Porous metal oxide-silica gel liquid chromatogram filling material, and preparation method thereof

A porous metal and liquid chromatography technology, which is applied in the field of metal oxide-silica gel microsphere packing and its preparation, can solve problems such as tailing, achieve the effects of small steric hindrance, solve peak tailing, and avoid strong adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

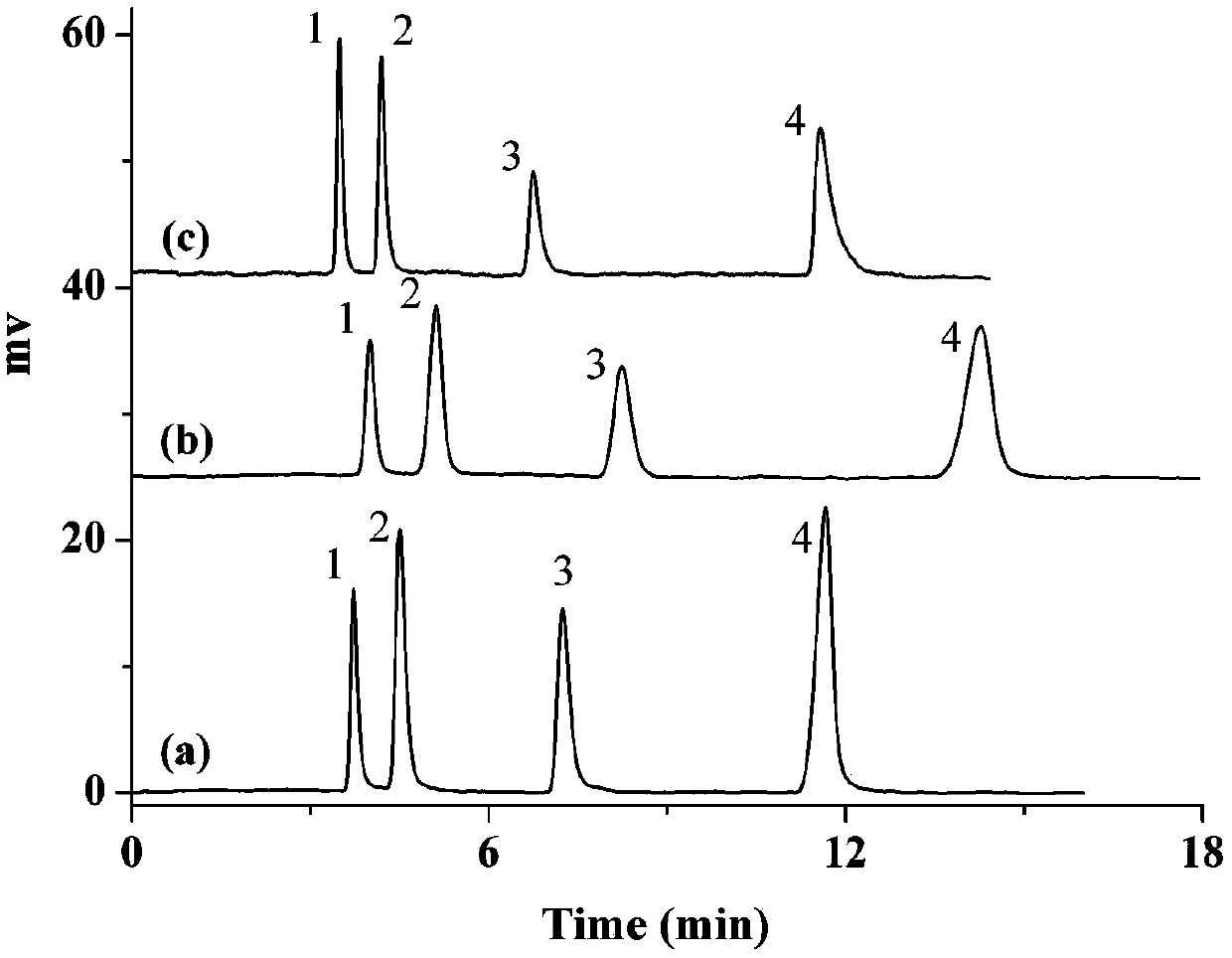

Image

Examples

Embodiment 1

[0025] Example 1: The inner and outer surfaces of porous silica gel microspheres are modified with zirconia-titania hybrid materials to form a zirconia-titania-silica gel matrix. The method refers to the document (Chinese invention patent, 201510920926.7), wherein the mass fraction of zirconium About 2%, the mass fraction of titanium is about 2%, and the specific surface area of the porous silica microsphere is 350m 2 / g, the particle size is 5μm, the pore size is 10nm; the specific surface area of the zirconia-silica gel matrix is 300m 2 / g. D-glucose-6-phosphate groups are modified on the surface of zirconia-titania-silica gel matrix. The modification process is to configure 20ml of D-glucose-6-phosphate disodium aqueous solution with a concentration of 0.03mol / L, and weigh zirconia-6-phosphate Soak 0.2 g of silica gel microspheres in the above solution and stir for 12 hours at a water temperature of 60°C to obtain a surface-modified D-glucose-6-phosphate group zircon...

Embodiment 2

[0030]The inner and outer surfaces of porous silica gel microspheres are decorated with zirconia-titania hybrid materials to form a zirconia-titania-silica gel matrix. The method refers to the document (Chinese invention patent, 201510920926.7), wherein the mass fraction of zirconium is about 3%. , the mass fraction of titanium is about 5%, and the specific surface area of the porous silica microsphere is 150m 2 / g, the particle size is 5μm, and the pore size is 10nm; the specific surface area of the zirconia-silica gel matrix is 140m 2 / g. D-fructose-1,6-diphosphate groups are modified on the surface of zirconia-titania-silica gel matrix, and the modification process is to prepare 10ml of D-fructose-1,6-diphosphate trisodium aqueous solution with a concentration of 200mM, and weigh Disperse 0.4 g of zirconia-silica gel microspheres in the above solution and heat and stir for 10 hours at a water temperature of 55°C to obtain a zirconia-silica gel material with surface-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com