High-performance silicone-acrylate-modified water-based epoxy emulsion and production method thereof

A technology of water-based epoxy emulsion and production method, which is applied in the direction of coating, anti-corrosion coating, filling slurry, etc., can solve the problems of unsatisfactory comprehensive mechanical properties, failure to meet market demand, unstable rheology, etc., and achieve excellent sealing and shielding Good performance, stable product quality, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

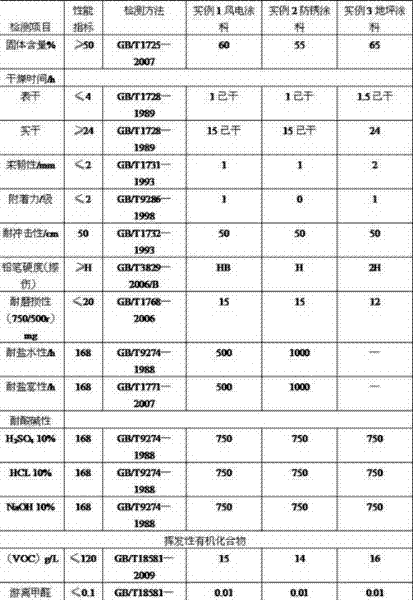

Embodiment 1

[0017] The first step is to prepare high-performance silicone-acrylate modified waterborne epoxy emulsion (code H500)

[0018] Weigh 286.10 kg of deionized water, 15 kg of polyether sulfate containing double bonds, 20 kg of methacrylamide isopropyl sulfonate, 16 kg of sodium 1-propenoxy 2-hydroxypropane sulfonate, and polyether containing double bonds. 8kg, sodium bicarbonate 0.5kg, ammonium persulfate 0.5kg, 618 epoxy resin 460kg, isooctyl glycidyl ether 40kg, added into the reactor, heated to 80-90℃ under stirring conditions. Start dropping the mixture of silicone and acrylate: β-(3.4 epoxycyclohexyl) ethyl trimethylsilane 10kg, methacrylic acid 0.5kg, styrene 5kg, 2-ethylhexyl acrylate 5kg, methacrylic acid Glycidyl ester 0.3kg, drip in 30min, keep the reaction temperature (85~90℃) for 2 hours. Then start to add the pre-emulsion mixture dropwise: 43kg of deionized water, 1.5kg of polyether sulfate containing double bonds, 1.5kg of methacrylamide isopropyl sulfonate, 1-propeno...

Embodiment 2

[0022] The first step is to prepare high-performance silicon-acrylic modified waterborne epoxy emulsion (code H400)

[0023] Weigh 304.9 kg of deionized water, 13.5 kg of polyether sulfate containing double bonds, 11 kg of methacrylamide isopropyl sulfonate, 11 kg of sodium 1-propenoxy 2-hydroxypropane sulfonate, and polyether sulfate containing double bonds. Ether 4.5kg, sodium bicarbonate 0.5kg, ammonium persulfate 0.8kg, 618 epoxy resin 380kg, ethylene glycol glycidyl ether 20kg, added into the reactor, heated to 80-90°C under stirring conditions. Start dropping the mixture of silicone and acrylate: 6kg of r-glycidoxypropyltrimethoxysilane, 0.5kg of methacrylic acid, 0.3kg of glycidyl methacrylate, 5kg of methyl methacrylate, butyl acrylate 5kg, drip in 30min, keep the reaction temperature (80~90℃) for two hours. Then start to drip the pre-emulsified mixture: 57kg of deionized water, 3kg of polyether sulfate containing double bonds, 2kg of methacrylamide isopropyl sulfonate, ...

Embodiment 3

[0028] The first step is to prepare high-performance silicone-acrylate modified waterborne epoxy emulsion (code H500)

[0029] The water-based epoxy floor coating is based on Example 1 of the present invention, a high-performance silicone-acrylate modified water-based epoxy emulsion (code H500).

[0030] The second step is to prepare water-based epoxy floor coating

[0031] Weigh 104kg of deionized water, 2.5kg of 750W wetting and dispersing agent, 2.5kg of 760 wetting and dispersing agent, 2.5kg of polysiloxane-polyether copolymer, 190kg of titanium dioxide R920, 10kg of superfine mica powder, and superfine sulfur powder 10kg, superfine glass powder 10kg, propylene glycol 10kg, water-based epoxy emulsion H500 650kg, 2-n-octyl-4-isothiazoline-3-ketoimidazole 1kg, polyurethane leveling agent 5kg, dispersed and ground, fineness 30 ~40μm, discharging and filtering, as the A component of the coating, and the B component is the XY593 modified amine compound curing agent of Xinyuan Chemic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com