Ordered membrane electrode of proton-exchange membrane fuel battery

A proton exchange membrane and fuel cell technology, applied in solid electrolyte fuel cells, fuel cells, battery electrodes, etc., can solve the problems of difficult preparation of electrodes, low performance, and high loading of precious metals, and improve battery performance and catalyst utilization. The effect of improving and improving the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

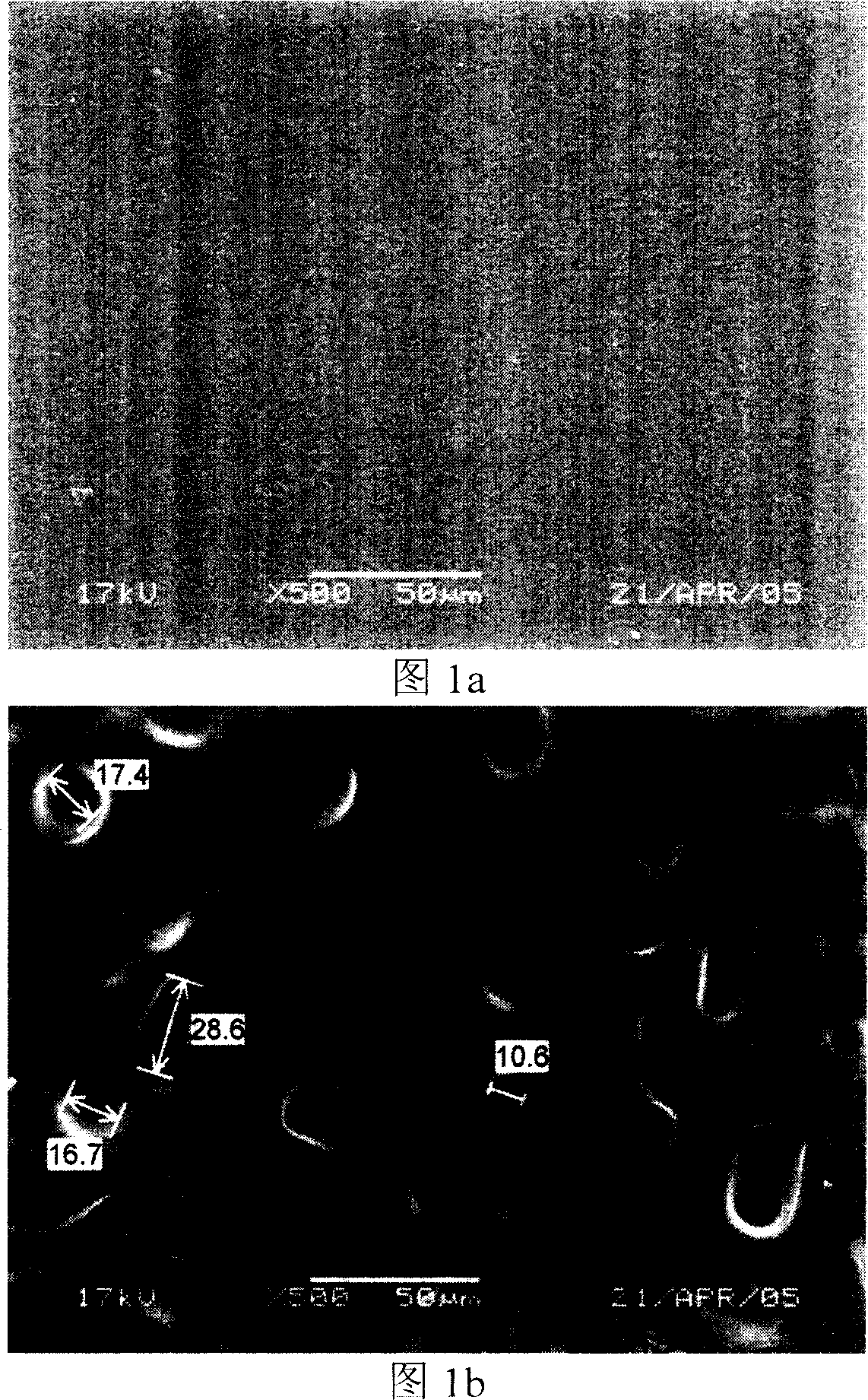

[0036](1) Take a piece of Na-type Nafion 115 membrane (Dupont) was kept under 0.06MPa negative pressure for 30 minutes. At 60°C, 320mg Nafion (5% aqueous solution, EW value 1100) will be sprayed on the surface of Nafion membrane, and the final loading of Nafion sprayed is 1mg / cm 2 . Fig. 1a. is the scanning electron microscope image of the unmodified Nafion film surface in embodiment 1; Fig. 1 b. shows the Nafion film surface scanning electron microscope image modified by Nafion solution;

[0037] (2) Add 96mg of PtRu black (Johnson Matthey), 1900mg of a mixed solution of isopropanol and water (water: isopropanol=1:20, mass ratio), mix well, then add 400mg of 5% Nafion, and then add Nafion solution 0.5M NaOH solution of the same quality, mixed evenly to obtain a catalyst slurry, sprayed on the membrane, and the final catalyst loading was 3.2mg / cm 2 .

[0038] Spray 1mg / cm on the other side of Nafion115 2 Nafion solution (Nafion dry weight). Accurately weigh 50 mg of Pt...

Embodiment 2

[0048] In order to facilitate comparison of the effects of the present invention, take a piece of Na-type Nafion115 film, the surface of which is not sprayed with Nafion solution, prepare catalyst slurry according to the method in Example 1, and directly spray on the film. The composition of the catalytic layer and the carrying capacity of the catalyst Example 1. without heat treatment.

[0049] The membrane electrode prepared by this method is denoted as MEA2.

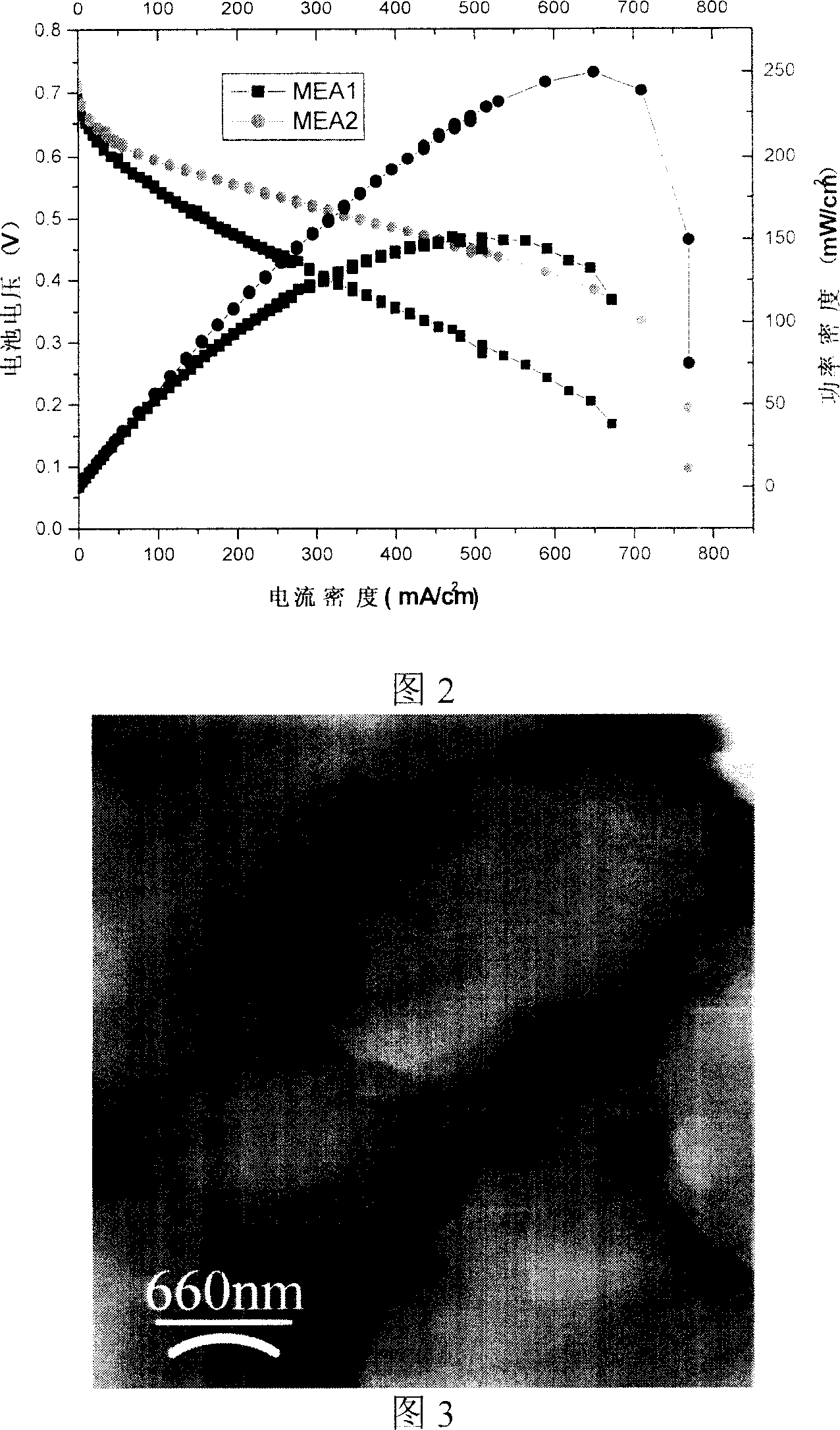

[0050] The cathode catalyst utilization rate of MEA2 is shown in Table 1, and the performance at 75°C is shown in Figure 2.

Embodiment 3

[0052] Prepare the electrode according to the steps in Example 1, except that in step (3), the prepared membrane electrode is treated at 160 ° C for 3 hours under nitrogen protection

[0053] The membrane electrode prepared by this method is denoted as MEA3.

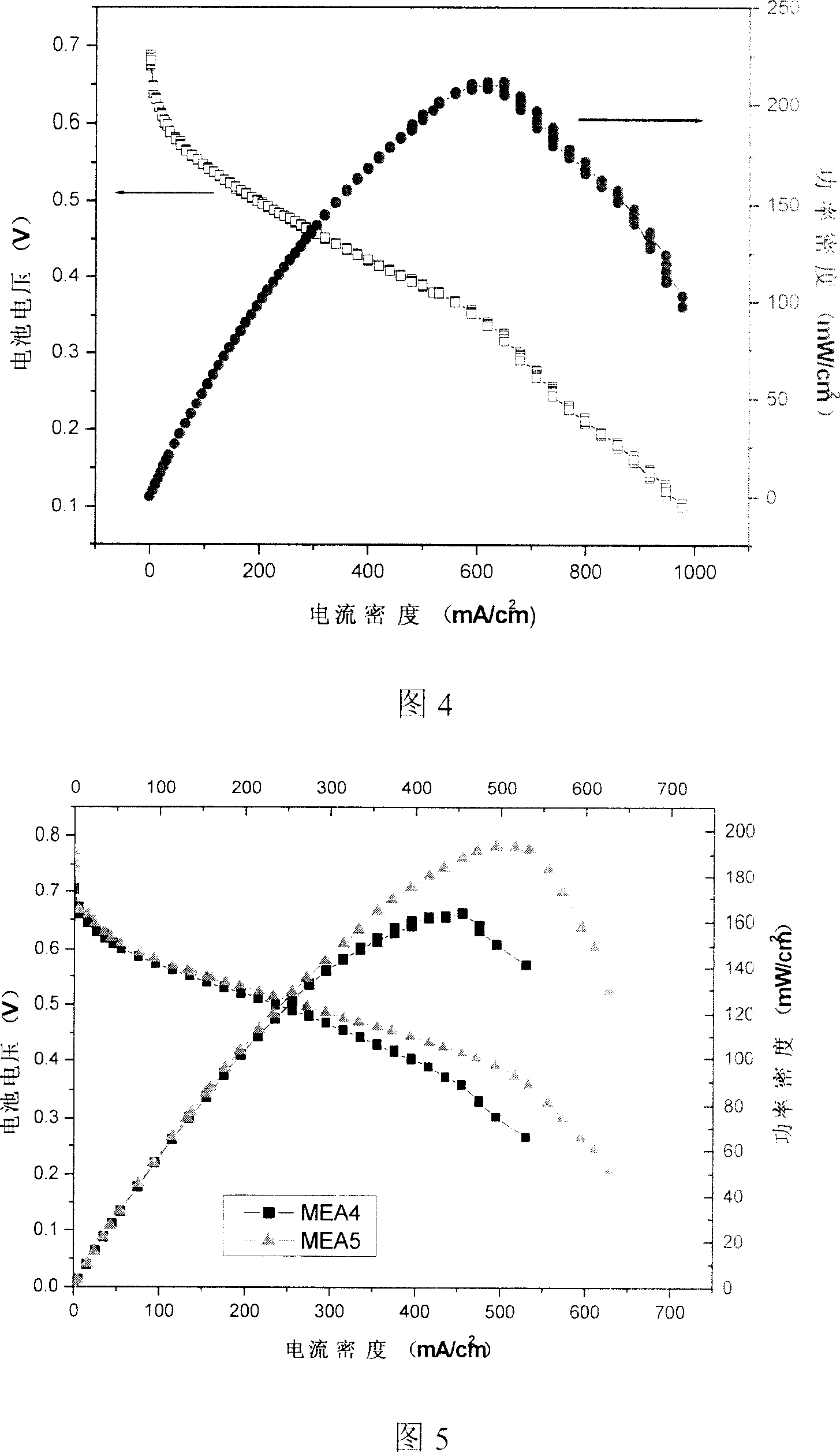

[0054] The cathode catalyst utilization of MEA3 is shown in Table 1, and the performance at 75°C is shown in Figure 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com