Patents

Literature

34 results about "Zirconia silica" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zirconia Silica Fume. Zirconia silica fume is a compound of zirconium dioxide, zirconium oxide melting products. The production of silicon-zirconium off special device which used to collect the silica powder, not only has the general characteristics of sillca , but also a certain amount of zirconia powder.

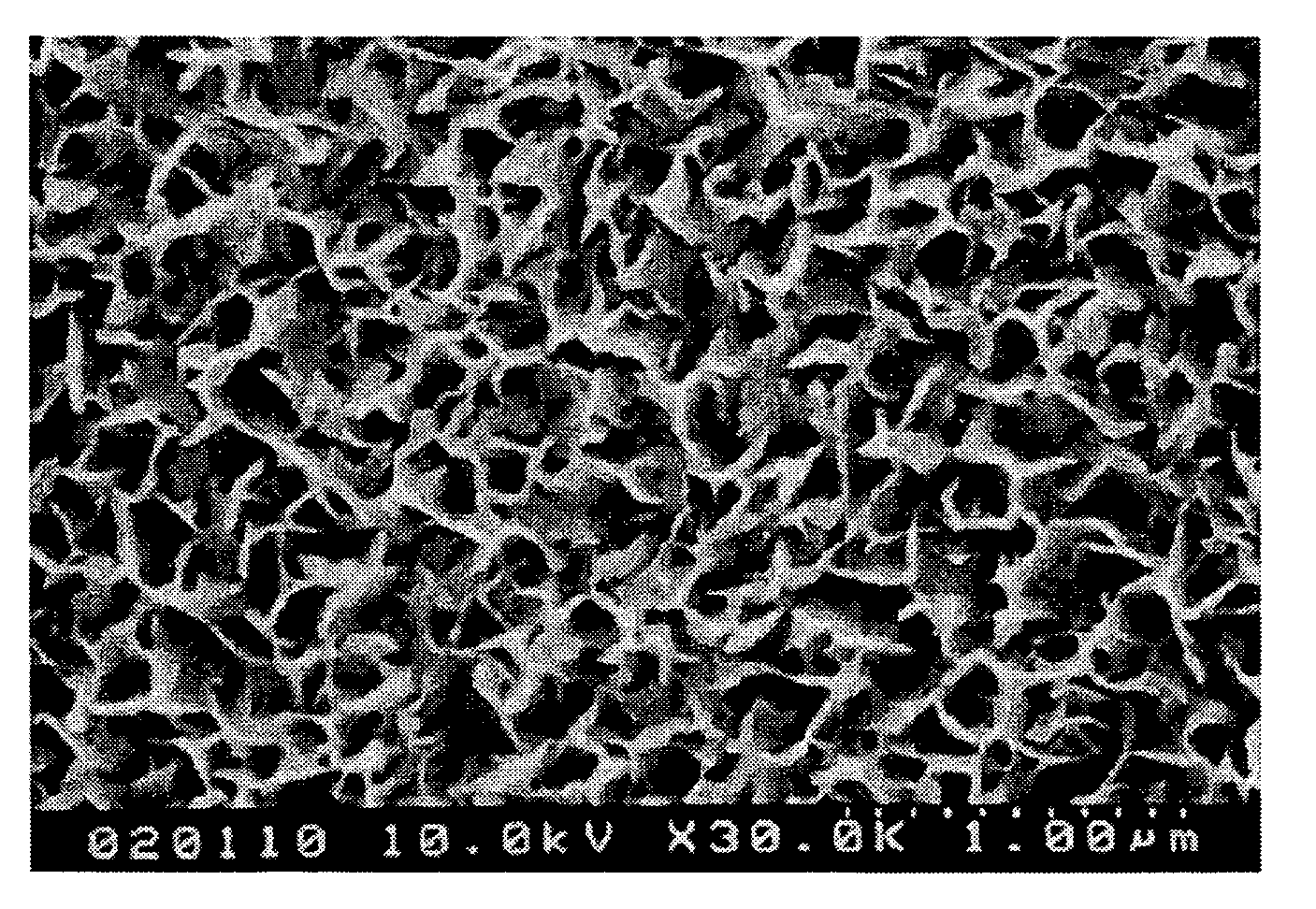

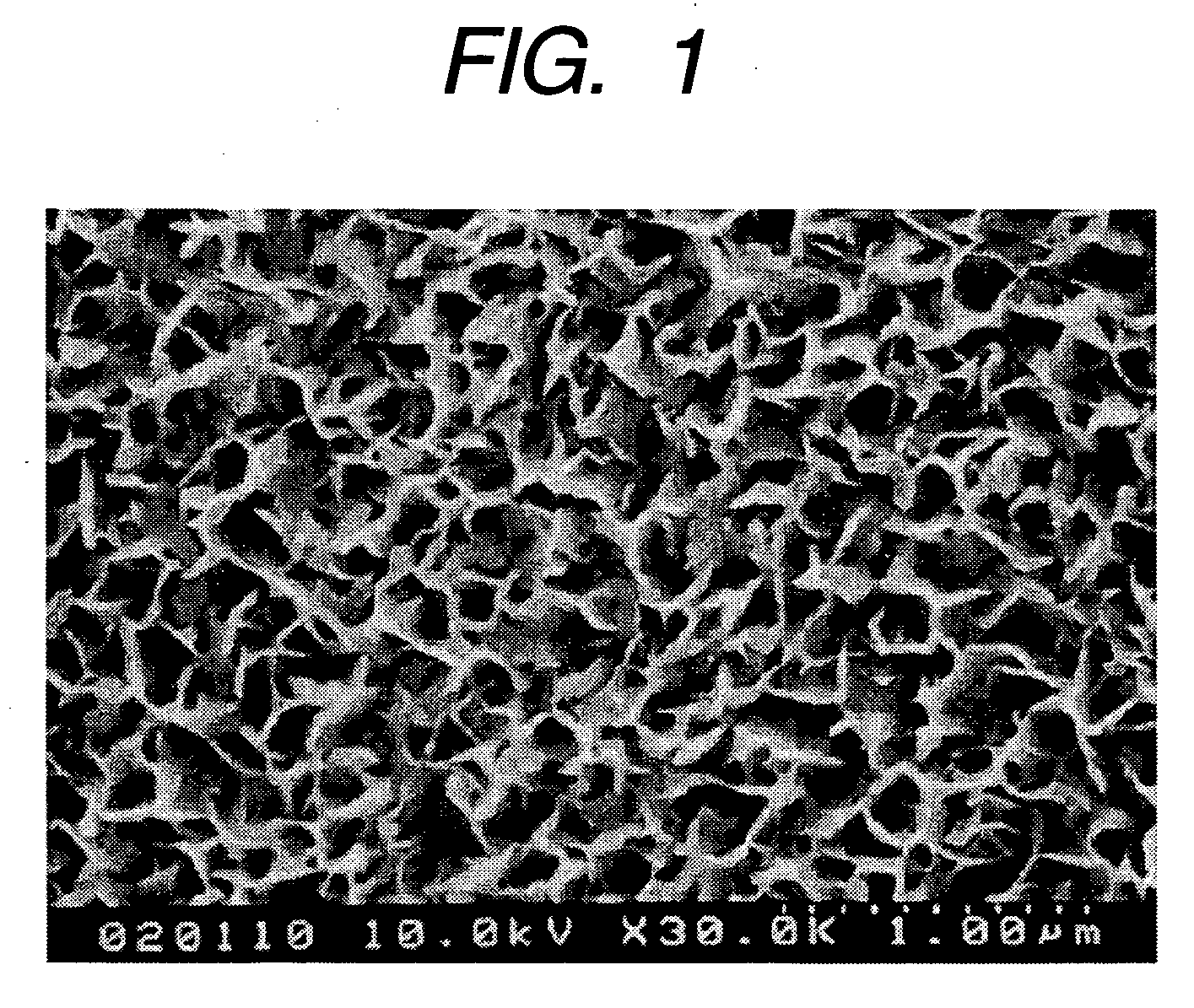

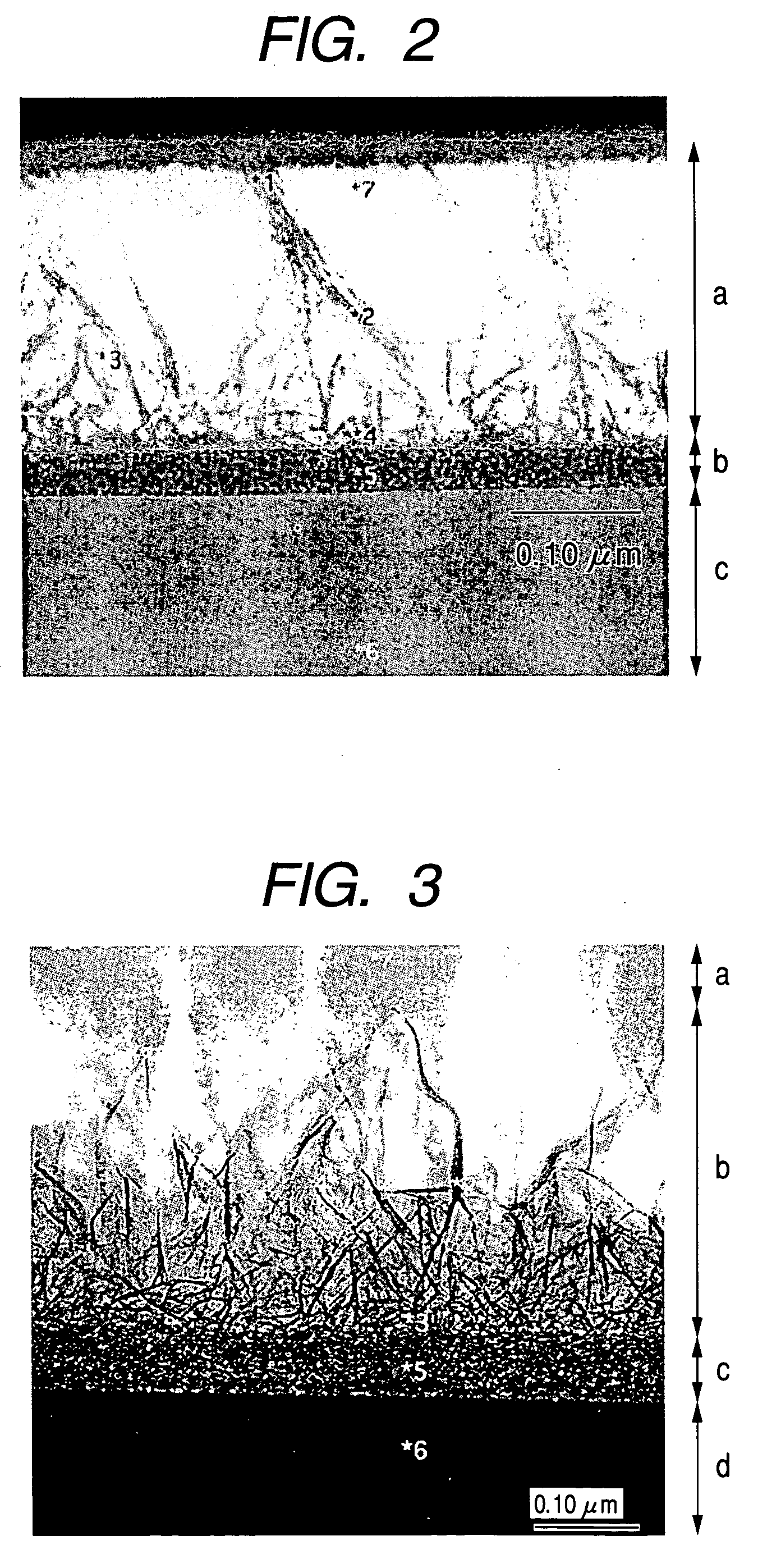

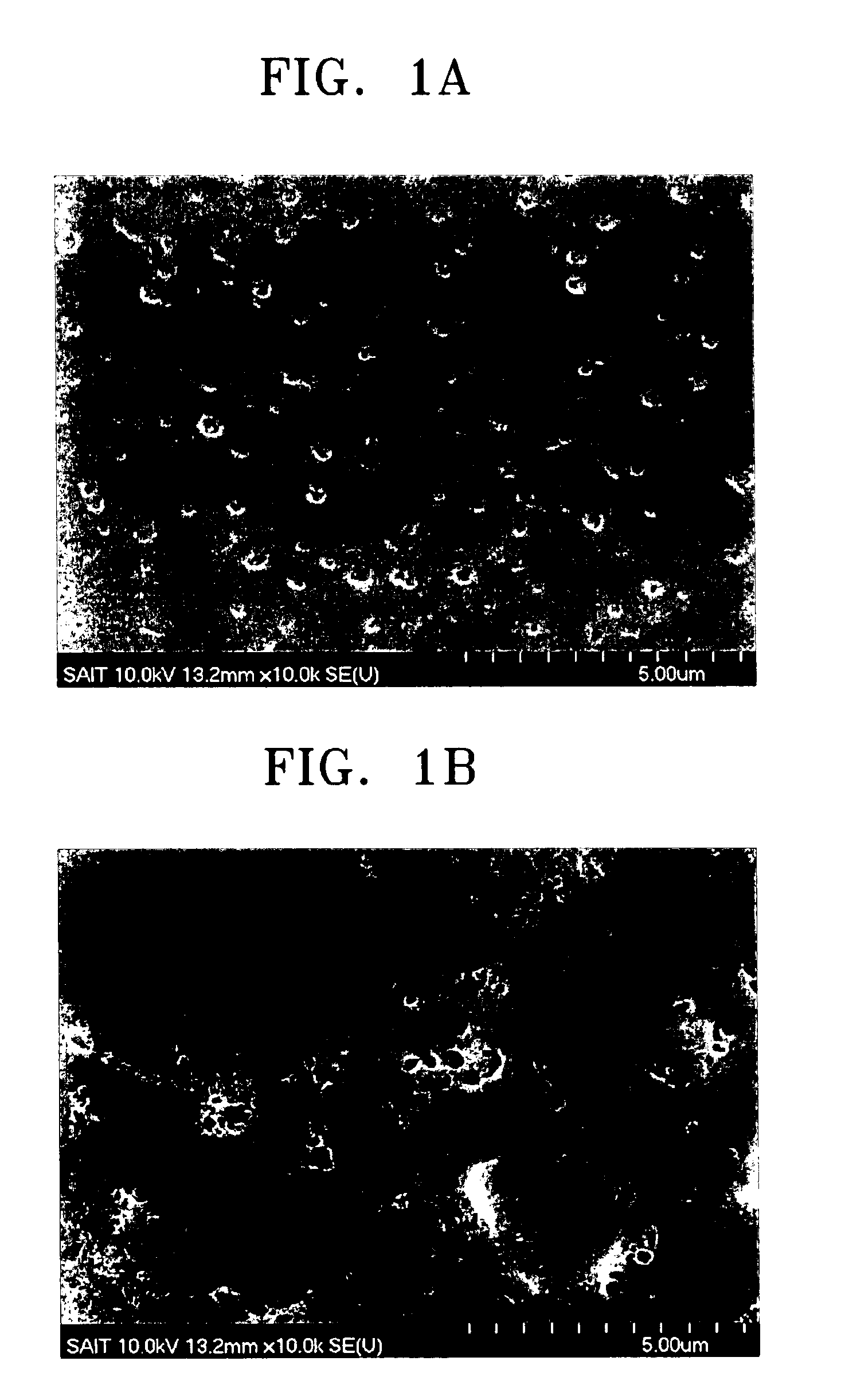

Film and antireflection film having fine irregularities on surface, production method for the same, and optical member using the same

InactiveUS20050233113A1Improve anti-reflection effectReduce reflectionDiffusing elementsLayered productsZirconia silicaZinc compounds

A transparent antireflection film, including fine irregularities mainly composed of alumina, and a transparent thin film layer supporting the fine irregularities, in which the transparent thin film layer contains at least one selected from the group consisting of zirconia, silica, titania, and zinc oxide. A production method for the aforementioned transparent antireflection film, including: forming a multicomponent film using an application liquid containing at least one compound selected from the group consisting of a zirconium compound, a silicon compound, a titanium compound, and a zinc compound, and at least an aluminum compound; and subjecting the multicomponent film to warm water treatment.

Owner:PUBLIC UNIVERSITY CORPORATION OSAKA CITY UNIVERSITY +1

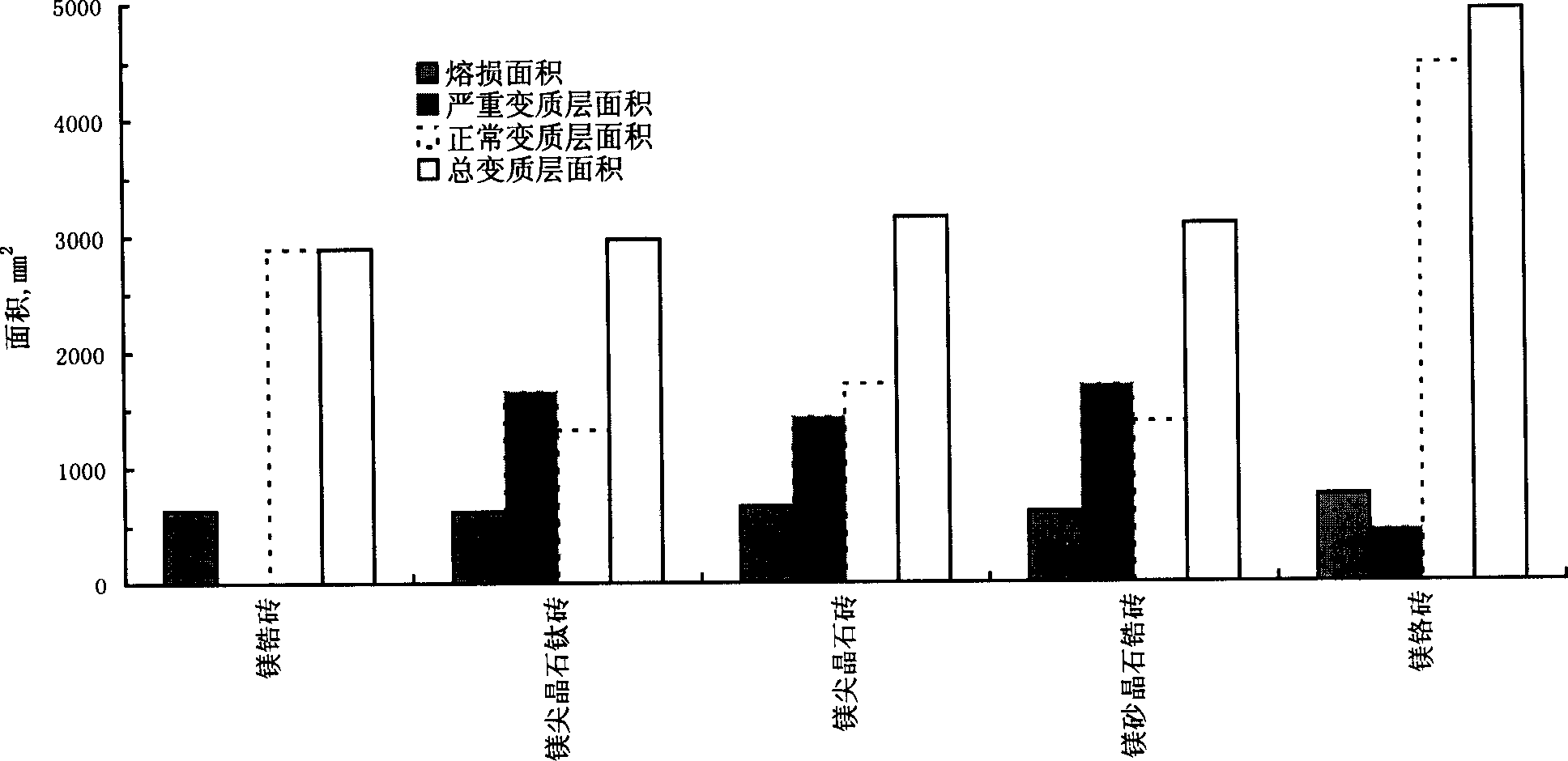

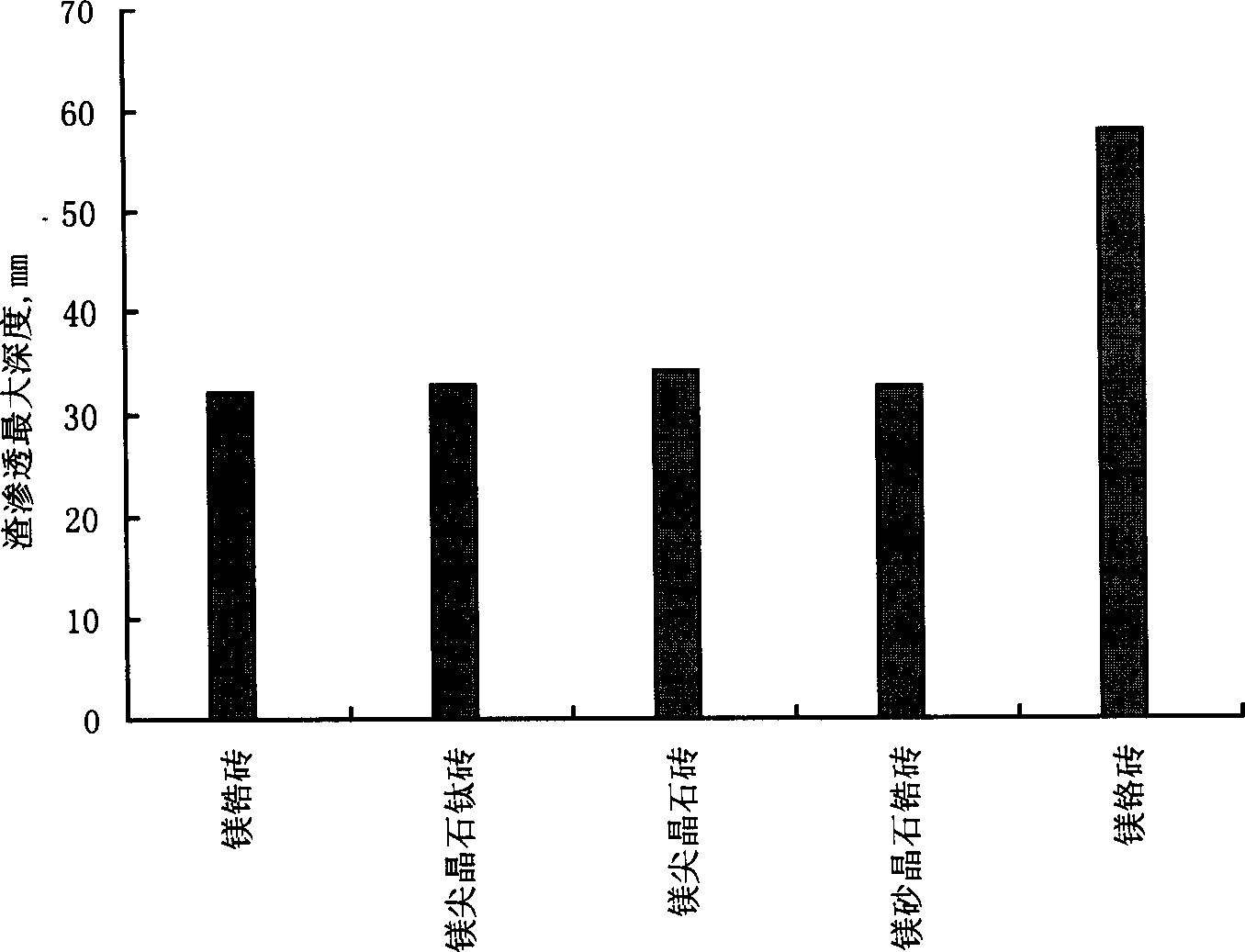

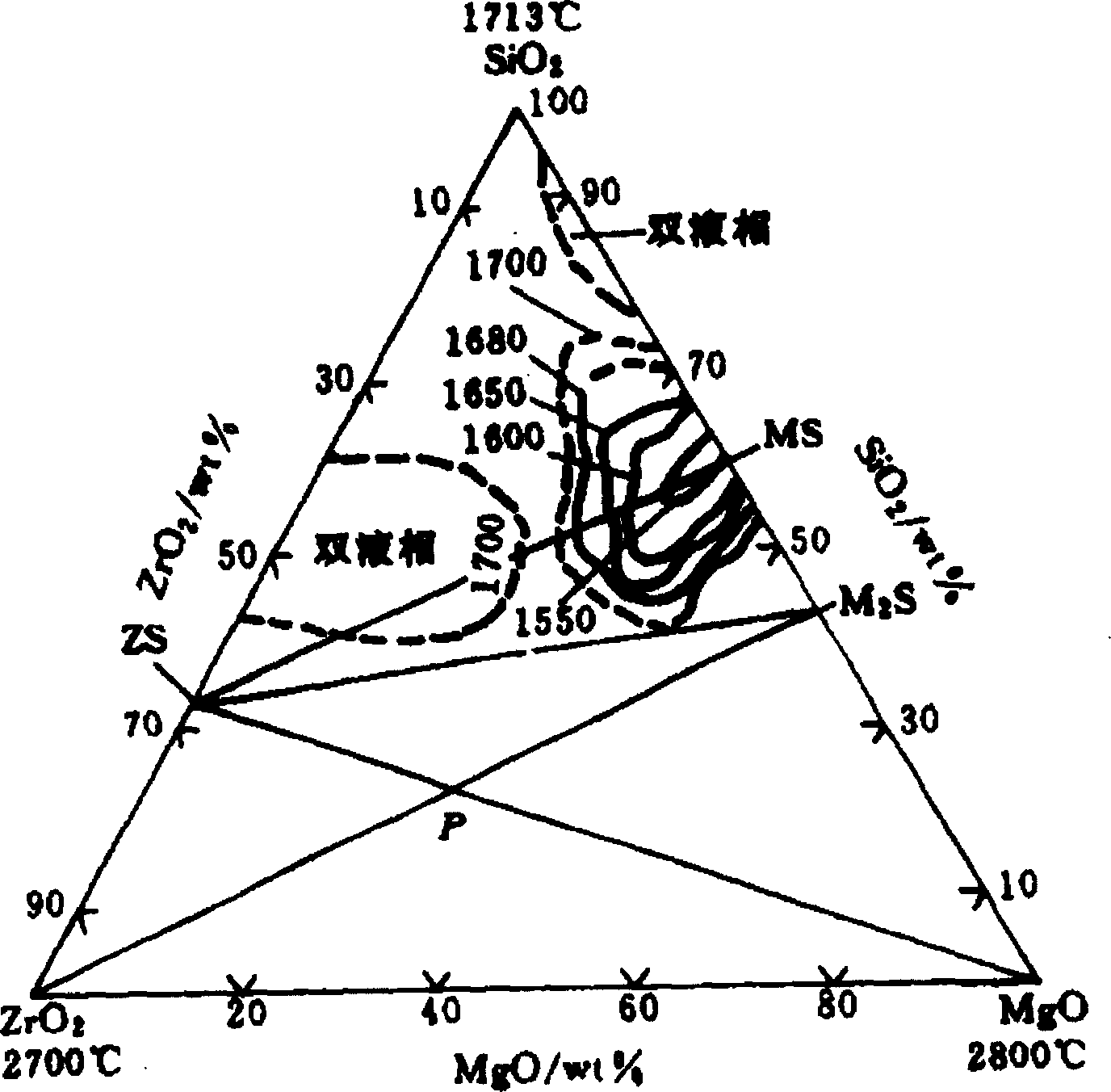

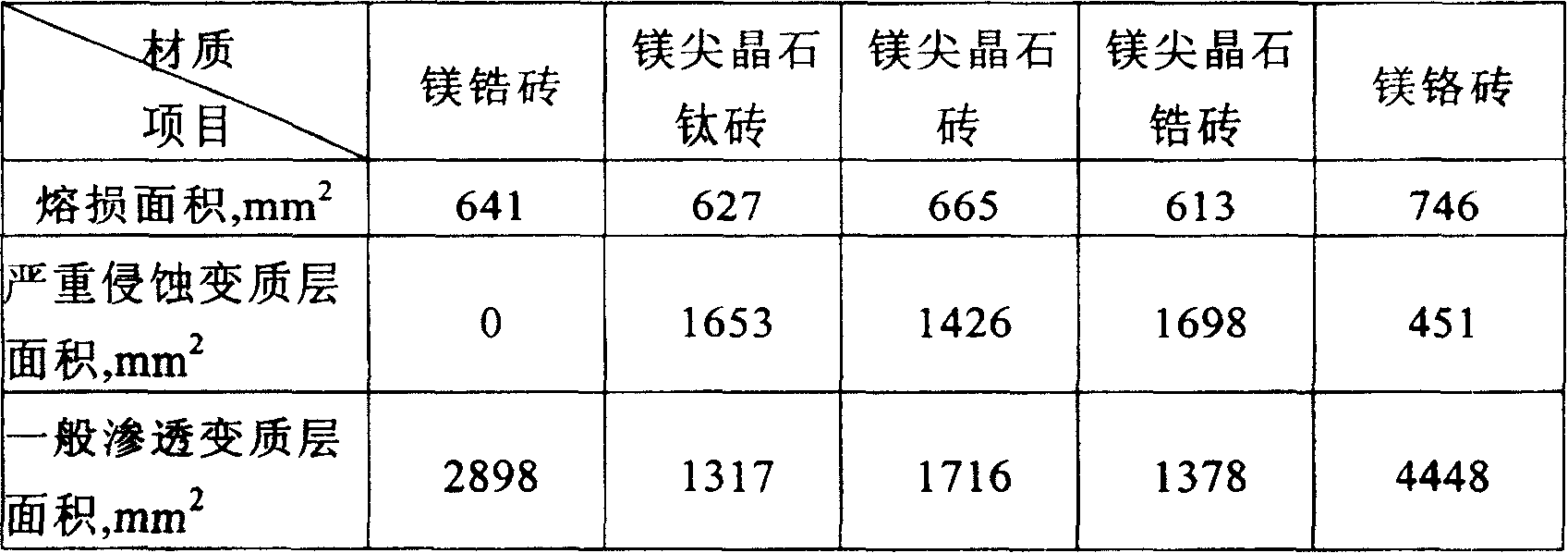

Chromium free refractory material for RH vacuum furnace lining

InactiveCN1715246AExtended service lifeStrong slag resistanceBlast furnace componentsBlast furnace detailsChromium freeZirconia silica

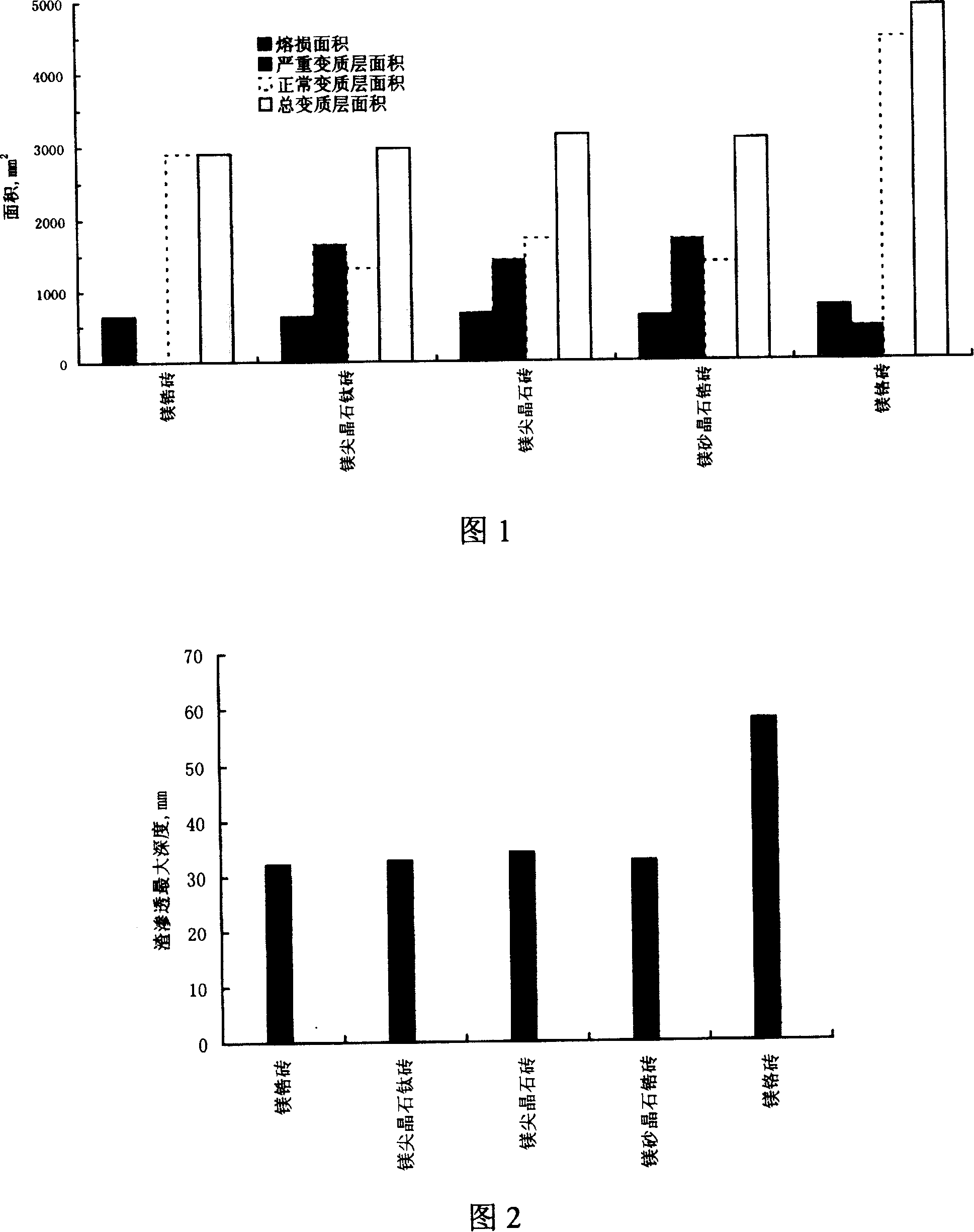

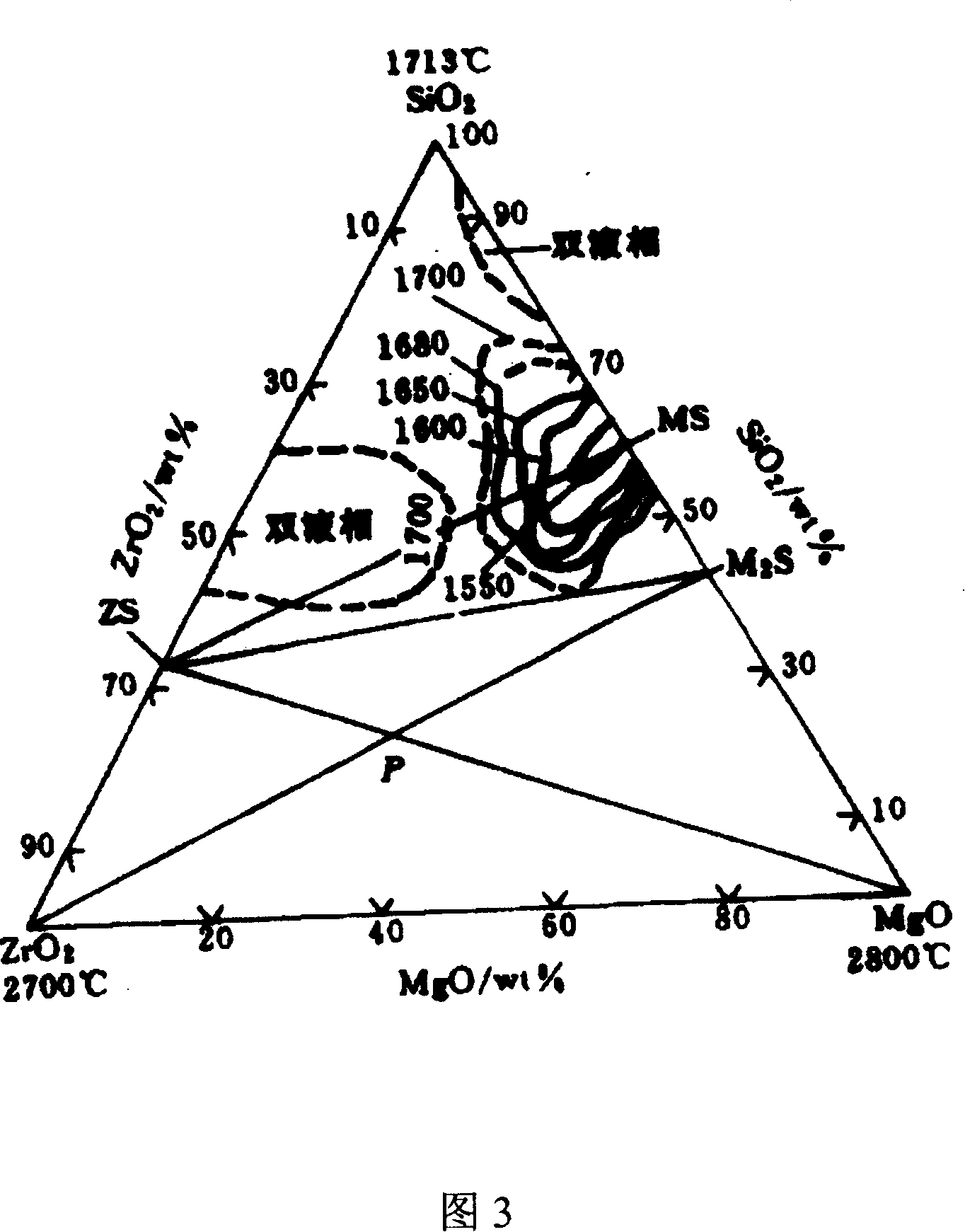

The chromium-free refractory material for RH vacuum furnace lining consists of one or several of magnetize, magnesia zirconia and magnesia zirconia silica 88-97 wt%, fine zirconia powder 1-6 wt%, fine zircon powder 0-9 wt%, and organic binding agent 1-3 wt%. It has the chemical composition of MgO 80-90 wt%, SiO2 1-4 wt%, and ZrO2 7-13 wt%. The organic binding agent is binding agent commonly for refractory material, such as sodium humate, calcium lignosulfonate, dextrin and Arabic gum. The MgO-SiO2-ZrO2 chromium-free refractory material has high slagging resistance and is significant for RH vacuum furnace to obtain long service life.

Owner:BAOSHAN IRON & STEEL CO LTD

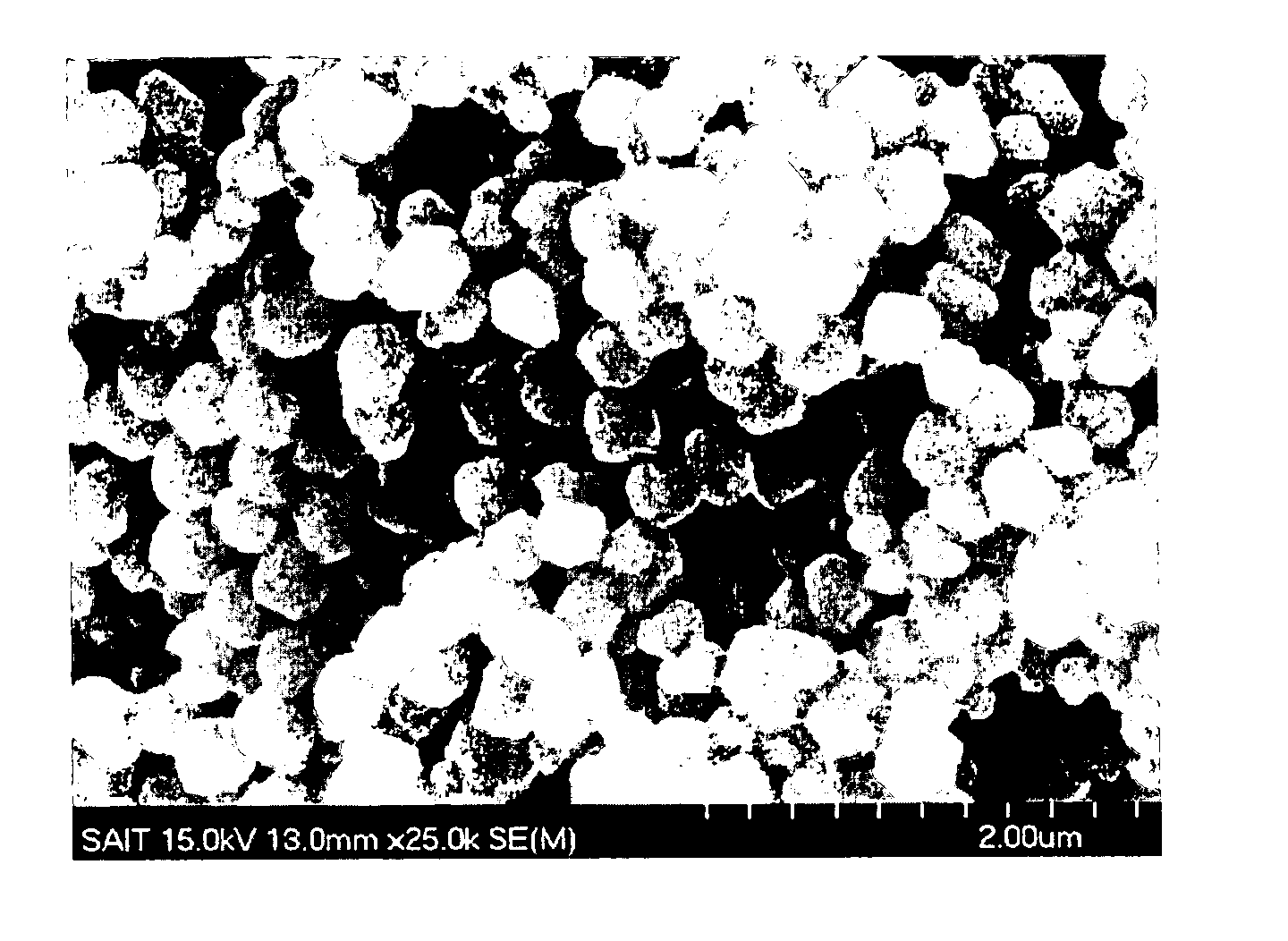

Electrode for fuel cell, method of producing the same, and fuel cell including the electrode

ActiveUS20070166600A1Excellent sustained ionic conductivityFinal product manufactureActive material electrodesZirconia silicaFuel cells

An electrode, a method of producing the same, and a fuel cell including the electrode are disclosed. The electrode includes: a support; and a catalyst layer formed on the support, the catalyst layer includes: a support catalyst; and a proton conductor having an amorphous phase greater than about 60% by weight. The proton conductor includes: at least one material from the group of B2O3, ZrO2, SiO2, WO3, and MoO3; and P2O5, the proton conductor being 0.5-60 parts by weight where the support catalyst is 100 parts by weight. The proton conductor can be synthesized at a low enough temperature so that it can be applied to the support with catalyst particles to form a catalyst layer. The coated proton conductor is in a solid state so the fuel cell is stable over time and it does not obstruct a fuel gas so that the catalyst can be more efficiently used.

Owner:SAMSUNG SDI CO LTD

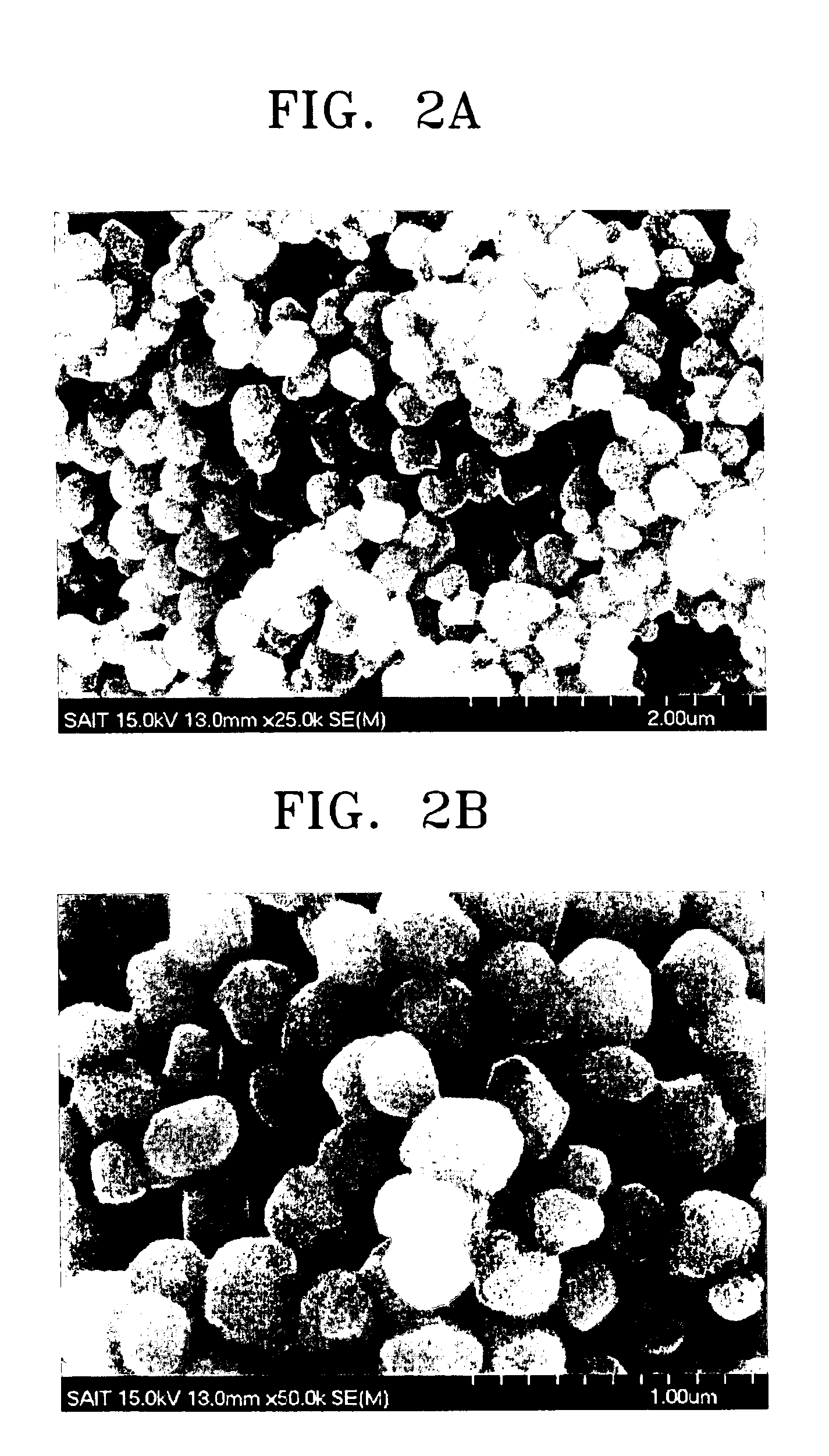

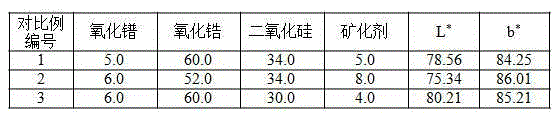

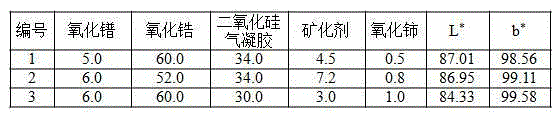

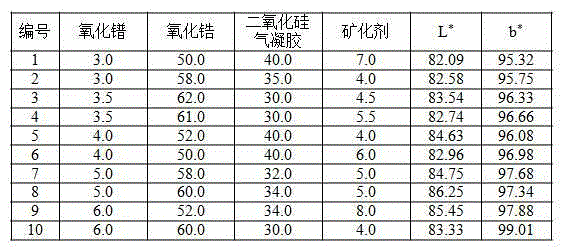

Small-particle-diameter praseodymium zirconium yellow ceramic pigment and preparation method thereof

The invention discloses a small-particle-diameter praseodymium zirconium yellow ceramic pigment which comprises the following components in percentage by weight: 3-6% of praseodymium oxide, 48-62% of zirconium oxide, 30-38% of silicon dioxide and 3-8% of a mineralizing agent, wherein the zirconium oxide selects the product which does not remove hafnium elements in the zirconium oxide production process, wherein the atom molar ratio of zirconium oxide to the hafnium elements is greater than 40:1; silicon dioxide selects silicon dioxide aerogel, wherein the BET specific surface area is 500-800 m<2> / g, the average particle diameter is 3-8 [mu]m, and the pore volume is 3-5. The praseodymium zirconium yellow pigment is small in particle diameter and relatively stable in structure, and is hard to damage in the ceramic ink preparation process. Meanwhile, the pigment is high in color strength in transparent glaze, and fine and smooth in color tone, and can be used as the high-grade ceramic pigment.

Owner:FOSHAN HUAYI CERAMIC COLORS CO LTD

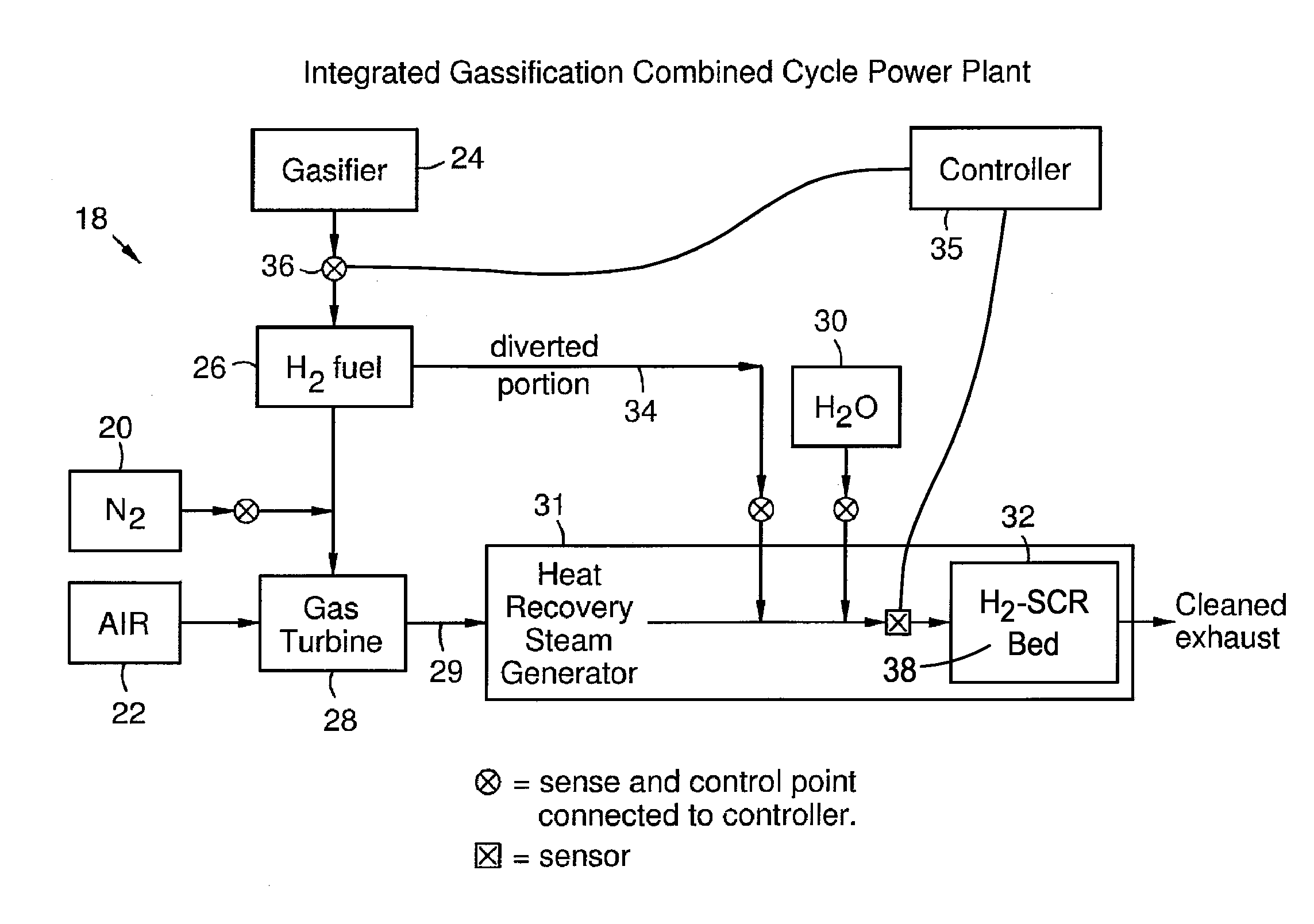

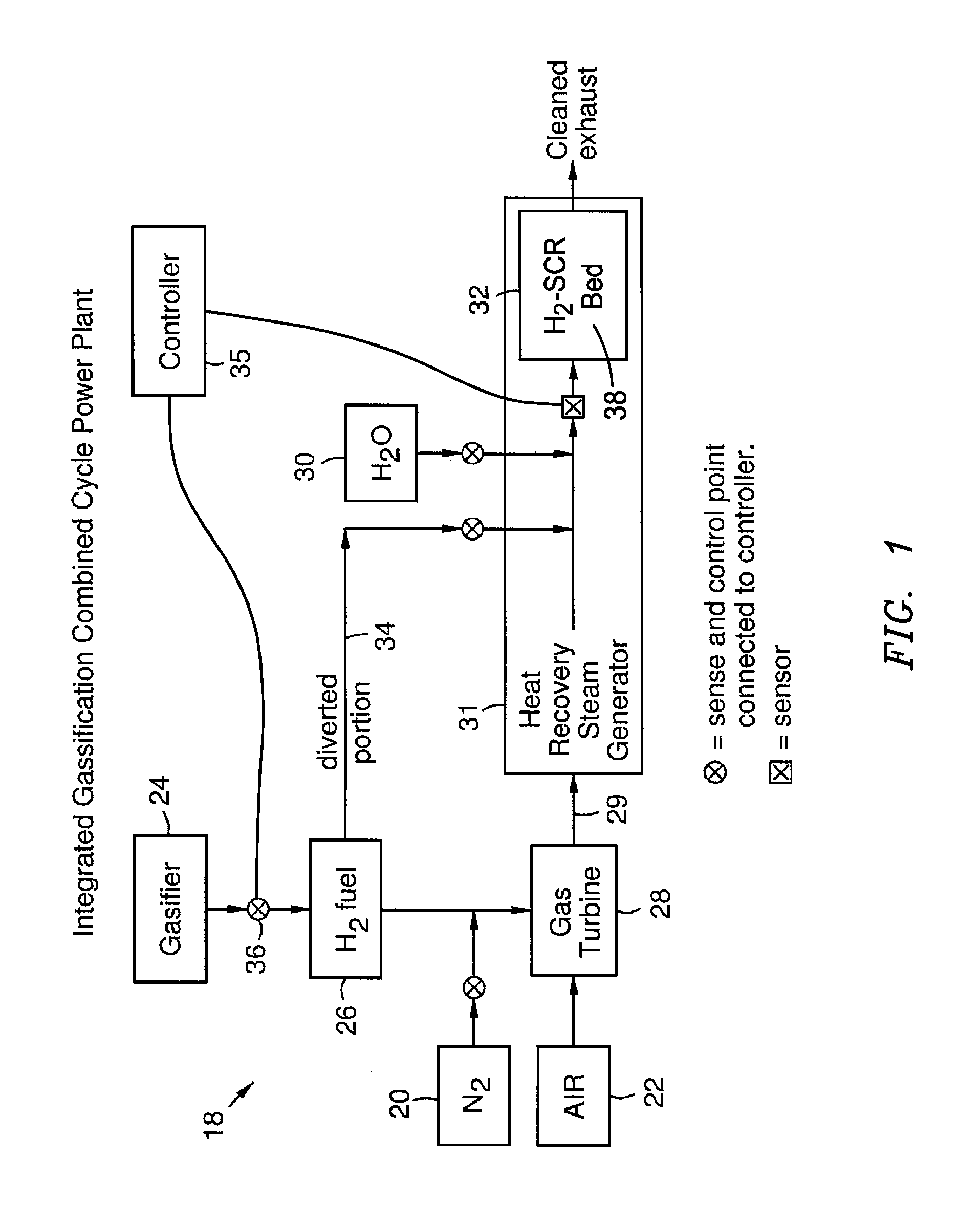

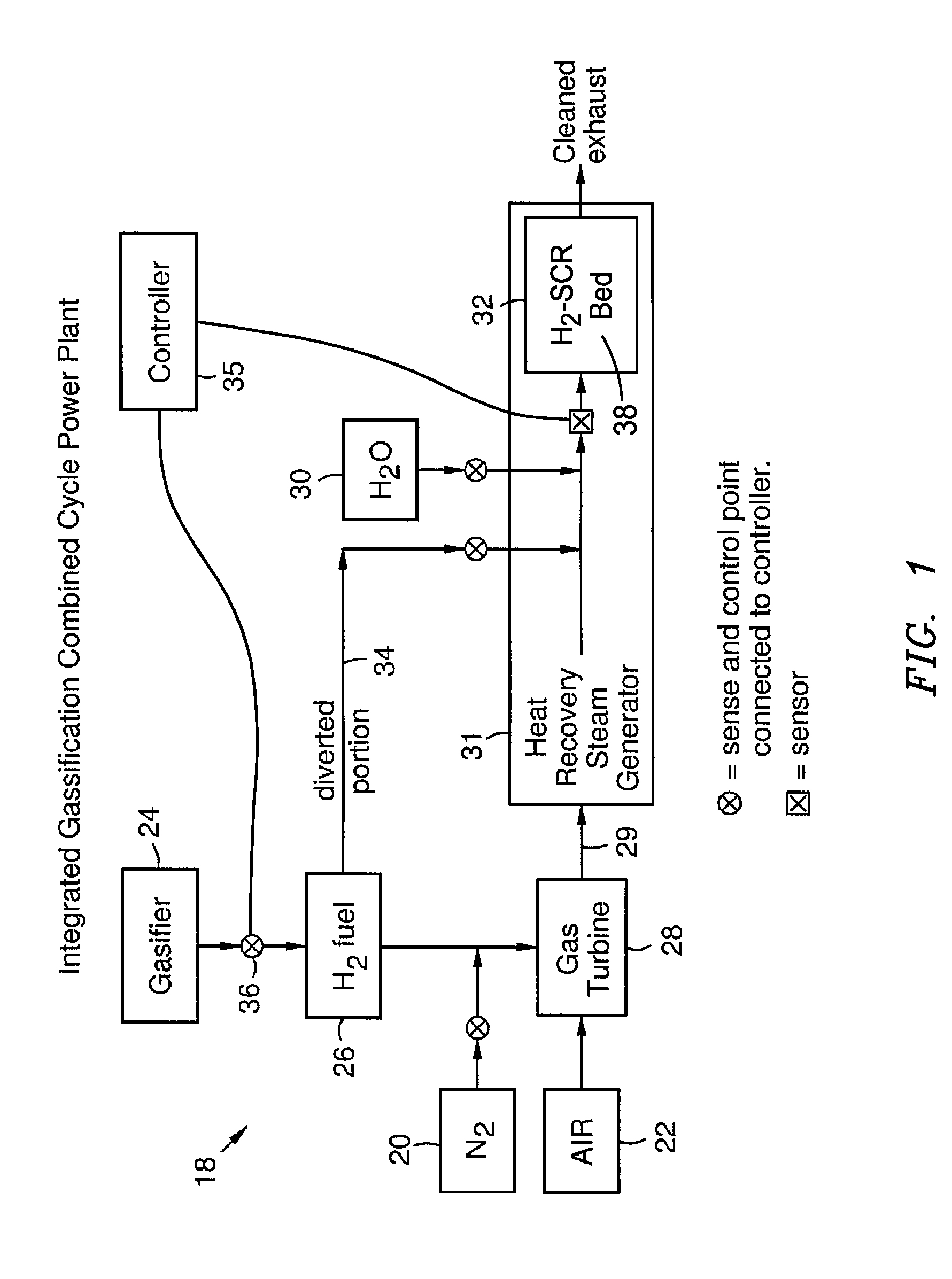

Selective Catalytic Reduction System and Process for Treating NOx Emissions Using a Palladium and Rhodium or Ruthenium Catalyst

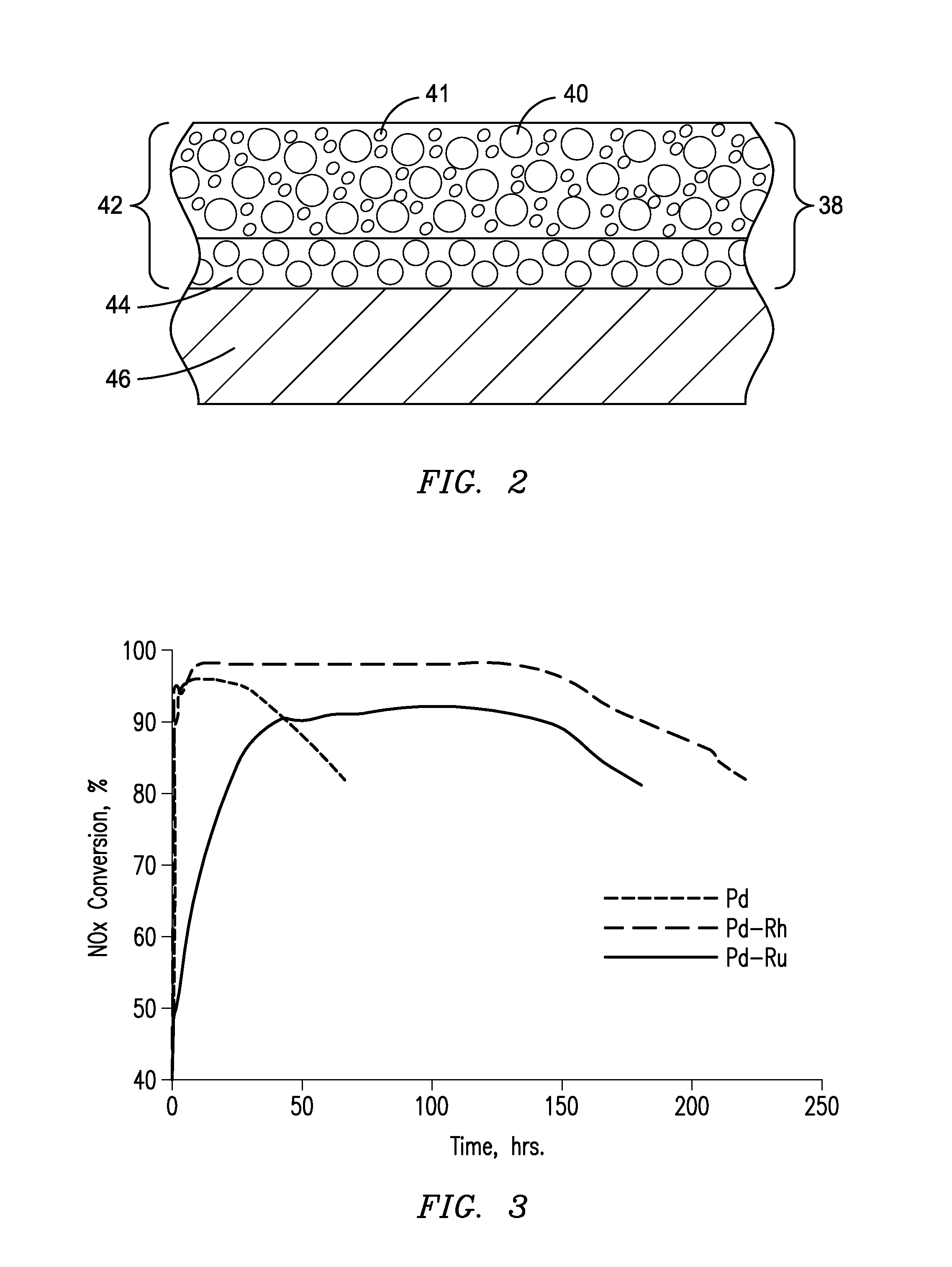

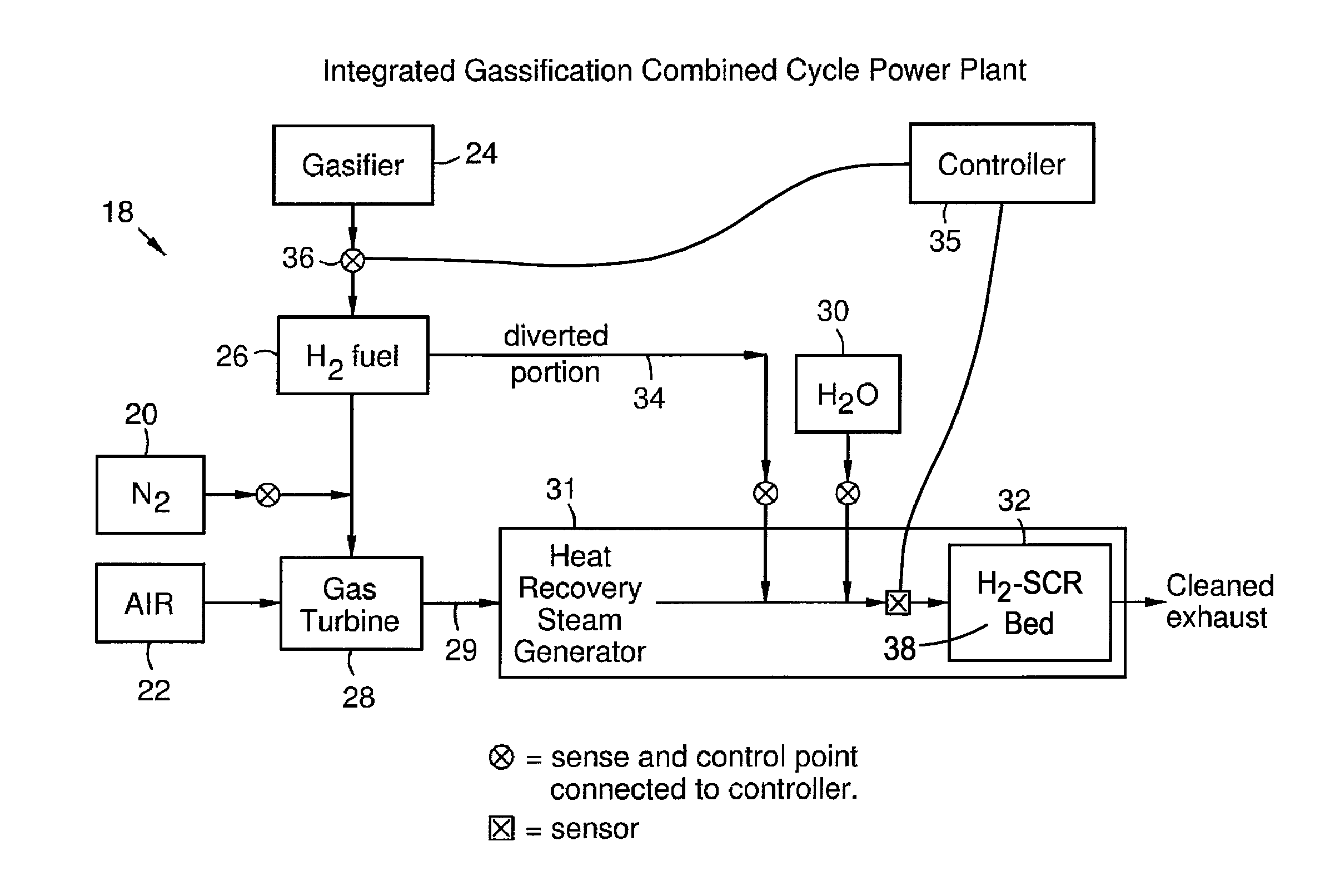

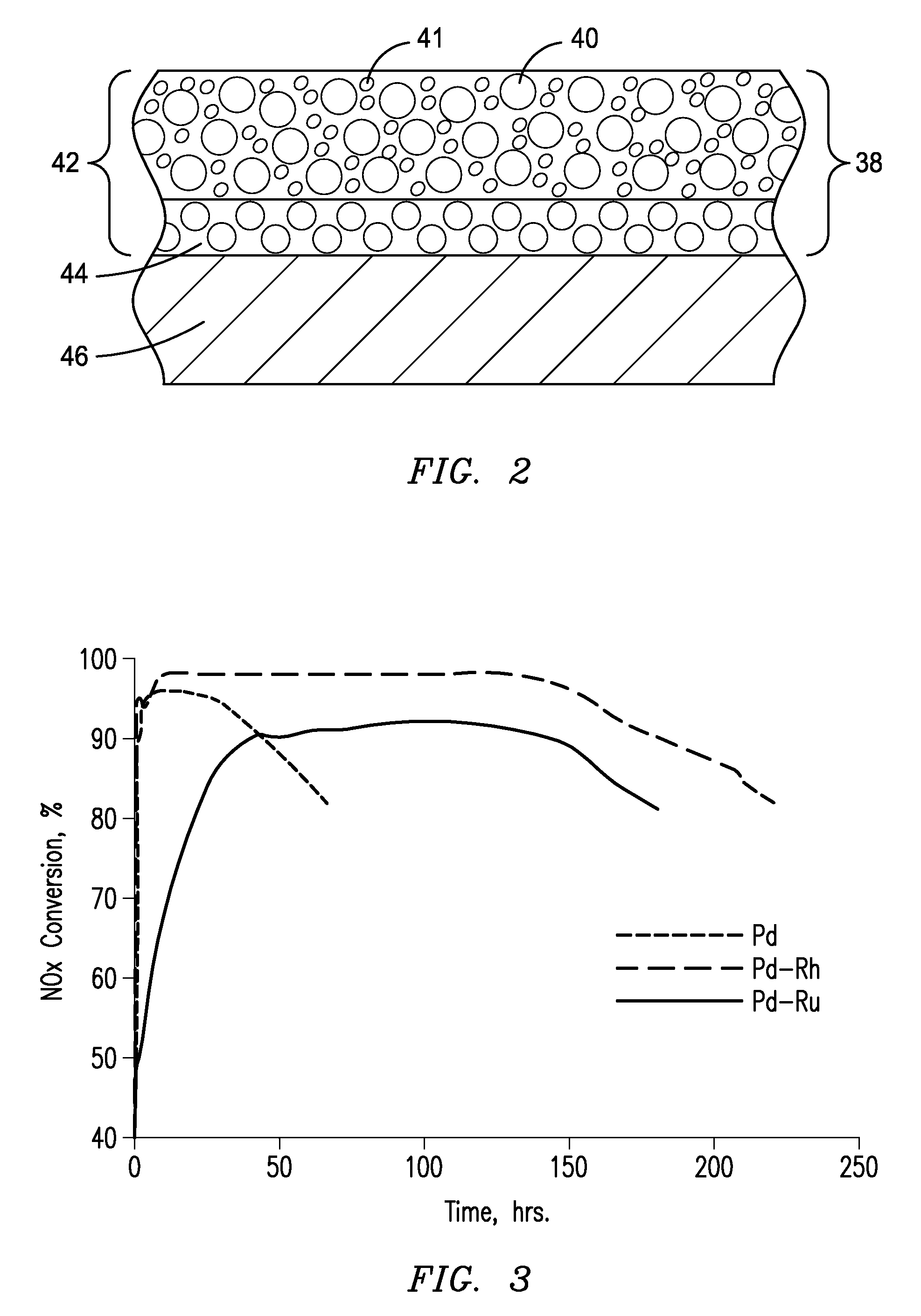

A process for the catalytic reduction of nitrogen oxides (NOx) in a gas stream (29) in the presence of H2 is provided. The process comprises contacting the gas stream with a catalyst system (38) comprising zirconia-silica washcoat particles (41), a pre-sulfated zirconia binder (44), and a catalyst combination (40) comprising palladium and at least one of rhodium, ruthenium, or a mixture of ruthenium and rhodium.

Owner:SIEMENS ENERGY INC

Selective catalytic reduction system and process for treating NOx emissions using a palladium and rhodium or ruthenium catalyst

A process for the catalytic reduction of nitrogen oxides (NOx) in a gas stream (29) in the presence of H2 is provided. The process comprises contacting the gas stream with a catalyst system (38) comprising zirconia-silica washcoat particles (41), a pre-sulfated zirconia binder (44), and a catalyst combination (40) comprising palladium and at least one of rhodium, ruthenium, or a mixture of ruthenium and rhodium.

Owner:SIEMENS ENERGY INC

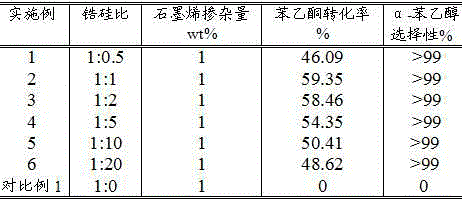

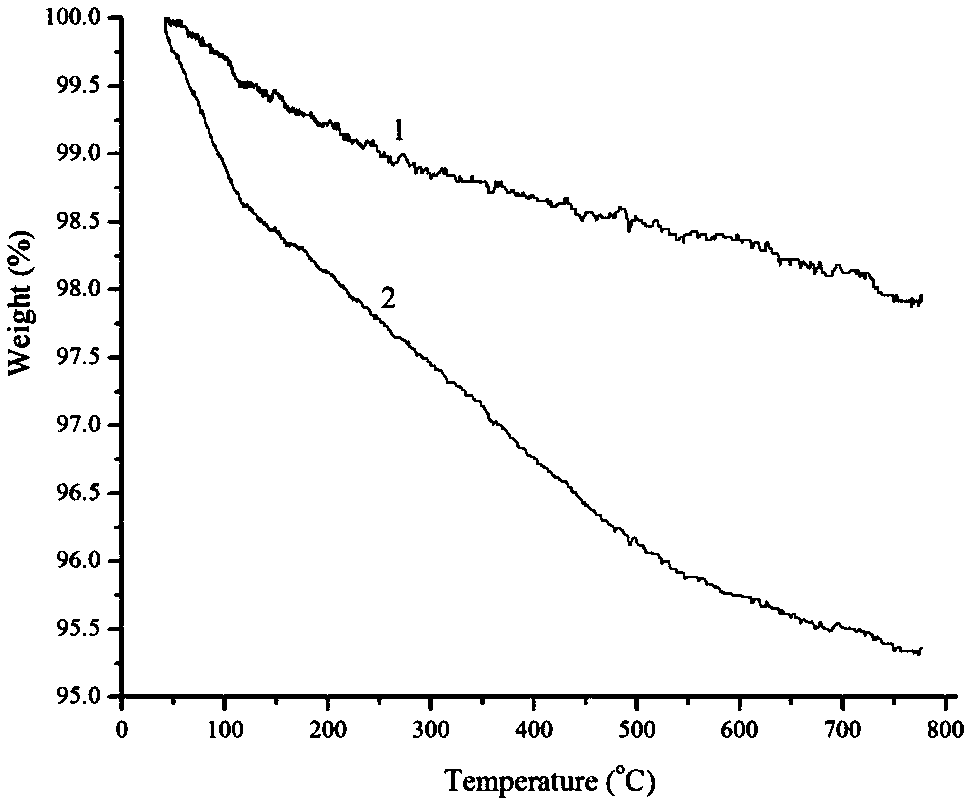

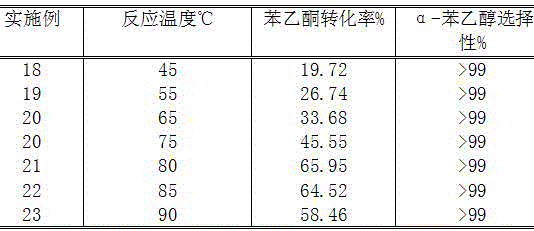

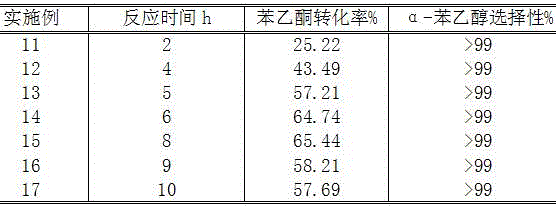

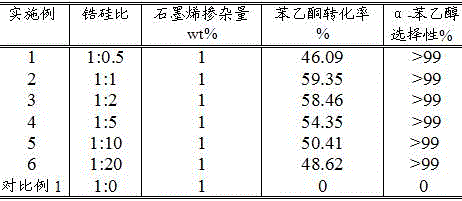

Method for preparing alpha-phenethyl alcohol by taking zirconia-silica/graphene hybrid material as catalyst

ActiveCN104529708ALower requirementMild reaction conditionsPhysical/chemical process catalystsOrganic compound preparationChemical synthesisDoped graphene

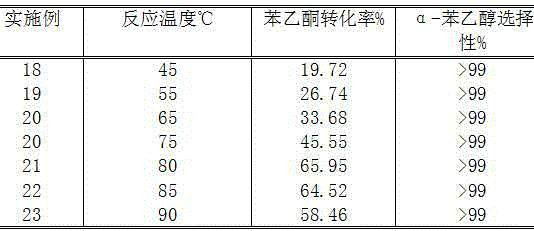

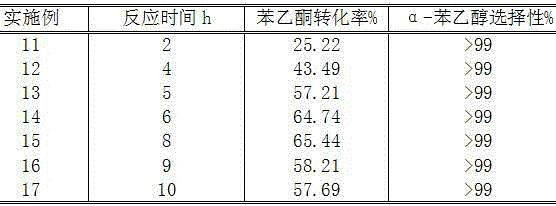

The invention discloses a method for preparing alpha-phenethyl alcohol by taking a zirconia-silica / graphene hybrid material as a catalyst and belongs to the technical field of chemical synthesis. The method comprises the following steps: by taking acetophenone as a raw material under normal pressure, taking alcohol as a hydrogen source and a solvent, and taking the zirconia-silica / graphene hybrid material as a catalyst, reacting at the reaction temperature of 45-90 DEG C for 2-10 hours, rectifying the reaction solution after the reaction is ended, taking the fraction at the temperature of 105-115 DEG C, thereby obtaining the alpha-phenethyl alcohol. According to the method disclosed by the invention, the zirconia-silica / graphene hybrid material is taken as the catalyst, the hybrid material is prepared by adding silica and doping graphene by virtue of an aerogel mode, the specific surface area and pore size of the catalyst are improved, dispersion of the surface active center is promoted, and the activity of the catalyst is increased. The catalyst is high in selectivity and high in water resistance, is easily separated in the reaction solution and can be repeatedly utilized after separation, the operation is convenient, and the preparation cost is reduced, so that the economic benefits are improved.

Owner:湖州度信科技有限公司

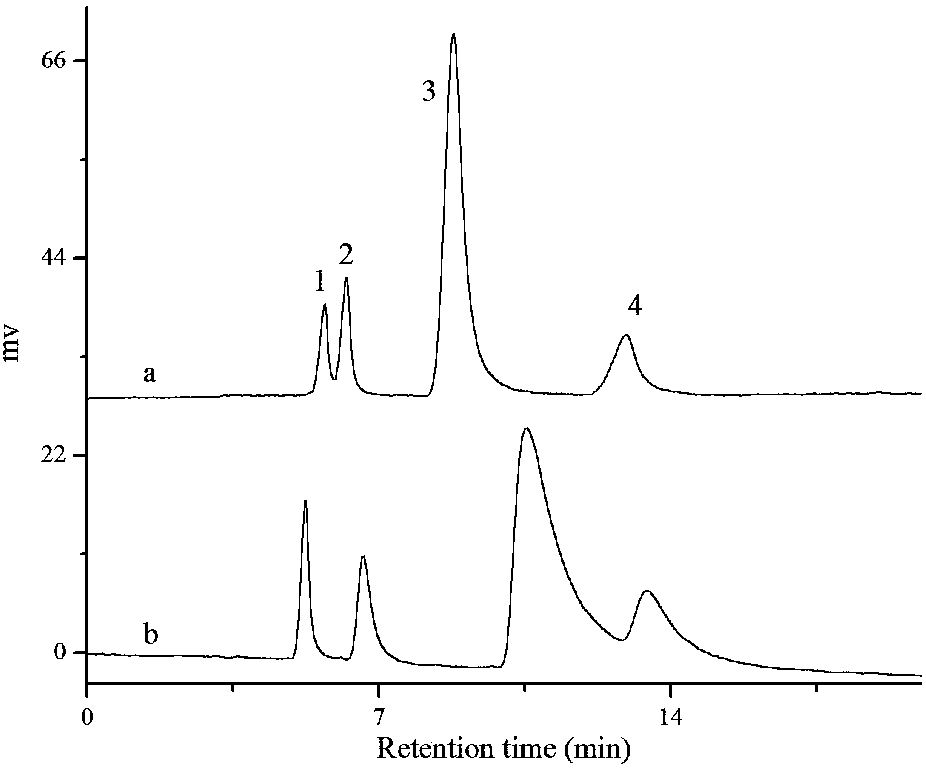

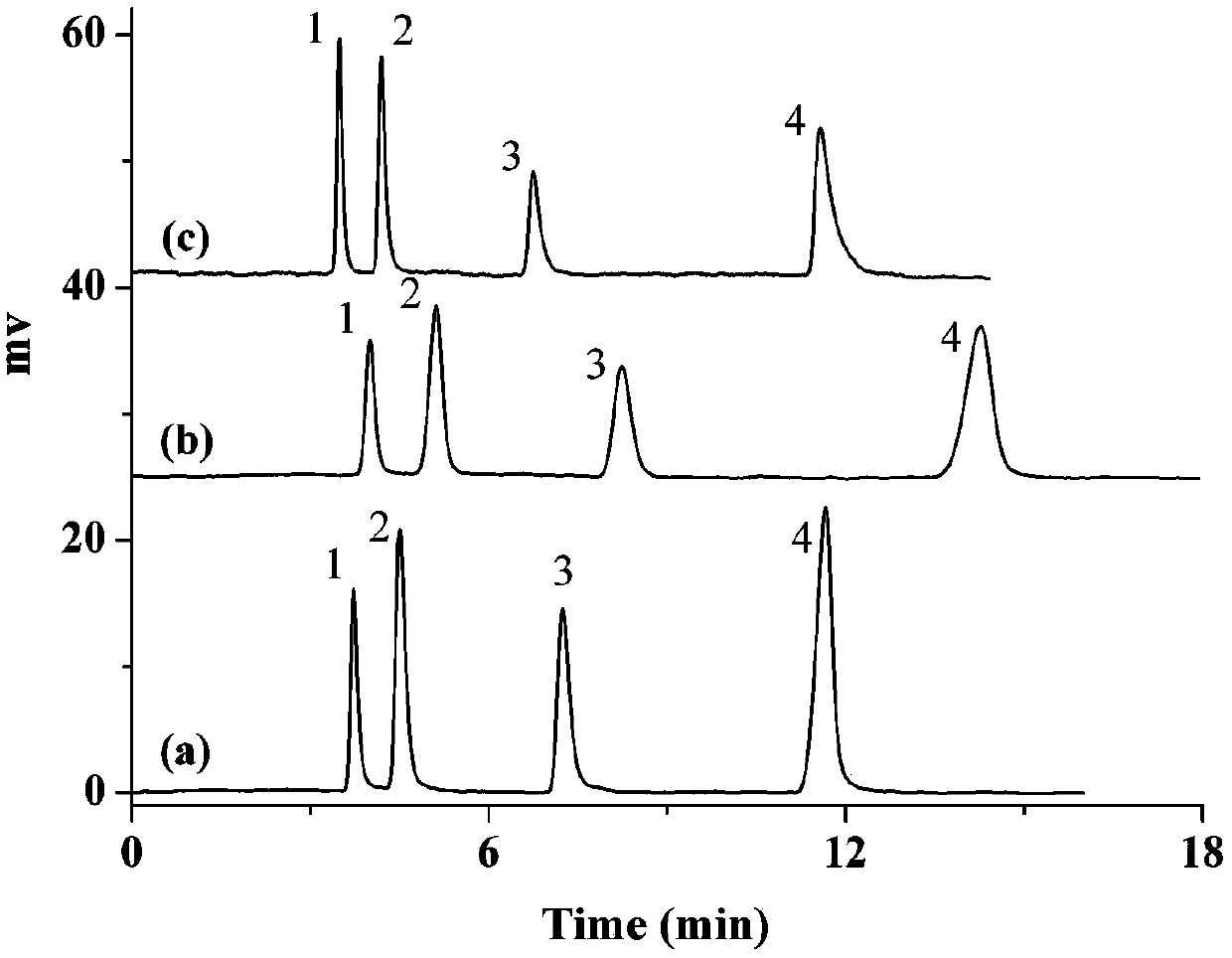

Zirconia-silica gel liquid-phase chromatographic packing and application thereof

ActiveCN108144593AImprove stabilityImprove thermal stabilityIon-exchange process apparatusOrganic compounds purification/separation/stabilisationChromatographic separationPhosphate

The invention discloses zirconia-silica gel liquid-phase chromatographic packing. According to the packing, the surface of a zirconia-silica gel matrix is modified with D-fructose-1,6-bis(dihydrogen phosphate). Compared with the conventional adenosine monophosphate modified zirconia-silica gel chromatographic packing, the packing provided by the invention has a better chromatographic separation property under a hydrophilic action mode. Compared with the prior silica-gel-matrix liquid-phase chromatographic packing, the material provided by the invention has good chemical stability, can be stably used in a pH range of 1-14, and has a better application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

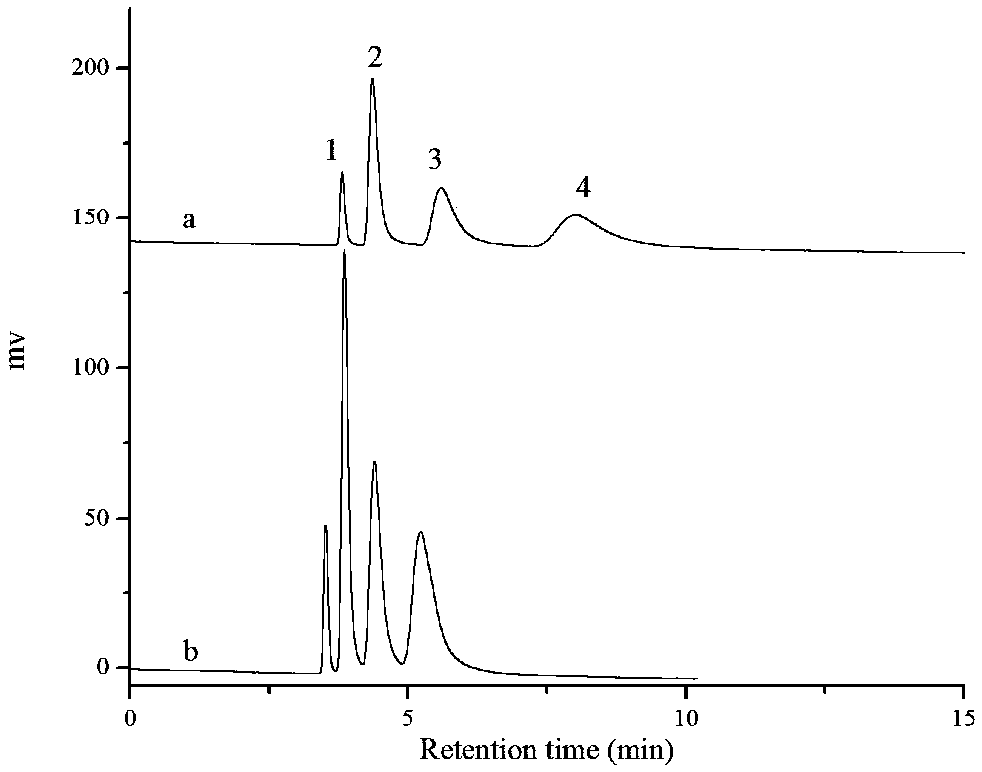

Porous metal oxide-silica gel liquid chromatogram filling material, and preparation method thereof

ActiveCN109847729AStrong adsorption to avoidSolve the problem of low column efficiencyOther chemical processesComponent separationChromatographic separationPhosphate

The invention discloses a porous metal oxide-silica gel liquid chromatogram filling material, and a preparation method thereof. According to the preparation method, the surface of a zirconia-silica gel, titanium oxide-zirconia-silica gel, or titanium oxide-silica gel matrix is modified with D-glucose-6-phosphate groups or D-fructose-1, 6-diphosphate groups, and fosfomycin sodium is adopted for endcapping processing. Compared with conventional adenosine monophosphate group or fructose bisphosphate group modified zirconia-silica gel chromatogram filling materials, the advantages are that: at hydrophilic effect mode, the porous metal oxide-silica gel liquid chromatogram filling material possesses better chromatogram separation performance; compared with conventional silica gel surface saccharide group modification method, the preparation method is simpler, and is friendly to the environment; the silica gel microspheres modified with metal oxides such as zirconia and titanium oxide can beused steadily at a pH value range of 1 to 14; and the application prospect is promising.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

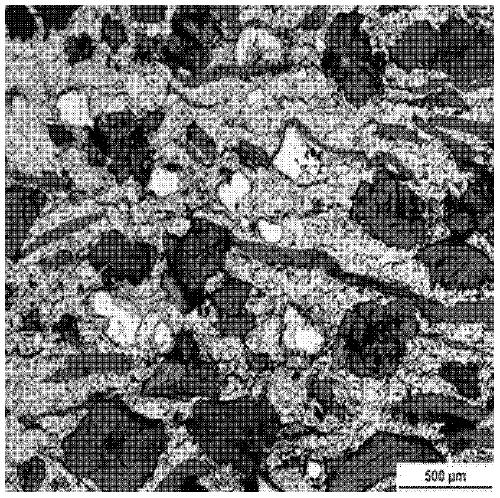

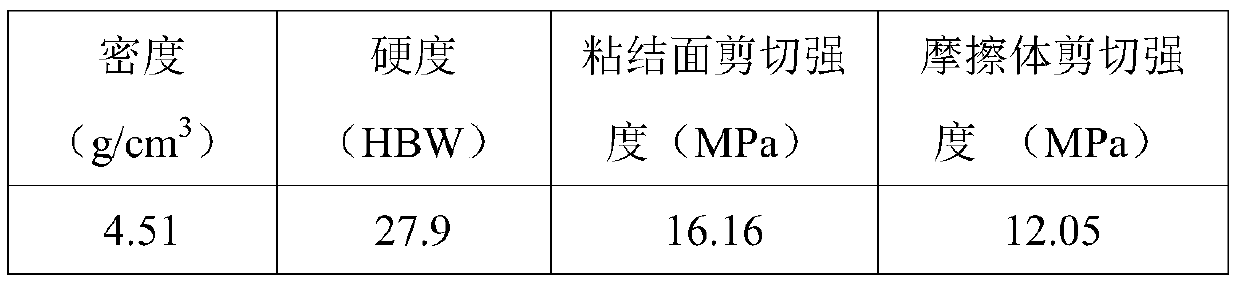

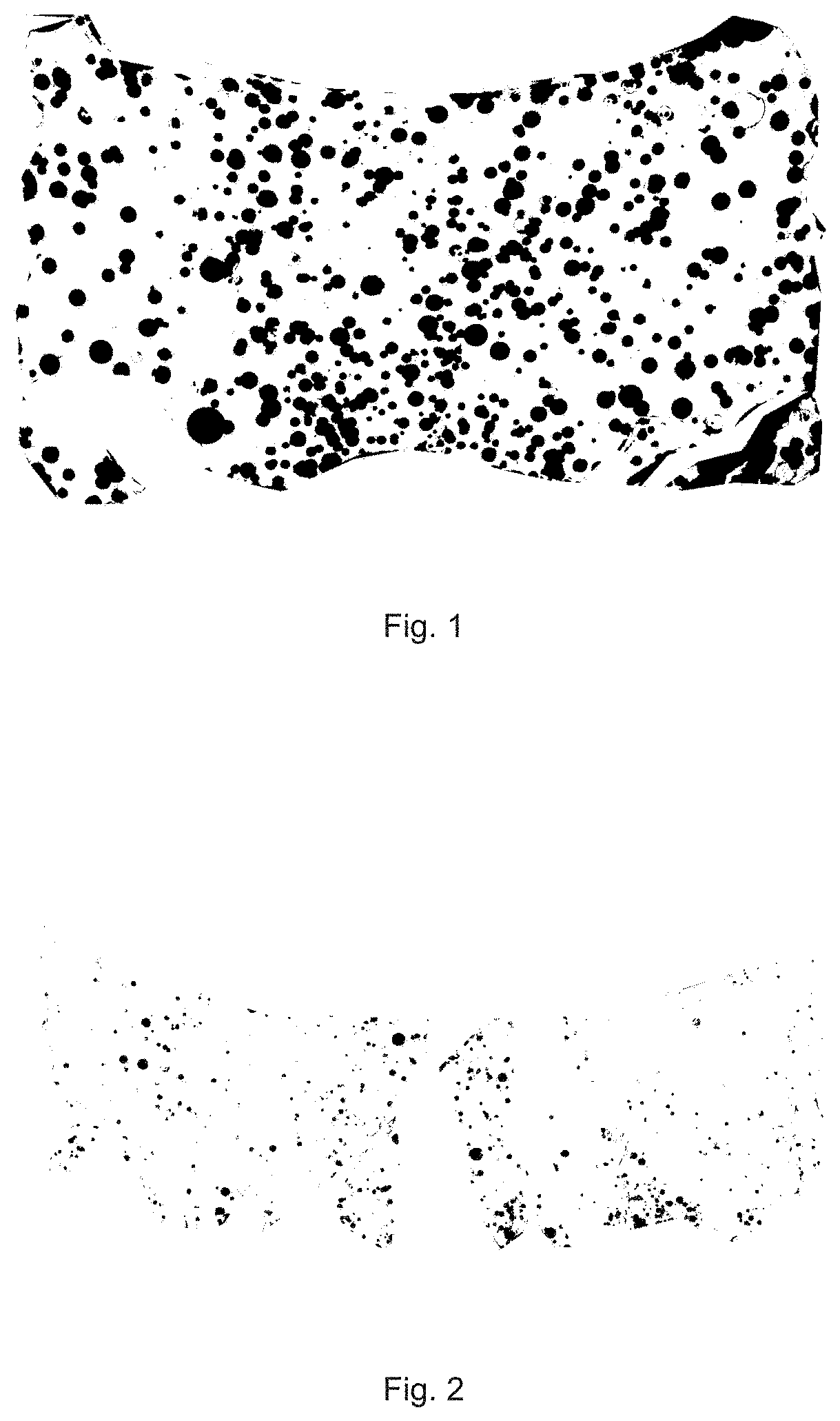

Copper-based powder metallurgy friction material for heavy-duty vehicle dry clutch and preparation method thereof

ActiveCN110102754BGood application effectGive full play to the synergistic effectTransportation and packagingMetal-working apparatusGraphite particleFerrochrome

A copper-based powder metallurgy friction material for a dry clutch of a heavy-duty vehicle and a preparation method thereof. The matrix components of the friction material are copper and iron, and the lubricating components are graphite particles, flake graphite, molybdenum disulfide and petroleum coke. The friction components are ferrochromium, zirconia and silicon dioxide, and the strengthening components are tin. The weight percent of the friction material composition is: copper powder 50%-60%, iron powder 1-10%, graphite particle powder 5-20%, flake graphite 1-5%, molybdenum disulfide powder 1-6%, petroleum Coke powder 1‑15%, ferrochrome powder 3‑9%, zirconia 3‑9%, silicon dioxide 1‑5%, tin powder 1‑4%. The preparation method of the friction material is as follows: preparing a mixture according to the composition of the powder metallurgy friction material, mixing the mixture evenly in a V-type mixer and pressing it into shape, and then sintering together with a copper-plated steel back to obtain a copper-based powder Metallurgical friction materials. The copper-based powder metallurgy friction material has a high and stable friction coefficient and excellent wear resistance.

Owner:CENT SOUTH UNIV

Zircon-based sintered concrete

ActiveUS20190367414A1Raise the possibilityCreep behavior at high temperatures is thereby improvedGlass furnace apparatusGlass forming apparatusZirconia silicaChemical composition

The present invention relates to a sintered concrete having the following mean chemical composition, as mass percentages on the basis of the oxides and for a total of 100%:ZrO2: 55 to 70%,SiO2: 25 to 40%,P2O5: 0.2 to 9.0%,Al2O3: 0.5 to 7.0%,CaO: >0.2%,CaO+MgO+B2O3+Fe2O3: 0.2 to 10.0%,MgO+B2O3+Fe2O3: ≤7.5%,B2O3+MgO: ≤4.5%,ZrO2+SiO2+P2O5+Al2O3+CaO+MgO+B2O3+Fe2O3: ≥95.0%,and containing more than 70% of zircon, as a mass percentage on the basis of the mass of the crystalline phases.

Owner:SAINT GOBAIN CENT DE RES & DEVS & DETUD EUROEN

Zirconia particles

Zirconia particles, methods of making zirconia particles, composite materials that contain the zirconia particles, methods of making the composite materials, and zirconia sols that contain the zirconia particles are described. The zirconia particles are substantially non-associated and have an average size no greater than 50 nanometers and may contain yttrium. The zirconia particles are prepared by a method that includes two separate hydrothermal treatments.

Owner:3M INNOVATIVE PROPERTIES CO

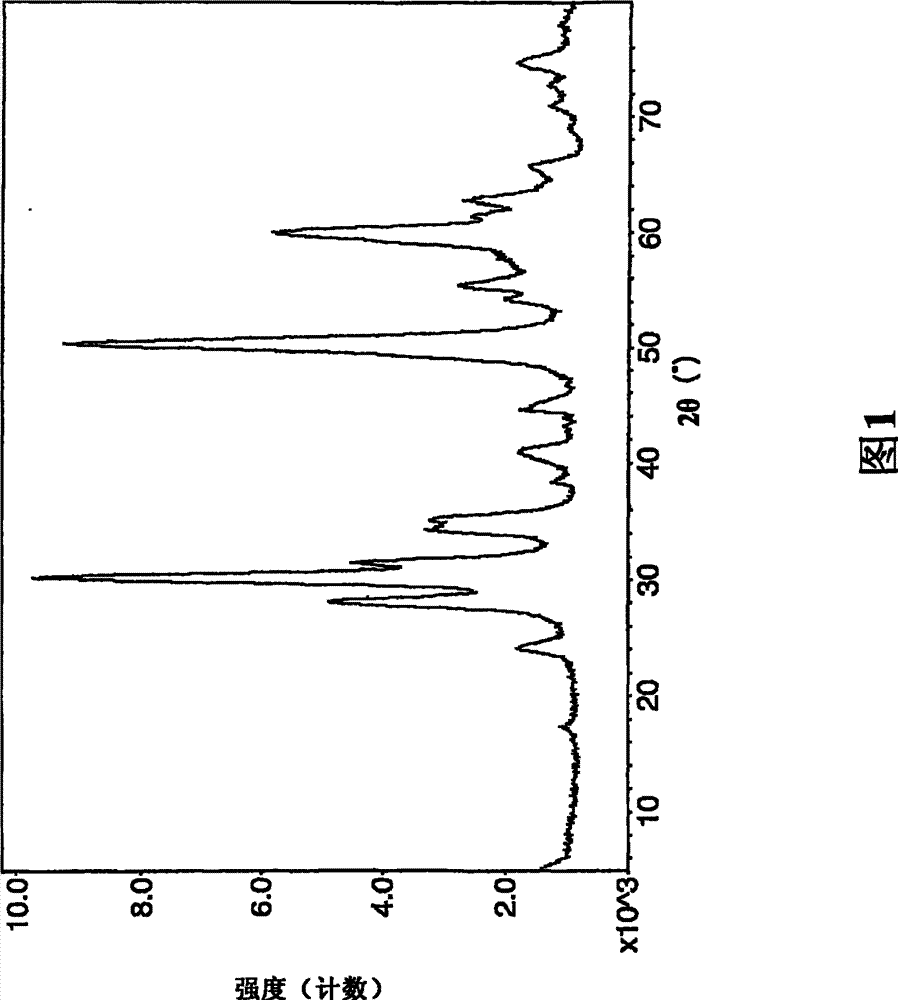

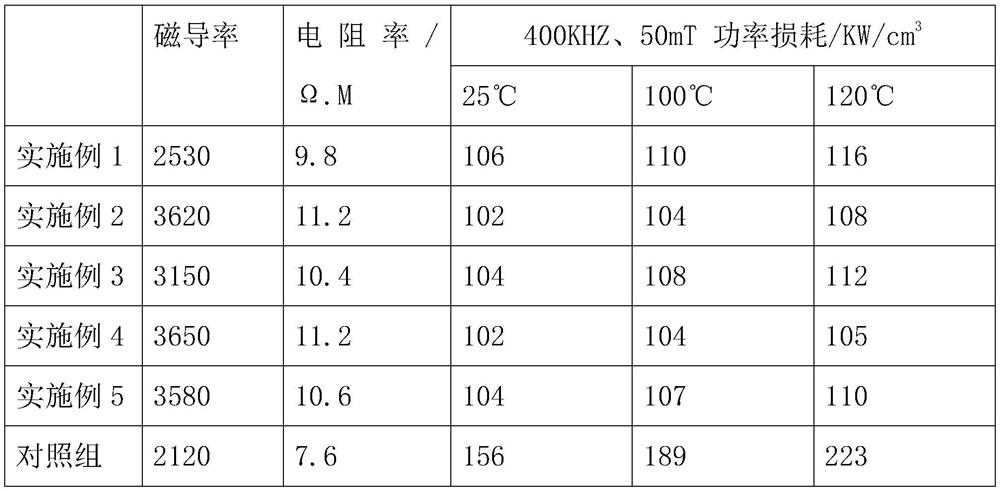

A kind of high frequency, wide temperature and low loss soft ferrite material and preparation method thereof

ActiveCN112408970BHigh resistivityReduce lossInorganic material magnetismCopper oxideManganese oxide

The invention discloses a high-frequency, wide-temperature and low-loss soft ferrite material, and in particular relates to the technical field of soft ferrite materials. The rest are manganese oxide; the auxiliary ingredients include calcium carbonate, cobalt trioxide, niobium pentoxide, titanium dioxide, zirconium dioxide, silicon dioxide, copper oxide, tantalum pentoxide and boron trioxide. The invention can effectively improve the resistivity inside the soft ferrite material, thereby reducing the eddy current loss of the magnetic core material during use, and titanium dioxide and tantalum pentoxide have the functions of reducing the loss peak and adjusting the temperature and frequency range at which the peak appears. , which can reduce the residual loss of the magnetic core material during use, and copper oxide can reduce Fe in the magnetic core material 2+ The content of ions can increase the resistivity of the magnetic core material, reduce the loss of the magnetic core material, and can meet the needs of people.

Owner:NANTONG GUANYOUDA MAGNET

Alumina ceramic for new energy automobile

The invention discloses aluminum oxide ceramic for a new energy automobile, which comprises the following components in percentage by weight: 90 to 95 percent of aluminum oxide, 2 to 5 percent of silicon carbide whisker, 2 to 5 percent of yttrium-stabilized zirconium oxide, 2 to 5 percent of silicon dioxide, 2 to 5 percent of titanium dioxide, 2 to 5 percent of nickel oxide and 1 to 5 percent of strontium carbonate. The catalyst comprises the following components in percentage by weight: 1 to 2wt% of silicon dioxide, 0.5 to 1wt% of titanium dioxide, 0.1 to 0.3 wt% of nickel oxide and 0.3 to 0.8 wt% of strontium carbonate. By adjusting the formula of the aluminum oxide ceramic, especially by adding the silicon carbide whiskers, the aluminum oxide ceramic piece prepared from the new material has the strength of 95 aluminum oxide ceramic and also has excellent explosion-proof performance. The material has good adsorbability to a coating on the surface of ceramic, and is an ideal material for high-power and high-current ceramic tubes.

Owner:冷水江市润辰新材料有限公司

A kind of preparation method of matte pet release paper

ActiveCN110904733BPromote absorptionGood matte effectCoatings with pigmentsPaper/cardboardZirconia silicaUltraviolet lights

The invention discloses a method for preparing matte PET release paper. First, fast-growing pine wood is used to obtain glassine base paper through the steps of pulp preparation, papermaking, and paper forming, and then a layer of PET film is coated on the upper and lower surfaces of the glassine base paper. Then, one side of the PET film is coated with a layer of matte agent, and the other side is coated with a layer of release agent to obtain a matte PET release paper. The matte PET release paper of the present invention not only has a very good absorption effect on ultraviolet light by adding zirconium dioxide, silicon dioxide and ultraviolet light absorbing agent to the matte agent, but also micron-sized zirconium dioxide and silicon dioxide It has a very good refraction effect on ultraviolet rays of different wavelengths, so the obtained matte PET release paper has a very good matte effect. The matte PET release paper prepared by the invention not only has a good matte effect, but also prevents the release agent on the release surface from being easily transferred to the matte surface after curling, and does not cause local sagging.

Owner:江苏双冠新材料科技有限公司

Metal oxide/silicon dioxide-coated quantum dot and method for preparing same

ActiveUS10696900B2Avoid damageEasy to makeMaterial nanotechnologyNanoopticsSilicon oxideSilicon dioxide

A metal oxide / silicon dioxide-coated quantum dot and a preparation method thereof are provided. The metal oxide / silicon dioxide is selected from aluminum oxide / silicon dioxide, zirconium dioxide / silicon dioxide, titanium dioxide / silicon dioxide or zinc oxide / silicon dioxide, and the content of the metal oxide / silicon dioxide in the metal oxide / silicon dioxide-coated quantum dot is 1 wt % to 98 wt %. The metal oxide / silicon dioxide-coated quantum dot is prepared by one of a sol-gel method and a pyrolysis method.

Owner:LI LIANG

Preparation method of matte PET release paper

ActiveCN110904733APromote absorptionGood matte effectCoatings with pigmentsPaper/cardboardZirconia silicaPapermaking

The invention discloses a preparation method of matte PET release paper. The preparation method includes: firstly, carrying out pulp blending, papermaking, paper forming and other steps on fast-growing pine to obtain glassine base paper, then laminating a layer of PET film respectively on the upper surface and lower surface of the glassine base paper, then coating one side of the PET film with a layer of matte agent, and coating the other surface side of the PET film with a layer of release agent so as to obtain the matte PET release paper. According to the invention, by adding zirconium dioxide, silicon dioxide and an ultraviolet absorber into the matte agent, a very good absorption effect on ultraviolet rays can be achieved, also micron-sized zirconium dioxide and silicon dioxide have very good refraction effect on ultraviolet rays of different wavelengths, so that the obtained matte PET release paper has a very good matte effect. The matte PET release paper prepared by the preparation method disclosed by the invention has a good matte effect, and also after curling, the release agent on the release surface does not easily transfer to the matte surface, and local sagging phenomenon cannot be caused.

Owner:江苏双冠新材料科技有限公司

Anti-corrosion photo album and production process thereof

ActiveCN112810352AImprove corrosion resistanceImprove mechanical propertiesAnti-corrosive paintsAlbumsSilicic acidSilanes

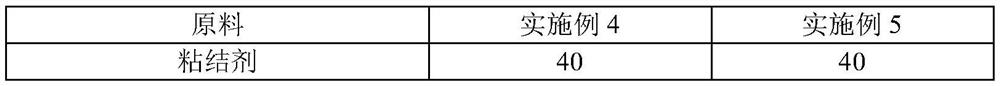

The invention relates to the technical field of photo album manufacturing, and particularly discloses an anti-corrosion photo album and a production process thereof. The anti-corrosion photo album comprises a photo album cover, the photo album cover is coated with an anti-corrosion layer, and the anti-corrosion layer is mainly prepared from, by weight, 30-50 parts of a binder, 15-20 parts of a filler, 3-5 parts of a coupling agent and 0.5-2 parts of a defoaming agent. The binder comprises cyanoacrylate and chitosan, the filler comprises zinc silicate, titanium dioxide, barium phosphate, zirconium oxide and silicon dioxide, the coupling agent is a silane coupling agent, and the defoaming agent is prepared from dimethyl silicone oil and polyether according to the mass ratio of (3-5): (2-3). The anti-corrosion photo album has the advantage of being good in anti-corrosion performance.

Owner:河南印爱文化艺术有限公司

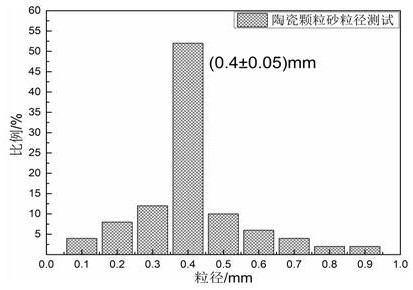

High-air-permeability spherical ceramic particle sand for casting mold core and preparation method and application of high-air-permeability spherical ceramic particle sand

ActiveCN114736008AHigh sphericityHigh dimensional accuracyFoundry mouldsFoundry coresThermal dilatationZirconia silica

The invention provides high-air-permeability spherical ceramic particle sand for casting a mold core and a preparation method and application of the high-air-permeability spherical ceramic particle sand. The spherical ceramic particle sand is prepared from, by mass, 5%-7% of zirconium oxide, 6%-8% of silicon dioxide, 60%-62% of aluminum oxide, 6%-9% of magnesium oxide, 2%-4% of yttrium oxide, 3%-4% of modifier, 2%-3% of dispersing agent and the balance bentonite. The ceramic particle sand is high in sphericity degree and small in thermal expansion coefficient, the use amount of a binder needed when the ceramic particle sand is used for casting a mold core is small, and the size precision of the mold core and an aluminum alloy casting is higher; the ceramic particle sand is good in heat resistance and high in abrasion resistance, can be repeatedly used for multiple times through heating, mixing and grinding during casting production, and is low in batch use cost and lower in environmental pollution.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

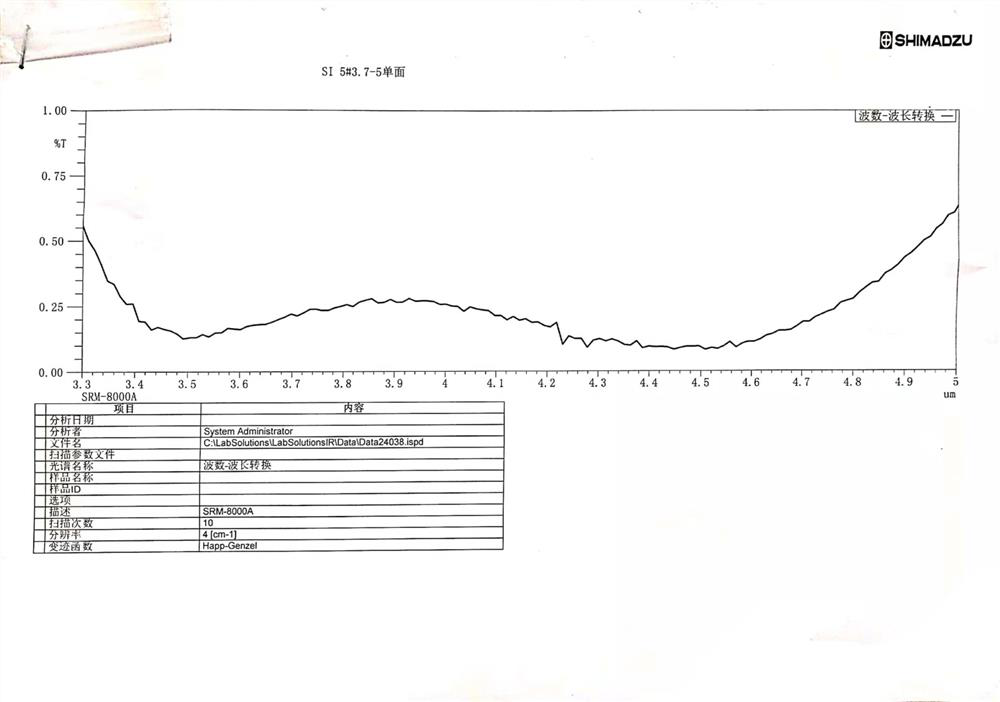

Manufacturing method of antireflection film on outer surface of infrared optical window and optical lens

PendingCN114438452AHydrophobicHigh hardnessVacuum evaporation coatingSputtering coatingFilm baseOptical thin film

The invention discloses a preparation method of an antireflection film on the outer surfaces of an infrared optical window and an optical lens, and relates to the technical field of optical film preparation. After an antireflection film substrate is cleaned, a power supply of a coating machine is turned on, a mechanical pump is started, and a pre-valve is opened to extract waste gas in the coating machine; high vacuum pumping is conducted on the anti-reflection film base body, when the frequency reaches 100 Hz, the low valve is closed, the pre-valve and the high valve are sequentially opened, and the vacuum is recovered to reach 6.0-6.5 E <-3 > Pa; heating the antireflection film substrate in a vacuum chamber, performing airflow control on the vacuum chamber, respectively putting zirconium oxide, silicon dioxide and titanium dioxide for coating into three crucibles of a coating machine, starting evaporation coating, and preserving heat after coating is completed; and finally, the coating machine and the equipment power supply are turned off, and the part is taken out after waiting for 12-16 hours. According to the invention, the requirement of cold reflection of an optical system is finally met, and the optical window can be wiped by absorbent cotton after being subjected to environmental corrosion of a salt spray test and a mould test for a long time, so that the optical window and the appearance meet the requirements.

Owner:洛阳微米光电技术有限公司

Biological ceramic gutta-percha point

PendingCN114099351AGood biocompatibilityImprove the development effectImpression capsDentistry preparationsPolymer scienceBiocompatibility

The invention relates to the technical field of gutta-percha points, in particular to a biological ceramic gutta-percha point. The biological ceramic gutta-percha tip comprises the following components: natural rubber, zinc oxide, barium sulfate, zirconium oxide, silicon dioxide, an antioxidant, a bioactive material and a pigment. The biological ceramic gutta-percha tip has good biocompatibility, the micro-gap and micro-leakage phenomena between the gutta-percha tip and filling paste are avoided, the developing effect is improved, and the brightness is improved by 20%; the bone regeneration inducing function is realized;

Owner:CHANGZHOU UNITED DENTAL MEDICAL INSTR CO LTD

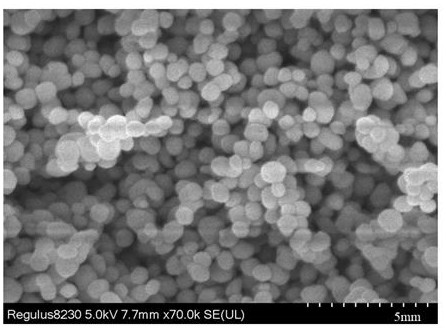

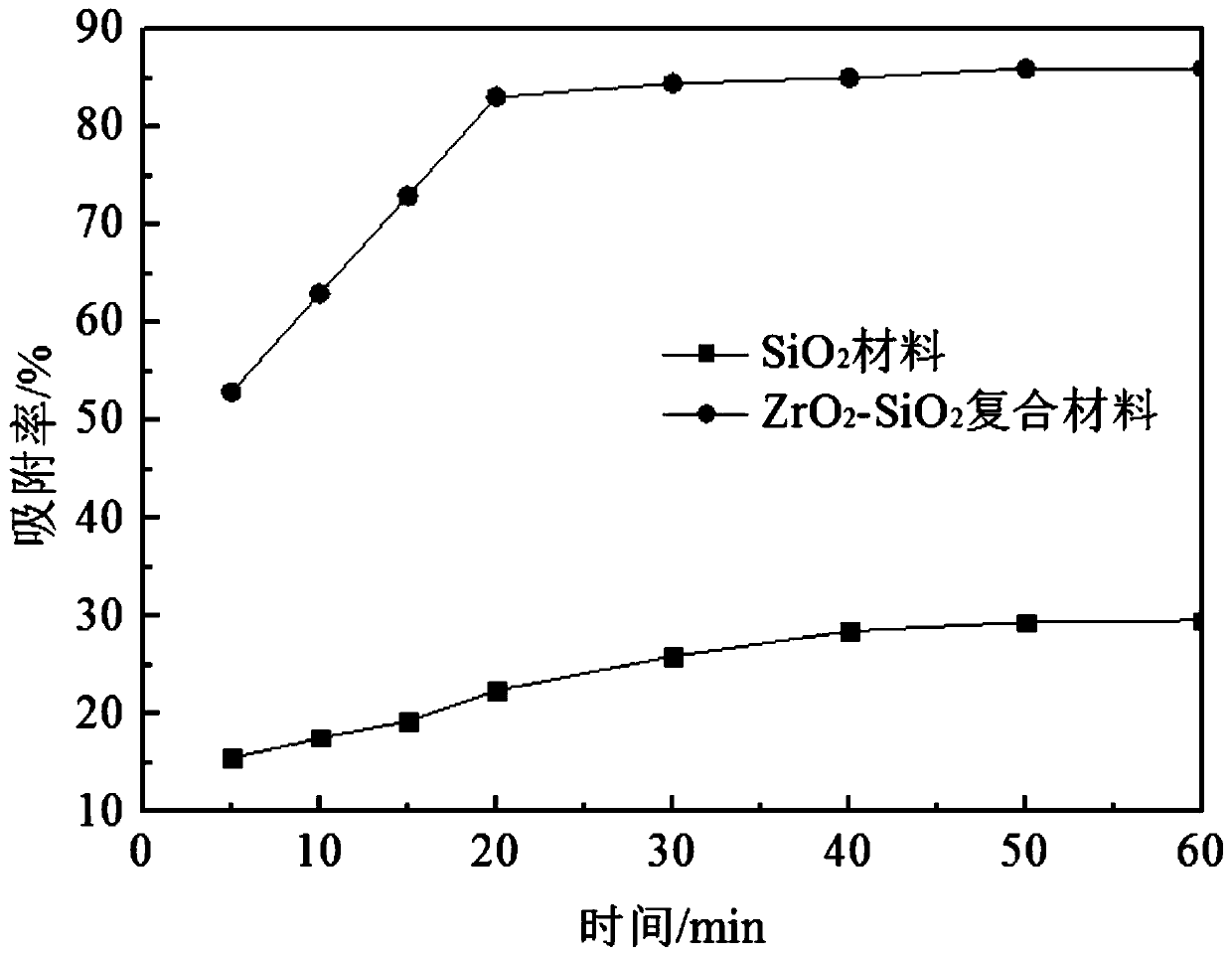

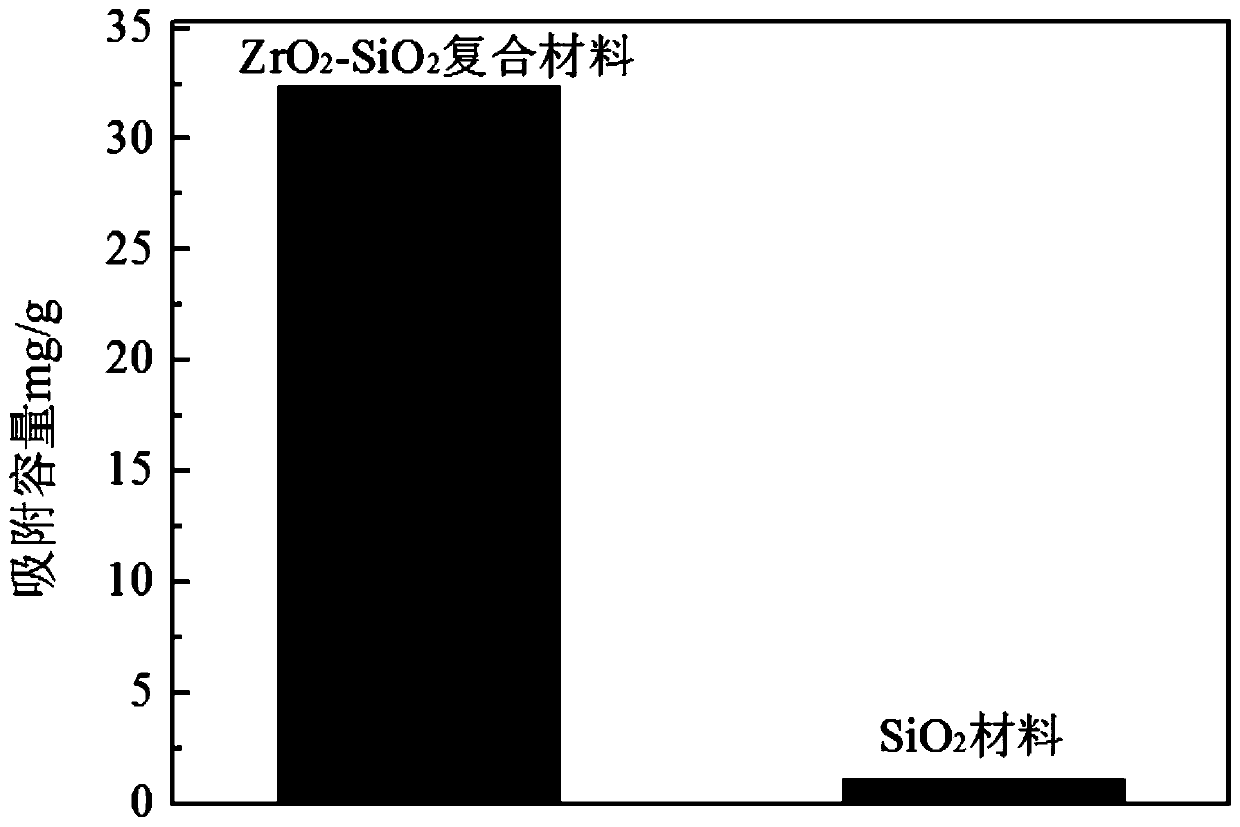

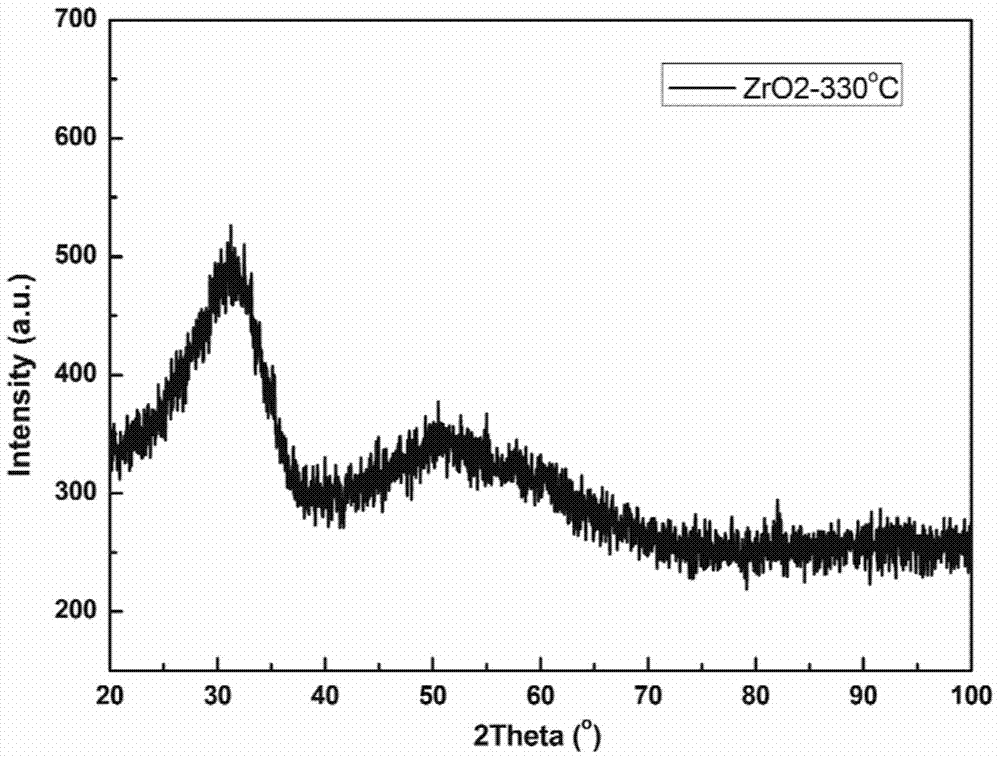

A kind of preparation method of zirconia-silicon dioxide composite adsorption material

ActiveCN107376828BFast adsorption rateHigh adsorption rateOther chemical processesWater contaminantsZirconia silicaZirconium dioxide

The invention discloses a preparation method of a zirconium dioxide-silicon dioxide composite adsorption material. SiO2 sol and ZrO2 sol are respectively prepared, then, the SiO2 sol and the ZrO2 sol are mixed and dried and are calcined at a certain temperature to obtain the ZrO2-SiO2 composite adsorption material. ZrO2 with a catalytic action is imported into a common SiO2 material to improve both the adsorption speed of an SiO2 material and the adsorption rate of the SiO2 material. The method is simple and has a good practical value.

Owner:XI'AN POLYTECHNIC UNIVERSITY

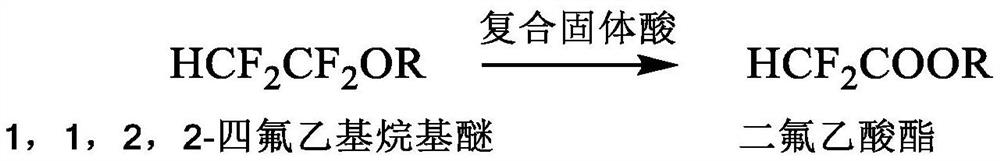

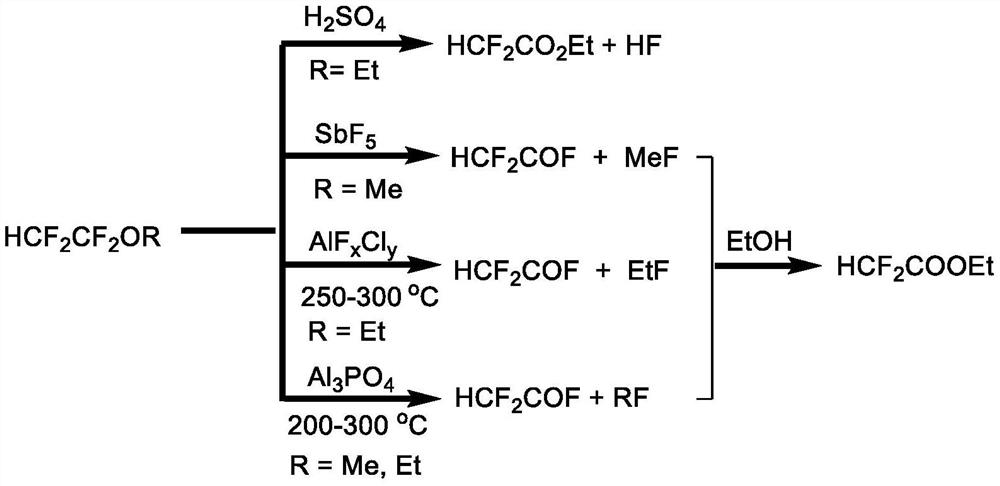

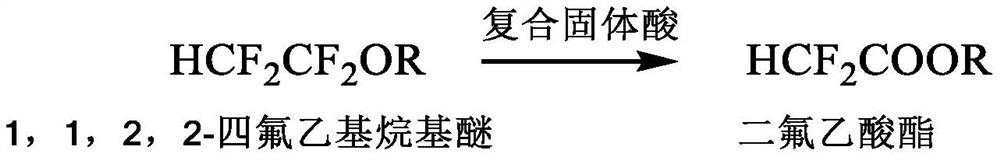

Composite solid acid as well as preparation method and application thereof

ActiveCN113751031AAtom economy is highHigh yieldPhysical/chemical process catalystsOrganic compound preparationFluoroacetic acidAluminium fluoride

The invention discloses composite solid acid as well as a preparation method and application thereof. The preparation method of the composite solid acid disclosed by the invention comprises the following steps: adding an oxide and a fluoride into water, filtering to obtain a solid, and heating the obtained solid at the temperature of 150-350 DEG C for 12-100 hours to obtain the composite solid acid, wherein the oxide is one or more of magnesium oxide, aluminum oxide, zinc oxide, iron oxide, copper oxide, titanium dioxide, zirconium dioxide, silicon dioxide, diatomite and montmorillonite; and the fluoride is one or more of magnesium fluoride, calcium fluoride, zinc fluoride, copper fluoride and aluminum fluoride. The composite solid acid can be applied to preparation of difluoroacetate compounds, and the preparation method is high in atom economy, simple in preparation step, suitable for continuous channelization reaction in preparation process, safe in technological process, short in reaction time, high in yield and few in three wastes, and is an environment-friendly preparation method.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI +1

Hydrotalcite and its production method

The present invention provides a method for producing hydrotalcite, wherein the obtained hydrotalcite has a low content of zirconia, and when the hydrotalcite is mixed with a resin such as polyvinyl chloride resin, the transparency of the resin is significantly improved. improve. The present invention relates to a method for producing hydrotalcite, which is a method for producing hydrotalcite using magnesium compounds and / or zinc compounds and aluminum compounds as raw materials. Slurry of all or part of at least one selected from the group consisting of hydroxides, oxides, and carbonates of the aforementioned raw materials; wet pulverization process using zirconia beads or zirconia-silica beads , wet pulverization of the slurry under specified conditions; hydrothermal treatment process, after adding the remaining raw materials to the obtained slurry, perform hydrothermal treatment to synthesize hydrotalcite with BET value and Zr content within the specified range .

Owner:SAKAI CHEM IND CO LTD

Chromium free refractory material for RH vacuum furnace lining

InactiveCN1325435CExtended service lifeStrong slag resistanceBlast furnace componentsBlast furnace detailsChromium freeZirconia silica

The chromium-free refractory material for RH vacuum furnace lining consists of one or several of magnetize, magnesia zirconia and magnesia zirconia silica 88-97 wt%, fine zirconia powder 1-6 wt%, fine zircon powder 0-9 wt%, and organic binding agent 1-3 wt%. It has the chemical composition of MgO 80-90 wt%, SiO2 1-4 wt%, and ZrO2 7-13 wt%. The organic binding agent is binding agent commonly for refractory material, such as sodium humate, calcium lignosulfonate, dextrin and Arabic gum. The MgO-SiO2-ZrO2 chromium-free refractory material has high slagging resistance and is significant for RH vacuum furnace to obtain long service life.

Owner:BAOSHAN IRON & STEEL CO LTD

A method for preparing α-phenylethyl alcohol using zirconia-silica/graphene hybrid material as a catalyst

ActiveCN104529708BLower requirementMild reaction conditionsPhysical/chemical process catalystsOrganic compound preparationChemical synthesisDoped graphene

The invention discloses a method for preparing alpha-phenethyl alcohol by taking a zirconia-silica / graphene hybrid material as a catalyst and belongs to the technical field of chemical synthesis. The method comprises the following steps: by taking acetophenone as a raw material under normal pressure, taking alcohol as a hydrogen source and a solvent, and taking the zirconia-silica / graphene hybrid material as a catalyst, reacting at the reaction temperature of 45-90 DEG C for 2-10 hours, rectifying the reaction solution after the reaction is ended, taking the fraction at the temperature of 105-115 DEG C, thereby obtaining the alpha-phenethyl alcohol. According to the method disclosed by the invention, the zirconia-silica / graphene hybrid material is taken as the catalyst, the hybrid material is prepared by adding silica and doping graphene by virtue of an aerogel mode, the specific surface area and pore size of the catalyst are improved, dispersion of the surface active center is promoted, and the activity of the catalyst is increased. The catalyst is high in selectivity and high in water resistance, is easily separated in the reaction solution and can be repeatedly utilized after separation, the operation is convenient, and the preparation cost is reduced, so that the economic benefits are improved.

Owner:湖州度信科技有限公司

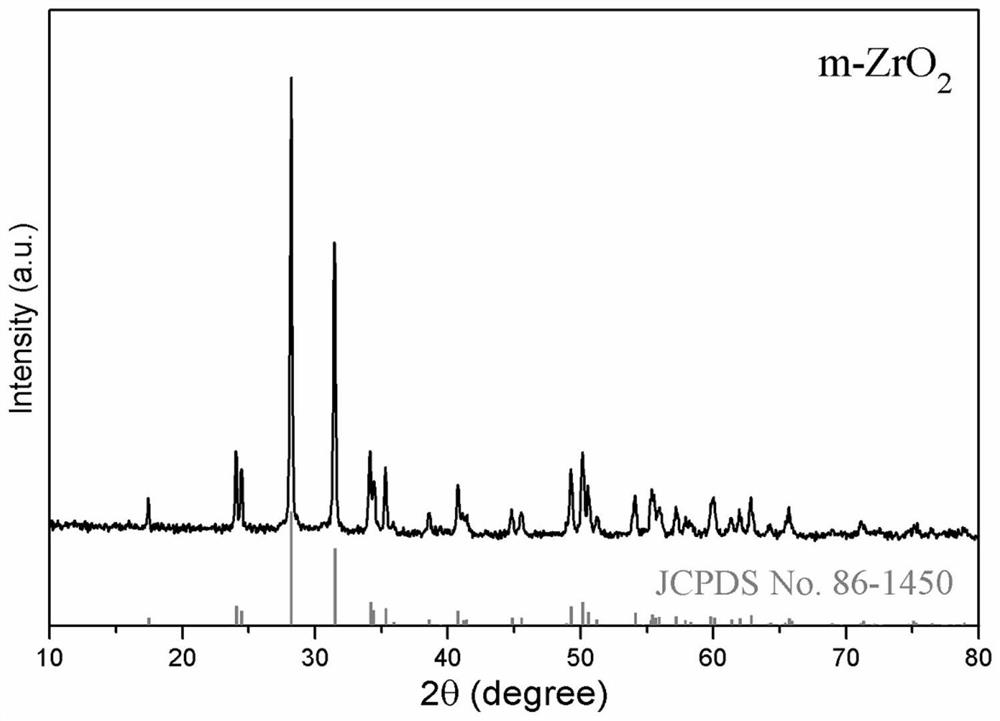

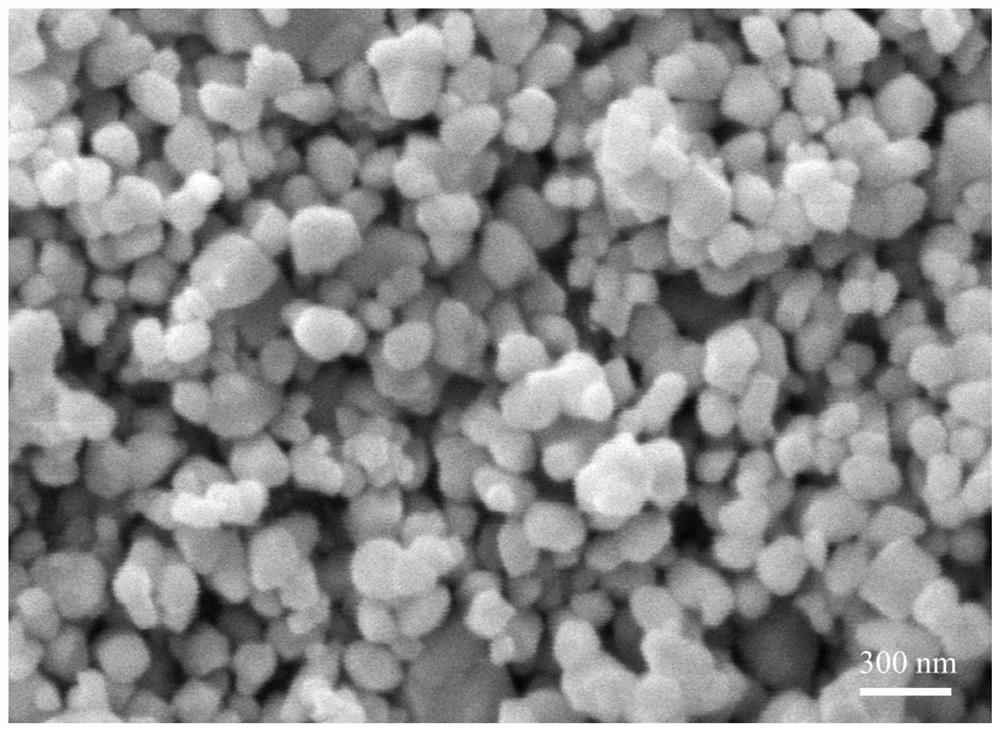

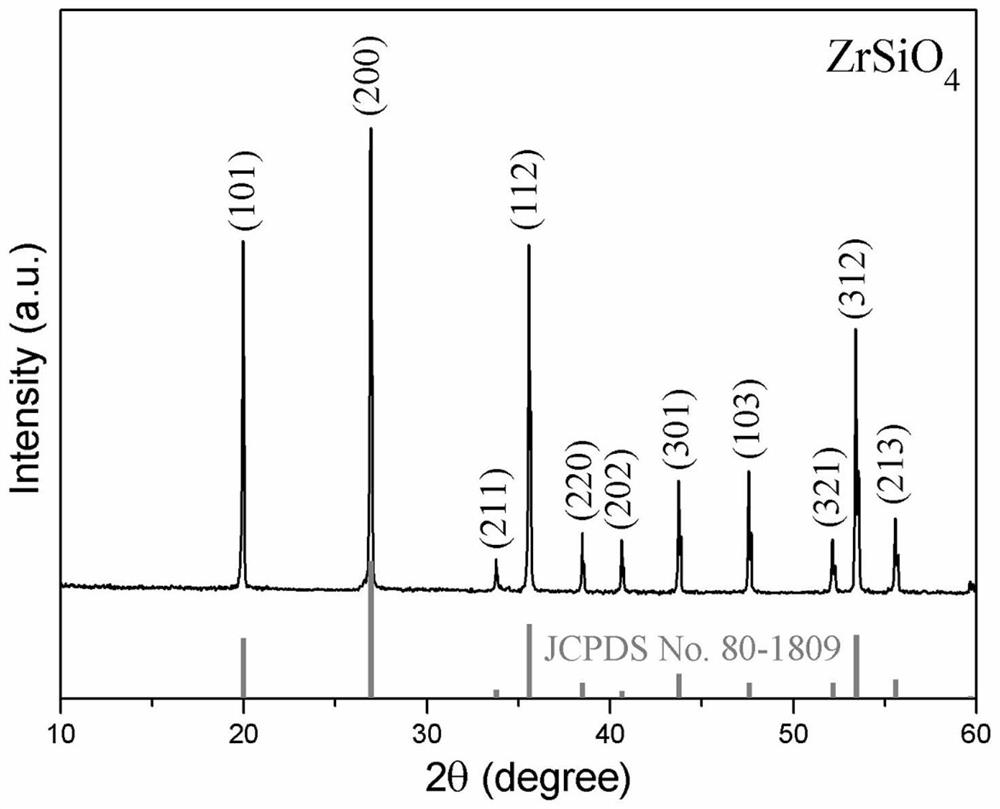

A kind of micron plate zirconium silicate powder and preparation method thereof

ActiveCN110203941BImprove wear resistance and anti-skid performanceWeak opacification effectMaterial nanotechnologySilicon compoundsZirconia silicaSilicic acid

The invention discloses micron-sized plate-like zirconium silicate powder and a preparation method thereof. The preparation method comprises the following steps of: uniformly mixing zirconium oxide, silicon dioxide, a molten salt and a forming agent to obtain a reactant; controlling the mol ratio of the zirconium oxide, the silicon dioxide and the forming agent to be 1: 1.05-1.10: 1-3: 0.005-0.04;placing the reactant in a closed container and keeping the temperature at 850-1150 DEG C to obtain a calcined product; and washing and drying the calcined product to obtain the micron-sized plate-like zirconium silicate powder. The preparation method is simple in process, less in environmental pollution and easy for industrial production. The prepared zirconium silicate powder has good crystallization, few defects, regular plate-like shape, micron-sized size and uniform distribution; when the micron-sized plate-like zirconium silicate powder is applied to ceramic glazed tiles, the wear resistance and skid resistance of the ceramic glazed tiles can be obviously improved, the opacifying effect is weak, and the ceramic glazed tiles have good application effect.

Owner:佛山科海意诺陶瓷科技有限公司 +1

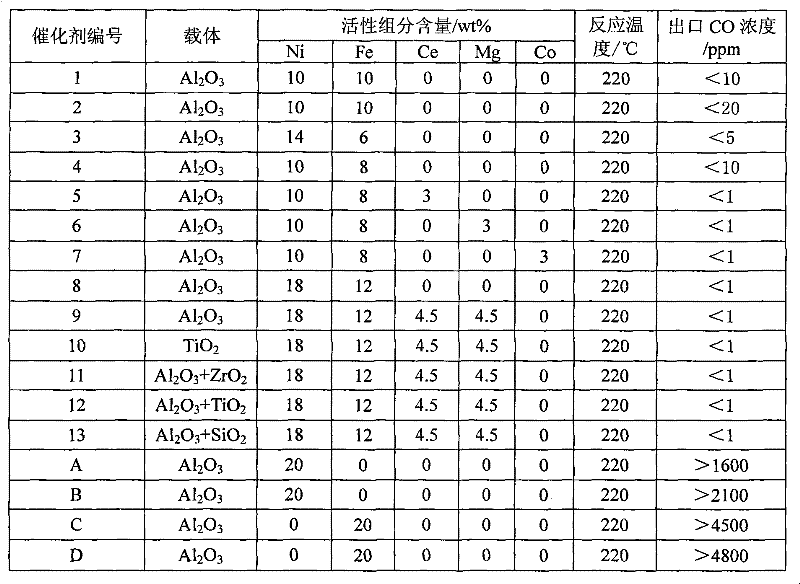

Bimetal methanation catalyst and preparation method thereof

InactiveCN101703933BSlight reductionHydrogen separation using solid contactCatalyst activation/preparationZirconia silicaPtru catalyst

The invention discloses a bimetal methanation catalyst for the removal of micro carbon monoxide from a hydrogen-rich gas and a preparation method thereof. The bimetal methanation catalyst contains active components, namely nickel oxide and ferric oxide, loaded on an oxide carrier and an assistant, wherein the assistant is at least one element selected from the main group I, the main group II, thesubgroup I, the subgroup III, the subgroup VI and the subgroup VIII of the periodic table, and the oxide carrier is alumina, titanium dioxide, zirconium dioxide and silicon dioxide or a mixture thereof. The catalyst of the invention can allow the micro carbon monoxide to be removed from the hydrogen-rich gas at a relatively low temperature and has the advantages of low load, high activity, relatively low cost and wide application prospect.

Owner:SHANXI UNIV

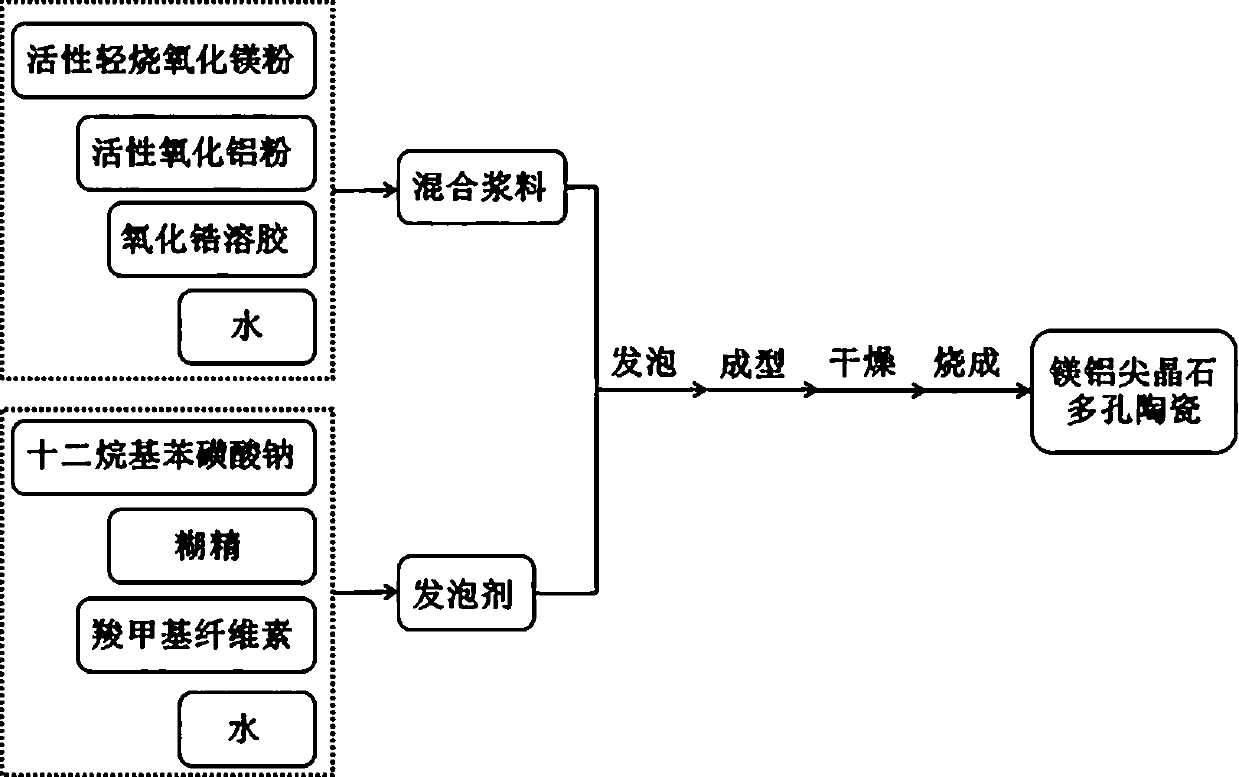

Preparation method of zirconia sol-reinforced magnesium aluminate spinel porous ceramic

The invention relates to a preparation method of a zirconia sol-reinforced magnesium aluminate spinel porous ceramic. The zirconia sol-reinforced magnesium aluminate spinel porous ceramic is obtainedby taking activated light calcined magnesia powder and activated alumina powder as powder materials, zirconia sol as a a reinforcing agent and water as a solvent, adding sodium dodecyl benzene sulfonate (SDS) as a foaming agent, dextrin as a foam stabilizer and carboxymethyl cellulose (CMC) as a thickening agent, and carrying out mixing, foaming, molding, drying and sintering. The zirconia sol-reinforced magnesium aluminate spinel porous ceramic is prepared with a foaming method which is simple in process; the zirconia sol is introduced into a magnesium aluminate spinel porous ceramic; and thestrength of the porous ceramic is enhanced by forming nano-zirconia particles on the hole walls, so that the magnesium aluminate spinel porous ceramic with the high strength and the high porosity isobtained.

Owner:UNIV OF SCI & TECH LIAONING

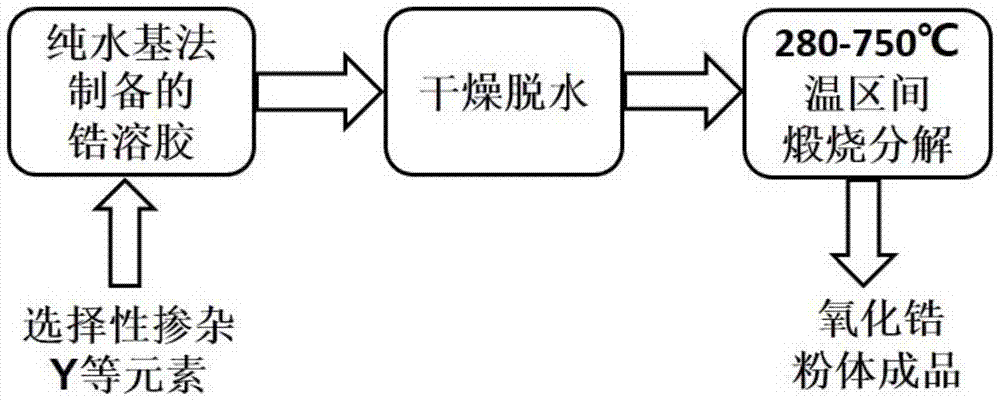

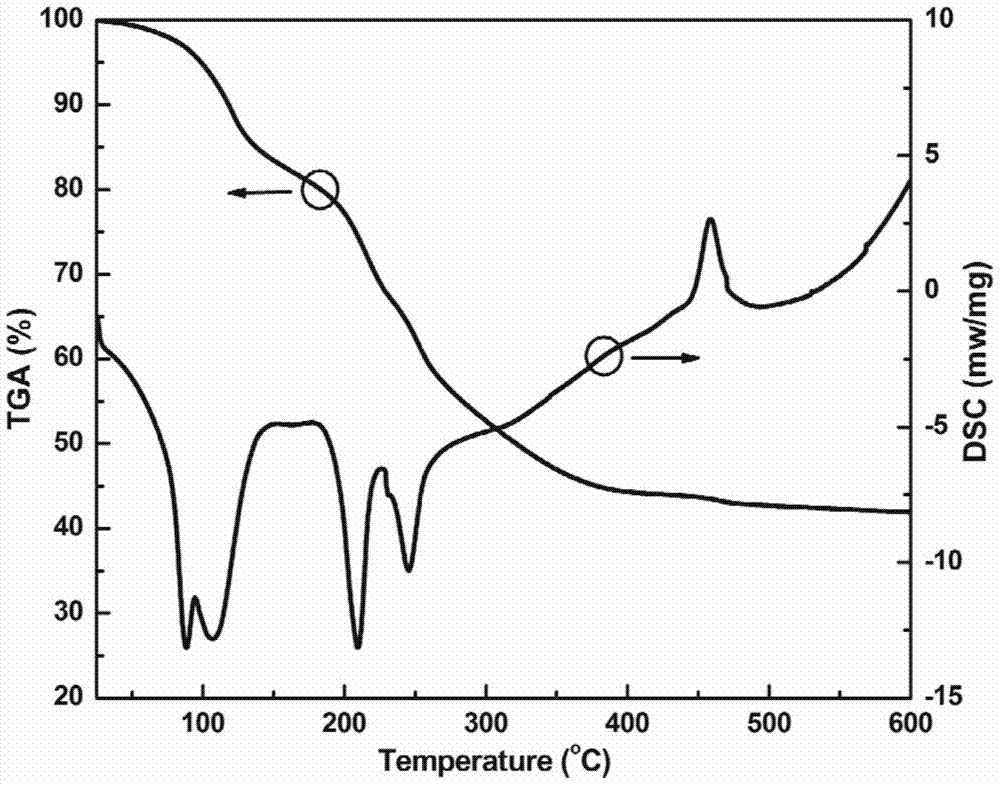

A method of preparing zirconium dioxide nanopowder by calcining zirconium sol at low temperature

ActiveCN105621480BPrecisely adjustable doping amountAvoid expensiveMaterial nanotechnologyZirconium oxidesDispersityCalcination

The invention provides a method for preparing zirconium dioxide nano powder by low-temperature calcination of zirconium sol. The method comprises the following steps: dissolving a raw material water-soluble zirconium inorganic salt in deionized water; adding an alkaline precipitant to generate a suspension, and centrifuging or filtering to obtain precipitate; adding mixed liquid of monobasic acid or monobasic acid and hydrogen peroxide into the precipitate, and continuously stirring for peptization to obtain a clear zirconium sol precursor; and finally, drying and dehydrating the zirconium sol precursor and calcining and decomposing in different temperature intervals, wherein amorphous zirconium dioxide nano powder as well as zirconium dioxide nano powder of which tetragonal phase can be kept stable without doping can be obtained, and the average particle size of the powder can be controlled between 3nm and 10nm. The preparation method of high-performance zirconium dioxide nano powder has the following advantages: the powder has small particle size, narrow distribution and good dispersity; the adopted raw material reagent is easily available and cheap; and the equipment requirements and operation technology are simple, the energy consumption is low, pollution is avoided, and industrial production is easy to realize.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com