Patents

Literature

144results about How to "Large reaction interface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

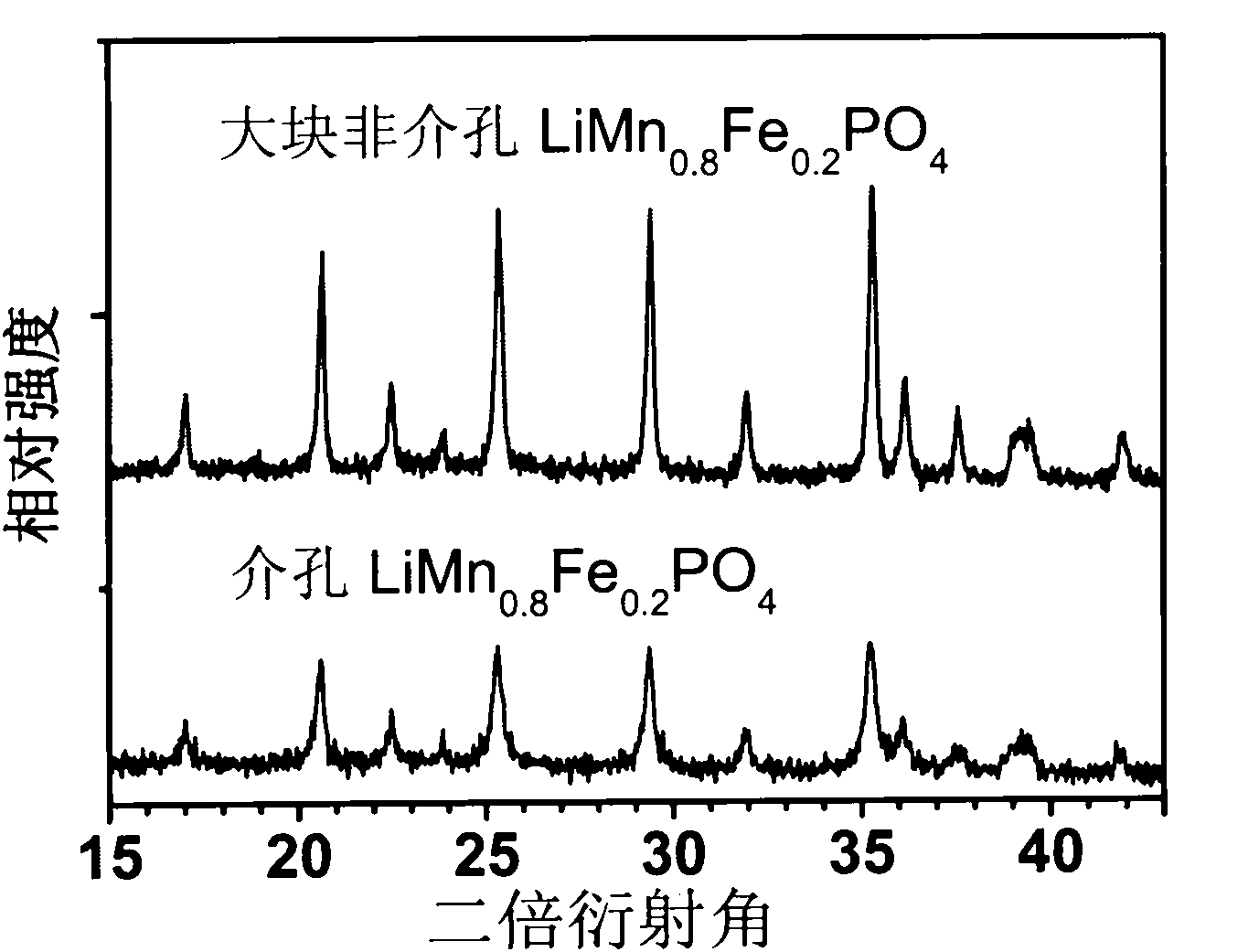

Phosphate material having mesoporous structure for lithium secondary batteries and preparation method thereof

InactiveCN101540398AImproved magnification performanceImprove power densityElectrode manufacturing processesSecondary cellsChemical compositionElectrical battery

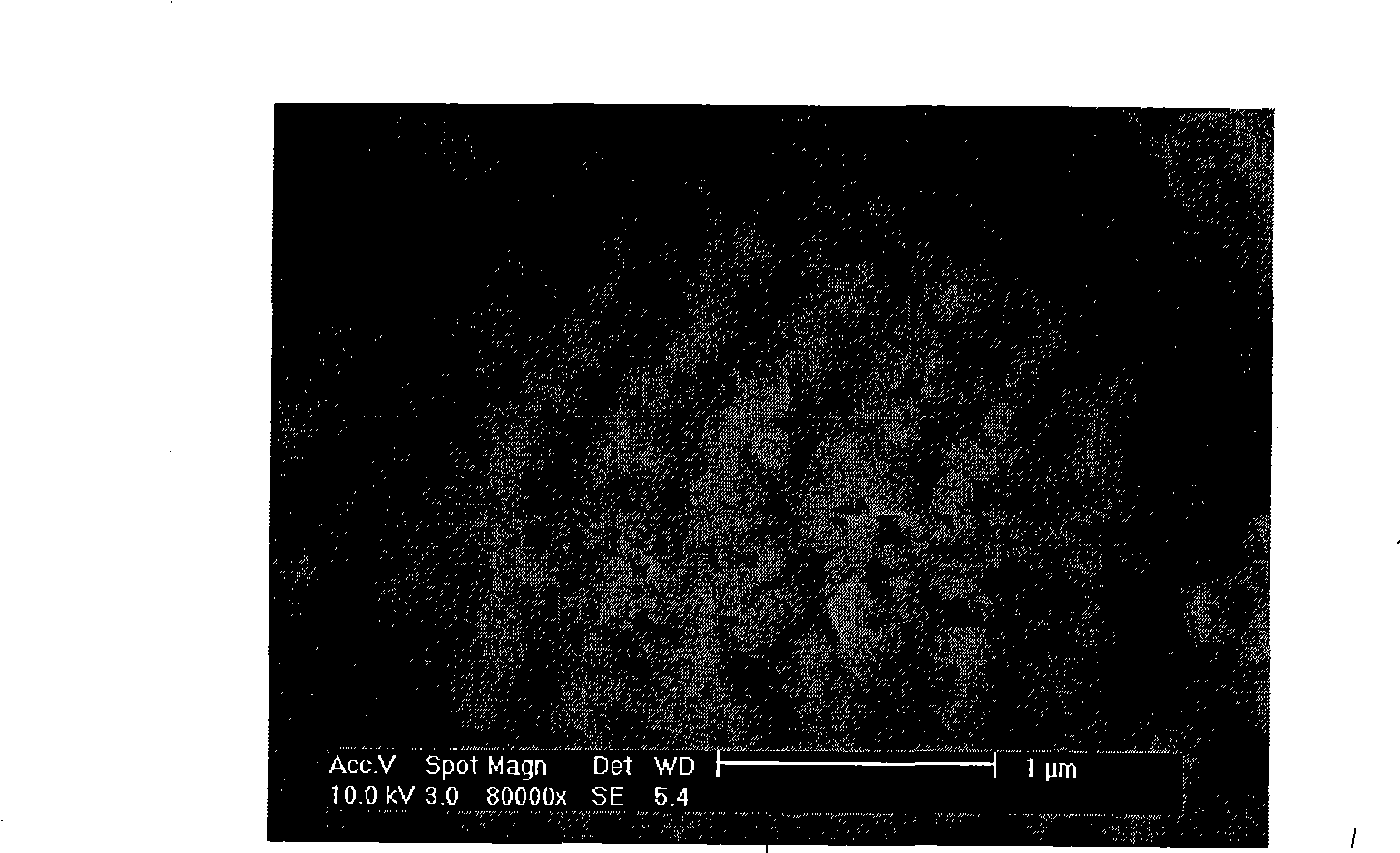

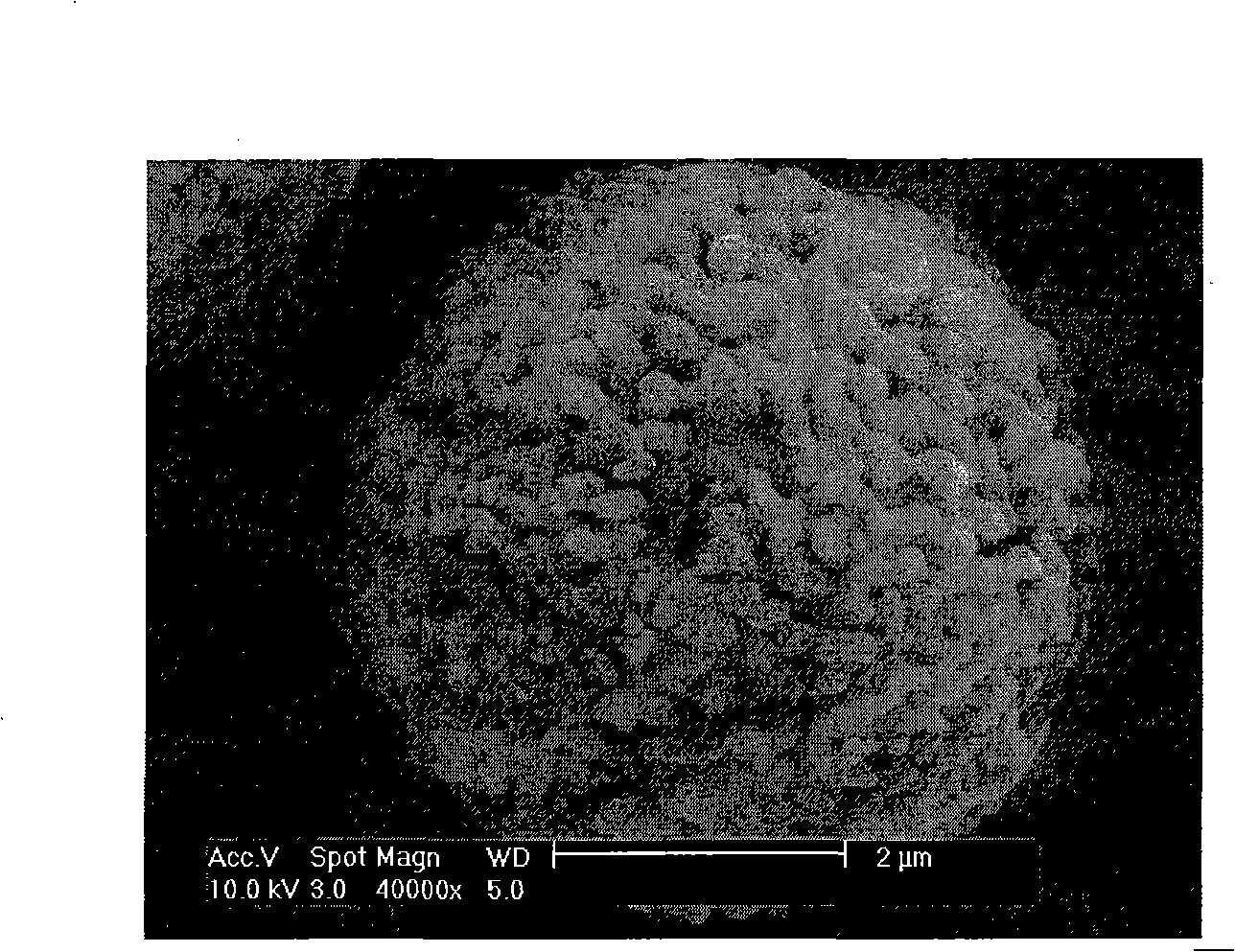

The invention relates to a phosphate material having a mesoporous structure for lithium secondary batteries and a preparation method thereof. The material having a mesoporous structure is secondary particles which have a mesoporous spherical or spheroid shape and are formed by the agglomeration of primary particles; the chemical composition of the material having the mesoporous structure is represented by the formula of LixAaMmBbPOzNn; the average particle diameter of the primary particles is 10nm to 1mum, the average particle diameter of the secondary particles is 100nm to 50mum, the average pore diameter of mesopores is 2 to 500nm; and the material having the mesoporous structure also comprises a layer of 2 to 100nm thick carbon coated outside the secondary particles and on the inner walls of the mesopores, wherein the content of the carbon accounts for 1 to 20 weight percent of the total weight of a substrate. The material is prepared by the steps of: firstly preparing pure-phase phosphate LiMPO4 or doped LiMPO4 sol; secondly, forming dry gel through heat treatment; and finally, forming the agglomerate secondary particles through sintering at high temperature. The phosphate material having the mesoporous structure can be directly used in secondary lithium batteries as an anode active material and can also be used by being mixed with the prior anode material as an additive. The material having the mesoporous structure can improve the rate performance and energy density of the prior anode material and batteries. The secondary lithium batteries containing the phosphate material having the mesoporous structure has high power density and high safety.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

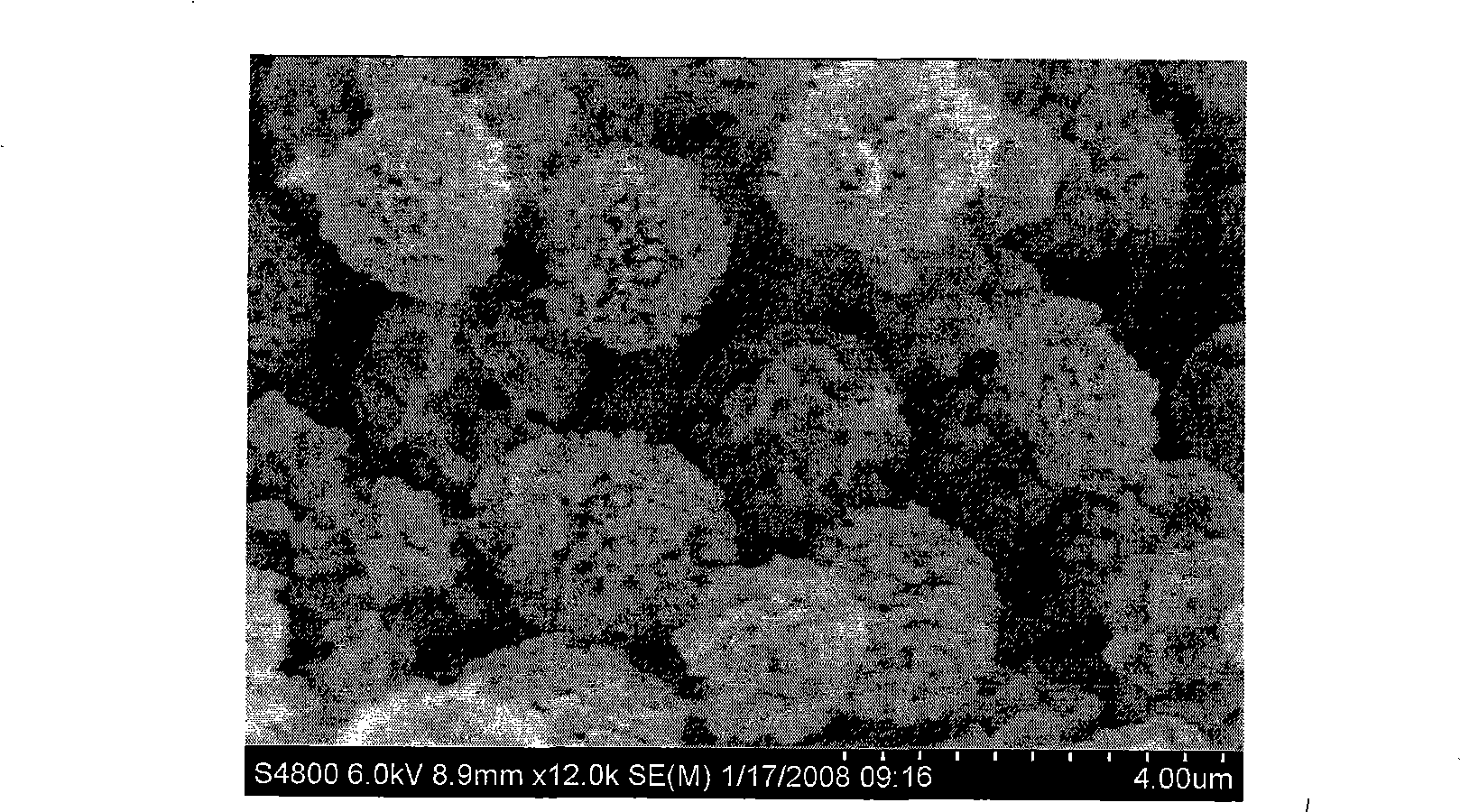

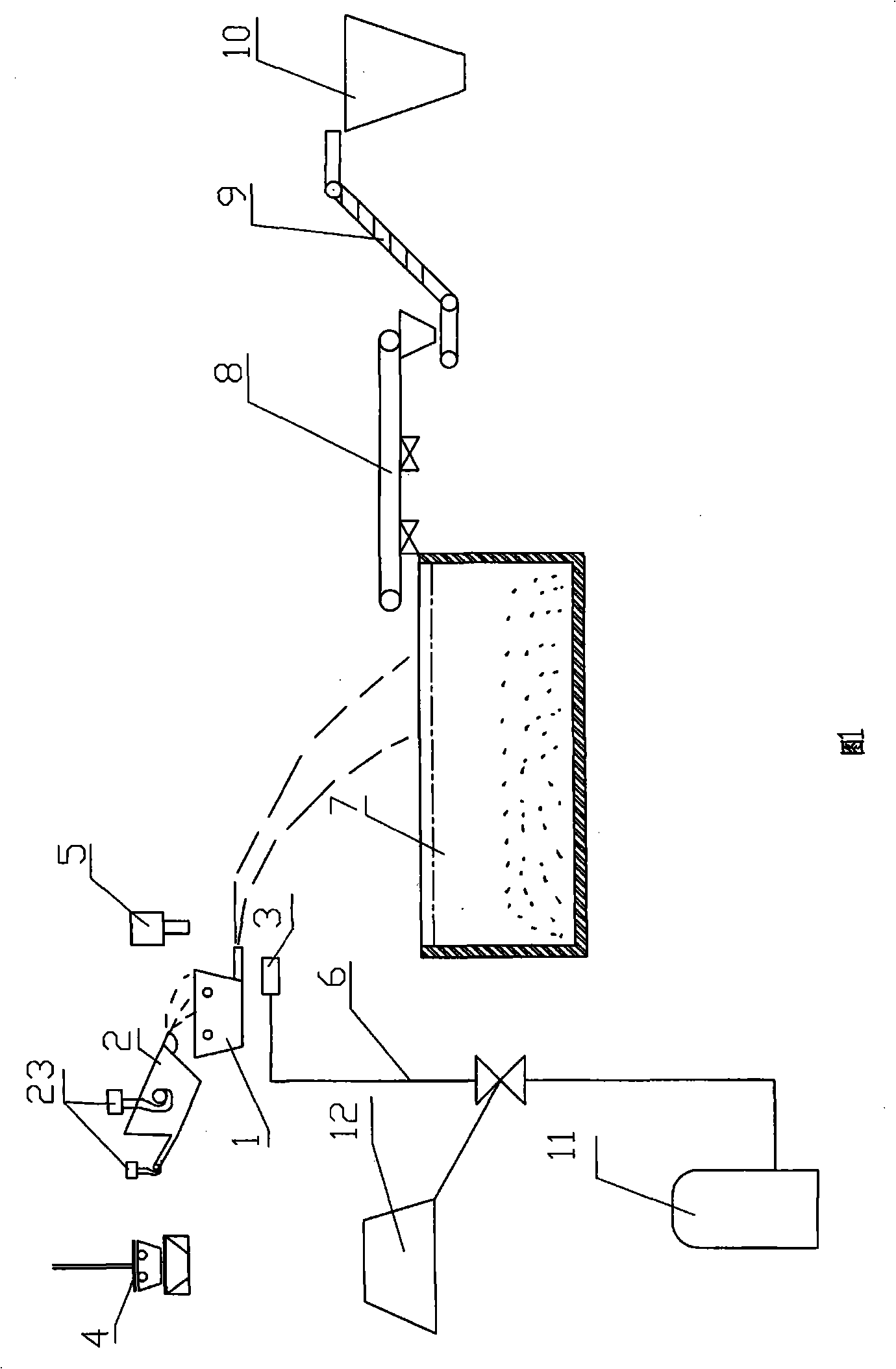

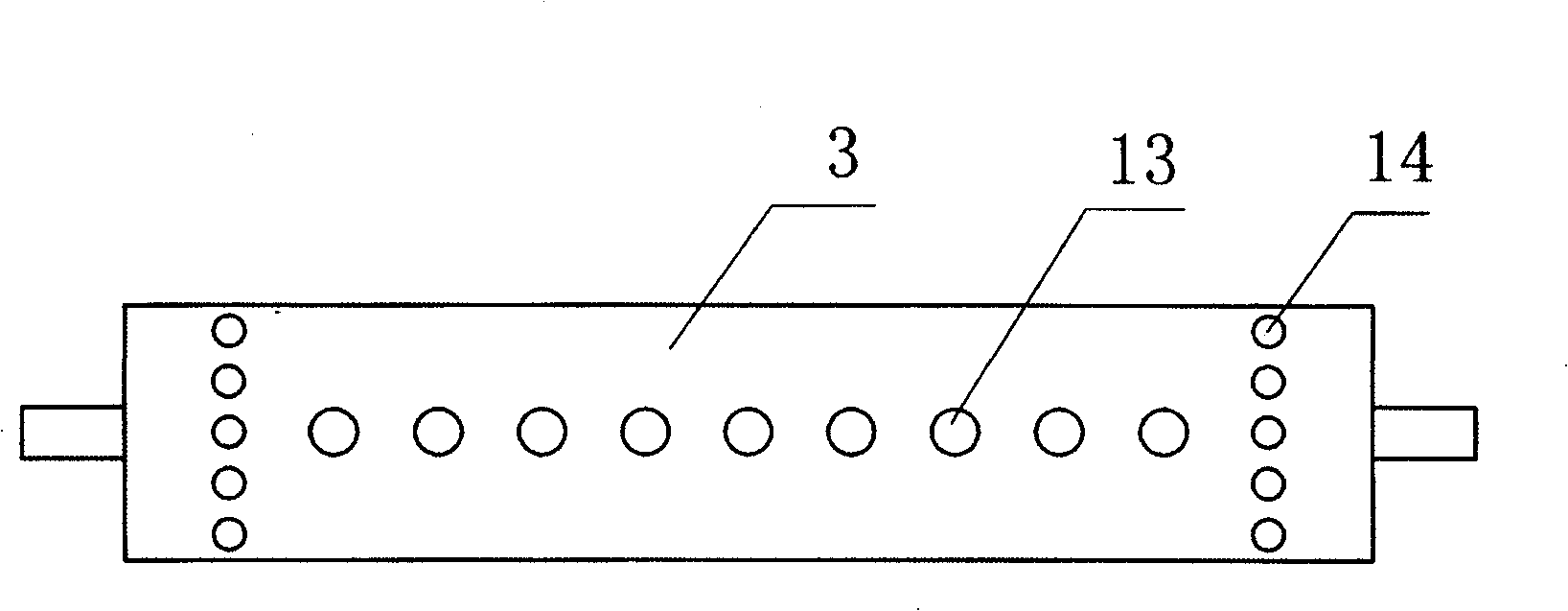

Wind-crushing water-cooling granulating method and device for high-temperature liquid-state steel slag, granulating steel slag and use thereof

ActiveCN101259991ALarge reaction interfaceImproved React interfaceSolid waste managementSlagLiquid state

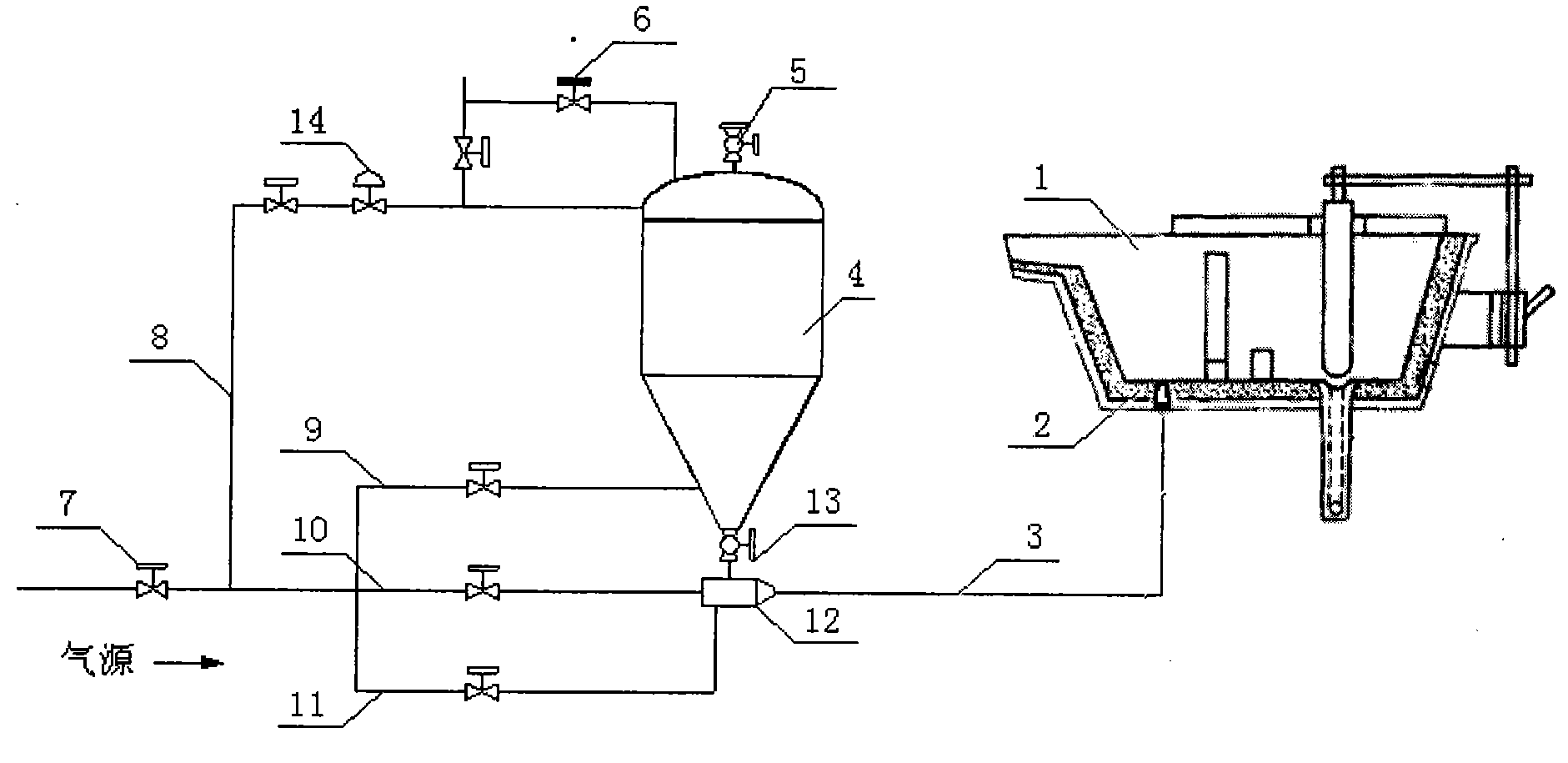

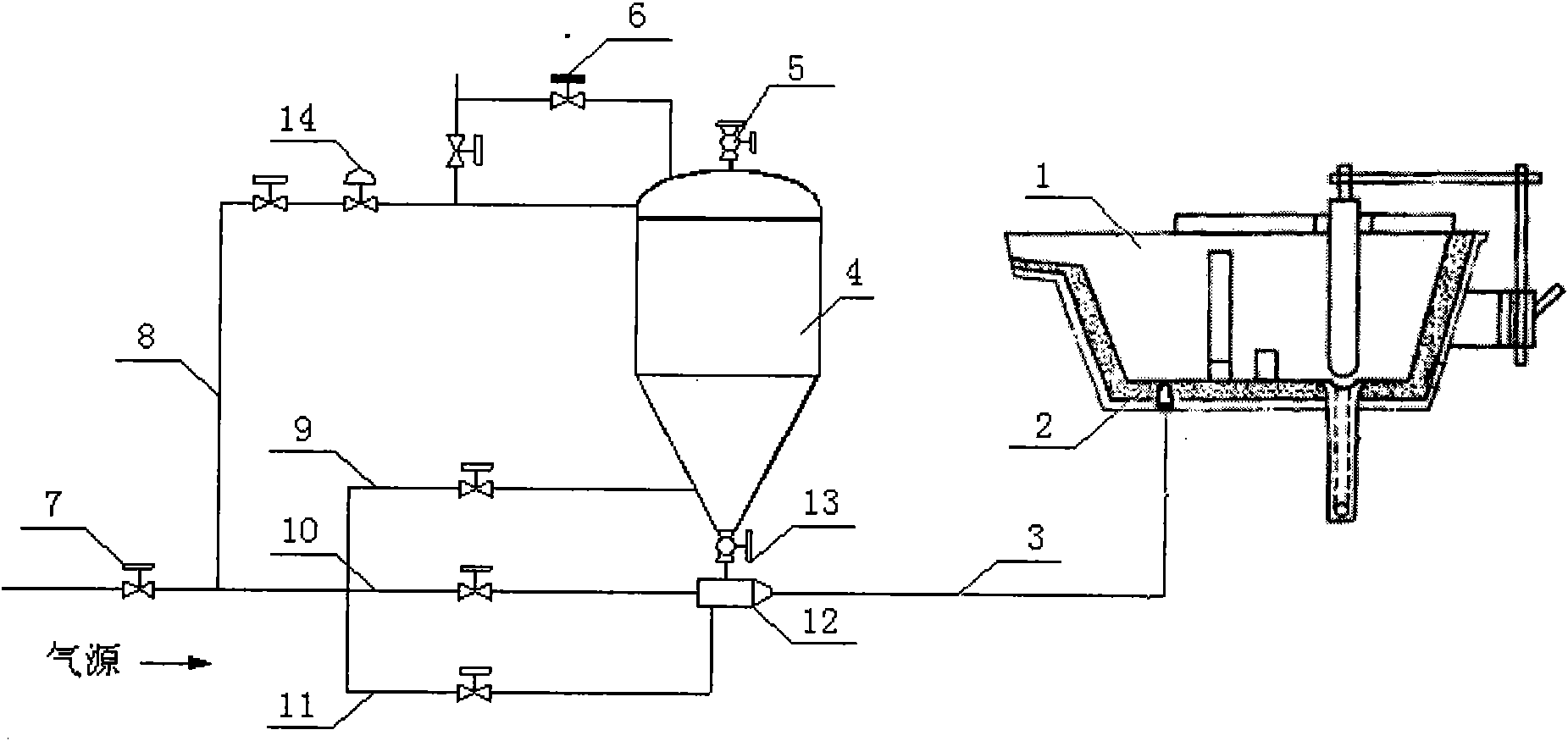

The invention provides a wind-crushing water-cooling granulating method of high-temperature liquid steel slag, a granulating device and granulated steel slag and use thereof. The invention belongs to the industrial waste comprehensive utilization filed and particularly relates to the treatment and the utilization of high-temperature liquid steel slag. The wind-crushing water-cooling granulating method of high-temperature liquid steel slag comprises the following steps: liquid steel slag flowing out from a tundish is granulated in the air through the high-speed compressed airflow ejected by a granulator; the granulated steel slag is dropped into a water pool so as to be cooled down; moreover, the pressure of the compressed air is controlled between 0.59 MPa and 0.70 MPa, and the degree of superheat of the liquid steel slag is controlled above 110 DEG C. The granulating device comprises a tundish, a granulator and a water pool, and is characterized in that: a tundish rapid heating-up device is arranged near the granulator; and a compressed air pipe is connected with a compressed air pressure automatic display monitoring device. The final blow rate of steel slag is increased from the 80 percent of the prior art to 95 percent and the steel slag has fine particle diameter; moreover, because unstable phase is eliminated, the steel slag can be directly used in the preparation of cement concrete of various strength grade labels from C30 to C80.

Owner:MAANSHAN IRON & STEEL CO LTD

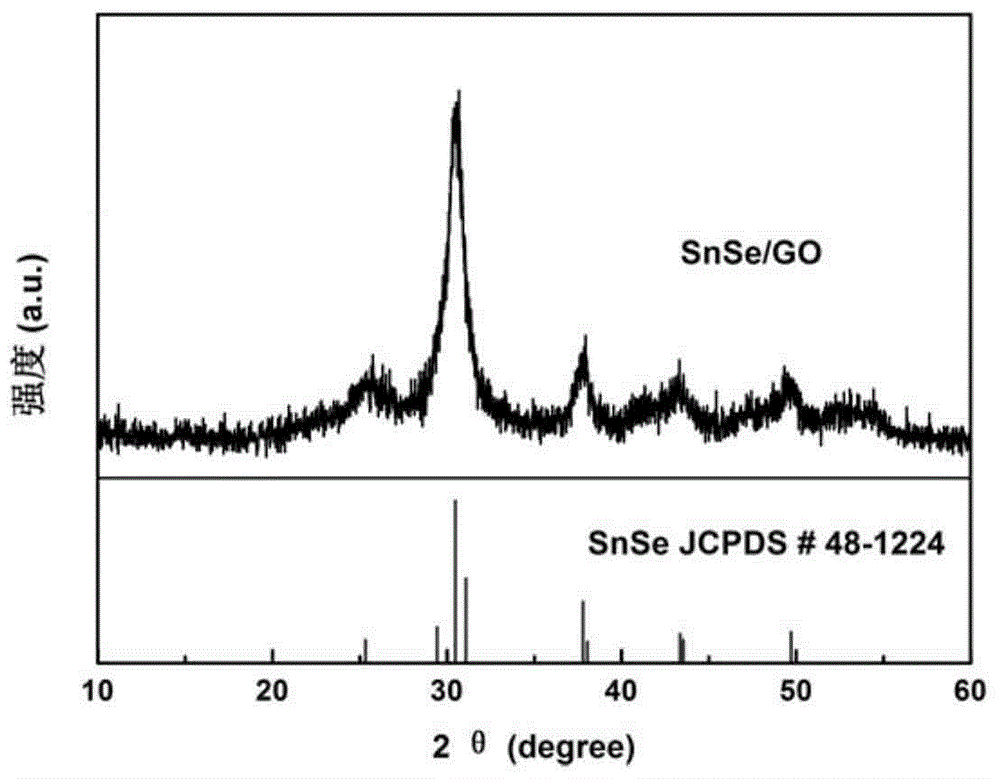

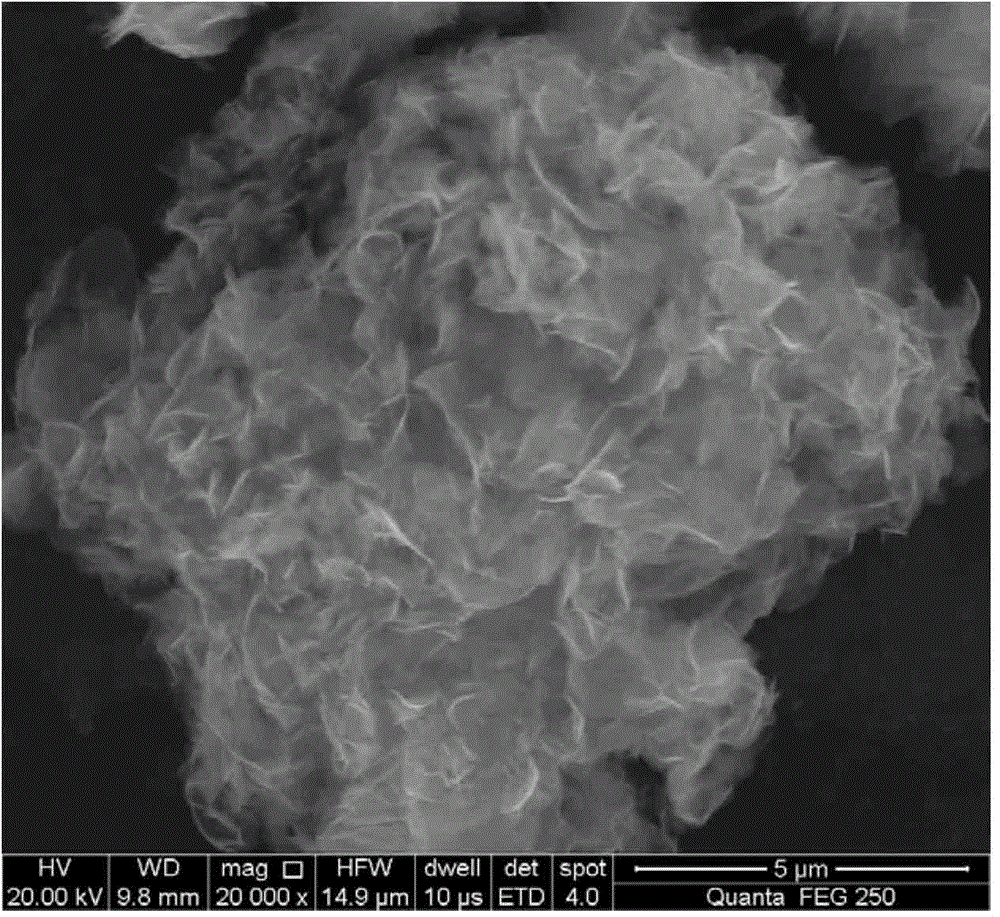

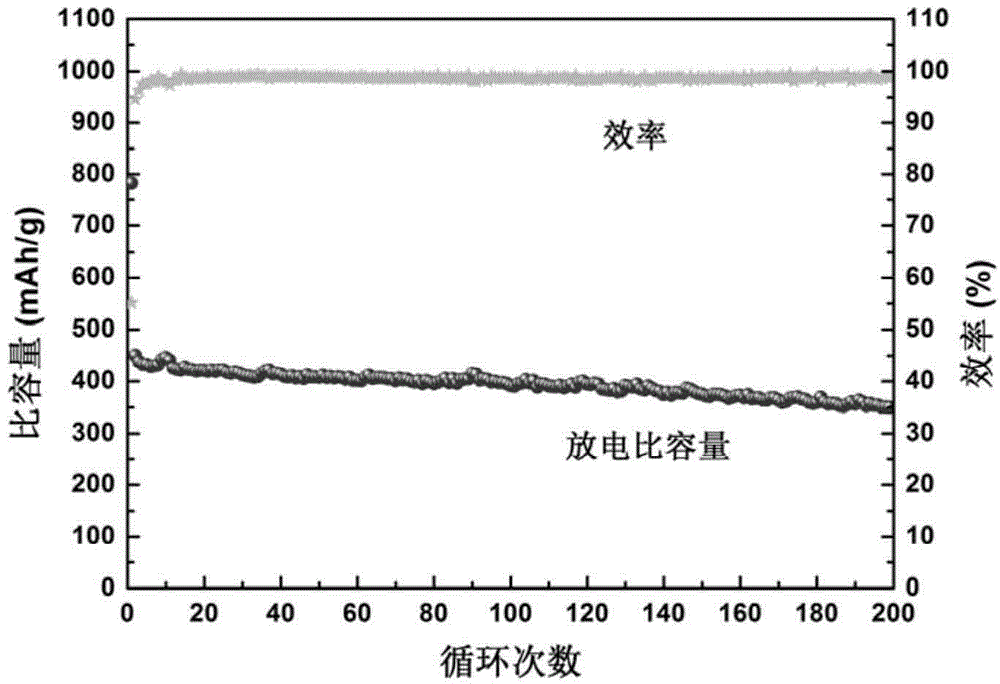

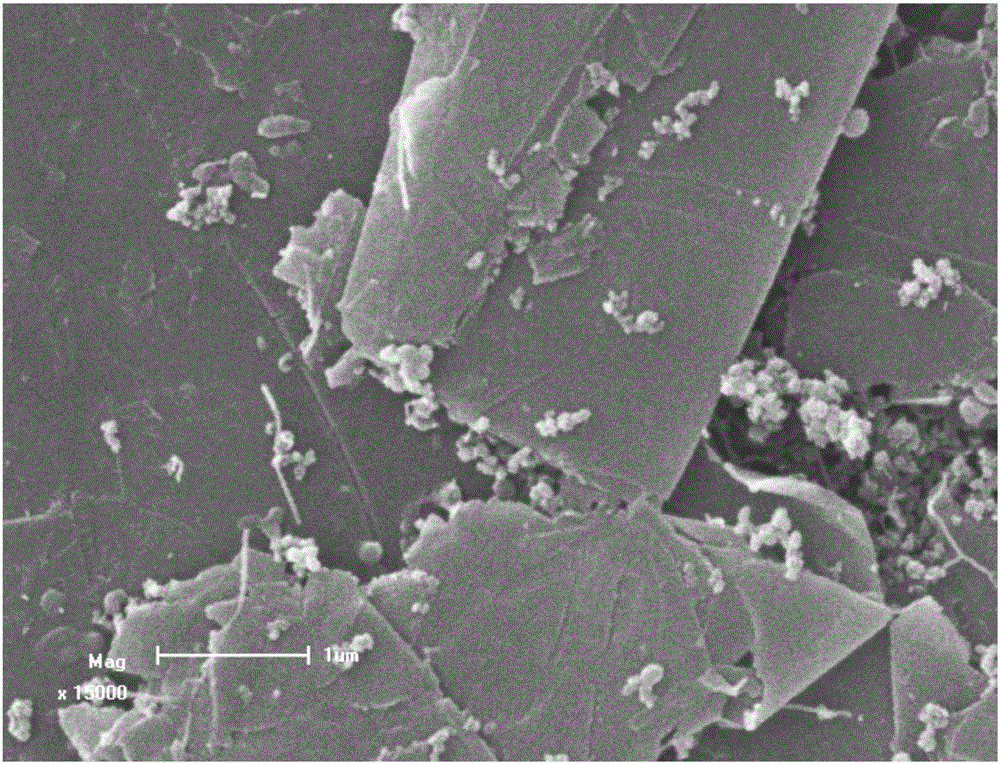

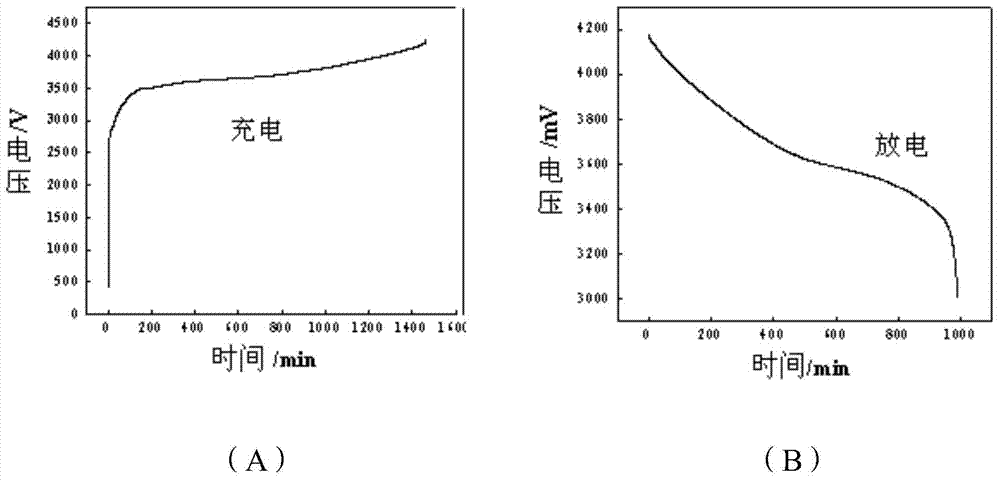

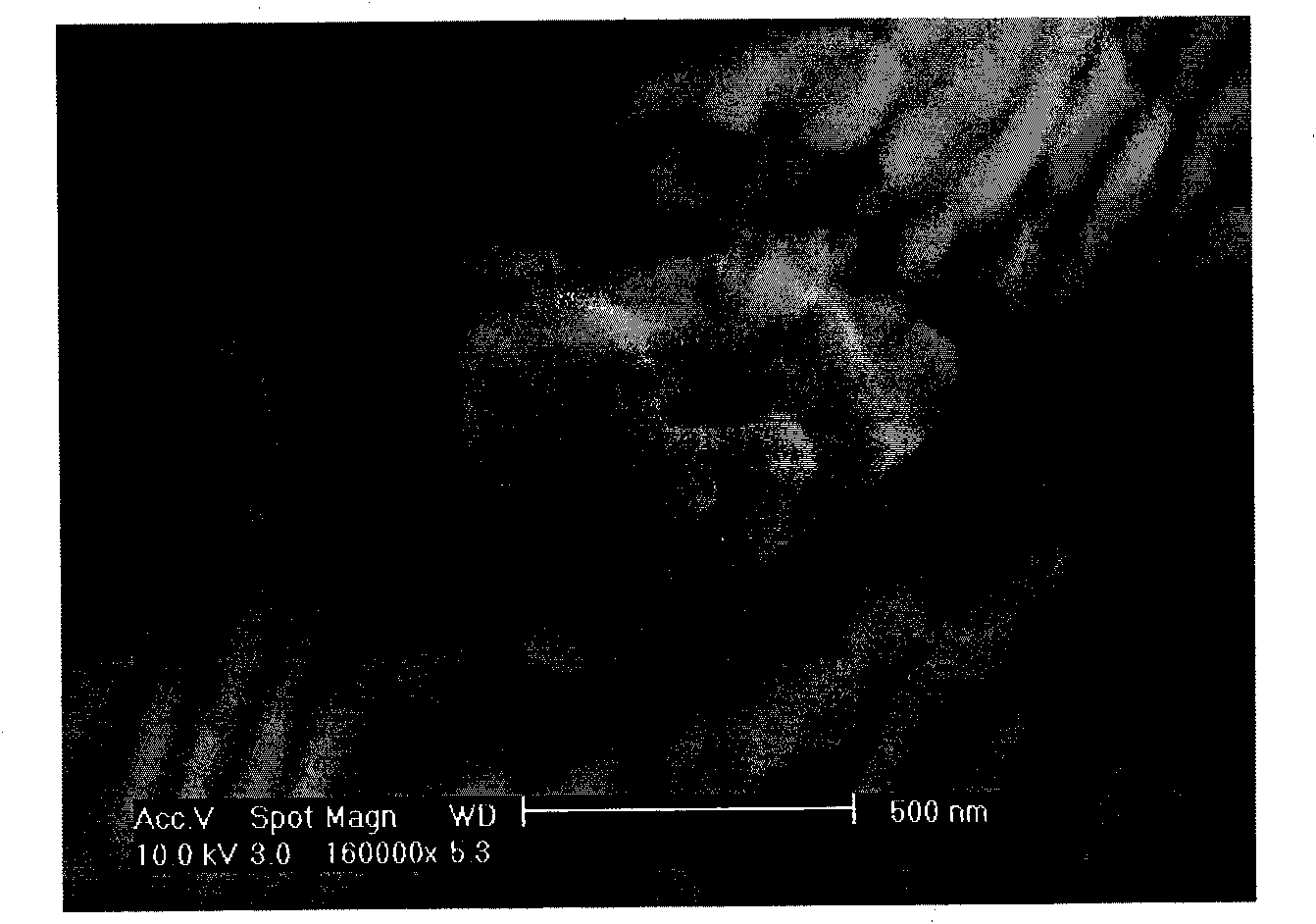

Stannic selenide/graphene oxide negative pole composite material for sodium ion battery and preparation method thereof

ActiveCN104617271AEasy to prepareGood repeatabilityMaterial nanotechnologyElectrode manufacturing processesOperabilitySodium-ion battery

The invention discloses a stannic selenide / graphene oxide negative pole composite material for a sodium ion battery and a preparation method thereof. The negative pole composite material is formed by uniformly growing nanometer stannic selenide on the surface of graphene oxide. The preparation method comprises the following steps of: ultrasonically dispersing graphene oxide powder into a mixed solution of water and ethylene glycol to obtain a dispersion solution; adding tin salt and selenite to the dispersion solution, then carrying out hydrothermal reaction, and placing a hydrothermal reaction product into an inert gas protective tube furnace for heat treatment so as to obtain a negative pole composite material which has nanometer sheet-like morphology and is formed by uniformly growing nanometer stannic selenide on the surface of graphene oxide. The composite material disclosed by the invention can be used for preparing the sodium ion battery which has the characteristics of high discharging specific capacity, excellent magnification property, long cycle life and the like. The preparation method disclosed by the invention has the advantages of simplicity, reliability, good process repeatability, high operability, low cost and suitability for industrialized production.

Owner:CENT SOUTH UNIV

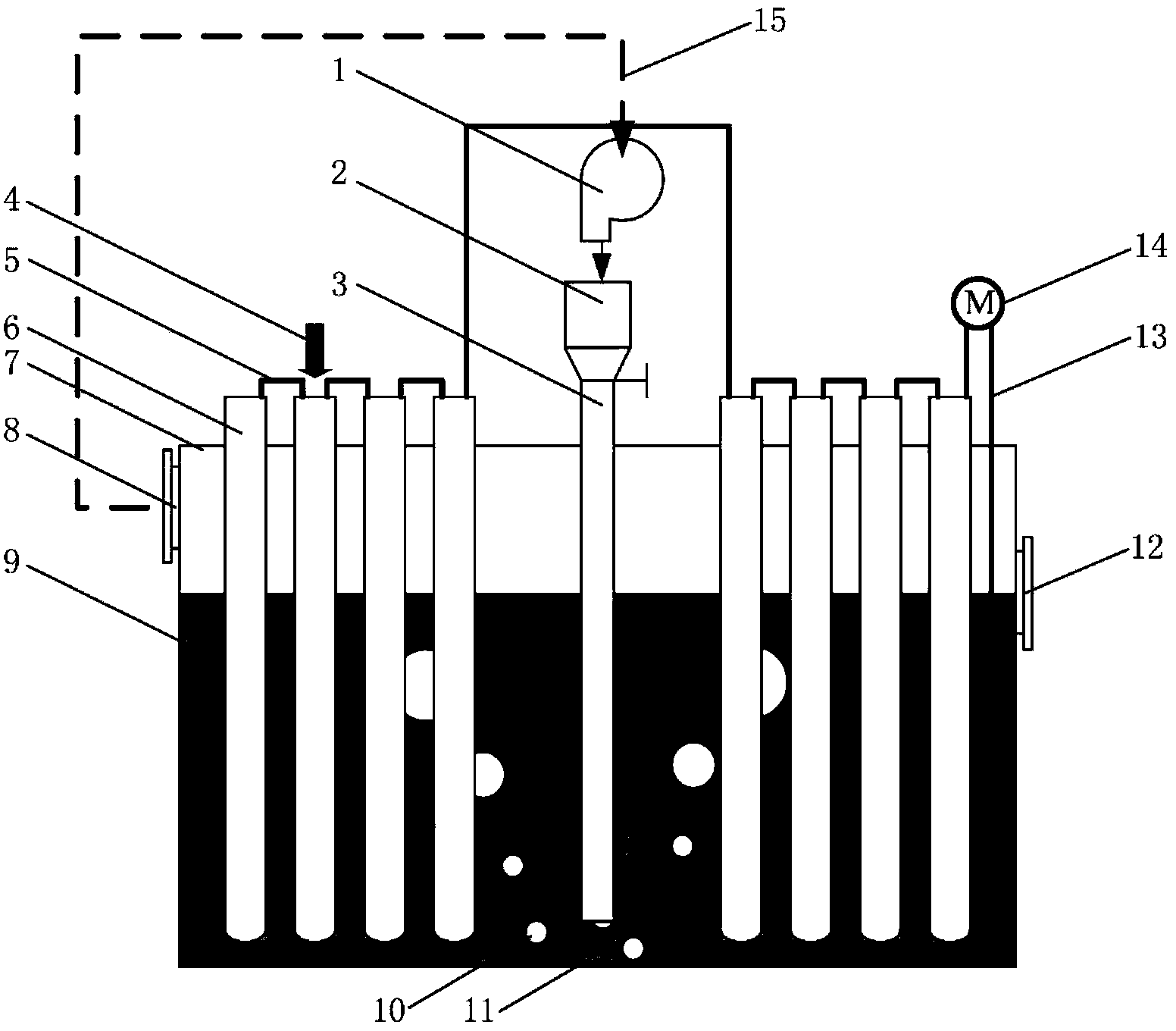

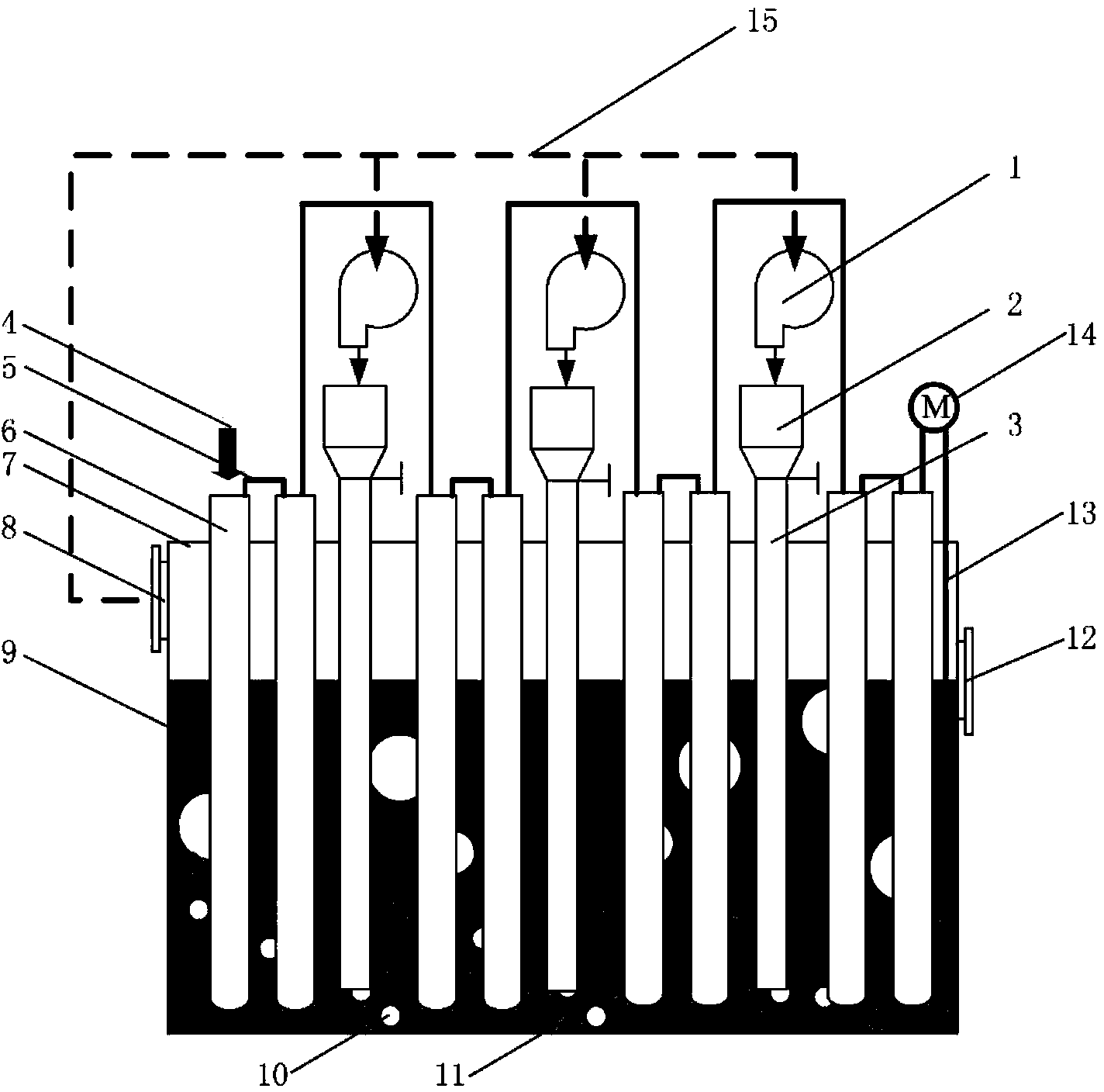

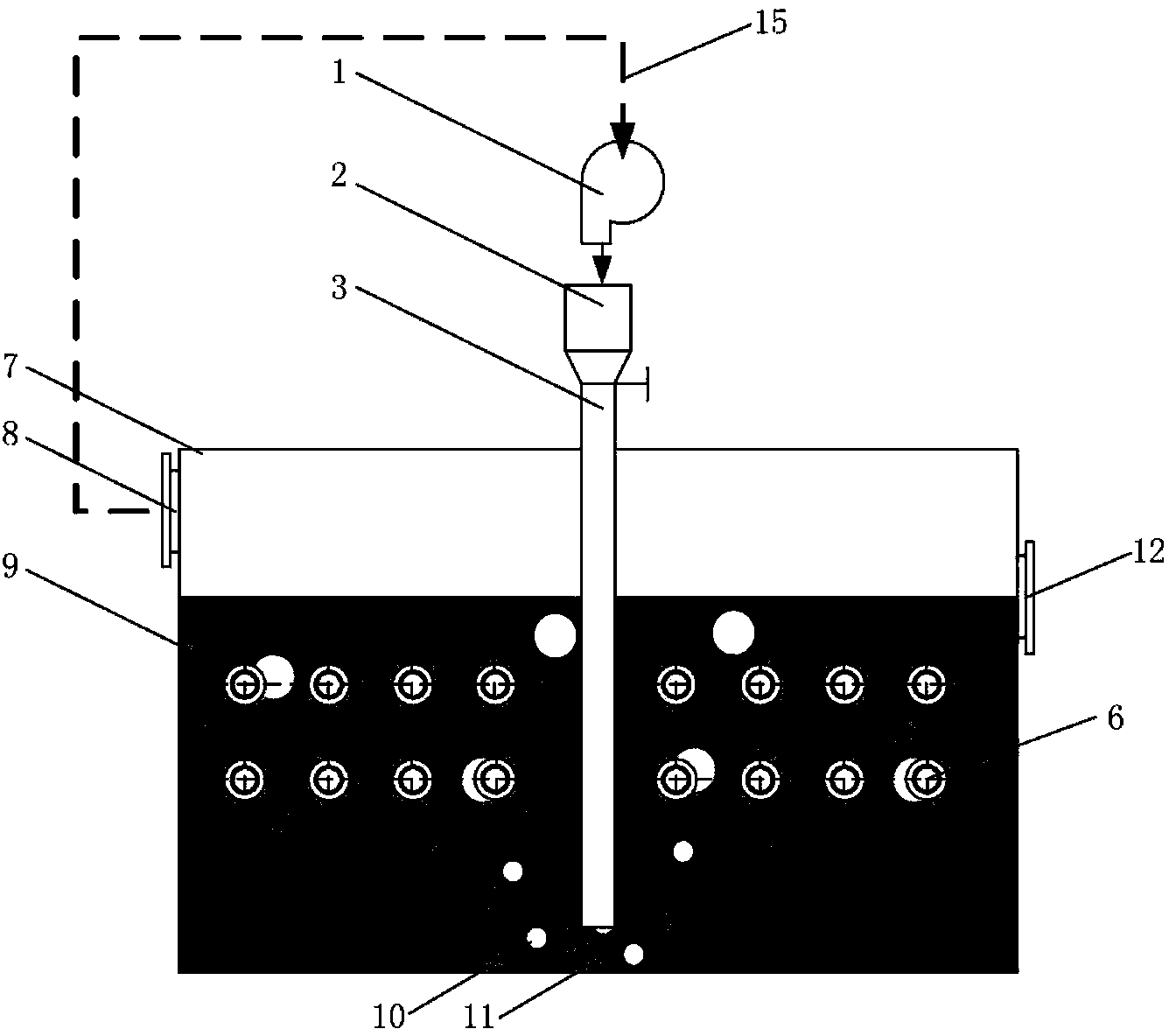

Generating and energy storage integrated device based on direct carbon fuel cells (DCFCs) with liquid metal positive electrode

ActiveCN103972526AMeet peak shaving needsGuaranteed power supplyReactant parameters controlCell electrodesElectrical batteryEngineering

The invention belongs to the field of fuel cells, and particularly relates to a generating and energy storage integrated device based on direct carbon fuel cells (DCFCs) with a liquid metal positive electrode. The generating and energy storage integrated device comprises a metal molten pool, the liquid metal positive electrode, the tubular solid oxide direct carbon fuel cells (SO-DCFCs) and a fluidization air distributing feeding system, wherein the tubular SO-DCFCs can be blind pipes and through pipes and can be inserted into the metal molten pool vertically or horizontally; the feeding system carries a fuel and a positive electrode material into the metal molten pool by virtue of carrier gas, and substances in the molten pool are stirred. The generating and energy storage integrated device provided by the invention has the advantages that chemical energy in the fuel and surplus electric energy in an power grid are changed into chemical energy in the liquid metal positive electrode to be stored, and the integration of a generating device and an energy storage device is realized; the integrated device is simple and compact, the reactivity of the carbon fuel and the metal positive electrode is high, the property of the cell is good, the friction of the cell caused by liquid state positive electrode fluidization is small, the service life of the cell is long, the seal is easy, the collection is convenient, and a large-scale electric pile is convenient to form.

Owner:TSINGHUA UNIV

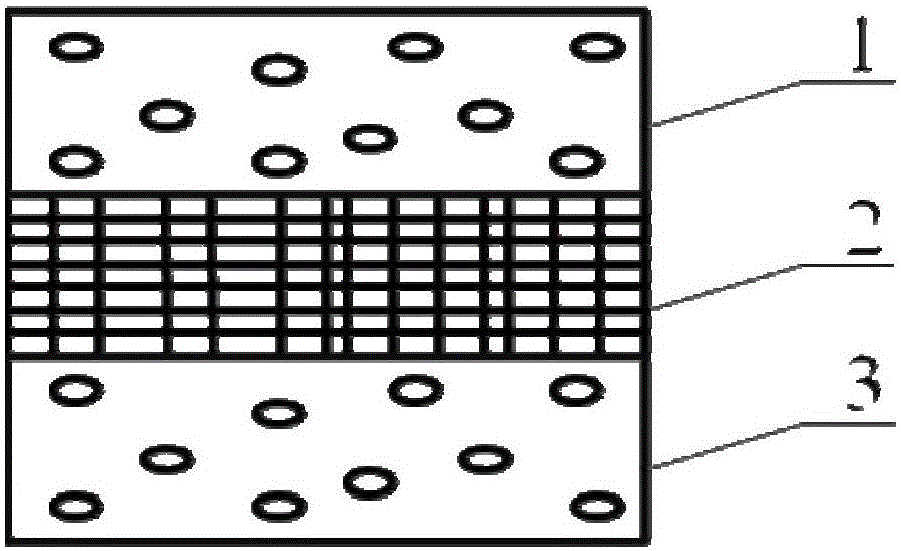

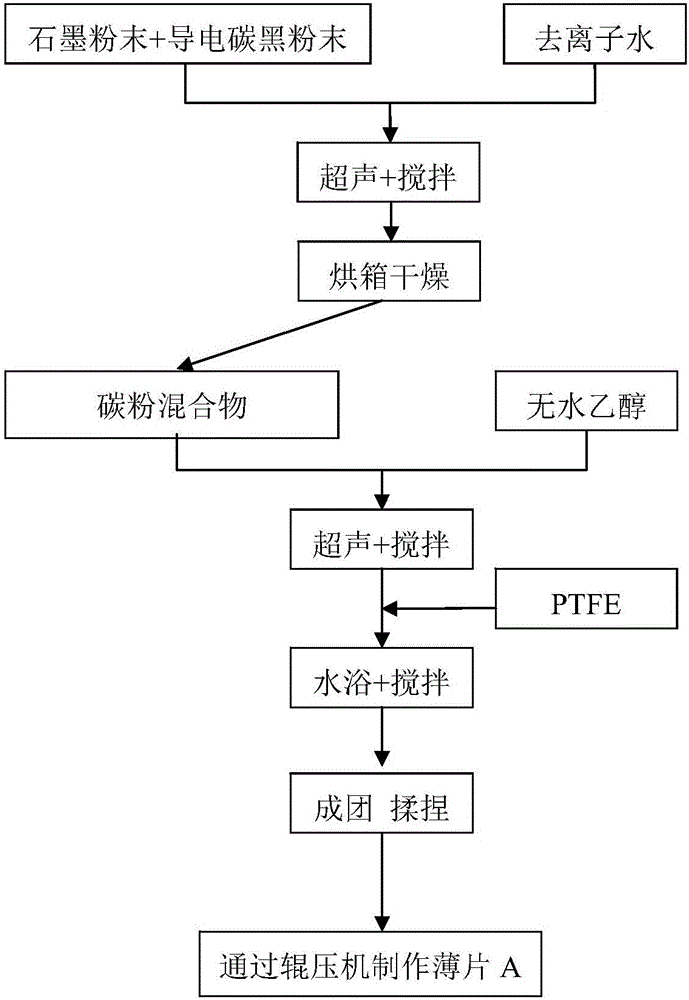

Preparation and application of graphite-carbon black mixed air diffusion cathode

ActiveCN105696018AIncrease the areaHigh porosityPhysical/chemical process catalystsElectrodesGraphite carbonAverage current

The invention discloses a preparation method of a graphite-carbon black mixed air diffusion cathode. The air diffusion cathode is of a composite layer structure composed of a diffusion layer, a stainless steel mesh and a catalyst layer which are laminated in sequence. The stainless steel mesh is a 60-mesh stainless steel mesh with the thickness being 0.1 mm. Catalyst layer materials are embedded in the stainless steel mesh. The preparation method of the graphite-carbon black mixed air diffusion cathode includes the steps that the 0.5 mm sheet-like catalyst layer formed by mixing graphite and conductive carbon black is prepared, the 0.5 mm sheet-like diffusion layer formed by pressing and sintering the conductive carbon black is prepared, the catalyst layer is embedded into the stainless steel mesh through rolling, the diffusion layer is attached to the other surface of the stainless steel mesh and then tightly combined with the stainless steel mesh after being rolled, and therefore the air diffusion cathode of the composite layer structure is prepared. The prepared air diffusion cathode is used for electro-catalysis synthesis of hydrogen peroxide, high catalytic efficiency is achieved, and average current efficiency is 80% or above.

Owner:TIANJIN UNIV

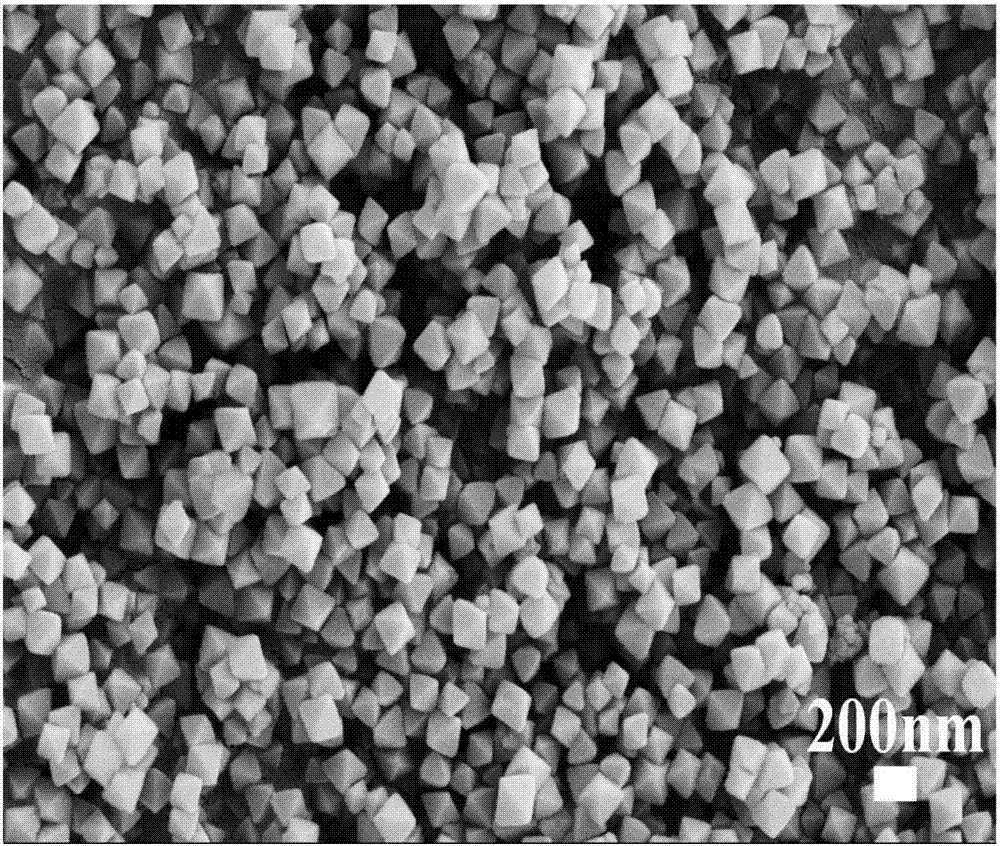

pH (potential of hydrogen) responsive metal organic framework nanometer crystal, preparation method and application

InactiveCN106928465AChange hydrophilicityHigh interface activityCarboxylic acid nitrile preparationOrganic compound preparationHydrogenMetal-organic framework

The invention discloses a pH (potential of hydrogen) responsive metal organic framework nanometer crystal, a preparation method and application. The pH responsive metal organic framework nanometer crystal comprises a metal organic framework and a pH responsive segment, wherein the pH responsive segment is graftedadhered to an organic ligand of the metal organic framework, and can be a pH responsive polymer, a chain segment containing a carboxylic group, or a chain segment containing a pyridine group. The pH responsive metal organic framework nanometer crystal has the advantages that the pH responsive segment is grafted onto the organic ligand of the metal organic framework, so that the contact angle of the metal organic framework is changed, namely that the hydrophilicity and hydrophobicity properties of the metal organic framework are changed, thereby increasing the interface activity of the pH responsive metal organic framework; the pH responsive segment has response property to the change of the pH value of the surrounding environment, the pH responsive metal organic framework has different hydrophilicity and hydrophobicity properties under different pH values, and then the pH responsive metal organic framework can be separated and recycled by adjusting the pH value.

Owner:SHANDONG NORMAL UNIV

Process for applying hydrogen to deoxygenation of liquid steel

The invention relates to a process for applying hydrogen to deoxygenation of liquid steel. The invention adopts the technical scheme that: when the oxygen blowing decarbonization in a converter comes to an end, or when steel ladle is refined or when the oxygen blowing decarbonization for RH ultra-low-carbon steel production comes to an end, the mixed gas of H2 or Ar-H2 is blown into liquid steel for deoxygenation, the flowrate of the mixed gas ranges from 40 to 3000m3 / h, the pressure ranges from 0.5 to 2.0 MPa, and the time of blowing the mixed gas into the liquid steel ranges from 5 to 30min. When converter or steel ladle or RH hydrogen blowing deoxygenation comes to an end, hydrogen which is dissolved in the steel is removed by argon blowing and vacuum treatment, wherein the step of blowing the gas into the liquid steel for deoxygenation is that the gas is blown into the liquid steel for deoxygenation by a gas permeable brick from the bottom of a top-bottom combined blown converter or from the bottom of the steel ladle or from an RH ascending tube; and in the mixed gas of Ar-H2, the volume content of Ar ranges from 10 to 80 percent, and the volume content of H2 ranges from 20 to 90 percent. The invention has the advantages that the process is simple, and the pollution of the liquid steel caused by deoxygenation can be reduced. The process used for removing oxygen in the steel can effectively increase the cleaness of the liquid steel and the quality of steel products.

Owner:WUHAN UNIV OF SCI & TECH

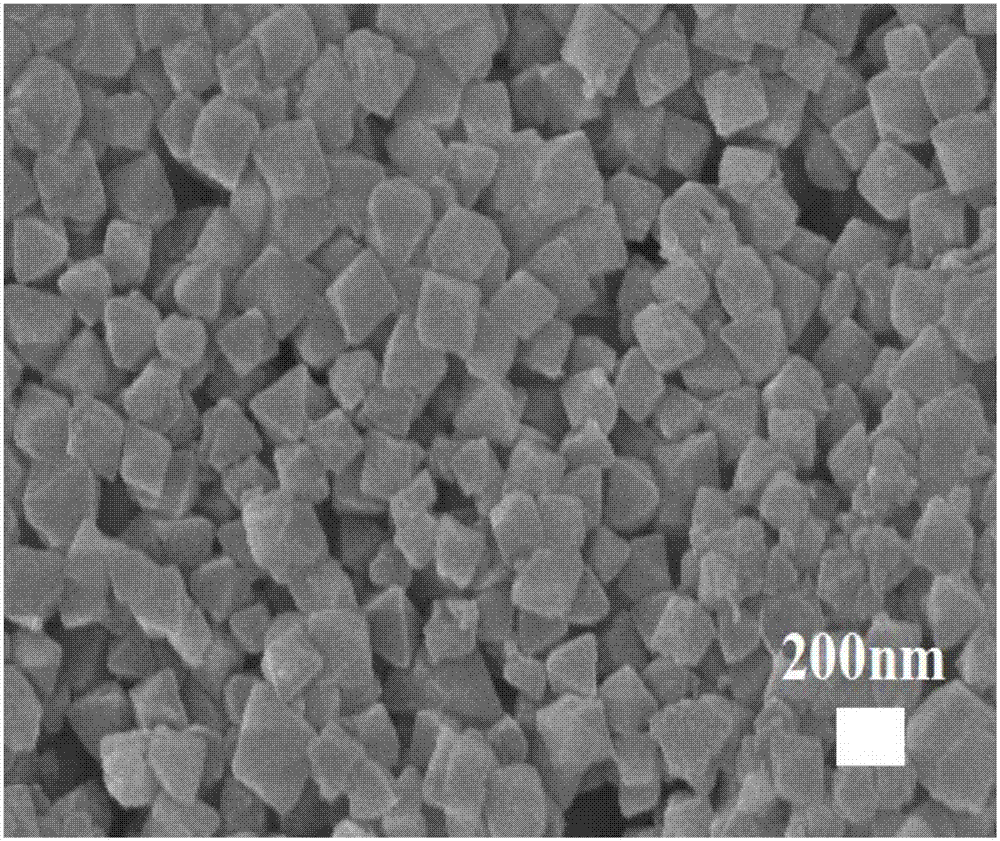

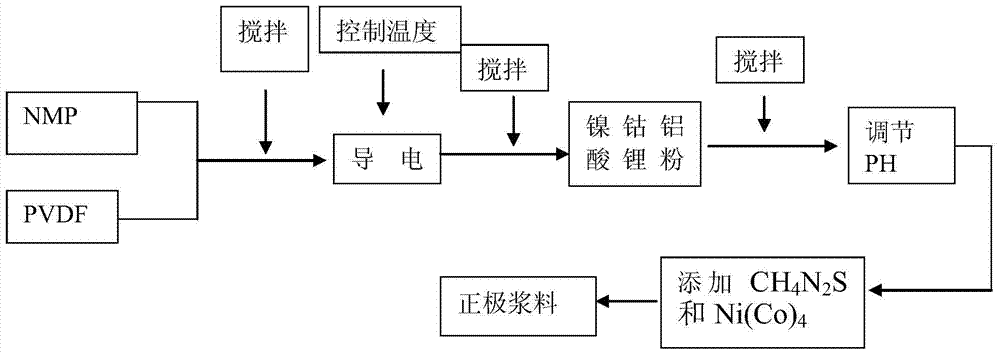

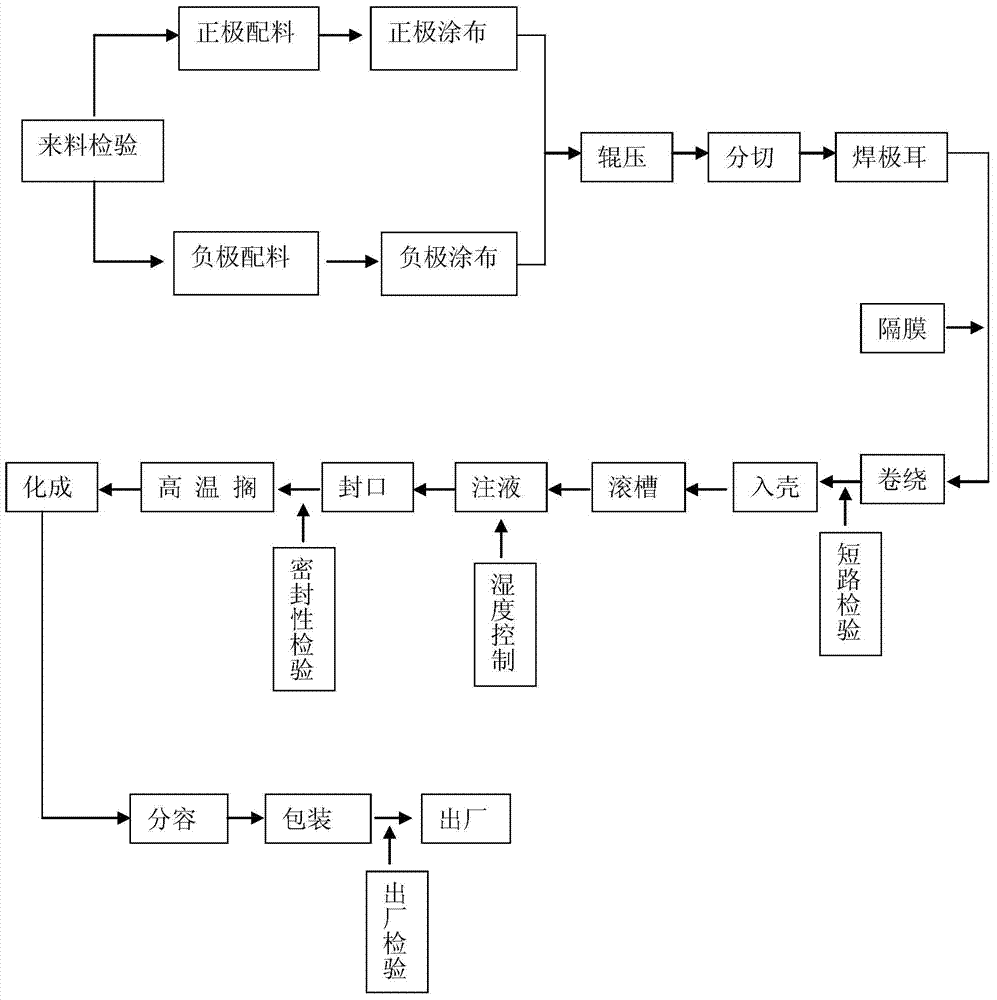

Positive slurry of lithium ion battery as well as preparation method and application of positive slurry of lithium ion battery

InactiveCN104332595AConductivity compensationIncrease electrolyte absorptionCell electrodesSlurrySodium-ion battery

The invention provides positive slurry of a lithium ion battery as well as a preparation method and application of the positive slurry of the lithium ion battery. The preparation method of the positive slurry of the lithium ion battery comprises the following steps: (1) uniformly agitating and mixing a solvent and an oily binding agent to obtain a mixture A; (2) adding graphene into the mixture A at 25-40 DEG C and agitating uniformly to obtain a mixture B; and (3) adding nickel cobalt lithium aluminate powder into the mixture B; agitating to obtain the positive slurry; and during the agitating period, adding oxalic acid to adjust the pH value of the slurry to 8-9.5. The battery prepared from the positive slurry of the lithium ion battery has the excellent charging / discharging circulating service life and has the high power and safety performance. The battery prepared by the invention is applicable to the fields of hybrid electric vehicles, telecommunication networks, outer spaces, defending equipment and the like.

Owner:SHENZHEN MOTTCELL NEW ENERGY TECH CO LTD

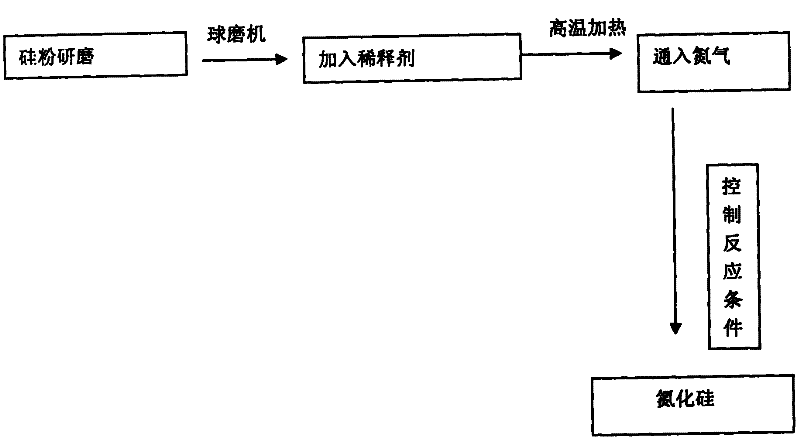

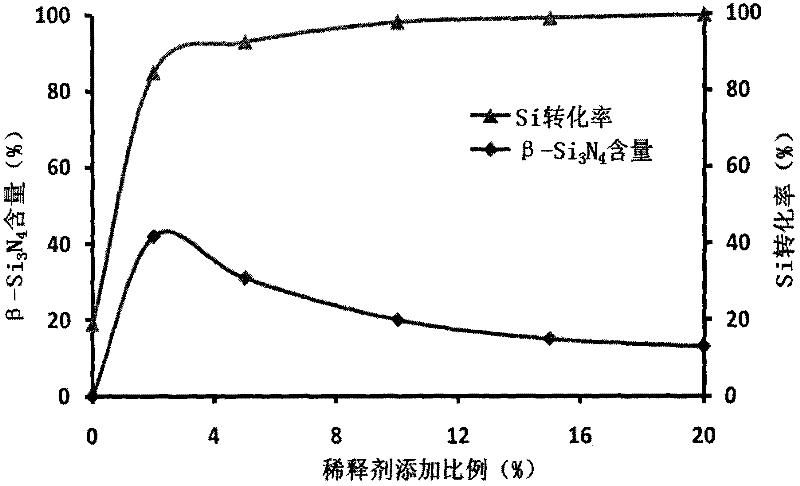

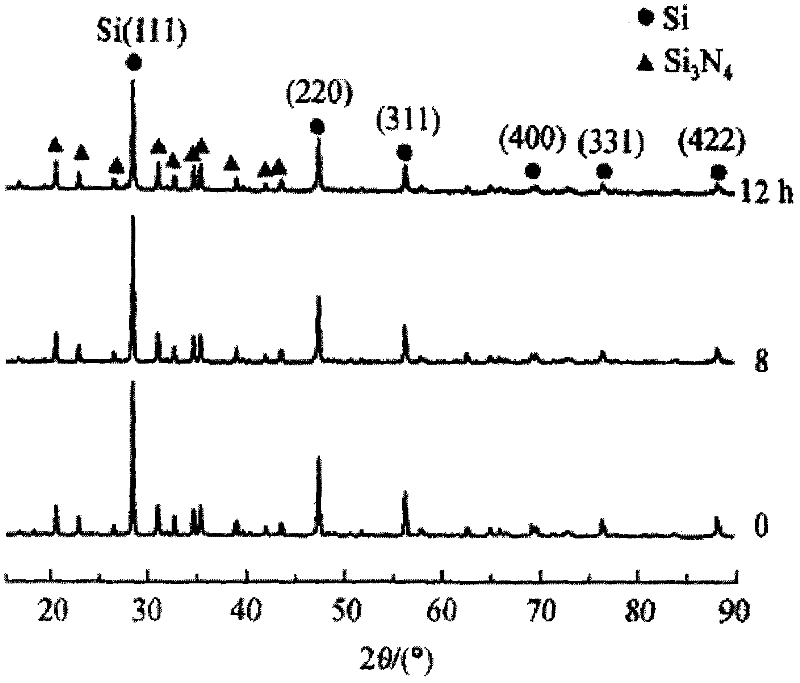

Production method of high-content alpha-crystal form silicon nitride powders

InactiveCN102173396ASmall granularityImprove defectsNitrogen compoundsChemical industryInorganic ChemicalSolid reaction

The invention discloses a production method of silicon nitride powders, in particular relates to a novel production method of silicon nitride powders with high content of alpha-Si3N4, and belongs to the technical field of inorganic chemistry. The method comprises the following steps: firstly pre-treating powdery raw materials by mechanical activation, and feeding a mixed diluting agent of alpha-Si3N4 and non-crystalline Si3N4 during the direct nitridation of silicon powders at a high temperature under normal pressure. By controlling the addition ratio of the diluting agent and the nitridation time and temperature, the silicon nitride powders with high content of alpha-Si3N4 are synthesized. The process improves the activity of solid-phase reactants, promotes the reaction between Si and N2, does not need high-temperature and high-pressure conditions, is easy to operate, adopts easily-available raw materials, increases the purity of products, has a low coat and a high efficiency, and is environment-friendly and energy-saving. The process is economical and highly-efficient and suitable for large-scale production.

Owner:GONGYI CITY HONGTAI SILICON NITRIDE MATERIAL

Integrated regenerative fuel cell structure

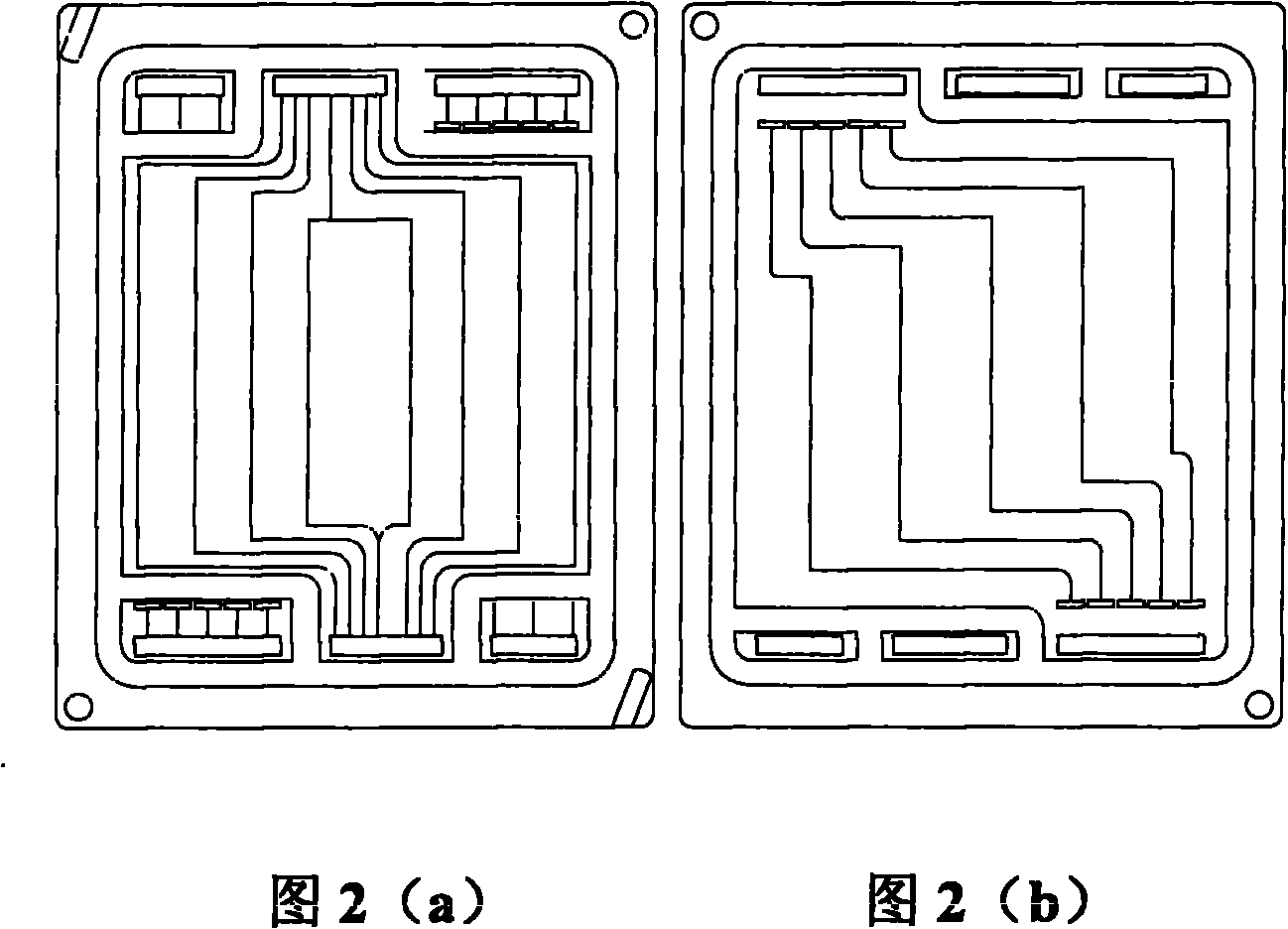

InactiveCN102074718AImprove electrical performanceAchieving surface contactCell electrodesRegenerative fuel cellsElectricityElectrolysis

The invention discloses an integrated regenerative fuel cell structure. In the cell structure, an anode insulating cushion plate [A2], an anode conducting plate [A3], a front special plate [A4], an anode flow field component, a double-effect membrane electrode component [M1], a cathode flow field component, a rear special water plate [B4], a cathode conducting plate [B3] and a cathode insulating cushion plate [B2] are stacked in turn to form a cell stack; two ends of the cell stack are provided with a front end plate [A1] and a rear end plate [B1]; and outer edges of the front end plate [A1] and the rear end plate [B1] are larger than those of other parts of the cell stack, areas of the front end plate [A1] and the rear end plate [B1] beyond the cell stack are provided with four edge holes at equal intervals, and screws are arranged in the edge holes to lock the cell stack. The integrated regenerative fuel cell has fuel cell and water electrolysis (WE) difunctional characteristic, can independently serve as a fuel cell and water electrolyzer, also can independently generate electricity or oxyhydrogen gas, and meets the requirement of a fixed fuel cell or transportation, including transportation tools and hydrogen refueling stations.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Method for removing ceramic core of hollow blade of turbine of aircraft engine

A method for removing a ceramic core of a hollow blade of a turbine of an aircraft engine comprises the four steps of primary core removing, secondary core removing, third core removing and ultrasonic cleaning. The concentration of KOH alkali liquor used in primary core removing is 40%, the concentration of KOH alkali liquor used in secondary core removing is 30%, and the concentration of KOH alkali liquor used in third core removing is 40%. Every time core removing is conducted, the temperature of the alkali liquor ranges from 160 DEG C to 200 DEG C, the pressure of the alkali liquor fluctuates between 0.4 MPa and 0.5 MPa, water is added every six hours, and soaking time is 48 hours. According to the method, the concentration of the alkali liquor is reduced, the water is added every six hours, and it is guaranteed that salt generated due to reactions is sufficiently dissolved; the alkali liquor is replaced every 48 hours, the concentration of the alkali liquor changes in a stepped mode, and it can be guaranteed that the chemical reactions are conducted effectively; the pressure of the alkali liquor fluctuates in a pulse mode, core cracking can be facilitated, the reaction interface between the alkali liquor and the core is enlarged, and the reacting dose is increased. Through the method, the ceramic core removing period can be shortened to six days from over twenty days, and the first pass yield of core removing can be higher than 90%.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Silicon/graphene oxide anode material for lithium battery and preparation method thereof

InactiveCN104916823AEasy to prepareGood repeatabilityFinal product manufactureCell electrodesNano siliconOperability

The present invention discloses a silicon / graphene oxide anode composite material for a lithium battery and a preparation method thereof. The anode composite material is formed by uniformly adsorbing nano silicon to the surface of graphene oxide. According to the preparation method, graphene oxide powder is ultrasonically dispersed in mixed solution of water and ethylene glycol to obtain dispersion liquid; the nano silicon and a dispersing agent are added into the dispersion liquid; ball milling is carried out until the nano silicon is completely dispersed; and drying is carried out to obtain the anode composite material with the sheet-like morphology, of which the nano silicon is uniformly adsorbed to the surface of the graphene oxide. The composite material can be used for preparing the lithium ion battery with the characteristics of high specific discharge capacity, excellent rate capability, long cycle life and the like; and the preparation method is simple and reliable, is good in process repeatability, has high operability, is low in cost and is suitable for industrial production.

Owner:田东

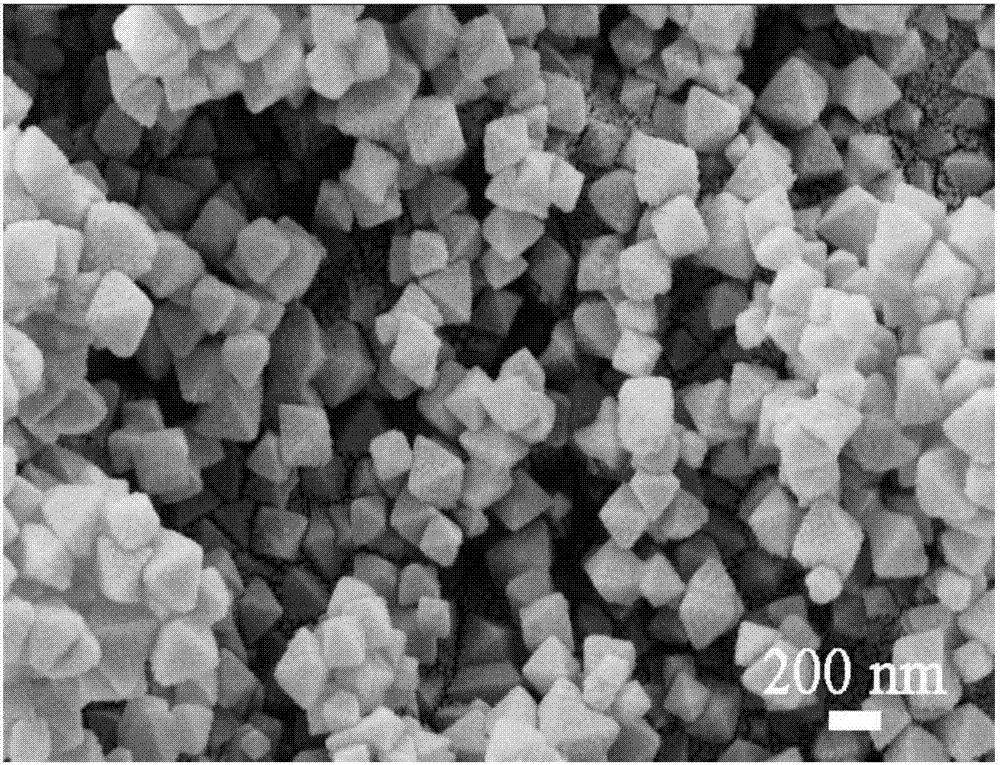

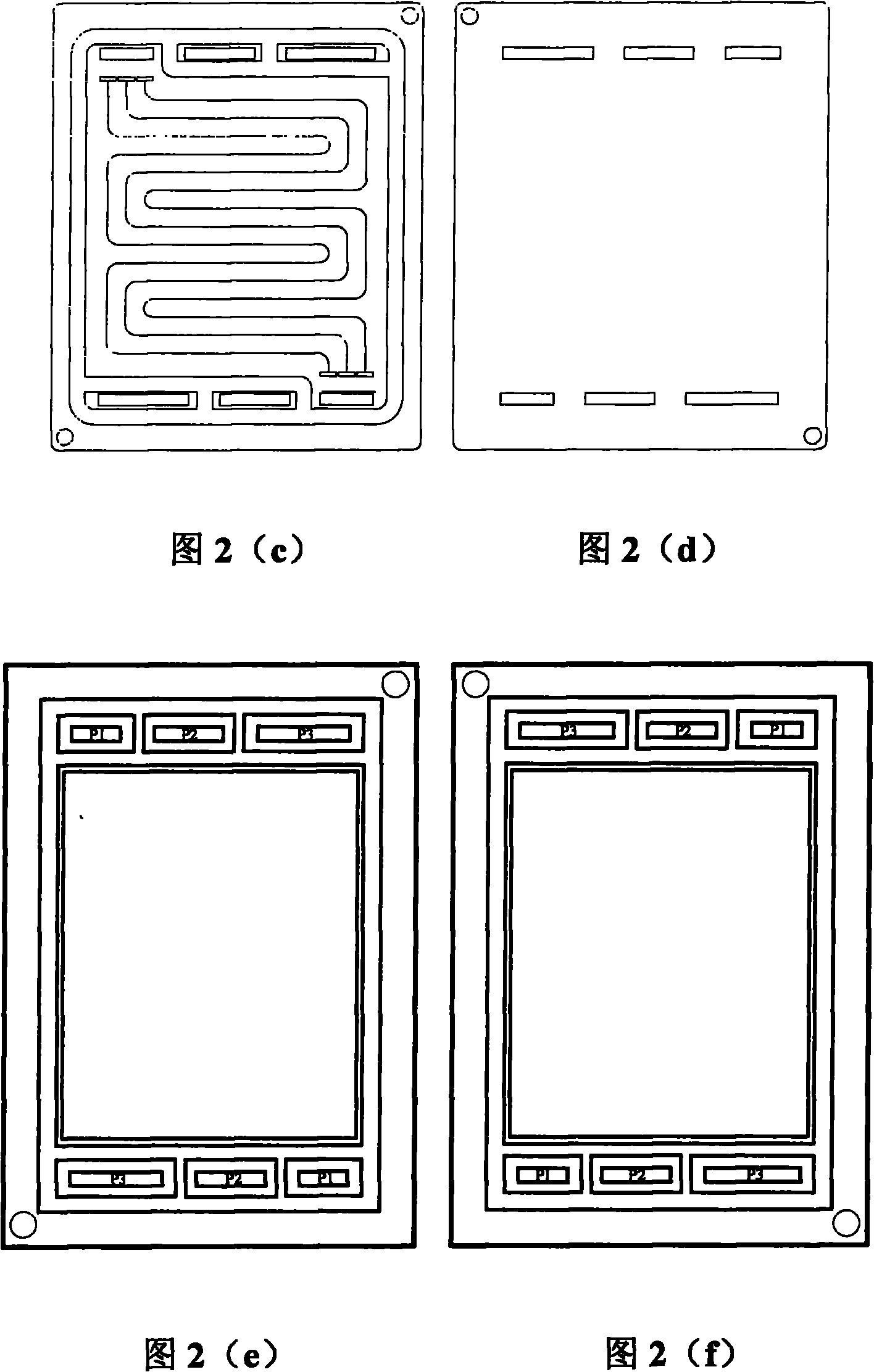

High-catalytic activity composite negative electrode material of intermediate-temperature solid oxide fuel cell and preparation method of composite negative electrode material

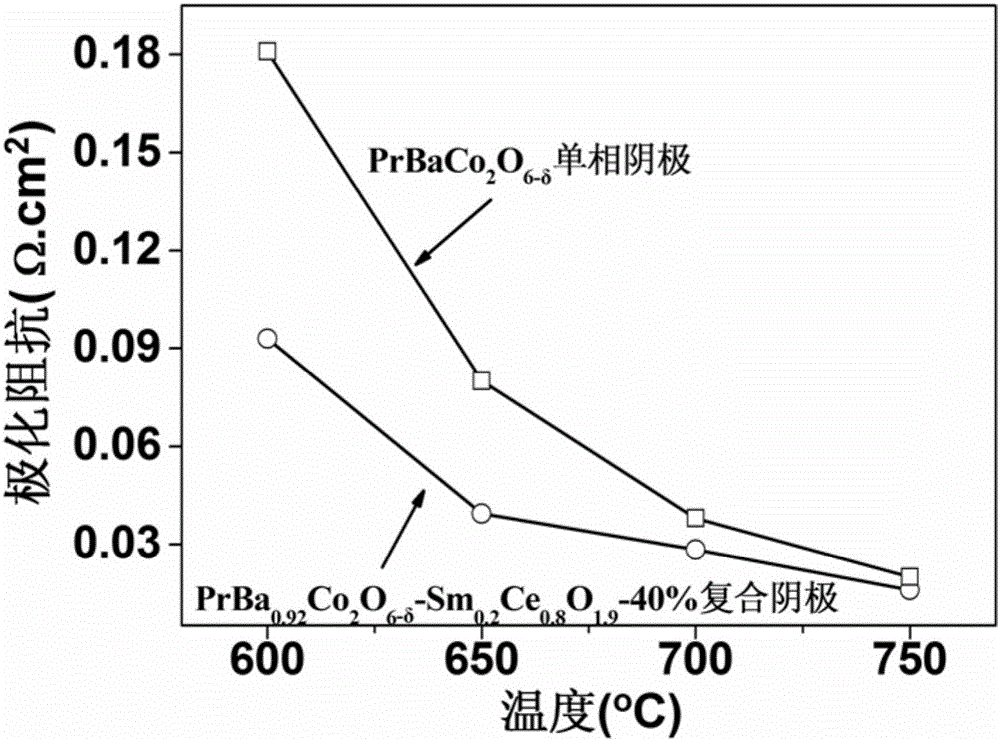

InactiveCN105870459ASimple preparation processEasy to operateCell electrodesElectrical conductorOxygen ions

The invention relates to a high-catalytic activity composite negative electrode material of an intermediate-temperature solid oxide fuel cell and a preparation method of the composite negative electrode material, and belongs to the technical field of an energy material. The composite negative electrode comprises a perovskite structured oxide PrBa<1-x>Co<2>O<6-Delta>, Pr<1-y>BaCo<2>O<6-Delta> or Pr<1-n>Ba<1-m>Co<2>O<6-Delta> in the absence of A-position cation and an oxygen ion conductor material Sm<0.2>Ce<0.8>O<1.9> or Gd<0.1>Ce<0.9>O<1.95>, wherein the mass percent of the oxygen ion conductor material accounts for 20-50%. The preparation method of the composite negative electrode material comprises the following steps of firstly, respectively preparing synthesis solutions of two constituents; secondly, mixing and uniformly stirring the two solutions to obtain a mixed synthesis solution of the two constituents, and heating the mixed synthesis solution to obtain mixed precursor gel; and finally, carrying out high-temperature sintering reaction to obtain composite negative electrode powder. The composite negative electrode material is prepared by a synchronous sintering reaction method, the preparation method has the advantages of simplicity in process, short preparation period, low cost and high efficiency, and is easy to operate, and the oxygen reduction catalytic activity of the negative electrode of the intermediate-temperature solid oxide fuel cell is effectively improved.

Owner:DALIAN UNIV OF TECH

High-purity crystalline inorganic fiber, molded body thereof, and method of production thereof

InactiveUS6348428B1Large reaction interfaceEasy to manufactureSilicaInorganic material artificial filamentsFiberMethods of production

A crystalline inorganic fiber or molded body thereof is thermally treated in gas atmosphere containing chlorine. The crystalline inorganic fiber or molded body thereof contains small impurities such as Fe, Cu and Ni. For example, Fe is 15 ppm or less, Cu is 1 ppm or less, and Ni is 0.5 ppm or less.

Owner:TOSHIBA MONOFRAX

Steel fusant desulfurizer

A steel fusant desulfurizer belongs to the field of steel smelting. The invention is characterized in that desulphurizing powder and straight iron powder are uniformly mixed by a ball mill and made into blocks by pressing; the desulphurizing powder is made of micrometer powder and nanometer powder, and the straight iron powder is adhesive using micrometer iron powder smaller than 250 meshes, and the weight ratio of the straight iron powder and the desulphurizing powder is (4-10):1; the desulphurizing powder comprises CaCO3 powder, CaO powder, CaF powder, Ca powder and Mg powder. The desulphurizing powder and straight iron powder are used for playing a pre-dispersion role for desulphurizing powder during ball milling so that the desulphurizing powder is unlikely to agglomerate into large granules and the reaction interface with S is enlarged. The desulphurizing powder and straight iron powder are pressed into blocks for increasing the proportion to facilitate the desulphurizing powder to permeate into the steel fusant to avoid floating into the dregs, thus improving the efficiency of desulphurization. When CaCO3 powder is used as the desulphurizing powder, the decomposed CaO fully contacts with S to generate CaS which is attached to the bubble of CO2, the CO2 floats up while S is removed from the fusant, thus purifying the fusant.

Owner:方克明

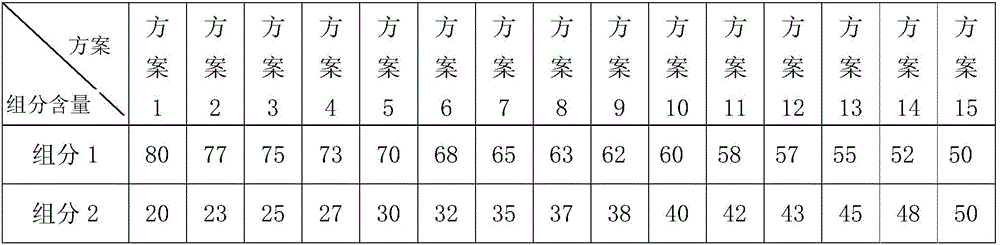

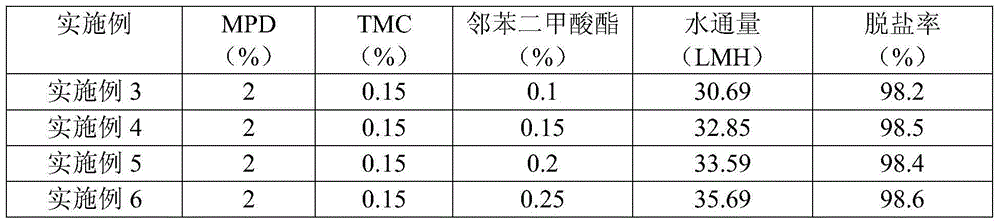

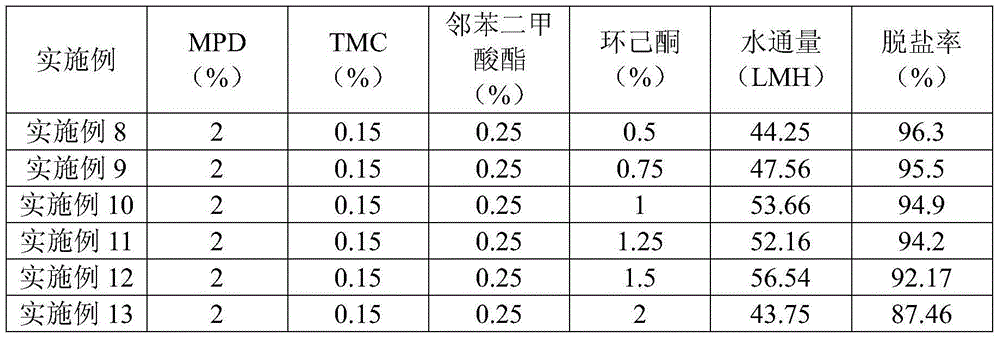

Preparation method for ultra-low-pressure high-flux reverse osmosis membrane

ActiveCN104607067AHigh reactivityIncrease water fluxSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisHigh fluxReverse osmosis

The invention provides a preparation method for an ultra-low-pressure high-flux reverse osmosis membrane. The method specifically comprises the following steps: S1: preparation of an aqueous solution; S2: preparation of an oil phase solution; S3: preparation of a dry polyamide membrane; and S4, preparation of the reverse osmosis membrane. According to the invention, lipid and ketone derivatives are added in the oil phase solution; the lipid materials and polybasic acyl chloride in an oil phase undergo complexation reaction, so the reaction activity of polybasic acyl chloride is greatly increased; and the ketone materials change dissolution difference between an aqueous phase and the oil phase, so the diffusion ability of polybasic amine monomer to an organic phase is enhanced, the reaction interface of interfacial polymerization is increased, and the effective area of the reverse osmosis membrane is increased, thereby increasing the water flux of the membrane.

Owner:北京碧水源智慧科技股份有限公司

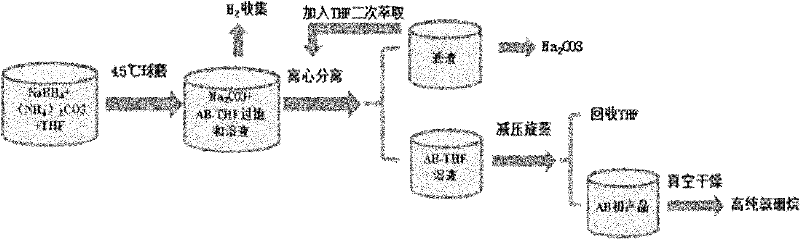

Method for preparing ammonia borane by wet chemical process

InactiveCN102530870ASmall particle sizeLarge reaction interfaceMetal hydridesChemical reactionDistillation

The invention provides a new method for preparing ammonia borane, which synthesizes ammonia borane with high efficiency by using an ammonium salt and a boron hydride as raw materials and an organic solvent as a reaction medium and by a wet chemical process. The method is characterized in that the chemical reaction between the starting raw materials is directly promoted by wet-process heating ball milling to form ammonia borane. Subsequently, ball milled pulp is subjected to centrifugal separation and reduced-pressure distillation, the clear liquid is obtained, and thus, high-purity ammonia borane crystal is obtained. The centrifugally separated and ball milled solid is subjected to multiple times of solvent extraction to achieve high yield.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

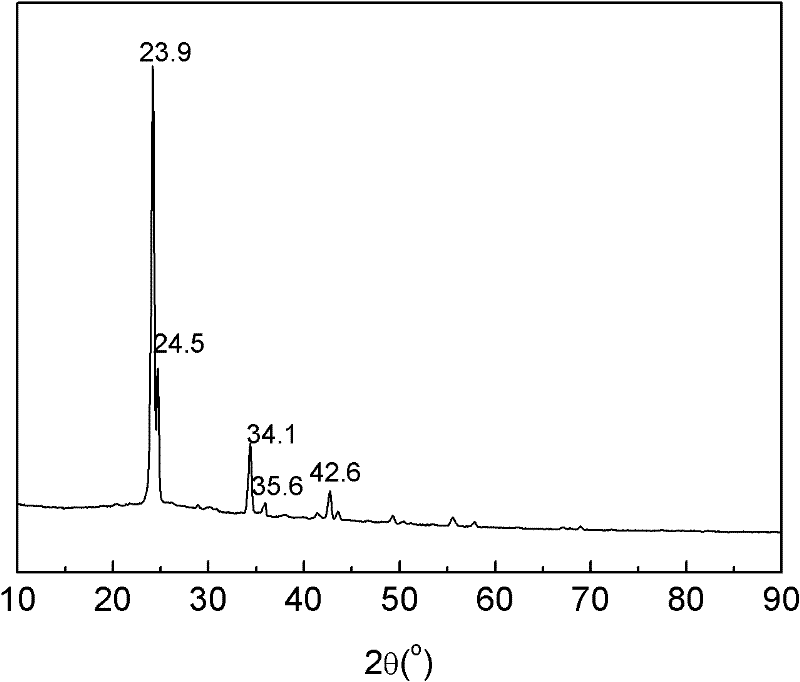

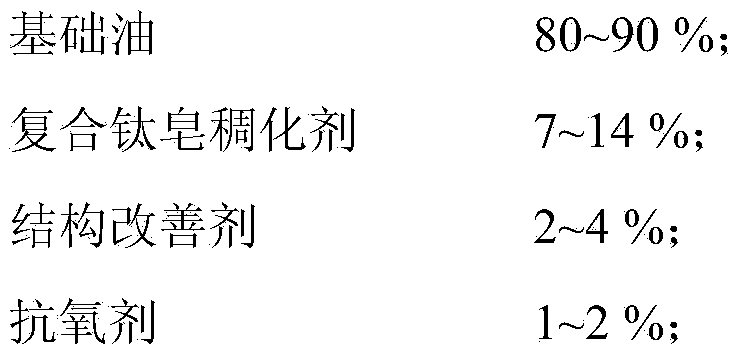

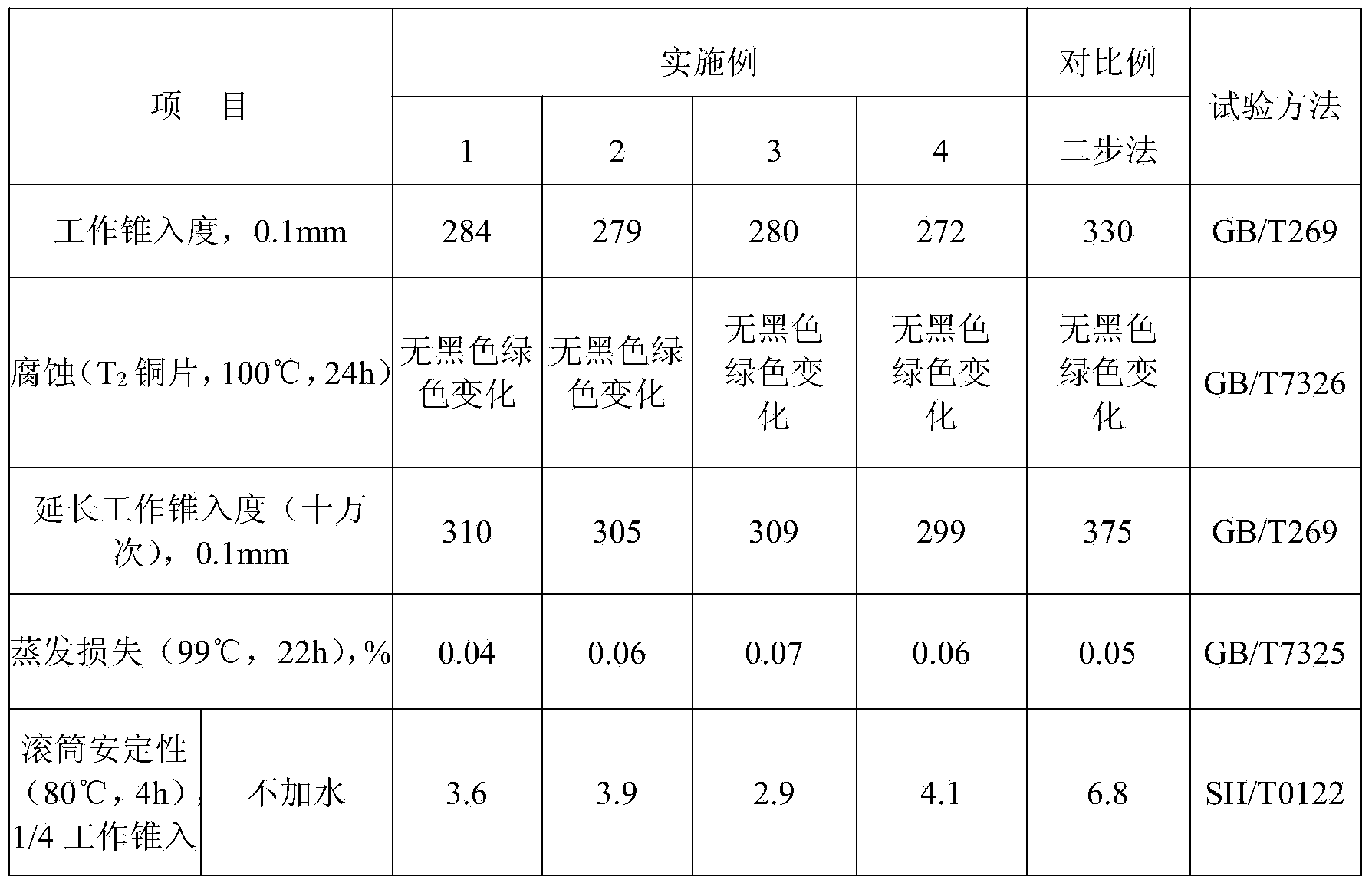

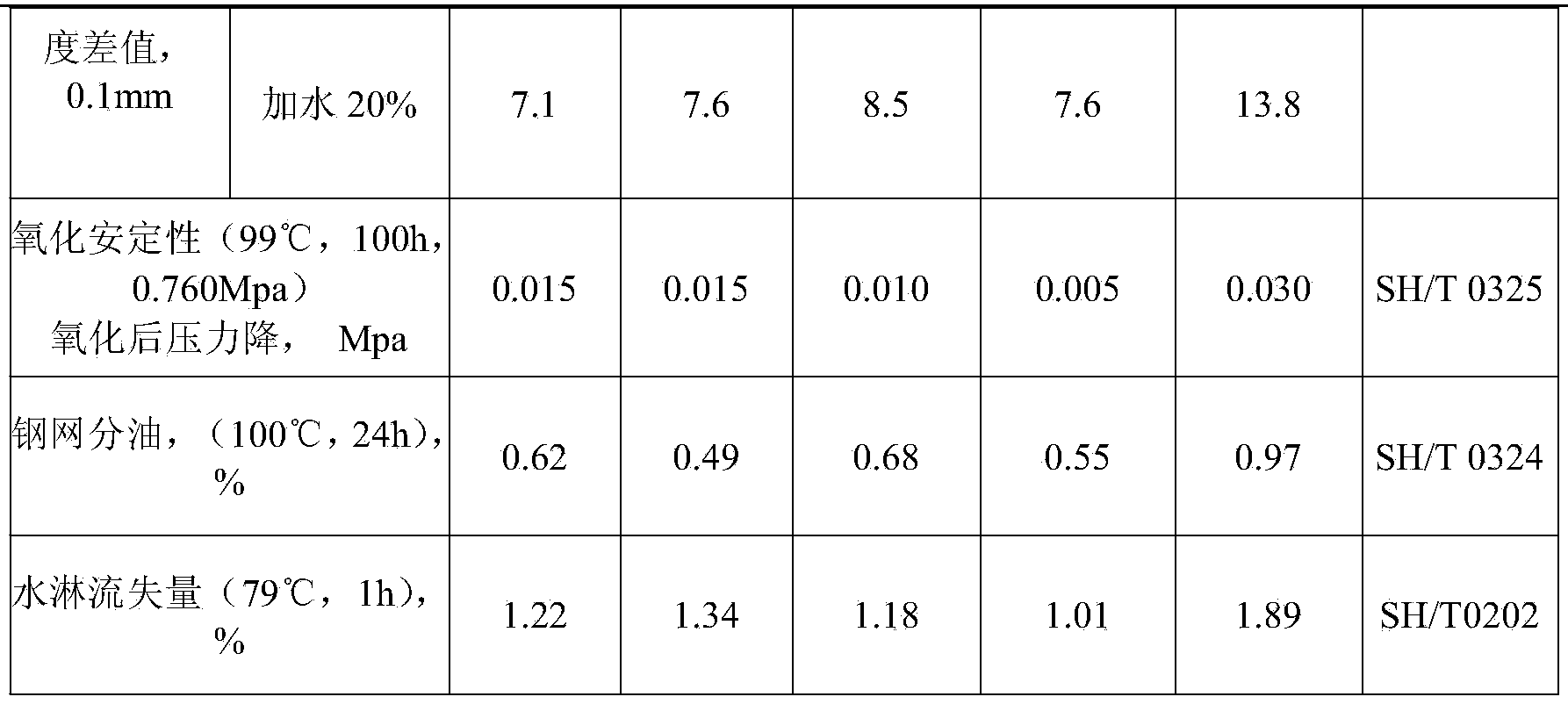

Compound titanium-based lubricant and preparation method thereof

ActiveCN104342243AStrong thickening abilityGood reproducibilityLubricant compositionAntioxidantMechanical stability

The invention relates to a compound titanium-based lubricant and a preparation method thereof. The compound titanium-based lubricant comprises the following formula components in percentage by mass: 80-90% of base oil, 7-14% of compound titanium soap thickening agent, 2-4% of structure modifier, and 1-2% of antioxidant. According to the preparation method, and through the introduction of a solvent and the base oil, the reaction interface can be increased, the reaction speed and reaction degree can be improved, the preparation time can be greatly shortened, the thickening capability of a compound titanium soap can be improved, the production cost can be lowered, the one-step reaction system is simple to operate, the reproducibility is high, and the quality stability of products is good. The compound titanium-based lubricant is good excellent mechanical stability and oxidization stability, and especially good in water resistance property.

Owner:苏州山河星程材料科技有限公司

Mesoporous phosphate anode material with olivine structure and preparation method and use thereof

InactiveCN102034958AMass energy density effectImprove electrochemical performanceElectrode manufacturing processesFinal product manufactureOrganic solventPhosphate

The invention provides a mesoporous phosphate anode material with an olivine structure and a preparation method and use thereof. The anode material is carbon-encapsulated primary particles with nano mesoporous channels, wherein the average pore size of the mesopores is 2 to 50nm; and the anode material also has good carbon encapsulation and small particle size. The preparation method comprises the following steps of: selecting a carbon source for carbon encapsulation; adding raw materials into an organic solvent according to a chemical molar ratio and performing ball milling by using a ball-milling medium with the particle size of 1 to 10mm; and presintering and sintering at high temperature to obtain the mesoporous phosphate anode material with the olivine structure; and the preparation method has the advantages that: the method has fewer steps and is convenient to operate and low in raw material cost. The anode material can be directly used as an anode material of a secondary lithium battery or serves as an additive to be mixed with the conventional anode material.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

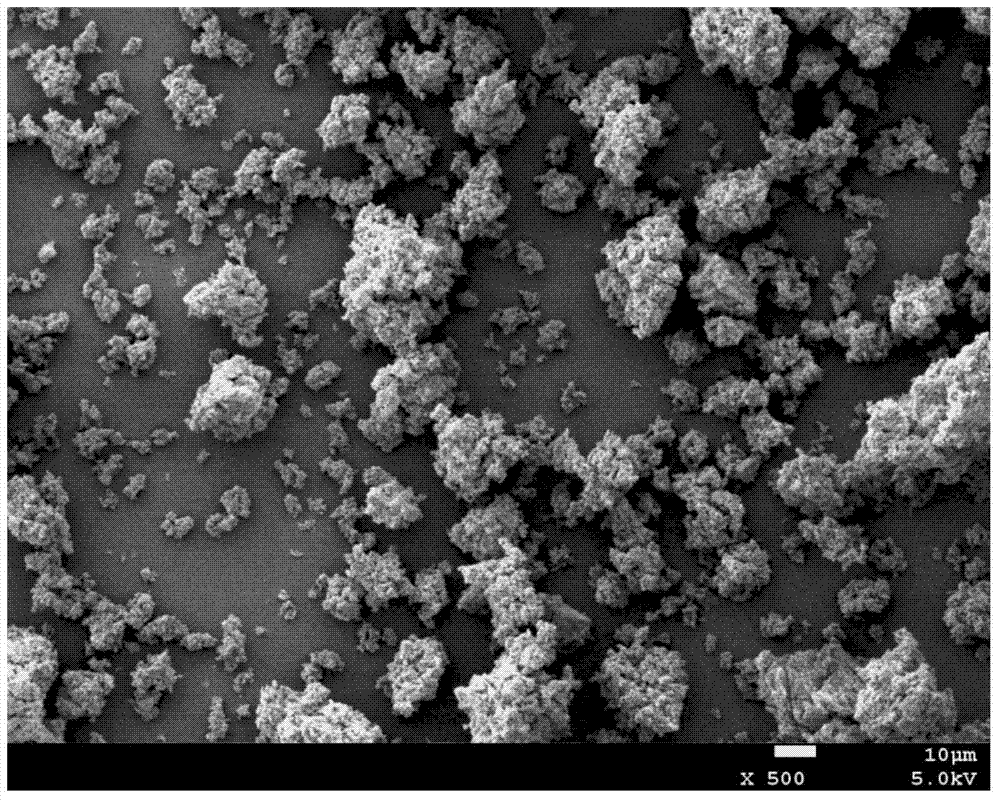

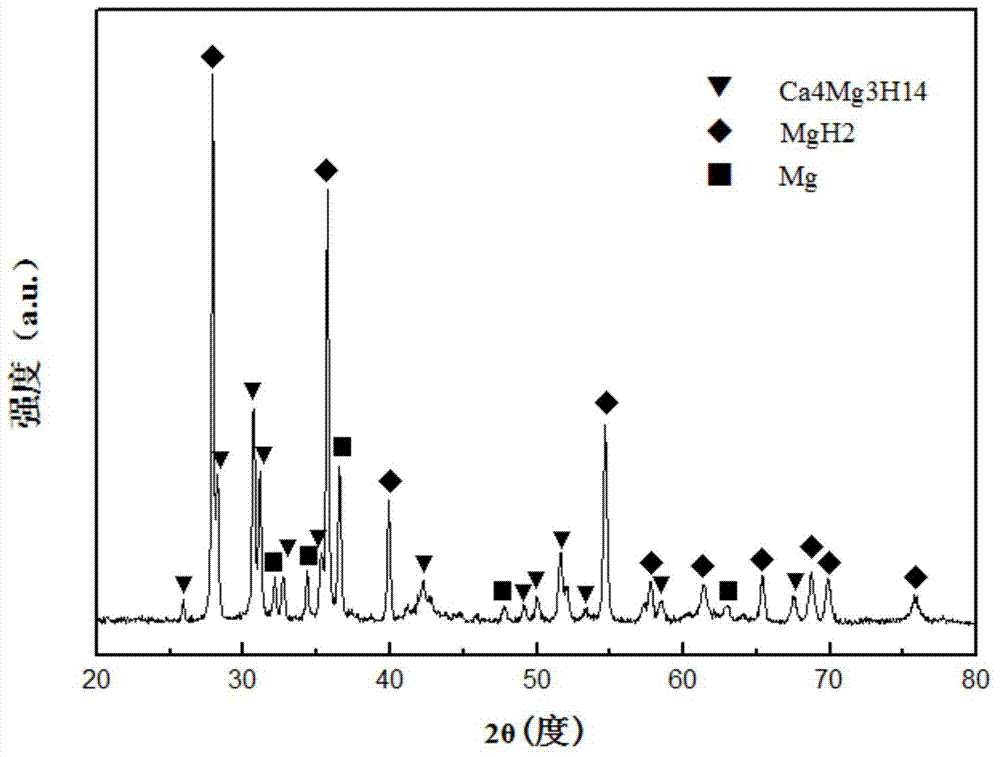

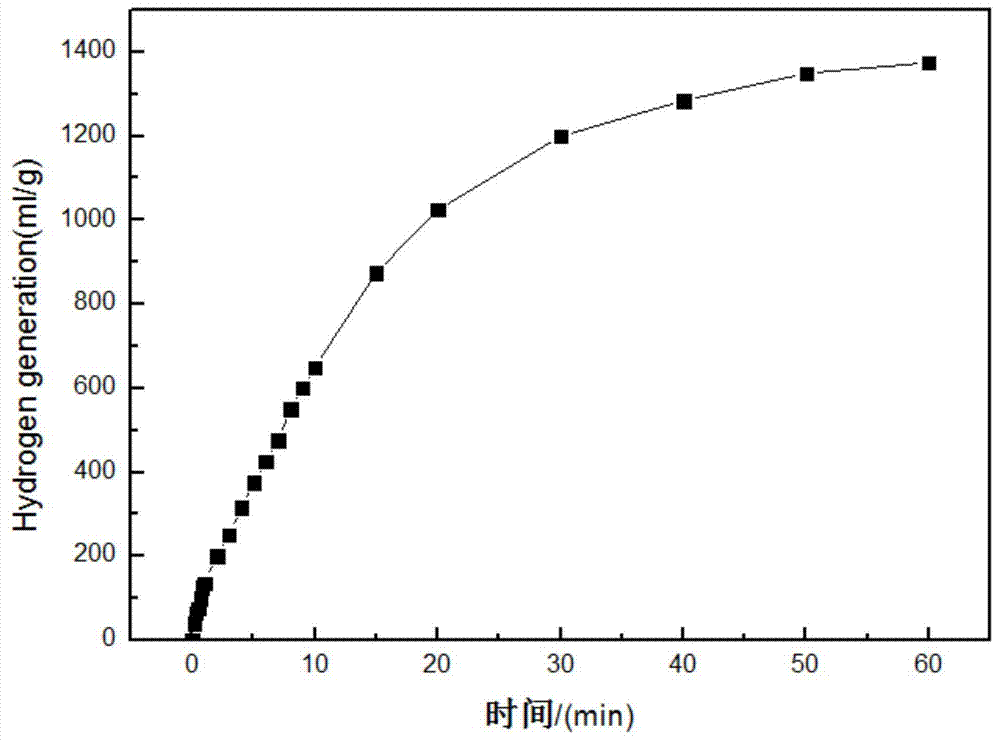

Magnesium-calcium-based hydride powder for wide-temperature zone hydrolysis hydrogen generation and preparation method for magnesium-calcium-based hydride powder

ActiveCN103787273AAvoid formingQuick releaseAlkali/alkaline-earth/beryllium/magnesium hydridesHydrogen productionGeneration rateRoom temperature

The invention discloses magnesium-calcium-based hydride powder for hydrolysis hydrogen generation. The magnesium-calcium-based hydride powder comprises the following components in percentage by mass: 14.2 to 50.2 percent of Ca4Mg3H14, 34.8 to 85.7 percent of MgH2 and 0.1 to 15 percent of Mg. In order to increase the hydrolysis hydrogen generation rate, other hydrides and / or salts can also be compounded, and the mass content of the other hydrides is 0 to 5 percent based on the total mass of the components Ca4Mg3H14, MgH2 and Mg; the mass content of the salts is 0 to 11 percent based on the total mass of the components Ca4Mg3H14, MgH2 and Mg; the content of the other hydrides and the content of the salts is not 0 simultaneously. According to the preparation method for the magnesium-calcium-based hydride powder, a magnesium-calcium alloy is activated for hydrogen absorption after being crushed and ball-milled. According to the magnesium-calcium-based hydride powder for the hydrolysis hydrogen generation, the hydrogen yield can be increased on the premise of ensuring the reaction safety and controllability, and particularly the hydrogen yield at room temperature and low temperature is increased.

Owner:SICHUAN UNIV

Pretreatment of material for smelting ferrosilicon

InactiveCN101020961AUniform compositionLarge reaction interfaceProcess efficiency improvementManufacturing cost reductionChemical reaction

The pre-treatment of material for smelting ferrosilicon includes: mixing the materials silica or quartz, coke and iron filings; and the subsequent mechanical cold pressurizing to form pellet. The material for smelting ferrosilicon has homogeneous components, increased reaction interface, high chemical reaction speed, raised product yield, raised air permeability, low power consumption, environment friendship and lowered ferrosilicon producing cost.

Owner:李垠平 +1

Method for preparing boron powder by combustion synthesis

InactiveCN1508070ASmall granularityHigh reactivityBoron/boridesElectrical resistance and conductanceCombustion

The method for preparing boron powder by using combustion synthesis process includes the following steps: mixing boron oxide and magnesium powder according to the ratio of 1-2.5:1 (weight), under the protection of argon gas grinding them for 3-30 hr. by using high-energy mill, making the said material into blank or directly using powder material and placing it into combustion synthesis reactor, using detonating process or using resistance wire to make initiation and implement combustion synthesis reaction, after the reaction is completed, using acid to wash and remove magnesium oxide so as to obtain the boron powder whose purity can be up to 90-97%.

Owner:丹东市化工研究所有限责任公司

Method for removing ceramic mold core of hollow blade of aeroengine

A method for removing a ceramic mold core of a hollow blade of an aeroengine comprises the three steps of primary core-removing, secondary core-removing and acid liquid neutralizing and cleaning, wherein the concentration of KOH alkaline liquid used for core-removing is 30%-40%, the temperature of the alkaline liquid for core-removing of each time is 150 DEG C, the core-removing pressure is 0.2-0.7 MPa, and the core-removing time of each time is 20 h. According to the method, the method that the concentration of the alkaline liquid is decreased, pressurizing and depressurizing are conducted atintervals in the process is adopted, so that the alkaline liquid is boiled and makes full contact with the mold core, thus, the scouring action is achieved, and the full core-removing effect is achieved; and the temperature of the alkaline liquid is increased by increasing the pressure instead of increasing the concentration of the KOH alkaline liquid, therefore, core-removing is facilitated, corrosion to a casting can be relieved, the core-removing time is shortened to two days, and the qualification rate of one-time core-removing reaches 98% or above.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

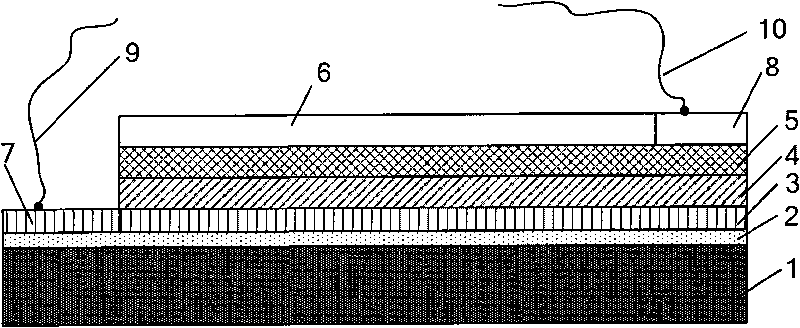

Solid electrolyte SO2 gas sensor and manufacturing method thereof

InactiveCN101726526AEnhanced interface bindingHigh sensitivityTelevision system detailsImpedence networksPhysical chemistryThin membrane

The invention relates to the field of SO2 gas sensors and discloses a solid electrolyte SO2 gas sensor and a manufacturing method thereof. The solid electrolyte SO2 gas sensor comprises a silicon substrate, and a SiO2 insulated layer, a conductive film, a Sn / SnF2 thin film, a LaF3 solid electrolyte thin film and a Pt net which are arranged on the silicon substrate in sequence. The conductive film is connected with a first lead; and the Pt net is connected with a second lead. In the technical scheme, the conductive film is an Al film; and the manufacturing method adopts an MEMS (Micro Electromechanical System) technology and has simple process and convenient realization.

Owner:XI AN JIAOTONG UNIV

Low-surface-alkalinity lithium nickel cobalt aluminate positive electrode material and preparation method thereof

InactiveCN108417796ALow structural firmnessSmall latticeCell electrodesSecondary cellsPhosphatePyrophosphate

The invention discloses a low-surface-alkalinity lithium nickel cobalt aluminate positive electrode material and a preparation method thereof. The lithium nickel cobalt aluminate positive electrode material is obtained by performing calcining on metal hydrogen phosphate and a lithium nickel cobalt aluminate positive electrode active material in oxygen flow. By adoption of metal hydrogen phosphatewhich is decomposed into pyrophosphate in calcining, reactant activity is improved, and a reaction with the residual alkali in the lithium nickel cobalt aluminate positive electrode active material ispromoted to generate a Li<3>PO<4> coating layer; compared with phosphate, hydrogen phosphate is lower in structural firmness, lower in lattice energy and easier in reaction, so that the calcining temperature can be obviously lowered; dry method coating of the lithium nickel cobalt aluminate positive electrode active material is converted from high temperature solid phase reaction (700 DEG C) in the prior art into a medium temperature solid phase reaction (400-600 DEG C), so that reaction difficulty is greatly lowered; and in addition, simple process, low cost and high production efficiency are achieved, so that realization of large-scale industrial production can be facilitated.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI +1

Treatment method of machine washable down feather

The invention discloses a treatment method of machine washable down feathers. The treatment method comprises the three steps of: 1) performing surface treatment to the down feathers with a pre-treatment solution containing an aluminum zirconium coupling agent to improve dispersibility of down feather fibers and expand a reaction interface of protein fibers, thereby laying a fundament for a subsequent crosslinking grafting reaction; 2) during crosslinking modification, with glutaraldehyde as a bridge, graft-adsorbing graphene oxide onto the down feather fibers, so that comprehensive performance of the down feather is effectively improved; and 3) performing reinforcement treatment with an after-treatment solution to obtain the down feather fibers being good in dispersibility, being not liable to agglomerate and having excellent toughness and malleability. The method effectively improves the problems of caking, fracture and the like during a machine washing process on conventional down feather products. Compared with the prior art, the treatment method is simple, can improve use convenience of the down feather products and has a huge market value.

Owner:ANHUI WANLING DOWN & FEATHER PROD

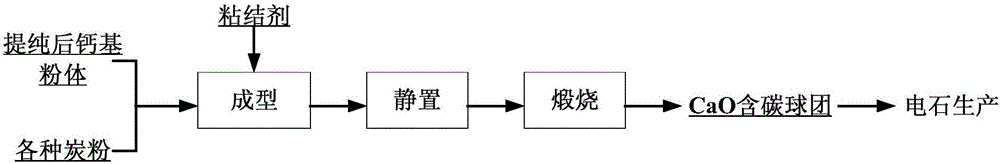

High-thermal-intensity CaO carbon-containing pellets and preparation method and application thereof

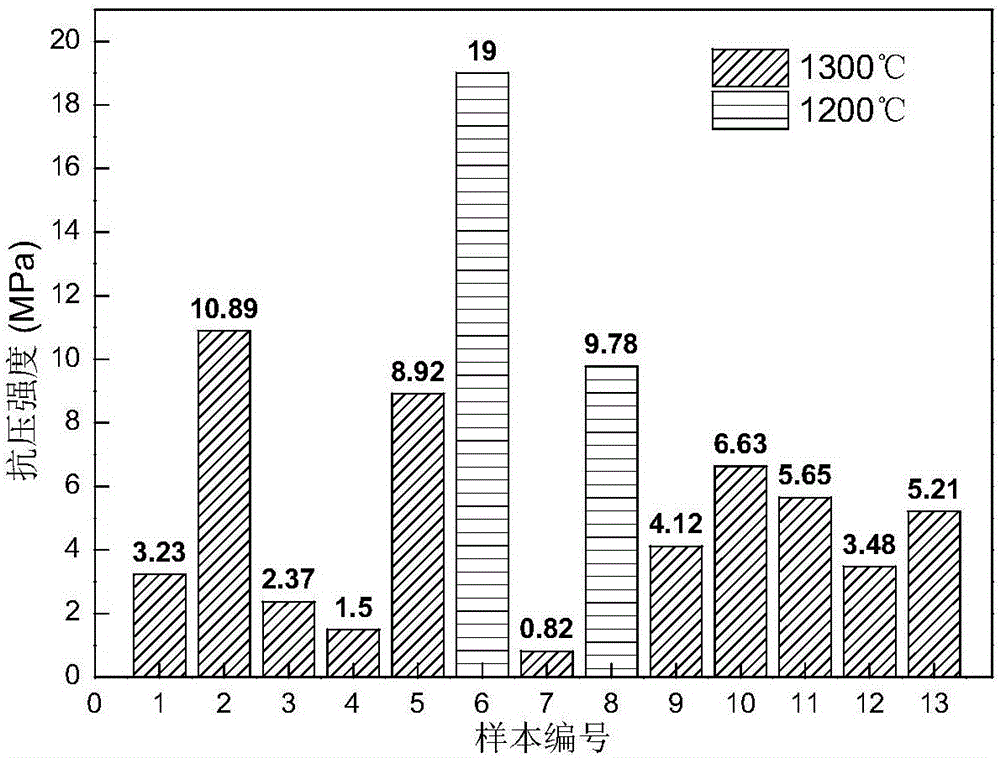

InactiveCN105819447AReduce manufacturing costIncrease cold strengthCalcium carbideCoal chemical industryEnergy consumption

The invention provides a high-heat-strength CaO carbon-containing pellet and its preparation method and application. The preparation method of the CaO carbon-containing pellet is: after mixing calcium-based powder, carbon-containing powder, inorganic binder and water The calcium-based carbon-containing pellets are obtained by cold pressing; the calcium-based carbon-containing pellets are optionally placed for a certain period of time, and then dried and calcined under control to obtain the CaO carbon-containing pellets. The thermal strength of the CaO carbon-containing pellets can reach up to 19Mpa at 1200°C, and can be greater than 10MPa at 1300°C; since the raw material is powder, the temperature for preparing calcium carbide is greatly reduced, and can be at 1800‑2000 ℃ to prepare calcium carbide; it solves the problem of large-scale recycling of solid waste in the coal chemical industry, and at the same time prepares high-performance and high-quality raw materials for calcium carbide production, reducing the energy consumption of calcium carbide production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing hydrocarbon fuel through rapeseed oil residues

InactiveCN105038837APromote cyclization reactionHigh saturationLiquid hydrocarbon mixture productionBio-feedstockMicrowave pyrolysisCycloparaffins

A method for preparing hydrocarbon fuel through rapeseed oil residues includes the following steps that firstly, silicon carbide spherical particles and an HZSM-5 spherical catalyst are weighed according to the mass ration of the silicon carbide spherical particles to the HZSM-5 spherical catalyst being 1:1-10:1, and the silicon carbide spherical particles and the HZSM-5 spherical catalyst are mixed evenly and added into a quartz reaction kettle; secondly, the quartz reaction kettle is placed in a microwave pyrolysis device and heated to 450-600 DEG C, mechanical stirring is conducted at the speed of 60-120 r / min, the rapeseed oil residues are added gradually, generated steam condenses, and the hydrocarbon fuel is obtained. The method is simple in process and quick in pyrolysis, obtained pyrolysis fuel is high in saturation degree, the content of cycloparaffin and aromatic hydrocarbons can reach 75%, the content of oxygen is low, low-temperature flowability is good, the calorific value is high, and stability is high.

Owner:NANCHANG UNIV

Battery anode material and preparation method thereof and lithium battery

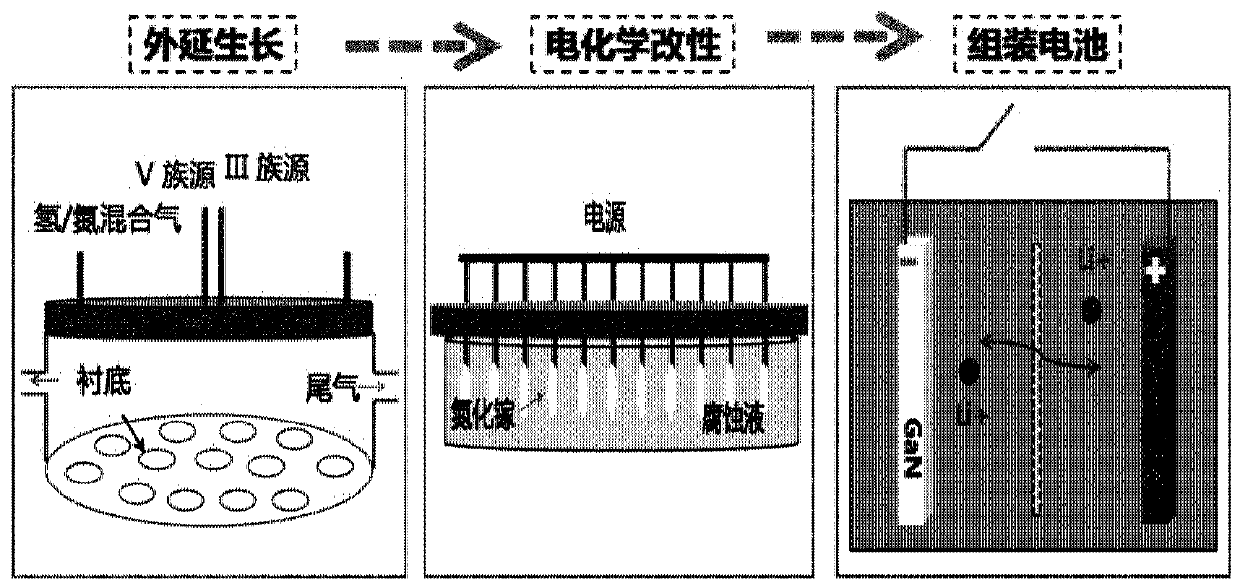

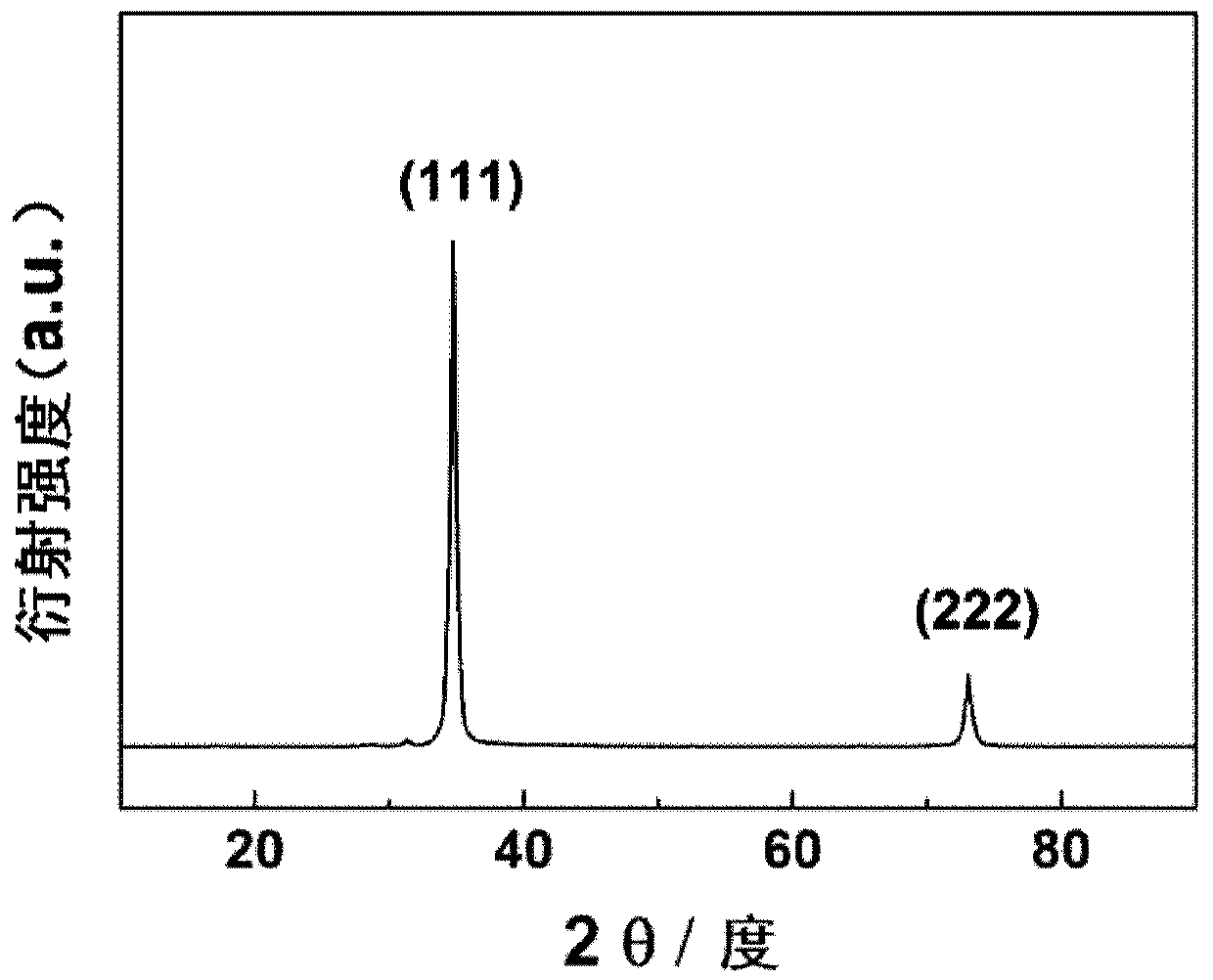

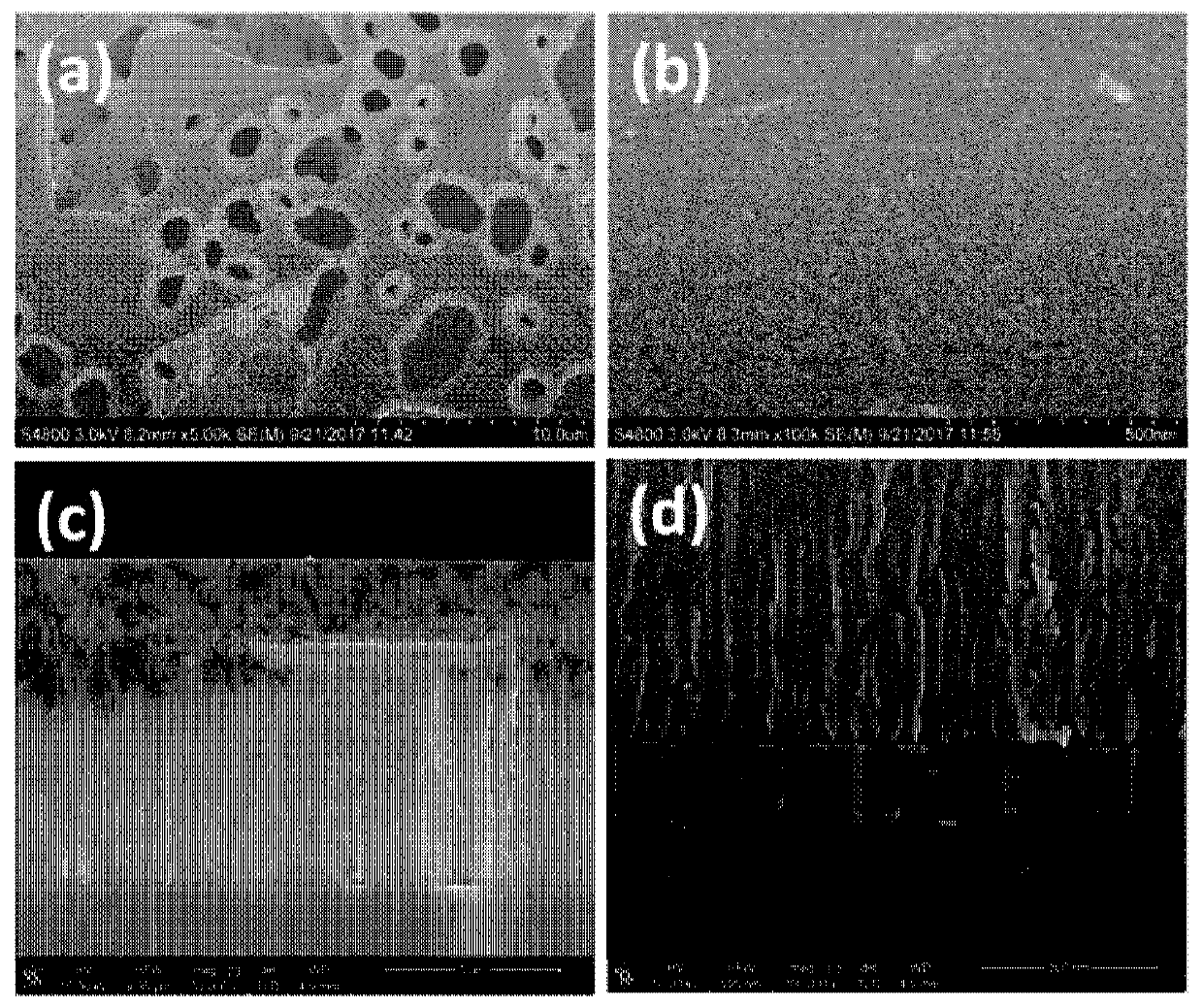

ActiveCN110336028AIncrease capacityGood cycle stabilityCell electrodesSecondary cellsGallium nitrideCyclic stability

The invention provides a battery anode material and a preparation method thereof and a lithium battery. The preparation method of the battery anode material comprises the following steps: epitaxiallygrowing a high-quality gallium nitride thin film on a conductive crystal substrate to obtain an epitaxial structure; and modifying the epitaxial structure through electrochemical corrosion, forming holes in the surface of the high-quality gallium nitride thin film and making the holes run through the epitaxial structure and forming a crystal gallium nitride material serving as the battery anode material. The crystal gallium nitride material is first used as the battery anode material and is directly used as an electrode in the lithium battery; the preparation method overcomes the technical challenge that the preparation technique of the crystal gallium nitride material is not compatible with the traditional electrode technique; and through adoption of the high-conductivity homogeneous substrate, epitaxial growth of the gallium nitride materials with different properties and structures and modification of the material through the electrochemical corrosion process, the high-quality gallium nitride electrode material is obtained, wherein the material has good cycle stability and high capacity, and has a good application prospect.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

System device for adding rare earth into continuous casting tundish and adding method

InactiveCN101811180AImprove dynamic conditionsHigh degree of homogenizationRare-earth elementTundish

The invention relates to a system device for adding rare earth into a continuous casting tundish and an adding method, belonging to the field of ferrous metallurgy. In the invention, a powder spraying tube is arranged between a tundish and a powder spraying pot, one end of the powder spraying tube is connected with a powder spraying pot, the other end is arranged at the slit of a slit-type air brick arranged at the lower part of the tundish, and argon is adopted to spray rare earth powder to the slit of the air brick by the powder spraying tube and then enters the tundish. In the invention, high-pressure powder airflow is utilized to intensively stir molten steel, thus shortening alloying time, greatly improving dynamical condition of metallurgy reaction, promoting homogenized degree of rare earth elements in steel, improving yield of alloy, having strong reproducibility and accurate sprayed elements, and controlling the components of smelt steel within a narrow range. The invention also solves the problem of environmental pollution, and has the advantages of saved investment, portable equipment, easy operation and the like.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com