Patents

Literature

1144results about How to "Small bulk density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

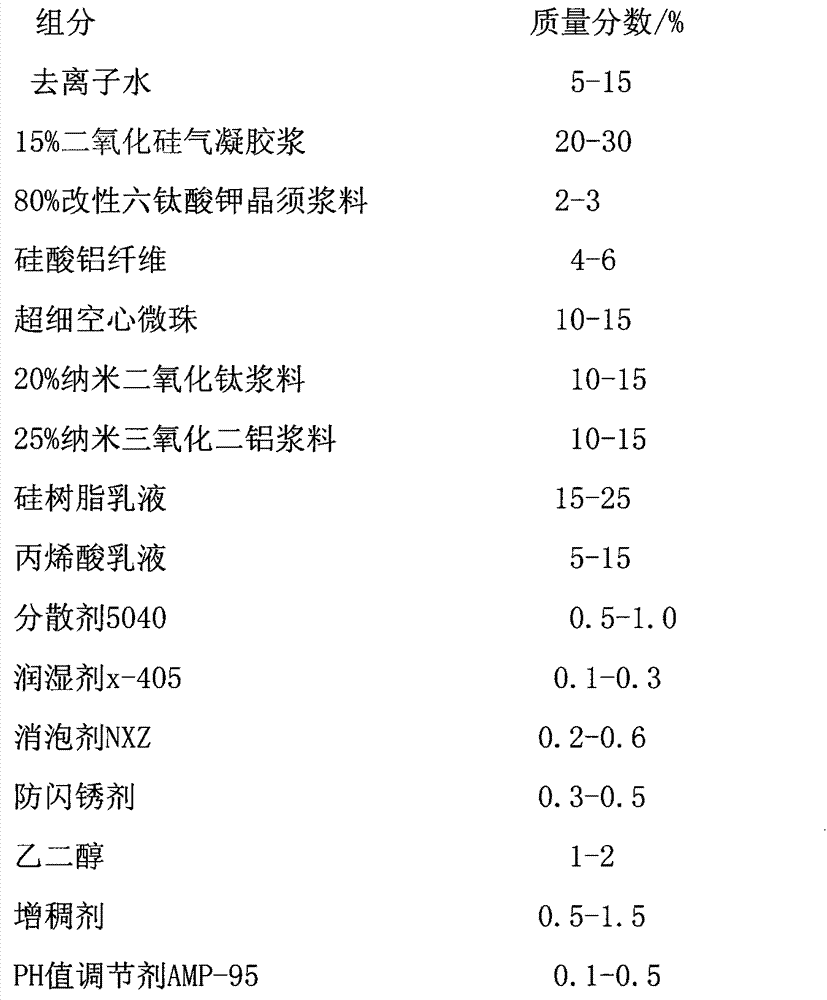

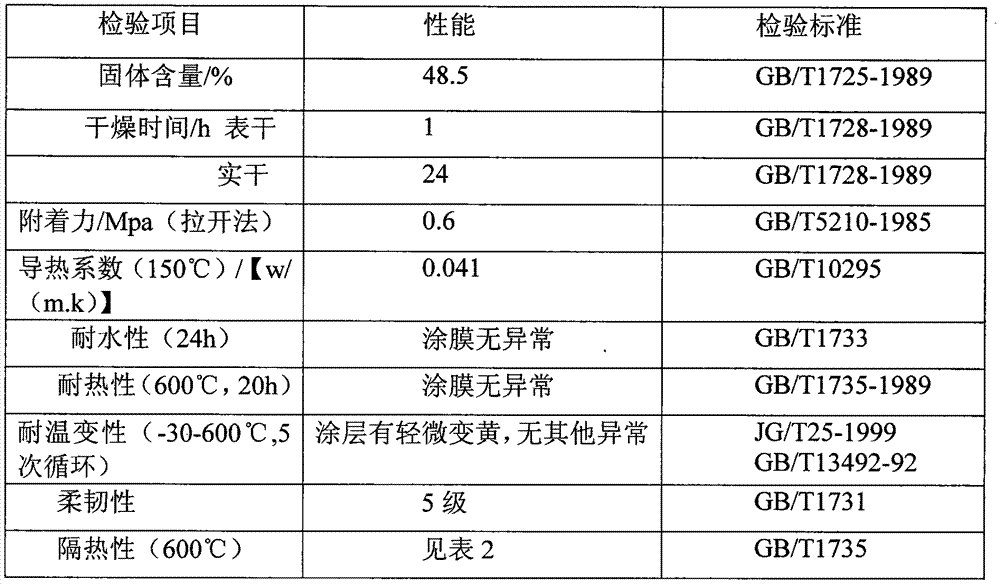

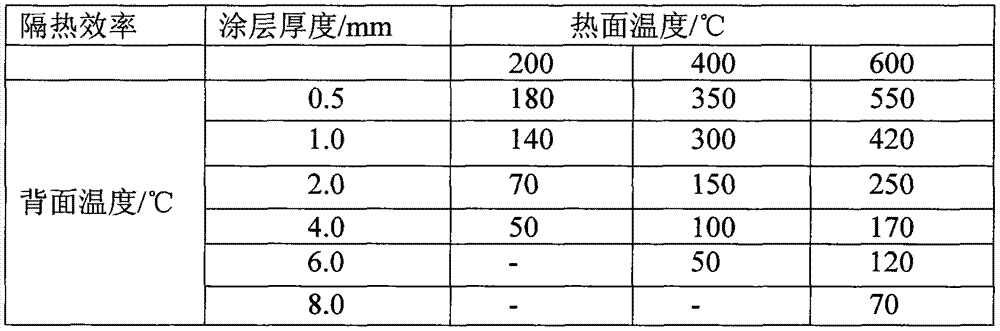

Nanometer high temperature resistant thermal insulation and prevention coating

The invention discloses a nanometer high temperature resistant thermal insulation and prevention coating. SiO2 aerogel, modified potassium hexatitanate whisker, aluminum silicate fiber, ultra-fine cenosphere, nanometer TiO2 and nanometer Al2O3 are used as a thermal insulation filler. A vacuum thermal insulation layer is formed by nano porous structures of SiO2 aerogel and cenosphere. The aluminum silicate fiber is used as a reinforcing and toughening material. The infrared shading performance of potassium hexatitanate whisker, nanometer TiO2 and nanometer Al2O3 are used as a thermal radiation shielding layer. A silicon resin emulsion and an acrylic emulsion are compounded to be an adhesive. Therefore, the nanometer 600 DEG C temperature resistant thermal insulation and prevention coating is prepared with matching of a variety of functional additives. The nanometer high temperature resistant thermal insulation and prevention coating has the characteristics of scumbling, thermal insulation, waterproofing, anti-crack, anti-corrosion, high temperature resistance, weather-proofing, durability and the like and is applicable to the field of industrial high temperature resistant thermal insulation energy conservation.

Owner:株洲中铁中南制造有限公司

Low-density composite foaming cement and preparation method thereof

The invention discloses low-density composite foaming cement and a preparation method thereof, relating to a light building material. The foaming cement is prepared by adopting a normal-temperature foaming technology, and comprises the following components in parts by weight: 100 parts of cement, 10-50 parts of active admixture, 1-5 parts of redispersible emulsion powder, 1-4 parts of water repellent, 0.5-1.5 parts of cellulose ether, 0.3-0.7 parts of reinforced fiber, 0.2-0.5 parts of foam stabilizer, 3-8 parts of foaming agent and 50-80 parts of water. The method comprises the following preparation steps of: proportionally mixing and stirring the cement, active admixture, redispersible emulsion powder, water repellent, cellulose ether, reinforced fiber, foam stabilizer, and water into cement slurry; adding the foaming agent; and stirring, molding by casting and naturally curing. The foaming cement disclosed by the invention has the advantages of low volume weight, small heat conducting coefficient, small shrinkage ratio, high intensity, integration of heat preservation, sound insulation, fire prevention and low carbon, simple and convenient production preparation process and easiness in controlling.

Owner:JIANGSU JINMAO TECH DEV

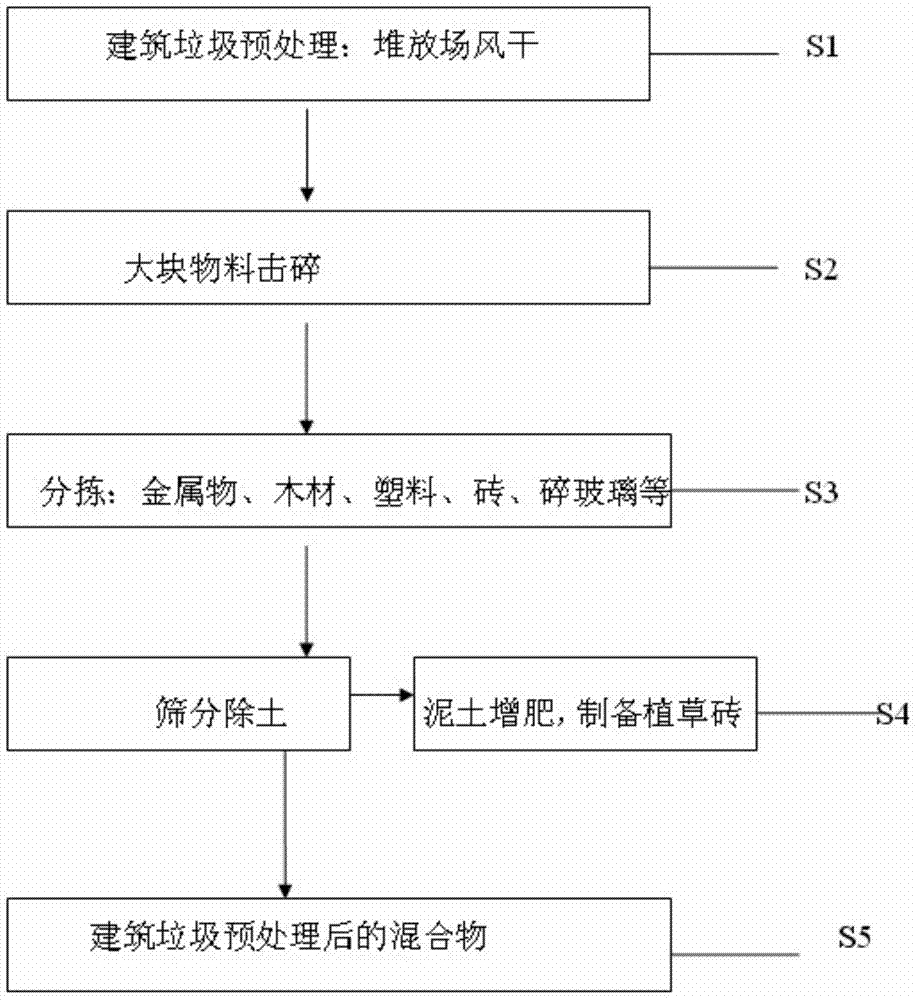

Ecological treatment technology for construction waste

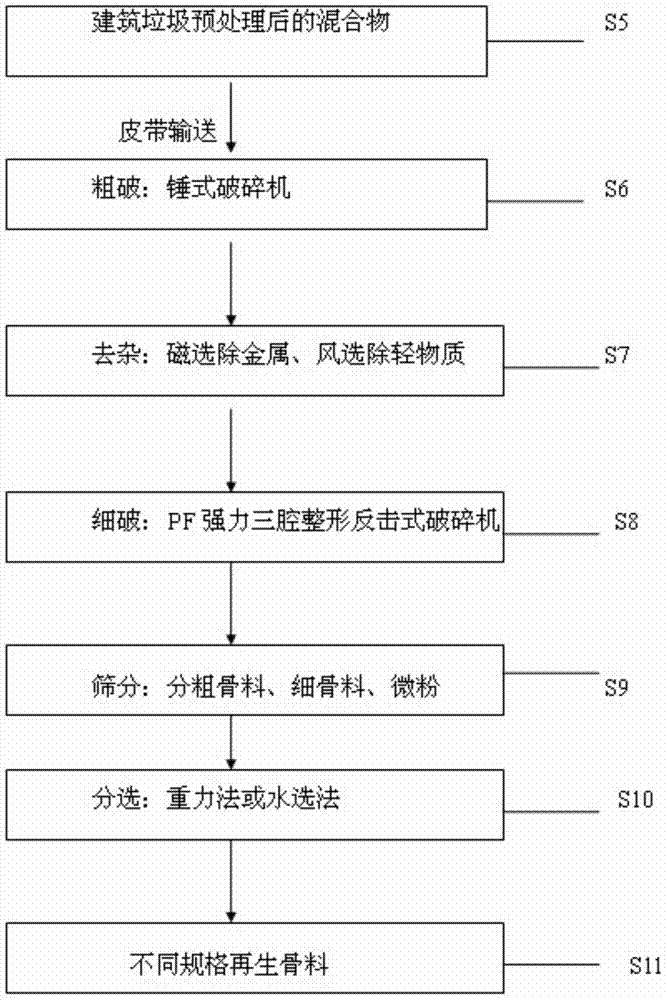

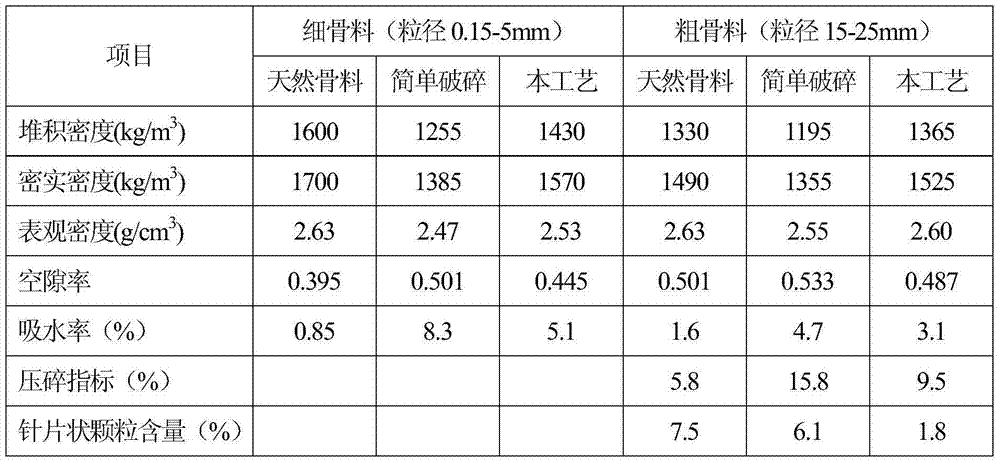

The invention belongs to the field of recycling of construction waste, energy conservation and environment protection, and construction materials, and relates to an ecological treatment technology for construction waste, and particularly relates to the ecological treatment technology for construction waste and a preparation method for regenerated novel construction materials, which can efficiently use the construction waste and does not generate secondary pollution. The ecological treatment technology comprises the following steps of pretreating in a construction waste dump, namely, air drying the construction waste, crushing big blocks, sorting and removing soil through vibrating, adding a fertilizer in the soil to be used for filling grass planting bricks; preparing recycled aggregate, namely, crushing roughly, removing impurities, precisely crushing and simultaneously reinforcing and shaping the recycled aggregate, screening out the recycled aggregate with particle size less than 0.15mm as well as 0.15-5mm, 5-15mm and 15-25mm and micro powder for the secondary time, finally, separating the brick from concrete by a gravitational method or a hydraulic mineral beneficiation method according to different densities of the brick and concrete in the mixed recycled aggregate. Recycling and high value-added utilization of the construction waste are realized, and the ecological treatment technology gets major breakthrough in recycling industry of construction waste.

Owner:DALIAN HONG YUAN GREEN BUILDING MATERIALS

Environmental protection type base fibre film, and its mfg. process

ActiveCN1559176AHigh strengthLose weightOrganic fertilisersPlant protective coveringsAdhesiveEngineering

An environmental protection type bast fibre film which is air permeable and impervious is prepared from bast fibres through opening fibres, removing dust and impurities, carding, stripping for netting, airflow netting, chemical sticking by adhesive to become film, applying the hydrophobic agent onto its surfaces, and cold rolling.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

Ceramic fiber building fireproof plate

The present invention is fireproof building board of ceramic fiber, and belongs to the field of ceramic fiber material technology. The fireproof building board of ceramic fiber is produced with aluminum silicate fiber or light refractory stuffing as base material, and through adding one or several kinds of enhancing fiber; adding proper amount of organic binding agent or inorganic binding agent, stuffing and additive; pulping; forming; drying and other steps. The fireproof building board of ceramic fiber is used as the heat insulating board in building, and has high fire rating, high fire resistance, high heat isolating performance, high strength, low density and low cost.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Preparation method of lodging-resistant multi-difference polyester low-elastic filament

ActiveCN106400179AImprove heat resistanceEasy to processMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyethylene glycol

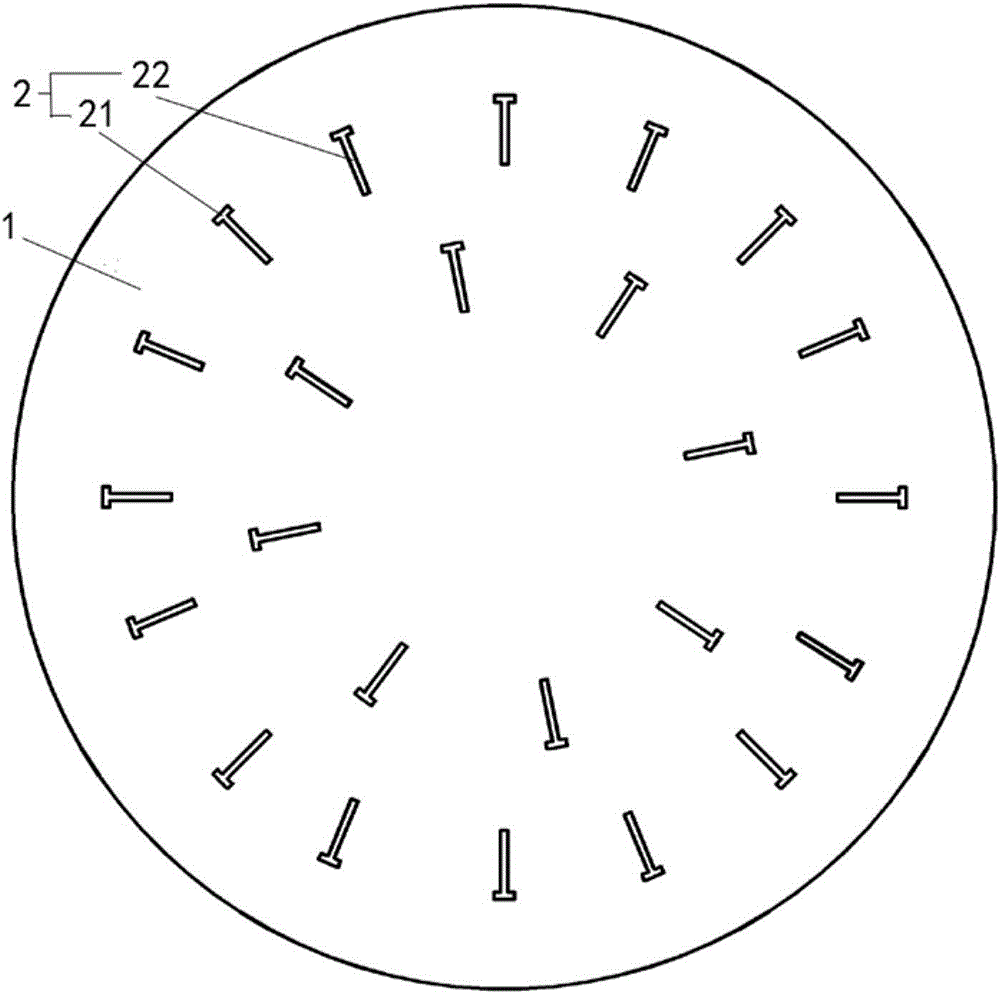

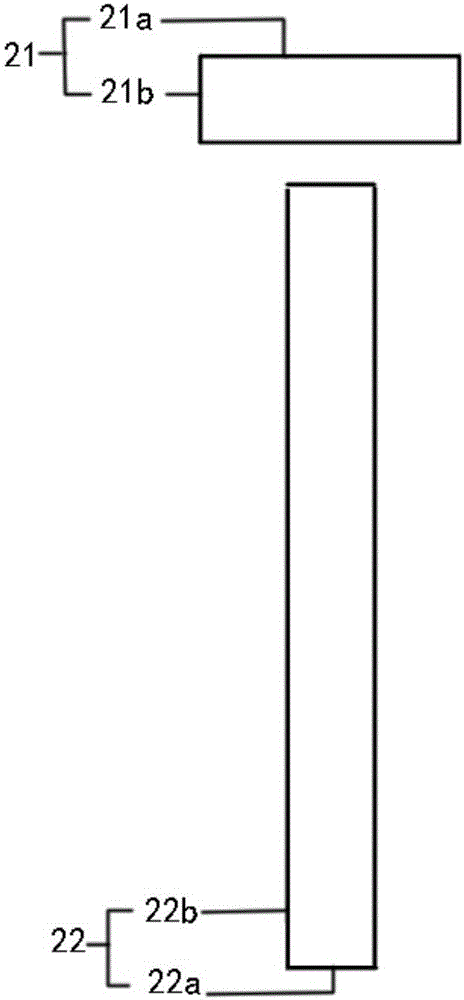

The invention relates to a preparation method of a lodging-resistant multi-difference polyester low elastic filament. The preparation method comprises the following steps: firstly, mixing nano sepiolite fibers, organic magnesium hydroxide whisker, organic barium sulfate nano powder, ethylene glycol, propylene glycol, p-hydroxybenzoic acid and sodium germanate to obtain a high-modulus composite alcohol solution; secondly, mixing organic wollastonite nano needle-like fibers, mica powder, polyethylene glycol, the propylene glycol, an antioxidant 1010, ethylene glycol antimony and protonated agent phosphoric acid to obtain a high-modulus composite promoter; thirdly, co-polycondensing the high-modulus composite multifunctional alcohol solution and the high-modulus composite promoter with purified terephthalic acid and the ethylene glycol to obtain high-modulus modified polyester; a melt of the high-modulus modified polyester is sprayed from a T-shaped spinneret orifice in a spinneret plate; the lodging-resistant multi-difference polyester low elastic filament is prepared by a special cooling mode and a low-temperature texturing process. The fiber prepared by the preparation method has multiple different properties of different crystallization, different orientation and different shrinkage; after different shrinkage, the appearance is good, and a brushed fabric prepared from the lodging-resistant multi-difference polyester low elastic filament is not easy to lodge.

Owner:荣翔化纤有限公司

Preparation method of microporous kyanite-based lightweight insulating refractory material

The invention relates to a preparation method of a microporous kyanite-based lightweight insulating refractory material. The preparation method is realized by comprising the following steps: (1) by taking kyanite, auxiliary materials and a cementing material as raw materials, adding a certain amount of dispersing agent, thickening time control agent and foam stabilizer, premixing, adding a certain amount of water, and mixing to prepare uniform slurry; (2) adding a certain amount of foaming agent in the slurry, mechanically agitating and foaming to prepare uniform foam slurry; (3) injecting the foam slurry into a mould, standing under a room-temperature environment so as to be cued and formed; (4) demoulding a green body, and then drying and sintering to obtain the microporous kyanite-based lightweight insulating refractory material. The prepared microporous kyanite-based lightweight insulating refractory material has the advantages of microfine air bore aperture (20-200mum), low volume density, high porosity, high strength, small sintering line change rate, low thermal conductivity, high usage temperature and the like. The raw materials are mainly kyanite, and other raw materials are common materials in refractory material industry, and are non-toxic and low-cost. The preparation method is simple and is easily controlled for the technology, and is suitable for industrial production.

Owner:ZHENGZHOU UNIV

Method for preparing microcrystalline foam glass by using high titanium blast furnace slag and waste glass powder

The invention discloses a method for preparing microcrystalline foam glass by using high titanium blast furnace slag and waste glass powder. The method comprises the following steps: grinding the high titanium blast furnace slag and waste glass powder, uniformly and fully mixing the high titanium blast furnace slag, the waste glass powder, a fluxing agent, a foaming agent and a foam stabilizer, pressing into a block, adding the mixture block into a heating device and preparing the microcrystalline foam glass at a low temperature according to a specific heat treatment process by using a one-step sintering method. According to the characteristic that the high titanium blast furnace slag which is rich in TiO2 can serve as a nucleation agent, the low-melting-point waste glass powder serves as a silicious raw material, a proper amount of corresponding fluxing agent and sintering process are matched, the preparation temperature is greatly reduced, and the preparation can be finished through one-step sintering; and therefore, the energy consumption can be reduced, the process is simplified, the cycle is shortened, the cost is saved, the product which is uniform in cells, moderate in cell diameter, low in volume density, low in water absorption rate, good in thermal insulation effect and high in mechanical strength can be obtained, and the additional value of high titanium blast furnace slag utilization is improved.

Owner:SICHUAN UNIV

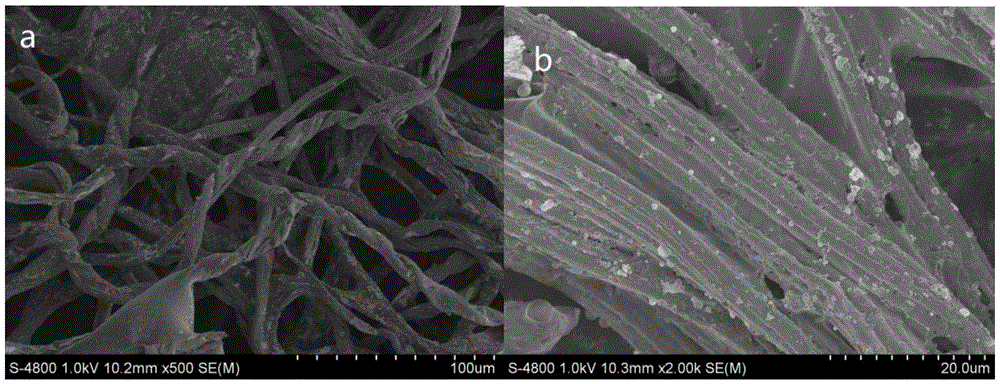

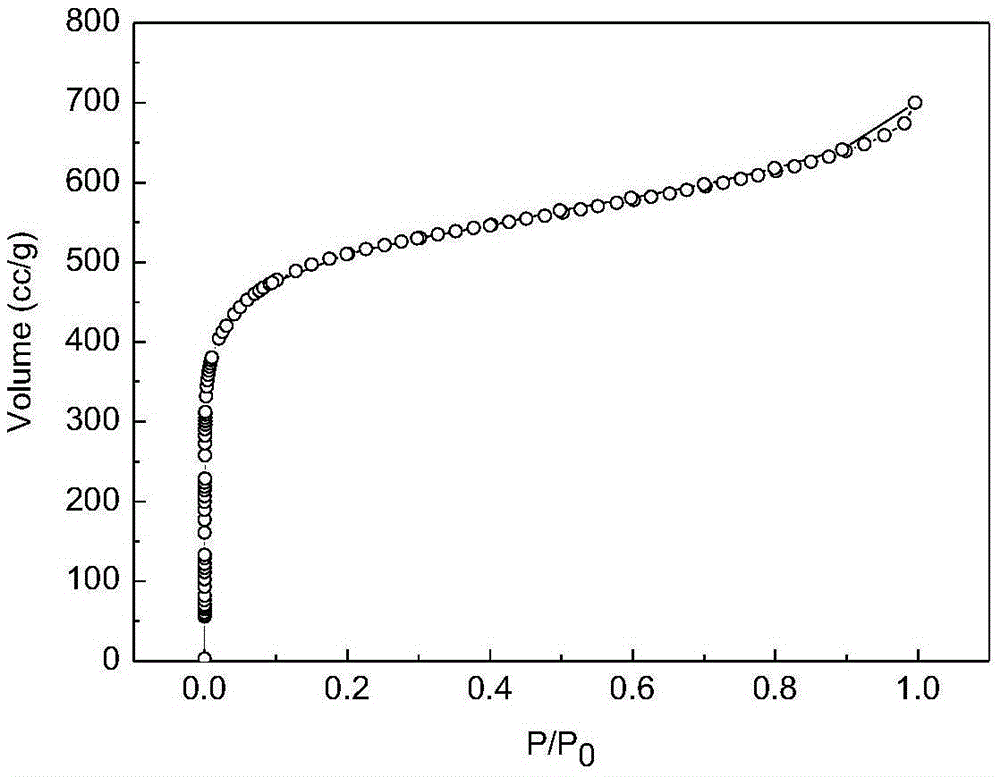

Method for efficiently preparing cotton based mesoporous activated carbon fiber

InactiveCN105480973AWide range of sourcesLow priceFibre chemical featuresChemistryHydrothermal carbonization

The invention relates to a method for efficiently preparing cotton based mesoporous activated carbon fiber. The method comprises a step (1) of washing cotton, placing the cotton in a hydrothermal reaction kettle, performing heating to 150-200 DEG C at the heating rate of 5-30 DEG C / min, performing hydrothermal carbonization, performing heat preservation for 1-3 hours and then performing cooling to room temperature; a step (2) of dipping carbonization materials obtained from the step (1) into activator solution, performing microwave-ultrasonic joint dipping for 5-30 minutes and then performing filtration, sending filtration materials to a microwave heating device, performing activation for 5-15 minutes at 250-350 DEG C and then stopping microwave output, and a step (3) of washing the activated materials to be neutral and performing drying to obtain the activated carbon fiber. According to the method, the characteristics of microwave inner heating and selective heating are fully utilized, the technological process is simple, the activation temperature is only 250-350 DEG C, the activation time is only 5-15 minutes, the mesoporous proportion of the activated carbon fiber of the product reaches 50-90%, and the adsorptive property is good.

Owner:HEBEI UNIV OF TECH

Light-weight corundum-spinel castable and preparation method thereof

The invention relates to a light-weight corundum-spinel castable and a preparation method thereof. The preparation method includes following steps: (A) employing 60-75 wt% of equal-diameter micro-porous corundum spheres as an aggregate, and employing 8-12 wt% of electric-fused white corundum fine powder, 2-8 wt% of electric-fused magnesite fine powder, 2-8 wt% of magnesium aluminate spinel fine powder, 6-12 wt% of [alpha]-Al2O3 micro powder, 0.5-2.5 wt% of chromium oxide powder and 3-7 wt% of an aluminum silicone gel powder as substrate materials, wherein the aggregate and the substrate materials form a raw material in total; (B) employing organic fibers accounting for 0.02-0.08 wt% of the raw material and a polycarboxylate water reducer accounting for 0.05-0.12 wt% of the raw material as additive materials, pre-mixing the substrate material with the additive materials and adding the aggregate with uniform mixing; (C) adding water accounting for 3-5 wt% of the raw material, stirring the mixture and performing cast moulding; and (D) maintaining the temperature at 110-200 DEG C for 12-48 h, roasting the moulded product at 800-1200 DEG C for 24-72 h to obtain the light-weight corundum-spinel castable. The light-weight corundum-spinel castable is low in apparent porosity, is low in volume density, is low in heat conductivity, is strong in anti-slag-erosion capability and is long in service life.

Owner:WUHAN UNIV OF SCI & TECH

Energy-saving consumption-reducing technique for preparing haydite by co-disposing polluted soil and desilting sediment

ActiveCN102173850APromote healthy developmentLow running costCeramicwareExpanded clay aggregateWater content

The invention relates to an energy-saving consumption-reducing environment-friendly method for preparing haydite by co-disposing municipal massive solid wastes, which comprises the following steps: directly mixing polluted soil and polluted desilting sediment (without energy-consuming drying), adding a conditioner, granulating, and firing at 900-1200 DEG C for 15-40 minutes. The test indicates that the prepared haydite product has the following properties: the bulk density is 500-900 kg / m<3>, the cylindrical compressive strength is 5.0-10.0 Mpa, and the water absorptivity is 4.8-9.2%; and the leaching toxicities of typical heavy metals are as follows: Cu<0.26 mg / L, As<0.03 mg / L, Cd<0.0002 mg / L, and Hg<0.0001 mg / L. The method provided by the invention fully utilizes the water-content complementarity of the polluted soil and sewage reservoir sediment as well as the characteristic of mutual catalytic degradation of heavy metal pollutants and organic pollutants, implements energy saving and consumption reduction in the technical field of traditional techniques for preparing haydite from solid wastes, lowers the cost and secondary pollution in solid waste disposal industry, enhances the properties of the solid waste haydite, and widens the application field of the solid waste haydite.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

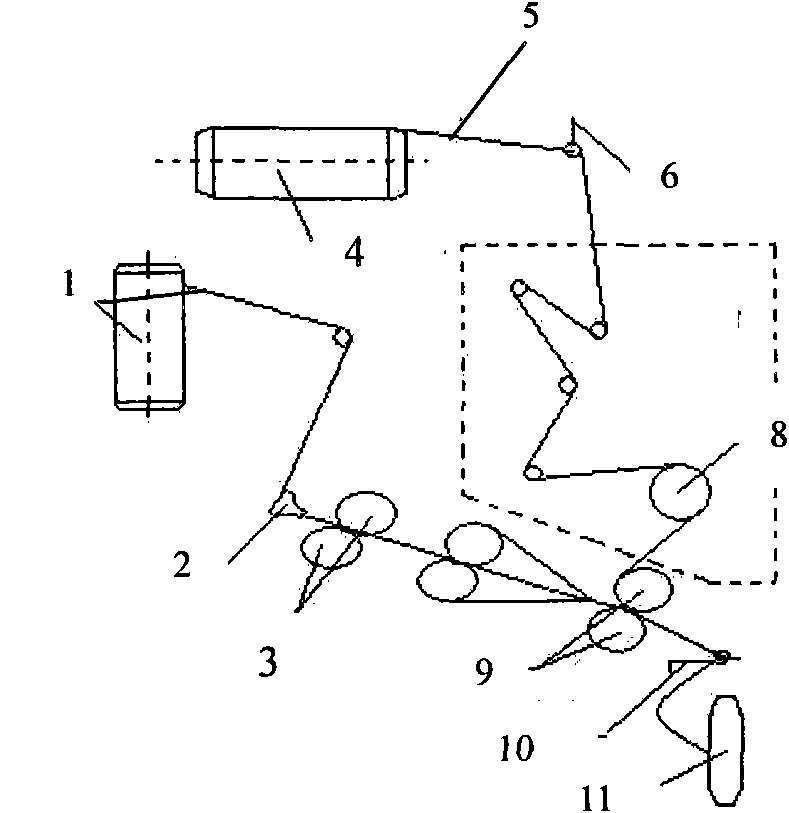

Yarn forming method for hollow yarns

The invention discloses a yarn forming method for hollow yarns, which comprises the following steps: making clad yarns in spinning equipment by using water soluble polyvinylalcohol fibers as core yarns and using comed slivers which are clad by fibers according to a ratio of 12 to 15 g / 10m; dissolving the core in water at the temperature of 5 to 100 DEG C; and obtaining 45s to 10s hollow yarns after the polyvinylalcohol dissolves in water from the clad yarns completely. The hollow yarns made by the yarn forming method of the invention has the advantages that: the volume density of the yarns is lowered by 15 to 30 percent; the apparent volume of the yarn aggrdgate is increased by 15 to 30 percent; the water absorptivity of the yarns is improved by 15 to 30 percent; and the bulkiness is improved.

Owner:JIAXING UNIV

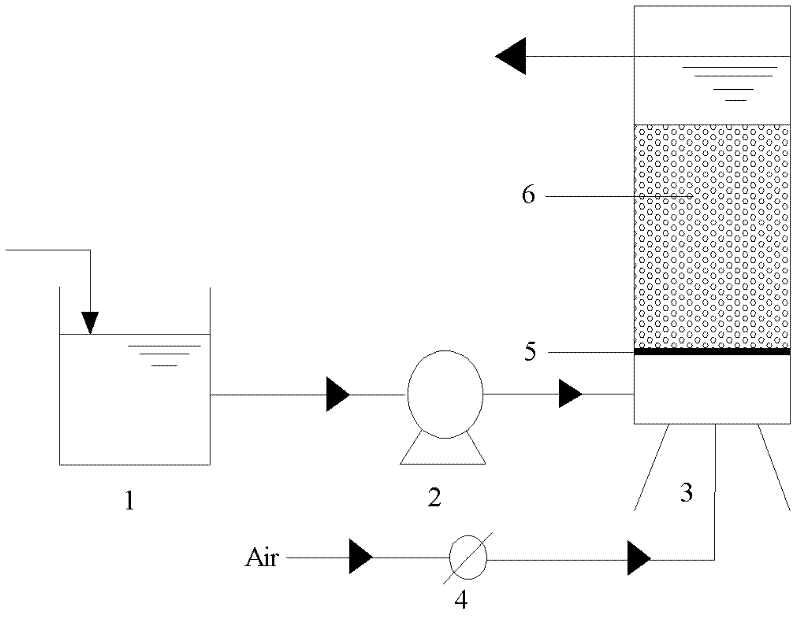

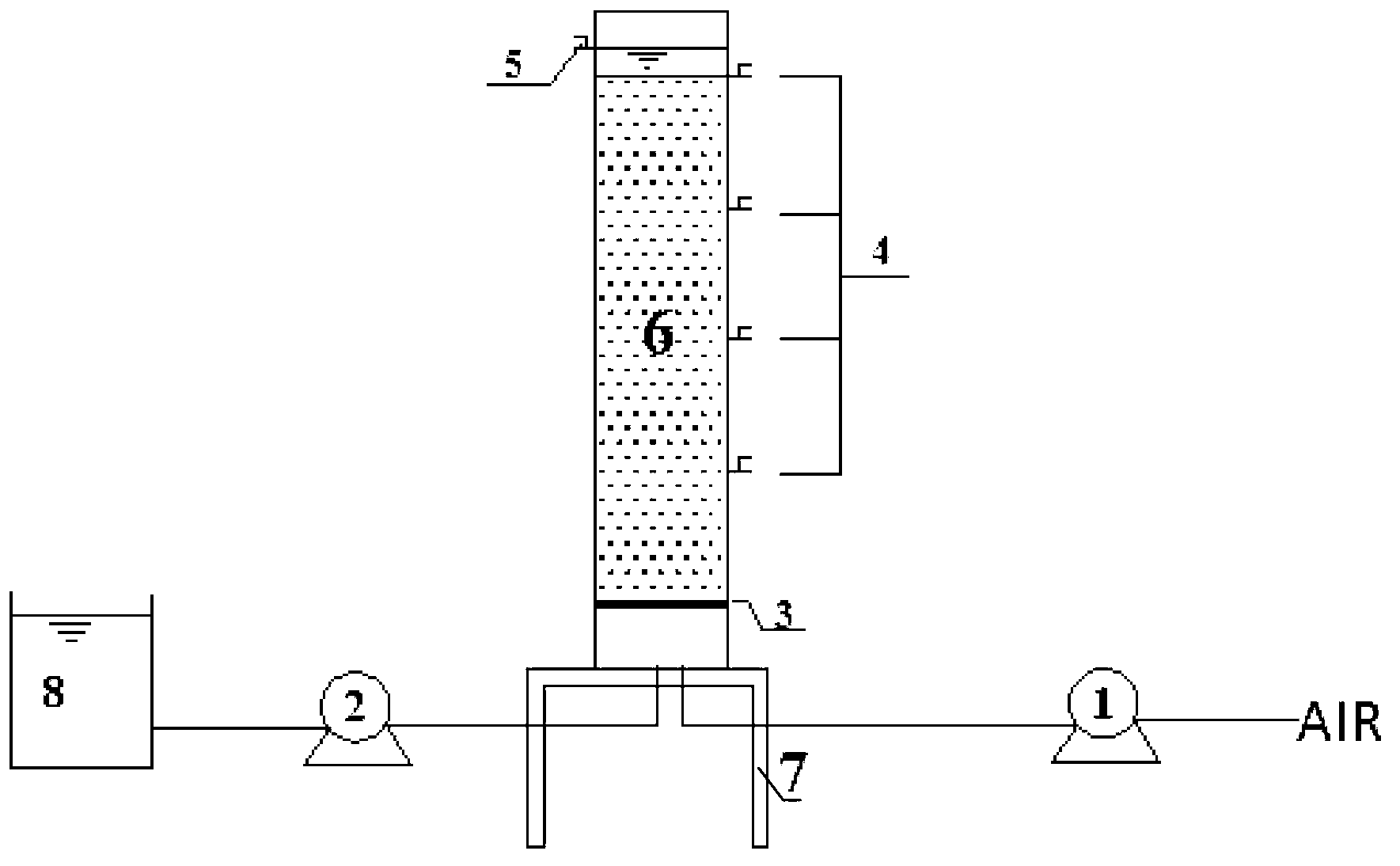

Granular anti-hardening acid-base dual-purpose ternary micro-electrolysis filler and preparation method thereof

ActiveCN102583659AReduce consumptionWith strengthWater/sewage treatmentElectrolysisChemical oxygen demand

The invention relates to a granular anti-hardening acid-base dual-purpose ternary micro-electrolysis filler and a preparation method thereof. The grain size of the filler ranges from 1mm to 5mm, and iron powder, aluminium powder and graphite powder are mixed in a mass ratio of (2-6):(2-6):1 to perform granulation and then are sintered by being isolated from air, thus obtaining the filler. The micro-electrolysis filler is applicable to micro electronic treatment on acid sewage or base sewage. According to the invention, the efficiency of micro electrolysis on the sewage is high, a filling areais not easy to harden, and the period of back flushing is long. When the ternary micro-electrolysis filler is used for treating the sewage, CODcr (chemical oxygen demand) of the sewage can be reducedefficiently in a short time, and the biochemistry of the sewage can be improved. According to the invention, the raw materials are easy to obtain, the preparation process is simple, the problem of filler hardening of the conventional micro-electrolysis technology is solved, and the filler is applicable to treatment on the base sewage.

Owner:SHANDONG UNIV

Lightweight reformed main iron runner pouring material

The invention discloses a lightweight reformed main iron runner pouring material. The pouring material comprises alumina, brown aluminum oxide, SiC, SiO2 micropowder, alpha-Al2O3 micropowder, spherical asphalt, aluminum oxide hollow sphere, explosion-proof fiber, metal silicon powder, andalusite fine ore powder, calcium aluminate cement and sodium tripolyphosphate. In the invention, lightweight reformation is carried out on the traditional heavy refractory material iron runner material by introducing the aluminum oxide hollow sphere into a main iron runner material; and due to the popularization and application of the lightweight reformed main iron runner pouring material, the consumption of the refractory material can be reduced for a user, the heat preservation and energy saving of high-temperature equipment are favorably promoted. By adding the aluminum oxide hollow sphere, the volume density of the product is reduced, the heat conduction coefficient is reduced, and the heat preserving effect on the main iron runner pouring material is achieved.

Owner:佘成其

Method for preparing anti-hardening granular ceramic iron-carbon micro-electrolysis filler from industrial wastes

ActiveCN103253741ARealize the recycling of solid wasteSave clay resourcesTreatment using aerobic processesWater contaminantsElectrolysisChemical oxygen demand

The invention relates to a method for preparing anti-hardening granular ceramic iron-carbon micro-electrolysis filler from industrial wastes. The method comprises the steps of mixing iron powder, lignin, red mud and clay, which are used as raw materials, in a mass ratio of (4-5):(2-3):(1-3):3, then pelleting, and burning under a reducing atmosphere. The particle size of the prepared anti-hardening granular ceramic iron-carbon micro-electrolysis filler is 4-6mm. When used for sewage treatment, the anti-hardening granular ceramic iron-carbon micro-electrolysis filler can improve the biodegradability of wastewater in a short time and reduce the CODCr (Chemical Oxygen Demand Cr) and toxicity of the wastewater, and is difficult to be hardened in use, long in service cycle and simple to maintain. The industrial wastes are used as raw materials, so that energy resources are saved, and the treatment of wastes with processes of wastes against one another is realized.

Owner:SHANDONG UNIV

Sintering expansion type light ceramsite produced by using oily sludge and manufacture method of sintering expansion type light ceramsite

ActiveCN103241970AImprove plasticityImprove yieldSolid waste managementClimate change adaptationSludgeSuperplasticizer

The invention relates to a sintering expansion type light ceramsite produced by using oily sludge and a manufacture method of the sintering expansion type light ceramsite. The manufacture method is characterized by comprising the following steps of: uniformly mixing raw materials including oily sludge, building waste residue, waste energy-saving lamp residue, boiler waste residue, wood material processing waste residue, calcium oxide, calcium sulfate, carboxymethylcellulose, calcium carbonate, ferric sulfide, a polycarboxylate superplasticizer, ferrous sulfate, magnesium sulfate and water by using a dual-shaft mixing and stirring machine, manufacturing into spherical particles with diameters of 5-20mm by using a disc pelletizing machine, drying, roasting by using a dual-cylinder rotary kiln, controlling the temperature to be 1,050-1,200 DEG C and the time to be 10-25 minutes, cooling and discharging from the kiln, then screening and manufacturing to be a sintering expansion type light ceramsite product. The sintering expansion type light ceramsite product has the advantages and effects of being light in weight, preserving and insulating heat, absorbing and insulating sound, comprehensively utilizing and recycling solid waste resources, and being free of pollution, low in cost and good in benefit, and accords with the requirements of saving energy, reducing emission, protecting environment and developing low-carbon economy in China.

Owner:清远绿由环保科技有限公司 +1

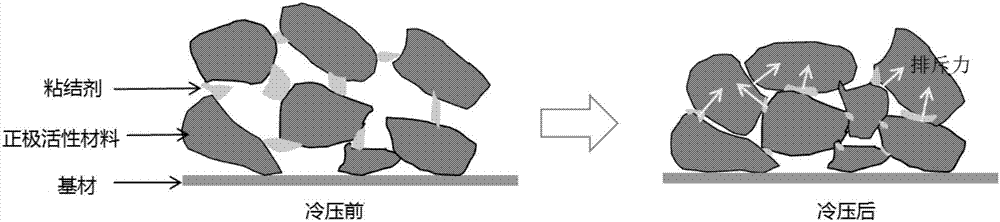

Lithium ion battery positive plate and manufacture method thereof

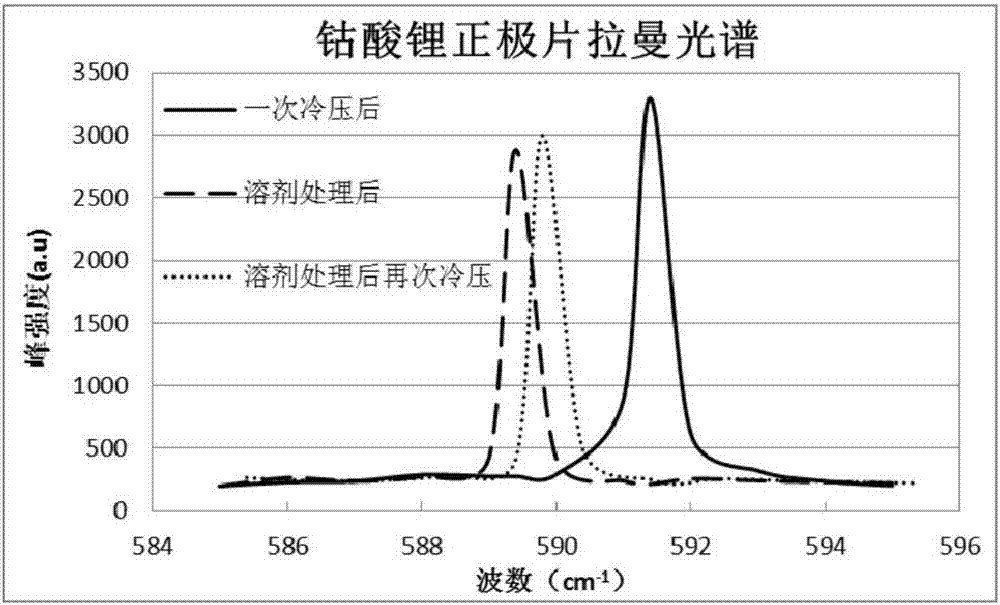

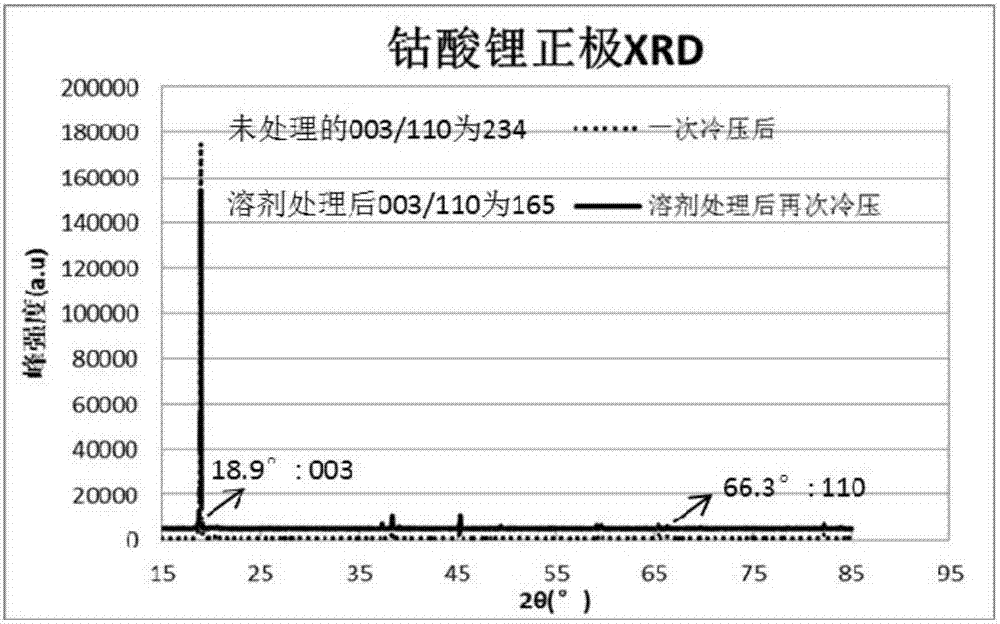

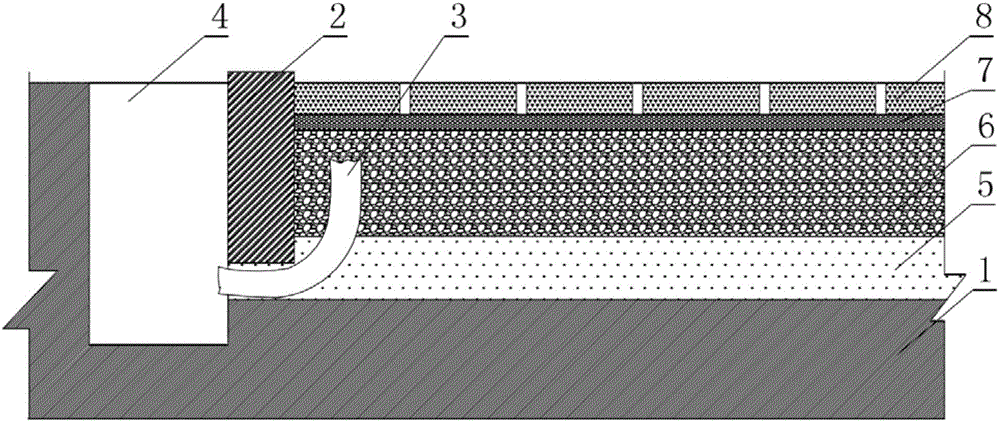

ActiveCN107403905AReduce stickingReduce thicknessSecondary cellsElectrode collector coatingSodium-ion batterySlurry

The invention discloses a manufacture method of a lithium ion battery positive plate. The manufacture method comprises the following steps: providing a positive current collector; preparing positive slurry containing an positive active material with a stratified-structured crystal form, uniformly distributing the positive slurry onto the positive current collector, drying, and carrying out primary cold pressing and slicing, so as to obtain a positive plate; carrying out infiltration on the positive plate by virtue of a solvent; and drying, and carrying out secondary cold pressing, so as to obtain the lithium ion battery positive plate. By carrying out infiltration on the positive plate which is subjected to primary cold pressing, residual stress of the positive plate can be effectively reduced, the expansion of the positive plate can be reduced, a lithium ion battery is thinned, and the energy density of the lithium ion battery is increased. The contact among particles of the positive active material is relatively close in a subsequent charging-discharging cycle process, and the cycle performance of the lithium ion battery is improved. Besides, the invention further discloses the lithium ion battery positive plate manufactured by the method and the lithium ion battery adopting the lithium ion battery positive plate.

Owner:NINGDE AMPEREX TECH

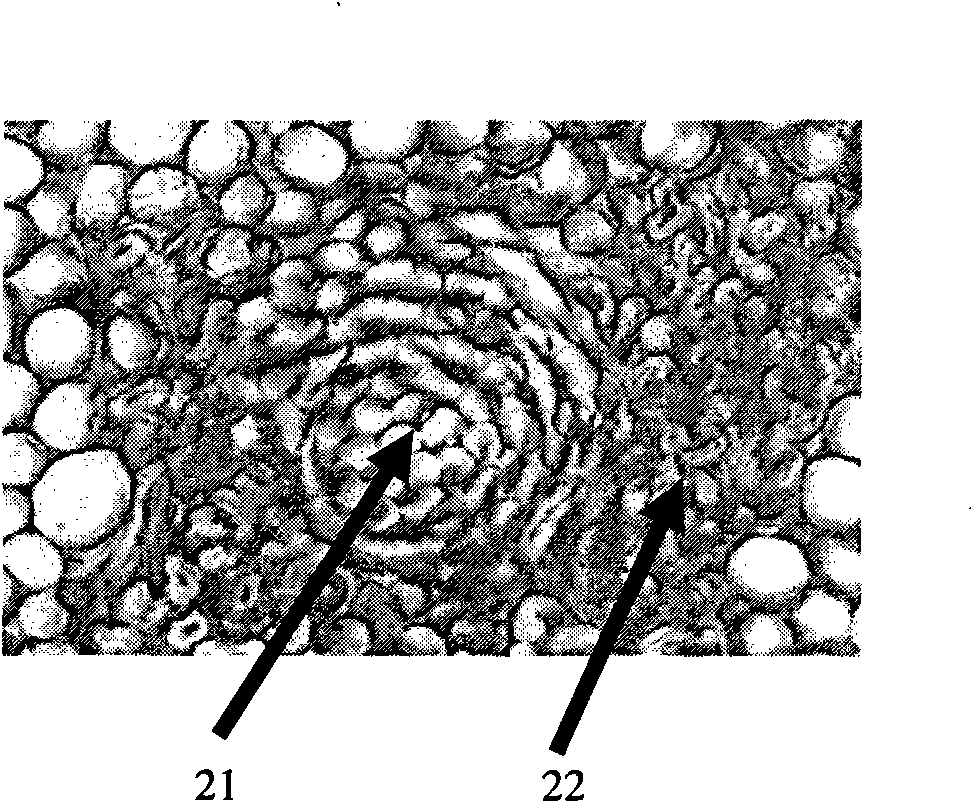

Alumina-magnesia refractory brick containing light porous aggregate and its making process

The present invention relates to one kind of alumina-magnesia refractory brick containing light porous aggregate and its production process. The technological scheme is that the alumina-silica refractory brick is produced with light porous Al2O3-MgO refractory material 30-70 wt%, compact Al2O3-MgO refractory material 0-35 wt%, fine magnesia powder 5-30 wt%, fine alpha-Al2O3 powder 3-10 wt%, fine corundum powder 0-25 wt% and fine spinel powder 0-25 wt%, and through mixture, adding waste pulp liquid in 3-7 wt% as binding agent, stirring, pressing to form adobe, drying at 100-150 deg.c for 12-48 hr, sintering at 1400-1600 deg.c for 2-5 hr and naturally cooling. The alumina-magnesia refractory brick has high macro porosity, small average pore size, low heat conductivity and high medium erosion resistance, and may be used in the permanent layer or work layer in high temperature kiln, furnace and container.

Owner:WUHAN UNIV OF SCI & TECH

Construction method for water-permeable and water-retaining water-permeable pavement structure

InactiveCN104878678AResolve disposal issuesSolve energy problemsPaving gutters/kerbsRoads maintainenceSurface layerRoad surface

The invention discloses a construction method for a water-permeable and water-retaining water-permeable pavement structure. The method comprises the steps of carrying out roadbed excavation, carrying out cushion laying, carrying out base course laying, carrying out leveling layer laying, carrying out surface layer laying and carrying out joint sand laying. According to the method, the process is simple, and the water-permeable pavement structure with high water permeability and high water retention is obtained through processing construction waste into recycled aggregate and constructing, so that the problem of construction waste disposal is solved, a great deal of building materials can be provided, meanwhile, energy problem, environmental problem and social problem resulting from the exploitation of natural stone resources are avoided, and thus the method is a multipurpose measure; particularly, the water-permeable pavement structure plays an important role in adjusting the humiture of urban ground surface due to high water permeability and high water retention.

Owner:SHENZHEN HUAWEI ENVIRONMENTAL PROTECTION BUILDINGMATERIAL

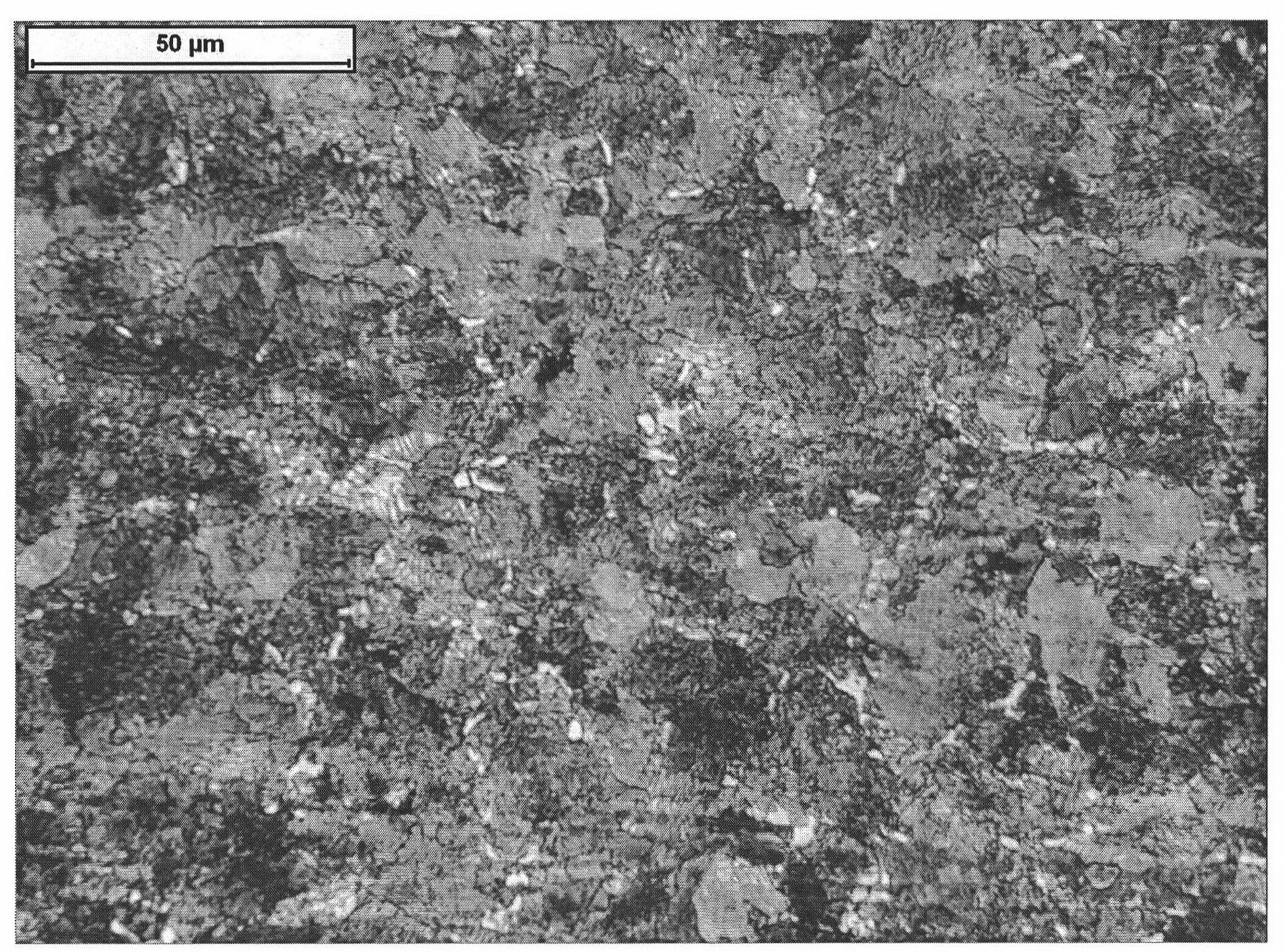

Preparation method for self-suspension propping agent in laboratory

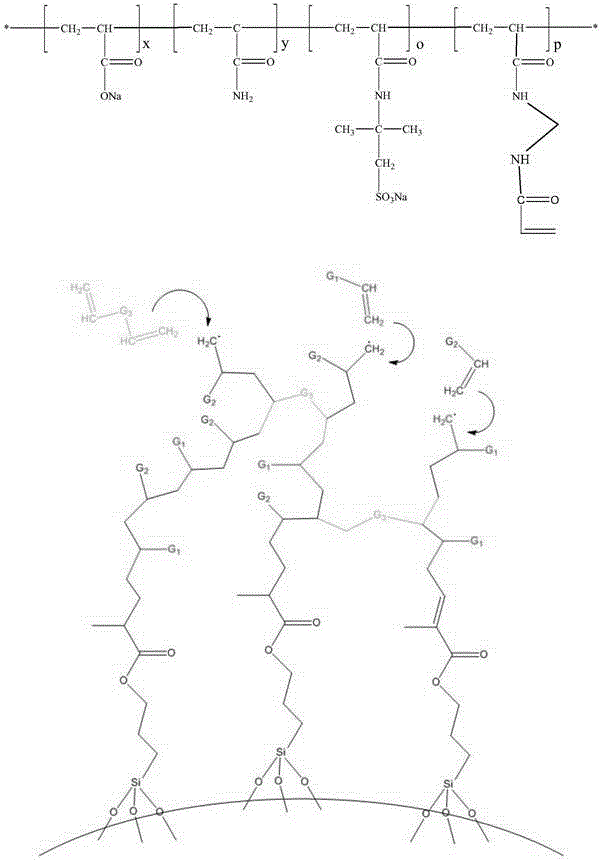

InactiveCN106634939AReduced fracturing costsShear stableFluid removalDrilling compositionFunctional monomerExpanded clay aggregate

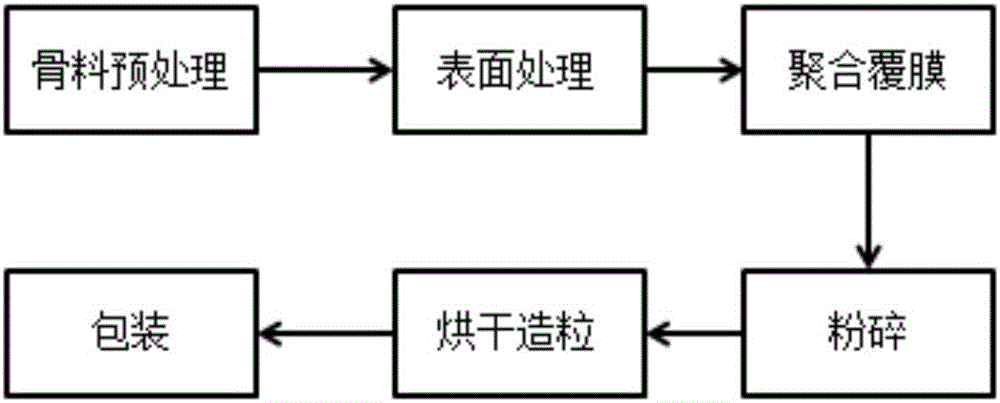

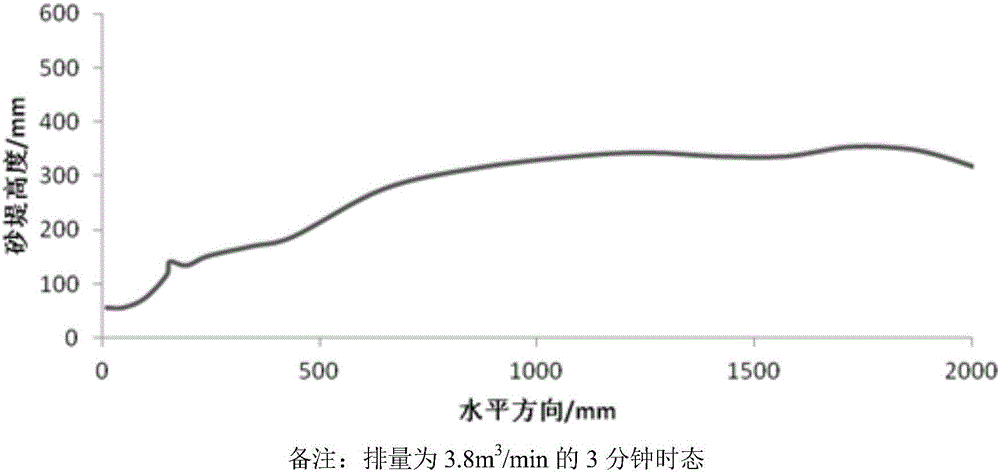

The invention belongs to the technical field of yield increasing and fracturing of petroleum engineering and provides a method for preparing a self-suspension propping agent in a laboratory. The method comprises the following steps: taking quartz sand / ceramsite / propping agent as aggregates; pre-treating with an organic solvent and treating the surface with a coupling reagent; polymerizing and coating; and crushing, drying, pelletizing and then packaging. A coating polymerizing product (as shown in the figure) is acquired through the polybasic polymerization of the reactant and acrylamide / sodium acrylate / functional monomer / cross-linking agent. The expansion times of the prepared self-suspension propping agent is 3-12 times; the self-suspension propping agent can be completely hydrated within 1min-2min; the hydrated layer is stably expanded at 2 DEG C to 193 DEG C; the self-suspension propping agent swells once encountering with water, the volume density is reduced from 2.4g / cm3 to 1.3g / cm3 and the excellent self-suspension characteristic after the clean water system swelling is presented. The self-suspension propping agent prepared in the laboratory can realize the onsite mixing for hydraulic fracturing construction, the water for fracturing is greatly reduced, the labor cost is lowered and the application prospect is wide.

Owner:王展旭

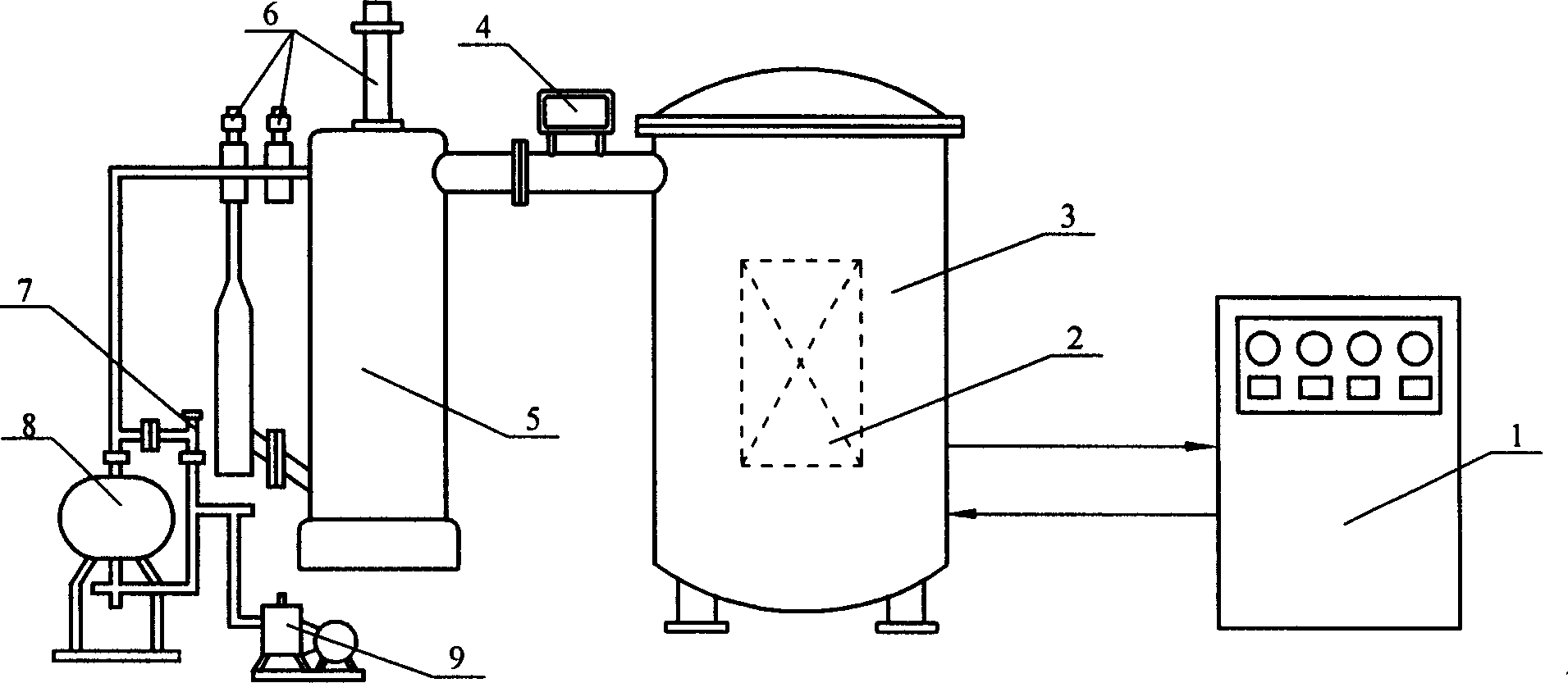

Method and device of obtaining active lime by vacuum calcining limestone

A process for preparing high-activity lime by vacuum calcining of lime stone includes such steps as crushing lime stone, loading in tank, heating in electric vacuum furnace at 750-900 deg.C under 100-1000 Pa, and quick cooling. Its activity is 380-450 ml.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

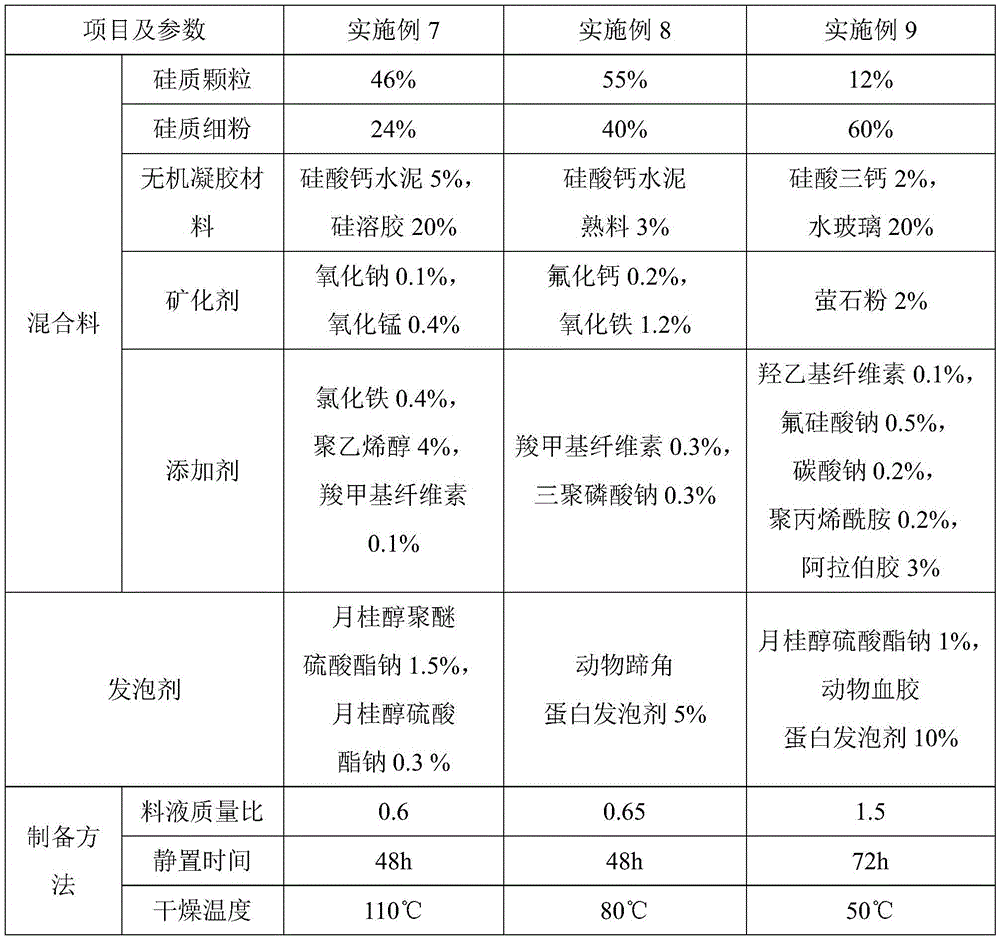

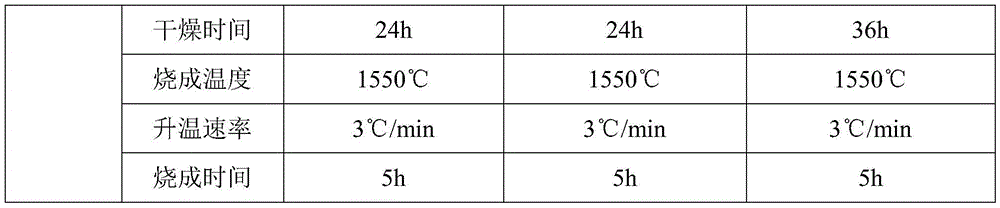

Micropore light weight silica brick and preparation method thereof

The invention discloses a micropore light weight silica brick and a preparation method thereof. The light weight silica brick is mainly prepared from a mixture and a foaming agent; a use quantity of the foaming agent is 0.1% to 10% of mass of the mixture; the mixture consists of the following components in percentage by mass: 70% to 95% of siliceous material, 1% to 25% of inorganic cementitious material, 0.1% to 15% of mineralizer, and 0.1% to 5% of additive, wherein the siliceous material consists of siliceous particles and siliceous fine powder, a particle size of the siliceous particles is 0.1 to 3mm, a particle size of the siliceous fine powder is smaller than or equal to 0.075mm, and a mass ratio of the siliceous particles to the siliceous fine powder is (1 to 65):(35 to 99). The obtained micropore light weight silica brick product has the advantages of fine aperture, small density, low thermal conductivity, high porosity, high mechanical intensity, high high-temperature volume stability, high resistance to the acid atmosphere, high slagging resistance and the like, is low in preparation cost and good in heat insulation effect, meets the harsh requirements of thermal equipment for a high-temperature environment and heat insulation, and is suitable for popularization and application.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Smoke-free and tasteless ceramic fiber board

The invention relates to a smoke-free and tasteless ceramic fiber board, which belongs to the technical field of ceramic fiber materials. The smoke-free and tasteless ceramic fiber board comprises raw materials and is characterized in that the raw materials do not contain organic bonding agents; and the manufactured ceramic fiber board is smoke-free and tasteless. The smoke-free and tasteless ceramic fiber board does not contain volatile organic compounds in the using process, belongs to green environmental-friendly inorganic materials, has excellent performances of heat resistance, fire resistance and heat insulation and excellent strength, greatly reduces the volume density and the production cost, and can be used for the fireproofing and heat preservation of household appliances and ceramic kiln industries. Compared with the conventional smoke-free and tasteless board, the smoke-free and tasteless ceramic fiber board expands the application field of ceramic fibers.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Micro closed-cell light-weight corundum refractory aggregate and preparation method thereof

The invention relates to a micro closed-cell light-weight corundum refractory aggregate and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: by using 45-65 wt% of gamma-Al2O3 fine powder, 30-50 wt% of alpha-Al2O3 micropowder and 1-10 wt% of nano aluminum oxide micropowder as raw materials, adding water accounting for 40-80 wt% of the raw materials, and carrying out wet milling with a planet ball mill for 0.5-3 hours; putting the slurry subjected to wet milling in a mold, standing at room temperature for 12-24 hours, and stripping; and drying at 110-200 DEG C for 12-36 hours, and keeping the temperature at 1750-1900 DEG C for 1-8 hours to obtain the micro closed-cell light-weight corundum refractory aggregate. The micro closed-cell light-weight corundum refractory aggregate has the characteristics of low apparent porosity, high closed porosity, low volume density, small average pore size, lower heat conductivity and high molten slag erosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

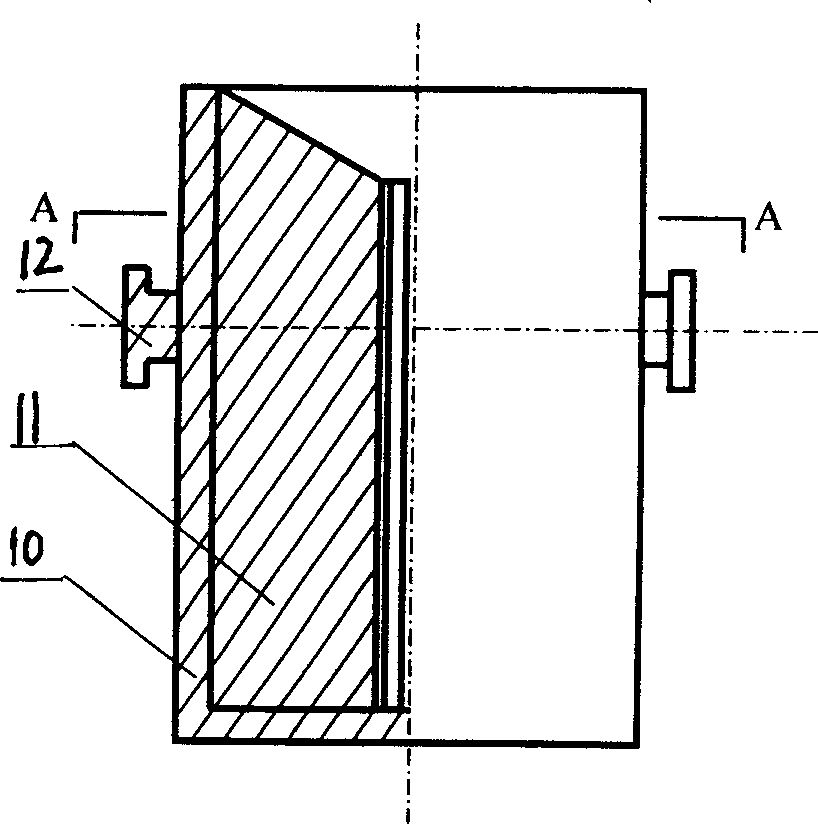

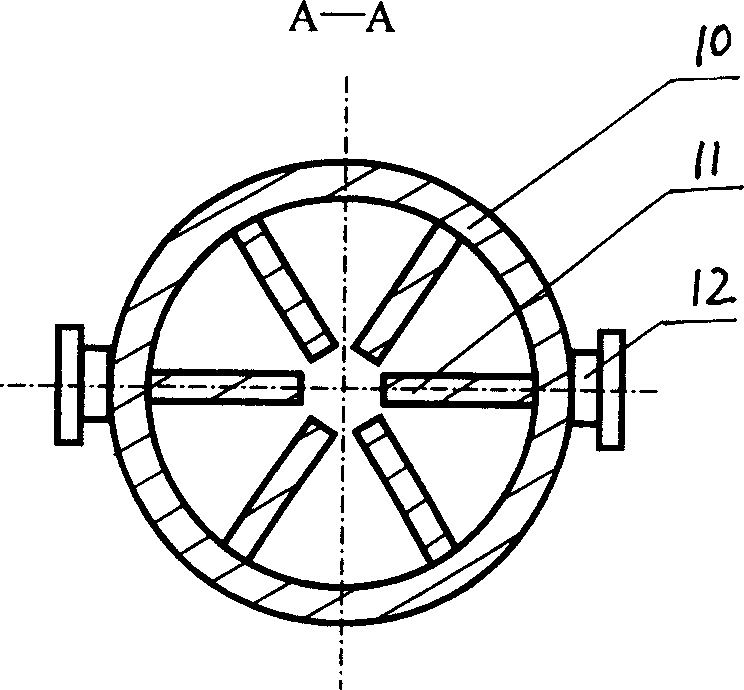

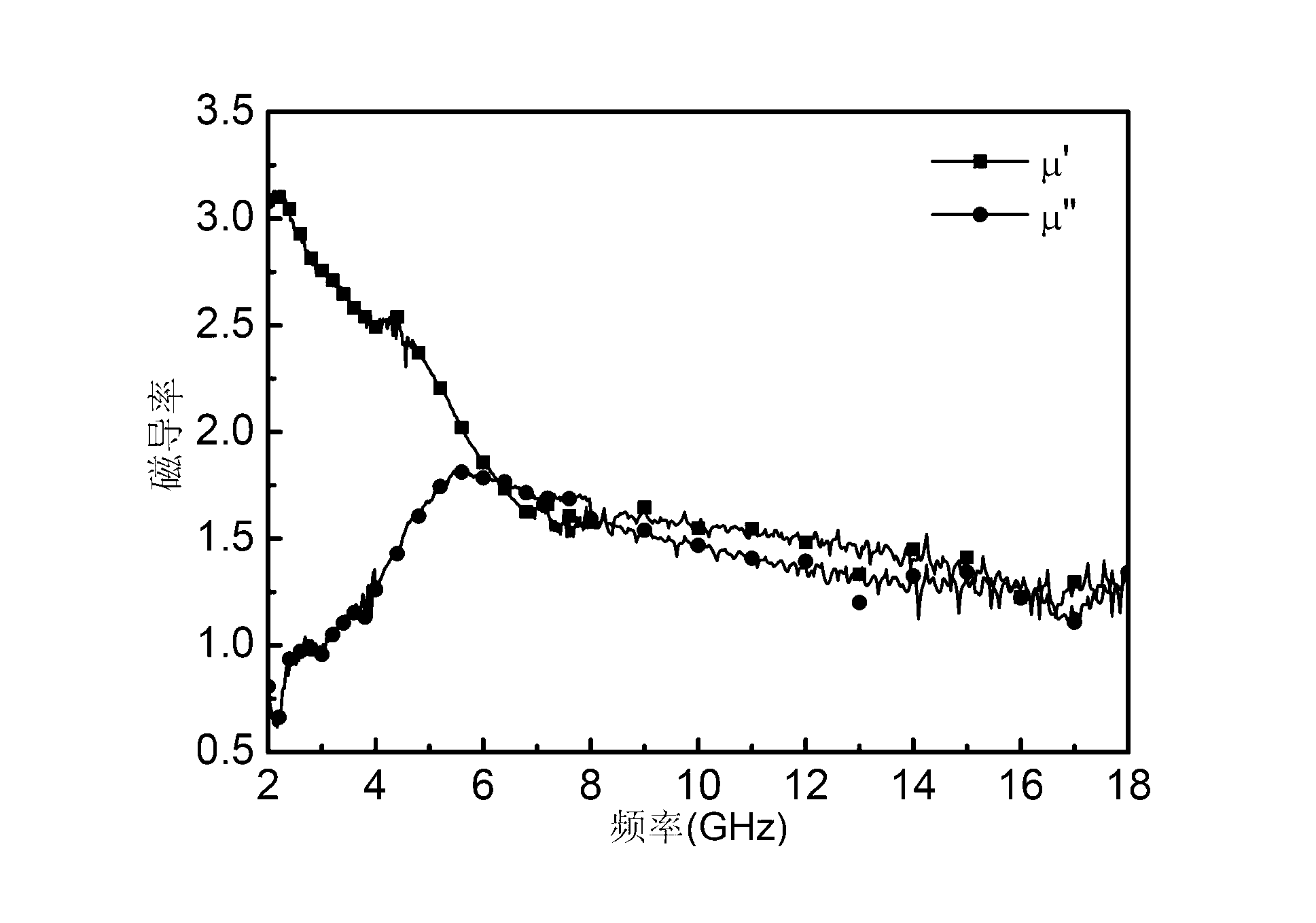

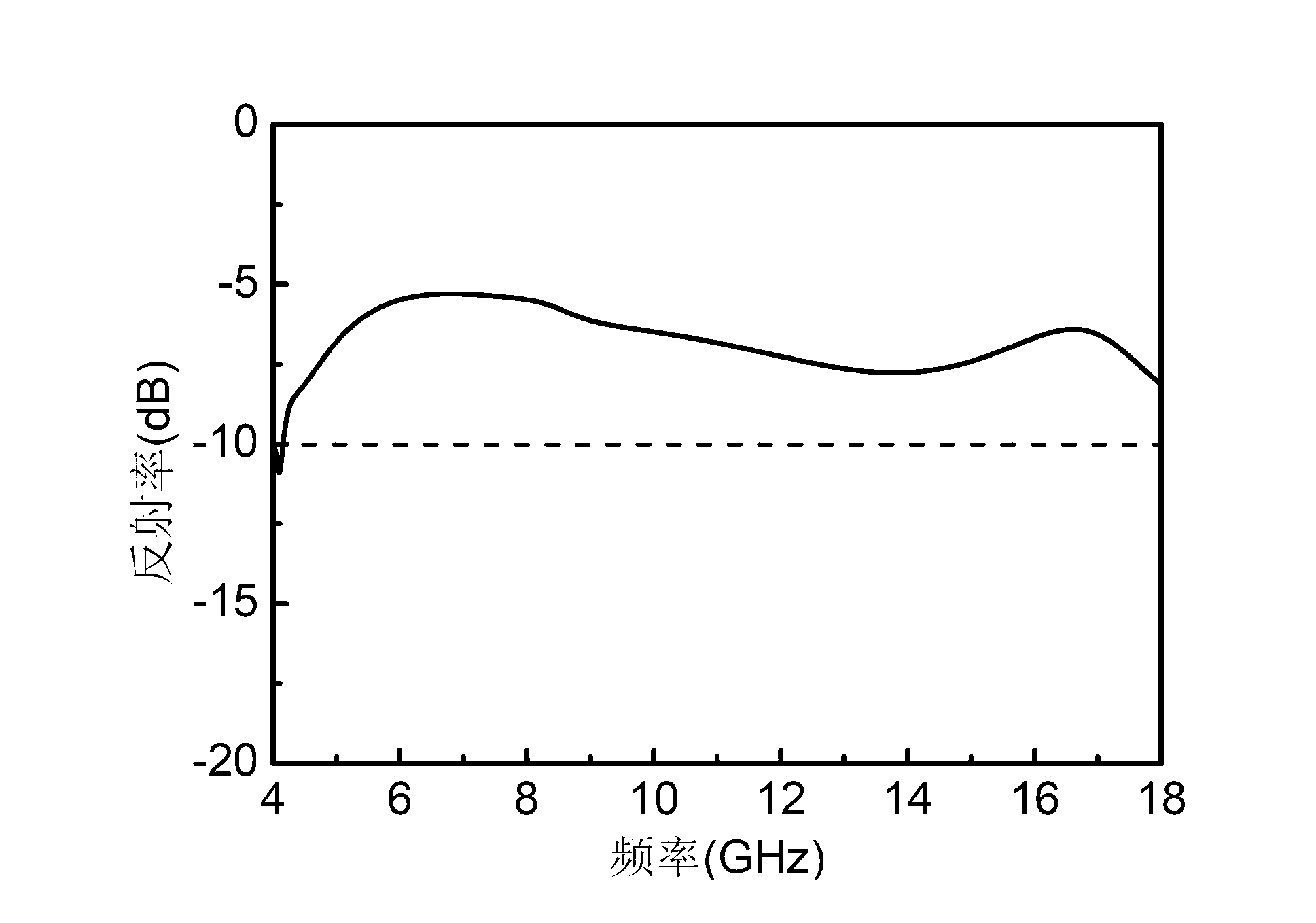

Electromagnetic wave absorbing material with periodic structure, and preparation method thereof

InactiveCN102709708ARaw materials are easy to getSimple structureMagnetic/electric field screeningLaminationDielectricElectromagnetic absorbers

The invention discloses an electromagnetic wave absorbing material with a periodic structure. The electromagnetic wave absorbing material comprises dielectric blocks formed by a magnetic wave absorbing material grid and a dielectric material, wherein the meshes on the magnetic wave absorbing material grid are through holes, and the dielectric blocks are embedded in the through holes of the magnetic wave absorbing material grid according to a certain periodicity. The preparation method of the electromagnetic wave absorbing material comprises the following steps of: selecting a magnetic wave absorbing raw material, and forming periodically arranged embedding holes on the magnetic wave absorbing raw material to obtain the magnetic wave absorbing material grid; then, selecting a dielectric material of which the relative dielectric constant is in a preset range, cutting the dielectric material into the dielectric blocks corresponding to the embedding holes in shape and size; embedding the prepared dielectric blocks in the embedding holes formed on the magnetic wave absorbing material grid one by one, and connecting together by an adhesive to get the electromagnetic wave absorbing material. The preparation method can effectively expand the operation bandwidth of the wave absorbing material without increase of the thickness, and simultaneously, can obviously reduce the volume density of the magnetic wave absorbing material.

Owner:NAT UNIV OF DEFENSE TECH

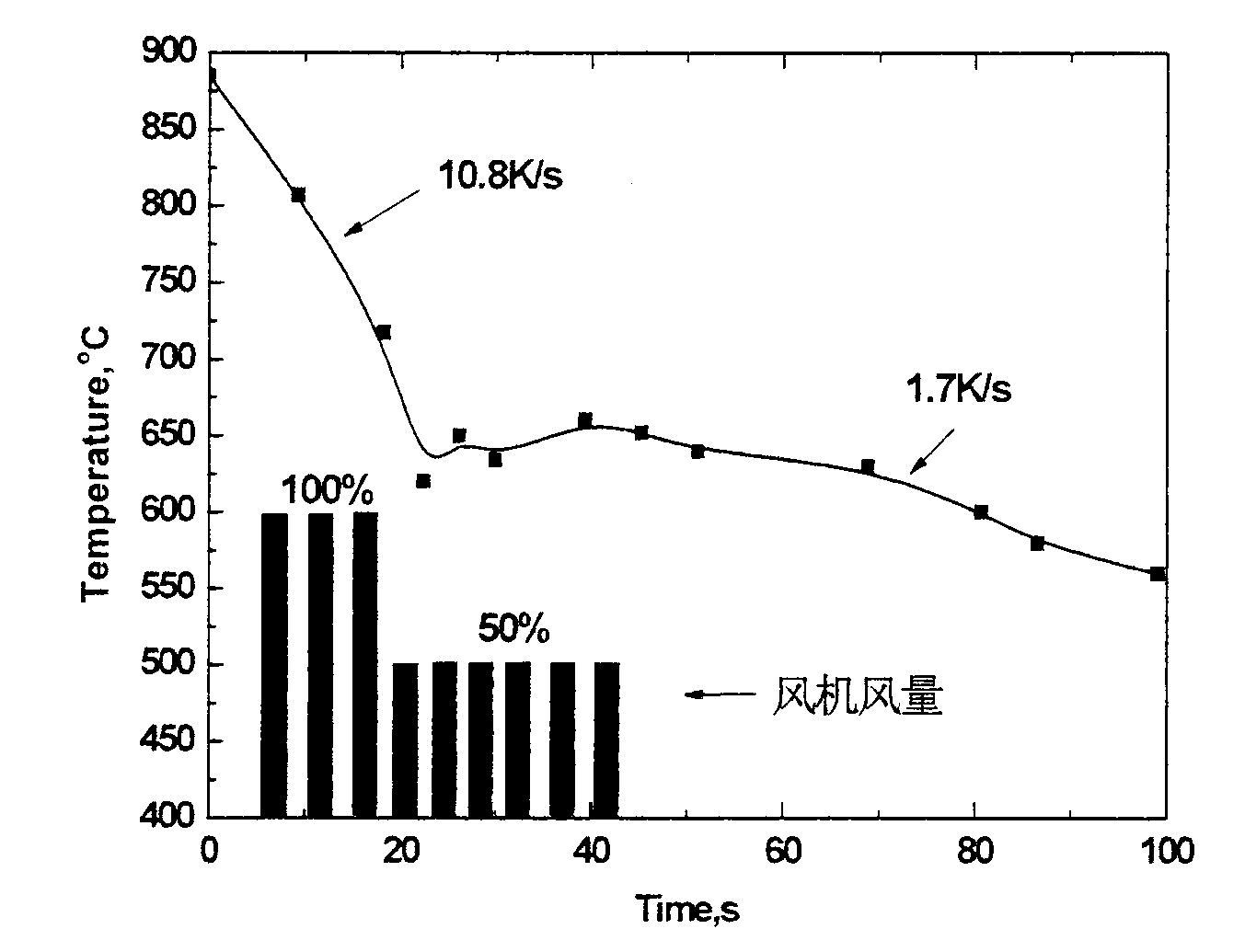

Vanadium-silicon microalloyed super-strength wire rod and production process thereof

InactiveCN103122437AAvoid it happening againSmall bulk densityHeat treatment process controlWire rodUltimate tensile strength

The invention discloses a vanadium-silicon microalloyed super-strength wire rod and a production process thereof. The vanadium-silicon microalloyed super-strength wire rod comprises basic chemical components including, by weight, 0.85-0.95% of C, 0.95-1.10% of Si, 0.50-0.60% of Mn, 0.20-0.35% of Cr, 0.01-0.05% of Ti, 0.005-0.050% of Al, 0.11-0.15% of V, selective components, including any of 0.01-0.15% of Ni, 0.001-0.25% of Cu, 0.0001-0.005% of B, 0.001-0.03% of Nb and 0.001-0.03% of M, the balance of Fe and impurities. The production process includes sequentially performed steps of heating, rolling and cold controlling. The cold controlling step uses Stelmor controlled cooling, cooling speed before phase change is above 10K / s, and the cooling speed in late phase change is 1-3K / s. The vanadium-silicon microalloyed super-strength wire rod is more than 13700MPa in tensile strength, more than 35% in section shrinkage and more than 95% in sorbite rate, and is applicable to production of products such as super-strength prestress steel strands and galvanized steel strands.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Aluminum-magnesium lightweight refractory material and preparation method thereof

The invention relates to an aluminum-magnesium lightweight refractory material and a preparation method thereof. The technical scheme comprises the following steps of: taking 60-85wt% of microporous corundum particles as an aggregate, taking 5-30wt% of fine corundum powder, and taking 2-10% of magnesium oxide micropowder and 4-9wt% of alpha-alumina micropowder as matrix materials; adding the matrix materials into the aggregate, additionally adding an adhesive which is 3-10wt% of the sum of the aggregate and the matrix materials, stirring uniformly and then mixing and milling for 15-30 minutes by a mixing mill, and molding by a brick pressing machine; and thermally processing the molded green body for 12-24 hours at 100-220 DEG C to obtain the aluminum-magnesium lightweight refractory material. The product prepared by the preparation method has the characteristics of small volume density, low apparent porosity, small average aperture, high refractoriness, large high-temperature strength, low thermal conductivity, good thermal shock resistance and strong capability resistant against the corrosion of media such as steel slag; and the prepared product is applicable to a working lining of a high-temperature industrial furnace.

Owner:WUHAN UNIV OF SCI & TECH

A coal ash-iron tailing based porous heat insulation material and a preparation method thereof

InactiveCN102167618AReduce pollutionImprove resource utilizationCeramic materials productionCeramicwareFoaming agentResource utilization

The invention belongs to the field of novel heat insulation material technology and specifically relates to a coal ash-iron tailing based porous heat insulation material and a preparation method thereof. The preparation method of the coal ash-iron tailing porous heat insulation material is characterized by mixing solid mixed powder and water, granulating and burning, wherein the water, by mass, accounts for 8% to 15% of the solid mixed powder, the solid mixed powder is prepared by mixing a powdery solid waste, a binder, a fluxing flexibilizer and a composite foaming agent, and the solid mixed powder comprises, by mass, 30% to 60% of the powdery solid waste, 30% to 50% of the binder, 5% to 20% of the fluxing flexibilizer and 5% to 10% of the composite foaming agent. The porous heat insulation material is characterized by high compressive strength, heat insulation and lightness and the method not only improves the use ratio of resources, but also reduces the environmental pollution caused by the waste.

Owner:WUHAN UNIV OF TECH

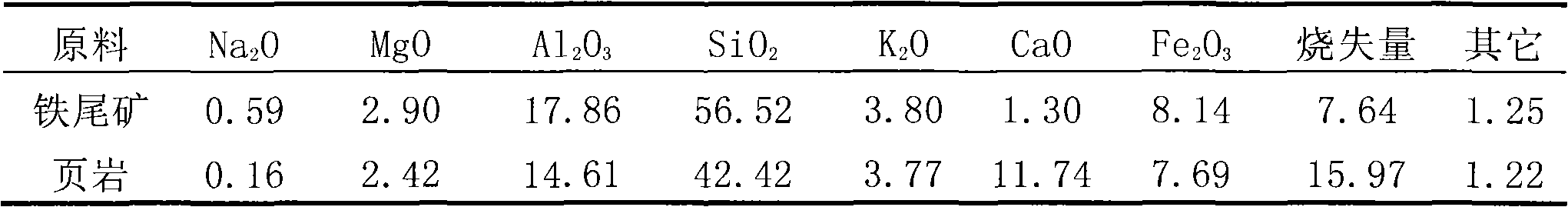

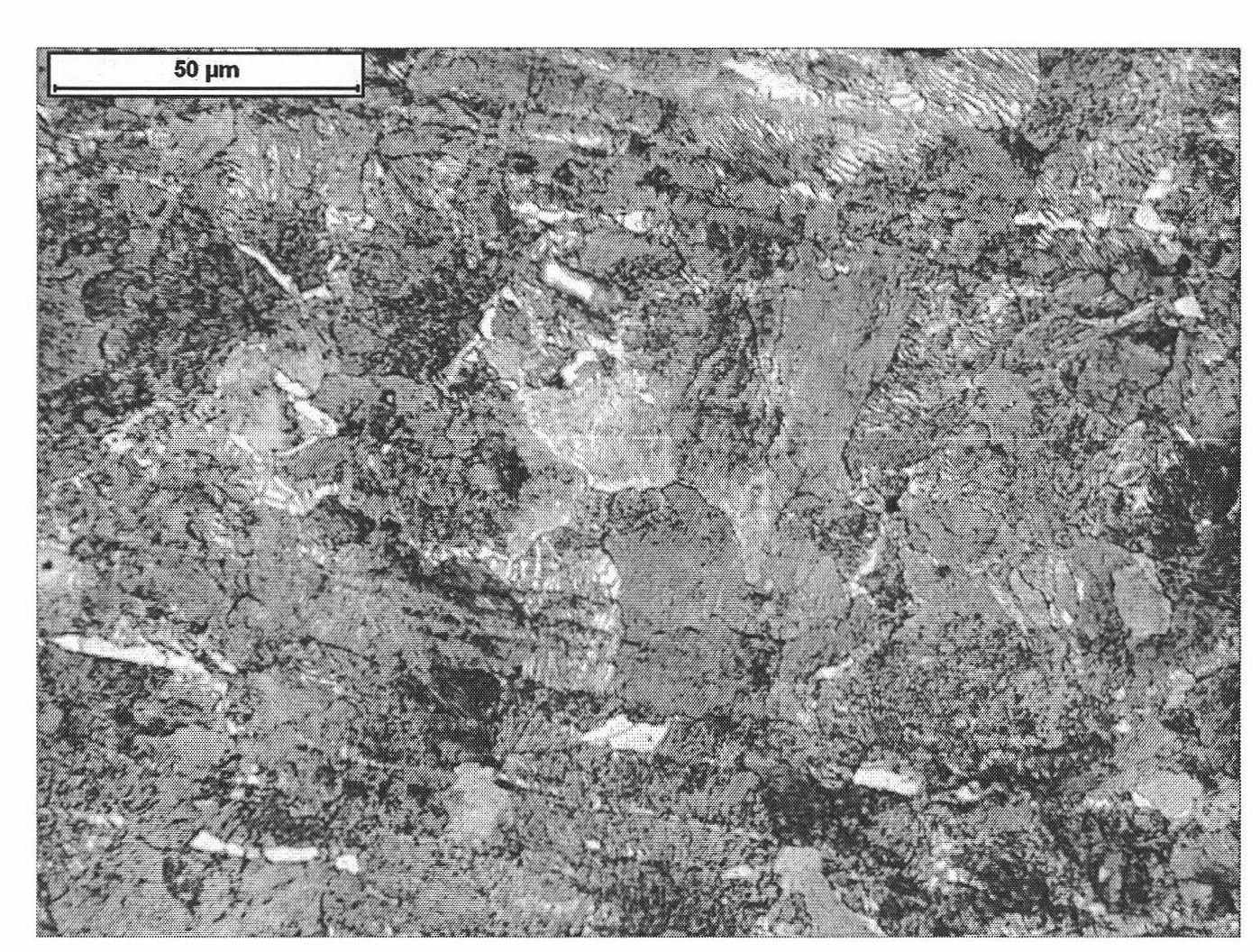

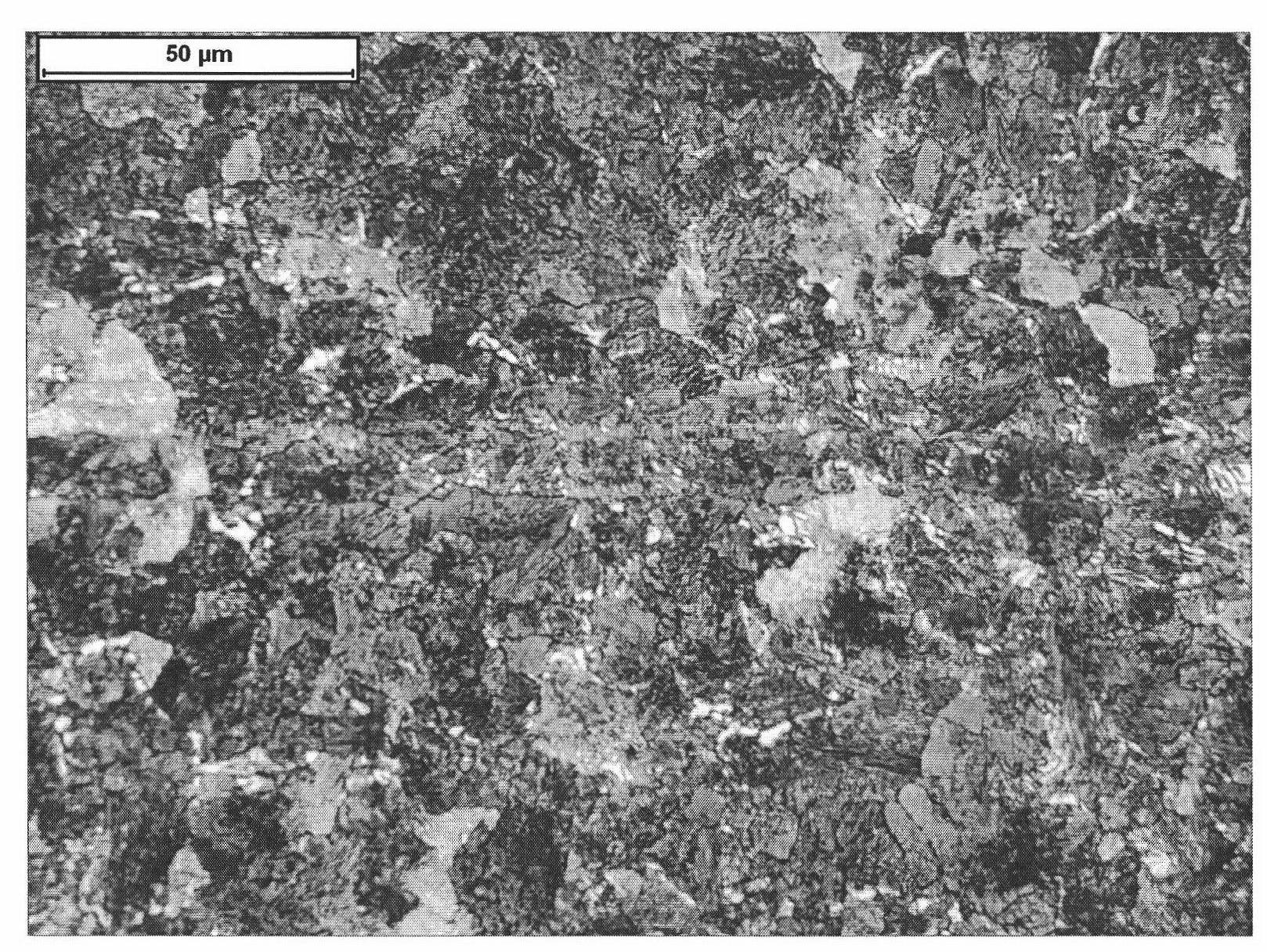

Porous insulation board and preparation method thereof

InactiveCN101805166AHigh compressive strengthImprove flexural strengthCeramic materials productionCeramicwareBreaking strengthBuilding energy

The invention relates to a porous insulation board and a preparation method thereof. The porous insulation board is characterized in that the porous insulation board is prepared by carrying out mixing, granulating and roasting on iron tailings, shale, foaming components, fluxing components and toughening components; the raw materials comprise the following components in percentage by weight: 20-60% of the iron tailing, 30-70% of the shale, 0.5-5% of the foaming component, 3-20% of the fluxing components and 3-15% of the toughening components. The insulation board prepared by the method of the invention has high compression strength and breaking strength, low water absorption, low volume density and excellent heat insulation effect, simultaneously greatly utilizes industrial tailings, and conforms to the sustainable development requirements and building energy saving requirements of China.

Owner:WUHAN UNIV OF TECH +1

Method for producing 65Mn hot rolled steel plate

InactiveCN101773930AImprove product qualityUniform tissue performanceMetal rolling arrangementsContinuous rollingSmelting

The invention discloses a method for producing a 65Mn hot rolled steel plate, which comprises the steps of smelting, refining, thin slab casting, soaking, high pressure water descaling, hot continuous rolling, cooling and reeling based on the process of thin slab casting and rolling. The molten steel superheat temperature is T superheat (30 DEG C <T superheat < / = 45 DEG C), the charging temperature of casting blanks is T charging (900 DEG C < / = T charging < / = 1050 DEG C), the final rolling temperature is T final (850 DEG C < / = T final < / = 950 DEG C), the reeling temperature is T reeling ( 550 DEG C < / = T reeling < / = 650 DEG C), the liquid core pressure of casting blanks is L pressure (2 < / = L pressure < / = 20mm), and the depth of a single-surface decarburized layer is 0.3 to 0.9 percent of the depth of the steel plate. The chemical constitutes of molten steel after being alloyed in a refining process comprise 0.62-0.70 wt.% of C, 0.17-0.37 wt.% of Si, 0.90-1.20 wt.% of Mn, less than or equal to 0.035 wt.% of P, less than or equal to 0.035 wt.% of S, less than or equal to 0.25 wt.% of Cr, less than or equal to 0.25 wt.% of Ni and the balance of Fe and inevitable impurities. The 65Mn hot rolled steel plate produced in the method has the characteristics of uniform structure property, high thermal stability and high strength, and the quality of the 65Mn hot-rolled steel plate is obviously improved.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com