Patents

Literature

388results about How to "Inhibit carbon deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing methyl acetate by carbonylating dimethyl ether

ActiveCN101613274AImprove stabilityHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reactionMolecular sieveMethyl acetate

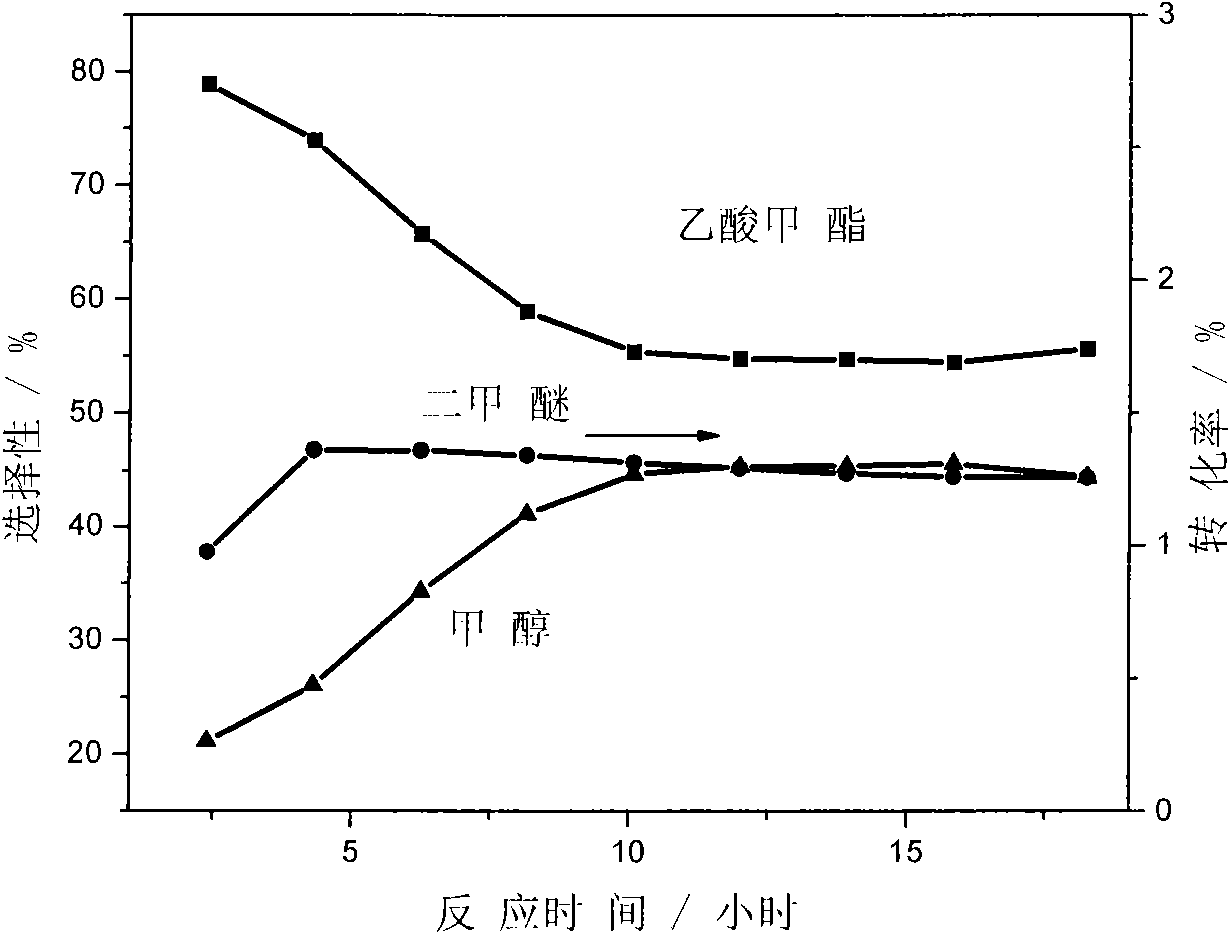

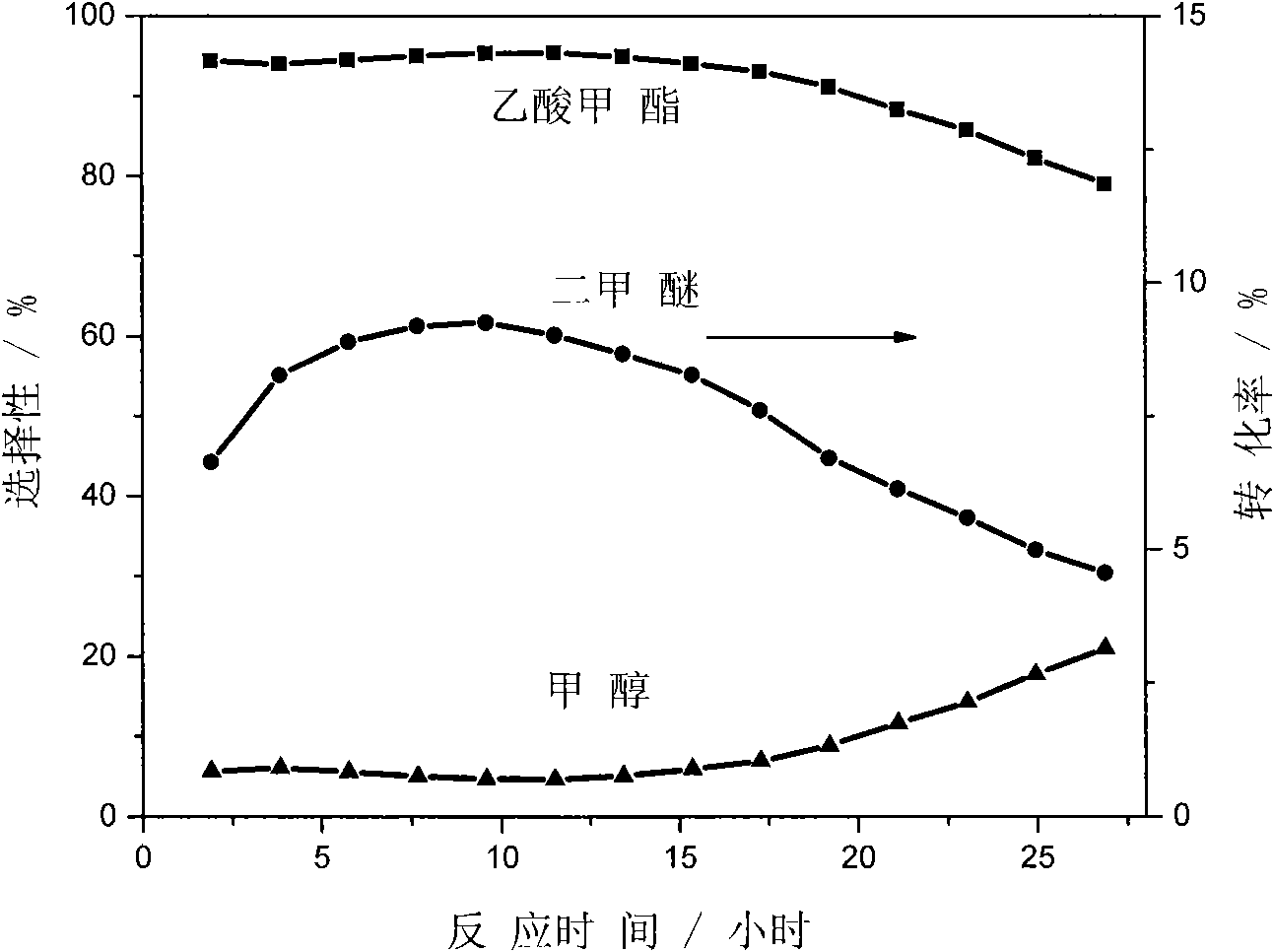

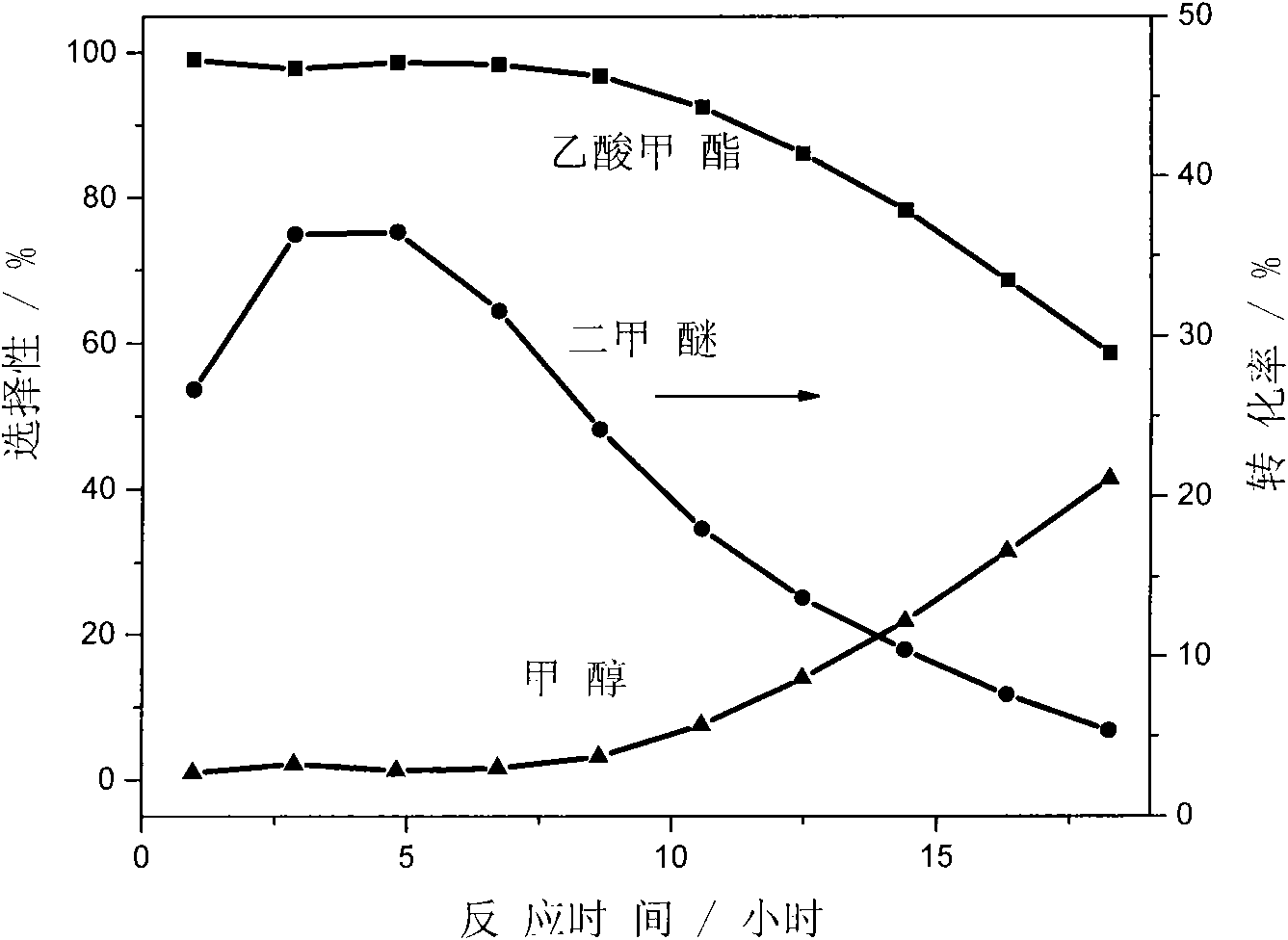

The invention discloses a catalyst modification method for preparing methyl acetate by carbonylating dimethyl ether. The method is applied to the reaction process in which the dimethyl ether reacts with the carbon monoxide to high selectively form methyl acetate in the presence of an acid molecular sieve catalyst, particularly a mordenite molecular sieve. Pyridine organic amines are utilized to modify the mordenite molecular sieve and modify a channel structure and the acidity of the molecular sieve, thereby effectively inhibiting carbon deposition and greatly improving the stability of catalysts. The use of the catalysts by the method can catalyze the carbonylation of dimethyl ether to obtain methyl acetate under mild conditions. The conversion rate of dimethyl ether is between 10 and 60percent, the selectivity of the methyl acetate is over 99 percent, and the activity of the catalysts is kept steady after the reaction is performed for 48 hours.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Hydrodewaxing catalyst and its preparation method

ActiveCN102451748AImprove the effect of impurity removalInhibit carbon depositionMolecular sieve catalystsRefining to eliminate hetero atomsImpurityChemistry

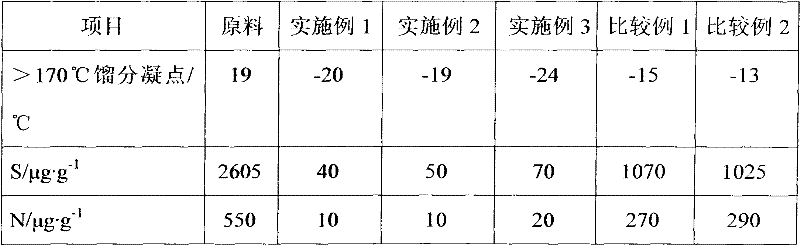

The invention discloses a hydrodewaxing catalyst and its preparation method. With the weight of the catalyst as the reference, the catalyst contains the following components of: by weight, 5-10% of tungsten oxide, 1-5% of nickel oxide, 40-50% of nanometer ZSM-5 molecular sieve, 10-40% of macroporous alumina and the balance being a binder. The catalyst is prepared by the following steps of: firstly kneading the nanometer ZSM-5 molecular sieve, macroporous alumina and the binder to prepare a carrier, dipping loaded active metal, and finally carrying out hydrothermal treatment. The hydrodewaxing catalyst provided by the invention has a good shape-selective catalysis function and simultaneously has a good hydrofinishing function, and is especially suitable for the hydrofinishing and pour point reduction processes of a waxy hydrocarbon oil material containing high content of impurities such as sulfur, nitrogen and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

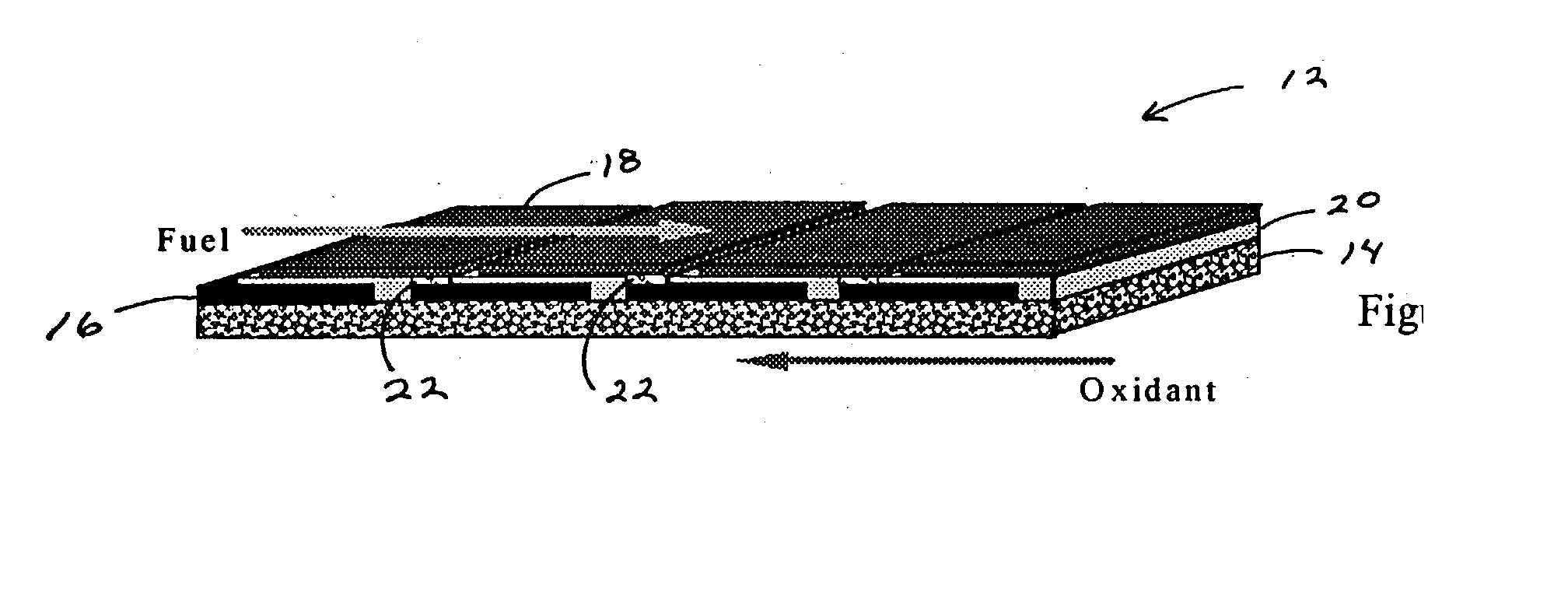

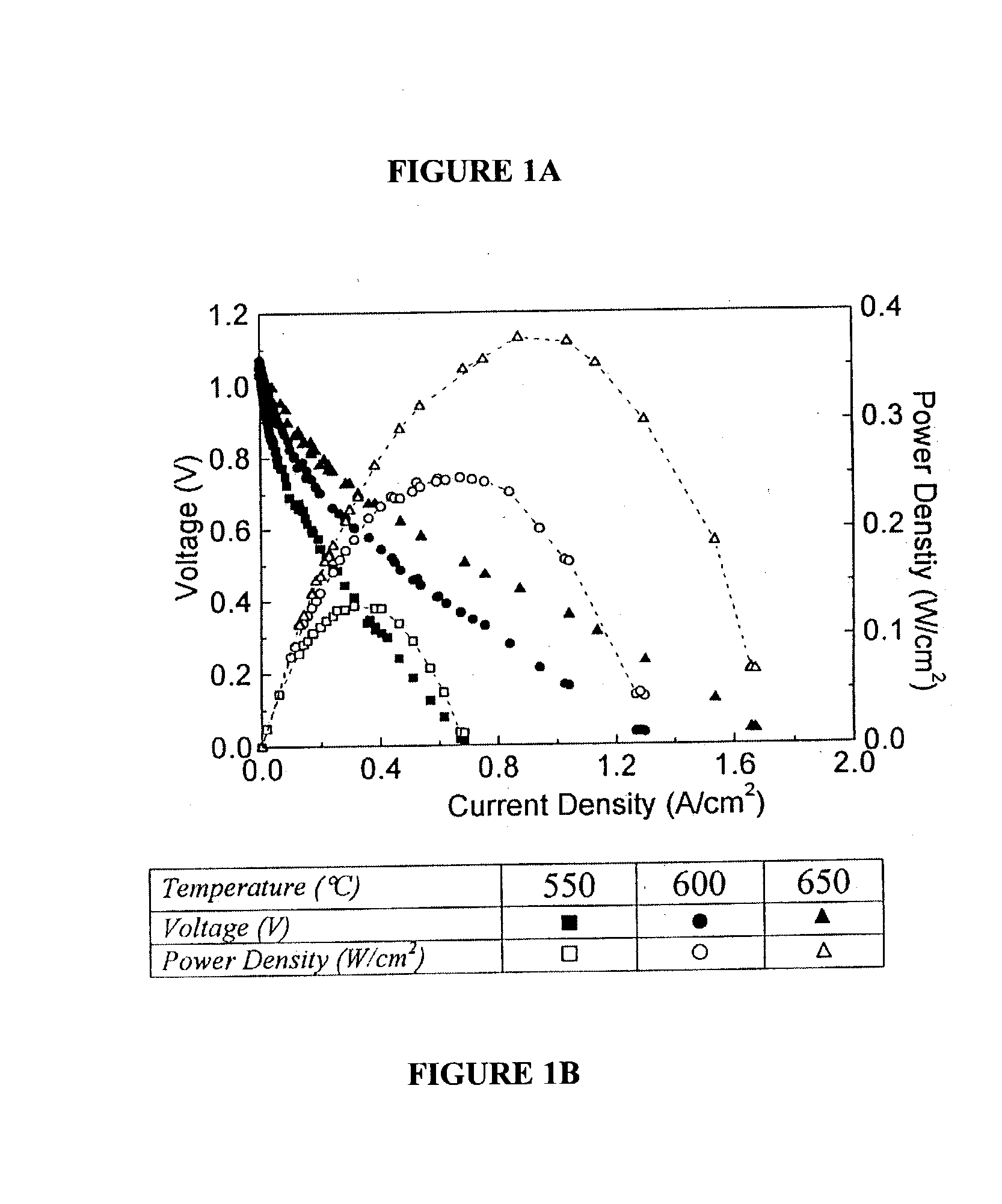

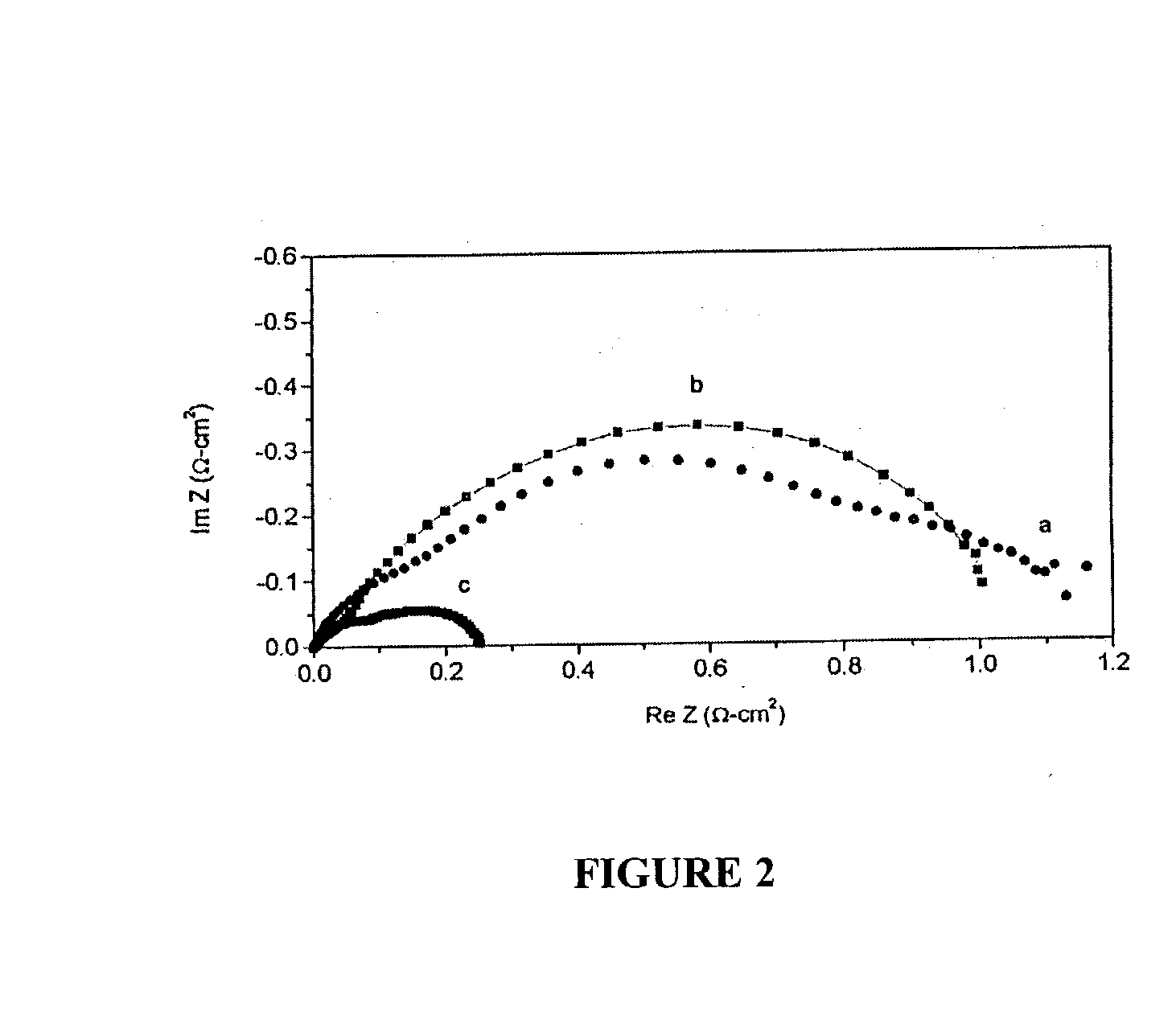

Direct hydrocarbon fuel cells

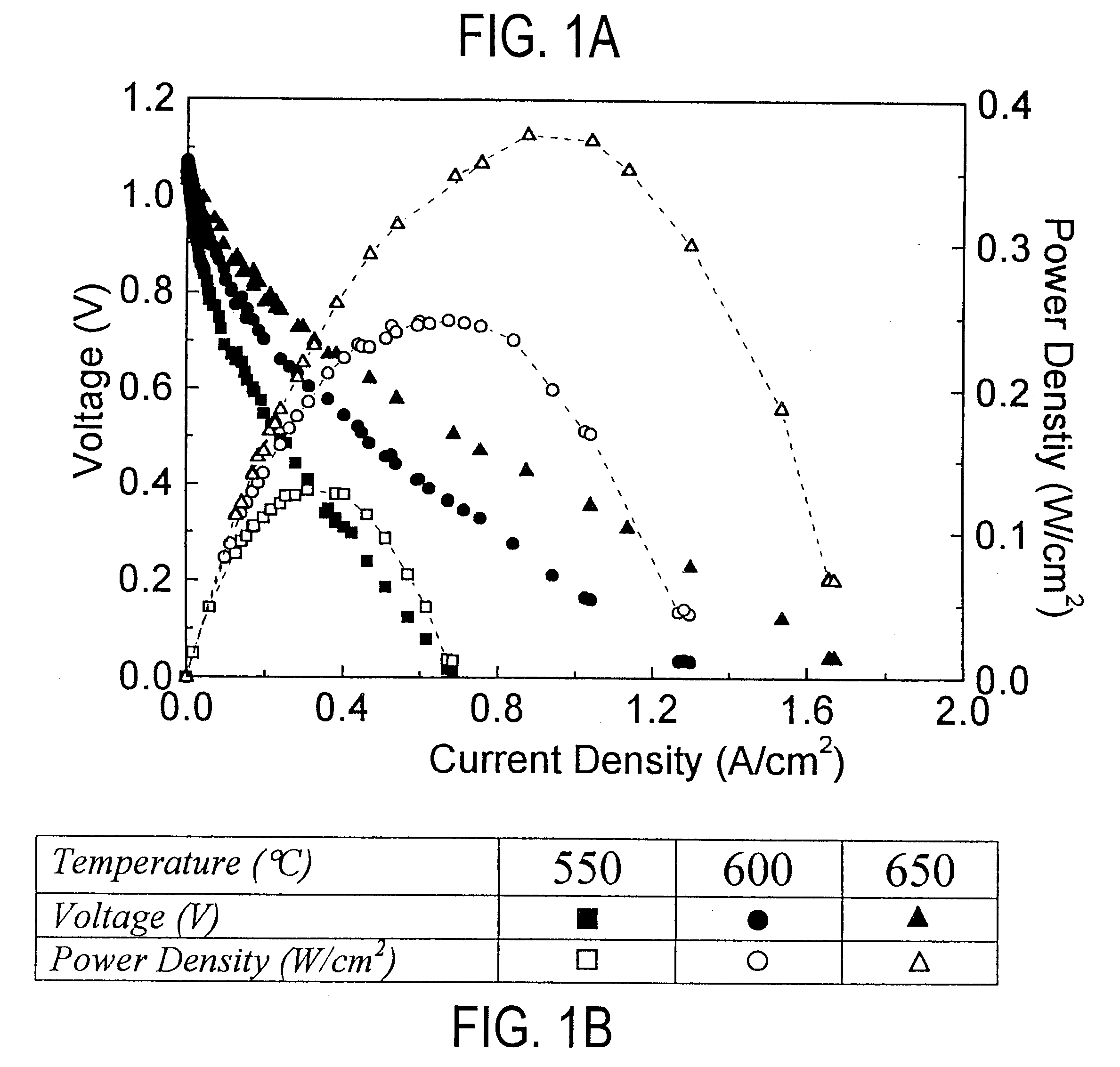

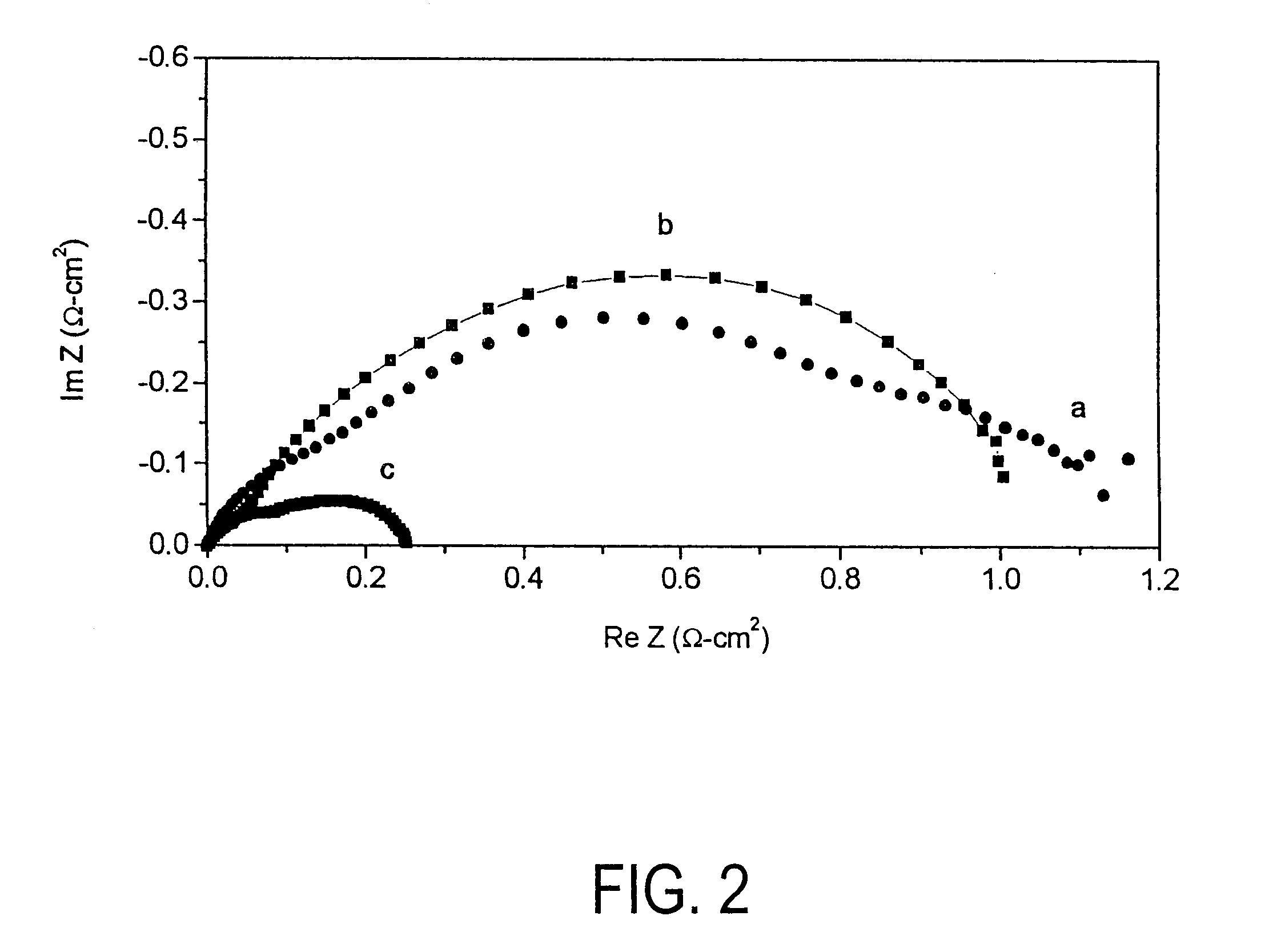

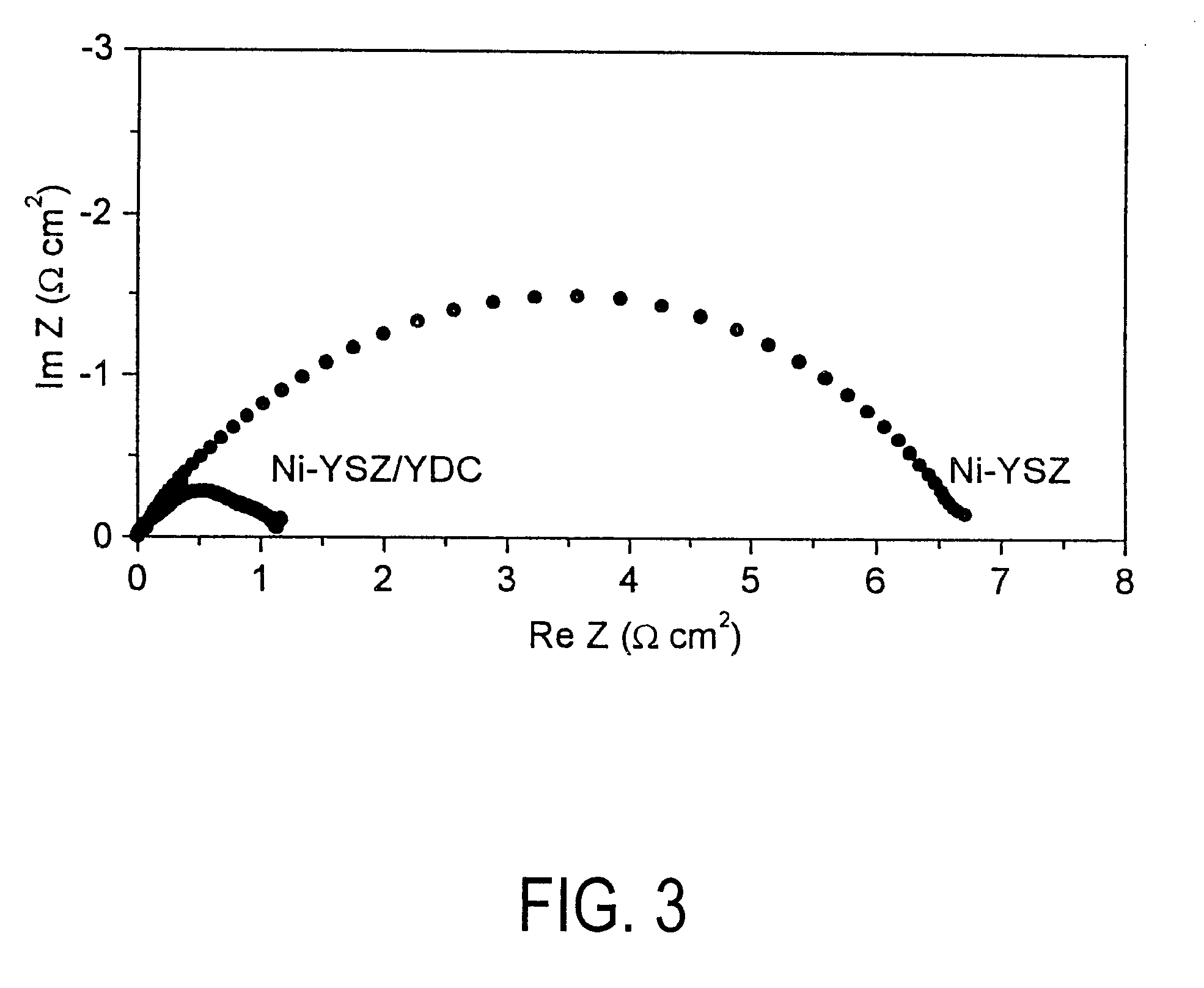

InactiveUS6214485B1Increase ratingsUseful power densityFuel cells groupingFinal product manufactureFuel cellsHydrogen

The direct electrochemical oxidation of hydrocarbons in solid oxide fuel cells, to generate greater power densities at lower temperatures without carbon deposition. The performance obtained is comparable to that of fuel cells used for hydrogen, and is achieved by using novel anode composites at low operating temperatures.

Owner:NORTHWESTERN UNIV

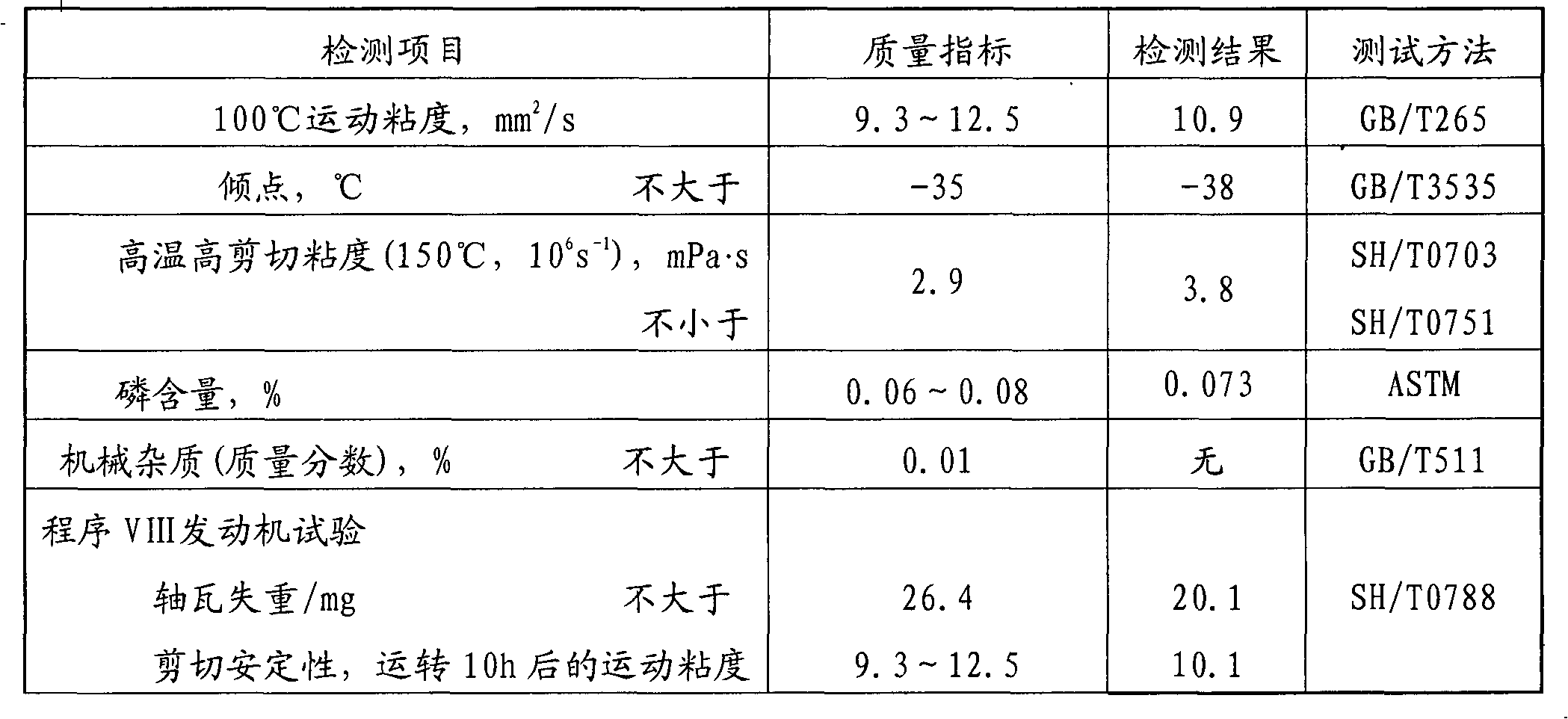

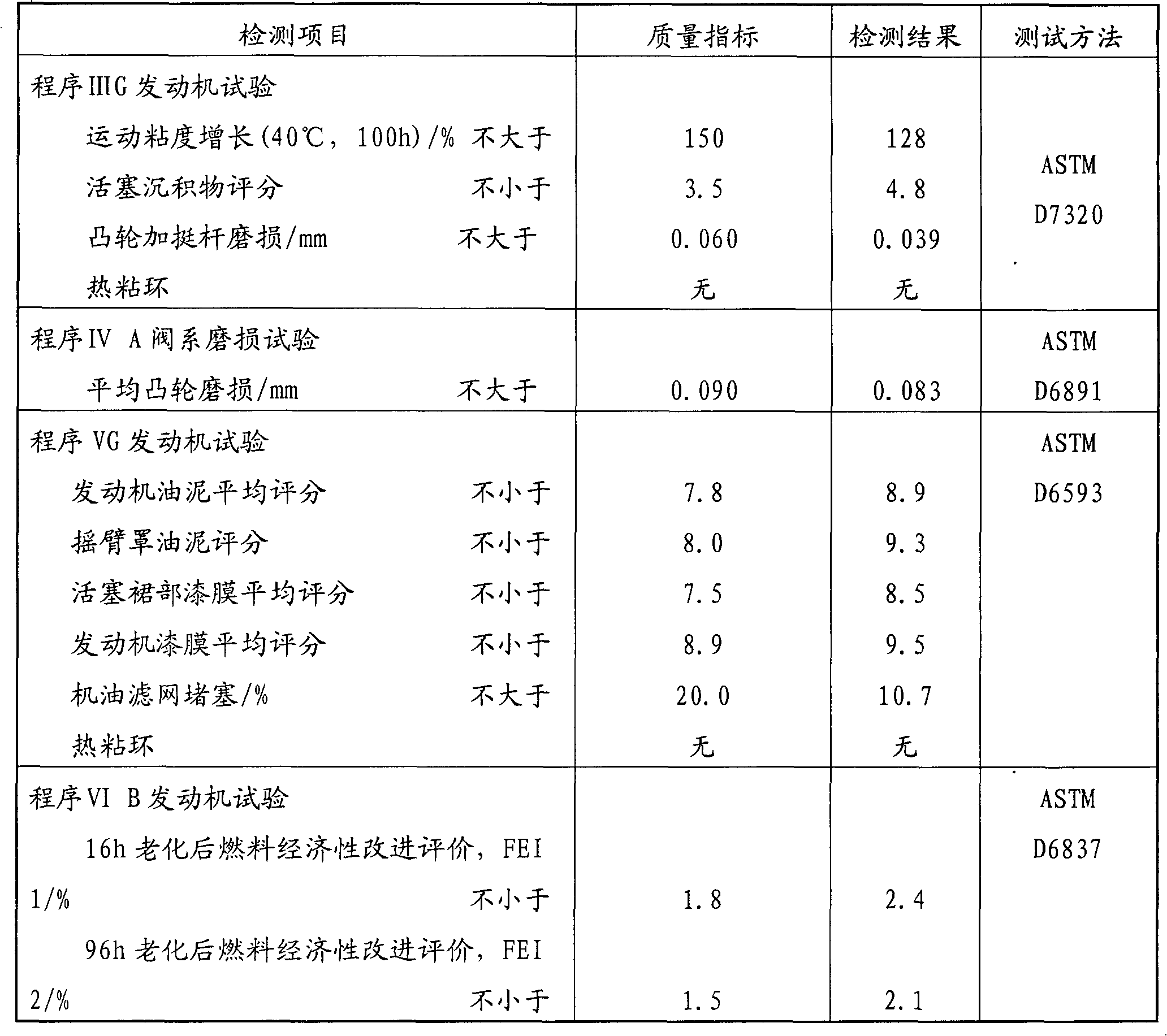

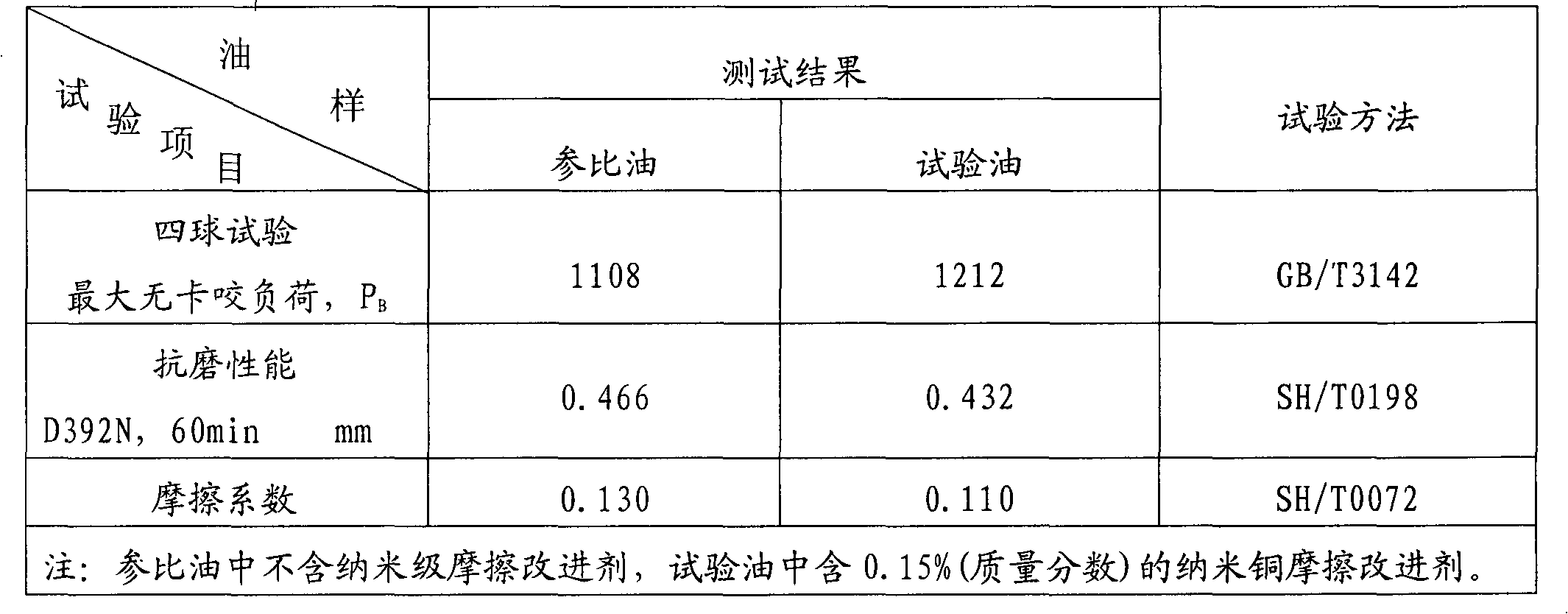

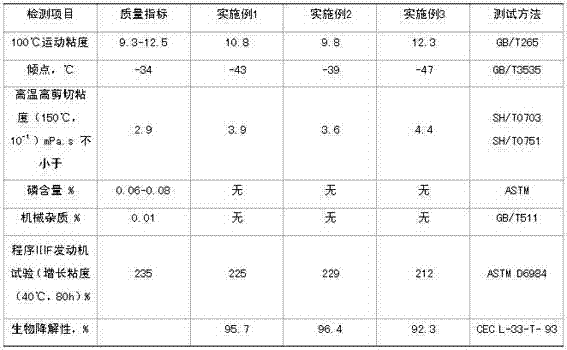

Energy-efficient long-life gasoline engine oil

InactiveCN101982534AReduce sulfur and phosphorus contentImprove carrying capacityLubricant compositionEcological environmentOil sludge

The invention discloses energy-efficient long-life gasoline engine oil prepared from the following components: synthetic base oil, a composite antioxygen, a metal cleaning agent, an ashless dispersant, a nano-level friction improver, a viscosity improver and a pour point reducer. The gasoline engine oil provided by the invention has the following advantages: requirements of API SM, ILSAC GF-4 and SAEJ300 are met and the service life is long; the complete synthetic base oil features low pour point, high viscosity index, good economy of fuel, degradability and reduced harm to the ecological environment; the phenol type antioxygen is combined with ZDDP, the anti-oxygen and antifriction properties are good and the catalyst poisoning in a tail gas processing unit is prevented; the acid neutralization capacity is good, the cleaning dispersibility is good and the oil sludge and carbon deposit are prevented from being generated; and the nano-level friction improver is added, the frictional factor is low, and the oil film features high carrying capacity and can automatically repair abraded surface and lengthen the service life of the engine.

Owner:GUANGDONG SANVO CHEM IND TECH

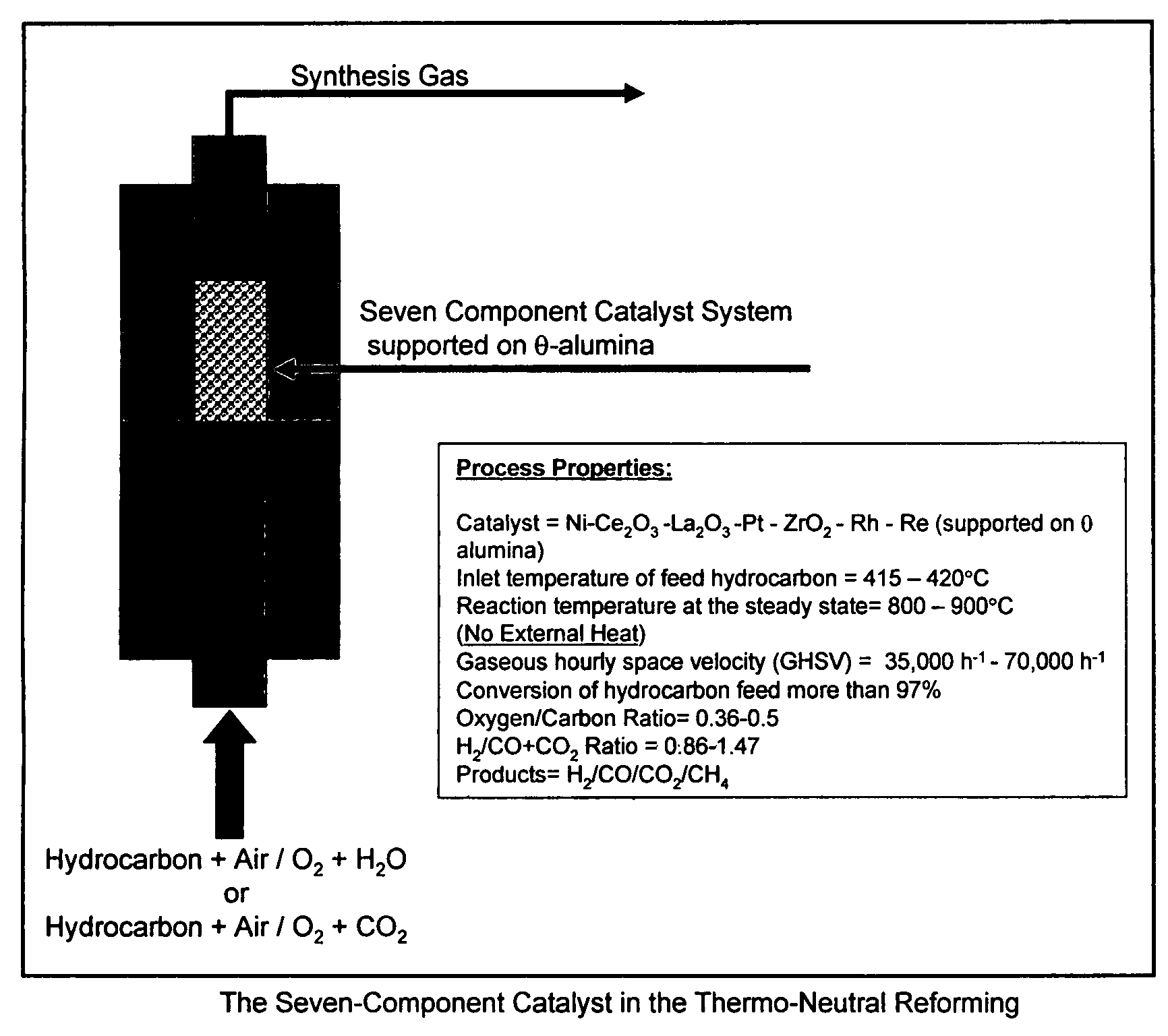

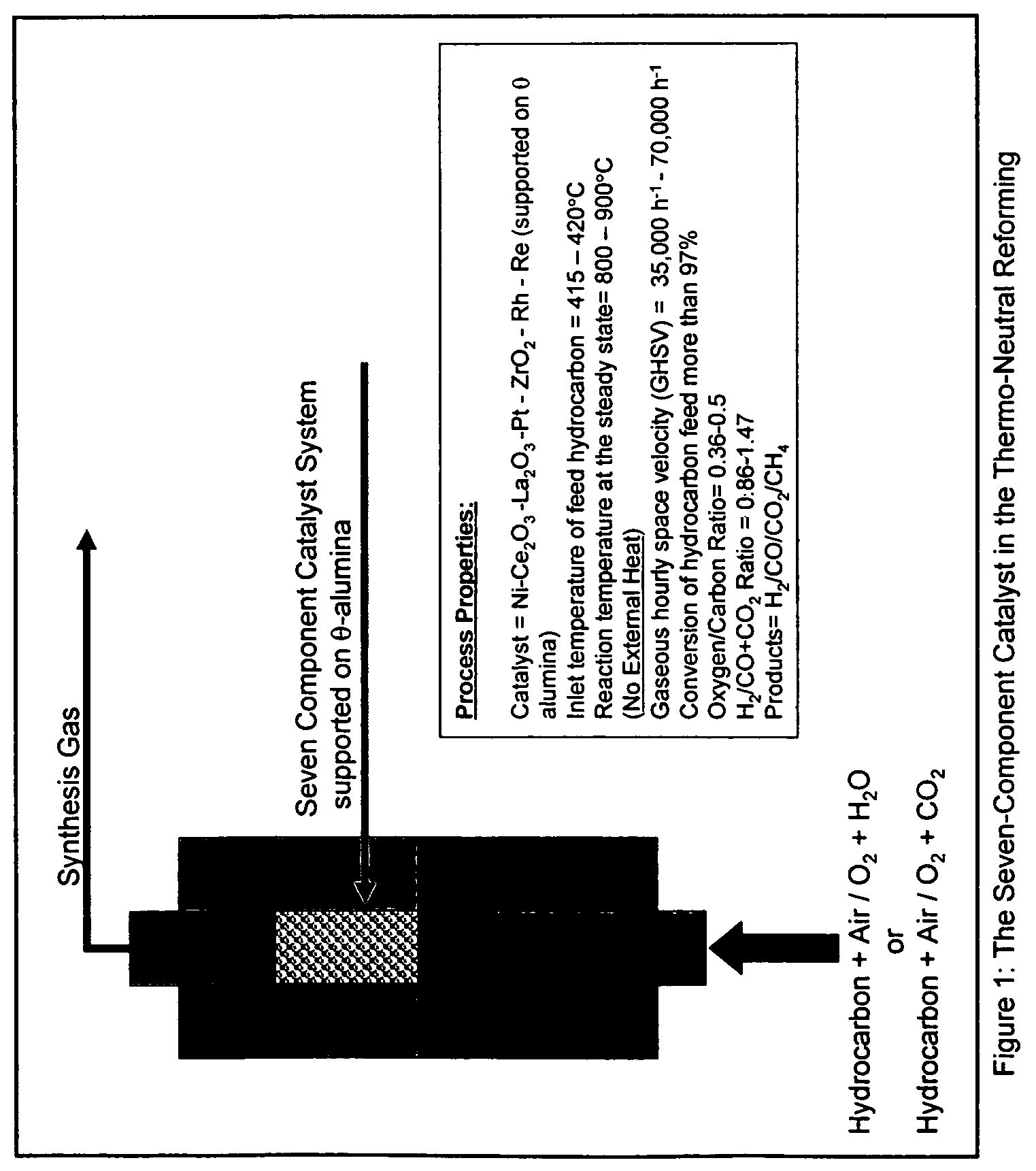

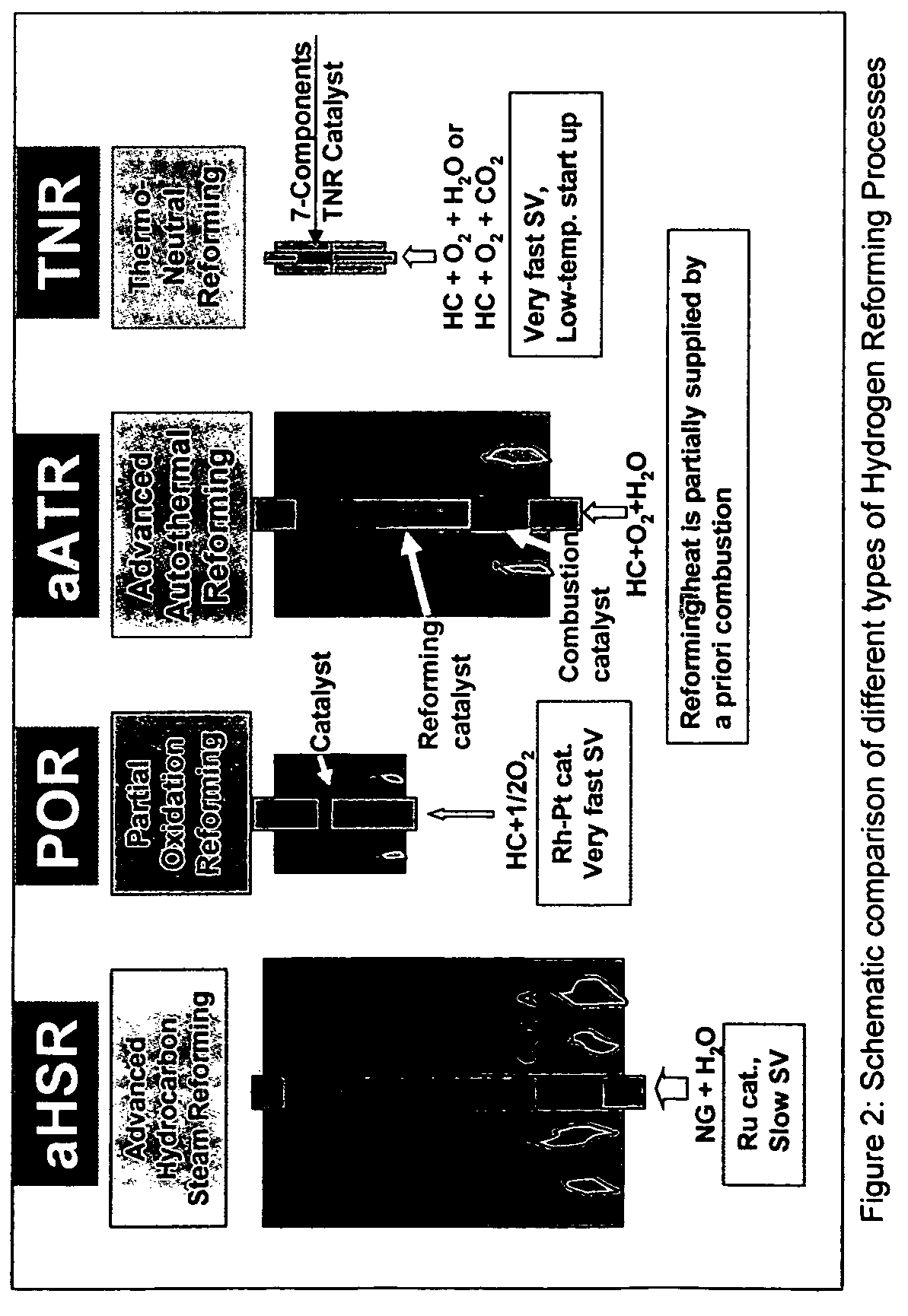

Oil-based thermo-neutral reforming with a multi-component catalyst

ActiveUS7700005B2Enhance the activity of the base metal-supported thermo-neutral reforming catalystProcesses liquid hydrocarbon fuels efficiently and reliablyHydrogenHydrocarbon from carbon oxidesSteam reformingCombustion

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Environment-friendly and energy-saving gasoline engine oil and preparation method thereof

The invention discloses environment-friendly and energy-saving gasoline engine oil and a preparation method thereof. The environment-friendly and energy-saving gasoline engine oil is prepared from the following raw materials in parts by weight: 70-85 parts of environment-friendly base oil, 0.8-3.0 parts of a complex antioxidant, 3.7-6.7 parts of a metal detergent, 5.8-7.8 parts of an ashless dispersant, 0.7-1.5 parts of a nanoscale friction modifier, 4.0-10.0 parts of a viscosity index improver and 0.2-1.0 part of a pour-point depressant. The preparation method comprises the following steps: feeding the environment-friendly base oil to an adjustable dehydrator; sequentially feeding the pour-point depressant, the viscosity index improver, the complex antioxidant, the metal detergent and the ashless dispersant when stirring at 58-65 DEG C, and stirring evenly; and feeding the nanoscale friction modifier, keeping at 58-65 DEG C, further stirring for 1.5 hours, and standing for 0.5 hour, so as to obtain the environment-friendly and energy-saving gasoline engine oil which meets the API SN / GF-5 requirements and is long in service life.

Owner:SHANGHAI INST OF TECH +1

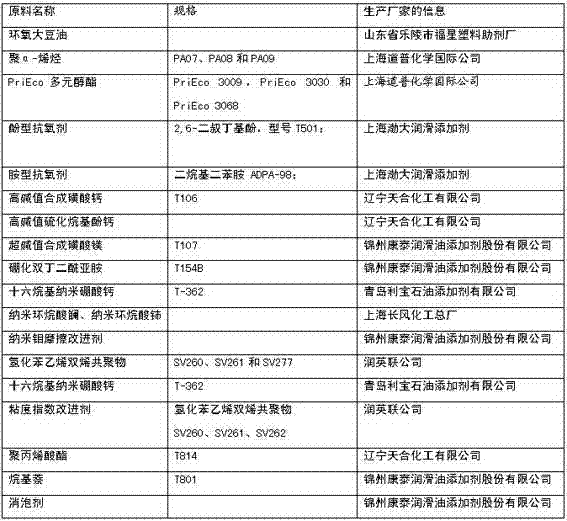

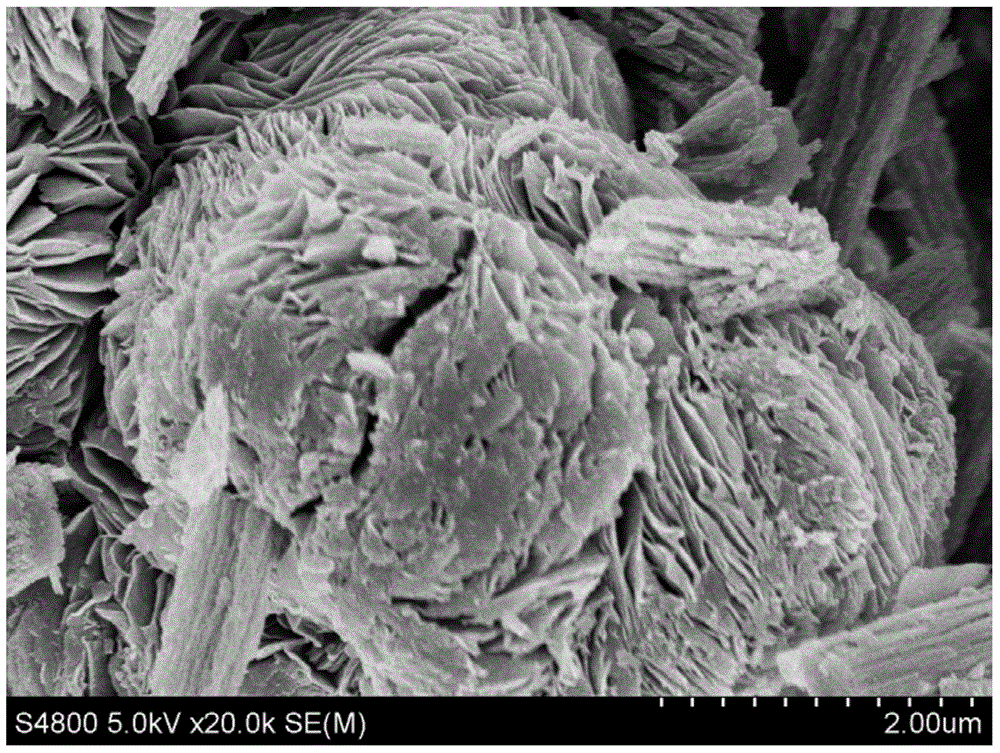

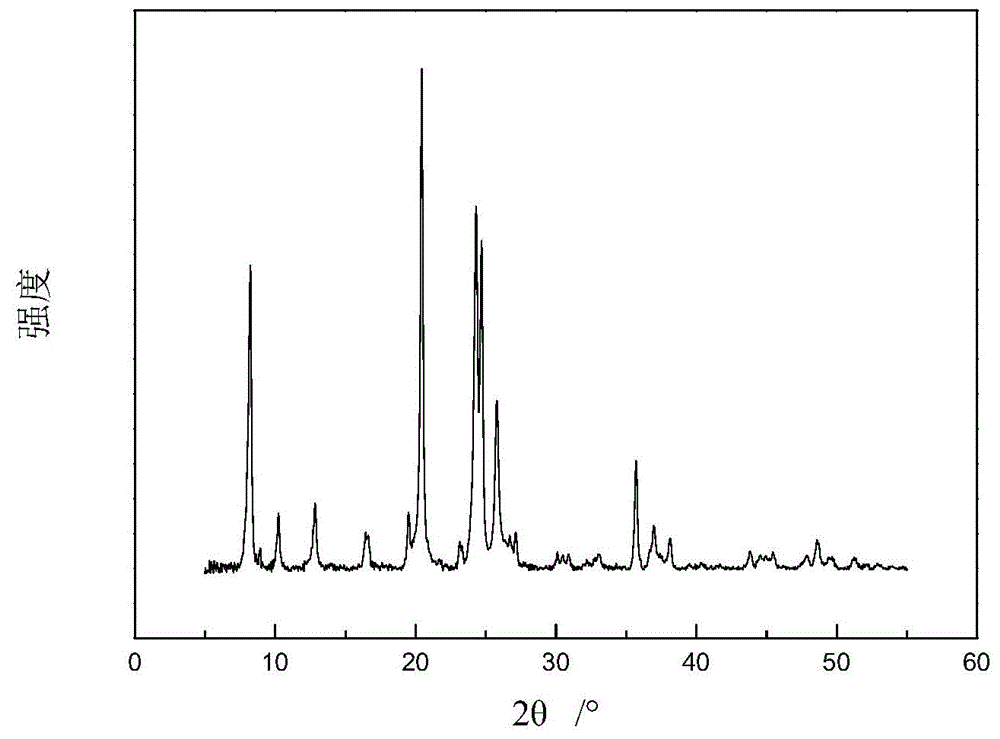

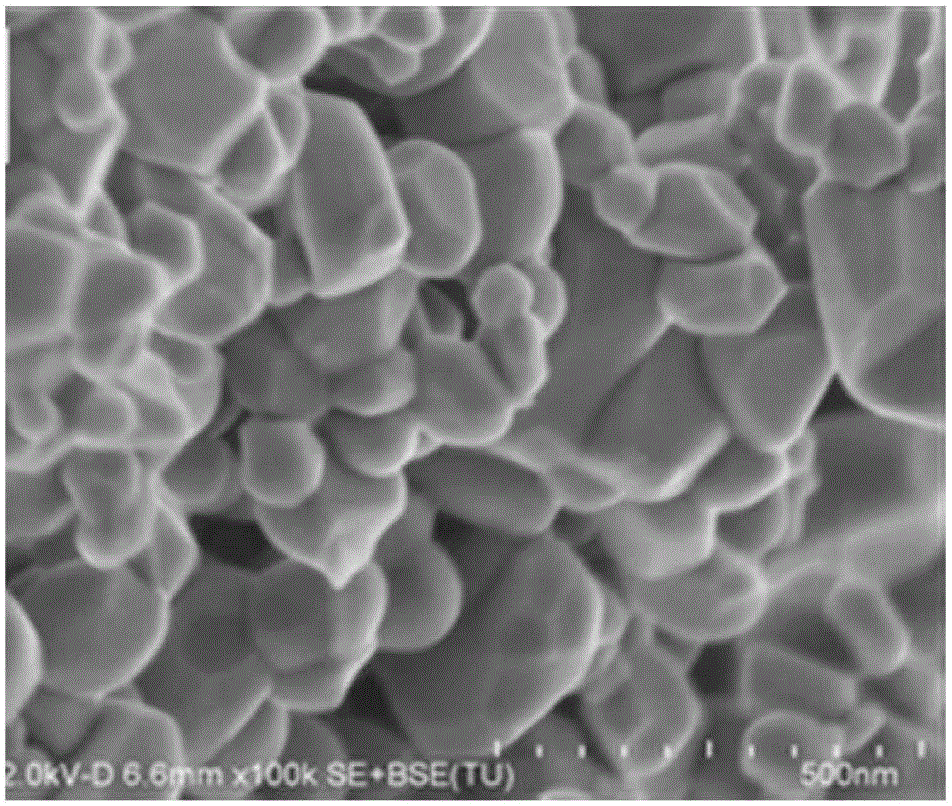

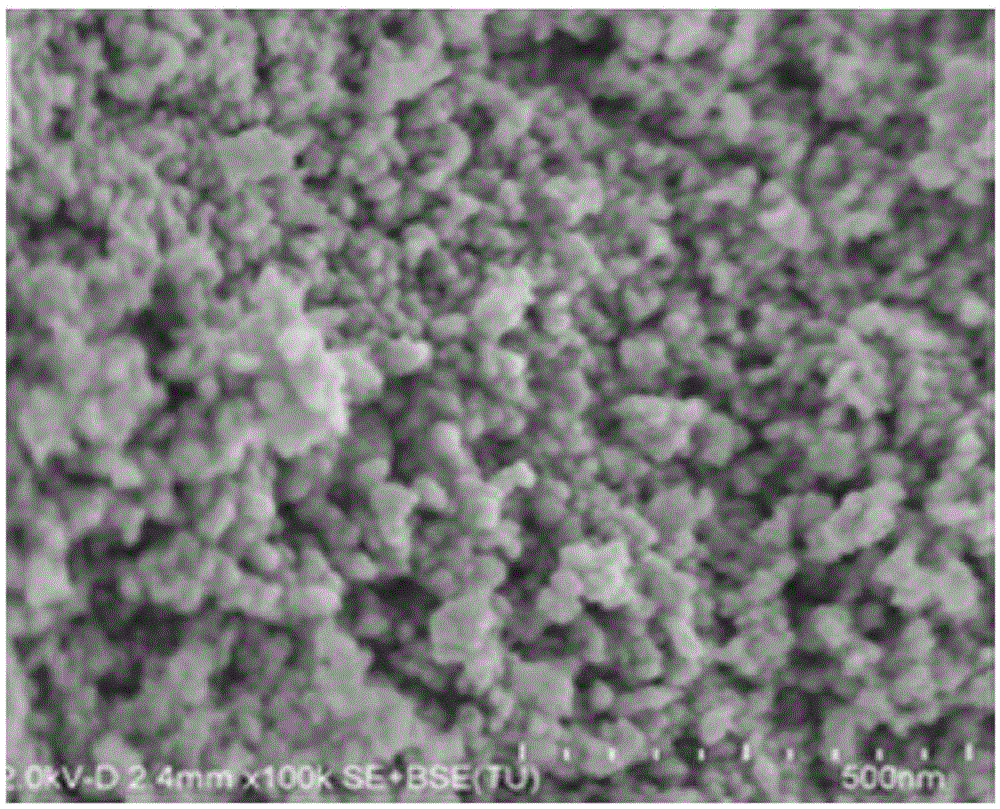

Preparation method of ZSM-22 molecular sieve nanosheet

ActiveCN104671253AExtended service lifeImprove diffusivityCrystalline aluminosilicate zeolitesMolecular sievePotassium hydroxide

The invention discloses a preparation method of a ZSM-22 molecular sieve nanosheet, relates to a preparation method of a ZSM-22 molecular sieve, and aims at solving the problems that an organic template agent adopted by an existing method for synthesizing the ZSM-22 molecular sieve is large in amount and high in cost, and molecular sieve grains exist in a form of an aggregate with a relatively large dimension. The preparation method comprises the following steps: 1, preparing prefabricated seed crystal from aluminum sulfate octadecahydrate, ethyl orthosilicate, 1,6-hexamethylendiamine, potassium hydroxide and deionized water; 2, preparing gel from aluminum sulfate octadecahydrate, silica sol, potassium hydroxide and deionized water; and 3, crystallizing and roasting. The ZSM-22 molecular sieve prepared by the method is in a regularly arranged laminated nanometer structure; the sheet thickness is only about 20nm; the amount of the organic template agent is significantly reduced in the synthesis process; the crystallization time is shortened; and the cost is reduced.

Owner:HEILONGJIANG UNIV

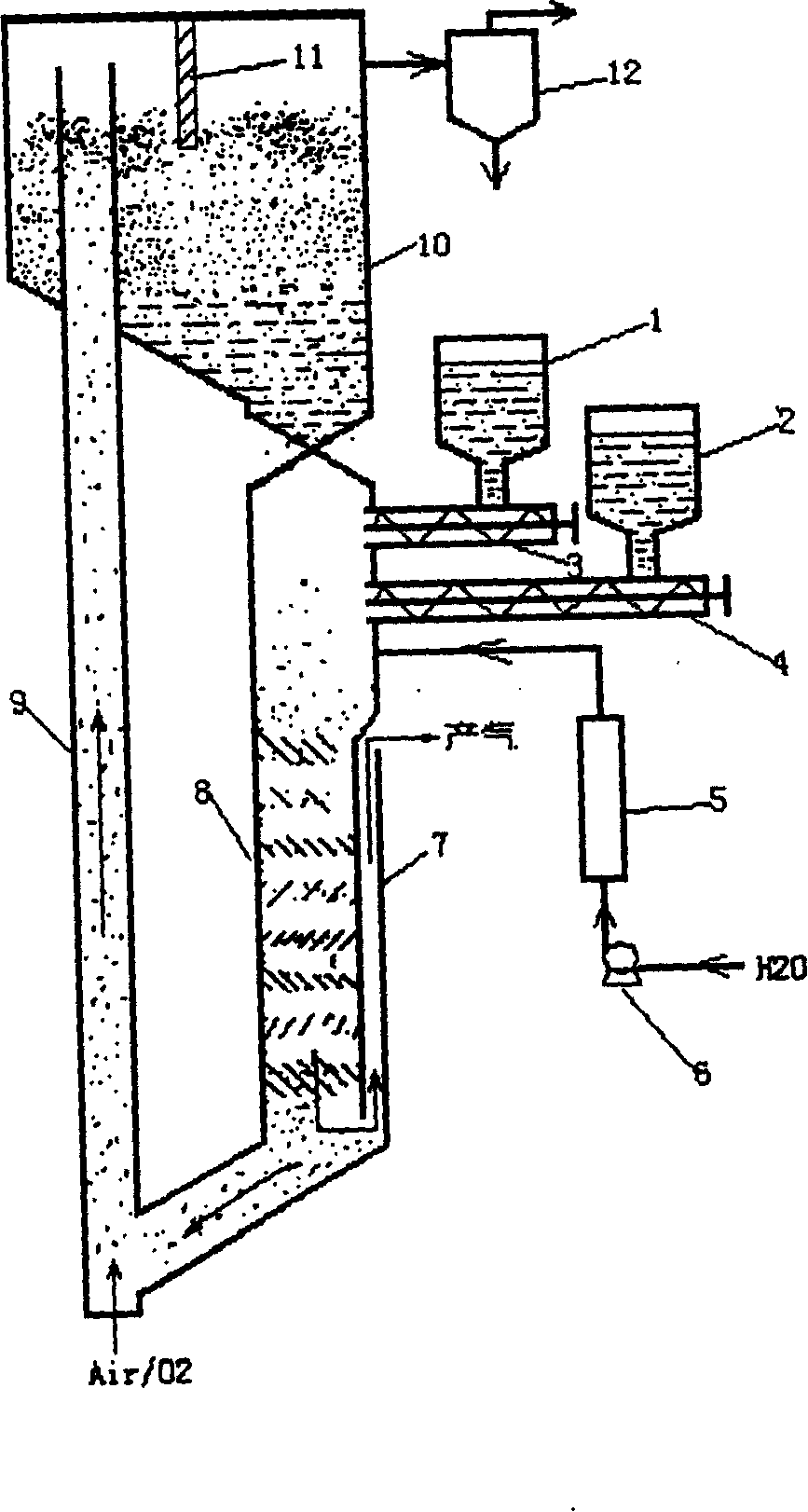

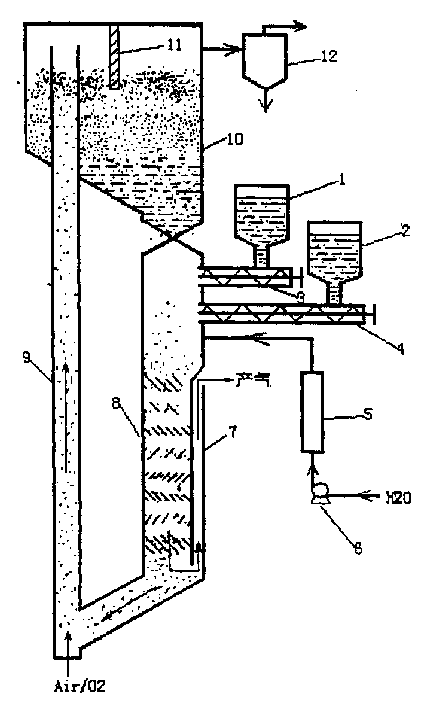

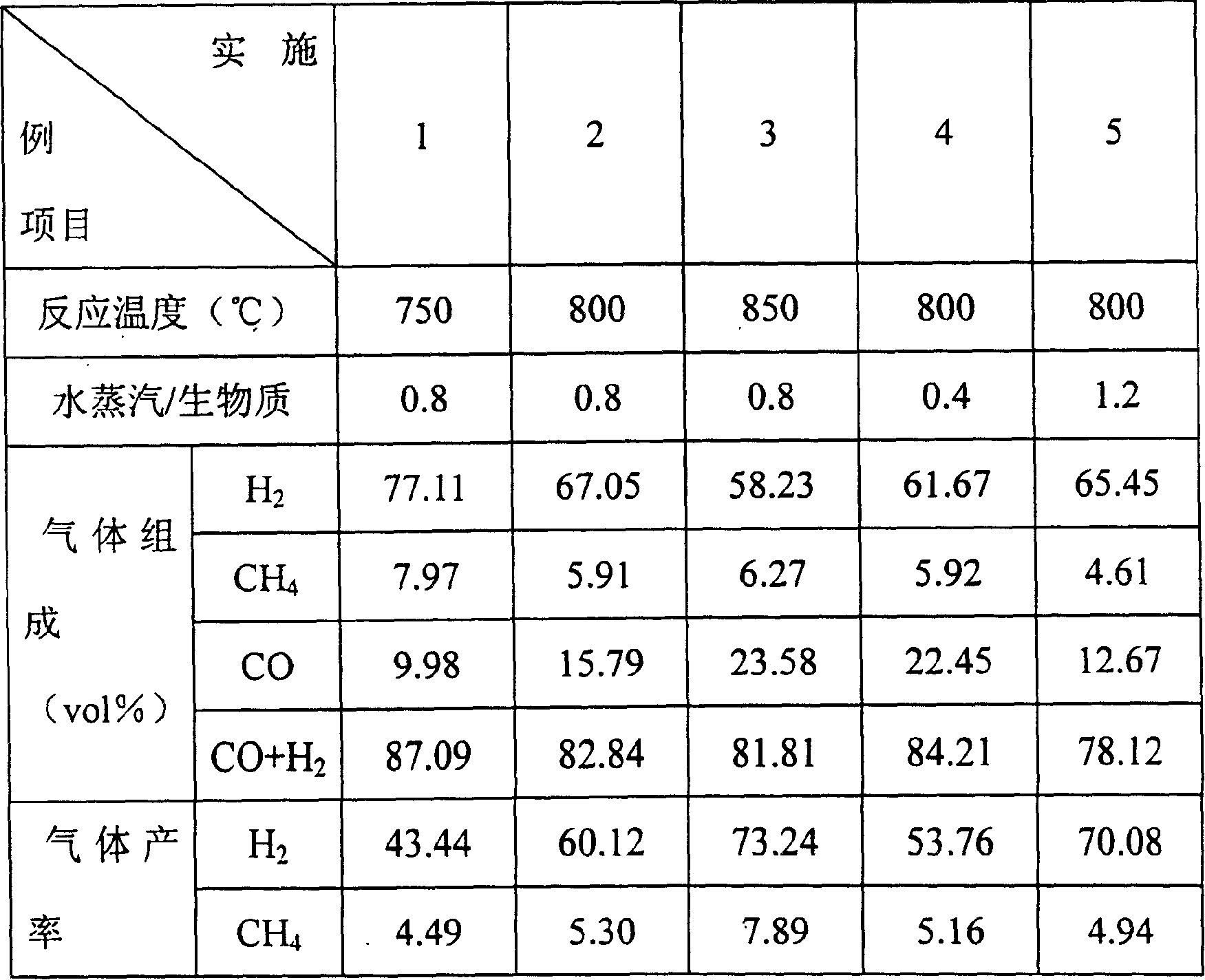

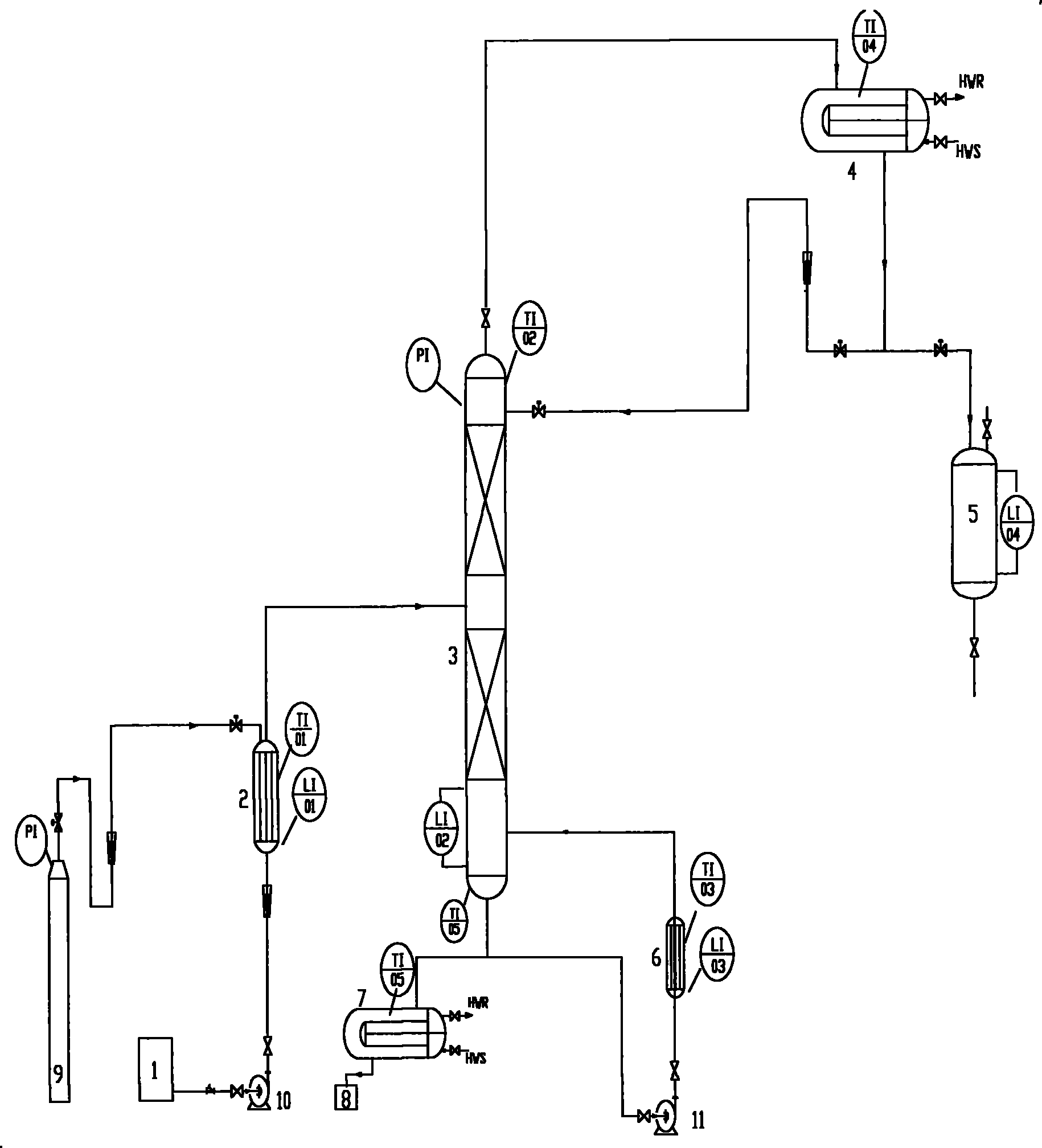

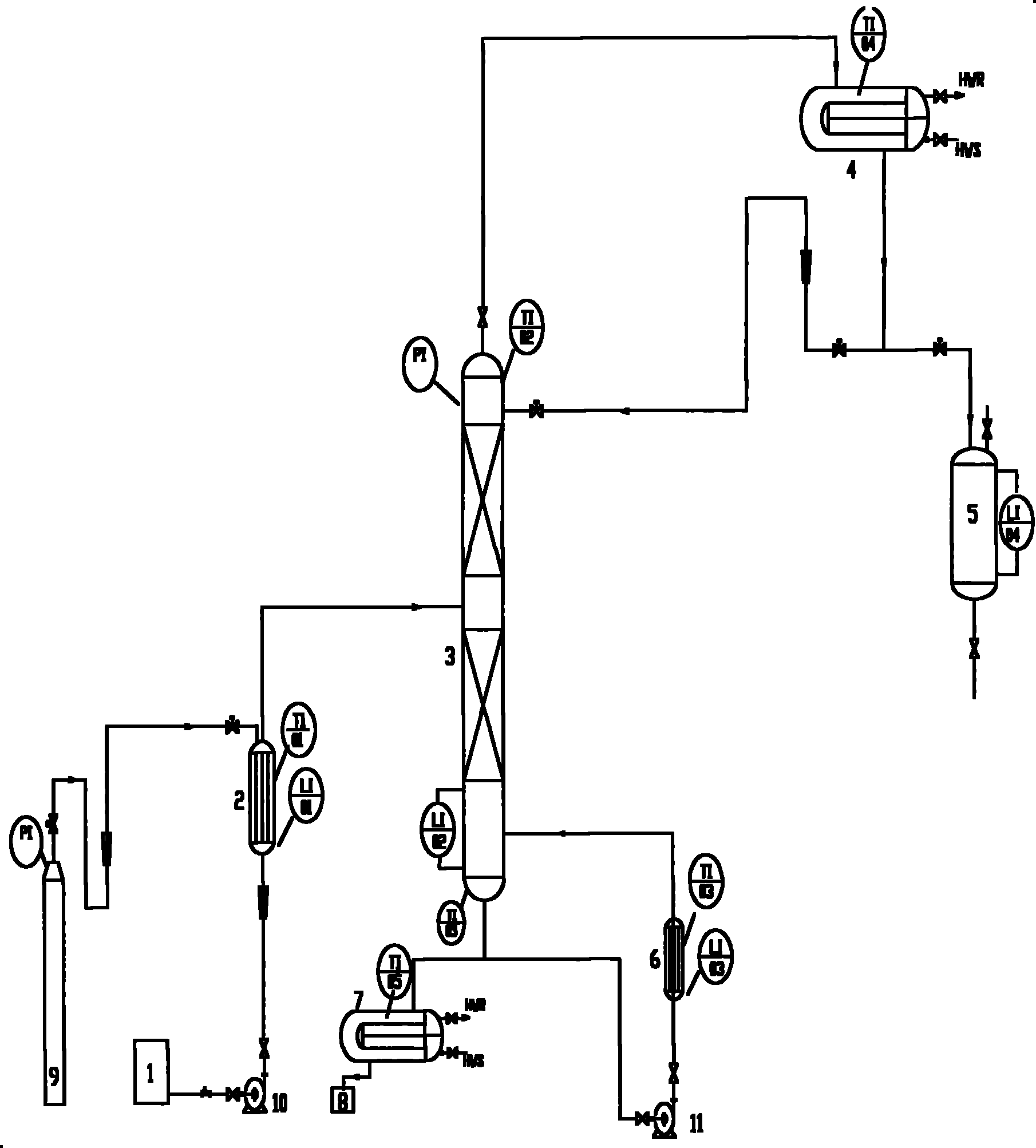

Process of catalyzing and gasifying fresh substance by solid thermophore for preparing hydrogen-rich gas

InactiveCN1482056AFast pyrolysisRapid mixing and heatingDirect heating destructive distillationHydrogen productionHydrogenHeat carrier

The present invention relates to the method of extracting hydrogen from biomass, and is especially the solid heat carrier catalyzing and gasifying method of preparing hydrogen-rich gas from biomass.The method includes mixed heating of solid heat carrier catalyst and biomass, fast thermolysis of biomass, catalytic gasifying and regeneration circulation of solid catalyst grain. The catalyst as solid heat carrier has accumulated heat for gasifying biomass. The technological apparatus consists of mobile bed reactor, material feeder, regenerating riser tube, catalyst storage tank, etc. The present invention makes the hydrogen in biomass converted into hydrogen gas at most, and the continuous switch-less regeneration of catalyst solves the problem of fast deactivation of catalyst. The present invention has low tar content, simple operation and high gas product purity, and is new technological process with great potential.

Owner:DALIAN UNIV OF TECH

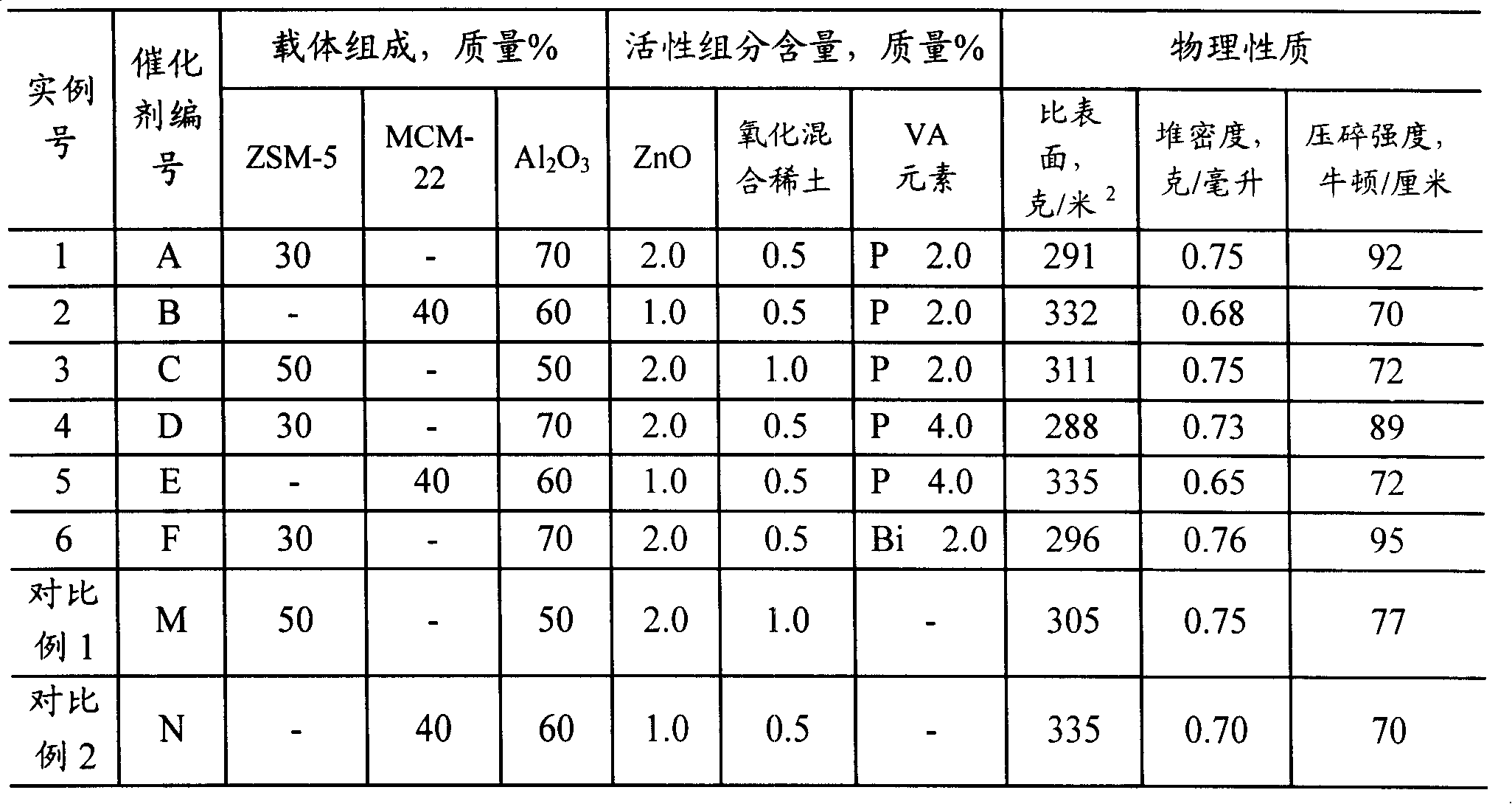

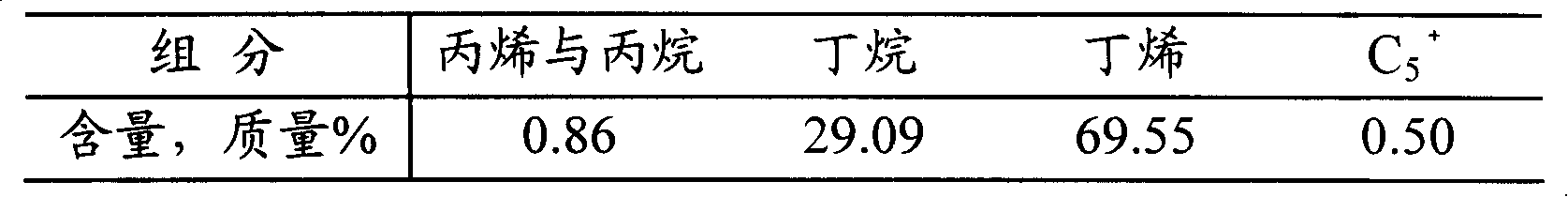

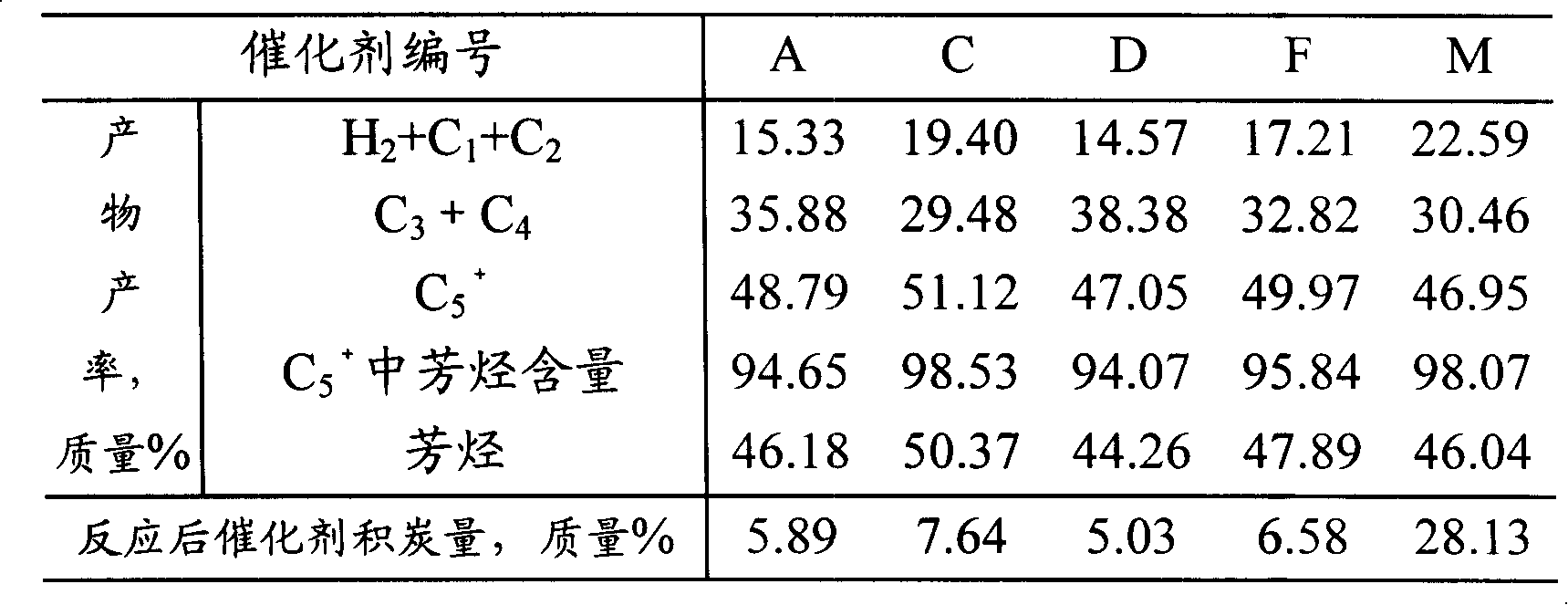

Light hydrocarbon aromatization catalyst and its preparing process

ActiveCN101172250AInhibit carbon depositionExtended service lifeMolecular sieve catalystsHydrocarbonsRare earthAromatization

The invention relates to light hydrocarbon aromatization catalyst, which includes a composite carrier and the components with the following content in the catalyst: 0.5 to 5.0 mass percent of ZnO, 0.1 to 5.0 mass percent of rare earth oxide, and 1.0 to 70 mass percent of VA element. The composite carrier comprises 20 to 70 mass percent of ZSM series zeolite or MCM series zeolite and 30 to 80 masspercent of binder. The light hydrocarbon aromatization catalyst has high yield of aromatic hydrocarbon and longer service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing high-purity cyclopentadiene

ActiveCN102060649AMild reaction conditionsControllableHydrocarbon by depolymerisationReboilerNitrogen gas

The invention relates to a method for preparing high-purity cyclopentadiene, which comprises the following steps of: heating a thermal decomposer containing purified conduction oil and a composite inhibitor and a rectifying reboiler to a specified temperature; adding dicyclopentadiene serving as a crude product into the thermal decomposer continuously and stably; allowing the depolymerized cyclopentadiene to enter a rectifying column; extracting high-purity cyclopentadiene from a tower top, heating a small amount of dicyclopentadiene and by-products by the reboiler at the tower bottom to rectify the small amount of dicyclopentadiene and by-products again, and recycling kettle liquid. The method has the advantages of simple equipment, high production capacity, little coking and long service life of the conduction oil serving as a raw material and the equipment.

Owner:PETROCHINA CO LTD

Start-up activation method for hydrogenation cracking process

ActiveCN102443426AImprove the activation effectLess investmentTreatment with hydrotreatment processesChemistryActivation method

The invention discloses a start-up activation method for a hydrogenation cracking process, which comprises the following steps that: (1) a hydrogenation cracking pre-refining reactor and a hydrogenation cracking reactor are adopted in the hydrogenation cracking process, and catalysts are ex-situ presulfurizing catalysts; (2) the hydrogenation cracking pre-refining reactor and the hydrogenation cracking reactor are used for carrying out operation including gas displacement, device airtightness and the like; and (3) activation oil and hydrogen gas enter a gas-liquid separator after entering the hydrogenation cracking pre-refining reactor under the ex-situ presulfurizing catalyst activation condition, a liquid phase separated out from the gas-liquid separator is circulated back to the hydrogenation cracking pre-refining reactor, the closed loop circulation is carried out in the hydrogenation cracking pre-refining reactor, a gas phase separated out from the gas-liquid separator enters the hydrogenation cracking reactor, and the gas phase discharged from the hydrogenation cracking reactor is circulated back to the hydrogenation cracking pre-refining reactor. Compared with the prior art, the method has the advantages that the catalyst sulfurization effect is good, and the excellent reaction effect is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

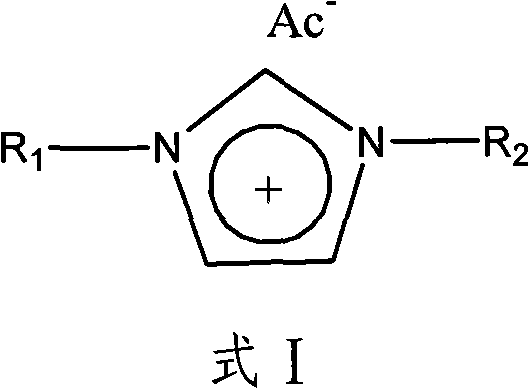

Supported ionic liquid catalyst and preparation method and application thereof

InactiveCN101773852ANot easy to loseExtended service lifeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveActive component

The invention provides a supported ionic liquid catalyst for preparing vinyl acetate in an acetylene method, the catalyst adopts mesoporous molecular sieve as a carrier and adopts zinc acetate as an active component, and the carrier and the active component are connected by imidazole acetate ionic liquid. The invention further provides a preparation method of the catalyst and an application in preparing the vinyl acetate in the acetylene method. The active component of the zinc acetate of the supported ionic liquid catalyst is bond-coupled on the surface of the carrier in a chemical method and is not easy to be lost in the reaction process; the carrier of the mesoporous molecular sieve provides suitable reaction space for catalytic reaction, and carbon deposition is not easy to be generated; the ionic liquid forms a pseudophase liquid microenvironment on the surface of the catalyst, thus improving the mass transfer and heat transfer in the reaction process; and the catalyst has good stability, long service life, high activity and good selectivity.

Owner:TSINGHUA UNIV

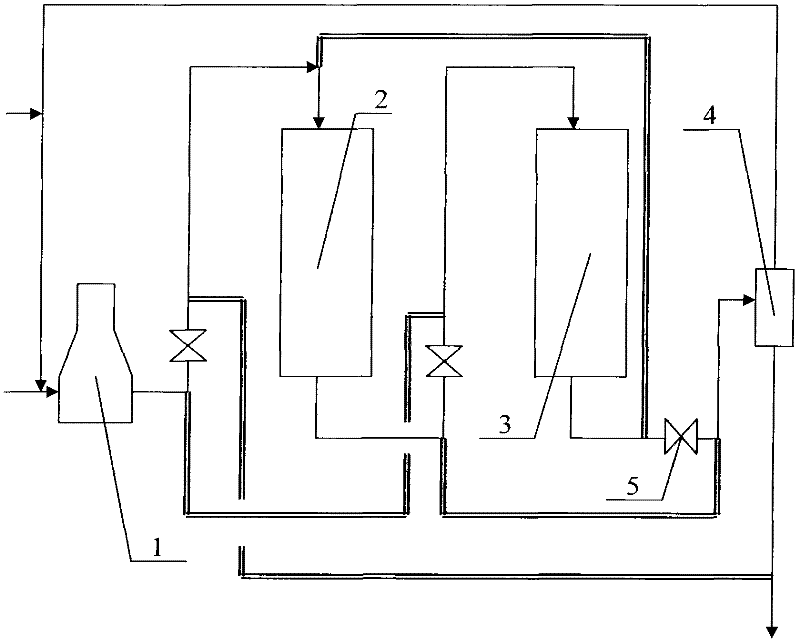

Solid oxide fuel cell power generation system based on oil fuel

InactiveCN110890572AImprove energy efficiencyAvoid Carbon DepositionFuel cell heat exchangeCombustion chamberFuel cells

The invention belongs to the related technical field of clean renewable energy sources. The invention discloses a solid oxide fuel cell power generation system based on oil fuel. The power generationsystem comprises a solid oxide fuel cell stack, an air heat exchanger, a combustion chamber, a fuel reformer, a steam evaporator and a premixer, wherein the air heat exchanger is connected to a cathode of the solid oxide fuel cell stack, the fuel reformer is connected to an anode of the solid oxide fuel cell stack, and the combustion chamber is connected to a tail gas outlet of the solid oxide fuel cell stack; the combustion chamber is respectively communicated with the air heat exchanger, the fuel reformer and the premixer; the water vapor evaporator is connected to the premixer; tail gas generated by the solid oxide fuel cell stack enters the combustion chamber and is subjected to catalytic combustion in the combustion chamber to obtain hot gas flow, and the hot gas flow enters the air heat exchanger, the fuel reformer and the premixer according to a preset volume ratio. According to the invention, the energy utilization efficiency is improved. The system is simplified.

Owner:HUAZHONG UNIV OF SCI & TECH

Direct hydrocarbon fuel cells

InactiveUS20040033405A1Increase ratingsUseful power densityFuel cells groupingCell electrodesHydrogenFuel cells

The direct electrochemical oxidation of hydrocarbons in solid oxide fuel cells, to generate greater power densities at lower temperatures without carbon deposition. The performance obtained is comparable to that of fuel cells used for hydrogen, and is achieved by using novel anode composites at low operating temperatures. Such solid oxide fuel cells, regardless of fuel source or operation, can be configured advantageously using the structural geometries of this invention.

Owner:NORTHWESTERN UNIV

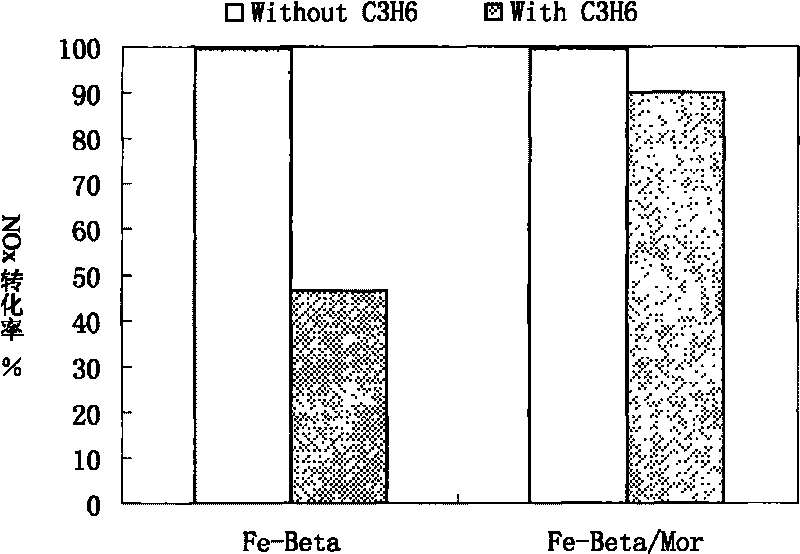

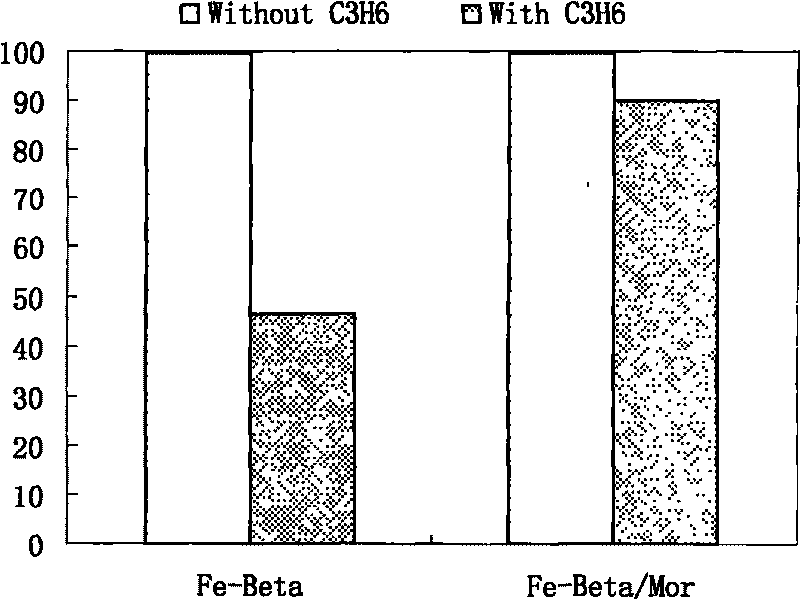

Fe molecular sieve composite catalyst and preparation method thereof

ActiveCN101711991AHigh catalytic activityInhibition of adsorptionMolecular sieve catalystsDispersed particle separationIon exchangeMordenite

The invention relates to a Fe molecular sieve composite catalyst, which comprises an active component Fe, a catalyst carrier Beta and a mordenite. A preparation method comprises the following steps of: 1, performing ion exchange on a Si / Al H-Beta molecular sieve and FeCl2; 2, removing Cl ions in the solution, and drying the obtained filter cake and roasting the filter cake in a muffle furnace to obtain the Fe / Beta molecular sieve catalyst; 3, placing the Fe / Beta molecular sieve catalyst in the water, adding the mordenite, and roasting the mixture to obtain the Fe / Beta / Mor molecular sieve composite catalyst; 4, dissolving the Fe / Beta / Mor molecular sieve into the de-ionized water, and adding concentrated nitric acid to obtain coating serum; and 5, dipping a Cordierite honeycomb ceramic carrier in the serum, blowing a residual liquid, and after drying the mixture in the shade, drying and roasting the mixture. The catalyst can efficiently purify NOx in the tail gas of a diesel vehicle, a lean-burning gasoline car and a lean-burning natural gas vehicle, and has the characteristics of environment protection and highly efficient catalytic activity.

Owner:TSINGHUA UNIV

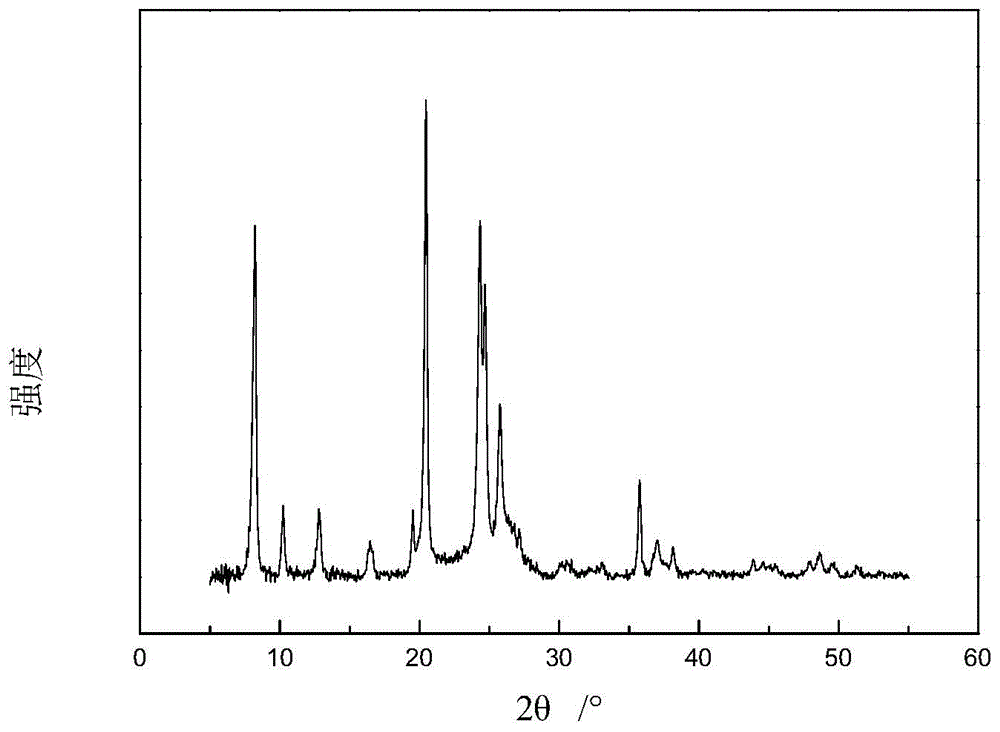

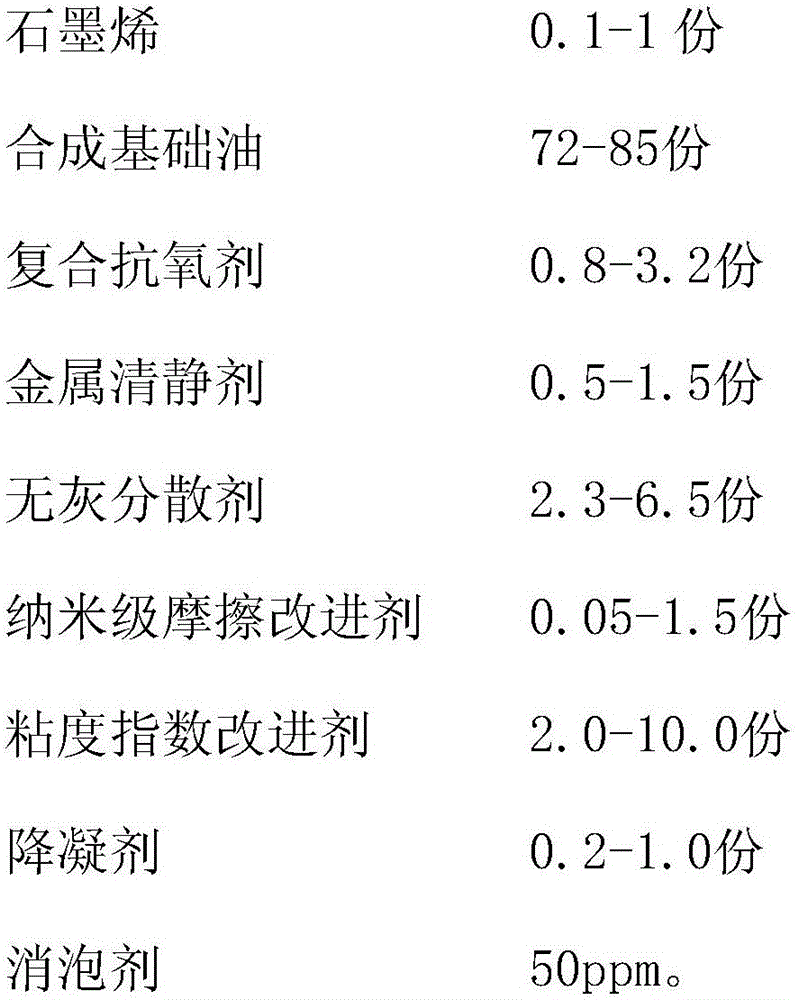

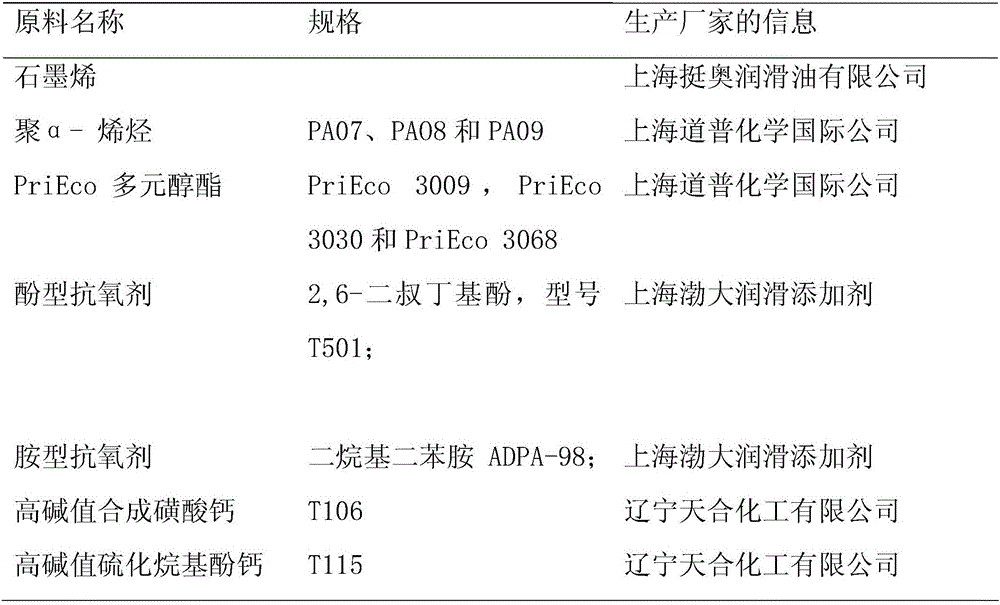

Graphene-containing lubricating oil and preparation method thereof

The invention relates to a graphene-containing lubricating oil and a preparation method thereof. The graphene-containing lubricating oil comprises the following components by weight: 0.1-1 part of graphene, 72-85 parts of synthetic base oil, 0.8-3.2 parts of a composite antioxidant, 0.5-1.5 parts of a metal detergent, 2.3-6.5 parts of an ashless dispersant, 0.05-1.5 parts of a nanoscale friction modifier, 2.0-10.0 parts of a viscosity index improver, 0.2-1.0 part of a pour point reducer, and 50ppm of a defoamer. The preparation method includes: putting the synthetic base oil into a blending kettle, performing stirring, then adding the pour point reducer, the viscosity index improver, the composite antioxidant, the metal detergent, the ashless dispersant, and the nanoscale friction modifier, stirring the substances evenly, adding graphene and the defoamer, maintaining the original temperature, stirring the materials evenly, and performing standing. The graphene-containing lubricating oil provided by the invention solves the problems of corrosion and selectivity in traditional lubricating oil additives, at the same time the process is improved, and the ultrasonic dispersion link of graphene is eliminated.

Owner:SHANGHAI INST OF TECH

Core-shell structure catalyst, and preparation method and application thereof

InactiveCN104226312AHigh activityExtended service lifeLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsHigh concentrationNanoparticle

The invention relates to a core-shell structure catalyst. Nanometer particles of a metal active component and nanometer particles of an assistant are used as a core, and a carrier and the assistant are used as a shell. The core-shell structure catalyst disclosed by the invention is wrapped by the shell layer, a micro-environment is formed in the closed interior of the shell layer, and in a catalytic reaction process, local high concentration is formed in an inner cavity usually by accumulation of reactants, so that the reaction is promoted to be relatively efficiently performed, and the integral activity of the catalyst is improved. In addition, in multiple liquid phase reactions, the shell layer can prevent active species in the micro-environment inside from outwards losing, and thus the service life of the catalyst is prolonged. In addition, for certain organic matter catalytic reactions, the shell layer can prevent carbon deposit in a reaction process, and the carbon deposit-resisting property of the catalyst is improved; meanwhile, after one layer of stable matter coats the surface of certain nanometer particles which are likely to agglomerate and inactivate to form the core-shell structure, the agglomeration trend of the nanometer particles is greatly weakened, and the stability of the catalyst is improved.

Owner:BEIJING UNIV OF CHEM TECH +1

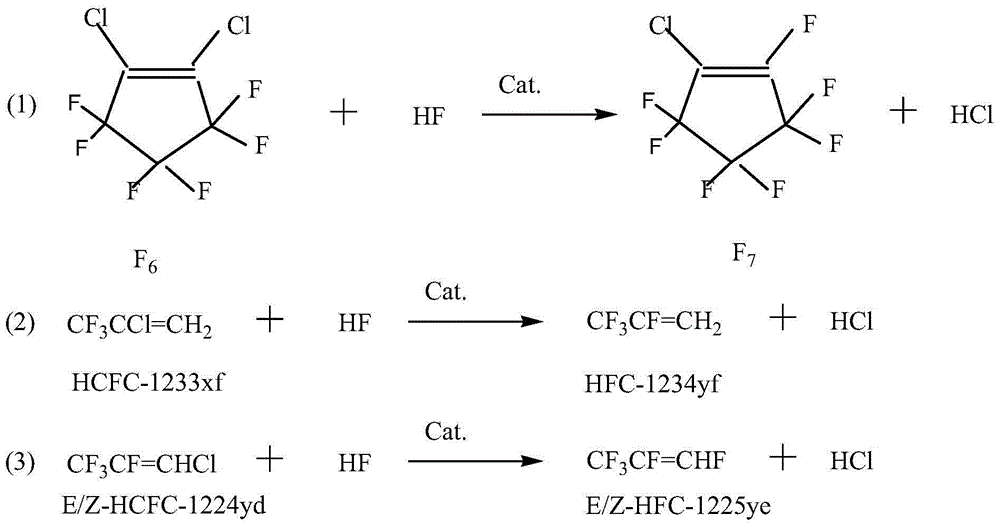

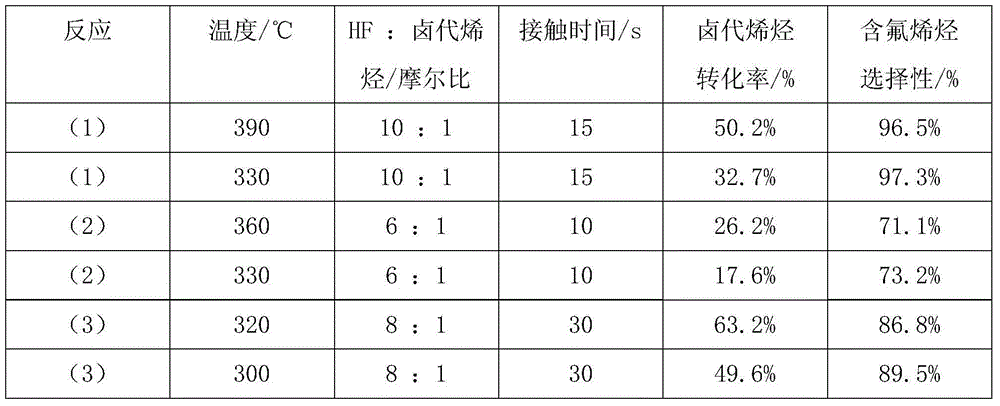

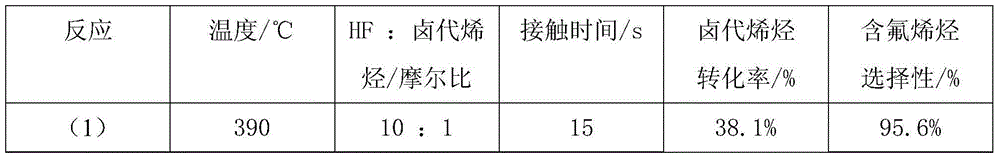

Fluorination catalyst, and preparation method and use thereof

ActiveCN104907065AIncrease the areaHigh pore volumePreparation by halogen replacementMetal/metal-oxides/metal-hydroxide catalystsChromium CompoundsChemical synthesis

The invention discloses a fluorination catalyst, and a preparation method and a use thereof, and belongs to the field of chemical synthesis. The precursor of the catalyst is formed by blending 40-95mass% of a trivalent chromium compound with 5-60mass% of tungstate, wherein the trivalent chromium compound can be chromic oxide or chromium hydroxide, and the tungstate can be zinc tungstate, nickel tungstate, magnesium tungstate, aluminum tungstate, silicotungstic acid, ammonium tungstate, ammonium paratungstate or ammonium metatungstate. The fluorination catalyst has the advantages of high use temperature, high catalysis activity and long service life, and can be mainly used in reactions for preparing fluorinated alkenes through gas phase catalysis of fluorination of alkenyl halides at a high temperature.

Owner:泉州宇极新材料科技有限公司

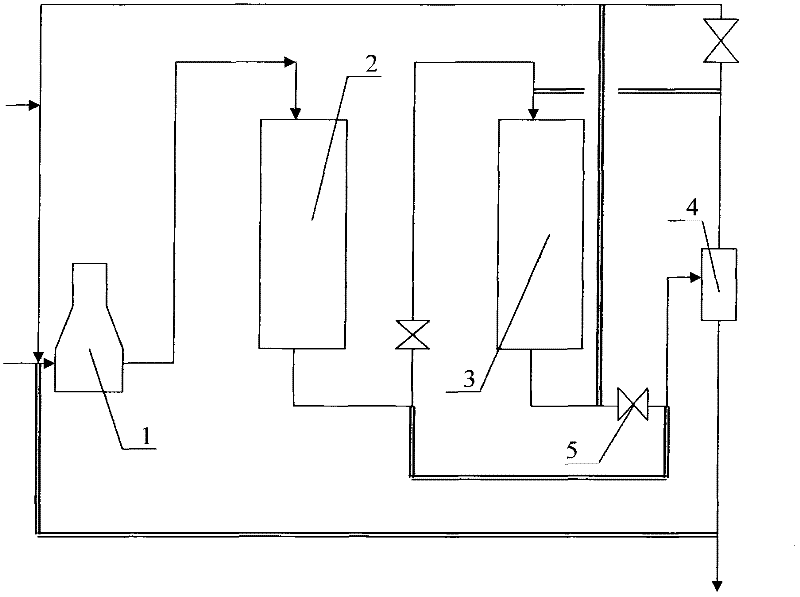

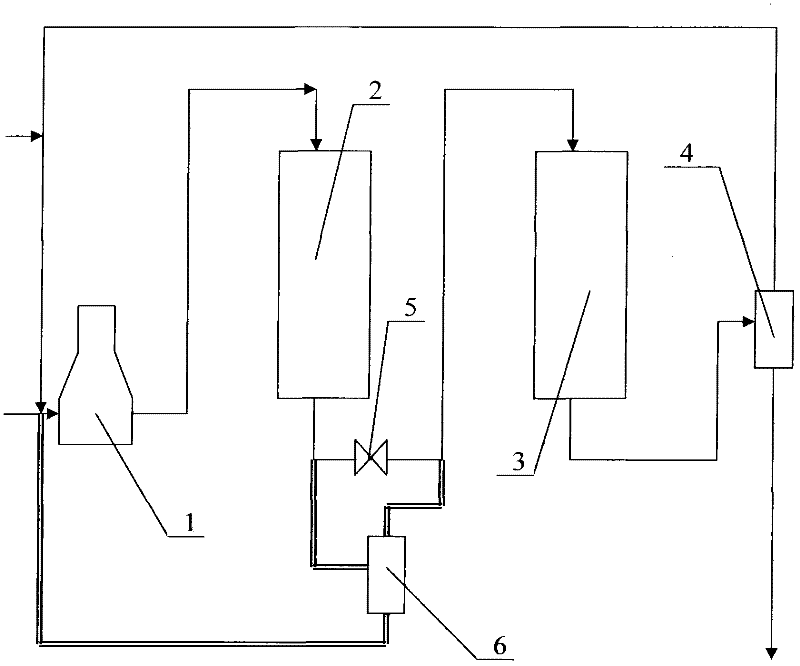

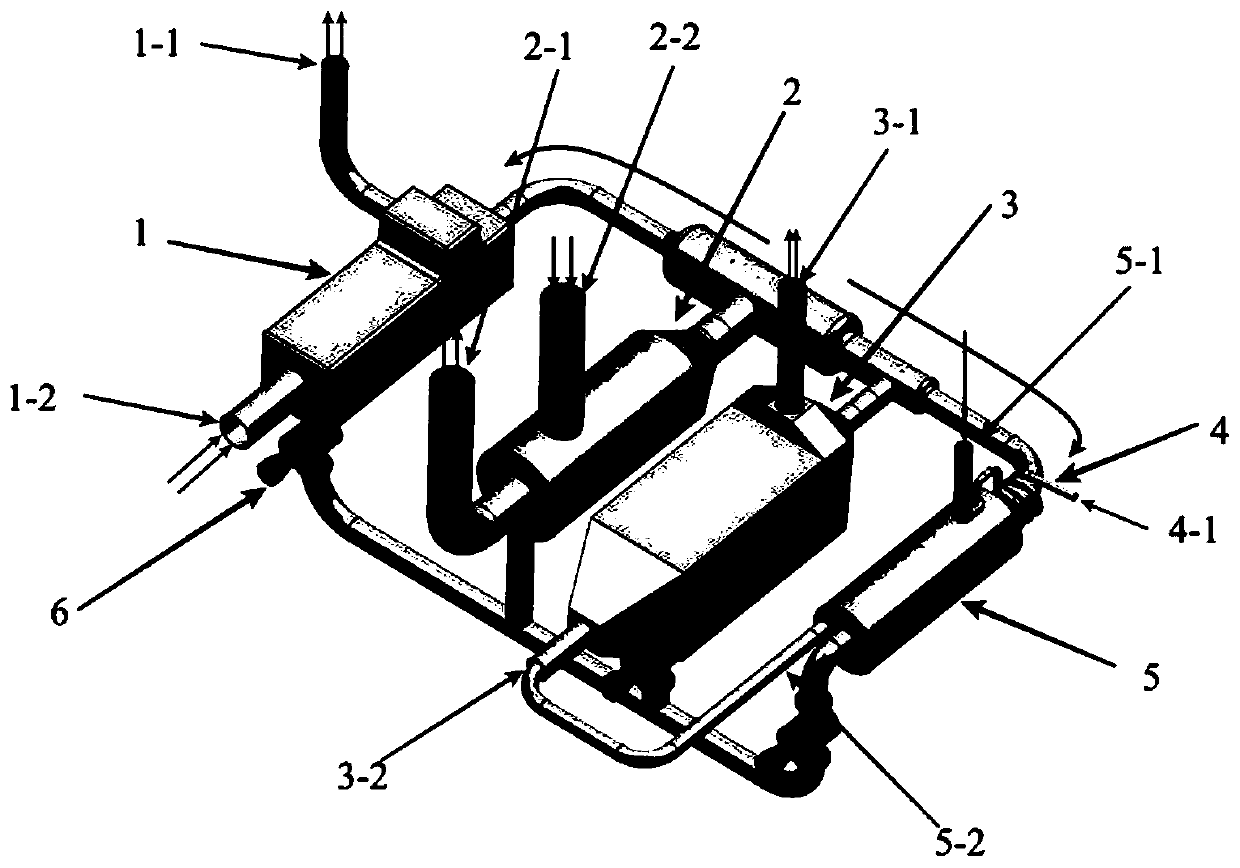

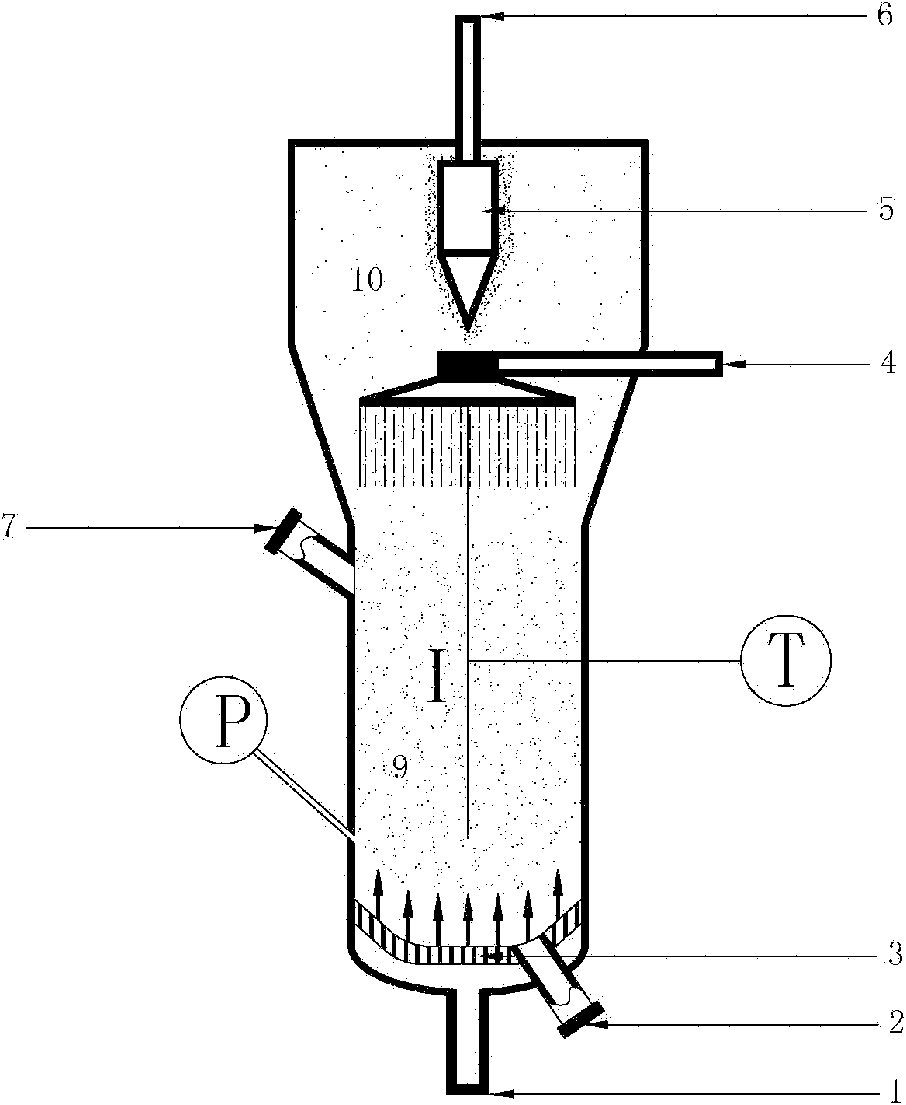

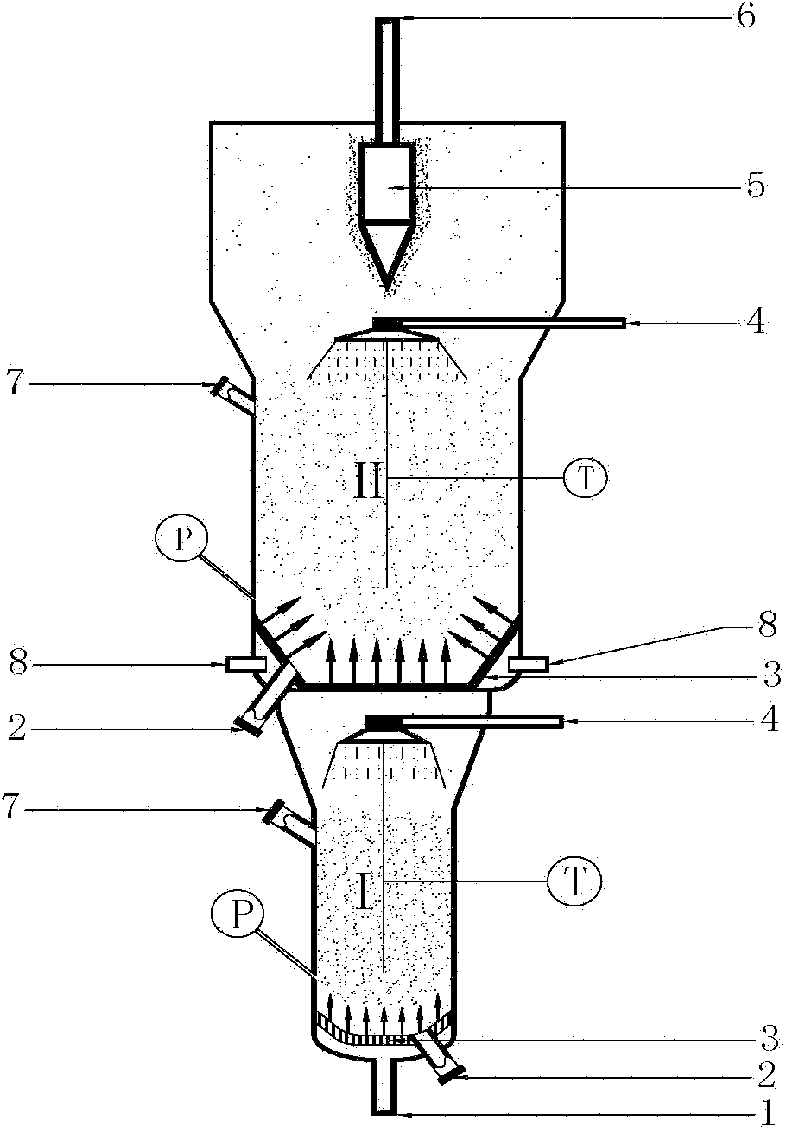

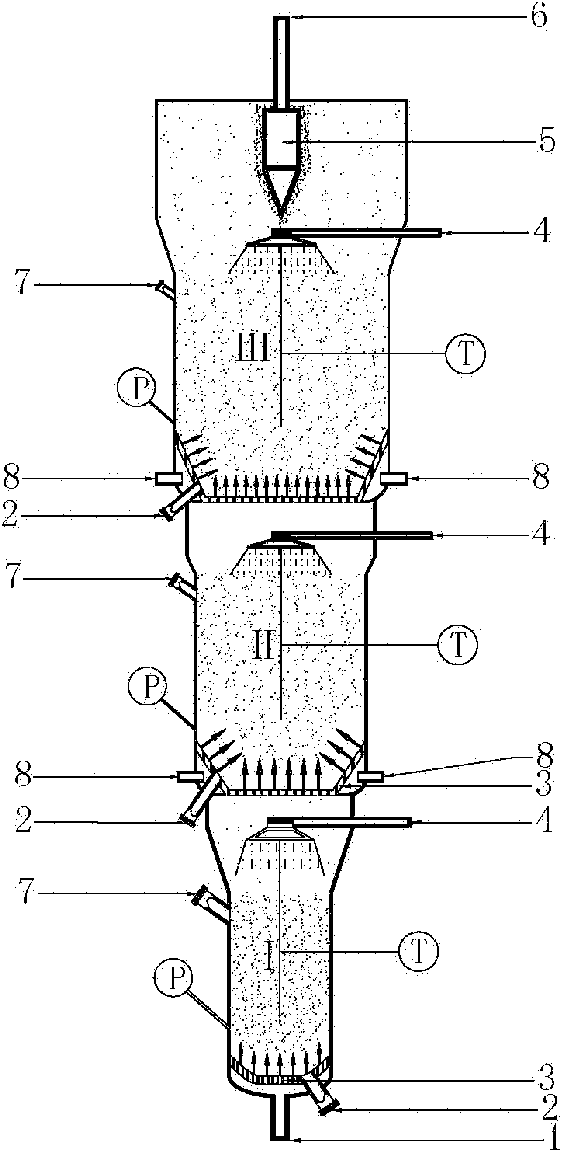

Fluidized bed reactor and method for methanation of gas mixture containing H2 and CO

ActiveCN102600771AReduce the numberExtend your lifeHydrocarbon from carbon oxidesChemical/physical processesGas solidContact high

The invention relates to a fluidized bed reactor and a method for methanation of gas mixture containing H2 and CO. The fluidized bed reactor of the invention comprises a material gas inlet 1, a catalyst outlet 2, a gas-solid separator 5, a product gas outlet 6, a catalyst inlet 7 and a material gas lateral line inlet, wherein one or more gas distribution plate 3 is arranged in the fluidized bed reactor in order to divide the reactor into several fluidized bed layers to form several catalyst dense-phase zones; a cooling water spraying device 4 is arranged above each layer of the catalyst dense-phase zone in order to control temperature of the reactor. Because the circulating cooling water directly contacts high-temperature product gas, the reactor of the invention strengthens heat transfer, is easy to control reaction temperature, reduces heat loss during the heat transfer and improves heat utilization rate during the reaction. The reactor has the advantages of large production flux, big operation elasticity, high CO conversion rate, high selectivity of produced methane, less catalyst dosage, high utilization rate of heat quantity and so on, so that the reactor has good industrial application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Catalytic cracking fluidized bed catalyst synthesized in situ

ActiveCN102371171AIncrease contentImprove conversion rateCatalytic crackingMolecular sieve catalystsNaphthaMicrosphere

The invention discloses a catalytic cracking fluidized bed catalyst synthesized in situ, which is mainly used for solving the technical problems of low naphtha conversion rate and low yields of ethylene and propylene when the conventional fluidized bed catalyst is used for catalyzing cracking of naphtha for preparing ethylene and propylene. The catalyst comprises the following components in parts by weight: (1) 0.5-15.0 parts of at least one selected from phosphorus, rare-earth or alkali-earth element oxide and (2) 85.0-99.5 parts of catalyst selected from microspheres which are synthesized in situ and contain a ZSM-5 molecular screen and of which the particle sizes are 10-200 mum. Due to the adoption of the technical scheme, the problems are well solved; and the catalyst can be applied to industrial production of preparation of the ethylene and the propylene by the catalytic cracking of the naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alkane dehydrogenation catalyst and preparation method thereof

ActiveCN104588011AImprove activity stabilityImprove surface propertiesHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneAlcohol

The invention discloses a preparation method of a dehydrogenation catalyst. The method comprises the following steps: loading Sn by adopting an immersion process with alumina as a carrier; drying, roasting, and carrying out surface modification on the Sn supported alumina carrier by using an alcohol solvent; drying the modified Sn-containing alumina carrier, and loading an active component Pt by adopting the immersion process; and loading alkali metal Na. The catalyst prepared through the method can promote Pt-Sn interaction, so the selectivity of a target product propylene is improved, and the active stability of the catalyst is also improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

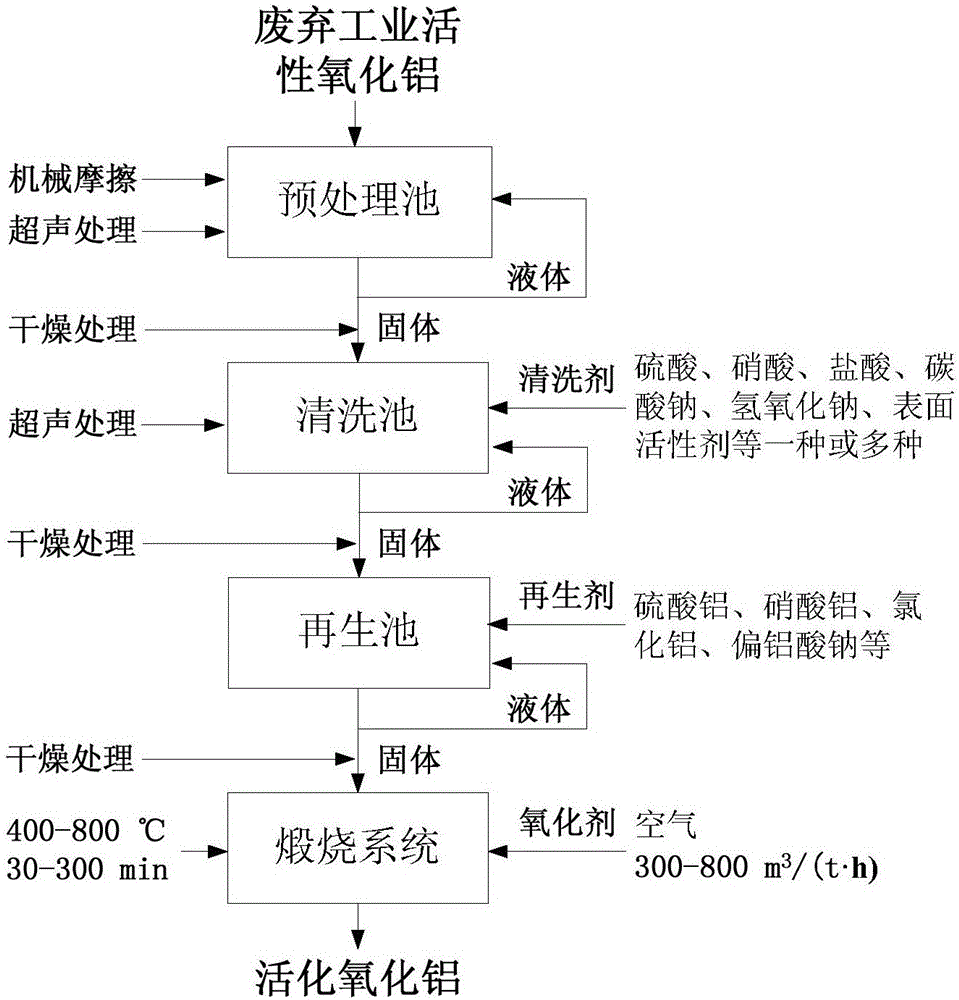

Method for activating and regenerating waste industrial activated aluminum oxide

ActiveCN106629796AHigh pore volumeRealize resource utilizationOther chemical processesAluminates/aluminium-oxide/aluminium-hydroxide purificationAir atmosphereActivated Aluminum Oxide

The invention discloses a method for activating and regenerating waste industrial activated aluminum oxide. The method comprises pretreatment, cleaning liquid impregnation treatment and regeneration treatment; adopted cleaning liquid is selected from at least one of acid liquor and alkali liquor and surfactant solution; the regeneration treatment comprises regenerated liquid impregnation and calcination treatment, and adopted regenerated liquid is selected from aluminum-contained solution; the calcination treatment is performed under air atmosphere, and air inlet amount is 300 to 800 m<3> / (h.t). According to the method for activating and regenerating the waste industrial activated aluminum oxide provided by the invention, an original pore structure channel is dredged through a physical and chemical method, and a new pore structure is regenerated on the basis of the existing pore structure to obtain activated aluminum oxide with high specific surface area and high pore volume.

Owner:杭州贝采催化剂有限公司 +1

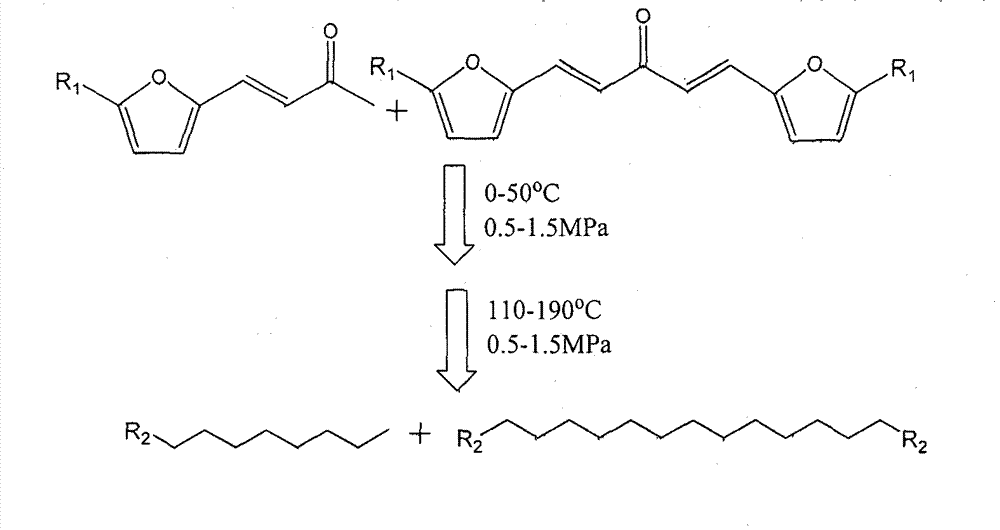

Novel technique for preparing long-chain alkane efficiently through multifunctional catalyst in one-step method

ActiveCN102850157ARedox activeExtend your lifeLiquid hydrocarbon mixture productionHydrocarbonsMetal metalPerylene derivatives

The invention relates to a novel technique for preparing long-chain alkane efficiently through a multifunctional catalyst in a one-step method. The novel technique can be used for producing the long-chain alkane in one step with high selectively under a relative mild condition, and solve the problems of strict reaction condition, low energy efficiency and low alkane selectivity in a process of preparing the long-chain alkane by biomass derivatives. According to the technique, condensation products (C8, C9, C13 and C15) of a biomass derivative, namely furfural or HMF (Hydroxy Methyl Furfural), and acetone are taken as the raw materials, and by designing the three-center multifunctional catalyst of metal (I)-metal (II)-acid, the original two steps of independent reactions which require strict reaction conditions and need different catalysts to join in are combined into an one-step reaction which requires tender reaction conditions, so that the selectivity on corresponding alkane (octane, nonane, tridecane and pentadecane) is improved greatly, the highest yield can be 97%, and meanwhile, a step of separating the product from the catalyst is omitted, therefore, the energy efficiency of the while process is improved by a great step.

Owner:EAST CHINA UNIV OF SCI & TECH

Catalyst for methanation and preparation method thereof

InactiveCN102500379AHigh mechanical strengthImprove stabilityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsCerium nitrateMethanation

The invention which belongs to the technical field of catalysis relates to a catalyst for methanation and a preparation method thereof. The preparation method comprises the following steps: 1, fully mixing alumina (or pseudoboehmite) with a pore forming agent and a binder, adding deionized water, granulating, drying, compression-molding, and roasting to prepare a catalyst carrier; and 2, dipping the catalyst carrier in a solution of nickel nitrate and lanthanum nitrate (or potassium nitrate, or potassium carbonate, or cerium nitrate, or cerous nitrate), drying, and roasting to prepare the catalyst. The catalyst prepared through the method of the invention, which has the advantages of high mechanical strength and good hydrothermal stability, is suitable for methanation reactions carried out under conditions that the CO content is high and the reaction temperature is high, and can effectively prevent carbon deposition.

Owner:CHINA PETROLEUM & CHEM CORP +1

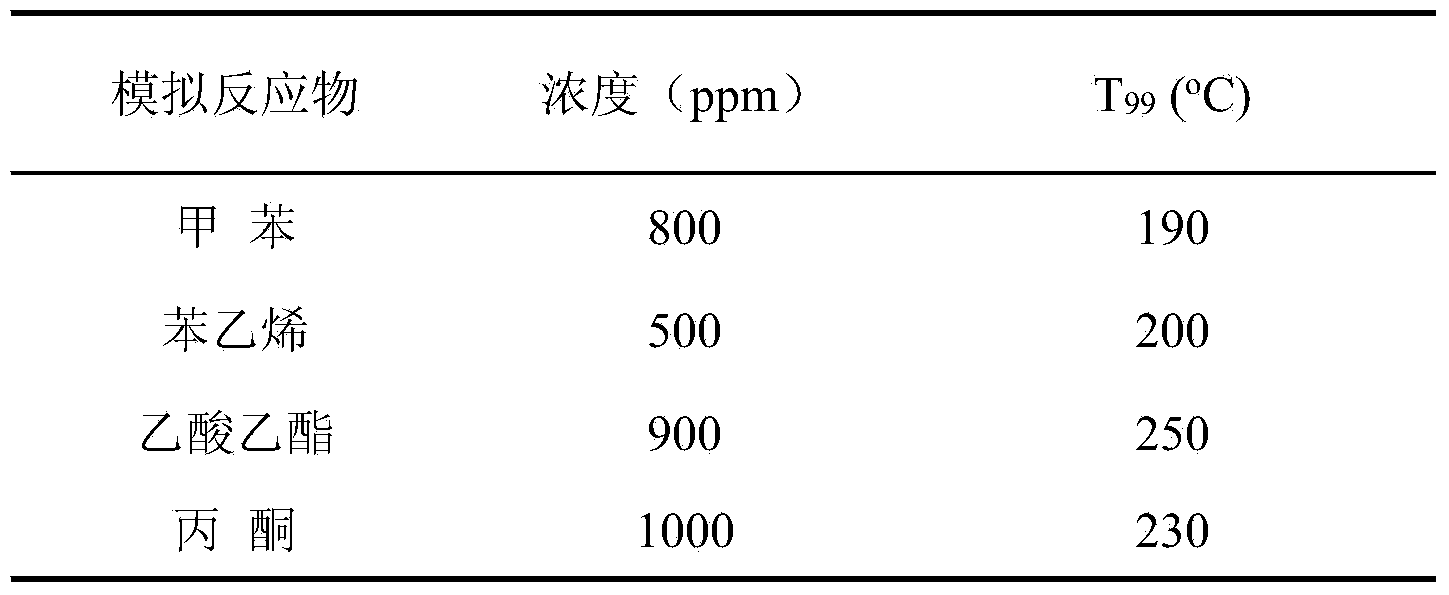

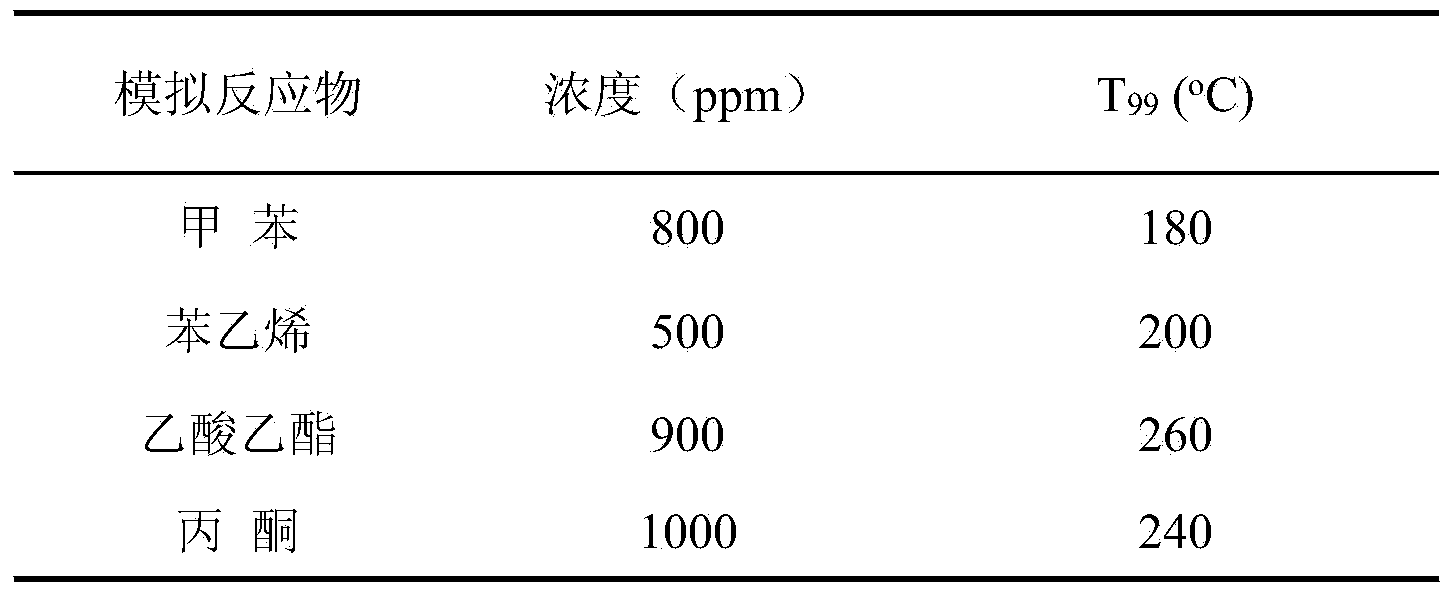

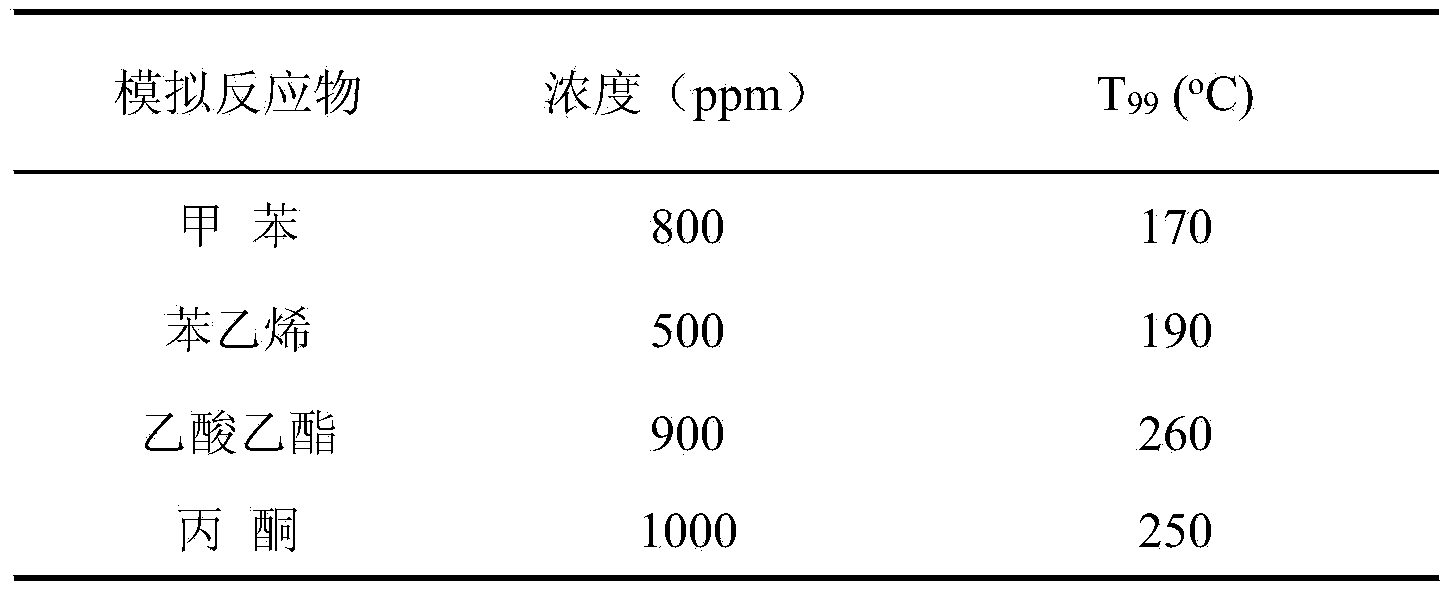

Monolithic Pd catalyst for purifying industrial organic waste gas and preparation method thereof

InactiveCN103240083AImprove oxidation capacityImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumHeat stability

The invention relates to a monolithic Pd catalyst for catalytic purification of industrial organic waste gas and a preparation method thereof. The catalyst comprises a cerium-zirconium solid solution, La2O3, Nb2O5, Al2O3, noble metal Pd and a cordierite-honeycomb ceramic supporter. The preparation method comprises the following step: coating the cerium-zirconium solid solution, La2O3, Nb2O5, a pseudo-boehmite binding agent and the noble metal Pd on the surface of the cordierite-honeycomb ceramic supporter in twice, wherein the total mass of the cerium-zirconium solid solution, La2O3, Nb2O5 and Al2O3 coated for each liter of catalyst is 40g; and the loading amount of Pd contained in each liter of catalyst is 0.3g. The catalyst can prevent surface carbon deposition, and has satisfactory burning resistance and heat stability.

Owner:ZHEJIANG NORMAL UNIVERSITY +1

Integral Pd-Pt catalyst for purifying industrial organic waste gas and preparation method thereof

ActiveCN103831104AImprove oxidation capacityImprove thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsCeriumCordierite

The invention discloses an integral Pd-Pt catalyst for purifying industrial organic waste gas and a preparation method thereof. The catalyst comprises a cerium-enriched mixed rare earth oxide, Al2O3, SiO2, K, precious metals Pd and Pt and a cordierite honeycomb ceramic carrier, wherein the cerium-enriched mixed rare earth oxide, a pseudo-boehmite binding agent and an acidic silicon sol are coated on the surface of the cordierite honeycomb ceramic carrier, KOH is further loaded, and the precious metals Pd and Pt are loaded through an impregnation method so as to prepare the catalyst; the total coating mass of the cerium-enriched mixed rare earth oxide, the pseudo-boehmite binding agent and the acidic silicon sol is 35g per liter of the catalyst, the K capacity is 0.1g per liter of the catalyst, the capacity of the Pd and Pt is that each catalyst contains 0.3g of the Pd, and the mass ratio of Pd to Pt is 1 to (0.25-4). The catalyst provided by the invention has the advantages that carbon accumulation on the surface of the catalyst can be prevented, the heat stability is good, the bonding strength of a catalyst coating is high, and the activity is good.

Owner:金华铂锐催化科技有限公司

Biomass pyrolysis gasification multifunctional iron-based catalyst and preparation method thereof

ActiveCN103394356AImprove stabilityImprove anti-sintering and anti-carbon abilityGas purification with selectively adsorptive solidsMetal/metal-oxides/metal-hydroxide catalystsMuffle furnacePyrolysis

A biomass pyrolysis gasification multifunctional iron-based catalyst and a preparation method thereof are disclosed. The preparation method is characterized by comprising the following steps: (1) carrier pretreatment: placing CaO in a muffle furnace for calcining, then grinding and screening to prepare CaO carrier particles; (2) introduction of a main active component: mixing the CaO carrier particles with a Fe(NO3)3.9H2O solution, stirring and immersing, drying, calcining and grinding; (3) introduction of an auxiliary active component: mixing the sample prepared by the step (2) with a Ce(NO3)3.6H2O solution, stirring, immersing, drying, placing the obtained sample in a muffle furnace for calcining, placing the calcined sample in a dryer to cool to room temperature, grinding, then mixing the obtained powder with a Zr(NO3)4.5H2O solution, stirring, immersing, drying, then placing the sample in a muffle furnace for calcining, then placing the calcined sample in a dryer to cool to room temperature, and then grinding; and (4) shaping of the catalyst: performing shaping on the obtained catalyst, and screening to obtain the catalyst finished product.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

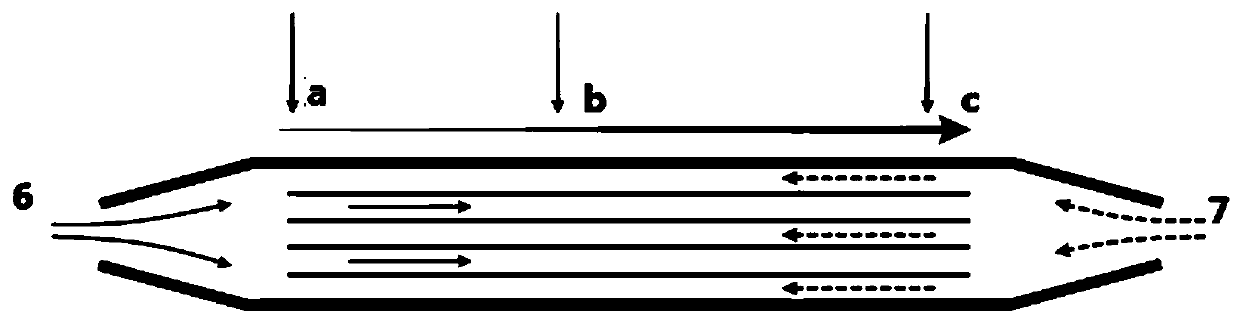

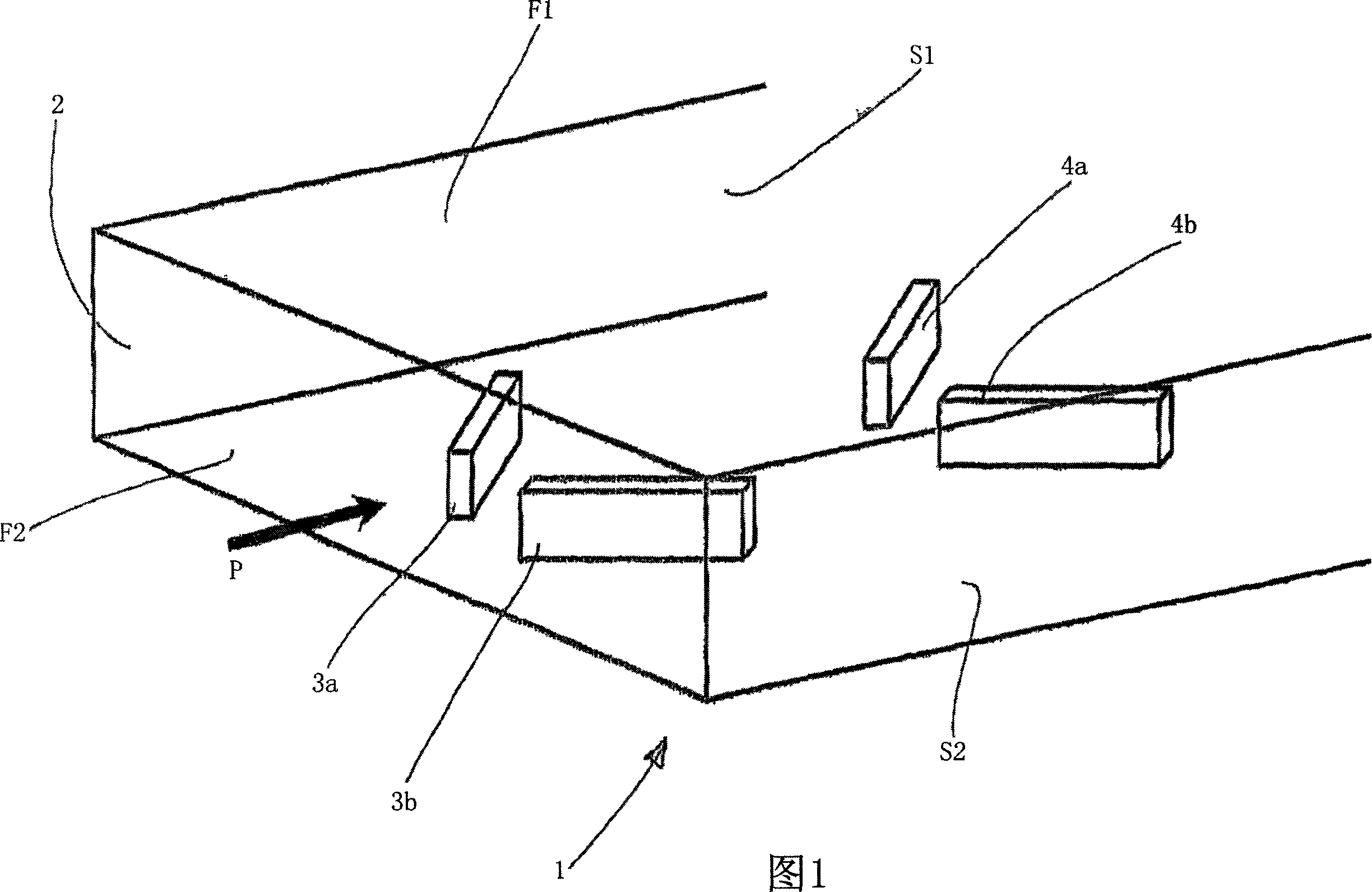

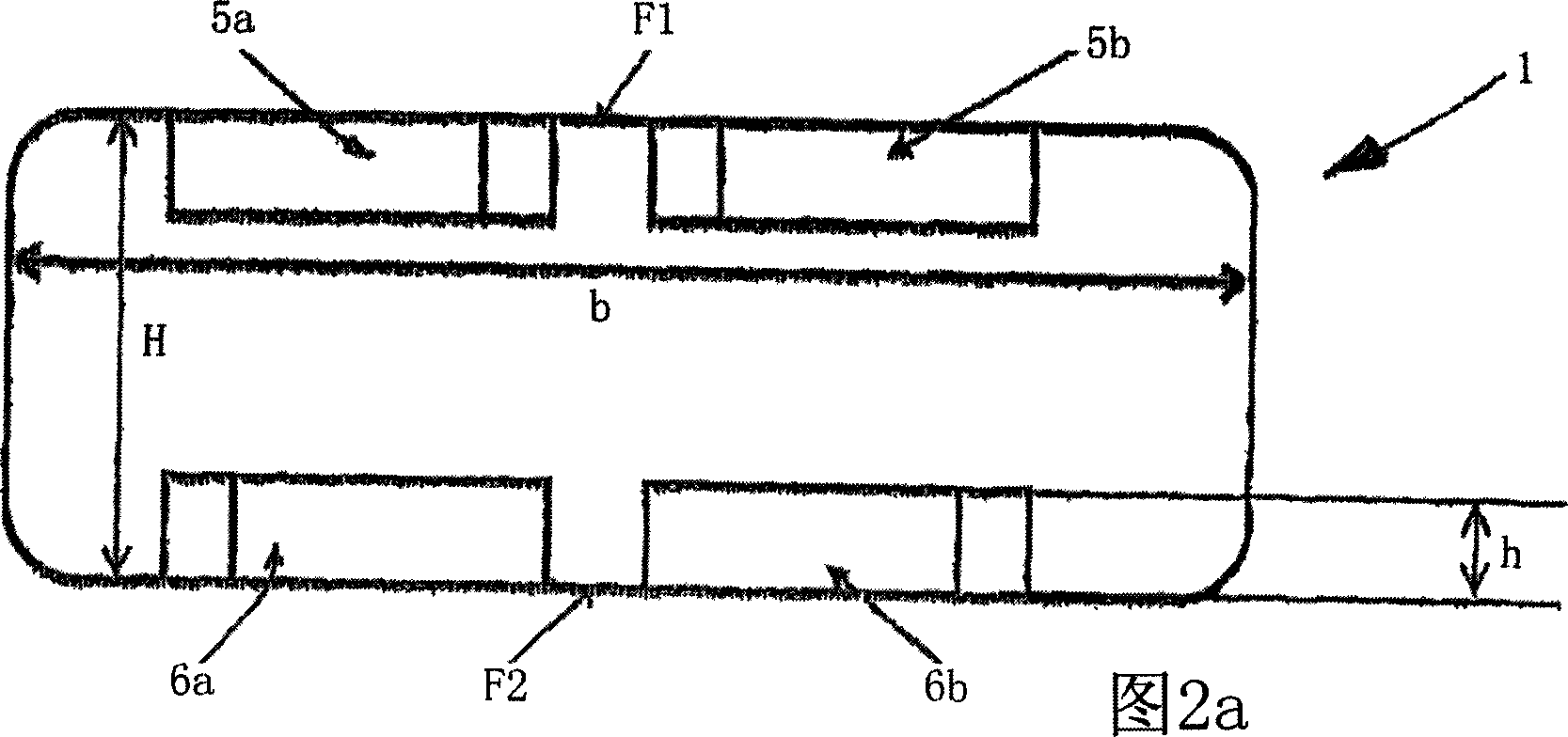

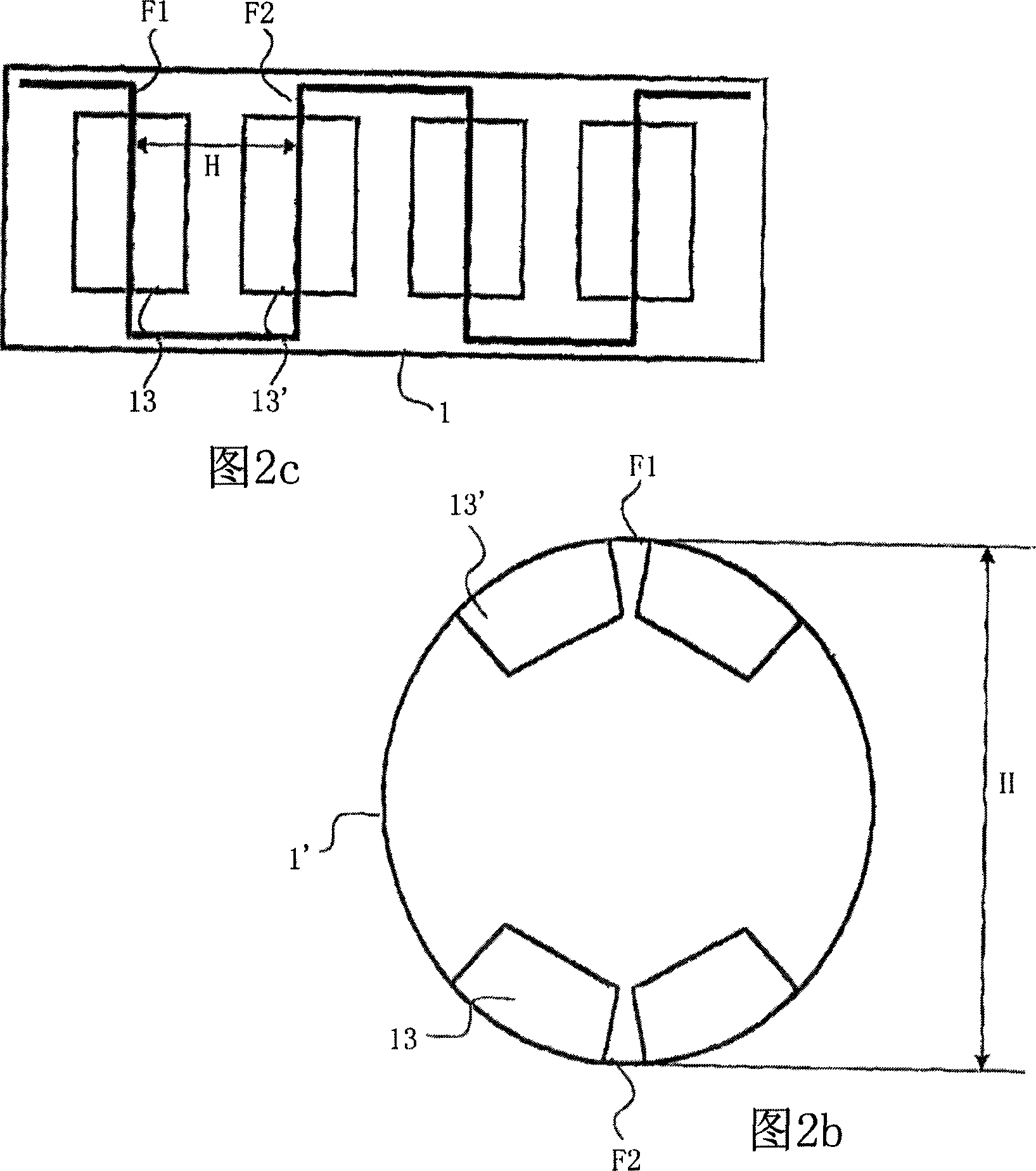

Flow channel for a heat exchanger and heat exchanger with the same

ActiveCN1875240ASpeed up heat transferInhibit carbon depositionRecuperative heat exchangersHeat transfer modificationStructural elementEngineering

The invention relates to a flow channel of a heat exchanger with two parallel heat transfer areas (F1, F2) that are arranged at a distance corresponding to a channel height H. Each heat transfer area (F1, F2) is provided with a structure that is formed by a plurality of structural elements which are placed next to each other in rows running perpendicular to the direction of flow P and extend into the flow channel. Each structural element has a width B, a length L, a height h, a flow-off angle alpha, and an overlap while being provided with a longitudinal axis.

Owner:BEHR GMBH & CO KG

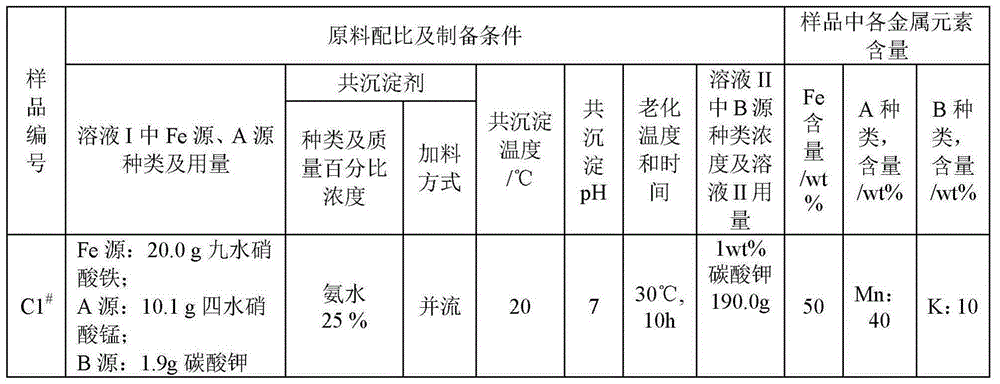

Iron-based catalyst prepared by coprecipitation-melting method, preparation method and application thereof

ActiveCN106466611AHigh activityImprove mechanical stabilityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalMechanical stability

The application discloses an iron-based catalyst prepared by a coprecipitation-melting method. The catalyst contains iron element Fe, metal element A and metal element B. The metal element A is at least one element selected from aluminium and / or transition metal. The metal element B is at least one element selected from alkali metal and / or alkaline earth metal. Each metal element exists in the form of single metal and / or metallic oxide. With total content of metal elements contained in the catalyst being 100 wt%, the content of the metal element Fe in the catalyst is 50-99 wt%, content of the metal element A in the catalyst is 0.1-50 wt%, and content of the metal element B in the catalyst is 0.01-40 wt%. The catalyst has high activity, high mechanical stability and low reactive carbon deposition amount. Thus, pulverization of the catalyst is avoided. In addition, the catalyst shows high low-carbon olefins selectivity in the Fischer-Tropsch synthesis.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High-temperature methanation catalyst for producing natural gas through coal and preparation method of catalyst

ActiveCN103706370AHigh mechanical strengthIncrease the areaCatalyst carriersGaseous fuelsAlkaline earth metalMethanation

The invention discloses a high-temperature-resistant methanation catalyst in a process of producing natural gas through coal. The high-temperature-resistant methanation catalyst comprises a carrier, an active component and assistants, wherein the carrier is a compound of CeO2, Al2O3 and ZrO2, the active component is Ni, the first assistant is one or two of alkaline earth metal oxides CaO and MgO, and the second assistant is one or two of transition metal oxides Cr2O3 and MnO. The high-temperature-resistant methanation catalyst disclosed by the invention has the advantages that the CeO2-Al2O3-ZrO2 compound oxide is used as the carrier to endow the catalyst with high mechanical strength, large specific surface area and heat resistance; the methanation activity of the catalyst is high and the thermal stability is strong; the alkaline earth metal oxide CaO and / or MgO are / is used as the first assistant to perfect the surface acidity of the carrier and inhibit carbon deposition of the catalyst; the Cr2O3 and / or MnO are / is used as the second assistant to beneficially improve the dispersibility of NiO particles and promote NiO reduction so as to improve the activity of the catalyst.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com