Method and device of obtaining active lime by vacuum calcining limestone

A calcined limestone, high activity technology, applied in the field of lime production, can solve the problems of loss of activity, green burning, low calcination temperature, etc., achieve high decomposition speed, solve pollution, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

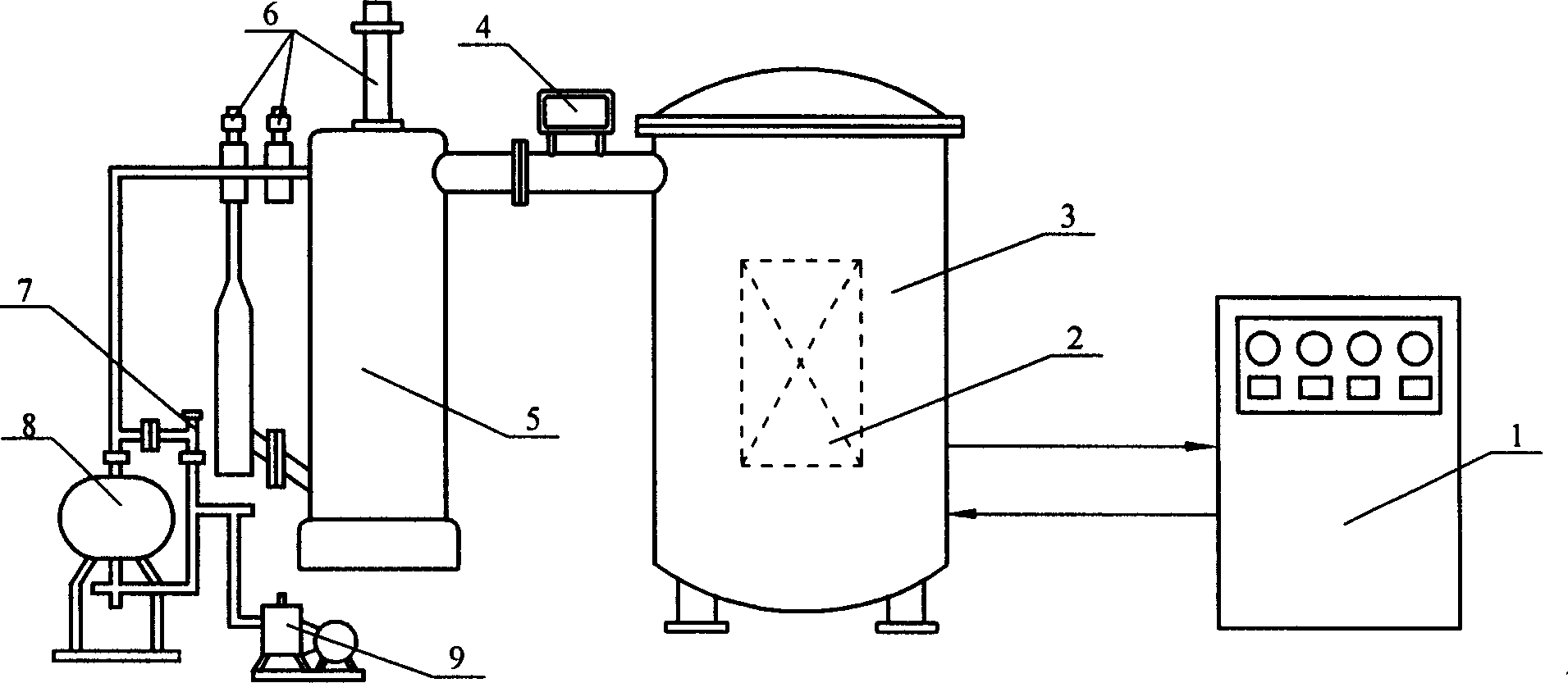

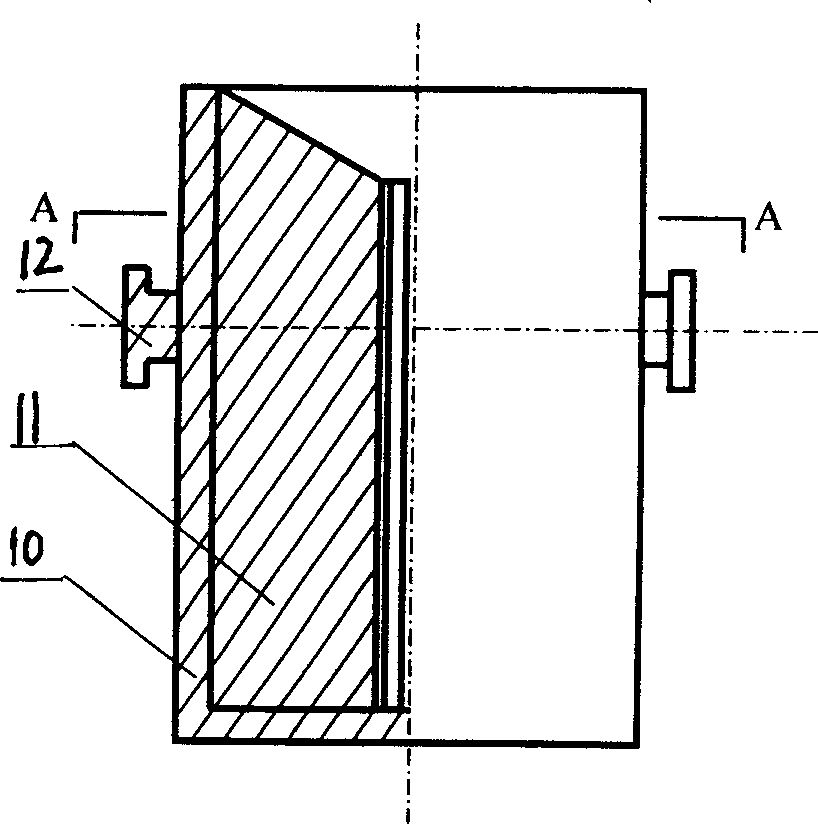

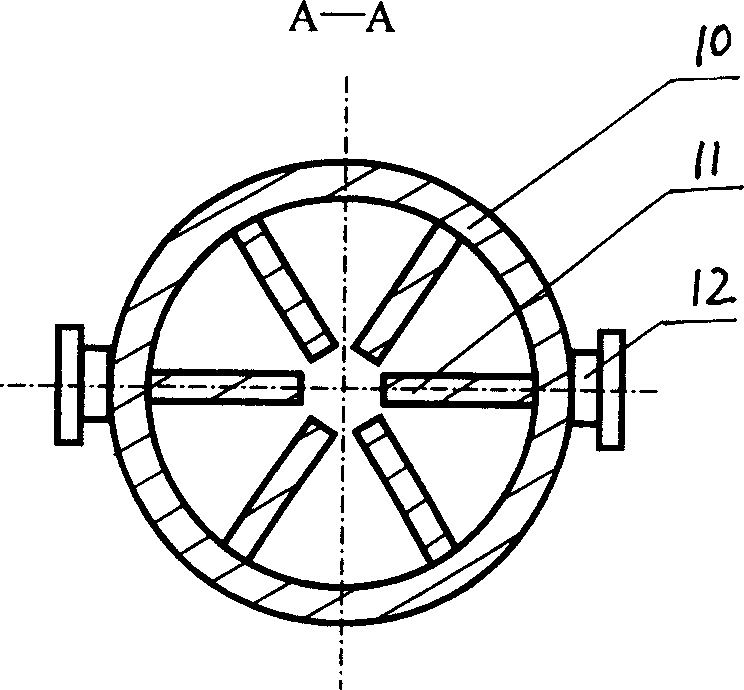

[0058] The device for obtaining highly active lime by vacuum calcining limestone given in this example consists of an electric furnace temperature measurement and control cabinet 1, a material tank 2, a vacuum electric furnace 3, a vacuum gauge 4, an oil diffusion pump 5, a vacuum valve 6, a bypass 7, and a Roots pump. 8. Mechanical pump 9 components. The vacuum electric furnace 3 is a tankless vacuum resistance furnace with a heating power of 120kW, an effective vacuum chamber volume of φ20mm×400mm, and an operating temperature of 700-1400°C; the electric furnace temperature measurement and control cabinet 1 is electrically connected to the vacuum electric furnace 3 for monitoring and control The operating temperature of the vacuum electric furnace 3; the vacuum system for monitoring and controlling the vacuum chamber pressure of the vacuum electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com