Vanadium-silicon microalloyed super-strength wire rod and production process thereof

An ultra-high-strength, micro-alloying technology, applied in the field of iron and steel metallurgy and steel rolling, can solve the problems of adverse effects of wire rod mechanical properties on drawing performance, easy formation of martensite, and wire rod performance hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and a preferred embodiment.

[0026] The chemical composition of vanadium-silicon composite microalloyed ultra-high strength wire rod in this embodiment is (wt%): C 0.90, Si 1.04, Mn 0.54, Cr 0.275, Ti 0.038, Al 0.034, V 0.112, and the balance of Fe and unavoidable impurities.

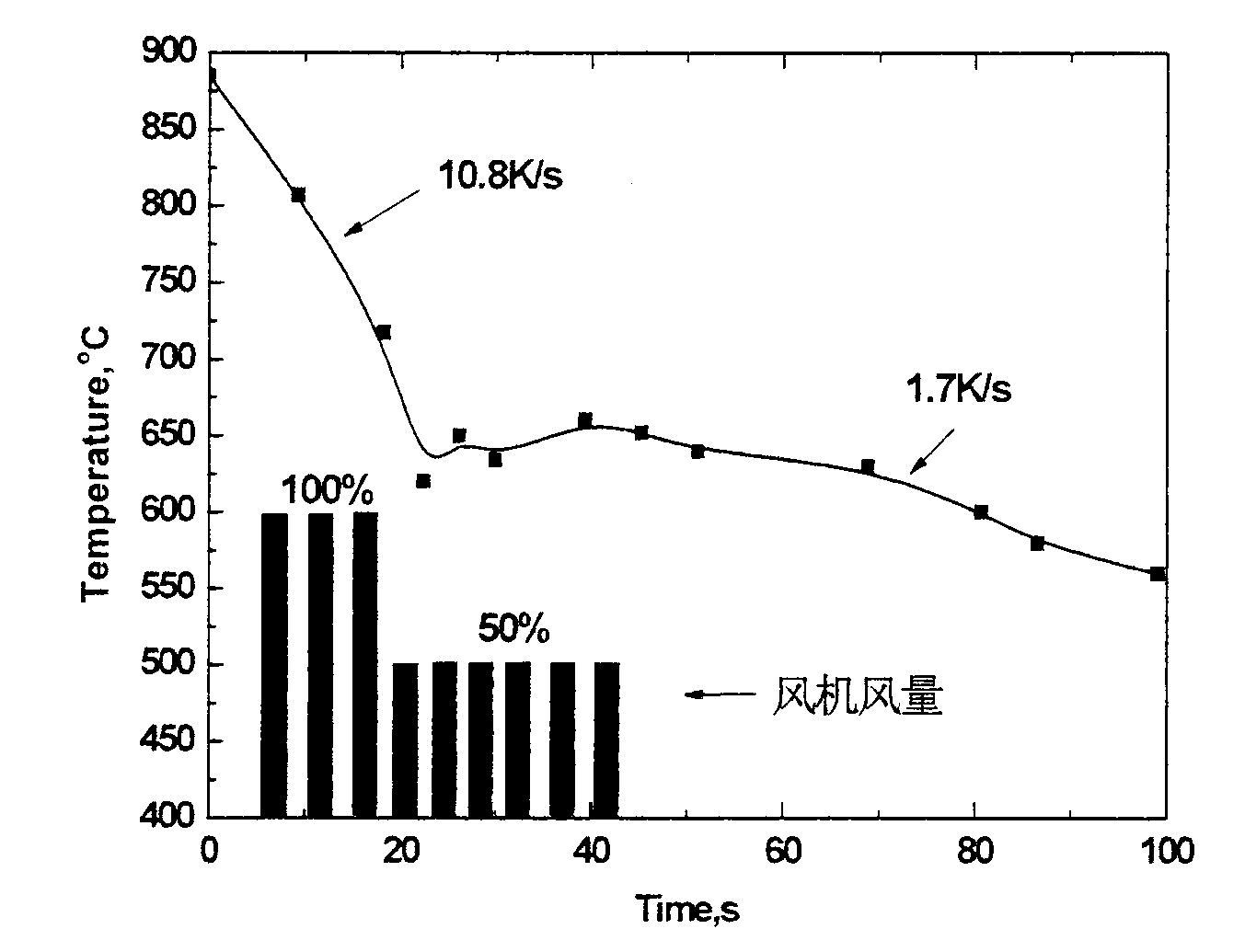

[0027] The preparation process of the vanadium-silicon composite micro-alloyed ultra-high-strength wire rod is as follows: the casting slab containing the above components is heated to 1120±20°C, the spinning temperature is 880±10°C, and the controlled cooling of Stelmor is in accordance with the controlled cooling conditions in Table 1. conduct. figure 1 Shown is the cooling curve measured on the Stelmor line. The cooling rate before the phase change is above 10K / s, and the cooling rate after the phase change is between 1-3K / s.

[0028] See Table 2 and Figure 2a-2b ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com