Process of catalyzing and gasifying fresh substance by solid thermophore for preparing hydrogen-rich gas

A solid heat carrier, catalytic gasification technology, applied in the manufacture of combustible gas, chemical instruments and methods, hydrogen, etc., can solve the problems of not finding a process, reducing hydrogen production rate, hydrogen consumption, etc., to improve the conversion rate of biomass carbon , Inhibit the effect of catalyst carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

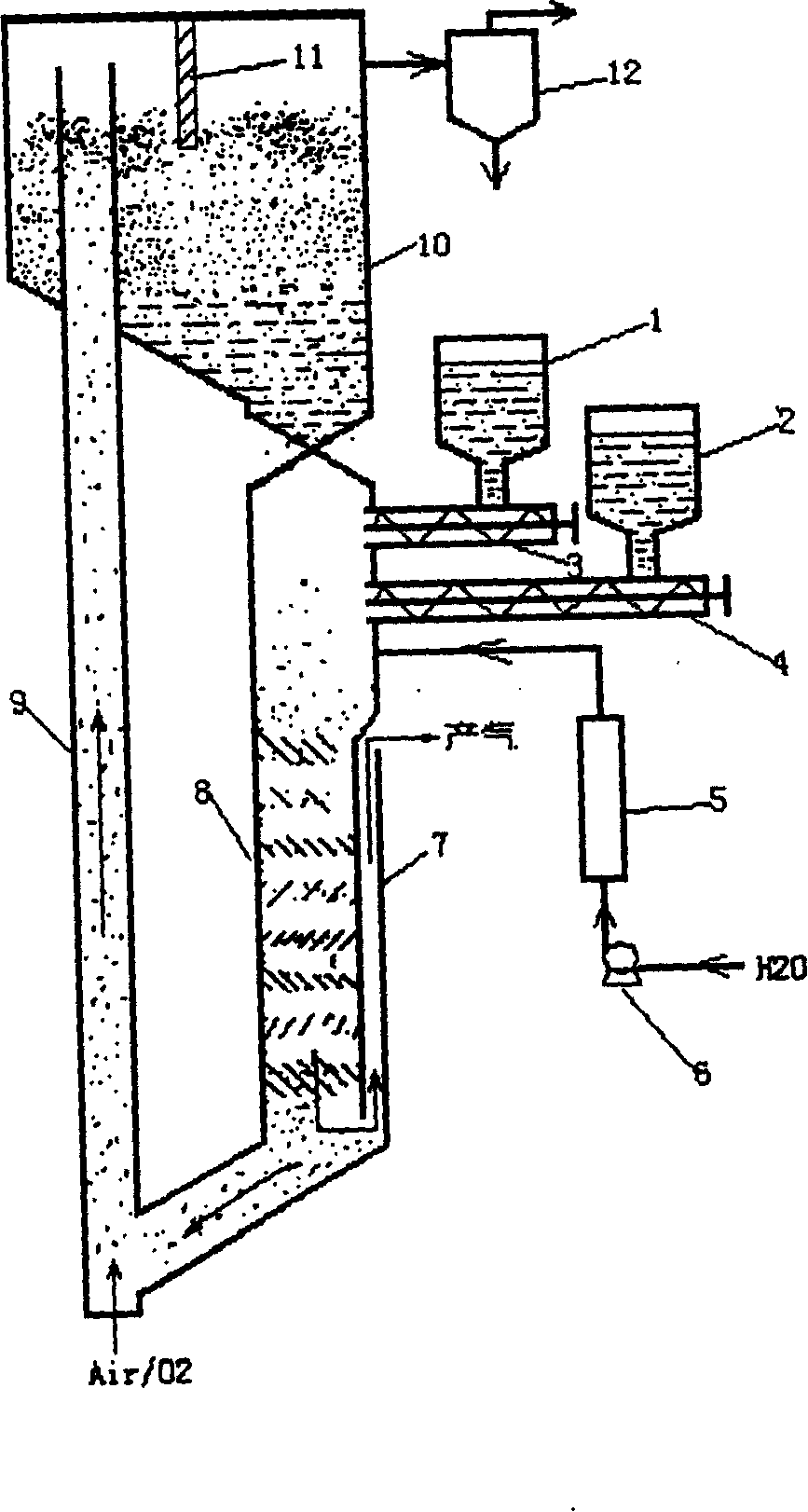

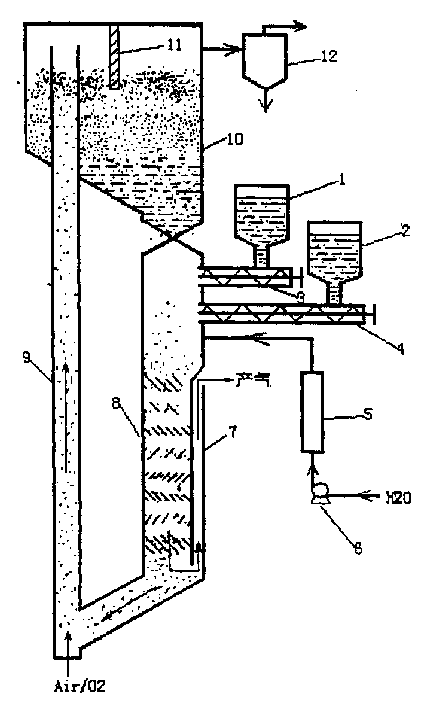

Method used

Image

Examples

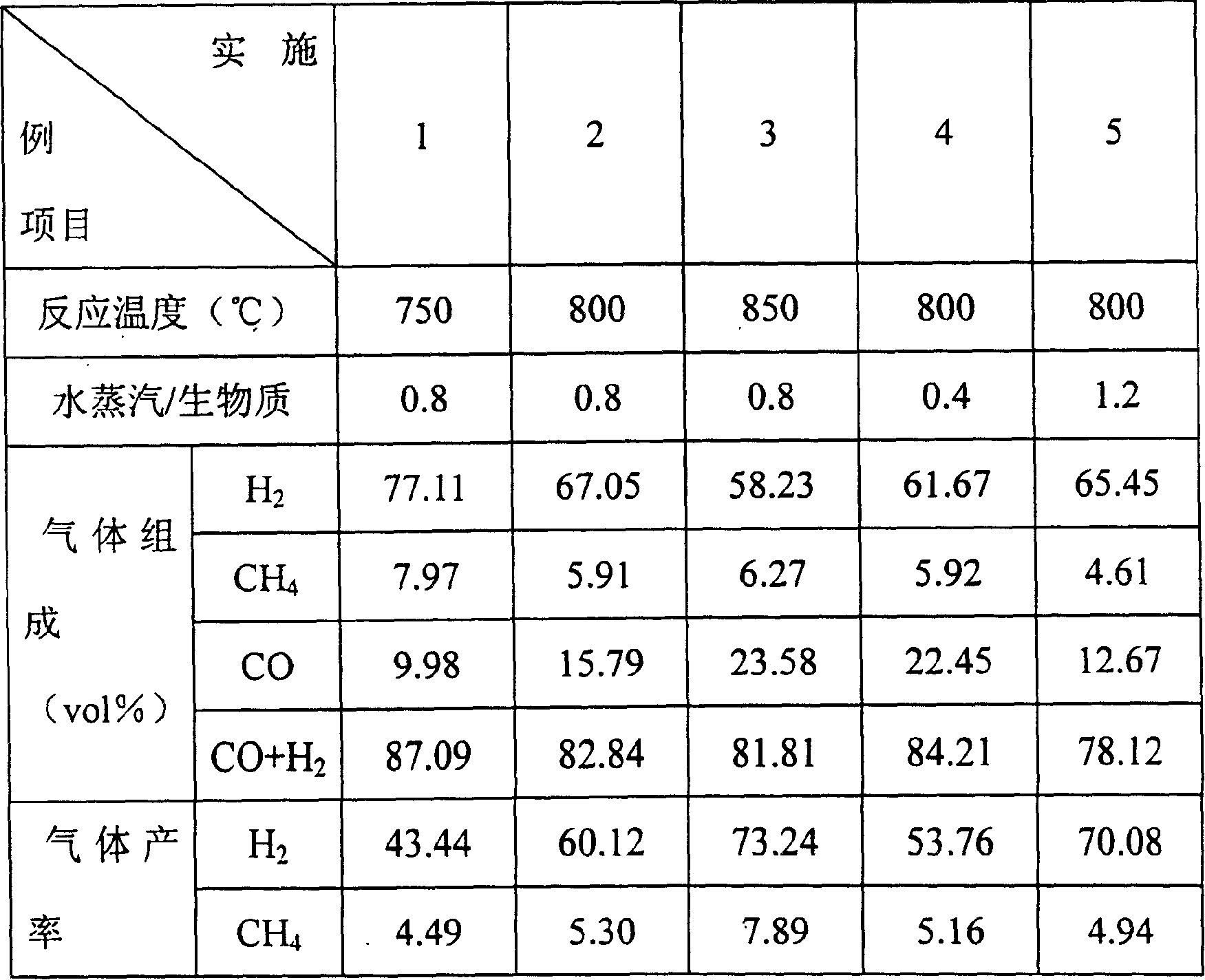

Embodiment 1

[0033] The biomass (apricot core) is crushed and sieved, and the biomass with a particle size of 8-16 meshes is selected and placed in a biomass tank. The catalyst (dolomite) is crushed to a certain particle size and then sieved, and the raw ore of 12 to 16 mesh is calcined in a muffle furnace at a calcination temperature of 900°C for 4 hours, and then put into a catalyst tank. Start the electromagnetic speed-regulating motor, add biomass and catalyst to the falling-bed reactor, control the reaction temperature to 750°C, and the value of the steam / biomass ratio to 0.8. The indicators of gas composition and yield are shown in Table 1.

Embodiment 2

[0035] Control reaction temperature is 800 ℃, all the other are the same as embodiment 1.

Embodiment 3

[0037] Control reaction temperature is 850 ℃, all the other are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com