Cotton fiber fabric and manufacture technology thereof

A textile and process technology, applied in the field of fabric production technology, can solve the problems of increasing weaving difficulty and weaving cost, unbalanced warp and weft strength of the cloth surface, and many non-twisting cloth processes, so as to improve the spinnability and fabric quality. Powerful harmony and reduced weaving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

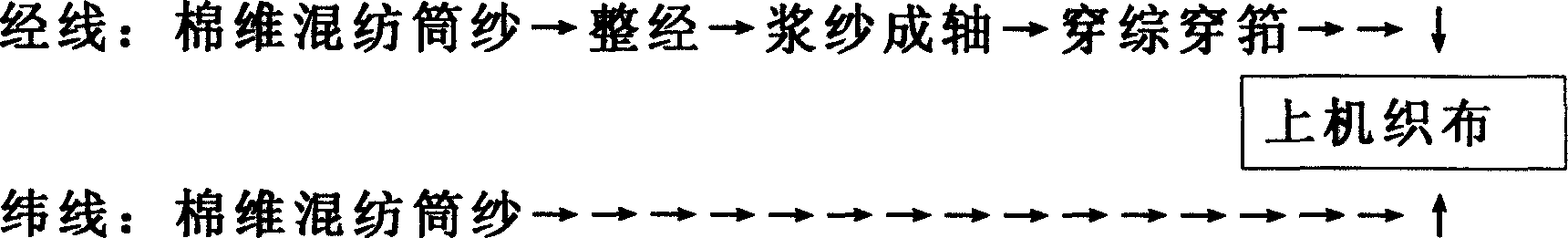

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with embodiment.

[0016] 1. Cotton yarn spinning

[0017] Cotton yarn is made by blending cotton fiber and water-soluble vinylon fiber, wherein the weight ratio of cotton fiber and water-soluble vinylon fiber can be 85:15 or 80:20 or 75:2 or 70:30. There are two ways to make it:

[0018] (1) Cotton mixing method. That is, it is completed on the cotton table in the first process of spinning. Take the cotton and water-soluble vinylon fiber in the above weight ratio and put them into the cotton table for mixing, mix evenly, and then complete the spinning process through cleaning, carding, drawing, roving, spun yarn and winding.

[0019] (2) Parallel mixed method. It is made by mixing cotton and water-soluble vinylon fiber in the drawing process. After cleaning and carding, take 6 cotton slivers and 2 vinylon, and draw them on the machine. Through drawing I, drawing II and drawing III, the purpose of u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com