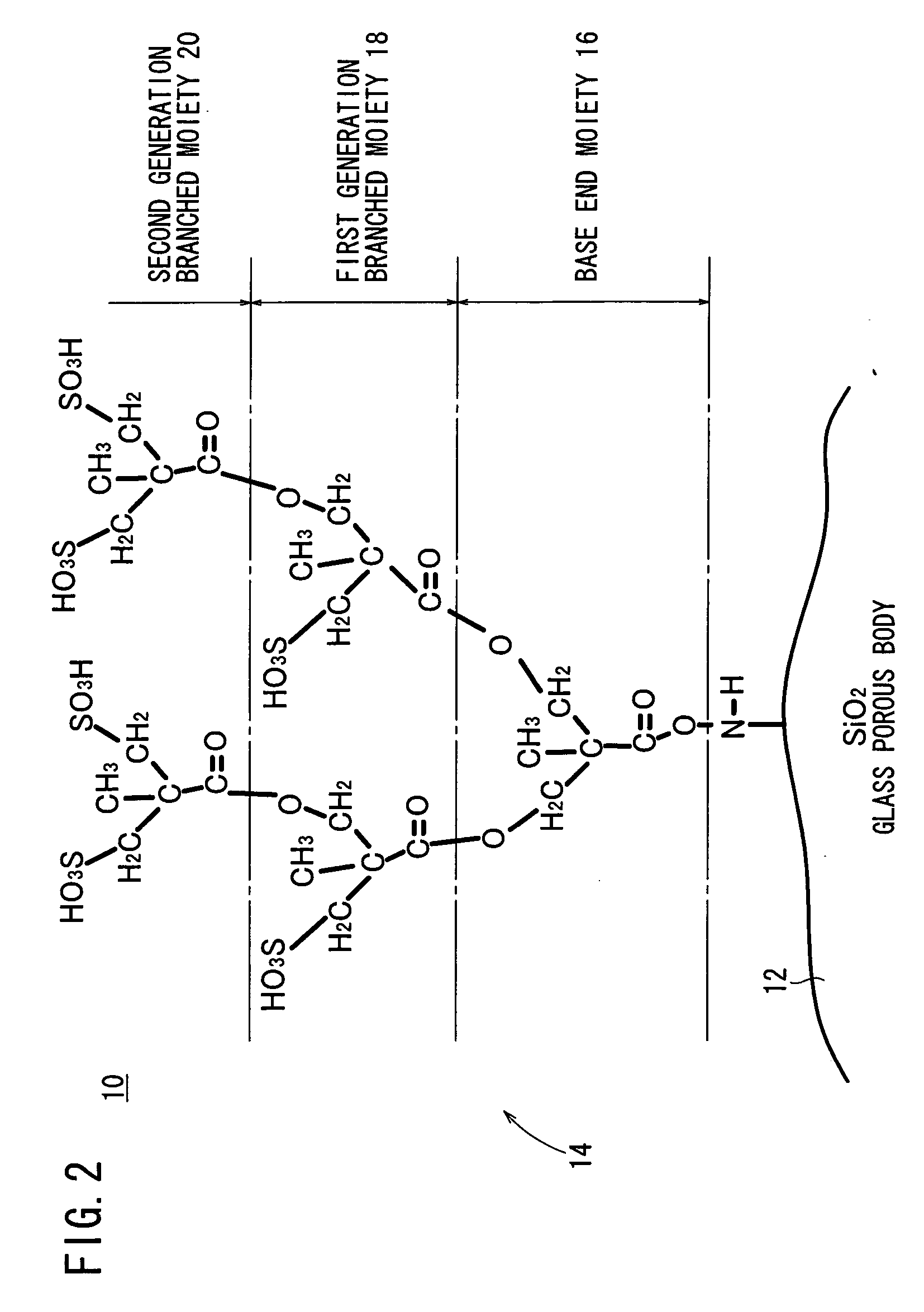

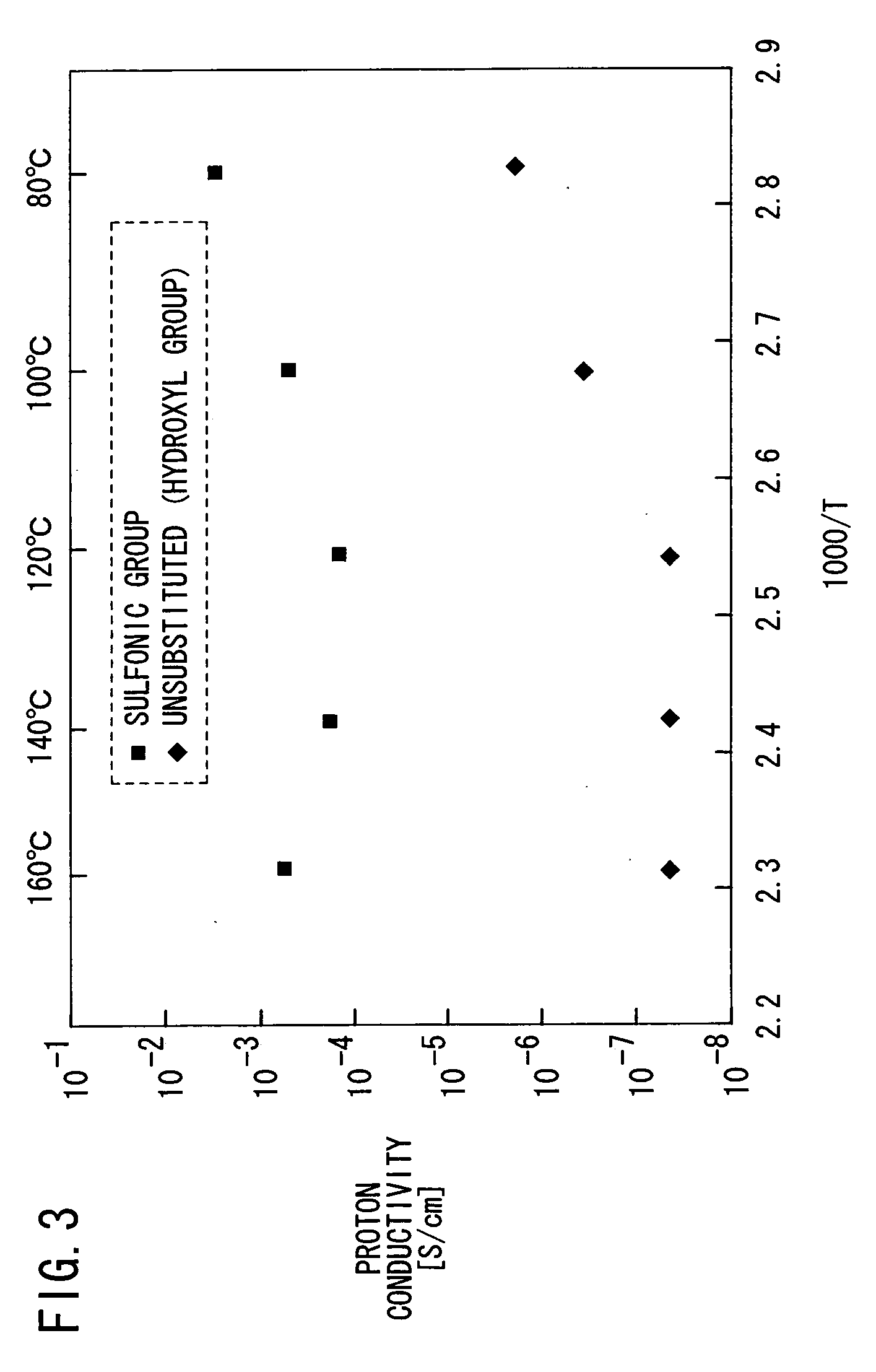

Proton conductor and method for producing the same

InactiveUS20050143530A1Improve proton conductivityNon-metal conductorsSolid electrolyte fuel cellsElectrical conductorProton

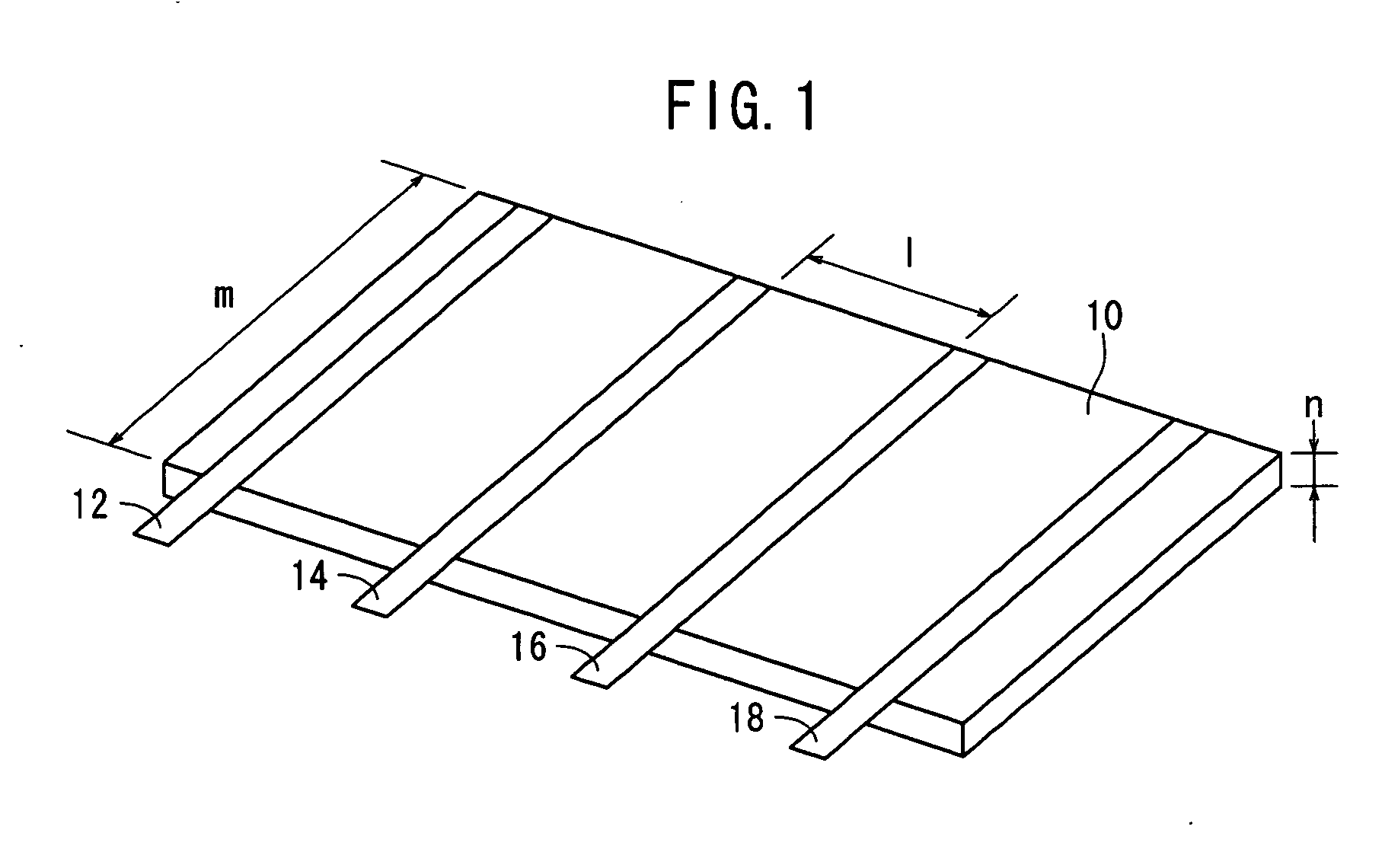

A hyperbranch polymer is bonded to a pore surface existing on a SiO2 glass porous body, such that the hyperbranch polymer is bonded to the pore surface only at the base end moiety. The hyperbranch polymer has a first generation branched moiety branched from the base end moiety, a second generation branched moiety further branched from the first generation branched moiety, and a third generation branched moiety further branched from the second generation branched moiety. A functional group, such as sulfonic acid group, from which a proton is capable of being dissociated, is bonded by substitution to the terminal end of the third generation branched moiety.

Owner:HONDA MOTOR CO LTD

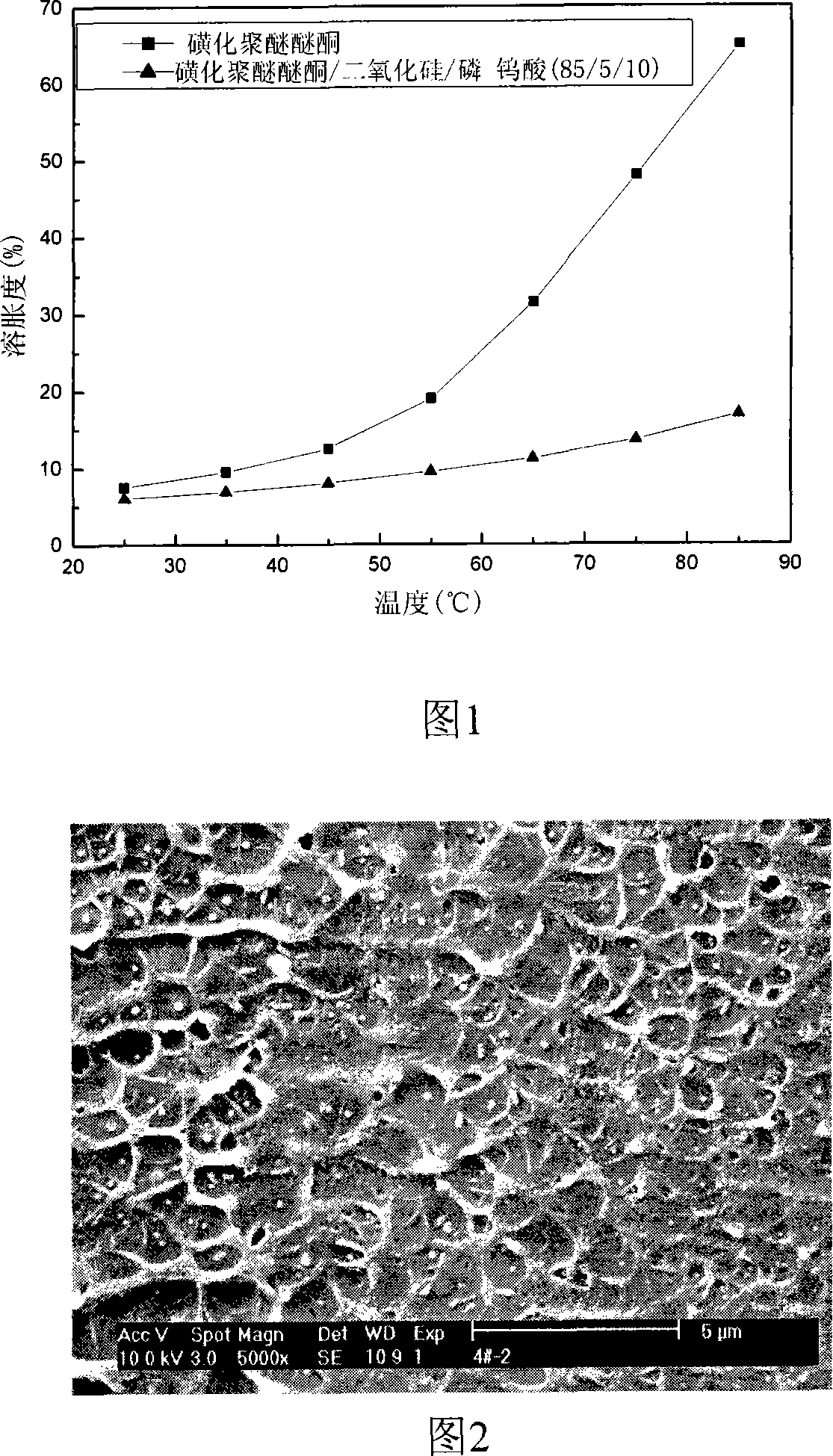

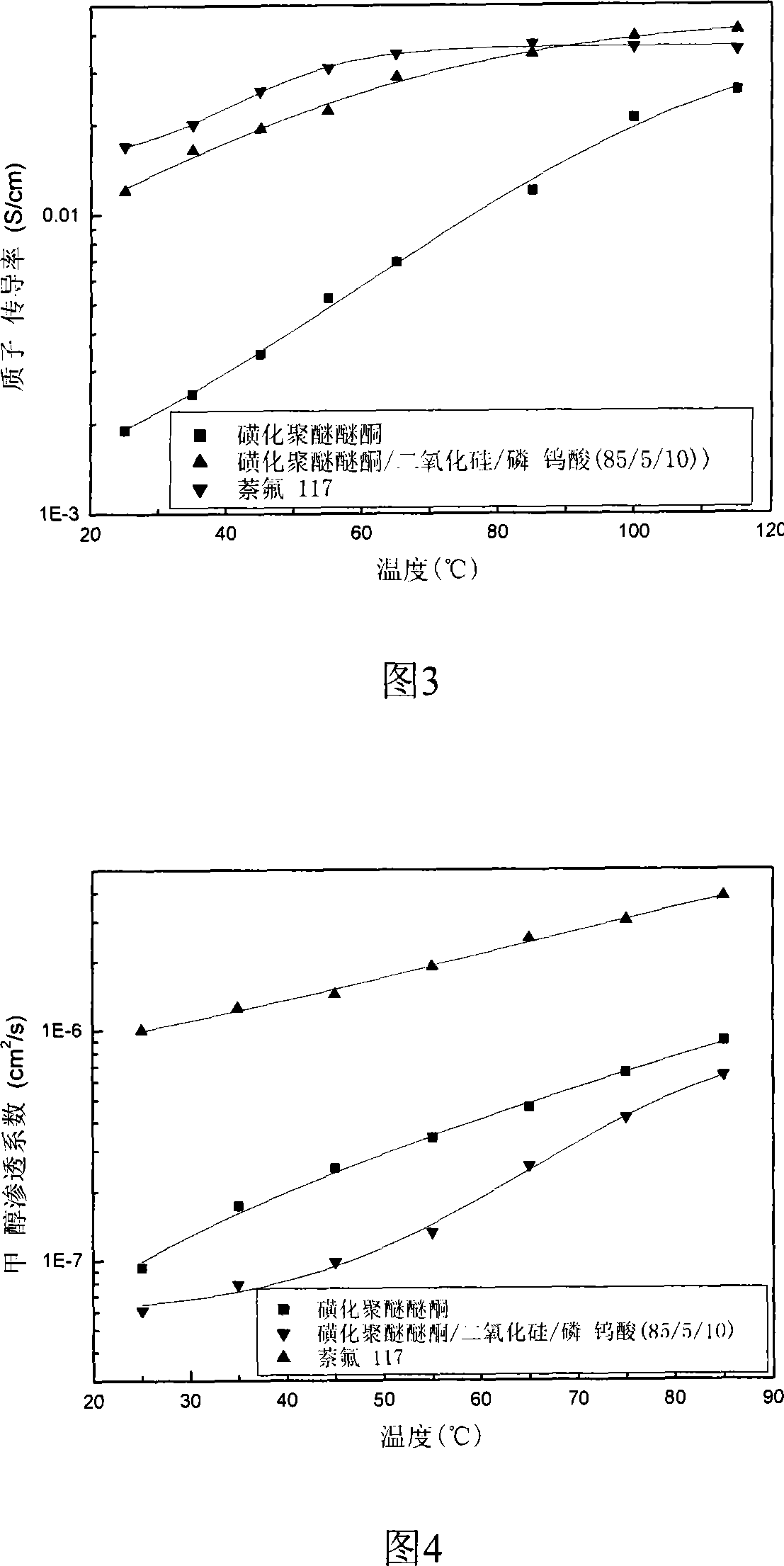

A proton exchange film for direct carbinol fuel battery and its making method

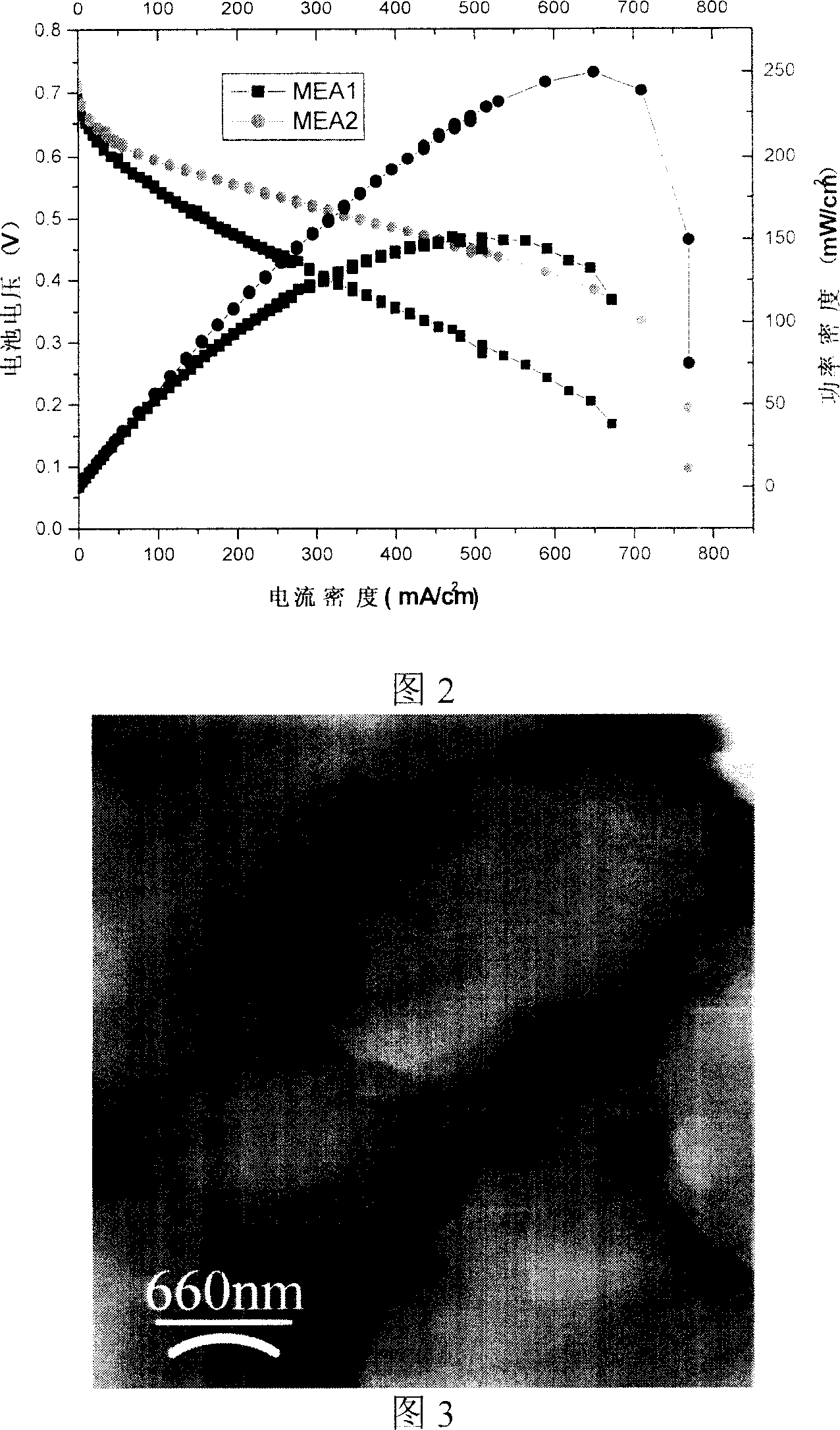

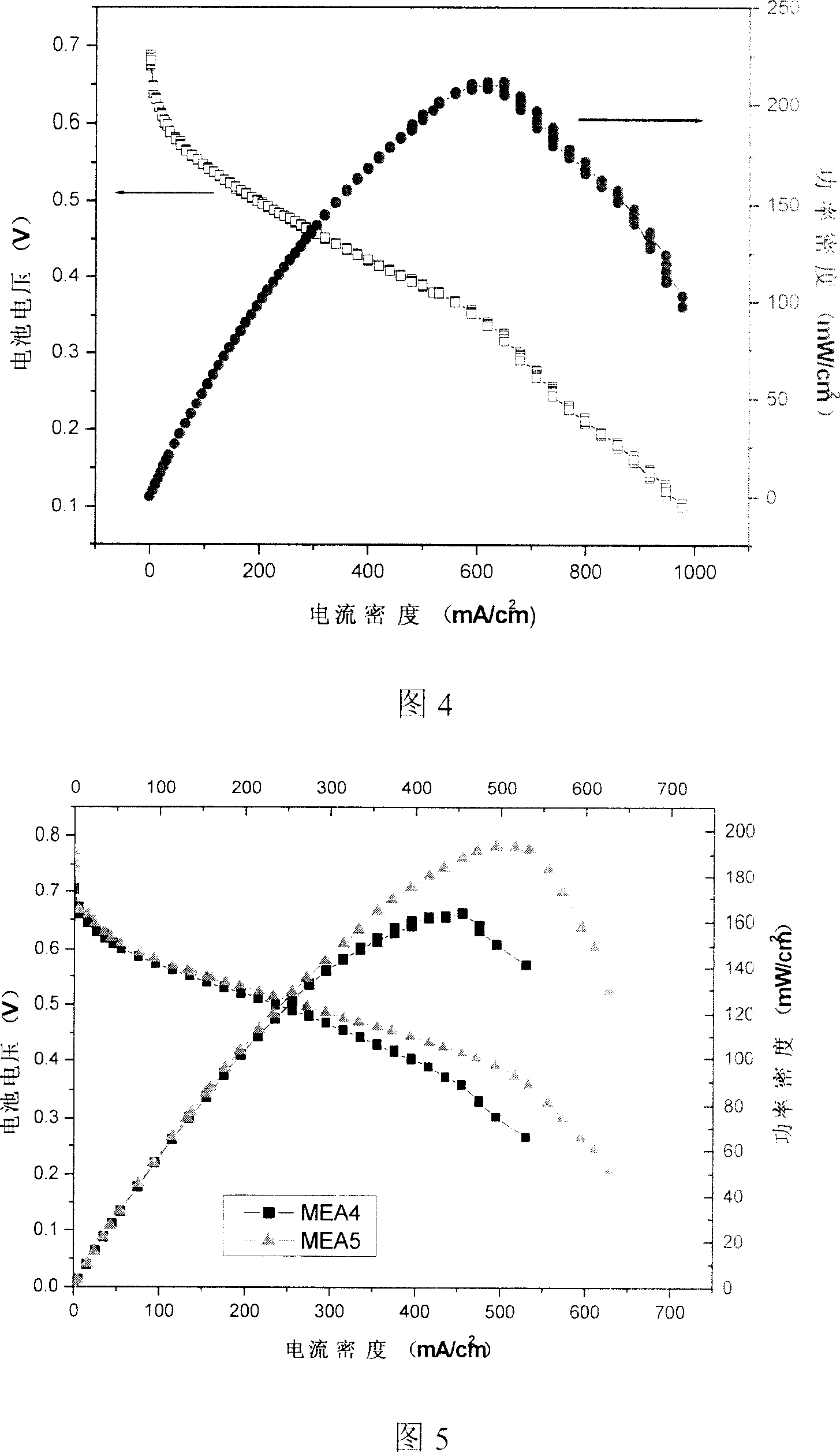

InactiveCN101188301AImprove proton conductivityImprove power densityFinal product manufactureSolid electrolyte fuel cellsElectrical conductorDiffusion resistance

The invention discloses a preparation method of a proton exchange membrane used for a direct methanol fuel cell. The method is realized by that polyether ether ketone is added into concentrated sulfuric acid to carry out sulfonation reaction, thereby obtaining sulfonated polyether ether ketone, then the sulfonated polyether ether ketone is dissolved in organic solvent, N, N (1)-Carbonyldiimidazole is added to stir for one to three hours, coupling agent is mixed for stirring the reaction for 1.5 to 4 hours, then inorganic crosslinking agent is mixed to react under the temperature of 50 to 80 DEG C. Proton conductors are mixed to continue getting the mixed solution of the sulfonated polyether ether ketone or the inorganic crosslinking agent or proton conductors under the temperature. Finally the proton exchange membrane for a direct methanol fuel cell is obtained by that the mixed solution of the sulfonated polyether ether ketone or the inorganic crosslinking agent or proton conductors is / are processed through membrane forming, drying and exuviation. The membrane has the advantages of good methanol diffusion resistance, low cost, high proton conductivity and good water-resistant swelling performance under high temperature. The preparation method is simple, the raw materials have low price, and the production cost is low.

Owner:SOUTH CHINA UNIV OF TECH

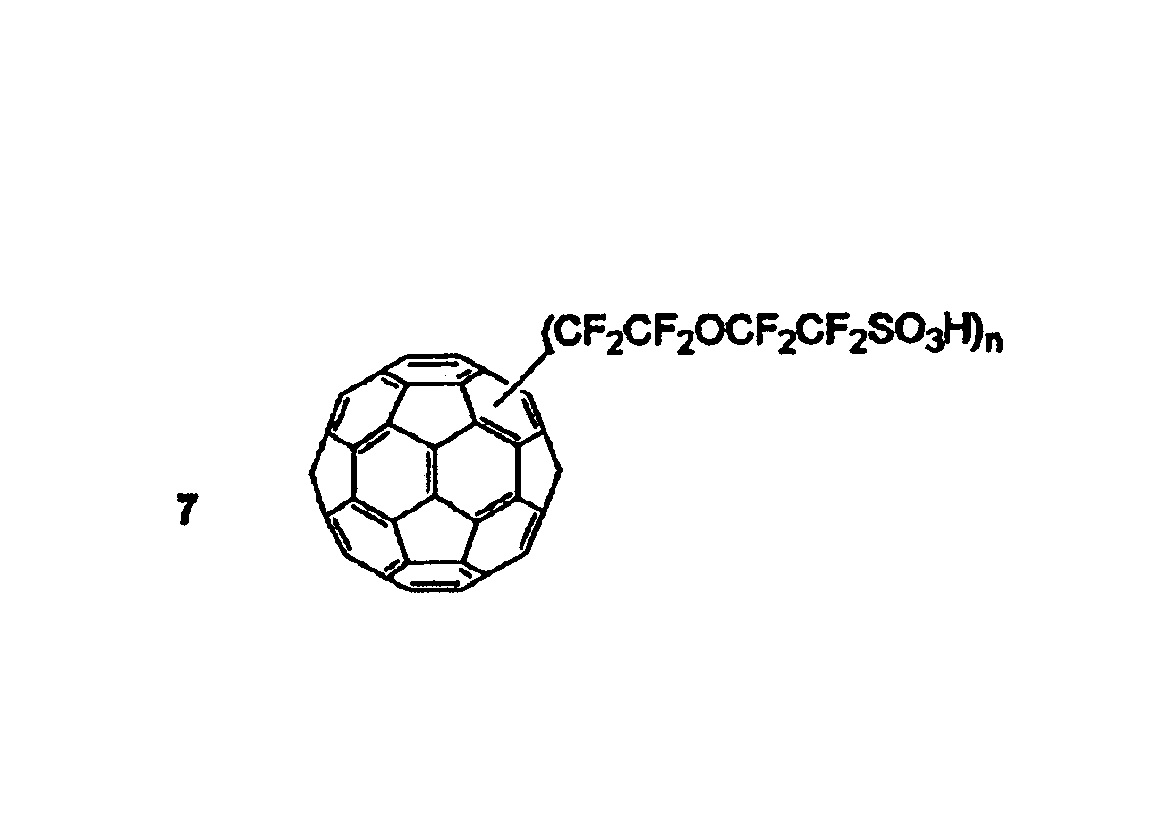

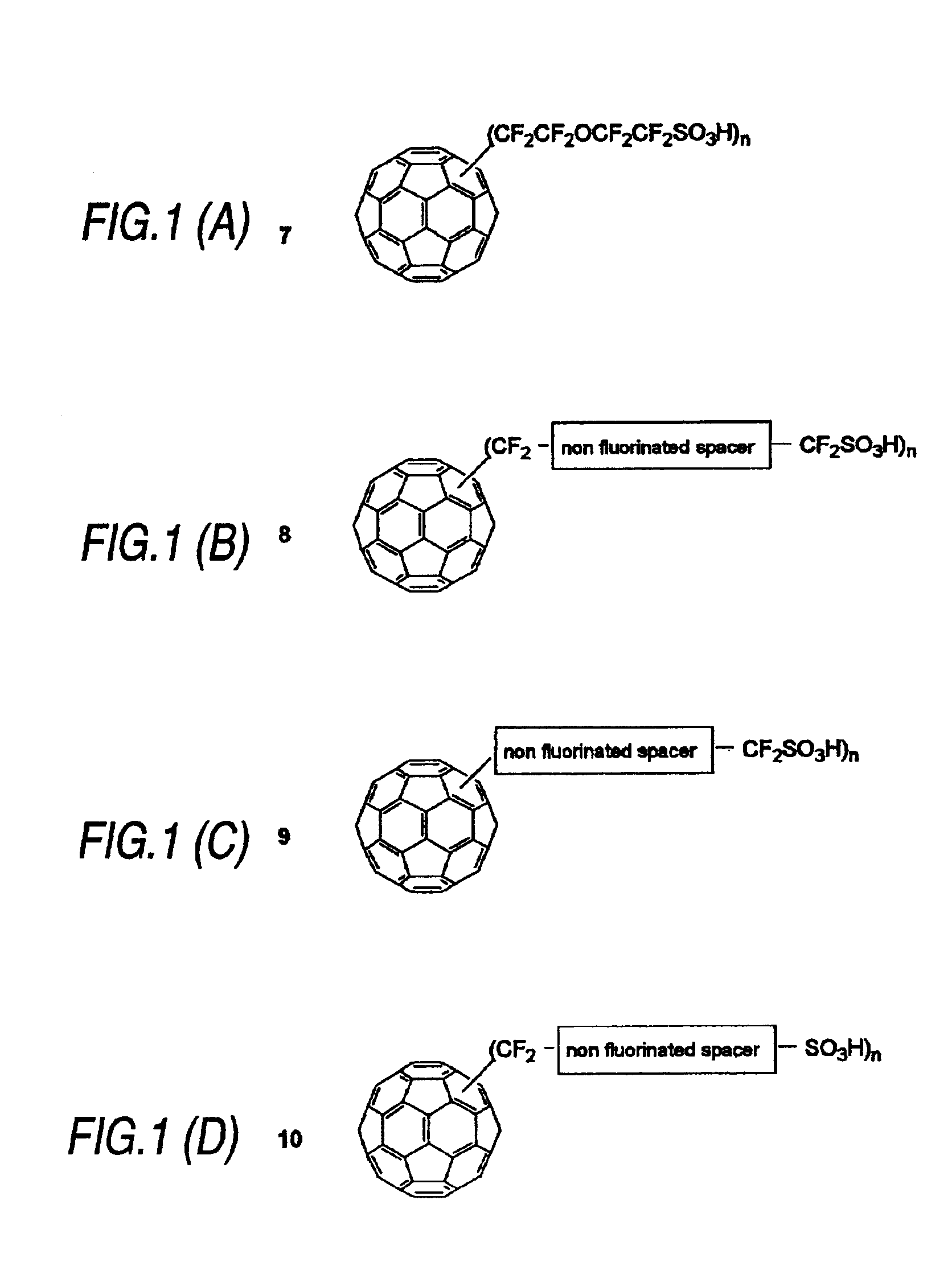

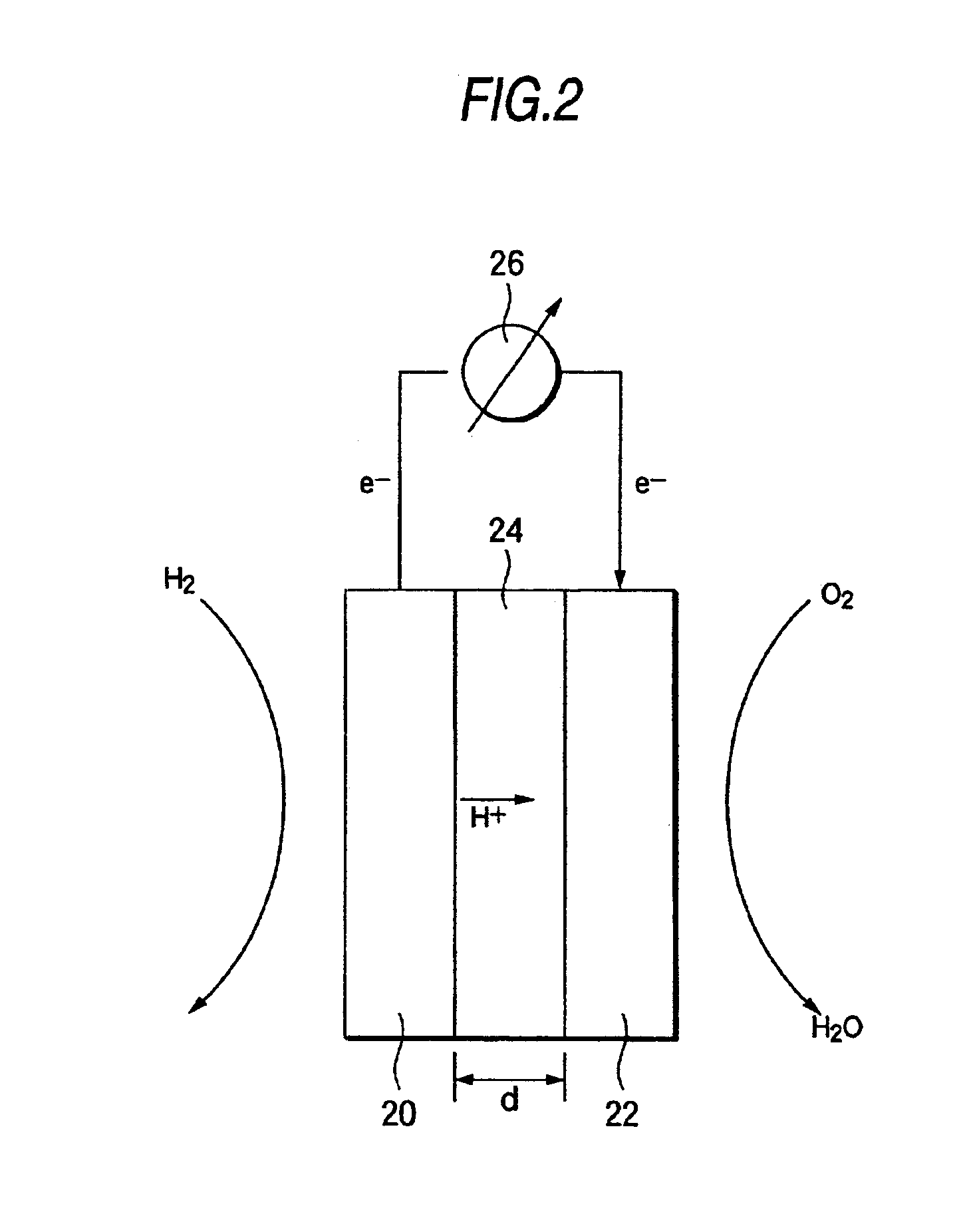

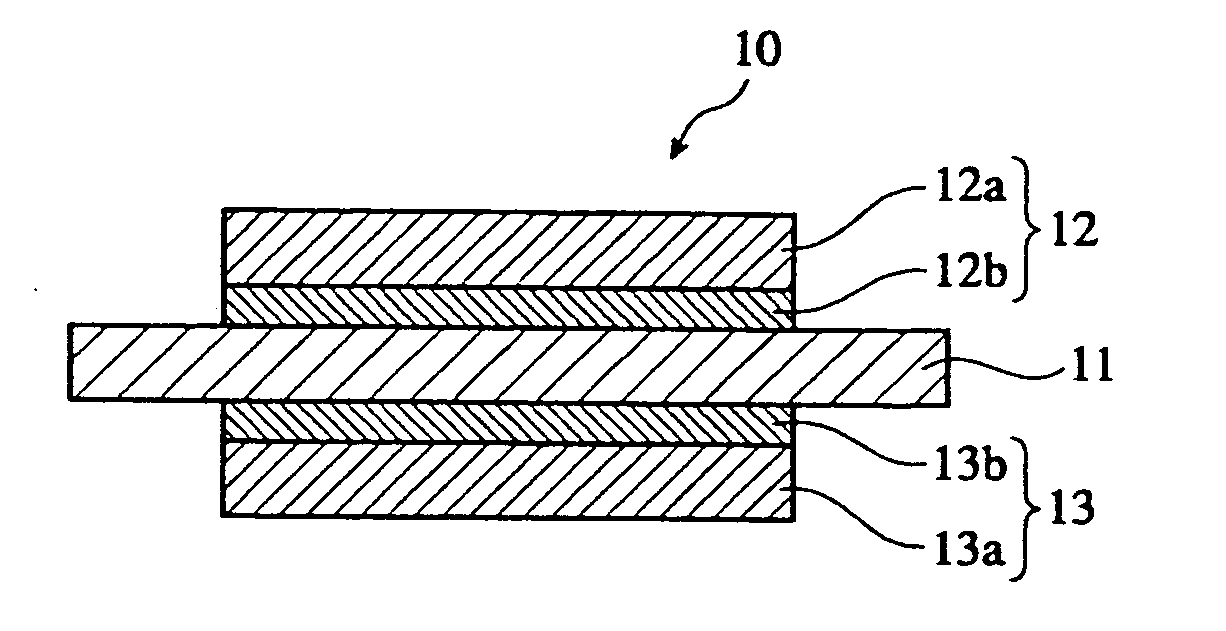

Fullerene based proton conductive materials

InactiveUS6890676B2Improve proton conductivityOvercome disadvantagesMaterial nanotechnologySolid electrolytesProtonConductive materials

A fullerene-based proton conductor including a proton conductive functional group connected to the fullerene by an at least partially fluorinated spacer molecule. Also, a polymer including at least two of the proton conductors that are connected by a linking molecule. Further, an electrochemical device employing the polymer as a proton exchange membrane, whereby the device is able to achieve a self-humidifying characteristic.

Owner:SONY CORP

Compound, and solid electrolyte, proton conductor, membrane electrode assembly and fuel cell comprising the compound

A solid electrolyte having a high ionic conductivity and not so much troubled by methanol-crossover through it is provided according to a method of sulfonation of a compound of the following formula (I), etc., followed by sol-gel reaction of the resulting compound, or according to a method of the sol-gel reaction followed by the sulfonation. wherein R1 represents a hydrogen atom, an alkyl group, an aryl group or a silyl group; R2 represents an alkyl group, an aryl group or a heterocyclic group; m1 indicates an integer of from 1 to 3; L1 represents a single bond, an alkylene group, —O—, —CO—, or a divalent linking group of a combination of any of these groups; L2 represents an n1-valent linking group; Ar1 represents an arylene or heteroarylene group having at least one electron-donating group; n1 indicates an integer of from 2 to 4; s1 indicates an integer of 1 or 2.

Owner:FUJIFILM HLDG CORP +1

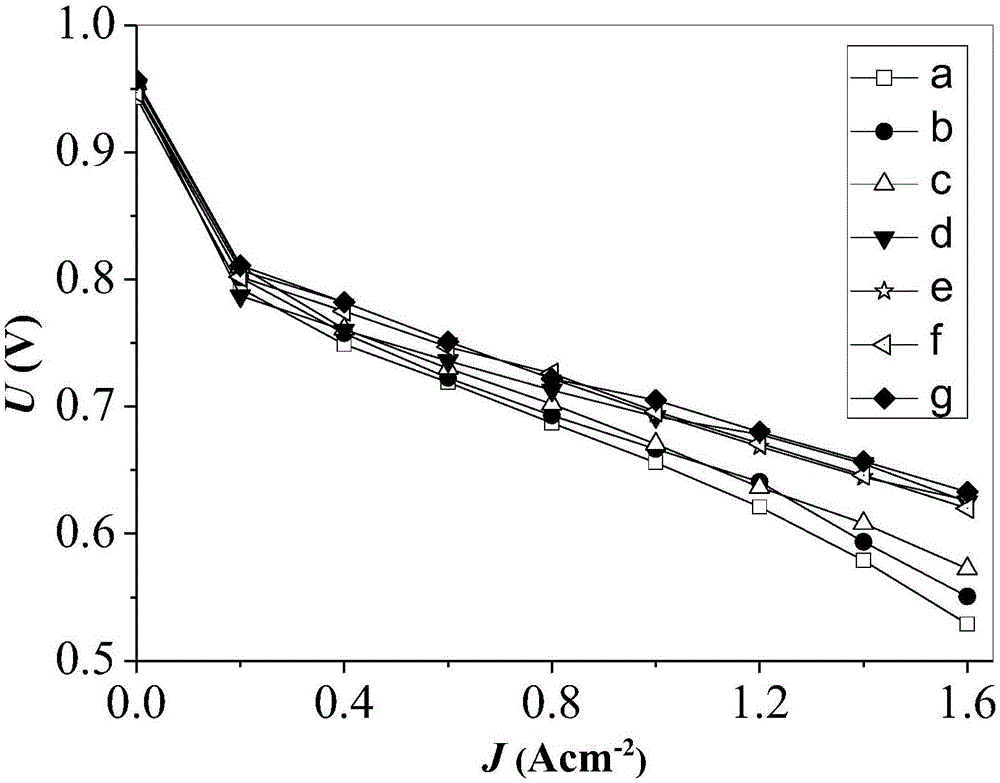

Preparation method of catalyst slurry for membrane electrode of fuel cell

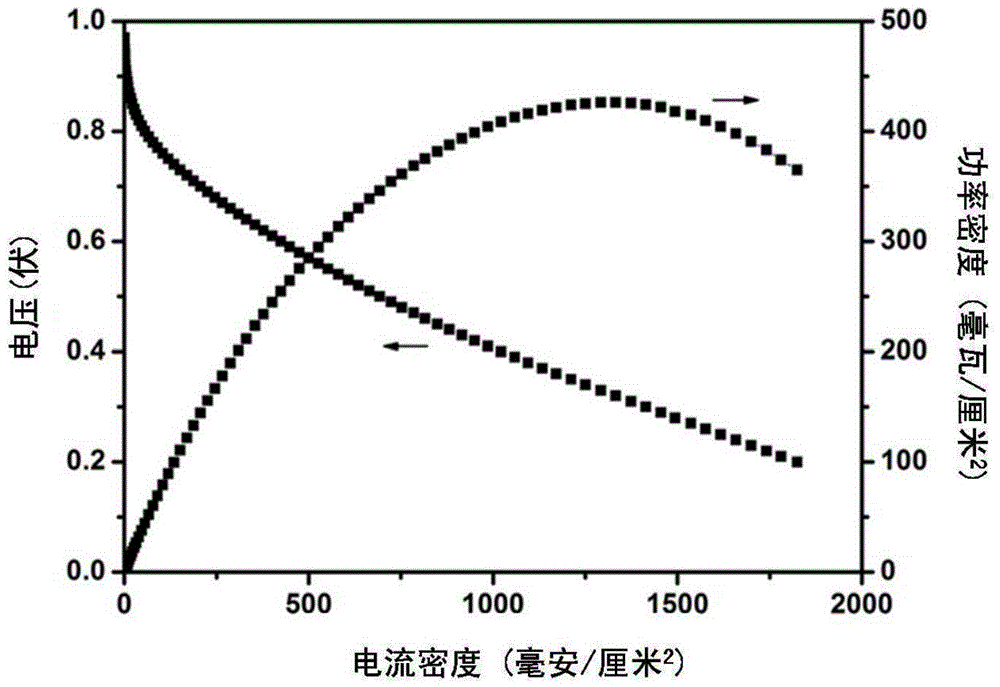

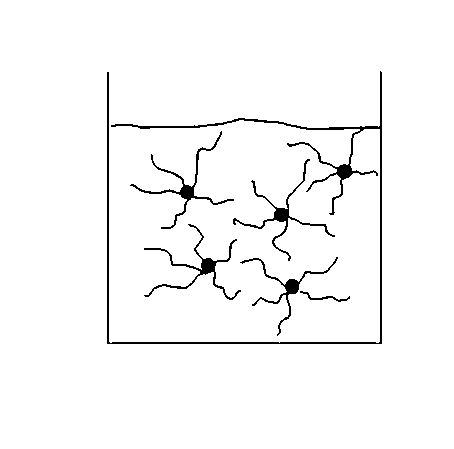

InactiveCN106654309AReduce reunionGood dispersionCell electrodesFuel cellsElectricityElectrical conductor

The invention relates to a preparation method of catalyst slurry for a membrane electrode of a fuel cell. The method comprises the following steps of (1) sequentially adding catalyst particles, water, a high polymer proton conductor solution, a Teflon solution, alcohol and a thickener for mixing; and (2) firstly stirring a mixture by using a magnetic stirrer, further stirring the mixture by using a shearing emulsifier or a homogenizer, finally carrying out oscillation by using an ultrasonic wave and obtaining the catalyst slurry. According to the preparation method, agglomeration of catalyst particles is effectively reduced and the dispersing performance of a catalyst is improved through controlling the material composition and the charging sequence and adjusting the stirring and dispersing mode. The electrochemical properties of the membrane electrode prepared by using the catalyst slurry are significantly improved; and furthermore, the process steps are simple, the operation is convenient and feasible, the raw materials are cheap and available, the energy consumption is low and the threshold is low.

Owner:TSINGHUA UNIV +1

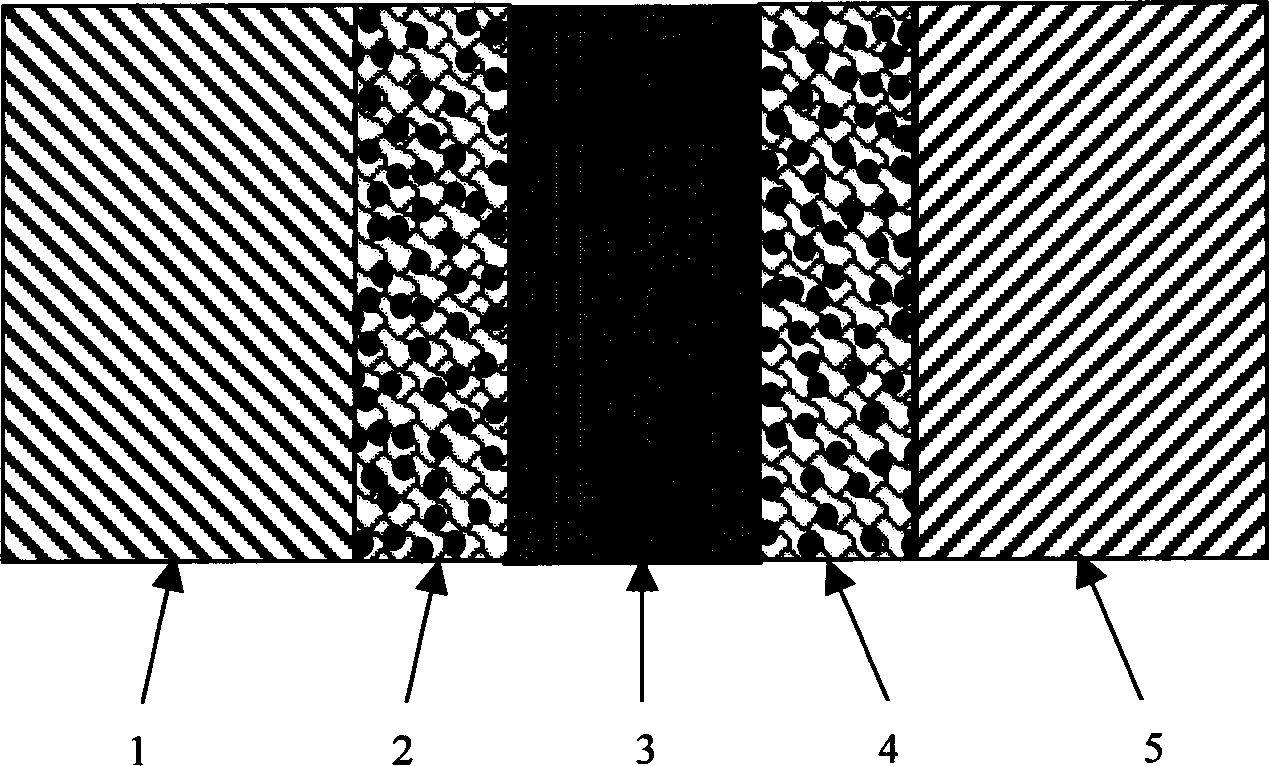

Membrane electrode for proton exchange membrane fuel cell and producing method thereof

InactiveCN1773755AImprove interface bonding performanceImprove stabilityCell electrodesFiberElectrical conductor

A film electrode used on proton exchange film fuel cell consists of five layers as middle layer of total F proton exchange film, two external layers of catalytic layers and two layers of diffusion layers outside of two external layers. Its preparing method includes embedding nanofibre proton conductor network in catalytic layer, preparing a layer of nanofibre proton conductor multiple film on total F proton exchange film surface by static spinning technique, coating ink containing catalyst in proton conductor fibre, drying and heat rolling to obtain film electrode containing nanofibre proton conductor network in catalytic layer.

Owner:SHANGHAI JIAO TONG UNIV

Solid oxide fuel battery anode and its production

InactiveCN1897337AOvercome carbon depositsOvercome stabilityCell electrodesCerium(IV) oxideMaterial physics

A solid oxide fuel battery anode and the preparation method, the characteristic is: adulterates the titanic mine cadmium acid lanthanum or the titanate compound oxide as the anode structure framework and the main electron conducting phase, uses the ion infusing method, the macromolecule modeling board method, the sol-gel method, or the suspending grain pulp spreading method, prepares the nanometer grain anode active substance multi-hole film with the thickness of 0.05-5 micron in the inner and outer hole surface of the multi-hole anode structure framework; the anode active substance includes the ceric oxide, or the adulterating ceric oxide, or the zirconia based oxygen ionic conductor electrolyte, or the cerate based proton conductor electrolyte, or the mixture of the above active substance, or the above active substance adding a small quantity of Ni or Ni-Cu and V2O5. The invention is structure stabilization, high conducting rate, high catalyzing activity of the fuel oxidation, matching with the closing material at physics and chemistry, structure size stabilization, anti-carbon deposition, is fit for the fuel operation of the hydrocarbon directly.

Owner:UNIV OF SCI & TECH OF CHINA

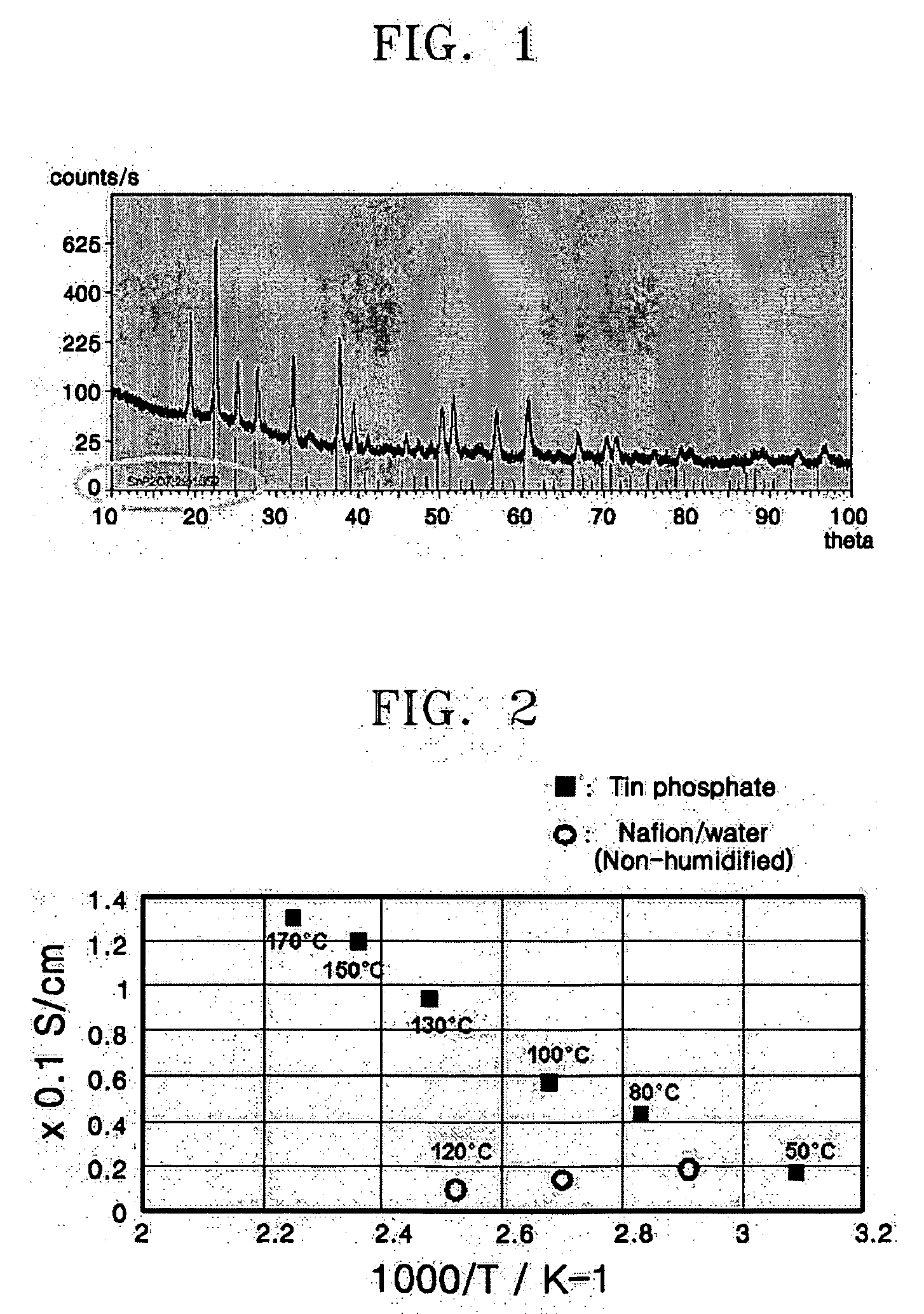

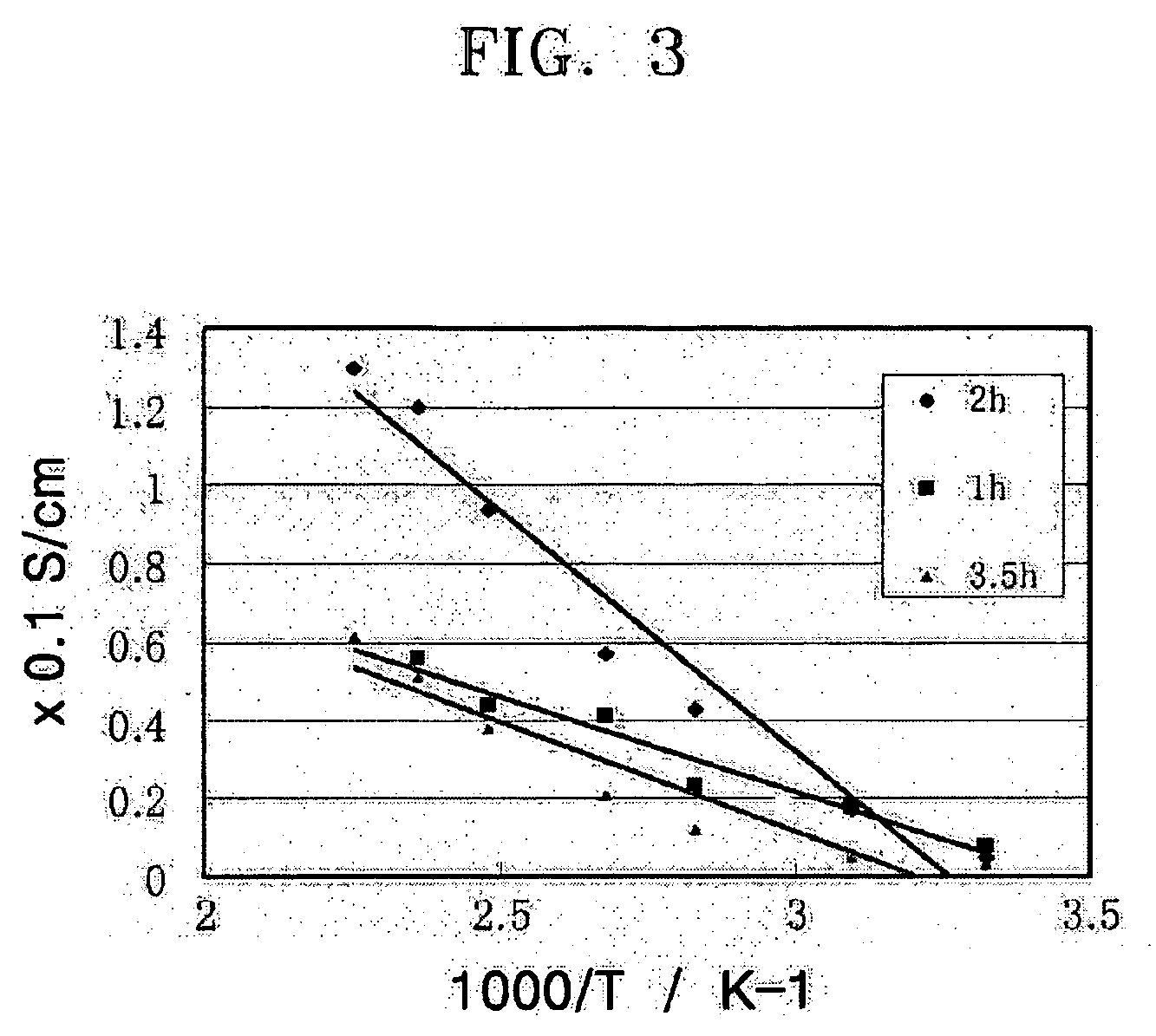

Proton conductor

The present invention provides a proton conductor comprising SnP2O7. The present invention also provides a fuel cell that comprising a cathode, an anode, and an electrolyte membrane, in which one of these components comprises SnP2O7. The SnP2O7 has high ionic conductivity of about 10−1 to 10−2 S / cm at about 80° C. or greater when non-humidified. In addition, SnP2O7 is water-insoluble, and stable at high temperatures. These properties make SnP2O7 suitable to act as a non-humidified proton conductor, or a high temperature non-humidified proton conductor.

Owner:SAMSUNG ELECTRONICS CO LTD +2

Proton conducting electrolyte membranes having nano-grain YSZ as protective layers, and membrane electrode assemblies and ceramic fuel cells comprising same

InactiveUS20110262839A1Prevent penetrationMaterial nanotechnologyCell electrodesElectrical conductorFuel cells

A proton conducting electrolyte membrane comprising a ceramic electrolyte layer including an inorganic proton conductor and a ceramic protective layer formed on at least one surface of the ceramic electrolyte layer and having proton conductivity; a membrane electrode assembly including the proton conducting electrolyte membrane; and a proton conducting ceramic fuel cell including the membrane electrode assembly. In the proton conducting electrolyte membrane, the ceramic protective layer may have an improved chemical bond with the ceramic electrolyte layer compared with a Pd metal protective layer, such that interlayer delamination may be lessened. Also, compared with a Pd metal protective layer, the ceramic protective layer is more appropriate for ceramic electrolytes such as BYZ and BYC that transmit protons or simultaneously transmit protons and oxygen ions used in a fuel cell operating at a temperature range of about 200 to about 500° C., for example, about 250 to about 500° C.

Owner:SAMSUNG ELECTRONICS CO LTD +1

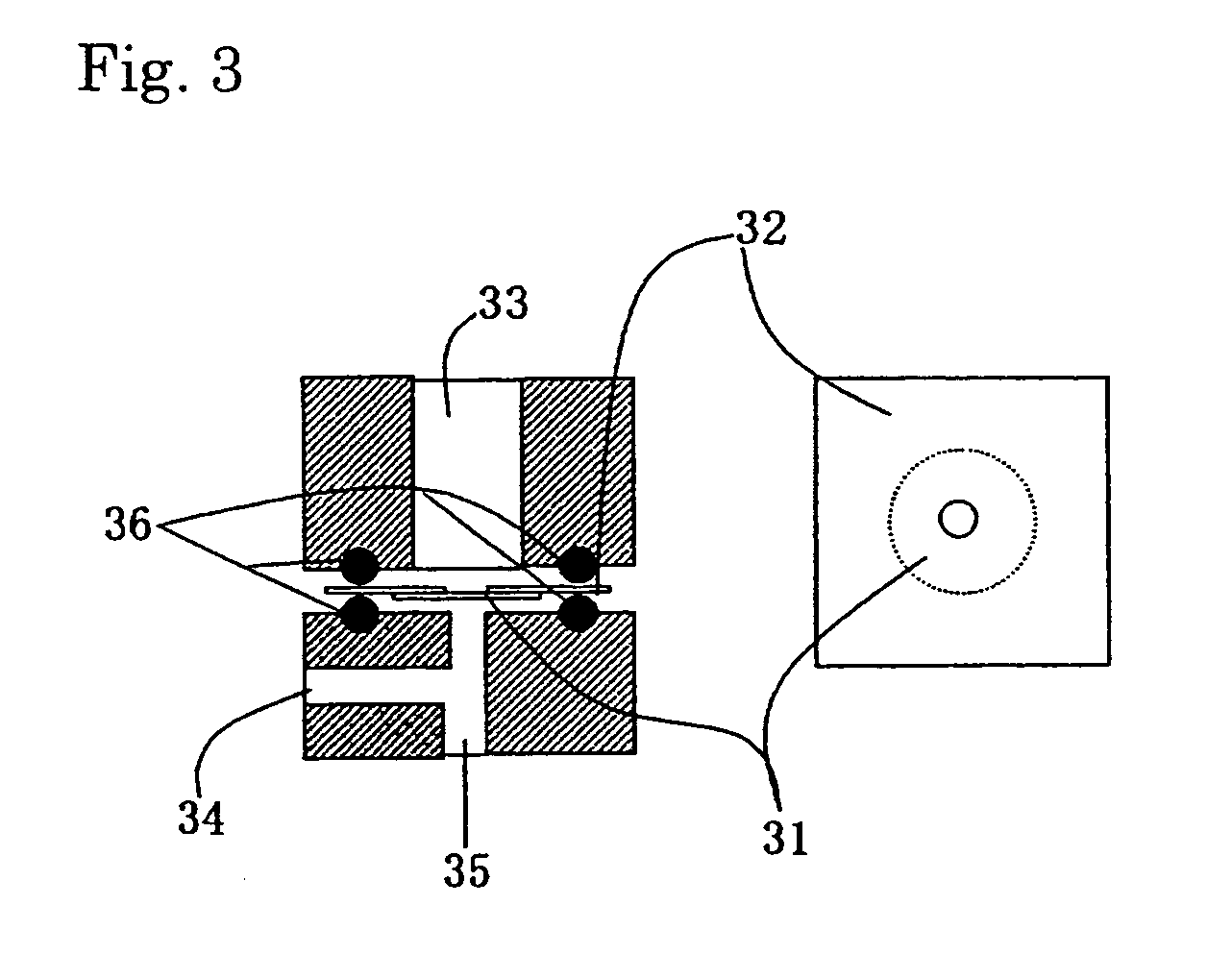

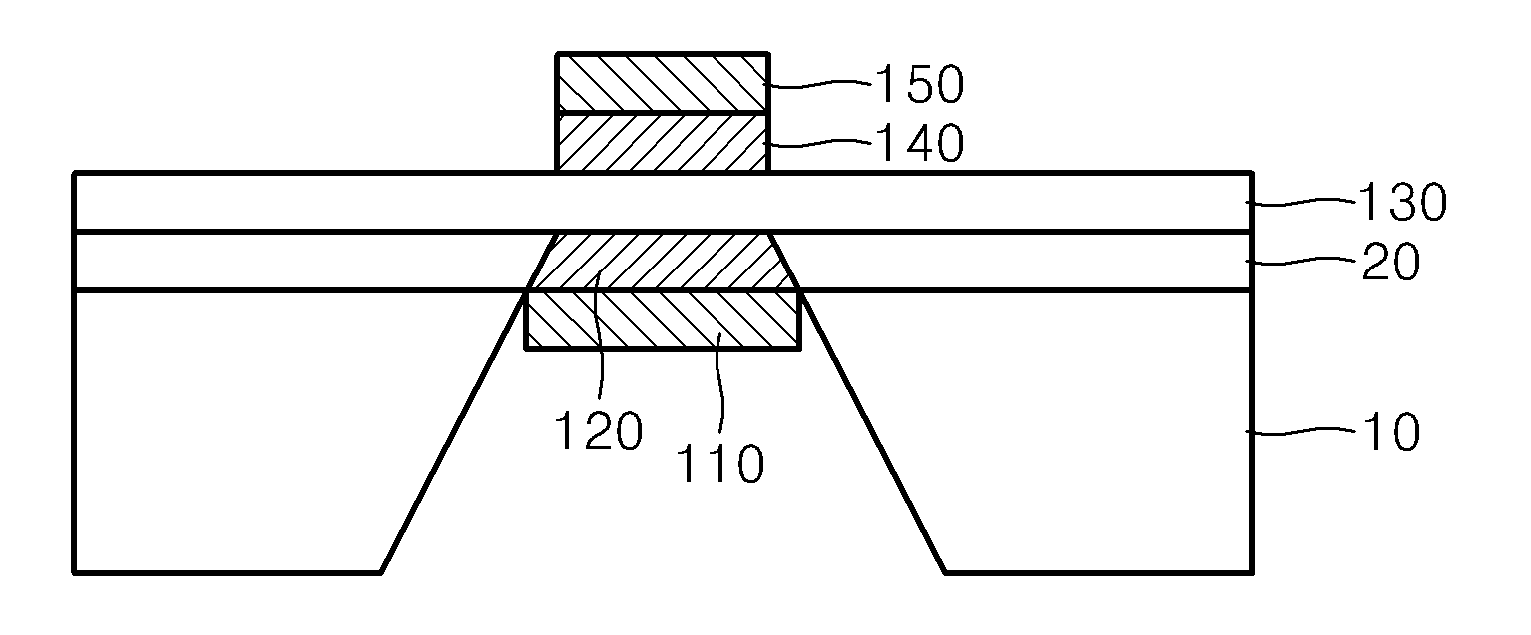

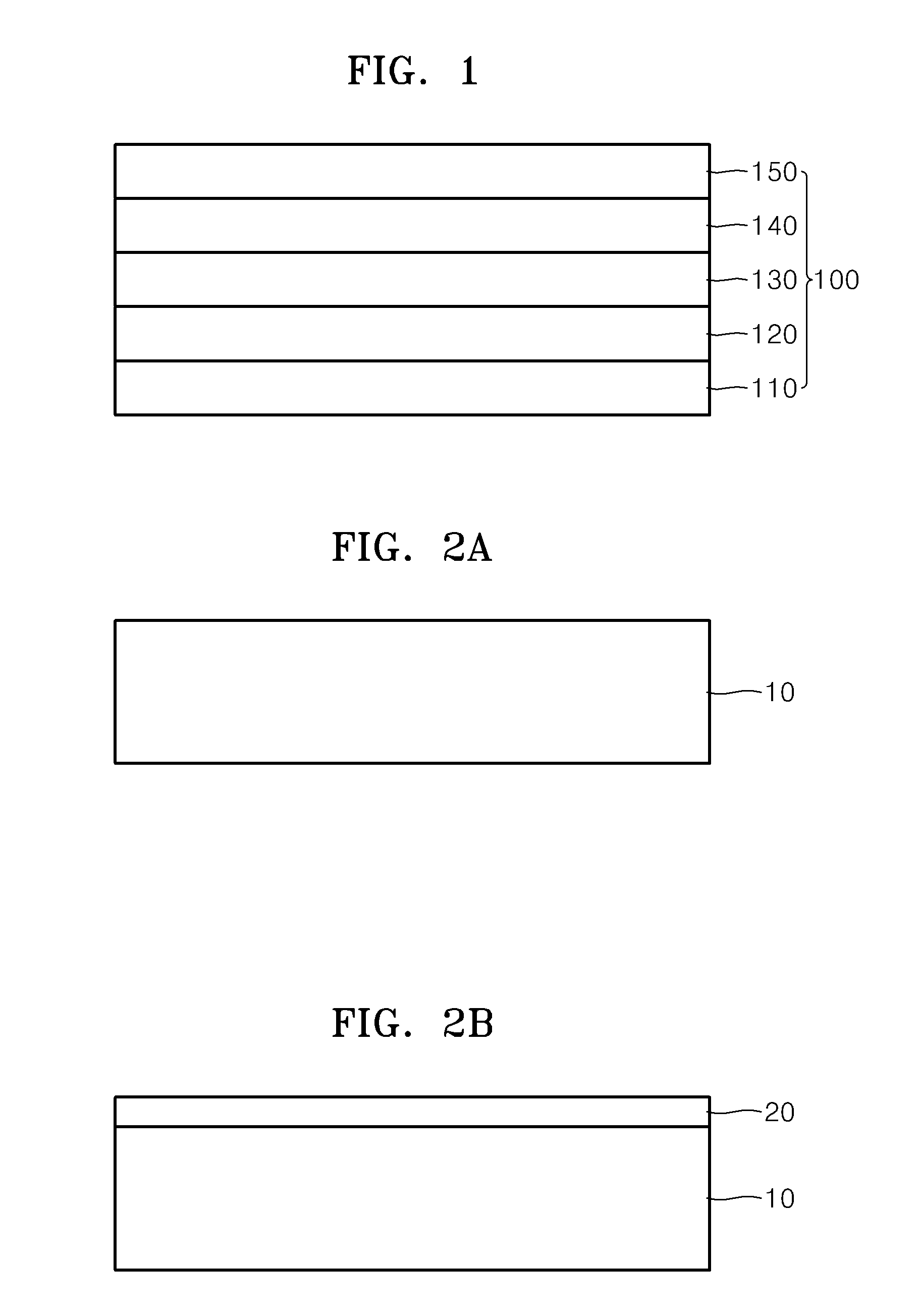

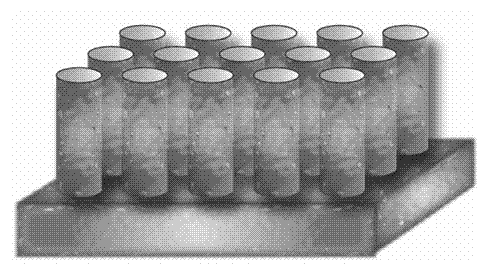

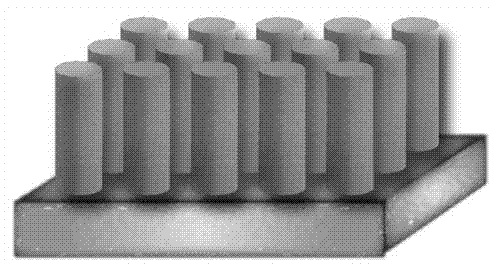

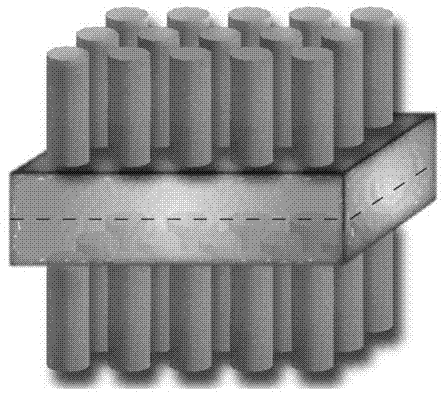

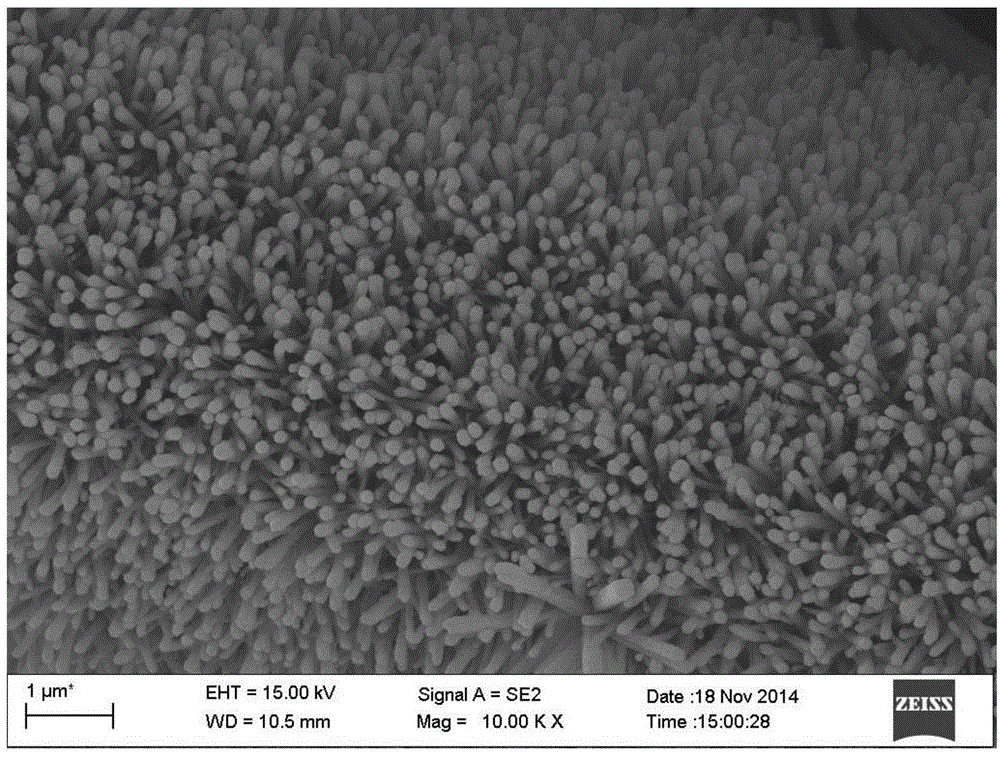

Three-dimensional proton conductor based ordered single electrode and membrane electrode as well as preparation methods

InactiveCN102738477AReduce dosageIncrease contact areaMaterial nanotechnologyCell electrodesPtru catalystElectrical conductor

The invention relates to a three-dimensional proton conductor based single electrode and a membrane electrode as well as preparation methods. According to the invention, firstly a three-dimensional proton conductor with a nanofiber array structure is prepared, then the proton conductor of the structure is prepared into an ordered single electrode, and two single electrodes are then combined into an ordered fucel cell membrane electrode. The single electrode is characterized in that a three-dimensional proton conductor is adopted as the basis, and a magnetron sputtering technology is employed for uniform vapor deposition of a layer of a nano-active metal catalyst on a nanofiber surface. The membrane electrode is characterized in that nanofiber arrays grow on two sides of the membrane electrode, and a layer of a nano-active metal catalyst is formed on surfaces of the nanofiber arrays through vapor deposition. The nanofiber arrays grow on two sides of the membrane electrode, so that the area of a catalytic layer is substantially increased while the proton conduction efficiency is ensured simultaneously, thus being in favor of mass transfer and reduction of proton conductor dosage. Meanwhile, the vapor deposition technology is adopted, the nano-active metal membrane has controllable thickness and is uniform, and while improving the catalytic performance of a noble metal or its alloy, consumption of the active metal catalyst can be reduced substantially.

Owner:WUHAN UNIV OF TECH

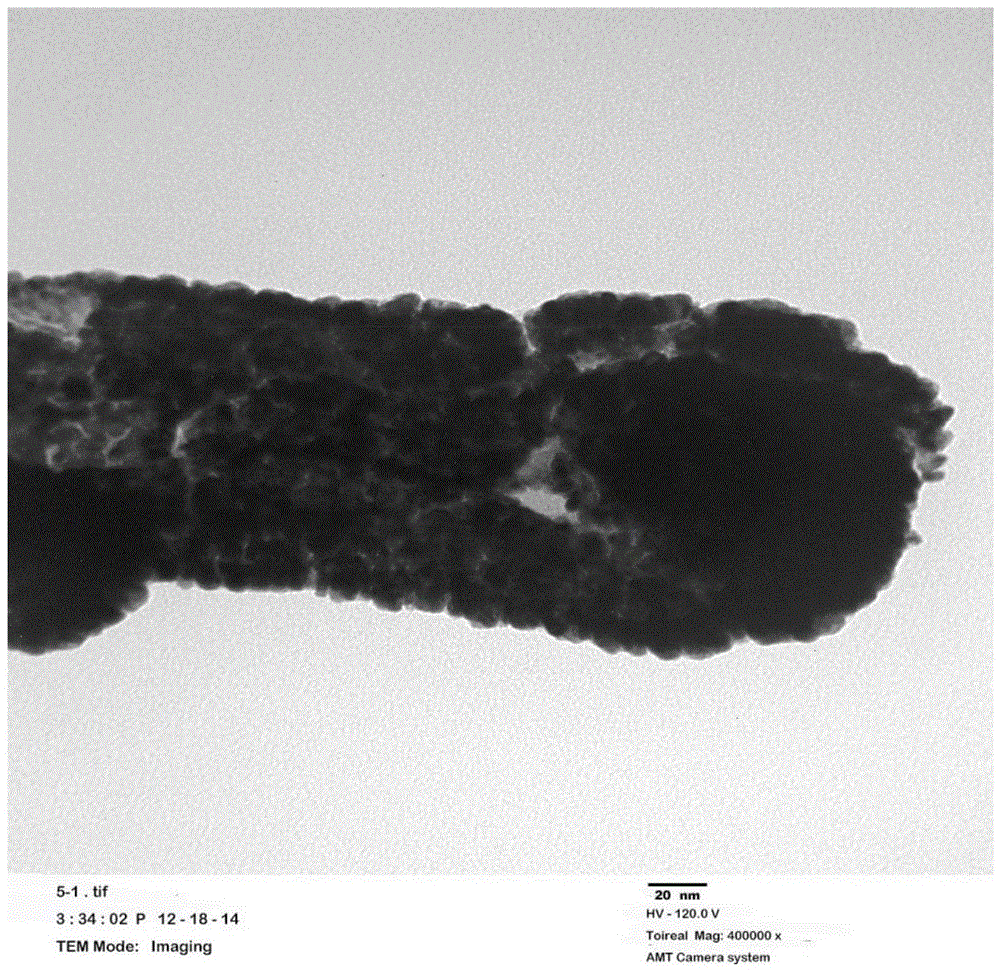

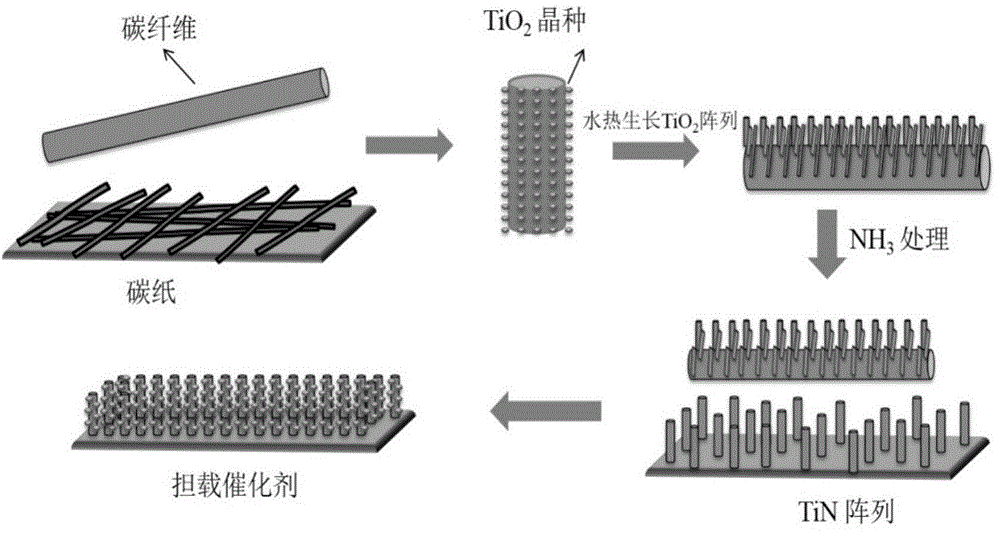

Preparation method for ordered ultra-thin catalyst layer, catalyst layer and application

ActiveCN106159285AIncrease the reaction areaIncrease profitCell electrodesElectrical conductorProton

The invention relates to a preparation method for an ordered ultra-thin electrode of a proton exchange membrane fuel cell. The preparation method comprises the steps of preparing an ordered electrode structure and establishing an ultra-thin catalyst layer; a process of impregnating and annealing is carried out on a carbon paper to obtain TiO<2> seed crystals; then a TiO<2> nanorod is grown through a hydrothermal method; a TiN ordered array is prepared through NH<3> etching; and the array is loaded with a catalyst to establish the ordered ultra-thin catalyst layer without containing a proton conductor (such as Nafion). The established ordered ultra-thin catalyst layer can be used for the proton exchange membrane fuel cell, other fuel cells and electrochemical devices.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

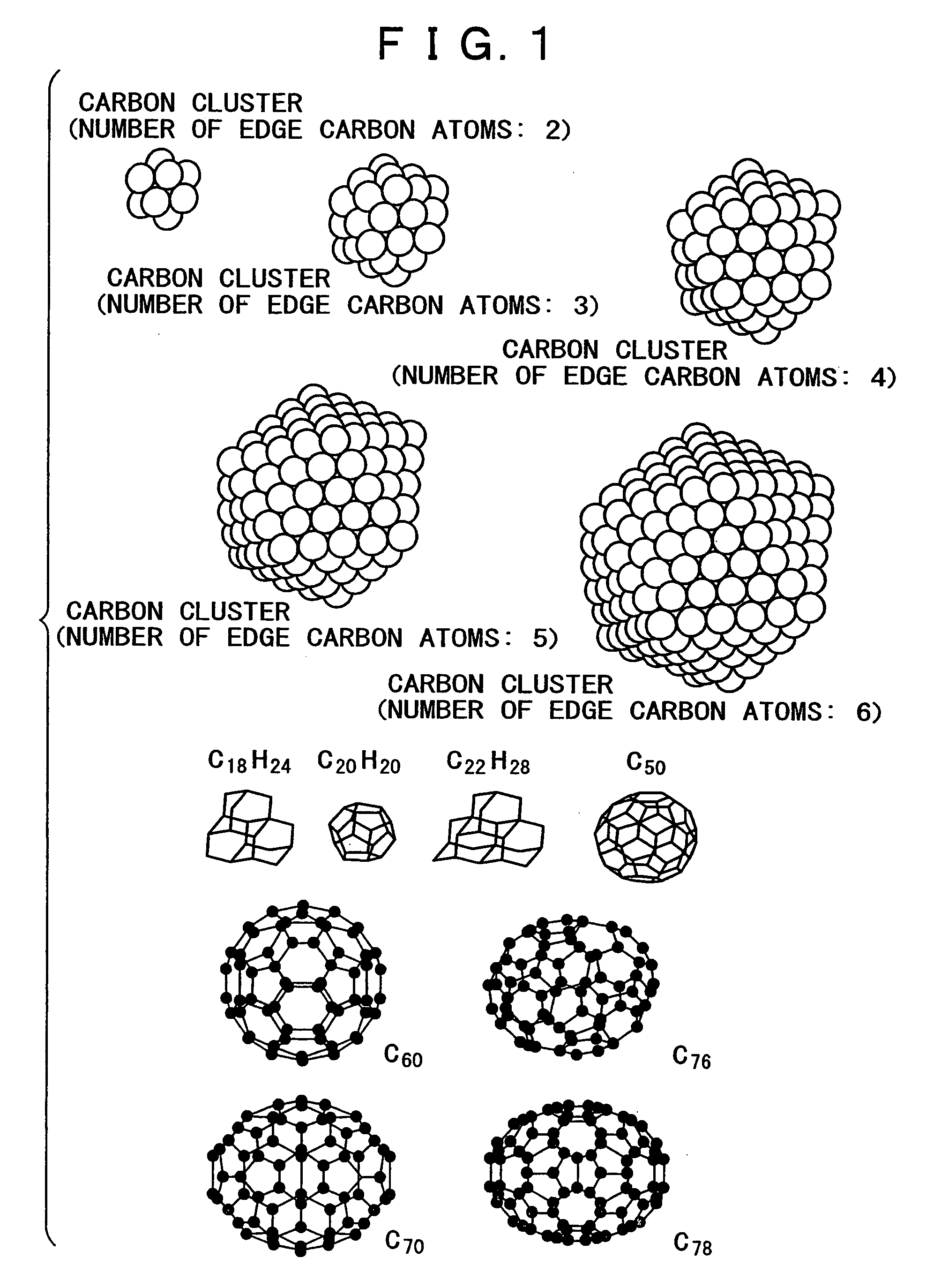

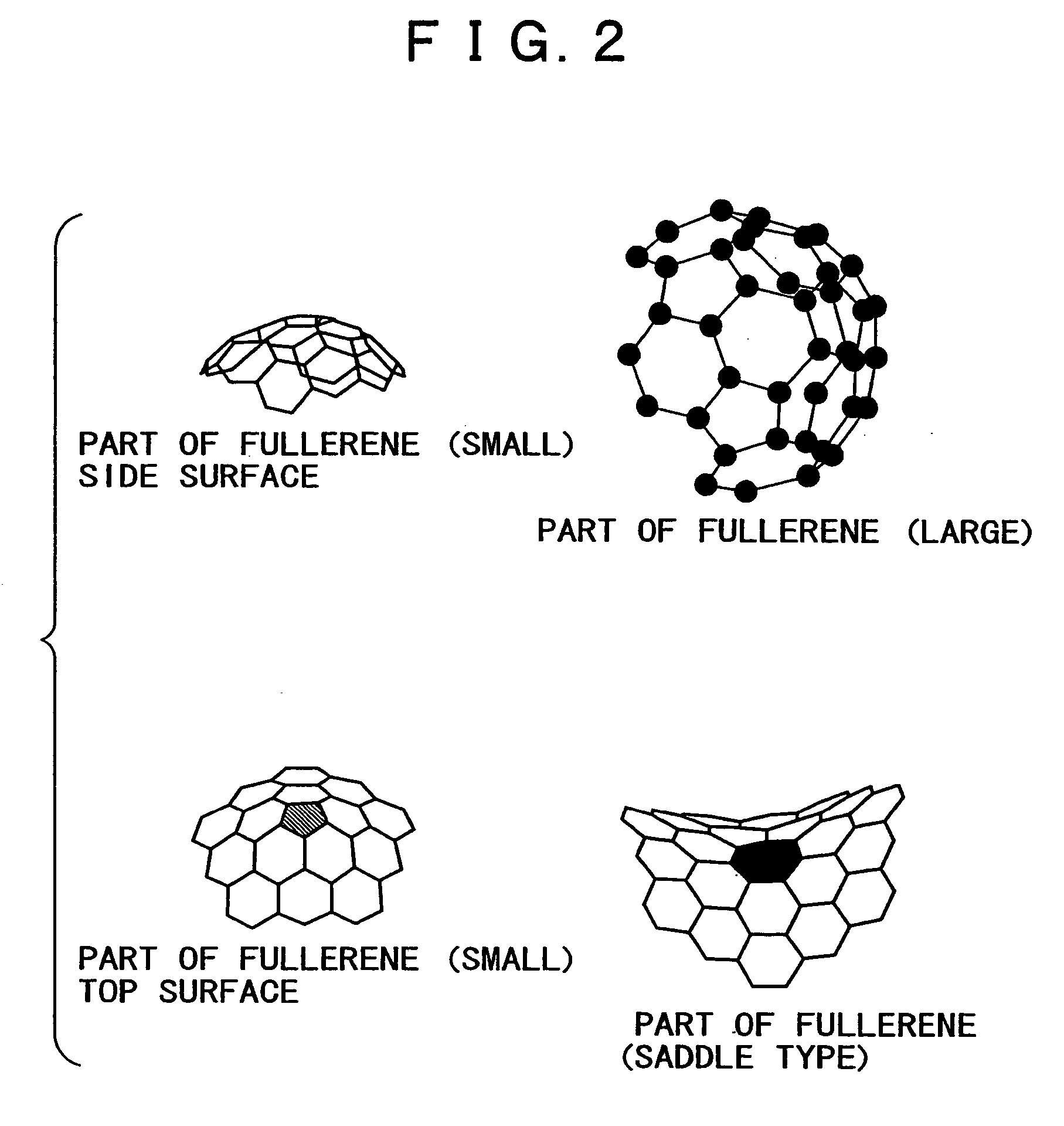

Proton conductor and electrochemical device using the same

InactiveUS20040115501A1Improve proton conductivityLight weightMaterial nanotechnologySolid electrolytesElectrical conductorCarbon nanotube

Disclosed is a proton conductor which does not need to replenish water and which can be used even in a dry atmosphere and in a high temperature range. The proton conductor includes carbon clusters having functional groups capable of releasing a proton, and a substance having portions capable of serving as proton-receiving portions. Alternatively, the proton conductor includes a substance having functional groups capable of releasing a proton, and carbon clusters having portions capable of serving as proton-receiving portions. Carbon clusters, particularly, those carbon clusters which have a specified molecular structure such as fullerenes and carbon nanotubes, with various acid functional groups introduced thereinto, show proton conductivity even in a dry state, and an addition of a substance for promoting the dissociation of protons to the carbon clusters enhances the proton conductivity drastically.

Owner:SONY CORP

Organic-inorganic composite proton exchange membrane for proton exchange membrane fuel cell and preparation method thereof

ActiveCN104659395AImprove developmentMeet the needs of different application fieldsFinal product manufactureSolid electrolyte fuel cellsSide chainHeteropoly acid

The invention discloses an organic-inorganic composite proton exchange membrane for a proton exchange membrane fuel cell and a preparation method thereof. The proton exchange membrane comprises a functional polymer (such as polyvinylpyrrolidone) of which the side chain contains N-heterocycle, heteropoly acid and skeleton polymers (such as polyvinylidene fluoride, polyethersulfone, polysulfone and polyethylene sulfone). The preparation method comprises adding the functional polymer, the skeleton polymers and the heteropoly acid into an organic solvent (such as N, N-dimethyl formamide, N, N-dimethyl acetamide and N-methyl-2-pyrrolidone), heating the mixture with stirring until complete dissolution so that a transparent and uniform proton exchange membrane solution is obtained, and carrying out solution casting or curtain coating to obtain the organic-inorganic composite proton exchange membrane. The organic-inorganic composite proton exchange membrane is uniform, transparent and compact, has excellent chemical stability, heat stability, mechanical properties and proton conductivity, and does not lost a proton conductor easily. The preparation method utilizes easily available and cheap raw materials, has simple processes, is suitable for large-scale production and can be widely used in fuel cells, flow cells, plumbic acid cells and a water-electrolyser.

Owner:北京海得利兹新技术有限公司

Fuel-cell catalyst slurry and preparation method thereof

The invention relates to fuel-cell catalyst slurry and a preparation method thereof. The catalyst slurry comprises the following raw materials in percentage by weight: 1-40% of solid particle catalyst, 0.1-30% of high polymer proton conductor, 1-60% of water, 1-60% of low-grade alcohol with C1-4, and 0.1-30% of high polymer dispersant, wherein the high polymer dispersant is one or a mixture including more than any two of polyvinylpyrrolidone, polyvinyl alcohol, sodium carboxymethylcellulose, polyoxyethylene and polyacrylamide. The preparation method of the slurry is simple to operate, the slurry has the characteristics of high dispersity and high stability by adding high polymers into the catalyst slurry, a catalytic layer prepared from the slurry is good in uniformity, and an electrode prepared from the slurry has a better discharge performance. The slurry is suitable for spray coating, brush coating, blade coating, screen printing and other numerous mechanical manners for automated production of electrodes. The advantages of high efficiency, time saving and labor saving are achieved.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

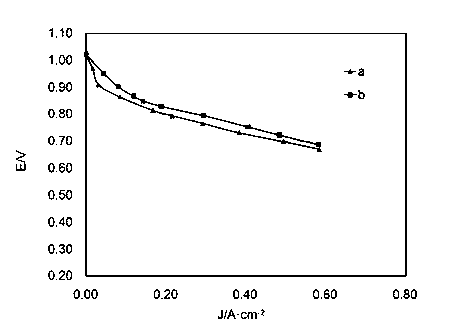

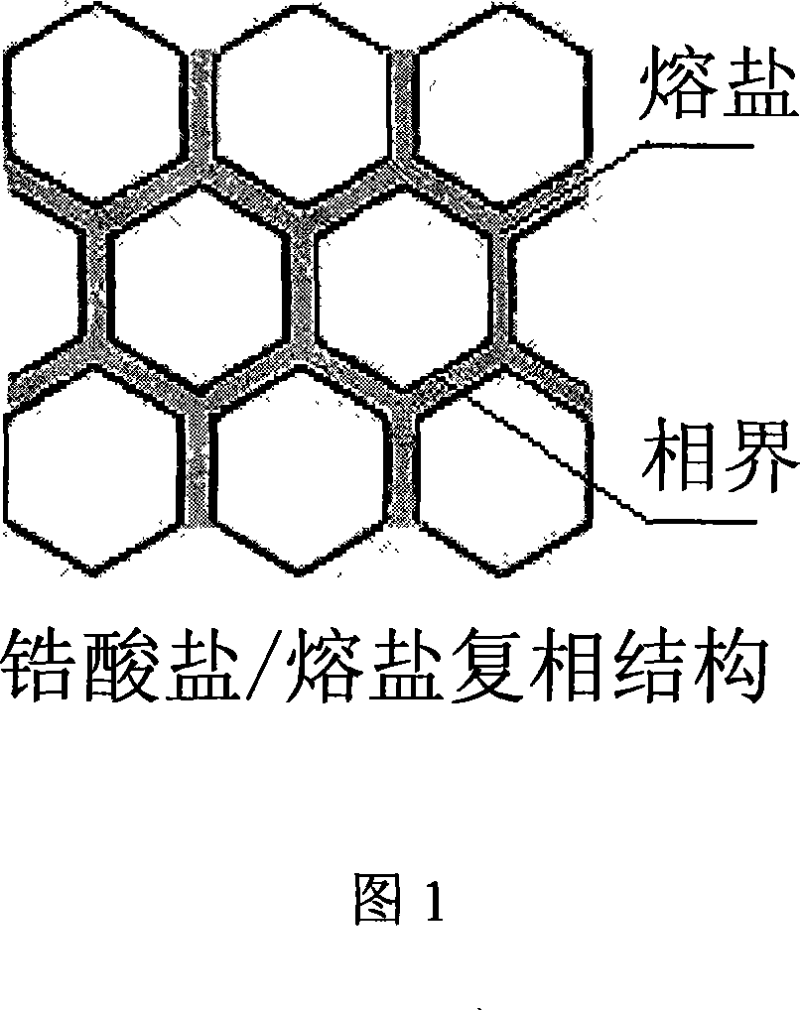

Multi-phase structure designed high-conductive electrical zirconate barium proton conductor and preparation method thereof

InactiveCN101037331AImprove conductivityImprove migration speedConductive materialElectrical conductorConcentration cell

The invention relates to a barium zirconate proton conductor designed by complex phase structure with a high electric conductivity and its manufacturing method. The invention is coating a layer of NaOH or sulfate around the crystal grain of the barium zirconate. The manufacturing method is: taking the BaCO3, ZrO2 and Y2O3 as raw material, water as medium, ball milling mixing for 4-10 hours, calcining for 4-12 hours in 1200-1400 DEG C; then adding 1-10% molar ZnO, ball milling mixing for 4-10 hours, adding 5-50% mol NaOH or K2SO4 or Na2SO4 or Li2SO4 in a way of hand lapping to make the mixture uniform; putting the mixing material into the die and dry pressing molding under a pressure of 50-120 MPa, and then isopressing under 200-350 MPa; sintering in the air of 1200-1500 DEG C with a heating rate of 2-10 DEG C / minute and keeping warm for 2-10 hours, then cooling to the room temperature to produce the barium zirconate proton conductor material with a high electric conductivity. The invention adopts the new designing thought of complex phase structure to establish a foundation for exploiting hydrogen gas and vapor sensor, hydrogen pump and concentration cell electrolyte material.

Owner:TIANJIN UNIV

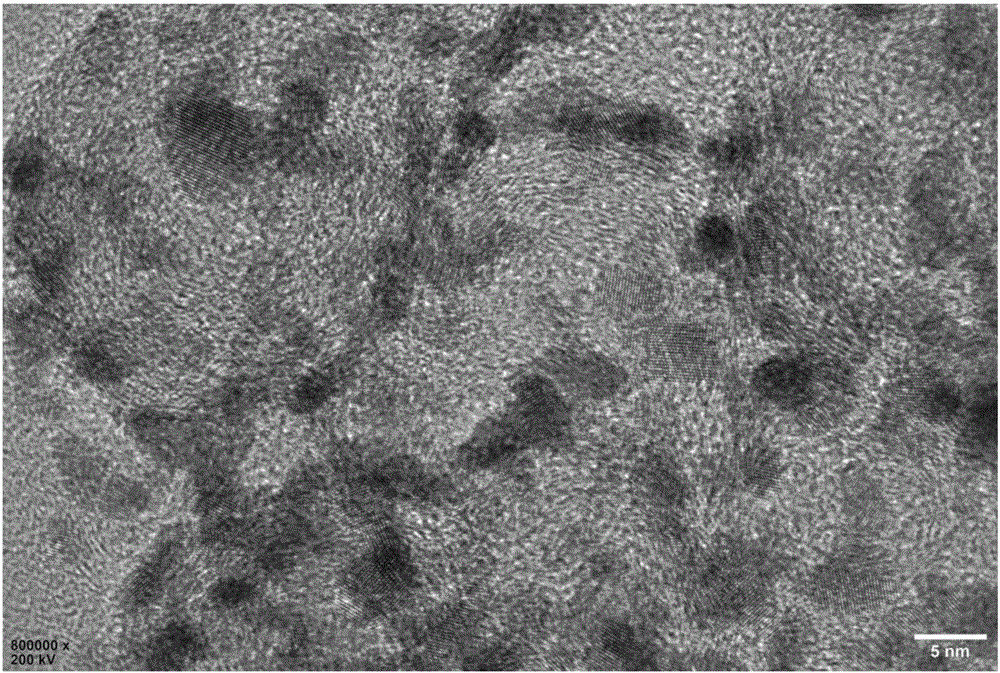

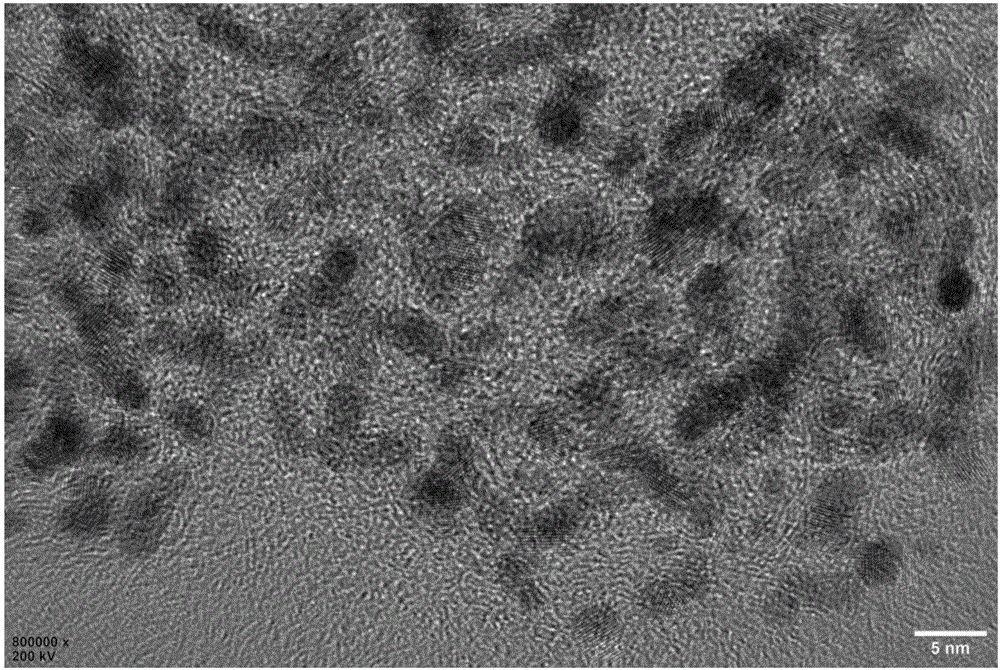

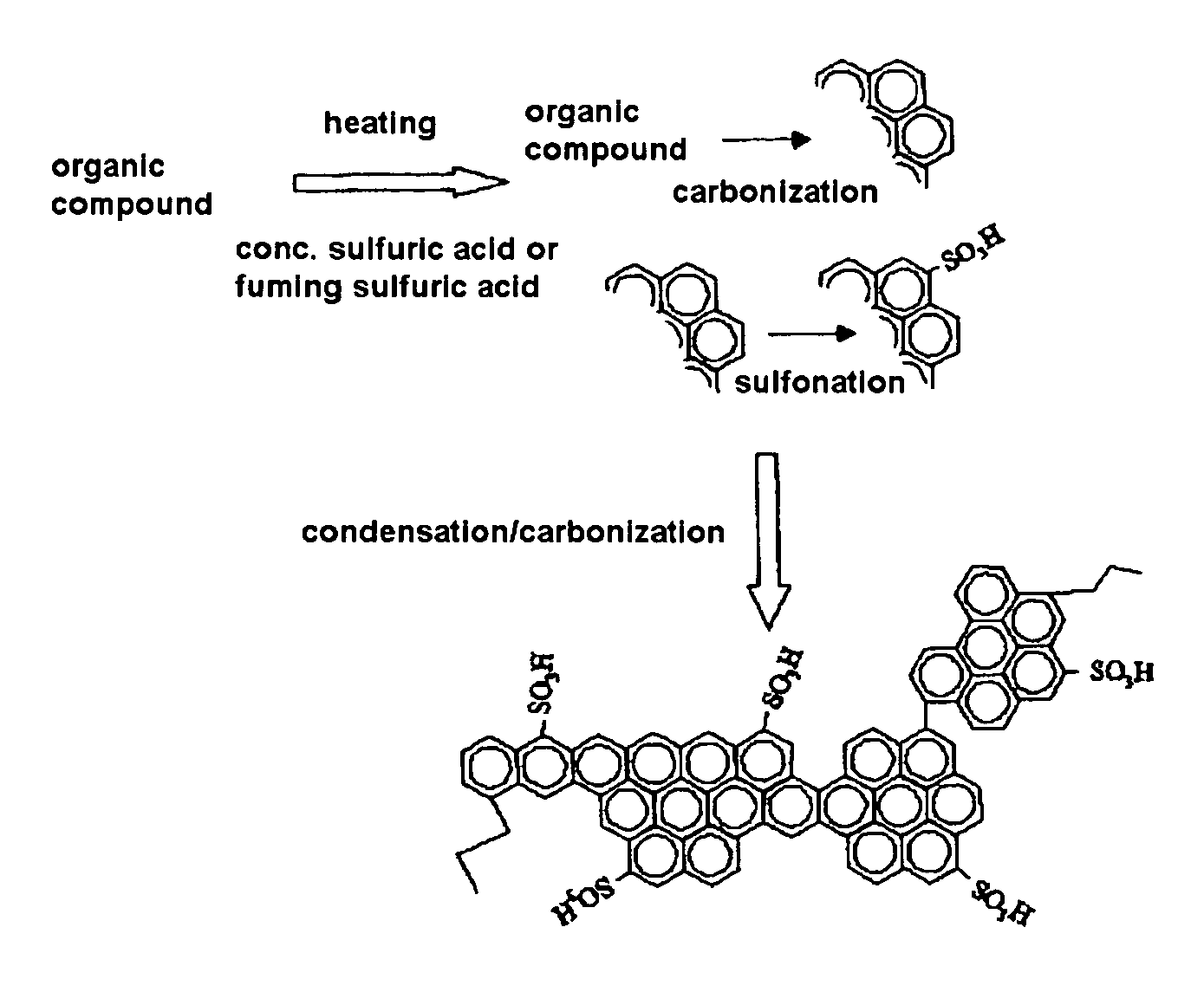

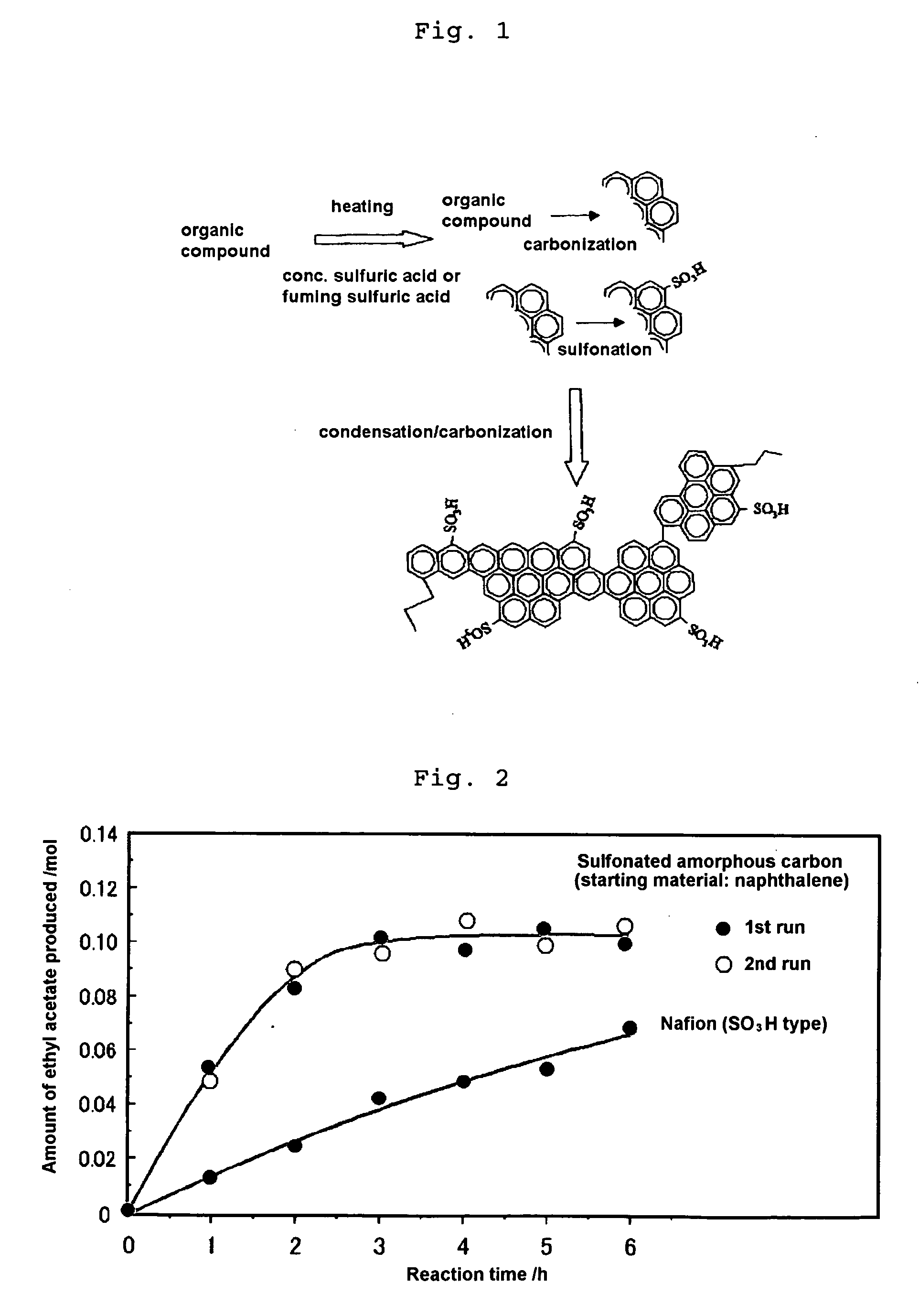

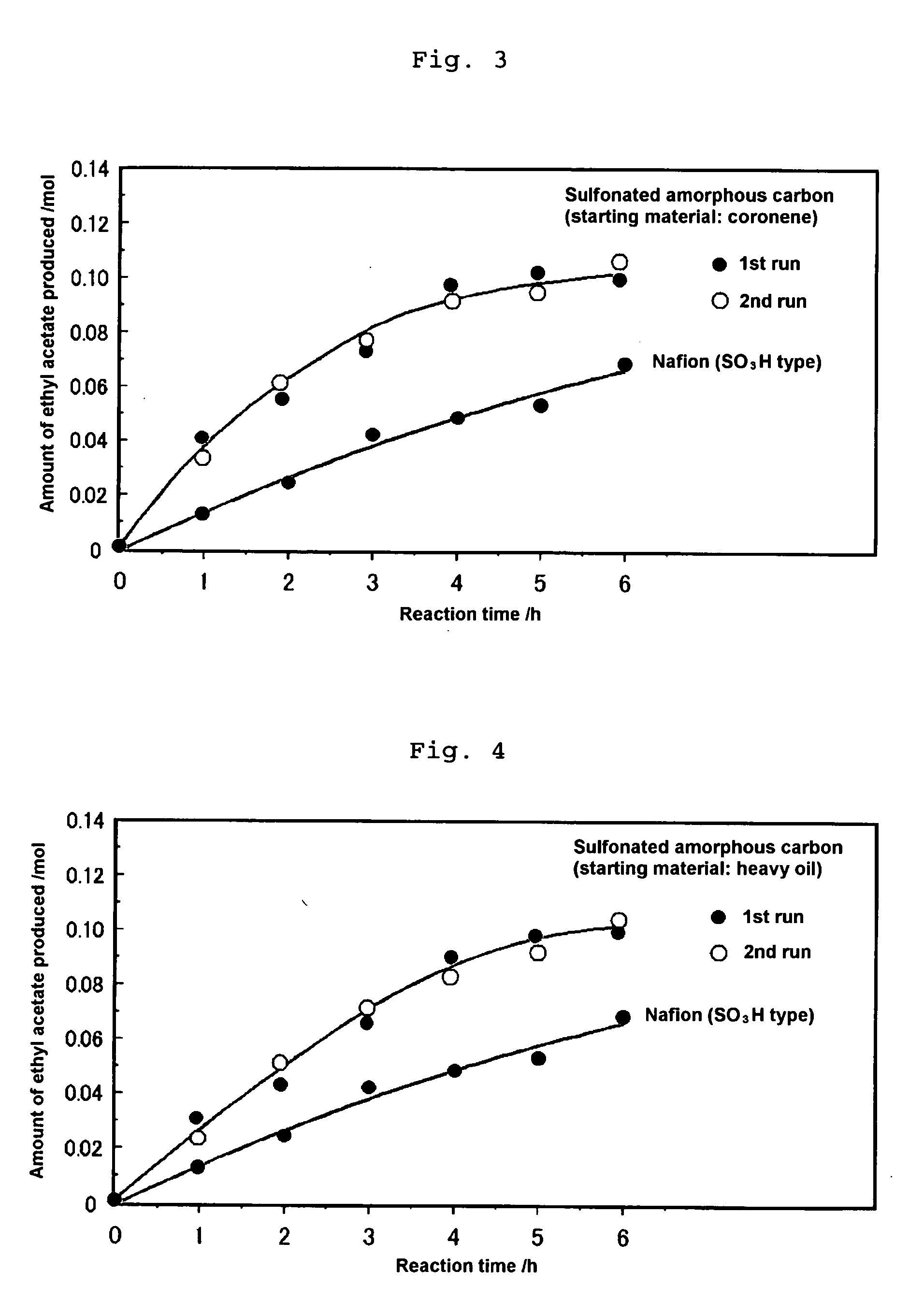

Sulfonated Amorphous Carbon, Process for Producing the Same and Use Thereof

InactiveUS20080227996A1Low costHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsElectrical conductorSolid acid

An amorphous carbon having sulfonate group introduced therein is provided which is characterized in that chemical shifts of a condensed aromatic carbon 6-membered ring and a condensed aromatic carbon 6-membered ring having sulfonate group bonded thereto are detected in a 13C nuclear magnetic resonance spectrum and that at least a diffraction peak of carbon (002) face whose half-value width (2θ) is in the range of 5 to 30° is detected in powder X-ray diffractometry, and which exhibits proton conductivity. This sulfonated amorphous carbon is very useful as a proton conductor material or solid acid catalyst because it excels in proton conductivity, acid catalytic activity, thermal stability and chemical stability and can be produced at low cost.

Owner:TOKYO INST OF TECH

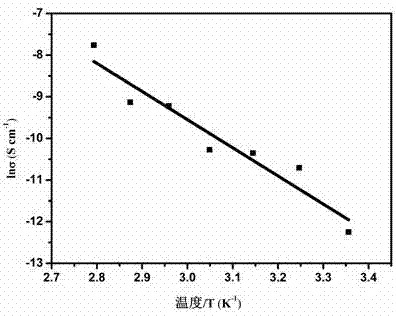

Preparation method of composite proton exchange membrane

ActiveCN101864163AInhibit swellingImprove proton conductivityFinal product manufactureCell component detailsElectrical conductorHeteropoly acid

The invention discloses a preparation method of a composite proton exchange membrane, comprising the following steps of: sulfonating, preparing a sulfonated polyether ether ketone solution; preparing polyaniline filter liquid, preparing membrane preparing liquid, casting to form a membrane, and the like. The composite membrane is prepared by using SPEEK (sulfonated polyether ether ketone) as a basal body and PANI (Polyaniline) and HPA (Heteropoly acid) as dopants, a material source is wide and does not need to be imported, a preparation process is simple, and used instruments are simple, thereby the cost of the membrane is reduced. A hydrogen bond formed by PANI and SPEEK is used for avoiding the swelling of the SPEEK and reducing methanol penetration, and the proton conductivity of the composite membrane is improved by the HPA. By changing the composition and the ratio between an alkaline polymer and a proton conductor, the novel PEM (proton exchange membrane) reaches optimum balance among high proton conductivity, low methanol penetration and low HPA dropout rate, the proton conductivity reaches 10-2S / cm, the methanol penetration rate of the composite proton exchange membrane is a half lower than that of an Nafion 117 membrane, and the HPA wastage rate does not reach 5 percent.

Owner:SUZHOU DACHENG YOUFANG DATA TECH CO LTD

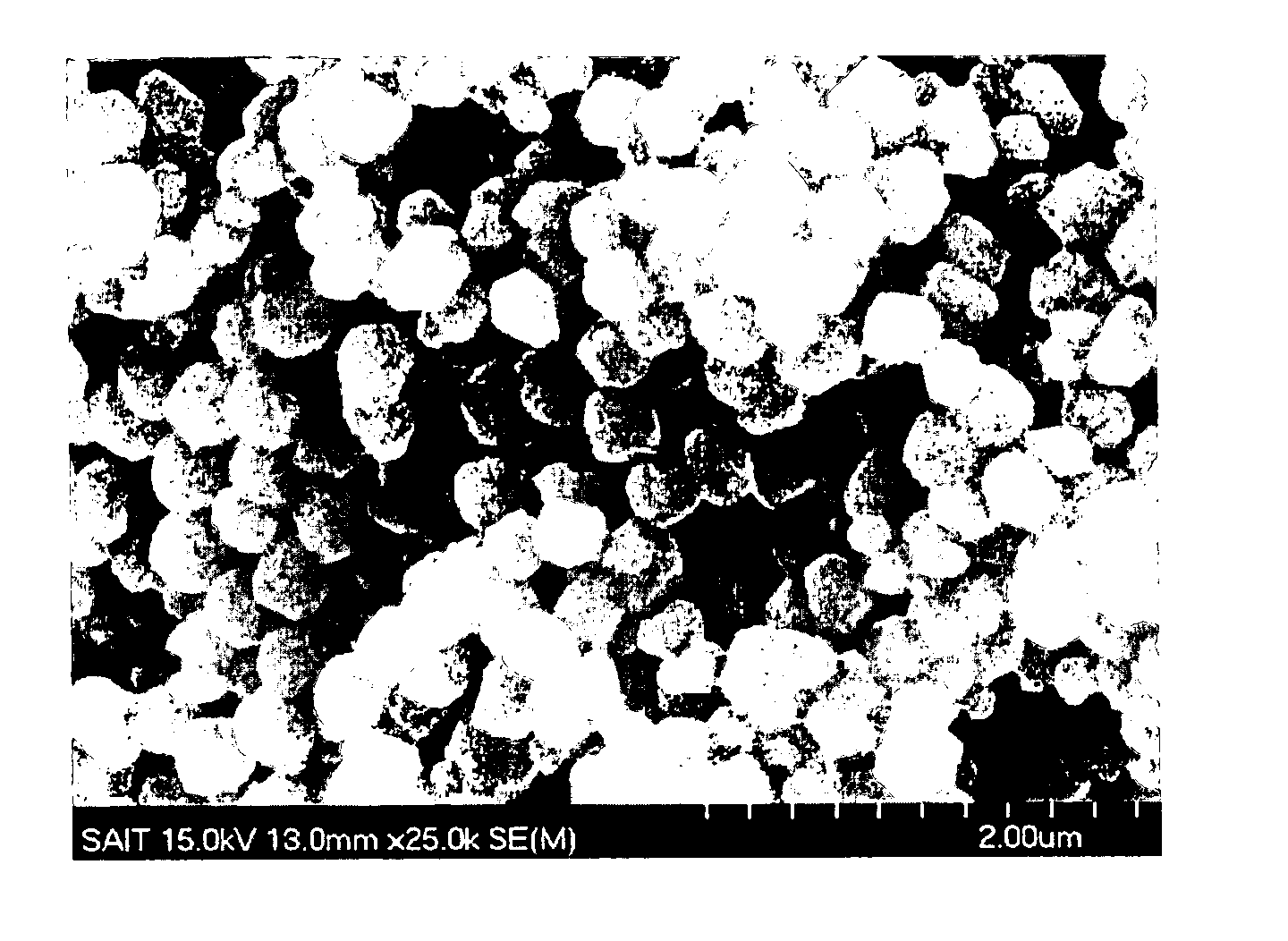

Proton conductor and electrochemical device using the same

InactiveUS20060141316A1Electrolyte holding meansIon-exchanger regenerationElectrical conductorProton

A proton conductor includes P2O5 and at least one of B2O3, ZrO2, SiO2, WO3, and MoO3. The proton conductor has an amorphous phase of 60 wt % or more. The proton conductor exhibits proton conductivity at temperatures above 100° C. without humidification.

Owner:SAMSUNG SDI CO LTD

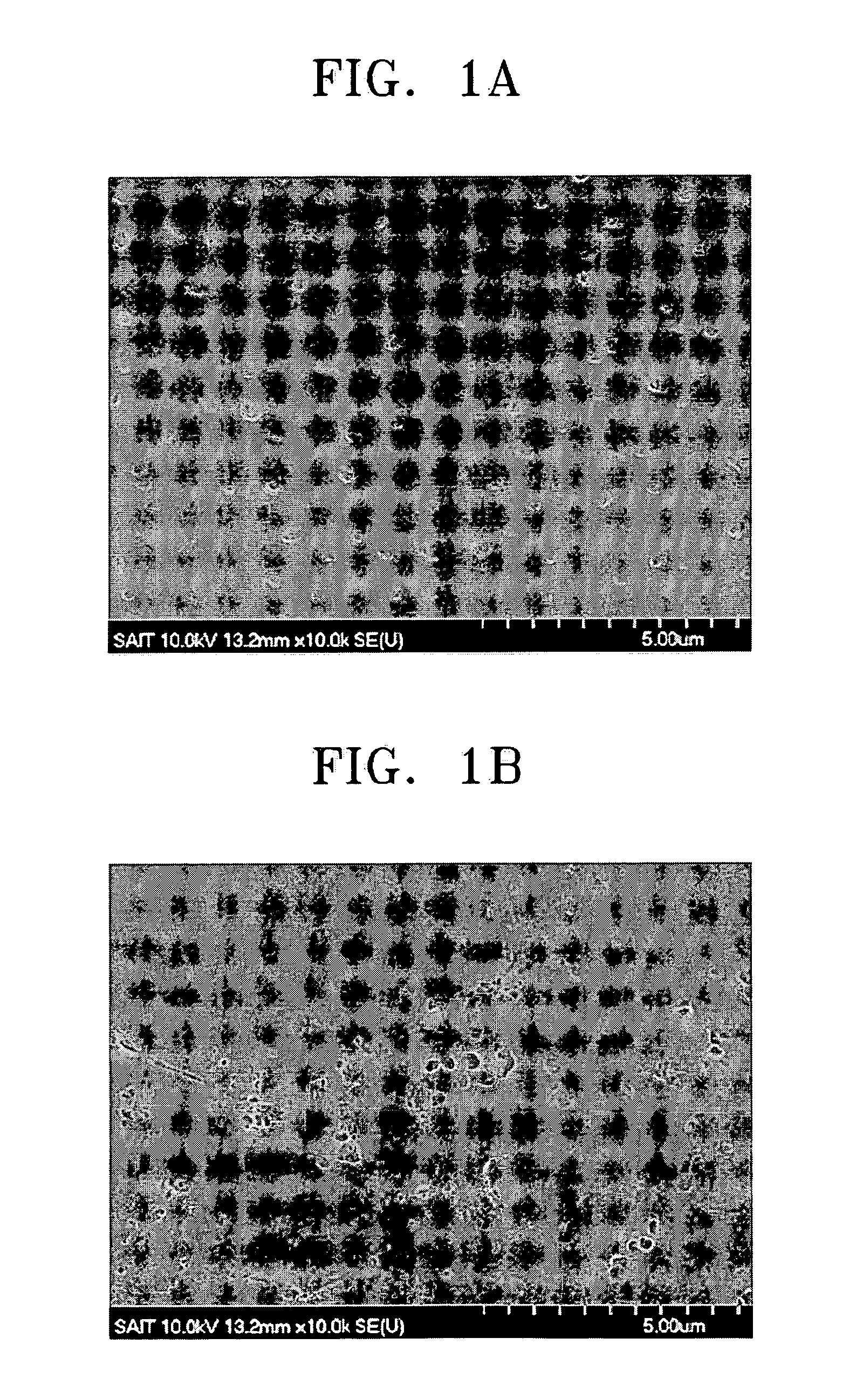

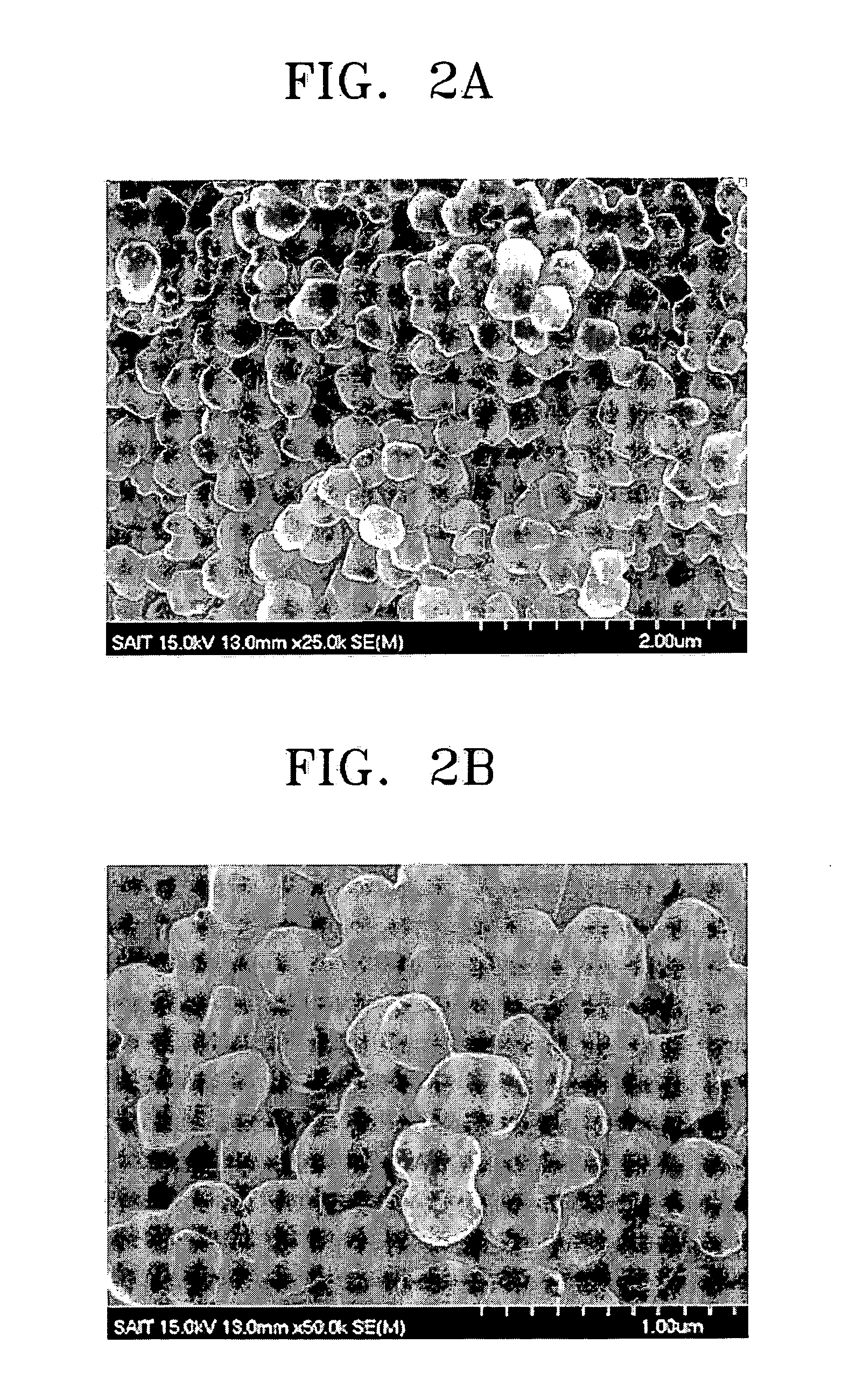

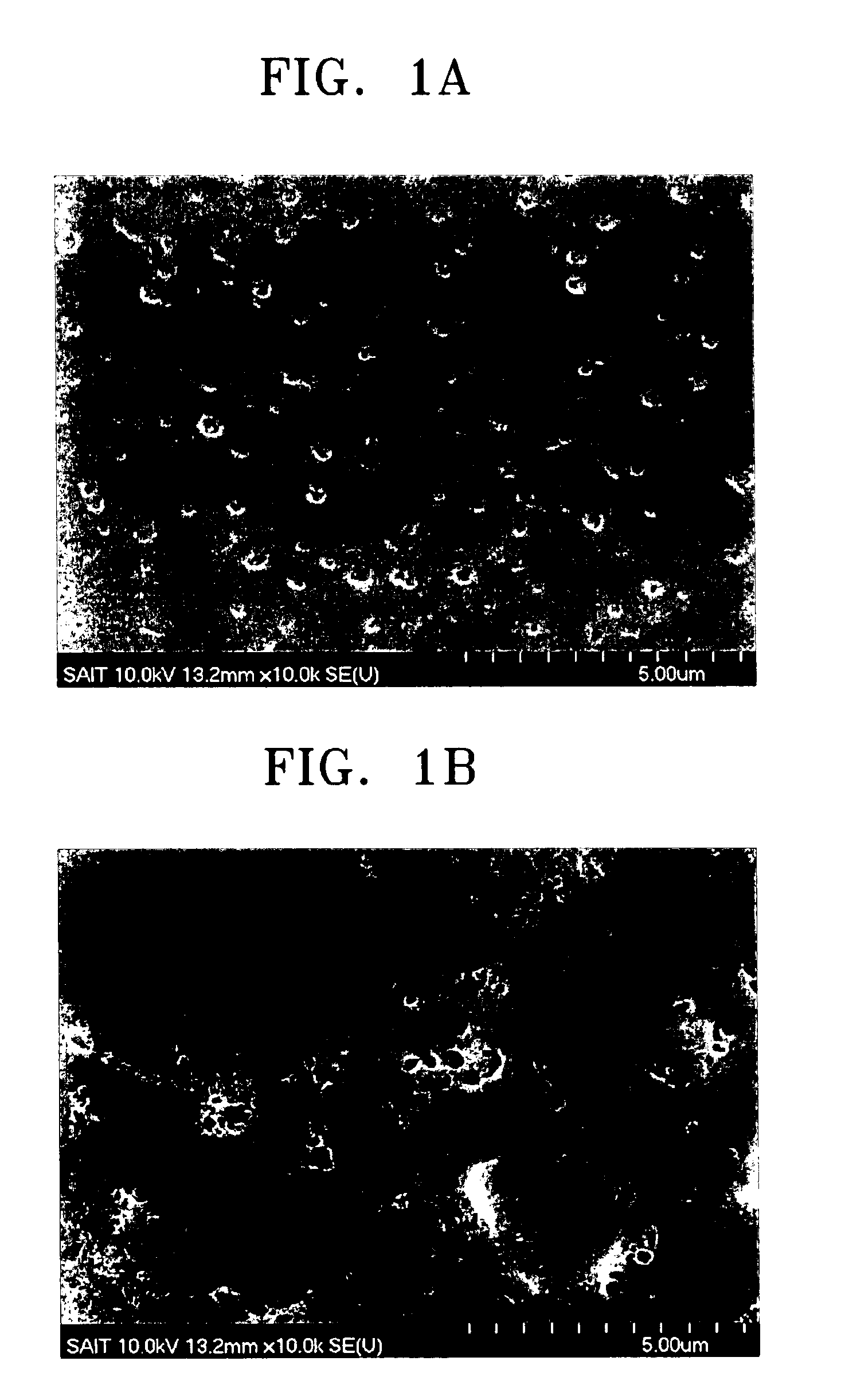

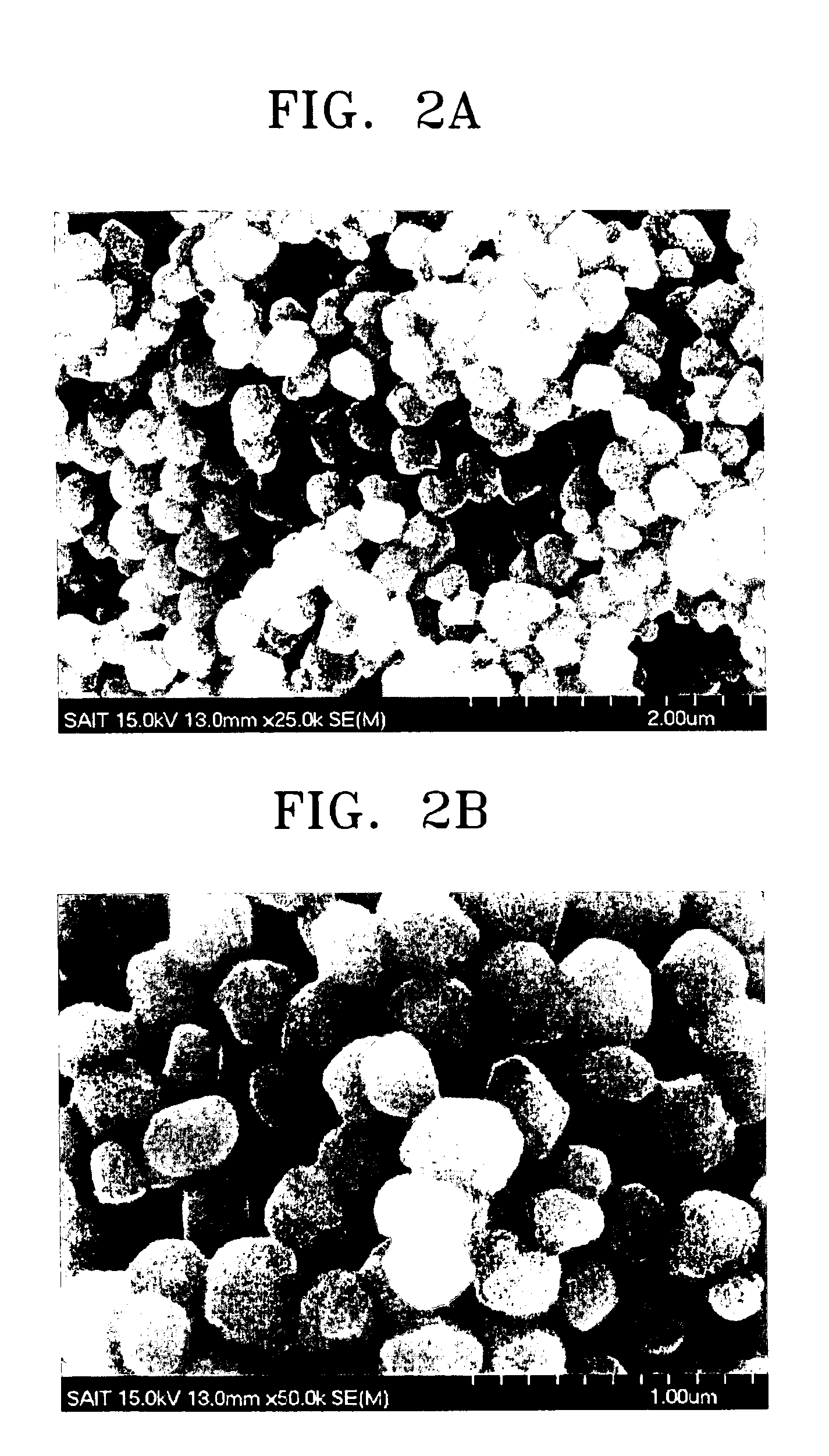

Electrode for fuel cell, method of producing the same, and fuel cell including the electrode

ActiveUS20070166600A1Excellent sustained ionic conductivityFinal product manufactureActive material electrodesZirconia silicaFuel cells

An electrode, a method of producing the same, and a fuel cell including the electrode are disclosed. The electrode includes: a support; and a catalyst layer formed on the support, the catalyst layer includes: a support catalyst; and a proton conductor having an amorphous phase greater than about 60% by weight. The proton conductor includes: at least one material from the group of B2O3, ZrO2, SiO2, WO3, and MoO3; and P2O5, the proton conductor being 0.5-60 parts by weight where the support catalyst is 100 parts by weight. The proton conductor can be synthesized at a low enough temperature so that it can be applied to the support with catalyst particles to form a catalyst layer. The coated proton conductor is in a solid state so the fuel cell is stable over time and it does not obstruct a fuel gas so that the catalyst can be more efficiently used.

Owner:SAMSUNG SDI CO LTD

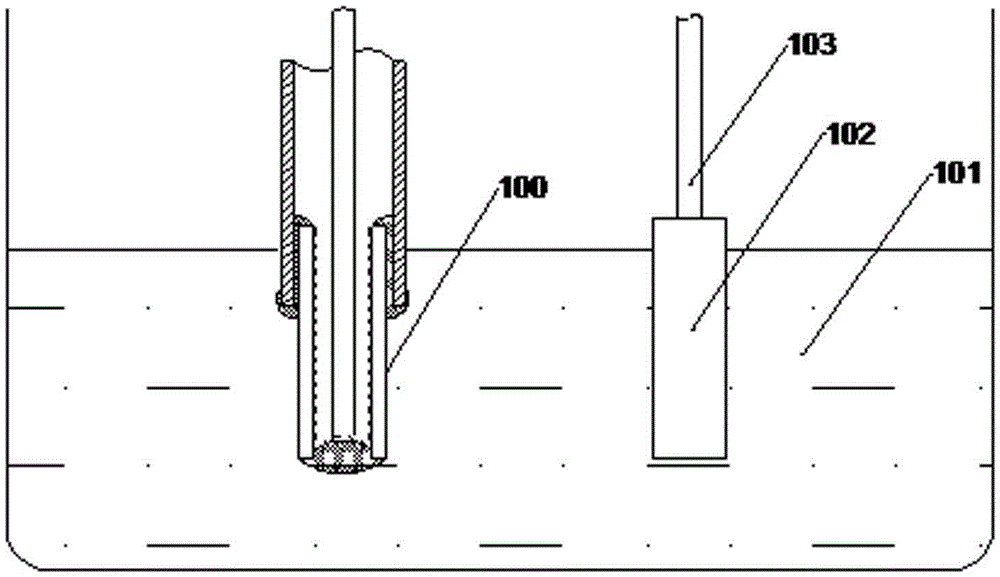

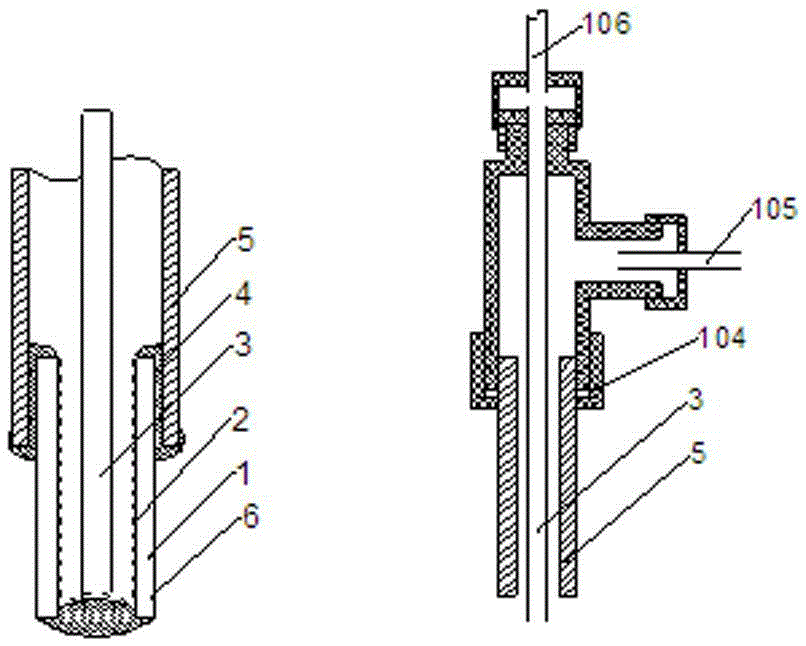

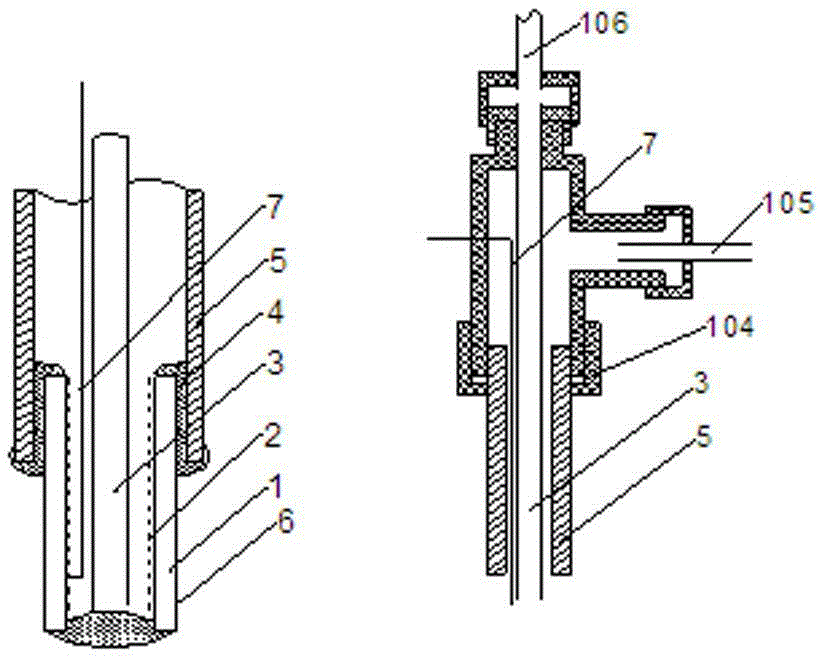

Sensor for measuring content of hydrogen in metal melt and measuring method

ActiveCN105319253AFast measurementThe result is accurateGas analyser construction detailsMaterial electrochemical variablesElectrical conductorAdhesive

The invention provides a sensor for measuring the content of hydrogen in a metal melt and a measuring method. The sensor structurally comprises a solid-state proton conductor element, a reference electrode, a quasi-to-be-detected electrode, a reference substance, a communicating pipe and an insulating ceramic adhesive. The measuring method comprises the following steps: (1) inserting a sensor and a corrosion-resistant electrode into a metal melt, ensuring that a solid-state proton conductor element is completely immersed into the metal melt and a quasi-to-be-detected electrode and the metal melt are in direct contact, wherein the contact surface is a to-be-detected electrode; (2) connecting a potentiometer, a reference electrode conductor or a metal gas-guide pipe and a corrosion-resistant electrode and measuring the potential difference between a reference electrode and the to-be-detected electrode; (3) calculating the hydrogen content S of the metal melt according to the measured potential difference, the temperature of the metal melt, and the saturated solubility of hydrogen in the metal melt. According to the sensor, the proton conductor element can be in direct contact with the metal melt, the atmosphere of balance between the reference substance and hydrogen in the metal melt can be quickly built, the measurement speed is higher, the measurement result is more accurate and the sensor is simpler by simplification.

Owner:NORTHEASTERN UNIV LIAONING

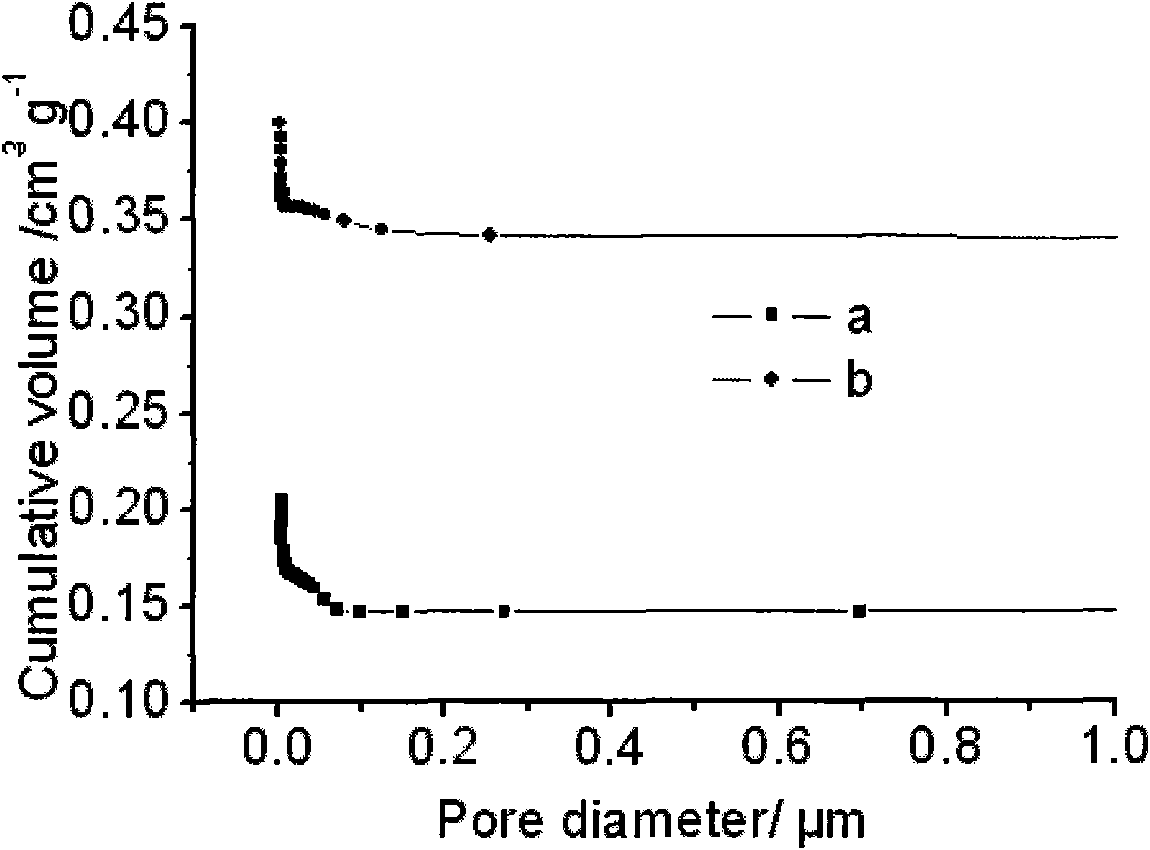

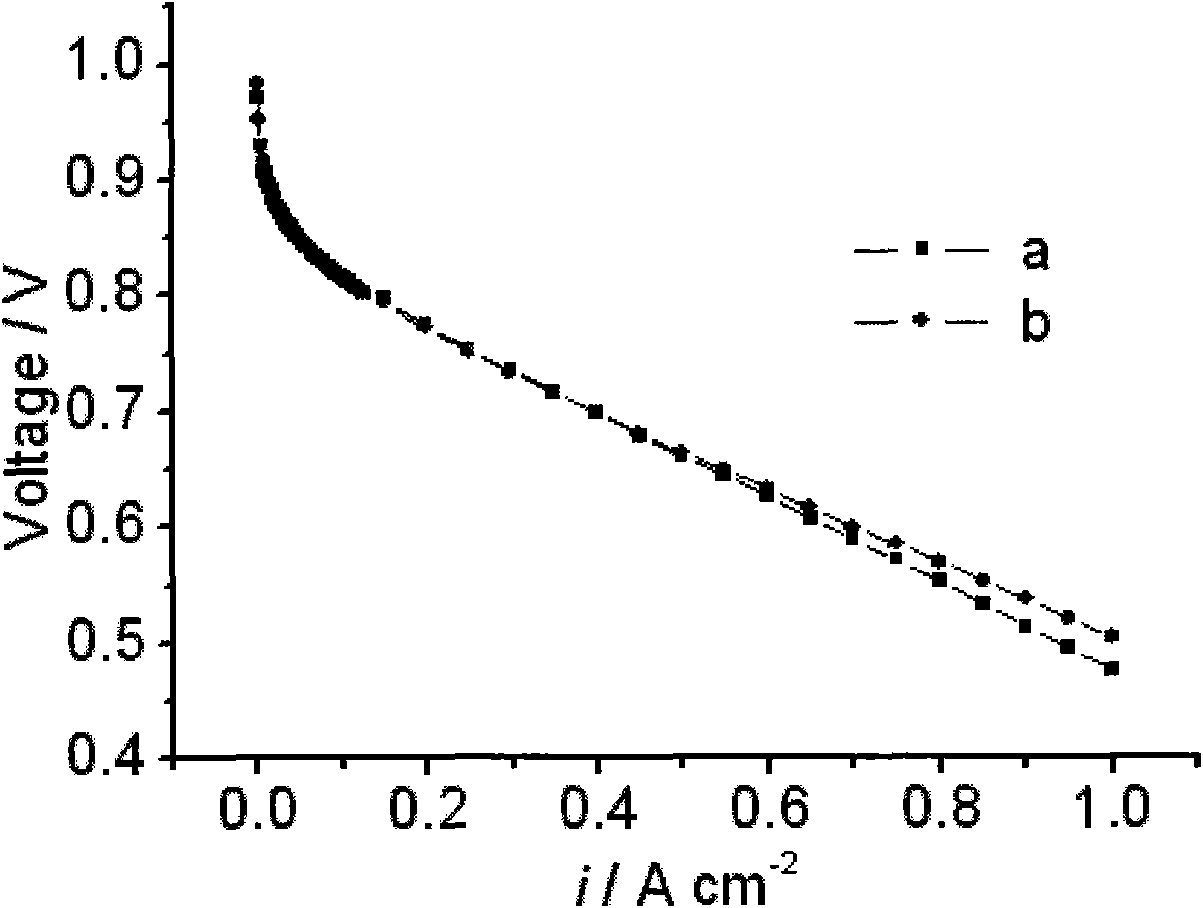

Catalyst sizing agent for preparing catalytic membrane electrode of fuel cell and preparation thereof

ActiveCN102255085ASimple methodIncrease profitCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPorosityElectrical conductor

The invention relates to a catalyst sizing agent for preparing a catalytic membrane electrode of a proton exchange membrane fuel cell. The catalyst sizing agent consists of an electric catalyst, proton conductor polymer distilled water and an organic solvent. The catalyst sizing agent is controlled in a colloid state, so that the pore structure of a prepared catalytic layer of a catalytic membrane electrode is improved, and the cell performance is enhanced. The conventional sizing agent for preparing the catalytic membrane electrode is in a solution state, so that the utilization ratio of a prepared electrode catalyst is not high, the porosity of a catalytic layer is very low, and the gas diffusion process is suppressed. In the invention, the composition and adding sequence of organic solvents in the sizing agent are changed. A preparation method of the catalyst sizing agent comprises the following steps of: conditioning a solution-state catalyst sizing agent with isopropanol, ethanol, ethanediol and the like; and dropwise adding the formed sizing agent into butyl acetate under ultrasonic oscillation condition to form a colloid-state catalyst sizing agent.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Polyacid-based metal organic frame proton conductor material of acid molecule functionalization and preparation method thereof

The invention discloses a polyacid-based metal organic frame proton conductor material of inorganic acid molecule functionalization. Polyanions and crystal water molecules are domain-limited in pore canals of the metal organic frame, wherein the structure thereof is HAaPOM-MOF, wherein HA is one of H2SO4 or H3PO4; and POM-MOF is the polyacid-based metal organic frame, and is one of [Ag8L5](PMo12O40)(H2O)10 or [Ag8L5](PW12O40)(H2O)13, wherein L is 5-phenyl tetrazole. The invention further discloses a preparation method for the polyacid-based metal organic frame proton conductor material of the inorganic acid molecule functionalization. The preparation method comprises the following steps: firstly preparing the polyacid-based metal organic frame, uniformly mixing the prepared polyacid-based metal organic frame and HA solution, separating the material, washing, drying to obtain the polyacid-based metal organic frame proton conductor material of the inorganic acid molecule functionalization.

Owner:XIJING UNIV

Composite proton exchange membrane

InactiveCN101867050AInhibit swellingImprove proton conductivityCell component detailsFuel cell detailsElectrical conductorHeteropoly acid

The invention discloses a composite proton exchange membrane which is prepared by taping mixed liquid of a sulfonated polyether ether ketone solution with a sulfonation degree of 50-70 percent, polyaniline filter liquid and heteropoly acid to form the membrane. The composite membrane is prepared by using SPEEK (Sulfonated Polyether Ether Ketone) as a basal body and PANI (Polyaniline) and HPA (Heteropoly acid) as dopants, the material source is wide and does not need to be imported, a preparation technology is simple, and instruments are simple, thereby the cost of the membrane is reduced; a hydrogen bond formed by PANI and SPEEK is used for avoiding the swelling of the SPEEK and reducing methanol penetration and the HPA dropout rate, and the proton conductivity of the composite membrane is improved by the HPA. By changing the composition and the ratio between an alkaline polymer and a proton conductor, the novel PEM (proton exchange membrane) reaches optimum balance among high proton conductivity, low methanol penetration and low HPA dropout rate, the proton conductivity reaches 10-2S / cm, the methanol penetration rate of the composite proton exchange membrane is a half lower than that of an Nafion 117 membrane, and the HPA wastage rate does not reach 5 percent.

Owner:NANTONG UNIVERSITY

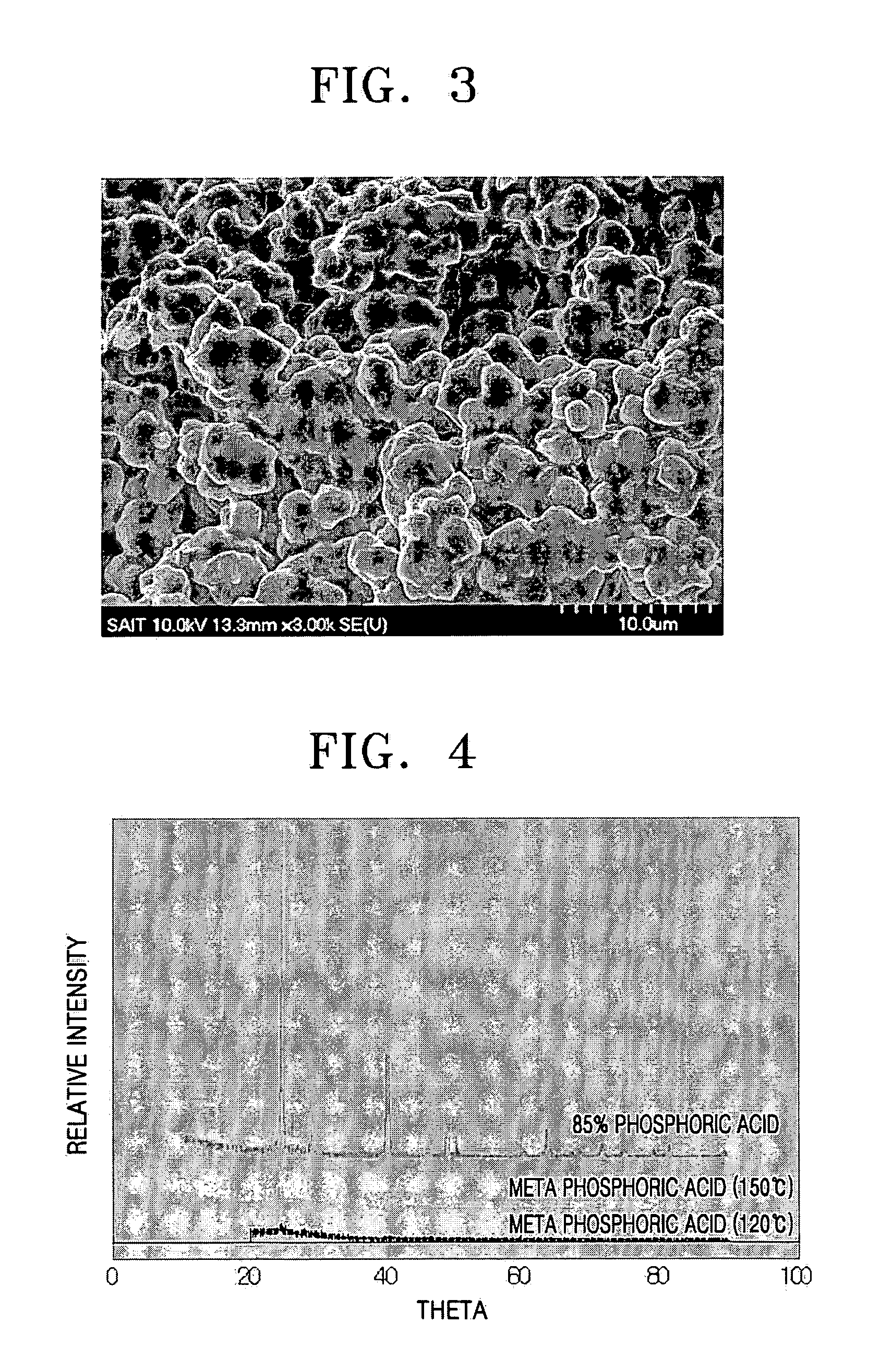

Solid proton conductor and fuel cell including the same

ActiveUS20090169956A1Improve proton conductivityMaterial nanotechnologySolid electrolytesFuel cellsElectrical conductor

Owner:SAMSUNG ELECTRONICS CO LTD

Zr-position doped high conductivity proton conductor material for La2Zr2O7 basal body and preparing method thereof

InactiveCN101033078AImprove electrical performanceEasy to prepareNon-metal conductorsRare earth metal compoundsAdjuvantWater vapor

This invention discloses a proton conductor material of high electric conductance of La2Zr2O7matrix doped at Zr bit and its preparation method, in which, the molecular structure of the material is: La2Zr2-xMxO7-delta, and M is Yb3+, Er3+, Gd3+ or Sc3+, x is 0.01-1, delta is x / 2. The preparation process includes: taking La2O3, ZrO2 and Yb2O3 or Er2O3, Gd2O3 or Sc2O3 as the raw materials to match with them according to the mol ratio of each material in terms of the molecular formula and adds dispersant in light of the mass percentage of the adjuvant then to ball-mill and mix them with the adjuvant with water or alcohol as the medium to be dried to get powder to be milled, dried, screened, synthesized and heat-preserved to get the material, which is ball-milled and pressed to be sintered in 1400-1650deg.C and cooled to the room temperature to get the material.

Owner:TIANJIN UNIV

Ordered membrane electrode of proton-exchange membrane fuel battery

InactiveCN1983684AImprove conductivityImprove performanceCellsCell electrodesElectrical conductorEngineering

The invention is concerned with a method to increase extraction efficiency of semiconductor LBD by texturing film transfer. Develop conventional semiconductor LBD, weld the core of flip semiconductor LBD, product template with micro / nanometer-figures by the designed light-etched domain, select and confect a kind of prepolymer in appropriate proportion and print the ultrastructure figure on the prepolymer colloid with micro / nanometer print technology and solidify the prepolymer colloid film, peel off the prepolymer film with ultrastructure figure and get the texturing film medium film. The step of texturing film transferring is spreading transparent PMMA glue on underlay of LBD, setting the side of texturing film with figure upside and pasting on the core of diode, setting the side of texturing film with figure peeled off upside and pasting on the core of diode, adding proper temperature to solidify the transparent agglutinating glue.

Owner:中科军联(张家港)新能源科技有限公司

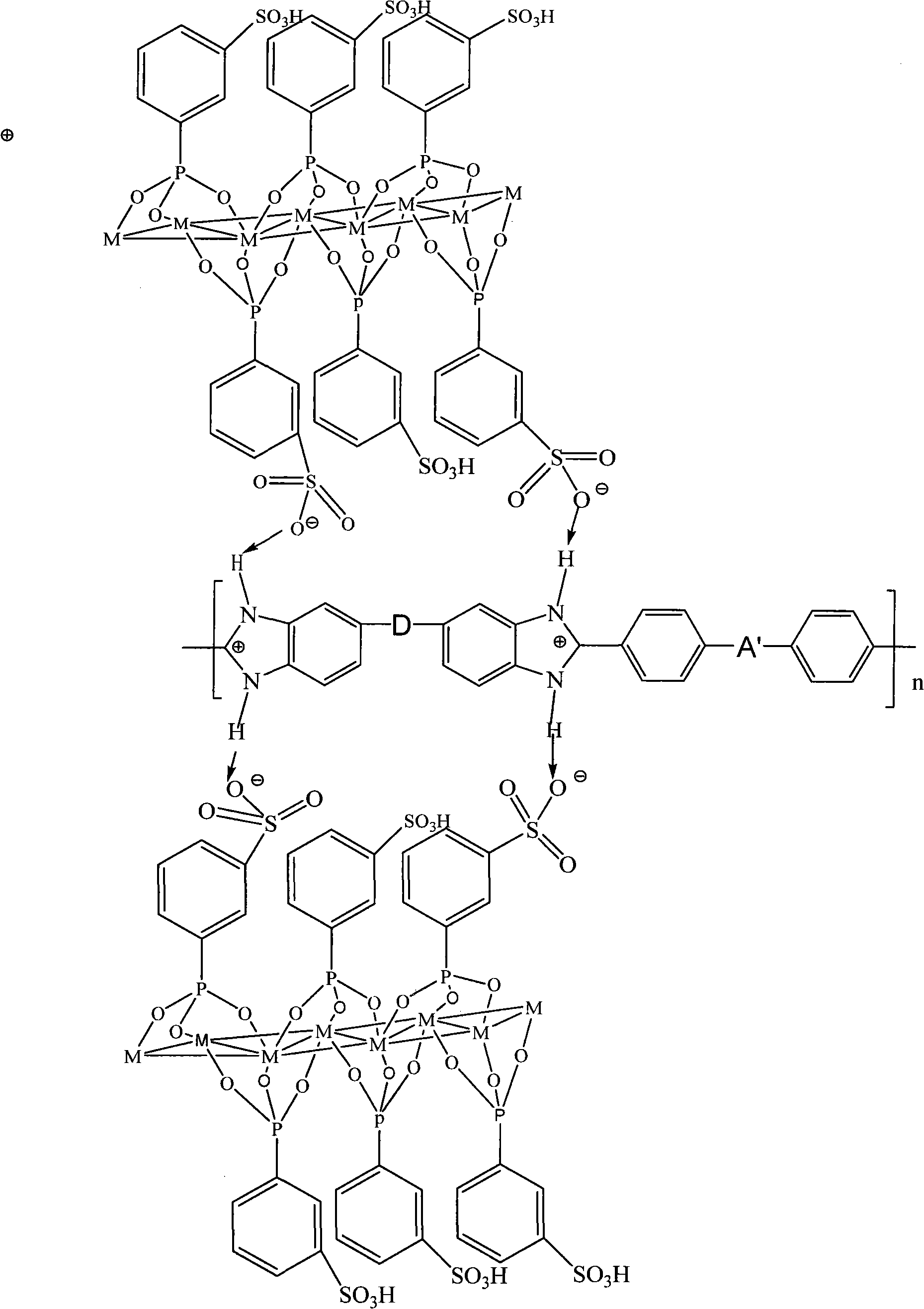

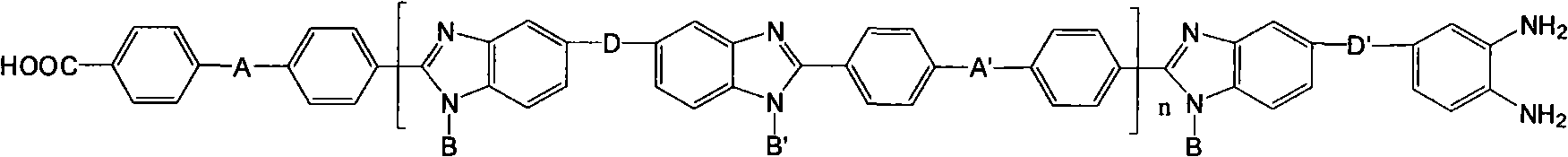

Preparation method of high-temperature proton conductor composite material

InactiveCN101775210AImprove mechanical propertiesImprove proton conductivityElectrolysisElectrical conductor

The invention relates to a preparation method of a high-temperature proton conductor composite material, which is characterized in that sulfonated triphenylphosphine salt is added into polybenzimidazole after the polybenzimidazole is dissolved in a solvent to obtain membrane casting solution, the membrane casting solution is poured onto a glass membrane casting plate to be dried for 24 hours at the temperature of 60 DEG C and then to be dried for 4 hours at the temperature of 100 DEG C, the glass membrane casting solution is steeped into a deionized water after being naturally cooled to the room temperature, then the membrane is torn off, and a polybenzimidazole-type high polymer material doped with sulfonated triphenylphosphine salt high-temperature proton conductor composite material is obtained. The sulfonated triphenylphosphine salt is used as the doping material, so the PBI has good proton conduction performance, and the sulfonated triphenylphosphine salt not only can make the PBI be well blended with the high polymer material, but also can improve the mechanical performance of the material. The composite material can be used at the temperature of room temperature to 180 DEG C, and the electric conductivity of the composite material is within 0.08 to 0.2 S / cm. The composite material can be applicable to the high-temperature proton exchange membrane material and other proton conduction material of the fuel cell, and also can be applicable to the fields such as the electrolysis, the sensor, the electro-luminescent material and the like.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com