Method for preparing big-compensating forcing white carbon black and high concentration ammonium fluoride through aminating of fluosilicic acid

A technology of ammonium fluorosilicate and ammonium fluoride, which is applied in the direction of ammonium halide, silicon oxide, etc., can solve the problems of increasing equipment investment, waste of fluorine and silicon resources, pollution of the environment, etc., and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

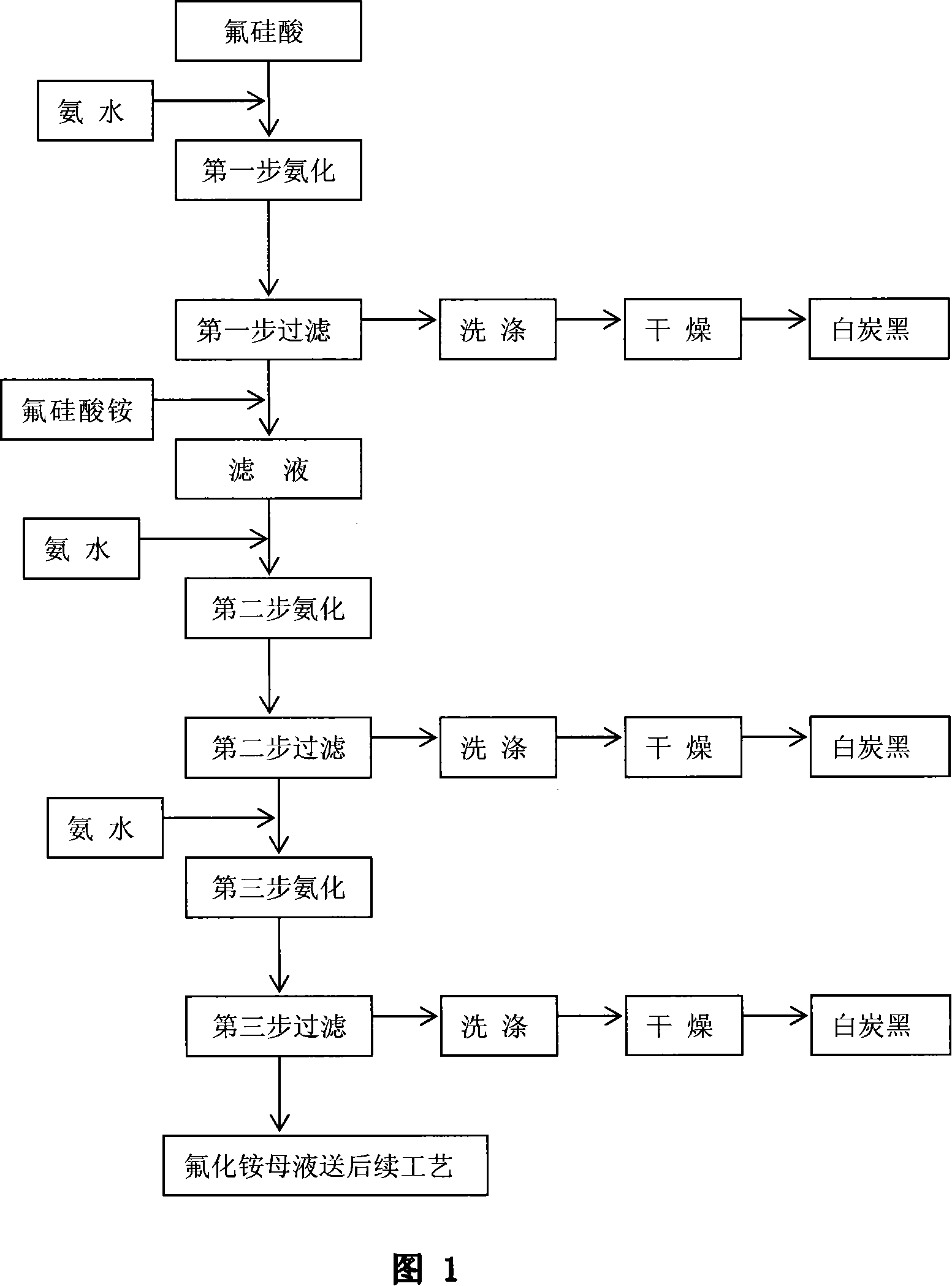

Image

Examples

Embodiment 1

[0020] Add 293.7g of 12% fluosilicic acid solution to the stirred reactor at a temperature of 27-32°C, first add 109.4g of 16% ammonia water to the fluosilicic acid solution, after the dropwise addition , the temperature is 45-50°C, the pH is 6.5-7.2, and it is aged for 30 minutes, and then the first step is filtered, and the filter cake is washed and dried to obtain a white carbon black product with a specific surface area of 265m 2 / g; Add ammonium fluorosilicate to the filtrate obtained by filtering in the first step, so that the content of ammonium fluorosilicate in the filtrate is 16%, and the temperature is 30-35°C. Add 35.4g of 28% ammonium fluoride to the filtrate Ammonia water, after the dropwise addition, the temperature is 42-47°C, and it is aged for 30 minutes, and the second step of filtration is carried out. The filter cake is washed and dried to obtain a white carbon black product with a specific surface area of 240m 2 / g, carry out the third-step ammoniatio...

Embodiment 2

[0022] Operation is with embodiment 1. The first step of ammoniation is the same as that of Example 1 with filtration. Add ammonium fluorosilicate to the filtrate obtained by filtering in the first step, so that the content of ammonium fluorosilicate in the filtrate is 12%, and the temperature is 20 to 25°C. Add 41.1g of ammonia solution with a concentration of 18%, drop After the addition is completed, the temperature of the solution is 30-35°C, and it is aged for 20-40 minutes, followed by the second step of filtration, and the filter cake is washed and dried to obtain a white carbon black product with a specific surface area of 260m 2 / g, carry out the third-step ammoniation of the filtrate obtained by the second-step filtration, the temperature is 20-25°C, add 41.4g of ammonia water with a concentration of 18% to it, after the dropwise addition, the temperature is 28-32°C, the pH >8.0, and aged for 20-40 minutes, then filtered in the third step, the filter cake was wash...

Embodiment 3

[0024] Operation is with embodiment 1. The first step of ammoniation is the same as that of Example 1 with filtration. Add ammonium fluorosilicate to the filtrate obtained by filtering in the first step, so that the content of ammonium fluorosilicate in the filtrate is 18%, and the temperature is 30 to 35°C. Add 35.1g of ammonia solution with a concentration of 28%, drop After the addition is completed, the temperature of the solution is 40-45°C, and it is aged for 20-40 minutes, followed by the second step of filtration, and the filter cake is washed and dried to obtain a white carbon black product with a specific surface area of 190m 2 / g, carry out the third-step ammoniation of the filtrate obtained in the second step of filtration, the temperature is 30-35°C, add 52.6g of ammonia water with a concentration of 28% to it, after the dropwise addition, the temperature is 38-42°C, and the pH >8.0, and aged for 20-40 minutes, then filtered in the third step, the filter cake w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com