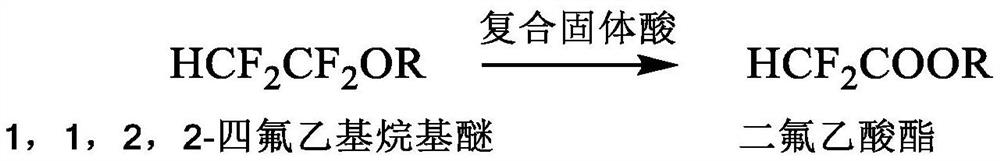

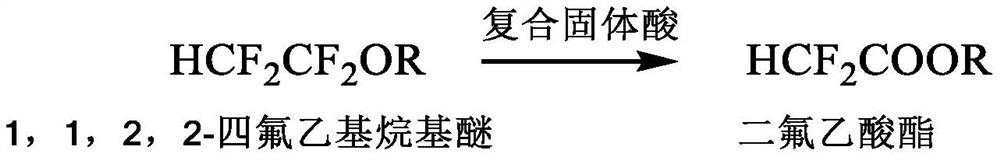

Composite solid acid as well as preparation method and application thereof

A technology for compounding solid acids and solids, which is applied in the preparation of carboxylic acid esters, the preparation of organic compounds, chemical instruments and methods, etc. The effect of high atomic economy, less three wastes and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

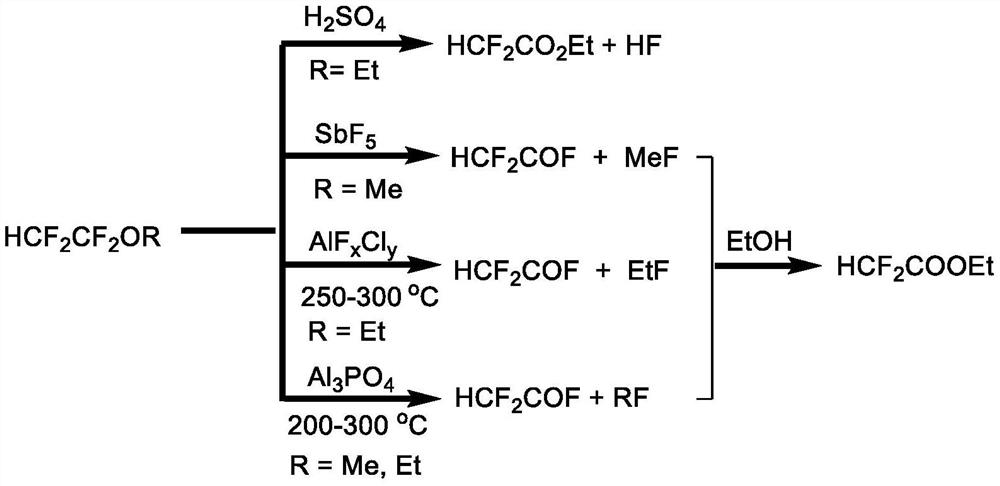

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Preparation of Type I Composite Solid Acid I-A: Add 40.3g (1.0mol) of magnesium oxide and 84.0g (1.0mol) of aluminum fluoride to 500mL of deionized water, stir for half an hour, let stand, filter to obtain powder block solid, under nitrogen condition , heated to 300°C, kept at the temperature for 24 hours, cooled to room temperature, and ground into 100-200 mesh powder to prepare composite solid acid I-A.

Embodiment 2

[0056] Preparation of Type I Composite Solid Acid I-B: Add 79.9g (1.0mol) of titanium dioxide and 62.3g (1.0mol) of magnesium fluoride to 500mL of deionized water, stir for half an hour, let stand, filter to obtain powder block solid, under argon condition , heated to 250°C, kept at the temperature for 36 hours, cooled down to room temperature, and ground into 300-400 mesh powder to prepare composite solid acid I-B.

Embodiment 3

[0058] Preparation of Type I Composite Solid Acid I-C: Add 101.9g (1.0mol) of alumina and 62.3g (1.0mol) of magnesium fluoride to 500mL deionized water, stir for half an hour, let stand, filter to obtain powder block solid, under argon condition , heated to 300°C, kept at the temperature for 24 hours, cooled down to room temperature, and ground into 100-200 mesh powder to prepare composite solid acid I-C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com