Patents

Literature

334results about How to "Improve fluffiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyester flax-like type different shrinkage composite yarn and preparation method thereof

ActiveCN108130624ASimple preparation processImprove fluffinessMelt spinning methodsConjugated synthetic polymer artificial filamentsYarnPolyester

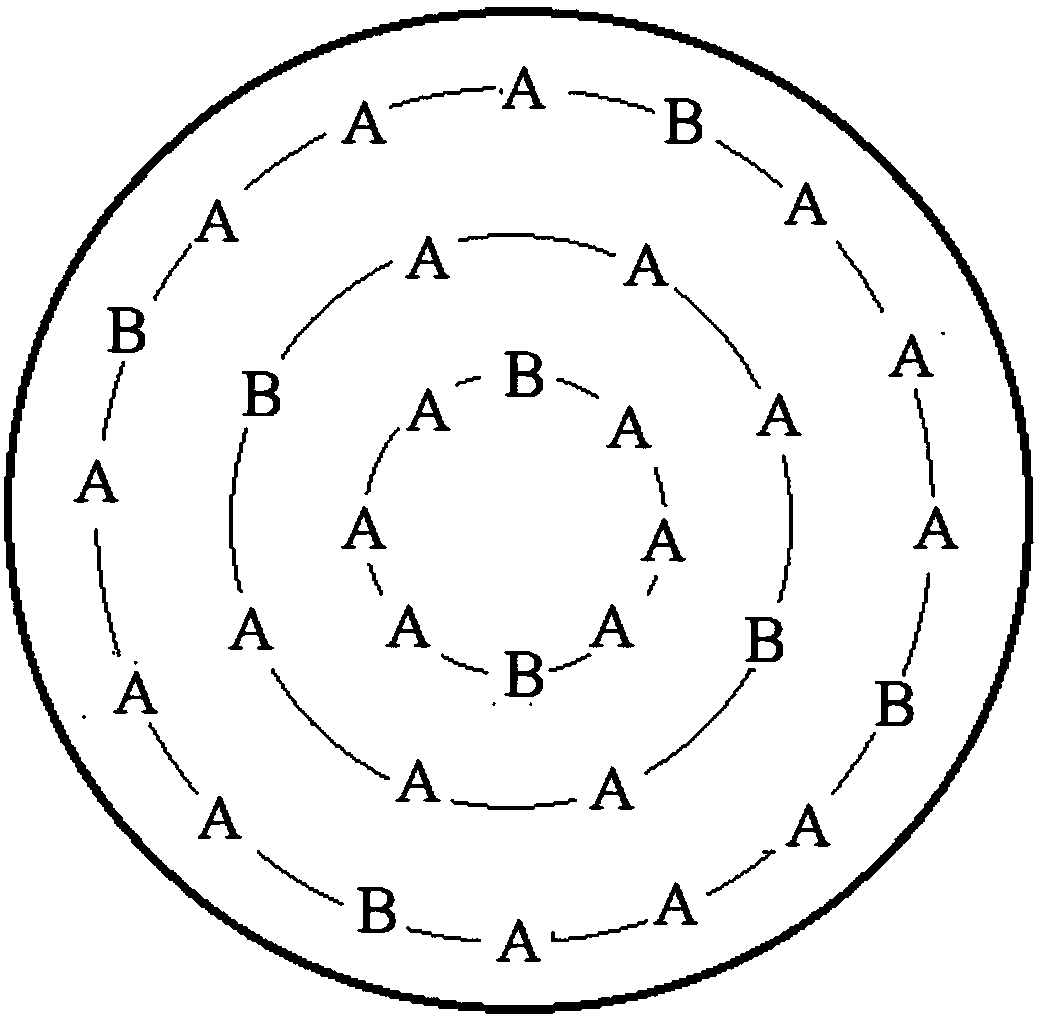

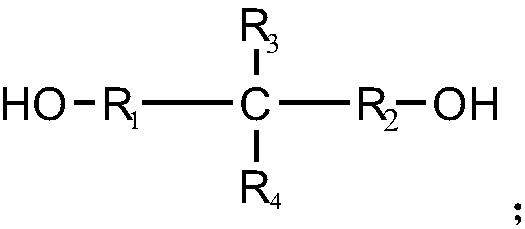

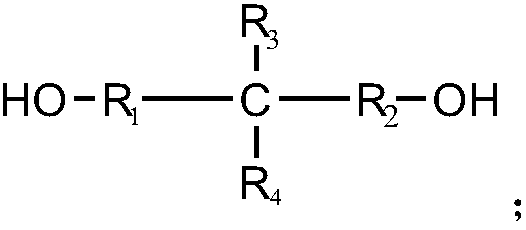

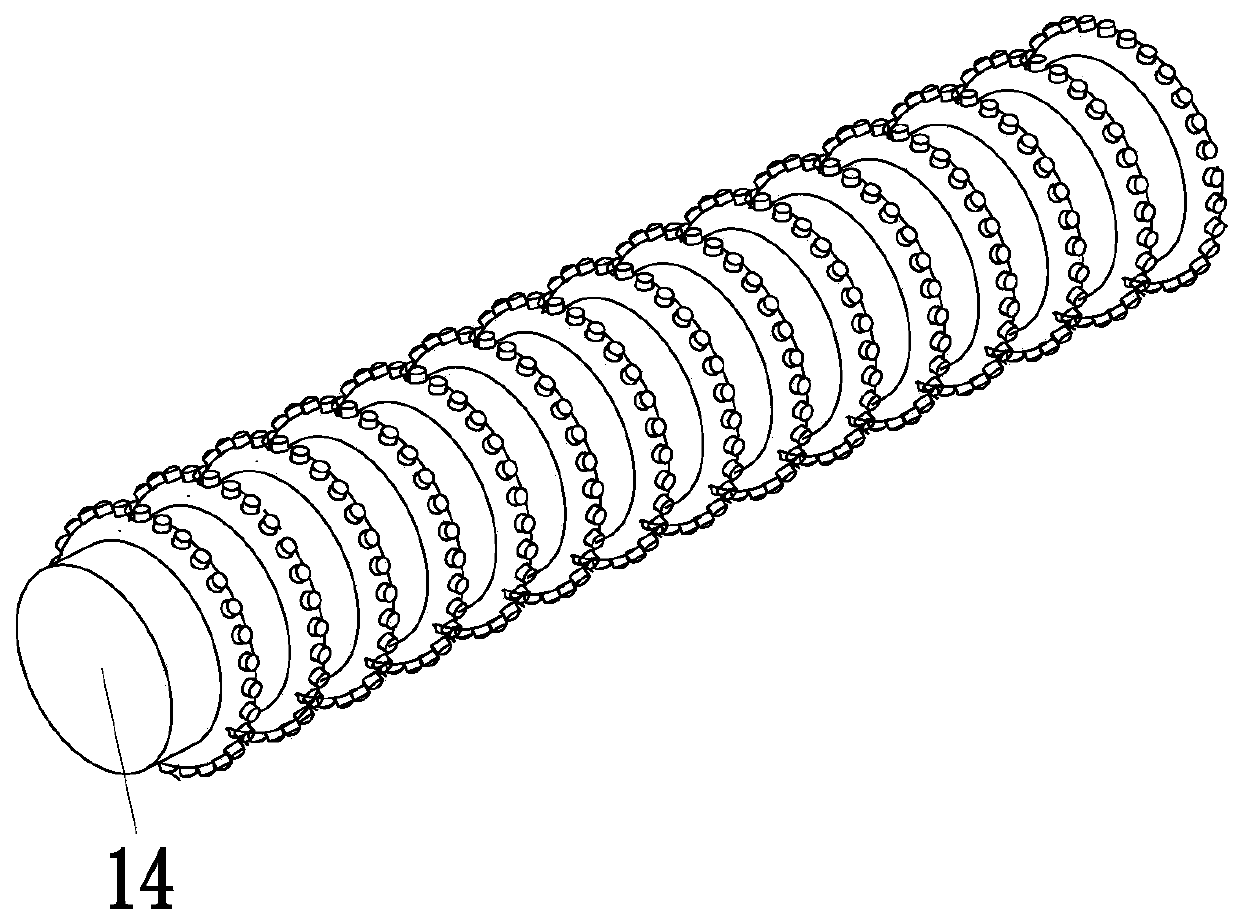

The invention relates to a polyester flax-like type different shrinkage composite yarn and a preparation method thereof. Firstly, a modified polyester yarn POY and a modified polyester yarn FDY are prepared respectively, then the modified polyester yarn POY and the modified polyester yarn FDY are compounded to prepare the polyester flax-like type different shrinkage composite yarn; the chromatic aberration [delta]E of the prepared polyester flax-like type different shrinkage composite yarn is less than 0.200; a bundle of the yarn POY or FDY extruded by a same spinneret plate contains a singleyarn shaped in a Chinese character 'wang' manner and a five-leaf single yarn; a molecular chain of modified polyester consists of a diol chain segment with a branched chain, and diol with the branchedchain has the structural formula defined in the specification, wherein R1 and R2 are straight-chain alkylene with the carbon atom number of 1-3 , R3 is alkyl with the carbon atom number of 1-5, and R4 is alkyl with the carbon atom number of 2-5. The method is simple and reasonable, and the prepared composite yarn has good fluffy property and moisture absorption and perspiration elimination properties.

Owner:JIANGSU HENGLI CHEM FIBER

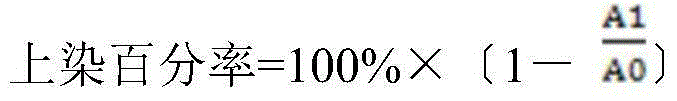

Liquid ammonia modified method of cotton fibriia and yarn

InactiveCN101413213AGood flexibilityImprove curling effectLiquid/gas/vapor removal by centrifugal forceTextile treatment by pouringYarnVegetable fibers

The invention provides a method for modifying cotton and long vegetable fiber or yarn by ammonia liquid, which comprises the following steps: firstly, drying pre-treatment of raw materials; secondly, ammonia leaching of the raw materials in a hermetical treatment tank; thirdly, spin-drying of the raw materials subjected to ammonia leaching when a creel is twirled; fourthly, drying of the raw materials subjected to spin-drying by ammonia flow when the creel rotates slowly; fifthly, flushing of the raw materials which are dried by the ammonia flow by airflow when the creel rotates slowly; and so on. The method keeps the inherent advantages of the cotton, the long vegetable fiber and the yarn, overcomes the defects of the cotton, the long vegetable fiber and the yarn, increases softness, crimp tendency and fluffiness of the cotton, the long vegetable fiber and the yarn, improves the dye-uptake rate, the leveling property and the showy dye level, and further solves the problems of energy conservation, efficiency improvement and environmental protection.

Owner:上海业安纺织科技有限责任公司

Green totally degradable warming material and producing method thereof

InactiveCN101509175AHigh strengthImprove stabilityHollow filament manufactureFilament/thread formingCardingKapok fiber

A green completely-degradable warm-keeping material and a production method thereof are disclosed, the weight percent of components thereof are: 40-60 parts of kapok fiber, 10-40 parts of polylactic bi-component fiber and 15-40 parts of polylactic hollow fiber; the material is formed by pre-needling at first and then the procedures of hot-melt shaping, cooling, winding, etc. after a fluffy three-dimensional netlike structure fiber net is formed by cotton plucking, cotton mixing, weighting, opening, mechanical carding and disordering. The inventive warm-keeping material employs the completely-degradable raw materials and has no pollution in the entire production process, the product has multiple functions of excellent strength, fluffiness, warm keeping, bacteriostasis and the like, which belongs to green environmentally-friendly products.

Owner:JIAXING UNIV

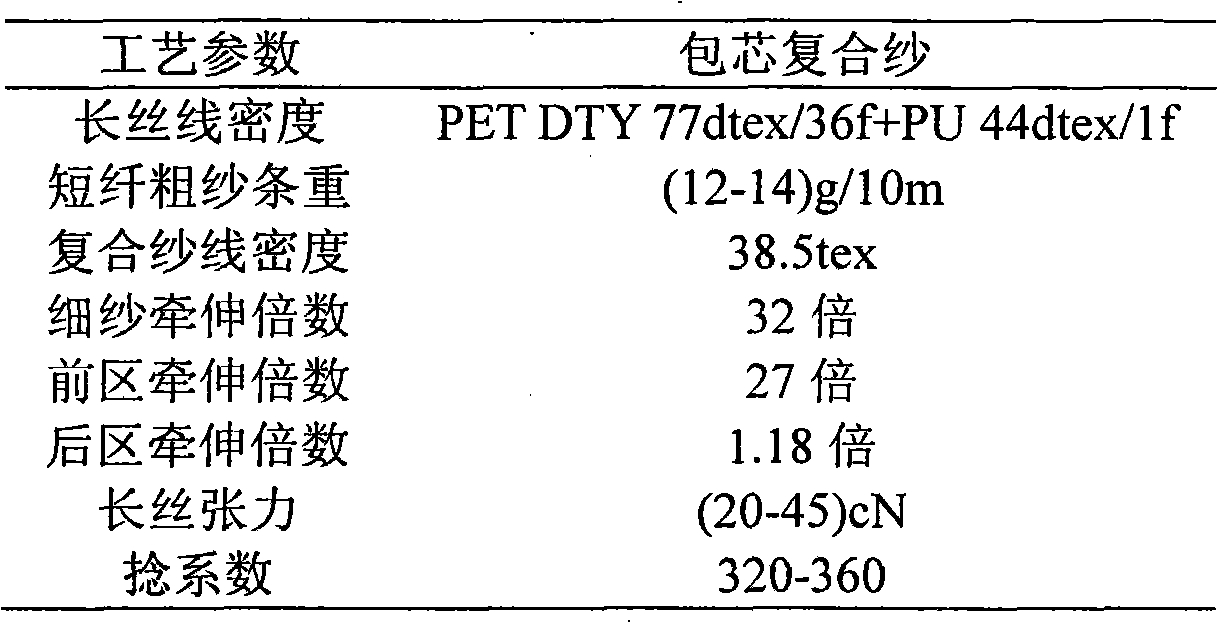

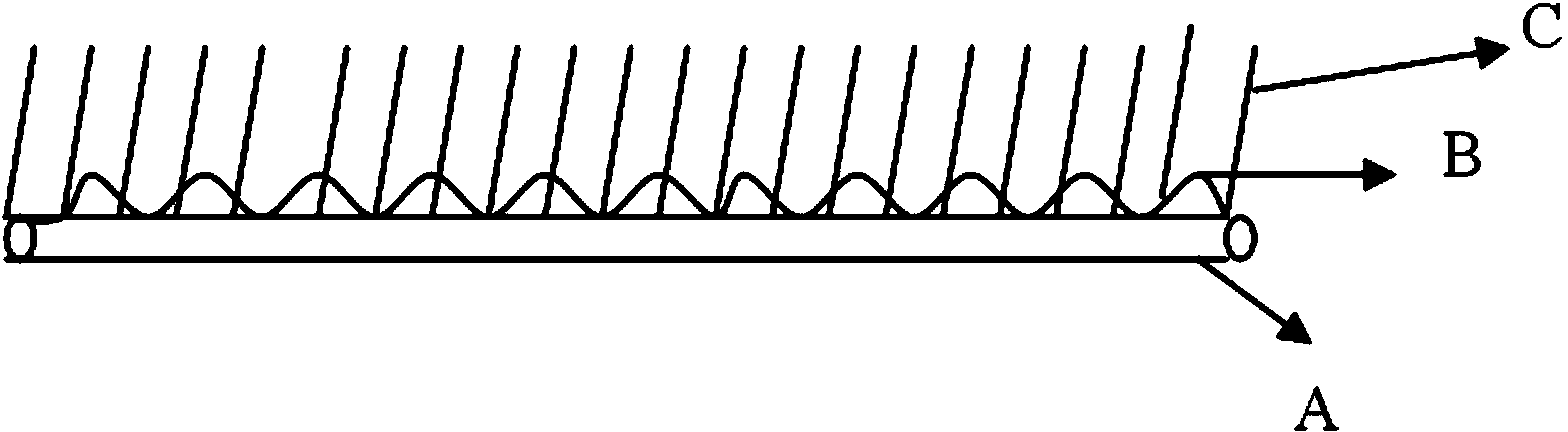

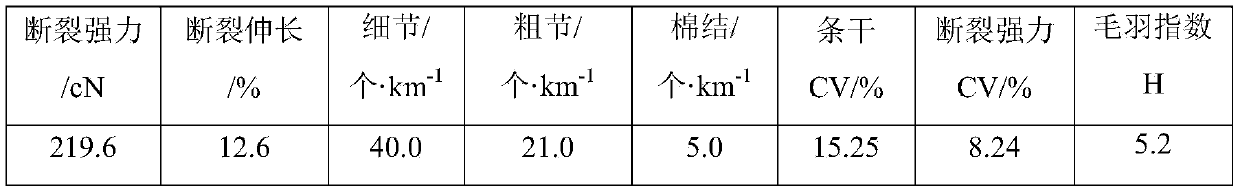

Spinning process of covering yarn with high hollowness degree, prepared covering yarn and process for weaving towel by utilizing covering yarn

ActiveCN102888686AIncrease warmthHigh hollownessBiochemical fibre treatmentBleaching apparatusCotton fibreEngineering

The invention provides a spinning process of covering yarn with high hollowness degree, a prepared covering yarn and a process for weaving towel by utilizing the covering yarn. The spinning process comprises the following steps of: compositing and twisting two crude cotton yarns and water-soluble vinylon filament with number of 4.1-7.3 tex to prepare a spun yarn with cotton fiber covering the water-soluble vinylon filament; and hydrolyzing the water-soluble vinylon filament to obtain the covering yarn with the high hollowness degree. The strength and the hollowness degree of the covering yarn with the high hollowness degree, prepared by the spinning process disclosed by the invention, are higher than the strength and the hollowness degree of a common hollow covering yarn with the same yarn count, the overing yarn with the high hollowness degree is soft and fluffy and has strong water absorbability and improved heat insulation performance; and the woven towel prepared by the process of the invention is light and fluffy, and has good heat insulation performance and resilience, high water absorption speed, large unit-area water absorption amount and high drying speed.

Owner:SUNVIM GROUP

Heating fiber underwear face fabric and processing technique thereof

InactiveCN101235573AGood flexibilityGood skin affinityWeft knittingDry-cleaning apparatus for textilesYarnCellulose fiber

The invention relates to a heating fiber underwear fabric, which is characterized in that the heating fiber underwear fabric is composed of raw materials with following weight percent: heating fiber 3-25%, anti-pilling acrylic fiber 30-52%, lenzing cellulose fiber 35-40%, polyamide fiber 4-6% and lycra elastic fiber 0.5-0.15%. A processing technique of the heating fiber underwear fabric comprises: firstly, spinning the heating fiber, the anti-pilling acrylic fiber and the lenzing cellulose fiber into sirospun union yarn, then, coating the lycra elastic fiber with the polyamide fiber, weaving and forming knitted underwear fabric, dying, soaping with nonionic soft finishing agent, vertically drying, shaping, and forming finished products of the heating fiber underwear fabric. The heating fiber underwear fabric of the invention has the advantages that the heating fiber underwear fabric not only has good skin-friendly property, low pilling tendency and comfortable elasticity, but also has good warmth retention effect.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV +1

Yarn forming method for hollow yarns

The invention discloses a yarn forming method for hollow yarns, which comprises the following steps: making clad yarns in spinning equipment by using water soluble polyvinylalcohol fibers as core yarns and using comed slivers which are clad by fibers according to a ratio of 12 to 15 g / 10m; dissolving the core in water at the temperature of 5 to 100 DEG C; and obtaining 45s to 10s hollow yarns after the polyvinylalcohol dissolves in water from the clad yarns completely. The hollow yarns made by the yarn forming method of the invention has the advantages that: the volume density of the yarns is lowered by 15 to 30 percent; the apparent volume of the yarn aggrdgate is increased by 15 to 30 percent; the water absorptivity of the yarns is improved by 15 to 30 percent; and the bulkiness is improved.

Owner:JIAXING UNIV

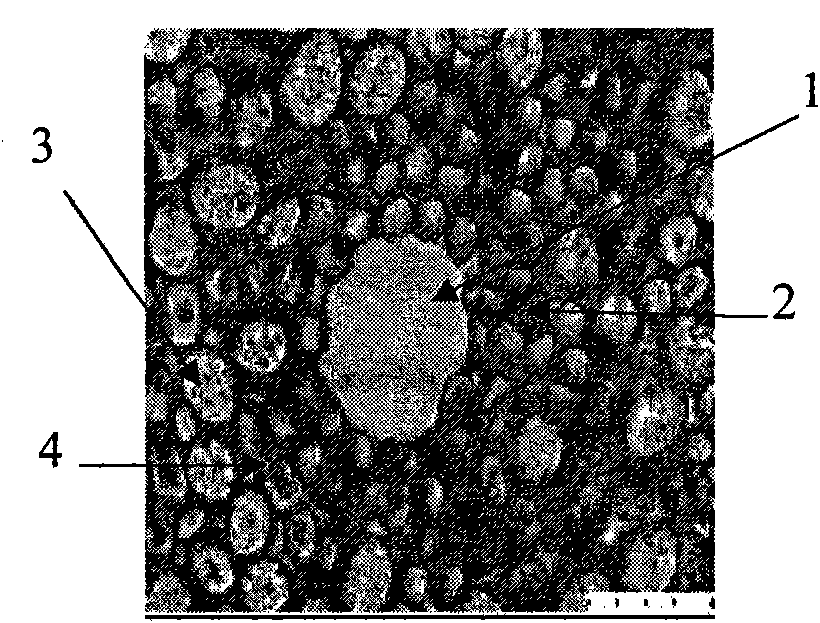

Three-component composite yarn and yarn forming method thereof

The invention provides three-component composite yarn which is formed by combined machining of 5%-30% of inner-layer core yarn and 70%-95% of outer-layer chopped fiber based on weight ratio via a ring spinning frame, wherein, the inner-layer core yarn of the composite yarn is formed by air texturing and machining of polyester filament yarn or polyamide filament yarn and polyurethane. The composite yarn of the invention has double modulus of elasticity and can improve generality of materials on garment after being made into fabrics, thus meeting the requirement for the modulus of elasticity in case of small deformation as well as the requirements for the modulus of elasticity and shape recovery ratio in case of large deformation, and improving close-fitting property, shape retention property and comfort while wearing clothes.

Owner:JIAXING UNIV

Composite differential shrinkage yarn and preparation method thereof

The invention relates to a composite differential shrinkage yarn and a preparation method thereof. The composite differential shrinkage yarn is formed by compositing of a POY (polyester pre-oriented yarn) body and an FDY (fully drawn yarn) body, both the POY body and the FDY body are made of modified polyester by means of spinning, the modified polyester is formed by polyester and amino fatty acid gylcol ester, the amino fatty acid gylcol ester is scattered among molecular chains of the polyester, and a hydrogen-bond interaction among the amino fatty acid gylcol ester and the molecular chains of the polyester enables opposite positions of the amino fatty acid gylcol ester and the molecular chains of the polyester to be fixed; in the condition with temperature ranging from 90 DEG C to 130 DEG C, free volume spaces among molecular chains inside a fiber of the composite differential shrinkage yarn are enlarged by 20-30v / v%. The composite differential shrinkage yarn has the advantages that the free volume of polyester fibers is increased by the aid of fatty acid ester, so that diffusing degree of dye is improved, dyeing property of the polyester fibers is improved, and the composite differential shrinkage yarn is applicable to fashion fabric, decorative fabric and the like formed by means of spinning, knitting and warp knitting.

Owner:JIANGSU HENGLI CHEM FIBER

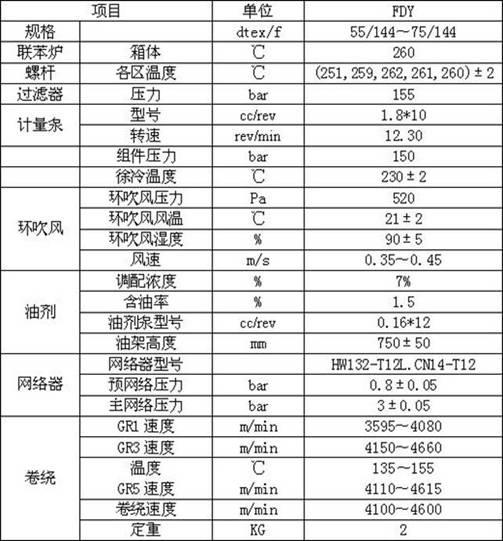

Porous superfine polyamide 6 fully-drawn yarn, preparation method thereof, and equipment thereof

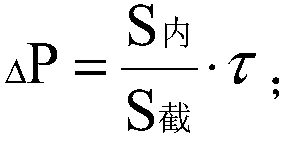

InactiveCN102493016AImprove mixing uniformityImproved pressure stabilityFilament forming substance formingArtificial thread manufacturing machinesYarnAir velocity

The invention relates to a porous superfine polyamide 6 fully-drawn yarn, a preparation method thereof, and equipment thereof. According to the invention, existing FDY production equipment is adopted. A raw material polyamide 6 is sliced and dried; an additive is added on line; the material is subject to screw extrusion and melt extrusion; the material is then cured with a gradually cooling manner and a circular air blow cooling manner; with a reasonably selected spinning temperature of 259-262 DEG C, an air temperature in the circular air blowing process of 19-23 DEG C, a humidity of 85-95%, an air velocity of 0.35-0.45m / s, an oiling and clustering position of 700-800mm, and a winding speed of 4100-4600m / min, the porous superfine polyamide 6 fully-drawn yarn product with a specification of 55dtex / 144f-75dtex / 144f is prepared. Flexible operation is adopted in the preparation method. The preparation method is advantaged in simple technology and low production cost. The product is advantaged in stable performance, good yarn evenness, and good coloration property.

Owner:SUZHOU UNIV

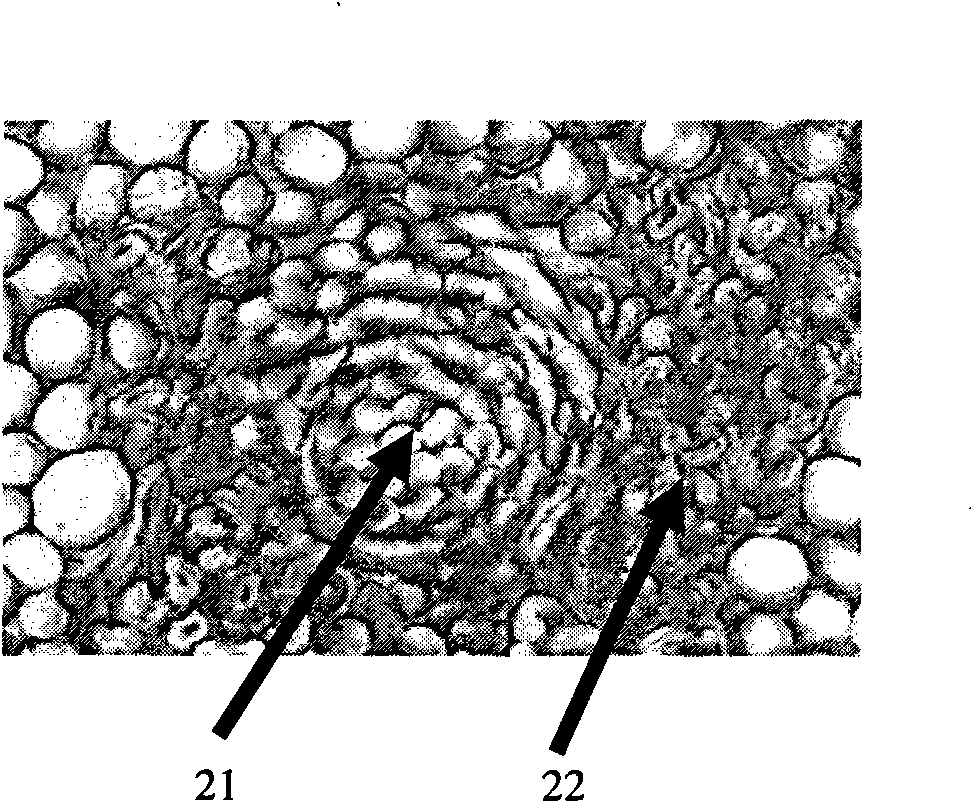

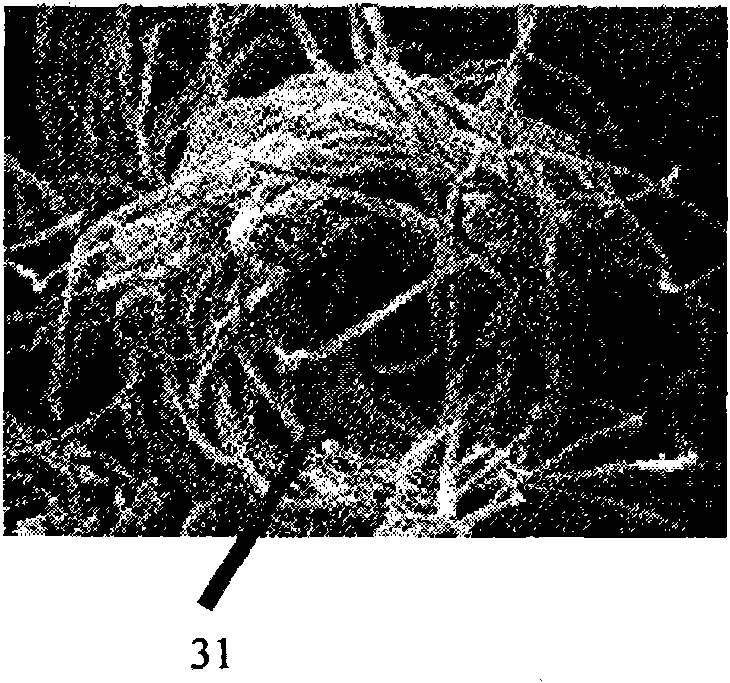

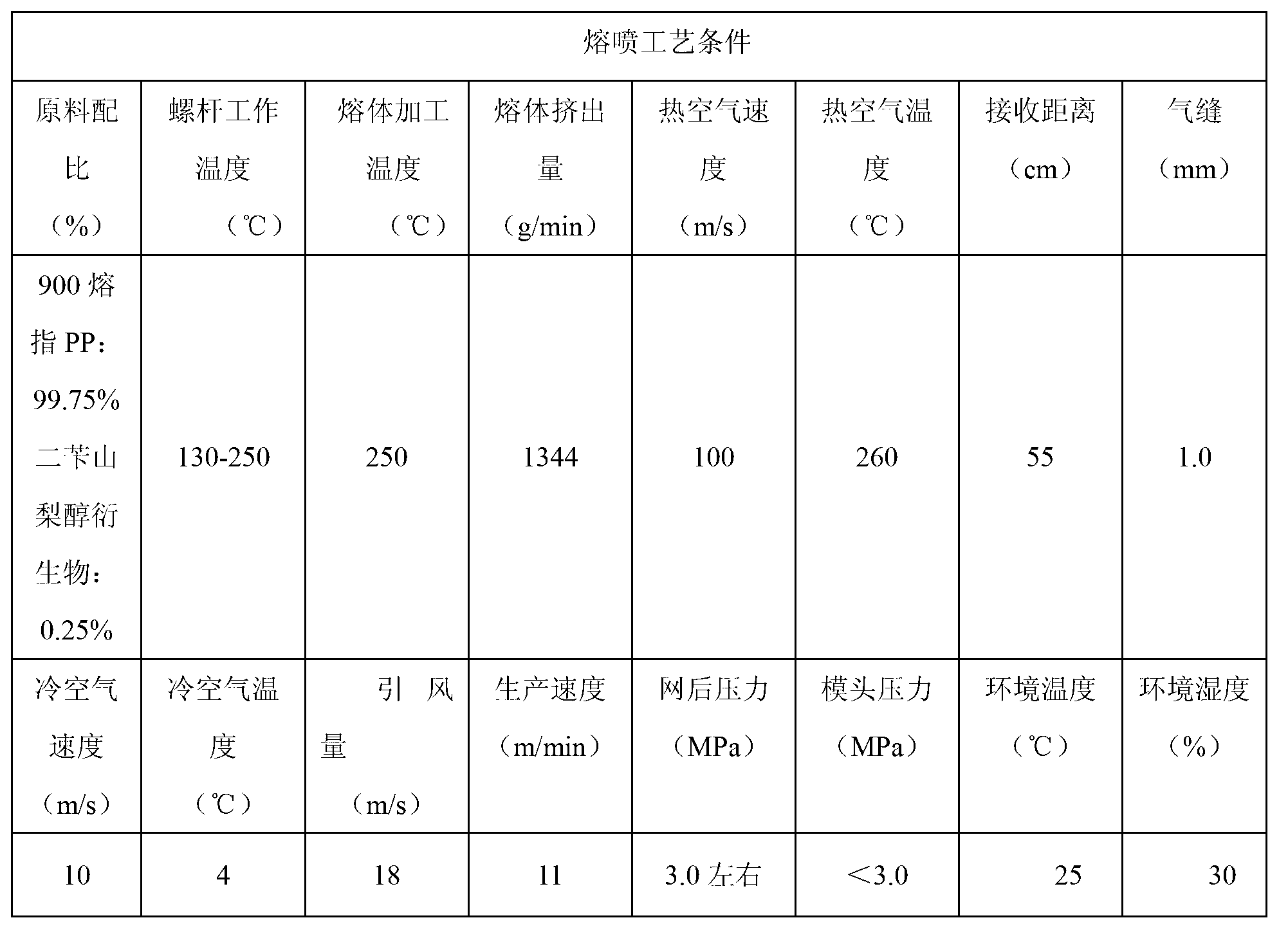

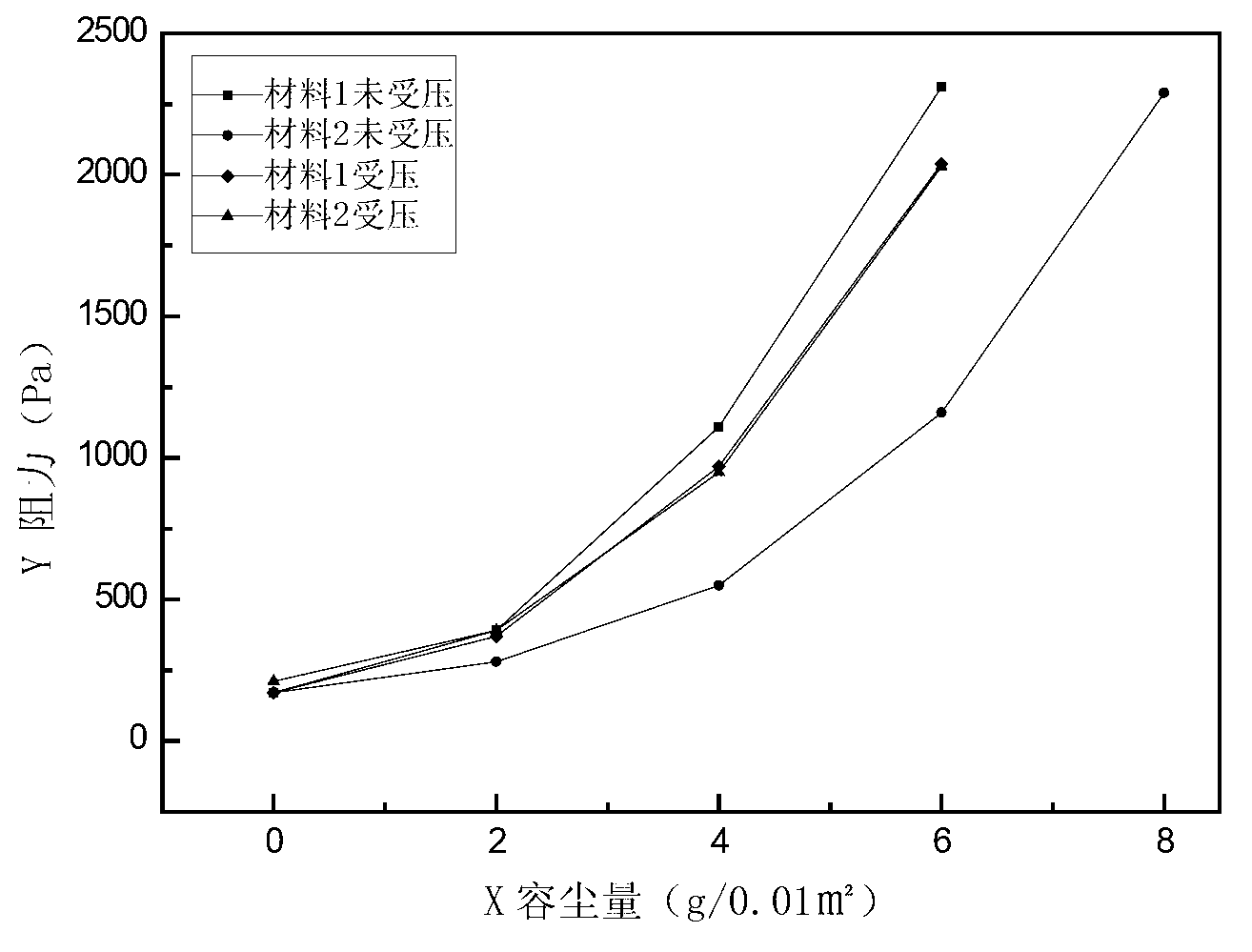

Melt spinning non-woven material and production method and application thereof

InactiveCN103046231AImprove interception effectSmall pressure lossSuction filtersLayered productsCrude fibrePolymer science

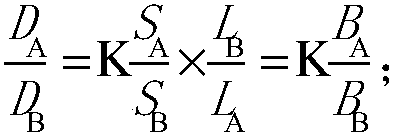

A melt spinning non-woven material is characterized in that the weight of the non-woven material weights 35 to 500 g / m<2> and being obtained by a polymer slice being directly melting to spin and the spine being weaved into webs. The melt spinning non-woven material consists of superfine fibers and crude fibers, the crude fibers are used as a framework and the superfine fibers are filled into the framework to form a fiber web to form a thickness matching structure. The fiber web has one layer or more, and when the layer number of the fiber web is more than one, a thickness increasing or gradient structure is formed through a multilayer structure. By means of the optimization of raw materials and process, the melt spinning non-woven material and a production method and an application of the melt spinning non-woven material can control a fiber web structure of the melt spinning non woven material: the distribution of fiber finenesses is controlled in a reasonable range, the fiber web has a large amount of superfine fibers and a certain amount of crude fibers; the crude fibers being used as a framework and the superfine fibers being filled into the framework improve the fluffiness of the material, and the material can still maintain some recovery capability when in use; and the fiber web forms a structure with some gradients.

Owner:ZHEJIANG ZHAOHUI FILTRATION TECH

Polyester wool-like different-shrinkage composite wire and preparing method thereof

ActiveCN108130605AConsistent extrusion speedGood moisture wickingArtificial filament heat treatmentMelt spinning methodsPolyesterAlcohol

The invention relates to a polyester wool-like different-shrinkage composite wire and a preparing method thereof. The method comprises the steps of firstly, modified polyester POY and FDY wires are produced separately; then, the POY and FDY wires are compounded to produce the polyester wool-like different-shrinkage composite wire, wherein the chromatic aberration delta E of the produced compositewire is smaller than 0.200. A bunchof POY or FDY wires extruded through the same spinneret plate contain double-cross single wires and trilobal single wires simultaneously, a modified polyestermolecular chain contains a dihydric alcohol chain section with a branch chain, and the structural formula of the dihydric alcohol chain section with the branch chain is shown in the description, wherein R1 and R2 are straight chain alkylidenes of which the number of carbon atoms is 1-3, R3 is an alkyl of which the number of carbon atoms is 1-5, R4 is an alkyl of which the number of carbon atoms is 2-5, and a matt agent in modified polyester is a mixture of amorphous titanium dioxide and amorphous silicon dioxide or calcium carbonate and amorphous silicon dioxide. The preparing method is simple and reasonable, and the prepared composite wire has good fluffy and hygroscopic and sweat releasingperformance.

Owner:JIANGSU HENGLI CHEM FIBER

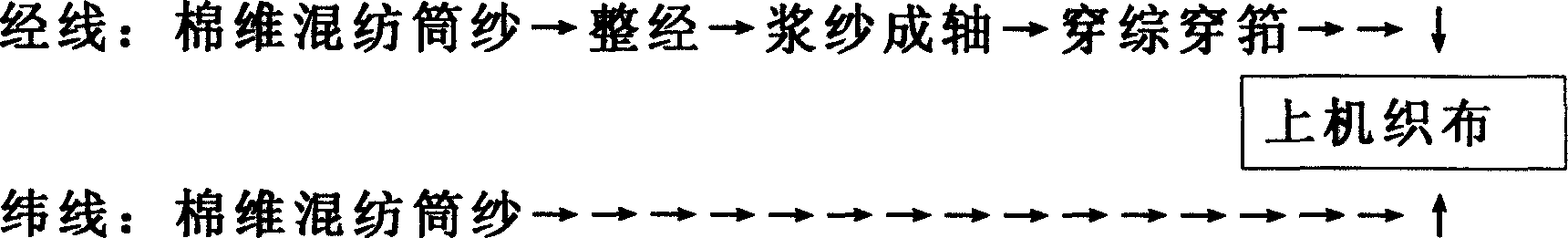

Cotton fiber fabric and manufacture technology thereof

The invention relates to a cotton textile and relative production, wherein it is characterized in that: its transverse line and longitudinal line use the cotton yarn mixed by cotton fiber and soluble vinylon fiber, while the mass between them is 70-85:15-30; and the production comprises: spinning the cotton yarn, warping, sizing, drying, spinning blank cloth, and following treatment. The inventive product is flexible, with wet adsorption, and high yield.

Owner:马伟华

Method for preparing cotton-like fabric through alkali decrement

InactiveCN102433729AThe texture of the cloth surface is dense and smoothSofter and fluffier than ultra cottonFibre typesFiberThermal insulation

The invention discloses a method for preparing cotton-like fabric through alkali decrement. The method comprises the steps of: a. first conducting unwinding treatment to polyester grey fabric, then carrying out sanding treatment; b. performing high temperature alkali decrement treatment in a high-temperature high-pressure overflow dyeing machine; c. dyeing and bleaching the treated fabric; d. carrying out shaping treatment to the dyed fabric for stabilizing the dimension; e. examining and packing a finished product. The high temperature alkali decrement technology consists of: with 10-15g / L of sodium hydroxide and 1g / L of a detergent, controlling the bath ratio at 1:15, first raising the temperature to 120-130DEG C at a speed of 2-5DEG C / min, conducting thermal insulation for 20-30min, then lowering the temperature to 50-80DEG C at a speed of 2-4DEG C / min, carrying out thermal insulation for 30-60min, and then lowering the temperature to normal temperature at a speed of 0.5-2.5DEG C / min. The fabric prepared by the method of the invention has the advantages that: 1. the fabric surface has dense and flat lines, the handfeel is soft and fluffy and surpasses cotton; 2. fibers have a strong fluffy feel, the luster is gentle, and the fabric surface can generates diffuse reflection to light and has gentle luster; 3. the fabric surface is smooth, has good permeability, and can improve chemical fibers, static resistance and stuffy feeling; the product can compare favorably with cotton fabric in terms of performances, and has lower price.

Owner:潘润华

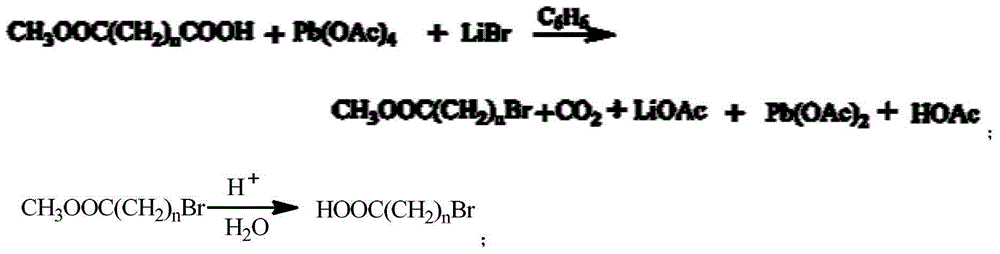

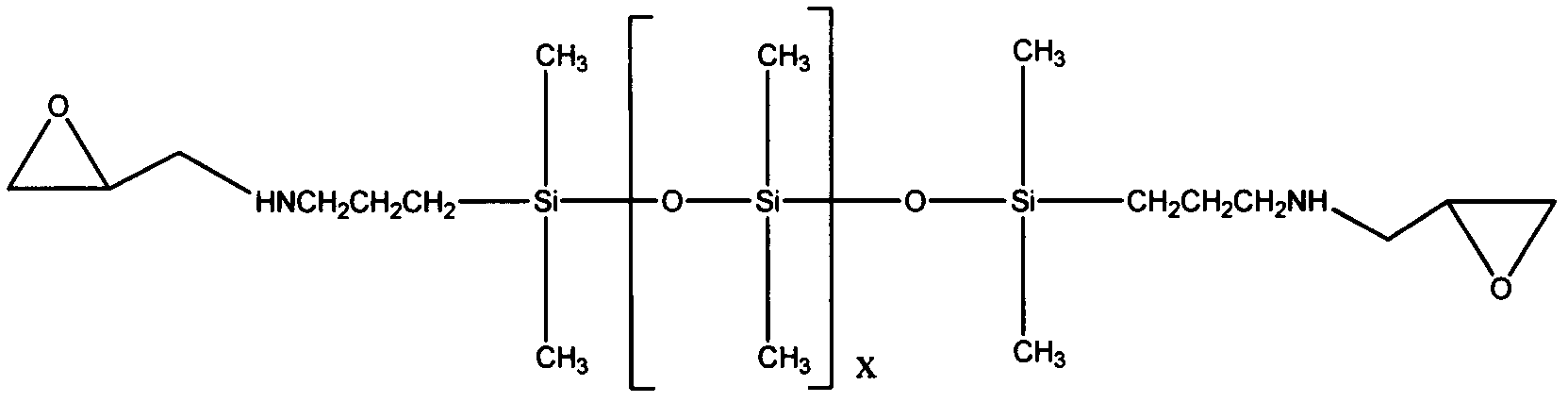

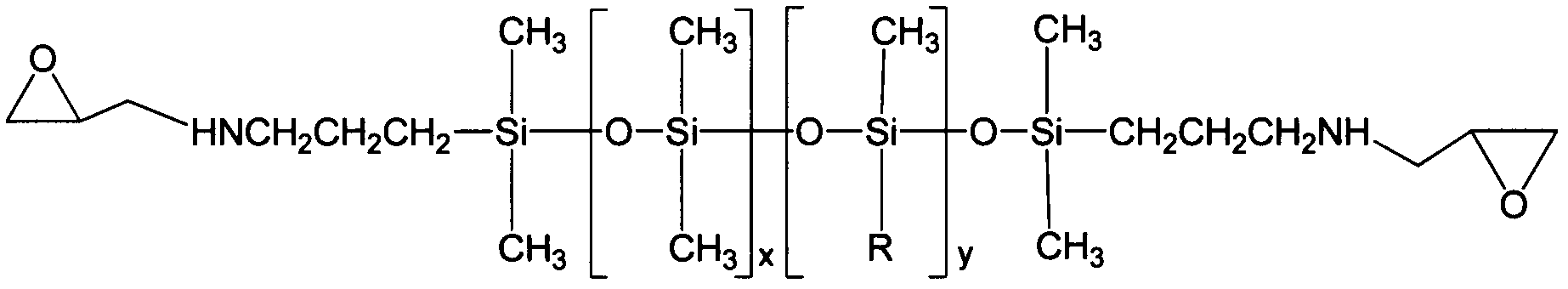

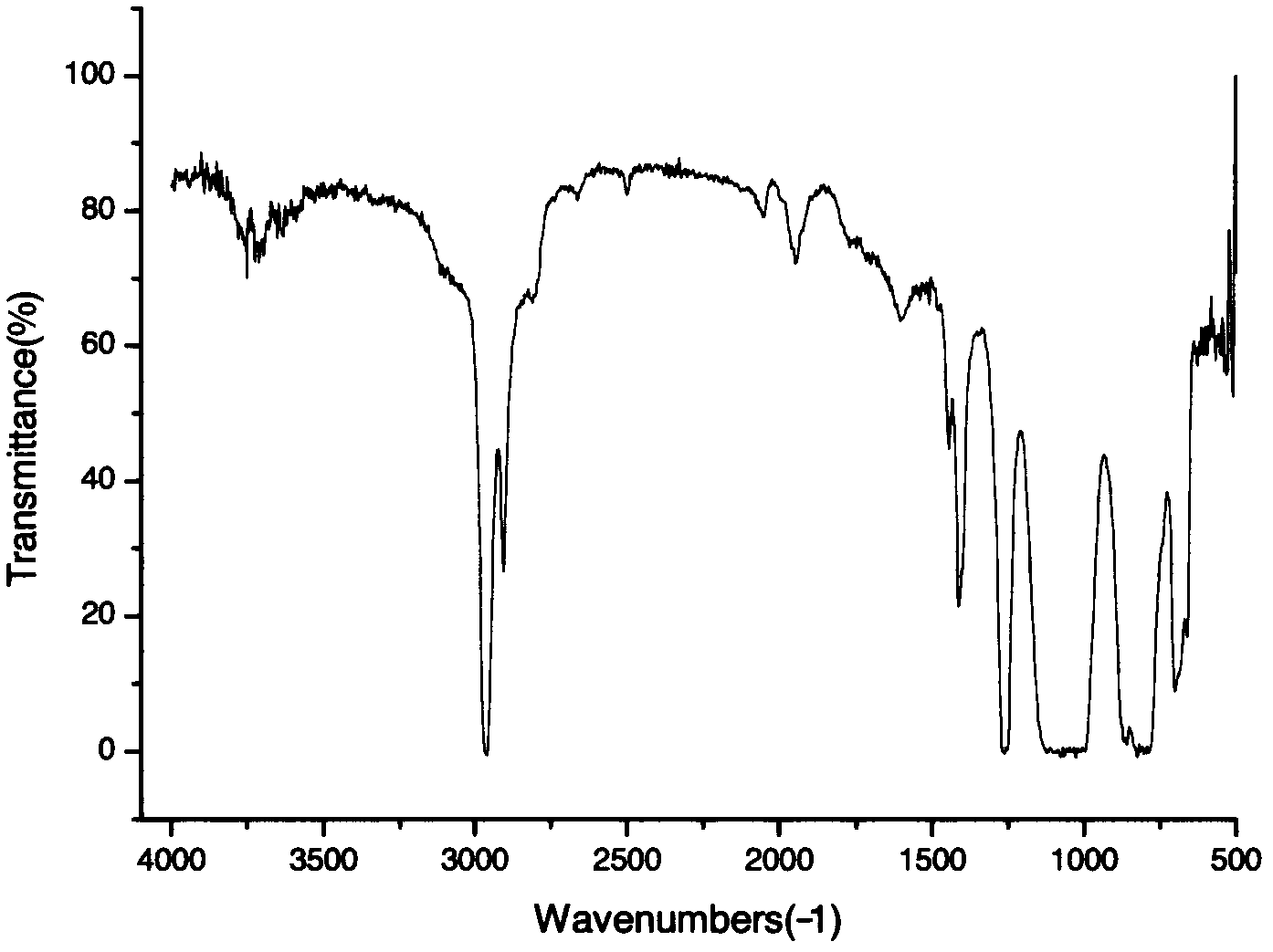

Preparation method of long-chain alkane and epoxy co-modified amino-terminated silicone oil

The invention relates to a preparation method of long-chain alkane and epoxy co-modified amino-terminated silicone oil. The structural formula of the long-chain alkane and epoxy co-modified amino-terminated silicone oil is represented by figure 1 in the specification. The preparation method of the modified silicone oil comprises the following steps: adding octamethylcyclotetrasiloxane, a long-chain alkane coupling agent and an amino-terminated silane end capping agent according to certain proportions, uniformly stirring, heating to 60-80DEG C, adding an alkaline catalyst, reacting under stirring for 0.5-1.5h, controlling the reaction temperature in a range of 90-140DEG C, carrying out a temperature maintenance reaction for a period of time, carrying out reduced pressure distillation to obtain a low-boiling-point substance which is modified silicone oil, dissolving the modified silicone oil in a solvent, reacting with epichlorohydrin at 50-100DEG C for 2-7h, and carrying out reduced pressure evaporation to remove the solvent in order to obtain the long-chain alkane and epoxy co-modified amino-terminated silicone oil. The long-chain alkane and epoxy co-modified amino-terminated silicone oil is mixed with an emulsifier and an acid, are added with deionized water in batch, and undergoes pH adjustment by the acid to about 7 in order to obtain an emulsion of the long-chain alkane and epoxy co-modified amino-terminated silicone oil. The long-chain alkane and epoxy co-modified amino-terminated silicone oil prepared in the invention overcomes the yellow disadvantage of amino silicone oil, and has the advantages of good lubrication property, good hydrophobicity and good fluffy feeling when the long-chain alkane and epoxy co-modified amino-terminated silicone oil is used for texture finishing.

Owner:JIANGNAN UNIV

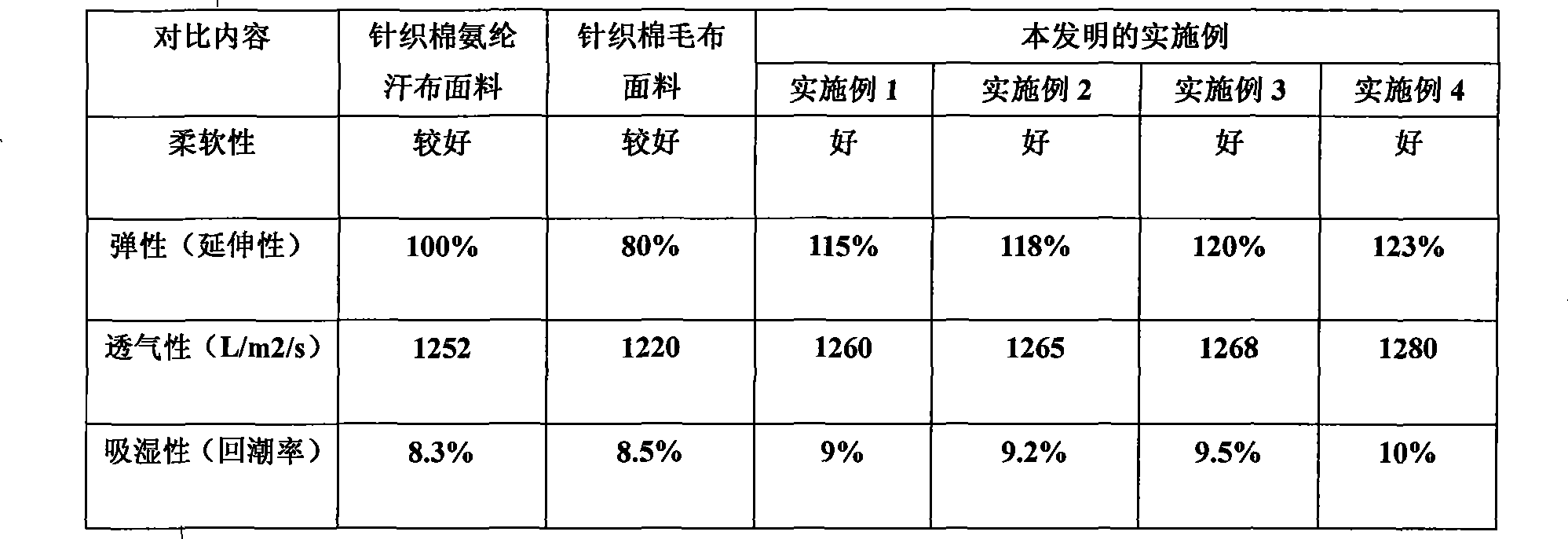

Knitting fabric for clothing and processing method thereof

InactiveCN101445993AReasonable proportion by weightImprove economyWeft knittingWarp knittingYarnAfter treatment

The invention relates to a knitting fabric for clothing and a processing method thereof. The knitting fabric comprises a covering weave and a ground weave, wherein, the raw material of the covering weave is cotton yarn, the raw material of the ground weave is terylene and spandex core-spun yarn, the content of the cotton yarn accounts for 94-97 percent, the content of the terylen fiber accounts for 2-5.7 percent, and the content of the spandex fiber accounts for 0.3-1 percent. The invention has the advantages that the knitting fabric for clothing has ideal softness, elasticity, air permeability and hygroscopicity, good fluffy effect, small water shrinkage and good shape-preserving effect; the method that the loop drying working procedure is arranged after the heat setting working procedure in the after treatment step is recommended, so that the fabric has soft hand-feel, ideal air permeability, excellent elasticity and concave-convex feel.

Owner:JIANGSU JINCHENZHEN TEXTILE

Soft polyester cotton down-proof fabrics and processing method thereof

The invention provides a soft polyester cotton down-proof fabrics and a processing method thereof; the fabrics is formed by interlacing warp yarns and filling yarns according to a plain structure; the warp yarn uses super fine denier terylene low elasticity filament with fineness of 50-75 D; the filling yarn uses polyester cotton blended yarn with fineness of 40-60s. The processing method is to process the warp yarn and filling yarn through the following steps in sequence: warping, slashing, drafting and denting, weaving, grey singeing, desizing, boiling-off and bleaching, tentering, sanding, soft windproof arrangement, moulding, calendering and preshrinking. The fabrics is lasting and excellence in down-proof performance, thin and soft, and small in sound.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

High-content aqueous polyurethane latex and preparation method thereof

The invention discloses high-content aqueous polyurethane latex and a preparation method thereof. (A) hydrogenated diphenylmethane diisocyanate, (B) fatty group diamino sulfonic acid sodium salt, (C) linear bihydroxyalkyl siloxane, (D) dimer acid polyester dibasic alcohol; (E) 2-methyl-2, 4 pentanediol, (F) 1, 3 cyclohexanediol, (G) chain extender, (H) fatty alcohol-polyoxyethylene ether TO7, and (J) deionized water are used for preparing the high-content aqueous polyurethane latex through a prepolymerization reaction, a chain-extending reaction and an emulsion reaction. The invention has the advantages of low production cost, 55% of solids content, good water pressure resistance, fastness, abrasion resistance, favorable washability and aqueous environmental protection.

Owner:郯城县华晨涂料有限公司

Method for processing fried squid slices

InactiveCN103315336AReasonable workmanshipImprove fluffinessFood preparationFood itemFood processing

The invention belongs to the field of food processing technologies and aims at providing a method for processing fried squid slices. The method comprises the steps of partitioning squid body slices into blocks, cleaning, pickling and frying, and is characterized in that the pickling step comprises the sub-steps of cutting the squid body slices, pricking, daubing sauce, daubing paste and steaming. The method for processing fried squid slices has the advantages that the process is reasonable, the operation is simple and convenient, and the finished product is rich in nutrition and good in mouth feel and is highly praised by customers.

Owner:RONGCHENG HONGYE IND

High-elastic warming gigging knitted fabric and manufacturing method thereof

The invention provides high-elastic warming gigging knitted fabric and a manufacturing method thereof. The high-elastic warming gigging knitted fabric comprises three layers, the first layer is a flat weft plain stitch layer, the intermediate reinforcing layer is wavy, and the gigging layer is shaped in fluffy polar fleece. The fabric is knitted by chinlon filaments, naked spandex filaments and polyester filaments. Elasticity of the fabric is improved and production cost is reduced by an independent naked spandex filament feeding method. Loops of a gigging surface of the fabric are lengthened, the fabric has excellent extensibility and fluffy sense of the fabric is improved. The chinlon filaments are used for the surface layer of the fabric, and pilling resistance is better. Furthermore, a weft-knitting loop knitting machine is adopted in the manufacturing method, gram weight of the fabric can be controlled better, and the manufactured fabric is more uniform.

Owner:NINGBO DAQIAN TEXTILE

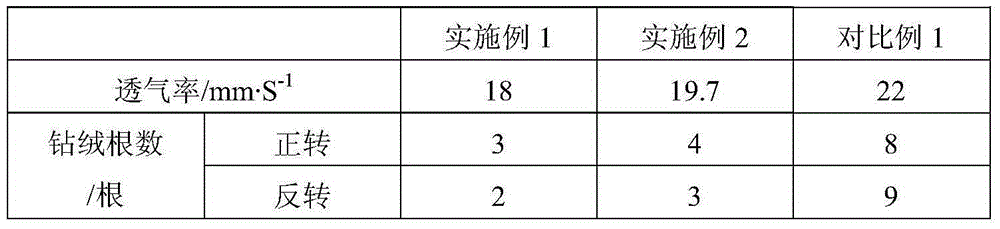

Method for preparing down-proof fabric

InactiveCN102493075AFiber shrinkageFully contractedFibre typesHeating/cooling textile fabricsVolumetric Mass DensityEngineering

The invention discloses a method for preparing down-proof fabric, which comprises the steps of: a, unwinding gray fabric and then adsorbing furs of the gray fabric, wherein the gray fabric is fine denier filament; b, adding the treated gray fabric into an overflow dyeing machine, carrying out high-temperature reduction operation through programmed heating; c, dyeing the gray fabric in dyeing solution; d, putting the fabric in a setting machine for setting, and then drying the fabric, and adding wind-proof agent for setting; and e, calendaring, checking the fabric, and packaging. The method disclosed by the invention has the advantages that: 1, as polyster fibers contract sufficiently under the condition of high temperature, grains on the surface of the fabric are dense and smooth; 2, the fine denier filament are applied to reacting with the polyster fibers in a certain amount of alkali solution at a high temperature, thereby slightly corroding fiber layers on the surfaces of the fibers, increasing air permeability and reducing static generation probability of the fibers, improving bulkiness of the fibers, and enhancing the sense of puffing of the fibers; 3, by adjusting tissues of the fabric, density is increased and printing and dyeing processes are adjusted, in this way, eiderdowns and wools can be prevented from penetrating down from the fabric; and 4, the fabric is excellent in performance and low in price.

Owner:GUANGDONG SI HAI WEI YE TEXTILE TECH

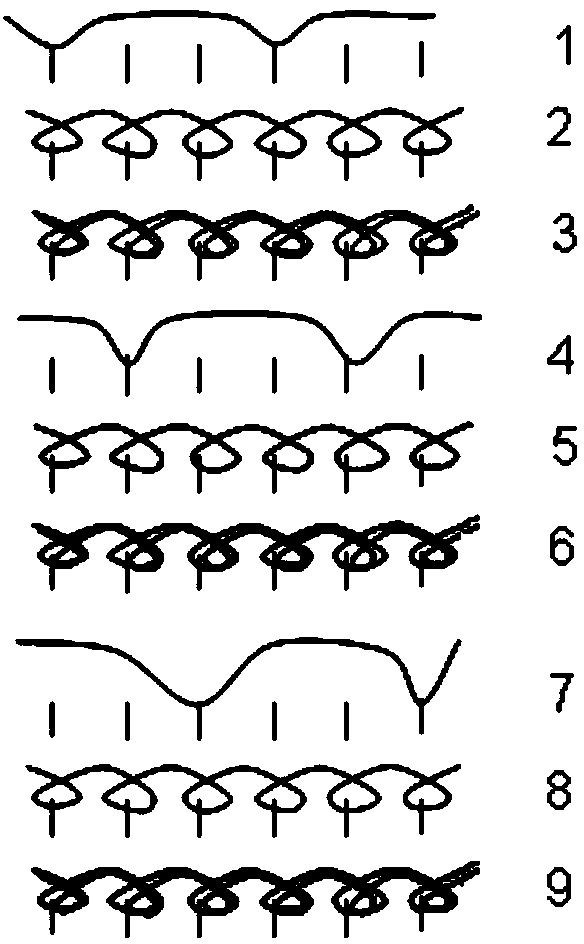

Production method for cashmere/yakwool covering yarn

The invention provides a production method for cashmere / yakwool covering yarns. Cashmere and yakwool fibers are respectively used to weave rough yarns in a wool spinning system. A parallel spinning method is used to weave yakwool / vinylon fascinated yarns by using yakwool rough yarns and vinylon filaments, and then the yakwool / vinylon fascinated yarns are used as core yarns, and the cashmere rough yarns are used as wrapping yarns to weave the covering yarns, and finally, a vinylon dissolution technology is used to remove vinylon, to obtain excellent quality cashmere / yakwool covering yarns. Using the above technology, the cashmere fibers and yakwool fibers can be made into excellent quality covering yarns in high additional value. Especially in the first step and the second step, the yakwool fibers and the cashmere fibers respectively weave rough yarns on a wool spinning system, thereby reducing damages on fibers. In the third step, the parallel spinning method is used to weave the yakwool / vinylon fascinated yarns, thereby improving fluffiness and strength of the yarns. Using the production method, the yakwool just needs to be processed in rough yarns, and the method prevents a procedure in which processing of the yakwool is relatively difficult.

Owner:ZHEJIANG HAONENG TECH CO LTD

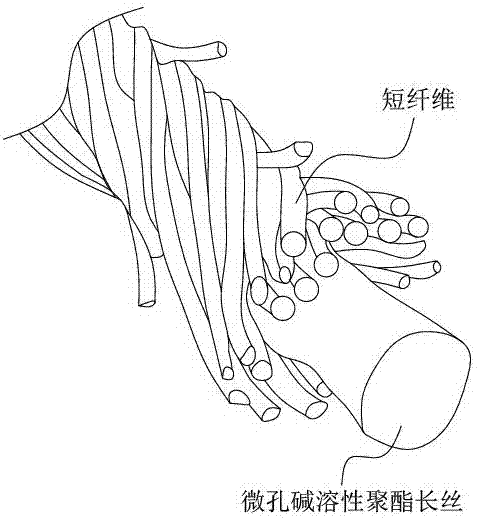

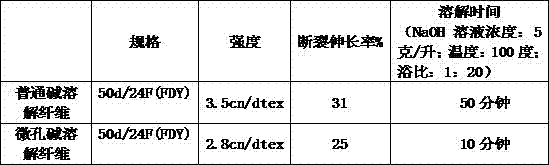

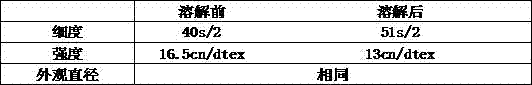

Method for preparing hollow textile from core spun yarn with microporous alkali-soluble polyester filament covered with short fiber

ActiveCN107502974AImprove comfortFeel goodFabric breaking/softeningFilament forming substance formingPolyesterYarn

The invention discloses a method for preparing hollow textile from core spun yarn with a microporous alkali-soluble polyester filament covered with short fiber. The method comprises a preparation step of foaming microcapsules, a preparation step of alkali dissolution slices containing the foaming microcapsules, a melt foaming and spinning forming step and a preparation step of the hollow textile. According to the method for preparing the hollow textile from the core spun yarn with the microporous alkali-soluble polyester filament covered with the short fiber, the polyester filament with a microporous structure is adopted, hollow yarn or hallow fabric is obtained in an alkaline dissolution manner, the polyester filament with the microporous structure can effectively increase the contact area of an alkaline solution, the dissolution speed is high, the dissolution time is short, dissolution is thorough, and the hollow textile prepared from the hollow yarn or the hollow fabric obtained through dissolution has good and comfortable hand feeling as well as good fluffy, soft, thermal-insulating and quick-drying characteristics.

Owner:余燕平 +3

Down feather washing technology

The invention discloses a down feather washing technology. The down feather washing technology comprises the following steps that first, dedusting is performed; second, feather is separated; third, pre-washing is performed, and some dust and impurities are removed, wherein every 0.5 KG to 1 KG of down feather is washed through 45 KG to 55 KG of clean water, and the cleaning time ranges from 4 min to 8 min; fourth, deep cleaning is performed, wherein pre-washed down feather is thrown into 25 KG to 35 KG of warm water with the temperature ranging from 30 DEG C to 40 DEG C, and special down feather detergent with the concentration being 1.5% to 3.5% and deodorant with the concentration being 0.2% to 0.4% are added; fifth, rinsing is performed, 25 KG to 35 KG of clean water is added for rinsing for 4 min to 5 min at each time, then sewage is drained, clean water is added for rinsing, and rinsing is performed for 10 times to 13 times; sixth, dewatering is performed, the rinsed down feather enters a centrifugal to be dewatered; seventh, half drying is performed; eighth, drying is performed; ninth, cooling is performed. The down feather washing technology has the advantages that adhering substances between down feather fibers are reduced, the fluffy degree of down feather is improved, the amount of static air in the down feather is increased, and the thermal insulating performance of the down feather is greatly improved.

Owner:江苏欣隆羽绒有限公司

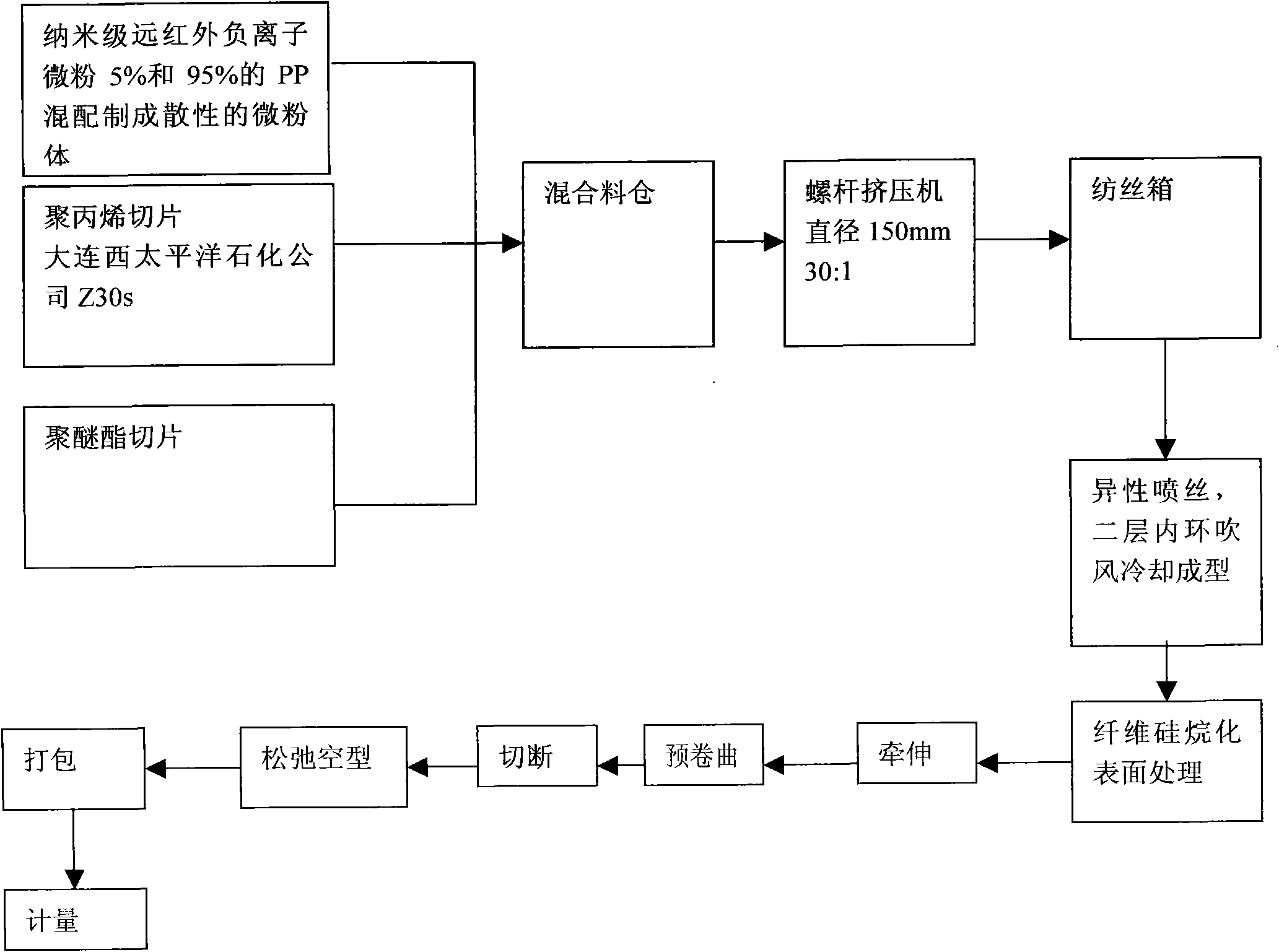

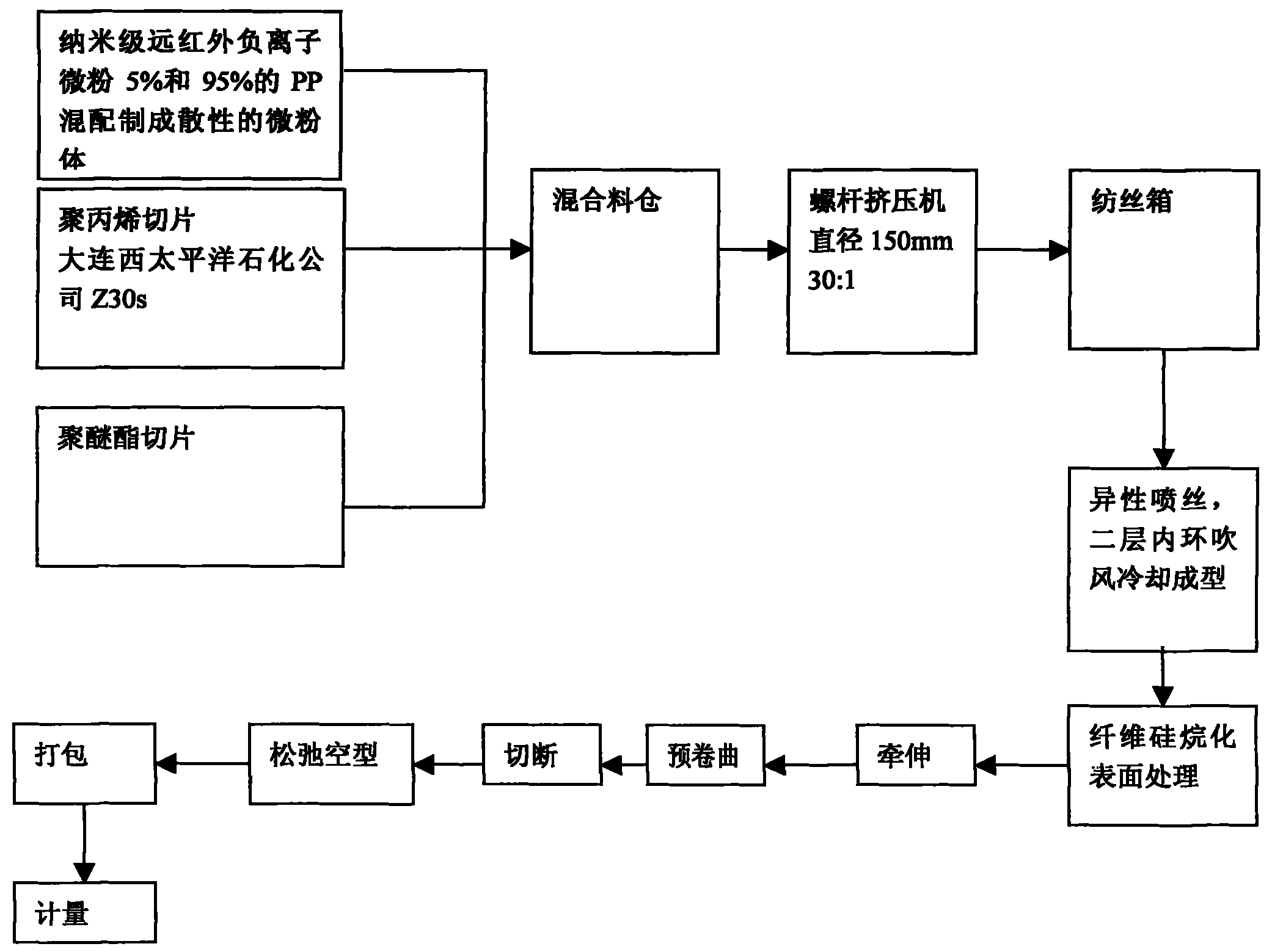

Method for producing down-like fiber

ActiveCN101886299AIncrease elasticityImprove fluffinessMelt spinning methodsConjugated synthetic polymer artificial filamentsTextile technologyPolymer science

The invention discloses a method for producing down-like fiber, and relates to the technical field of textiles. The down-like fiber is formed by blending, melting and spinning polypropylene, polyether ester and far infrared anionic micro powder with the grain diameter of less than 30 nanometers. The method can spin the novel down-like fiber with health-care and environment-friendly function, high elasticity, high fluffy property, light weight and heat insulation. The down-like fiber can be applied to health-care and warm-keeping filling of down garments, quilts, sleeping bags and pillow inners and applied to decorative fabrics of spun yarns, non-woven fabrics and the like, and the environment-friendly and health-care function of the down-like fiber is favorable for human health and improvement of air quality.

Owner:YANGZHOU YONGHUI TEXTILE TECH

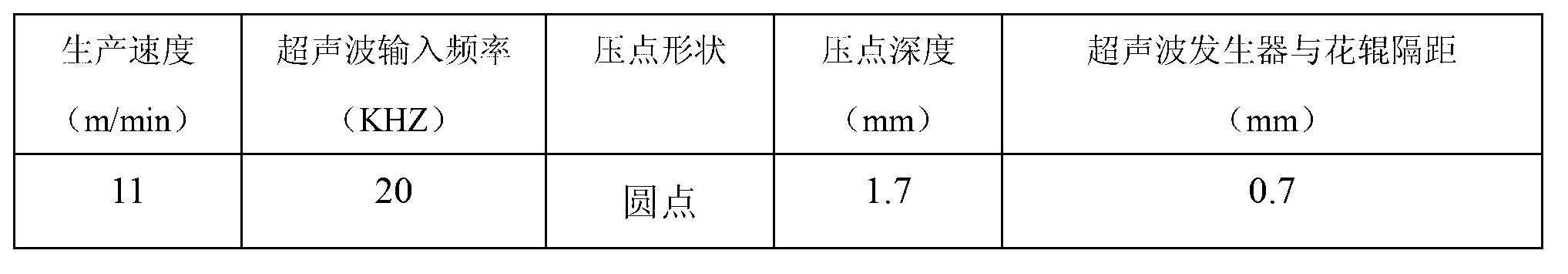

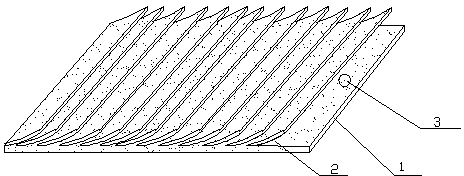

High temperature resistant air filtering material and preparation method thereof

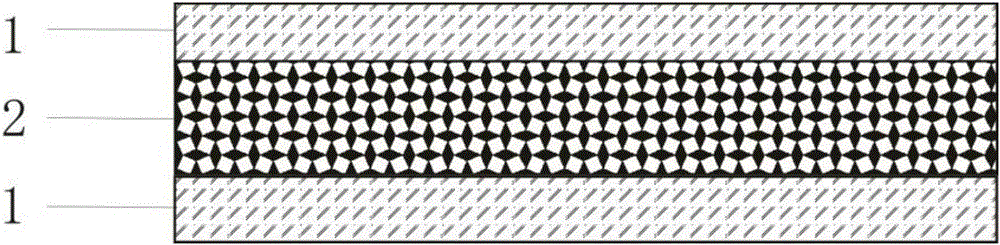

ActiveCN106757775AIncrease bulkiness and resistance to deformationHigh bond strengthLaminationLamination apparatusWoven fabricMetallurgy

The invention discloses a high temperature resistant air filtering material and a preparation method thereof. The filtering material comprises three layers, the upper and lower layers are high temperature resistant non-woven fabric layers, the middle layer is a high temperature resistant staple fiber inserted ultra-fine glass fiber non-woven fabric layer. According to the filtering material, in the production process of the glass fiber, the air flow is used for transmitting the high temperature resistant staple and distributing the staple into the ultra-fine glass fiber. After the mixing of the high temperature resistant staple and the ultra-fine glass fiber, sand blasting is used for making the two materials bonded to form a multi-dimensional, multi-sizeable and fluffy high temperature resistant staple inserted ultra-fine glass fiber non-woven fabric layer, then the ultrasonic adhesion technology is used for compounding the upper and lower surfaces of the high temperature resistant staple inserted ultra-fine glass fiber non-woven fabric layer with the high temperature resistant non-woven fabric layer. The high temperature resistant air filtering material has the advantages of being fluffy and soft, good in elasticity, high in porosity, and good in uniformity. The material prepared by using the method has good air permeability, good filtering performance, pressure resistance performance and high temperature performance, can resist ash removal vibration, is not prone to breaking which can invalidate the filtering material.

Owner:榆林天盛缘玻璃纤维科技有限公司

Single knit fabric and production method thereof

Owner:TORAY IND INC

Full-orlon super-soft carpet yarn

The invention relates to full-orlon super-soft carpet yarn belonging to the technical field of carpet yarn. The invention is characterized in that the full-orlon super-soft carpet yarn is formed by blending 88-92 percent of 1.67D superfine orlon fibers and 12-8 percent of 3D fine-denier high-shrinkage orlon fibers by ring spinning and is spun by the following technical conditions and the process flows: carding a hair bulb prepared by two orlon fibers on a gilling machine; uniformly mixing different short orlon fibers; carding 2-4 strands of orlon fibers on a gilling machine; further uniformly carding, mixing, combing, smoothening and further drafting mixed wool tops to obtain roving yarn; then, further drafting the roving yarn to prepare spun yarn; deseaming the spun yarn; and carrying out the procedures of doubling, twisting, reeling and slub dying two pieces of single yarn to finish spinning. A carpet spun by the full-orlon super-soft carpet yarn has favorable softness, strength, resilience, light fastness and heat resistance.

Owner:浙江义乌金汇化纤有限公司

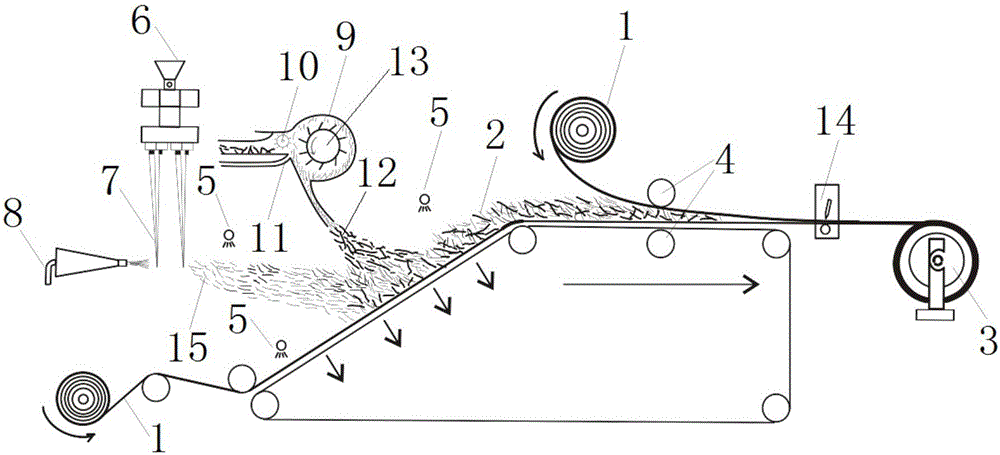

Acrylic and Richcel fiber florescent denim and weaving method thereof

InactiveCN104278410AChromatography is completeImprove fluffinessSingeingWoven fabricsDenimThermal insulation

The invention provides acrylic and Richcel fiber florescent denim and a weaving method thereof. The denim brings the characteristics of acrylic and Richcel fiber into full play, so that the fluffiness, the thermal insulation and the light fastness of the denim in autumn and winter are improved, and the cloth cover has a fluorescent colorful effect.

Owner:JIANGSU DELIHENG COTTON

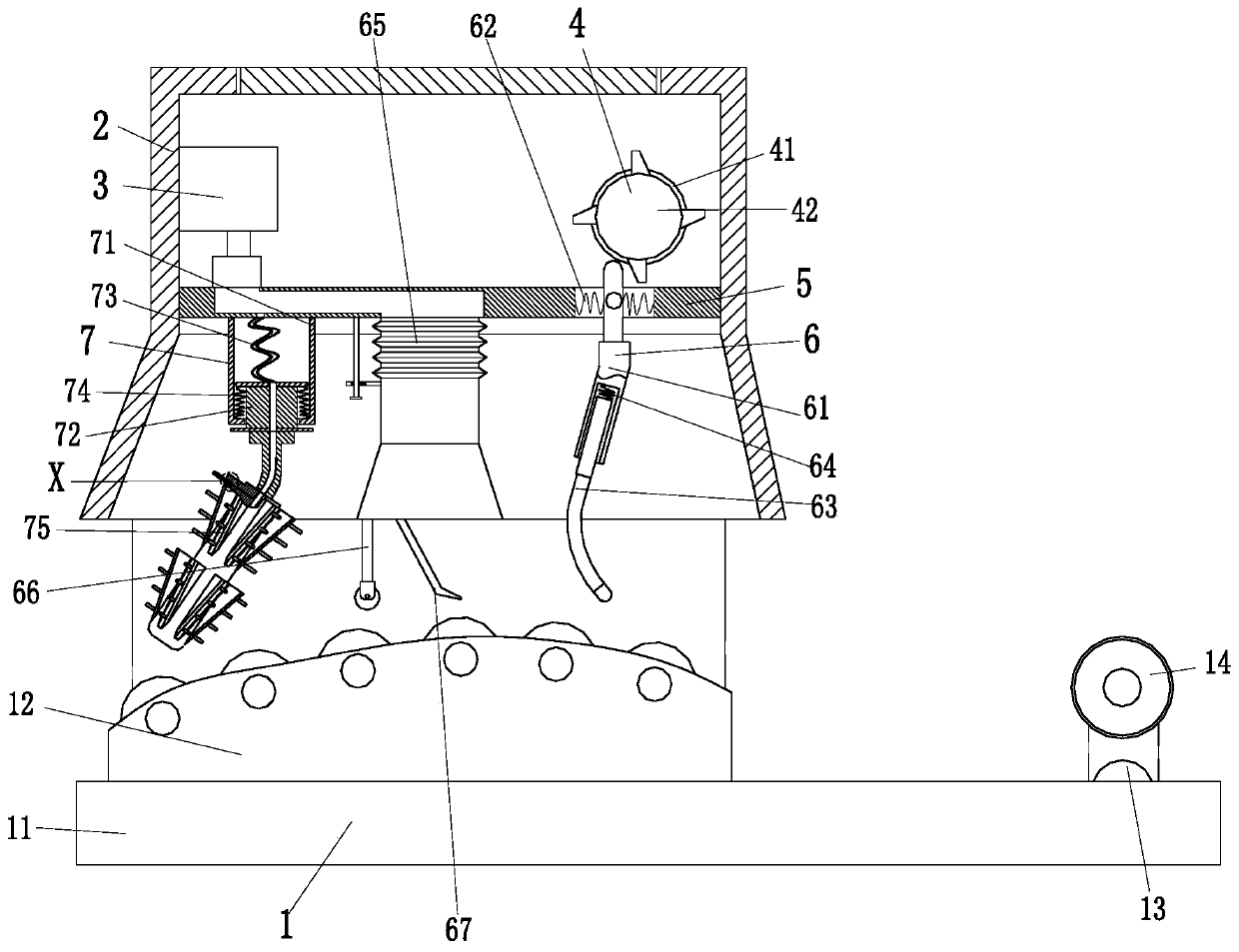

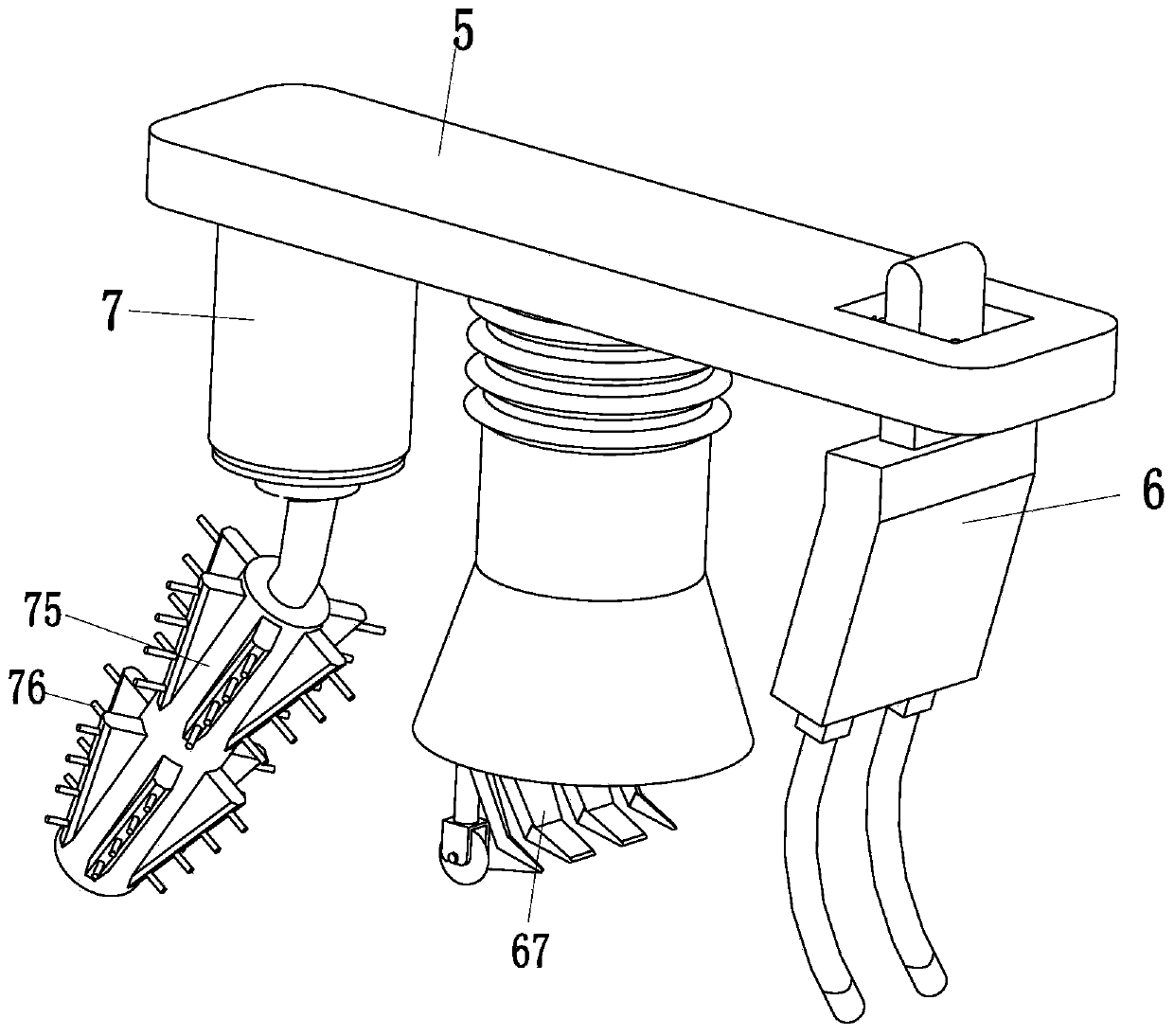

Textile intelligent carding machine

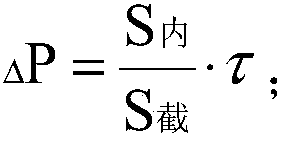

ActiveCN110230161AReduce fluffinessImprove fluffinessMechanical cleaningPressure cleaningEngineeringTextile

The invention relates to a textile intelligent carding machine. The textile intelligent carding machine comprises a conveying bed body, a dust-proof box, a dust collector, a driving device, fixed plates, dust suction devices and carding devices, wherein the dust-proof box is mounted at the left end of the conveying bed body; the dust collector is mounted at the left end of the interior of the dust-proof box; the driving device is mounted at the right end of the interior of the dust-proof box; the fixed plates are uniformly mounted on the lower side of the interior of the dust-proof box; a carding device is arranged at the left end of each fixed plate; the dust suction device is arranged at the right end of each fixed plate. The textile intelligent carding machine can solve the problems that personnel usually card fuzzing surfaces by a rake, as a contact area between tooth ends of the rake and flannelette is large, fuzz presses down easily during carding, and the direction of the fuzz is difficult to straighten; as the area of the tooth ends of the rack is large, fuzzy balls and miscellaneous lines in deep layers of the fuzzing surfaces are difficult to scrape, and the situation that the tooth ends of the rack downward pushes the fuzzy balls and miscellaneous lines during scraping easily occurs.

Owner:扬州金晟华线业有限公司

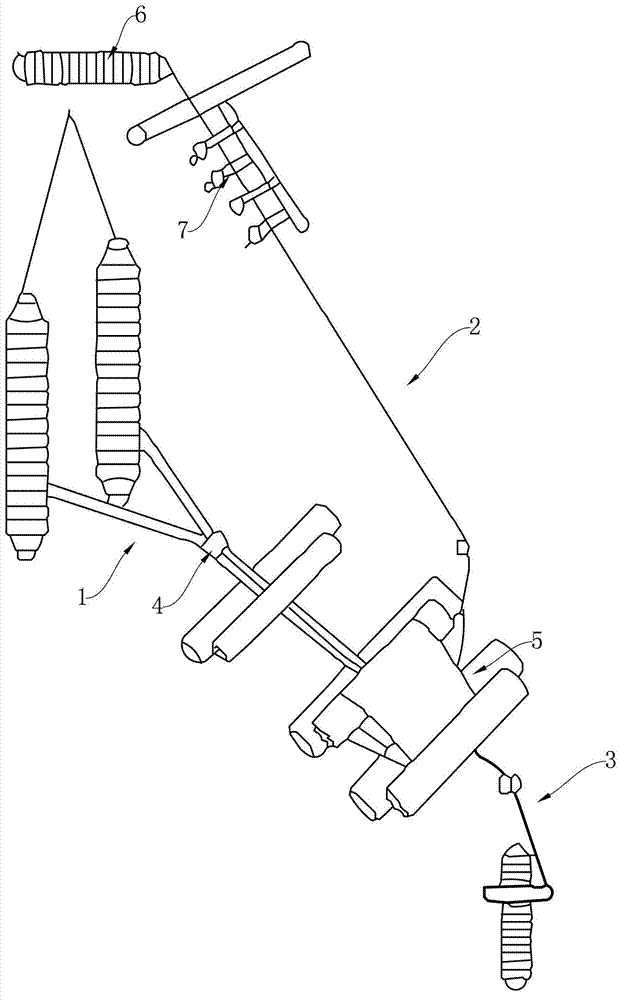

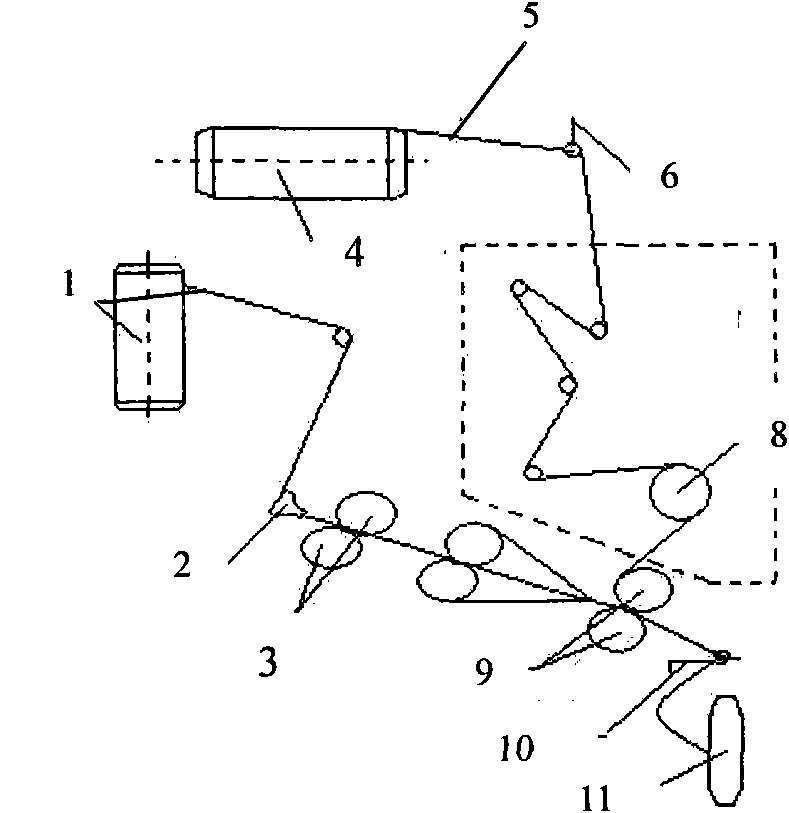

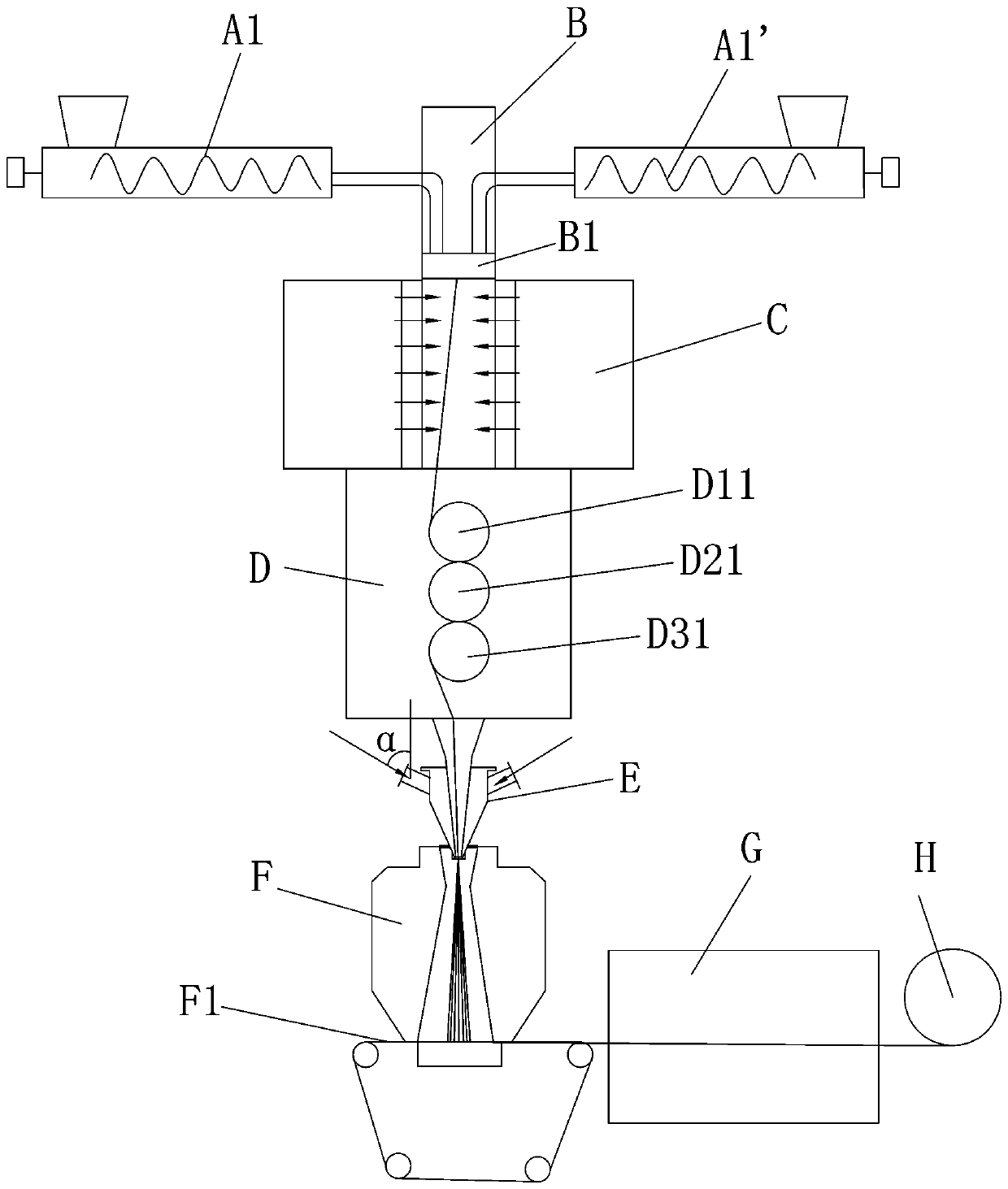

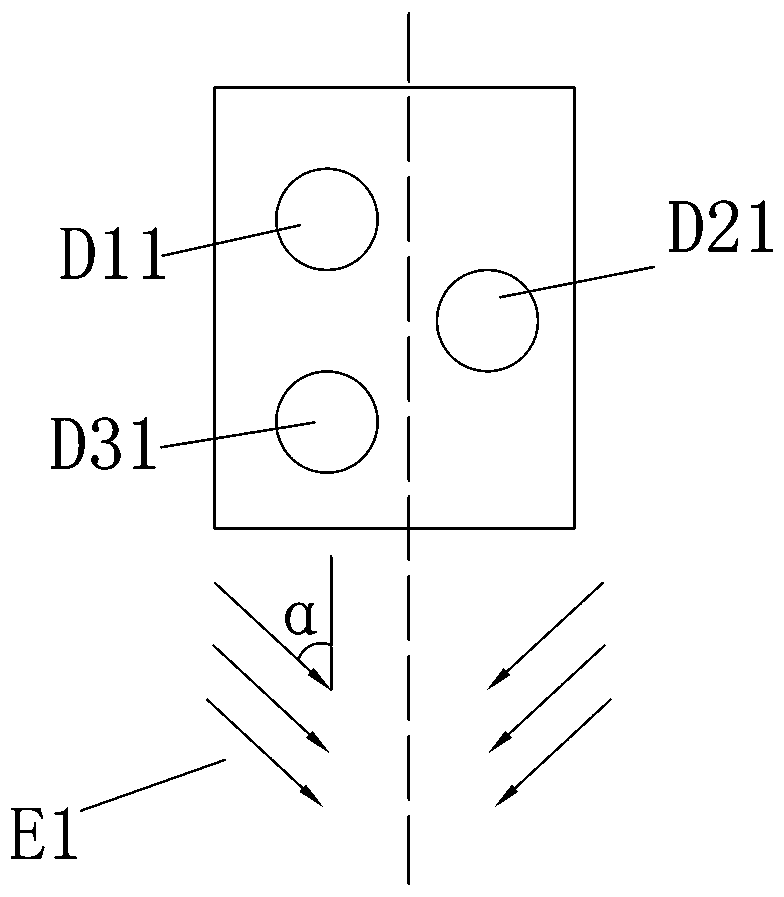

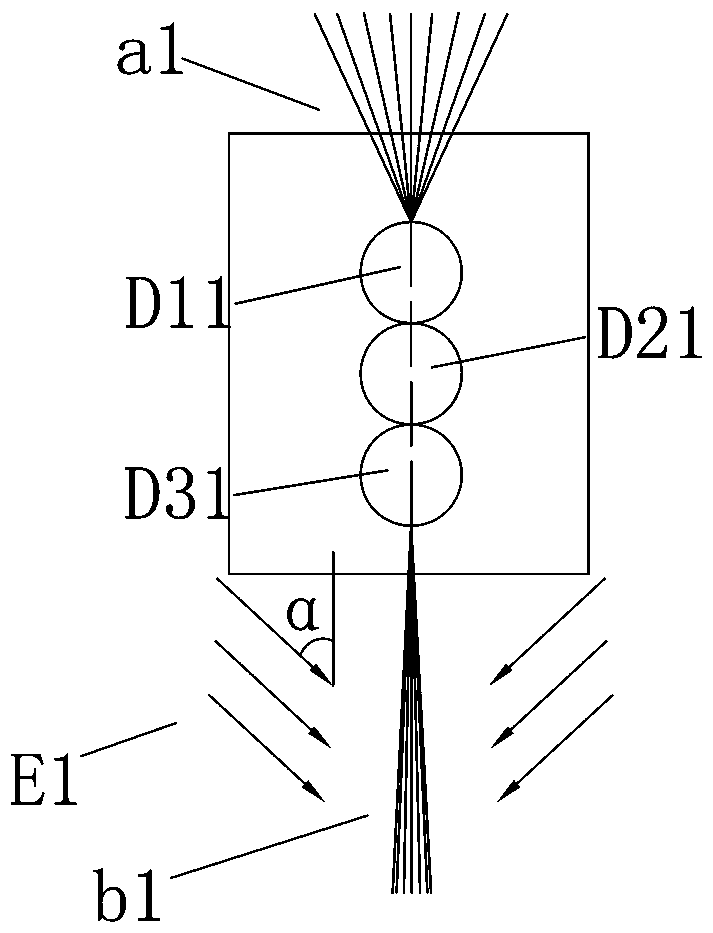

Manufacturing equipment and manufacturing method of spunbonded non-woven fabric

PendingCN110093719AGood flexibilityImprove fluffinessNon-woven fabricsStretch-spinning methodsCold airEngineering

The invention discloses manufacturing equipment of a spunbonded non-woven fabric. The manufacturing equipment comprises hot melt extrusion devices, a spinning device, a side cold air blowing device, amechanical drafting device, a hot air crimping device, a wire and net laying device, a net forming device and a cutting and winding device which are sequentially connected to one another; the hot melt extrusion devices at least consist of two groups and are connected to the spinning device; the mechanical drafting device is provided with at least three drafting rollers, the drafting rollers are longitudinally staggered and arranged on both sides of the lower portion of the side cold air blowing device in two groups and can be horizontally moved to the same vertical line, and the rotation speeds of the drafting rollers close to a spinneret plate are sequentially lower than those of the drafting rollers away from the spinneret plate; the hot air crimping device is located at hot air blowingpositions on both sides of the hot air blowing device just below the mechanical drafting device, and the range of an included angle between a side hot air blowing direction and the longitudinal direction is from 5 degrees to 90 degrees. The invention also discloses a manufacturing method of the spunbonded non-woven fabric. The spunbonded non-woven fabric produced by means of the manufacturing equipment and the manufacturing method is soft and fluffy.

Owner:XIAMEN YANJAN NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com