Patents

Literature

746results about How to "Calcination temperature is low" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

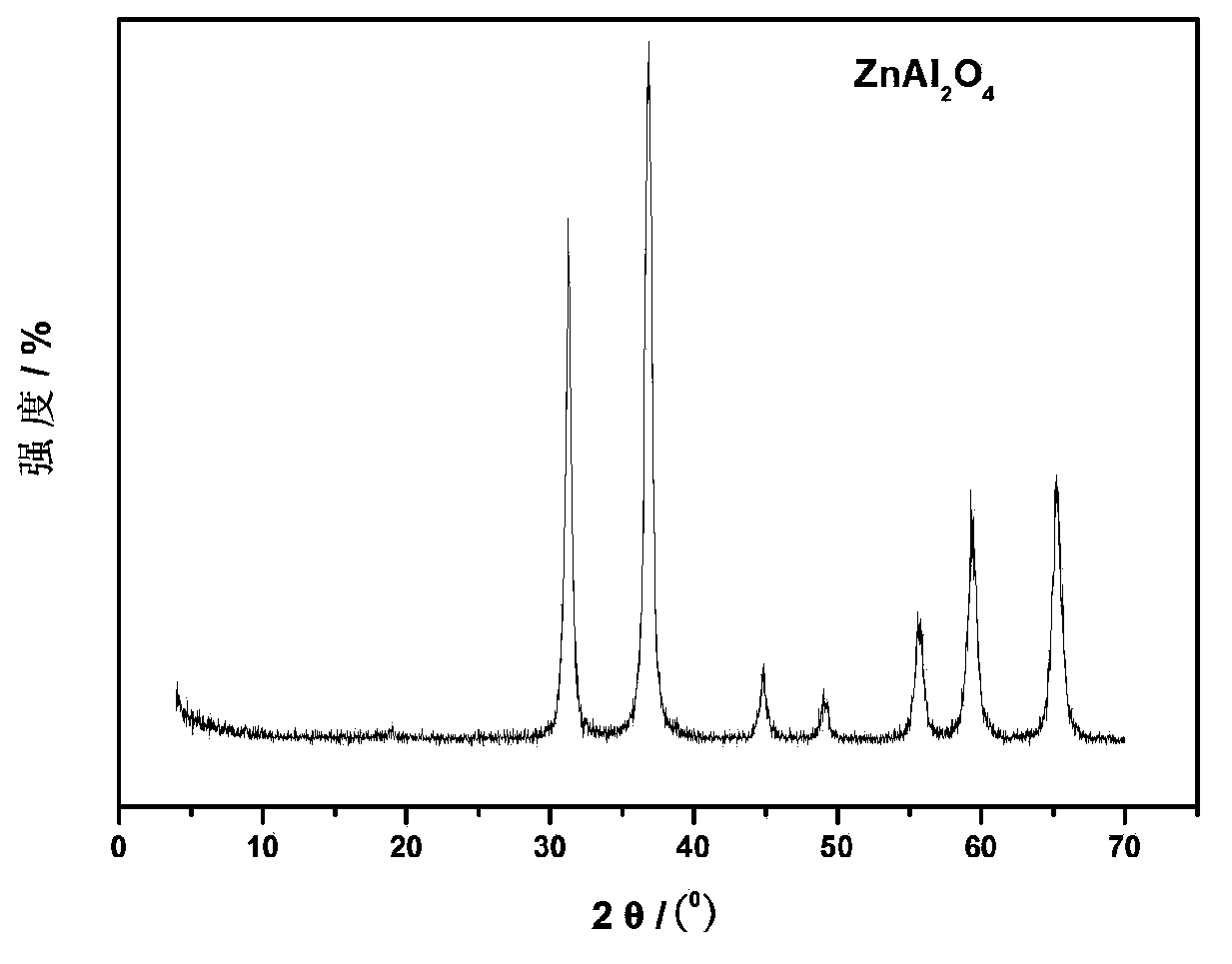

Method for preparing nanometer gahnite

ActiveCN103449503AReduce pollutionGood quality powderZinc oxides/hydroxidesNanotechnologySucroseGlycerol

A method for preparing nanometer gahnite. The preparation method is as below: dissolving zinc salt in water, adding an aluminum source, stirring for 10-30 min, adding a pore-enlarging agent, stirring, ageing at 20-100 DEG C for 30-60 min, drying, and calcining at 500-1200 DEG C. The molar ratio of the raw materials is as below: Zn:Al:water=1:2:16-35; calculated by the weight of zinc oxide being 100%, the addition amount of the pore-enlarging agent is 0.5-30%; and the pore-enlarging agent is one or more selected from sucrose, glycerol, ammonium carbonate, ammonium hydrogen carbonate, polystyrene latex and polyethylene glycol.

Owner:PETROCHINA CO LTD

Method for producing synthetic rutile

InactiveCN101244841AAvoid pollutionReduce manufacturing costTitanium dioxideIlmenitePollution prevention

The invention relates to a production method of artificial rutile, belonging the technical field of chemical engineering, which provides a method of producing high-taste artificial rutiles made of raw ilmenite containing Mg with high Ca contents and has good production continuousness, low energy consumption and less pollution. The production method provided by the invention comprises the following steps: a. ilmenite concentrate is oxidized and roasted at 800-1100 DEG C, and then reduced and roasted at 600-900 DEG C; b. the reduced and roasted ilmenite concentrate is leached by hydrochloric acid with 18-24 percent concentration under normal pressure; c. cleaned and filtered; d. the filter cake is collected and calcined. The production method can used for producing artificial rutile, and has the advantages of low production cost, environmental pollution prevention, low production energy consumption, and easy capacity for continuous production, thereby enjoying wide application prospect.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

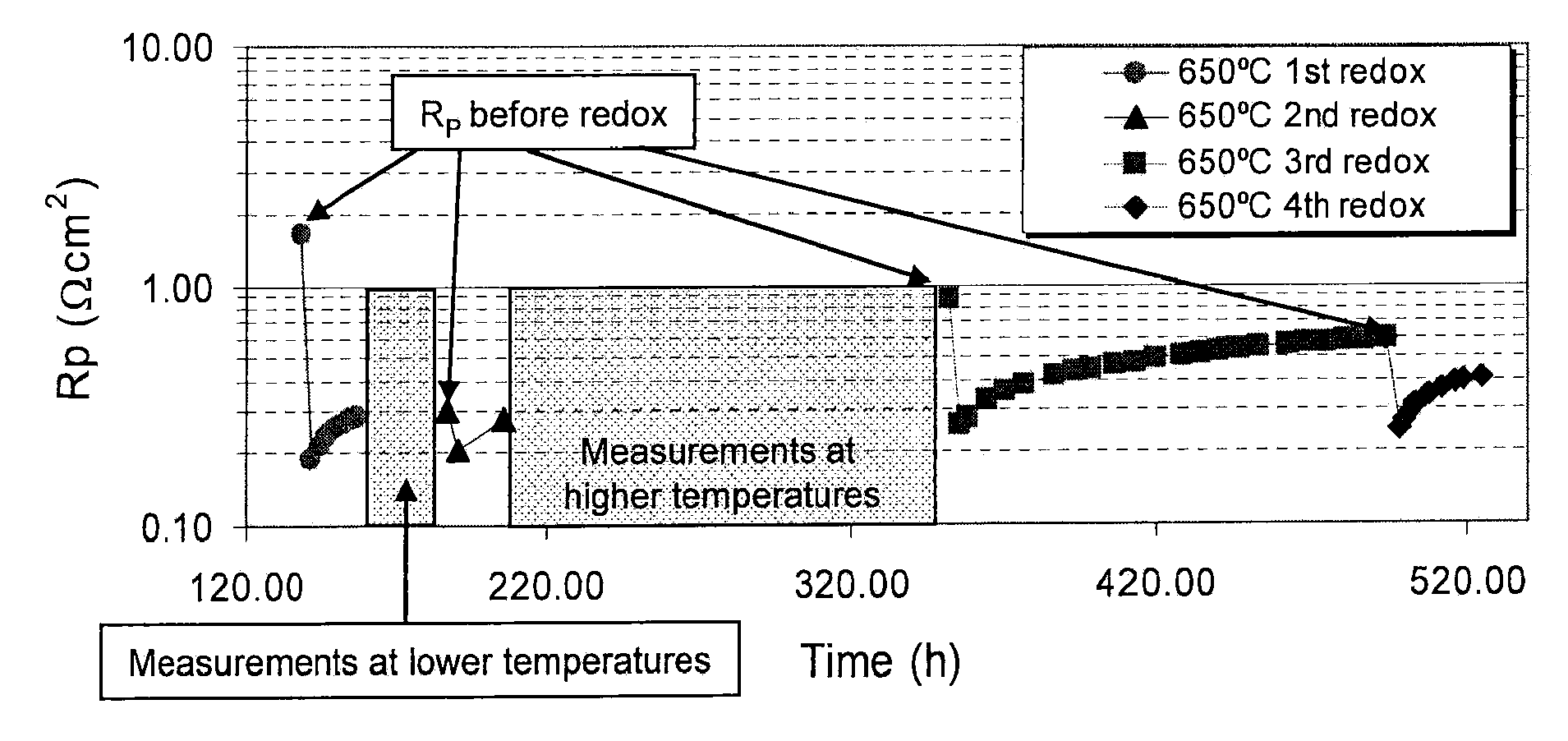

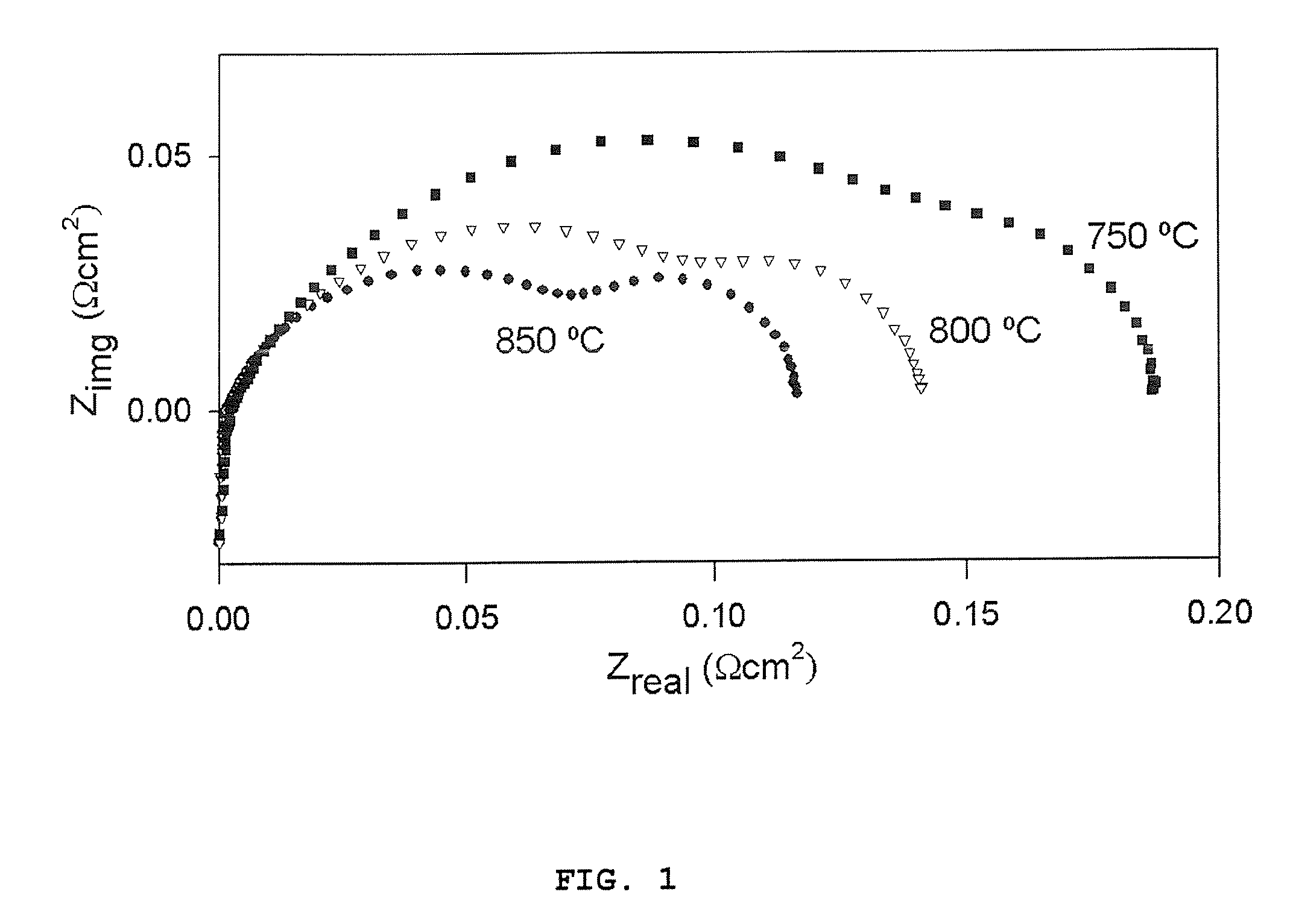

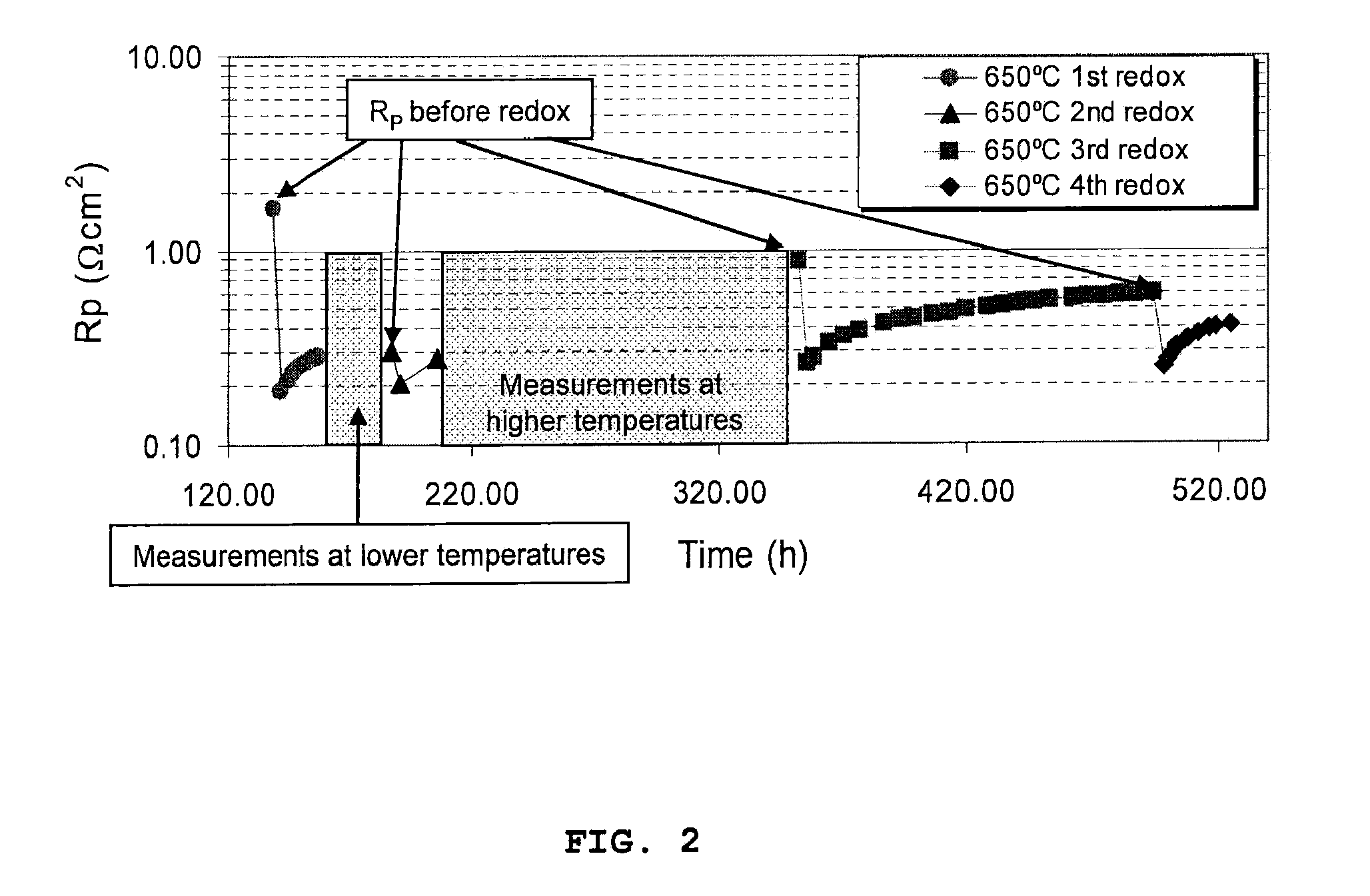

Ceria and strontium titanate based electrodes

InactiveUS20090061284A1High BET surface areaSpeed up calcination procedureFuel cells groupingCell electrodesStrontium titanateVanadium doping

A ceramic anode structure obtainable by a process comprising the steps of: (a) providing a slurry by dispersing a powder of an electronically conductive phase and by adding a binder to the dispersion, in which said powder is selected from the group consisting of niobium-doped strontium titanate, vanadium-doped strontium titanate, tantalum-doped strontium titanate, and mixtures thereof, (b) sintering the slurry of step (a), (c) providing a precursor solution of ceria, said solution containing a solvent and a surfactant, (d) impregnating the resulting sintered structure of step (b) with the precursor solution of step (c), (e) subjecting the resulting structure of step (d) to calcination, and (f) conducting steps (d)-(e) at least once.

Owner:DANMARKS TEKNISKE UNIV

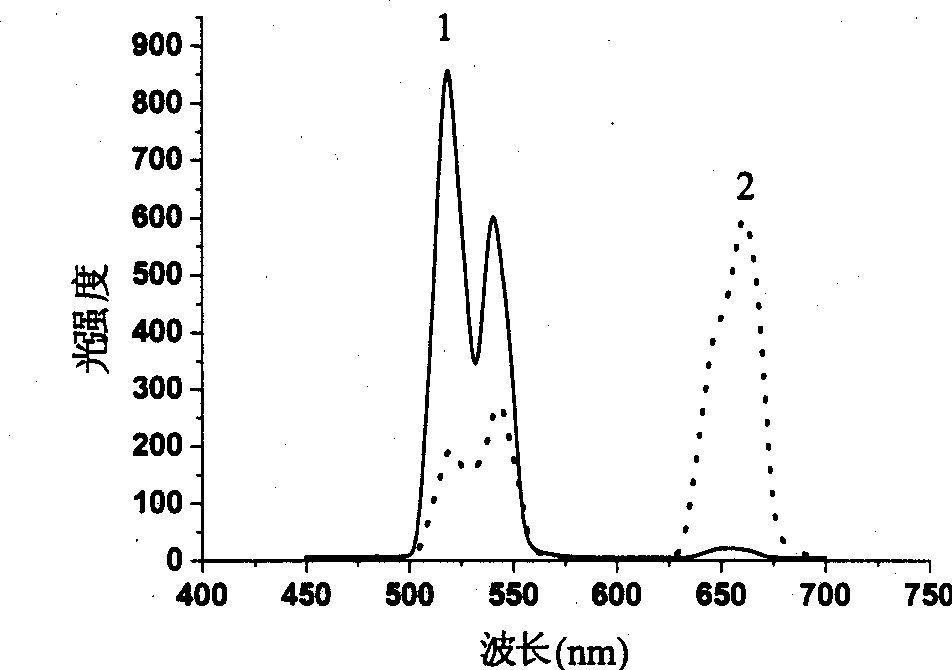

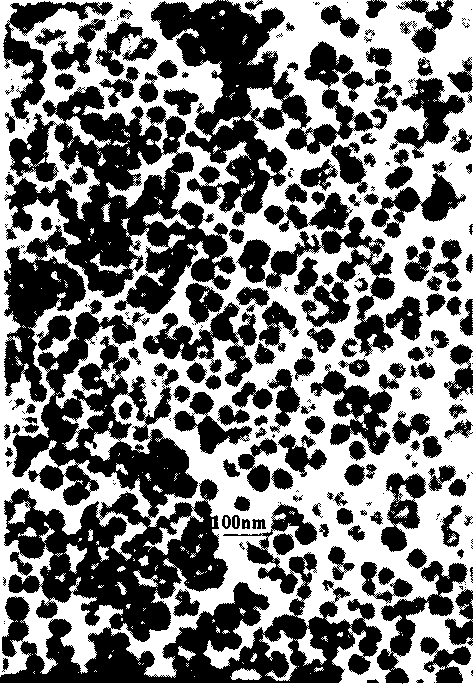

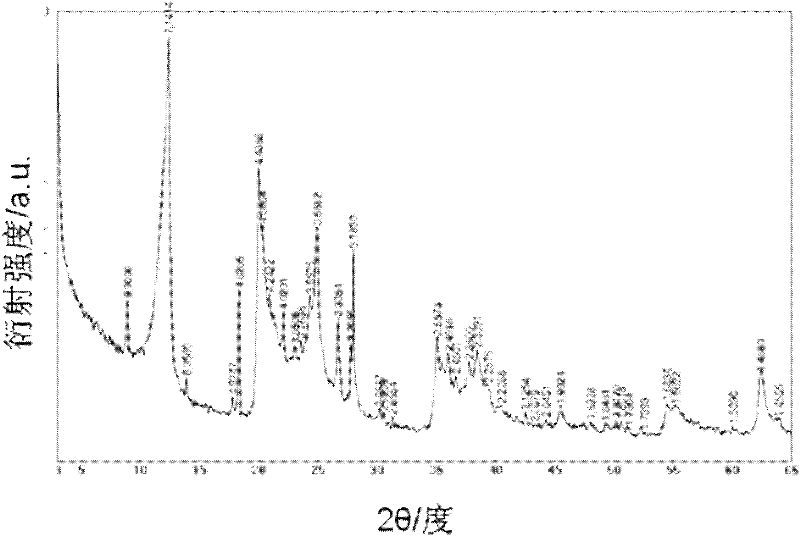

Up converting fluorescent material with nanometer level molybdate substrate and its prepn

The present invention belongs to the field of nano fluorescent material. Lanthanum oxide (or yttrium or gadolinium oxide), ytterbium oxide and erbiom oxide (or thulium or holmium oxide) are first dissolved in acid to prepare solution; complexone and sodium or potassium molybdenate are added into the solution to produce precipitate, which is centrifugally separated and water washed to prepare aqueous gel, aqueous gel or further prepared alcoholic gel is finally cinerated in a high temperature furnace or heated in a hydrothermal reactor to obtain the nano level up converting fluorescent material. The said material has lanthanum molybdenate as matrix and ytterbium molybdenate and erbium molybdenate as dopant. The material thus prepared has small and homogeneous size, average size 50-60 nm and high light glowing strength and may meet the requirement as biological molecular fluorescent mark material.

Owner:CAPITALBIO CORP +1

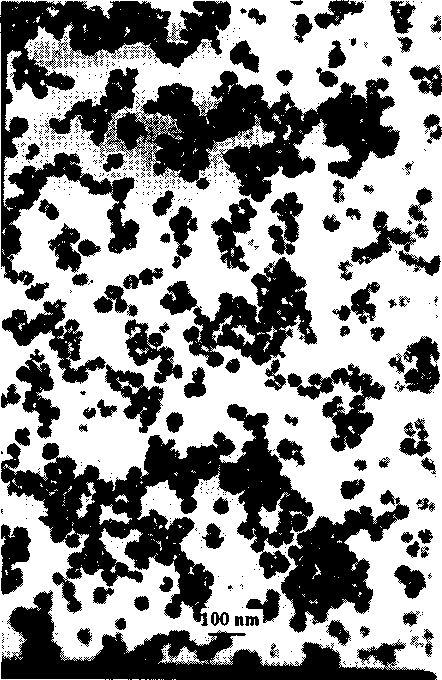

Nano-class conversion fluorescence material on fluoride matrix and its preparing process

InactiveCN1376759ASmall and uniform particle sizeThe particle size can be adjusted at willNanotechLuminescent compositionsYtterbium fluorideGadolinium oxide

A nano-class conversion fluorescent material used for biomolecular fluorescent marker is prepared through dissolving yttrium (or lanthanum or gadolinium) oxide in acid to obtain solution A, adding aminocarboxylic comple, adding it to the solution of fluoride, centrifugal treating, drying to obtain precursor, and high-temp calcining. Its advantages are 37-166 nm of granularity, low calcining temp and strong fluorescence.

Owner:CAPITALBIO CORP +1

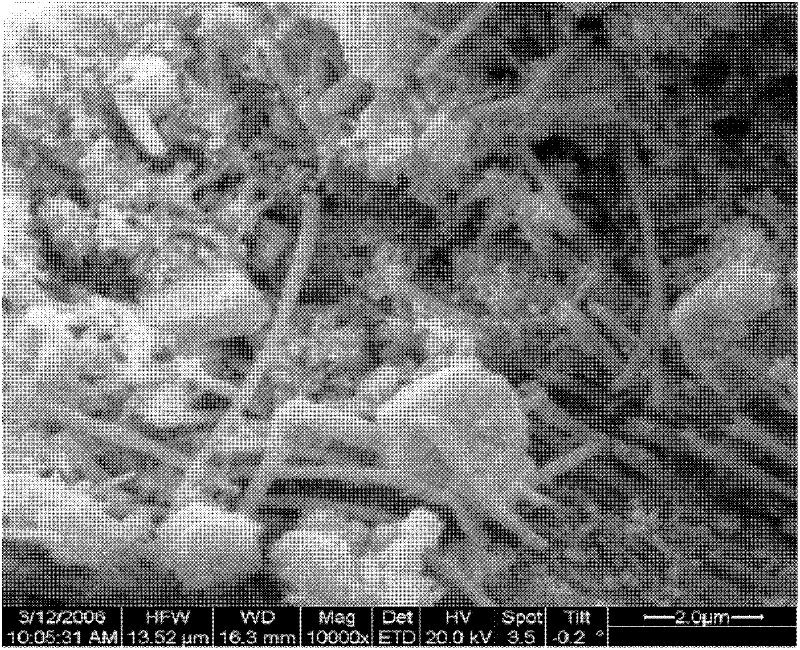

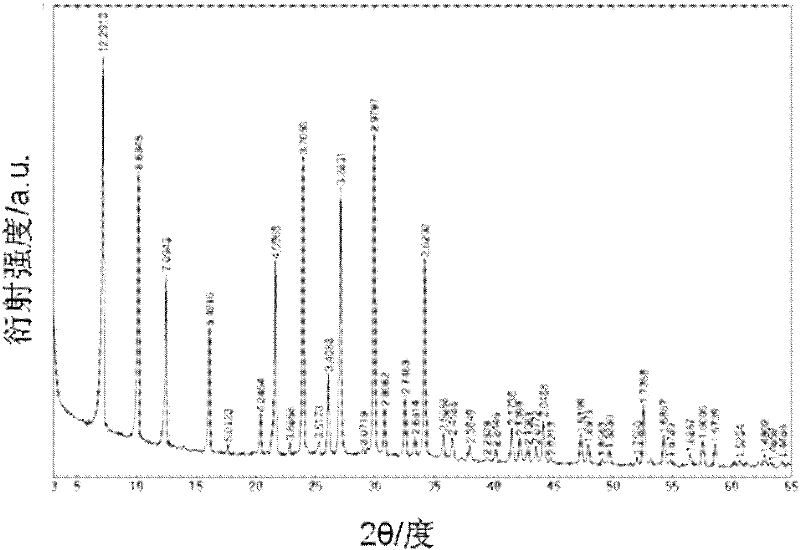

Method for preparing 3A type zeolite molecular sieve

InactiveCN102351213ACalcination temperature is lowReduce pollutionAluminosilicate zeolite type-AMolecular sieveIon exchange

Belonging to the field of molecular sieve synthesis, the invention relates to a method for preparing a 3A type zeolite molecular sieve. The preparation method of a 3A type zeolite molecular sieve is characterized by comprising the steps of: 1) calcination of kaolin, thus obtaining metakaolin; 2) preparation of a 4A molecular sieve: mixing metakaolin and a NaOH aqueous solution uniformly, thus obtaining a mixture; filtering the mixture, washing the filter cake with distilled water, and conducting filtration again, drying the filter cake from second filtration at a temperature of 90-100DEG C for 2-4h, thus obtaining the 4A molecular sieve; 3) preparation of a 3A type zeolite molecular sieve: reacting the 4A molecular sieve with a KCl solution in a reaction vessel for 3-5h at a temperature of 70-90DEG C, then conducting cooling, washing, and filtering, drying the obtained filter cake at a temperature of 90-100DEG C for 2-4h, thus obtaining the 3A type zeolite molecular sieve. The method of the invention has simple process and low calcination temperature, and the prepared 3A type zeolite molecular sieve has great calcium ion exchange capacity and good performances.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

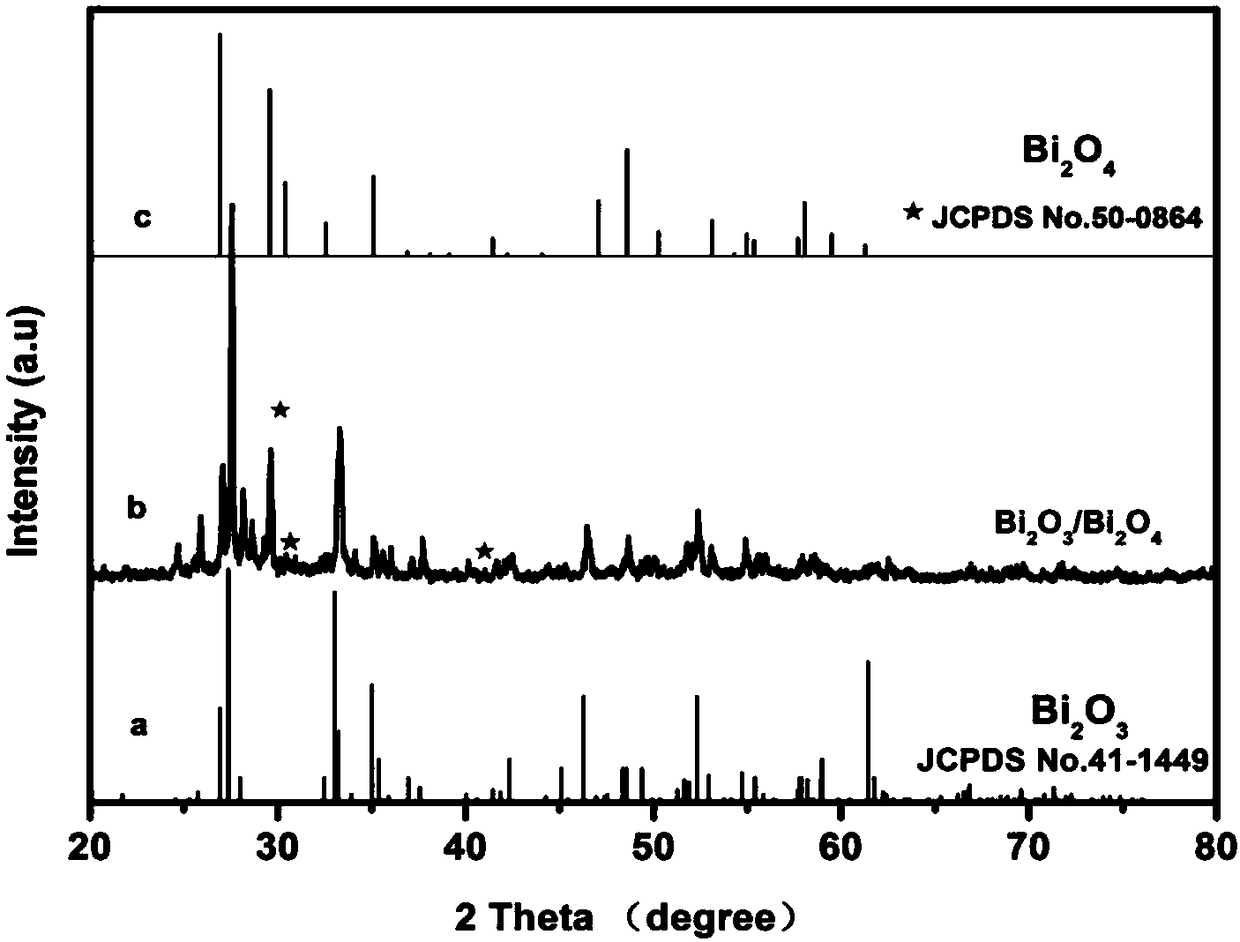

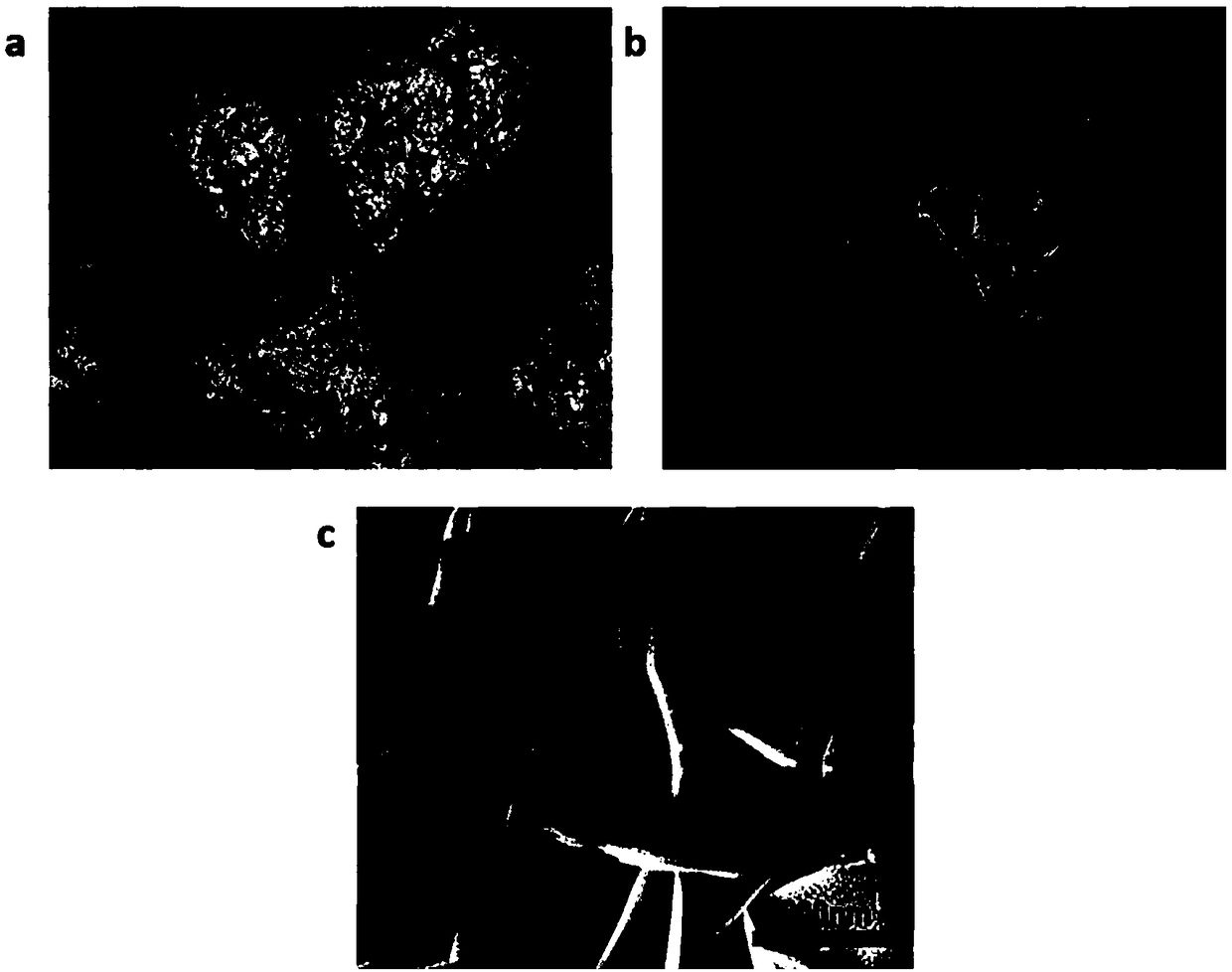

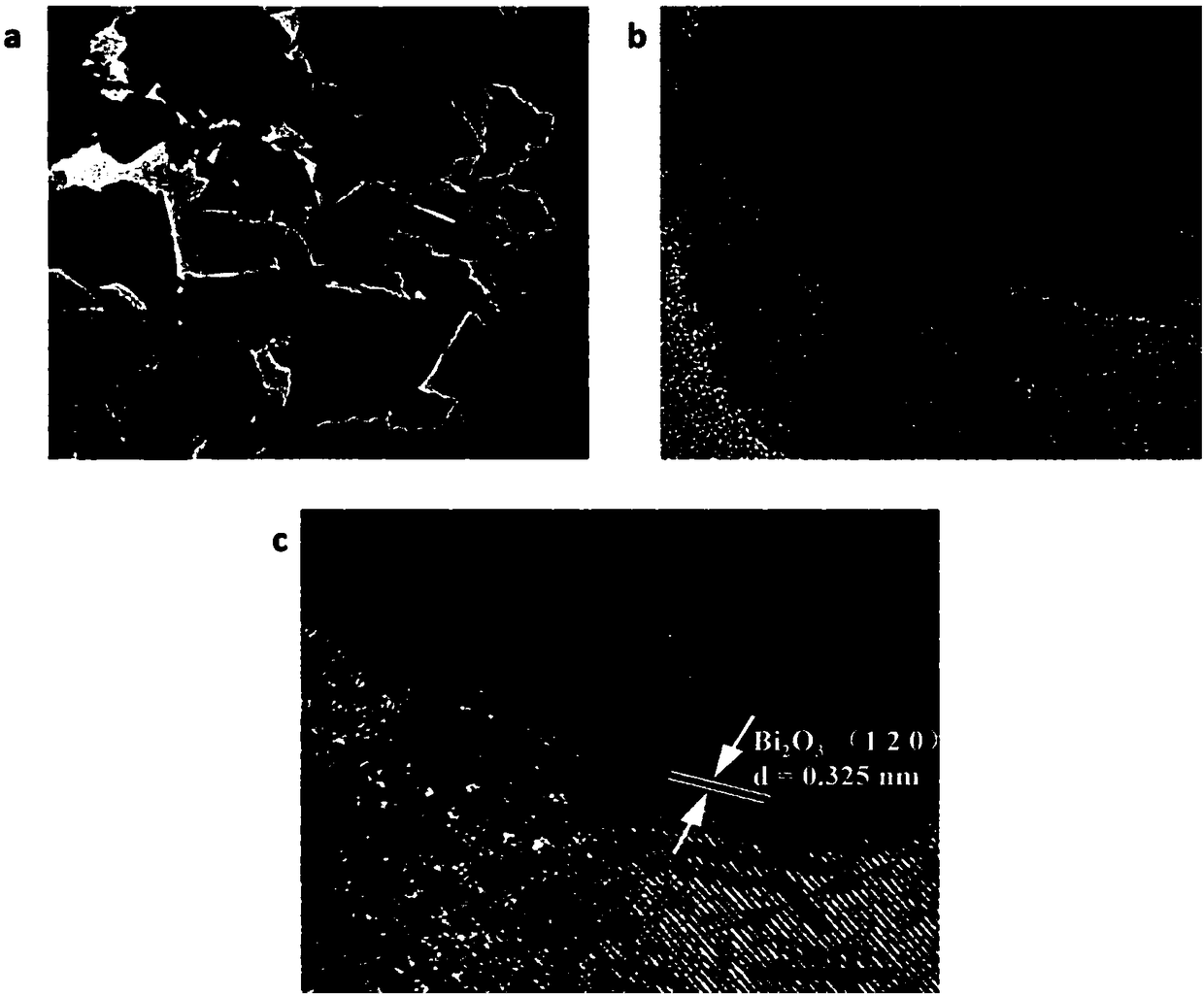

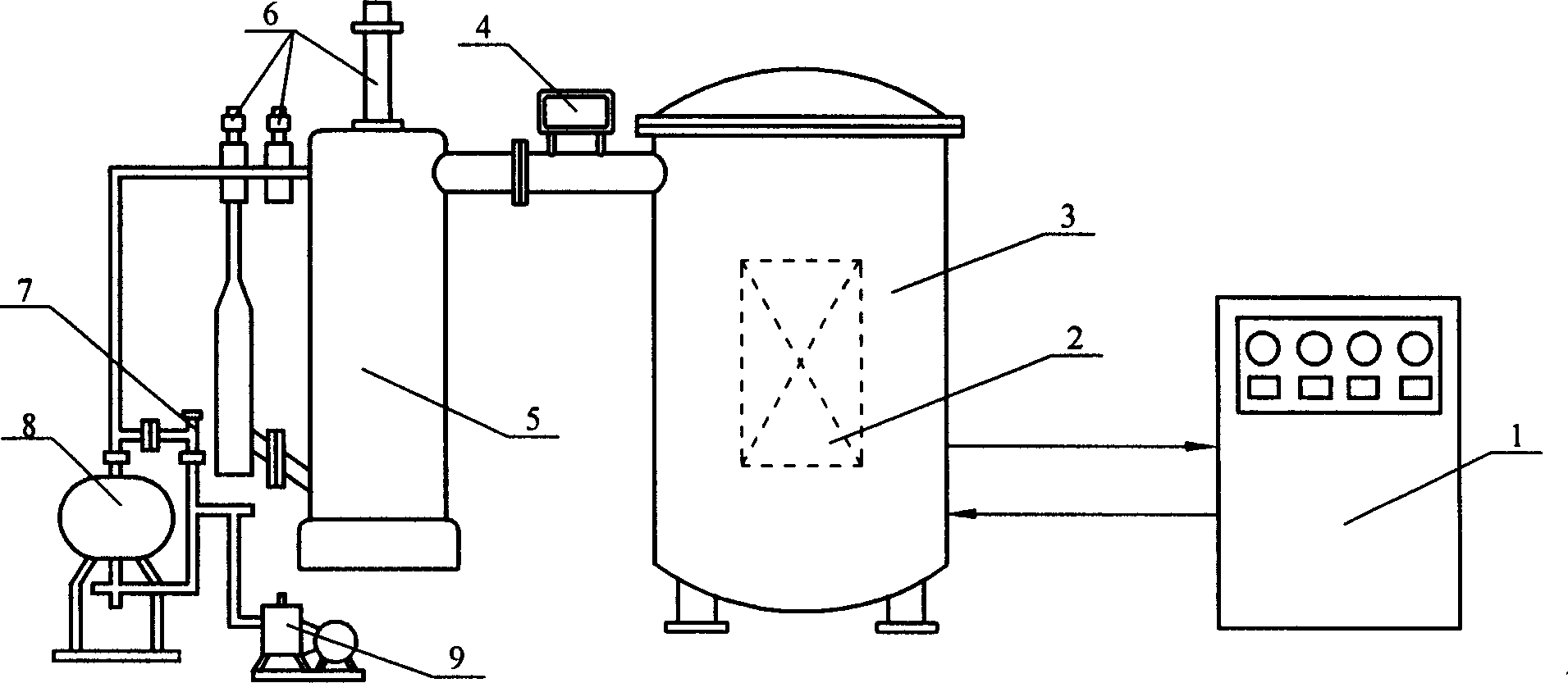

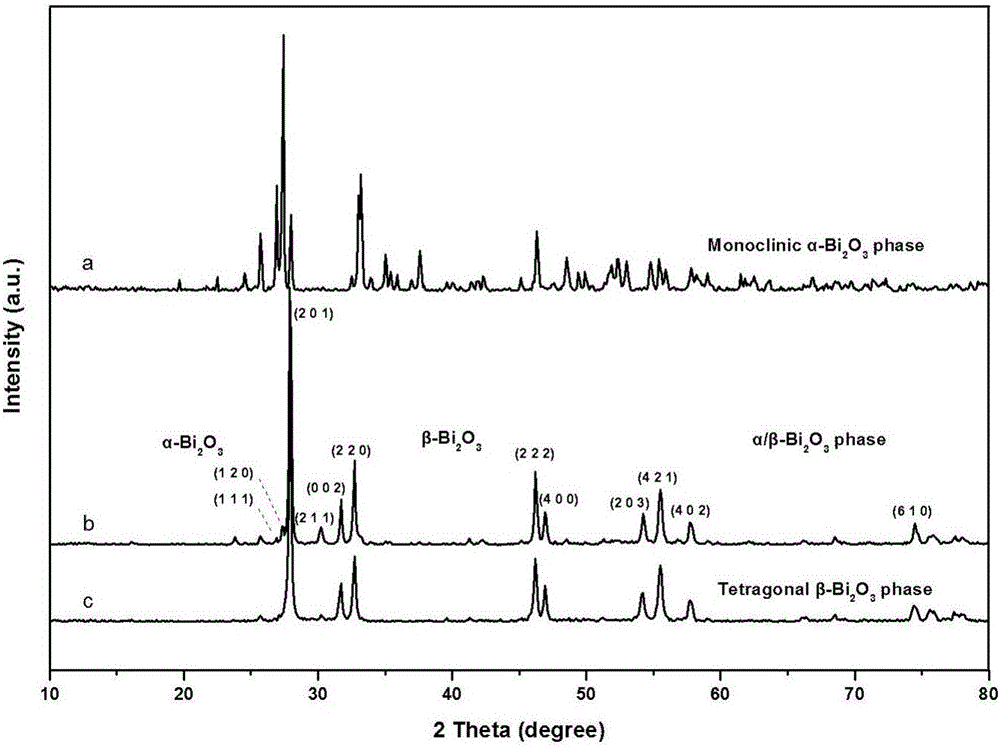

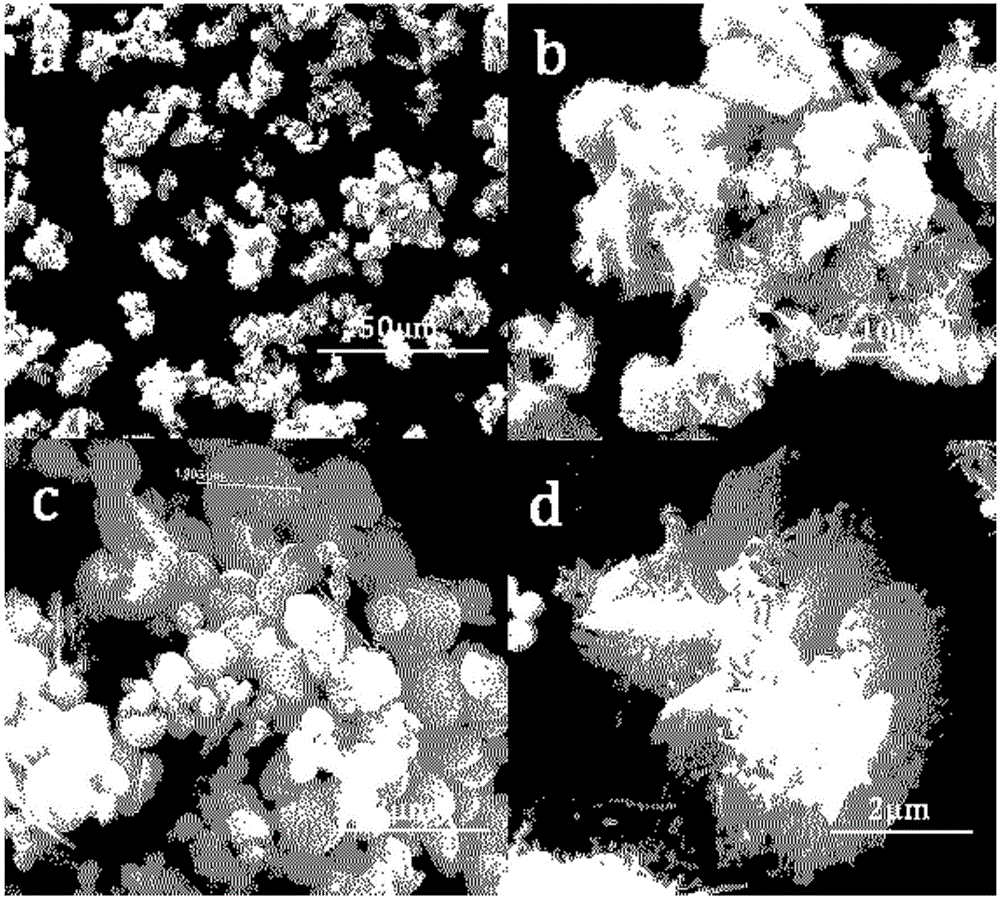

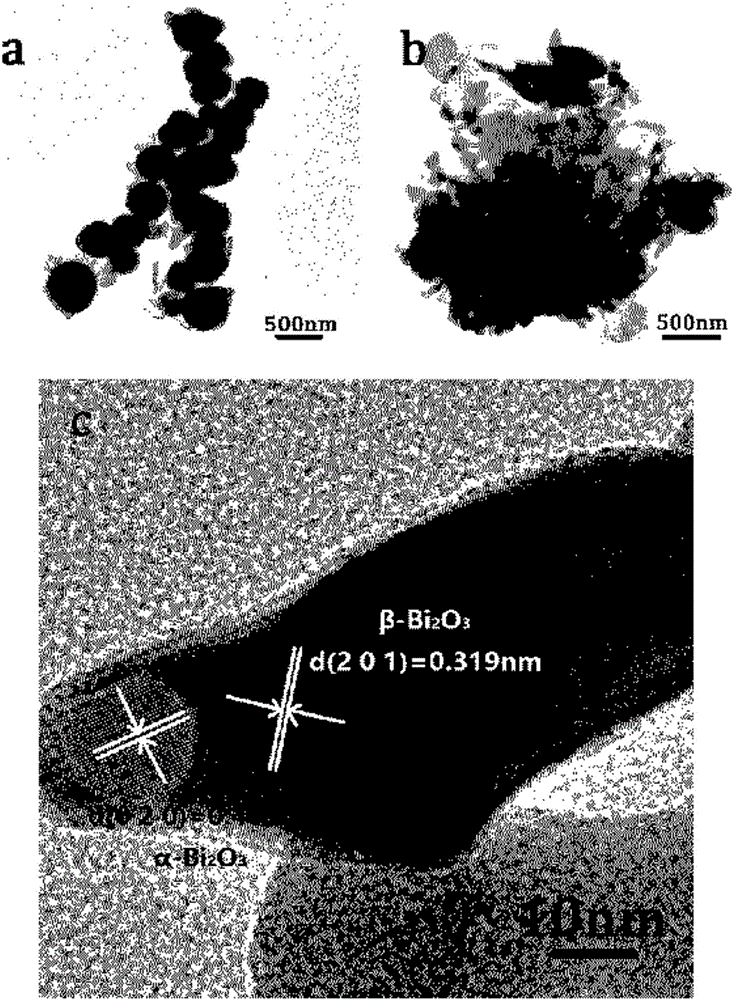

Bismuth oxide/bismuth tetraoxide heterojunction photocatalyst, preparation method and use thereof

ActiveCN108273492AOvercoming the disadvantage of low photocatalytic activityReduce typesWater/sewage treatment by irradiationWater treatment compoundsHeterojunctionMuffle furnace

The invention provides a preparation method and use of a Bi2O3 / Bi2O4 phase heterojunction photocatalyst. The preparation method comprises the following steps: firstly, mixing 2.8 g of bismuth salt with 0-1.87 g of alkali uniformly to prepare a paste; then, placing a mixture into a muffle furnace and calcining at 100-450 DEG C for 0.5-4.0 h; washing a calcined substance with deionized water; and drying at 60 DEG C to obtain earthy yellow to reddish brown solids which are the Bi2O3 / Bi2O4 heterojunction photocatalyst. The Bi2O3 / Bi2O4 phase heterojunction photocatalyst prepared in the invention isused for degrading organic pollutants in water, and has higher visible light catalyzing activity than a commercial Bi2O3 photocatalyst.

Owner:YUNNAN UNIV

Method and device of obtaining active lime by vacuum calcining limestone

A process for preparing high-activity lime by vacuum calcining of lime stone includes such steps as crushing lime stone, loading in tank, heating in electric vacuum furnace at 750-900 deg.C under 100-1000 Pa, and quick cooling. Its activity is 380-450 ml.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for producing rutile type white titanium pigment by using crystal seed method of double action

InactiveCN1415548APhase change low temperature fastImprove migration speedTitanium dioxideDual effectTitanium

A process for preparing rutile-type titanium pigment powder by dual-effect crystal seed method includes such steps as preparing dual-effect crystal seeds, hydrolyzing titanium liquid while adding the crystal seeds while plays the role of crystal nucleus of hydrolized metatitanic acid particle, and calcining where it plays the role of the crystal nucleus for rutile-type phase change. Its advantages are low calcining temp, low cost and high output.

Owner:NANKAI UNIV

Method for preparing solid electrolyte by using lithium lanthanum zirconium oxide precursor coated powder

ActiveCN104124467ACalcination temperature is lowHigh sintering activitySecondary cellsElectrical batteryElectrochemistry

The invention discloses a method for preparing a solid electrolyte by using lithium lanthanum zirconium oxide precursor coated powder. The method specifically comprises the steps of dissolving a certain amount of lanthanum nitrate and zirconium nitrate into water, adding a precipitator, namely ammonium carbonate, controlling the pH value to ensure that La<3+> and Zr<4+> ions are simultaneously precipitated, and filtering and washing the precipitate; weighing a certain amount of lithium oxalate, dissolving lithium oxalate into water, adding the precipitate into the lithium oxalate solution, stirring, evaporating, crystallizing, and separating out lithium oxalate crystal on the surface of the precipitate to form precursor powder with a coated structure. The prepared powder has the advantages of uniform mixing, fine grains, high purity and the like; through the formed specific coated structure, the calcination temperature of the powder is low, the sintering time of the powder is short, and the room-temperature lithium ion electric conductivity of the sintered lithium lanthanum zirconium oxide is more than 2.2*10<-4>S / cm. According to the method, the process is simple, the cost is low, the preparation conditions are easy to control, and the prepared solid electrolyte is good in electrochemical stability and high in electric conductivity and can be used for preparing all-solid-state lithium ion batteries.

Owner:WUHAN UNIV OF TECH

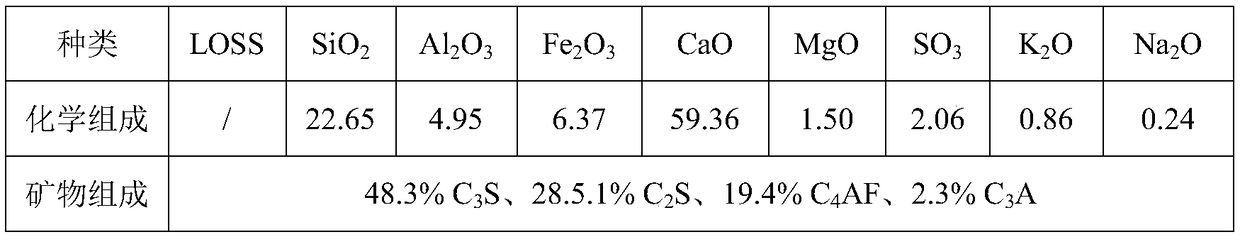

Belite-sulphoaluminate-ferrous aluminate cement and preparation method thereof

ActiveCN105060745ALow firing temperatureImprove performanceCement productionToxic industrial wasteMaterials science

The invention discloses belite-sulphoaluminate-ferrous aluminate cement which comprises the following components by mass percent: 38-70% of beta-C2S, 27-37% of C4A3S-(refer to the description) and 3-25% of C4AF. The invention further discloses a preparation method of the belite-sulphoaluminate-ferrous aluminate cement. The preparation method comprises the following steps: with industrial waste residue and industrial gypsum as the raw materials, mixing the raw materials with aluminous corrective addition namely bauxite or tailing bauxite, forming, performing hydrothermal reaction, crushing, calcining and grinding to obtain the belite-sulphoaluminate-ferrous aluminate cement. According to the invention, the low-carbon belite-sulphoaluminate-ferrous aluminate cement is prepared at low temperature; in addition, limestone is not used, so that no carbon dioxide is generated to increase the environmental pressure; moreover, the calcining temperature is low, so that the energy consumption is low, and the preparation method is a low-carbon and environment friendly preparation method.

Owner:天瑞集团萧县水泥有限公司

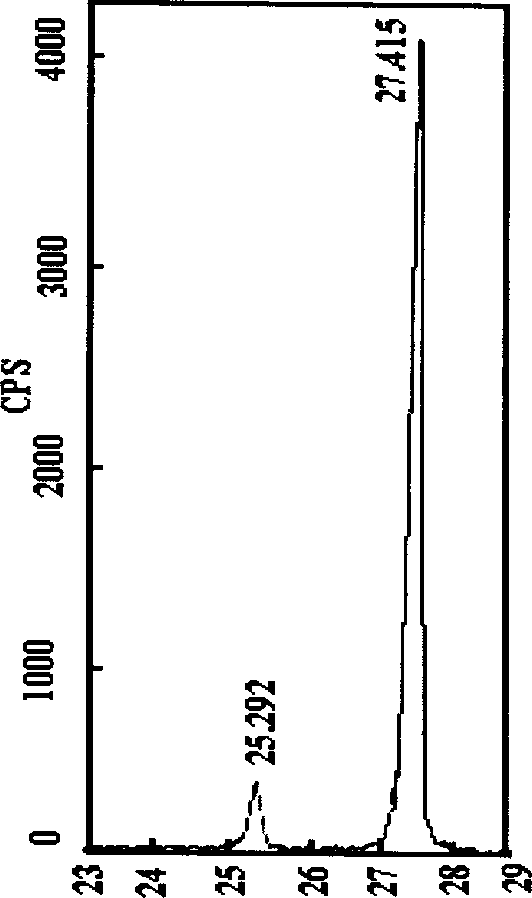

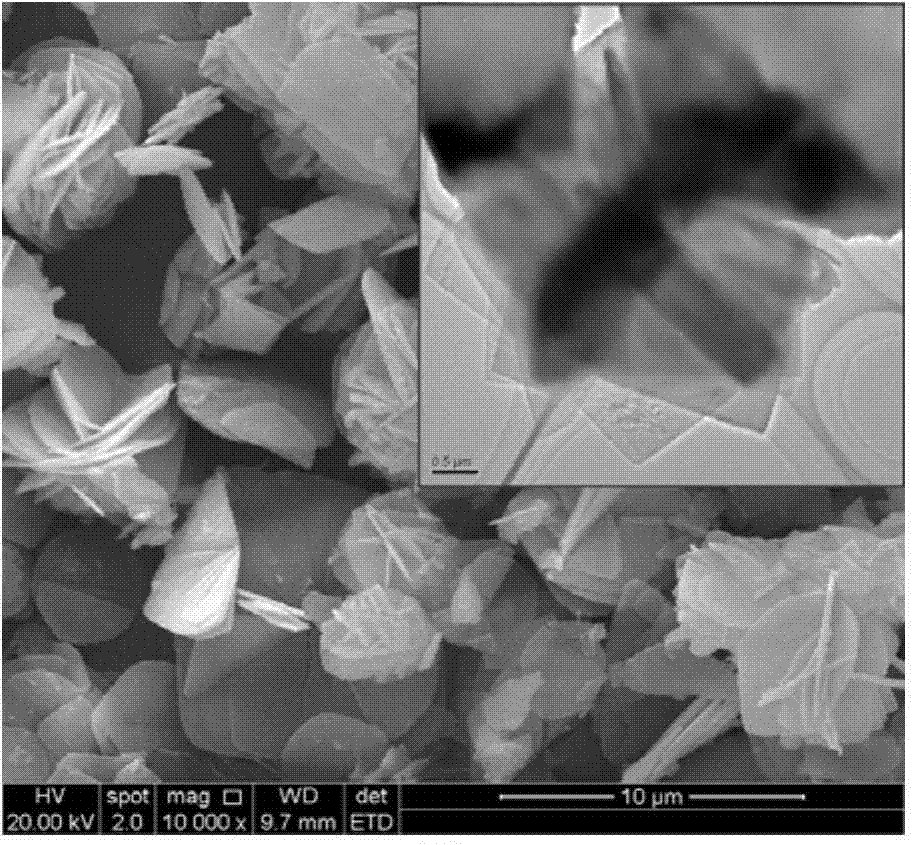

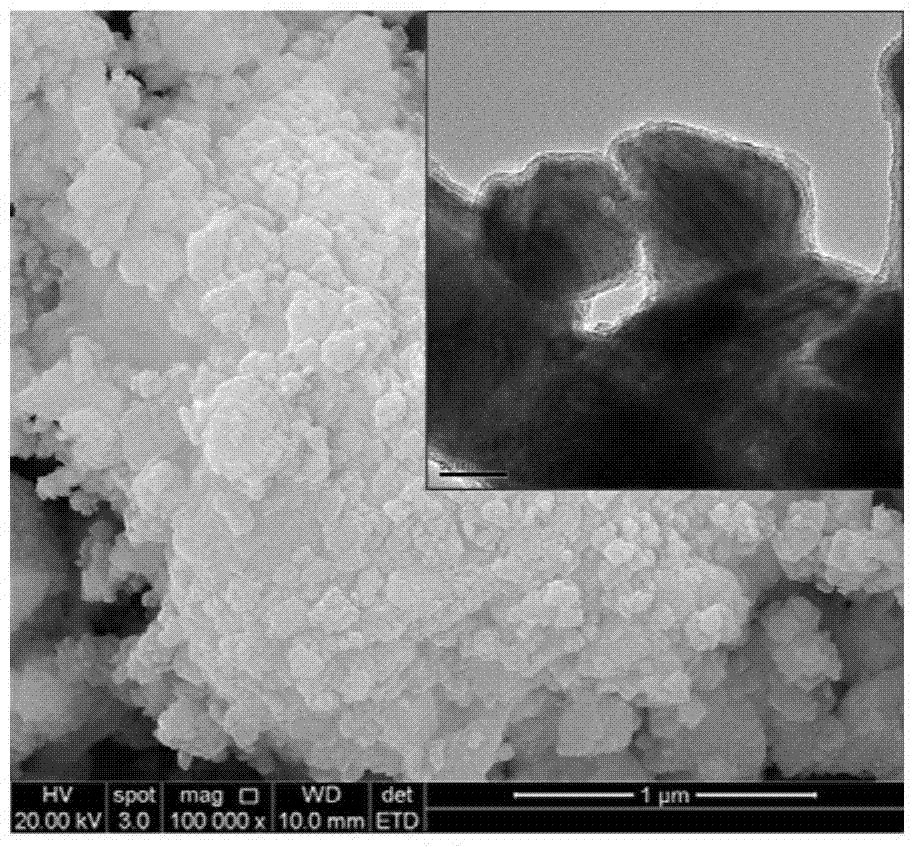

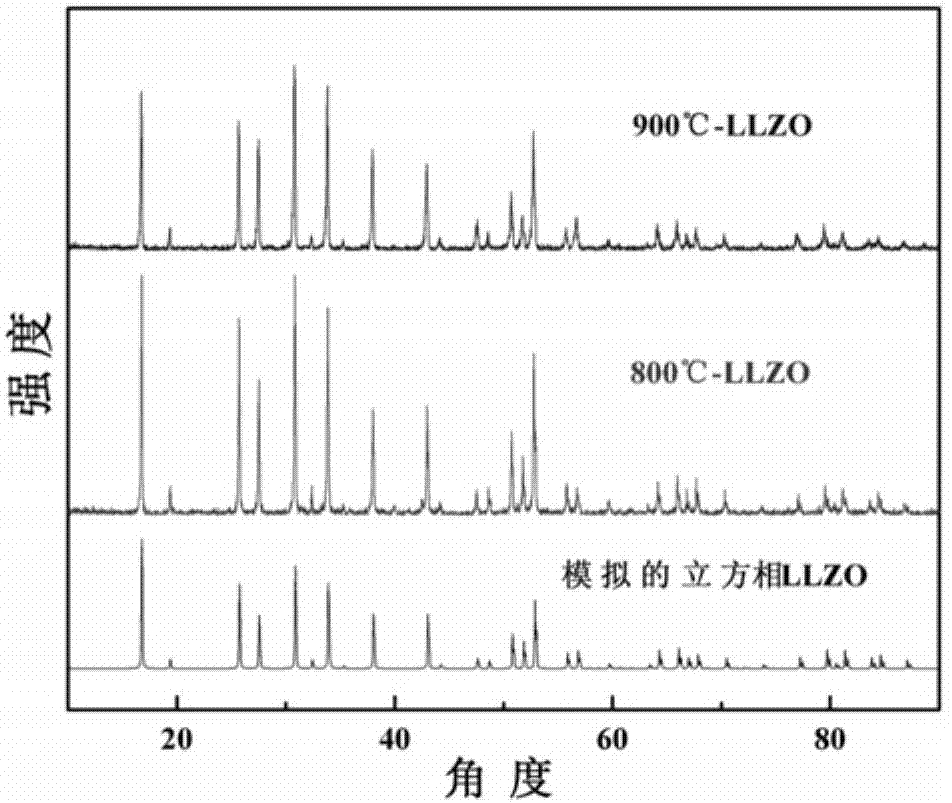

Preparation method of LLZO powder

The invention provides a preparation method of LLZO powder. The LLZO powder is prepared by adopting soluble lithium acetate as a lithium source, water as a solvent medium and ZrO2 with high specific surface area as a coating template of a lithium salt through simple mechanical ball-milling and drying and calcining methods. According to the method, reduction of the grain size is facilitated, reduction of the calcination temperature is facilitated, the grain size of the prepared LLZO powder is in nanoscale, the phase is single and the energy consumption is low. The problem that the excessive lithium source needs to be added to compensate the loss of a lithium element due to high temperature in synthesis and sintering when the powder is synthesized is solved; and a compact sheet body with good lithium ion conductivity can be further obtained through granulation, compaction and sintering.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

High-purity ultrafine transition metal carbide single-phase high-entropy ceramic powder and preparation method thereof

ActiveCN110330341APrimary particle size is smallCalcination temperature is lowTransition metal carbidesGranularity

The invention discloses high-purity ultrafine transition metal carbide single-phase high-entropy ceramic powder and a preparation method thereof, belongs to the technical field of super-hard ceramic materials, and particularly relates to the preparation method of the high-entropy ceramic powder. The invention aims to solve the problems of high oxygen content, high residual carbon content, low purity, large particle size and poor sphericity of a multi-component carbide high-entropy ceramic material prepared with the prior method. The chemical formula of the high-purity ultrafine transition metal carbide single-phase high-entropy ceramic powder is (Hfx1Nbx3Tax4Tix2Mx5)C. The method comprises the following steps: 1, weighing materials; 2, mixing; and 3, calcining. The high-purity ultrafine transition metal carbide single-phase high-entropy ceramic powder prepared in the invention has the advantages of small particle size, low oxygen content and low free carbon content. The high-purity ultrafine transition metal carbide single-phase high-entropy ceramic powder can be obtained in the invention.

Owner:HARBIN INST OF TECH

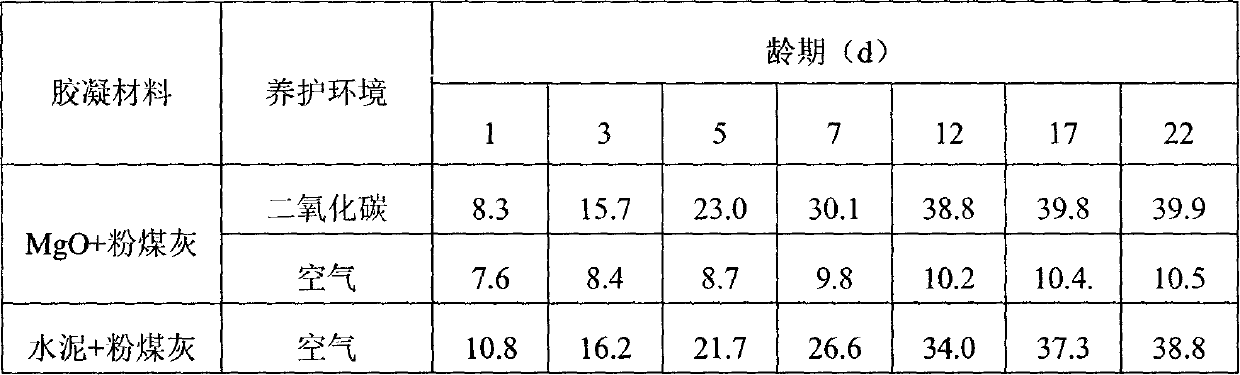

Production process of building envelope products

InactiveCN102909783ACalcination temperature is lowReduce production energy consumptionShaping reinforcementsCeramicwareSilica fumeIndustrial waste

The invention discloses a production process of building envelope products and belongs to the field of civil engineering. Light calcined magnesia power or mixture of light calcined magnesia power and quicklime is proportionally mixed with mineral admixtures such as granulated blast-furnace slag, coal ash, silica fume, red mud tailing powder and slag to obtain cementing material, the cementing material is mixed with aggregate and water into mixture used for producing building envelope material, and the building envelope material is finally hardened under CO2 environment into building envelope products such as building blocks, plates and tiles by means of mixing, forming, precuring and the like. The production process is low in production energy consumption, CO2 emitted from industrial waste residue and in industrial production is effectively utilized, and the building envelope products are new energy-saving environment-friendly products.

Owner:于浩

Biological aerated filter packing and preparation method thereof

ActiveCN102531157AExtensive sources of raw materialsLow priceSustainable biological treatmentBiological water/sewage treatmentPorosityExpanded clay aggregate

The invention discloses biological aerated filter packing and a preparation method thereof. The raw materials of the biological aerated filter packing have the following composition in percentage by weight: 75 to 85 percent of aggregates, 5 to 30 percent of iron oxide and 10 to 20 percent of pore-forming agent. The biological aerated filter packing is obtained after the raw materials are ground and calcined. The biological aerated filter packing disclosed by the invention has the advantages of high porosity, large specific surface area, high strength, strong water resistant performance, high water absorption and the like. Moreover, relative to commercially available ceramsite and zeolite particles, porous ceramsite disclosed by the invention has high adsorption performance for phosphorus, can be repeatedly utilized by secondary calcination after reaching an adsorption saturation state and cannot pollute the environment.

Owner:HEFEI UNIV OF TECH

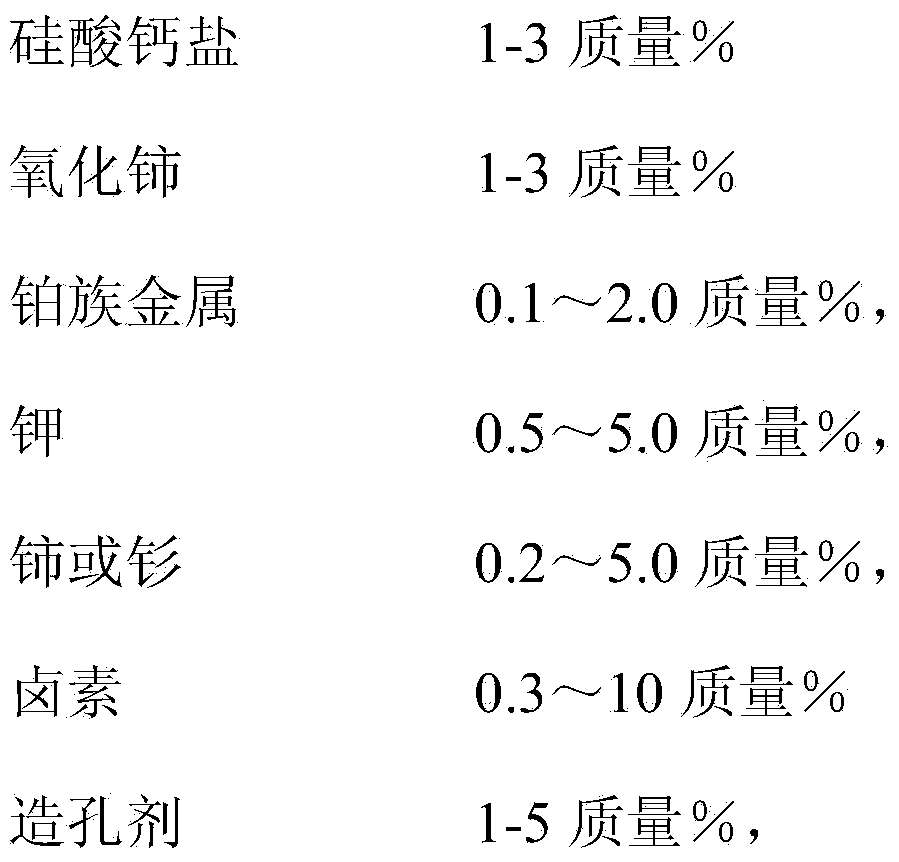

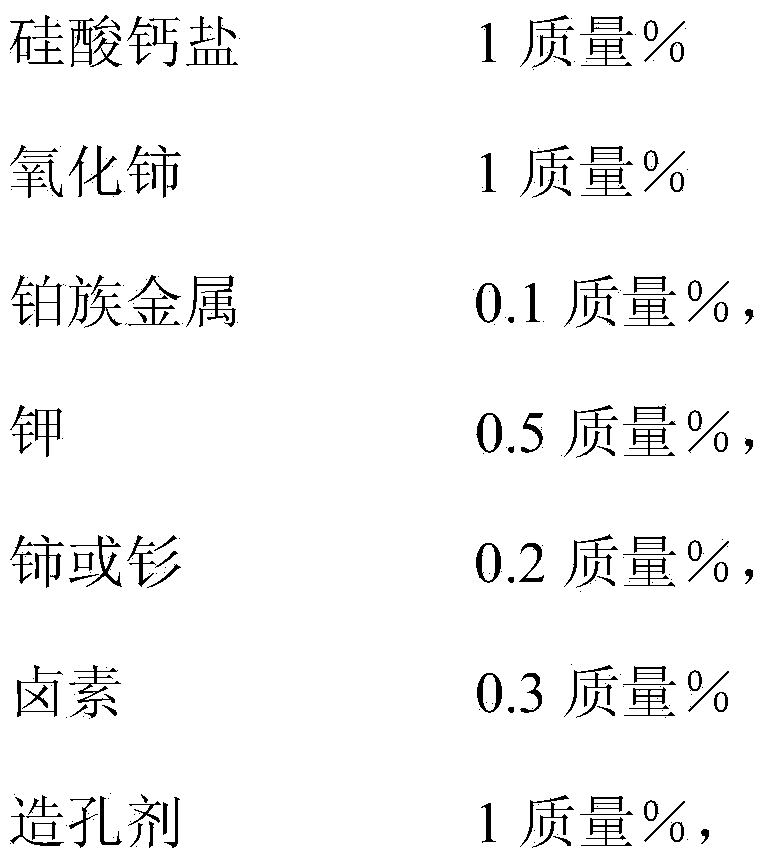

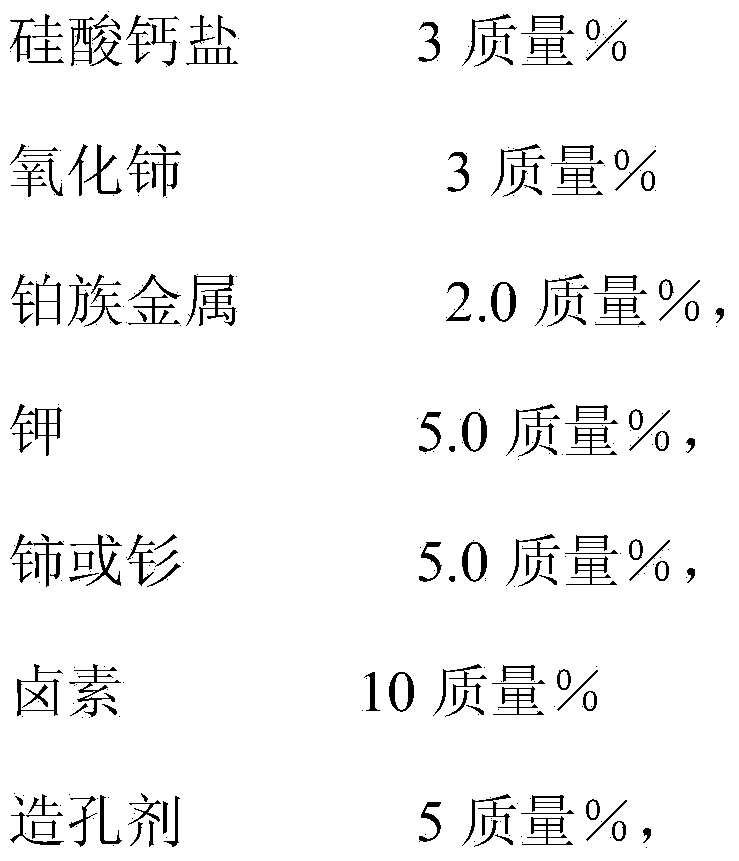

Preparation method of catalyst for preparing propylene by virtue of propane dehydrogenation

InactiveCN104368364AAvoid it happening againAvoid Contaminated SituationsPhysical/chemical process catalystsHydrocarbonsCalcium silicateHydrogen halide

The invention discloses a preparation method of a catalyst for preparing propylene by virtue of propane dehydrogenation. The catalyst comprises an aluminum oxide carrier and active components with the following contents in percentage by mass calculated based on the carrier: 1-3% of calcium silicate salt, 1-3% of cerium oxide, 0.1-2.0% of a platinum group metal, 0.5-5.0% of potassium, 0.2-5.0% of cerium or samarium, 0.3-10% of halogen, 1-5% of a pore forming agent and the balance of impurities, wherein the molar ratio of cerium or samarium to the platinum group metal is 7:8; the platinum group metal is platinum; and halogen is chlorine. The preparation method comprises the following steps: soaking, drying and roasting the aluminum oxide carrier by using a soluble compound solution of cerium or samarium and a calcium silicate salt solution, then soaking, drying and roasting by using a solution containing compounds of the platinum group metal and hydrogen halide, and then soaking, drying and roasting by using a potassium salt solution; and then mixing cerium oxide and the pore forming agent with corresponding amounts, and roasting for 3 hours at 600 DEG C to obtain the catalyst for preparing propylene by virtue of propane dehydrogenation.

Owner:华玉叶

Alpha/beta-bismuth oxide phase heterojunction photocatalyst as well as preparation method and application thereof

ActiveCN106732524AEfficient degradationEfficient removalWater/sewage treatment by irradiationWater treatment compoundsHeterojunctionSource material

The invention provides an alpha / beta-Bi2O3 phase heterojunction photocatalyst as well as a preparation method and application thereof. The method comprises the following steps: firstly dissolving 2-4mmol of a bismuth source material in 70mL of a reductive solvent, magnetically stirring for 30 minutes under the room temperature, then adding 0-2.0mL of aniline into the solution, and continuing to stir for 10 minutes; transferring the mixed solution into a reactor, putting the mixed solution in a drying oven for carrying out solvothermal reaction for 8-12 hours at the temperature of 150-180 DEG C to obtain a bismuth-based precursor; washing, drying and grinding the precursor, putting the precursor in a muffle furnace for calcining for 0.5-2.0 hours at the temperature of 300 DEG C to obtain yellowish green powder which is the alpha / beta-Bi2O3 phase heterojunction photocatalyst. The prepared alpha / beta-Bi2O3 phase heterojunction photocatalyst is used for degrading organic pollutants in water; compared with commercial TiO2 (P25), pure-phase alpha-Bi2O3 and pure-phase beta-Bi2O3 photocatalysts, the alpha / beta-bismuth oxide phase heterojunction photocatalyst has higher visible-light catalytic activity.

Owner:YUNNAN UNIV

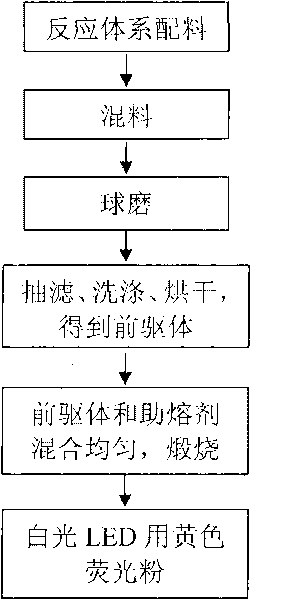

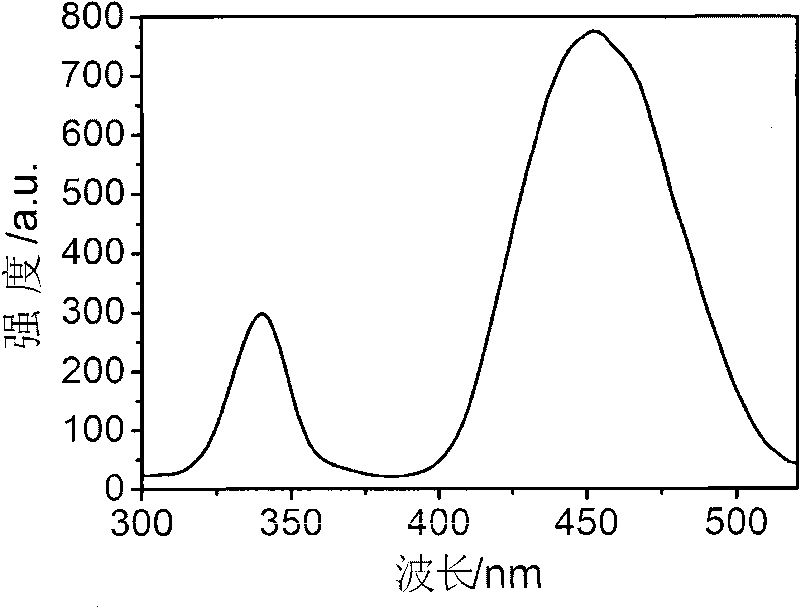

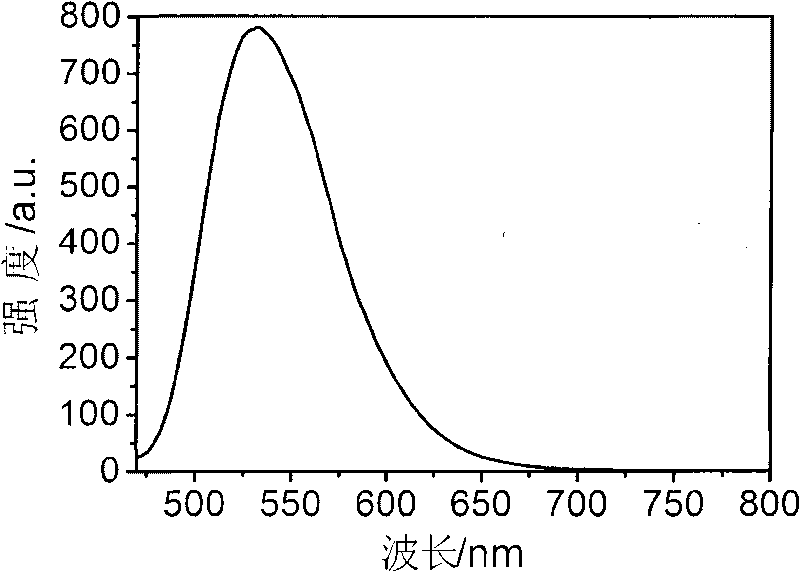

Method for combining yellow fluorescent powder used for white light LED

InactiveCN101760196AIncrease productivityCalcination temperature is lowGas discharge lamp usageLuminescent compositionsCeriumReducing atmosphere

The invention provides a method for combining a yellow fluorescent powder used for a white light LED and belongs to the preparation technique of rare earth fluorescent powders. The chemical formula thereof is (Y1-x-yMyCex)3Al5O12, wherein M is one chosen from Tb, Gd, Sm and Yb, x is more than or equal to 0 but less than or equal to 0.1 and y is more than or equal to 0 but less than or equal to 0.1. The method comprises the following steps of: weighting yttrium salt, M salt, cerium salt, aluminum salt according to the element measurement and a defined amount of surface active agent and fluxing agent, fully mixing the reactants, the surface active agent and a defined amount of ligand, ball-milling while adding proper lubricant, filtering, washing and drying so as to acquire a precursor, mixing the precursor with the fluxing agent, and burning in a reducing atmosphere so as to acquire the needed fluorescent powder. The method for combining the fluorescent powder of the invention has the advantages of low burning temperature, short time, high production efficiency, small grain size, narrow distribution, excellent lighting performance and capable of being efficiently aroused by the blue light LED chip.

Owner:SICHUAN UNIV

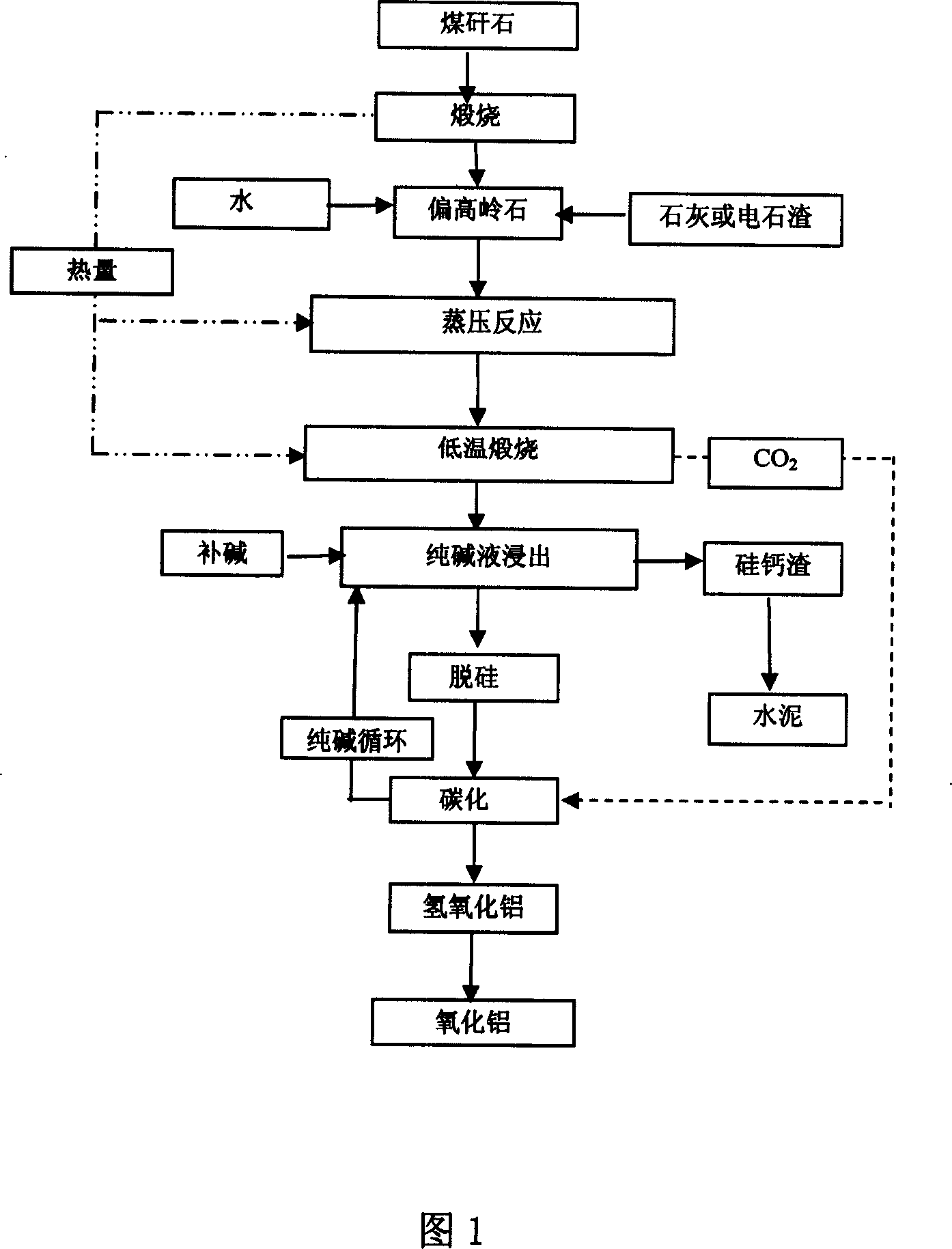

Method for extracting aluminum hydrate or alumina from coal gangue and method for producing cement from fag end

InactiveCN101028935AReduce manufacturing costRealize comprehensive utilizationAluminium oxide/hydroxide preparationCement productionSteam pressureAluminium hydroxide

A process for extracting aluminum hydroxide (or oxide) from coal gangue and using the residual dregs to prepare cement includes such steps as calcining coal gangue, mixing with lime or calcium carbide dregs and water, steam pressure reaction to generate the resultant containing hydrated calcium silicoaluminate and calcium hydroxide, calcining to obtain the dodecylcalcium hepatoaluminate and dicalcium silicate, extracting in sodium carbonate solution, adding lime for desiliconizing, carbonizing to obtain aluminum oxide, calcining to obtain aluminum oxide, and using the SiCa dregs to prepare cement.

Owner:CHANGAN UNIV

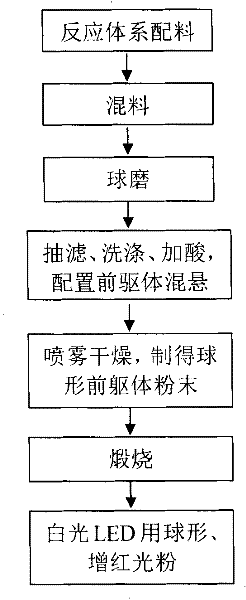

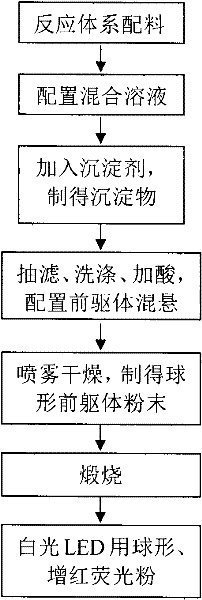

Ball-shaped red-enhanced phosphor used in white light LED, and preparation method thereof

InactiveCN102220131AIncrease productivityCalcination temperature is lowEnergy efficient lightingLuminescent compositionsChemical reactionStructural formula

The invention relates to ball-shaped red-enhanced phosphor used in white light LEDs, and a preparation method thereof. The structural formula of the phosphor is: YxREyMzCemAl5-nAnO12, wherein RE is at least one among Tb, Gd, Sm, Yb, La, and Lu; M is at least one among Mg, Ba, Ca, and Sr; A is at least one among Ga, Cu, Zn, Ni, Ge, and Si; 1.8<x<3; 0<=y<=0.8; 0<=z<=0.2; 0<m<=0.2; 2.9<x+y+z+m<3.1; 0<=n<=0.5; and 0<y+z+n<1. The preparation method is that: proper amounts of Y salt, RE salt, M salt, Ce salt, Al salt and A salt are weighed according to the stoichiometric ratio of the elements in the structural formula; the salts are well-mixed with a proper amount of surfactant; a precursor is then prepared with a mechanical solid-phase reaction method or a coprecipitation method; the mixture is processd through vacuum-filtrating and washing; a certain amount of volatile acid is added to the mixture, such that a suspension liquid is prepared; the suspension liquid is then produced into ball-shaped precursor power through spray drying; the ball-shaped precursor power is processed through pre-sintering, and then calcined under a reductive atmosphere, such that target phosphor is obtained. The phosphor provided by the present invention is ball-shaped. Red shifts occur in the emitted wavelength of the phosphor. The phosphor has good color rendering property, and can be effectively excited by blue-light chips.

Owner:CHONGQING UNIV OF ARTS & SCI +1

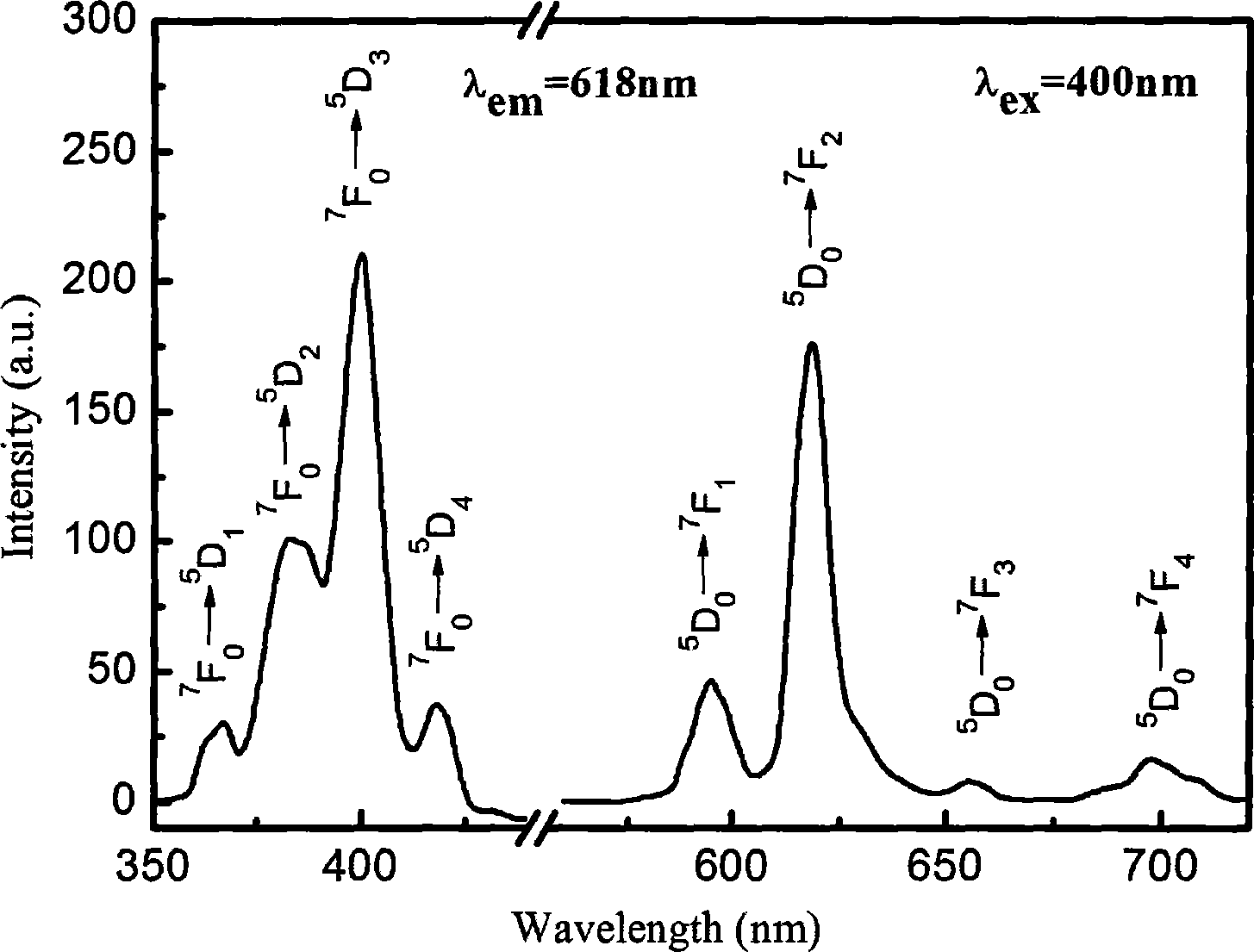

Preparation of doped calcium titanate (CaTiO3: Eu3+) fluorescent powder

InactiveCN101376523AGood chemical stabilitySmall grain sizeTitanium compoundsLuminescent compositionsAlcoholDissolution

The invention relates to a preparation method of Eu-doping calcium titanate CaTiO3:Eu<3+> fluorescent powders, which comprises the steps as follows: a soluble europium salt, a calcium salt and Ti(OC4H9)4 are weighed according to the mole ratio that is 1:49:50 to 1:4:5 among Eu<3plus>, Ca<2plus> and Ti<4plus>, and are respectively dissolved in absolute ethyl alcohol, and the confected solution is stirred for ample dissolution; (2) a mixed ethanol solution of the europium salt and the calcium salt is added in an ethanol solution of Ti(OC4H9)4, and a sol is obtained through stirring; (3) the sol is placed at the temperature ranging from 0 to 50 DEG C to obtain a wet gel which is put in a baking box for drying; (4) the dried gel is milled into powders, the obtained powders are calcined for 2 to 8 hours to obtain the CaTiO3:Eu<3plus> fluorescent powders. In the preparation method, the prepared CaTiO3:Eu<3plus> fluorescent powders have high chemical durability, small grain size, pure crystalling phase and low calcination temperature; the preparation method has simple technology, and is easy for industrialized production.

Owner:DONGHUA UNIV

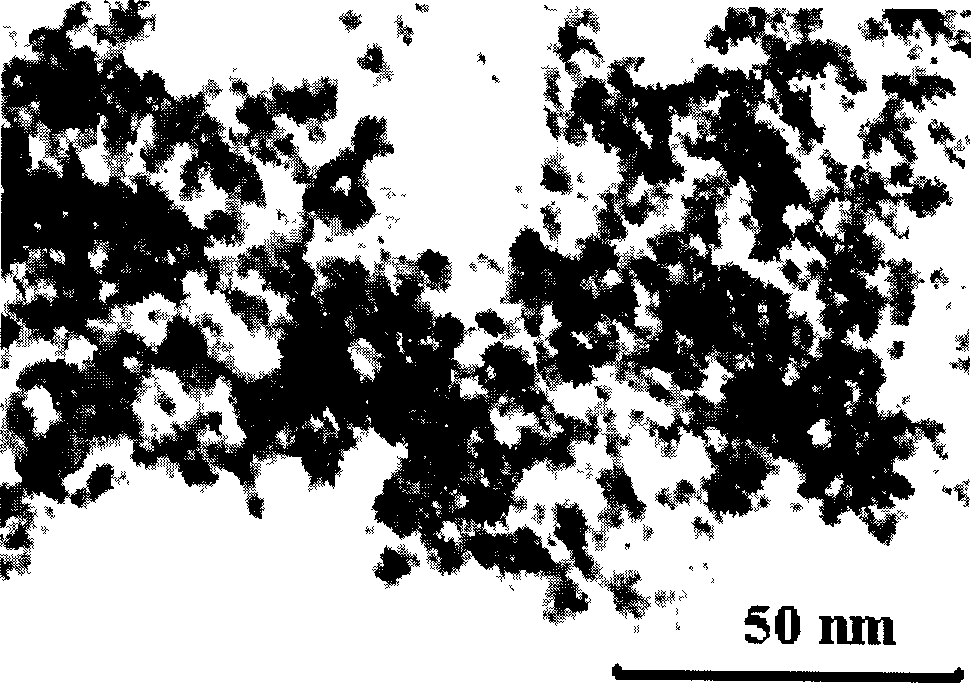

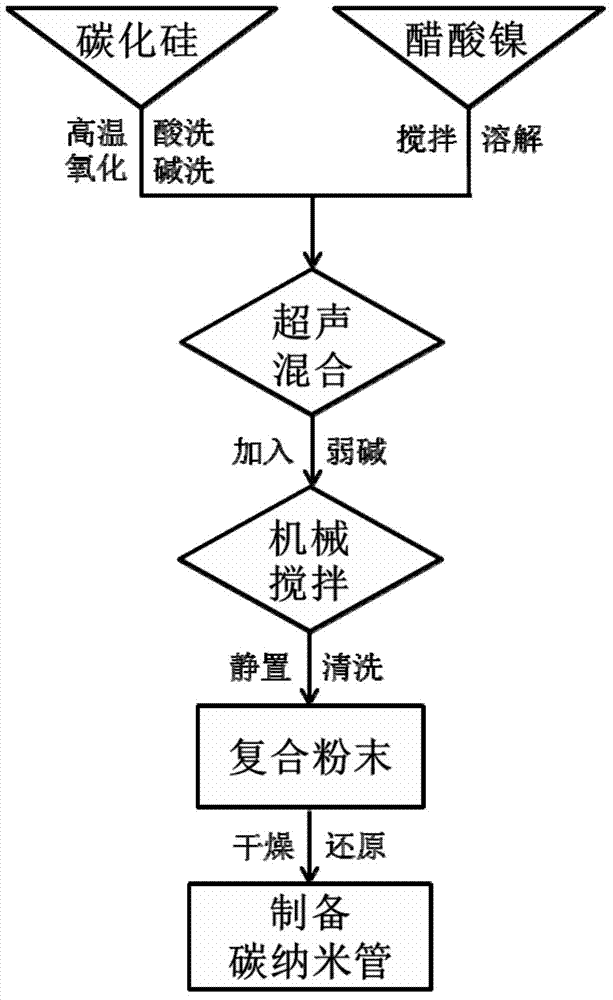

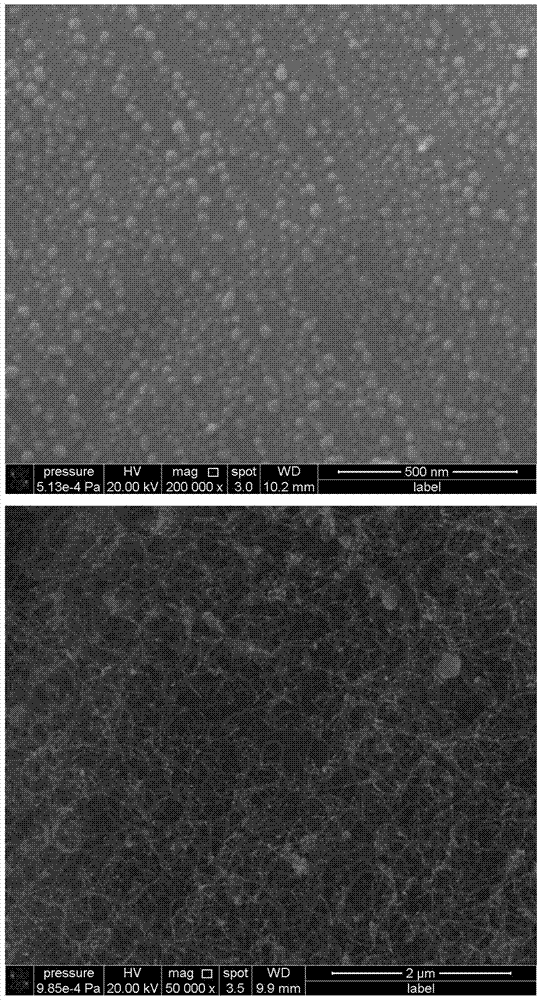

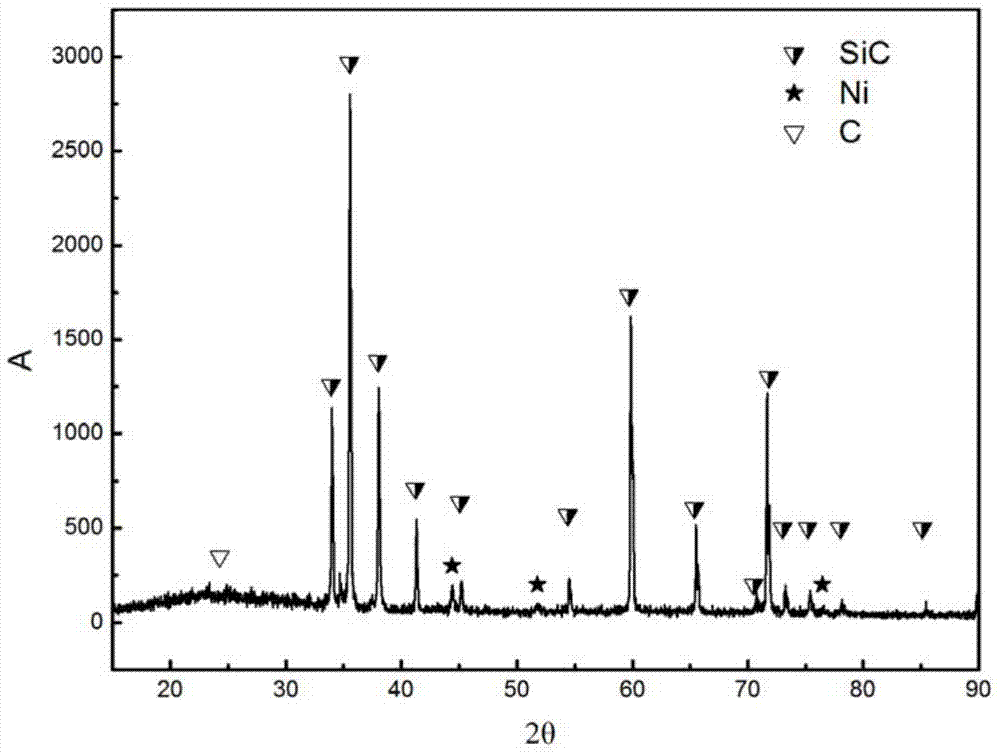

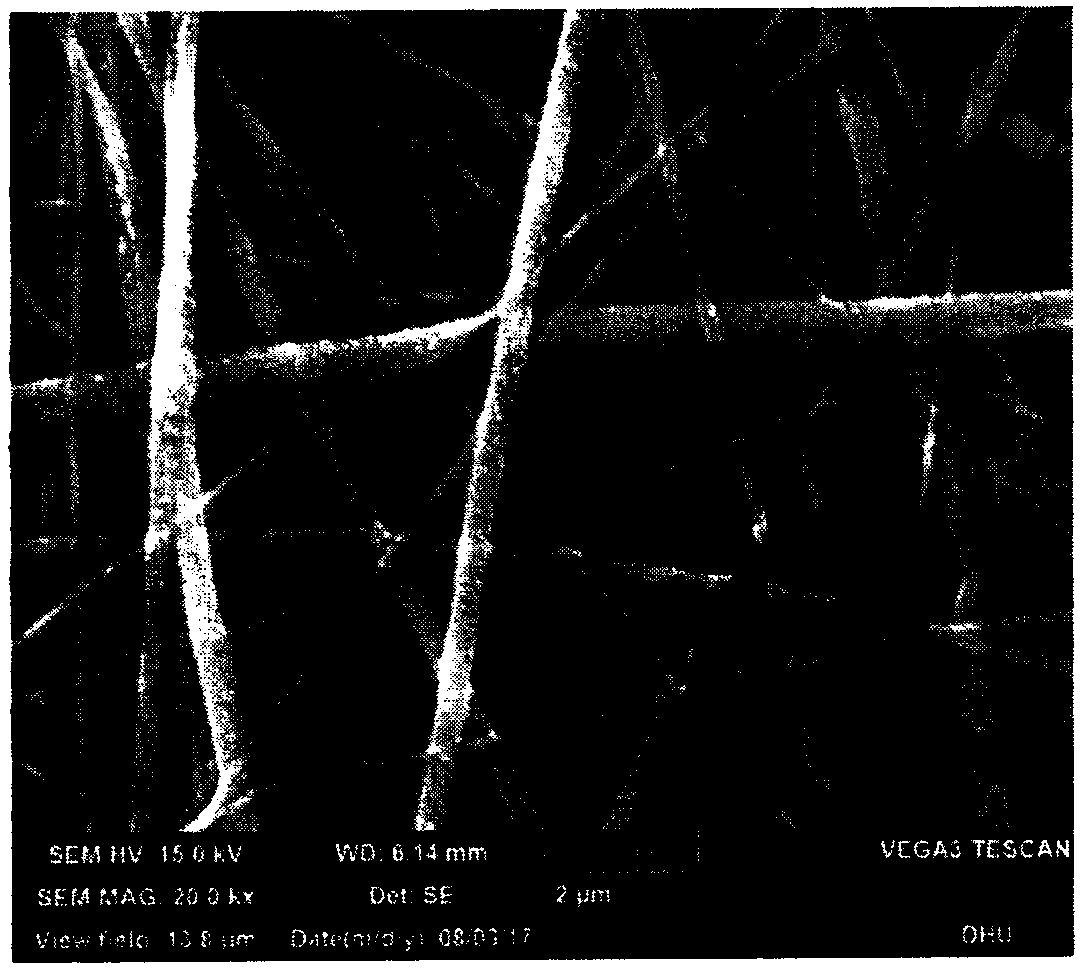

Method for preparing carbon nano tubes on surfaces of silicon carbide particles through in-situ synthesis

ActiveCN103754878AImprove adsorption capacityCalcination temperature is lowMaterial nanotechnologySilicon carbideNano catalystGas phase

The invention provides a method for growing multi-walled carbon nano tubes on the surface of micron silicon carbide powder in situ. The method comprises the steps of firstly oxidizing, acid-washing and alkali-washing the surface of the silicon carbide powder to remove silicon oxide and other impurities on the surface; secondly wrapping the surface of silicon carbide with a layer of uniformly distributed nano-catalyst particles by adopting the method of chemical codeposition, then putting the powder into a quartz tube furnace, and preparing the carbon nano tubes on the surface of silicon carbide in situ through catalytic cracking by utilizing the method of chemical vapor deposition. By adopting the method, uniform distribution of the carbon nano tubes on the surface of micron silicon carbide can be achieved, the difficulty that the carbon nano tubes are easy to agglomerate is solved, and a basis is provided for preparing high-performance multi-scale composite materials. The method is simple and has high feasibility. The prepared carbon nano tubes are uniformly dispersed on the surface of silicon carbide and are controllable in quantity.

Owner:深圳优越科技新材料有限公司

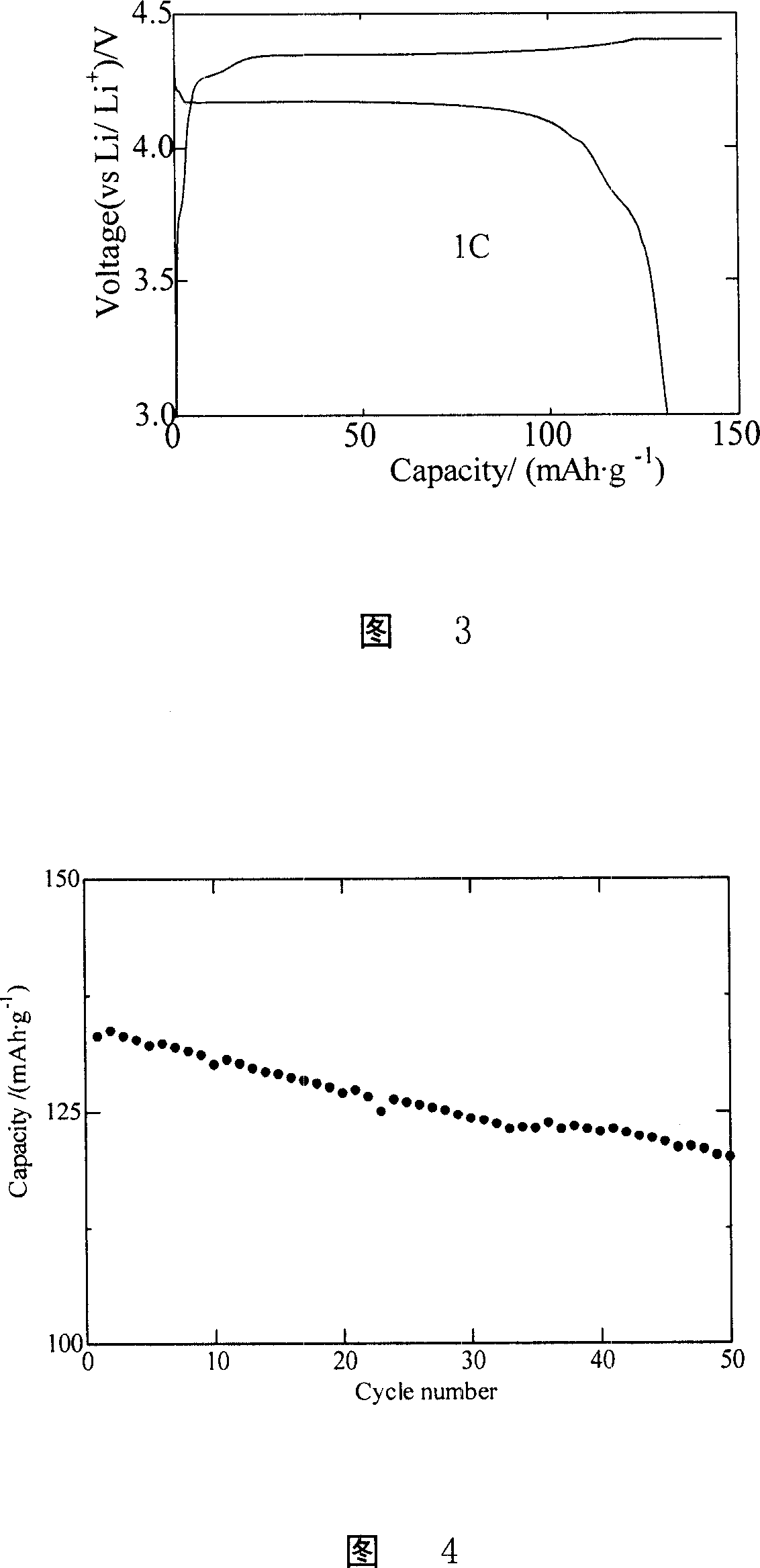

Synthesizing lithium ion cell positive material fluorophosphoric vanadium-lithium by sol-gel method

InactiveCN101005134ASolve easy oxidationUniform particle size distributionElectrode manufacturing processesFluoride preparationPhosphateVacuum drying

The disclosed sol gel method includes steps: stirring, and mixing objects: water solutions of lithium salt, villiaumite, vandic salt in pentavalence, phosphate, and chelating agent according to mol ratio 2í†2í†1-2í†2í†4; controlling pH at 7-11, carrying out reaction in stirred reactor under 40-80 deg.C for 1-5 hours to form gel; drying the gel in vacuum drying oven for 5-15h under 80-150 deg.C, and cracking the dried gel for 1-4h; after being ground evenly, the dried gel is roasted at 400-800 deg.C under atmosphere of inert gases for 5-20h so as to obtain finished product. Using vandic salt in pentavalence as raw material, the invention solves issue that vanadium ion is to be oxidized. The invention reduces burning temperature; producing fine and grain size even distributed material so as to raise conductivity. Adjustable synthesis temperature can obtain material with different granularities. Advantages are: simple and convenient method, and shortened synthetic cycle.

Owner:CENT SOUTH UNIV

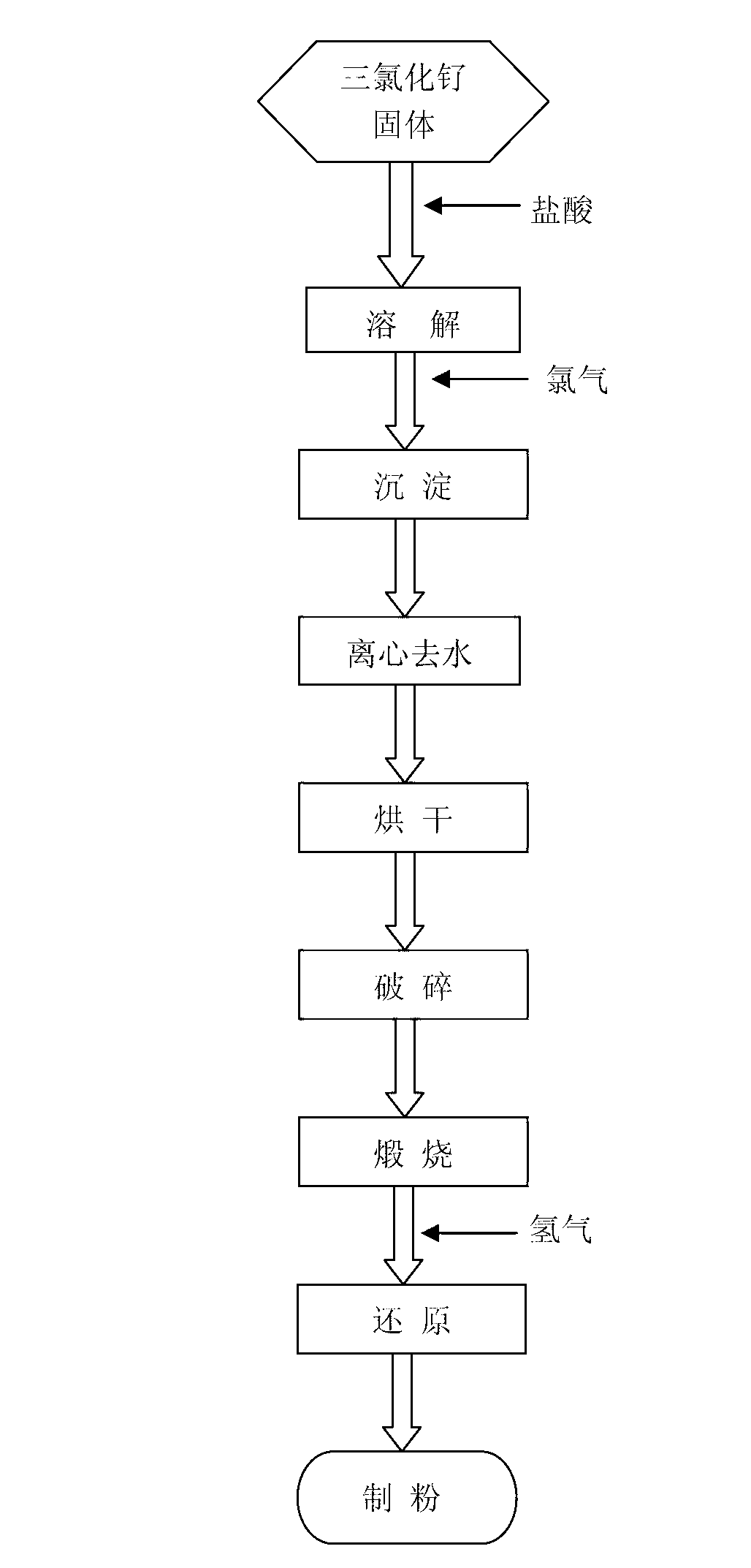

Method for preparing target-used Ru (ruthenium) powder

The invention provides a method for preparing target-used Ru powder and relates to the technical field of precious metal powder production. The method for preparing the target-used Ru powder comprises the steps as follows; 1) solvation, 2) precipitation, 3) centrifugal filtration, 4) drying, 5) crushing, 6) calcination, 7) reduction and 8) powder preparation. According to the method, oxidation reaction is performed by means of chlorine gas to oxidize Ru (III) in a solution into Ru (IV), simultaneously, the concentration of Ru is controlled in a range of 45-55 g / L, the concentration of hydrochloric acid is controlled in a range of 8-12 mol / L, the oxidizing temperature is controlled in a range of 90-100 DEG C, and the mixing speed is 60-90 revolutions / min, so that 99.9% of (NH4)2RuCl6(IV) in the solution can be precipitated, the (NH4)2RuCl6(IV) is separated from impurities, and the purity of the (NH4)2RuCl6(IV) is improved.

Owner:GUIYAN RESOURCE YIMEN

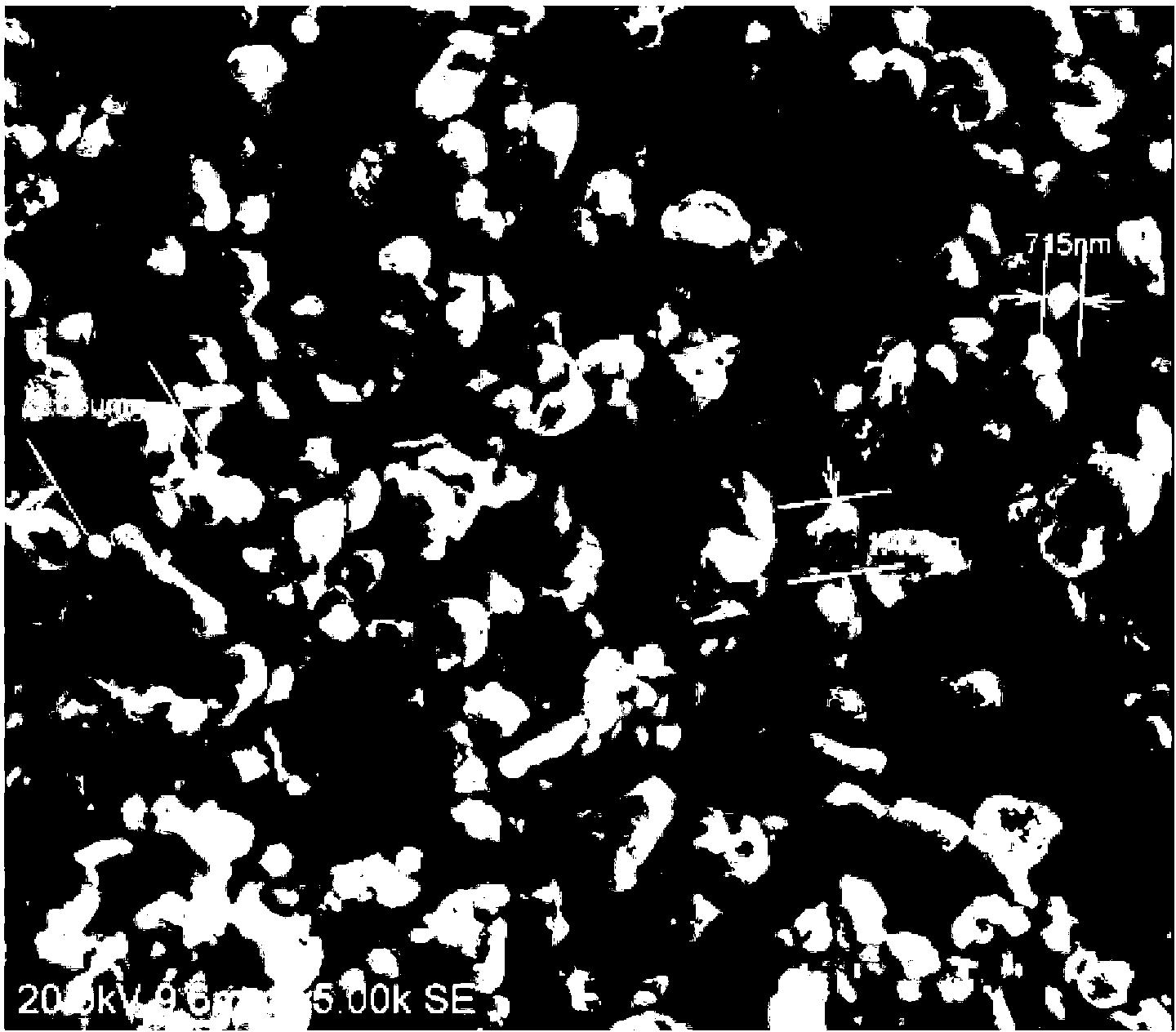

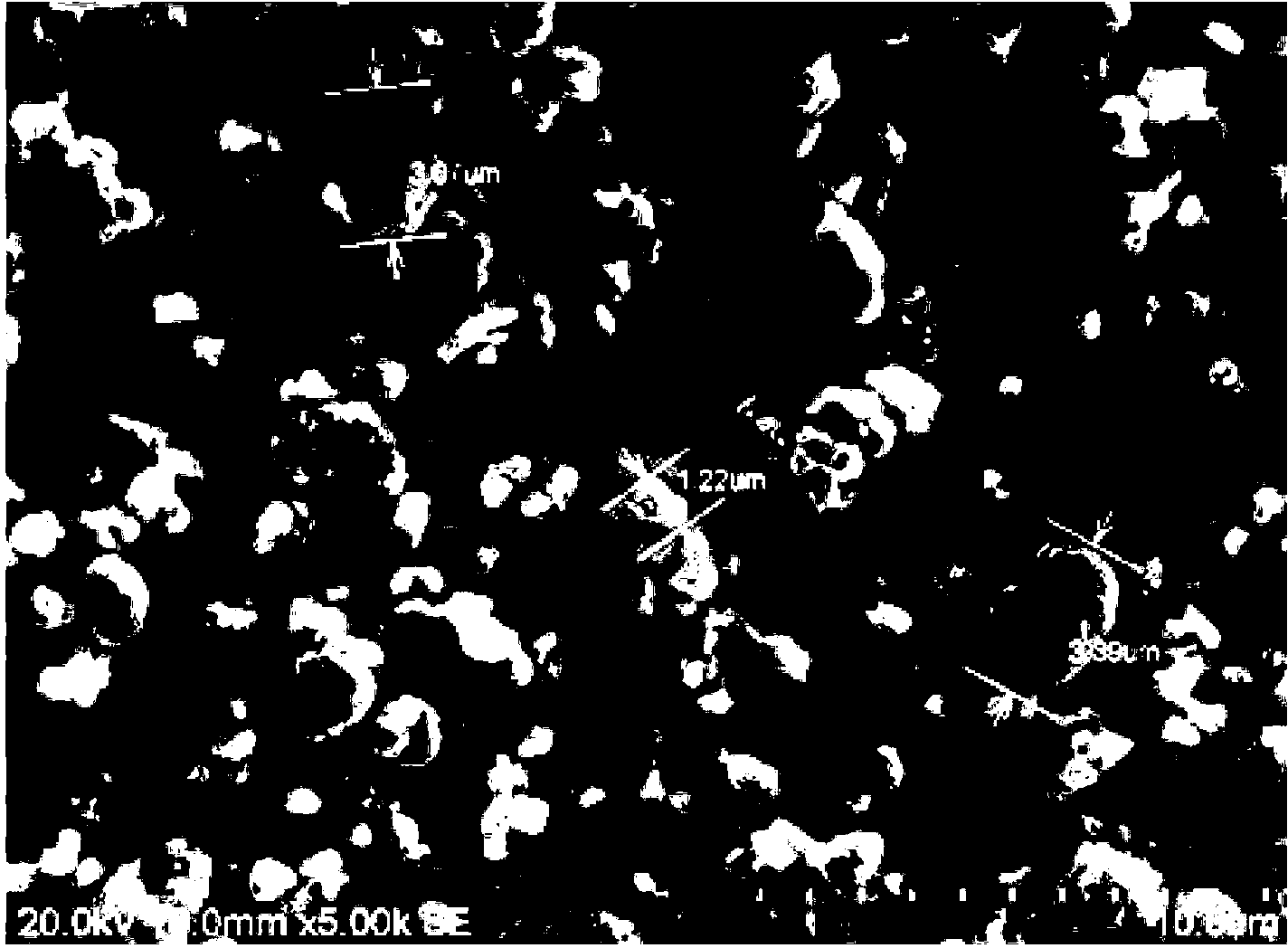

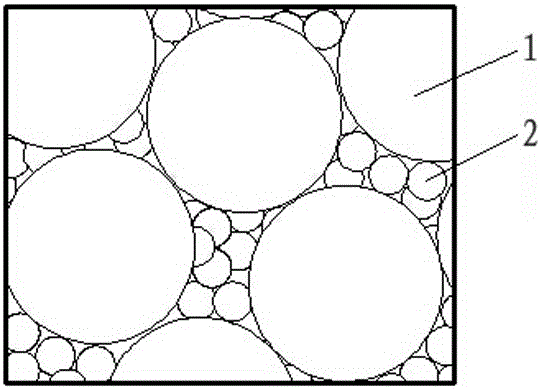

Ultrathin high-purity ceramic wafer and preparation process thereof

ActiveCN105693221AImprove thermal conductivityNo change in dielectric propertiesSolid contentNanometre

The invention relates to an ultrathin high-purity ceramic wafer and a preparation process thereof. Ceramic powder of the ceramic wafer is a mixture of micron powder and nanometer powder, and the nanometer powder accounts for 10-30% the volume of the ceramic powder; the median diameter of the micron powder is smaller than or equal to 3.0 microns; the median diameter of the nanometer powder is smaller than or equal to 0.2 micron; the micron powder particles are in contact with one another, and gaps among the micron powder are filled with the nanometer powder; preparation processes of tape casting zone generation and solid phase sintering are adopted, the ceramic powder serves as the solid phase of a sizing agent, and the mass of the ceramic mass accounts for 65% or above of that of the sizing agent; the solid phase sintering temperature is 100 DEG C or above lower than that of the theoretical sintering temperature of the micron powder. According to the ultrathin high-purity ceramic wafer and the preparation process thereof, the mixture of the micron powder and the nanometer powder serves as the ceramic powder, the volume ratio of the micron powder and the nanometer powder is reasonably regulated, and the sintering temperature is lowered without adding a sintering agent; an ultrathin ceramic plate which is flat in surface is prepared through the processes of raising the solid content and raising the sintering temperature, and the ceramic wafer still maintains a high heat-conducting property and does not change the dielectric property.

Owner:SHANTOU UNIV

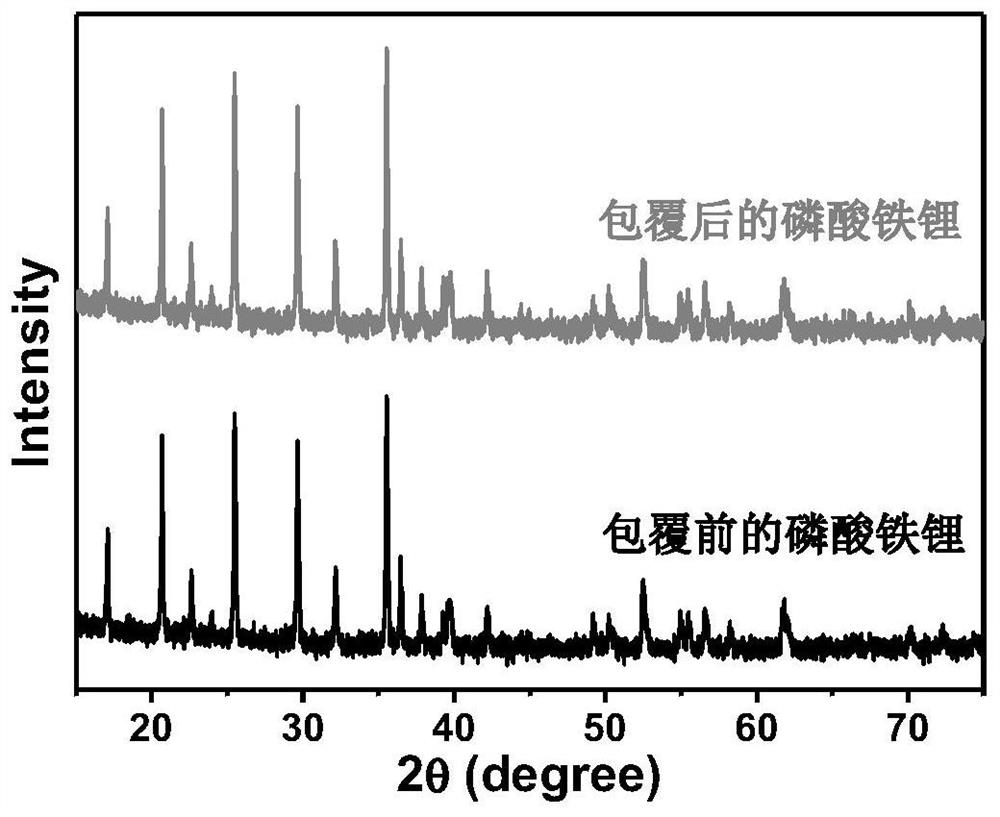

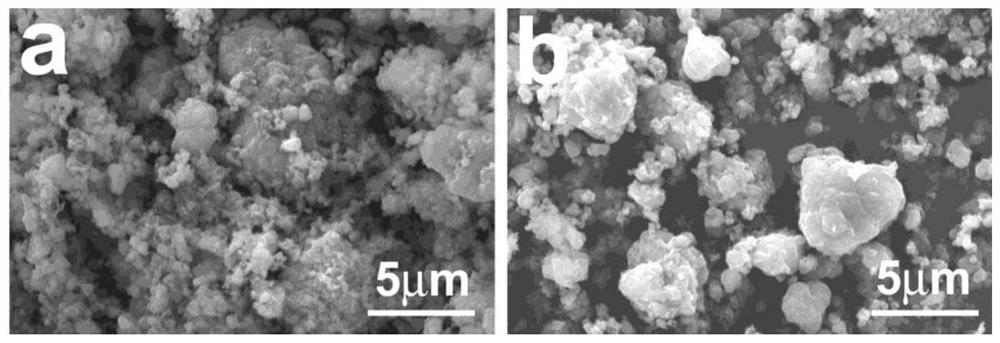

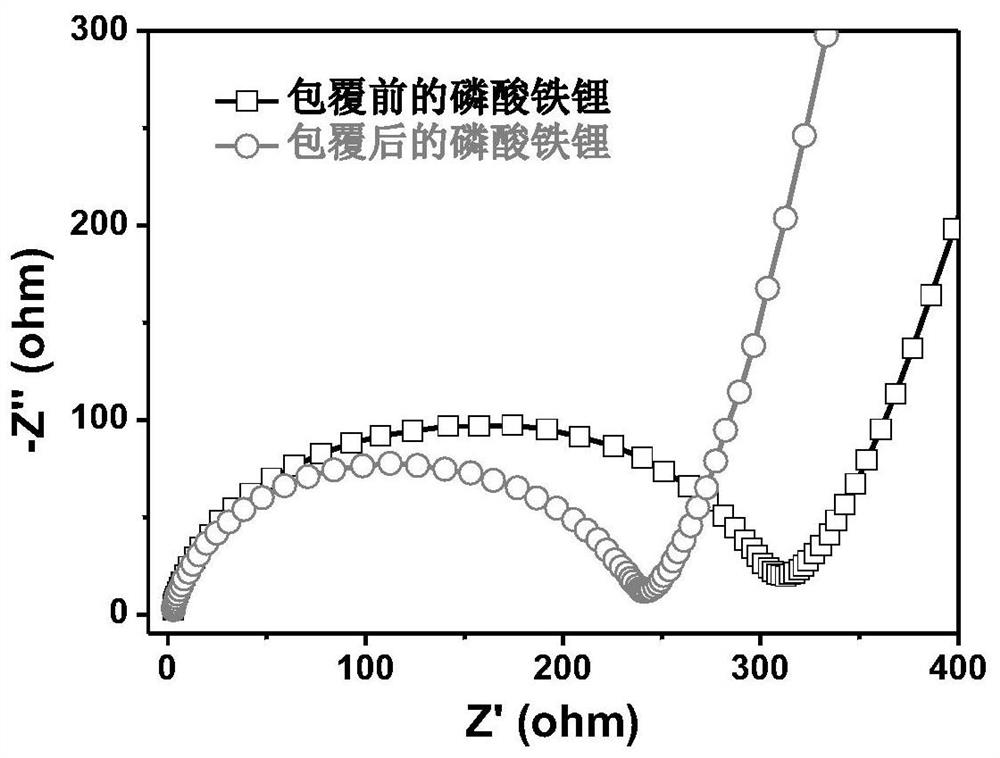

Method for compositely coating lithium battery positive electrode material with tungsten oxide and nitrogen-doped carbon

ActiveCN111900401AImprove conductivityImprove electrochemical stabilityFinal product manufactureCylindrical casing cells/batteryElectronic conductivityPolymerization

The invention belongs to the technical field of manufacturing of lithium battery cathode materials, and specifically relates to a method for compositely coating a lithium battery cathode material withtungsten oxide and nitrogen-doped carbon. A coating layer is formed on the surface of the lithium battery positive electrode material by polymerization of a carbon precursor and precipitation of a tungsten precursor. Curing and bonding of coating layer are realized through a calcining process. According to the present invention, the method has characteristics of low cost, low energy consumption and simple operation, and the lithium battery positive electrode material prepared through the method has characteristics of excellent electronic conductivity and excellent electrochemical stability.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

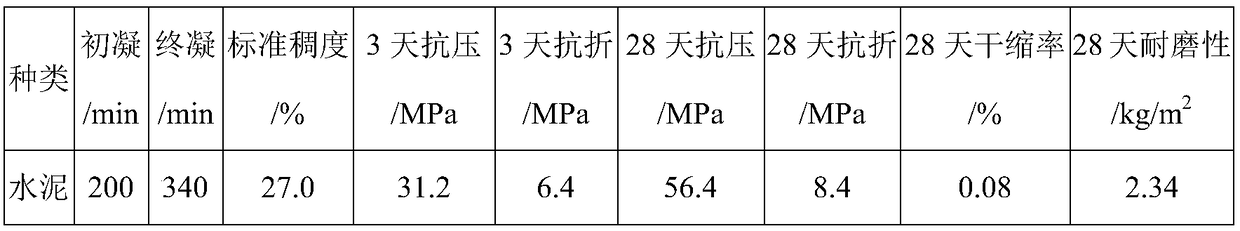

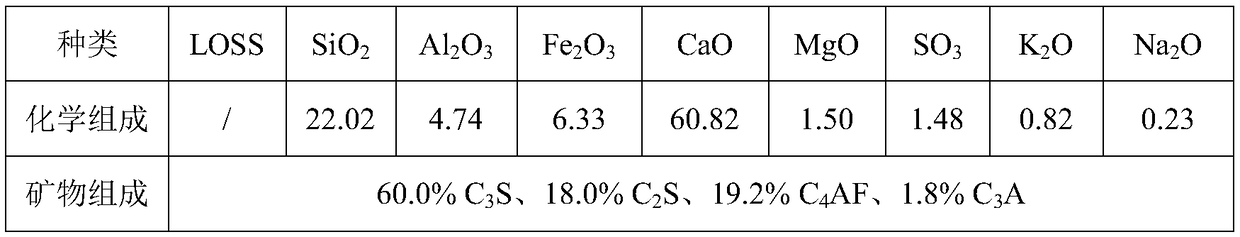

Road delayed-coagulation cement and preparation method thereof

InactiveCN108726904AReduce consumptionReduce calcination temperature and liquid phase viscosityCement productionResource utilizationEconomic benefits

The invention relates to road delayed-coagulation cement and a preparation method thereof. The road delayed-coagulation cement comprises special cement clinker, limestone waste, modified steel slag powder and phosphorus gypsum. According to the road delayed-coagulation cement, a cement raw material is prepared from carbon-containing shale, the phosphorus gypsum serves as mineralizing agents of clinker calcination, steel slag powder is prepared in a crushing, iron removing and grinding manner, the steel slag powder and the limestone waste serve as cement admixtures, and the phosphorus gypsum serves as a cement delayed coagulant. By the aid of the technical scheme, the prepared road delayed-coagulation cement has the advantages that coagulation time is suitable, early strength is high, laterstrength is rapidly increased, breaking strength is high, abrasion resistance is good, dry shrinkage performance is low and the like. Efficient resource utilization of solid waste such as the carbon-containing shale, the limestone waste, steel slag and the phosphorus gypsum is achieved, and the road delayed-coagulation cement has important economic benefits and social benefits.

Owner:GEZHOUBA SONGZI CEMENT

Method for preparing magnesium potassium titanate by directly utilizing magnesium oxide

ActiveCN102230223ALow costReduce corrosion lossPolycrystalline material growthFrom solid stateMicrowaveTitanium

The invention discloses a method for preparing magnesium potassium titanate by directly utilizing magnesium oxide, belonging to the technical field of inorganic material preparation. The method is mainly characterized in that: magnesium oxide, titaniferous compound and potassium titanate are directly taken as raw materials, the raw materials are mixed to be uniform, the mixture is calcined for 30 minutes to 24 hours at high temperature of 900-1300 DEG C, magnesium potassium carbonate (K2MgTi4O10, namely K2O. MgO. 4TiO2) can be prepared by one-step synthesis, and the obtained magnesium potassium carbonate after calcination is smashed, thus the finished product is obtained. Magnesium oxide is utilized as a reaction raw material, material cost is reduced, no fluxing agent is used in the preparation process, and no alkali magnesium raw material is used, thus rapid equipment corrosion loss in the high temperature alkali environment is reduced in the preparation process of the magnesium potassium titanate, the method is more applicable to mass production, and the process is simplified; meanwhile, calcination under microwave catalysis is utilized to speed up synthetic reaction of the magnesium potassium titanate, thus the production efficiency is improved.

Owner:北京无界实验科技有限公司

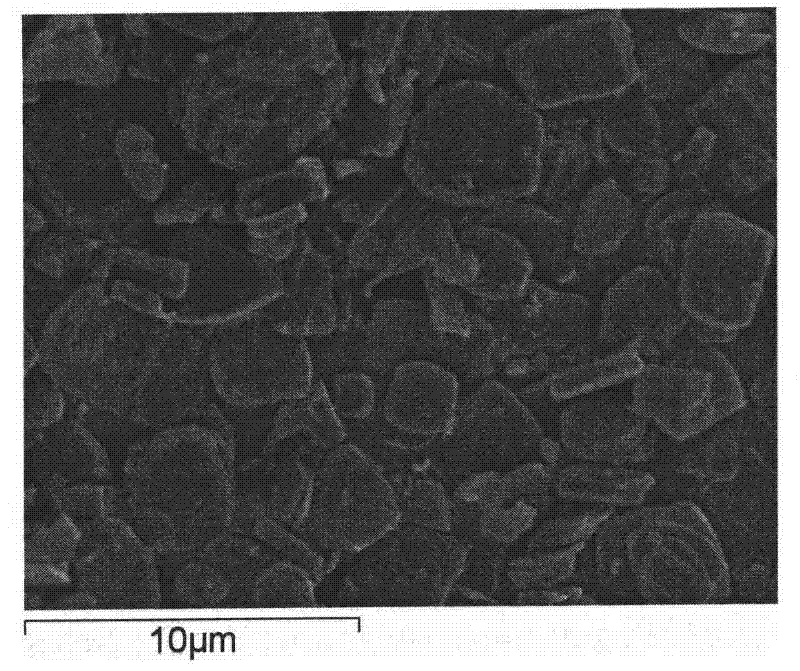

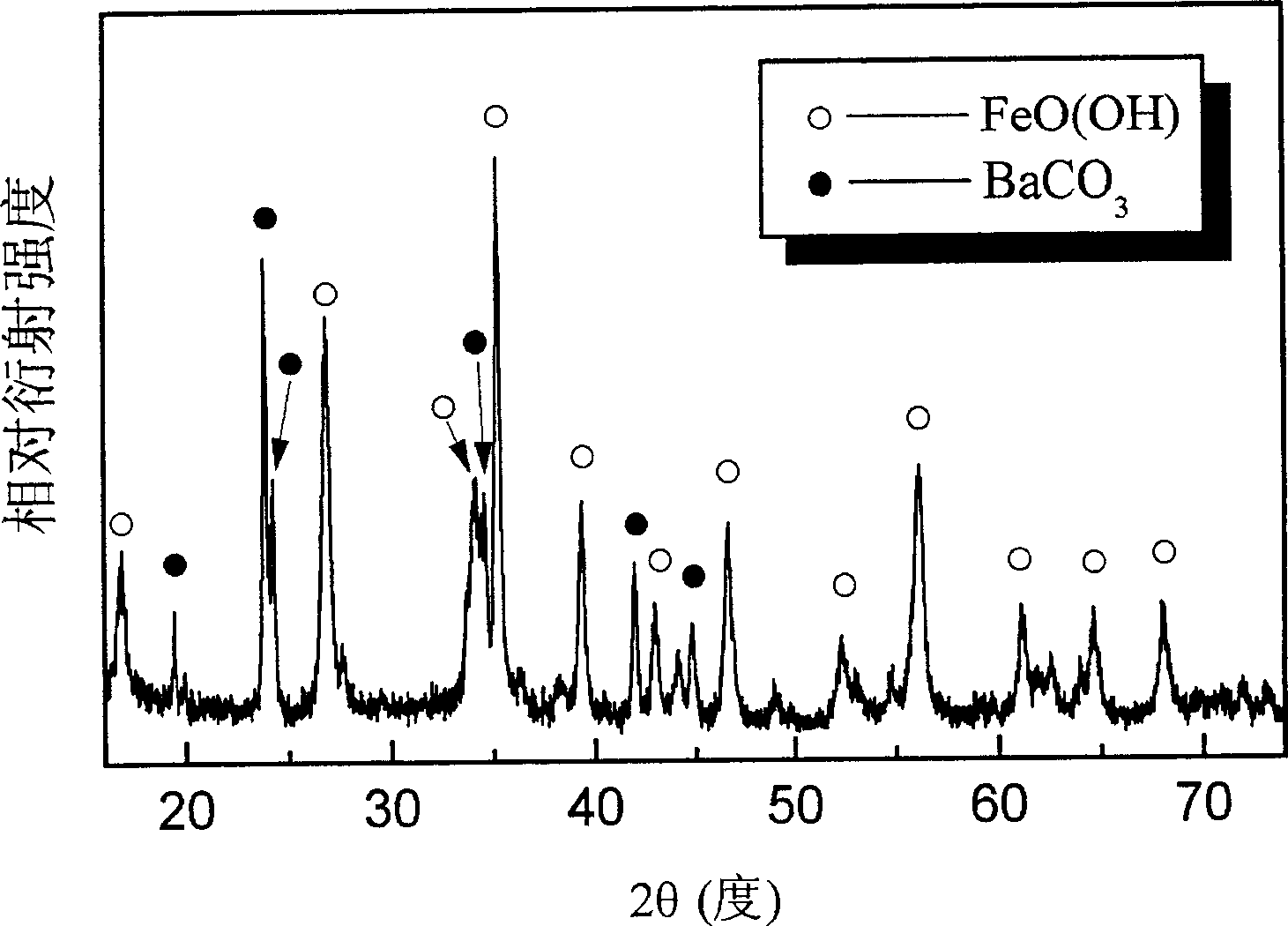

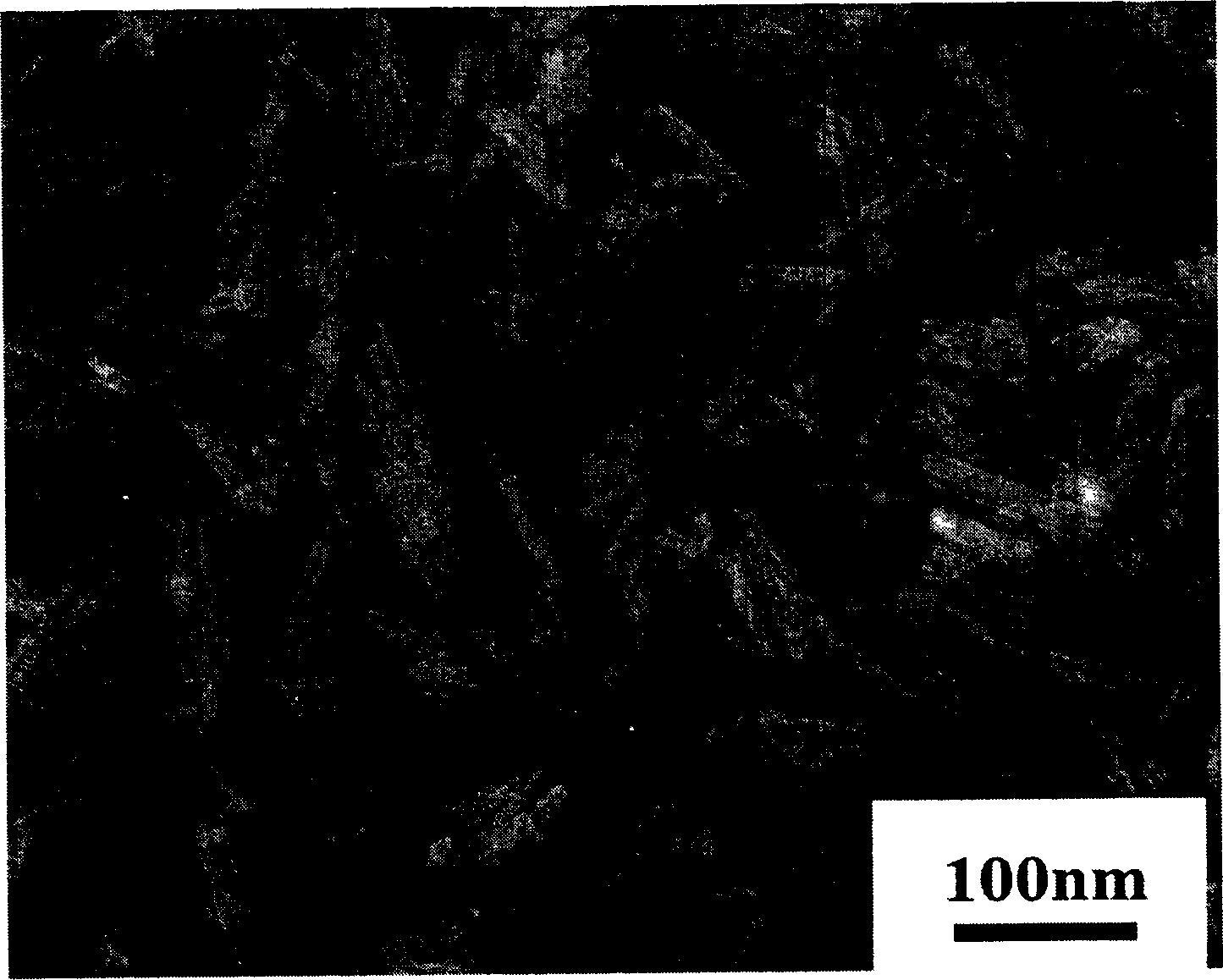

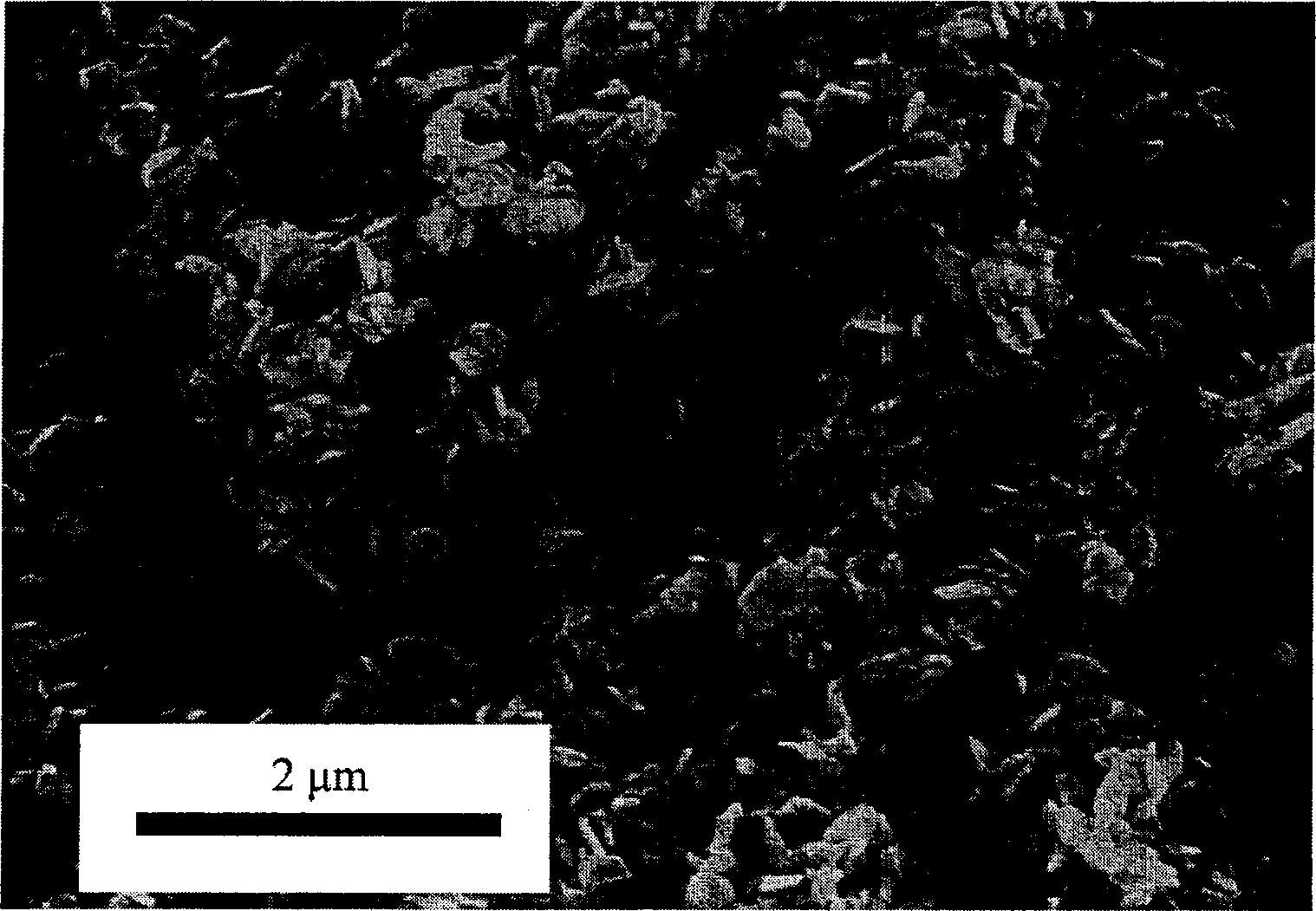

Hexagonal sheet-like barium ferrite magnetic nanometer powder preparation method

InactiveCN1880272ACalcination temperature is lowShort calcination timeHigh volume manufacturingHigh density

A preparing method of hexagonal piece barium ferrite nanometer magnetic powder includes: the predecessor body composed with the mixture of powdered BaCO3 and FeO(OH) powder the fineness of which belongs to nanometer is burnt for hexagonal piece barium ferrite nanometer magnetic powder. The optimal fineness of powered BaCO3 is nanometer and optimal nanometer FeO(OH) powder is the spindly FeO(OH) powder. The invention is suitable for application of perpendicular magnetic recording medium of high density and microwave absorber. The invention has the outstanding advantages as follows: well energy conservation effect for low calcinations heat and short calcinations time; high purity and good crystal model; simple process, low level demand for production facility, that is suitable for mass production in industry.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Manufacturing method of flexible titanium dioxide/carbon composite porous nanofiber membrane material

PendingCN109112728ACalcination temperature is lowShort calcination timeElectro-spinningNon-woven fabricsCarbon compositesFiber

The invention provides the manufacturing method of a flexible titanium dioxide / carbon composite porous nanofiber membrane material. The method comprises the following steps of step1, dissolving a titanium source and a high molecular polymer in an organic solvent to obtain a precursor solution; step2, carrying out electrostatic spinning on the obtained precursor solution under electrostatic high pressure to obtain a precursor nanofiber membrane on a receiving device; and step3, calcining The precursor nanofiber membrane under the protection of an inert gas atmosphere to obtain the flexible titanium dioxide / carbon composite porous nanofiber membrane material. In the invention, an electrostatic spinning technology is simple, there are many spinning raw materials, a calcining temperature for manufacturing the flexible composite porous nanofiber is low, calcining time is short, manufacturing cost is greatly reduced and production efficiency is increased, and a large scale production potential is possessed.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com