Patents

Literature

108results about How to "Accurate materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

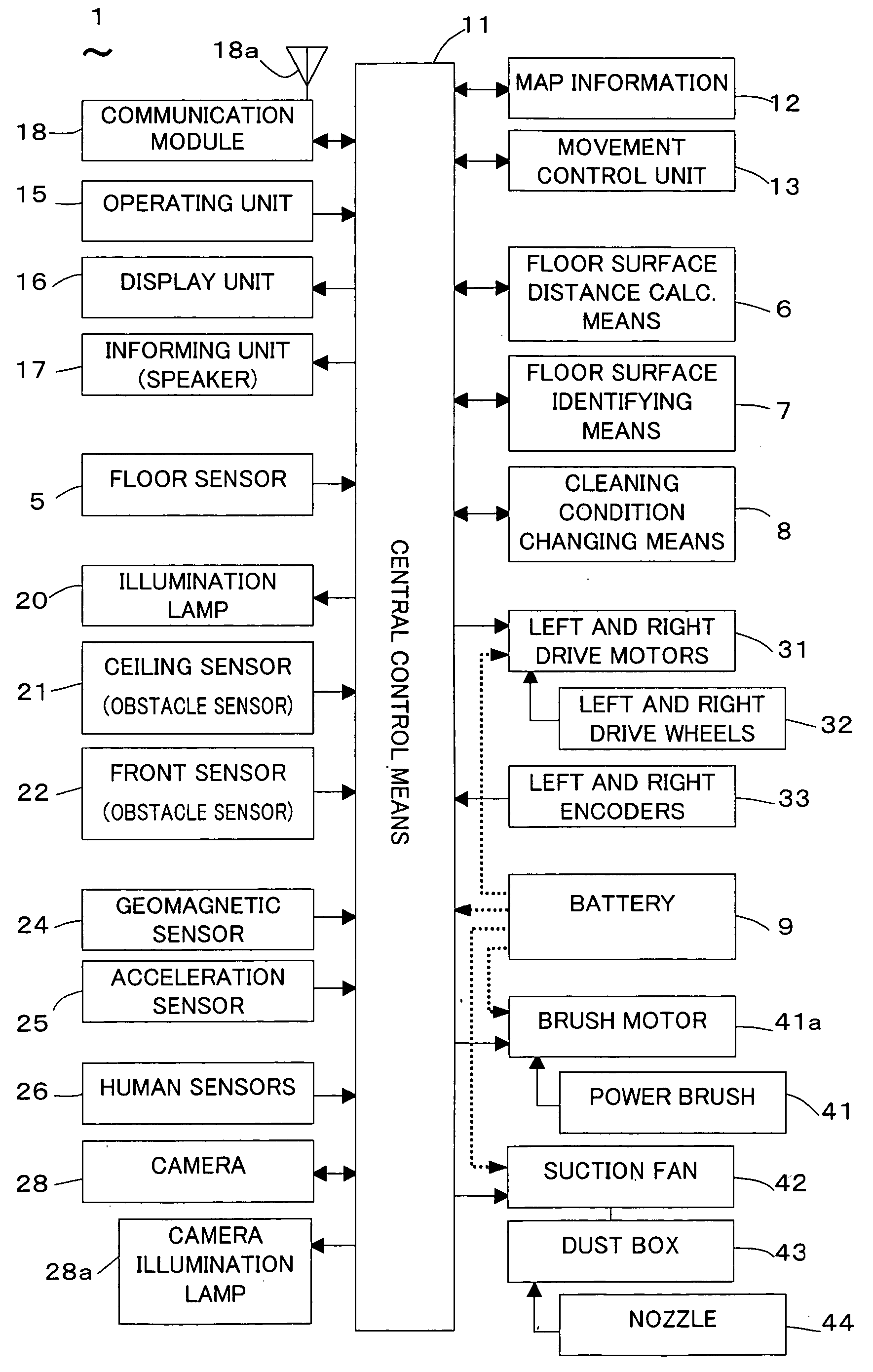

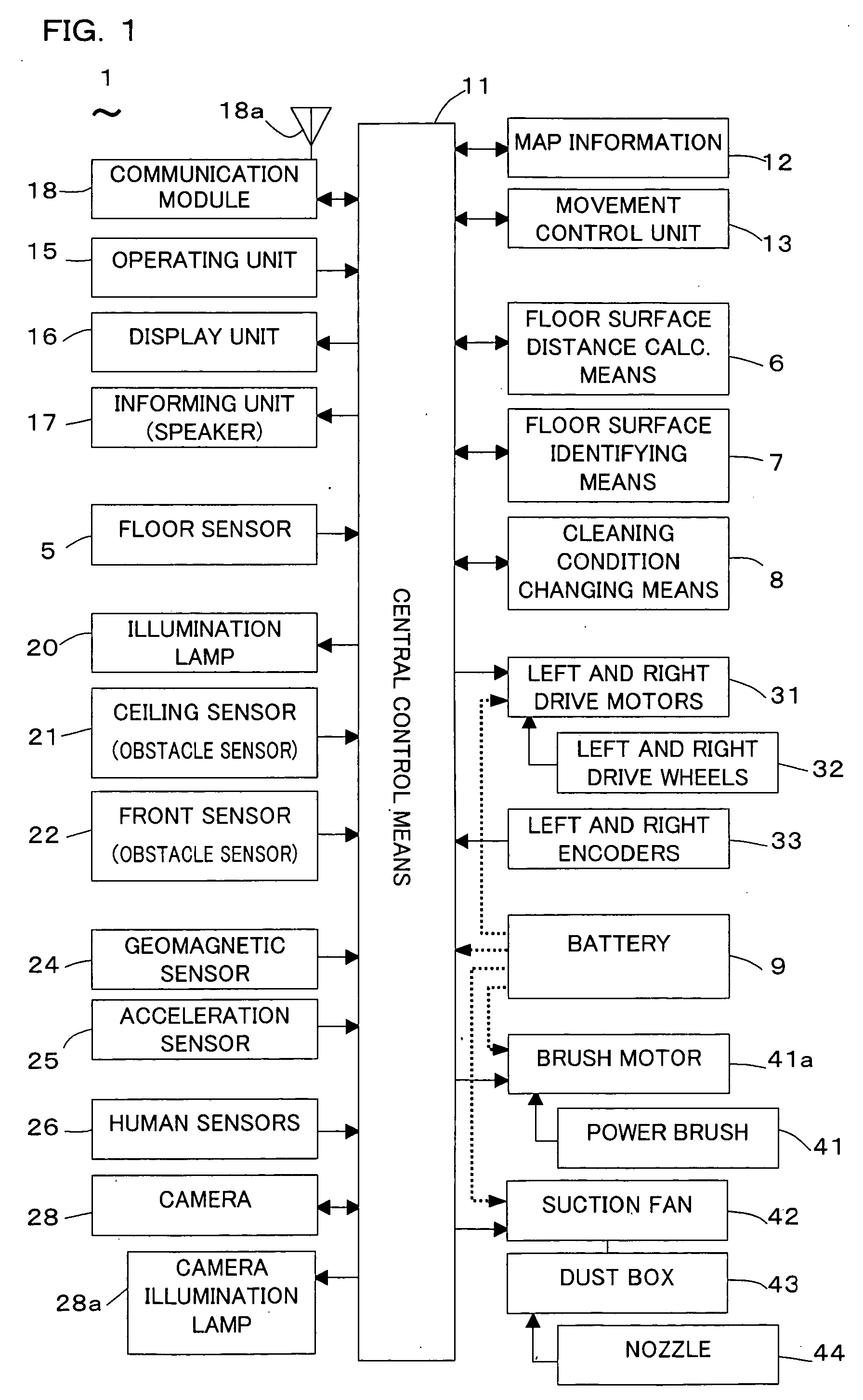

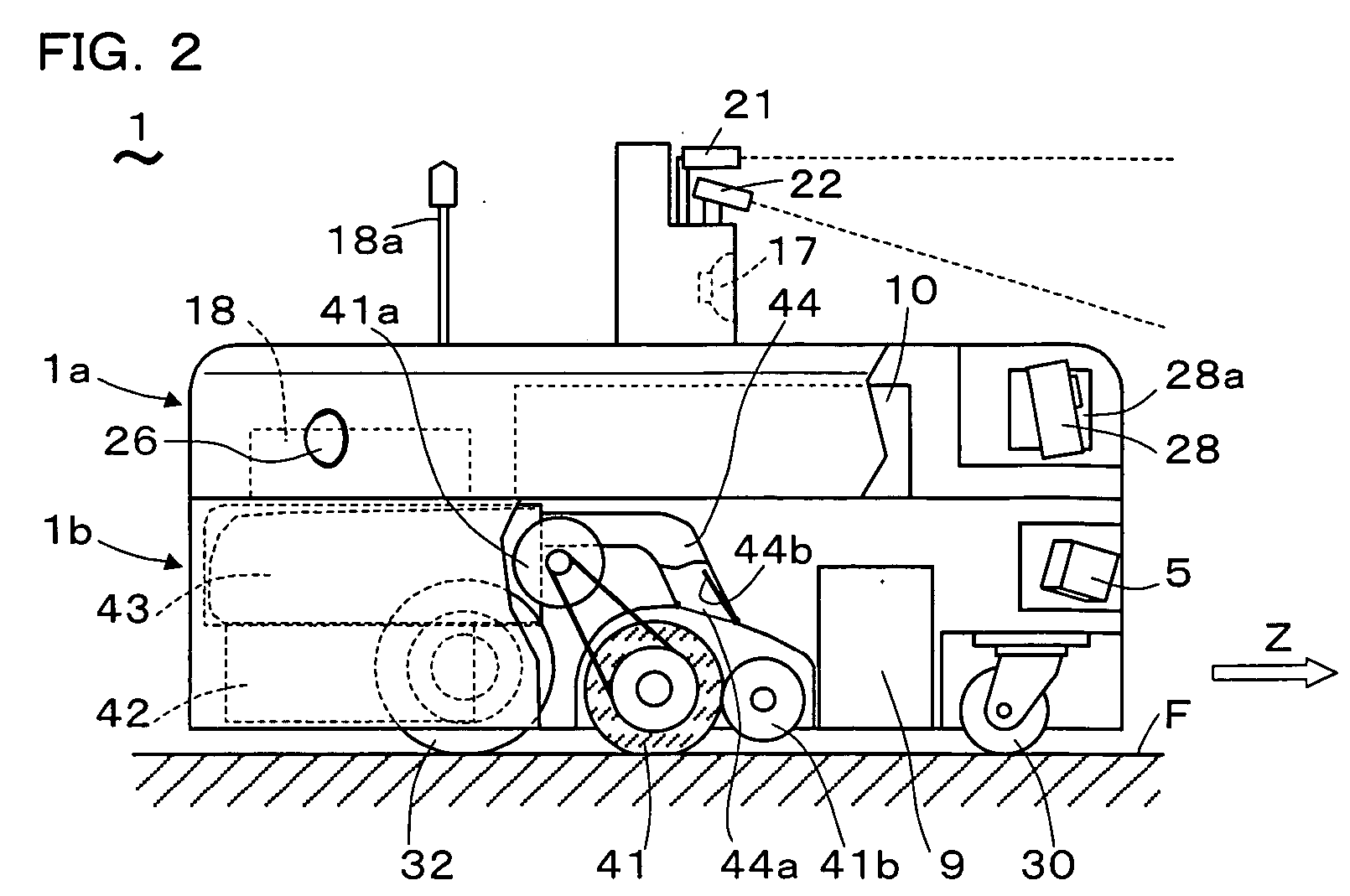

Autonomous vacuum cleaner

InactiveUS20050166354A1Accurate materialsHigh resolutionAutomatic obstacle detectionTravelling automatic controlCMOSLine sensor

An autonomous vacuum cleaner comprises: obstacle detection sensors; moving means; a cleaning means including a power brush, a suction fan and a nozzle for sucking up dust on a floor surface; floor surface sensors each comprising a passive-type CMOS line sensor to receive light from the floor surface for detecting floor surface conditions. It performs cleaning while autonomously moving. Based on received light signals of the floor surface sensors, distance distributions to floor surface areas within the viewing angle of each sensor are derived. Detection of a step on the floor surface and identification of the material of the floor surface (polished floorboard, tatami or carpet) are performed by analyzing spatial frequency in the distance distribution. Based on the identification, cleaning conditions including at least the moving speed, the dust suction force of the suction fan or the brushing strength of the power brush are changed. With simple structure using one same floor sensor, this autonomous vacuum cleaner can detect a step on a floor surface and can more accurately identify the material of the floor surface, thereby enabling meticulous cleaning.

Owner:FUNAI ELECTRIC CO LTD

Methods for identifying materials that can help regulate the condition of mammalian keratinous tissue

InactiveUS20070196344A1Accurately and efficiently screenAccurate materialsCosmetic preparationsBiocideIrritationMethod selection

Methods for identifying materials that can help regulate the condition of mammalian keratinous tissue (e.g., skin, hair, and / or nails), and the use of such materials selected by such methods (e.g., preparation of cosmetic compositions). The methods can also be used to generate data that can be used to support marketing claims and advertising claims, and to provide irritation and / or safety information. The methods can be used as an element of a method of doing business.

Owner:THE PROCTER & GAMBLE COMPANY

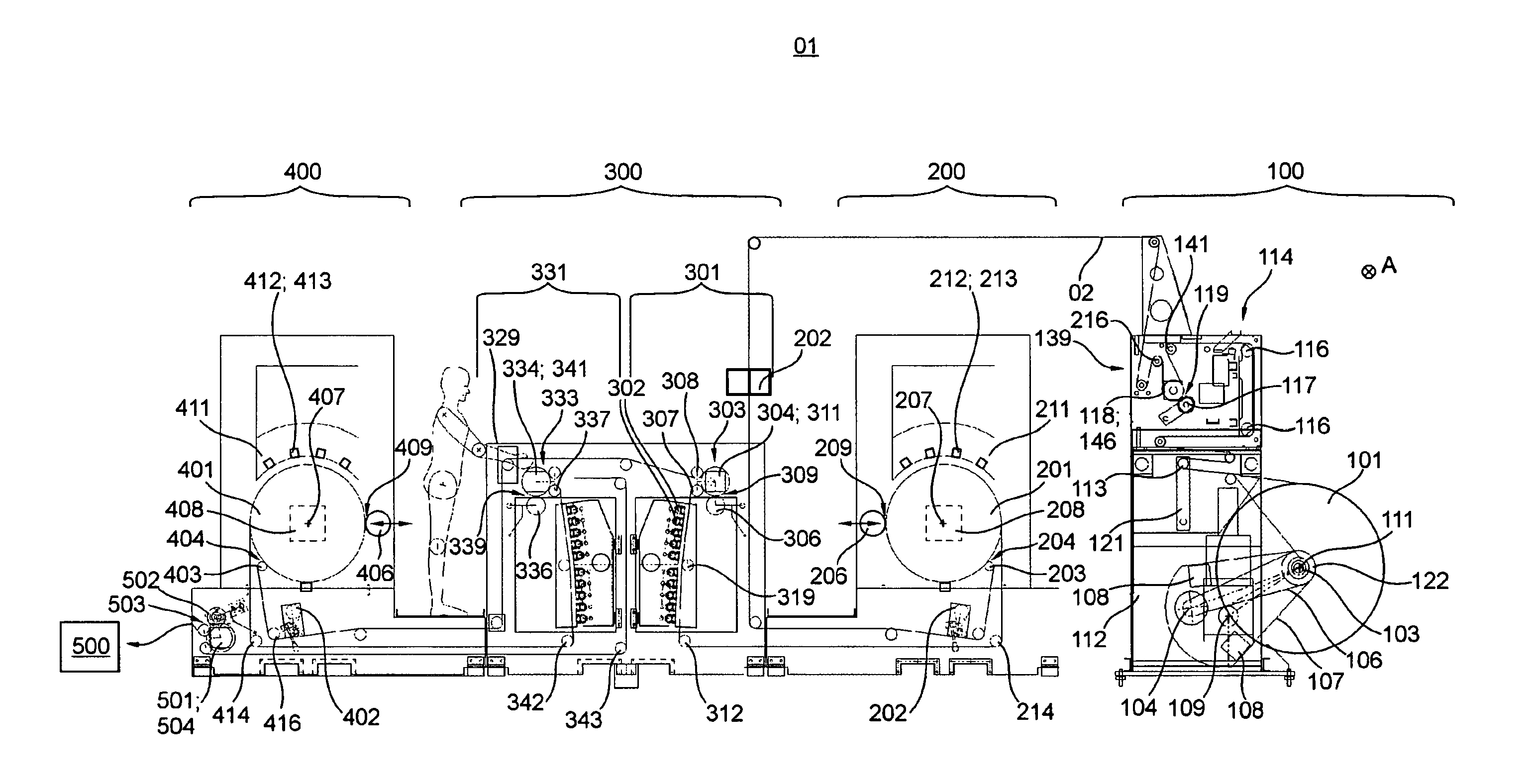

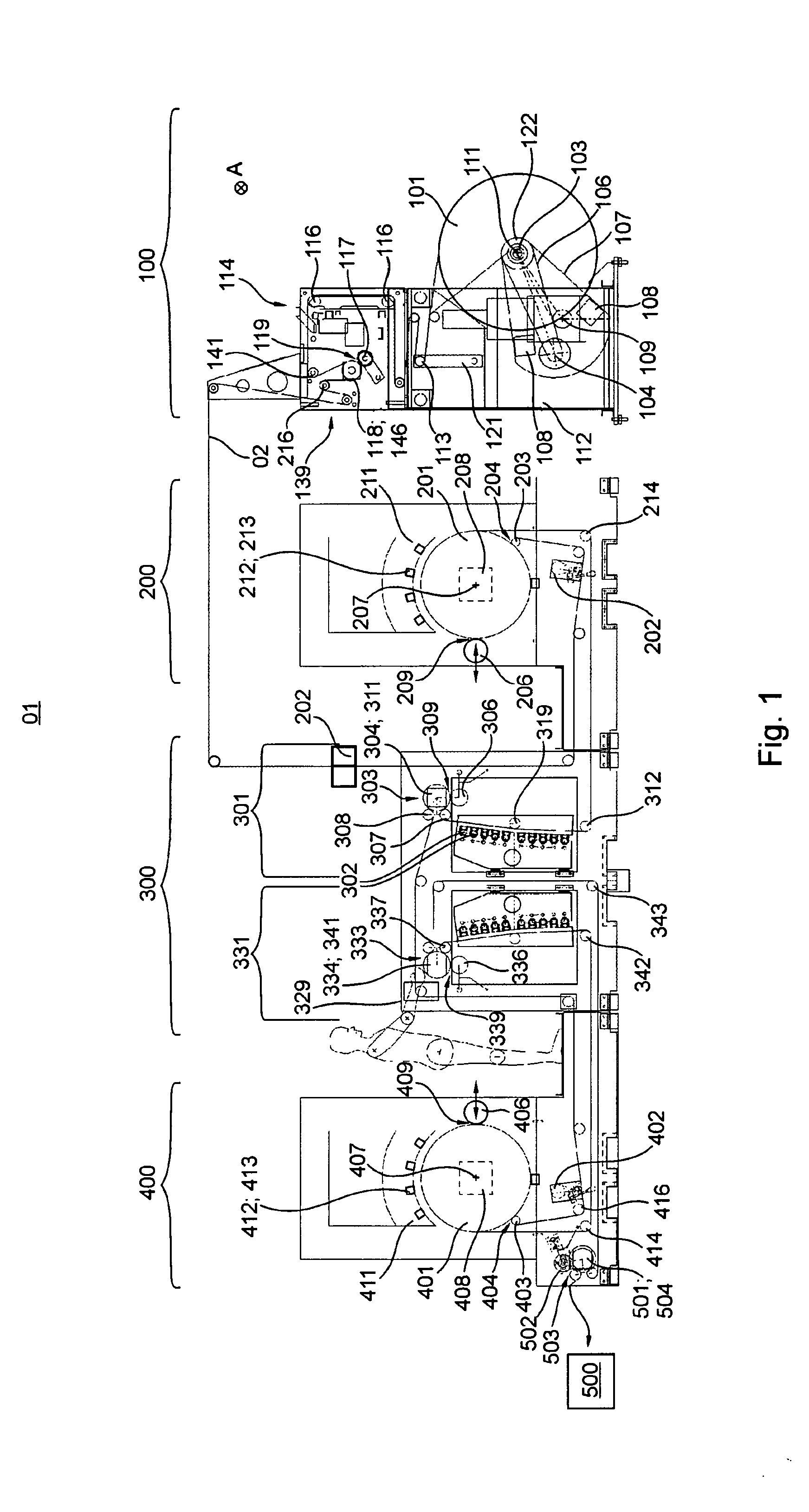

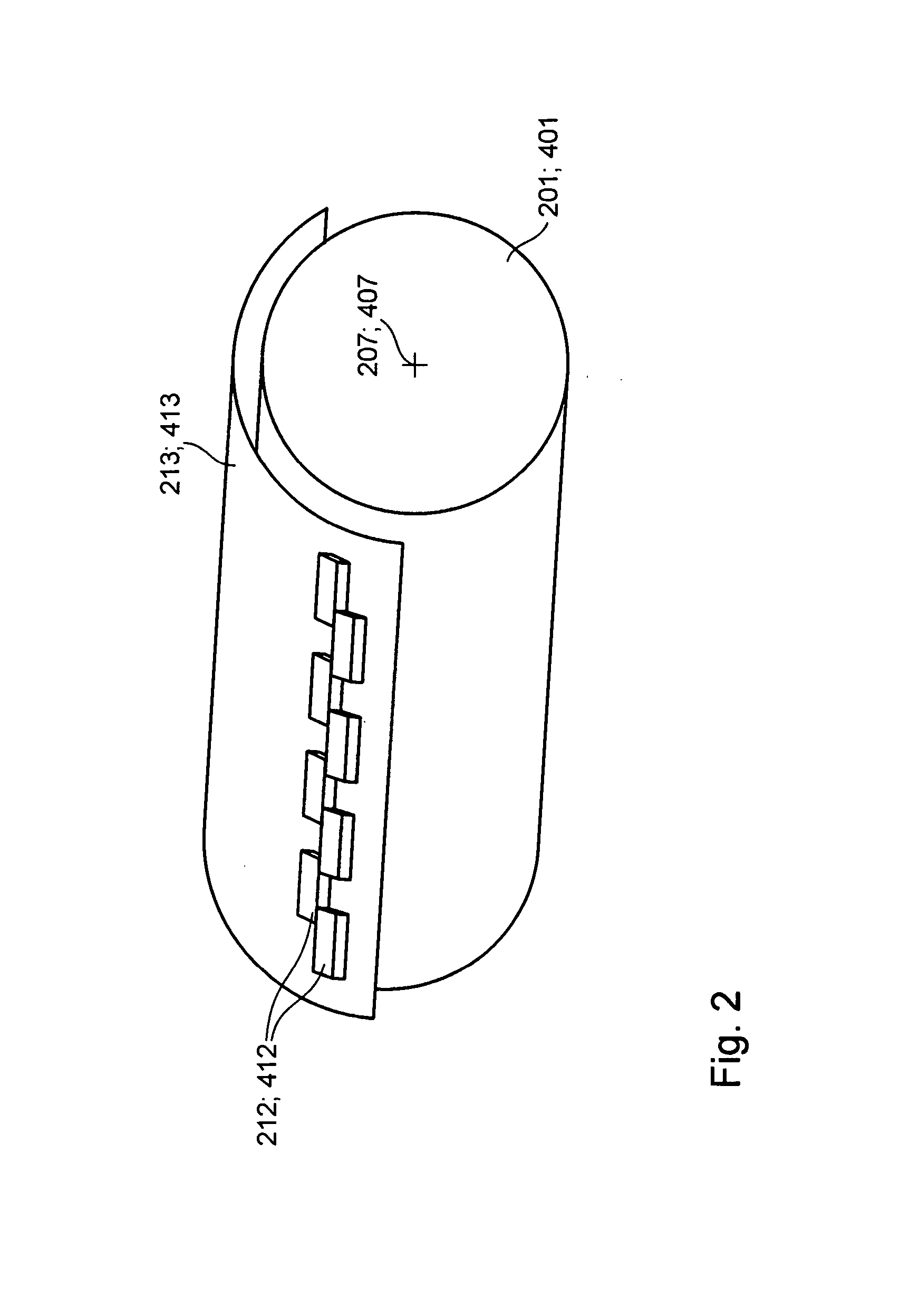

Printing machine and method for adjusting a web tension

ActiveUS20140104360A1Improve color registration and registerSave time and materialTypewritersOther printing apparatusDrive motorInkjet printing

The invention relates to a printing machine having at least one printer unit comprising at least one inkjet printhead, a central printing cylinder, and a drive motor of its own dedicated to the central printing cylinder. A conveying path of a printing material web through the printing machine has at least one first section and one second section, each defined by contact points of the printing material, which have motor-powered rotation bodies. At least the first section has a dedicated first measuring device for measuring a web tension of the printing material web in the first section. At least the second section has a dedicated second measuring device for measuring the web tension of the printing material web in the second section. A machine controller is arranged, by means of which the web tension in at least the first section and / or in the second section of the conveying path of the printing material web can be adjusted and / or is adjusted, taking into consideration at least both a measuring result from the first measuring device and a measuring result from the second measuring device. The invention further relates to a method for adjusting a web tension of a printing material web.

Owner:KOENIG & BAUER AG

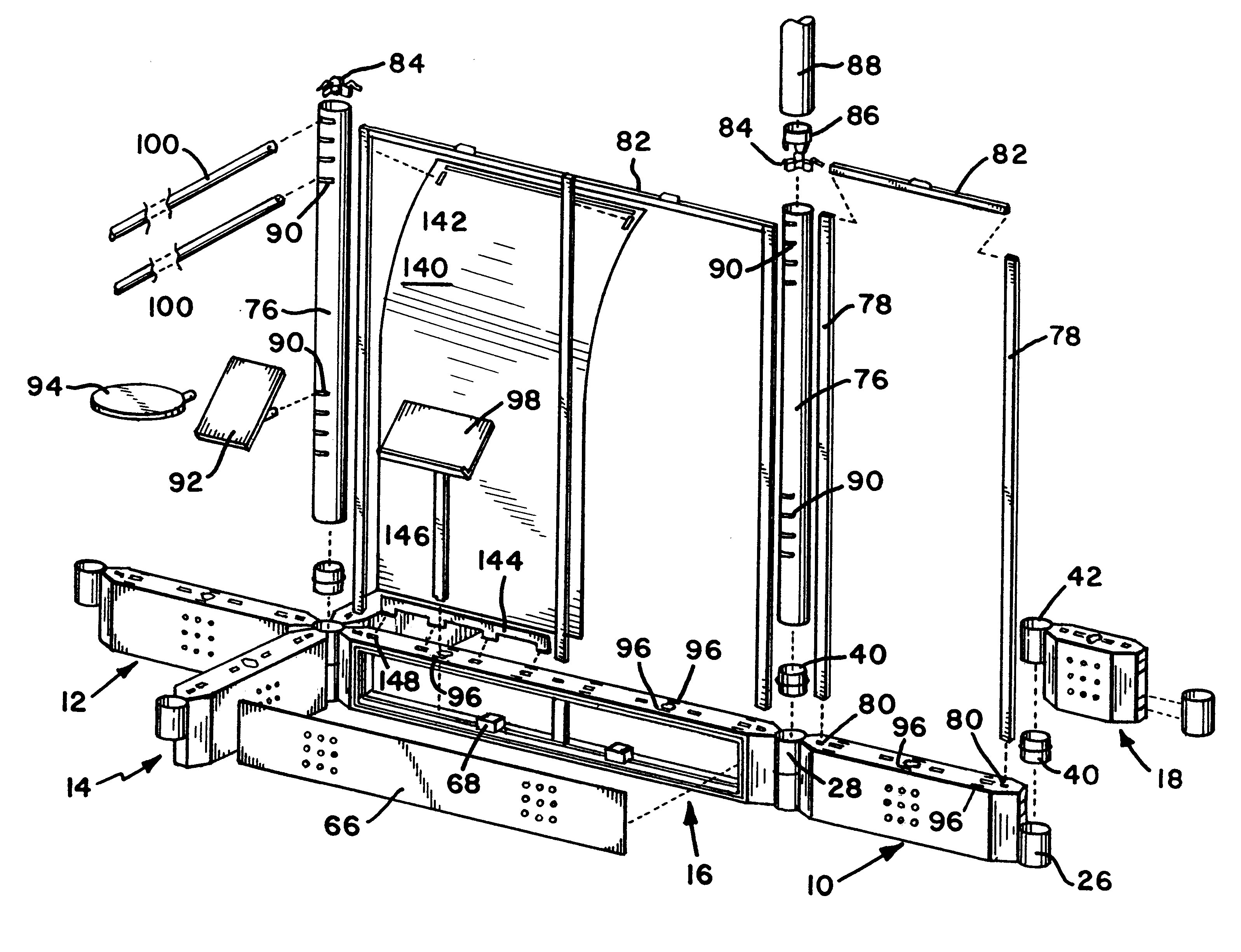

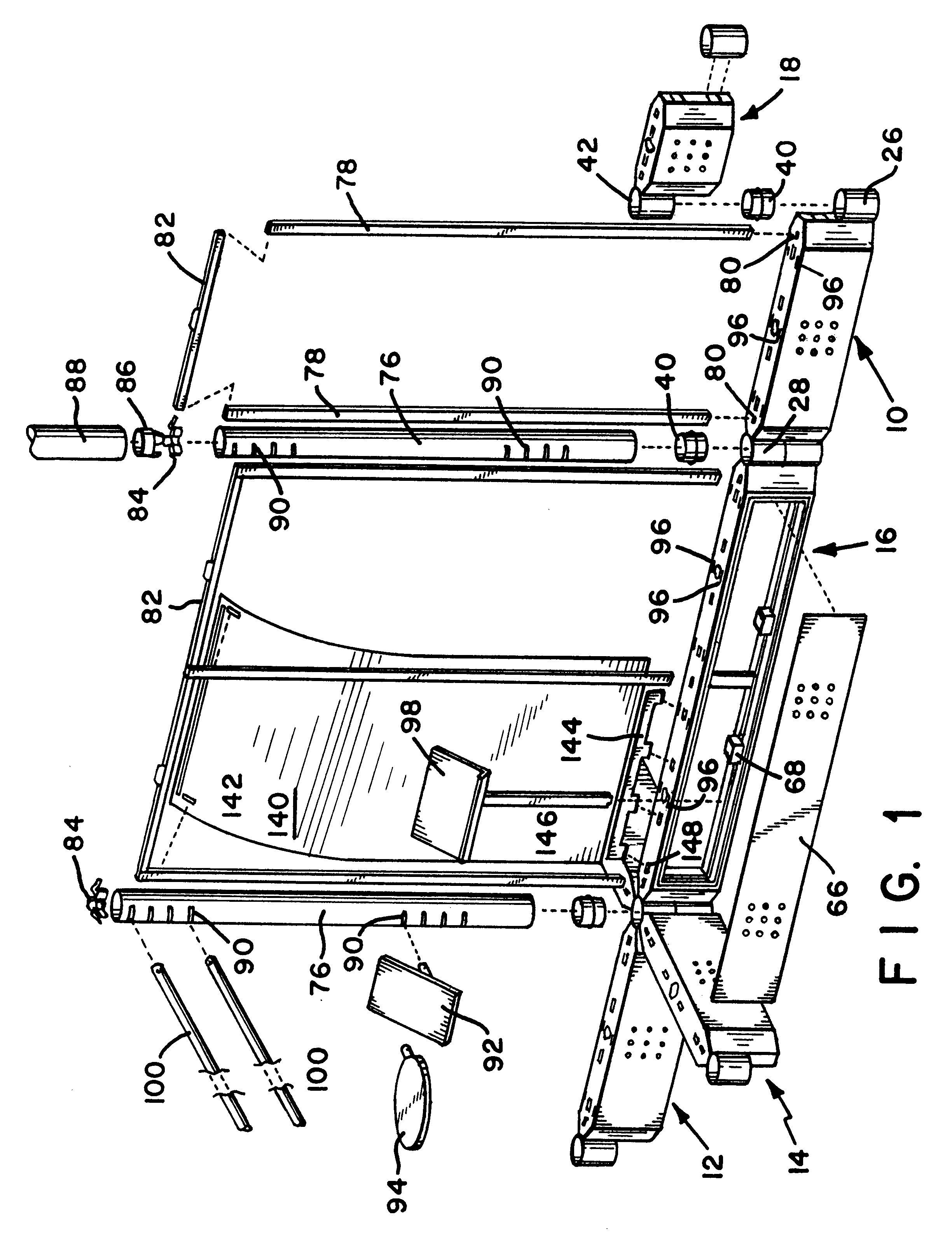

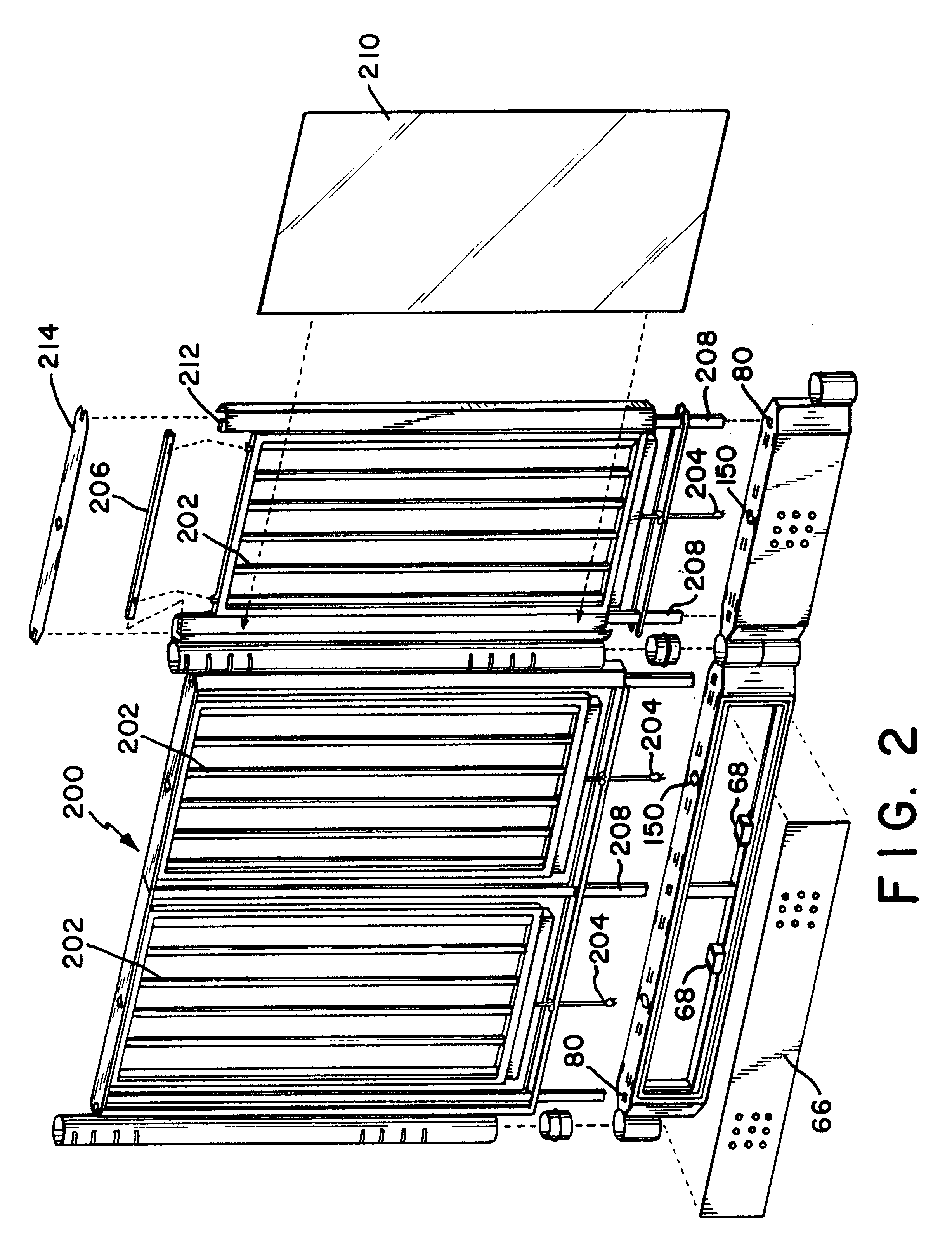

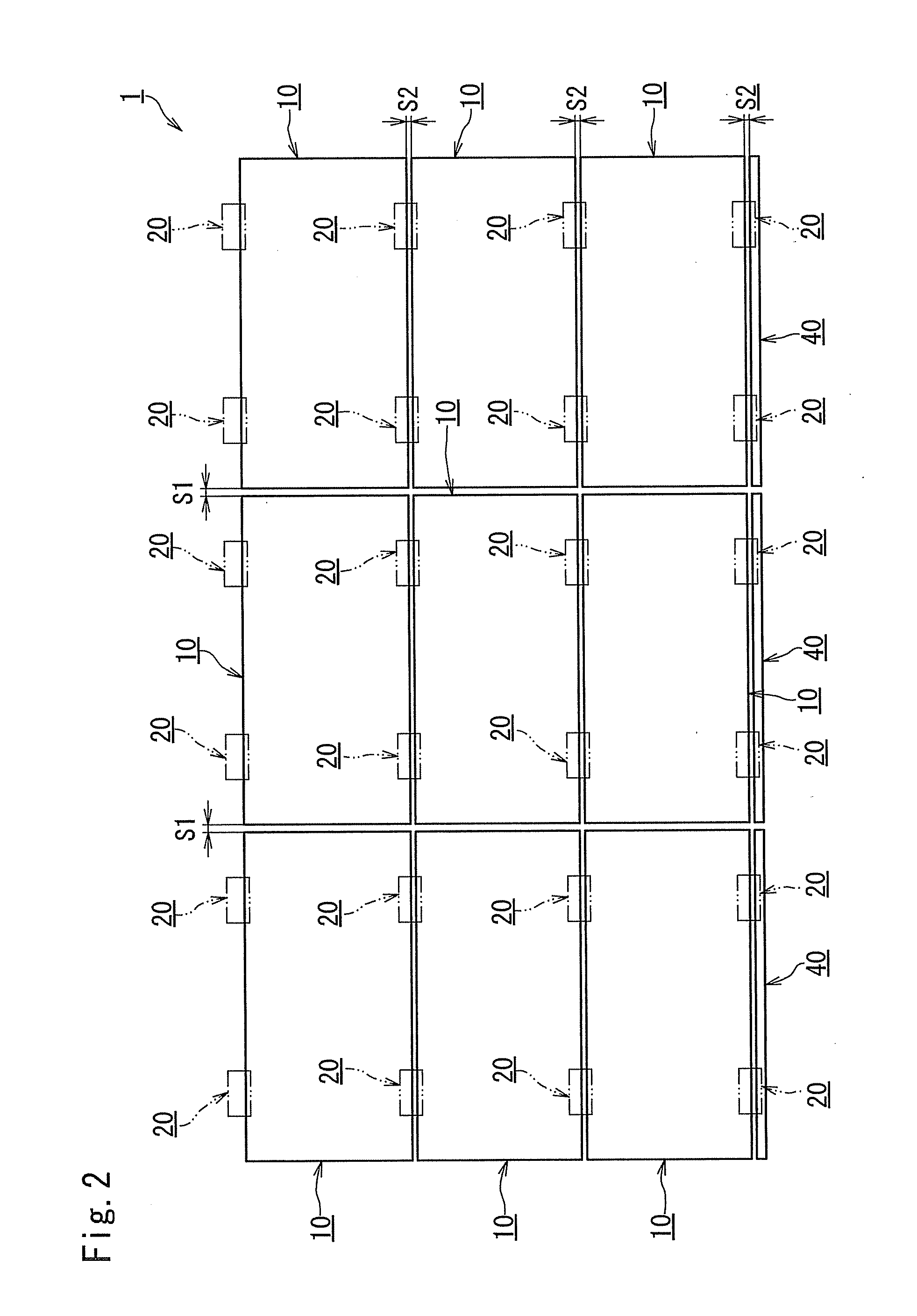

Modular display system

InactiveUS6226931B1Compact storageFacilitates accurate positioningScreensBuilding roofsDisplay deviceEngineering

A modular display system includes base units angularly positionable relative to one another on a floor area to define a lower edge of a display space. Base units include an elongated body and a pair of detachable end members connectable to the opposed ends of the elongated body at upper or lower positions. An end member connected at a lower position at one end of the body is connectable at a plurality of angles to an end member on an adjacent base unit connected at the upper position. The angular connection allows the display area to be defined and adjusted prior to installation of vertical elements forming walls. Vertical supports, preferably including columns positioned over the end members between the base units and uprights supported in sleeves in the base units are removably connectable to the base units. Crossbars are removably connectable to the upper ends of the vertical supports for defining an upper edge of the display space. Sheet material displays are positionable on the base units, vertical supports and crossbars to define walls. Electrical outlets are integrated into the system and attachment points for display accessories and shelves are provided.

Owner:CANFIELD INDS

Material dispenser with applicator

Owner:LOREAL SA

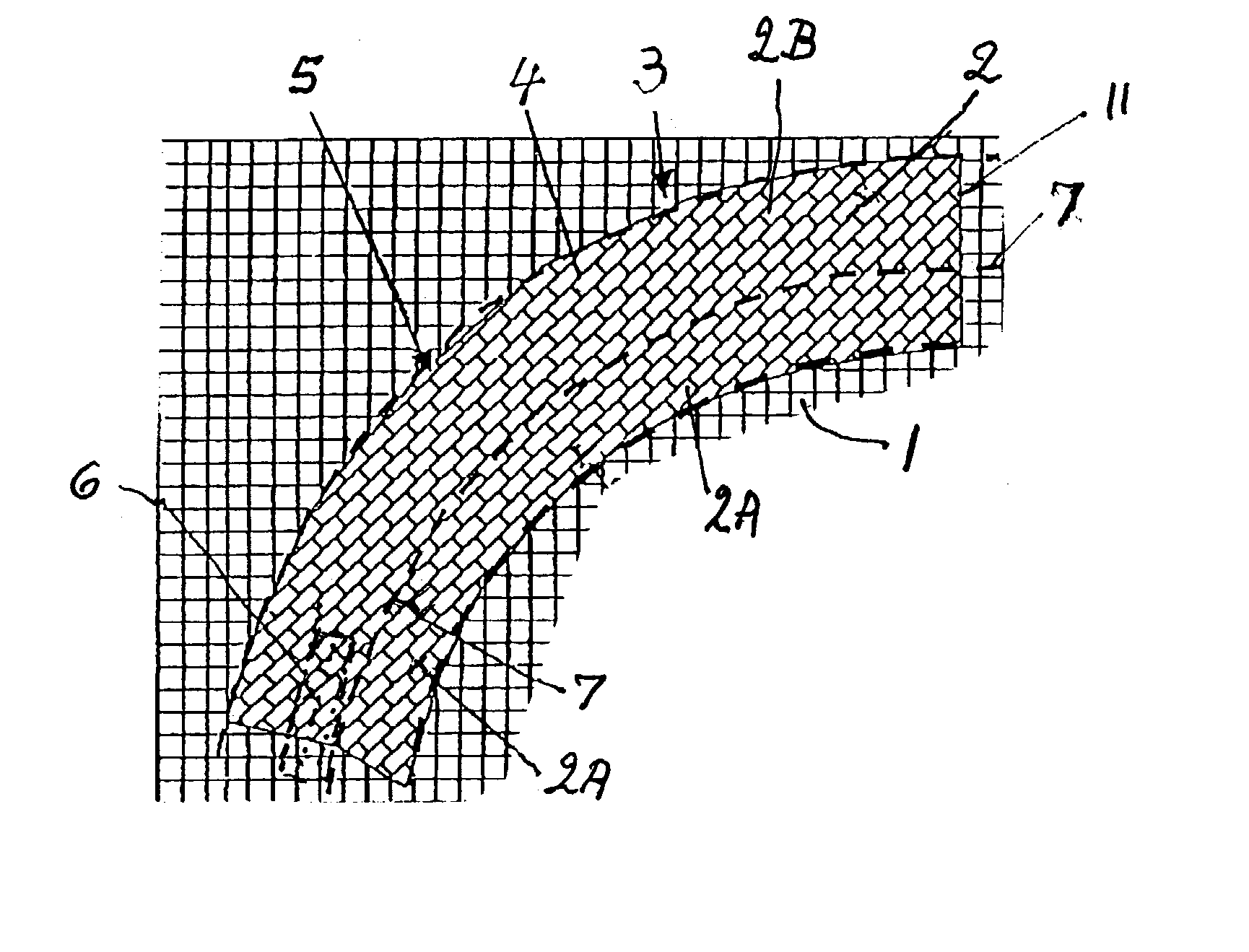

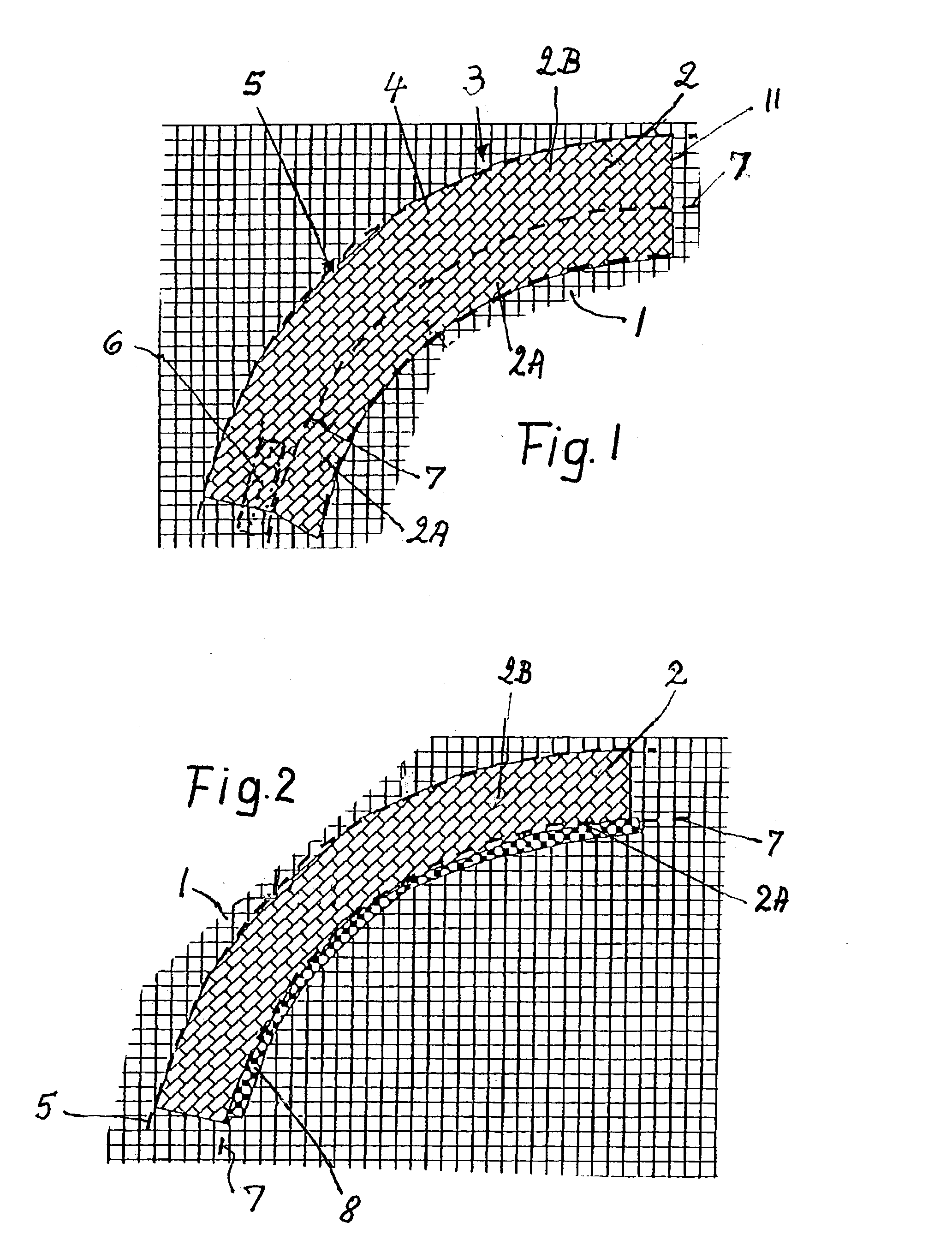

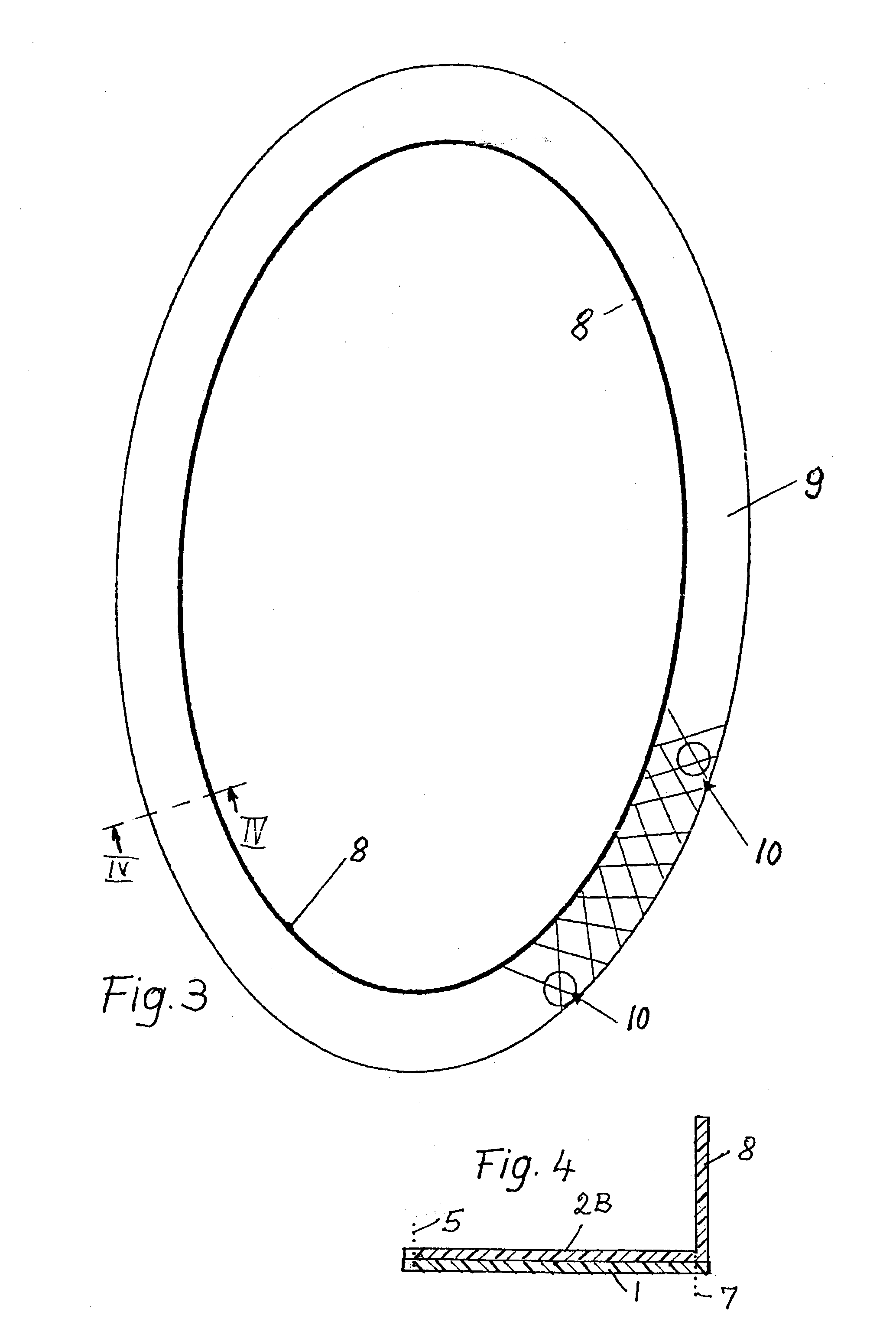

Method for producing a three-dimensional fiber reinforced ring frame component

InactiveUS20030222371A1Produced economicallyAccurate materialsAircraft accessoriesLaminationRing fibersBand shape

A closed ring fiber reinforced frame structure is produced by first preparing a prepreg. A section of the prepreg is formed into a flange preferably after impregnation by folding the flange section along a folding line. The folding line is formed by securing a deformable or drapable fiber ribbon material, for example by sewing or stitching to a carrier substrate which is preferably also a fiber material. The sewing seam or stitching line becomes the folding line. The ribbon material is so secured to the carrier substrate that the fiber orientation of the ribbon material is uniformly distributed all around a ring component that is formed of the ribbon material on the substrate. The impregnated ring component with its substrate is then cured after the folding of the flange to complete the ring frame structure.

Owner:INST FUER VERBUNDWERKSTOFFE GMBH +1

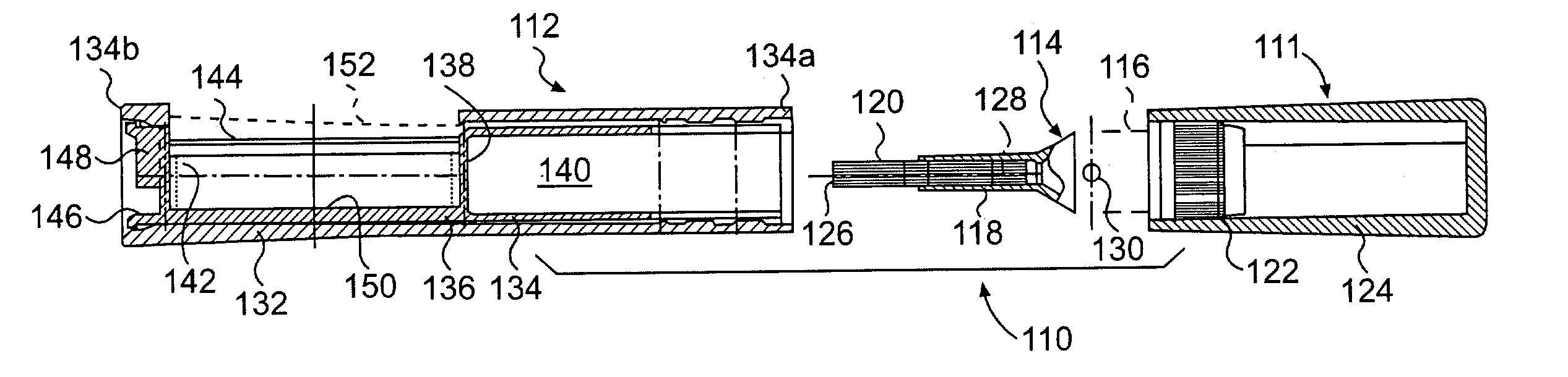

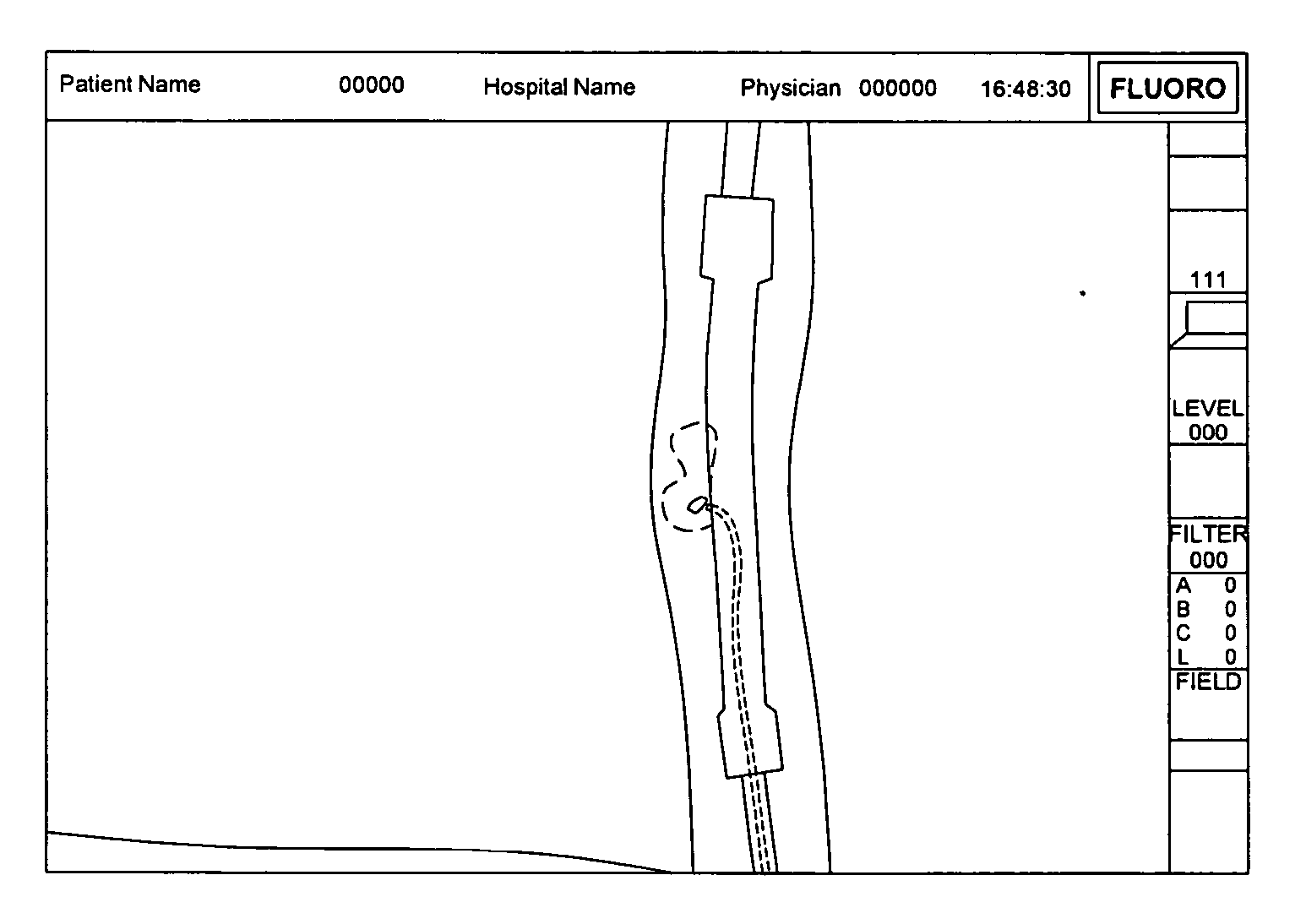

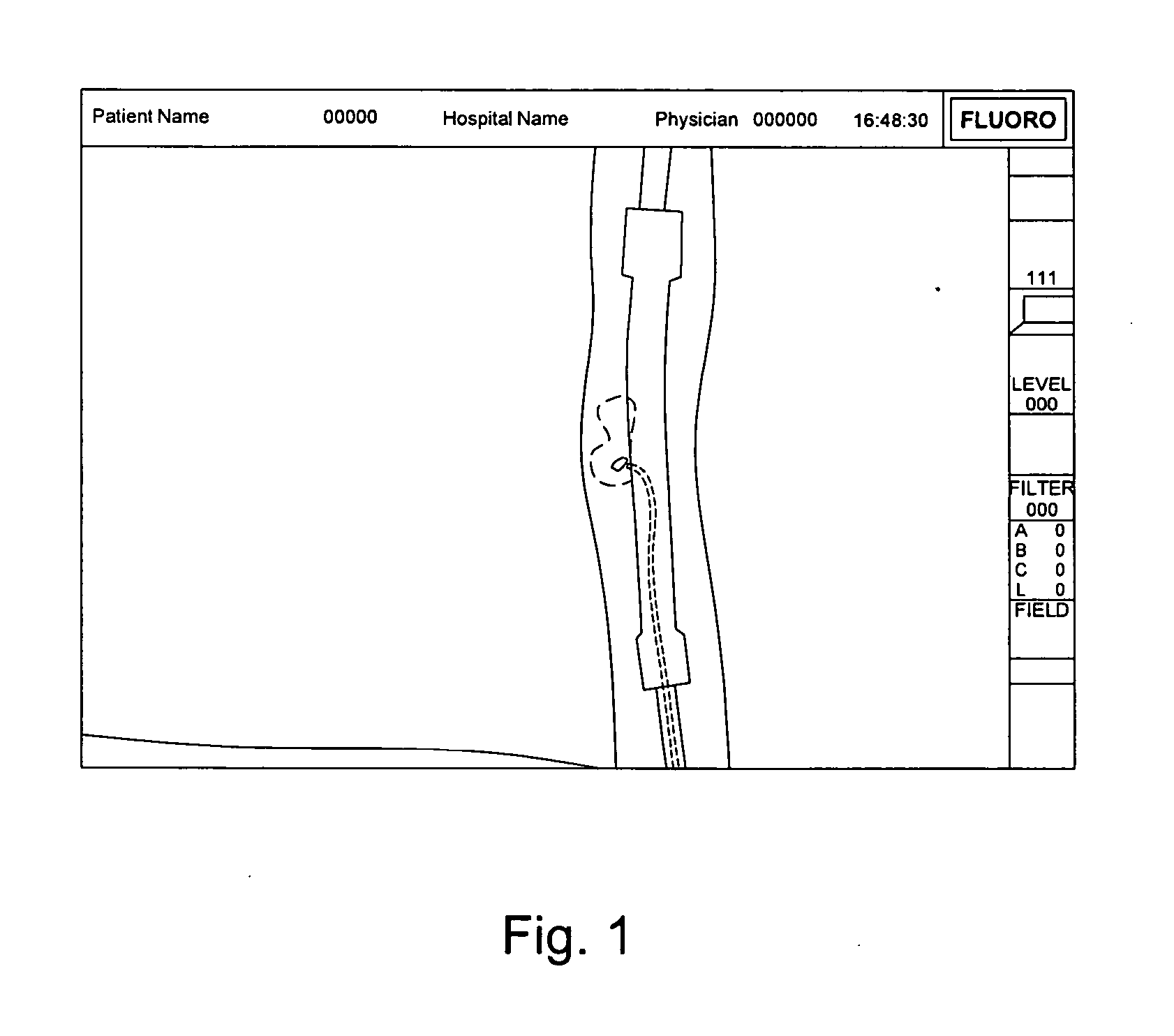

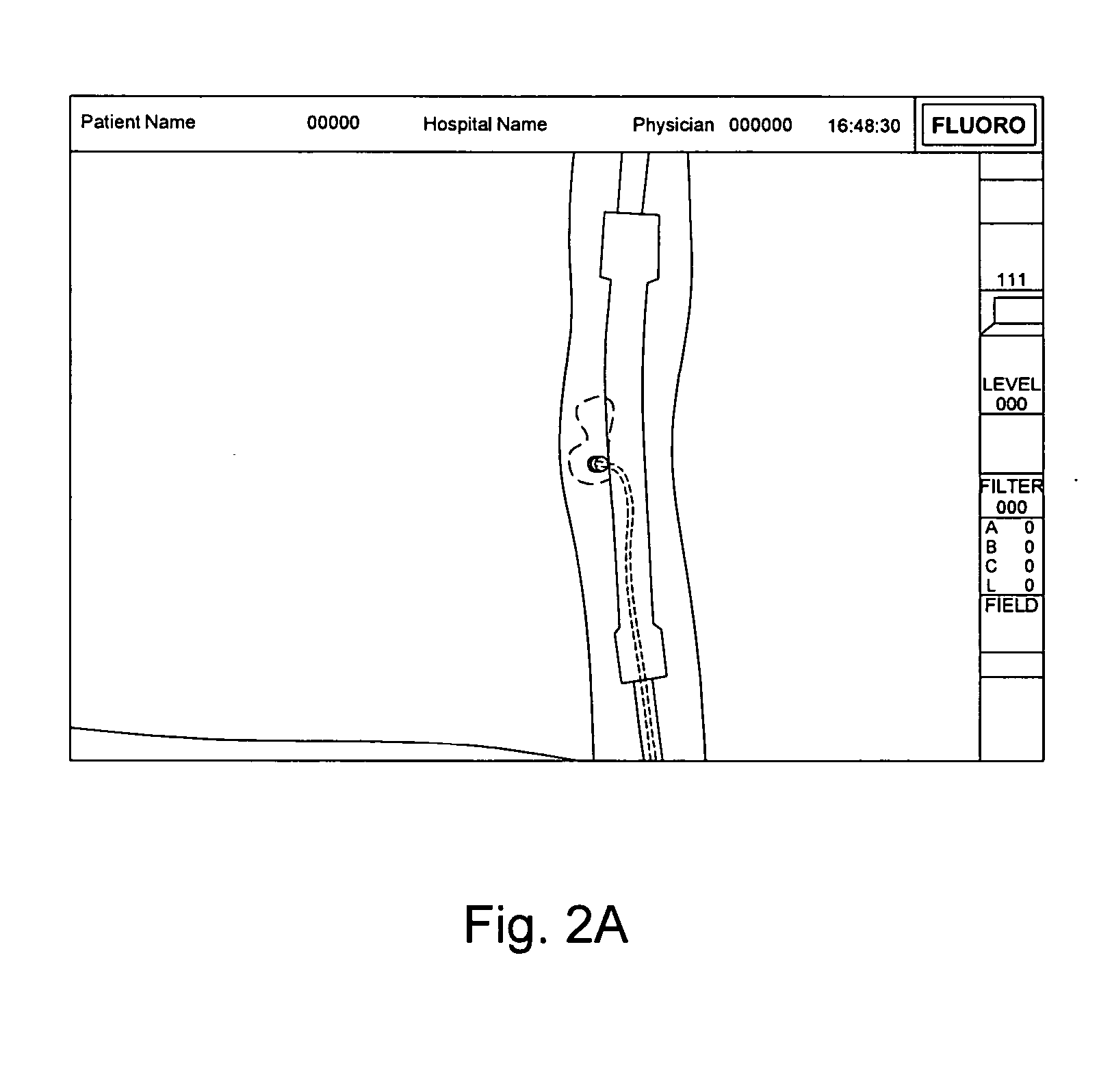

Method of Navigating Medical Devices in the Presence of Radiopaque Material

InactiveUS20080077007A1Easy to navigateExpanded indicationsSurgeryDiagnostic recording/measuringRadiologyX ray image

A method of navigating the distal end of a medical device through an operating region in a subject's body includes displaying an x-ray image of the operating region, including the distal end of the medical device; determining the location of the distal end of the medical device in a reference frame translatable to the displayed x-ray image; and displaying an enhanced indication of the distal end of the medical device on the x-ray image to facilitate the navigation of the distal end of the device in the operating region.

Owner:STEREOTAXIS

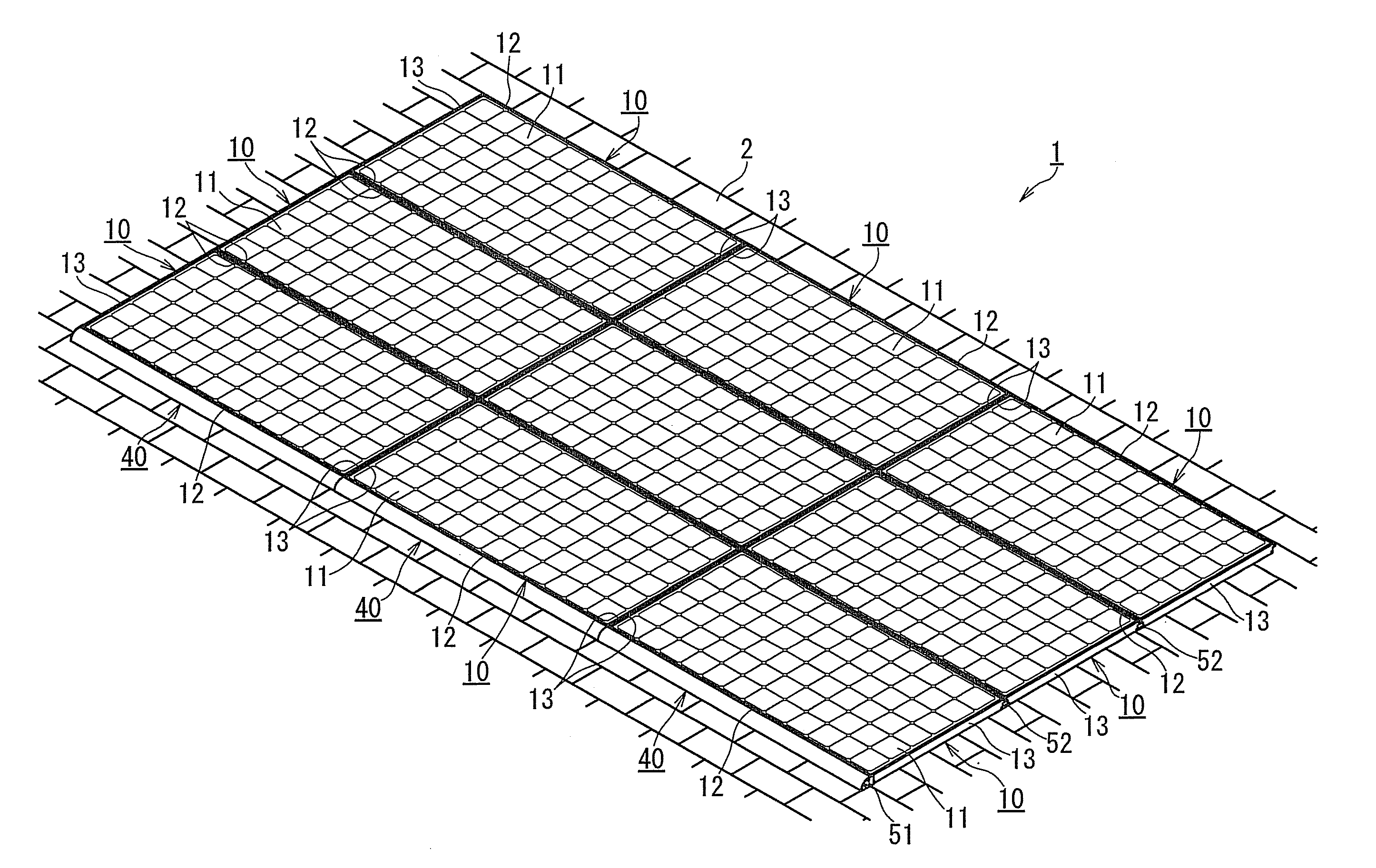

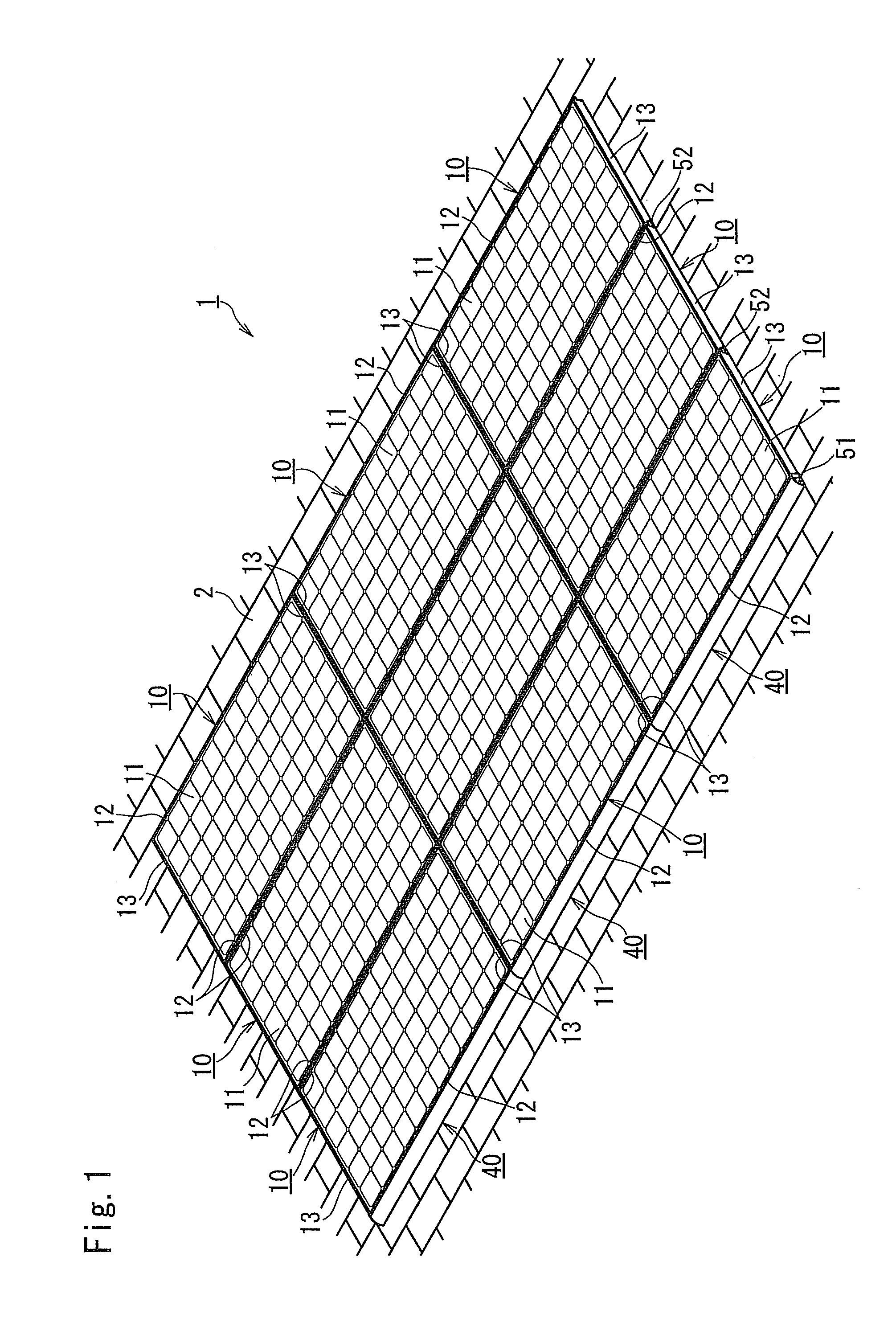

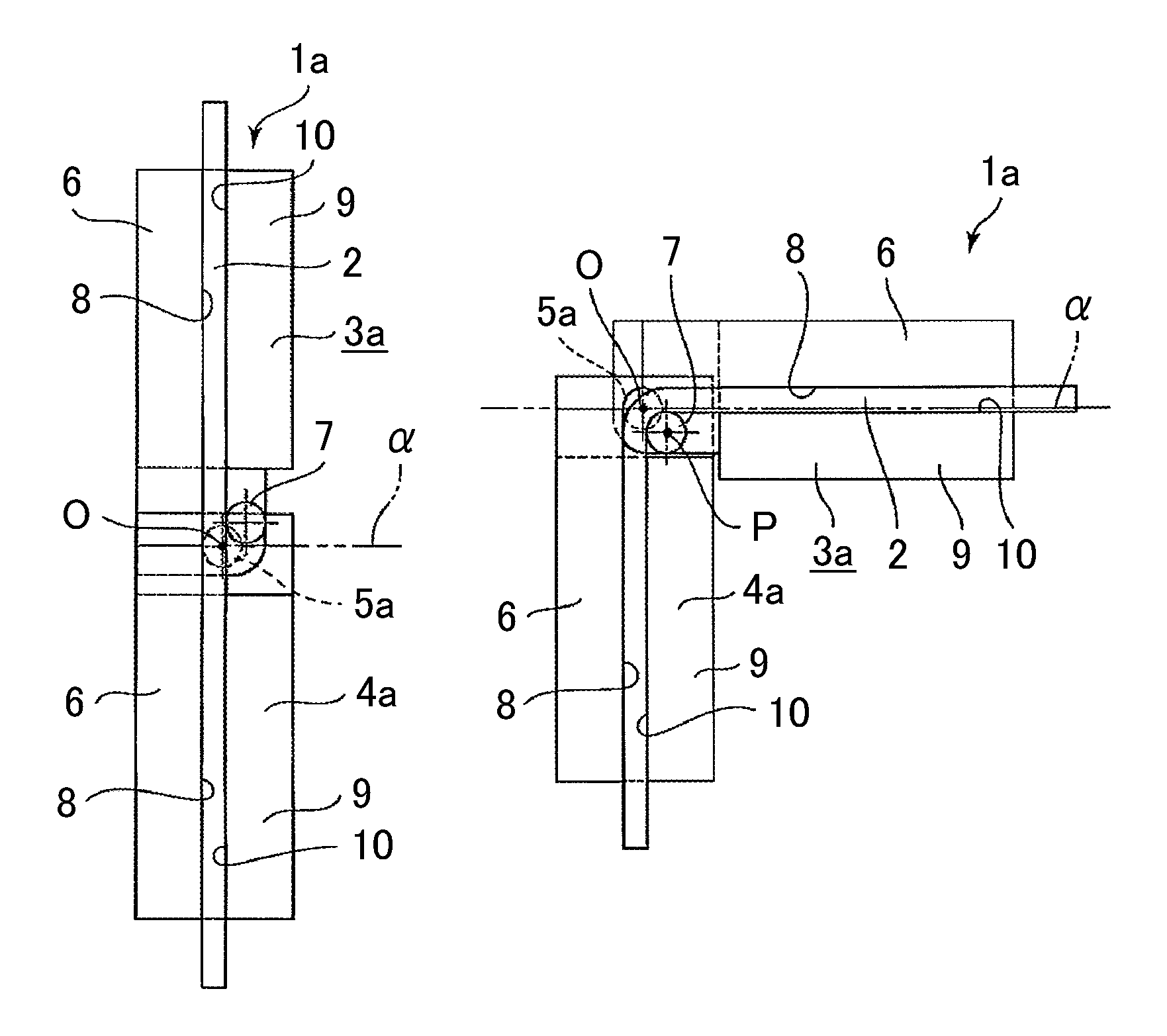

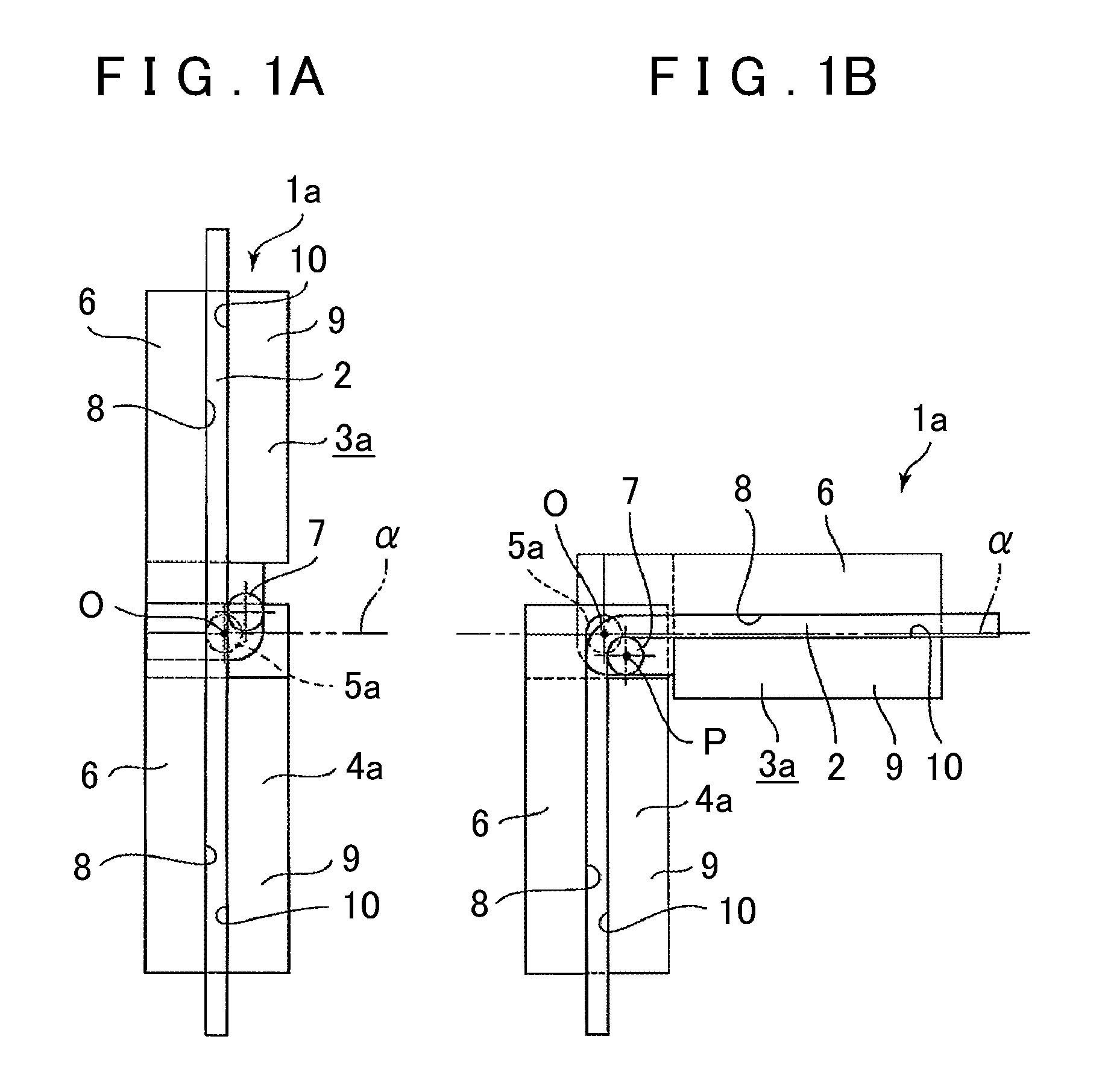

Auxiliary member

ActiveUS20120180406A1Accurate materialsUniform heightPhotovoltaic supportsSolar heating energyEngineeringMechanical engineering

Owner:YANEGIJUTSUKENKYUJO CO LTD

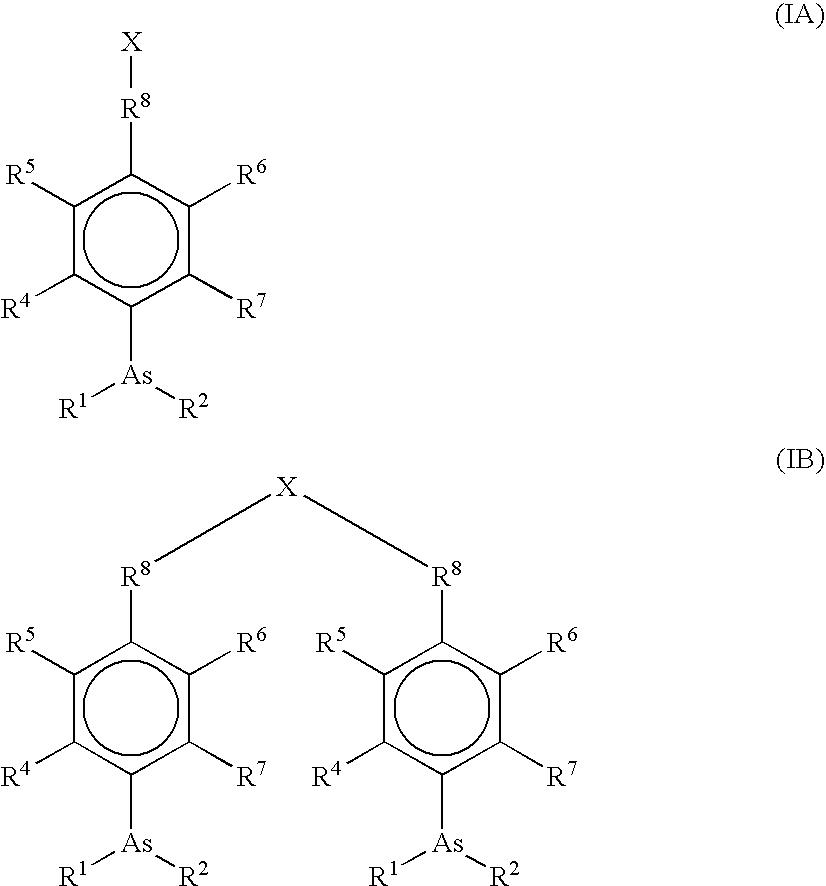

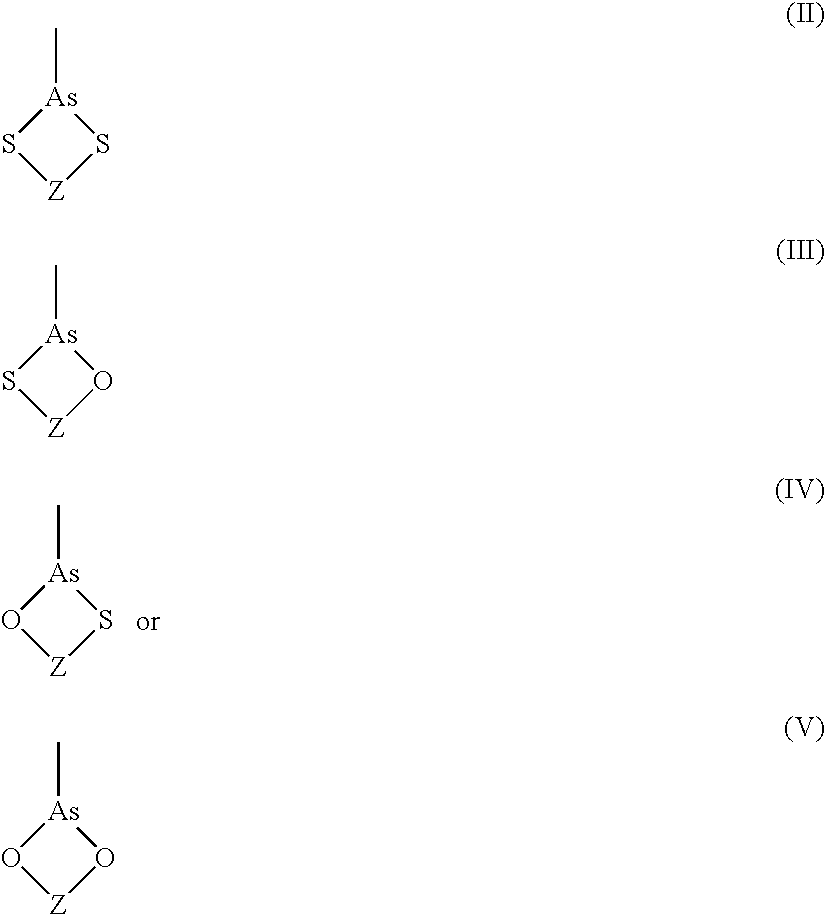

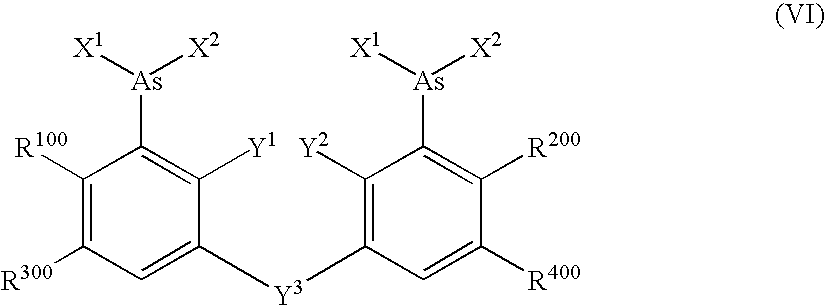

Ultra-high specificity fluorescent labeling

InactiveUS20060141531A1Reduce undesirable background noiseAccurate measurementGroup 8/9/10/18 element organic compoundsGroup 5/15 element organic compoundsEnergy transferFluorescence

A self-assembled relay probe for detecting a target material is provided including: a first peptide tag bound to the target material; and a first fluorescent conjugate including a first fluorochrome and a first tag binding group; wherein the first fluorescent conjugate selectively associates with the first tag. The probe further includes a second peptide tag bound to the target material; and a second fluorescent conjugate including a second fluorochrome having a longer wavelength and distinct excitation and emission maxima from the first fluorochrome and a second tag binding group. Upon exposure to the target material, the first and second fluorescent conjugates independently associate with the first and second peptide tags, respectively, so as to be a distance apart represented by about 0.1 times R0 to about 2 times R0, such that upon excitation of the first fluorescent conjugate, fluorescence resonance energy transfer results in excitation of the second fluorescent conjugate, yielding detectable emission from the second fluorescent conjugate.

Owner:RUTGERS THE STATE UNIV

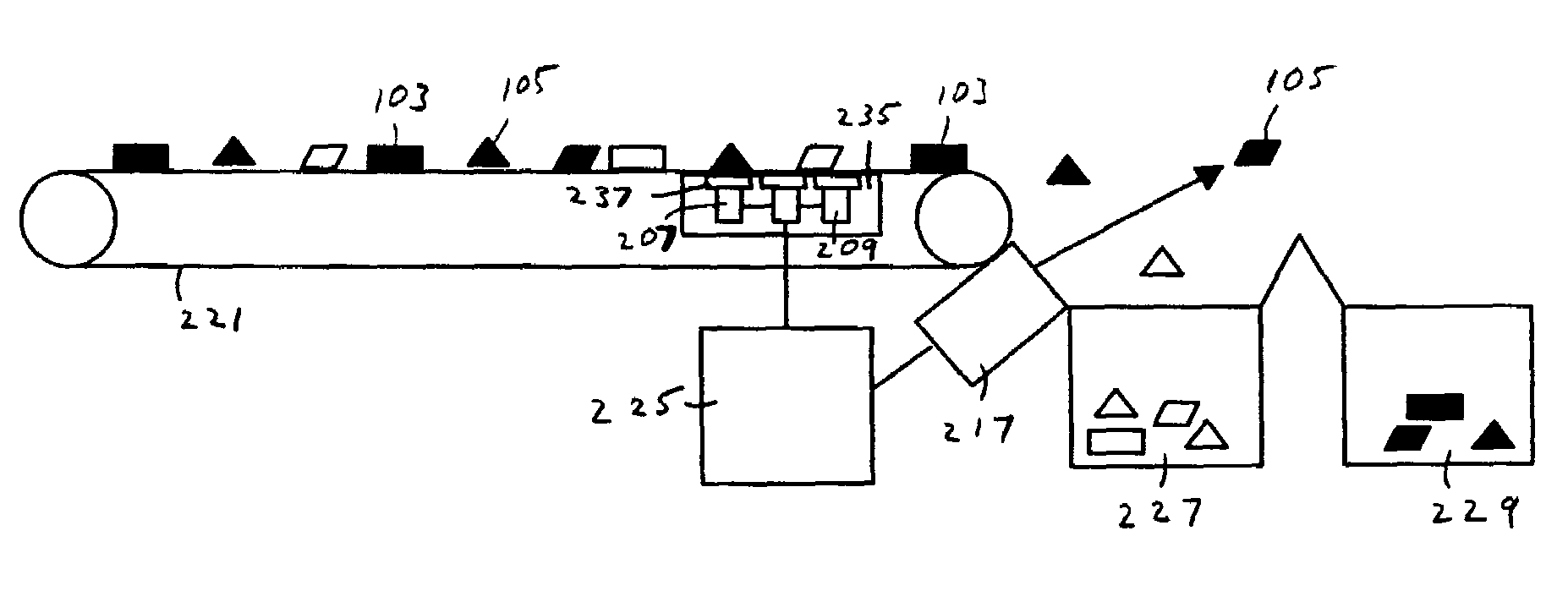

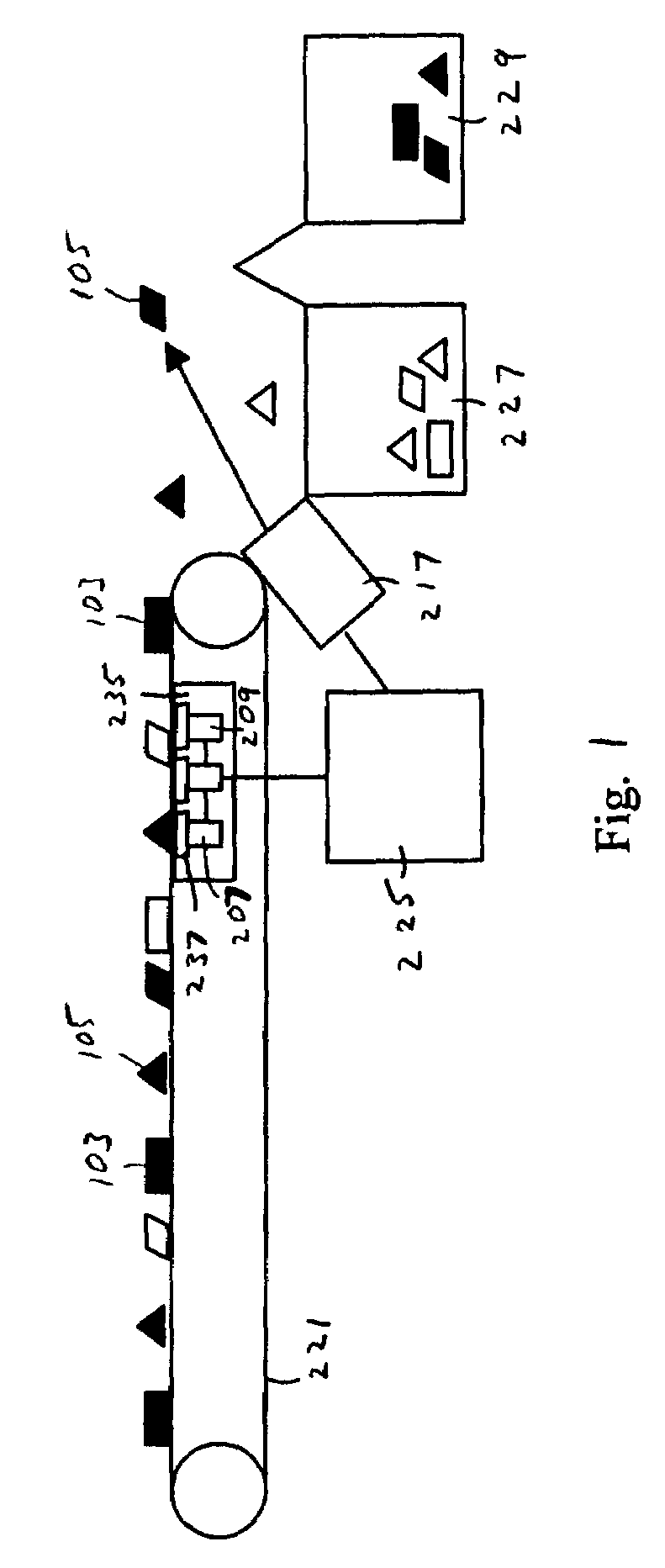

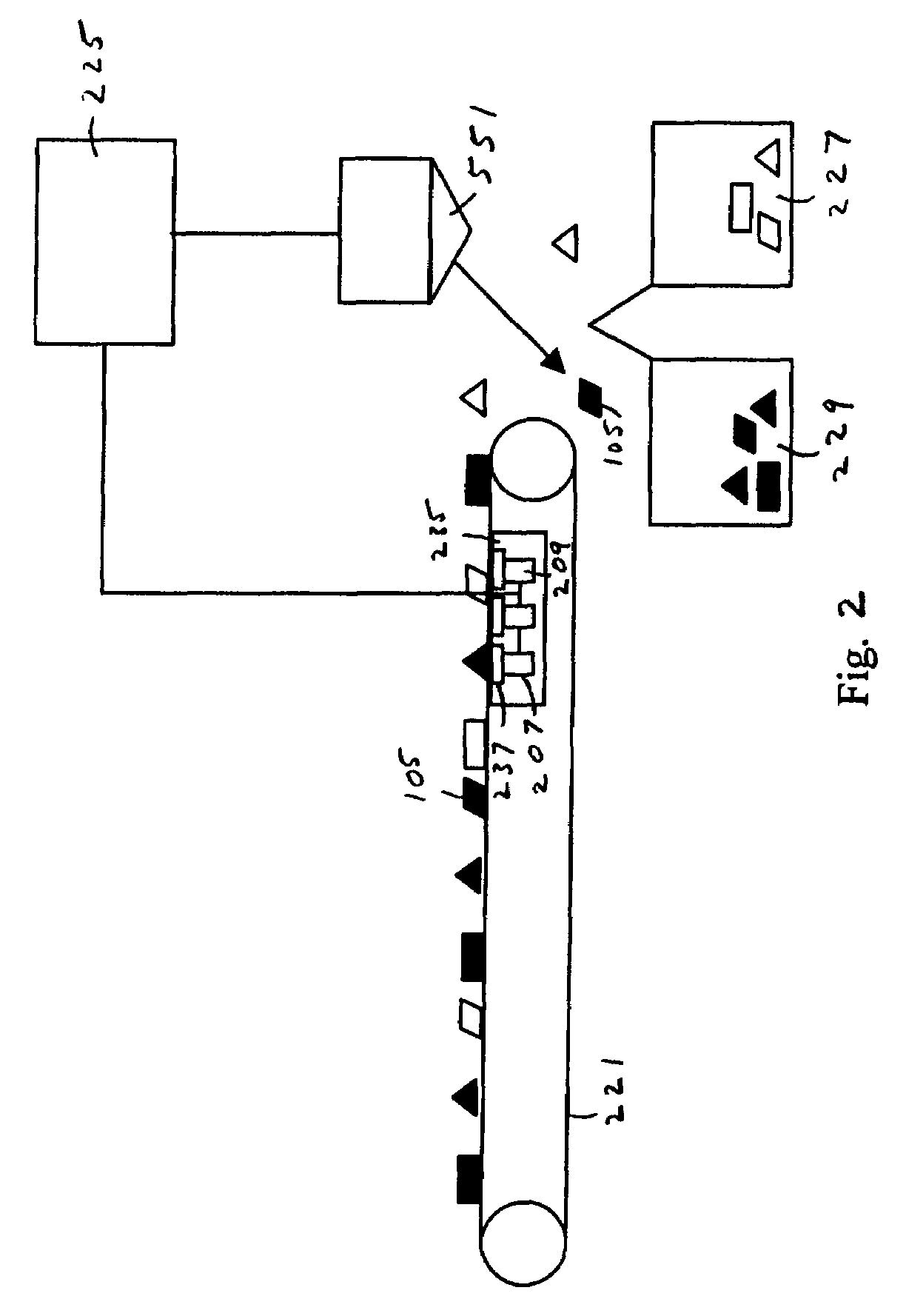

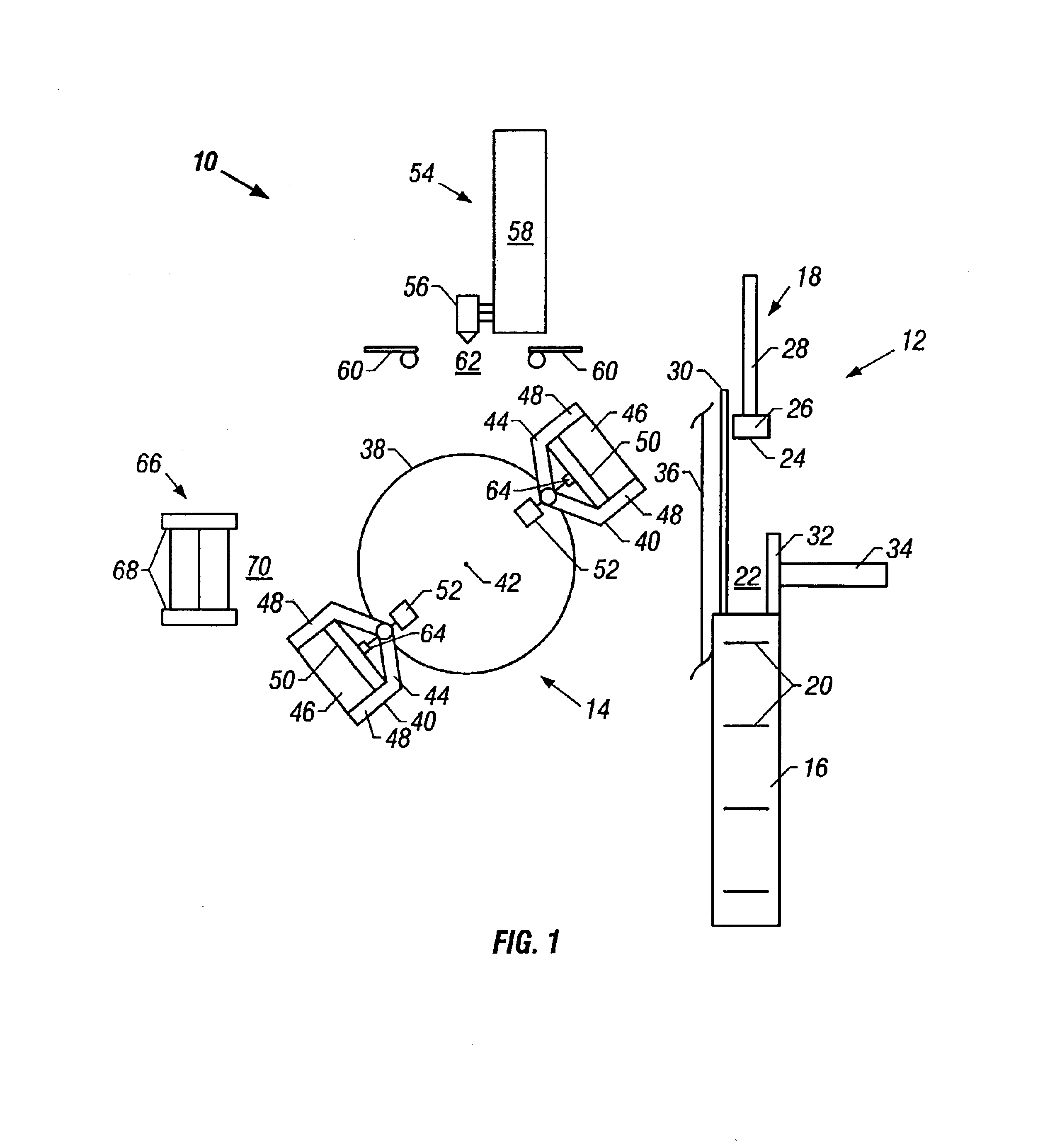

Method and apparatus for sorting fine nonferrous metals and insulated wire pieces

InactiveUS7658291B2Accurately determinedAvoid crosstalkMagnetic property measurementsUsing electrical meansCopper wireNonferrous metal

A system for sorting fine nonferrous metals and insulated copper wire from a batch of mixed fine nonferrous metals and insulated wire includes an array of inductive proximity detectors, a processing computer and a sorting mechanism. The inductive proximity detectors identify the location of the fine nonferrous metals and insulated copper wire. The processing computer instructs the sorting mechanism to place the fine nonferrous metals and insulated copper wire into a separate container than the non-metallic pieces.

Owner:VALERIO THOMAS A

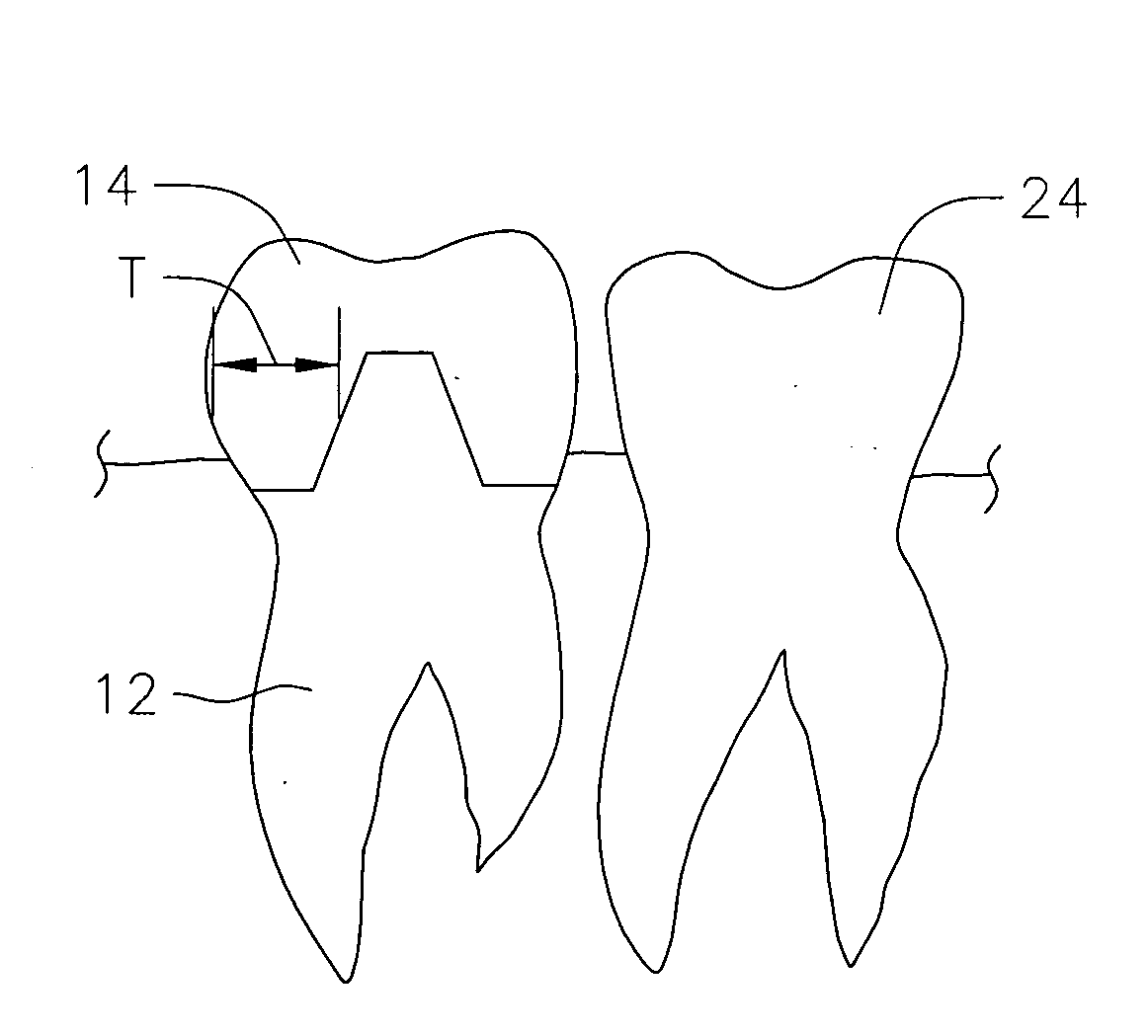

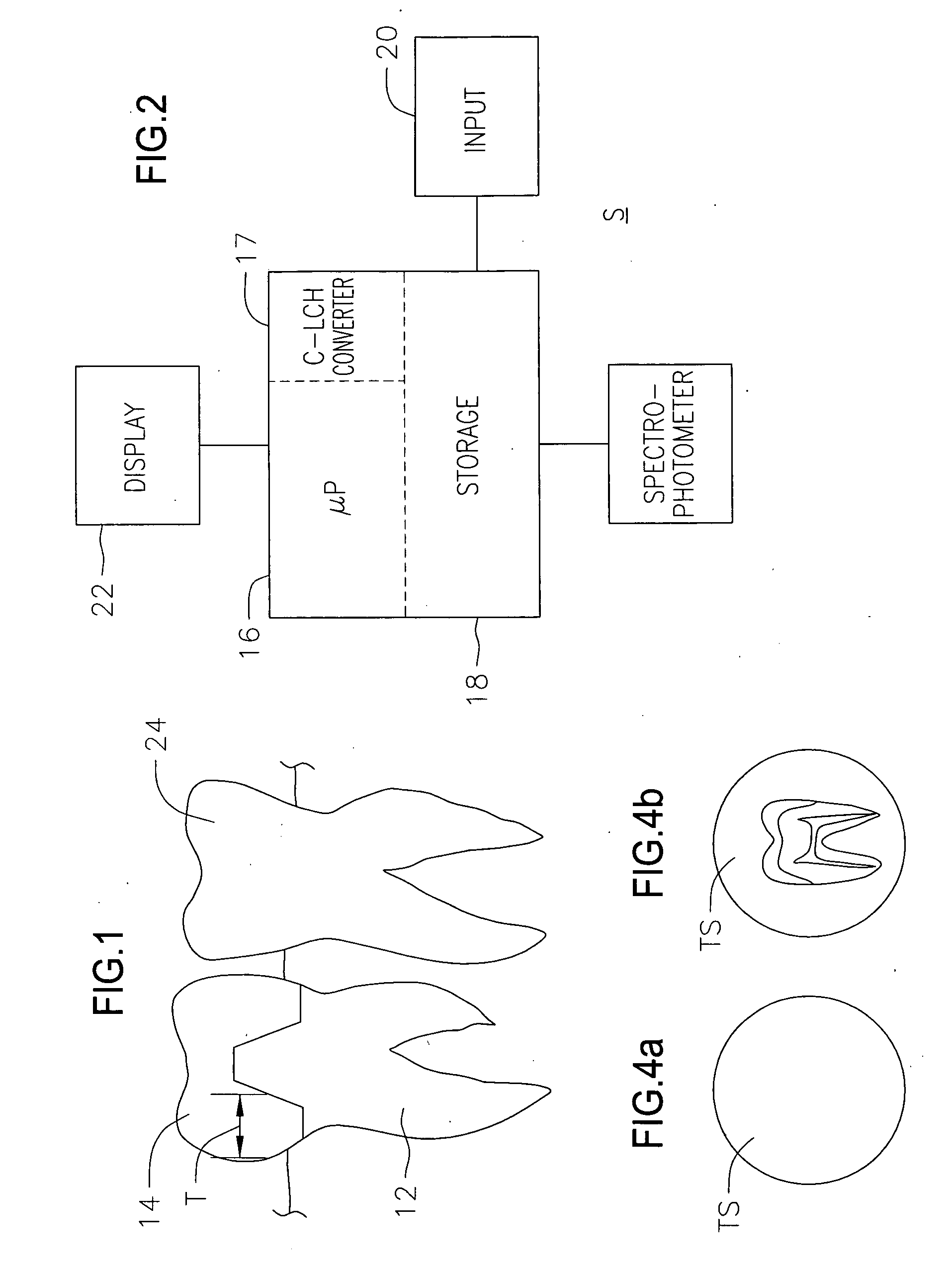

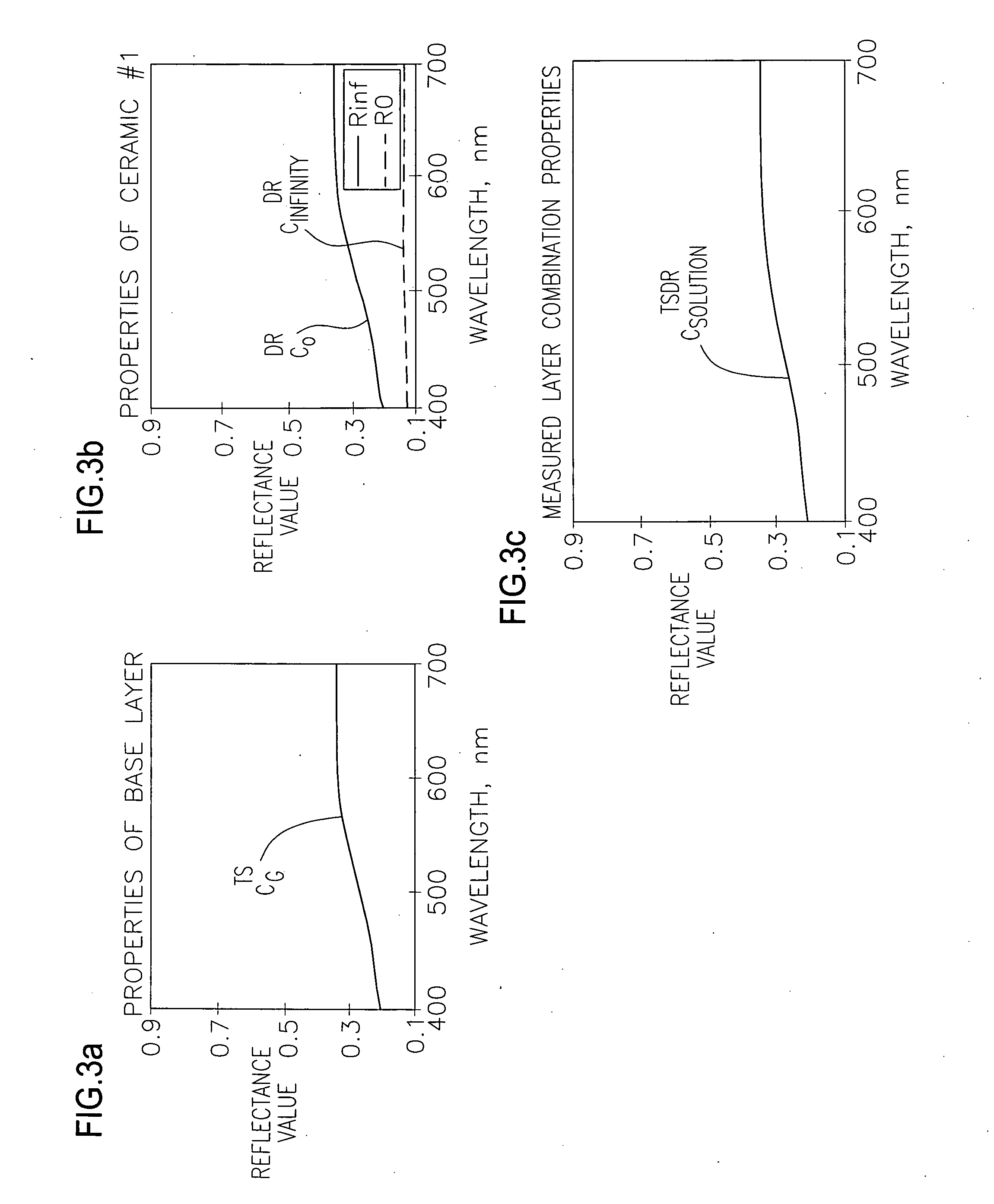

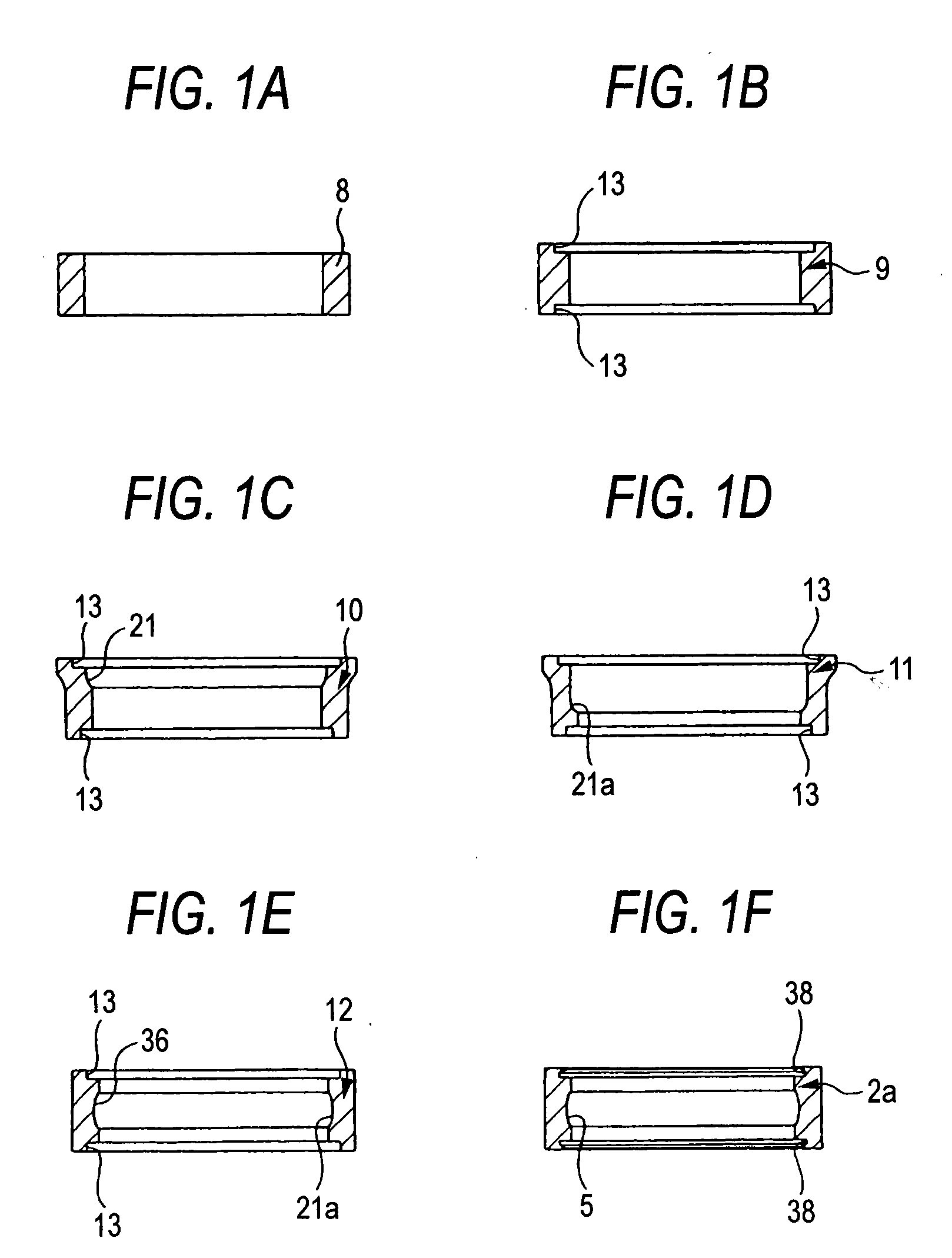

Method and apparatus for selecting translucent dental materials

InactiveUS20080160485A1Increase and decrease weightImprove matchMechanical/radiation/invasive therapiesTooth crownsDental prosthesisSemi transparent

The present invention relates to a shade or color determination apparatus and method for dental restorations where translucent materials are used that account for the influence of underlying tooth structure and each successive layer on the final shade of the dental restorations when an opaque layer of dental material is not used in the fabrication of the dental restoration.

Owner:TOUCHSTONE C ALEX

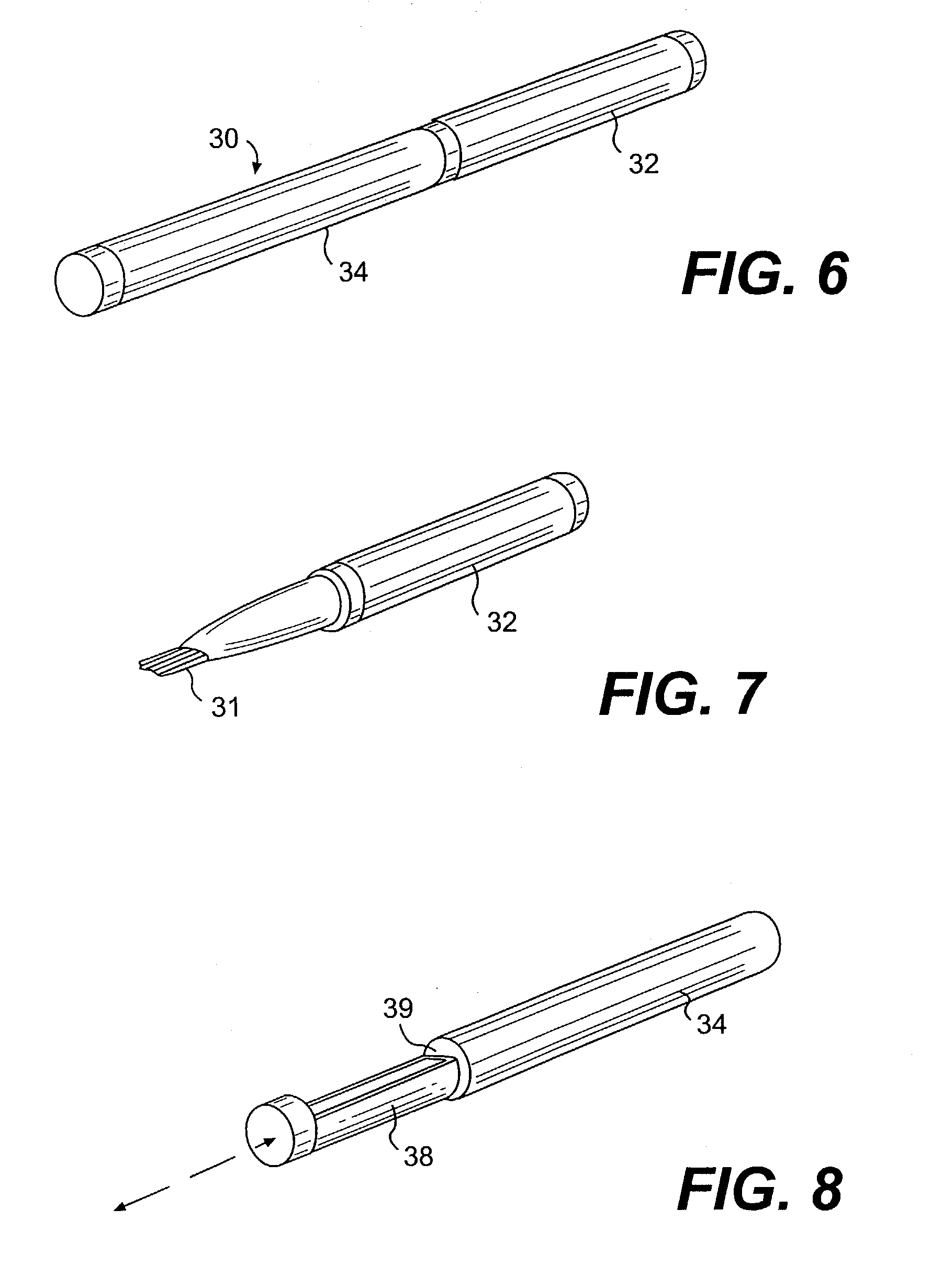

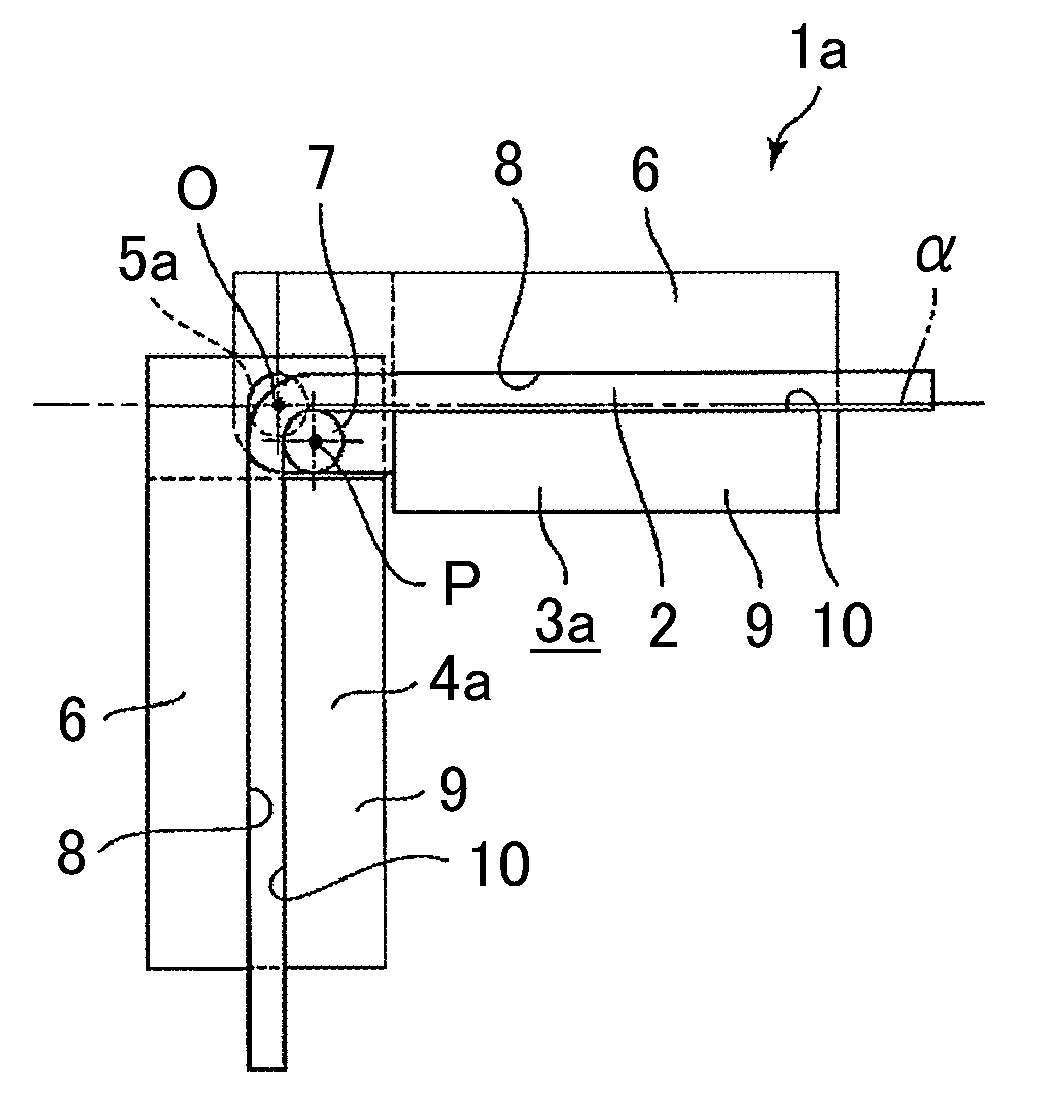

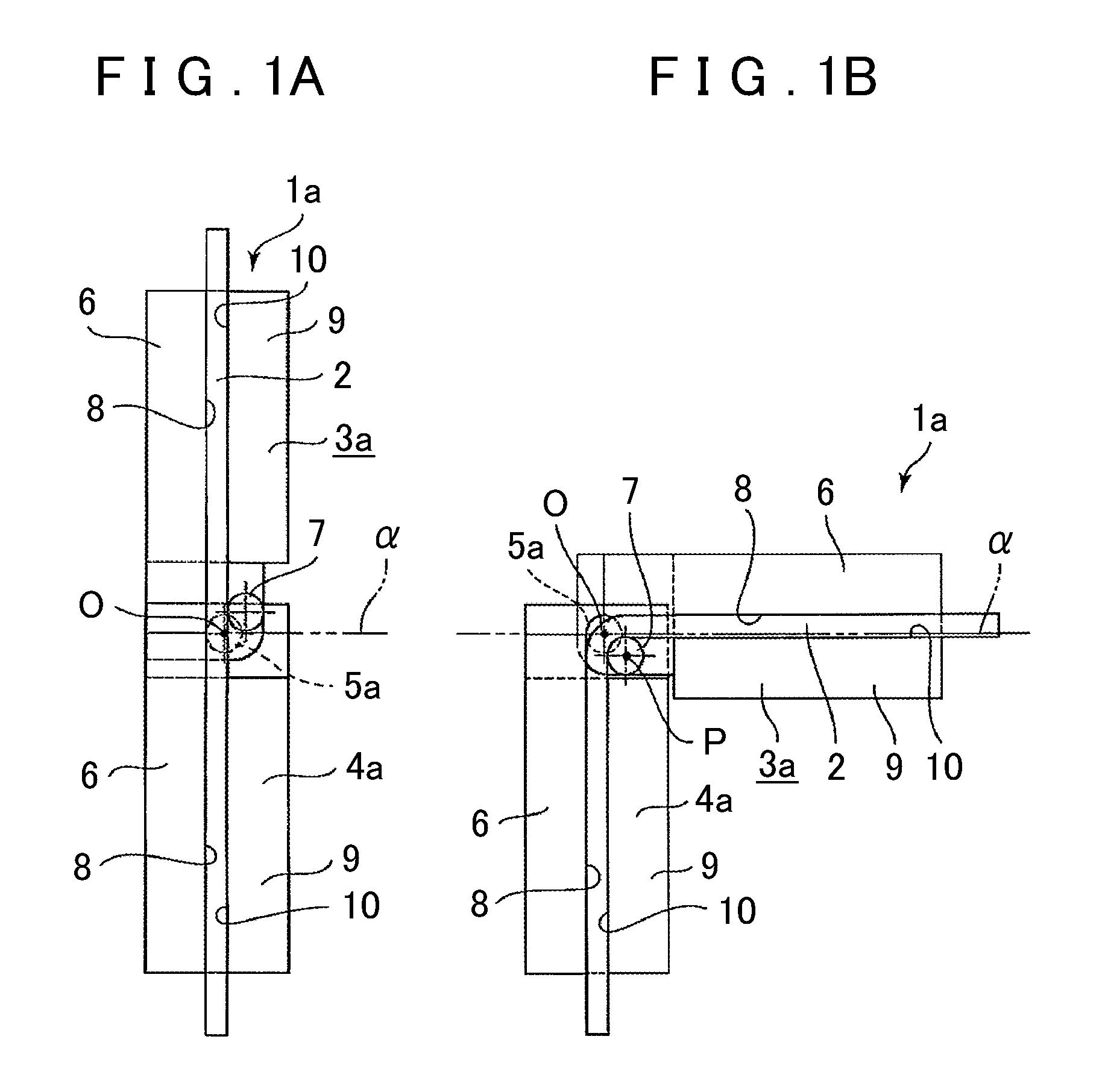

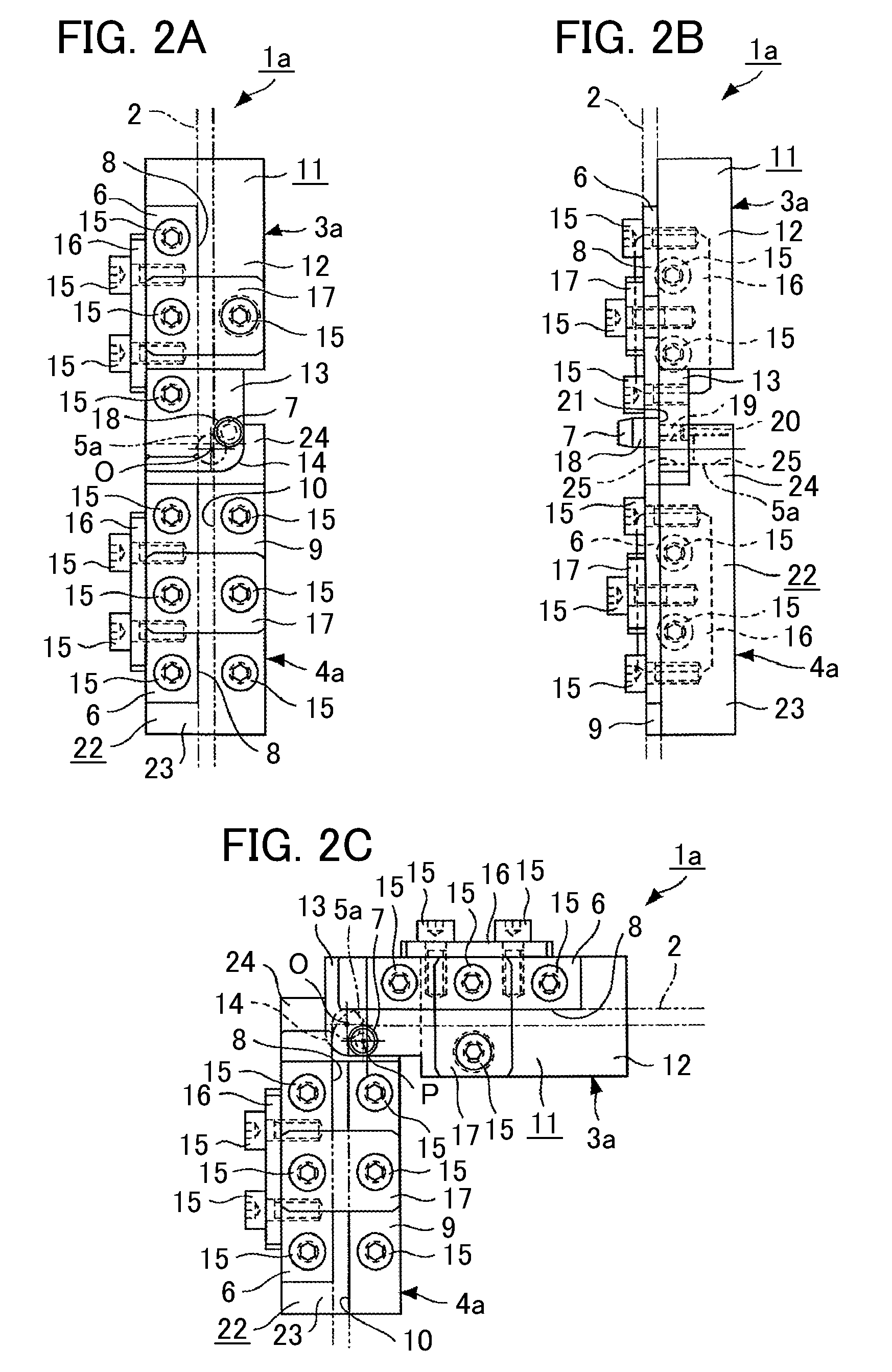

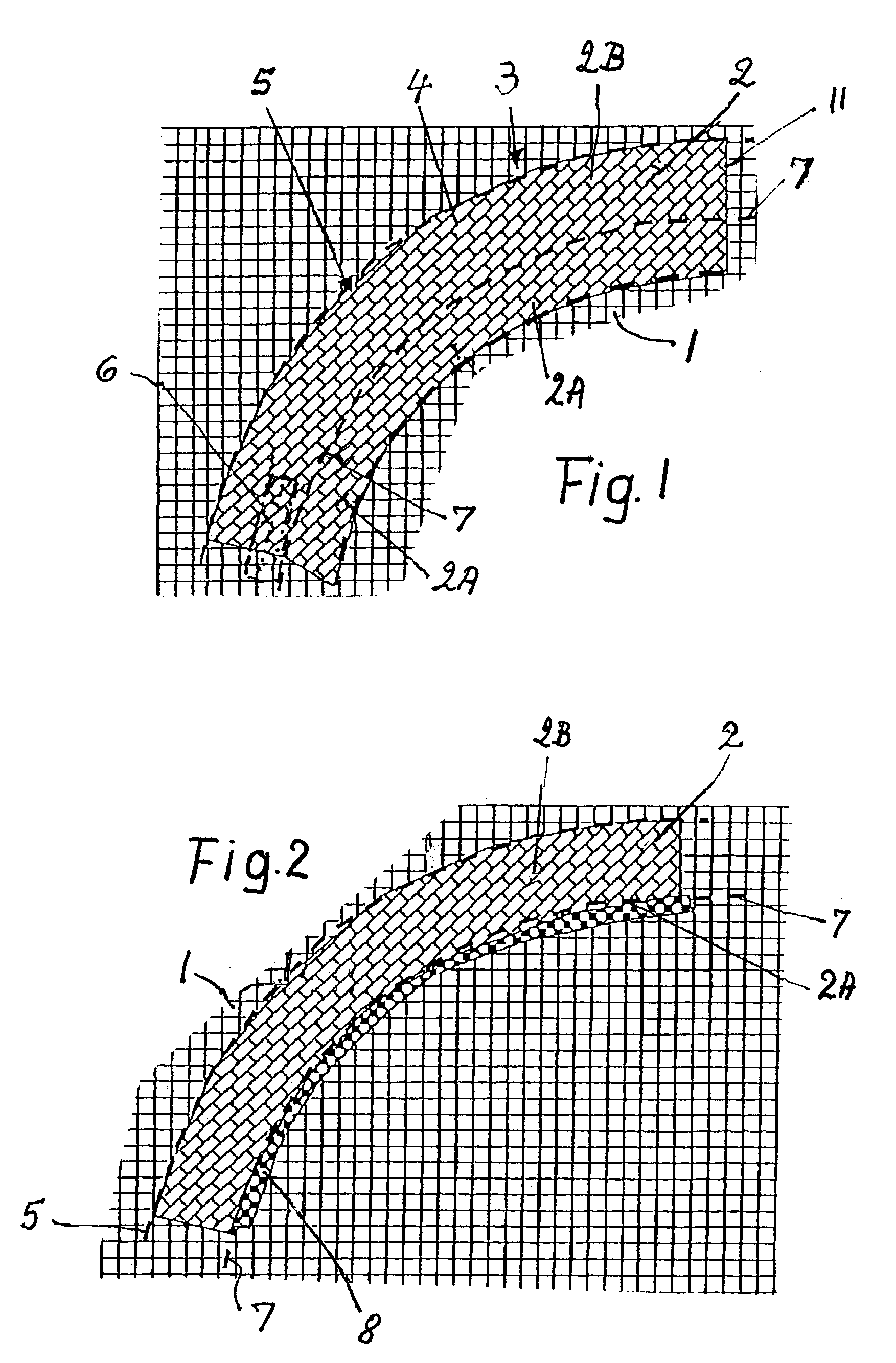

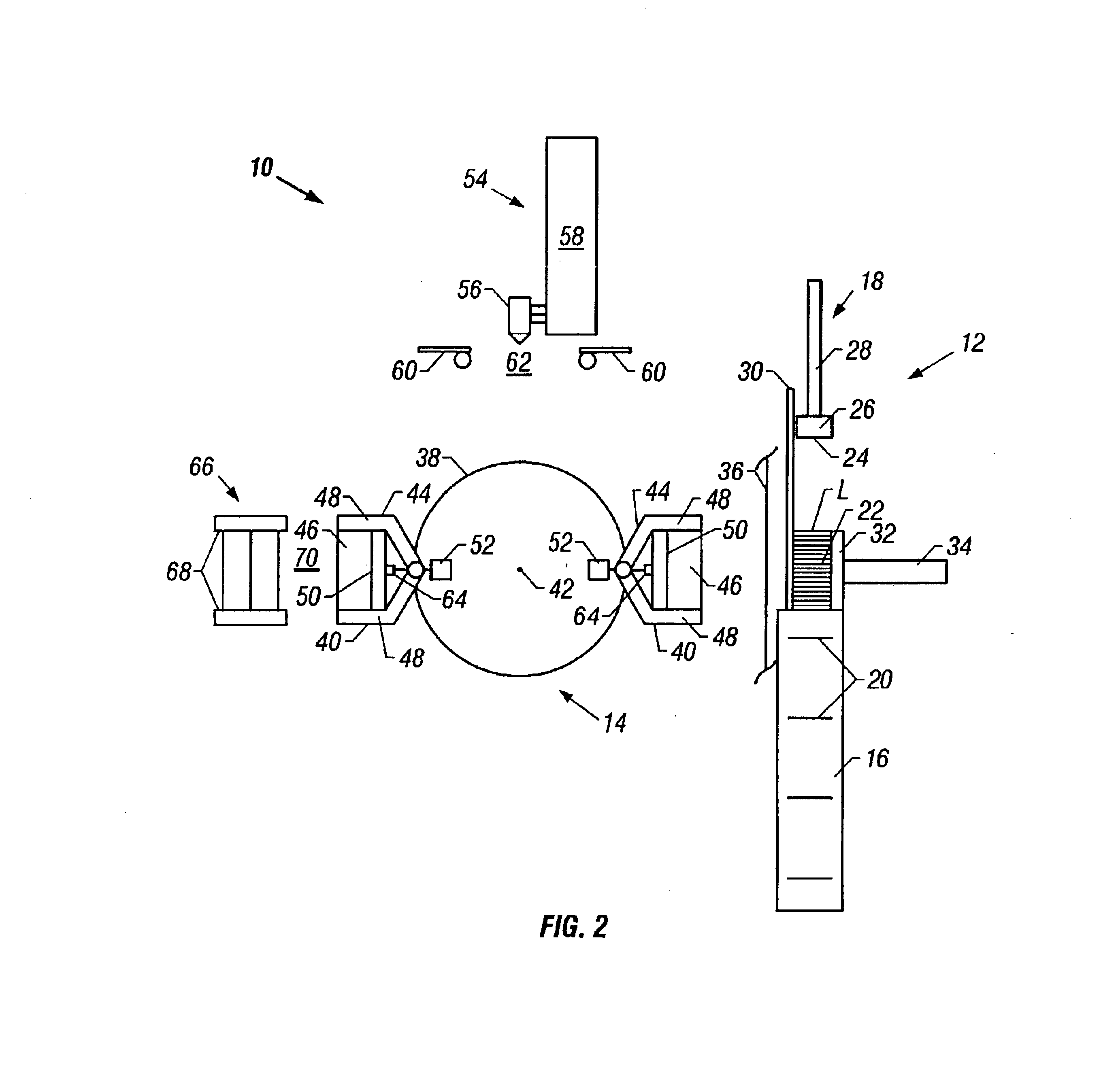

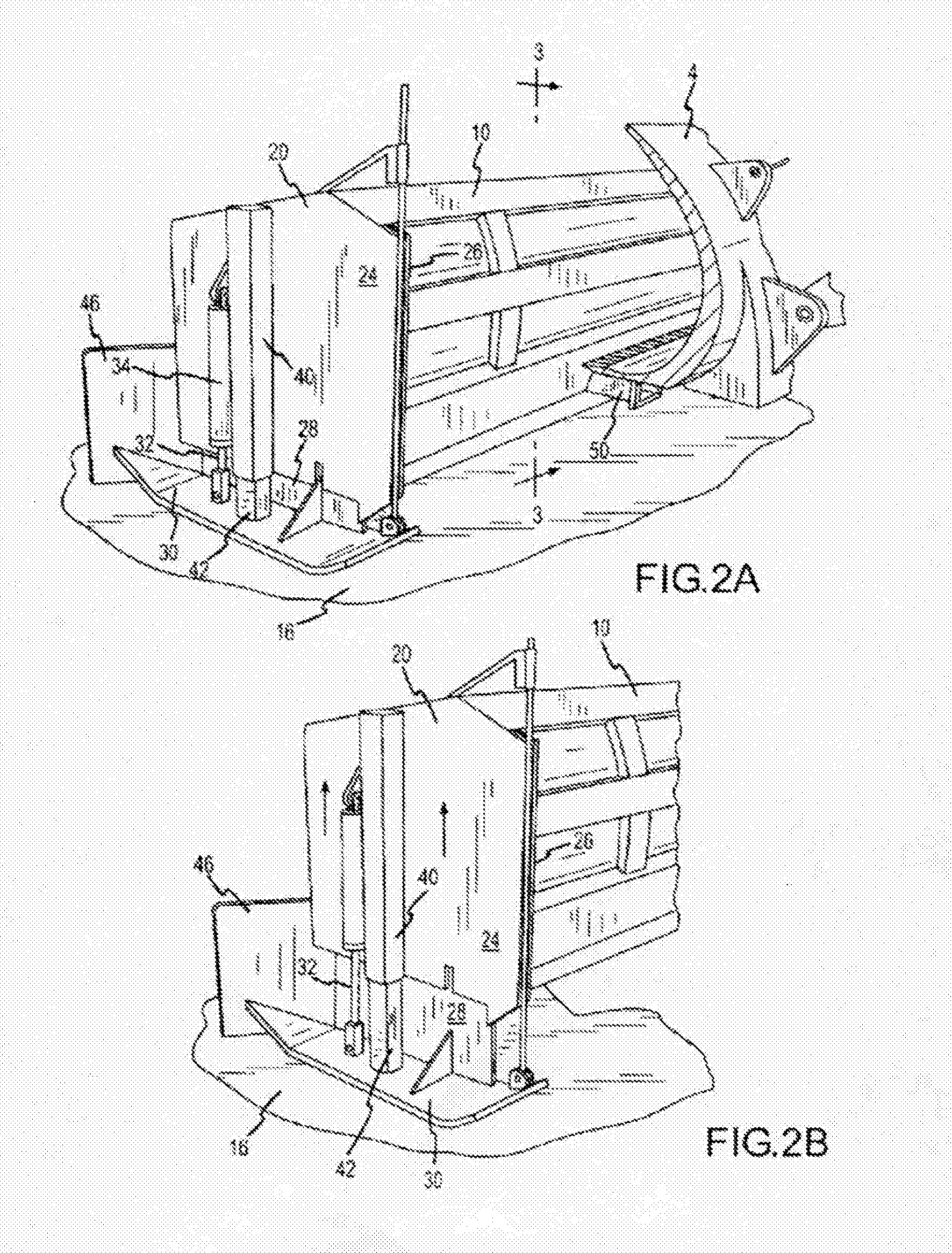

Bending apparatus and bending machine

ActiveUS20100170317A1Prevent materialQuality improvementManufacturing dynamo-electric machinesNon destructiveCentre of rotation

A bending apparatus for performing accurate non-destructive bending of material includes first and second jigs that are rotatable about a rotary shaft and that bend the material attached to the jigs as they rotate relative to each other. The first jig includes a bending section that is arranged offset from a rotary center to a rotating side of the material and that has a partially cylindrical surface with a radius of curvature corresponding to the radius of curvature of an inner peripheral surface of the material. Each of the first and second jigs has a suppressing section for suppressing displacement of the material, and a bending center of the material is arranged such that the material is not displaced relative to the first and second jigs when the material is bent.

Owner:AISIN AW CO LTD

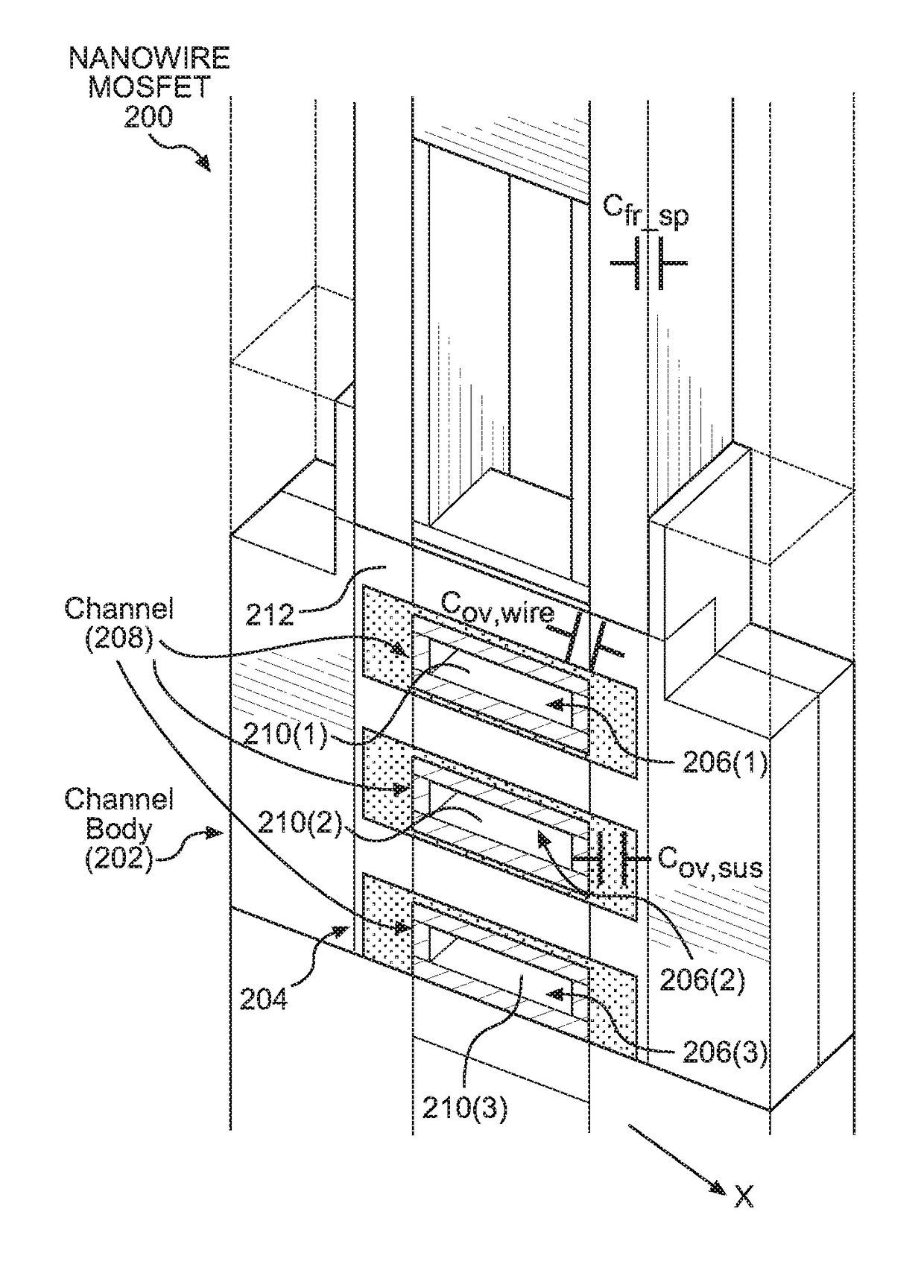

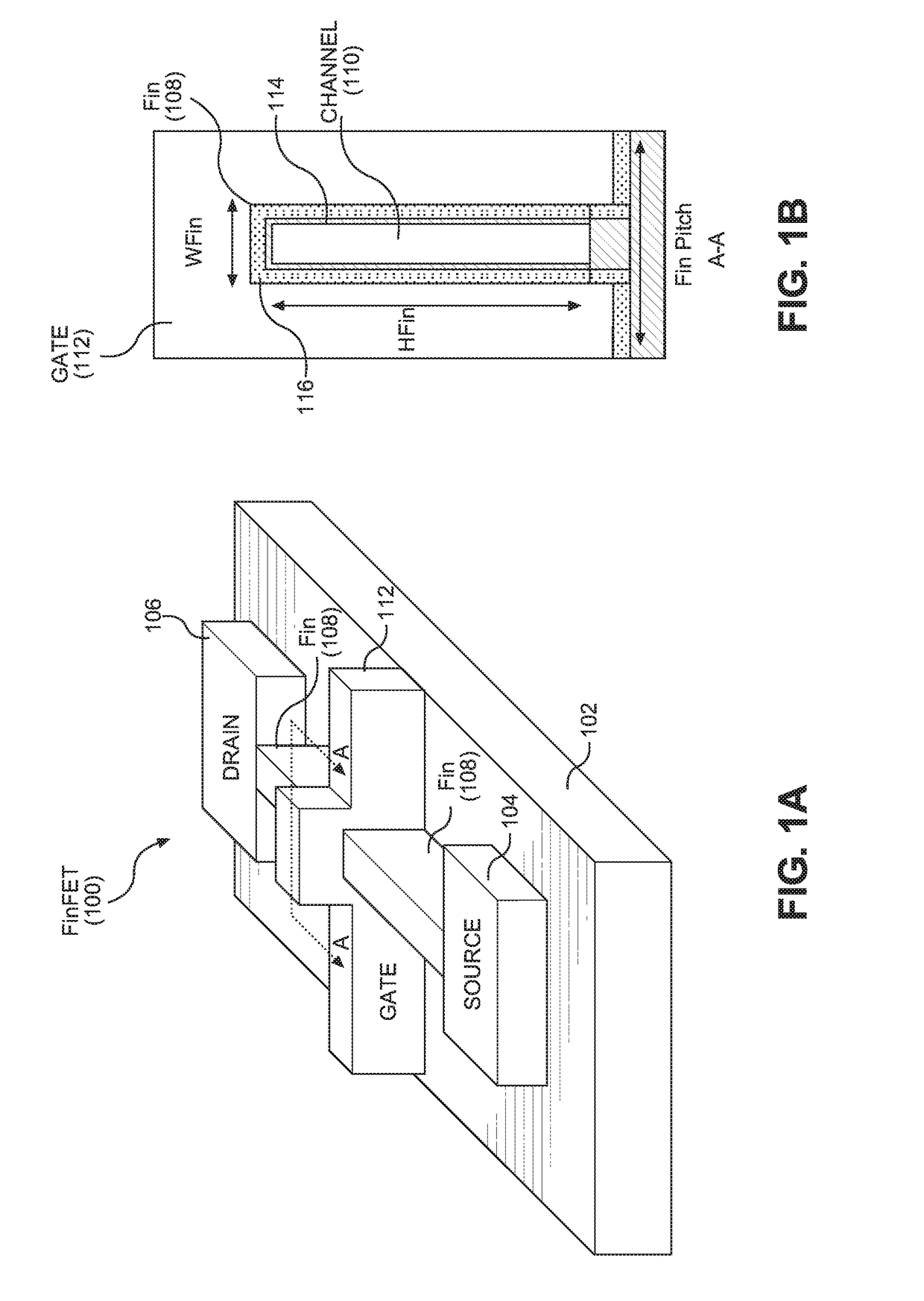

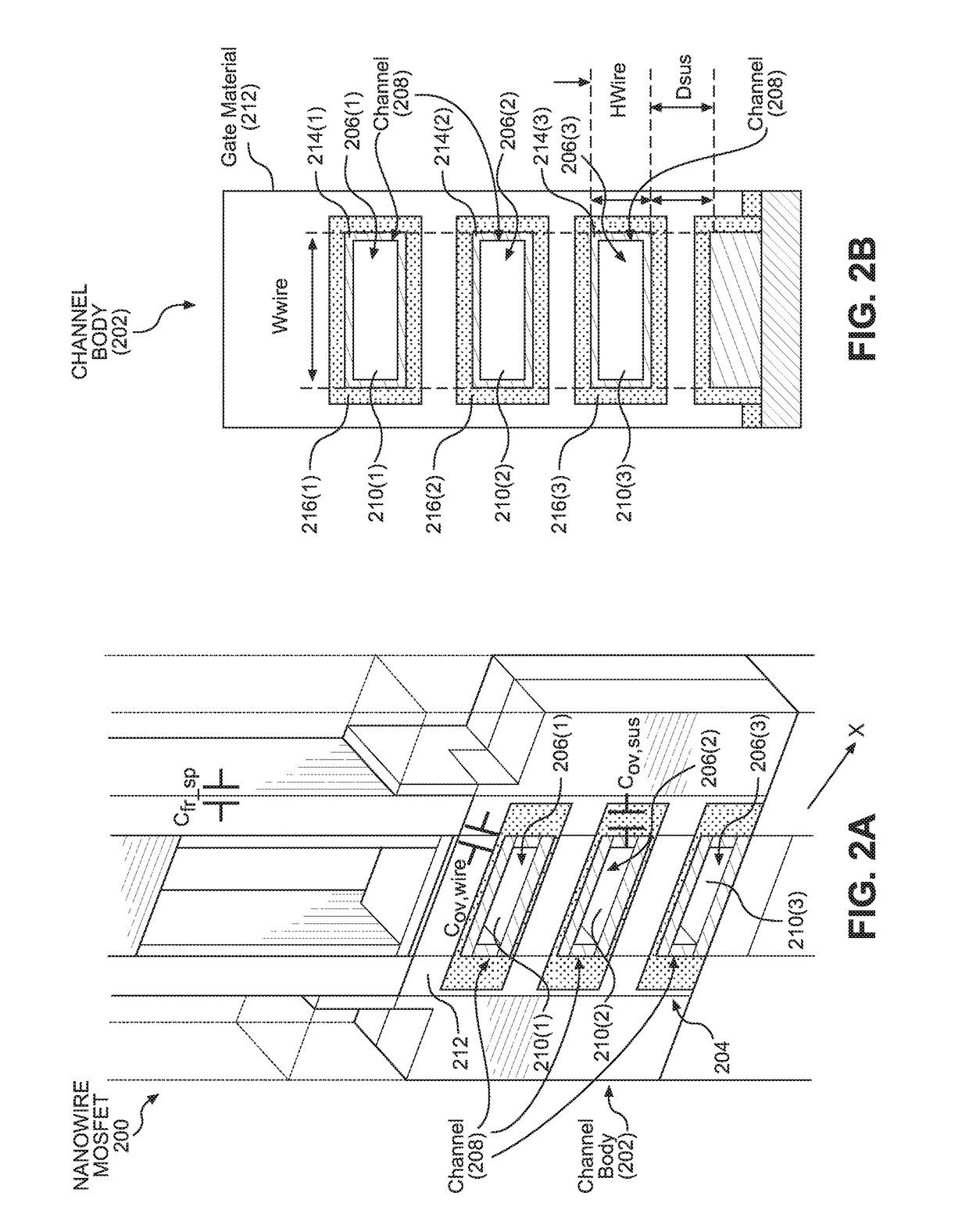

NANOWIRE METAL-OXIDE SEMICONDUCTOR (MOS) FIELD-EFFECT TRANSISTORS (FETs) (MOSFETs) EMPLOYING A NANOWIRE CHANNEL STRUCTURE EMPLOYING RECESSED CONDUCTIVE STRUCTURES FOR CONDUCTIVELY COUPLING NANOWIRE STRUCTURES

InactiveUS20170207313A1Increase widthIncrease channel current densitySemiconductor devicesMOSFETNanowire

Nanowire metal-oxide semiconductor (MOS) Field-Effect Transistors (FETs) (MOSFETs) employing a nanowire channel structure employing recessed conductive structures for conductively coupling nanowire structures are disclosed. Conductive structures are disposed between adjacent nanowire structures to conductively couple nanowire structures. Providing conductive structures in the nanowire channel structure increases the average cross-sectional area of nanowire structures, as compared to a similar nanowire channel structure not employing conductive structures, thus increasing effective channel width and drive strength for a given channel structure height. The precision of a gate material filling process is also eased, because gate material does not have to be disposed in areas between adjacent nanowire structures occupied by conductive structures. The conductive structure width can also be recessed with regard to width of nanowire structures in the nanowire channel structure to allow for a thicker metal gate to lower the gate resistance, while providing excellent electrostatic gate control of the channel.

Owner:QUALCOMM INC

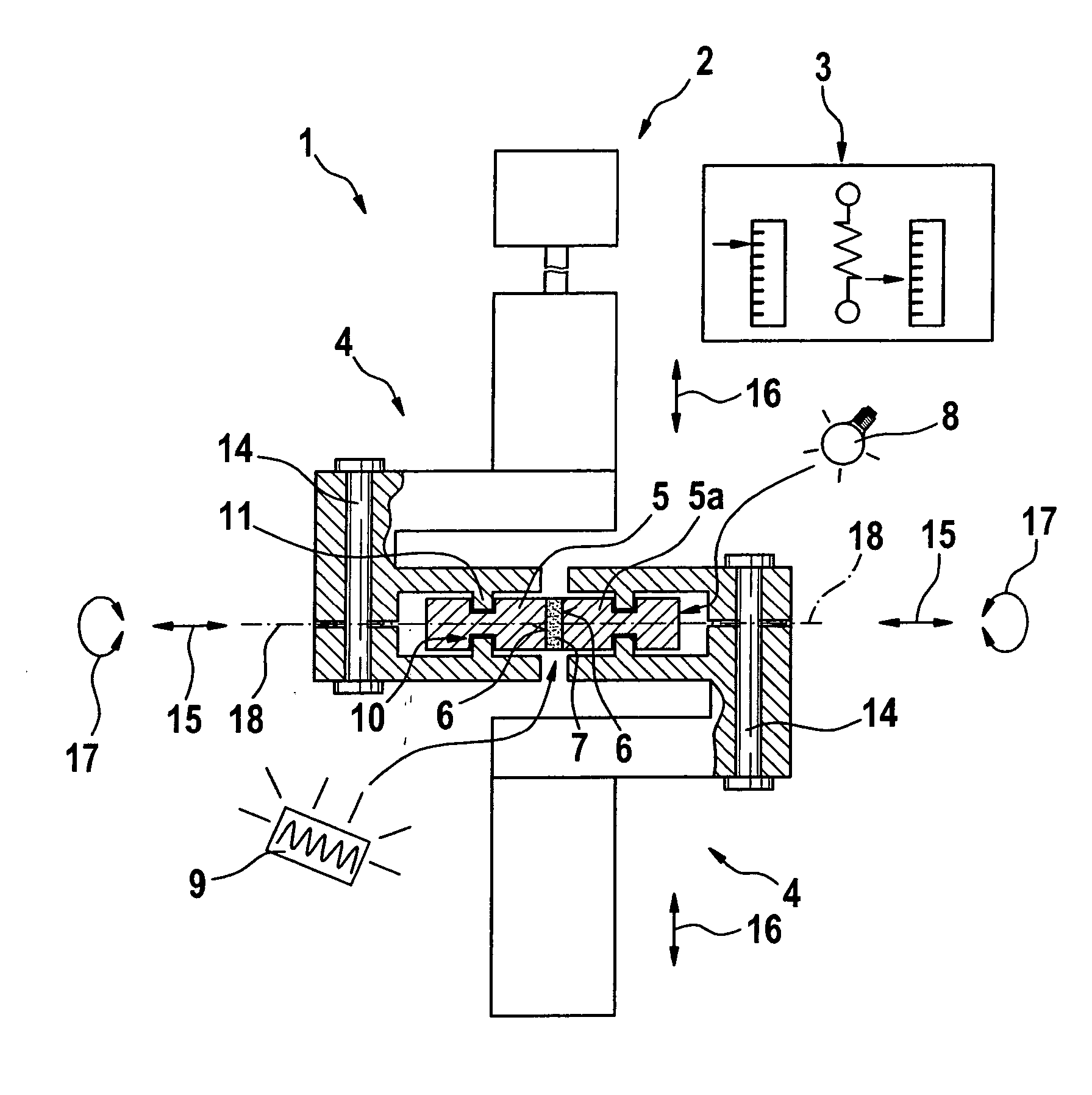

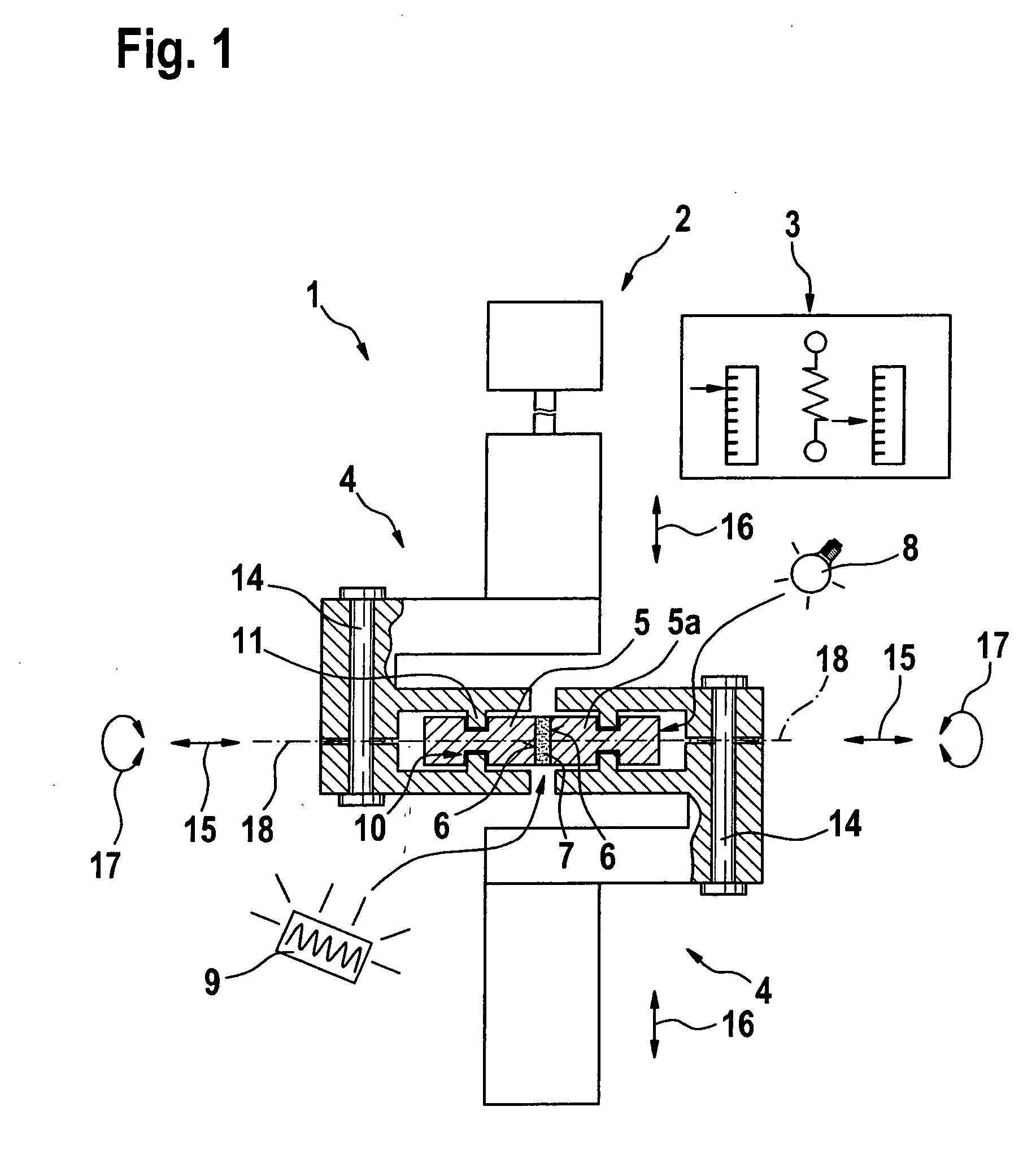

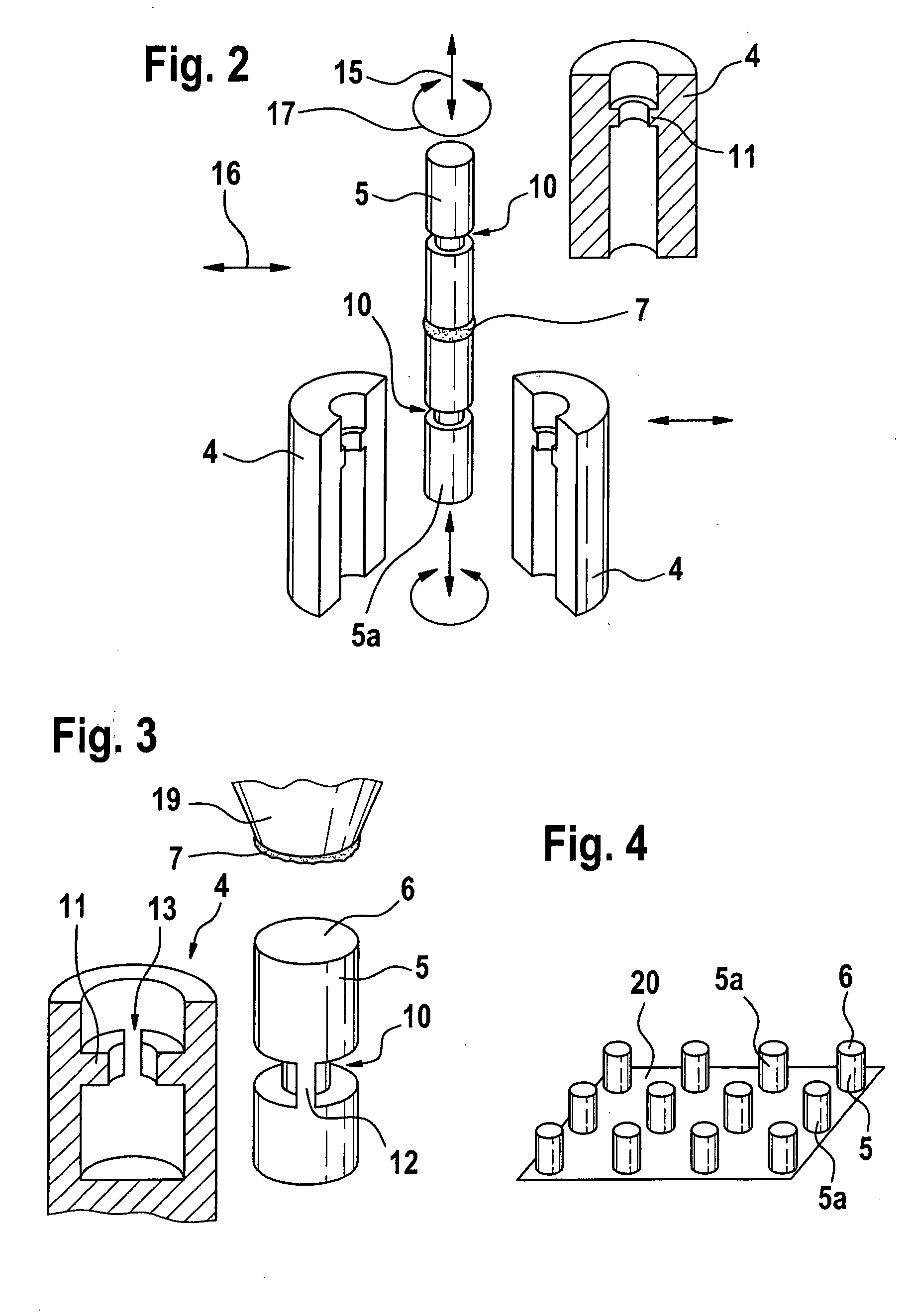

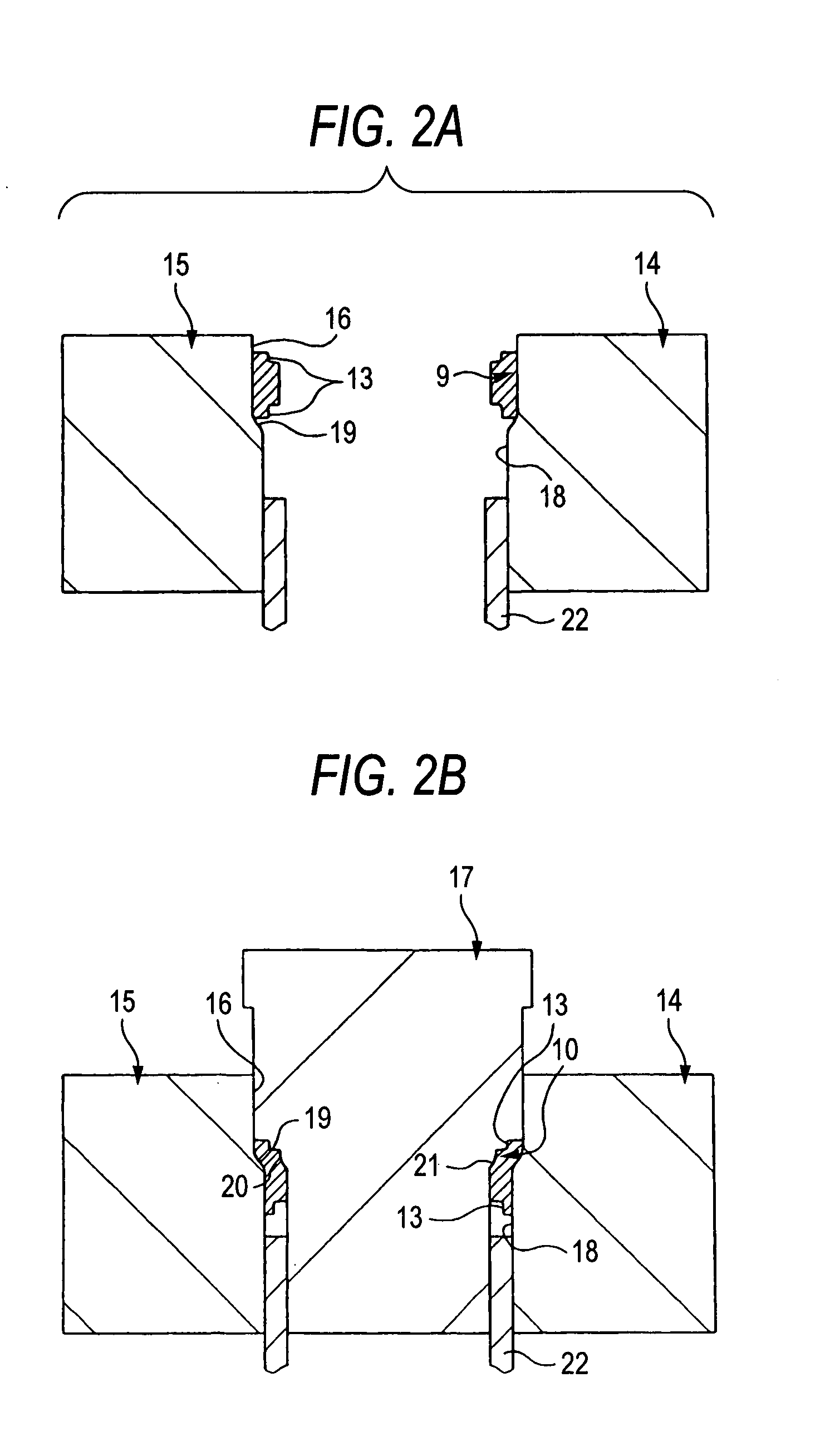

Device for testing material properties with regard to combined tensile and shear loads, in particular for testing adhesives

InactiveUS20050193829A1Accurate material propertyPrecise definitionMaterial strength using tensile/compressive forcesUsing mechanical meansAdhesiveEngineering

A device for testing material properties with regard to combined tensile and shear loads, in particular for testing adhesives, includes a device for applying the force, a measuring device, a test piece receptacle, and a test piece having a bonding surface. The test piece is dimensionally stable within the intended limits of the force to be applied. This measure ensures that the shear forces acting on the joint act approximately at a right angle to the bonding surface over the entire test period, so that realistic conclusions may be drawn with regard to the material properties of the tested adhesive.

Owner:ROBERT BOSCH GMBH

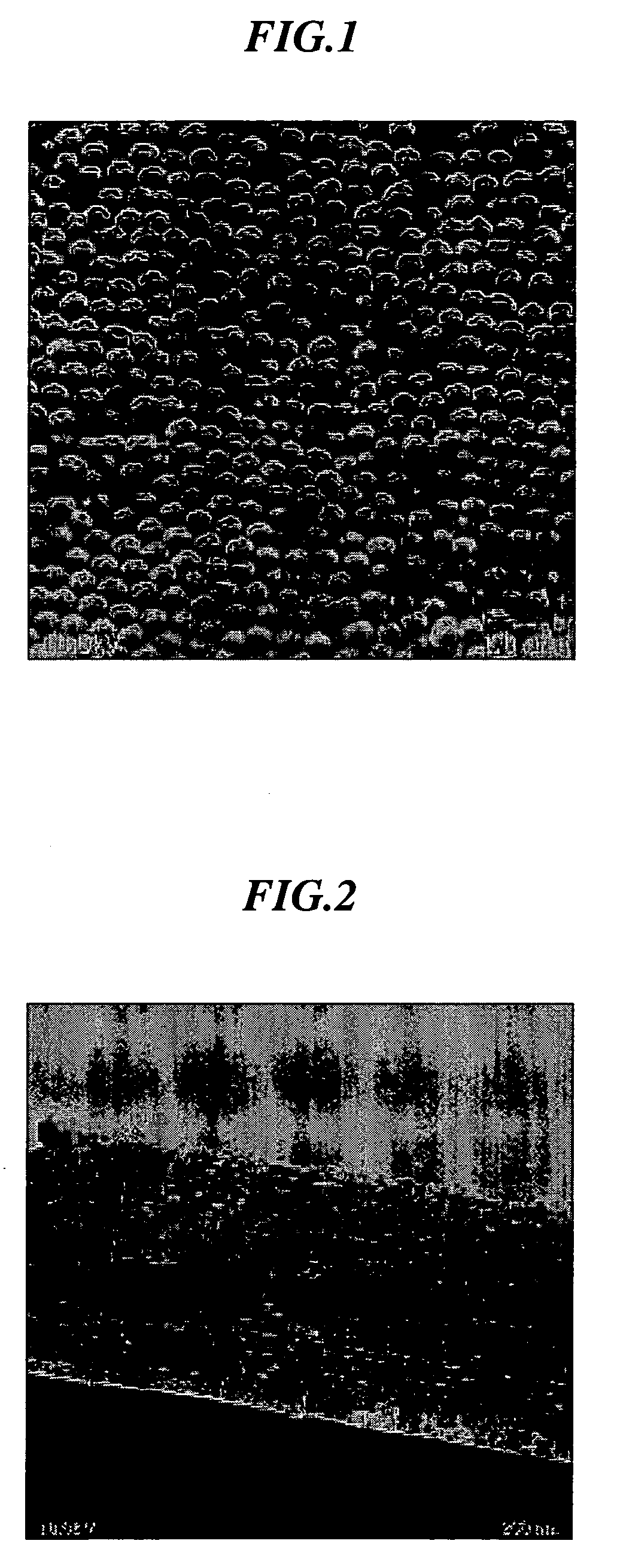

Three-dimensional periodic structure, three-dimensional periodic porous structure, and method for producing these

InactiveUS20060078736A1Robust and stableSimple designOptical filtersSynthetic resin layered productsBackbone chainCore shell

The three-dimensional periodic structure of the present invention comprises a matrix made of an inorganic oxides in which core-shell particles are disposed so as to contact with each other, the core-shell particles each comprising a core portion made of a fine particle and a shell portion made of a crosslinked hydrophilic organic polymer backbones, wherein the hydrophilic organic polymer backbones and the inorganic oxides hybridize into an organic / inorganic a composite.

Owner:KAWAMURA INST OF CHEM RES

Method for producing a three-dimensional fiber reinforced ring frame component

InactiveUS7014806B2Produced economicallyPrecise positioningAircraft accessoriesLaminationRing fibersBand shape

Owner:INST FUER VERBUNDWERKSTOFFE GMBH +1

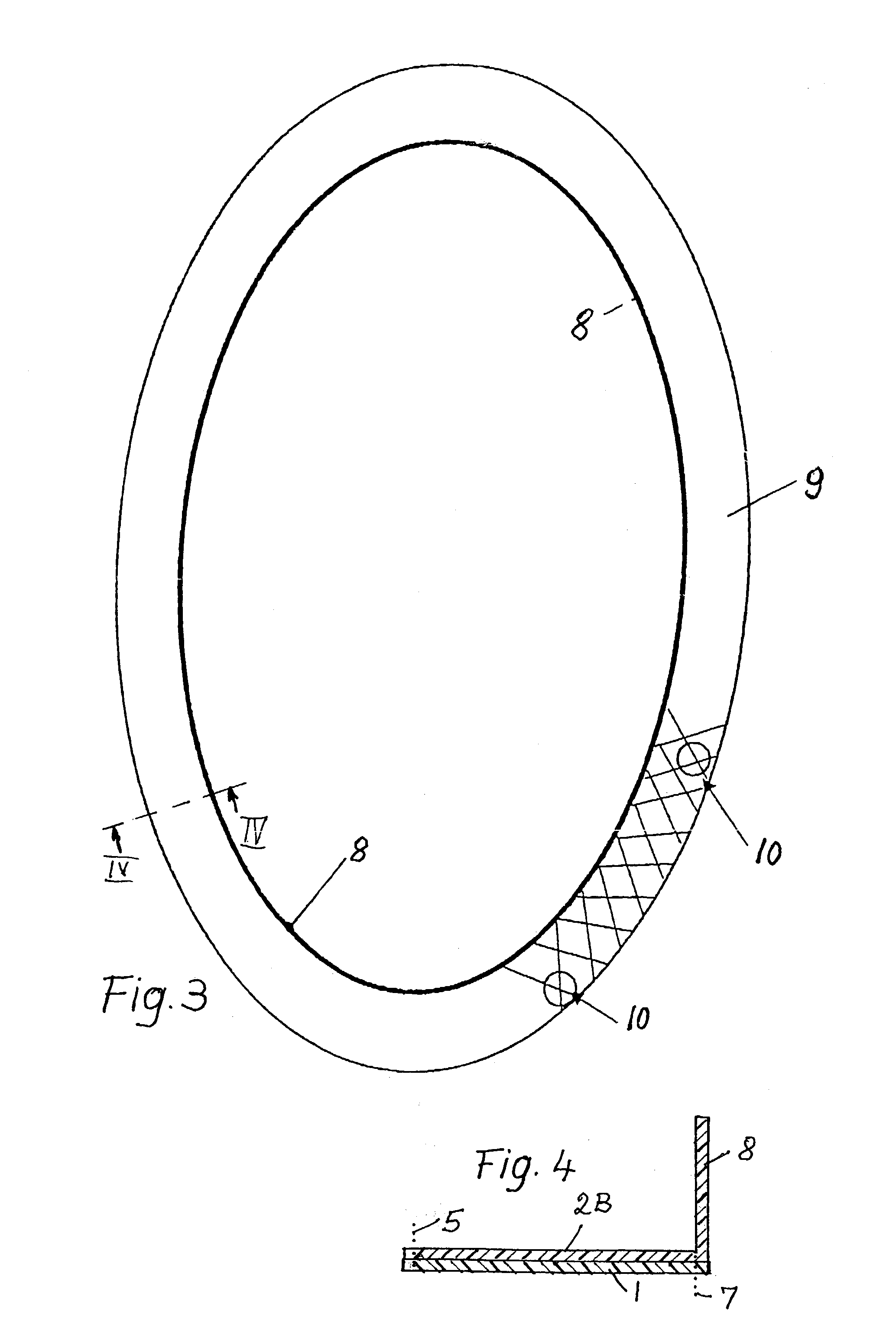

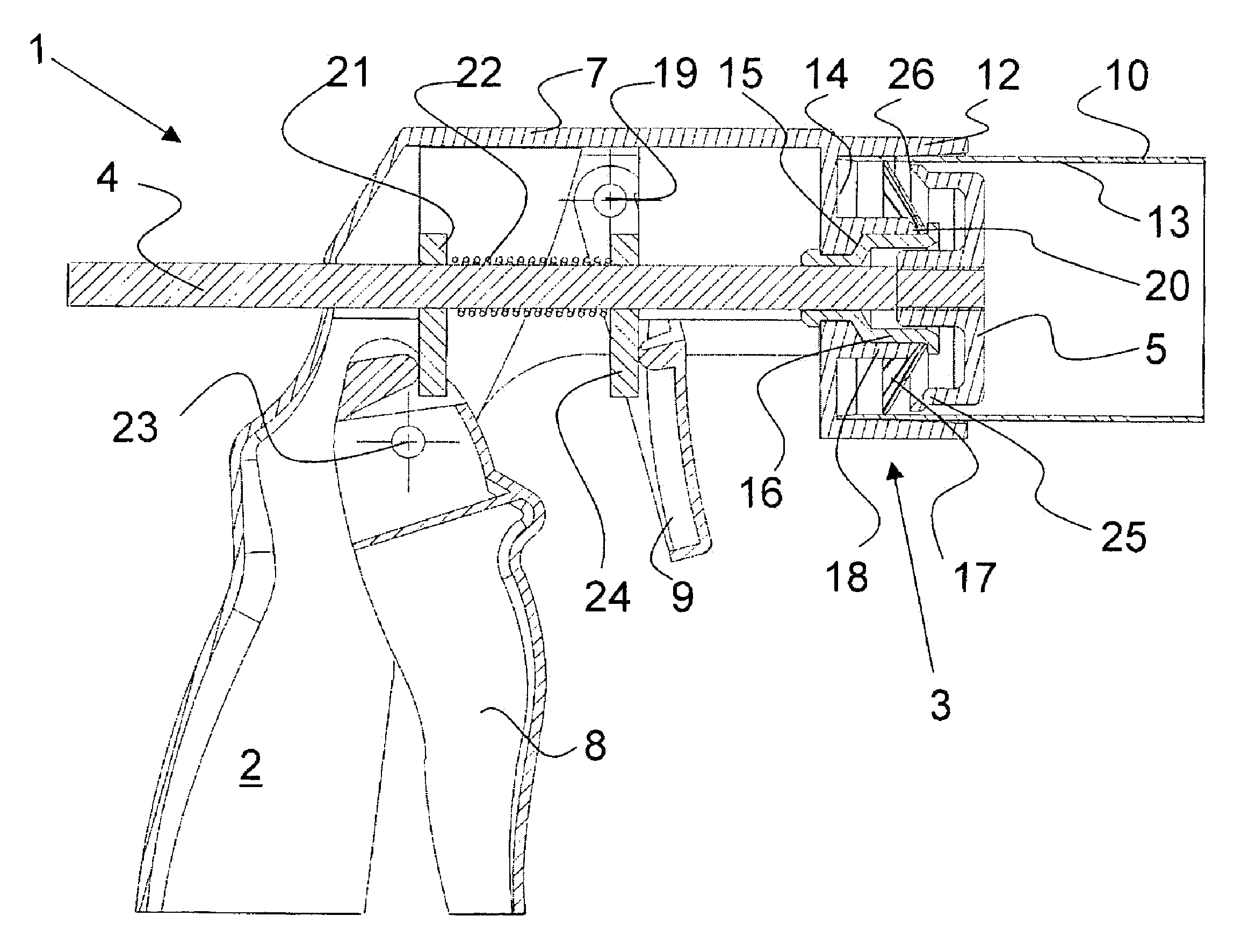

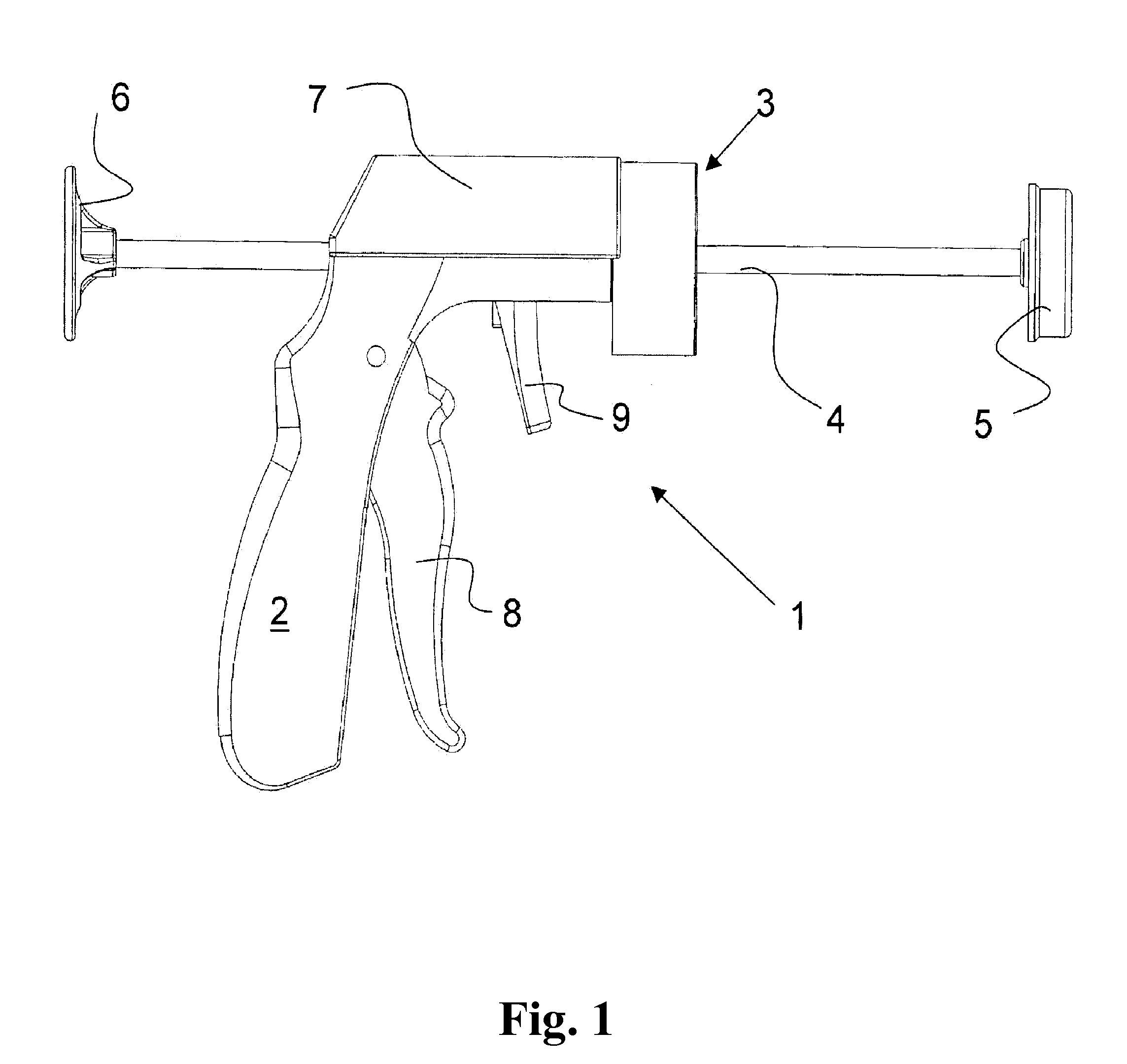

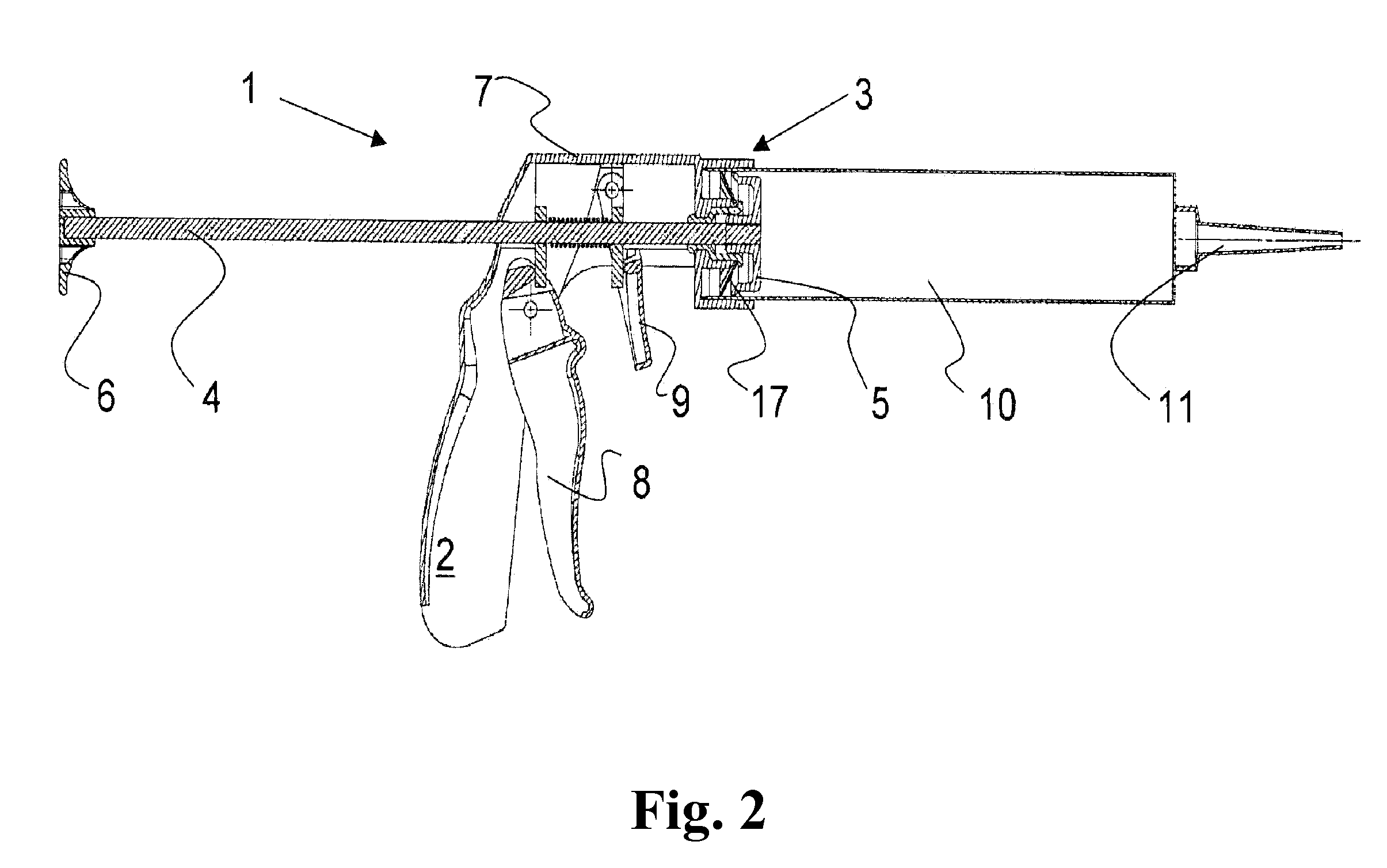

Cartridge pistol with a cartridge holder

ActiveUS20090218372A1Prevent bulk materialPromote exchangeLiquid surface applicatorsLarge containersEngineeringMechanical engineering

A cartridge gun is provided. The cartridge gun comprises a cartridge holder, a plurality of resilient gripping elements, a displaceable piston rod for moving a piston in a cartridge, and an actuating device for displacing the piston rod. The cartridge holder comprises a cylindrical base for receiving the floor region of the cartridge in which the gripping elements project radially outwardly from the center of the cartridge holder in the direction towards the housing into an annular groove of the base up to the outside wall of the annular groove in the base and are held in the center of the base by means of a hub. Means are further arranged at the front end of the piston rod which are designated to press the ends of the resilient gripping elements in the direction towards the housing when the piston rod is fully retracted, allowing the removal of the cartridge from the cartridge gun.

Owner:RAY TECHNOLOGY GROUP BV

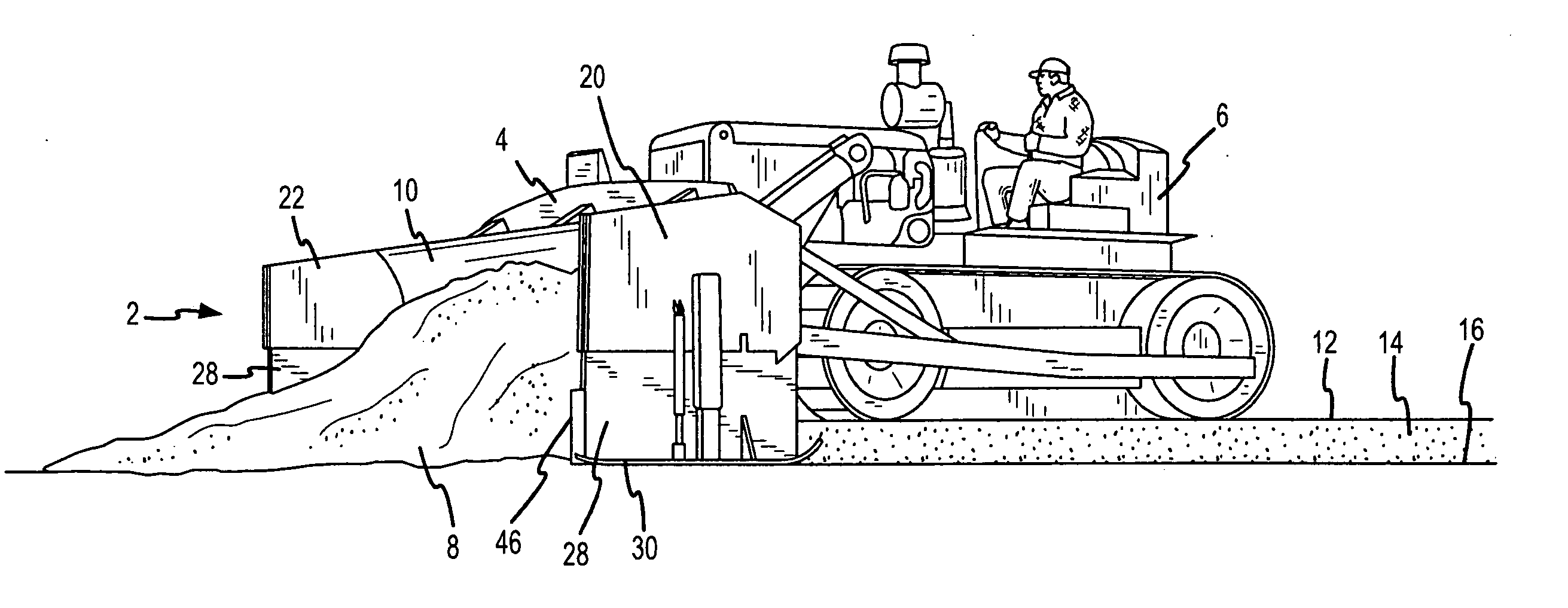

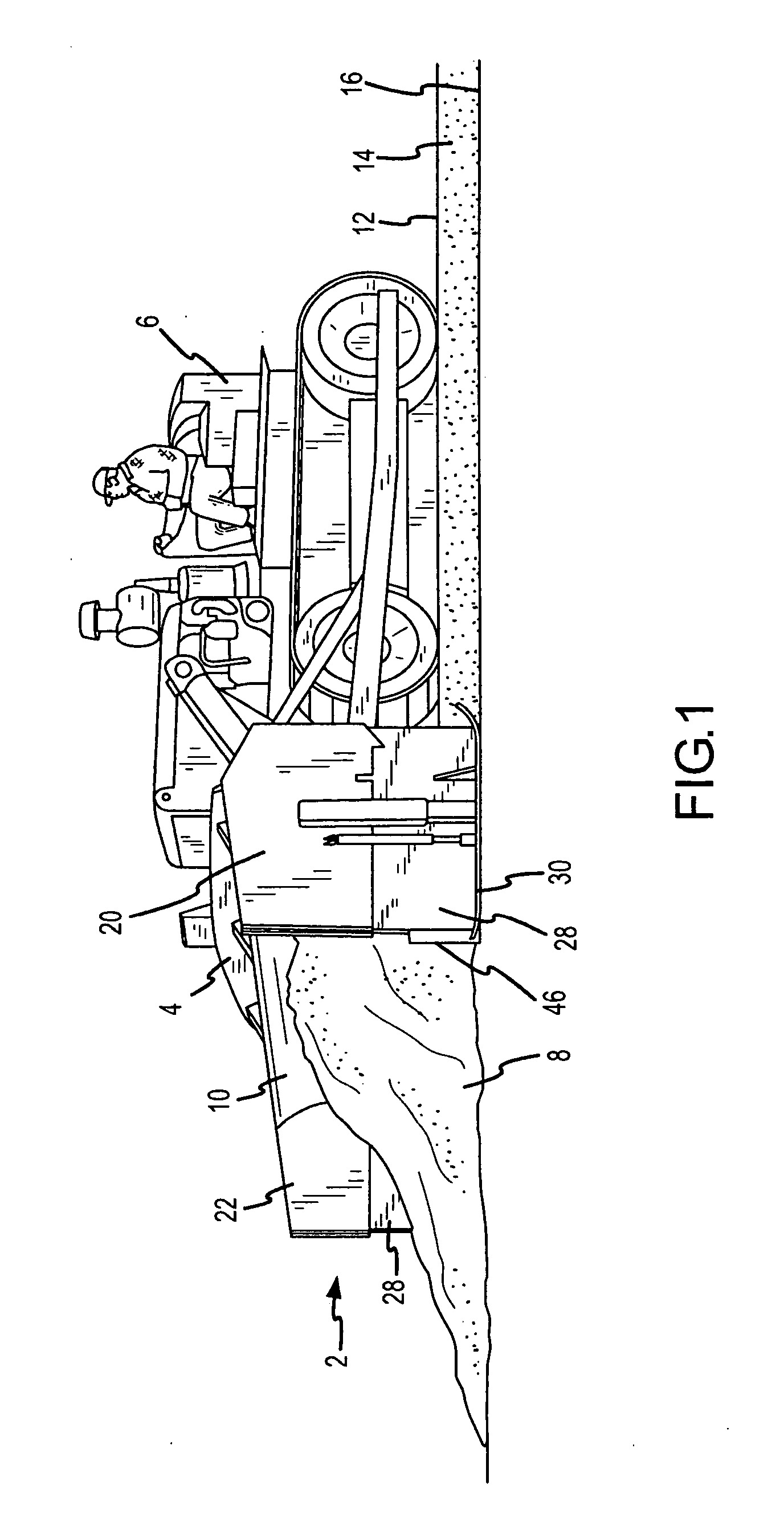

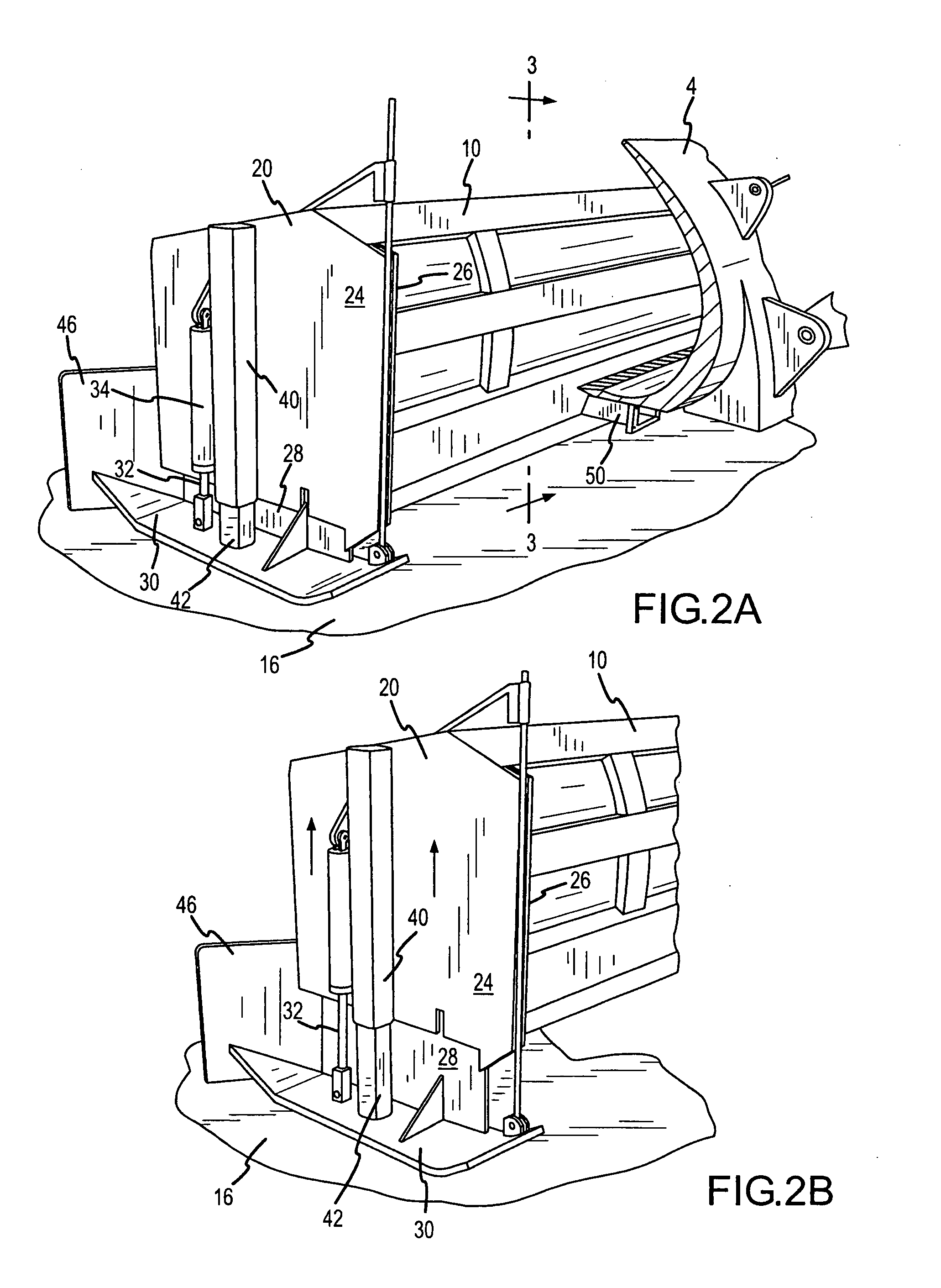

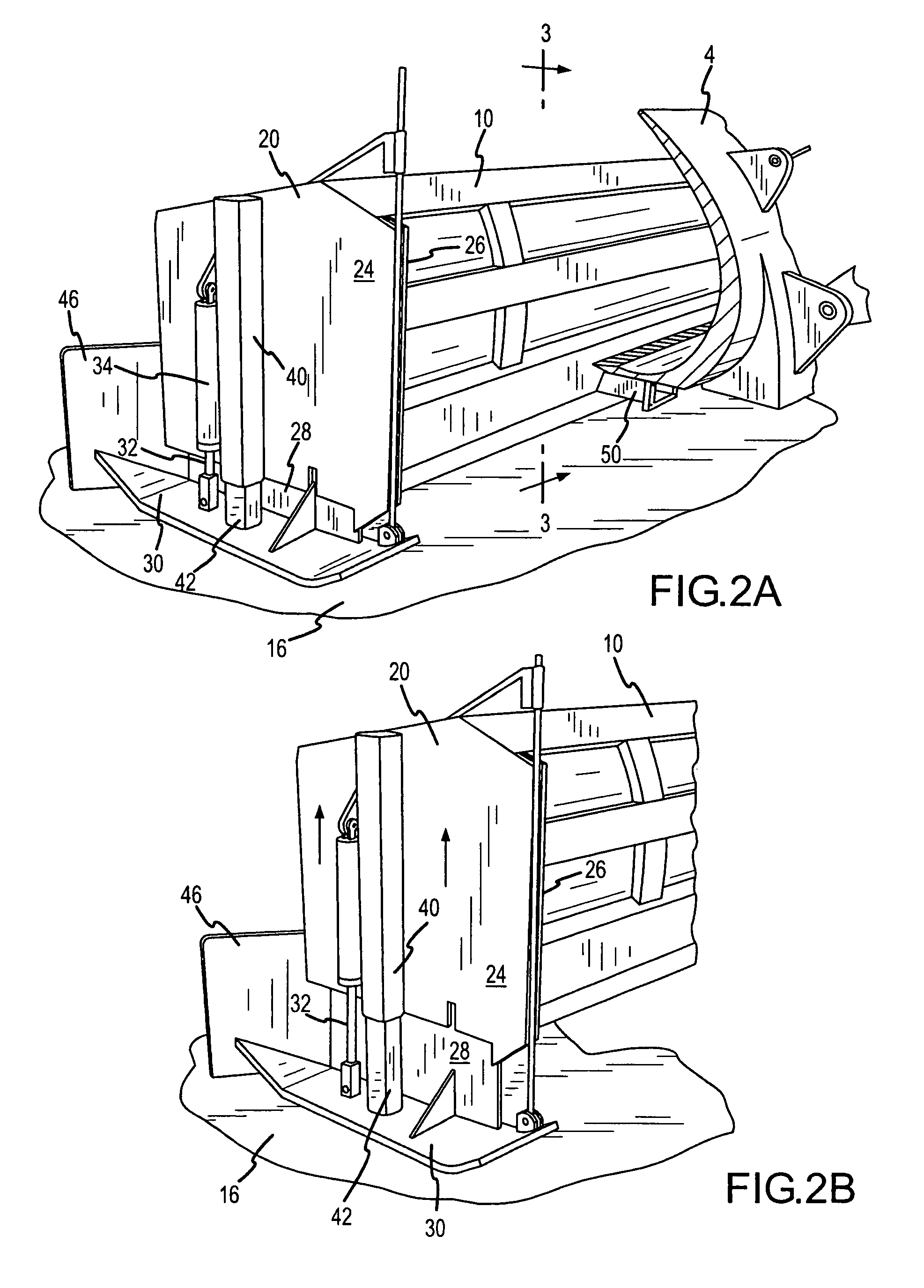

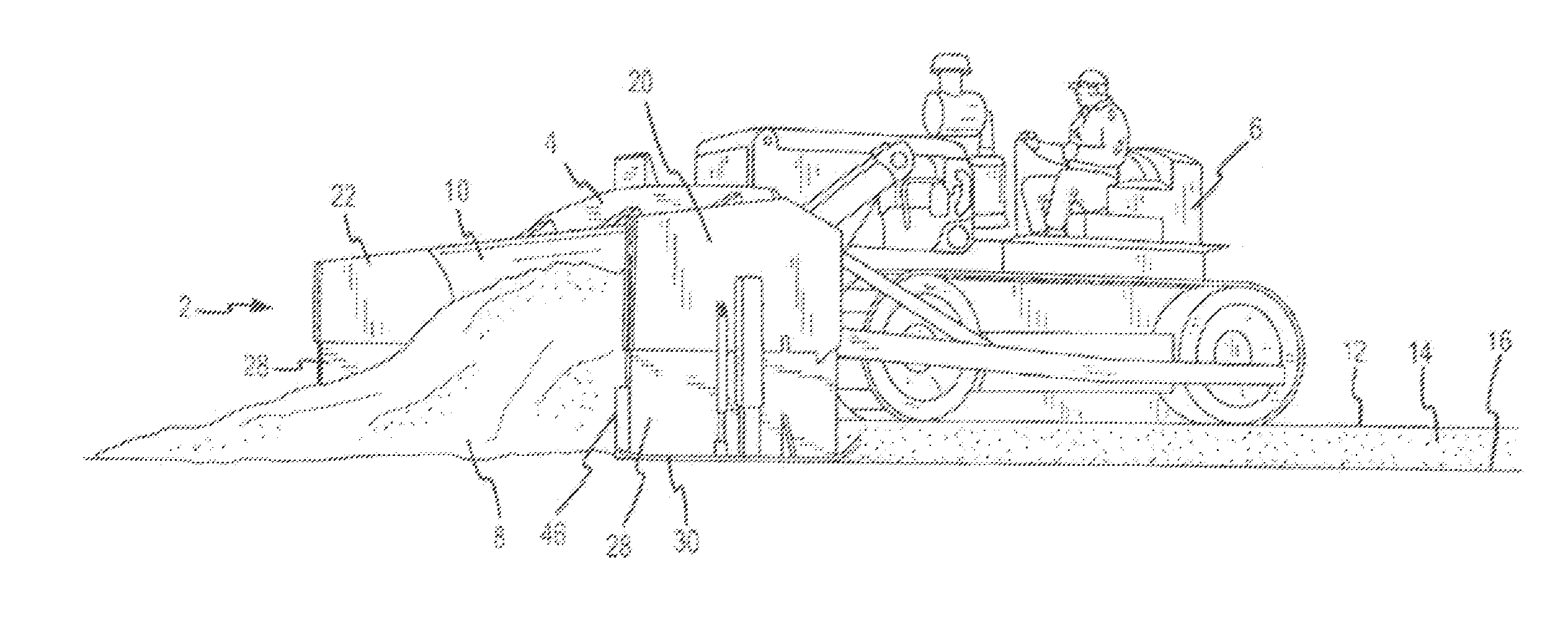

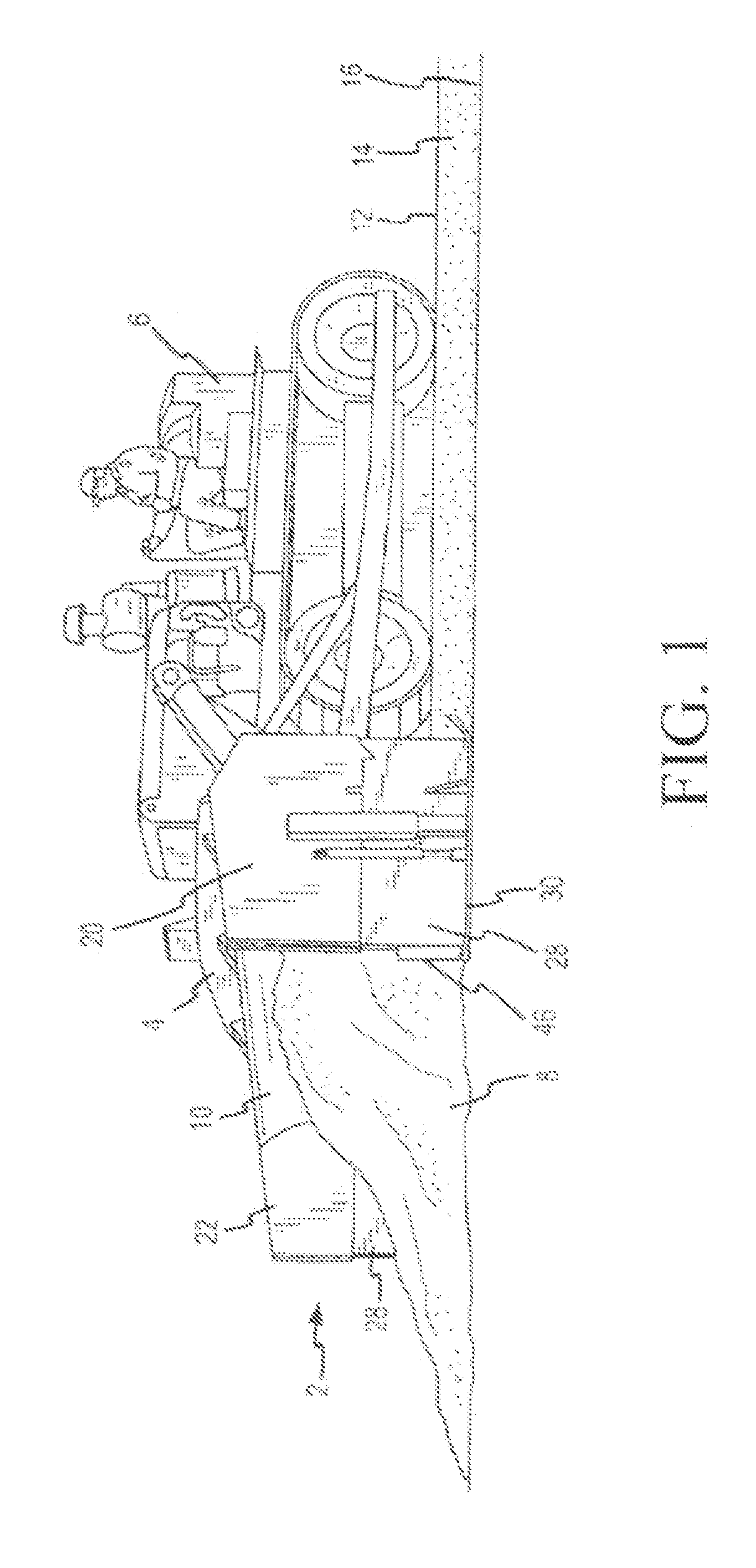

Road grader/spreader

InactiveUS20070235202A1Depth accurateAccurate materialsAgricultural machinesSoil-working equipmentsGround contactEngineering

Owner:MULLETT MYRON L

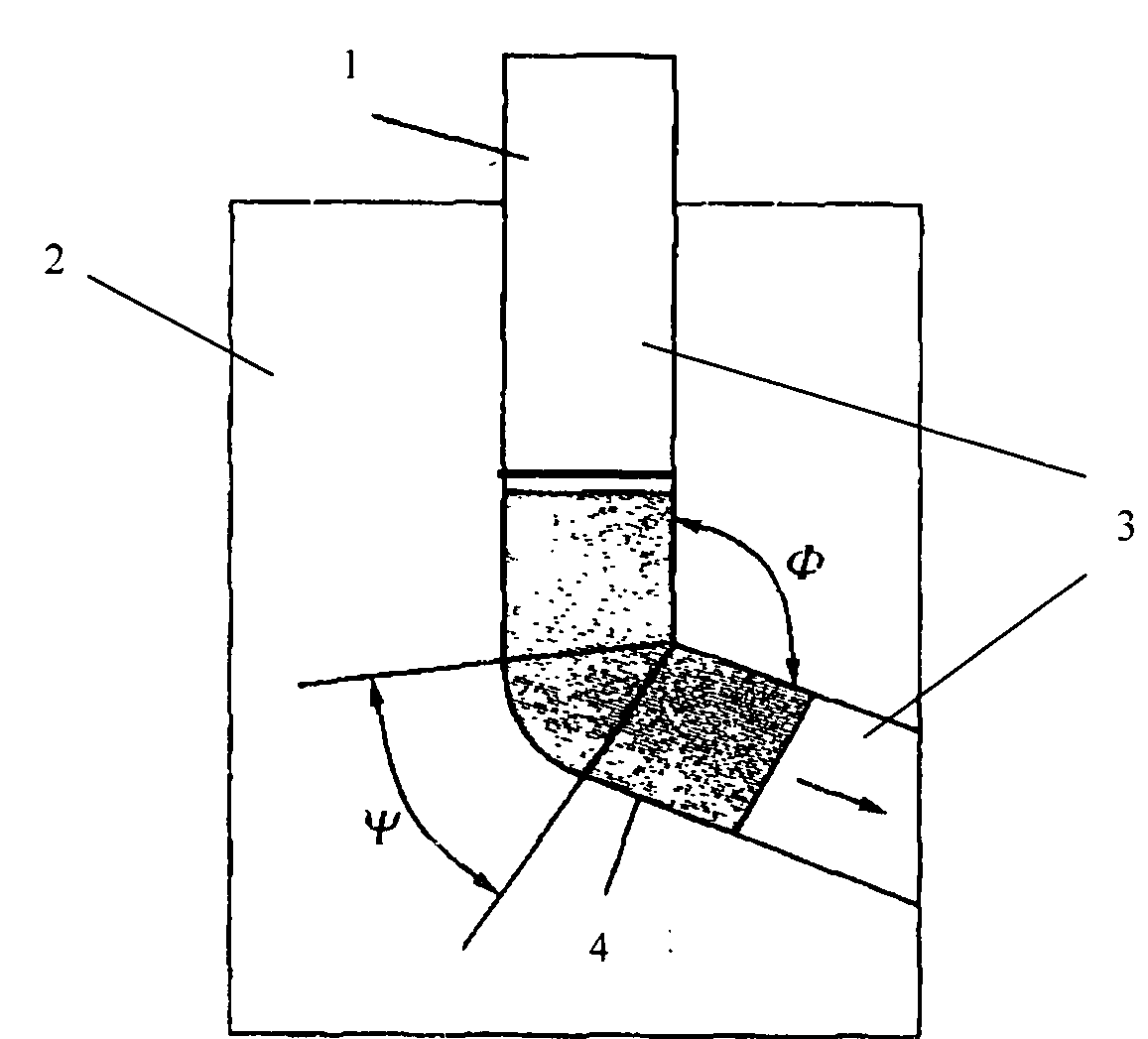

Preparation method of laminated composite materials of different alloys

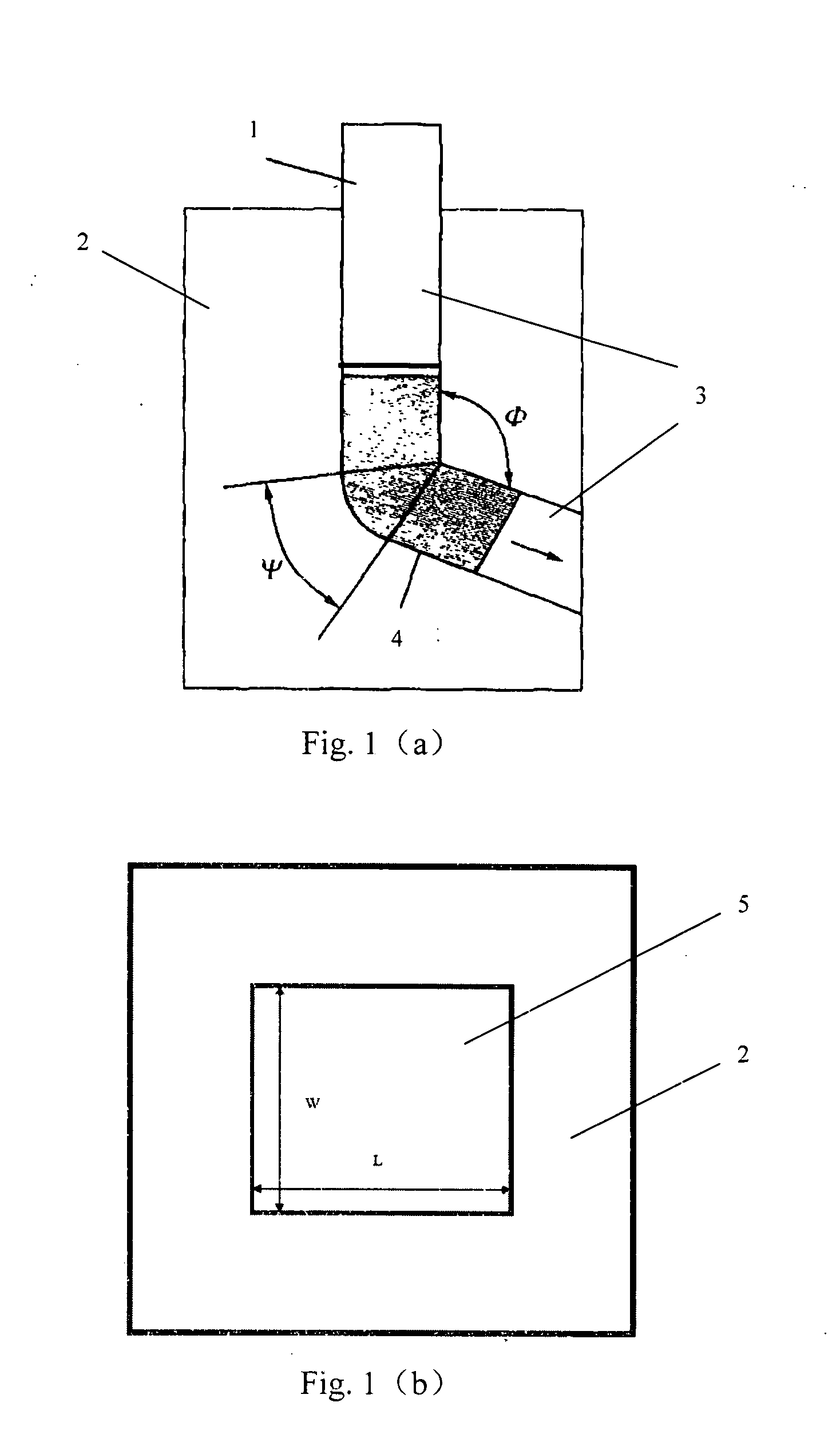

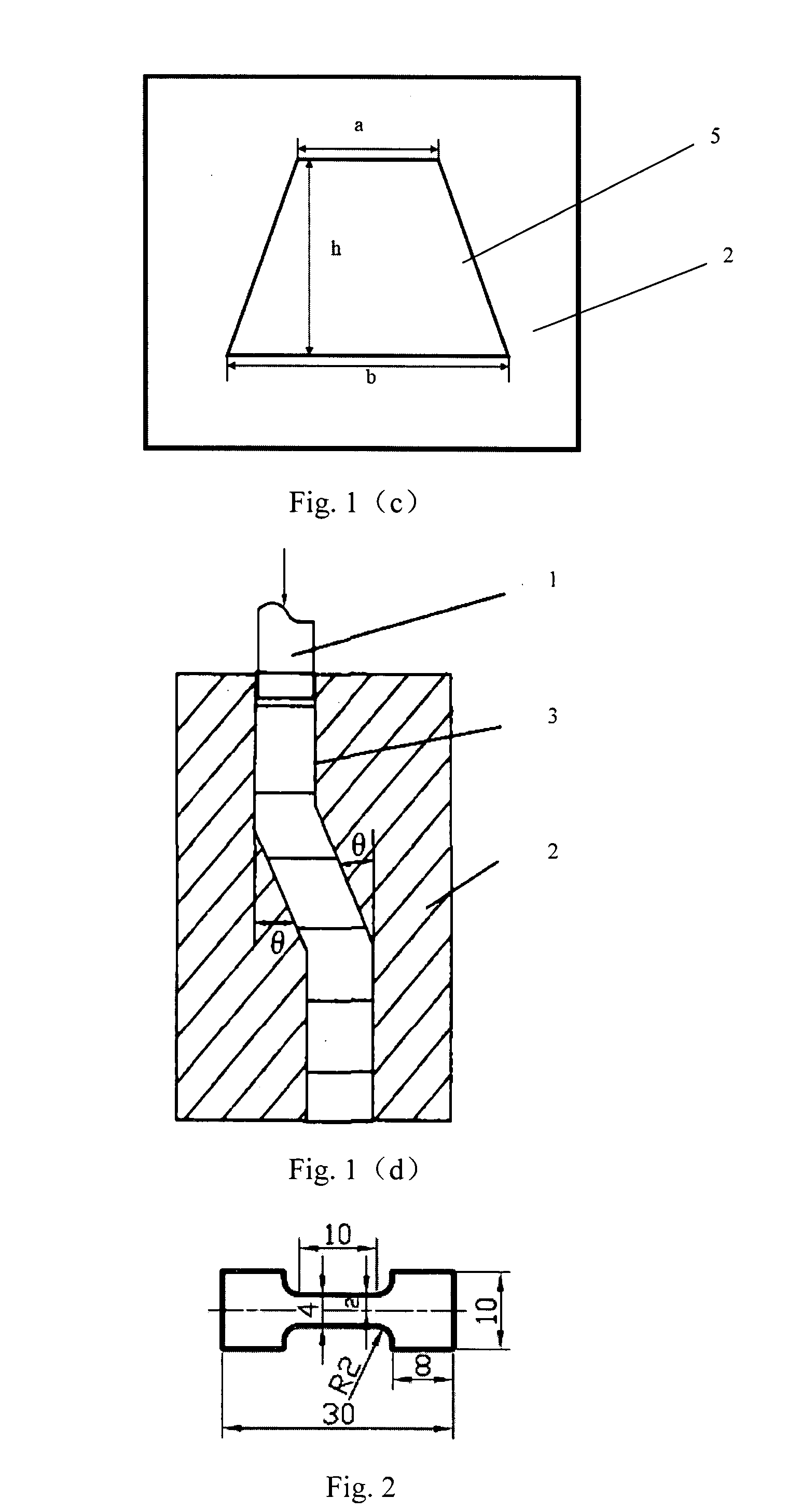

ActiveUS20080276681A1Low costImprove reliabilityExtrusion control devicesMetal layered productsBond interfaceShearing deformation

The invention relates to a new preparation technique of composites, in details, i.e. a method of producing laminated composite materials of different alloys. In the preparation method, the bi-layer or multi-layer composites are prepared by means of the equal channel angular extrusion / pressure (ECAE / ECAP). Firstly, the appropriate alloys pairs or groups are selected, and the rational arrangements are carried out after pre-treating surfaces; then, the clad process is performed by extrusion and shear deformation in ECAE die; finally, the composite material is produced after one single pass or multiple passes clad extrusion. The annealing treatment can be performed subsequently to enhance the interfacial bonding strength by diffusion after the clad extrusion, and the heat treatment parameters consist of annealing temperature and holding time, which are chosen carefully to meet the demands of the refining microstructures and good properties for both the interfaces and individual component metals. Consequently, the layer-metal composite is produced with the firmly bonding interface, good microstructures and excellent properties. In the invention, the selection and assembling manners of the materials are very free, such as composites with bi-layer or interval multi-layer manners, and the method is suitable for most of the metal materials. The invention is a new method of fabricating composites and the preparation cost is low enough to meet the demand of large-scale industrial production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Road grader/spreader

InactiveUS7686537B2Depth accurateAccurate materialsAgricultural machinesSoil-shifting machines/dredgersGround contactSlide plate

Owner:MULLETT MYRON L

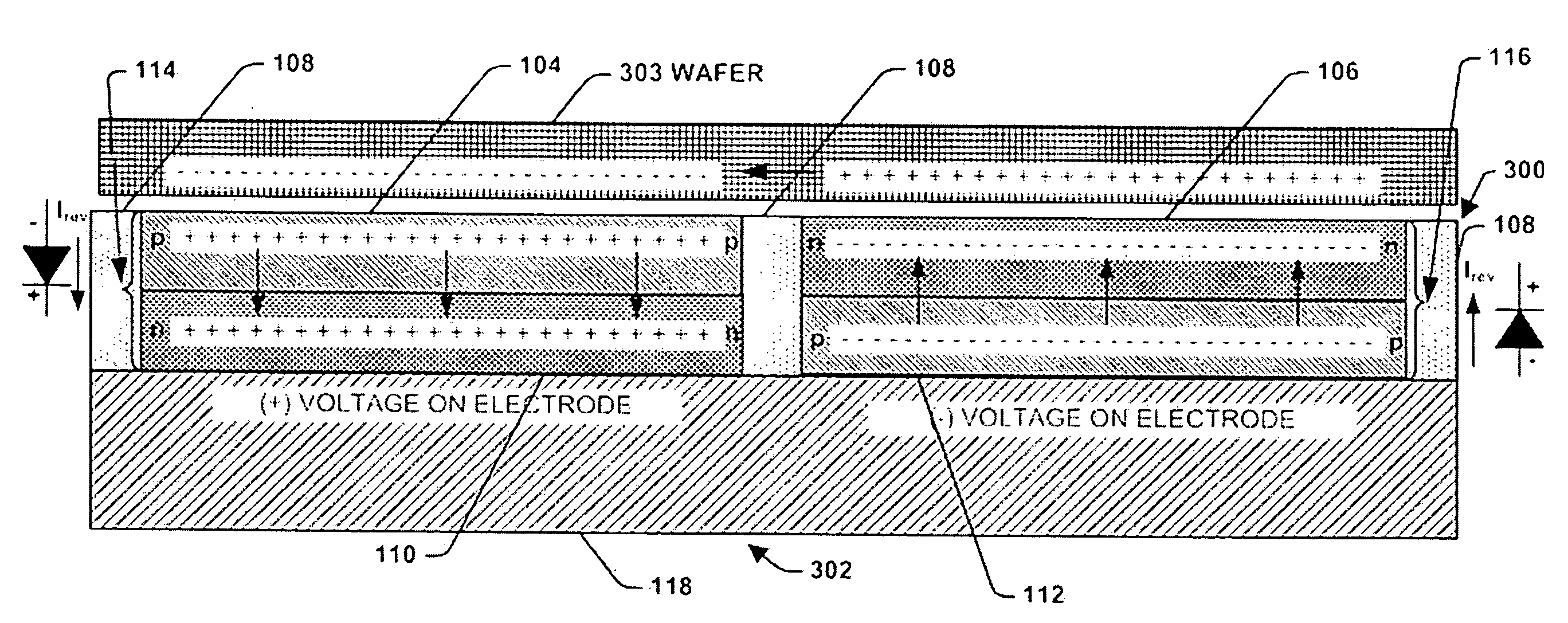

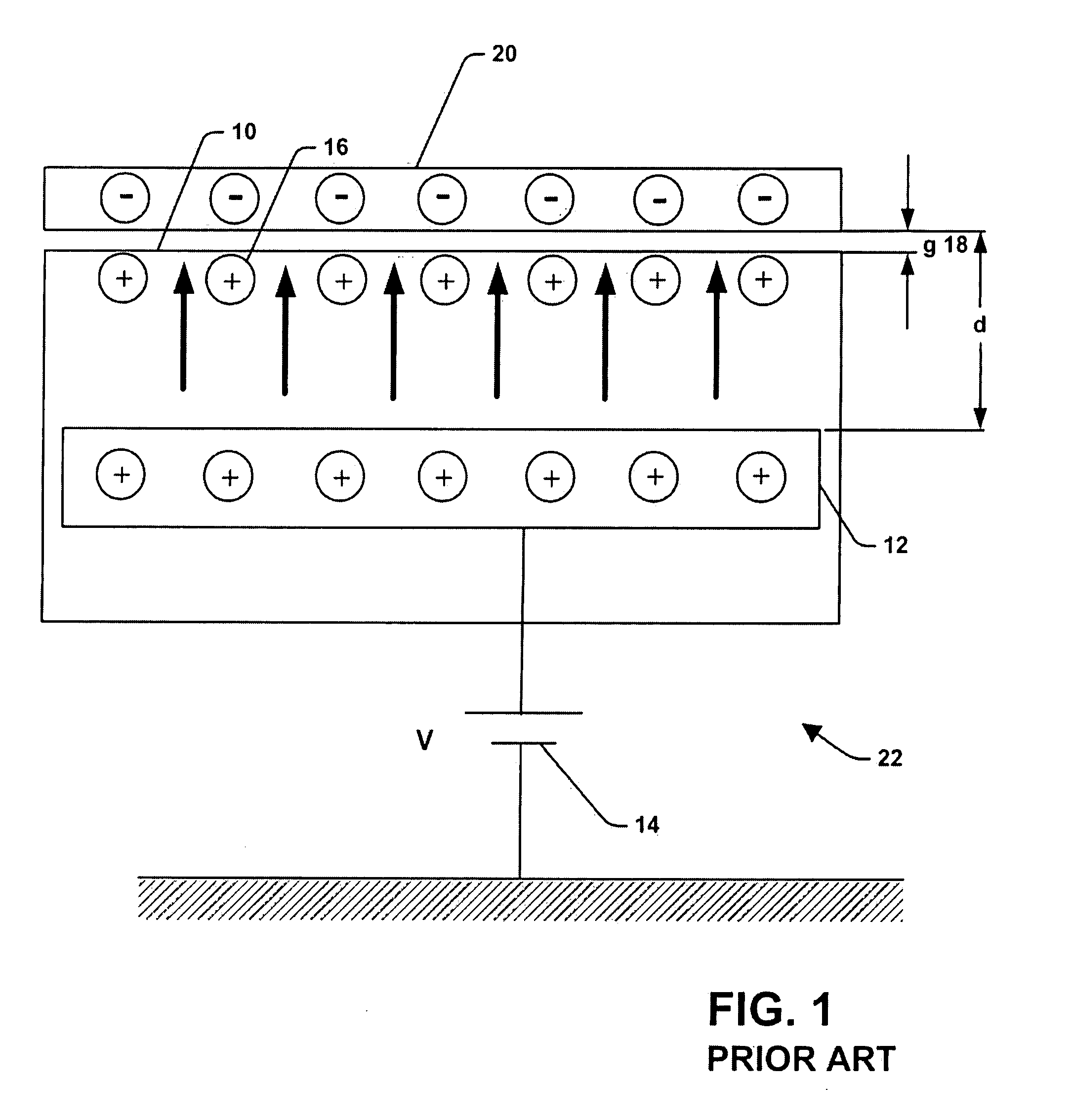

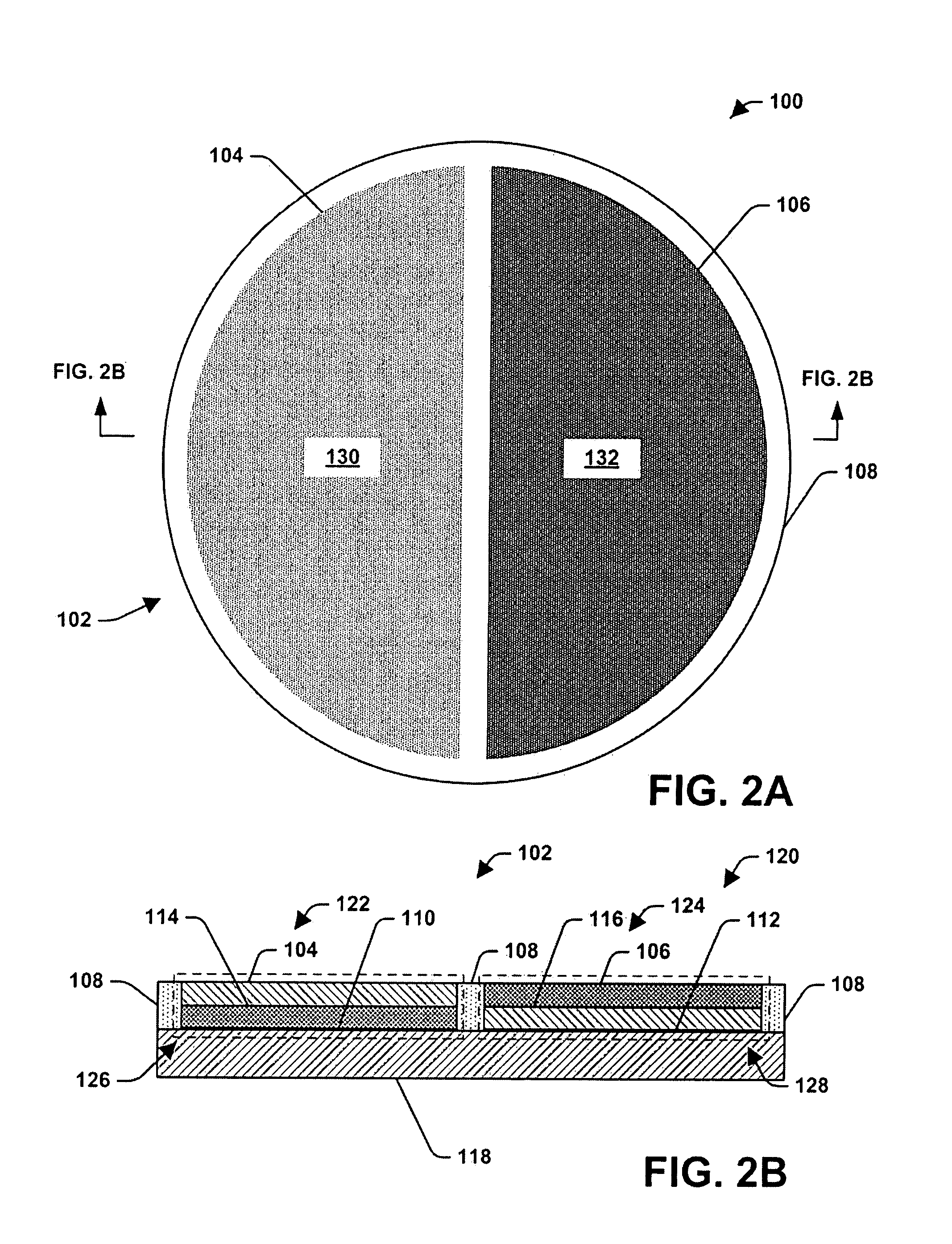

Low-cost electrostatic clamp with fast de-clamp time

InactiveUS20080100984A1Maintain good propertiesExcellent characteristicsSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A method for manufacturing a semiconductor wafer electrostatic clamp, comprising providing a mounting plate, forming an insulative layer on an insulating portion of the mounting plate, forming a first electrode on a first portion of the mounting plate, forming a second electrode on a second portion of the mounting plate, forming a first segment having a first conductivity over the first electrode, forming a first region having a second conductivity over the first segment that creates an n-p type composite, forming a second segment having a third conductivity formed over the over the second electrode, forming a second region having a fourth conductivity formed over the second region that creates an p-n type composite.

Owner:AXCELIS TECHNOLOGIES

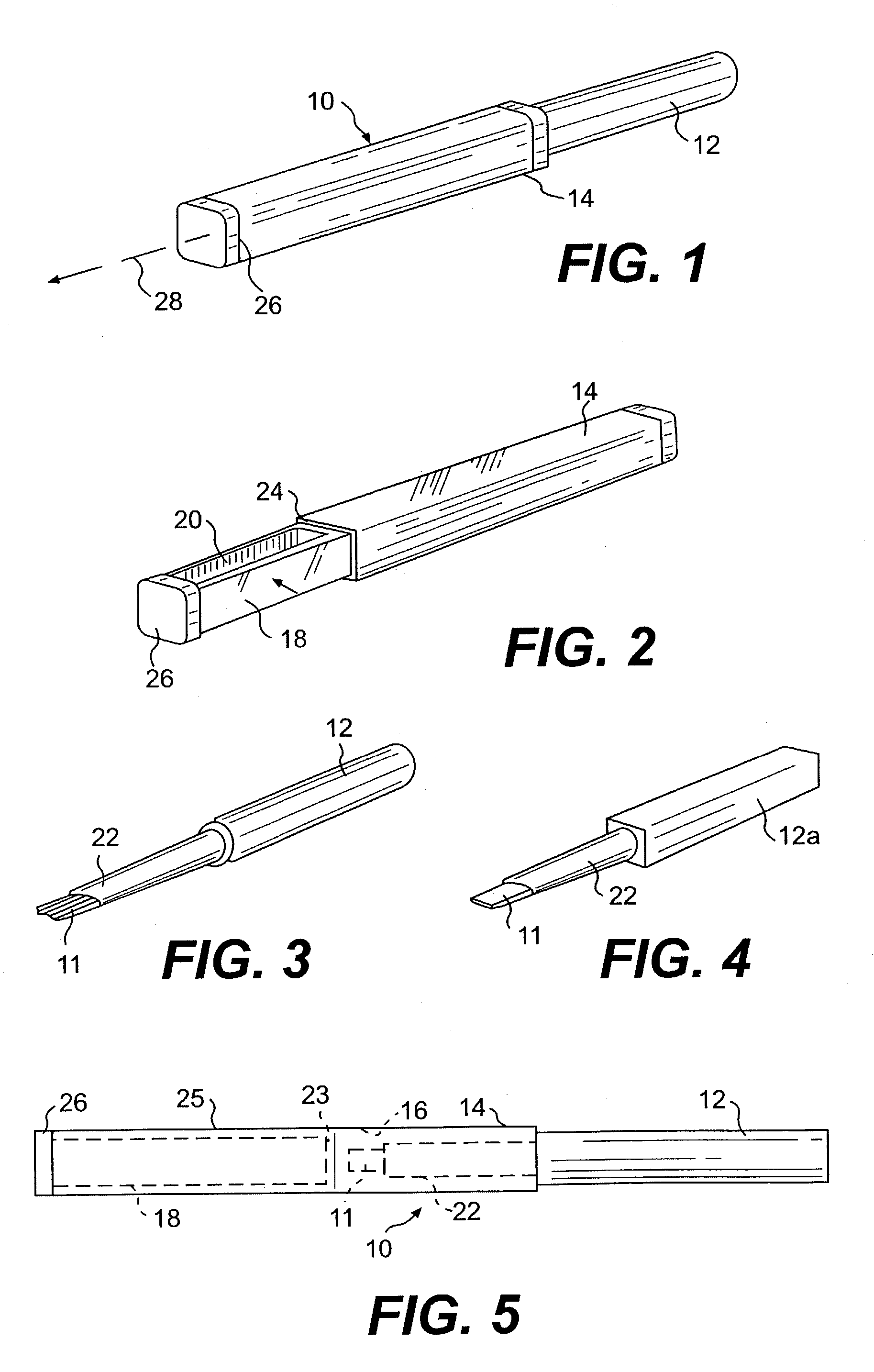

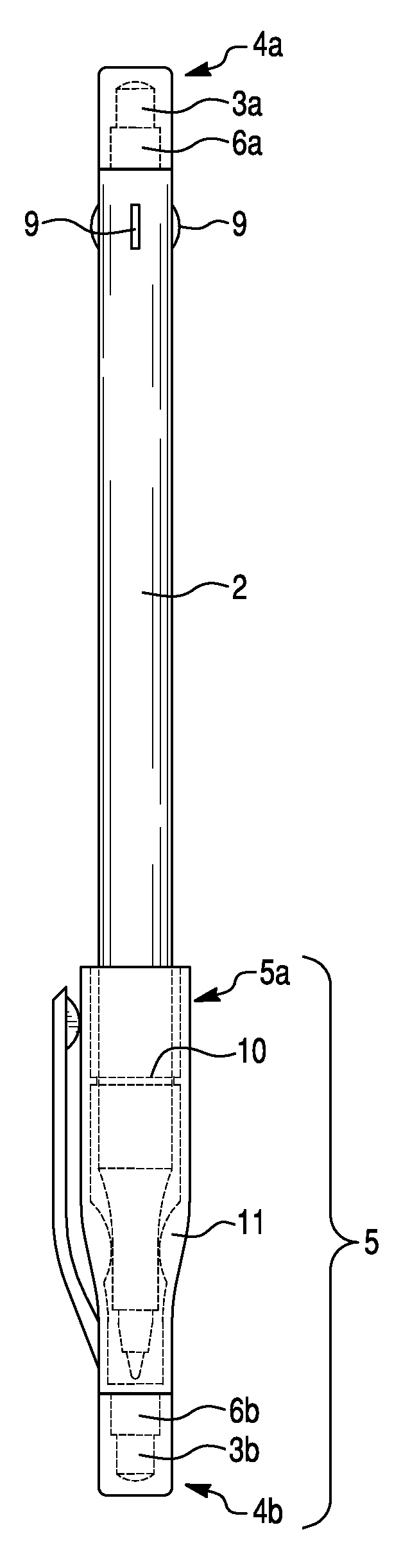

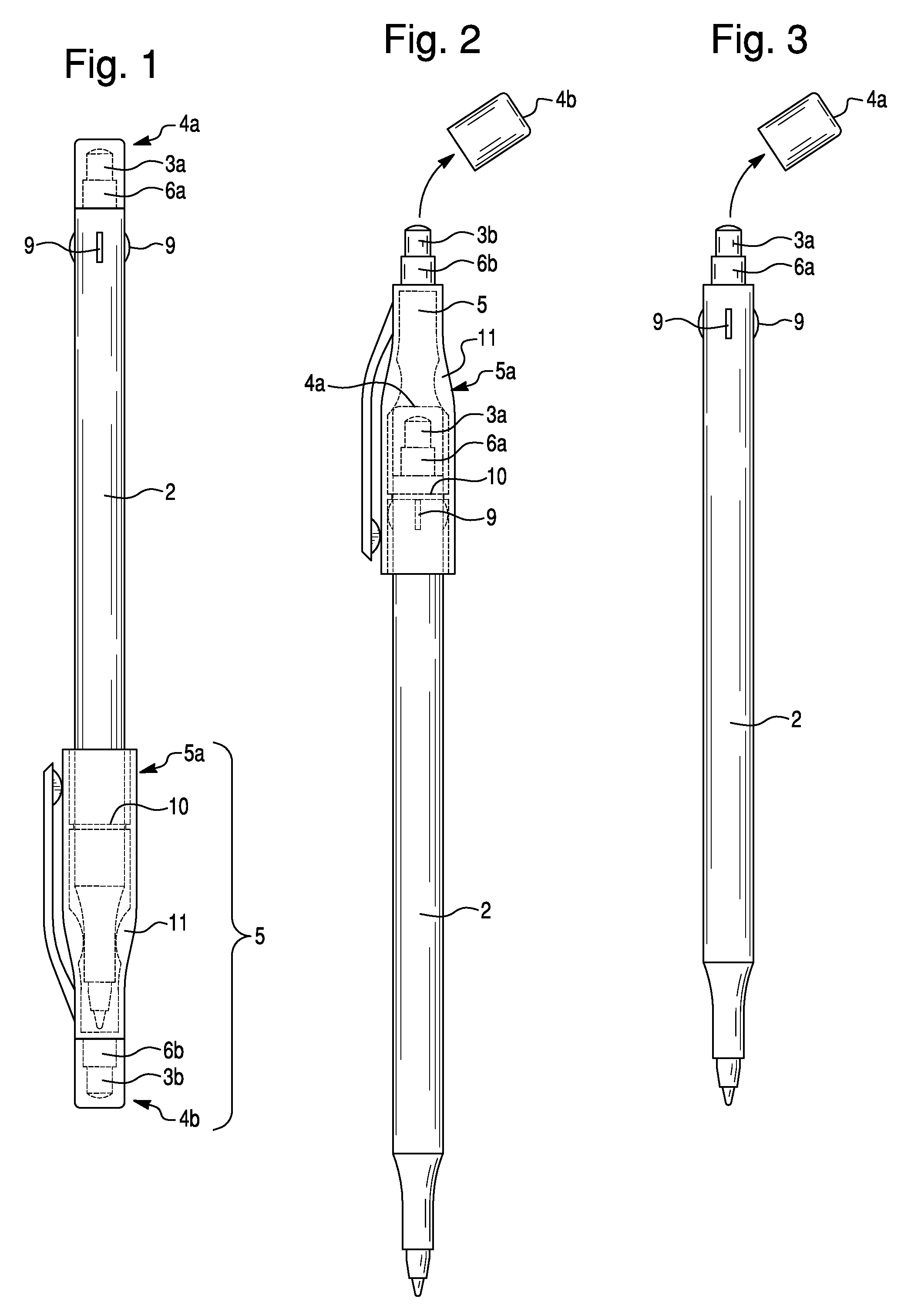

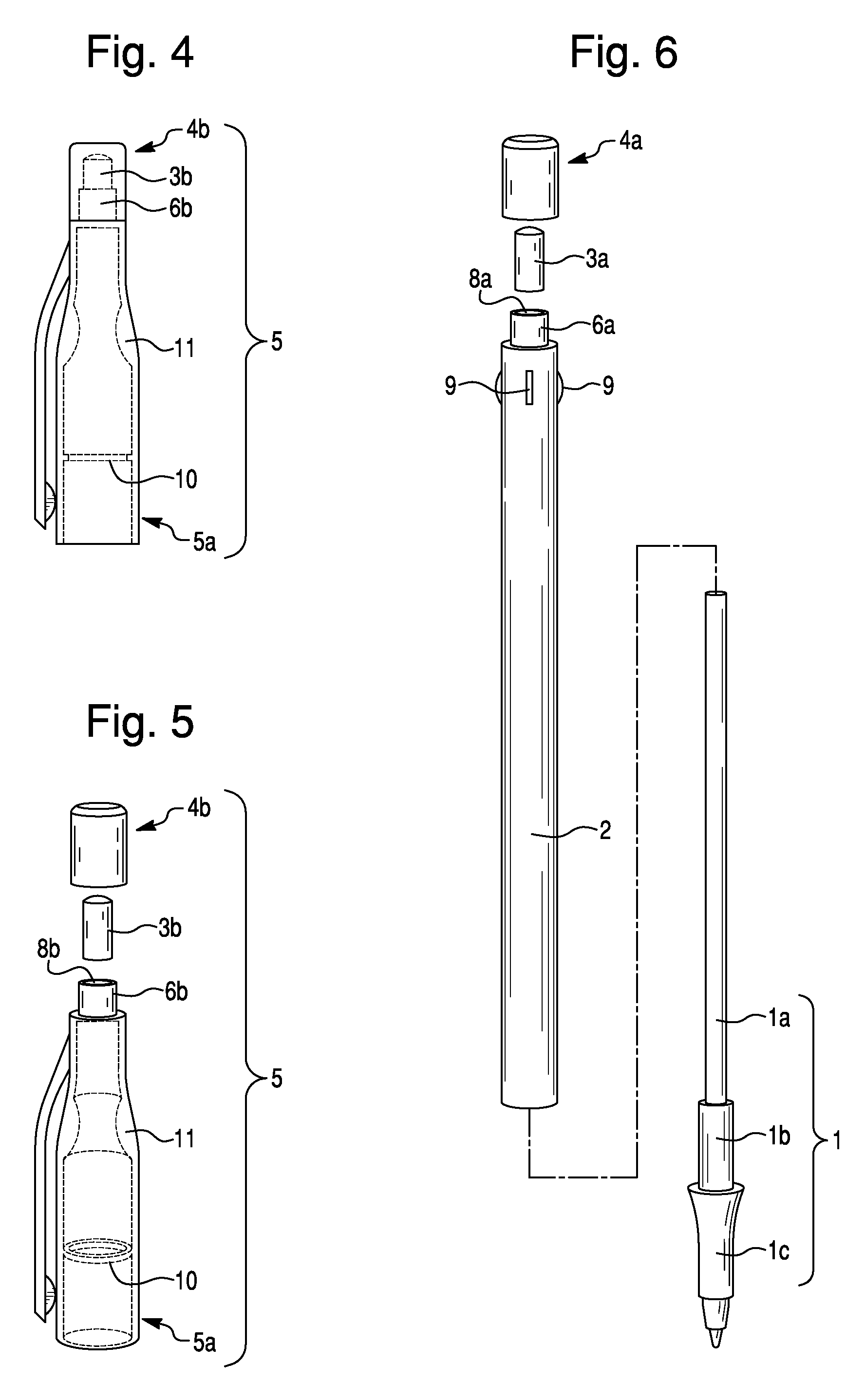

Correction Stick Equipped Pen and Pen Cap

InactiveUS20100028068A1Improve convenienceLow costErasing devicesLiquid surface applicatorsDual purposeEngineering

A correction stick equipped pen and pen cap relating to an ink pen with a detachable pen cap, wherein the pen has a dual purpose of writing with ink on one end and whiting out mistakes on the other end with a correction stick; and the pen cap also has a dual purpose of capping the pen and whiting out mistakes with a correction stick as well. It includes a main tubular body having a first end portion comprising a writing end and a second end portion comprising a correcting end wherein the second end portion is formed with a neck with an inner circular flange and a circular recess above said circular flange wherein a correction stick is snugly-fitted into said circular recess; and a correction stick equipped pen cap, wherein a correction stick is snugly seated at a circular recess at the tip of the said pen cap.

Owner:RAZALAN JULIUS M

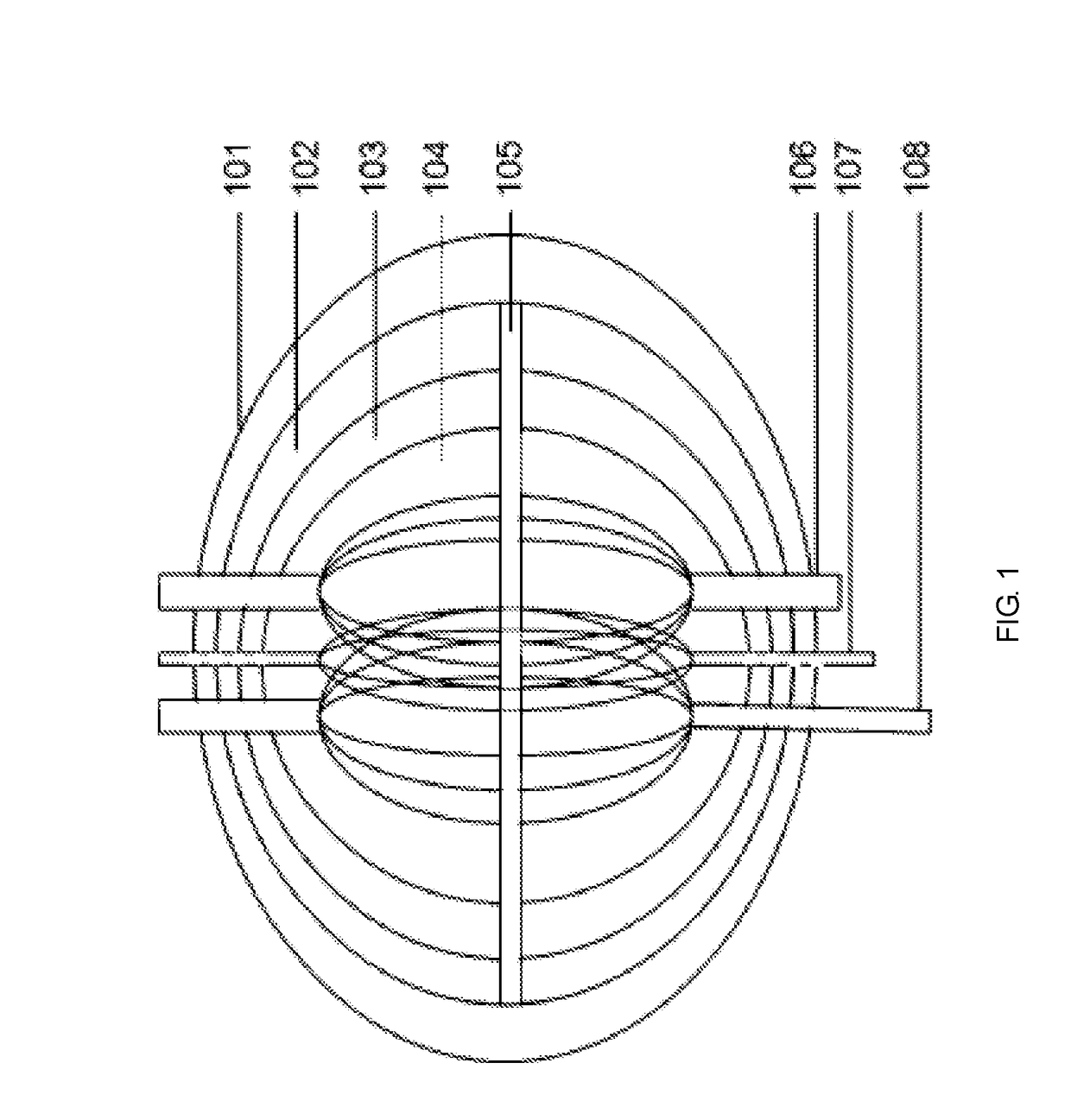

Raceway Ring for Radial Ball Bearing and Manufacturing Method Thereof, and Manufacturing Method of High Accurate Ring and Manufacturing Apparatus Thereof

InactiveUS20080089631A1Improve accuracyReduce manufacturing costMetal-working apparatusBall bearingsBall bearingEngineering

A manufacturing method of a raceway ring for a radial ball bearing, the radial ball bearing has the raceway ring has at least one of an outer ring formed with an outer ring raceway, of which sectional shape is arcuate, and which is formed entire of circumference on an axially intermediate portion of an inner circumferential face as a raceway surface; and an inner ring formed with an inner ring raceway, of which sectional shape is arcuate, and which is formed entire of circumference on an axially intermediate portion of an outer circumferential face as the raceway surface and plurality of balls rollably provided between the inner ring raceway and the outer ring raceway. The manufacturing method of the raceway ring has a high accurate material working process of preparing a high accurate material of which volume is substantially the same as that of the raceway ring of the radial ball bearing which is a finished product by cold working and a raceway ring working process of plastically deforming the high accurate material by cold working and forming the raceway surface on the axially intermediate portion of either outer or inner circumferential face wherein working for removing material is not conducted before a heat treatment.

Owner:NSK LTD

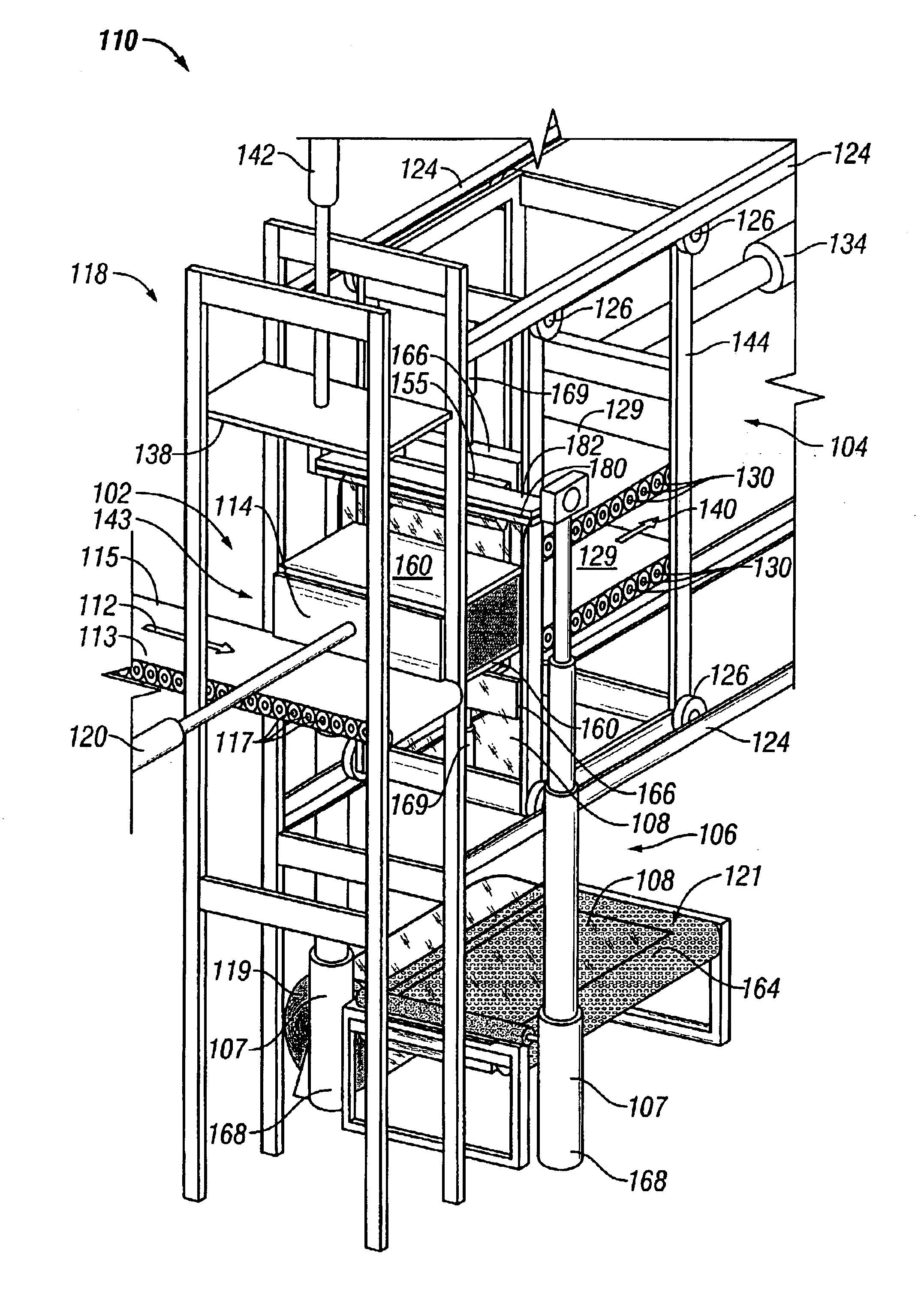

Log bander apparatus and method

InactiveUS6865862B2Increase productionPrecise positioningPaper article packagingWrapper folding/bending apparatusEngineeringTurret

A log packaging apparatus for packaging logs using a turret or a shuttle. The turret or shuttle can be used in conjunction with a wrap conveyor. The turret system can include a rotatable turret with at least one clamp movable into different positions in the apparatus, a log station at which logs are received, and a log ejector for ejecting logs from the log station into clamps of the turret. Logs can be ejected from the log station, through wrap material, and into the turret clamps. In other embodiments, a wrap conveyor inserts wrap material between a shuttle and a log station at which logs are received. Logs in such embodiments can pass from the log station to the shuttle through the wrap material.

Owner:C G BRETTING MFG

Grape planting method

InactiveCN105981553ANo reduction in productionKeep the tasteCultivating equipmentsHorticultureShootDisease damage

The invention provides a grape planting method. The grape planting method comprises the steps of cutting shoot selecting, seedling land preparing, transplanting and managing. According to the grape planting method, pit manure, organic fertilizer and inorganic fertilizer are combined together to be used, the organic fertilizer is taken as a main fertilizer source, and nutrient substances needed in the grape growing process are guaranteed by supplementing the inorganic fertilizer; through fine management on grape seedlings, pest and disease damage is prevented from occurring, and the using variety and number of pesticides are decreased; cutting-shoot asexual reproduction is adopted, material obtaining is precise, management is scientific and reasonable, and the taste and plumpness of grapes are effectively kept while the grape yield is not decreased.

Owner:YUNNAN JINYIYUAN AGRI TECH

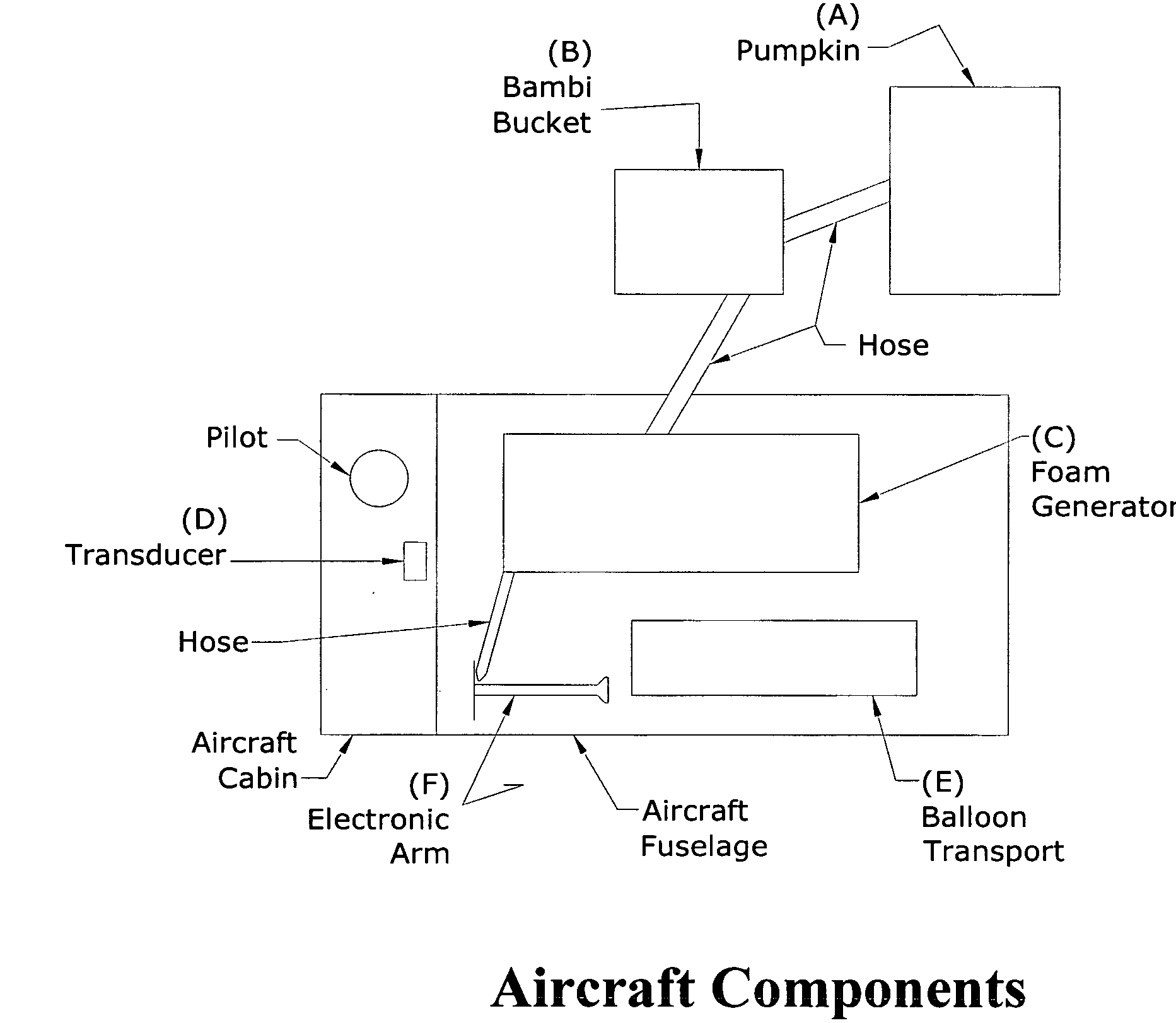

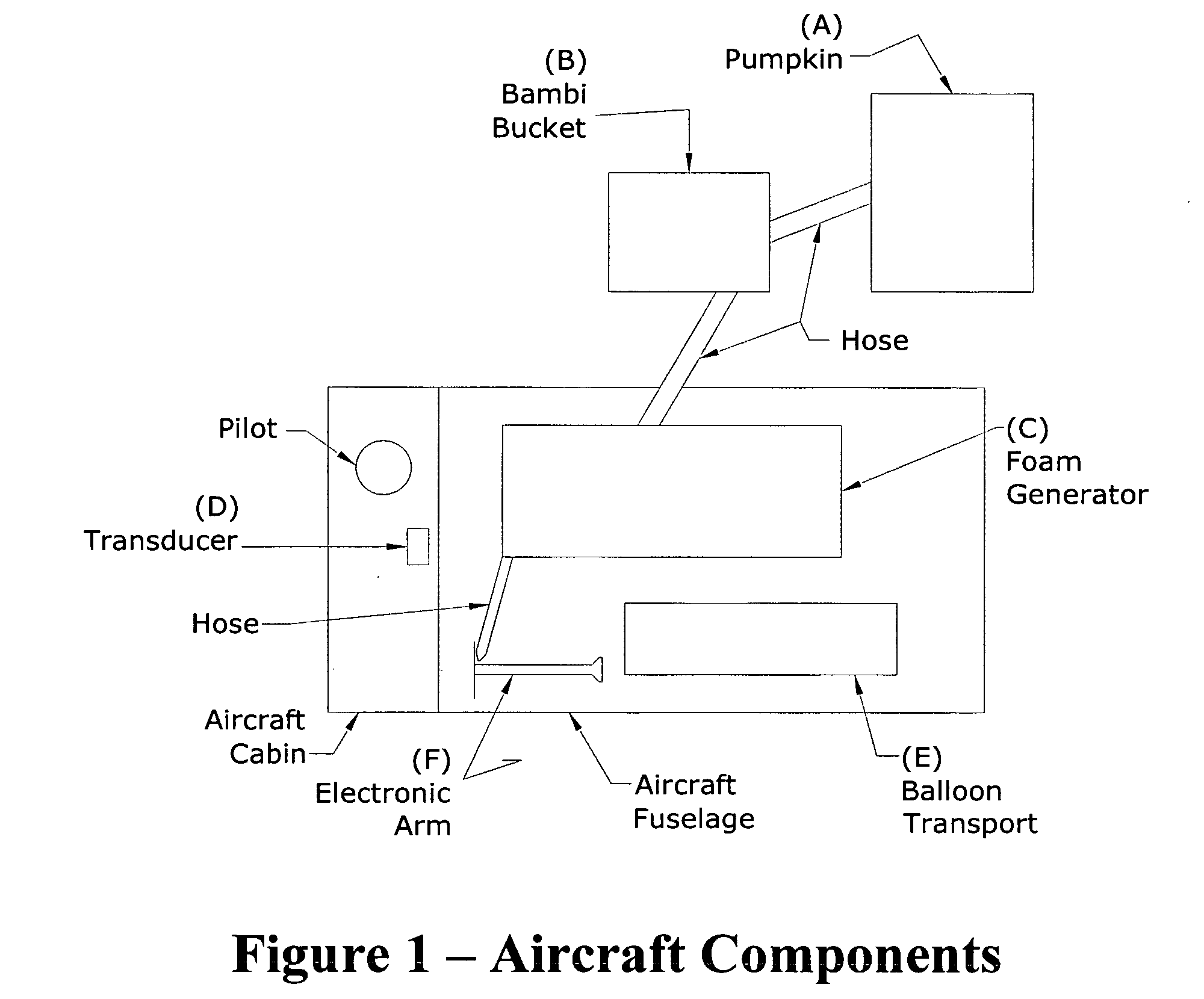

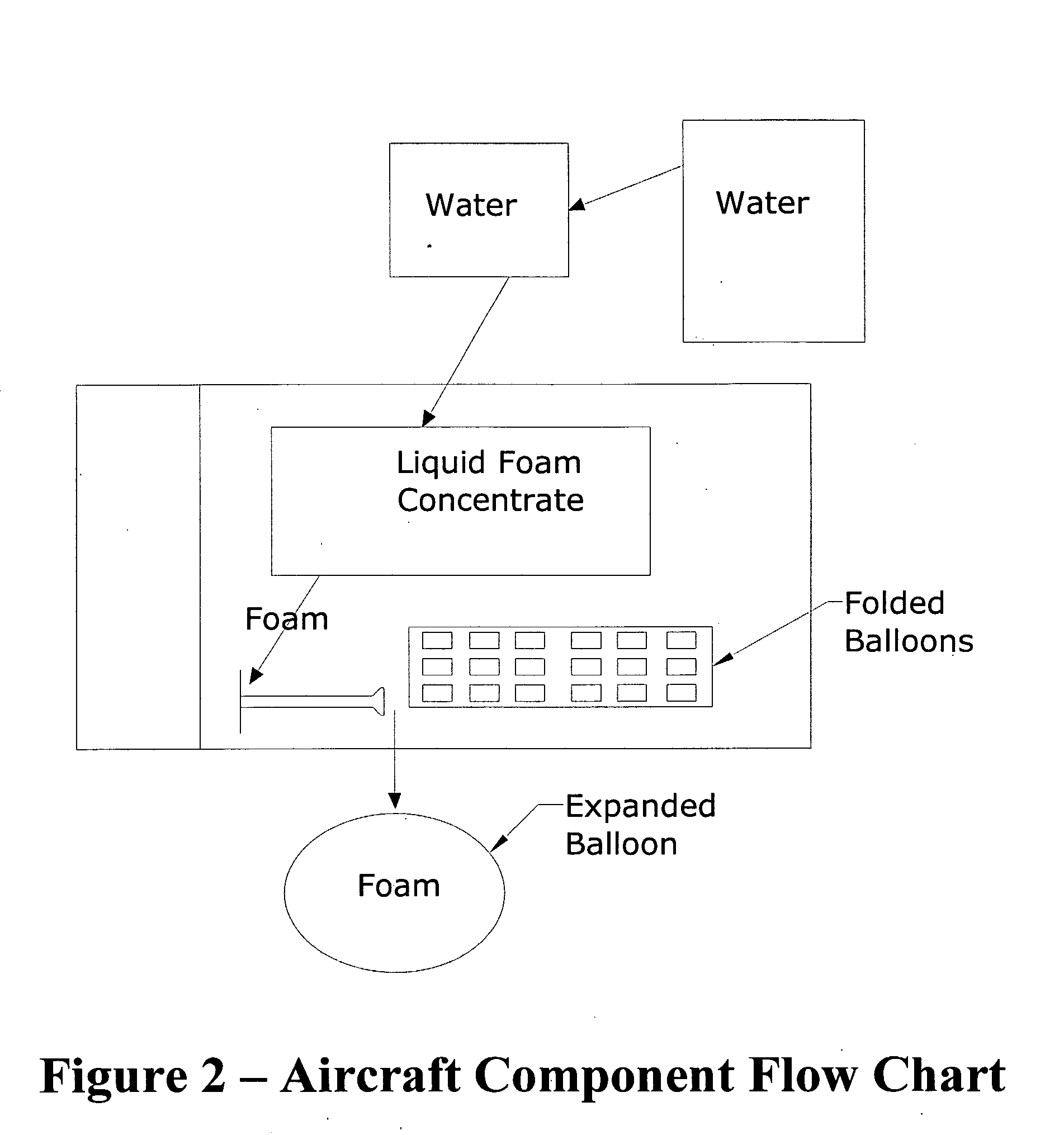

New technique for fire fighting-large scale open fires

InactiveUS20080087444A1Rapidly and accurately disburseImprove abilitiesFire rescueCompressed air foam systemEnvironment of Albania

An invention is presented that will usher in a new and markedly improved era of open, large scale fire fighting. ‘The Invention’ places a CAFS (compressed air foam system) into the fuselage of a helicopter or fixed-wing plane. The CAFS then generates high volumes of effective fire-extinguishing and preventive micellar-foam solution at the attack point of the fire itself rather than refilling at a remote base. It accesses ater contained in a helicopter's Bambi Bucket and refills from a fixed wing plane or other water containing reservoir. The foam solution is then packaged into balloons, made of fire retardant and bio-friendly material, that are accurately and rapidly dropped upon the target fire.‘The Invention” therefore utilizes and adapts currently available equipment, personnel, and fire-fighting technology to allow a simple, rapid, effective and drastically cost-saving means of extinguishing open fires. All communities and businesses will be able to protect their communities and environment and the lives of their animals and citizens.

Owner:HELD JERRY M

Bending apparatus and bending machine

ActiveUS8555694B2Accurate materialsPreventing any damage to materialManufacturing dynamo-electric machinesNon destructiveCentre of rotation

A bending apparatus for performing accurate non-destructive bending of material includes first and second jigs that are rotatable about a rotary shaft and that bend the material attached to the jigs as they rotate relative to each other. The first jig includes a bending section that is arranged offset from a rotary center to a rotating side of the material and that has a partially cylindrical surface with a radius of curvature corresponding to the radius of curvature of an inner peripheral surface of the material. Each of the first and second jigs has a suppressing section for suppressing displacement of the material, and a bending center of the material is arranged such that the material is not displaced relative to the first and second jigs when the material is bent.

Owner:AISIN AW CO LTD

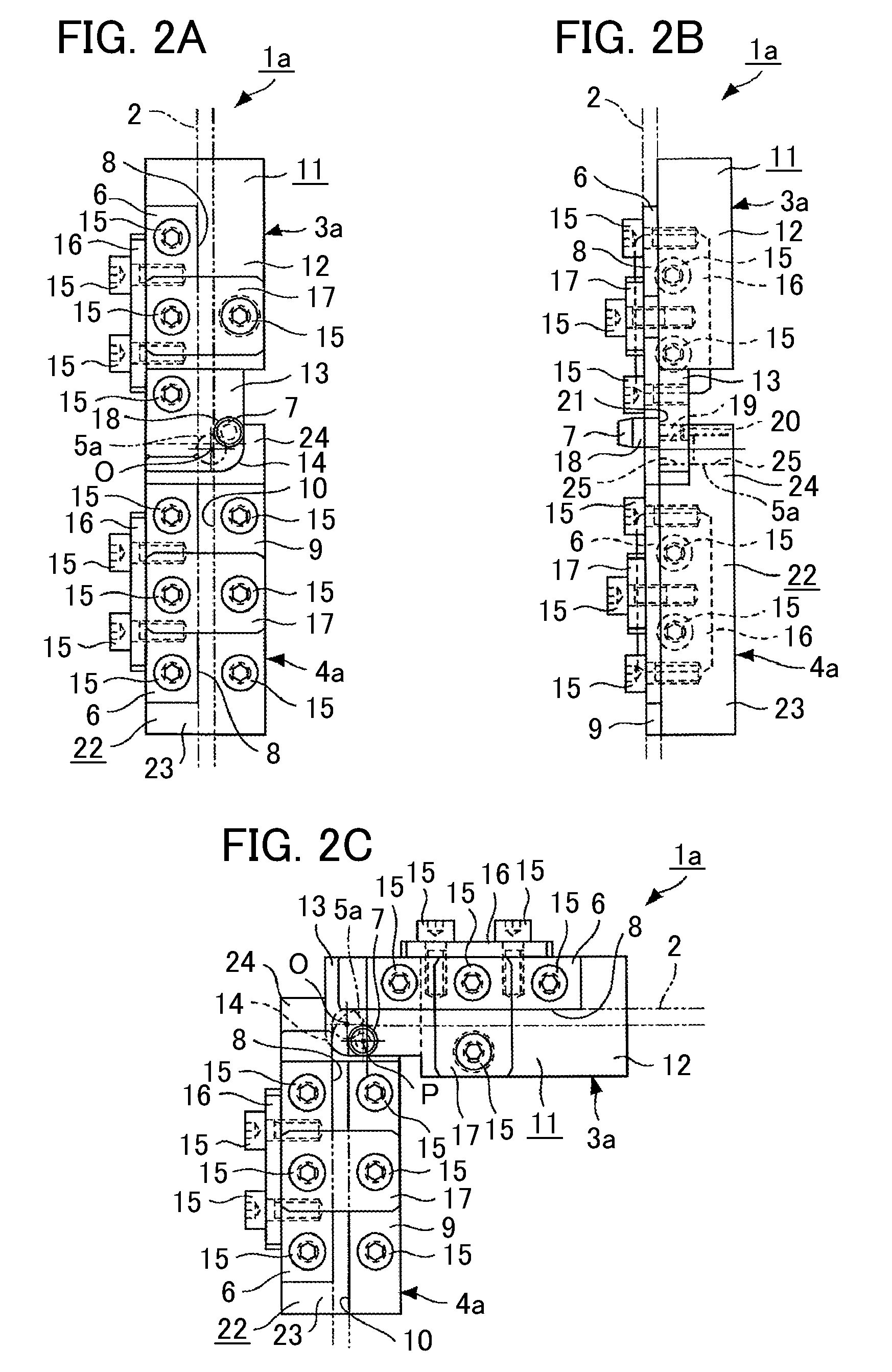

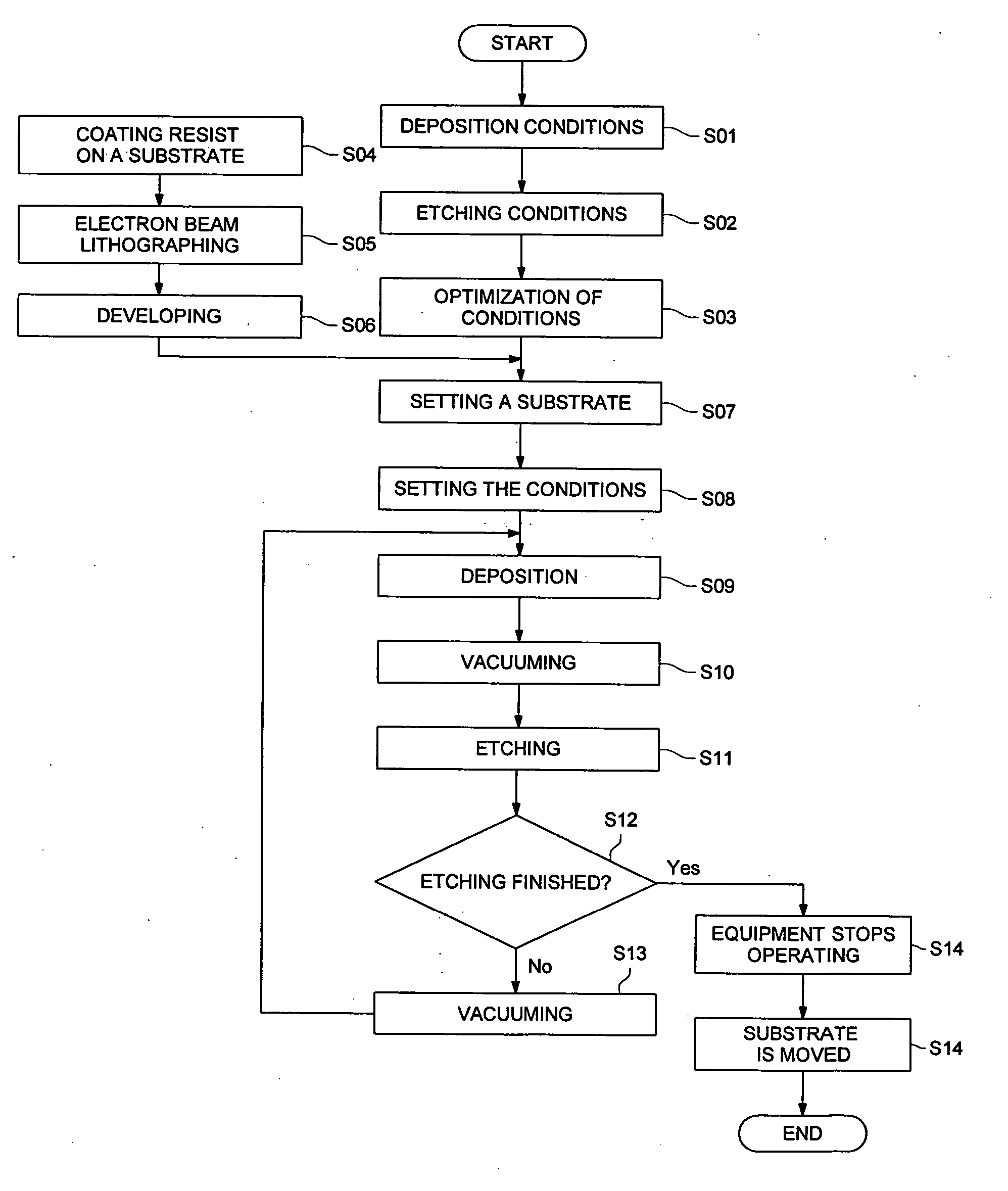

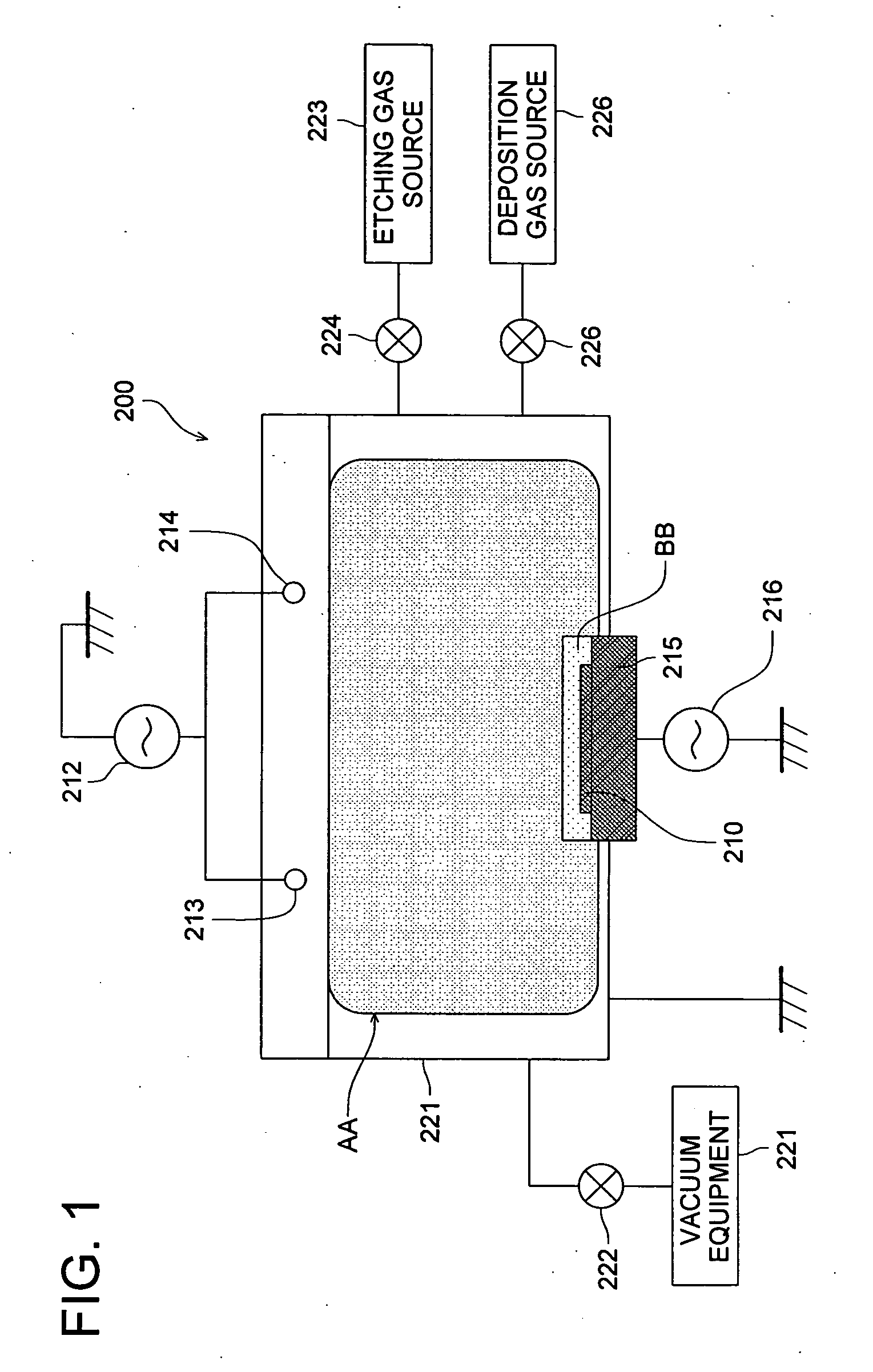

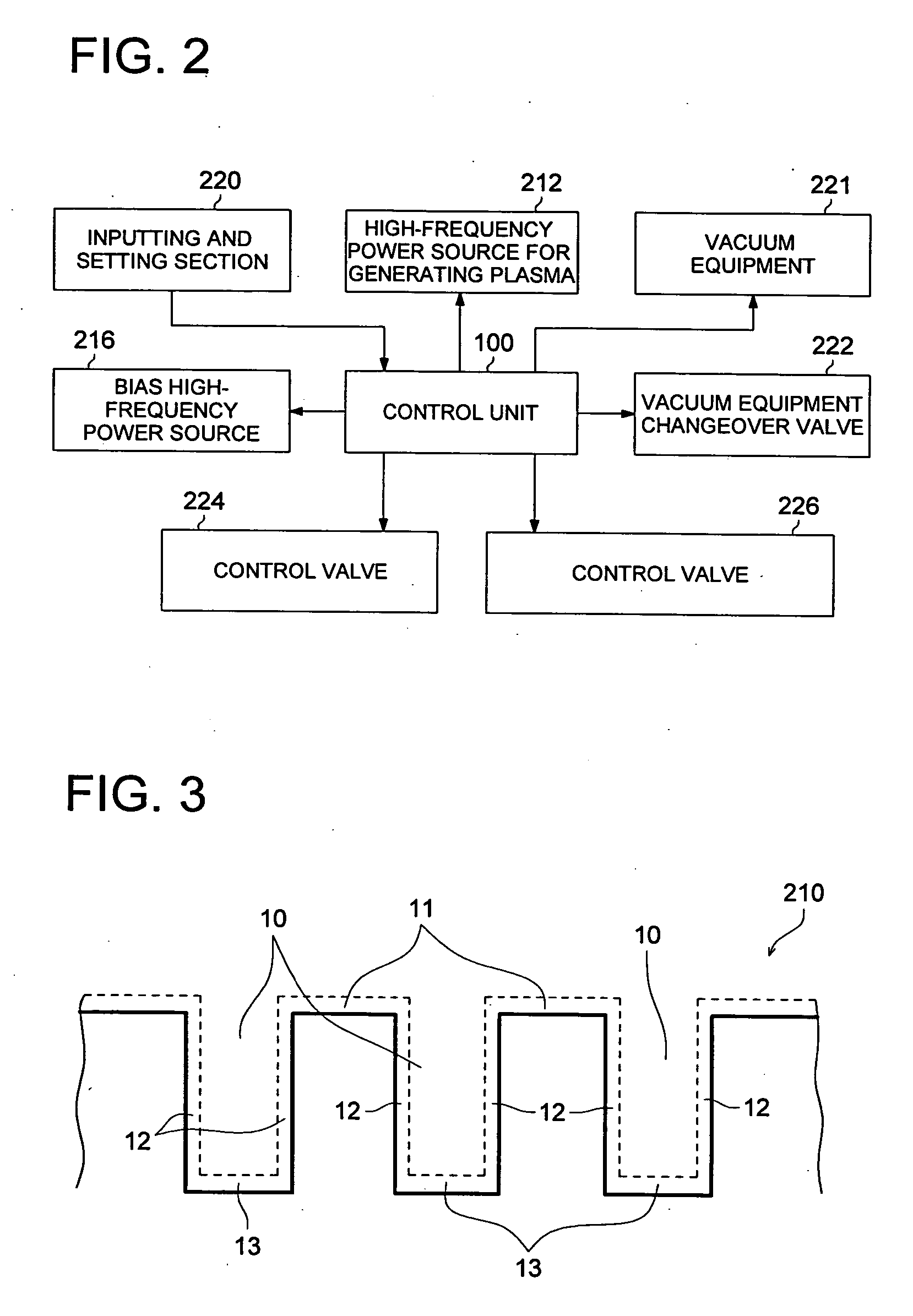

Plasma etching method

InactiveUS20060037937A1Accurately substrate materialStable executionVacuum gauge using ionisation effectsDecorative surface effectsProduct gasDeposition process

A plasma etching method for processing a substrate material, wherein a deposition process (S09) that uses a deposition gas as a process and an etching process (S11) that uses an etching gas as a process gas are alternately and repeatedly executed, thereby etching a substrate material, and a vacuuming process (S10, S13) is interposed between the two processes so that the process gas which has just finished being used is expelled out when the process gases are switched. Thus, the etching gas and the deposition gas do not mix during each process, thereby accurately creating a high-aspect-ratio recessed and protruding pattern on the surface of a substrate material.

Owner:KONICA MINOLTA INC

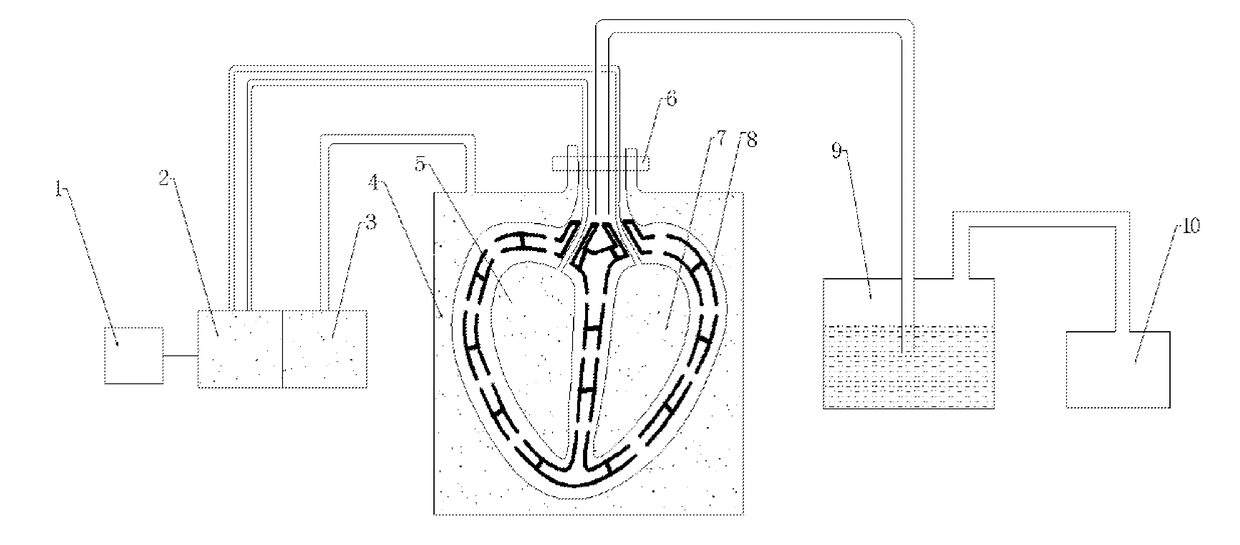

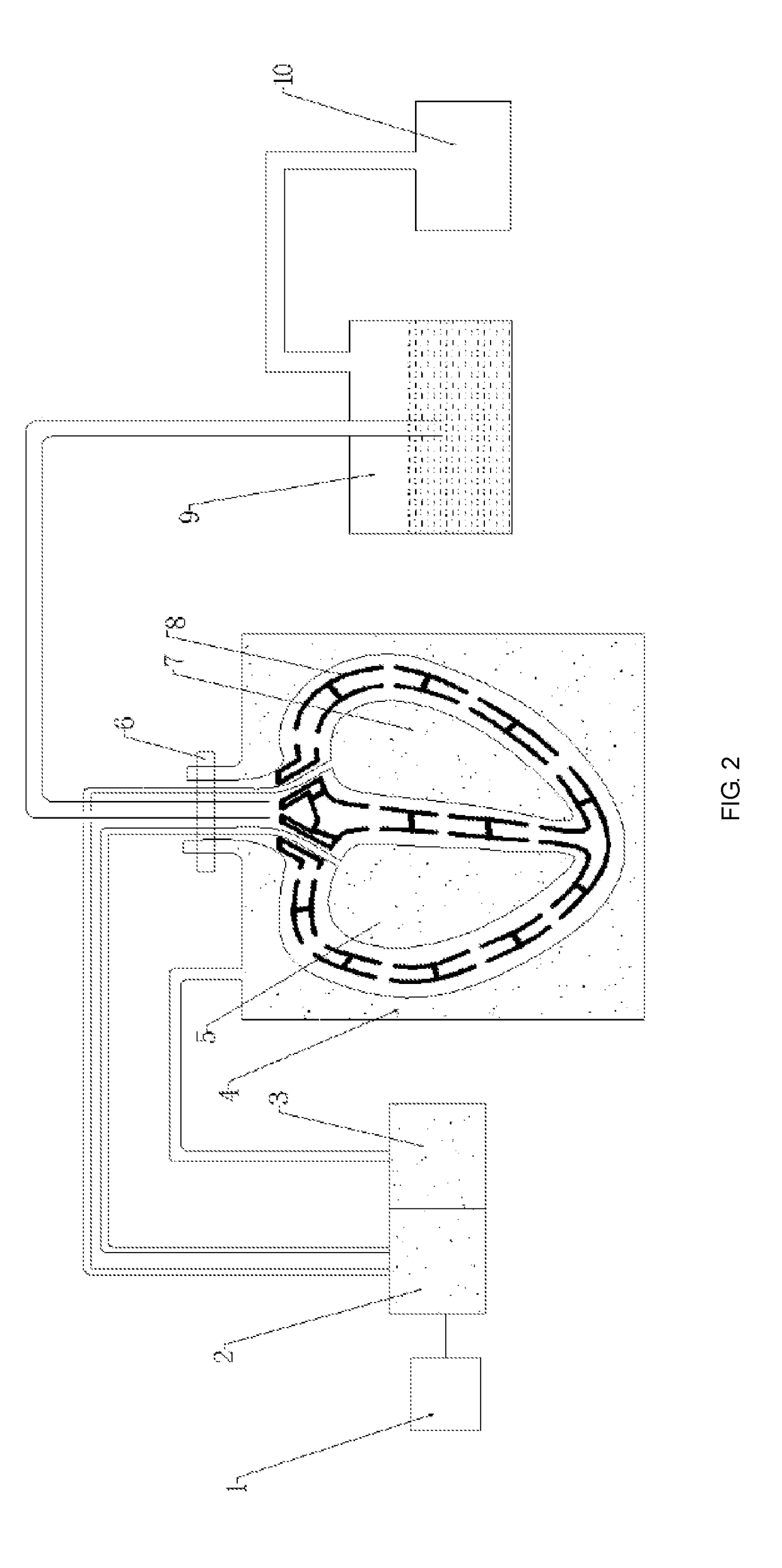

Full-function artificial organ fitting body as well as preparation and culture methods thereof

ActiveUS20170360551A1Precise positioningHigh mechanical strengthBioreactor/fermenter combinationsBiological substance pretreatmentsVeinNervous system

A full-function artificial organ fitting body comprises a cortex layer and an organ body tissue area. The organ body tissue area comprises a growth area, a differentiation area, a docking area, a branch arterial system, a branch nervous system and a branch venous system. The branch arterial system, the branch nervous system and the branch venous system are distributed in the differentiation area and form a main body three-dimensional skeleton structure with the outer growth area and the middle docking area.

Owner:LIU CHANG

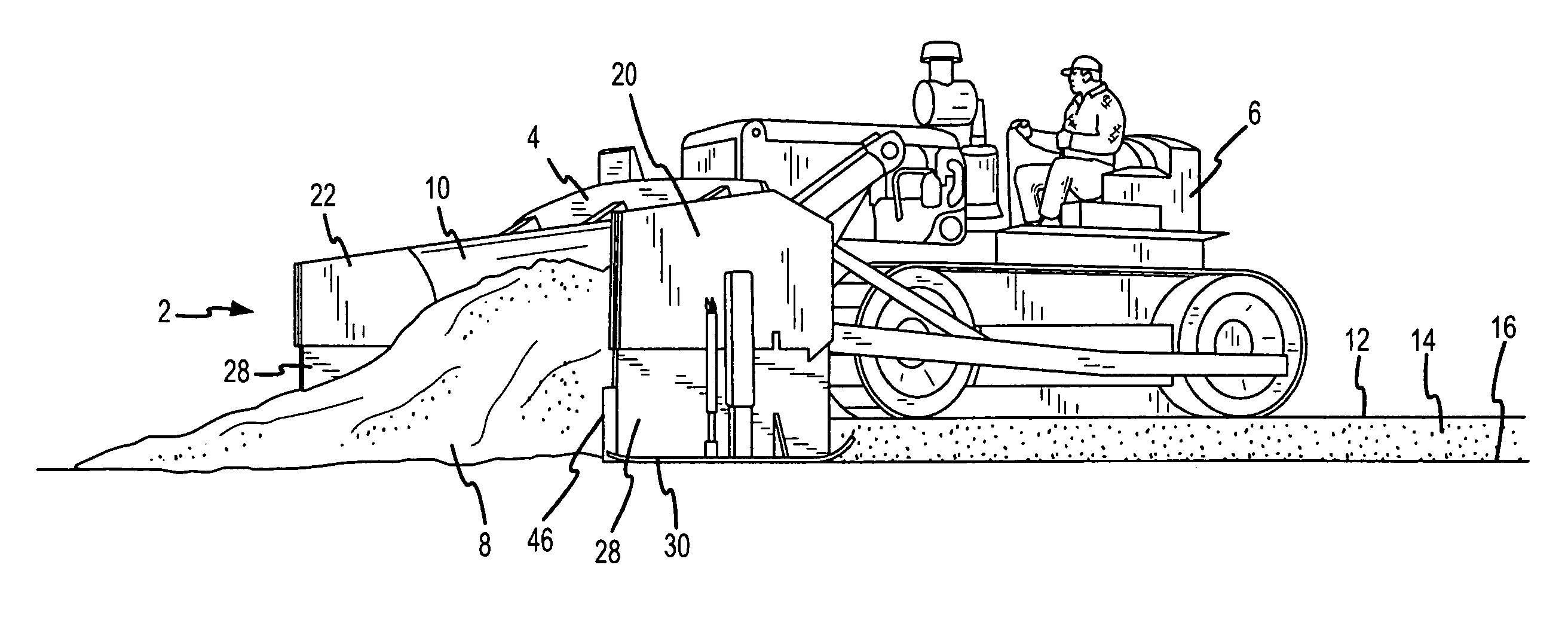

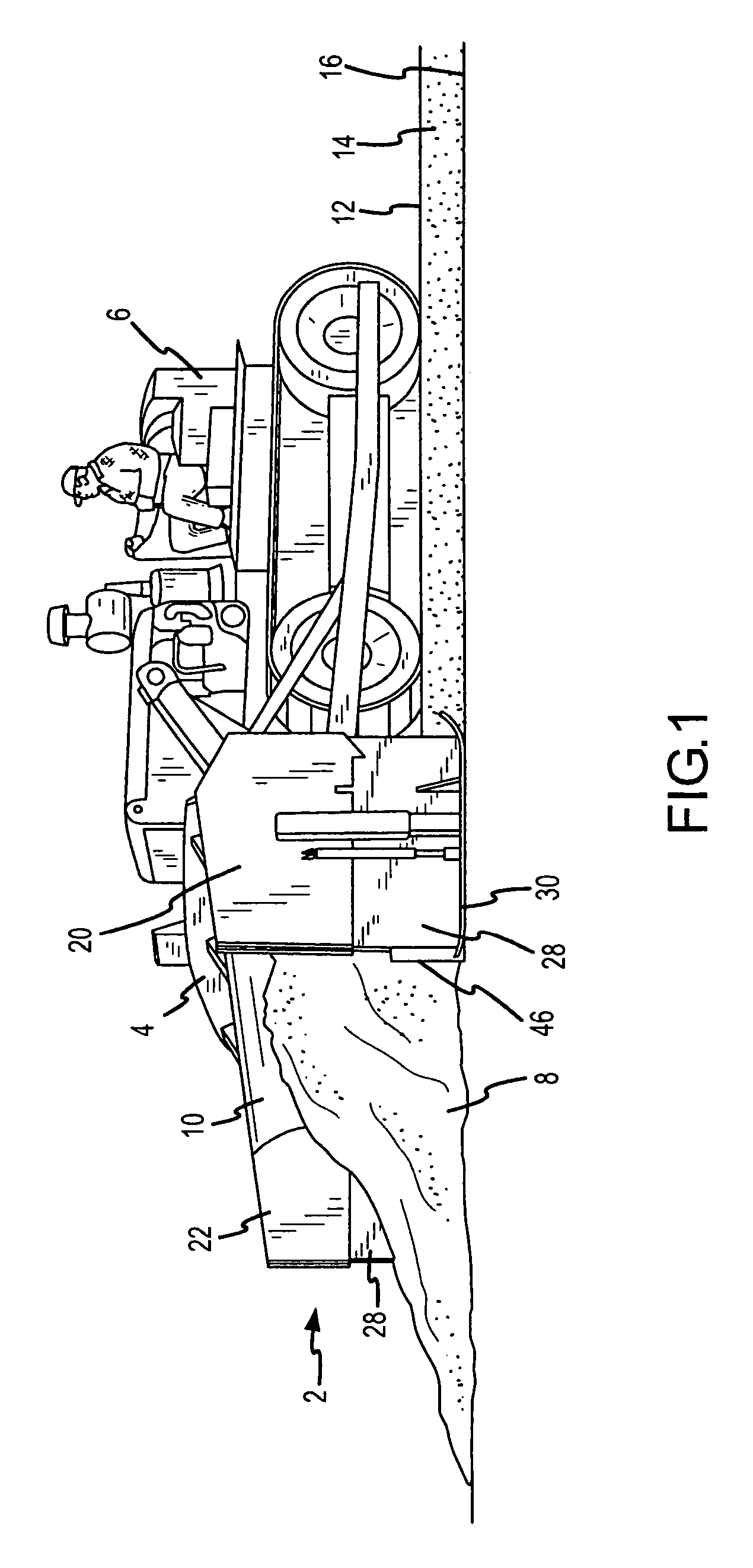

Road Grader/Spreader System and Method

InactiveUS20100326684A1Depth accurateAccurate materialsSoil-working equipmentsMechanical machines/dredgersGround contactEngineering

The present invention is a road grader attachment that attaches to a bulldozer. The attachment has an elongated blade with mutually parallel side members attached to the lateral ends of the blade where each of the side members comprise a pair of spaced apart walls that house a plate movable in an up and down direction within the side member. Each of the movable plates is attached at its lower edge to a ground contacting skid. A hydraulic piston interconnects each side member with its respective interior plate for moving the plate up and down within the side housing member in order to raise or lower the skid that is attached to the movable plate

Owner:MULLETT MYRON L

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com