Method for producing down-like fiber

A production method and down-imitation technology, which is applied in the fields of textile, environmental protection, non-woven decorative fabrics, and health care, can solve the problems of reducing warmth retention, clumping, and dampness of down, and achieve the effect of improving health and air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

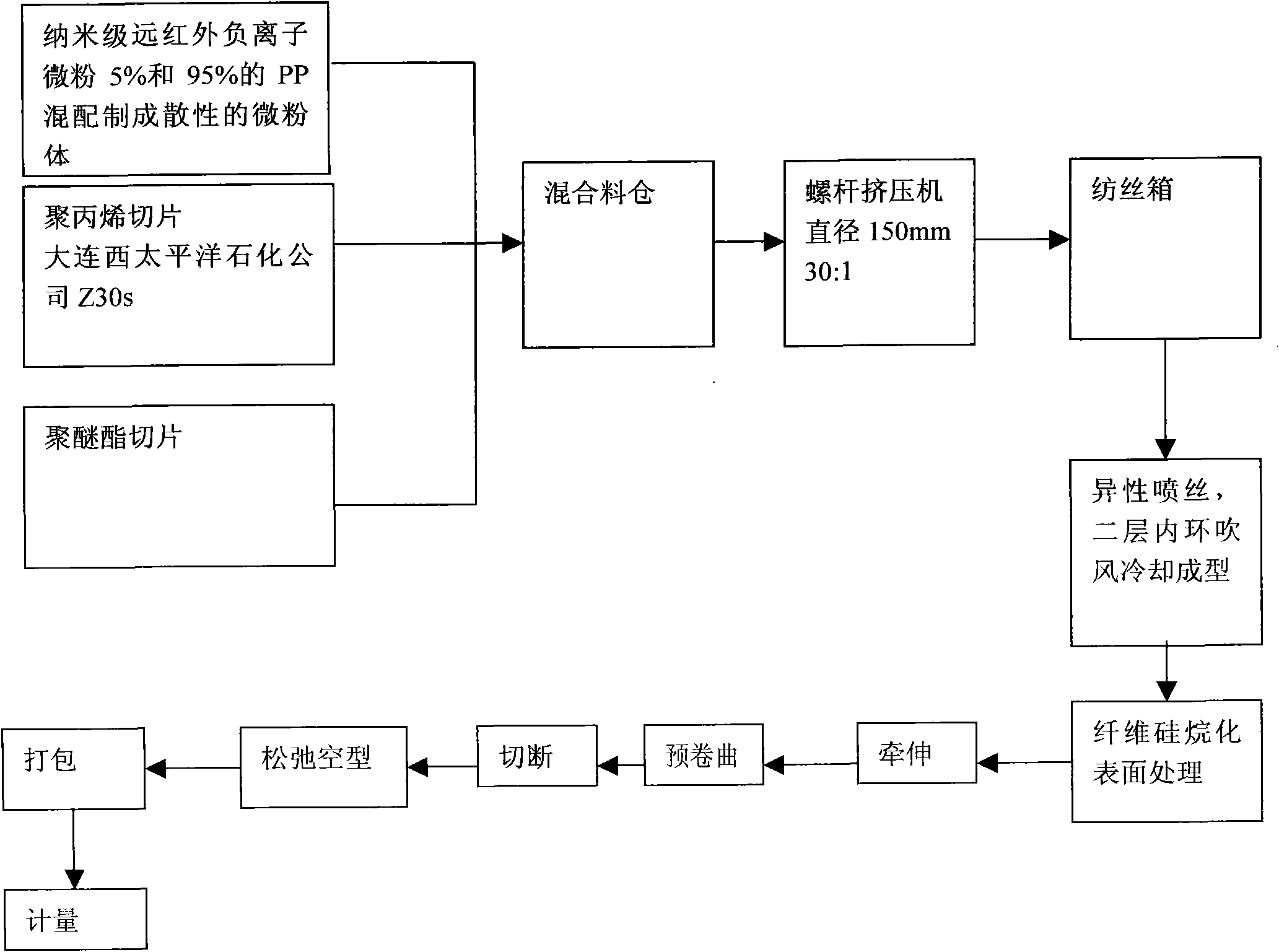

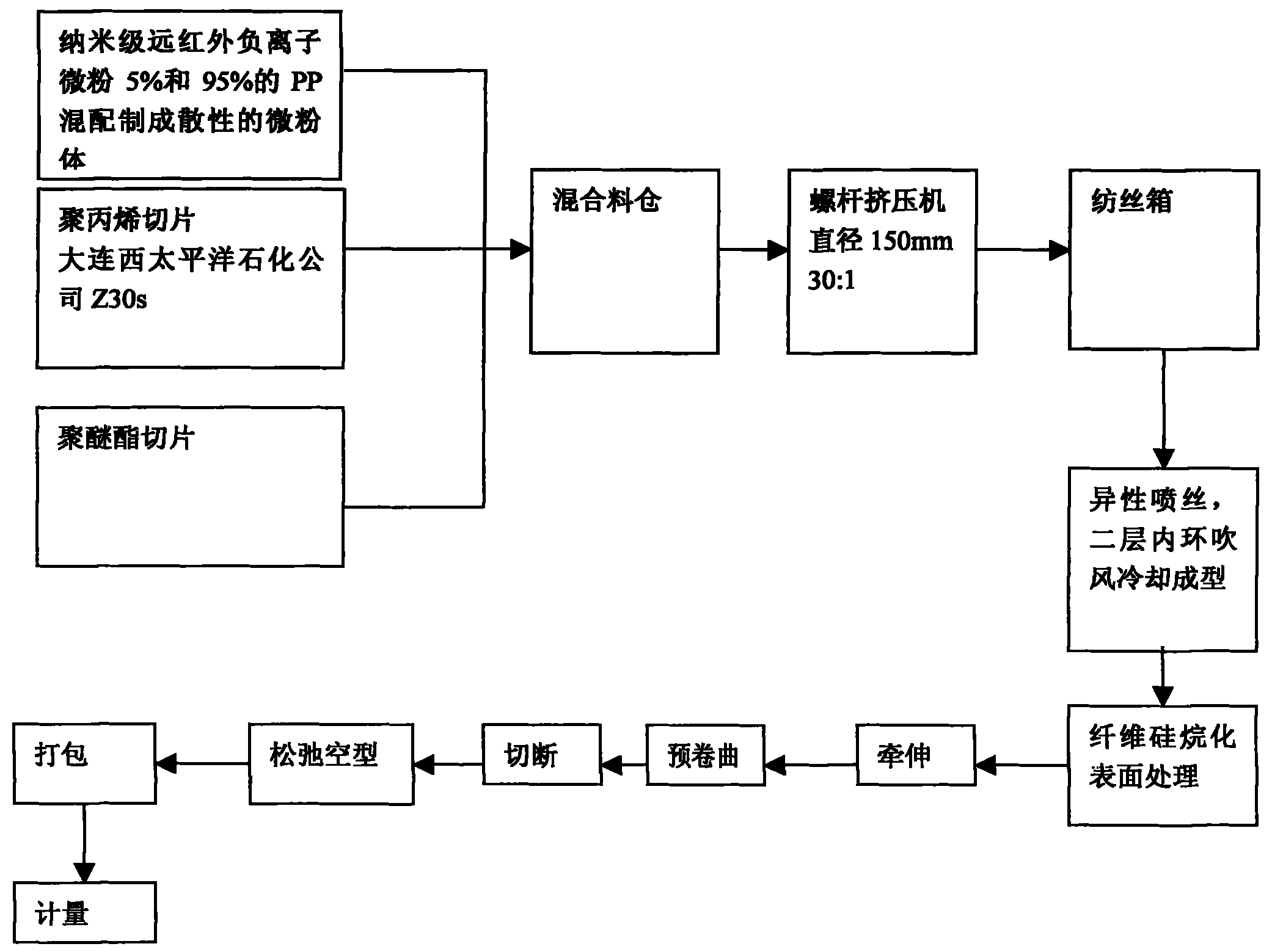

Method used

Image

Examples

Embodiment Construction

[0014] 1. Raw materials:

[0015] Polypropylene: Z30s.MFI=18~20g / 10min, isotacticity>97.5%, ash content<25ppm. Weight: 58kg.

[0016] Polyetherester: XI3003. Weight: 36kg.

[0017] Far-infrared negative ion powder: Particle size: <30nm. Weight: 6kg.

[0018] Fiber surface treatment agent: polysiloxane formed by mixing reactive aminosiloxane and polydimethylsiloxane of hydroxyl sealant in a certain proportion. Weight: 4.5kg.

[0019] 2. Equipment: one-step short-range spinning combined machine.

[0020] Melt spinning machine: screw diameter 150mm, 30:1, six spinning boxes, spinneret diameter 360×2210400 holes C-type (diameter 1.17×0.8), Y-type.

[0021] In the primary fiber crystallization area under the spinneret, arrange a horizontal two-layer annular blowing system blowing from the center to the periphery to the primary fiber, and adjust the wind speed at the outlet to 1.2±0.2m / s, and the temperature to 20°C±2°C.

[0022] The temperature of the seven zones of the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com