Patents

Literature

109 results about "Ammonium fluorosilicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium fluorosilicate (also known as ammonium hexafluorosilicate, ammonium fluosilicate or ammonium silicofluoride) has the formula (NH₄)₂SiF₆. It is a toxic chemical, like all salts of fluorosilicic acid. It is made of white crystals, which have at least three polymorphs and appears in nature as rare minerals cryptohalite or bararite.

Small crystal particle Y-shaped molecular sieve and preparation method thereof

ActiveCN101759198AReduce pollutionEasy to makeFaujasite aluminosilicate zeoliteAmmonium fluorosilicateOxygen

The invention discloses a small crystal particle Y-shaped molecular sieve and a preparation method thereof. The property of the small crystal particle Y-shaped molecular sieve is as follows: the molar ratio of Si, O2 / Al2O3 is 10.0-120.0, the cell parameters are 2.420-2.445 nm, the crystallization retention is larger than 95 percent, and B acid / L acid is above 7.0. Due to higher raw material thermal and hydrothermal stability, higher silicon-aluminum ratio, good stability and uniform framework silicon-aluminum structure, the small crystal particle NaY molecular sieve can ensure the framework continuity of the molecular sieve, reduce the collapse possibility of the framework structure and maximally keep the integrity of a silicon-aluminum-oxygen structure in the modification, namely in the ammonia exchange, ammonium fluorosilicate dealumination and silicon reinsertion, hydro-thermal treatment, aluminum salt and acid mixed water solution treatment process, thereby having high crystallization retention. The Y-shaped molecular sieve can be taken as an active component of a hydrocracking catalyst, thereby improving the activity of the catalyst, the selectivity of the molecular sieve and the product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

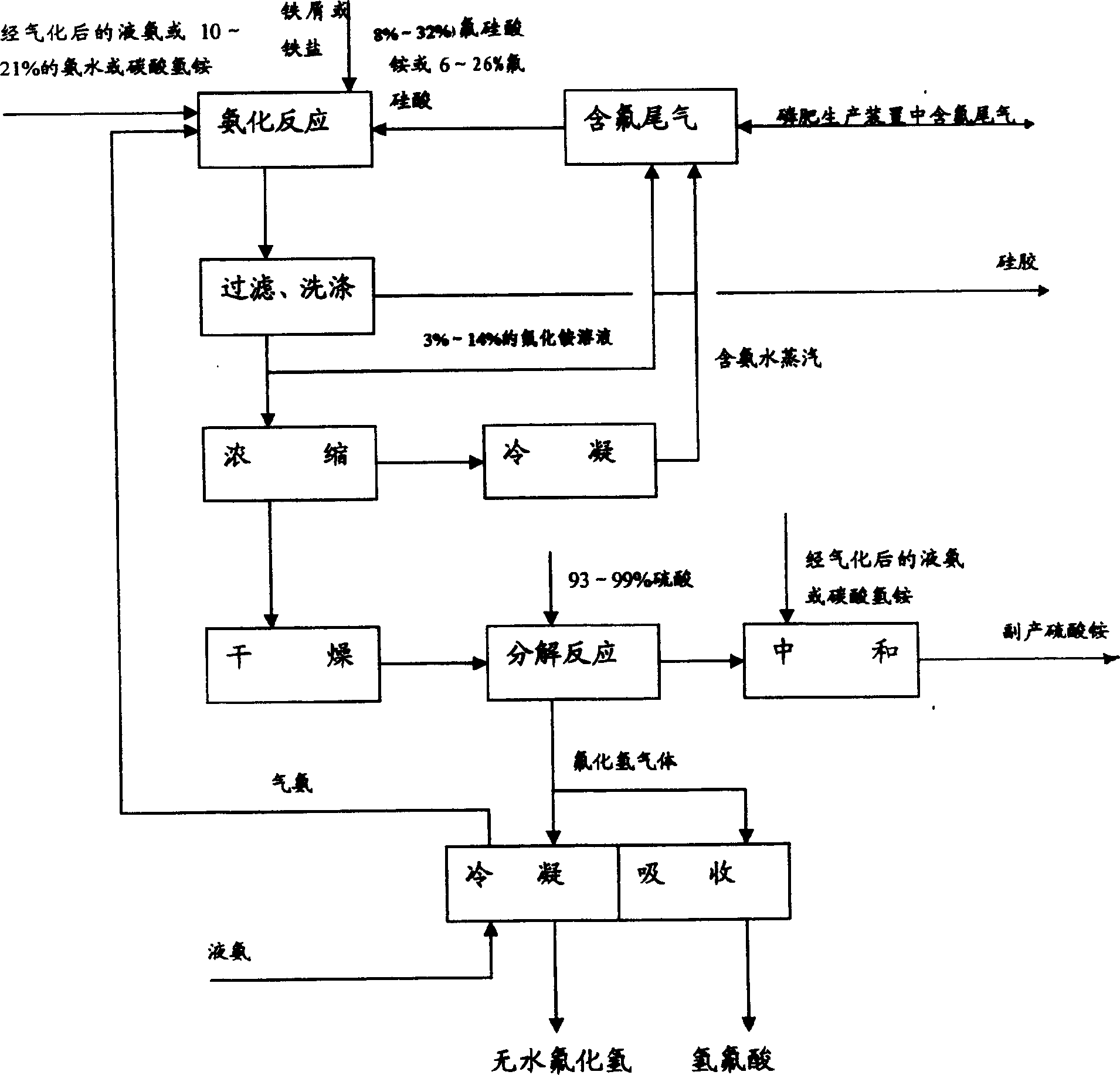

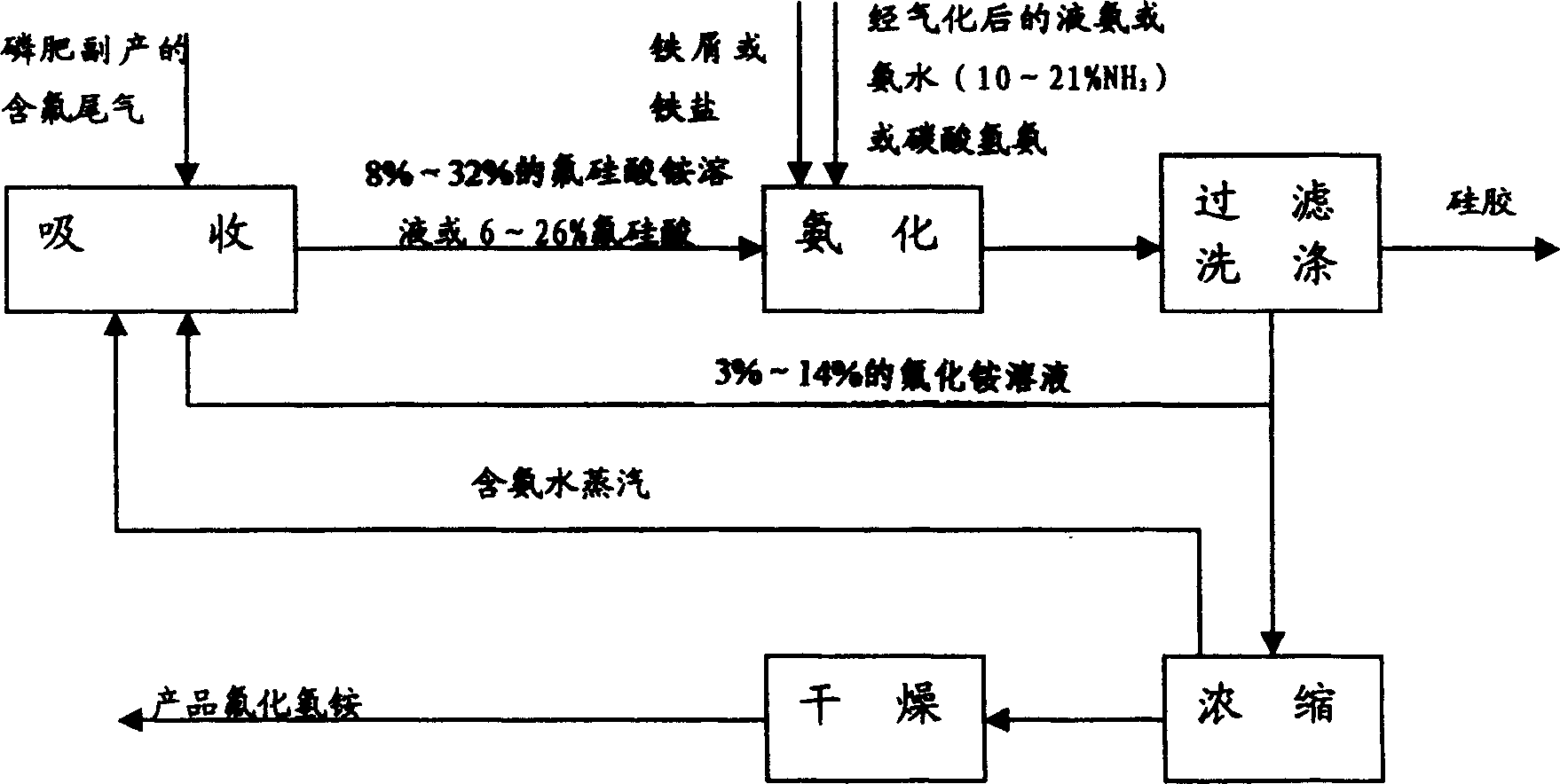

Method for comprehensively utilizing phosphate fertilizer by-product

InactiveCN1554570AReasonable designReduce material requirementsSolid waste disposalFluorine/hydrogen-fluorideIron saltsAmmonium fluorosilicate

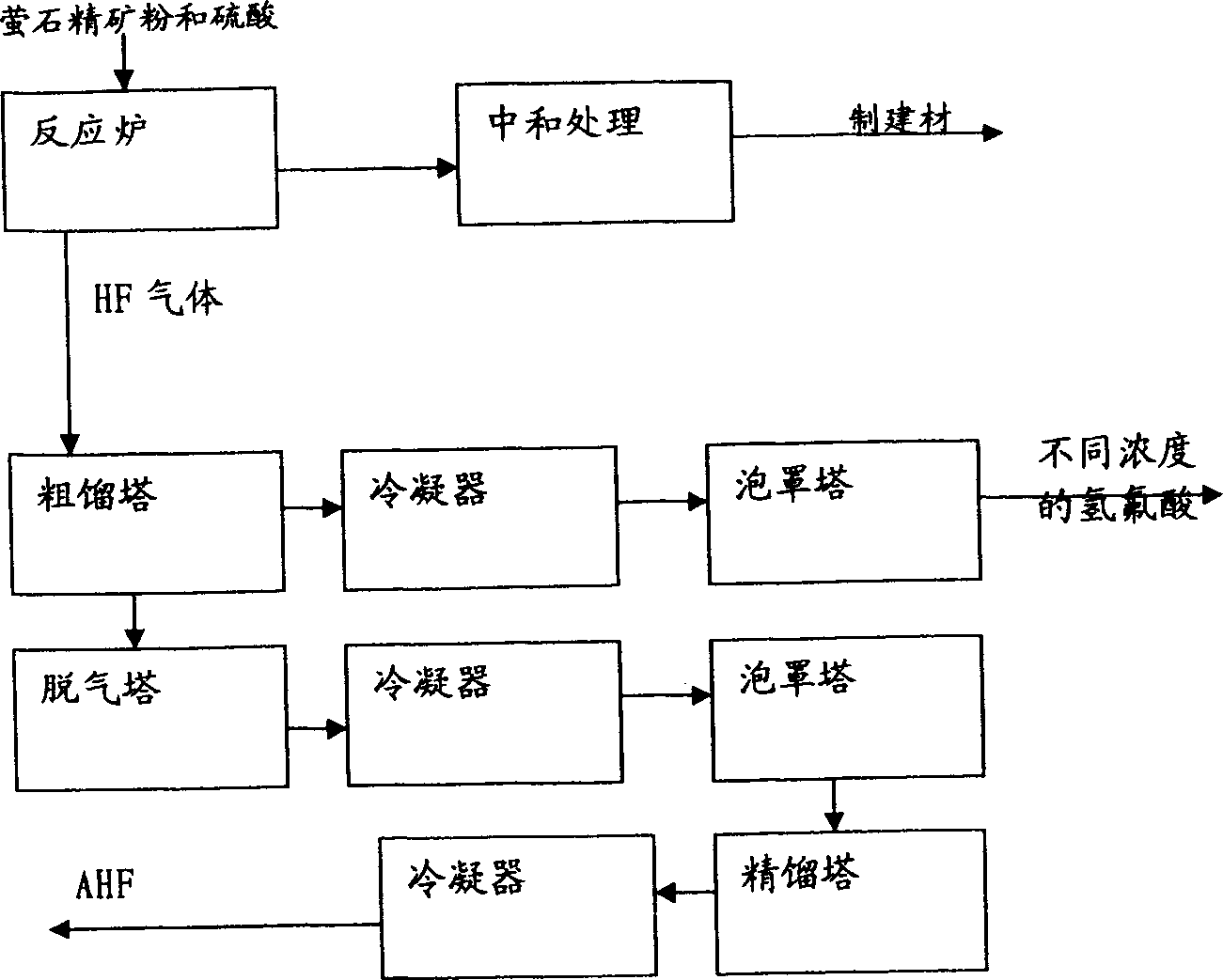

The method of comprehensively utilizing phosphate fertilizer by-product includes utilizing ammonium fluoride solution of 3-14% concentration to absorb side product fluorine containing tail gas ammonium fluorosilicate solution; adding iron scrap or iron salt to fluorosilicic acid as one other by-product to eliminate phosphorus; adding liquid ammonia, ammonia water or ammonium bicarbonate; filtering, washing, and eliminating silica precipitate; returning ammonium fluoride solution to phosphate fertilizer absorbing system, concentration and drying to obtain ammonium hydrogen fluoride; reacting solid ammonium hydrogen fluoride and sulfuric acid at high temperature to obtain HF gas, absorbing HF gas to obtain hydrofluoric acid, purification and condensation to obtain anhydrous HF; and mixing the mixture of ammonium sulfate and ammonium bisulfate with ammonium bicarbonate or ammonia in a mixer, curing and crushing to ammonium sulfate fertilizer.

Owner:云南三环化工有限公司 +1

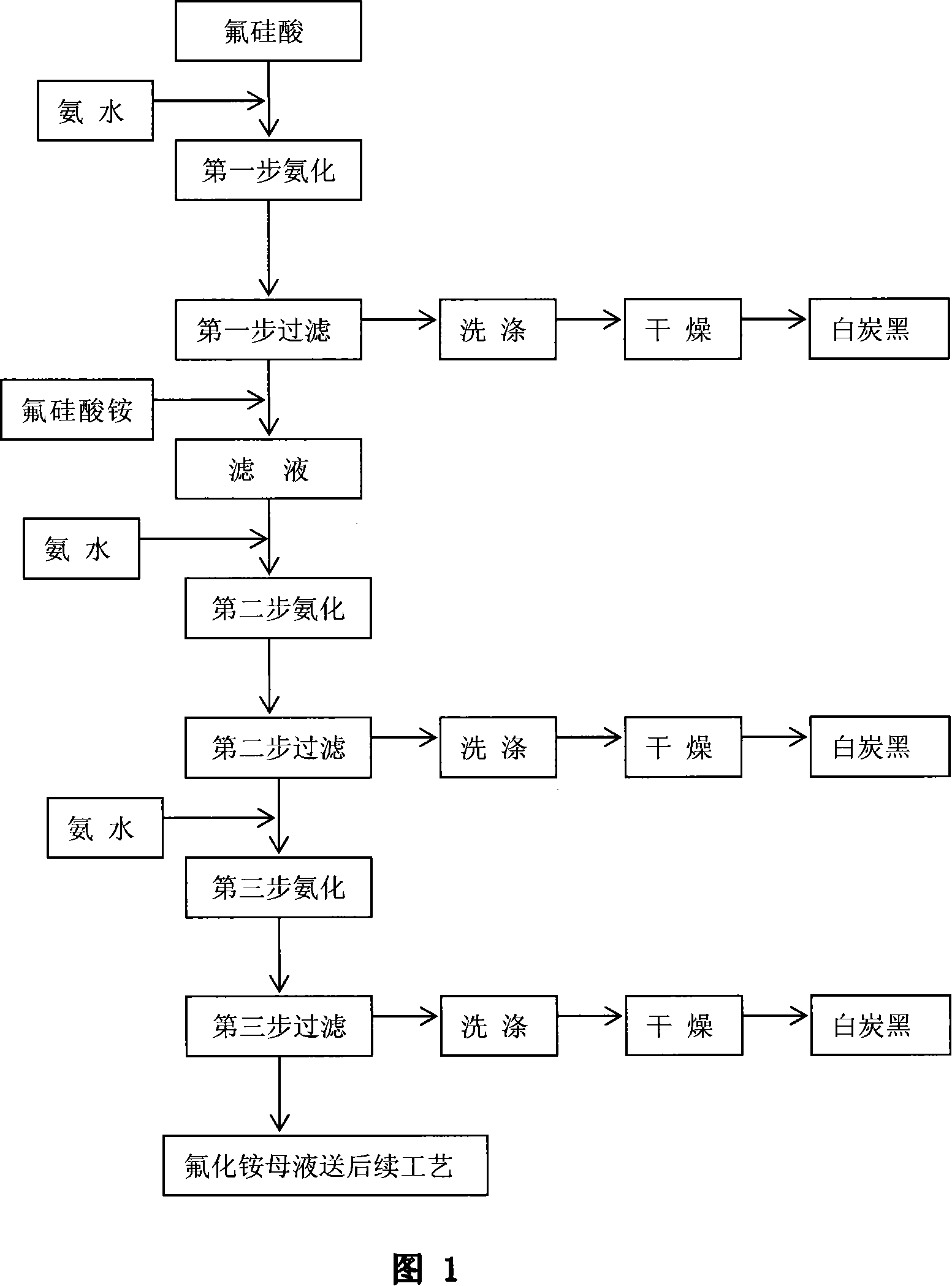

Method for preparing big-compensating forcing white carbon black and high concentration ammonium fluoride through aminating of fluosilicic acid

ActiveCN101139094AFacilitate subsequent processingReduce energy consumptionSilicon oxidesAmmonium halidesHigh concentrationSal ammoniac

A preparation method of highly reinforced white carbon black and high concentration ammonium fluoride through fluosilicic acid ammoniation relates to a preparation method of chemical product, in particular relating to a preparation method of inorganic power material. The invention carries through ammoniation reaction by steps with the fluosilicic acid and ammonia. The white carbon black is acquired after filtrating, washing and drying. The invention is characterized in that the ammonia is added in by steps and the filter is carried through by steps. The steps are that a, 30 to 70 percent of the total ammonia is added in the fluosilicic acid to carry through ammoniation reaction, the reaction liquid is aged, filtrated to acquire a filter cake and a filter liquid; the ammonium fluorosilicate is added in the filter liquid acquired in step a and then the ammonia is added to carry through ammoniation reaction, the reaction liquid is aged, filtrated to acquire the filter cake and the filter liquid; c, the left ammonia is added in the filter liquid acquired in step b and then the reaction liquid is aged and the aged liquid is filtrated to acquire the filter cake and high concentration ammonium fluoride mother liquid; d, the filter cakes acquired by filtrating are respectively washed and dried to prepare the white carbon black.

Owner:YUNNAN YUNTIANHUA

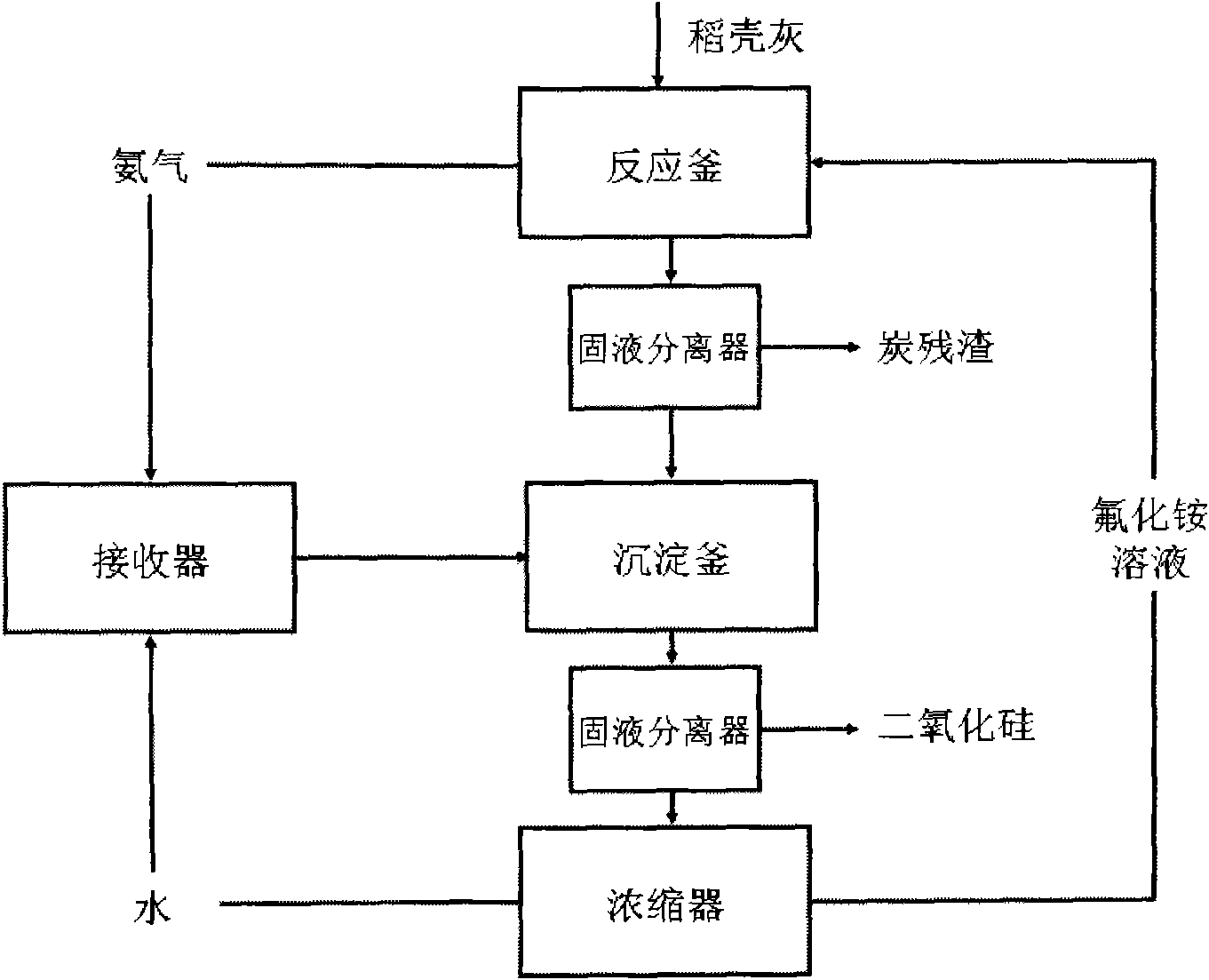

New method for preparing silicon dioxide by utilizing rice hull ash

The invention discloses a new method for preparing silicon dioxide by utilizing rice hull ash, comprising the following steps: neutralizing and dissolving the soluble impurities in the rice hull ash by utilizing a sulfuric acid solution; adding an ammonium fluoride solution in proportion; heating and dissolving to generate ammonium fluosilicate and discharge ammonia; modulating the concentration of the ammonia water to be 10-30wt% by the ammonia generated in the water recovering reaction; placing into a seal stillpot; regulating the temperature to be 50-90 DEG C; adding the ammonium fluosilicate solution into the ammonia water in proportion; separating out the sedimentation; ageing for 0.5-3h; filtering and performing solid-liquid separation; returning the filter liquor to a silicon dissolving procedure for recycling after the filter liquor concentration is adjusted; and washing and drying the filter cakes to obtain the silicon dioxide. The method of the invention takes the regenerated resource rice hull ash as a silicon source, and adopts constant-voltage low-temperature liquid phase dissolving silicon; and the reactant ammonium fluoride and the by-product ammonia can be recycled, which not only saves the energy consumption and lowers the cost, but also has no other by-product generation and no greenhouse gas emission, thus belonging to a low-carbon green new process.

Owner:JILIN UNIV

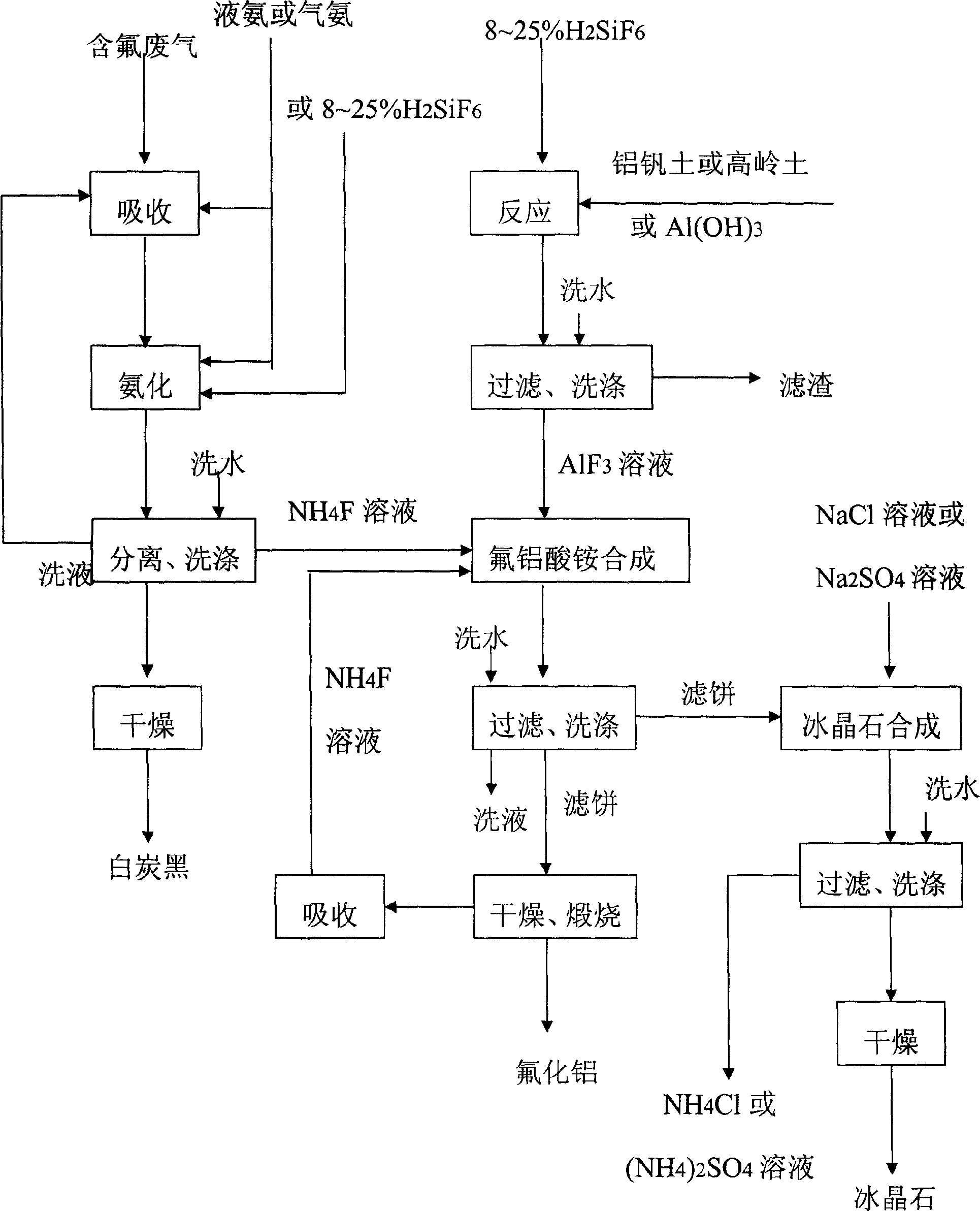

Fluorine-containing waste gas utilization method in phosphorus fertilizer production

The present invention relates to utility method for fluoric gases in phosphoric acid manufacture. Bring directly the ammonium fluoride and / or ammonia in system to obtain solution with (NH4)2SiF6 25~37%; use ammonia to ammoniate the solution and prepare deposition of silicon dioxide (white carbon black) with specific surface area of 100í½180m2 / g and NHF solution with concentration of 30~45%; use the two solutions to react, filter, wash and obtain filter cake; based on it, prepare cryolite and aluminun fluoride with high quality and low cost.

Owner:夏克立

Method for producing ammonium bifluoride by recovering fluorine resource from fluorine-containing silicon slag

ActiveCN102491370AReduce dosageIncrease concentrationSolid waste disposalAmmonium halidesHydrogen fluoridePhysical chemistry

The invention discloses a method for producing ammonium bifluoride by recovering a fluorine resource from fluorine-containing silicon slag. The method comprises the following steps of: dissolving fluorine-containing silicon slag and an ammonium fluoride solution, cooling an obtained ammonium fluosilicate solution, introducing gas ammonia, and precipitating white carbon black out; filtering and washing to obtain a white carbon black solid and an ammonium fluoride solution; introducing anhydrous hydrogen fluoride into the ammonium fluoride solution, uniformly mixing the anhydrous hydrogen fluoride with the ammonium fluoride solution, and fully reacting till the pH of the solution is 2-4 to obtain an ammonium hydrogen fluoride of which the mass concentration is 21-37 percent; mixing with a crystallized ammonium hydrogen fluoride mother solution, and performing triple-effect evaporation and concentration till the mass concentration of the ammonium hydrogen fluoride is 60-80 percent; feeding into a crystallizer, and cooling and crystallizing for 3-7 hours to obtain an ammonium hydrogen fluoride solid-liquid mixture; and separating to obtain an ammonium bifluoride product and an ammonium bifluoride mother solution. The method has the advantages of low using amount of fluorine hydride, high concentration of ammonium bifluoride, low energy consumption in a concentrating process, low production cost, easiness and convenience for operating, and easiness for realizing industrialization.

Owner:WENGFU (GRP) CO LTD +1

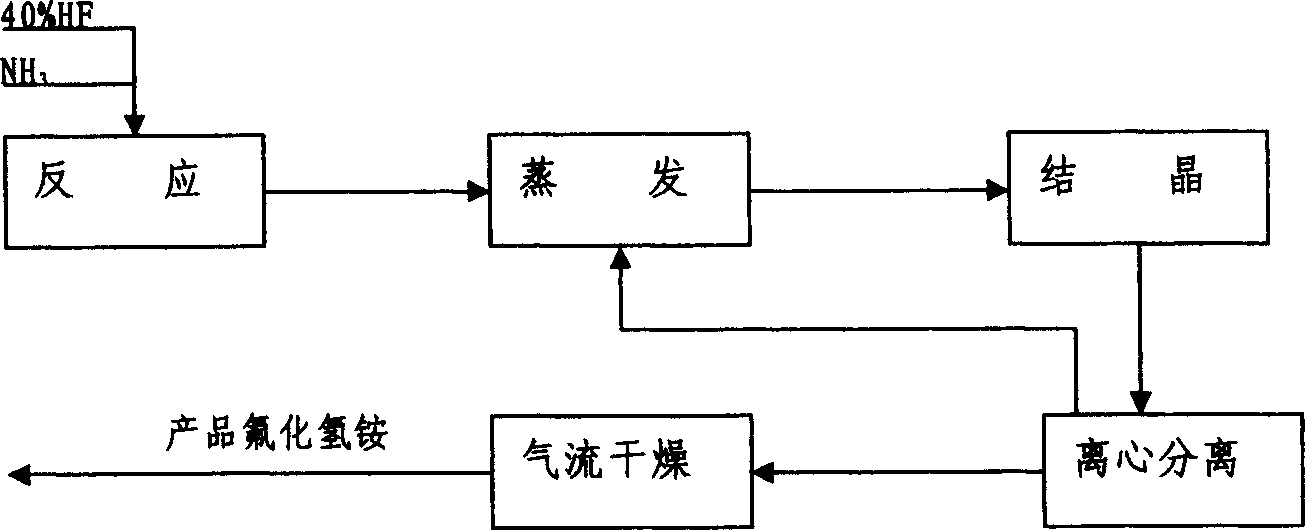

Process for preparing ammonium hydrogen fluoride

InactiveCN1554586AReasonable designReduce material requirementsFluoride preparationSolid waste disposalIron saltsHexafluorosilicic acid

The present invention discloses production process of ammonium hydrogen fluoride. Ammonium fluoride solution in 3-14% concentration is used to absorb fluorine containing tail gas as side product of phosphate fertilizer production to obtain ammonium fluorosilicate solution of 8-12% ammonium fluorosilicate content. Iron scrap or iron salt is added into ammonium fluorosilicate solution or one other side product from phosphate fertilizer production to eliminate phosphorus; and through adding gasified liquid ammonia or ammonia water or ammonium bicarbonate, filtering, washing to eliminate SiO2 precipitate, returning ammonium fluoride solution to phosphate fertilizer absorbing system, concentration and drying, the ammonium hydrogen fluoride product is obtained.

Owner:云南云天化国际化工有限公司 +1

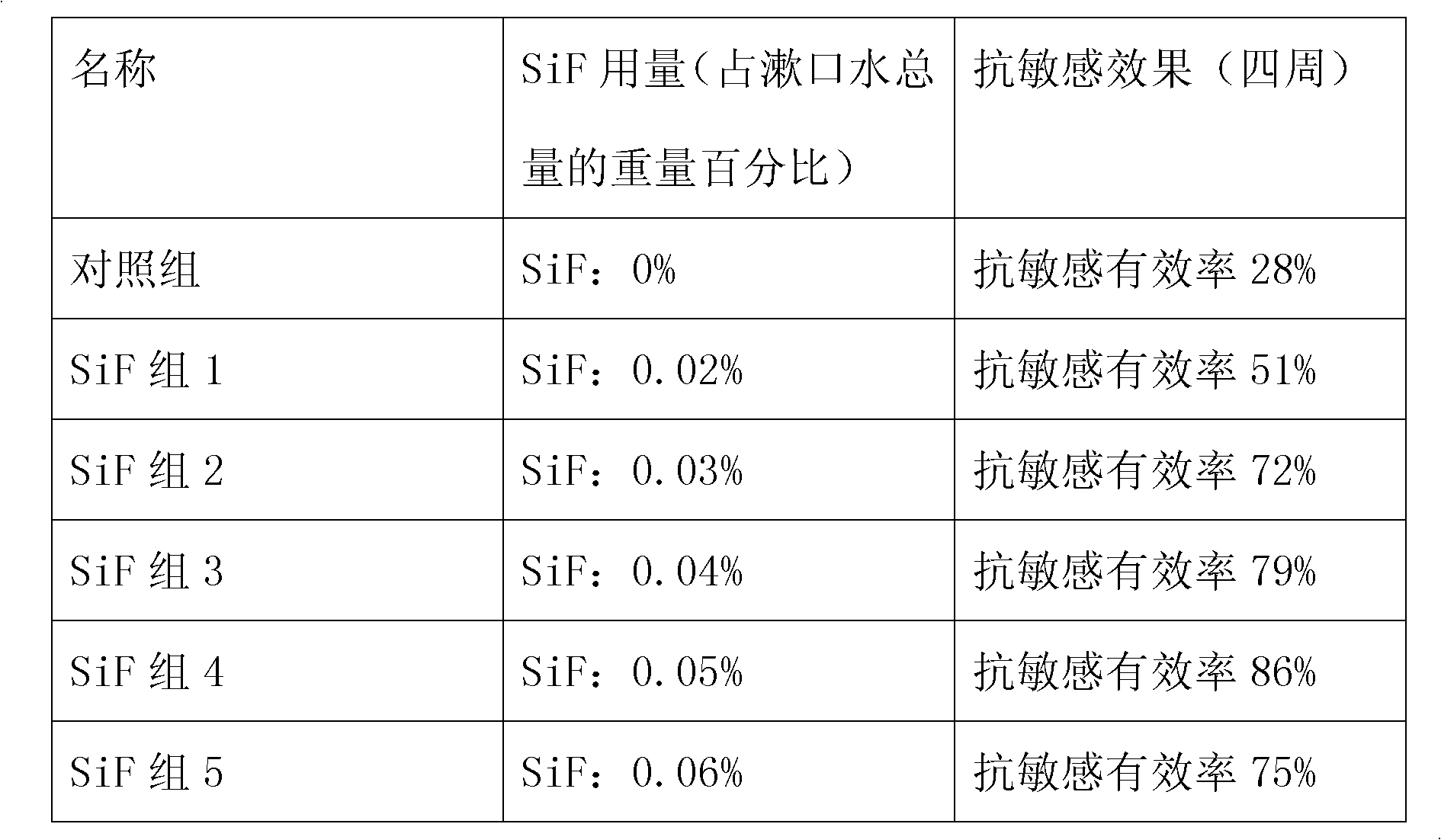

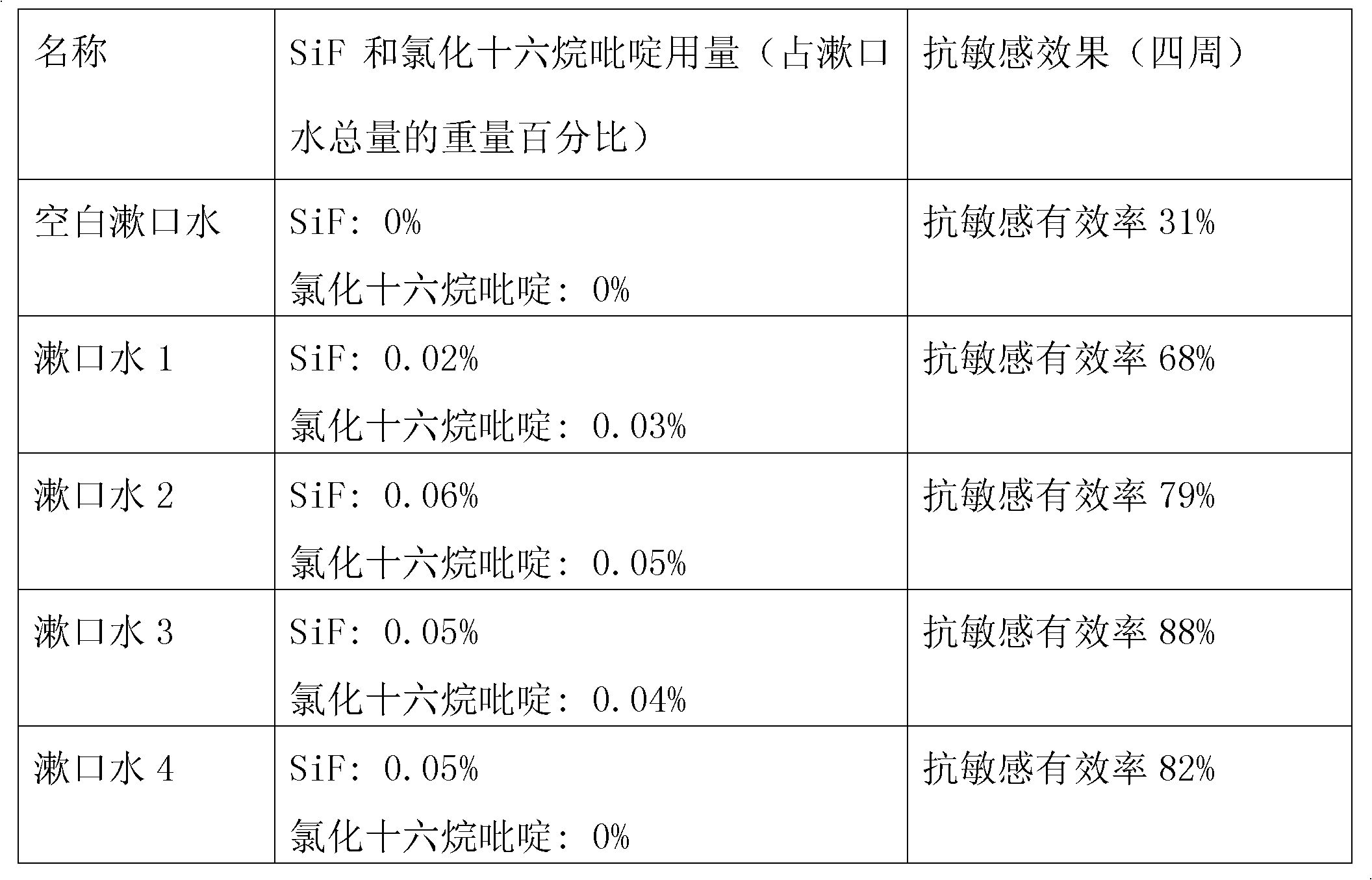

Anti-caries and antiallergic mouth wash

InactiveCN101999990AReduce cancer riskNo discolorationCosmetic preparationsToilet preparationsOral healthMouth wash

The invention discloses anti-caries and antiallergic mouth wash, which belongs to the field of oral cavity care. The anti-caries and anti-sensitive mouth wash comprises 0.02 to 0.06 mass percent of ammonium fluorosilicate, 0.03 to 0.05 mass percent of cetylpyridinium chloride and auxiliary ingredients such as a moisturizing agent, a surfactant, a preservative and the like. Compared with the conventional antiallergic mouth wash, the anti-caries and antiallergic mouth wash has the advantages that: the ammonium fluorosilicate serving as a functional material is added into the mouth wash, so the antiallergic effect is more obvious and durable; the mouthfeel is good; the anti-caries and antiallergic mouth does not comprise alcohol, so the alcohol carcinogenic danger is reduced and the anti-caries and antiallergic mouth wash is safer; side effects such as teeth discoloring and the like are not generated; and anti-caries and antibacterial effects are achieved and oral health can be maintained better.

Owner:SICHUAN UNIV

Chemical metallurgy method for extracting beryllium oxide from chrysoberyl

InactiveCN103088206AFully consider the protectionFully consider the comprehensive utilizationProcess efficiency improvementWater vaporDump leaching

The invention discloses a chemical metallurgy method for extracting beryllium oxide from chrysoberyl. The chemical metallurgy method is a comprehensive treatment technology for carrying out chemical metallurgy on refractory chrysoberyl with not more than 0.5% of Be. The chemical metallurgy method is characterized by comprising the following steps of: carrying out structural transformation roasting on the minerals by using ammonium fluosilicate as a structural transforming agent in the presence of activator limestone; cooling the roasted minerals and using water to spray dump leaching beryllium; precipitating beryllium for the ammonium fluoroberyllate solution by using ammonium bicarbonate to obtain basic beryllium carbonate; calcining the basic beryllium carbonate to release carbon dioxide and water vapor to obtain the product beryllium oxide; and concentrating and crystallizing a beryllium-precipitated solution which is the beryllium fluoride solution under reduced pressure, and drying the concentrated and crystallized solution in air flow to obtain the product ammonium fluoride. The chemical metallurgy method disclosed by the invention is simple in process, low in price, free of pollution, high in metal recovery rate, low in production cost and capable of effectively separating and extracting beryllium in the chrysoberyl.

Owner:戴元宁

Method for recycling waste gas containing fluorine

InactiveCN101708418AAchieve high temperature generationAchieve water balanceDispersed particle separationSilicon oxidesSolubilityAmmonium fluorosilicate

The invention relates to a method for recycling waste gas containing fluorine, belonging to the technical field of chemical industrial production. The method comprises the following steps: absorbing silicon tetrafluoride by an ammonium fluoride solution to produce ammonium fluosilicate, then ammoniating the ammonium fluosilicate to reduce the ammonium fluosilicate to ammonium fluoride, and simultaneously, generating precipitate silica (silica white); after separating the precipitate silica (silica white), by using the changing solubility of ammonium fluoride resulting from the change of temperature, separating the ammonium fluoride by cooling and crystallization; simultaneously, in order to ensure water balance of the overall system and diversification of products, enabling part of the ammonium fluosilicate and potassium chloride (or potassium sulfate) to carry out metathetical reaction to generate potassium fluosilicate precipitate and ammonium chloride (or ammonium sulfate); and after the precipitate silica is separated, concentrating and crystallizing a mother solution to obtain ammonium chloride (or ammonium sulfate) fertilizer. The invention is mainly applied to the fertilizer production industry.

Owner:SHANDONG HONGRI ACRON CHEM

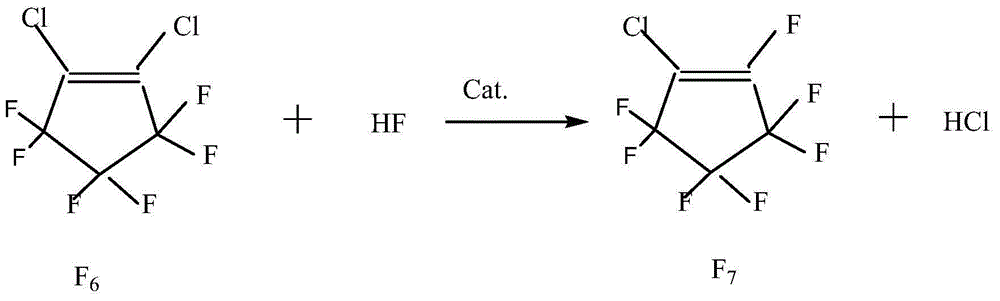

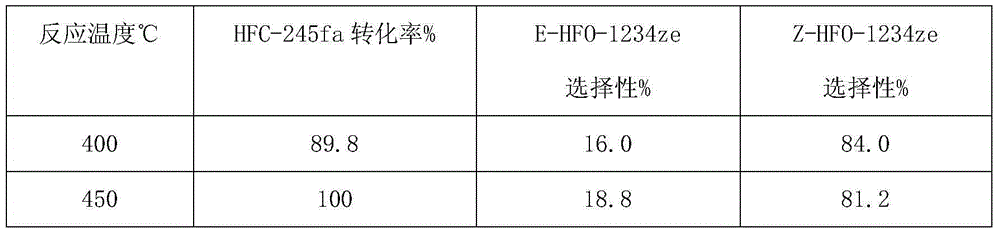

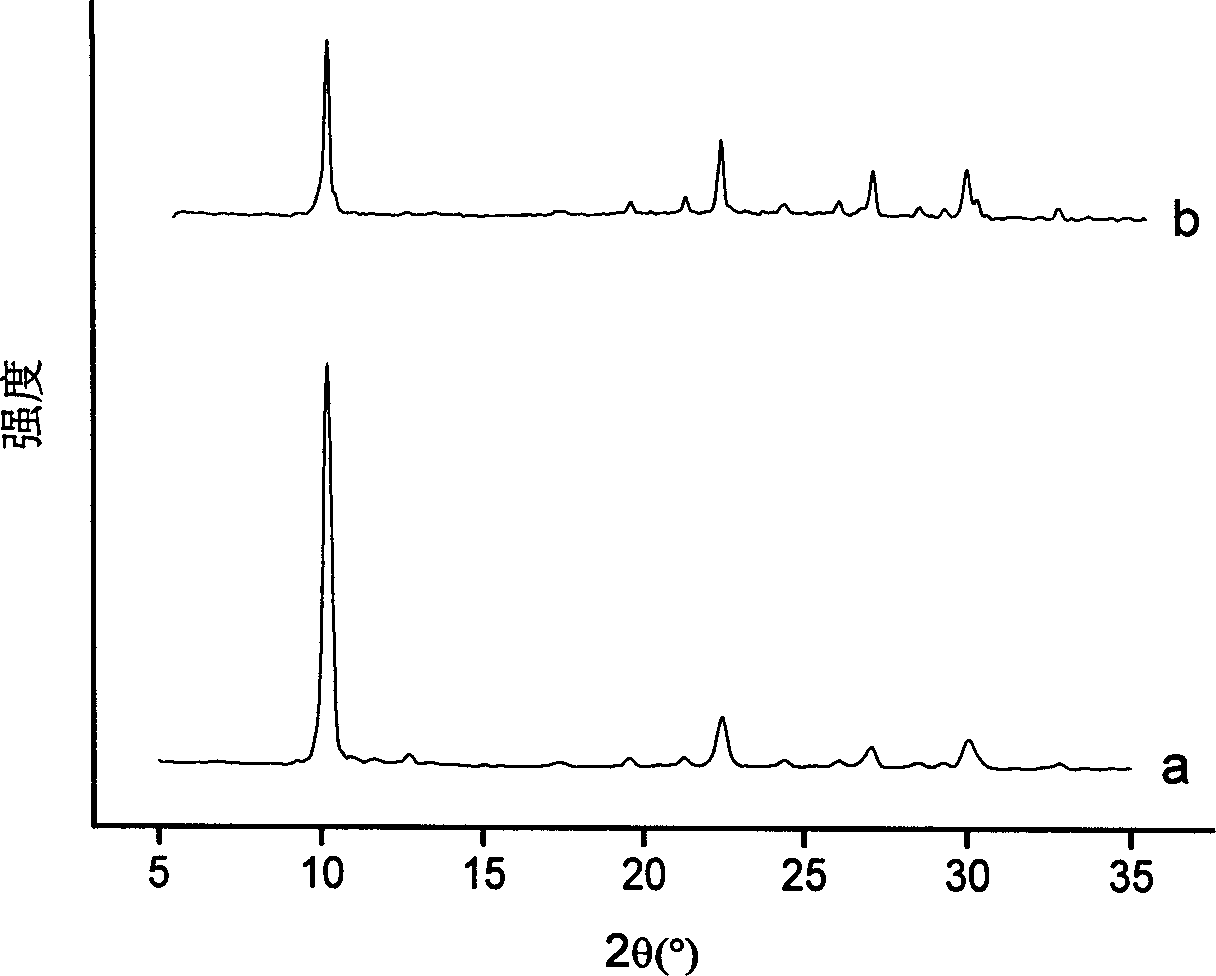

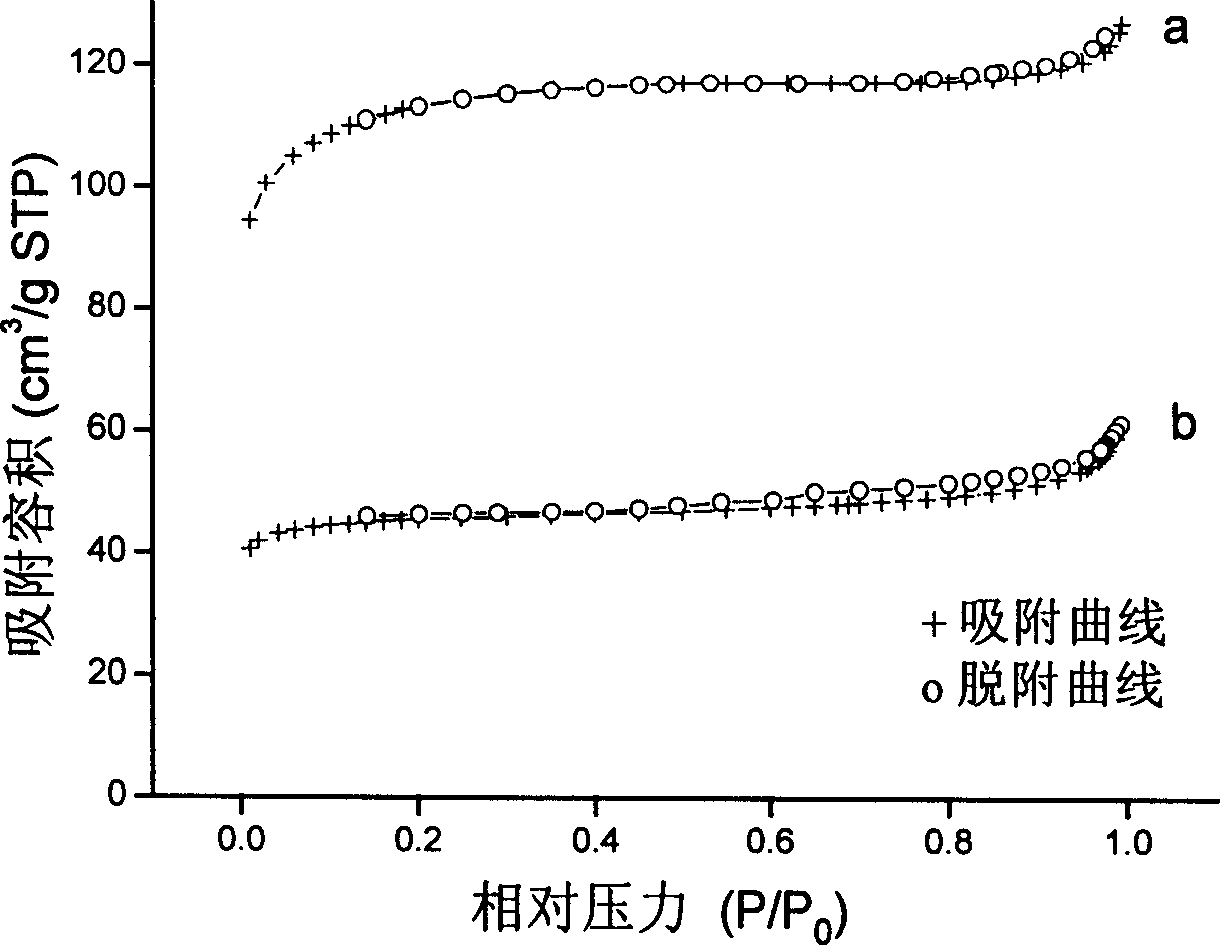

Chromium base catalyst, and preparation method and use thereof

InactiveCN104907063AInhibit carbon depositionCatalytic activity unchangedPreparation by hydrogen halide split-offPreparation by halogen replacementCalcium silicateChemical synthesis

The invention discloses a chromium base catalyst, and a preparation method and a use thereof, and belongs to the field of chemical synthesis. The precursor of the catalyst is composed of 90-99.9mass% of a trivalent chromium compound and 0.1-10mass% of a silicon-containing compound, wherein the trivalent chromium compound is chromic oxide or chromium hydroxide, and the silicon-containing compound can be zinc silicate, nickel silicate, magnesium silicate, aluminum silicate, zirconium silicate, barium silicate, bismuth silicate, ammonium fluorosilicate, nickel hexafluorosilicate, zinc fluorosilicate, magnesium fluorosilicate, aluminum fluorosilicate or calcium fluorosilicate The chromium base catalyst has the advantages of large specific surface area, effective inhibition of carbon formation, and long service life, is mainly used for gas phase catalysis of reactions for preparing hydrofluorocarbons or fluorinated alkenes from halogenated hydrocarbons or halogenated alkenes at a high temperature, and can also be used for gas phase catalysis of reactions for preparing hydrofluoroalkenes through hydrogen fluoride removal of hydrofluorocarbons at a high temperature.

Owner:BEIJING YUJI SCI & TECH

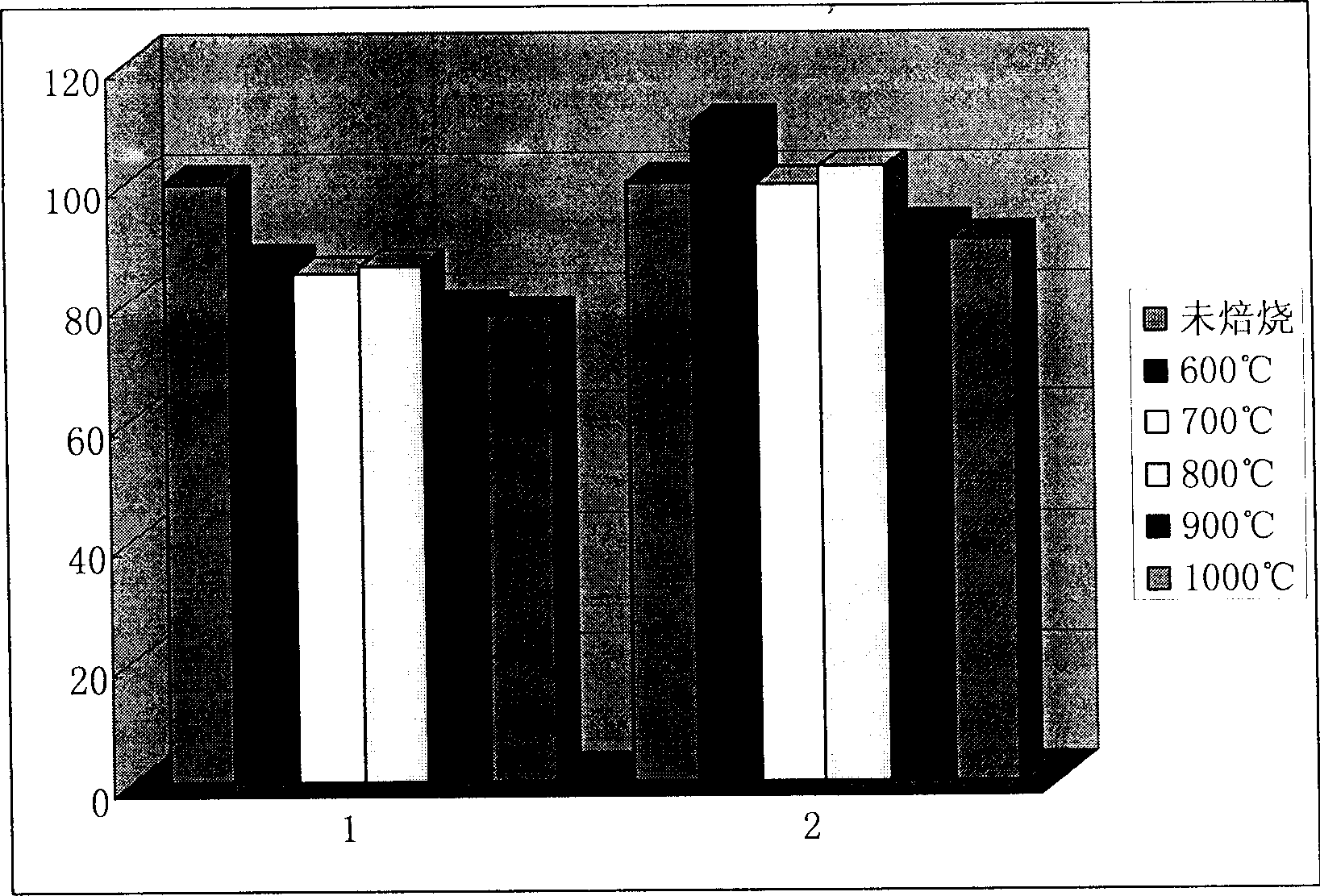

High silicon super stabilizing natural foresite and it preparation process

InactiveCN1724363APore structure is perfectly openCrystalline aluminosilicate zeolitesIon exchangeAmmonium fluorosilicate

A natural high-Si desmine with super thermal stability (more than 1000 deg. C) and open artery structure is prepared from natural STI zeolite through acid exchange, ammonium exchange, calcining, ammonium fluorosilicate exchange and calcining.

Owner:FUDAN UNIV

Method for preparing nano-scale white carbon black product

ActiveCN102942185AUniform particle sizeAvoid affecting product qualityMaterial nanotechnologySilicaMicroreactorPhysical chemistry

The invention discloses a method for preparing a nano-scale white carbon black product, comprising the following steps of: regulating the PH value of 3-15% ammonium fluosilicate at 15-50 DEG C to a range of 6-7 by using an alkaline dispersion phase or continuous phase substance; and then feeding the ammonium fluosilicate into a micro-reactor, adding the alkaline dispersion phase or continuous phase substance into the micro-reactor with excess of 10-30%, staying for 1-3 seconds, and then keeping the temperature in the micro-reactor at 15-50 DEG C, thereby obtaining a solid-liquid mixture; filtering the solid-liquid mixture so as to obtain the solid part, namely the nano-scale white carbon black; washing the nano-scale white carbon black by using water until the mass percent content of fluoride is less than 0.05%, thereby obtaining semi-finished product nano-scale white carbon black; and feeding the semi-finished product nano-scale white carbon black into a microwave drier for drying until meeting the international standard, thereby obtaining the product nano-scale white carbon black. The method provided by the invention is short in reaction time, low in reaction temperature and low in energy consumption; and the particle sizes of the generated particles are evenly distributed.

Owner:贵州瓮福蓝天氟化工股份有限公司

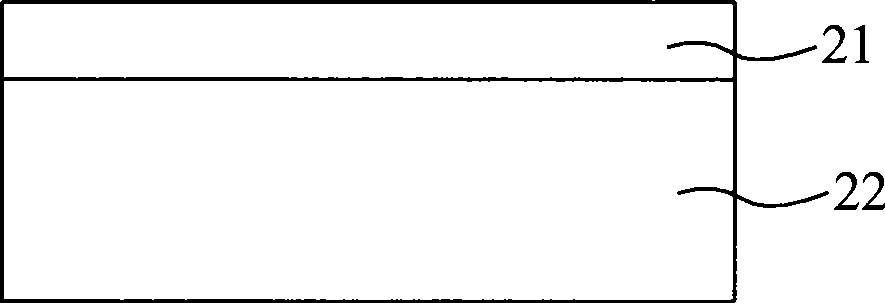

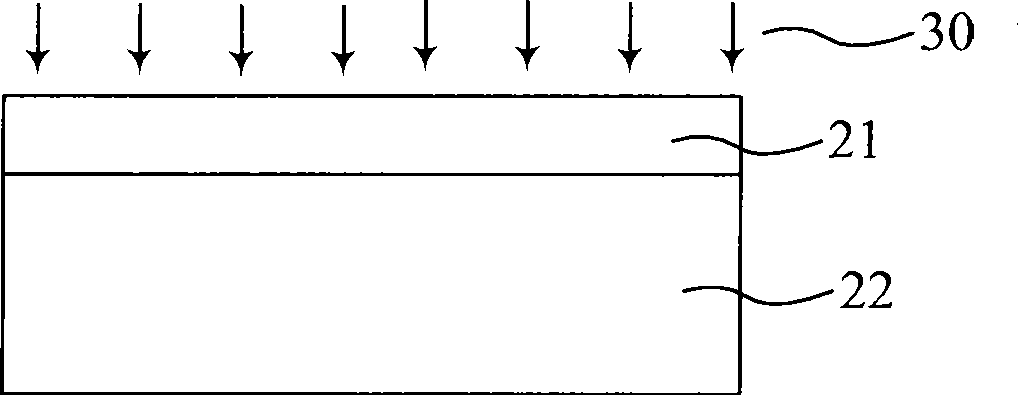

Method for removing silicon oxide layer on surface of silicon substrate and contact hole forming

InactiveCN101459071AAvoid damageQuality improvementSemiconductor/solid-state device manufacturingSurface oxidationAmmonium fluorosilicate

A method for removing silicon oxide layers from the surfaces of silicon substrates includes steps of disposing a silicon substrate with a silicon oxide layer into an etching device, wherein the silicon oxide layer is formed on the surface of the silicon substrate while NH4F atom groups formed in the etching device react with the silicon oxide layer on the surface of the silicon substrate to generate solid (NH4)2SiF6, and heating the silicon substrate to gasify the (NH4)2SiF6 on the silicon substrate, and exhausting the (NH4)2SiF6 gas from a heating device. Correspondingly, the invention further provides a method of forming contact holes. The method for removing silicon oxide layers from the bottom surfaces of silicon substrates prevents damages to the surfaces of the silicon substrates in the prior art by steps of transforming the natural silicon oxide layer on the surface of the silicon substrate into ammonium fluorosilicate which passivates the surface of the silicon substrate, then heating to gasify the ammonium fluorosilicate, exhausting the ammonium fluorosilicate gas and removing the silicon oxide layer from the surface of the silicon substrate.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method for preparing ammonium fluorosilicate by utilizing fluorine-containing white slime in anhydrous hydrogen fluoride production

ActiveCN102674367AReduce pollutionReduce utilizationSilicon halogen compoundsSolid waste disposalHydrogen fluoridePhysical chemistry

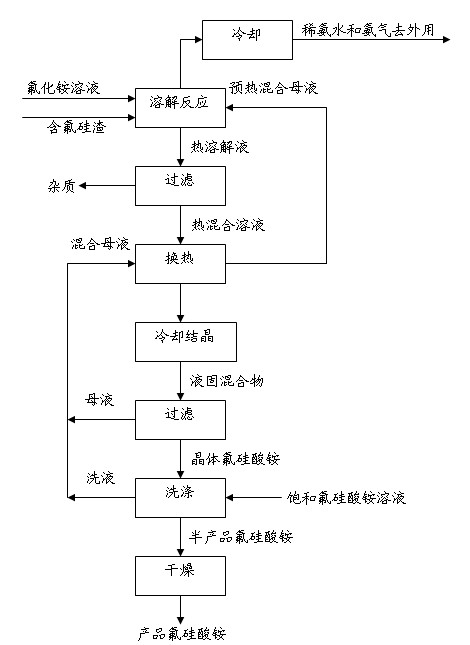

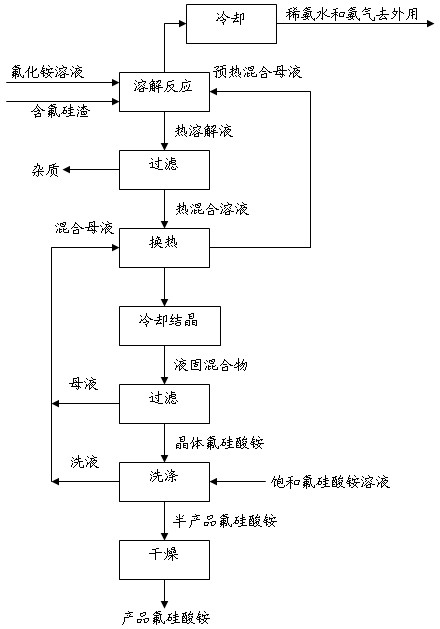

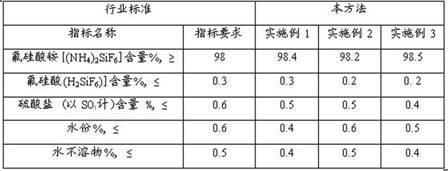

The invention discloses a method for preparing ammonium fluorosilicate by utilizing fluorine-containing white slime in anhydrous hydrogen fluoride production. The method comprises the following steps of: under the condition that the mol ratio of ammonium fluoride calculated based on SiO2 to the fluorine-containing white slime is 9-15, adding the fluorine-containing white slime, a mixed mother liquid and a supplementary ammonium fluoride solution under the conditions that the temperature is 90-108 DEG C and the pressure is minus 15 to 0Kpa, performing a dissolution reaction until the white slime is completely dissolved, so as to obtain a dissolved solution; while the dissolved solution is hot, filtering the dissolved solution to remove undissolved SiO2 and mechanical impurities, so as to obtain a mixed solution; performing heat exchange on the mixed solution until the temperature is 60-70 DEG C; cooling to 12-30 DEG C, separating out ammonium fluorosilicate crystal and performing liquid solid separation, so as to obtain a crystallization mother liquid and crystal ammonium fluorosilicate; washing and filtering to obtain the crystal ammonium fluorosilicate; and drying the crystal ammonium fluorosilicate, so as to obtain the product ammonium fluorosilicate. The method disclosed by the invention has the advantages of simple technical process, less equipment, simplicity and convenience in operation and low production cost.

Owner:WENGFU (GRP) CO LTD +1

Method for producing ammonium fluoride by recovering fluorine resources

InactiveCN102491369AIncrease concentrationReduce pollutionSilicaAmmonium halidesPhysical chemistryAmmonium fluorosilicate

The invention discloses a method for producing ammonium fluoride by recovering fluorine resources. The method comprises the following steps of: dissolving fluorine-containing silicon dregs and ammonium fluoride at the temperature of between 95 and 108 DEG C to obtain a transparent ammonium fluosilicate solution, cooling, introducing ammonia gas until the pH value is between 9.0 and 9.8, precipitating to separate white carbon black out, filtering to obtain a white carbon black solid and an ammonium fluoride solution, and returning the ammonium fluoride solution according to the quantity required by reacting with silicon dregs; mixing the residual ammonium fluoride solution with a mother solution formed by crystallizing ammonium fluoride, and concentrating the mixture in a concentration device until the mass concentration of the ammonium fluoride is between 60 and 80 percent; conveying the ammonium fluoride into a cooling crystallizer, cooling and crystallizing for 4 to 7 hours, and precipitating ammonium fluoride crystals to obtain an ammonium fluoride solid-liquid mixture; and filtering and separating the ammonium fluoride solid-liquid mixture to obtain the ammonium fluoride crystals. By the method, the concentration of the ammonium fluoride can be improved, the energy consumption in the concentration process can be reduced, fluorine in the fluorine-containing silicon dregs is recovered, phosphorite associated fluorine resources are utilized fully, and the pollution of the fluorine-containing silicon dregs to environment is reduced.

Owner:WENGFU (GRP) CO LTD +1

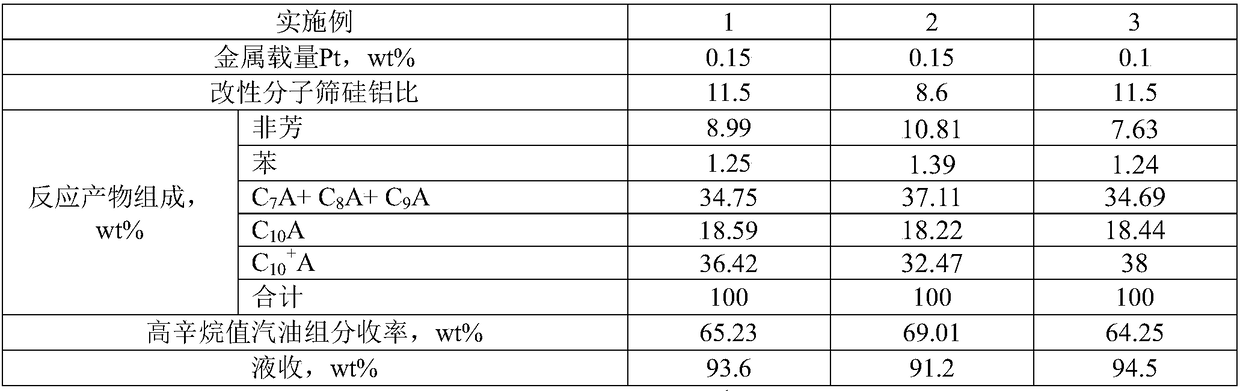

C10+ heavy aromatic hydrocarbon selective hydrogenation ring-opening catalyst and preparation method thereof

ActiveCN108940354AGood dispersionHigh activityMolecular sieve catalystsHydrocarbon oils refiningPlatinumMolecular sieve

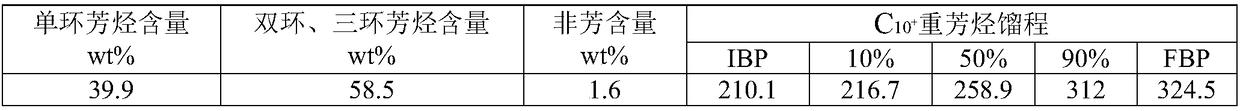

The invention discloses a C10+ heavy aromatic hydrocarbon selective hydrogenation ring-opening catalyst and a preparation method thereof. The catalyst includes, by mass, 50-80% of HY molecular sieve,0.05-0.35% of platinum, and the balanced being Al2O3, wherein molar ratio of SiO2 to Al2O3 is 8-13, the specific surface area of the catalyst is 450-600 m<2> / g and pore volume is 0.35-0.7 cm<3> / g. Thepreparation method includes: performing composite modification on the HY molecular sieve with ammonium fluorosilicate and a platinum solution, performing extrusive molding with the Al2O3, drying androasting a semi-product, finally performing equivalent-volume impregnation with the platinum solution, and drying and roasting the product. The catalyst has higher heavy aromatic hydrocarbon lightening activity and stability, and is especially suitable for selective hydrogenation ring-opening on large-molecular heavy aromatic hydrocarbon in poor quality to co-produce light BTX aromatic hydrocarbonor high-octane number gasoline.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

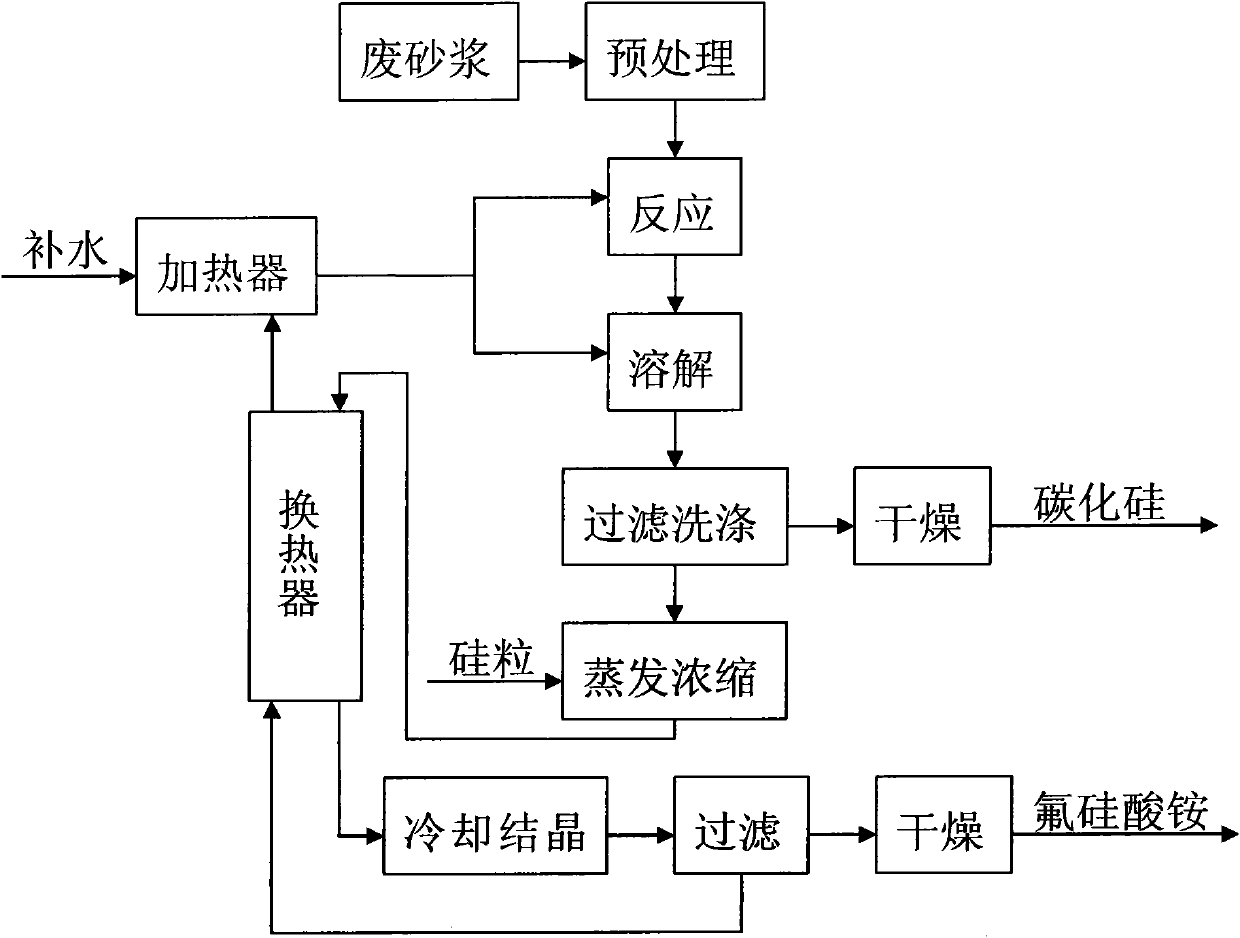

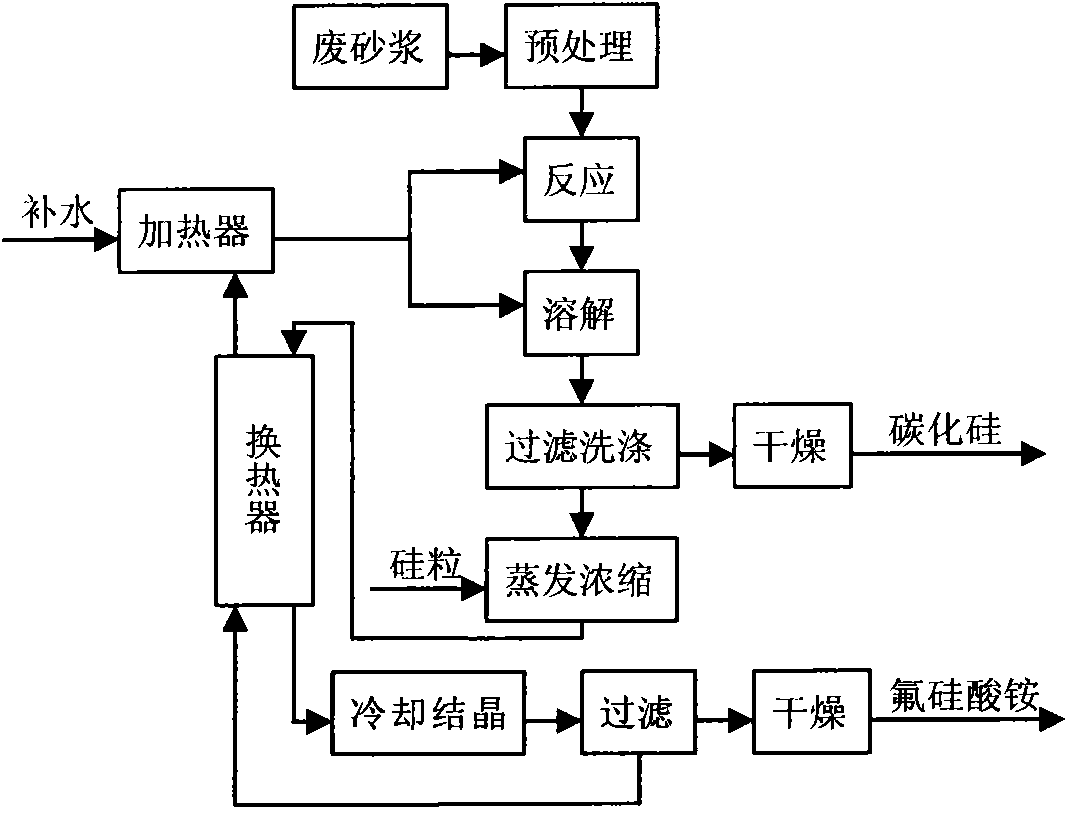

Method for recovering silicon carbide in waste cutting mortar by using ammonium bifluoride

The invention discloses a method for recovering silicon carbide in waste mortar generated in a process for cutting monocrystalline silicon and polycrystalline silicon rods or processing silicon chips by using ammonium bifluoride, which comprises the steps of: dissolving silicon in preprocessed waste mortar by using an ammonium bifluoride solution, adding water for dissolving to ensure that the silicon forms a solution, and filtering to obtain the silicon carbide as a target product; carrying out low-temperature crystallization on the generated ammonium fluosilicate solution, and filtering to obtain an ammonium fluosilicate product; and dissolving the ammonium fluosilicate with a crystallized water solution, and repeatedly using the ammonium fluosilicate. All components are reasonably utilized in the whole process without wastewater emission and secondary pollution, and requirements for a green chemical process are met. The invention has the advantages of higher reaction rate, milder process conditions, low equipment investment, simpleness in operation, easiness in industrialization, and remarkable economic benefit and social benefit.

Owner:TARIM UNIV

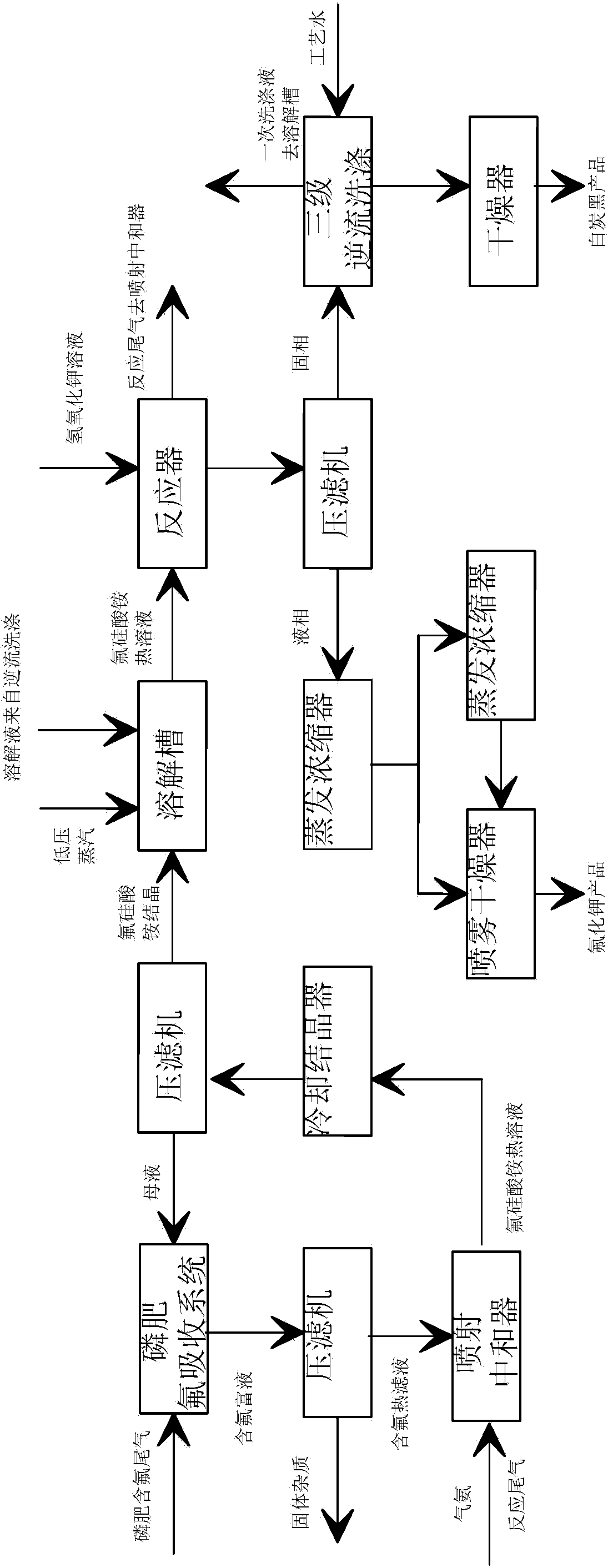

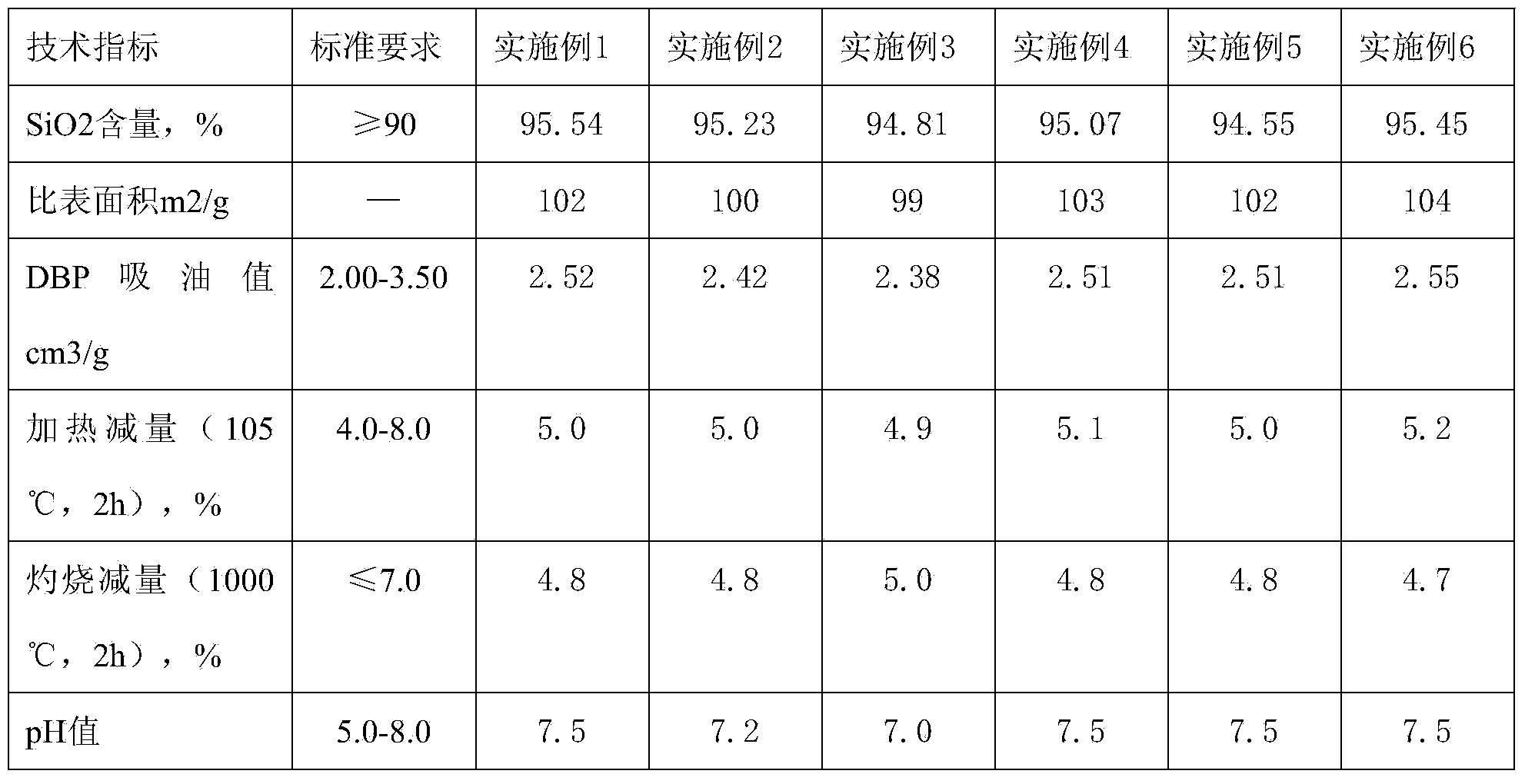

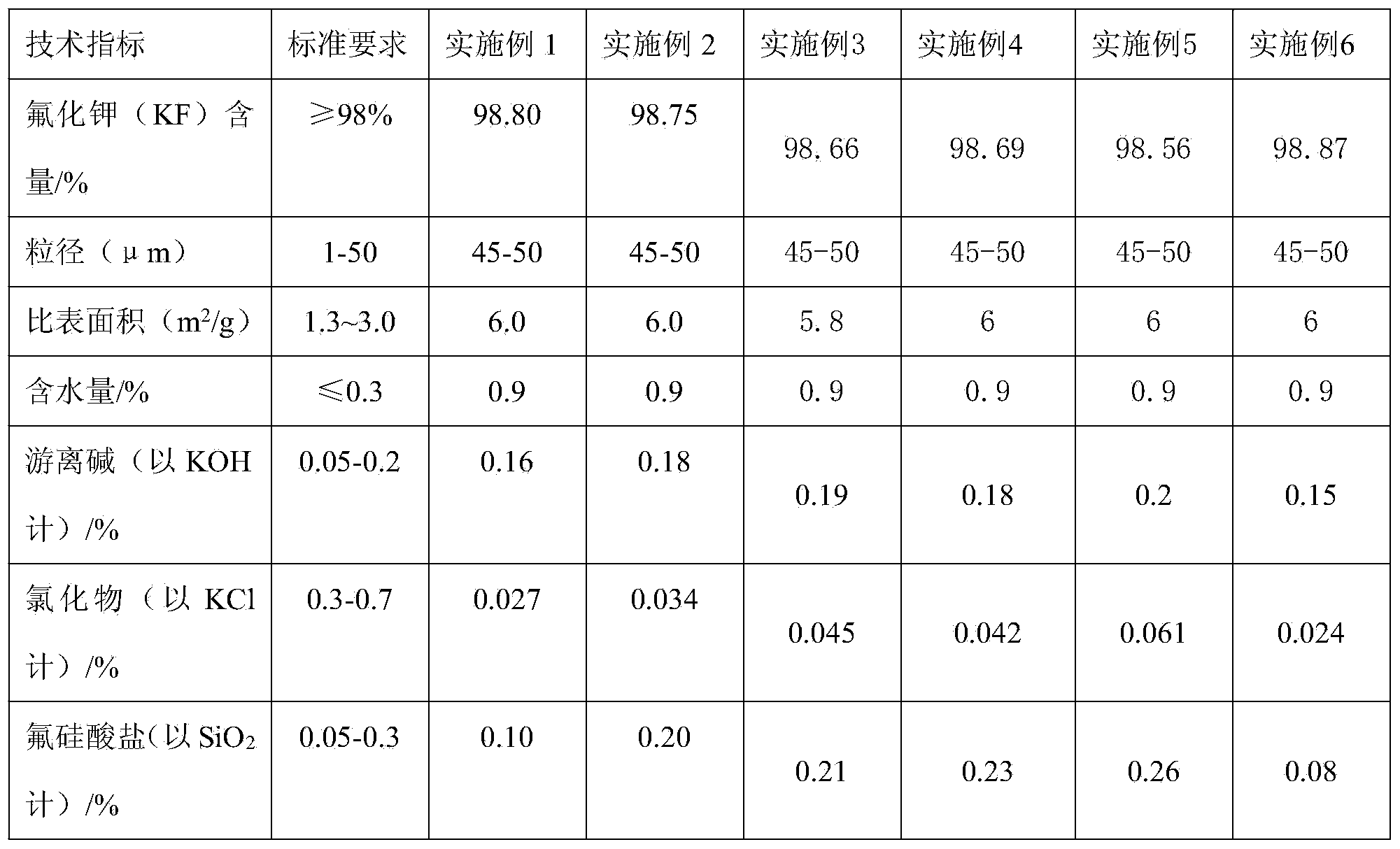

Method for preparing potassium fluoride and coproducing ultrafine white carbon black from ammonium fluorosilicate byproduct in phosphate fertilizer production

ActiveCN103663499AIncrease added valueReduce manufacturing costSilicaAlkali metal fluoridesFiltrationPotassium fluoride

The invention relates to a method for preparing potassium fluoride and coproducing ultrafine white carbon black from an ammonium fluorosilicate byproduct in phosphate fertilizer production, which comprises the following steps: reacting a 20-40% ammonium fluorosilicate solution and a 30-35% potassium hydroxide solution at 80-85 DEG C, wherein the pH value at the end point of the reaction is 8-10, and the reaction tail gas is used as a neutralizing raw material for preparation of solid ammonium fluorosilicate; aging the reaction slurry, and performing hot filtration; washing the solid phase, and drying to obtain the white carbon black product; and concentrating to crystallize the liquid phase and drying, or concentrating the liquid phase and performing spray drying, thus obtaining the potassium fluoride product. According to the invention, the high-added-value potassium fluoride product is obtained, and the ultrafine white carbon black product is coproduced at the same time; no waste water, waste gas and solid waste are discharged; and the method is simple in process, low in cost, friendly to environment and high in economic benefits.

Owner:ANHUI LIUGUO CHEM CO LTD +1

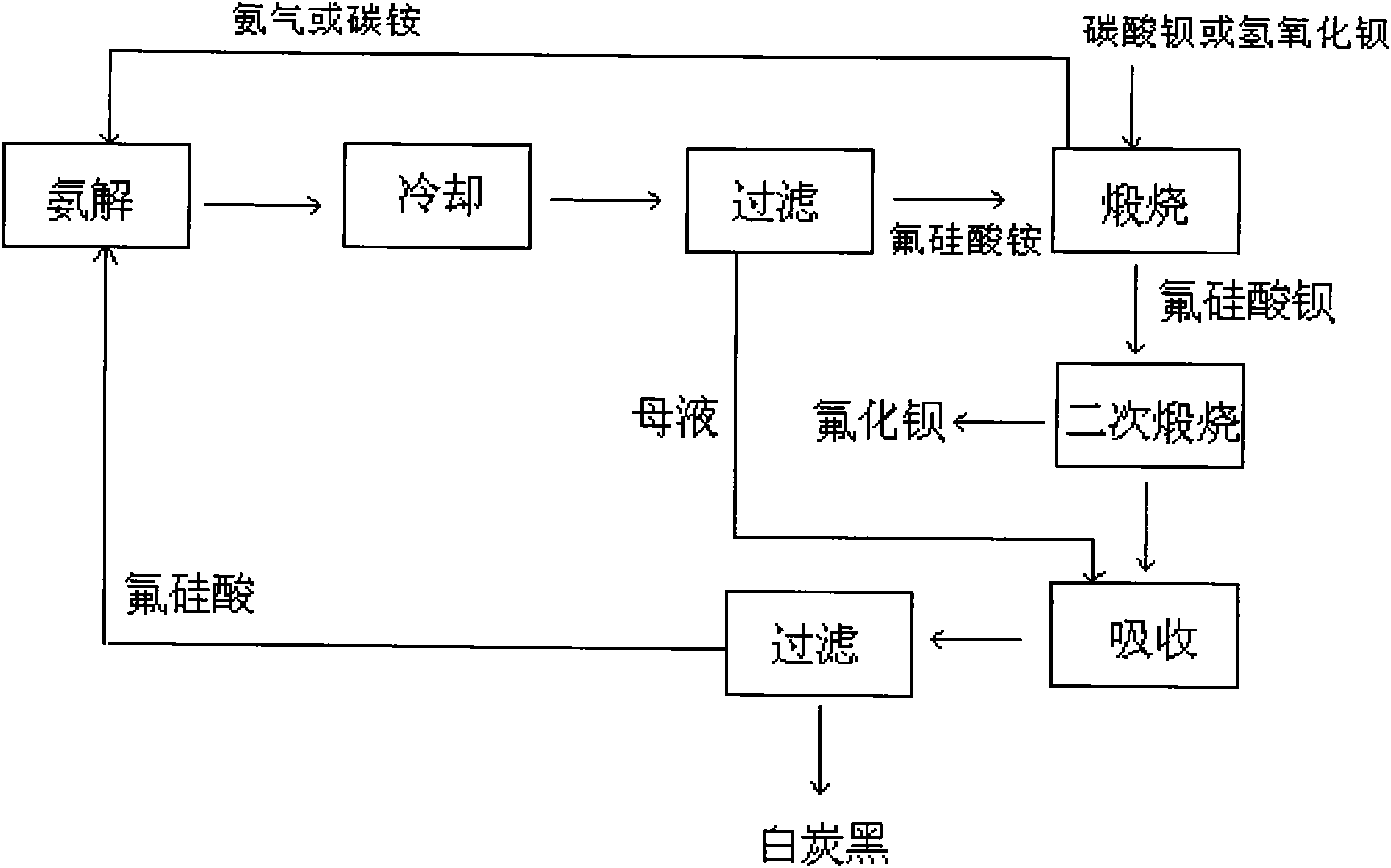

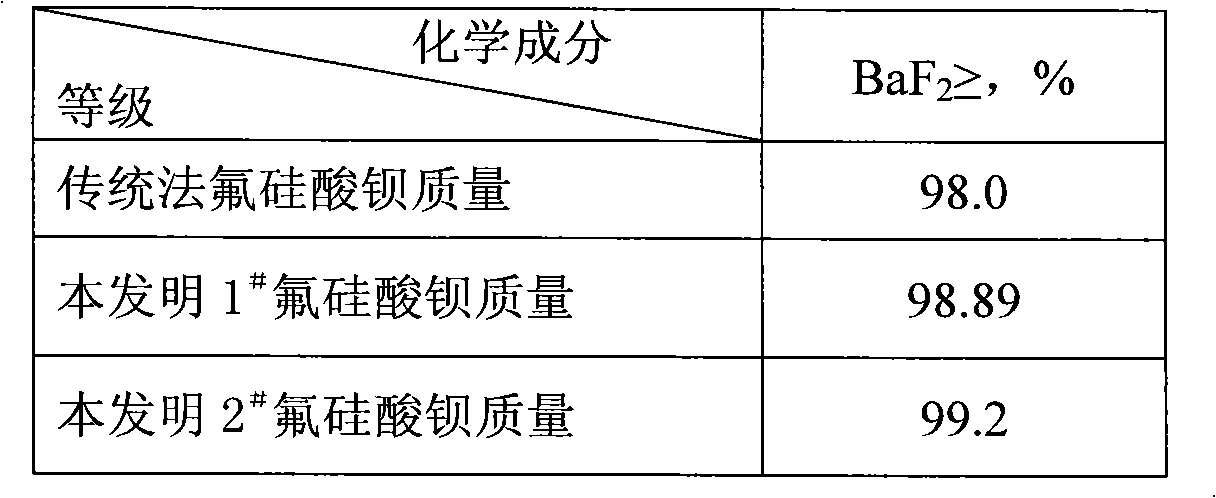

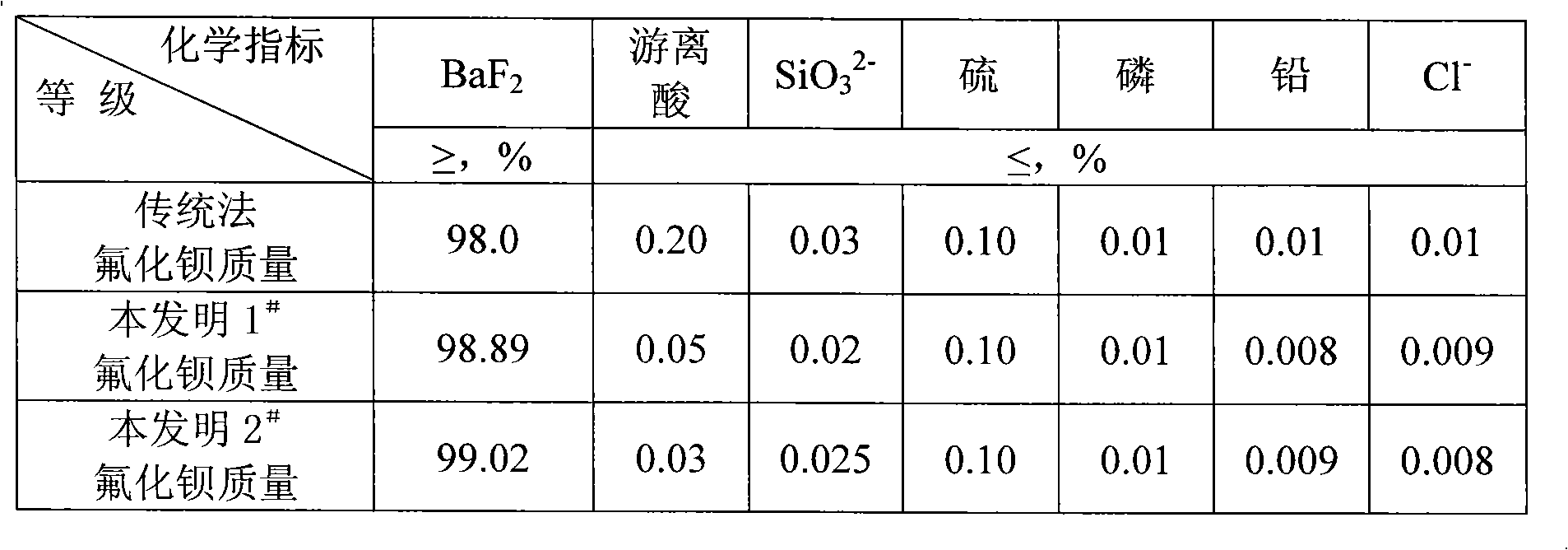

Method for dry preparation of barium fluorosilicate and barium fluoride

InactiveCN101676213AReduce the impactReduce total usageAlkaline-earth metal silicatesCalcium/strontium/barium fluoridesBarium saltAmmonium fluorosilicate

The invention relates to a method for dry preparation of barium fluoride and barium fluorosilicate, which specifically comprises the following steps: adding ammonia water or ammonium bicarbonate in fluorosilicic acid solution for carrying out reaction, cooling and filtering for preparing an ammonium fluorosilicate product; evenly mixing the prepared ammonium fluorosilicate with barium carbonate orbarium hydroxide according to the theoretical amount, and generating the barium fluorosilicate and ammonia or the ammonium bicarbonate; introducing the generated ammonia or the ammonium bicarbonate into the fluorosilicic acid solution, carrying re-ammonolysis for preparing the ammonium fluorosilicate and emptying the remaining gas; calcining the generated barium fluorosilicate for generating thebarium fluoride and silicon tetrafluoride gas; and using water for absorbing the generated silicon tetrafluoride gas and carrying out hydrolysis, filtering, preparing the fluorosilicic acid solution and being used for ammonolysis. The raw material of the fluorosilicic acid adopted by the method is a byproduct which is a hazardous waste generated during the production process of a phosphate fertilizer, thereby having few uses and causing serious impact on the environmental protection; and the method just utilizes the fluorosilicic acid as the raw material for ammonolysis for further preparing the ammonium fluorosilicate, the dry reaction of the ammonium fluorosilicate with a barium salt or alkaline solution of barium is carried out for preparing the barium fluorosilicate, and calcining theprepared barium fluorosilicate for preparing the barium fluoride.

Owner:DO FLUORIDE CHEM CO LTD

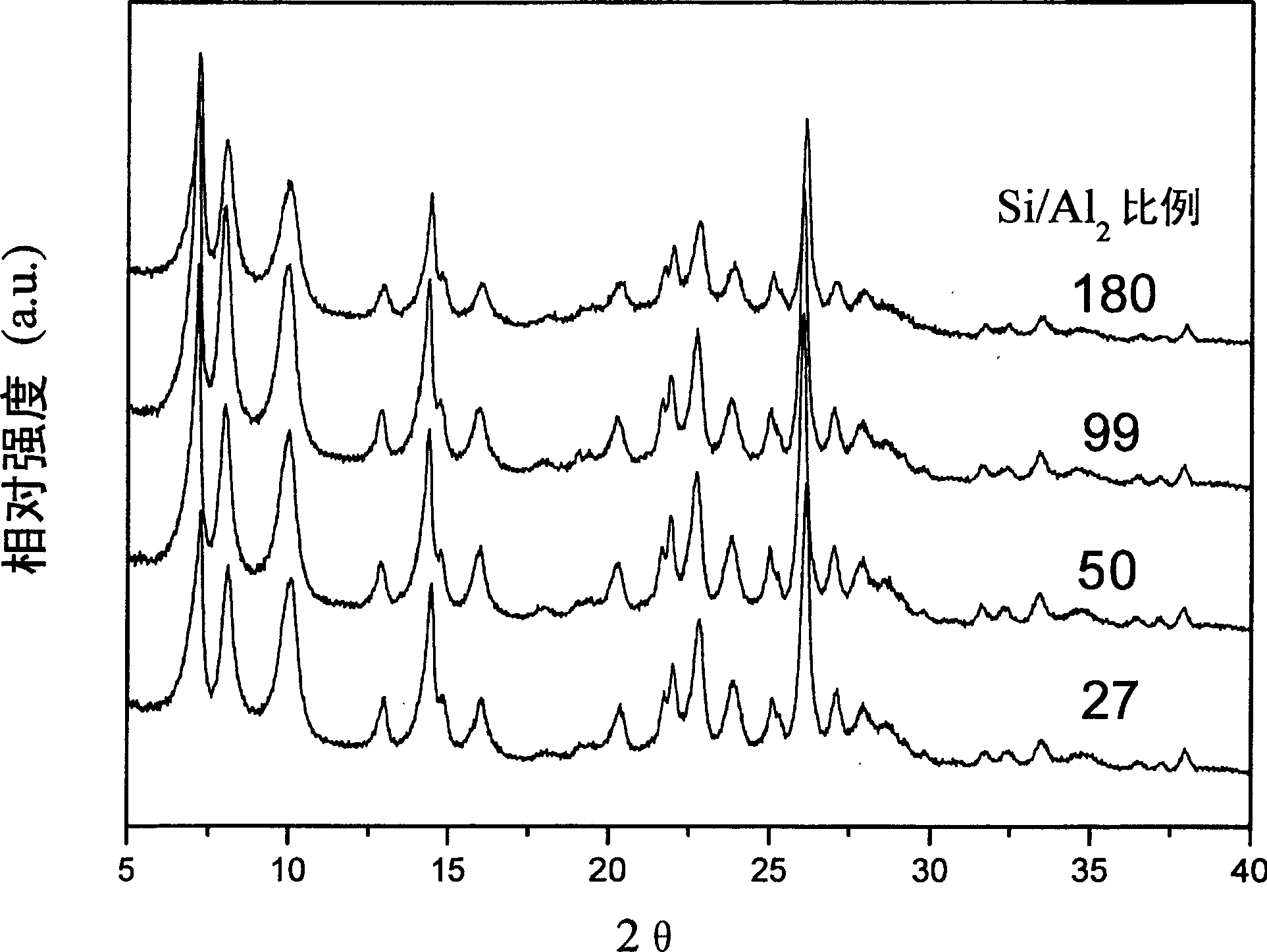

Method for preparing MCM-22 molecular sieve in high silicon

This is the preparation of MCM-22 zeolite with high silicon. By using this method, at room temperature to100 deg.C, MCM-22 zeolite with low silicon aluminium ratio (Si / Al2ú“30) and 0.01-0.8mol / L fluorin ammonium silicate was reacted for 0.5h-48h, and MCM-22 zeolite with high silicon was obtained. In addition, the silicon aluminium ratio can be changed in the range of 50í½180, these products with high crystal degree, meanwhile, there is no other crystal phase formed in the treatment process.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

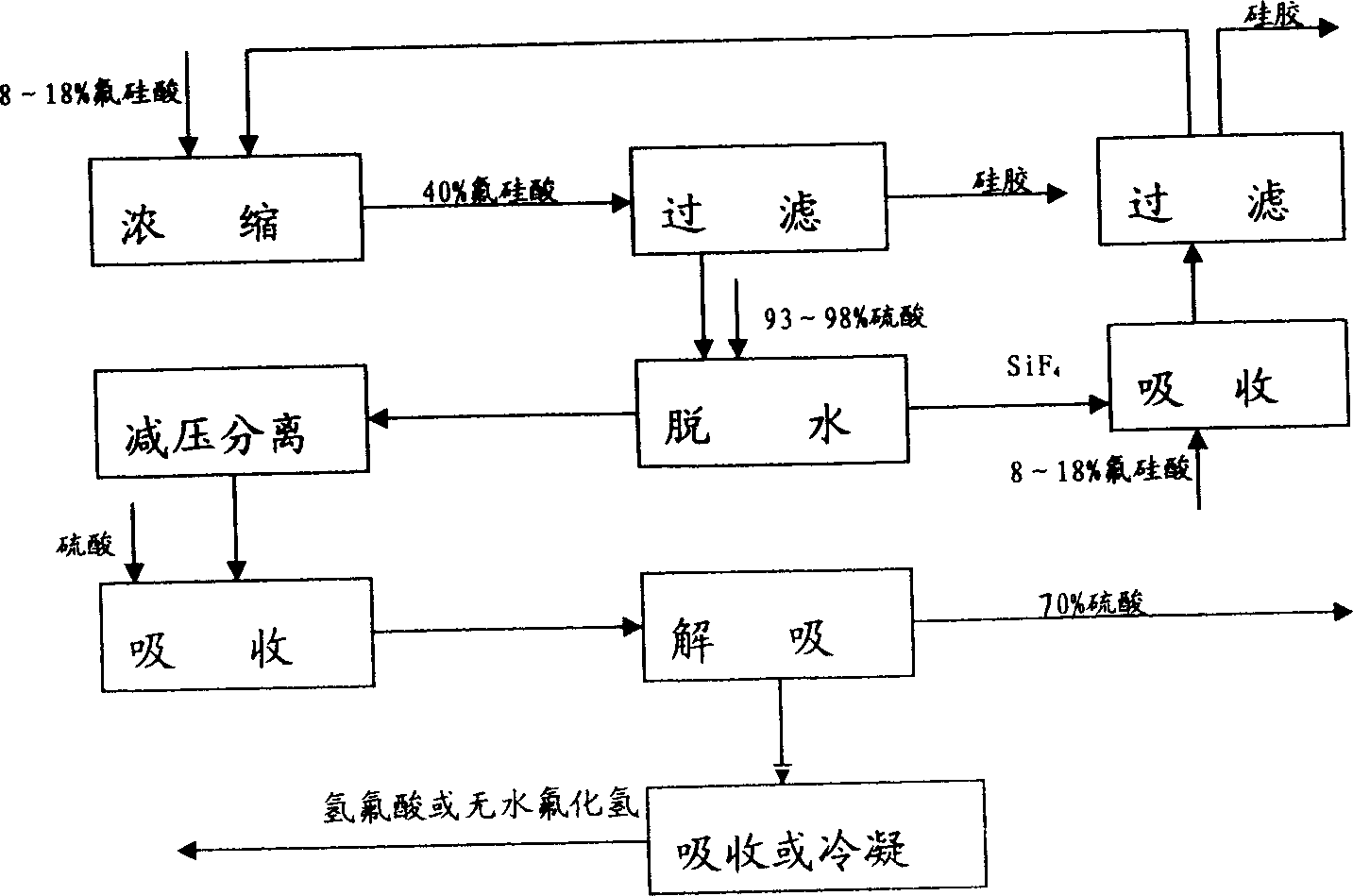

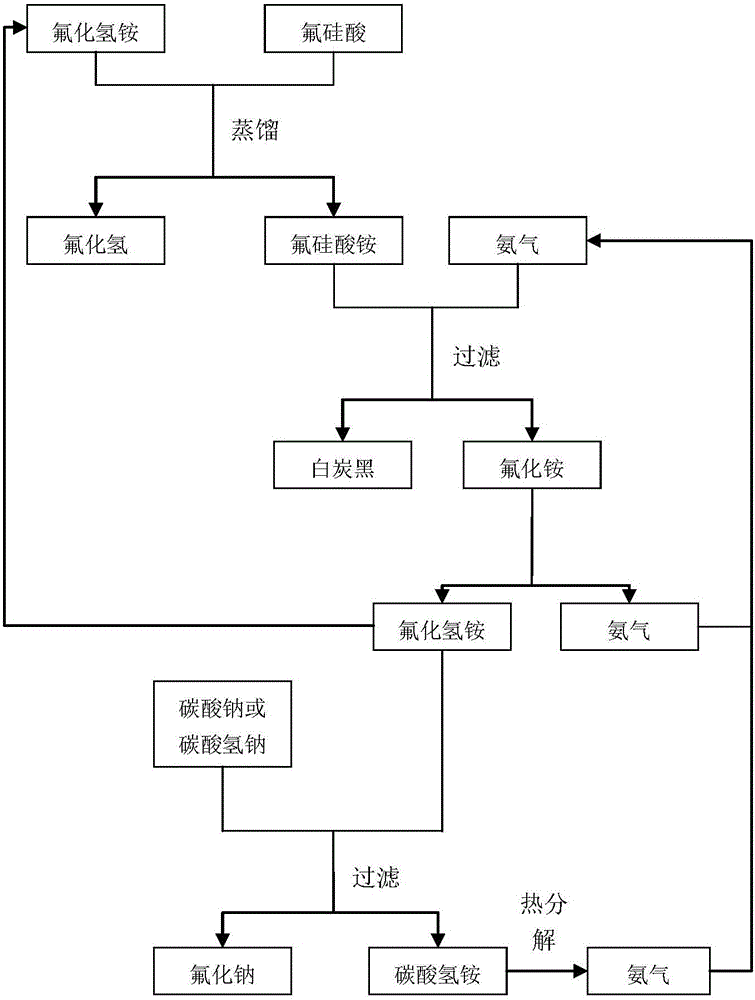

Method for preparing hydrogen fluoride and sodium fluoride by use of fluosilicic acid

ActiveCN106348248AWide variety of sourcesLow costSilicaHydrogen fluorideSodium bicarbonateFiltration

The invention discloses a method for preparing hydrogen fluoride and sodium fluoride by use of fluosilicic acid. The method comprises the following steps of: adding ammonium bifluoride into fluosilicic acid for reaction, and performing distillation, thereby obtaining a hydrogen fluoride gas and an ammonium fluosilicate solid; 2) adding aqueous ammonia into ammonium fluosilicate for reaction, performing filtration to obtain white carbon black, heating and distilling a filtrate to obtain an ammonia gas and an ammonium bifluoride solid; and 3) reacting the ammonium bifluoride obtained in the step 2) with sodium carbonate or sodium bicarbonate, filtering the filtrate after reaction is over, thereby obtaining a sodium fluoride precipitate, distilling the filtrate, and collecting the ammonia gas. The method is wide in raw material source, low in cost, low in equipment requirement, less in pollution and low in energy consumption, is capable of repeatedly using ammonium bifluoride and aqueous ammonia and converting ammonium bifluoride and sodium carbonate or sodium bicarbonate into sodium fluoride and hydrogen fluoride which are relatively high in application value and wide in application range, and has favorable economic benefits and environmental benefits.

Owner:张旭

Remover composition

InactiveCN1786834ASemiconductor/solid-state device manufacturingPhotosensitive material processingOrganic acidChemical compound

The present invention provides a stripper composition for cleaning semiconductor substrates or semiconductor elements, wherein: (1) the stripper composition contains 65% by weight or more of water, (2) the stripper composition contains: ( 1) At least one selected from sugars, amino acid compounds, organic acid salts and inorganic acid salts, and ammonium fluorosilicate in a release agent composition with a content of 0.01 to 1% by weight; or (II) organic Phosphonic acids and fluorinated compounds. The release agent composition of this invention can be used suitably for manufacture of electronic components, such as a high-quality LCD, memory, CPU.

Owner:KAO CORP

Preparation method of nanometer silicon dioxide

ActiveCN102502669AImprove surface activityAvoid reunionSilicaNanotechnologyActive agentAmmonium fluorosilicate

The invention discloses a preparation method of nanometer silicon dioxide, which comprises the following steps of: adding lauryl sodium sulfate into ammonium fluorosilicate solution as a surfactant; introducing ammonia solution and carrying out ammoniation reaction on the ammonium fluorosilicate solution, wherein the adding quantity of ammonia is 110-150 percent of theoretical amount; reacting at a normal temperature, strictly controlling the agitating speed, the adding speed of the ammonia and the reaction time, controlling the aging time within 60-150 min, adding polypropylene solution as a filter aid and carrying out solid-liquid separation after agitation; and calcining after the silicon dioxide is precipitated, washed and dried to obtain silicon dioxide powder with a median grain size of between 38-55 nm. The preparation method has the beneficial effects that as the ammonium fluorosilicate and the ammonia are taken as raw materials to prepare the nanometer silicon dioxide, and the lauryl sodium sulfate is taken as the surfactant, the surface activity of the silicon dioxide is improved; the reaction conditions are strictly controlled to prepare a silicon dioxide product with excellent performance; and the integrity of silicon dioxide powder crystals is ensured.

Owner:WENGFU (GRP) CO LTD

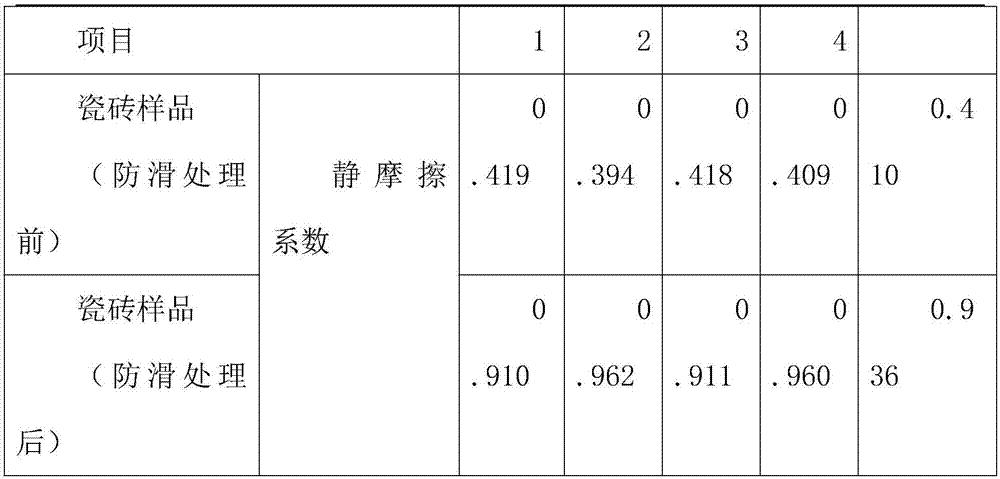

Formula of anti-skid agent for floor tile and preparation method of anti-skid agent

InactiveCN107325790AReduce glossImprove permeabilityOther chemical processesStatic friction coefficientEther

A formula of an anti-skid agent for a floor tile comprises octadecanolpolyoxyethylene ether OP-10, ammonium fluorosilicate, a surfactant A, a surfactant B, sodium chloride, alpha hydroxy acid and water. The original appearance of the floor tiles is not changed and not destroyed by adopting the anti-skid agent; glossness of the floor tile is seriously damaged and reduced by 20 degrees or more after construction by using an original anti-skid agent with strong acidity, glossness of the floor tile is decreased by 1 to 5 degrees and not destroyed after construction by using the anti-skid agent provided by the invention; the static friction coefficient of the floor tile can reach 0.936, which is far beyond the previous effect of corrosion of an acidic solution to the floor tile.

Owner:河北畅步地面防滑工程技术有限公司

Activated carbon adsorbent for haze preventing gauze mask and preparation method thereof

InactiveCN104383875AEasy to prepareEasy to operateOther chemical processesDispersed particle separationEpoxySkin sensitization

The invention relates to an activated carbon adsorbent for a haze preventing gauze mask. The adsorbent is prepared from the following raw materials in parts by weight: 80-90 parts of activated carbon, 5-8 parts of vermiculite, 2-3 parts of magnesium oxide, 2-3 parts of agar, 7-10 parts of attapulgite clay, 2-3 parts of an epoxy resin solution, 8-10 parts of flower mud leftover materials, 2-3 parts of starch, 1-1.3 parts of ammonium fluorosilicate, 5-7 parts of USY molecular sieves, 230-250 parts of a sodium hydroxide solution of 1Mol / L, 240-260 parts of a calcium chloride solution of 1Mol / L, an appropriate amount of water and 3-5 parts of addition agents. The preparation method for the adsorbent disclosed by the invention is simple, is easy to operate and is suitable for industrial large-scale production, the air filtration effect is good, and the effects of resisting bacteria and preventing haze are good. The addition agents are used, so that skin sensibility can be prevented, the adsorbent can refresh people and restore consciousness, and the filtration property is improved.

Owner:FANCHANG BEISI PRODIVITY PROMOTION CENT

Method for preparing white carbon black through waste silicon slag

InactiveCN105271254ASatisfy the requirement of supplementary functionWide range of sourcesSilicaChemical reactionHigh energy

The invention relates to a preparing method for white carbon black, and belongs to the field of inorganic chemistries. The preparing method is a method in which waste silicon slag serves as raw materials and is subjected to a series of chemical reactions to extract the white carbon black. The preparing method includes the steps that firstly, the waste silicon slag with silicon dioxide and ammonium fluoride is chemically reacted to generate ammonium fluosilicate and ammonia gas; secondly, the obtained ammonium fluosilicate and ammonium hydroxide are chemically reacted to generate silicon dioxide and ammonium fluoride; finally, the obtained silicon dioxide is aged, washed and dried, and the white carbon black is prepared. According to the preparing method for the white carbon black, the technological process is short, and the number of required devices is small; raw material sources are wide and cheap, and high-energy-consumption products such as water glass are not used; the method is low in investment and cost, high in product added value and free of environmental pollution.

Owner:GUIZHOU RES INST OF CHEM IND

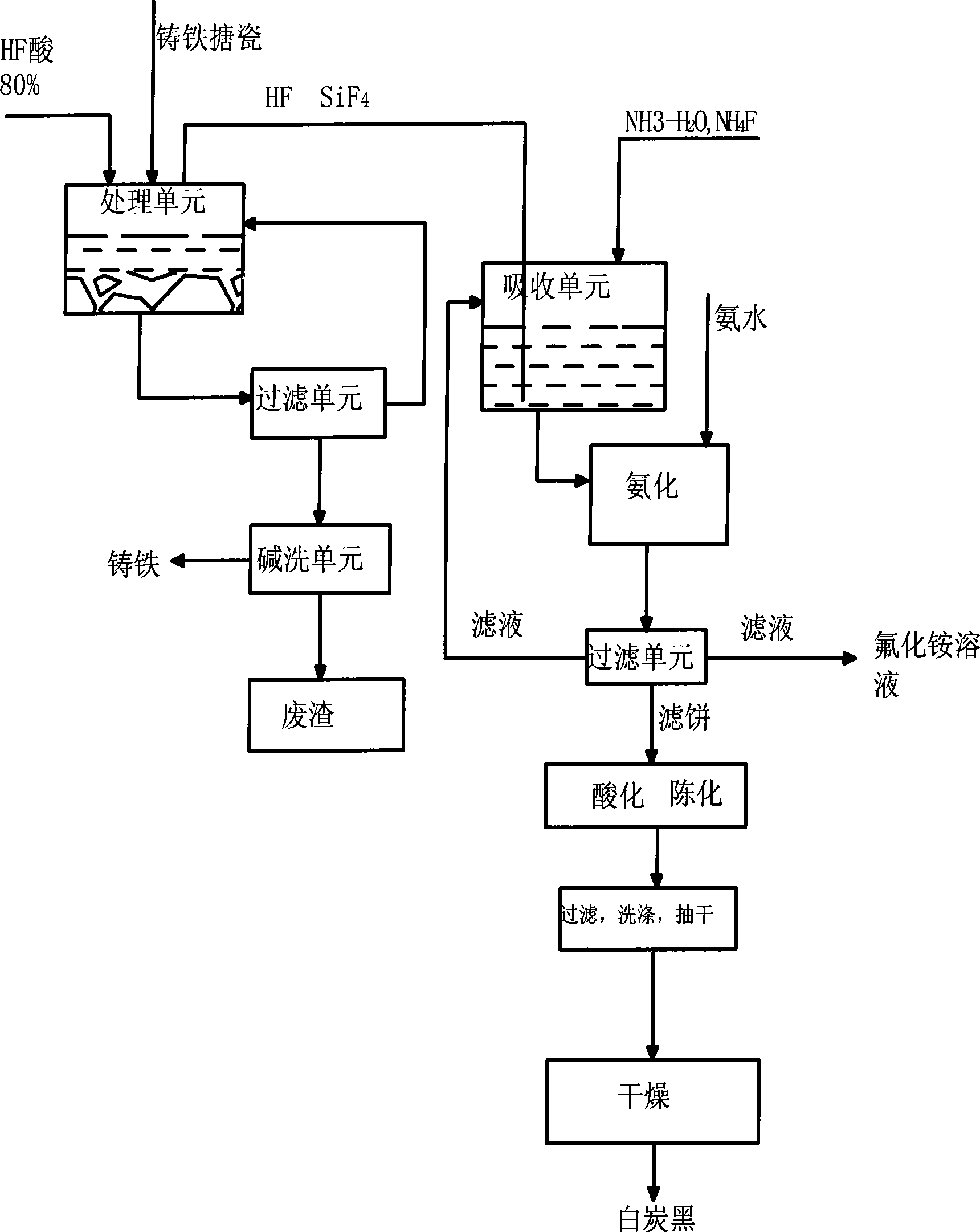

Method for removing porcelain by hydrofluoric acid and co-producing white carbon black

InactiveCN101531369ASolve the problem that cannot be recycled by mechanical sandblastingReasonable useSilicaAmmonium fluorosilicateSilicon tetrafluoride

The invention discloses a method for removing porcelain by hydrofluoric acid and co-producing white carbon black, comprising the following steps: (1) immersing cast iron enamel defective products in a reaction vessel with hydrofluoric acid water solution, carrying out the heating reaction, generating silicon tetrafluoride gas, filtering, re-inputting filtrate into the reaction vessel, washing other substances by sodium hydroxide water solution, recovering cast iron and further processing waste residues; (2) using ammonia water to simultaneously absorb the silicon tetrafluoride gas and hydrogen fluoride gas, using ammonium fluoride water solution to absorb the silicon tetrafluoride gas which is not absorbed and heating, thereby obtaining ammonium fluosilicate solution; (3) using ammonia water to regulate pH for reaction, generating sediment, filtering, separating, acidifying a filter cake by sulfuric acid, aging, filtering, washing by water and drying, thereby obtaining the white carbon black. The recovery rate can be more than 90 percent by using the method to process the cast iron enamels, and the method has the advantages of short reaction time, reasonable utilization of the acid, high utilization rate of raw materials and low production cost.

Owner:TIANJIN UNIV

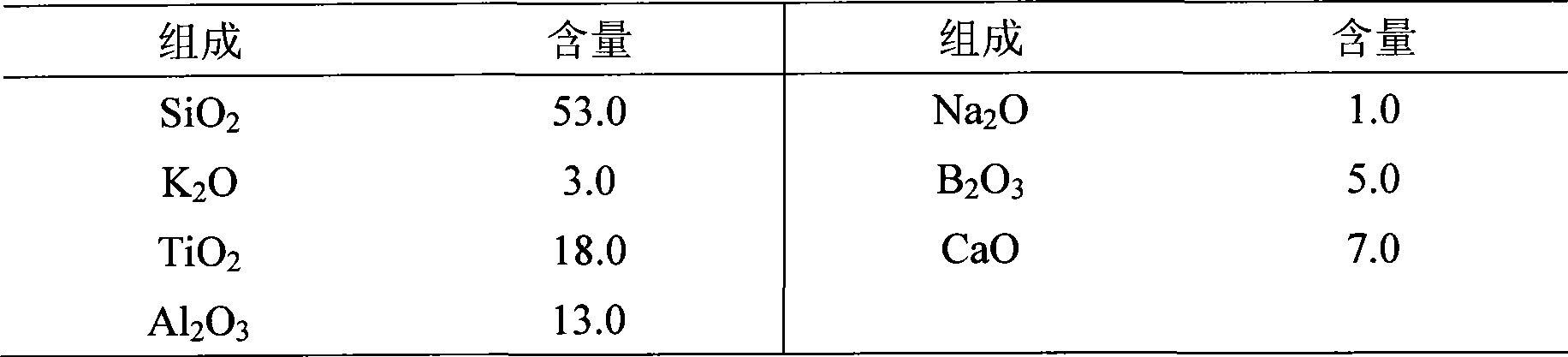

High borosilicate glass and preparation method thereof

The invention discloses high borosilicate glass and a preparation method thereof. The preparation method comprises the following steps: fusing, mixing and insulating silicon dioxide, boric oxide, aluminum oxide, sodium nitrate, sodium chloride, ammonium fluosilicate and cullet at 1570-1650 DEG C; and then cooling to prepare the high borosilicate glass, wherein based on 100 parts of silicon dioxide, the content of boric oxide is 5-10 parts by weight, the content of aluminum oxide is 2-4.5 parts by weight, the content of sodium nitrate is 0.5-1.5 parts by weight, the content of sodium chloride is 1.3-3.5 parts by weight, the content of ammonium fluosilicate is 0.1-0.5 part by weight and the content of cullet is 25-30 parts by weight. The high borosilicate glass prepared by the method disclosed by the invention has more excellent fire resistance and surface compressive stress.

Owner:XIN LI DE GLASS PROD

Preparation method of high-purity silicon dioxide

InactiveCN102874821ALow costSimple operation processSilicaAmmonium halidesSilicon tetrafluorideAmmonium fluorosilicate

The invention discloses a method for preparing high-purity silicon dioxide. The method comprises the steps as follows: getting kieselguhr as a raw material to react with an ammonium fluoride aqueous solution at certain temperature; precipitating, filtering and centrifuging to obtain an ammonium fluosilicate solution; evaporating and crystallizing to obtain high-purity ammonium fluosilicate solid; thermally decomposing the ammonium fluosilicate solid to obtain high-purity silicon tetrafluoride; carrying out reaction between the silicon tetrafluoride gas and the high-purity ammonia water to obtain silicon dioxide precipitate; then separating the solid and liquid, washing, and drying in vacuum to obtain the high-purity silicon dioxide powder. The preparation method disclosed by the invention is low in cost of raw material and simple in operation technology, has no pollutant produced in the production process, and the prepared silicon dioxide powder has purity more than 6N.

Owner:TIANJIN SURE ENERGY LUBRICATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com