Fluorine-containing waste gas utilization method in phosphorus fertilizer production

A waste gas and phosphate fertilizer technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as product quality, economic competition, and limited fluorite reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

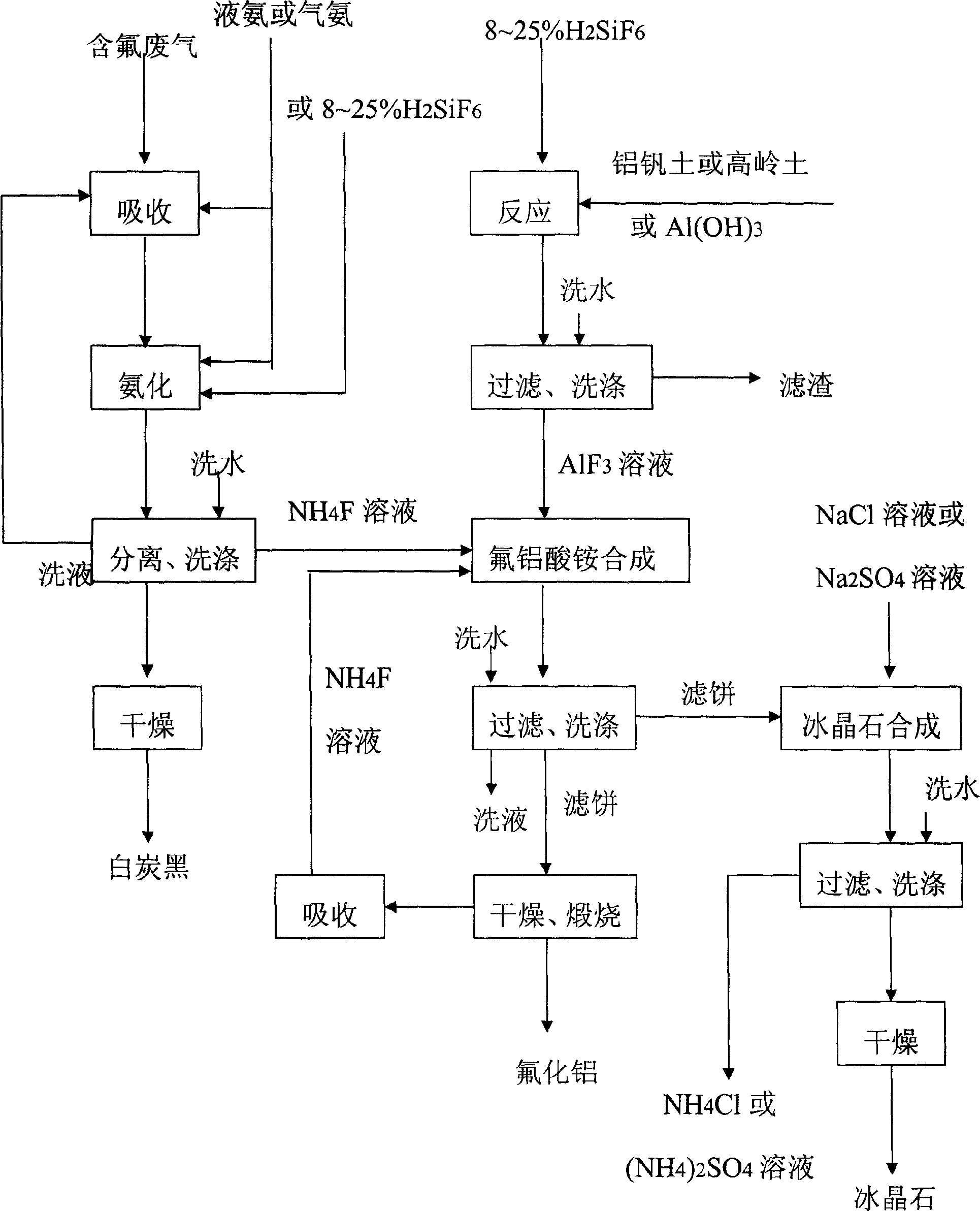

Method used

Image

Examples

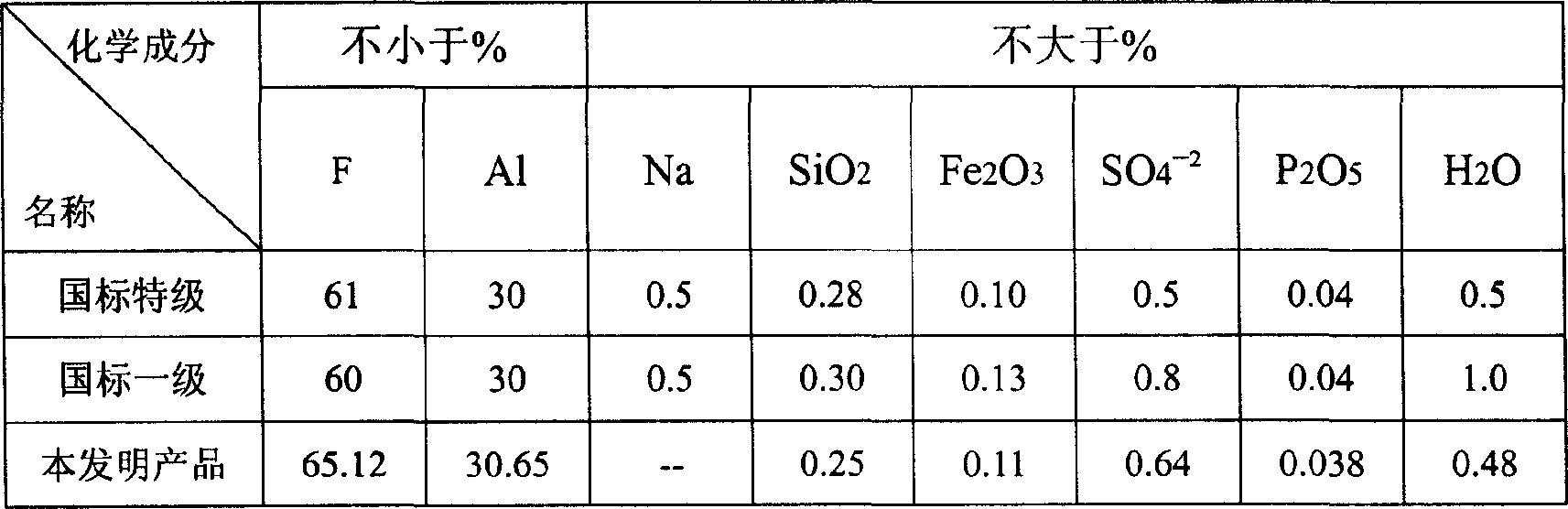

Embodiment 1

[0044] Bring the concentration to ~20% NH 4 The F solution is introduced into the exhaust gas absorption system of the chemical formation chamber with an annual output of 100,000 tons of ordinary calcium for absorption, and the concentration ~ 34% (NH 4 ) 2 SiF 6 Solution, add it and liquid ammonia to the ammoniator at the same time and control its pH value at 7.2-7.5, feed liquid ammonia into the ammoniator and control the final pH value of the ammoniation reaction to be above 8, and the temperature at 50-70°C In between, the obtained slurry was aged for 1 hour and then filtered, washed countercurrently with clean water until the eluate was close to neutral, and the filter cake was dried at 110°C to obtain a specific surface area of 110m 2 / g of precipitated silica (silica) product and a concentration of 40.6% NH 4 Ammonium fluoride solution of F; add concentration of 15% H in another reactor 2 SiF 6 Fluorosilicic acid, after preheating to 75°C, add a theoretical amoun...

Embodiment 2

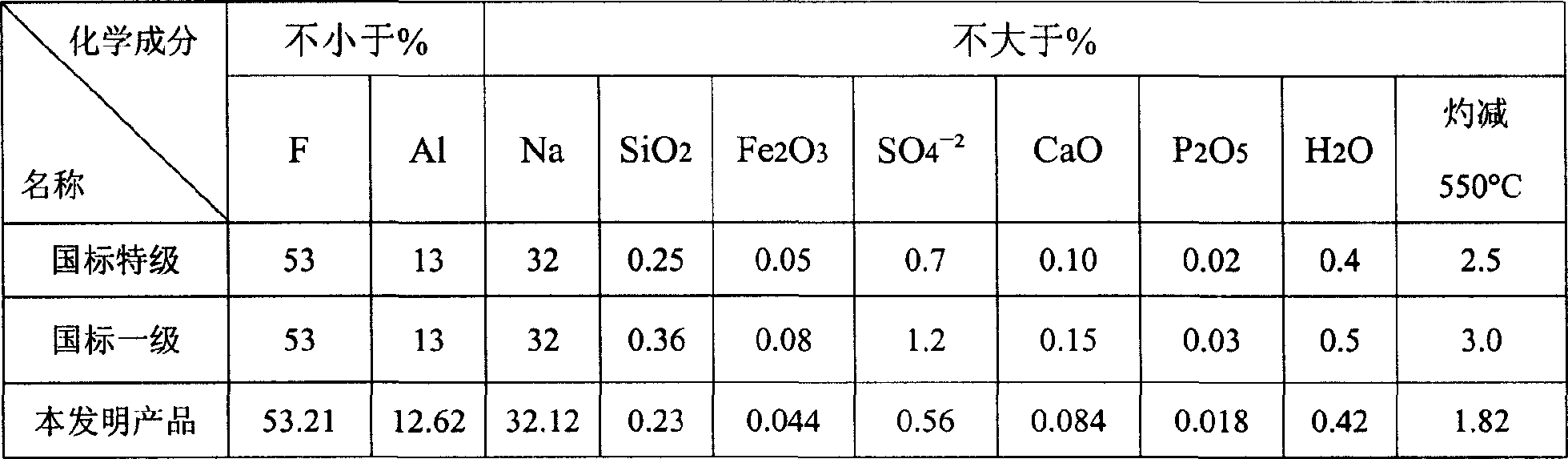

[0049] The ammonium fluoroaluminate filter cake in Example 1 was dried at 110°C and then calcined at 550°C for 1.5 hours to obtain the aluminum fluoride product. The gas produced by calcining was absorbed to obtain a concentration of 42.6% NH 4 The ammonium fluoride solution of F is returned to react with the aluminum fluoride solution in Example 1 to produce ammonium fluoroaluminate for the production of aluminum fluoride again. The product quality is shown in Table 2.

[0050] Table 2. Aluminum fluoride national standard and process product quality of the present invention

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com