Low-surface-alkalinity lithium nickel cobalt aluminate positive electrode material and preparation method thereof

A technology of nickel cobalt lithium aluminate and cathode material, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve problems such as harsh reaction conditions, achieve easy reaction, improve solid-phase reaction rate, improve reaction activity and Effect of Solid Phase Reaction Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

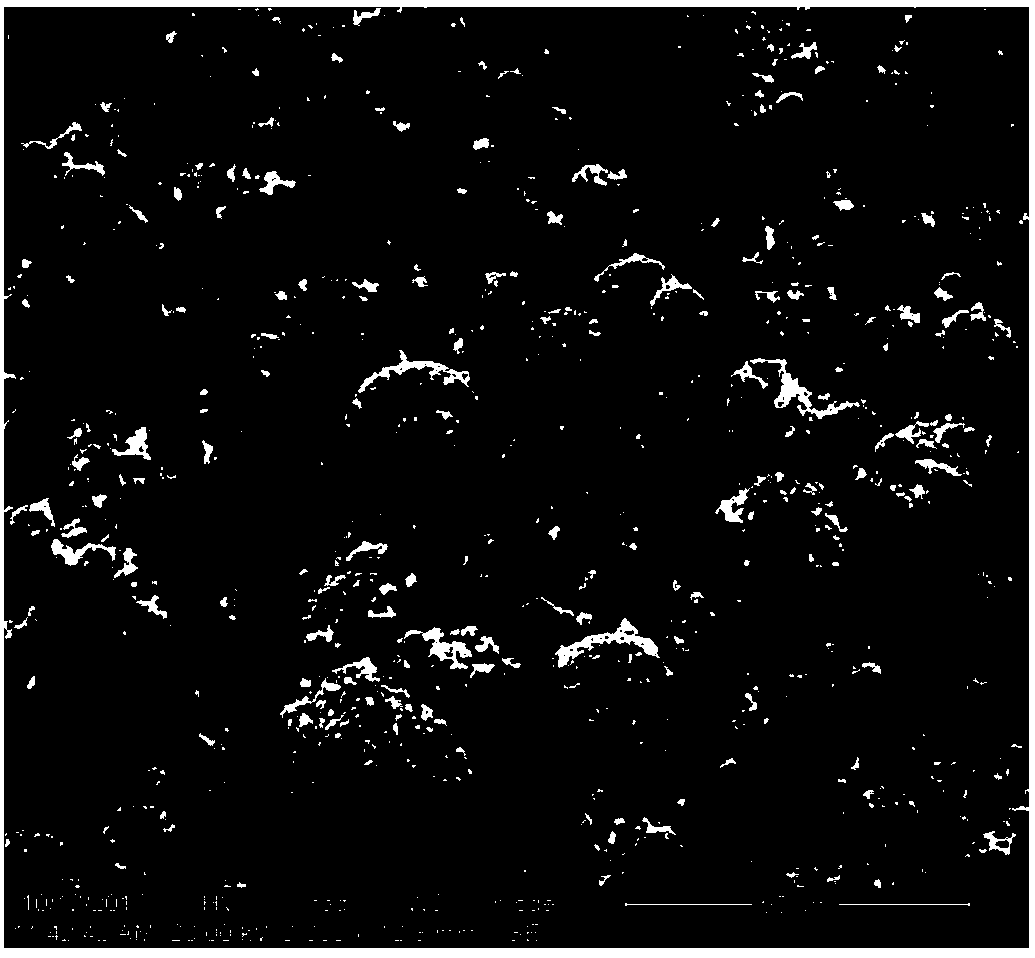

Image

Examples

Embodiment 1

[0028] A kind of preparation method of nickel-cobalt lithium aluminate cathode material with low surface alkalinity: Ni x co y al z (OH) 2 The ternary precursor and LiOH were weighed at a molar ratio of 1:1.05, and after being fully mixed, the mixed powder was transferred to a corundum boat and pushed to the center of the tube furnace for calcination, while oxygen was introduced at a heating rate of 5°C / Min, first heat-preserve and react at 480°C for 4 hours, then heat up to 750°C and sinter for 15 hours to obtain the positive electrode active material of nickel cobalt lithium aluminate; add the obtained positive electrode active material of nickel cobalt lithium aluminate and magnesium hydrogen phosphate at a ratio of 98.5:1.5 In the ball mill tank, set the ball mill speed to 230r / min. After ball milling for 2 hours, heat it to 550°C in an oxygen stream and keep it warm for 5 hours to obtain a low surface alkaline nickel-cobalt-lithium-aluminate positive electrode material...

Embodiment 2

[0030] A kind of preparation method of nickel-cobalt lithium aluminate cathode material with low surface alkalinity: Ni x co y al z (OH) 2 The ternary precursor and LiOH were weighed at a molar ratio of 1:1.05, and after being fully mixed, the mixed powder was transferred to a corundum boat and pushed to the center of the tube furnace for calcination, while oxygen was introduced at a heating rate of 5°C / Min, first heat preservation reaction at 480°C for 5 hours, then heat up to 750°C and sinter for 13 hours to obtain the positive electrode active material of nickel cobalt lithium aluminate; add the obtained positive electrode active material of nickel cobalt lithium aluminate and zirconium hydrogen phosphate at a ratio of 99:1 In the ball mill tank, set the ball mill speed to 200r / min. After ball milling for 3 hours, heat it to 450°C in an oxygen flow and keep it warm for 5 hours to obtain a low surface alkaline nickel-cobalt lithium aluminate cathode material. The pH was m...

Embodiment 3

[0032] A kind of preparation method of nickel-cobalt lithium aluminate cathode material with low surface alkalinity: Ni x co y al z (OH) 2 The ternary precursor and LiOH were weighed at a molar ratio of 1:1.05, and after being fully mixed, the mixed powder was transferred to a corundum boat and pushed to the center of the tube furnace for calcination, while oxygen was introduced at a heating rate of 5°C / Min, first heat-preserve and react at 500°C for 4 hours, then heat up to 750°C and sinter for 14 hours to obtain the positive electrode active material of nickel cobalt lithium aluminate; Add 99:0.5:0.5 into the ball milling tank, set the ball milling speed to 250r / min, after ball milling for 3 hours, heat to 600°C in the oxygen flow, and keep it warm for 5 hours to obtain a low surface alkaline nickel cobalt lithium aluminate cathode material, The pH value measured by the pH test is 11.81, and the first-cycle discharge specific capacity is 187.8mAh g by the electrochemical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com