Patents

Literature

75 results about "Aluminium fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium fluoride refers to inorganic compounds with the formula AlF₃·xH₂O. They are all colorless solids. Anhydrous AlF₃ is used in the production of aluminium metal. Several occur as minerals.

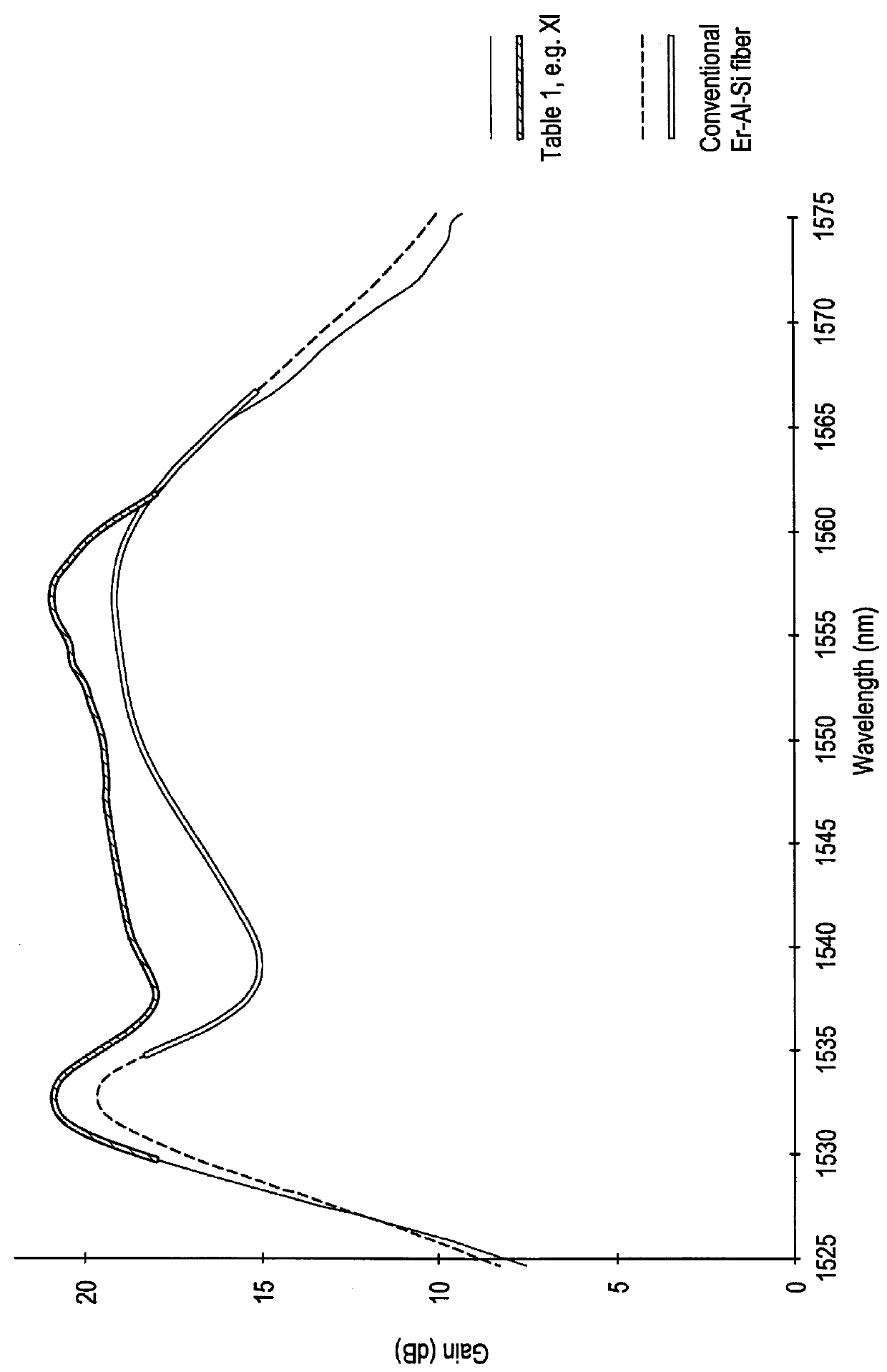

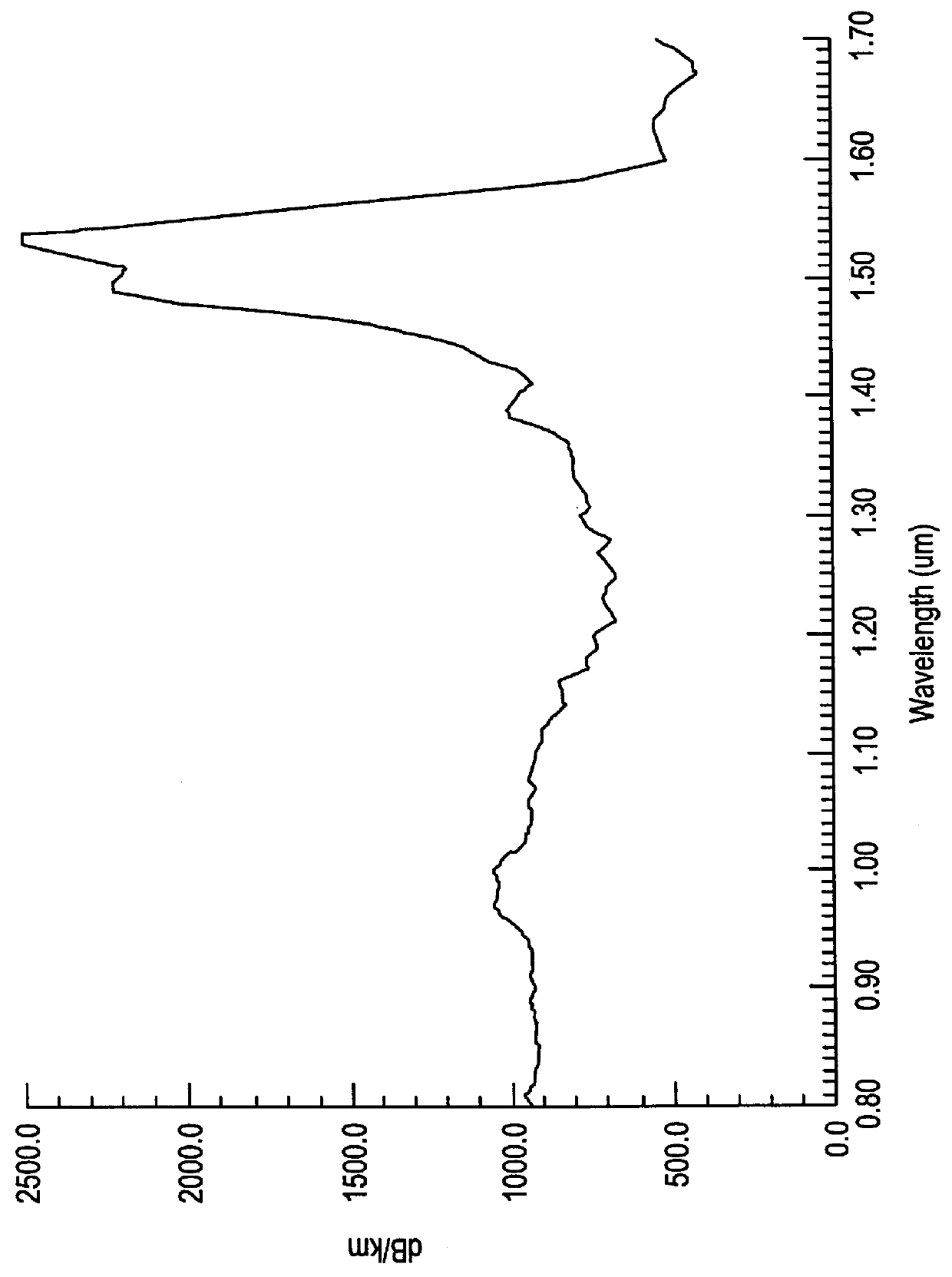

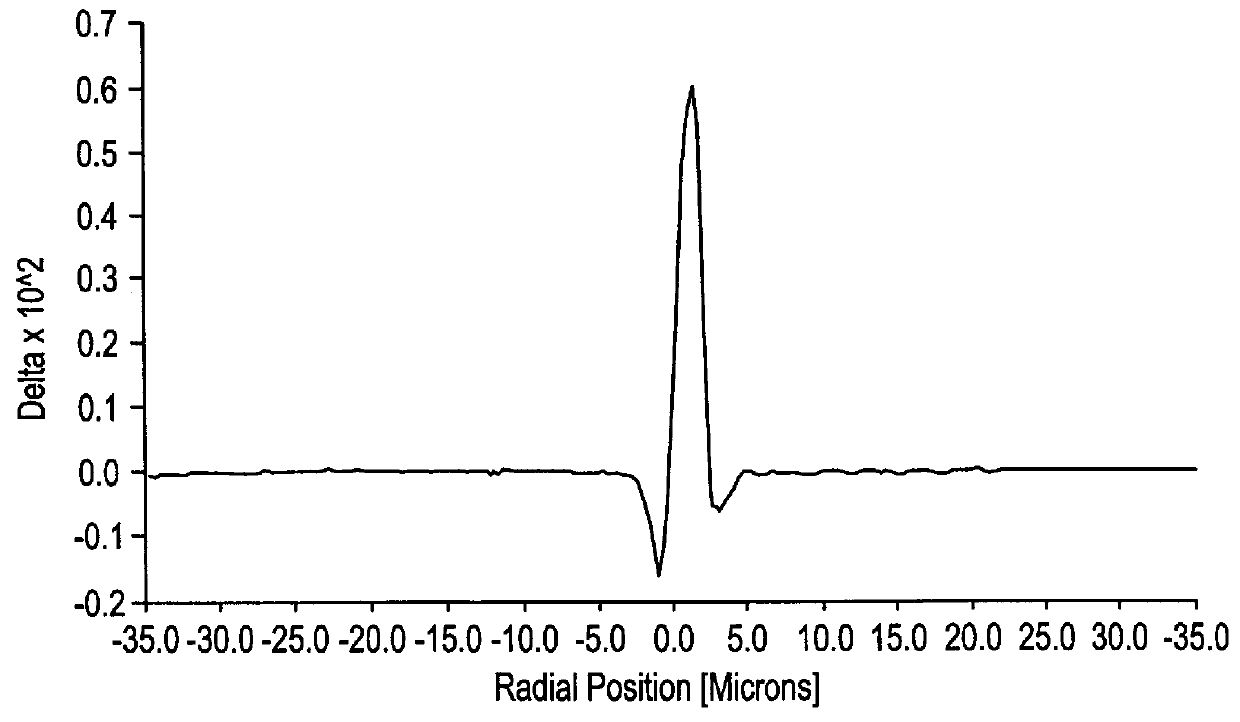

Composition for optical waveguide article and method for making continuous clad filament

An optical article having a rare earth doped, fluorinated aluminosilicate glass core composition consisting essentially, in mole %, of: - SiO2 0-90 - GeO2 0-90 - Na2O 0-25 - Li2O 0-10 - K2O 0-25 - Rb2O 0-25 - Cs2O 0-25 - Al2O3 5-40 - Ga2O3 5-40 - RE2(1)O3 0-40 - RE2(2)O3 0-1 - Er2O3 0.001-5 - Yb2O3 0-5 - PbO 0-15 - RO 0-20 - ZnO 0-10 - ZrO2 0-2 - TiO2 0-2 - Nb2O5 0-10 - Ta2O5 0-10 - P2O5 0-5 - B2O3 0-15 - As2O3 0-10 - Sb2O3 0-20 - Na2Cl2 0-10 - Bi2O3 0-5, and - up to 15 weight % fluorine in the form of at least one of a fluorinated component of the glass composition and a batch constituent selected from a group consisting of at least one of AlF3, REF3, NH5F2, NaF, Na2SiF6, Na3AlF6, where RE(1) is at least one of Y, La, Gd, and Lu; RE(2) is at least one of Ce, Pr, Nd, Sm, Eu, Tb, Dy, Ho, and Tm; R is at least one of Ba, Ca, Mg, and Sr; (SiO2+GeO2) is in the range (40-90); and (Al2O3+Ga2O3)>(RO+"alk"2O+RE2O3) where "alk" is at least one of Li, Na, K, Cs, and Rb. A cullet-in-tube method for making continuous clad filament is also described. The invention provides for an optical waveguiding article having relatively high gain, a relatively flat gain spectrum, compatibility with conventional silica fiber, good durability and ease of manufacture.

Owner:CORNING INC

Alkali-free liquid accelerating agent and preparation method thereof

The invention belongs to the technical field of tunnel construction, and relates to an alkali-free liquid accelerating agent for tunnel wet jet concrete and a preparation method thereof. The alkali-free liquid accelerating agent is characterized in that aluminium sulphate is adopted to serve as a main accelerating component; aluminium is added to an aluminium sulphate solution to be polymerized in a form of aluminium fluoride; aluminium ions are introduced to the greatest extent so as to reduce other ion introduction; and the accelerating effect is ensured. The alkali-free liquid acceleratingagent comprises the following components in percentage by mass: 30-55% of aluminium sulphate, 5-15% of aluminium hydroxide, 10-30% of hydrofluoric acid, 0.5-5% of water glass, 0-0.2% of stabilizing agent, and the balance of water. For jetting concrete, the alkali-free liquid accelerating agent disclosed by the invention has the positive effects that: ordinary cement can be initially solidified within 2 min in lower doping quantity and finally solidified within 4 min; the 1d strength of cement plaster can achieve above 15 MPa; the 28d compressive strength ratio is more than 100%; and the alkali-free liquid accelerating agent has good adaptability to different types of cements.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Method of producing aluminium scandium alloy by electrolysis

The invention relates to the method for producing the alloy of aluminium and scandium by using oxides of aluminium and scandium as the raw materials. Fused salt electrolysis process is adopted to electrolyze and separate out aluminium and scandium so as to form the alloy. The weight ratio of the electrolyte of fused cryolite is as following: alumina 1%-10%, scandium oxide 0.1%-10%, cryolite as the rest and the unavoidable impurities. The ratio between sodium fluoride and aluminium fluoride is 2-3. The relevant parameters are as following: temperature of electrolysis 900-990 deg.C, operating voltage of the electrobath 3.0V-6.5V and the electrode distance 2.0cm-7.0 cm. The invention possesses the features of no need of high pure metal scandium, shortened technological flow and high metal yield so as to reduce the cost of the alloy greatly.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Brazing flux without corrosion for aluminum and aluminum alloy brazing

InactiveCN101439449ASimple preparation processLow costWelding/cutting media/materialsSoldering mediaPotassium fluorideTin Fluorides

The invention relates to a corrosion-free soldering flux used for braze welding aluminium and aluminium alloy. Counted by weight percentage, the soldering flux used for braze welding the aluminium and aluminium alloy comprises the following components: 32.0-34.0 percent of cesium fluoride, 44.0-46.5 percent of aluminium fluoride, 20.5-23.5 percent of potassium fluoride, 0.5-2.5 percent of one, two or three materials selected from tin fluoride, zinc fluoride and lithium fluoride. The corrosion-free soldering flux of the invention has low melting point and better soldering performance.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

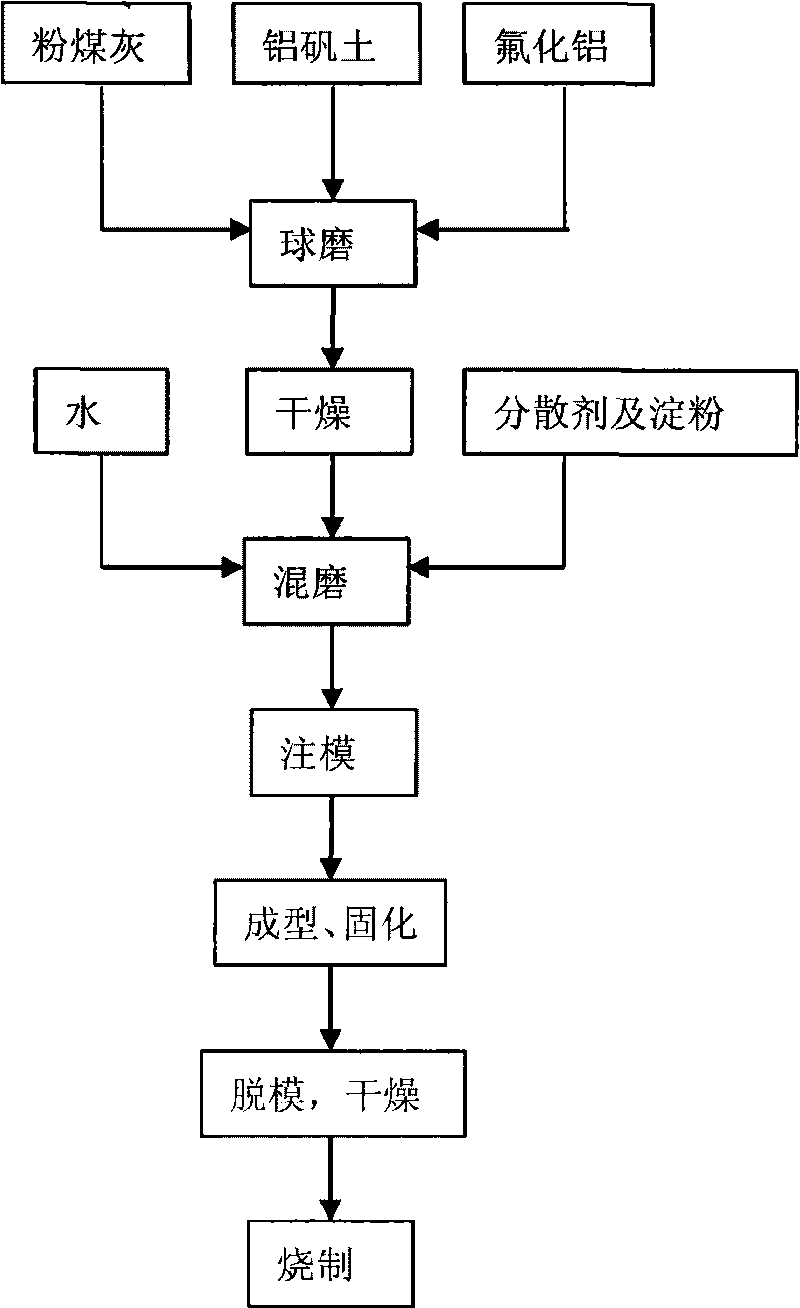

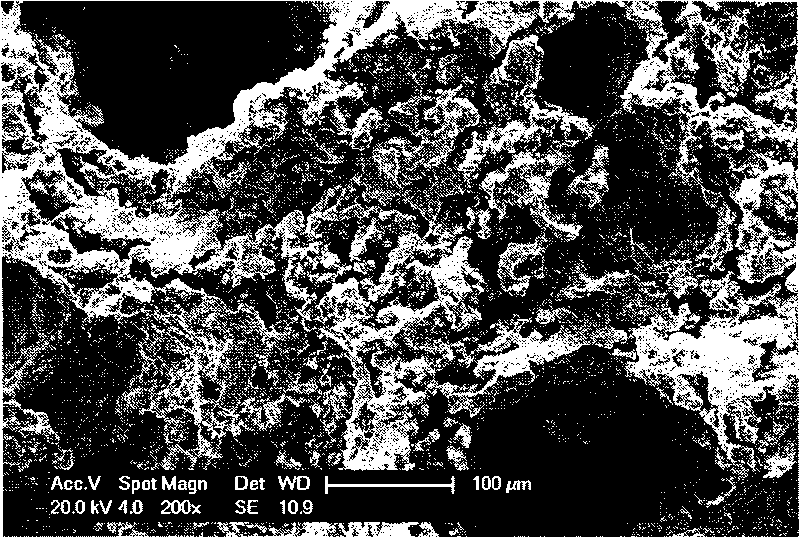

Method for preparing porous mullite

InactiveCN101759430AHigh strengthImprove high temperature resistanceCeramicwarePore distributionMullite

The invention discloses a method for preparing porous mullite, which comprises the following steps of: (1) performing magnetic separation to fly ash to remove iron; (2) proportioning the iron-removed fly ash, bauxite and aluminium fluoride; (3) adding a dispersing agent and a firming agent to prepare a mixed sizing agent; (4) pouring into a mold, and demolding after heating and curing; (5) preserving the demolded dry blank at the temperature of 350-400 DEG C for 0.5-2 h; (6) preserving the temperature at 1300-1500 DEG C for 2-4 h, and cooling. The method not only greatly utilizes fly ash which is a solid pollutant to achieve the purposes of energy saving, pollution reduction and environmental protection, but also has simple technology. The prepared porous mullite ceramics have reasonable pore diameter distribution, even pore distribution, high mullite content and great high-temperature resistance, and are applicable to multiple application requirements on high and low temperatures.

Owner:TIANJIN UNIV

Brazing procedure of aluminium electric-magnetic wires and Guinea gold

ActiveCN101015875AMeet welding requirementsGood resistance to temperature changesCellsMetallic material coating processesCopper atomElectrical resistance and conductance

A method for solder welding aluminum electromagnetic wire and brass comprises aluminum electromagnetic wire and brass connector. The invention comprises that first plating nickel on the surface of brass connector to improve the connecting strength between the solder and the brass connector and the corrosion resistance of aluminum copper connector, while said nickel layer can insulate aluminum atom and copper atom to avoid them to form rigid metal compound layer which will reduce the strength of connector, then using drug Al-Si rigid solder as non-corrosion aluminium fluoride potassium, using flame welding to weld the aluminum electromagnetic wire and the nickel layer of brass connector, the brass connector is treated with neutral oil removing, ultrasonic oil removing, water washing, acid washing, water washing, activating, waster washing, nickel plating, and drying. The inventive aluminum electromagnetic wire and brass connector have same anti-drawing strength, while the resistance of aluminum copper connector is less than the aluminum electromagnetic wire.

Owner:顺特电气设备有限公司

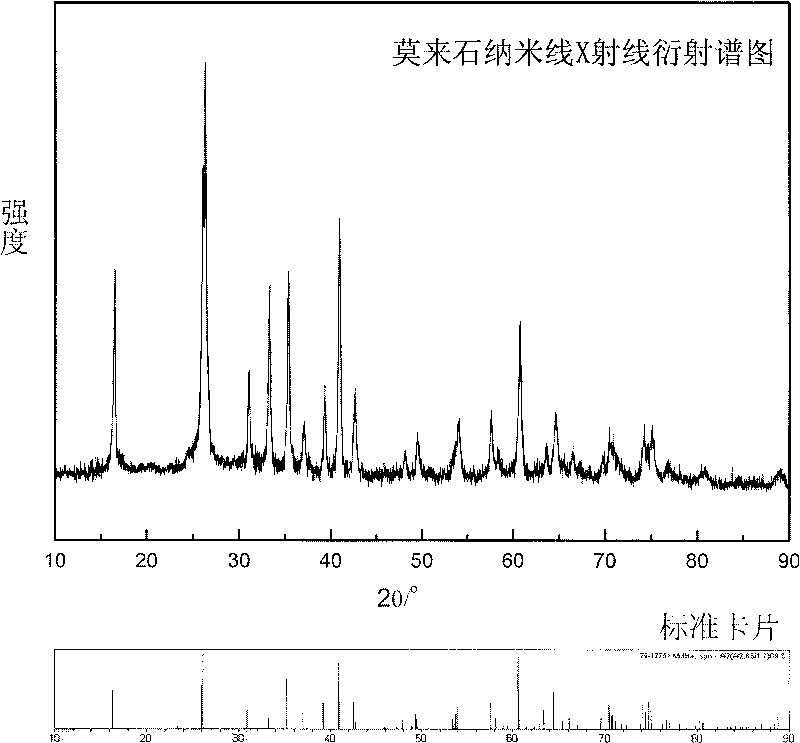

Preparation method of mullite whiskers

InactiveCN1785893ALow costImprove performancePolycrystalline material growthSingle crystal growth detailsCrucibleAluminium fluoride

The present invention relates to a preparation method of mullite whiskers, belonging to the field of new material technology. Its preparation method includes the following steps: using industrial pure aluminium sol and silicon sol as raw material, adopting sol-gel process to prepare mullite precursor body dried gel, then mixing the dried gel powder and industrial pure aluminium fluoride, high-temperature calcining in closed alumina ceramic crucible so as to obtain the invented mullite whiskers.

Owner:SHANDONG UNIV

A kind of sodium-free refining agent for aluminum and aluminum alloy and production method thereof

The invention discloses a sodium-free refining agent for aluminum and aluminum alloy, which consists of the following ingredients in percentage by weight: 15 to 25 percent of potassium aluminium fluoride, 5 to 15 percent of calcium fluoride, 10 to 25 percent of potassium carbonate, 10 to 25 percent of potassium sulfate, 5 to 15 percent of barium sulfate, 15 to 30 percent of potassium chloride and3 to 5 percent of anhydrous aluminium chloride. The invention also discloses a production method of the sodium-free refining agent. Because the sodium-free refining agent does not contain sodium salts, compared with sodium-containing refining agents, the sodium-free refining agent effectively solves the problem of antimony modification and phosphor modification influence caused by more or less sodium salt contained in the existing refining agent and overcomes the defects of alloy casting performance influence, melt flowability reduction and sodium brittleness possibly caused by the sodium element in aluminum-magnesium system alloy with the magnesium content being higher than 2 percent. A better use effect can be obtained in the antimony modification and phosphor modification alloys and high-magnesium-aluminum alloy. The invention belongs to the qualitative improvement on the prior art.

Owner:HEBEI SITONG NEW METAL MATERIAL CO LTD

Method used for preparing fluorine salt taking aluminium fluoride as main component from electrolyte-containing material produced in aluminium electrolysis

ActiveCN110194478AElectrolyte composition is stableEfficient recyclingIron oxides/hydroxidesAluminium fluoridesAluminium electrolysisAluminium fluoride

The invention provides a method used for preparing a fluorine salt taking aluminium fluoride as a main component from electrolyte-containing material produced in aluminium electrolysis. The method comprises following steps: the electrolyte-containing material is mixed with a soluble aluminium salt or an aluminium salt solution, and reaction is carried out at 50 to 100 DEG C; a reaction product issubjected to solid liquid separation, after separation, an obtained solid product is washed and dried so as to obtain the fluorine salt taking aluminium fluoride as a main component, and a liquid solid product obtained through separation and a solid product washing solution obtained in washing of the solid product are mixed so as to obtain a mixture, a strong basicity hydroxide or a solution of the strong basicity hydroxide is added into the mixture to remove calcium and iron impurities in the mixture; evaporation concentration desalting is carried out, and separation is carried out so as to obtain a concentrated mother liquor; a carbonate or a solution of the carbonate is added to remove Lithium-ion impurities in the concentrated mother liquor, after impurity removing, an obtained solution is adopted in diluting or washing step in the method. The method is capable of converting the excess electrolyte-containing material produced in aluminium electrolysis into aluminum fluoride, so that effective circulation of fluoride element in aluminium electrolysis enterprises is realized, and great meaning on aluminium electrolysis industry development of China is achieved.

Owner:郑州于斯新创科技有限公司

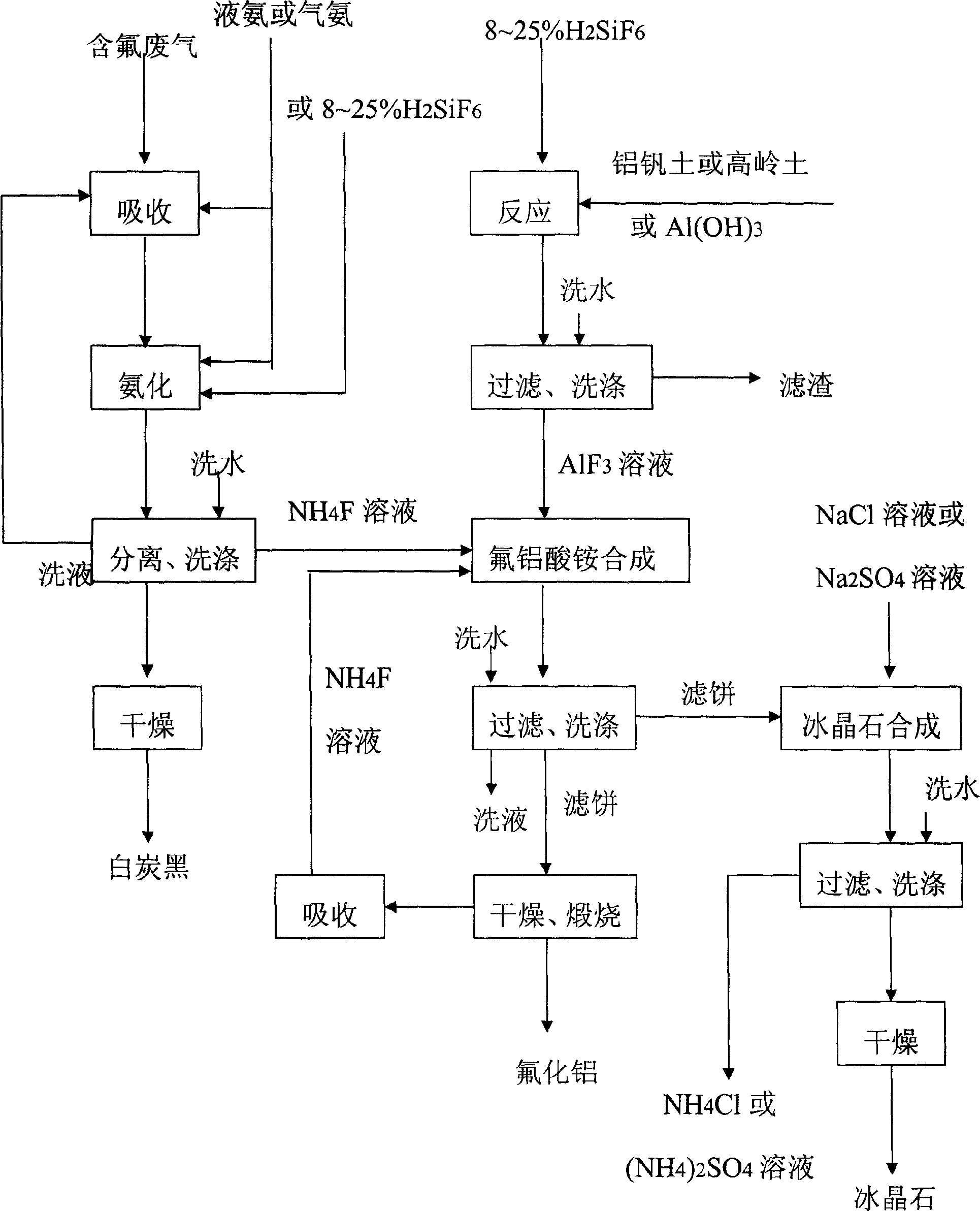

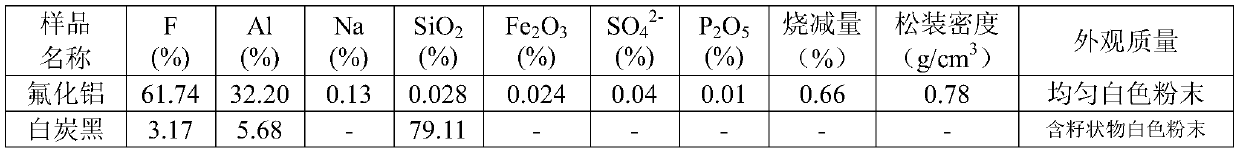

Fluorine-containing waste gas utilization method in phosphorus fertilizer production

The present invention relates to utility method for fluoric gases in phosphoric acid manufacture. Bring directly the ammonium fluoride and / or ammonia in system to obtain solution with (NH4)2SiF6 25~37%; use ammonia to ammoniate the solution and prepare deposition of silicon dioxide (white carbon black) with specific surface area of 100í½180m2 / g and NHF solution with concentration of 30~45%; use the two solutions to react, filter, wash and obtain filter cake; based on it, prepare cryolite and aluminun fluoride with high quality and low cost.

Owner:夏克立

Recovery method of rare earth elements in NdFeB (neodymium iron boron) waste materials

InactiveCN104087755AHigh recovery rateImprove solubilityProcess efficiency improvementRare-earth elementRecovery method

The invention discloses a recovery method of rare earth elements in NdFeB (neodymium iron boron) waste materials, belonging to the technical field of recovering of rare earth resource. The recovery method comprises the following steps: (1) evenly mixing aluminum fluoride powder and cryolite powder according to the mass ratio of 1:1-1:10, to obtain a cryolite-aluminum fluoride mixture; (2) crushing the NdFeB waste materials into granules with granule size of 4-6mm and burying into the cryolite-aluminum fluoride mixture; (3); putting cryolite-aluminum fluoride mixture with buried NdFeB waste materials into an electric furnace and reacting for 3-12h at the temperature of 900-1200 DEG C; and (4) conducting solid-liquid separation to the product obtained after reaction to obtain solid residue and fused salt respectively, wherein the solid residue is waste steel, and the fused salt is a rare earth fluoride-cryolite-aluminum fluoride mixture. The unoxidized rare earth elements in the NdFeB waste materials can be selectively extracted through aluminum fluoride, rare earth oxidized into oxides can be better dissolved by cryolite, and therefore the recovery rate of rare earth can be greatly improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Comprehensive utilization method of aluminum electrolytic carbon residue

InactiveCN109759423AReduce solubilityEasy to form precipitateSolid waste disposalFlotationKeroseneAluminium fluoride

The invention relates to the technical field of aluminum electrolysis, in particular to a comprehensive utilization method of aluminum electrolytic carbon residue. According to the comprehensive utilization method, the aluminum electrolytic waste carbon residue is crushed, screened and ball-milled, then floatation is conducted, water glass is treated as a depressor, kerosene is treated as a capture agent, and carbon is obtained; an electrolyte discharged from the bottom of a floatation tank is filtered, and a filter-out material is obtained; a mixed solution containing HNO3 and Al(NO3)3 is added in the filter-out material, a reaction is conducted under 60-65 DEG C for 1-1.5 h, and a solid-liquid mixture is obtained; and solid-liquid separation is conducted on the solid-liquid mixture, filter residue is obtained, the filter residue is leached with a high concentration hydrofluoric acid solution, solid-liquid separation is conducted, and AlF3 is obtained. According to the comprehensive utilization method, carbon powder and the electrolyte in the aluminum electrolytic wasted carbon residue are effectively separated, and environment pollution caused by fluorine emission is avoided. Therecycled carbon powder and aluminum fluorine can be returned to be used for aluminum electrolysis, raw material consumption of aluminum electrolysis is lowered, and the environmental benefits and theeconomic benefits are remarkable.

Owner:HENAN UNIV OF SCI & TECH

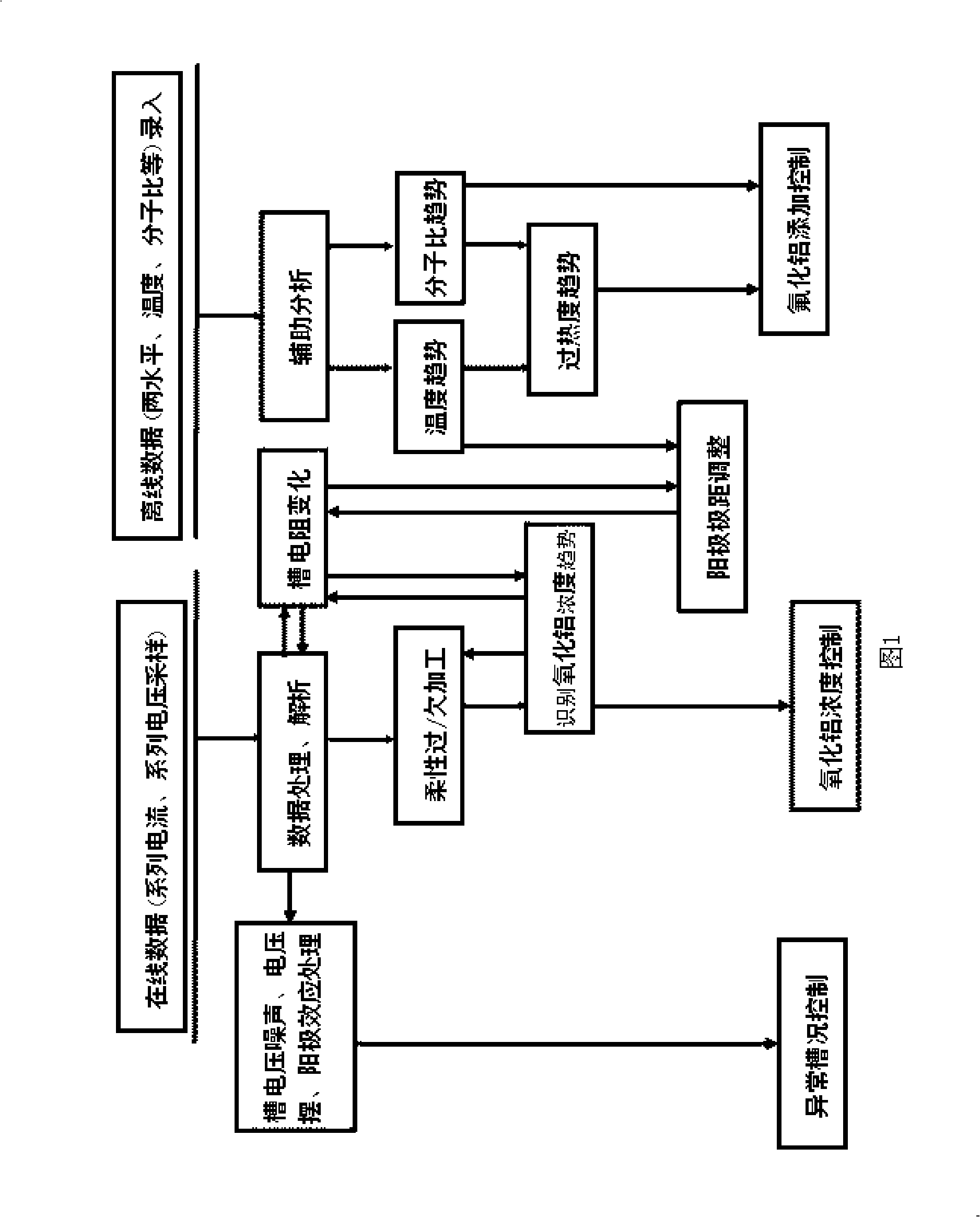

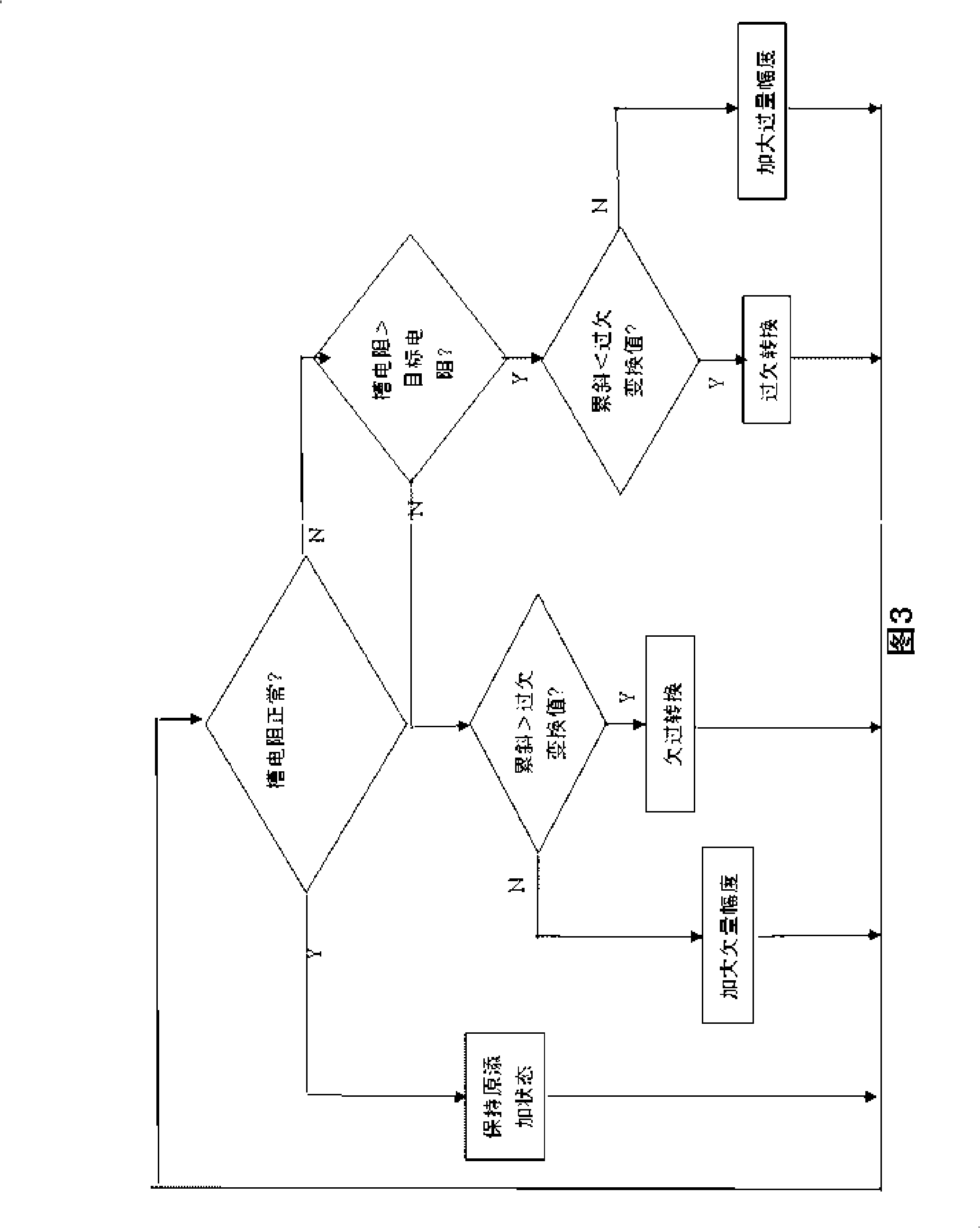

Computer real-time control method for monitoring temperature trend of aluminum cell

The invention discloses an aluminum electrolysis heat tendency computer real-time control method which can adapt the superheat or overcooling change of the tank circumstance in a wider range and monitor the superheat degree of the electrolytic tank in real time, which belongs to the automatic control field of the aluminum electrolysis. During the tank voltage analysis and control step, the tank voltage is analyzed in real time, the amplitude variable is calculated according to the voltage change curve, which comprises an instantaneous amplitude and an analysis cycle amplitude; and a target voltage control step is set, and the target voltage is adjusted between the setting voltage and the upper limit of the safety voltage according to the fluctuation situation of the tank voltage. In the invention, the amplitude variable is induced into the aluminium fluoride adding rate control step and the aluminium oxide adding rate control step, and the aluminium quantity planning step is set, to ensure the electrolytic tank to operate under the states of material balance and energy balance. The superheat degree can be controlled in real time through the aluminum electrolysis heat tendency computer real-time control method, to ensure the electrolytic tank to operate under the stable and highly effective state, and the management intensity and difficulty of the operator of the electrolytic tank to be reduced.

Owner:四川启明星铝业有限责任公司

Alkali-free liquid setting accelerator preparation method

ActiveCN110128044AShorten the initial and final setting timeSolve the requestAlkali freeAluminium hydroxide

The invention discloses an alkali-free liquid setting accelerator preparation method, which comprises: weighing 35-40% by mass of aluminum sulfate, 10-15% by mass of fluorosilicic acid, 12-16% by massof aluminum hydroxide, 2-3% by mass of sodium silicate, and the balance of water; preparing an aluminum fluoride liquid containing SiO2 particles, and preparing an aluminum fluoride mother liquor; and uniformly mixing and stirring the mother liquor, a sodium silicate solution and an aluminum sulfate solution to prepare the alkali-free liquid setting accelerator, wherein the fluorosilicic acid istaken from a phosphorus fertilizer production waste liquid, the reaction temperature is less than or equal to 25 DEG C, and the mass fraction of the aluminum fluoride in the prepared alkali-free liquid setting accelerator is 7-8%. In the prior art, the strong corrosion raw material hydrofluoric acid is used in the aluminum fluoride preparation process using the conventional method, the existing process for preparing aluminum fluoride from hydrofluoric acid and aluminum hydroxide has harsh requirements on equipment and has risk, and other problems exist. With the method of the present invention, the problems in the prior art can be avoided; and the AlF3 in the solution obtained by the reaction is mainly soluble AlF3, and the generated SiO2 particles have a large specific surface area so asto thicken the solution, such that the stability of the solution is increased.

Owner:HUBEI UNIV OF TECH

Method for removing alkali metal via electrolytic aluminum liquid

ActiveCN102719856AAchieving Alkali Metal ContentMeet processing performance requirementsAluminium fluorideMachining

The invention discloses a method for removing alkali metal via electrolytic aluminum liquid. The method comprises the steps of: filling aluminum fluoride powder-mixed inert gas into the electrolytic aluminum liquid; and mixing the electrolytic aluminum liquid in the gas filling process, wherein the content of the aluminum fluoride powder is converted according to a detected concentration of alkali metal in the electrolytic aluminum liquid before the alkali removal treatment. The method provided by the invention has the following beneficial effect that the inert gas and the aluminum fluoride powder are used for removing the alkali metal, so that the alkali metal in the electrolytic aluminum liquid can be directly removed online, requirement that the content (5ppm) of the alkali metal of aluminum melt is better than the European related product standard is realized, the machining property requirements of high-grade, precision and advanced aluminum alloys can be realized, the purification requirements on high-quality aluminum melt by production of high-grade aluminum machining materials can be satisfied and the potential safety and environmental hazards in alkali metal removal by chlorine used by numerous enterprises at present can be avoided.

Owner:FUJIAN NANPING ALUMINUM

Production process for preparing aluminium fluoride by using ammonium bicarbonate

InactiveCN101654273AReduce utilizationEfficient use ofAluminium fluoridesAluminium chlorideO-Phosphoric Acid

The invention relates to a production process for preparing aluminium fluoride by using ammonium bicarbonate, which solves the problem that the prior wet-method aluminium fluoride production process adopts more expensive aluminium hydroxide as a raw material, reduces production cost and is easy to carry out industrial production. The process is characterized in that fluosilicic acid reacts with ammonium bicarbonate to generate ammonium fluoride solution and silicon dioxide deposition; then, the filtered and separated ammonium fluoride solution reacts with aluminum chloride hexahydrate to prepare soluble Beta-AlF3.3H2O and ammonium chloride solution; soluble Alpha-AlF3.3H2O is converted into insoluble Beta-AlF3.3H2O through crystallization; and the finished product of aluminium fluoride isobtained through separation, washing, drying and calcination. The process is the most economical process for producing aluminium fluoride from a by product fluosilicic acid of enterprises for producing phosphoric acid and calcium superphosphate by a wet-method.

Owner:HUBEI YUANDA FUCHI PHARMA CHEM

Analysing method of excess alumina content in aluminium electrolyte

ActiveCN1912611AThorough responseImprove measurement accuracyPreparing sample for investigationMaterial electrochemical variablesAluminium fluorideSodium fluoride

A method for analyzing content of surplus aluminium fluoride in aluminium electrolyte includes mixing sodium fluoride of 15%-35% as mass of testpiece with aluminium electrolyte testpiece and adding analysis water to submerge it, placing it on sand bath of 100-120deg.c for drying it then sintering it at temperature of 740-760deg.c for 15-25min., adding water and grinding it then placing it in beaker for extracting out unreacted surplus sodium fluoride, calculating out content of unreacted surplus sodium fluoride and calculating out content of surplus aluminium fluoride reacted with sodium fluoride.

Owner:兰州铝业有限公司 +1

Non-solder brass solder coating material for aluminium product

InactiveCN1701905AImprove performanceGood brazing effectWelding/cutting media/materialsSoldering mediaPotassiumAluminium fluoride

Soldered coating material without solder of aluminum product belongs to material engineering technique field. The components and corresponding weight shares are: silica flour 30í½49úÑ, potassium aluminium fluoride 20í½30úÑ and synthetic resin. Paint the coating prepared by rolling transfer application on aluminium surface of flat separation with coating thickness under 40um; dry the coating at 150Degí½220 Deg, then it presents outstanding effect in continual CAB braze welding technique and achieves advanced level in domestic and foreign. This invention overcomes the existing complex technique, increases reliability and stability of soldered joint.

Owner:SHANGHAI JIAO TONG UNIV

Non-carbon anodes with active coatings

InactiveUS20070193878A1Easy to operatePrevent oxidationIsotope separationPotassium fluorideAluminium fluoride

A cell for electrowinning aluminium from alumina, comprises: a metal-based anode having an electrochemically active outer part comprising a layer that contains predominantly cobalt oxide CoO; and a fluoride-containing molten electrolyte in which the active anode surface is immersed. The electrolyte is at a temperature below 950° C., in particular in the range from 910° to 940° C. The electrolyte consists of: 6.5 to 11 weight. % dissolved alumina; 35 to 44 weight % aluminium fluoride; 38 to 46 weight % sodium fluoride; 2 to 15 weight % potassium fluoride; 0 to 5 weight % calcium fluoride; and 0 to 5 weight % in total of one or more further constituents.

Owner:MOLTECH INVENT

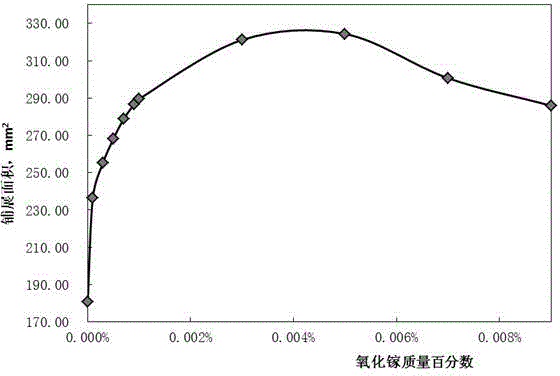

Caesium rubidium soldering flux containing gallium oxide

ActiveCN104551450ASatisfy brazing requirementsGood spreadabilityWelding/cutting media/materialsSoldering mediaRubidiumAluminium fluoride

The invention discloses a caesium rubidium soldering flux containing gallium oxide, belonging to the brazing material field of non-metallic materials. The caesium rubidium soldering flux containing gallium oxide is characterized in that the caesium rubidium soldering flux containing gallium oxide comprises the following components in proportion in mole number: 0.12-0.5 mole of rubidium fluoride (RbF), 0.12-0.5 mole of cesium fluoride (CsF), 0.001-0.2 mole of aluminium oxide (Al2O3), 0.001-0.02 mole of potassium fluoride (KF), 0.0001-0.02 mole of gallium oxide (Ga2O3), and 0.159-0.479 mole of aluminium fluoride (AlF3). According to the caesium rubidium soldering flux containing the gallium oxide, the requirement on brazing the aluminium-copper, the aluminium-steel and the aluminium-aluminium can be satisfied simultaneously and the caesium rubidium soldering flux containing gallium oxide has high activity.

Owner:ZHEJIANG YONGWANG WELDING MATERIALS CO LTD

Blue ssuperindividual corundum and preparation method thereof

ActiveCN101906663AChemically stableNo pollution in the processPolycrystalline material growthSingle crystal growth detailsAluminium fluorideZirconium dioxide

The invention discloses a blue superindividual corundum and a preparation method thereof. The preparation method comprises the following steps of: carrying out mixing, smelting, temperature reduction solidification, blowing-in grinding, magnetic separation impurity removal, screening and secondary magnetic separation impurity removal on one ton of alumina powder, anatase titanium dioxide, titanium stone powder, aluminium fluoride and zirconium dioxide powder; and then carrying out magnetic separation by using a magnetic separator so as to obtain the blue superindividual corundum. Because iron ores are not used, the smelting process causes no smoke and odour, and the processing process of a product causes no hydrogen sulfide gas, therefore the whole production process causes no pollution to the environment; in addition, because a right amount of the zirconium dioxide is added, the zirconium dioxide and the alumina appear in a crystal combining way, therefore true specific weight and granularity are obviously increased, chemical property is more stable, strength achieves 33 N, density achieves 4.02 g / cm<3>, the content of Al2O3 contained in the blue superindividual corundum achieves more than 99.55 percent, and the content of various impurities is lower.

Owner:XIXIA ZHENGHONG MONOCRYSTALLINE CORUNDUM

Anti-oxidation coating for carbon anodes in aluminum electrolysis

The invention relates to a technology for preventing high-temperature oxidation of carbon anodes during aluminum electrolysis production, specifically to an anti-oxidation coating for carbon anodes in aluminum electrolysis. The coating comprises, by weight, 30-40% of alumina powder, 10-20% of sodium fluoride, 10-20% of aluminium fluoride, 1.0-5.0% of a complex anti-oxidant, 10-15% of a binder, 2-5% of a suspending agent and the rest of a solvent. The high-temperature anti-oxidation coating can effectively raise oxidation resistance of carbon anodes at high temperature, has an effect of resisting corrosion of cryolite slag to the coating, effectively reduces carbon anode consumption in aluminum electrolysis production, prolongs service life of carbon anodes, saves consumption cost of carbon anodes, decreases discharge of gas generated by high-temperature oxidation-combustion of carbon anodes, and obviously improves the working environment.

Owner:SHENYANG RES INST OF FOUNDRY

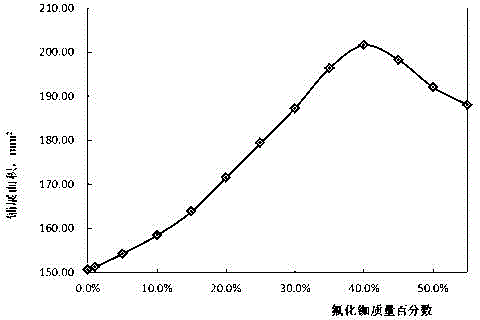

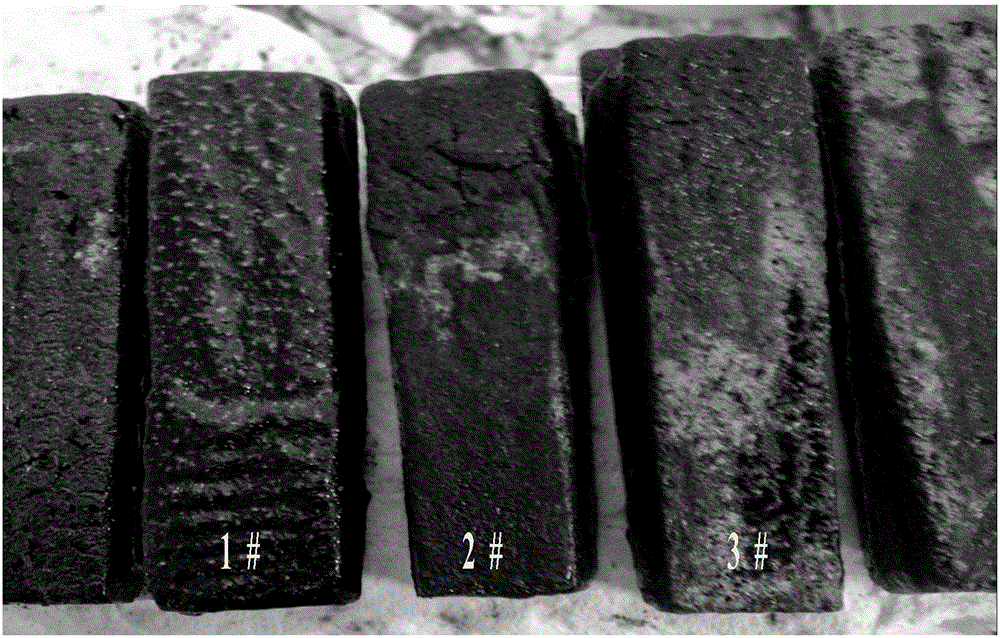

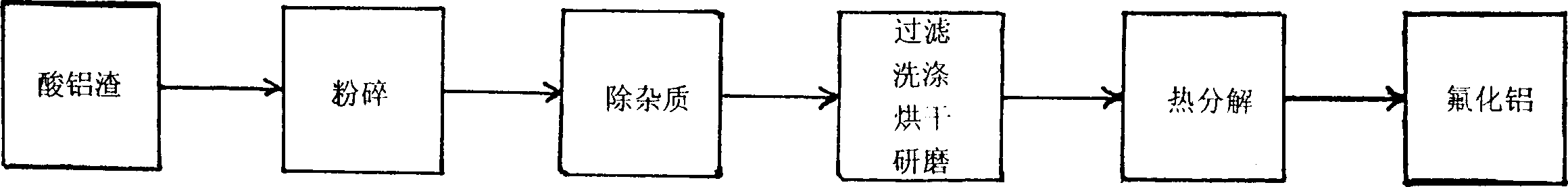

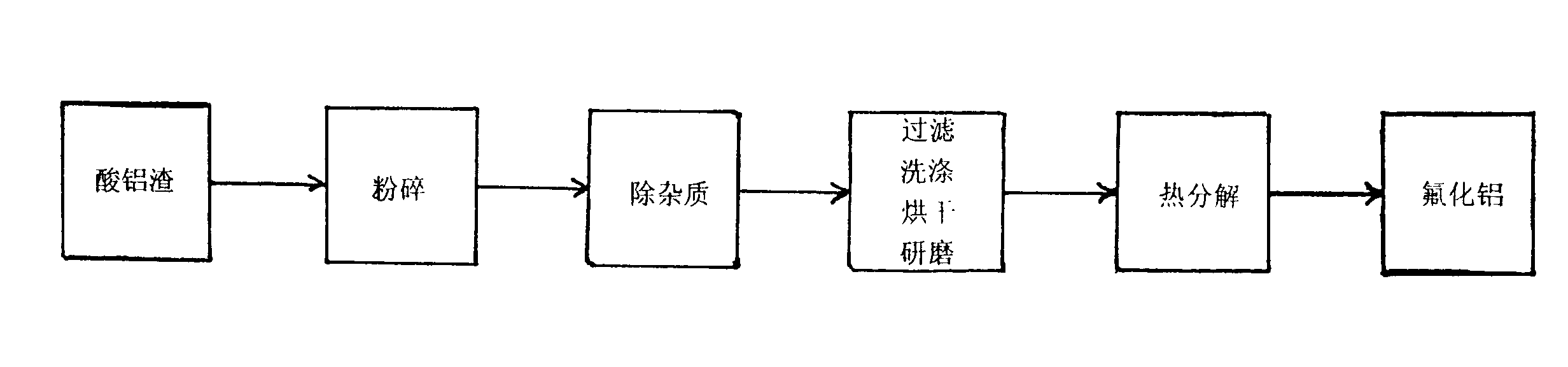

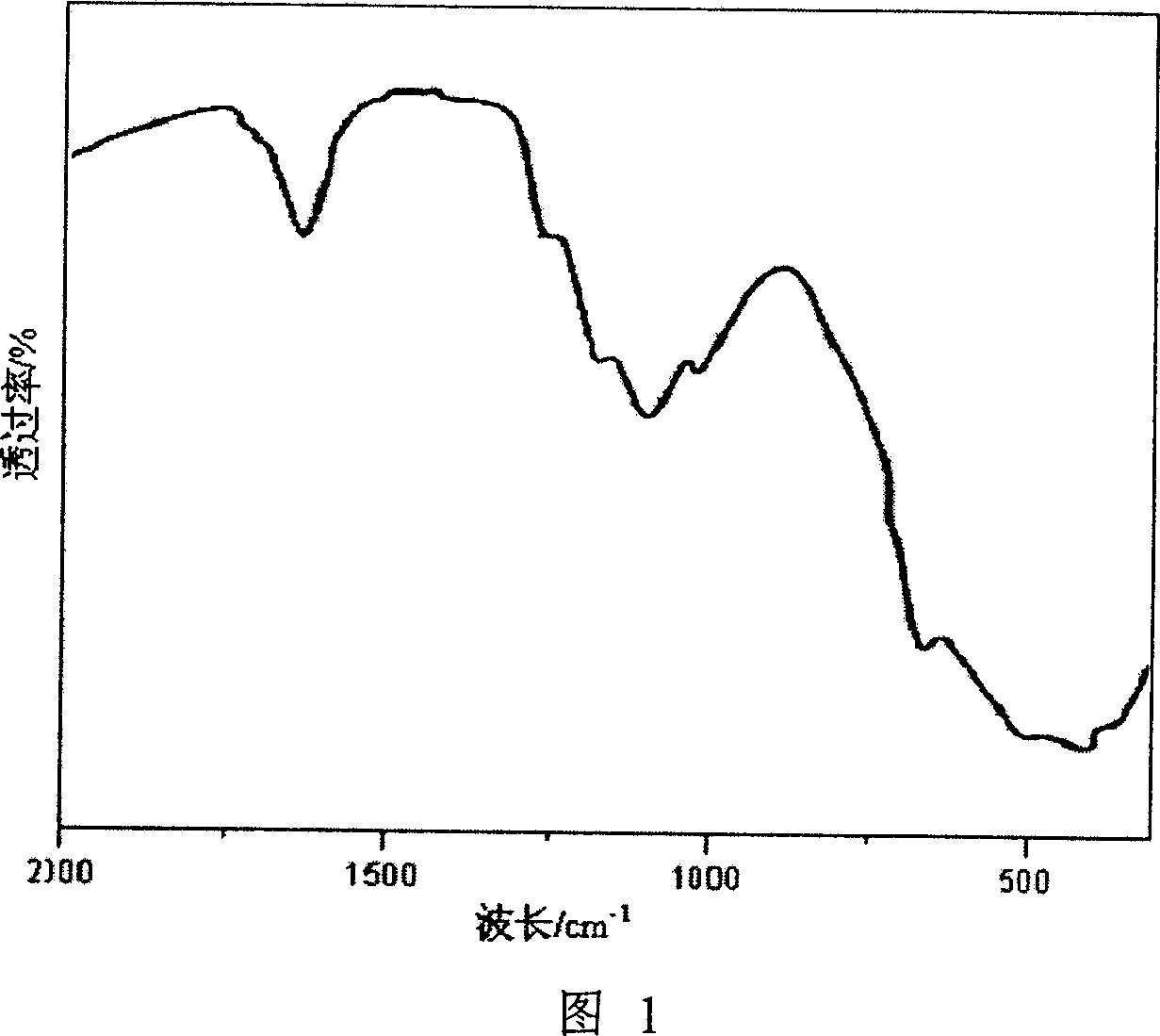

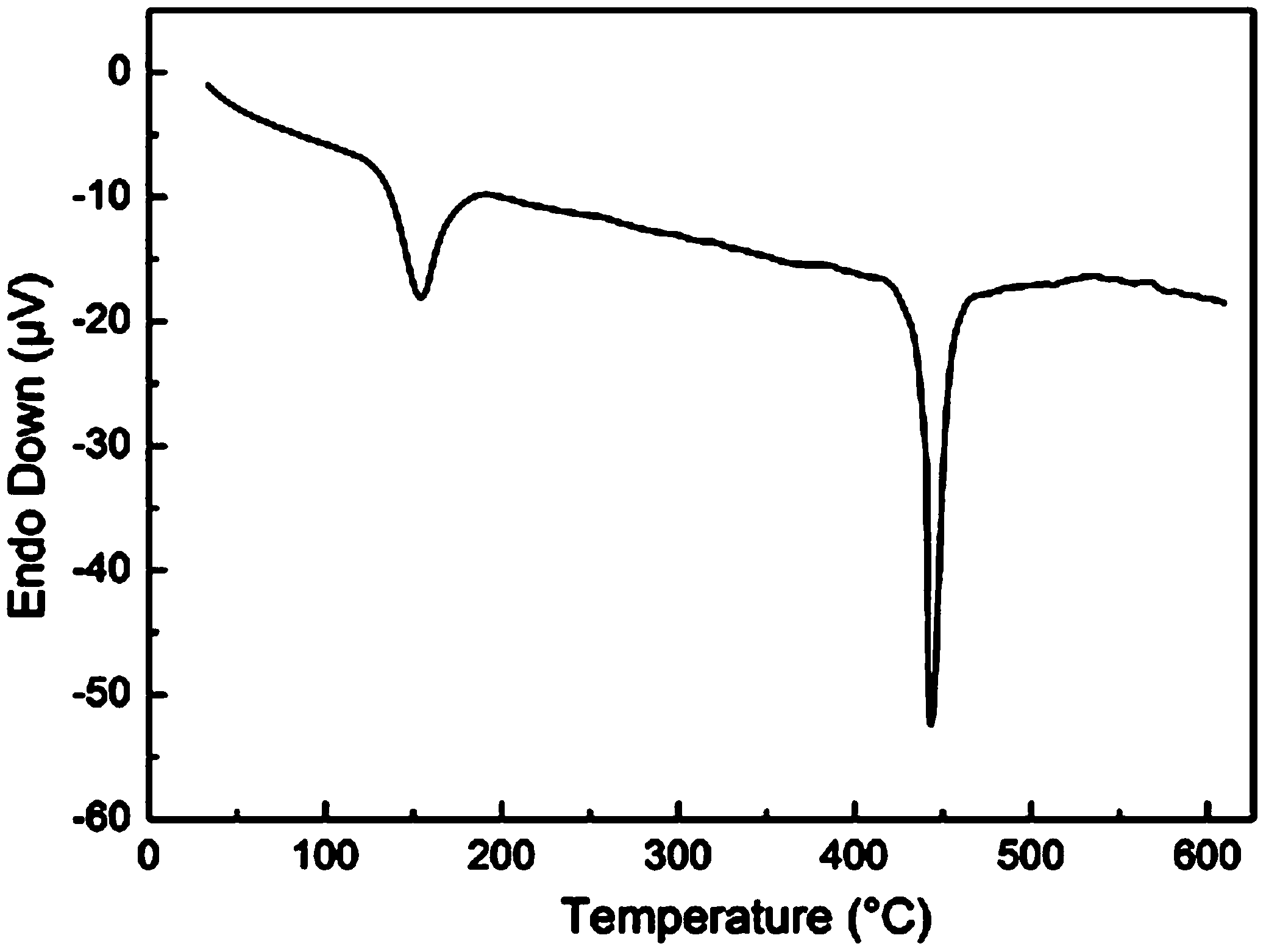

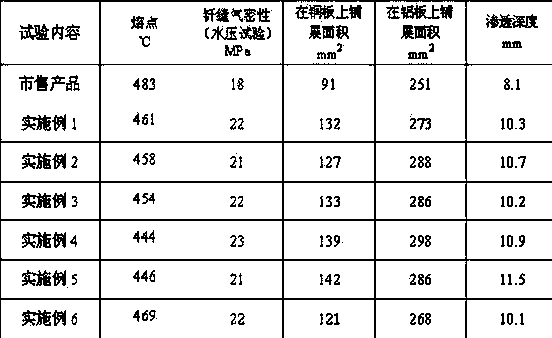

Process for preparing industrial aluminium fluoride from acidic aluminium slag

InactiveCN1382633AImprove protectionSave resourcesSolid waste disposalAluminium fluoridesSlagFerrosilicon

A process for preparing industrial aluminium fluoride from acidic aluminium dregs, which is the waste generated in producing aluminium section and contains ammonium fluoaluminate, other ammonium salts and ferrosilicon, includes pulverizing dried raw material, adding the mixed solution of HF 1-30% and HCl 1-30%, stirring at temp from ordinary temp 80 deg.C for 60-90 min while reaction of ferrosilicon compound on HF and HCl, filtering for separating raw material from mother liquid, washing in clean water, dripdrying, baking at 120 deg.C for 1 hr, grinding, decomposing at 500-800 deg.C for 40-60min, and cooling. Its advantages are simple process and recovering ammonium fluoride as by-product.

Owner:周民强

Rare-earth-containing composite solid super acidic catalyst and its preparing method

InactiveCN1935373AHigh catalytic efficiencyDoes not cause crystallizationMetal/metal-oxides/metal-hydroxide catalystsAluminium chlorideRare earth

The present invention discloses a composite type solid super acidic catalyst containing rare earth. It is formed from ZrO2 carrier containing sulfuric acid radical ion, TiO2 carrier, rare earth metal oxide and halide of aluminium, in which the content of sulfuric acid radical ion is 10-20%, halide content of aluminium is 1-5%, water content in the catalyst is 0-1%, ZrO2 carrier content is 43-80% TiO2 carrier content is 43-80%, rare earth metal oxide content is 3-10% and the specific surface area of said catalyst is 100-300 sq.m / g. The halide of aluminium is selected from aluminium fluoride or aluminium chloride or mixture of both them, and the described rare earth metal oxide is one of lanthanum oxide or cerium oxide or samarium oxide or mixture of their two kinds.

Owner:SHANGHAI INST OF TECH

Fluoride brazing flux for copper-aluminum dissimilar metal and preparation method for fluoride brazing flux

ActiveCN103769776AReduce the temperatureLow melting pointWelding/cutting media/materialsSoldering mediaPotassium fluorideCopper fluoride

The invention relates to the field of brazing materials, in particular to fluoride brazing flux for copper-aluminum dissimilar metal and a preparation method for the fluoride brazing flux. The fluoride brazing flux consists of cesium fluoride, aluminum trifluorid, potassium fluoride, copper difluoride and assistant. The preparation method comprises the following steps: mixing the cesium fluoride, the aluminum trifluorid, the potassium fluoride, the copper difluoride, zinc difluoride and lithium fluoride powder with zinc powder or ZnAl alloyed powder in proportion, adding a proper amount of deionized water and grinding in a mortar to form paste, and then, drying and grinding.

Owner:ZHEJIANG XINRUI WELDING MATERIAL

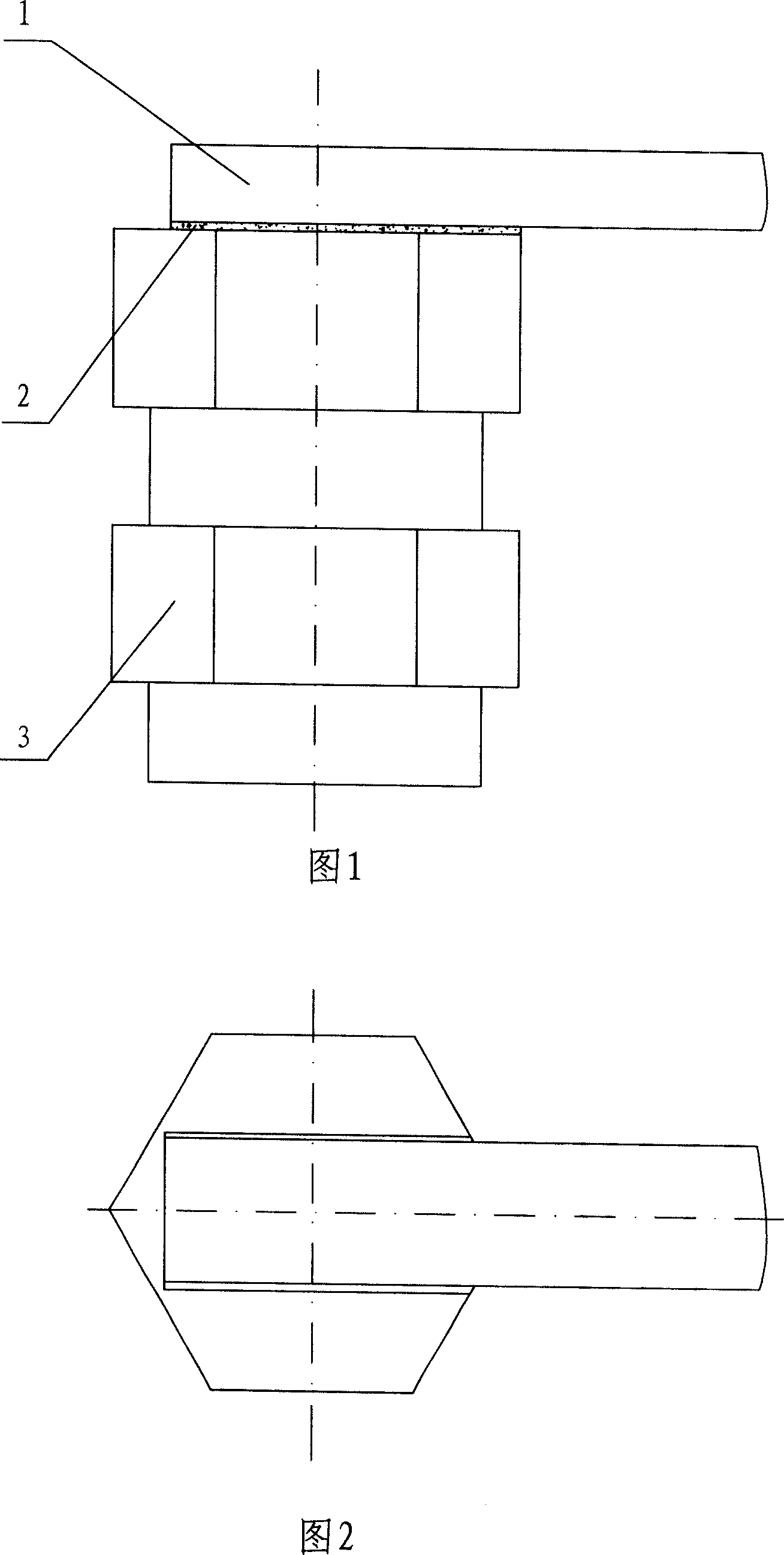

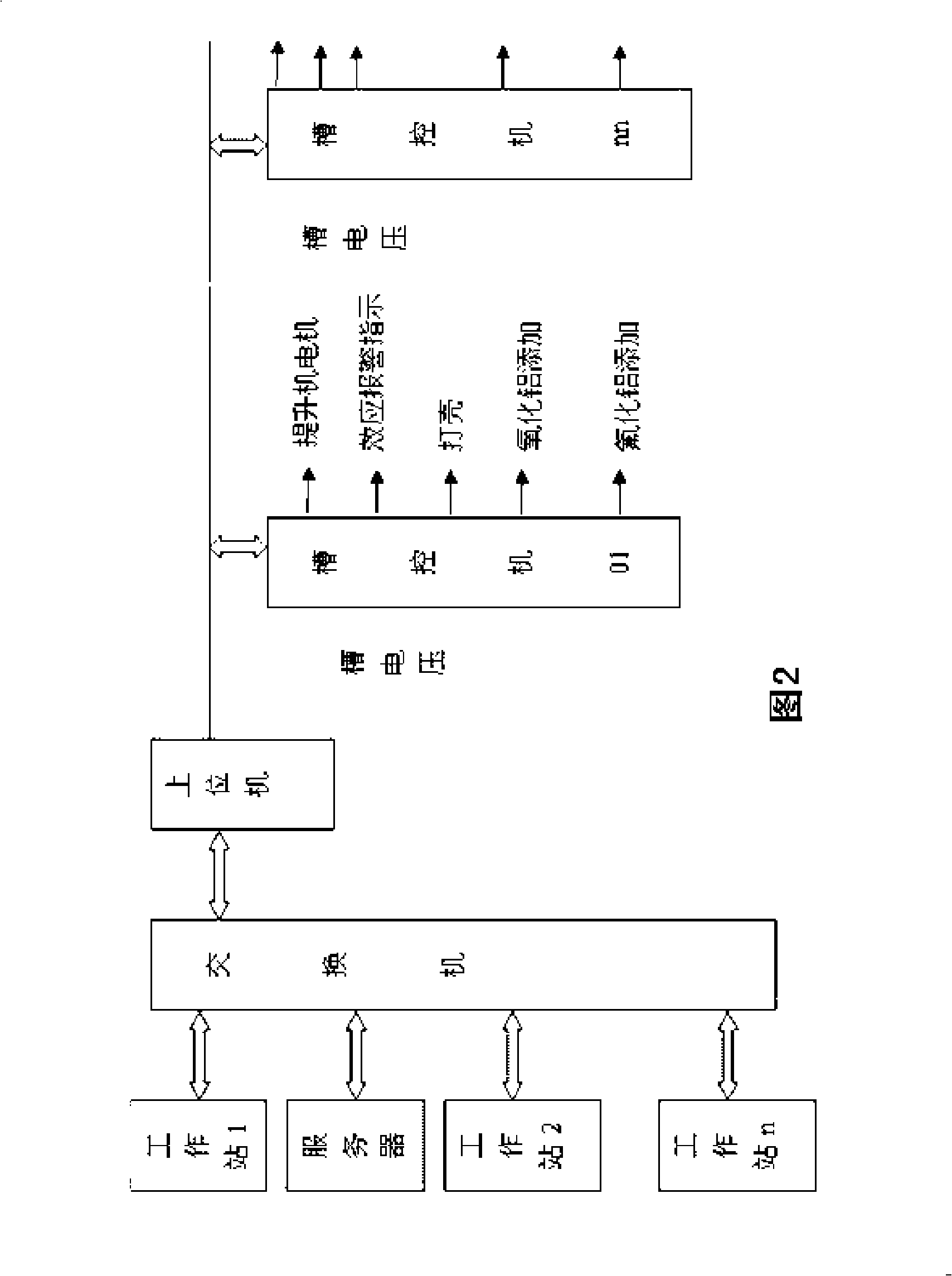

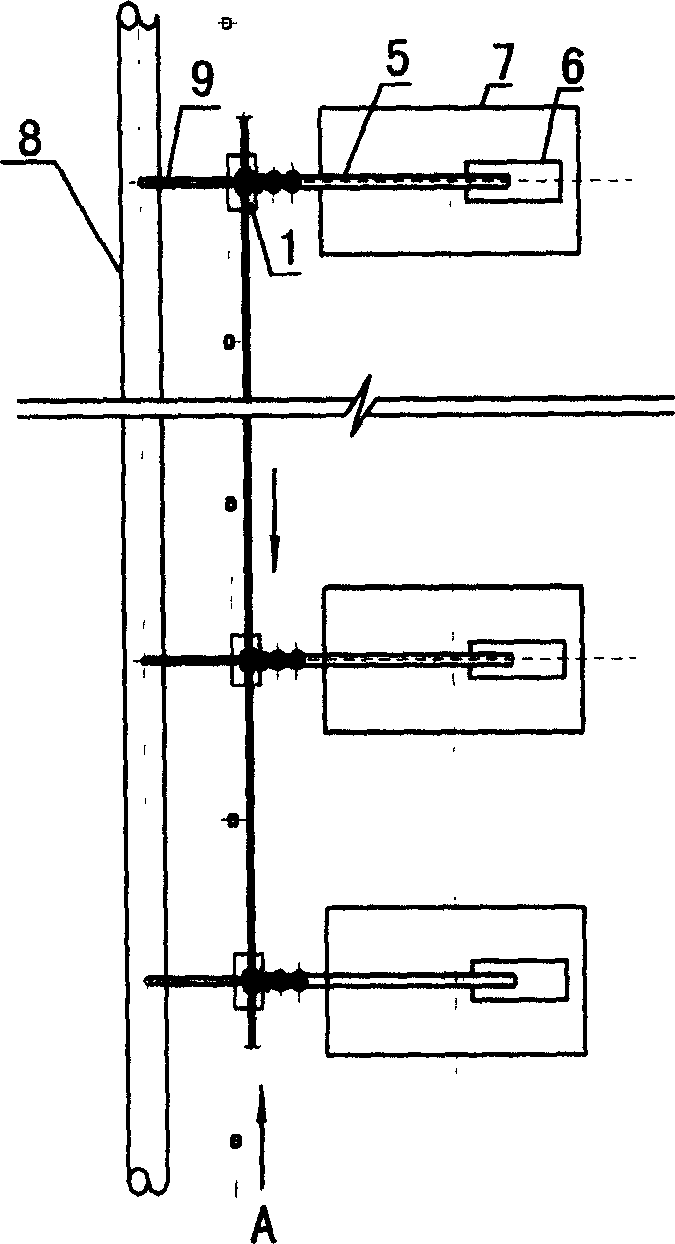

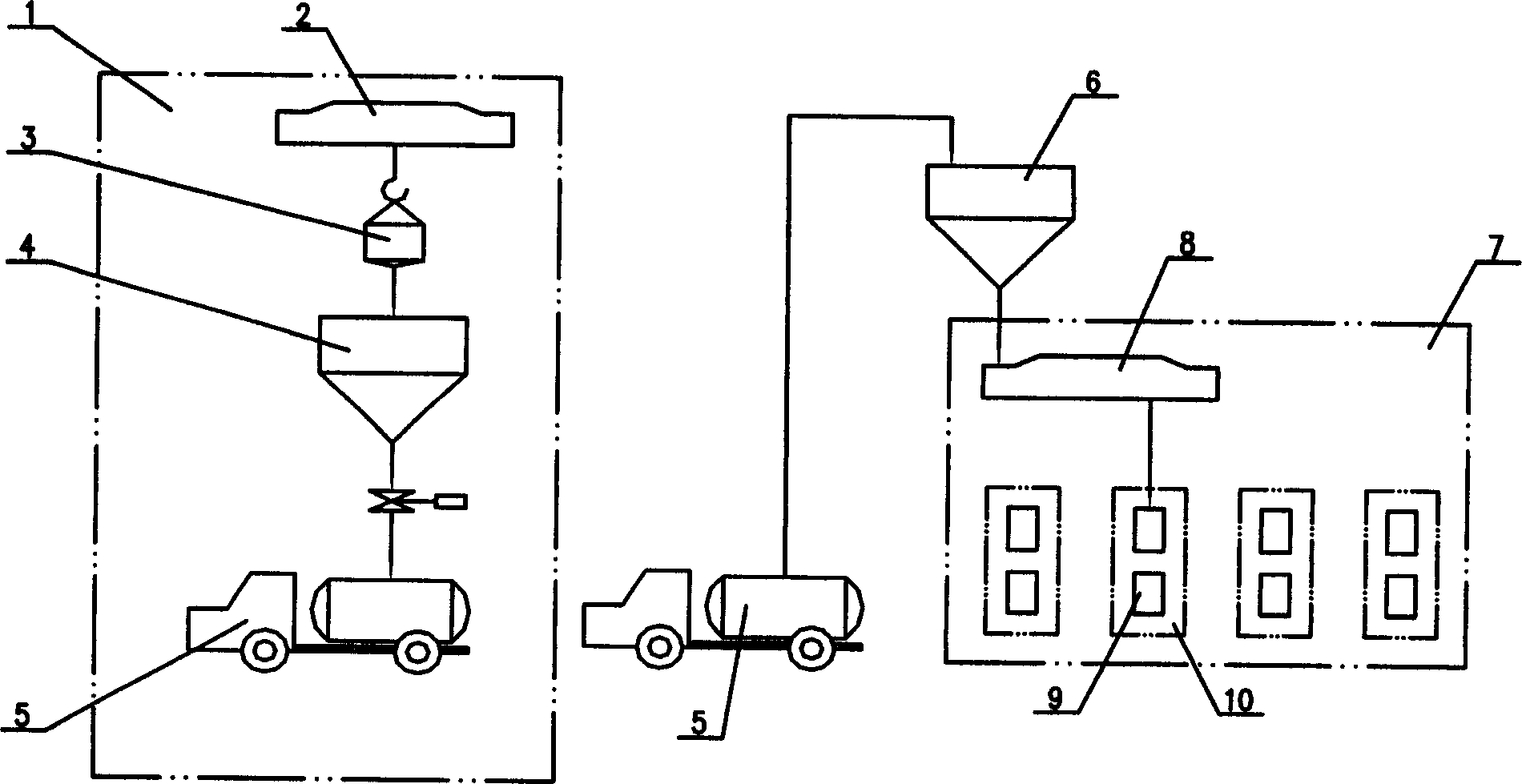

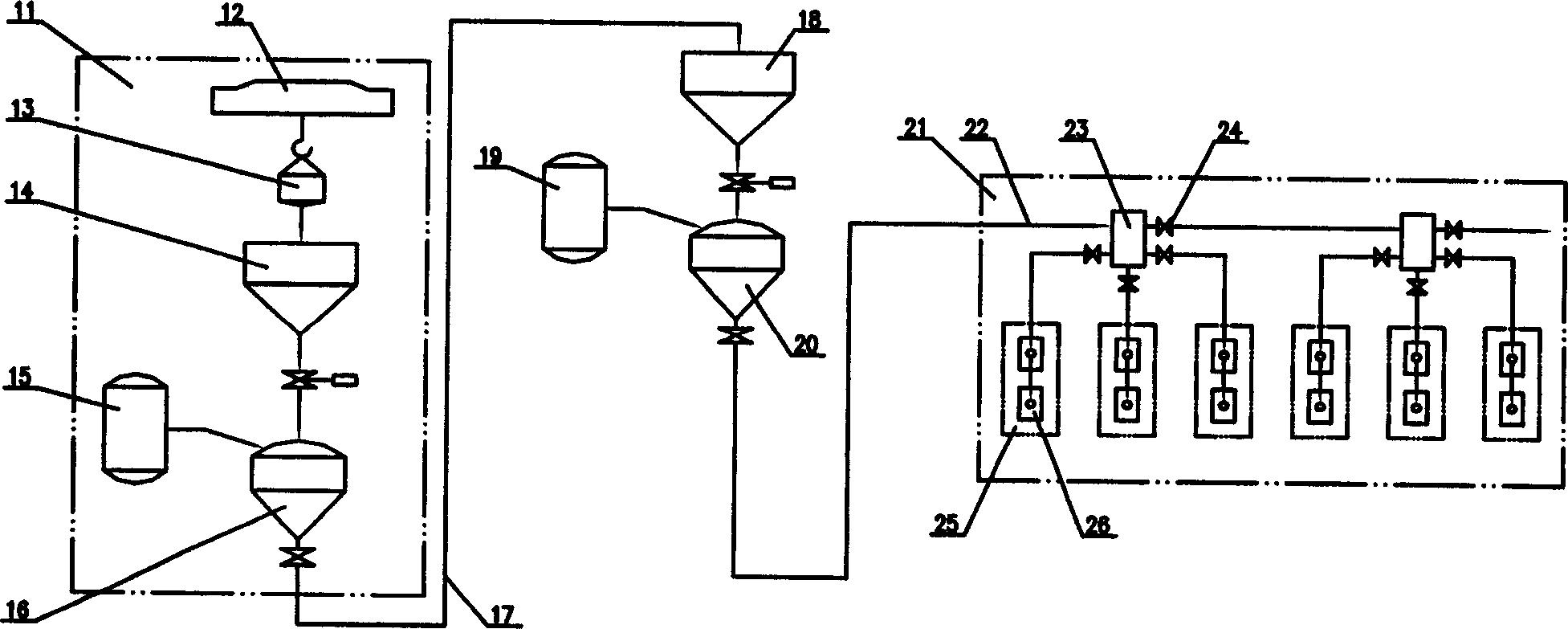

Process and device adding aluminium fluoride raw material to aluminium electrolyic tank

The invention discloses a method of adding aluminium fluoride into the aluminium electrobath and its device. It adopts the wind-driving sluice to add the alumina and aluminium fluoride to the enriching box of the aluminium electrobath at the same time. That is the material of alumina and aluminium fluoride is input into the wind-driving sluice at the same time. Mixing them in the wind-driving sluice and then putting them into the material box and then into the aluminium electrobath. The advantages are simple structure and reliable work, increasing the useful life of the electrobath.

Owner:GUIYANG AL-MG DESIGN & RES INST

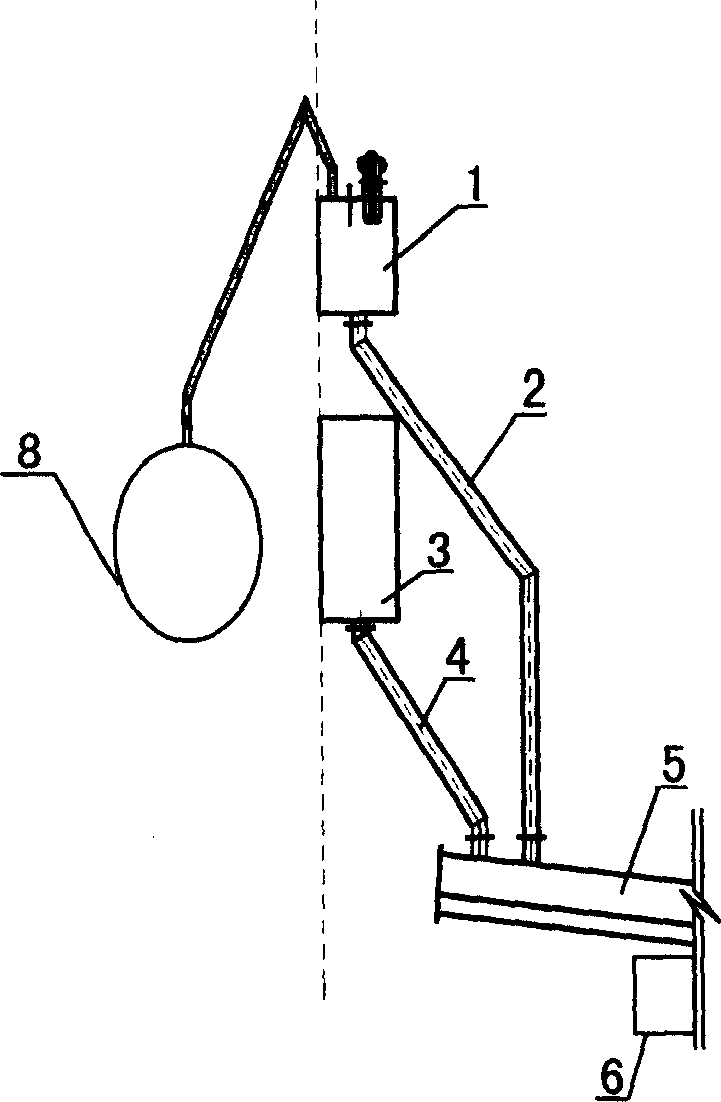

Charging method of adding aluminium fluoride into electrolytic bath fluoride salt material box and its charging device

The invention discloses a material handling device adding aluminium fluoride to electrolytic cell fluoride salt charging box and its method. It includes the following steps: using lifting crown block to hang aluminium fluorides to laying off equipment; unpacking to pressure vessel; using dense-phase transport pipeline to transport aluminium fluoride to transship storehouse and laying off equipment; using its dense-phase transport pipeline to transport the aluminium fluoride to electrolytic cell fluoride salt charging box. The method optimizes the aluminium fluoride adding type, reduces energy consumption, manual operation, and production cost.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Method for preparing aluminium-silicon alloy and aluminium fluoride through reducing silicon tetrafluoride by utilizing aluminium

The invention provides a method for preparing aluminium-silicon alloy and aluminium fluoride through reducing silicon tetrafluoride by utilizing aluminium, relates to the technical field of materials, in particular to a method for preparing aluminium-silicon alloy and aluminium fluoride through reacting silicon tetrafluoride with aluminium. The method comprises the following steps: a, melting 100-110kg of industrial aluminium powder in a graphite crucible and maintaining the temperature at 800-900 DEG C; b, introducing 20-100kg of industrial silicon tetrafluoride gas into the graphite crucible at a speed of 3-5kg / min so as to react with molten aluminium, thus obtaining soild aluminium fluoride and molten aluminium-silicon alloy; and c, separating the obtained solid aluminium fluoride from the molten aluminium-silicon alloy. By utilizing the method provided by the invention, the problems such as the three wastes, high energy consumption and the like existing in a traditional process route can be solved, the environment load is smaller, and the environmental benefits are higher.

Owner:YUNNAN CHEM RES INST

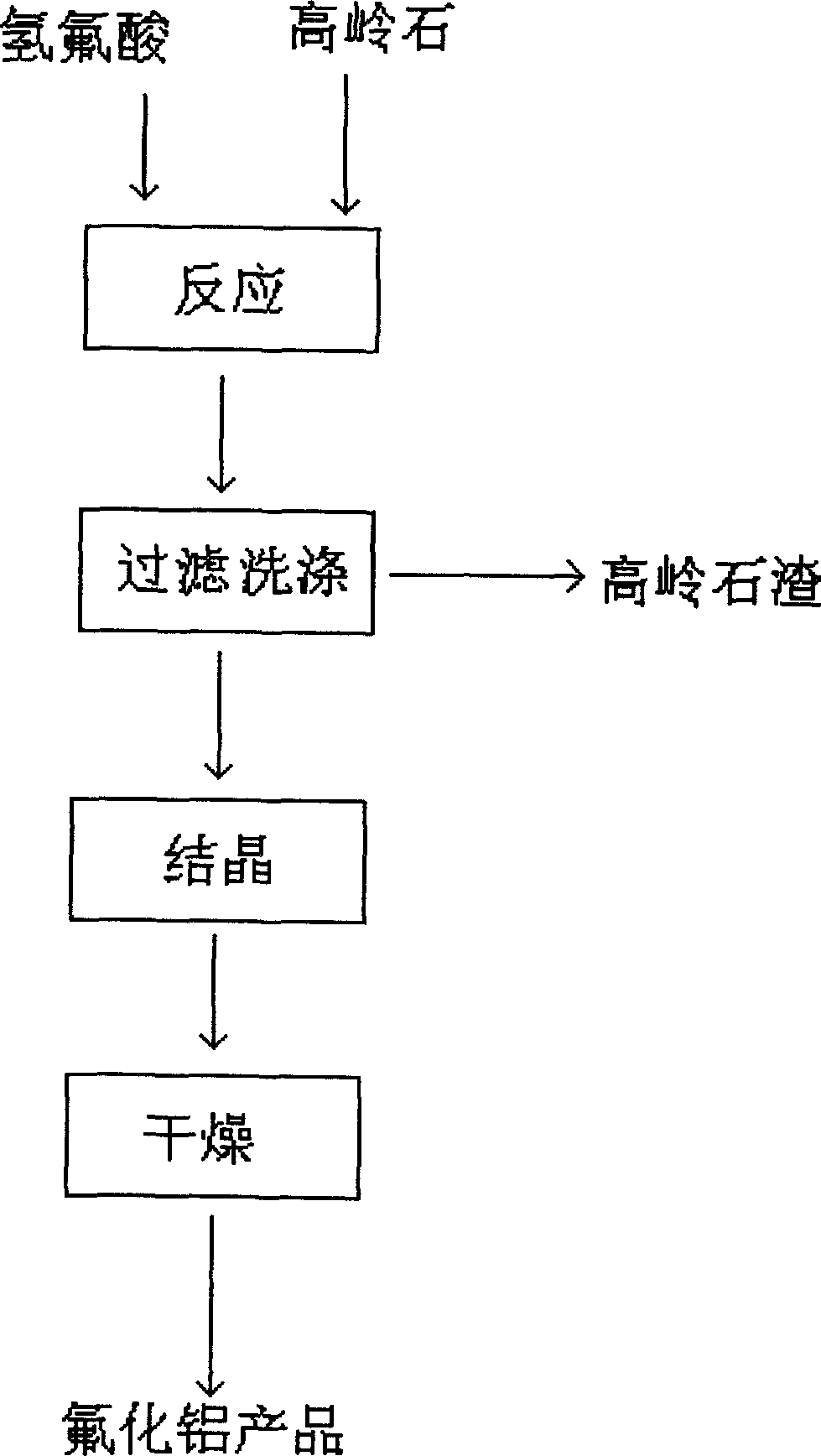

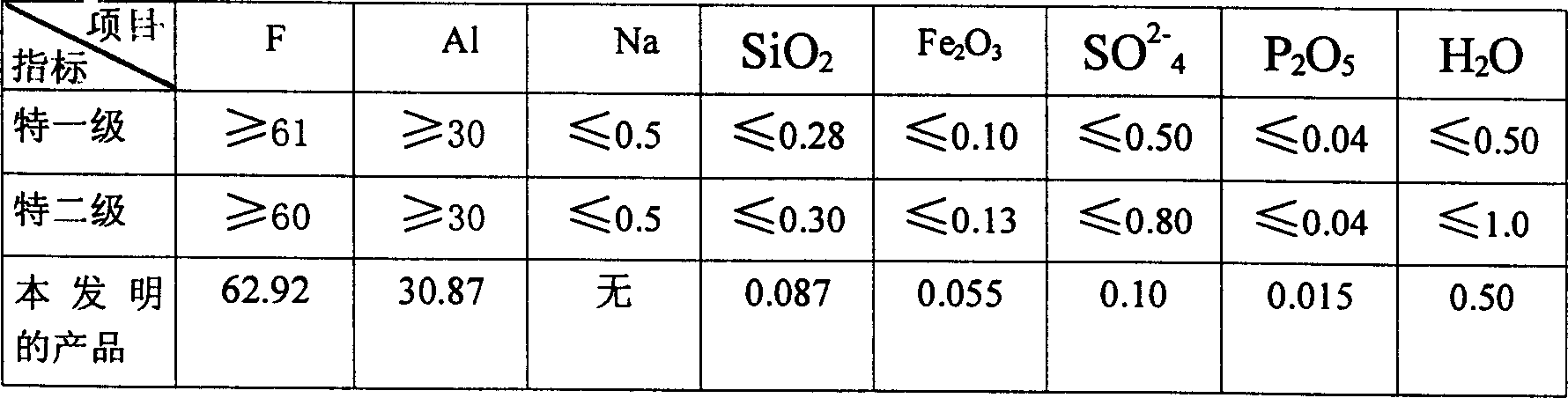

Method for producing aluminum fluoride

A process for preparing aluminium fluoride incldues such steps as reaction between hydrofluoric acid and kaolinite at 80-100 deg.C for 10-30 min, filter, washing the kaolinite dregs with filtrate to obtain solution of aluminium fluoride, crystallizing to obtain trihydrated aluminium fluoride, and drying.

Owner:DO FLUORIDE CHEM CO LTD

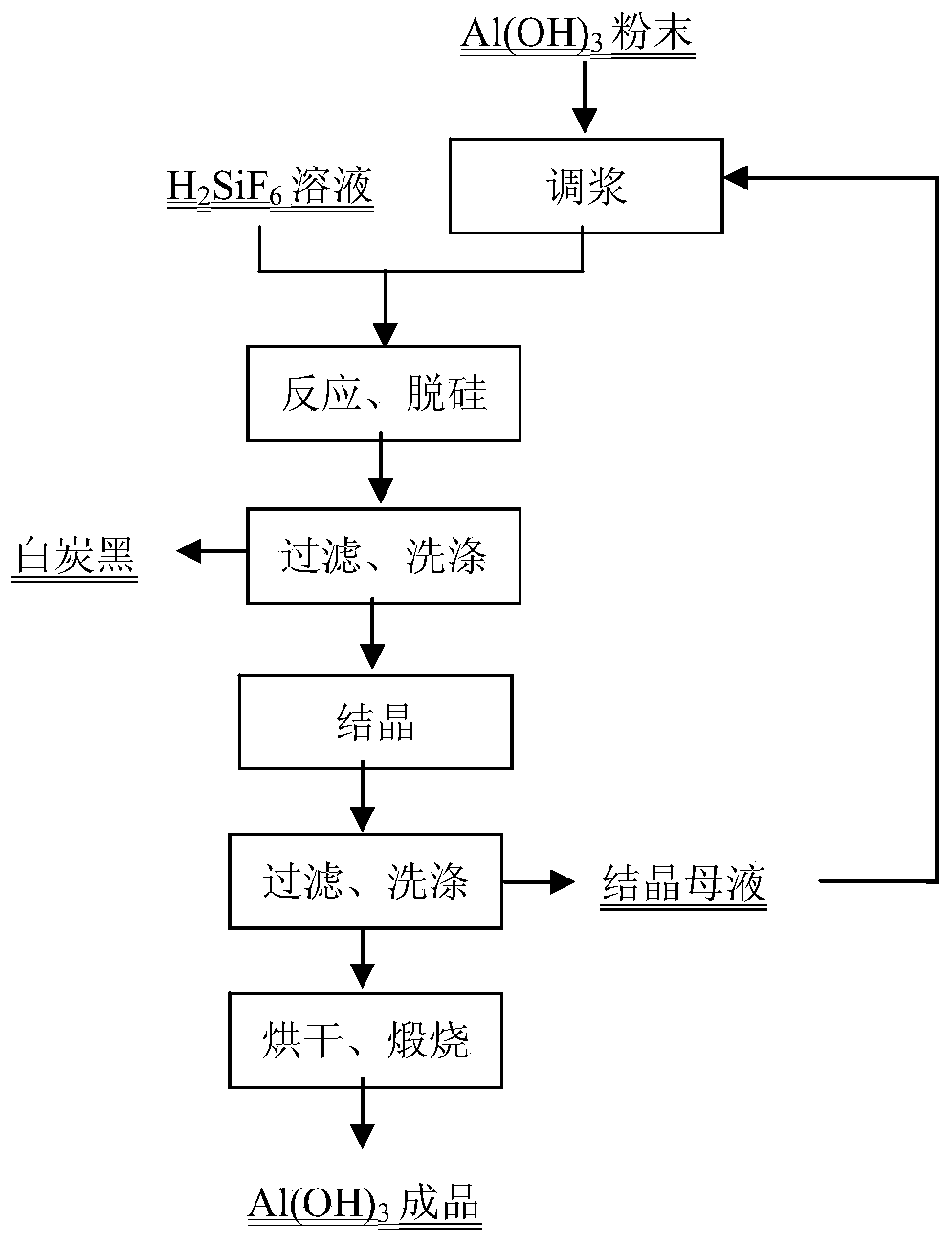

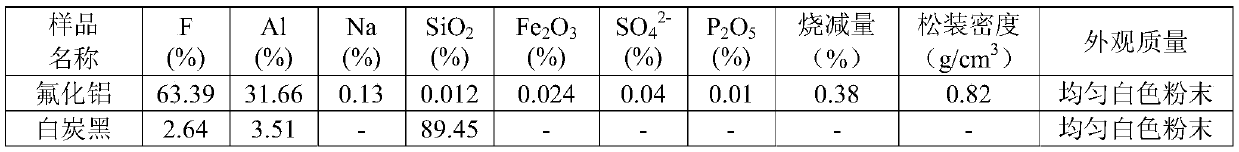

Method for directly producing aluminum fluoride by fluorosilicic acid

InactiveCN110316749AAvoid wrappingHigh recovery rateSilicaAluminium fluoridesReaction rateAluminium hydroxide

The invention relates to a method for directly producing aluminum fluoride by fluorosilicic acid. A phosphoric acid industrial by-product, namely, fluorosilicic acid, aluminum hydroxide and an aluminum fluoride crystallization mother liquor are adopted as raw materials, the aluminum fluoride crystallization mother liquor is adopted for pre-adjusting aluminum hydroxide powder into slurry, the slurry is pumped into a pre-heated fluorosilicic acid solution for a reaction, and an aluminum fluoride product is obtained after desiliconization, crystallization, drying and calcination. On the premise of not changing the reaction rate of the aluminum hydroxide and the fluorosilicic acid, the crystallization mother liquor and the aluminum hydroxide pre-adjusted slurry are recycled, so that the aluminum hydroxide fully reacts with the fluorosilicic acid, an encapsulation phenomenon generated in the direct reaction process of the aluminum hydroxide powder and the fluorosilicic acid and a channel overflowing phenomenon caused by excessive foam are avoided, and a production technology with high utilization rate of aluminum, smooth process and stable operation is provided for directly producing the aluminum fluoride by the fluorosilicic acid.

Owner:KUNMING CHUAN JINNUO CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com