Catalyst sizing agent for preparing catalytic membrane electrode of fuel cell and preparation thereof

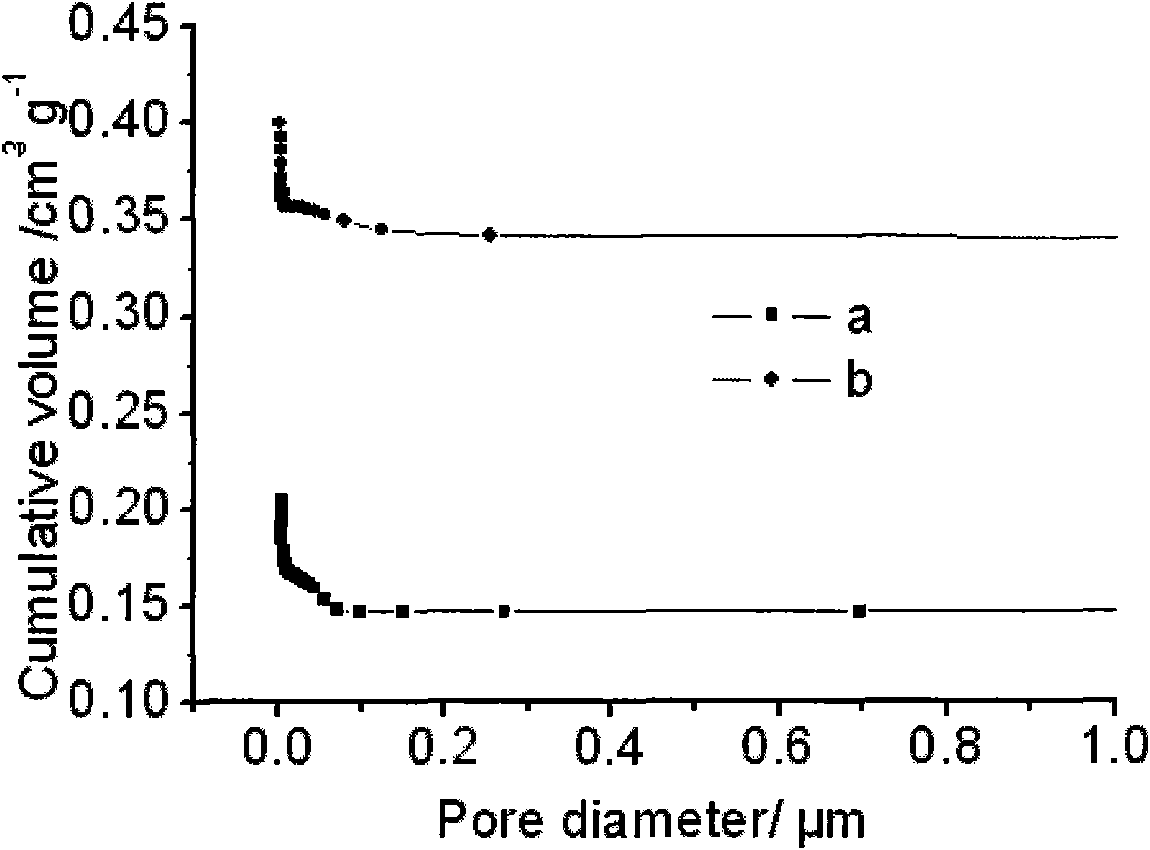

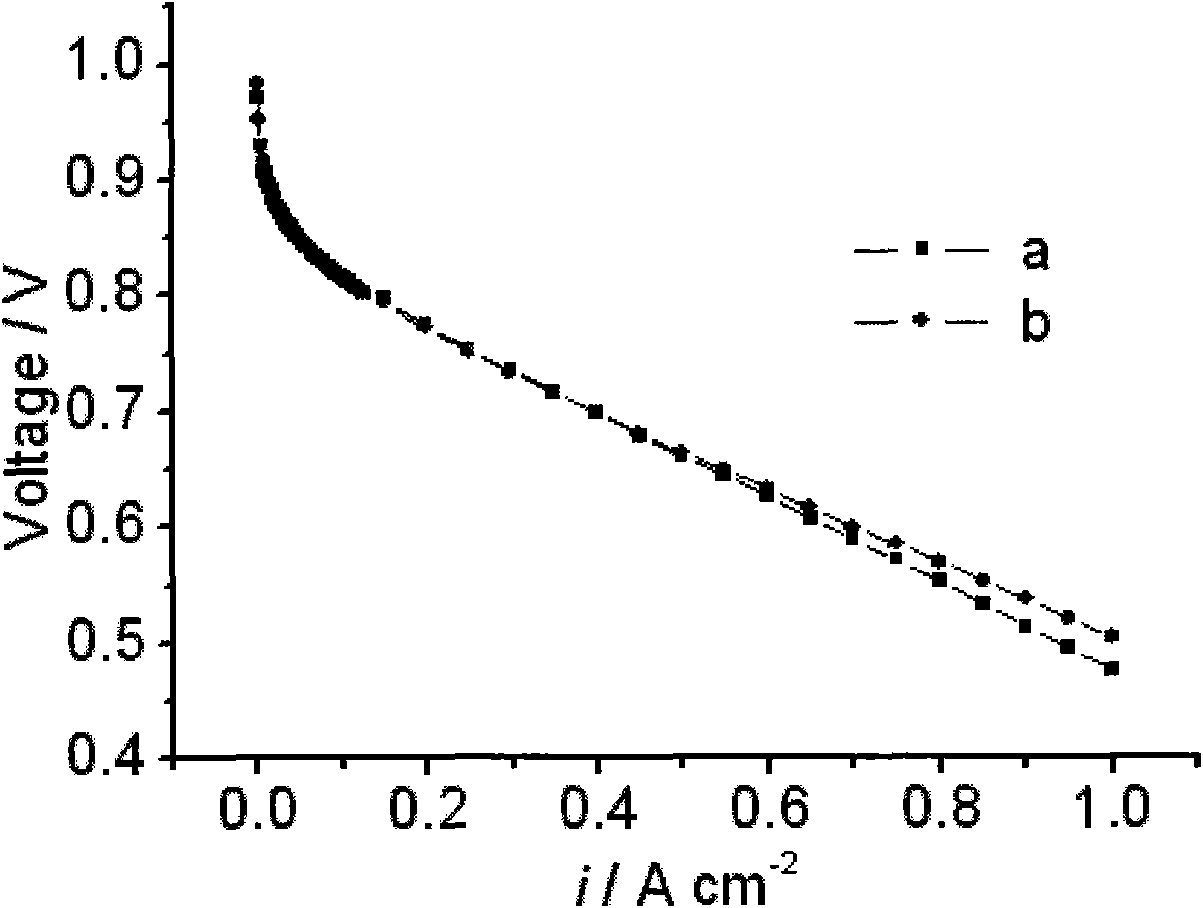

A catalyst slurry, fuel cell technology, applied in battery electrodes, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as unsatisfactory catalytic layer performance and influence on gas mass transfer process. , to achieve the effect of improving the gas mass transfer process, increasing the utilization rate, and improving the pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 50mg of 50wt.% Pt / C electrocatalyst, wet it with 2ml of distilled water, add 2g of isopropanol, and oscillate evenly with ultrasonic to form a uniform feed liquid, then add 5wt.% of Proton conductor polymer 500mg, continue to ultrasonically oscillate for half an hour, add ethylene glycol 250mg during the oscillating process; then weigh 2g of butyl acetate, and add the prepared catalyst slurry to it under ultrasonic oscillating conditions, this After the process is completed, a colloidal catalyst slurry can be formed.

[0029] The proton exchange membrane ( 115) Lay flat on the vacuum heating platform, set the temperature of the heating platform at 80°C, turn on the vacuum pump to make the film firmly adsorb on the platform.

[0030] Spray the above-mentioned catalyst slurry directly on the surface of the membrane. When spraying at the beginning, control the spraying with a relatively small flow rate (0.1-0.2ml / min). When a thin layer of catalyst is formed on th...

Embodiment 2

[0036] The difference from Example 1 is that the electrocatalyst used is a Pt-Pd alloy catalyst.

Embodiment 3

[0038] The difference with example 1 is: the proton exchange membrane adopted is 212 film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com