Preparation method of high-temperature proton conductor composite material

A technology of proton conductors and composite materials, which is applied in the field of preparation of high-temperature proton conductor composite materials, can solve various problems, and achieve the effects of improving mechanical properties, good application prospects, and wide use

- Summary

- Abstract

- Description

- Claims

- Application Information

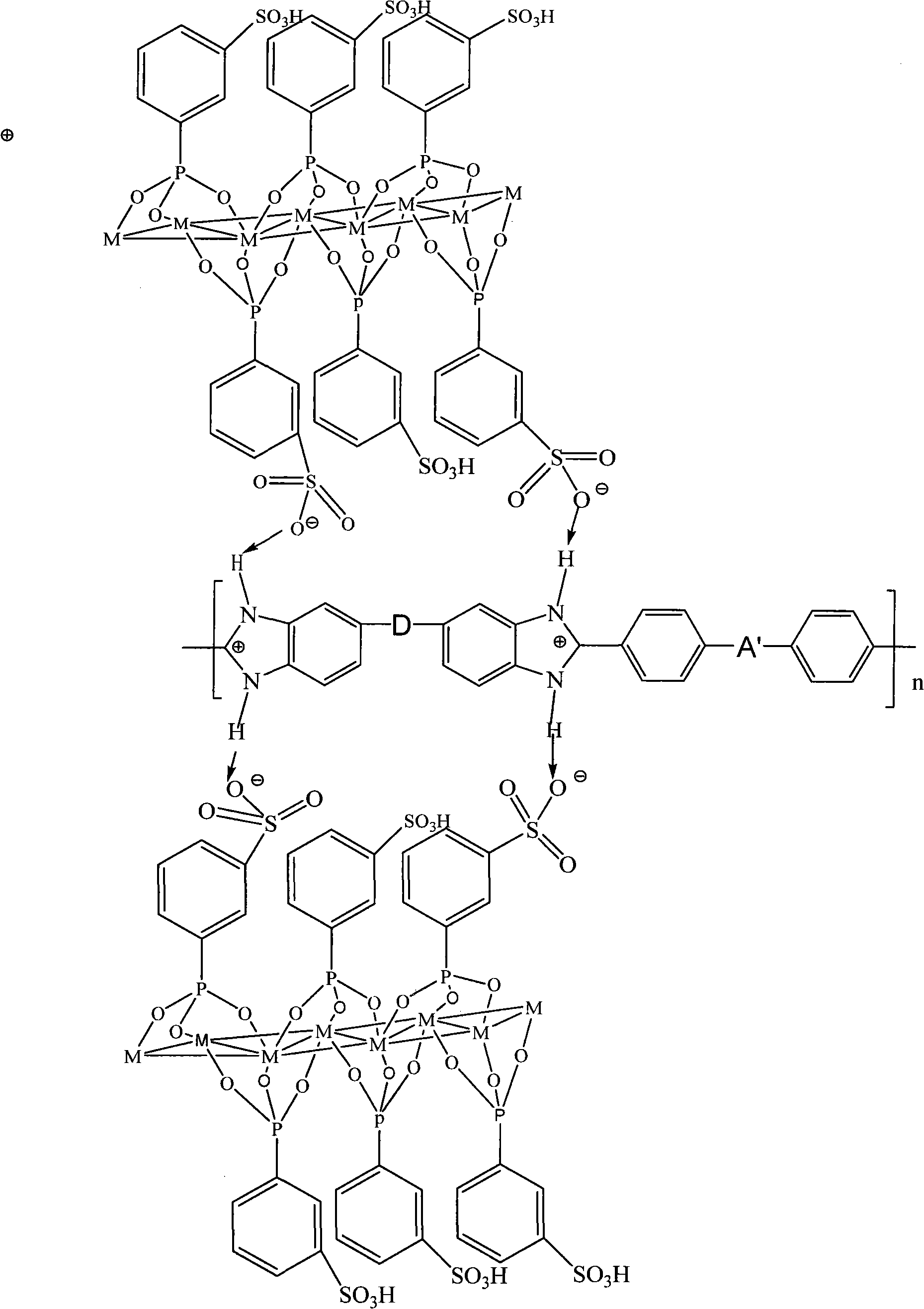

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

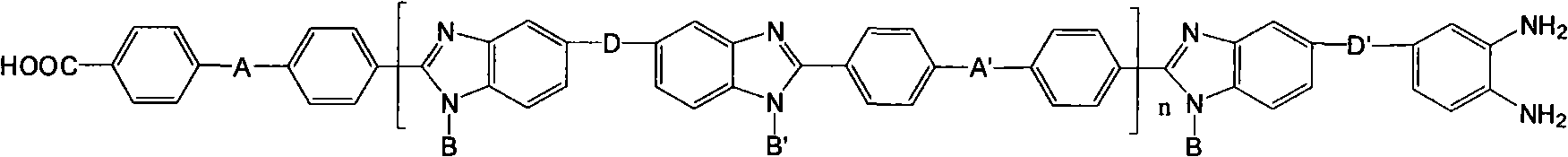

[0035] The preparation of [embodiment 1] PBI (known technology)

[0036] With stirrer, N 2 Add the PPA of 25g 84% in the 250ml three-neck flask of inlet and condenser tube, and 0.774g4,4'-dicarboxy diphenyl ether, oil bath is heated to 150 ℃ and under N 2 Continue stirring for 30min under protection to remove the air in the round bottom flask, add 0.6428g (3mmol) 3 in the flask, 3'-diaminobenzidine, N 2 React under protection at 220°C for 5-12 hours, pour the resulting viscous solution into deionized water to obtain a brown strip polymer, wash with deionized water until weakly acidic, then wash with 10% NaOH solution until neutral, dry, and mechanically pulverize Get PBI powder.

Embodiment 2

[0037] [embodiment 2]: the preparation of other types of PBI (known technology)

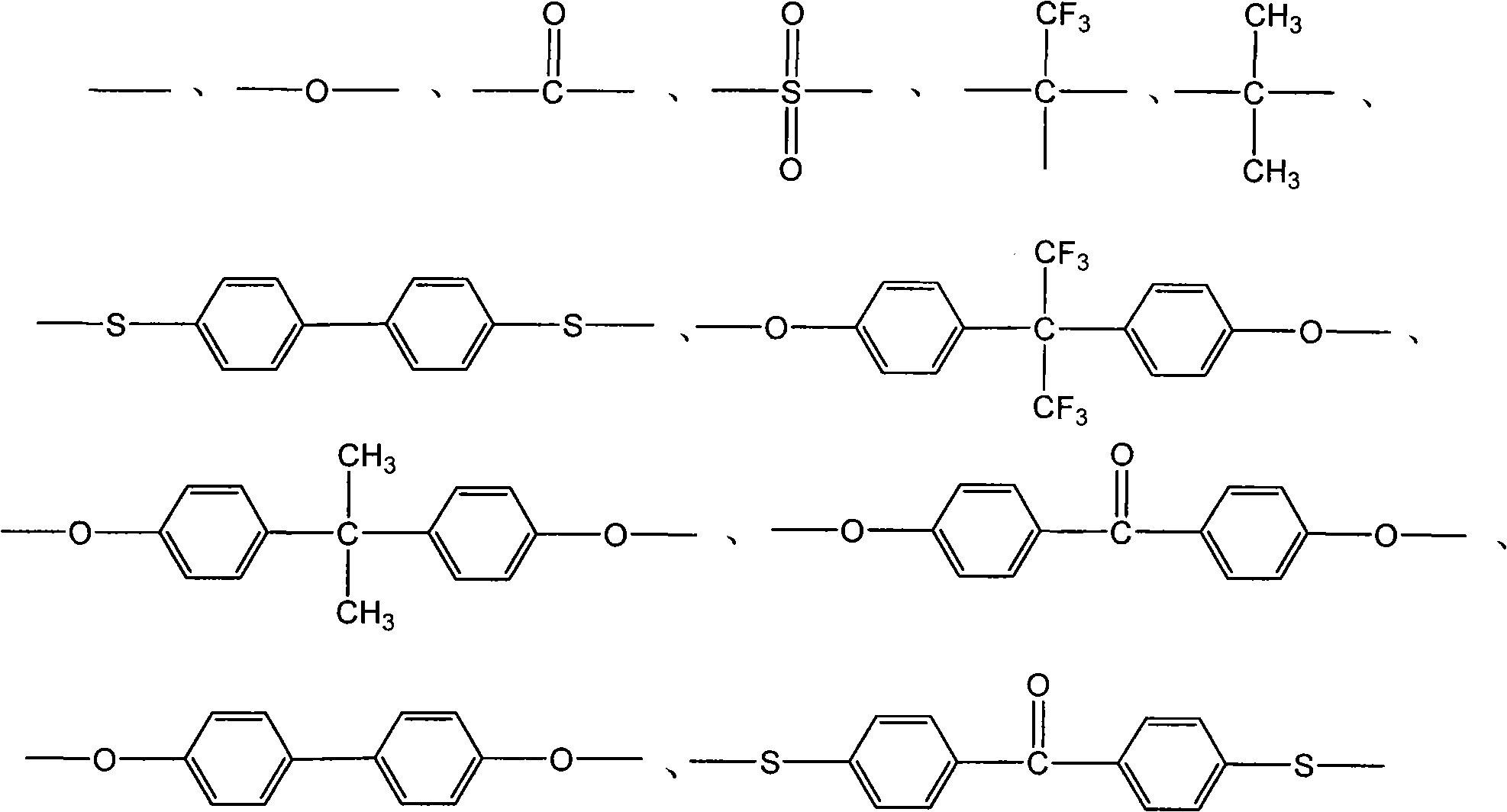

[0038] The preparation method of other types of PBI is the same as that of Example 1, except that the aromatic diacids and aromatic tetramines and the proportions of the reaction raw materials are changed.

[0039] The synthetic method of the hyperbranched PBI is the same as the above embodiment, except that the aromatic tetraamine is changed into aromatic hexamine or other polyamines.

Embodiment 3

[0040] [embodiment 3]: the preparation of phenylphosphonic acid (known technology)

[0041] Add 26.6mL of phosphorus trichloride, 6.5mL of dry benzene, and 11g of anhydrous aluminum trichloride into a three-necked flask equipped with an electric stirrer, a reflux condenser, and a dropping funnel, stir, and slowly heat until the benzene boils. Heated to reflux for 8h. Stop heating, add 18mL of phosphorus oxychloride dropwise while hot, and finish adding dropwise in 0.5h. Then add 40mL of petroleum ether, and reflux for 0.5h. After cooling, a yellow viscous liquid was obtained. The yellow viscous liquid was washed with petroleum ether to obtain a hard solid. Petroleum ether was evaporated to obtain a light yellow liquid with yellow crystals. After standing for 6 hours, a light yellow paste was obtained. After adding ethanol, stirred and filtered to obtain a yellow powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com