Preparation and application of graphite-carbon black mixed air diffusion cathode

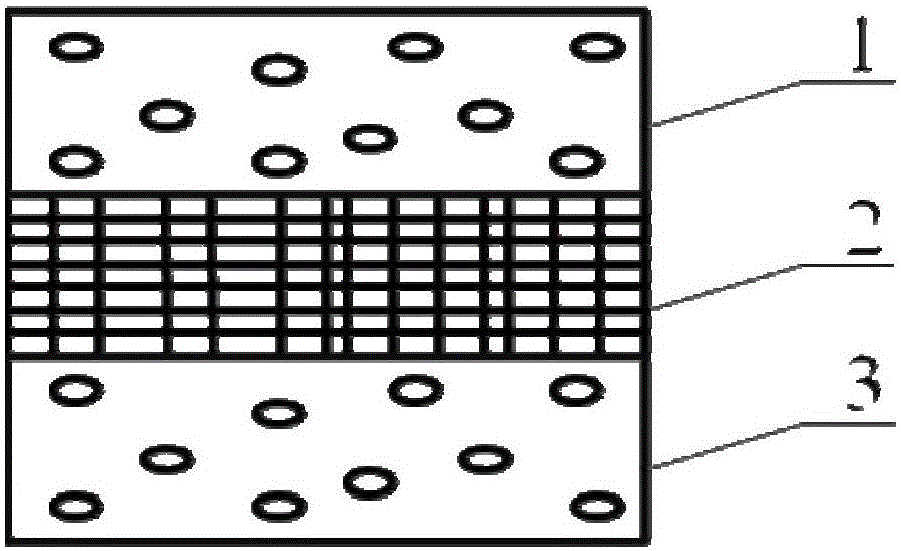

A technology of mixing air and diffusing cathode, applied in electrodes, chemical instruments and methods, electrolysis process, etc., can solve problems such as increasing cost, and achieve the effect of increasing porosity, increasing specific surface area, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

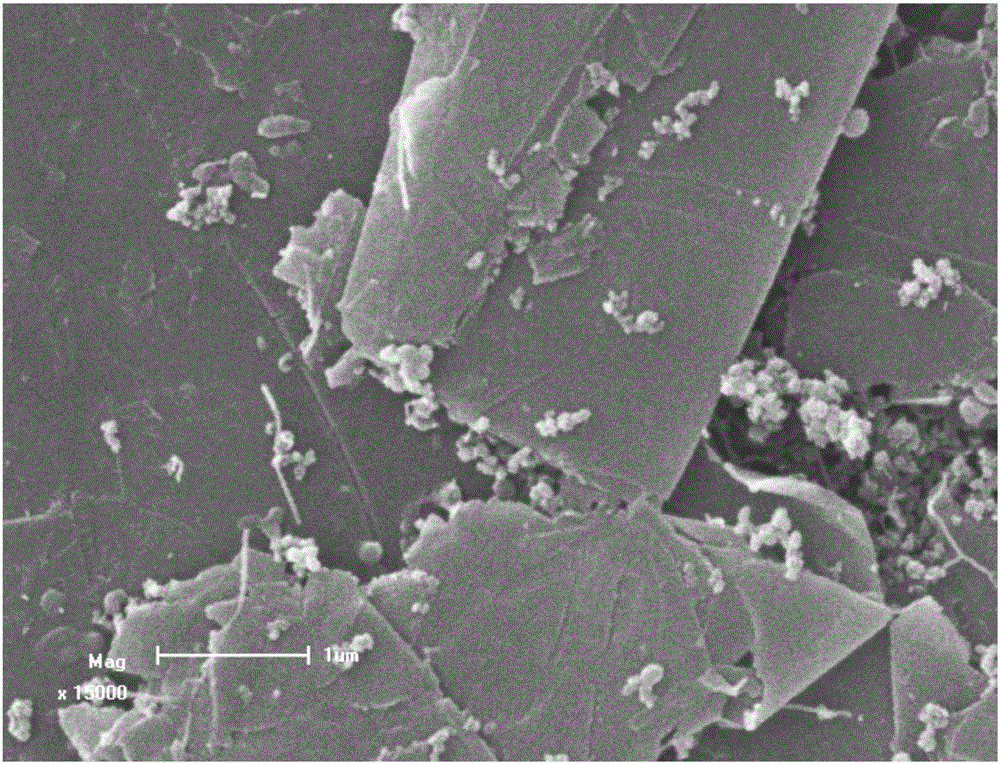

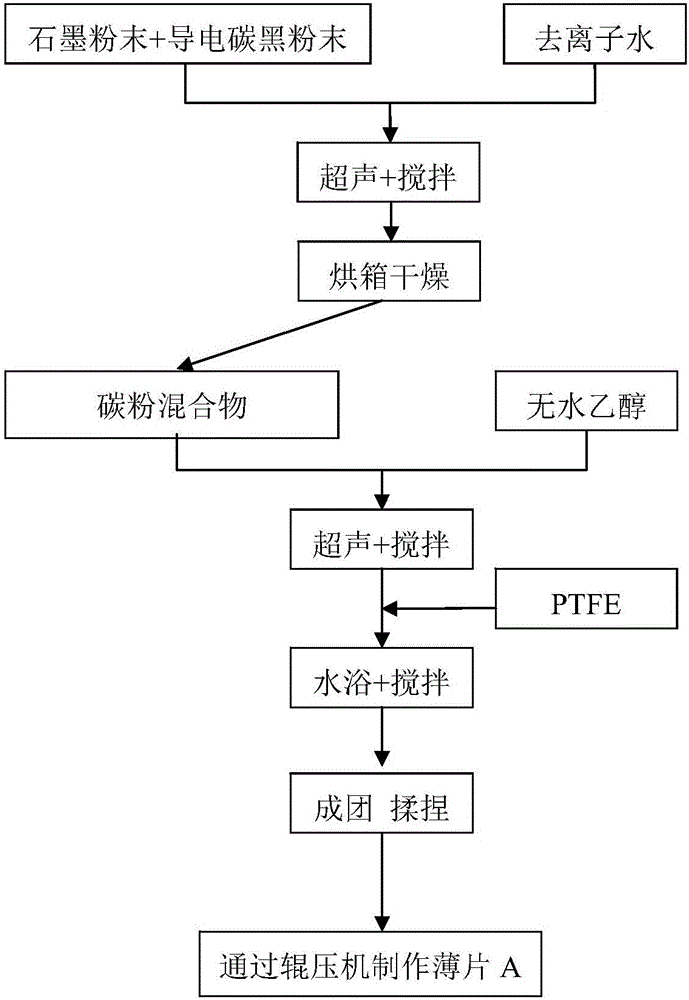

[0030] Embodiment 1: the preparation of a catalyst layer in a kind of graphite-carbon black mixed air diffusion cathode sheet, such as image 3 As shown, take 1.2g model HTF0325, particle size 40μm, powdered graphite with a purity >99.9% and 4.8g model VulcanXC-72R, powdered conductive carbon black with a particle size 30nm to form a carbon powder mixture, and the carbon powder mixture in After ultrasonic cleaning and drying in deionized water, mix with 36 mL of absolute ethanol, and ultrasonically stir for 10 minutes to fully disperse and dissolve the mixed carbon powder in absolute ethanol. During the process of ultrasonic stirring, add 2.5 mL of mass volume The polytetrafluoroethylene emulsion with a concentration of 1.5g / mL was then ultrasonically stirred for 10 minutes to obtain a mixed substance; the above mixed substance was stirred in a water bath at 80°C for 2 hours to make the mixed substance into a micelle-like substance, and the gel was kneaded by hand Let the exce...

Embodiment 2

[0031] Embodiment 2: the preparation of catalytic layer in a kind of graphite-carbon black mixing air diffusion cathode sheet, its step is the same as embodiment 1, and difference only is that the amount of powdery conductive carbon black is 4g, and the amount of powdery graphite is 2g ; The final catalytic layer is denoted as CL3.

Embodiment 3

[0032] Embodiment 3: the preparation of catalytic layer in a kind of graphite-carbon black mixing air diffusion cathode sheet, its step is the same as embodiment 1, and difference only is that the amount of powdery conductive carbon black is 3g, and the amount of powdery graphite is 3g ; The final catalytic layer is denoted as CL4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com