Yarn forming method for hollow yarns

A yarn forming and hollow technology, which is applied in the field of fabric fibers, can solve the problems of loss of softness, etc., and achieve the effect of increasing bulkiness and water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is described in detail below.

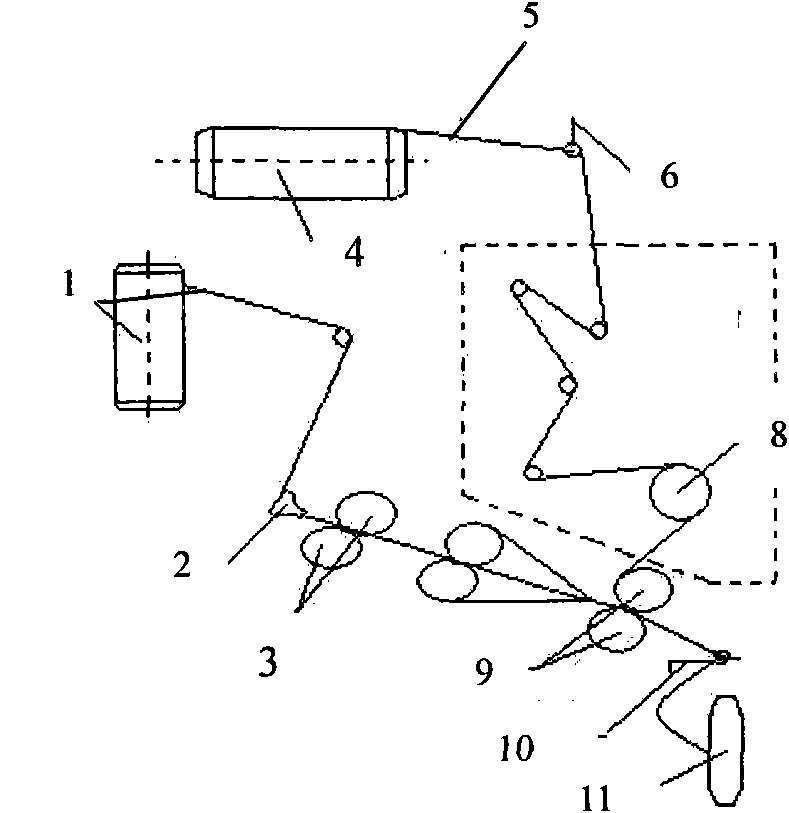

[0023] Example Yarn formation of hollow yarn

[0024] The combed cotton sliver 1 as the outsourcing fiber is fed into the rear roller 3 through the upper bell mouth 2 of the FA506 ring spinning frame for drafting, and at the same time as the 60 core yarn wound on the edged bobbin 4 s The PVA yarn filament 5 is guided by the core yarn unwinding device 6 and the core yarn tension control device 7, and then fed into the nip of the front roller from the rear 9 sides of the front roller, so that the core yarn and cotton fiber strands merge into twisting area, and finally drawn out by the core yarn guide hook 10 to form the core-spun yarn on the bobbin 11.

[0025] The yarn-forming process parameters of the core-spun yarn can be found in Table 2.

[0026] Table 2 Yarn forming process parameters of core-spun yarn

[0027]

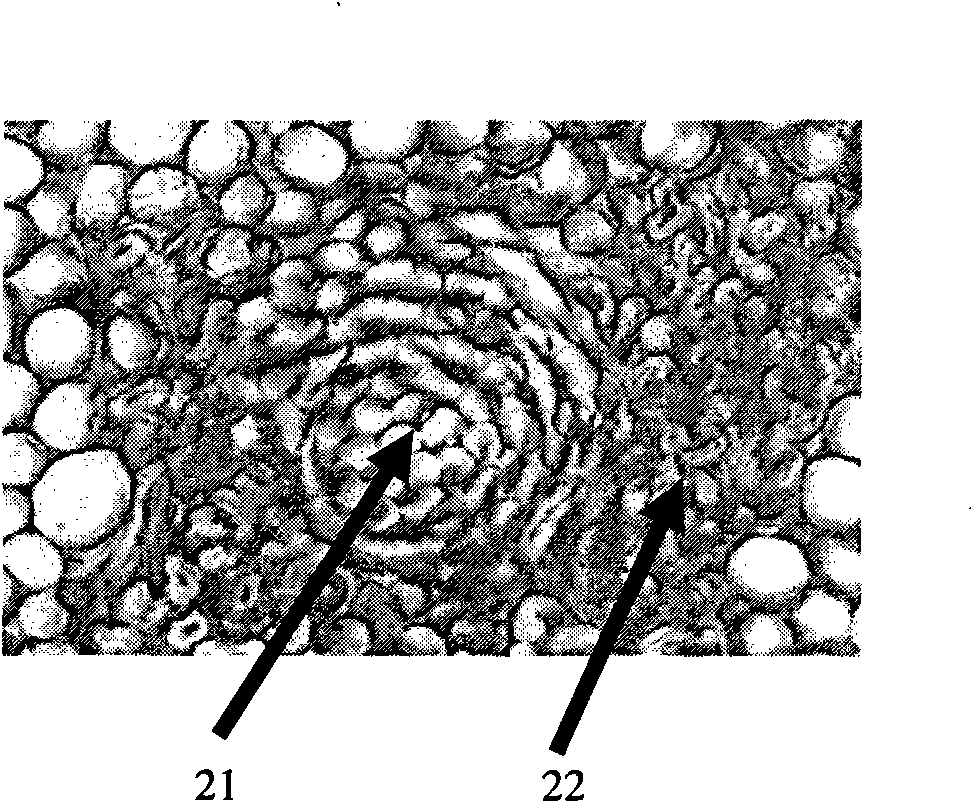

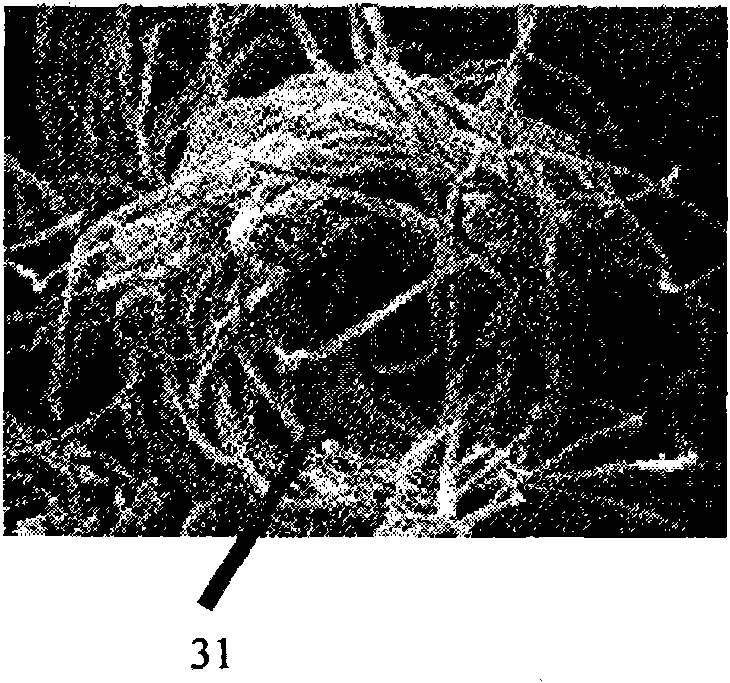

[0028] The structure of the core-spun yarn obtained is shown in figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com