Air cylinder rod machining device and machining control method

A technology of processing equipment and cylinder rods, which is applied in the field of cylinder rod assembly equipment, can solve the problems of low efficiency of cylinder rods, achieve the effects of improving production efficiency and quality, improving quality, and easily grabbing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

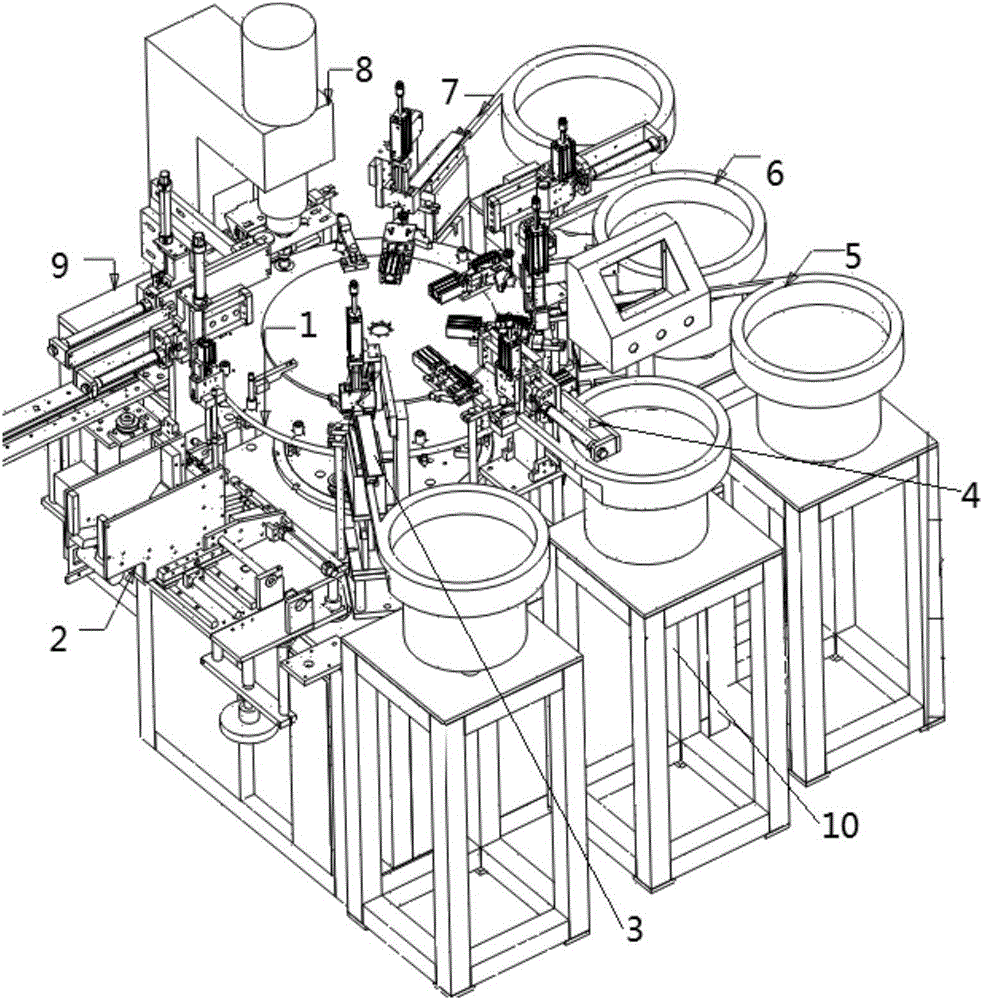

[0049] combine figure 1 , a cylinder rod processing equipment, including a turntable dividing mechanism 1 and an electric control system 10, and also includes a cylinder rod automatic feeding and placement mechanism 2, an automatic feeding and installation mechanism, an automatic piston rod riveting mechanism 8 and a product blanking system 9, Among them, the electronic control system 10 respectively controls the action execution process of the turntable dividing mechanism 1, the cylinder rod automatic feeding and placement mechanism 2, the automatic feeding and installation mechanism, the piston rod automatic riveting mechanism 8 and the product blanking system 9, and the turntable dividing mechanism 1 Receive the cylinder rod to be processed from the cylinder rod automatic feeding and placement mechanism 2, the automatic feeding and installation mechanism cooperates with the turntable dividing mechanism 1 for installation and processing, and the piston rod automatic riveting ...

Embodiment 2

[0059] Present embodiment is a kind of cylinder rod processing method of application example 1, and its steps are:

[0060] A. According to the cylinder rod processing equipment described above, the cylinder rod body is placed in the cylinder rod automatic feeding and placement mechanism 2, and the cylinder rod body rolls down from the piston rod rolling frame, facing the hydraulic cylinder push rod , the hydraulic cylinder push rod pushes the cylinder rod into the hole on the rotating column that matches the outer diameter of the cylinder rod body, the rotating column rotates so that the cylinder rod body is vertically upward, and the mechanical arm takes the cylinder rod body away and places it on the turntable In the cylinder rod clamp on the split mechanism 1;

[0061] B. Turntable dividing mechanism 1 stops after rotating, and the material placed in the vibration plate of the lower iron sheet automatic feeding and installation mechanism 3 is the lower iron sheet. The elec...

Embodiment 3

[0068] This embodiment is a control method of a cylinder rod processing equipment of Example 1, and its steps are:

[0069] A. The electronic control system 10 controls the cylinder rod automatic feeding and placing mechanism 2, and places the cylinder rod on the cylinder rod fixture on the turntable dividing mechanism 1;

[0070] B. The electric control system 10 controls the rotation of the vibration plate of the automatic feeding and installation mechanism and the turntable dividing mechanism 1. After the materials come out of the vibration plate, they move forward along the slide rails to the material fixture in sequence;

[0071] C. The electric control system 10 controls the turntable dividing mechanism 1 to stop rotating, the cylinder rod clamp on the turntable dividing mechanism 1 is facing the material fixture of the automatic feeding and installation mechanism, and the mechanical arm of the automatic feeding and installation mechanism clamps the material from the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com