Patents

Literature

102results about How to "Chromatography is complete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

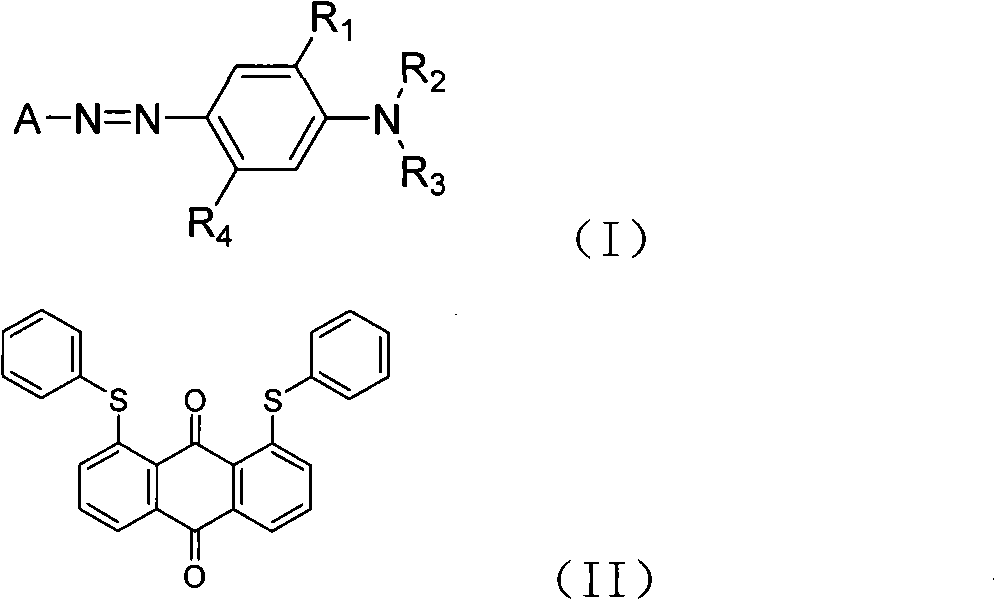

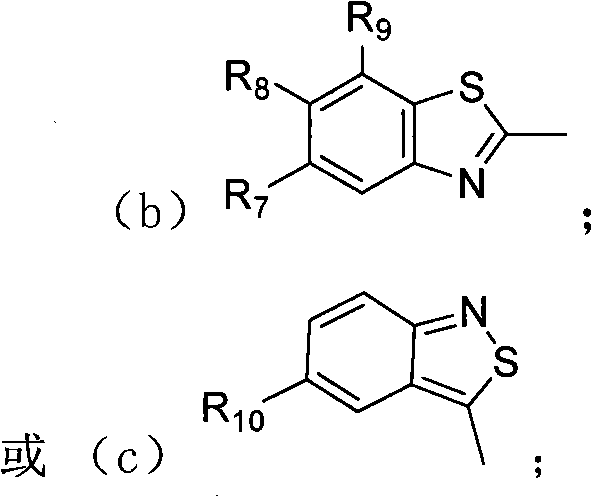

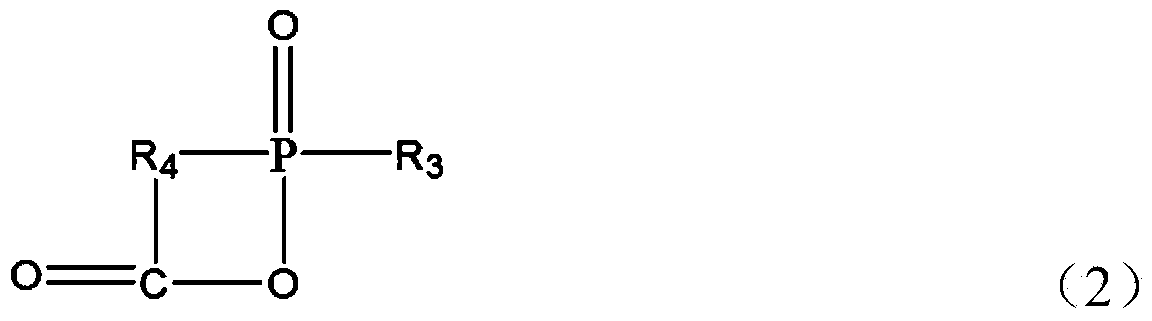

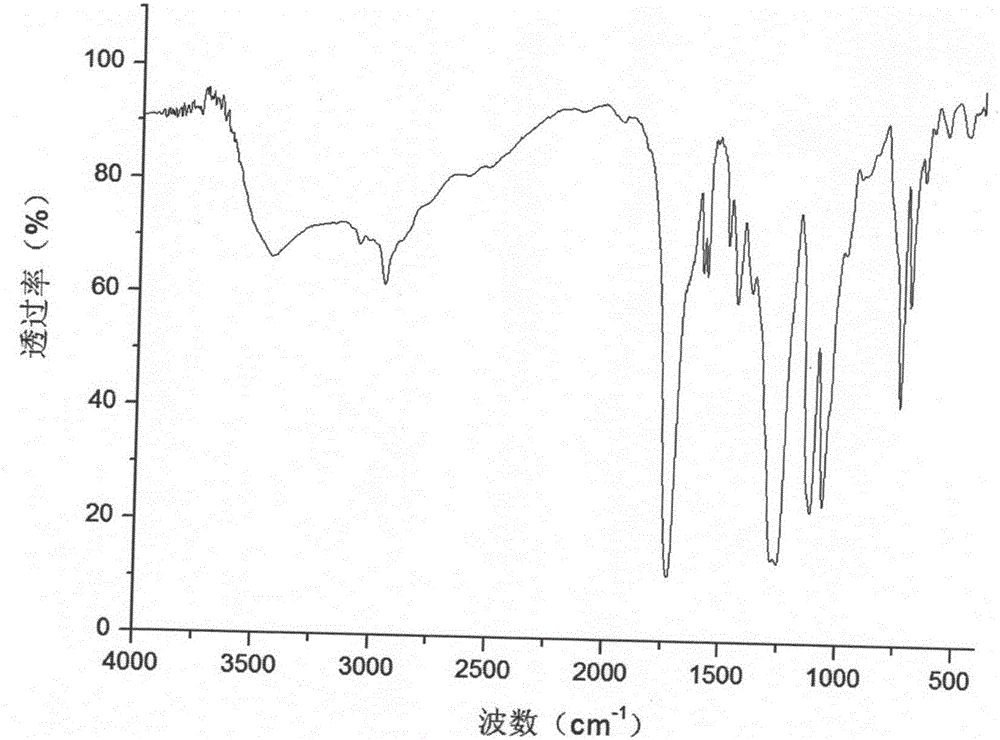

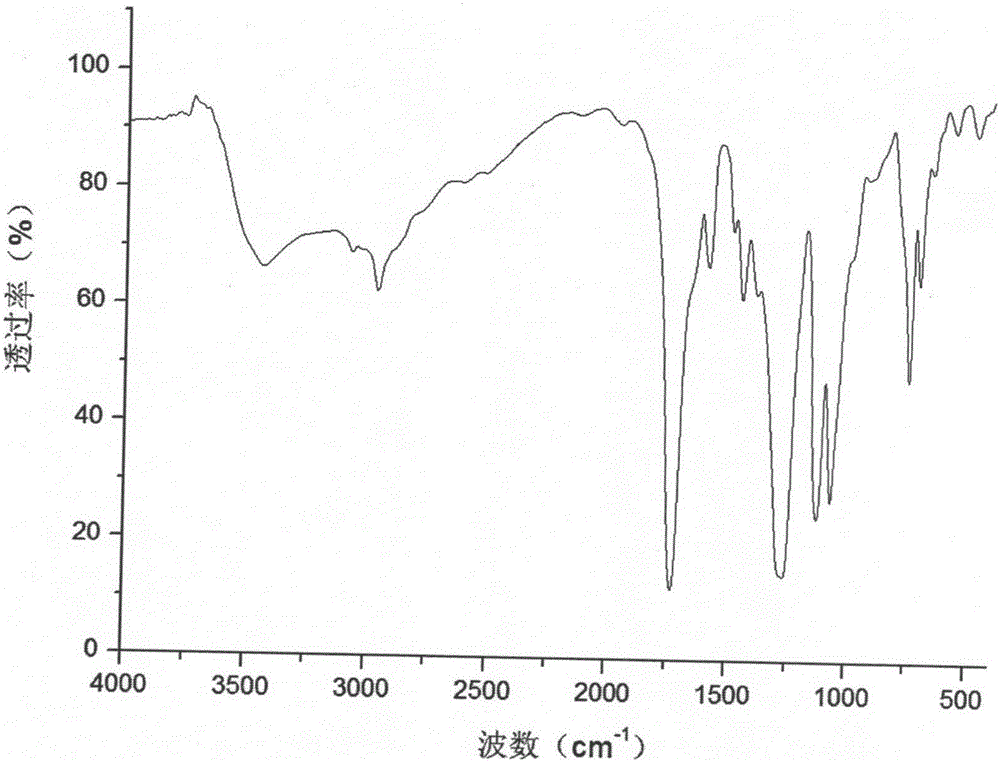

Azo dye composition and application thereof

ActiveCN101265369AChromatography is completeBright shadeOrganic dyesDyeing processAlkalinityDisperse dye

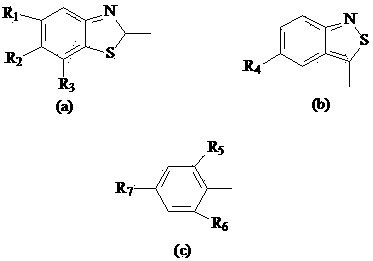

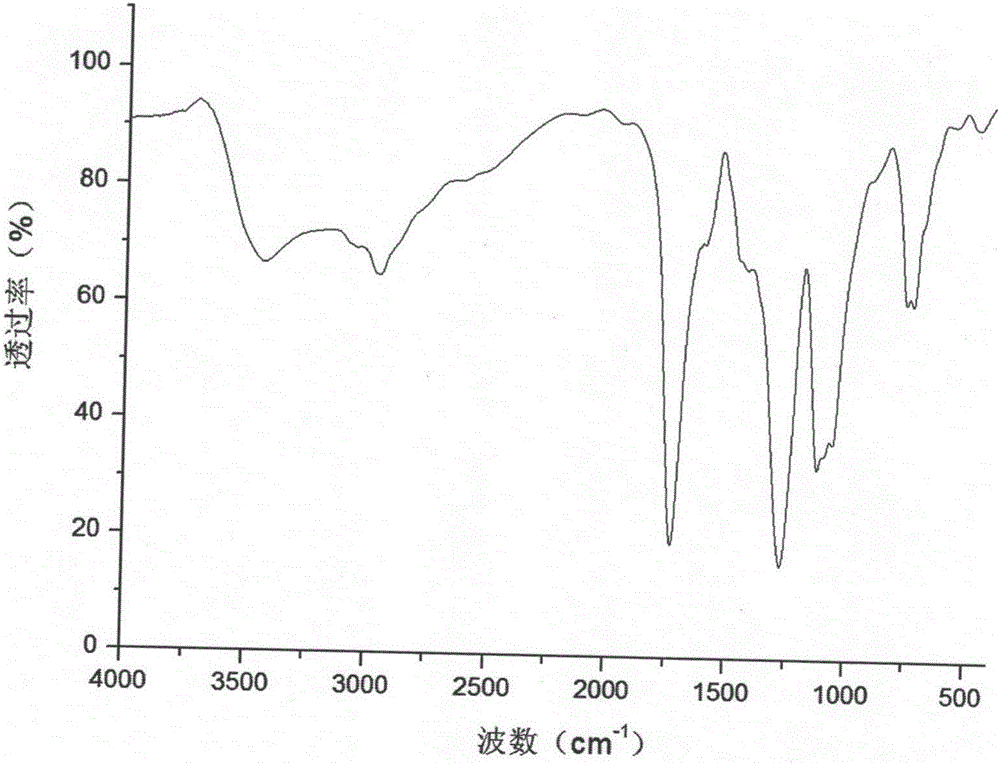

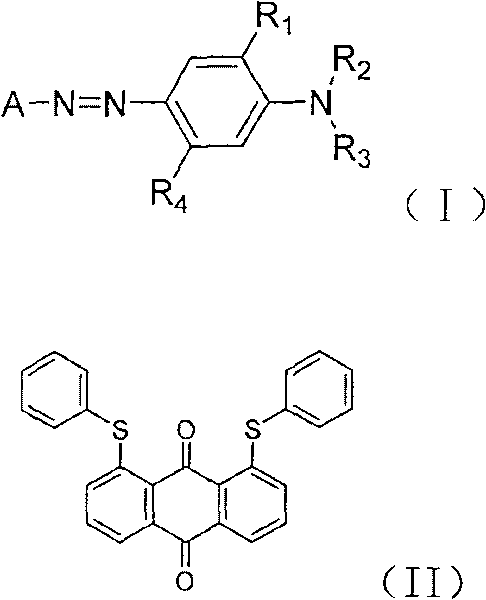

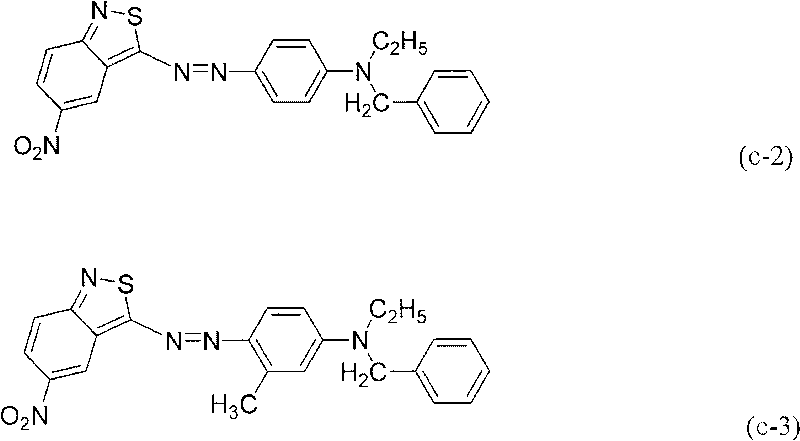

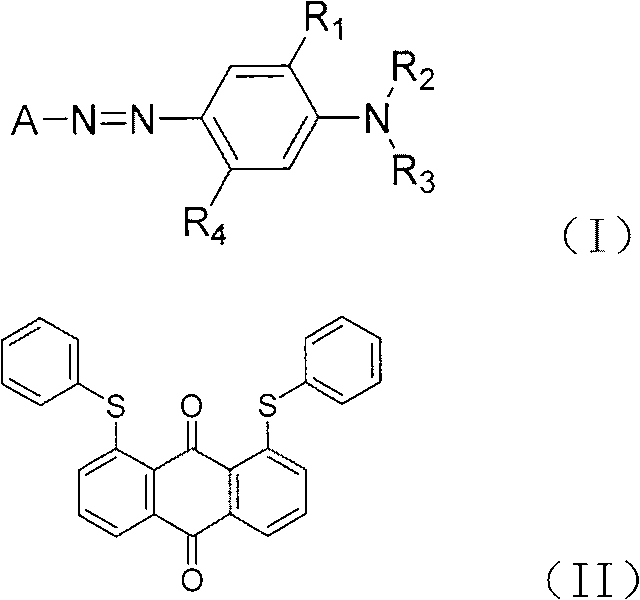

The invention relates to an azo dye compound and the application thereof. The compound is the combination of at least two dyes with A in the general formula (I) selected from any structure of (a), (b) or (c); any combination with A to be at least one from (a), at least one from (b) or at least one from (c); or the combination of at least one dye shown by the general formula (1) and at least one general disperse dye, or / and a dye as shown by the formula (2). Each substituent is shown as the claim of right. The compound can dye polyester and blended fabric thereof under the condition of strong alkalinity with pH more than or equal to 11 and less than or equal to 14; the alkalinity condition can effectively remove slurry and oil on the fabric, and overcomes the defect that decomposition products can be separated out in an acid bath, and cause dyeing defect. The cloth and the fabric adopting the azo dye compound are neat and have excellent styles. In addition, the polyester fiber and the blended fabric thereof can be pretreated with alkalinity and be dyed in a bath and at one step, thus improving the efficiency, and reducing the manufacturing cost and the waste water from dyeing.

Owner:浙江昱泰染化科技有限公司

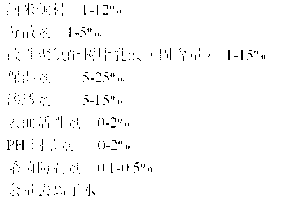

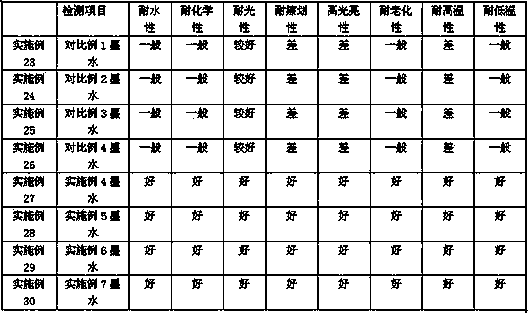

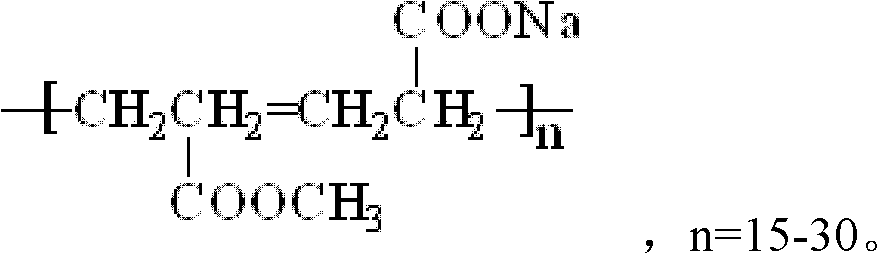

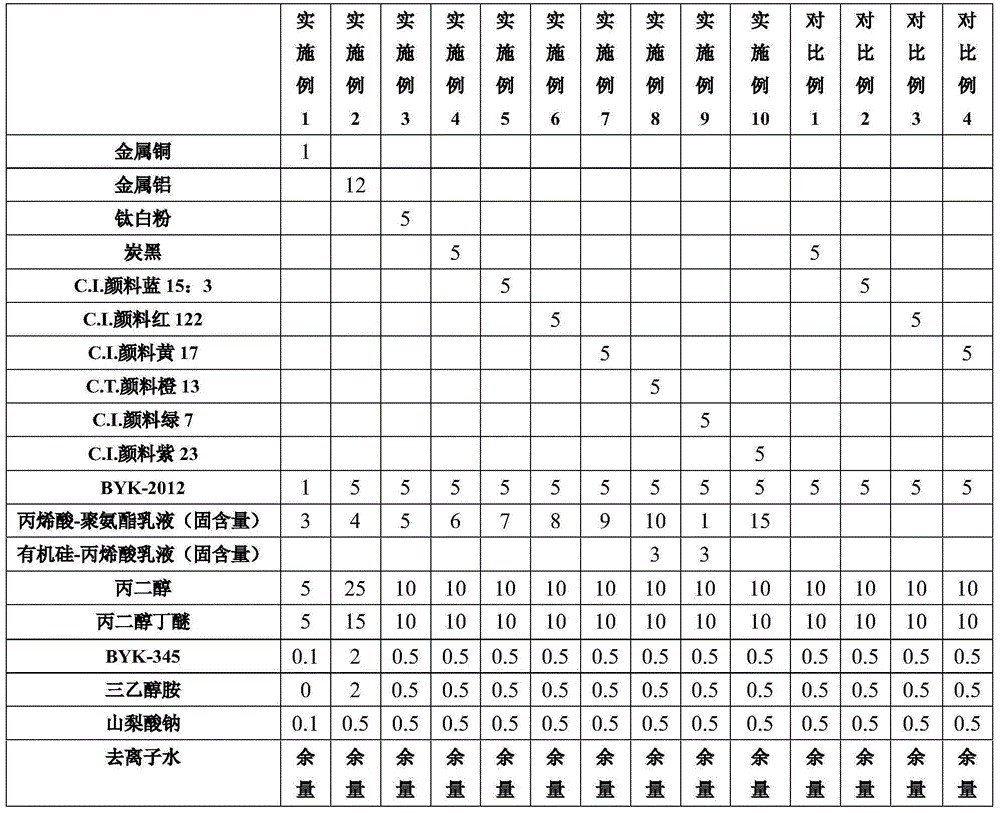

Water-based pigment ink for quality improvement

A water-based pigment jet ink comprises 1-12wt% of a nanopigment, 1-5wt% of a dispersant, 1-15wt% of a modified polyurethane resin emulsion (solid content), 5-25wt% of a humectant, 5-15wt% of an osmotic agent, 0-2wt% of a surfactant, 0-2wt% of a PH adjusting agent, 0.1-0.5wt% of a sterilization antiseptic, and the balance deionized water. The ink has the advantages of excellent preservation stability and printing smoothness, particle nanometer level, complete chromatogram, substantially increased comprehensive properties comprising the light resistance, the water resistance, the chemical resistance, the scratch resistance, high brightness, the high and low temperature resistances, the ageing resistance and the like, and application range enlargement.

Owner:深圳市凌普鑫科技有限公司

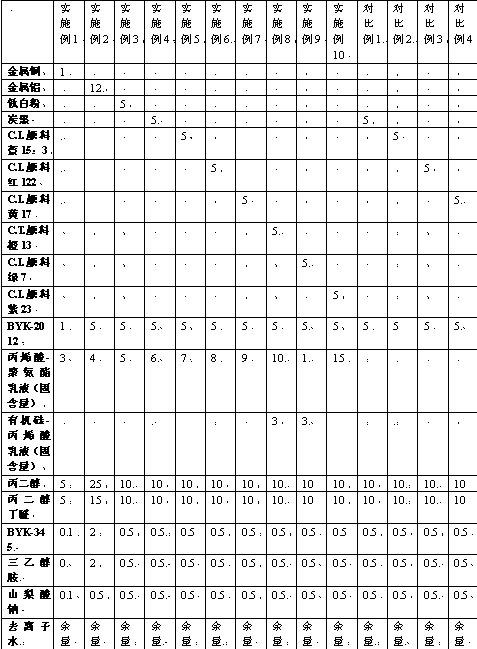

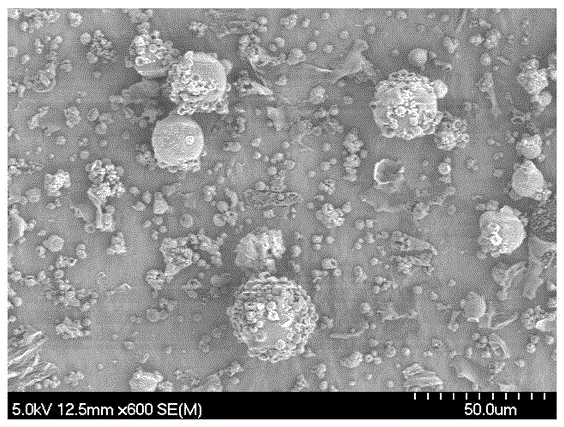

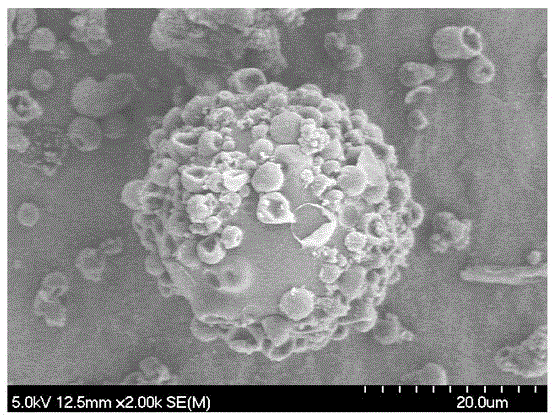

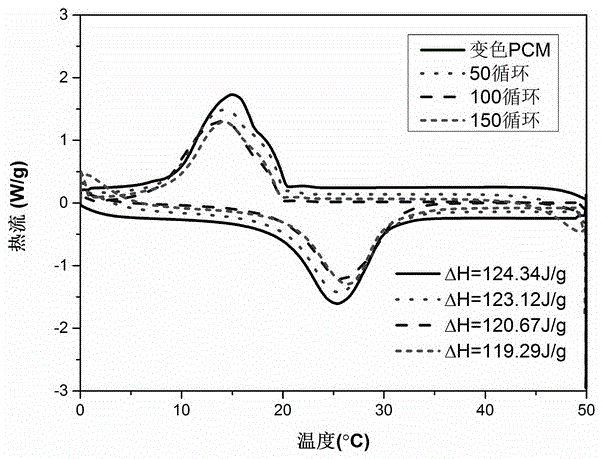

High-efficiency phase change energy storage microcapsule with thermochromic function, and preparation method thereof

ActiveCN105670601AOvercome the defect of single functionChromatography is completeHeat-exchange elementsTenebresent compositionsAlkanePolymer science

The invention relates to a high-efficiency phase change energy storage microcapsule with a thermochromic function, and a preparation method thereof. The core of the microcapsule is a high-grade aliphatic hydrocarbon, alcohol, acid or lipid organic phase change material, and the wall of the microcapsule is a polymer formed by surface modified thermochromic powder and an organic polymer monomer. The preparation method of the microcapsule comprises the following steps: carrying out surface modifying treatment on the thermochromic powder with a coupling agent; mixing the surface modified thermochromic powder, the organic phase change material and the organic polymer monomer as an oil phase, and adopting an aqueous solution of a surfactant as a water phase; and adding the oil phase to the aqueous phase, and carrying out high speed emulsification and polymerization to form the high-efficiency phase change energy storage microcapsule with a thermochromic function. The preparation method has the advantages of simple preparation process, and easy control of the reaction process; and the material has the advantages of wide thermochromic temperature range, abundant color, high heat storage ability and long recycling life, and is hopeful to be applied in the fields of chromogenic indication, coatings and building materials.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

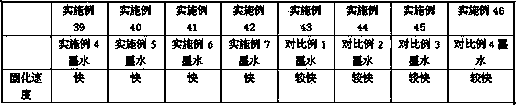

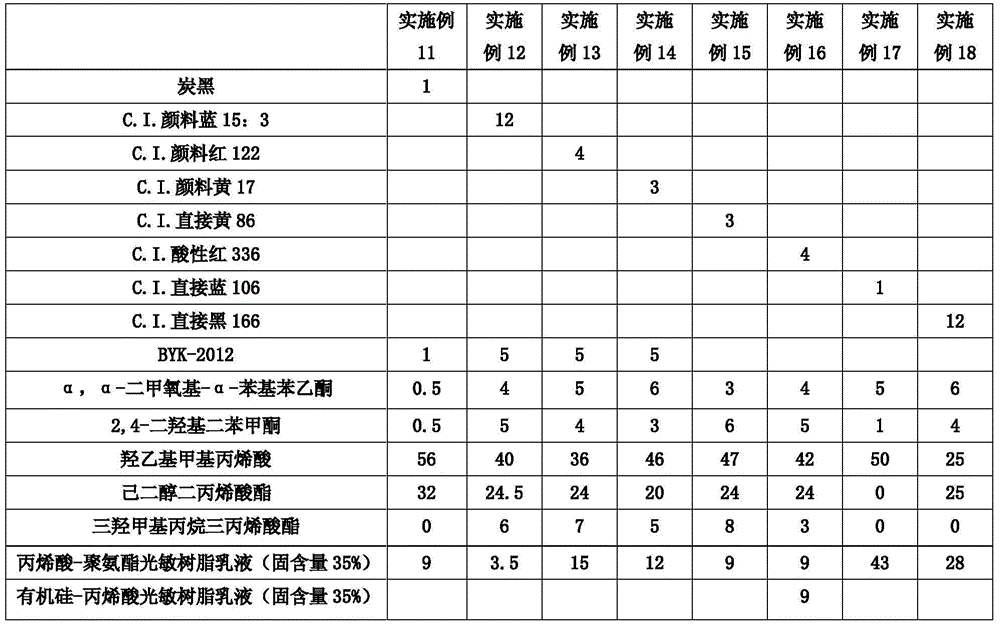

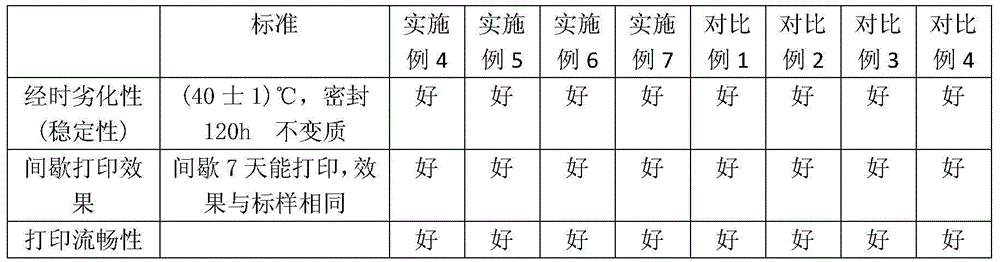

Ultraviolet-curing water-based inkjet ink

The invention discloses ultraviolet-curing water-based inkjet ink. The ultraviolet-curing water-based inkjet ink at least comprises the following components in percentage by weight: 1%-12% of nanometer pigment / water-soluble pigment, 1%-5% of dispersing agent, 1%-15% of UV (Ultraviolet)-curing modified polyurethane resin emulsion (solid content), 1%-10% of photoinitiators, 20%-50% of reactive diluents, 5%-25% of humectants, 5%-15% of penetrating agents, 0%-2% of surfactants, 0%-2% of pH regulators, 0.1%-0.5% of sterilization preservative, and the balance of deionized water. The ultraviolet-curing water-based inkjet ink is characterized in that the ink has excellent storage stability and printing fluency; the ink has excellent performances including water resistance, light resistance, solvent resistance, scratch resistance, ageing resistance, high-low temperature resistance, high brightness, good adhesive strength and quick curing speed, is suitable for various printers to print various uncoated and nonprinting coating media, hydrophobic and oily media, and is wide in application area.

Owner:NANJING CHEMBRIDGE TECH MATERIAL

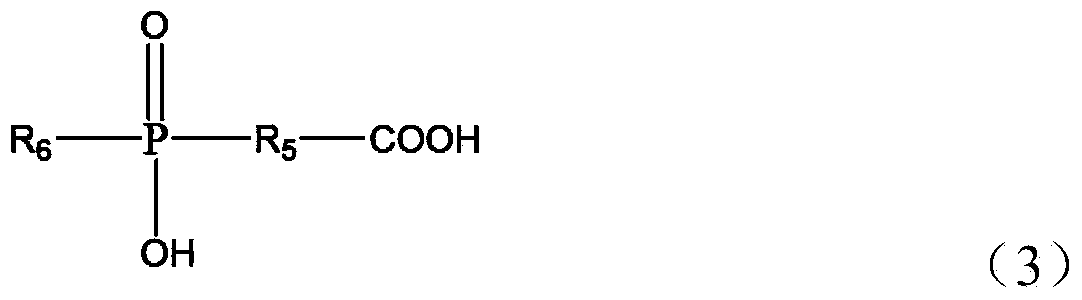

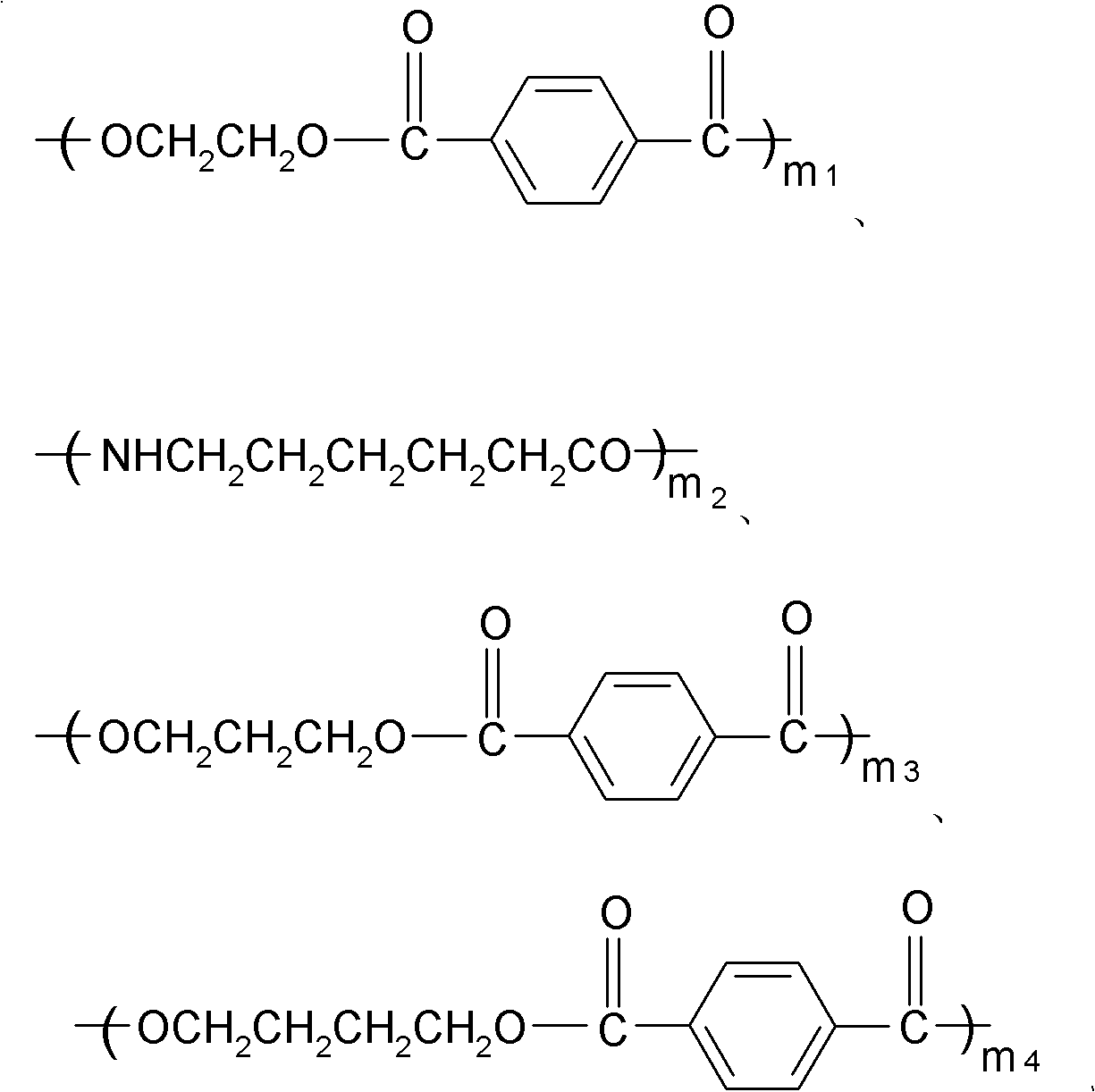

Preparation method of cationic dyeable flame-retardant polyester resin

The invention discloses a preparation method of cationic dyeable flame-retardant polyester resin. The manufacturing method is characterized by comprising the following steps: performing an esterification reaction on a halogen-free copolymerized phosphorus-based flame retardant, ethylene glycol and a composite catalyst to prepare an esterification solution of the halogen-free copolymerized flame retardant; performing ester exchange reaction on sulfoisophthalic acid dimethyl ester and the ethylene glycol to prepare a sulfonate-based bis(hydroxyethyl) isophthalate solution; performing an esterification reaction on terephthalic acid (or dimethyl terephthalate), the ethylene glycol and auxiliaries, then adding a catalyst, a stabilizer, the auxiliaries, the esterification solution of the phosphorus-based flame retardant (or a prepolymer solution of the phosphorus-based flame retardant) and the sulfonate-based bis(hydroxyethyl) isophthalate solution, performing condensation polymerization reaction, and cooling and dicing after the end of reaction to prepare the cationic dyeable flame-retardant polyester resin. The cationic dyeable flame-retardant polyester resin prepared by the method disclosed by the invention has the characteristics of good spinnability, polyester fiber cationic dye boiling dyeing under normal pressure conditions, complete chromatogram and strong dye adhesion.

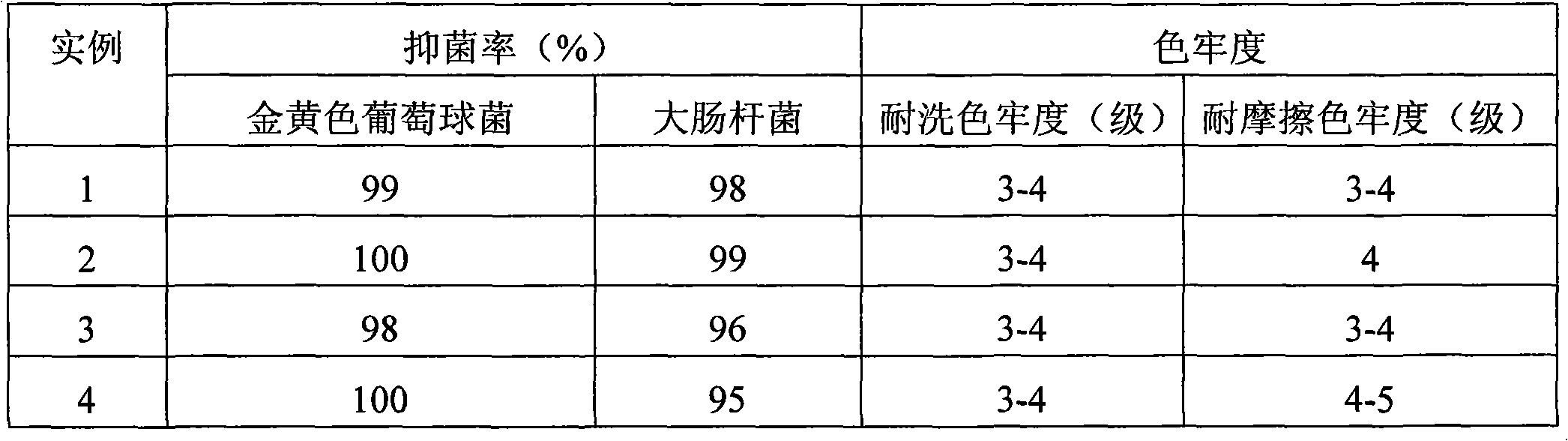

Method for dying cotton fiber by utilizing tea vegetable dye

ActiveCN101956334AHas antibacterial effectHigh color fastnessDyeing processVegetal fibresFiberSocial benefits

The invention provides a method for dying cotton fiber by utilizing tea vegetable dye. In the method, natural tea vegetable dye is extracted from fresh tea leaves, and is utilized to dye cotton fiber by different mordanting methods. After being dyed by the method the invention, the cotton fiber has the advantages of good dyeing color fastness, more color spectrums and good bacteriostatic effect. Through the method, multiple colors can be dyed, the color and lustre are soft, archaic and natural, thus people can feel natural and healthy; the dyed cotton fiber has the characteristics of good dyeing fastness, washing and wear resistance, strong repeatability and uniform dyeing; the existing dyeing equipment is used to dye directly without adding equipment and increasing cost; the method is environmentally friendly and is beneficial to human health; and the method can be applied to clean production of textile industry and can realize large-scale production. The method can efficiently use resources of summer tea and autumn tea, develop and produce tea-dyeing cotton textiles which are environmentally friendly and have archaic, simple and elegant colors and bacteriostatic effect, and the market prospect is broad, thus being capable of not only generating great economic benefits but also obtaining great social benefits.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI +1

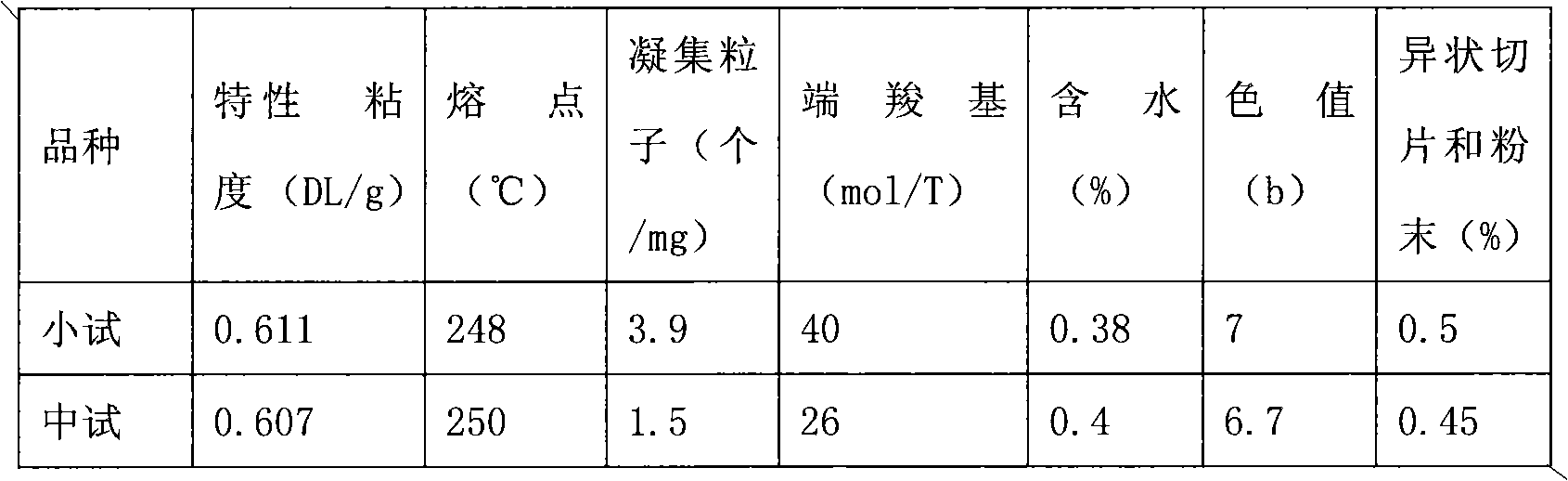

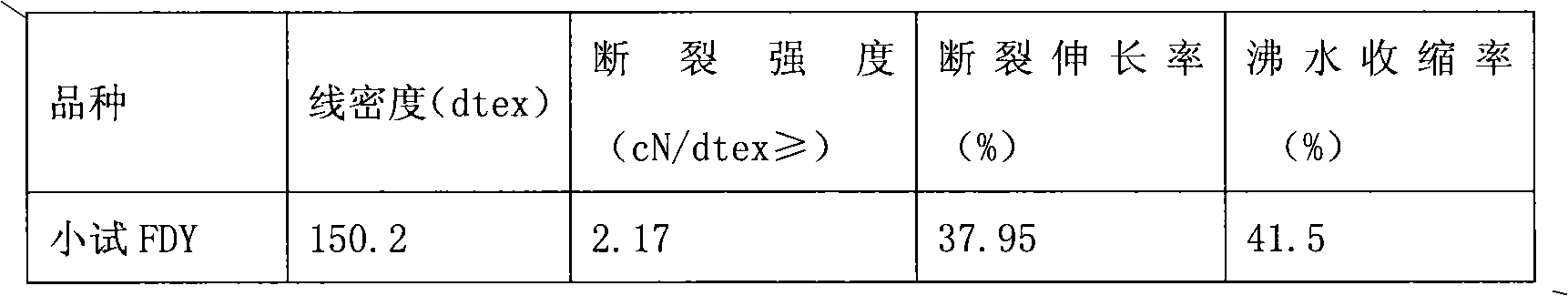

High-shrinkage cation normal-pressure easy-to-dye polyester chip and preparation method thereof

The invention discloses a high-shrinkage cation normal-pressure easy-to-dye polyester chip and a preparation method thereof. The high-shrinkage cation normal-pressure easy-to-dye polyester chip comprises the following components: 66-68 percent of purified terephthalic acid, 23-21 percent of glycol, 3.2-5.5 percent of isophthalic acid digylcol ester-5-sodium sulfonate, 2.1-3.3 percent of polyethylene glycol, 0.5-0.7 percent of isophthalic acid, 3.1-4 percent of hexanedioic acid, 0.012-0.036 percent of antimony acetate and 0.005-0.055 percent of antioxidant. The high-shrinkage cation normal-pressure easy-to-dye polyester chip is subjected to an esterification reaction at the pressure of 0.25-0.3MPa and the temperature of 250-260DEG C and a polycondensation reaction at the temperature of 230-270DEG C and at the vacuum degree of 0.08-0.098MPa and temperature preservation after the temperature reaches 272-278DEG C. The high-shrinkage cation normal-pressure easy-to-dye polyester chip has the advantages of high dyeing rate and dye suction rate at normal temperature and normal pressure, bright color, favorable performances of high shrinkage and resisting pilling, spinnability, drafting property and favorable physical property and post treatment performance of fibers.

Owner:PETROCHINA CO LTD

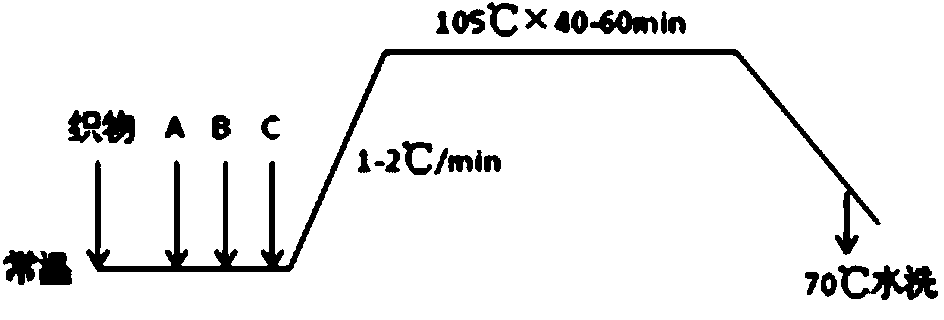

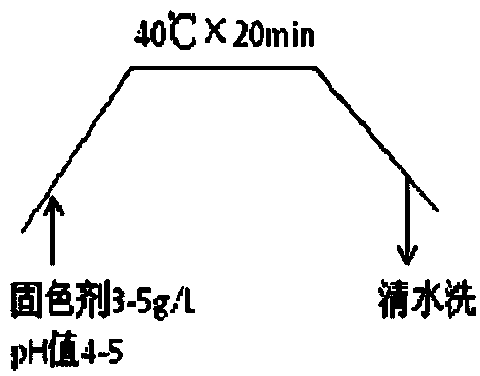

Nylon sea-island microfiber leather fabric composite dye and application thereof

ActiveCN103525123AConsistent dyeingApplicable dyeingOrganic dyesDyeing processAcid dyeIncrease temperature

The invention relates to nylon sea-island microfiber leather fabric composite dye and application thereof. The dye is formed by combining acid dye and active dye. The application is as follows: at normal temperature, sequentially adding an acid level dyeing penetrating agent and composite dye to a dye bath, regulating pH value to 5-6, soaking a fabric in the dye bath, increasing temperature to 105-110 DEG C, preserving for 40-60min, and completely washing at 70-80 DEG C to obtain the dyed fabric; soaking the dyed fabric in a fixation bath, increasing temperature to 40-50 DEG C, preserving for 20-30min and washing. The composite dye formed by combining the acid dye and the active dye, is free from components violating against national technical standard for safety, can consistently dye poly urethane (PU) and nylon superfine fiber, and in particular can dye nylon microfiber leather. The composite dye is complete in chromatography, good in compatibility, synchronous to dye and easy to control quality.

Owner:DONGHUA UNIV +1

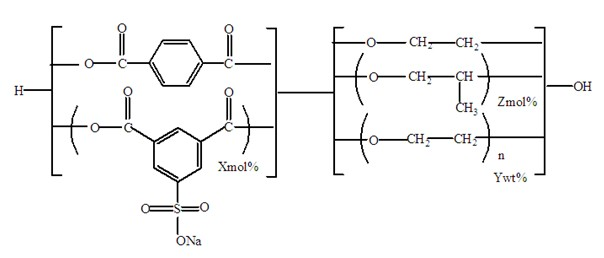

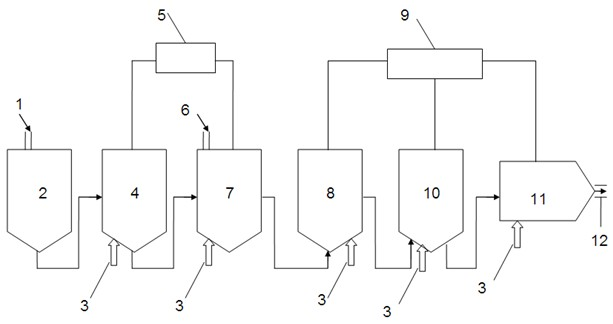

Hydrophilic copolyester slices prepared by continuous method and preparation method thereof

InactiveCN102504224AChange molecular structureImprove hydrophilicityMonocomponent polyesters artificial filamentArtifical filament manufactureCopolyesterDibasic acid

The invention discloses a continuous method for preparing hydrophilic copolyester slices and the hydrophilic copolyester slices prepared by the preparation method. The preparation method of the hydrophilic copolyester slices prepared by the continuous method comprises the following steps: continuously and uniformly adding pure terephthalic acid, ethylene glycol, benzene dibasic acid binary alcohol ester-5-sodium sulfonate, polydibasic alcohol, other dibasic alcohols, a delustering agent and the like into a beating kettle in proportion, performing esterification, prepolycondensation and polycondensation reactions, discharging, pelletizing and drying to get the hydrophilic copolyester slices. A continuous polymerization device is adopted for synthesis; and in the prepared hydrophilic copolyester slices, the molecular structure of polyester is changed by adding hydroxyl-containing components and inorganic powder into copolyester slices, thus the hydrophilic property is good. The preparation method is simple, the manufacturing process has no special requirements on the polymerization device, and the hydrophilic copolyester slices can be produced on existing domestic or imported equipment, so that the production cost is slow and industrial production is easy to realize.

Owner:DONGHUA UNIV

Color printing and dyeing technology of active ink dye on linen fabric

A color printing and dyeing technology of an active ink dye on linen fabric relates to a linen active color printing and dyeing technology. The invention aims to solve the technical problem about linen printing and dyeing at home and aboard. The printing and dyeing technology provided by the invention comprises the following steps: 1, sizing, drying and curing; 2, active digital jet-printing and drying; 3, wet steaming for color fixation; and 4, washing, soaping, washing, drying and shaping. According to the invention, active ink is, for the first time, transferred to linen fabric in a non-contact way. Through tests and application, color printing and dyeing is successfully realized, and the technology has put into production. Thus, the natural fiber has a wider development space. The technology provided by the invention is a brand-new printing mode which is different from the tradition.

Owner:HARBIN LONGWELL TECH DEV CO LTD

Blended yarn weaving and ecological finishing method for silk-ramie fibers colored by vegetable dyes

InactiveCN104862870AIncrease color spectrumChromatography is completeSucessive textile treatmentsWeft knittingYarnSpinning

The invention relates to a blended yarn weaving and ecological finishing method for silk-ramie fibers colored by vegetable dyes. One or two kinds of ramie fibers colored by vegetable dyes and silk colored by vegetable dyes and one or more kinds of cotton fibers, Tencel fibers and modal fibers are made into blended colored spun yarns by adopting the spinning modes of compact spinning, Siro compact spinning, spinning conducted through air exhaust type revolving cups and air-jet vortex spinning. The yarns are directly woven into gray fabric through knitting equipment without oil and wax application, and the gray fabric is subjected to water scrubbing and low temperature drying shaping at the temperature lower than 140 DEG C and then is subjected to preshrinking processing to become finished product fabric. The blended colored spun yarns are plied to be used as warp yarns, sizing-free weaving is conduced through tatting equipment, and fabric obtained after sizing-free weaving is calendared by a calender under normal temperature or processed by a preshrinking machine to become finished product fabric. High temperature processing is not needed in aftertreatment of the fabric, finished products have soft hand feel and are smooth, softening agents are omitted, and safety and environment friendliness are facilitated. Besides, the bacterium resistance and inhibition performance of the fabric colored by the vegetable dyes is guaranteed effectively.

Owner:邱平

Process for dyeing silk and wool with skullcap

The invention opened a method of dying the true silk crepe-de-chine and the wool using scutellaria dyestuff. The process: a. put the scutellaria dyestuff which the pH is 3-6.5 on the true silk crepe-de-chine and the wool; b. do the fore and mordanting by the mordant which is 2-20 %( w / w). The dyestuff is the natural, soft, simple and innoxious to the human.

Owner:SHANGHAI JIAO TONG UNIV

Composite coloring pearlescent pigment and preparation thereof

InactiveCN103013186AChromatography is completeColorfulInorganic pigment treatmentPhysical chemistryTitanium oxide

The invention discloses a composite coloring pearlescent pigment, which is formed by coating a mica base material with titanium oxide and transition metal oxide and is provided with a layered oxide outer membrane structure. A preparation method of the pearlescent pigment comprises the steps of adjusting a pH value of a suspension formed by uniformly mixing mica and water to be 1.5-4.5, obtaining a reaction mother solution, adding a titanium compound and a mixed solution of transition metal water soluble salt to the reaction mother solution, uniformly stirring, obtaining a reaction mixture, adjusting a pH value of the reaction mixture to be 8-10, obtaining a turbid solution, conducting solid-liquid separation, drying, obtaining a solid matter, thoroughly roasting the dried solid matter at 600-1000 DEG C, cooling, and obtaining the composite coloring pearlescent pigment. According to the composite coloring pearlescent pigment, as an outer membrane coating coated by titanium oxide and transition metal oxide is formed, the composite coloring pearlescent pigment has effects with relatively complete color spectrum and relatively showy color, has relatively excellent glossiness, and has a relatively wide application scope.

Owner:FUJIAN NORMAL UNIV

Production method of spunbonded polyester embroidery thread and product of same

ActiveCN102080285ALittle strengthLow boiling water shrinkageDyeing processMelt spinning methodsPolyesterYarn

The invention belongs to the chemical fiber manufacturing field, and particularly relates to a production method of a spunbonded viscose polyester embroidery thread. The production method comprises the following steps: preparing bright modified polyester; carrying out melt spinning, drawing and winding to obtain modified polyester drawn yarns according to the characteristics of the bright modified polyester; and twisting the modified polyester drawn yarns, and dyeing the yarns to obtain the colored polyester embroidery thread product. The invention further provides the colored polyester embroidery thread prepared by the production method. The colored polyester embroidery thread is bright polyester fibers with a triangular cross section, and has bright color; the obtained embroidery thread has the advantages of complete color spectrum, rich color and higher color fastness, and is not darkened after being washed; and meanwhile the embroidered pattern is not deformed due to low boiling water shrinkage and stable structure.

Owner:浙江双兔新材料有限公司

Method for dyeing modified polyester

ActiveCN101906726AEvenly distributed sequenceHigh tensile strengthDyeing processDisperse dyeAcid dye

The invention relates to a method for dyeing modified polyester. The modified polyester has the performances of dyeing with an acid dye and a disperse dye at normal temperature. By dyeing the modified polyester with a weak acid dye under the environment that the pH value is 2-6, the dye-uptake rate can reach over 70 percent and the color fastness can reach over 3-4 grades. In addition, in the invention, the modified polyester is dyed with the disperse dye at normal temperature. The dyeing process has no requirement on the kinds of the disperse dyes and complete color spectrum; and by dyeing with carrier-free assistants at normal temperature and normal pressure, the dyeing-uptake rate can reach over 90 percent and the color fastness can reach over 4 grades. In addition, the dyeing process is simple and controllable and is beneficial to being popularized and applied.

Owner:CHINESE TEXTILE ACAD

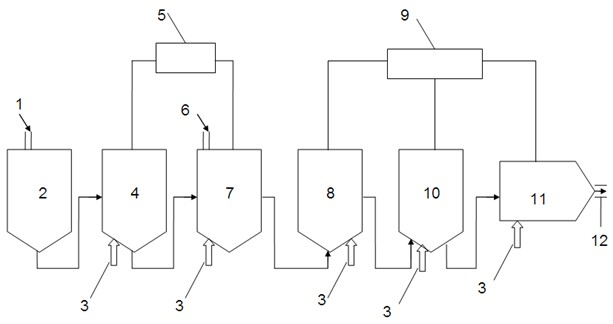

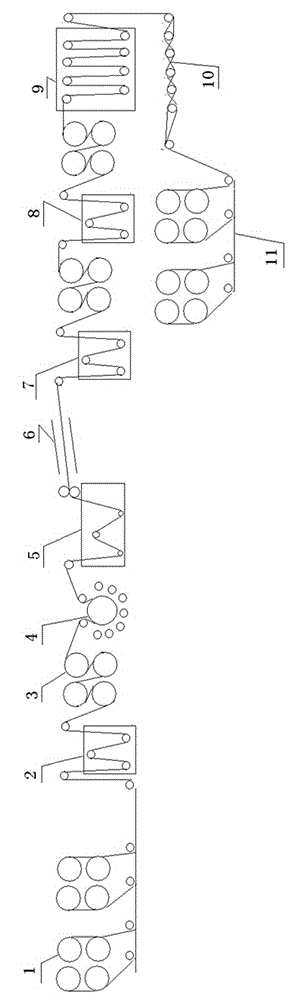

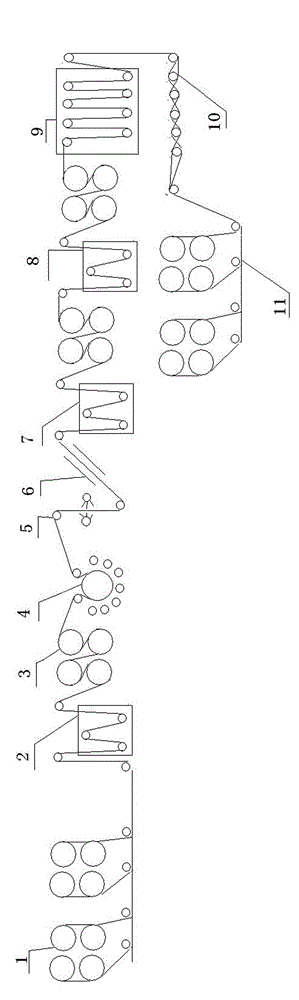

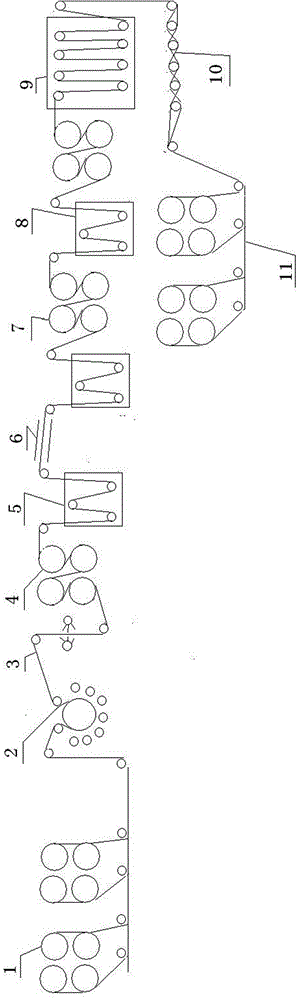

Sizing dyeing equipment assembly for producing colorful yarns by coating padding and sizing dyeing method of sizing dyeing equipment assembly

InactiveCN104928867AHigh color fixing rateAvoid residueSucessive textile treatmentsLiquid/gas/vapor removalYarnProcess engineering

The invention discloses a sizing dyeing equipment assembly for producing colorful yarns by coating padding. The sizing dyeing equipment assembly for producing colorful yarns by coating padding comprises a multi-unit constant-tension reeling and unreeling system, an ultrasonic positive ion modifying system, a drying system, a plasma processing system, a coating padding system, an infrared ray constant-temperature preprocessing and wet and short steaming system, a fixation and drying system, a slashing system, an intelligent constant-tension yarn storage rack, a lease system and a reeling system. Yarns are subjected to coating pad dyeing by the coating padding system, the traditional dip dyeing procedure is replaced, pollution is avoided, residues of coating in a dip dyeing bath are avoided, pollution discharge load is reduced after dyeing, the composite cost of dyeing is reduced, and the ecological environment is improved. The yarns have colorful patterns, demands of the market and changeable demands on aesthetic appreciation of customers are met, and the technical problem that the design and the color in the current dyeing market are changeable is solved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for dyeing slubby yarn cotton fabrics into raindrop or silk rain style

The invention relates to a method for dyeing slubby yarn cotton fabrics into a raindrop or silk rain style, which belongs to the field of dyeing of the slubby yarn cotton fabrics. The method comprises the following steps of: padding the slubby yarn pure cotton fabrics subjected to boiling and bleaching pretreatment with a resisting agent, oven-drying the padded slubby yarn pure cotton fabrics, padding the slubby yarn pure cotton fabrics with a reactive dye and an alkaline agent, and performing steaming, color fixation, washing and oven-drying to obtain the products. The method of the invention has the advantages of simplicity, low cost and suitability for industrial production; and the dyed fabrics are bright in color, complete in color pattern and high in color fastness, and have the unique dyeing style of different color shades, raindrops or silk rain.

Owner:DONGHUA UNIV

Water-based pigment ink for quality improvement

Owner:深圳市凌普鑫科技有限公司

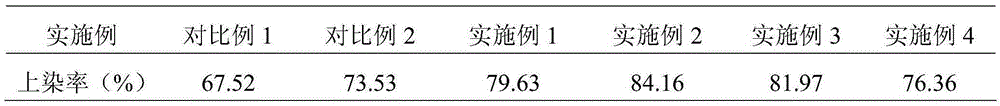

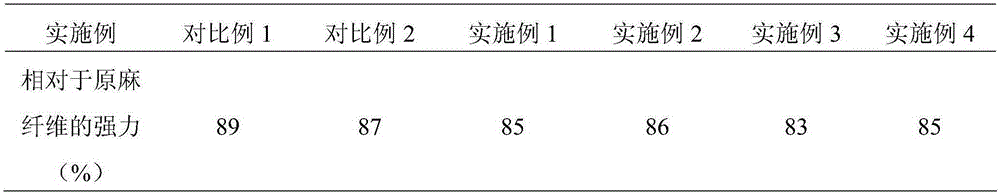

Application of ultrasonic technology to hemp fiber dyeing

ActiveCN105239430AChromatography is completeHigh fastnessDyeing processUltrasonic technologyPhotochemistry

The invention provides application of an ultrasonic technology to hemp fiber dyeing. The application includes the specific steps that 1, firstly reactive dye are dissolved in water for being prepared into dye liquor, textile to be processed is dipped into the dye liquor, neutral salt with the final concentration being 0-100 g / L is added, and ultrasonic treatment is conducted for 10-60 minutes at the temperature of 30-60 DEG C; 2, the temperature is raised to 90 DEG C under the state that no ultrasonic exists, alkaline agents with the final concentration being 10-50g / L is added, and color fixing is conducted for 30-60 minutes under the condition; 3, the textile is taken out after dyeing, washed with soap, washed with water and dried; the concentration of the reactive dyes is 1-5 o.w.f; the bath ratio is 1:20-50. By means of the application of the ultrasonic technology to hemp fiber dyeing, the dye-uptake of the reactive dye can be greatly raised, the dyeing temperature is lowered, and the dyeing time is reduced.

Owner:JIANGNAN UNIV

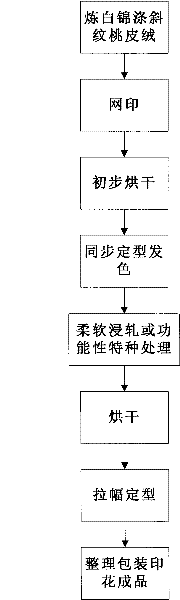

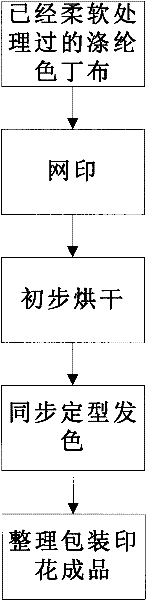

Steam-cleaning free printing process for disperse dye

ActiveCN101899784BImprove the authenticity rateImprove liquidityEster polymer adhesivesDyeing processScreen printingDisperse dye

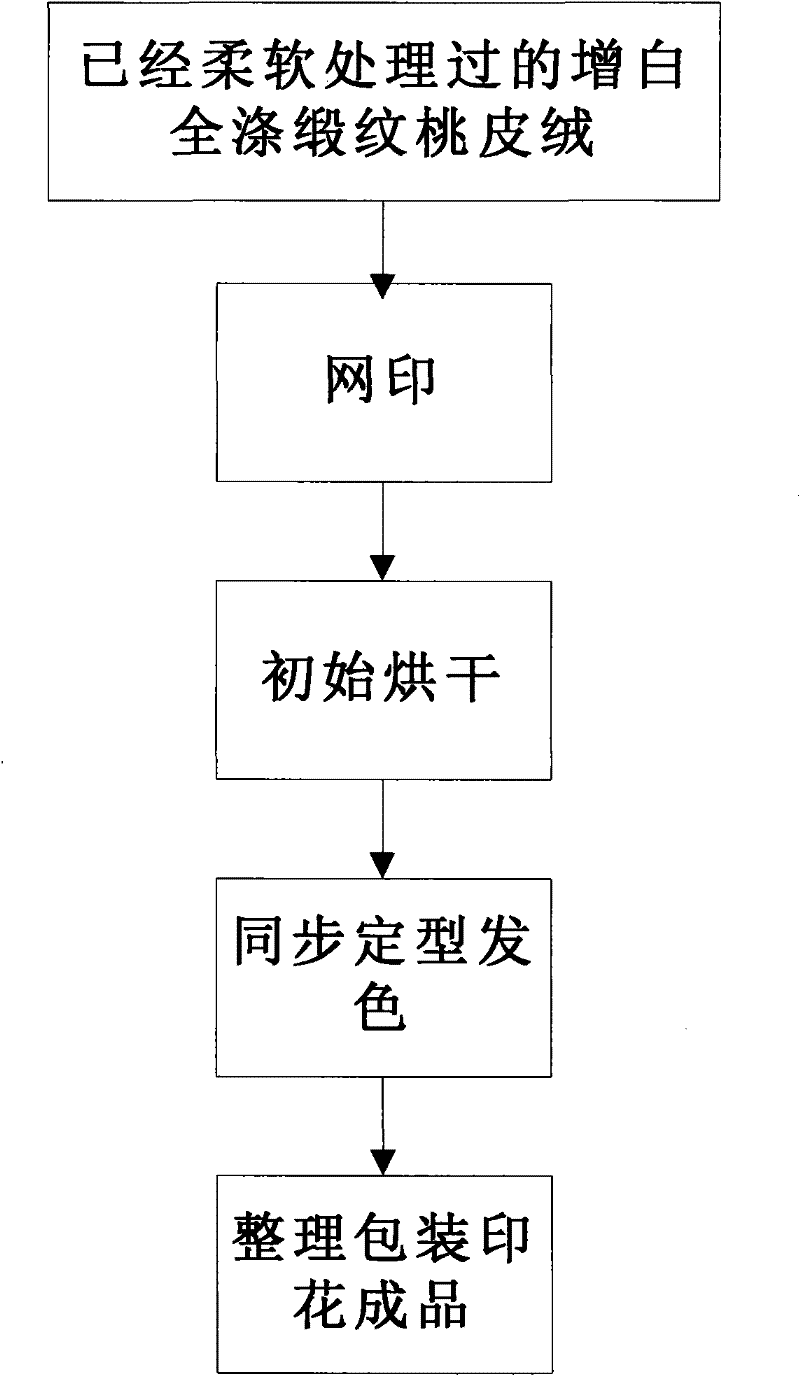

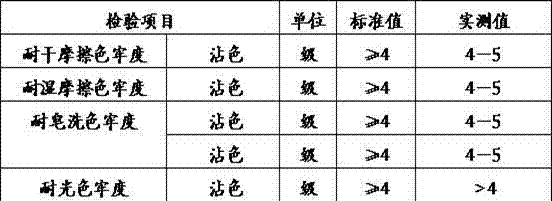

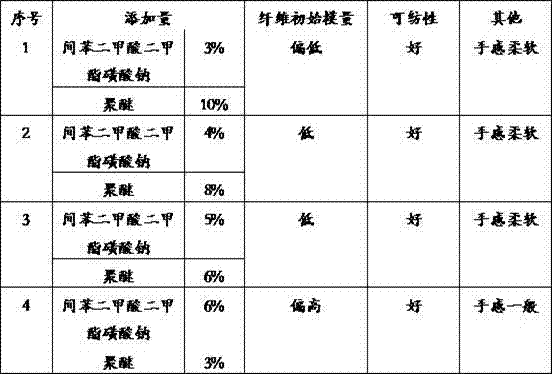

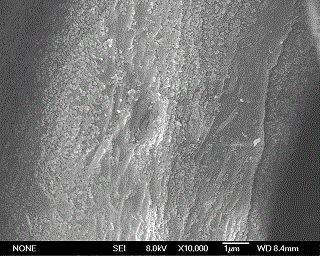

The invention discloses a steam-cleaning free printing process for disperse dye. The steam-cleaning free printing process is characterized by comprising the following steps of: (1) matching the premixed steam-cleaning free printing slurry with the disperse dye and a thickening agent and printing the mixture on fabric in a rotary screen printing machine or a flat screen machine by using a manual printing process according to the conventional process; (2) baking the fabric for 4-10 minutes at the temperature of 110-130DEG C before descending the screen printing machine; and (3) baking and developing while shaping at the temperature of 160-180DEG C and classifying and packaging to form a printed finished product, or carrying out soft padding treatment or functional special treatment, drying,tentering, shaping, classifying and packaging to form the printed finished product. By using the process, the rate of graded products of every 100 meters can be improved by 1-2 percent and the process can be freely compatible with the colors of paint while printing the disperse dye, thereby thoroughly eliminating the pollution of printing sewage and water with color to the environment. The printed finished products have bright color, are transparent, attractive, elegant and luxury and feel soft and smooth.

Owner:DONGGUAN CTL NEW MATERIAL TECH

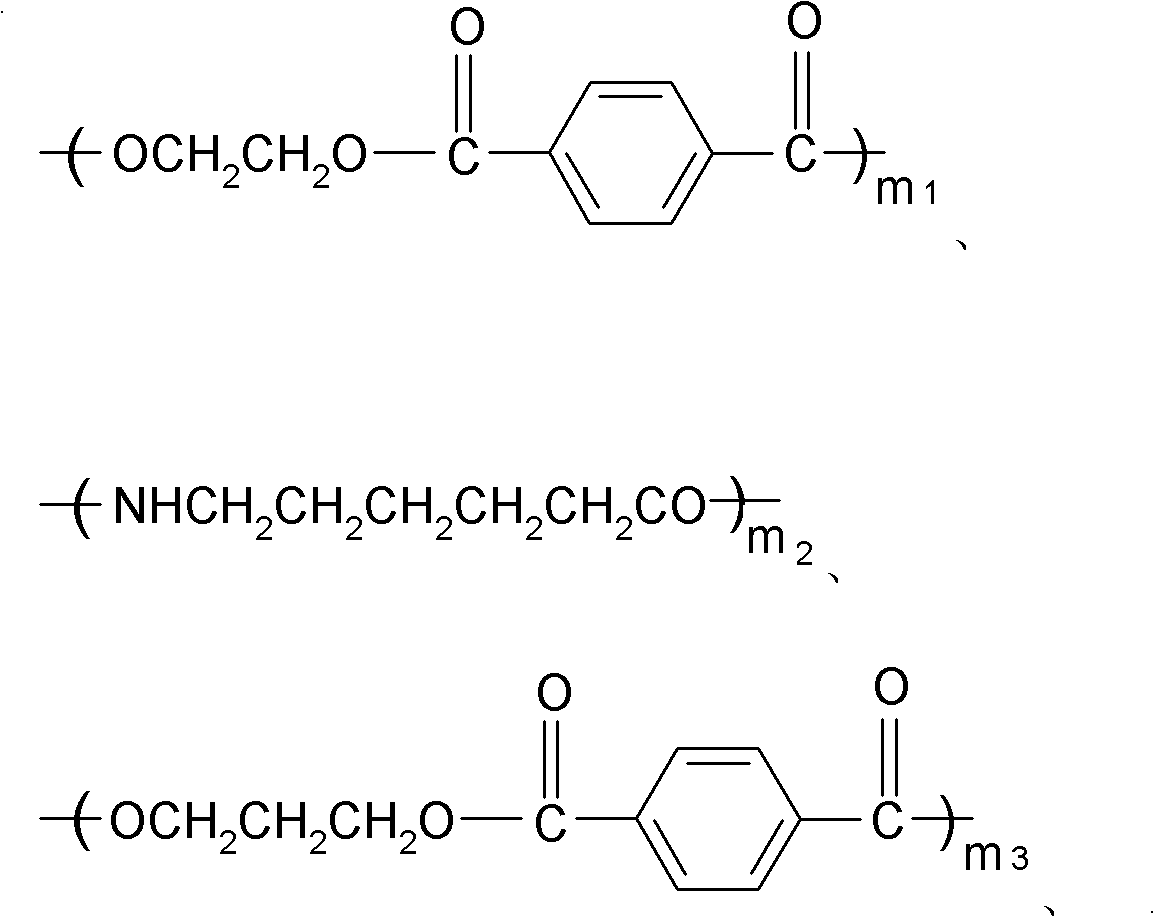

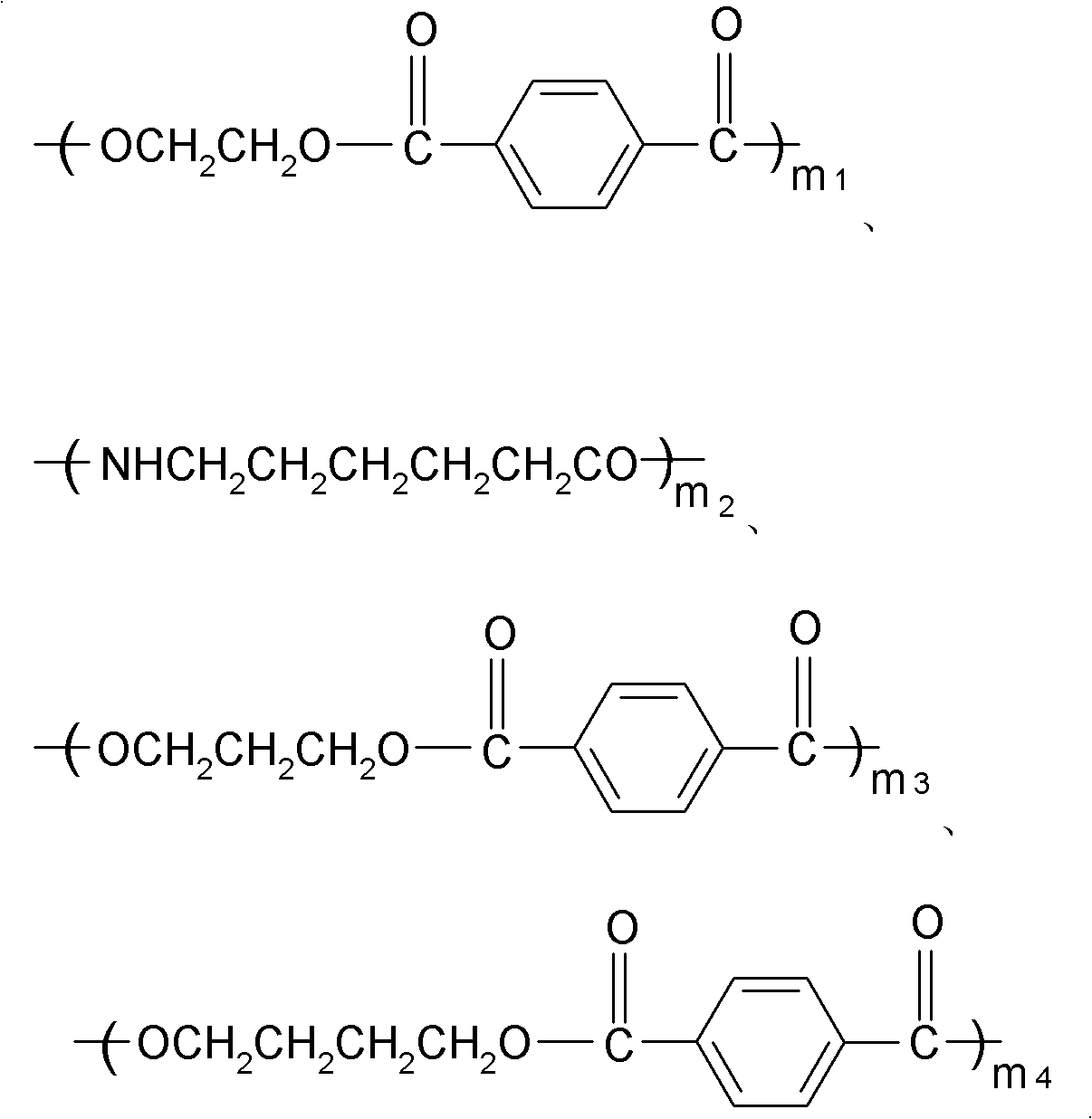

Preparing method of normal-temperature normal-pressure deeply-dyeable polyester filament

ActiveCN108003333AImprove flexibilityEasy to dye under normal pressureMonocomponent copolyesters artificial filamentDyeing processFiberSulfonate

The invention relates to a preparing method of a polyester fiber, and discloses a preparing method of a normal-temperature normal-pressure deeply-dyeable polyester filament. The problems that due to the limitation of a preparing method, the dyeing temperature of a polyester fiber is high, the requirement of high-temperature dyeing for equipment is high, energy consumption is high, and production cost is improved are solved. According to the technical scheme, the method is characterized in that raw materials include polyester, a third monomer and a fourth monomer, the third monomer is one of sodium dimethyl isophthalate sulfonate, diethyl isophthalate sulfonate and diethylene glycol isophthalate sulfonate, and the fourth monomer is fatty binary acid or polyether. The aims of dyeing the polyester filament at normal temperature and normal pressure and being good in dyeing effect, small in energy consumption in the dyeing process and low in cost are achieved.

Owner:SHAOXING GLOBAL CHEM FIBER

One-bath one-step dyeing method for polyester/cotton blended fabric

ActiveCN106223073AWide variety of sourcesChromatography is completeDyeing processPolyesterWastewater

The invention relates to a one-bath one-step dyeing method for a polyester / cotton blended fabric. The polyester / cotton blended fabric is firstly treated by a cationic compound and then is dyed by an anionic dye. The method has excellent dyeing effects on the polyester / cotton blended fabric, is simple in operation and high in efficiency, saves water and energy and reduces waste water emission.

Owner:YUYUE HOME TEXTILE

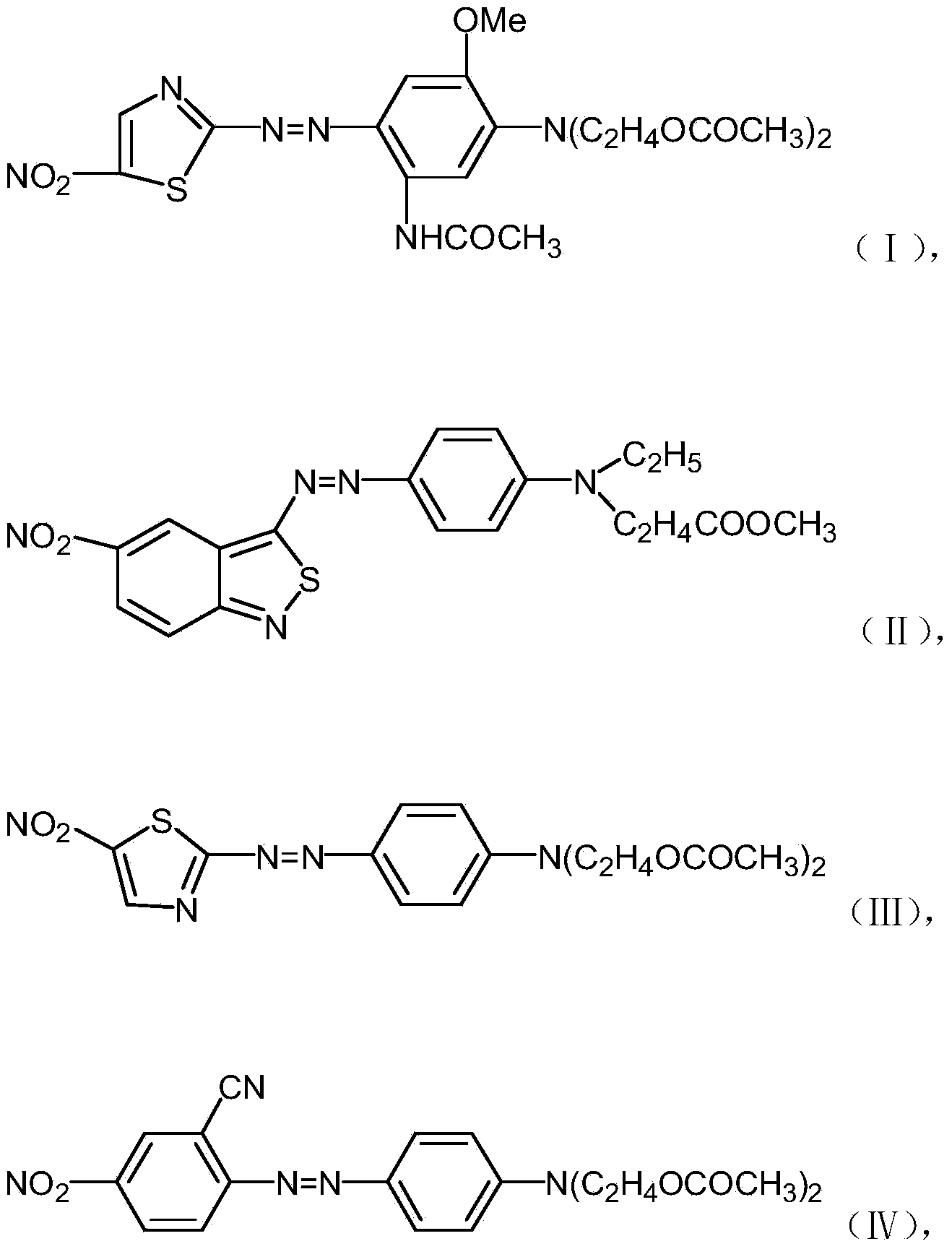

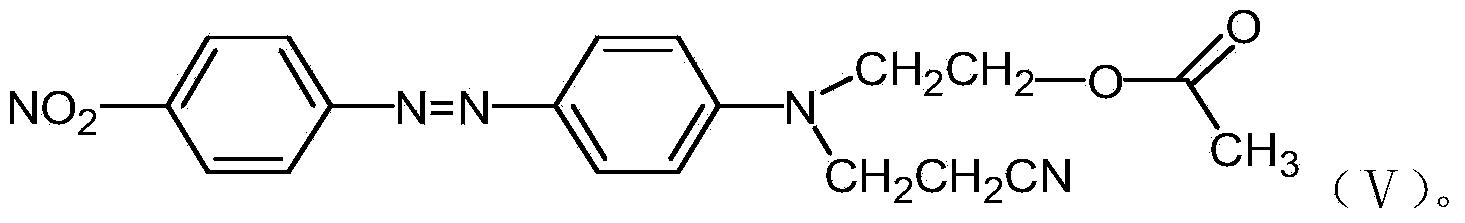

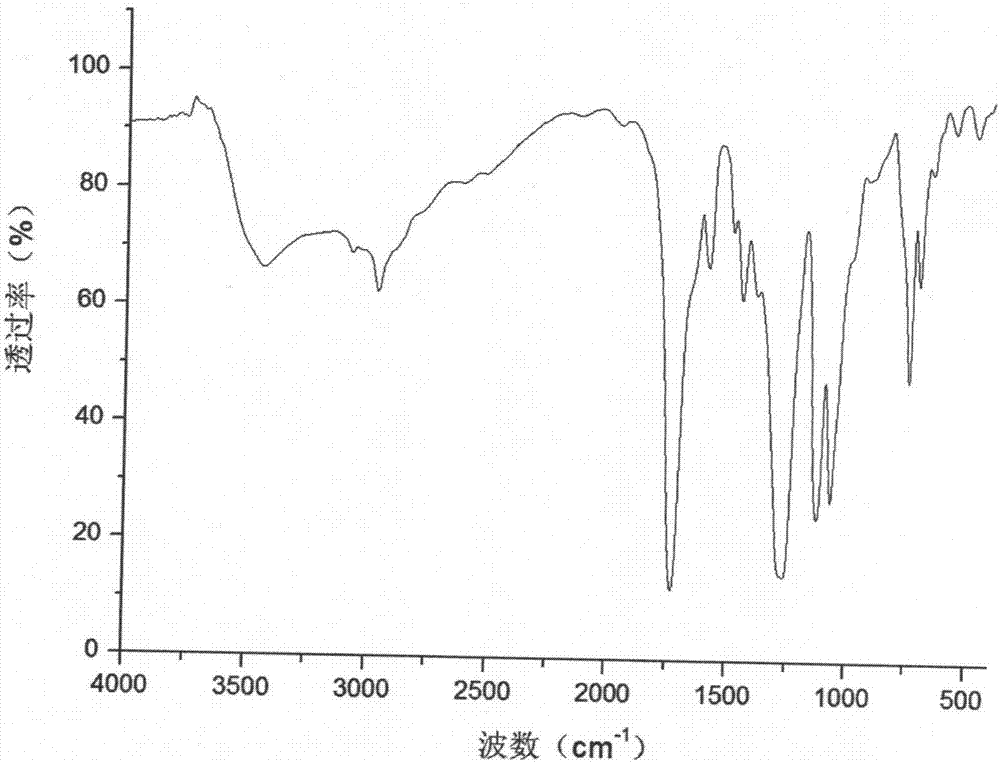

Acetate fiber monoazo dye mixture, as well as preparation method and applications thereof

InactiveCN104031411AChromatography is completeExcellent fastness performanceOrganic dyesDyeing processCompound EChemical compound

The invention discloses an acetate fiber monoazo dye mixture. According to the total mass of the dye mixture, the acetate fiber monoazo dye mixture comprises the following active ingredients in percentage by weight: 10-40% of compound A, 5-30% of compound B, 0.5-50% of compound C, and the balance of dispersing agent, or 10-40% of compound A, 3-30% of compound D, 1-40% of compound E, and the balance of dispersing agent, or 2-35% of compound A, 5-25% of compound B, 0.1-10% of compound C, 4-20% of compound D, 5-30% of compound E, and the balance of dispersing agent. The acetate fiber monoazo dye mixture is reasonable in formula, excellent in dying performance, wide in applications, high in the added value of the product, and can be used for dying acetate fibers under the low-temperature condition. The invention further discloses a preparation method of the acetate fiber monoazo dye mixture, which comprises the following steps of: mixing all the active ingredients according to a proportion, adding water and grinding, and conducting spray drying, and the preparation method is simple in technology steps, strong in operability, low in cost, and suitable for industrial production.

Owner:上海贝通色彩科技有限公司

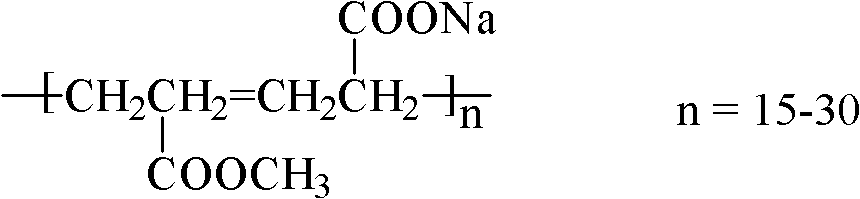

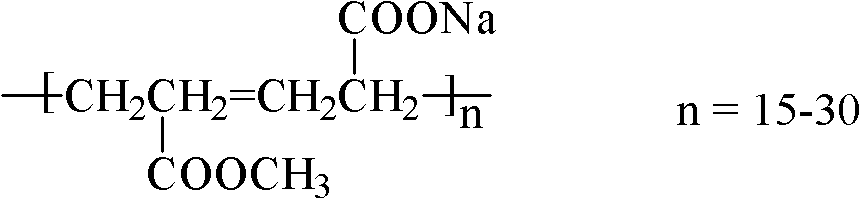

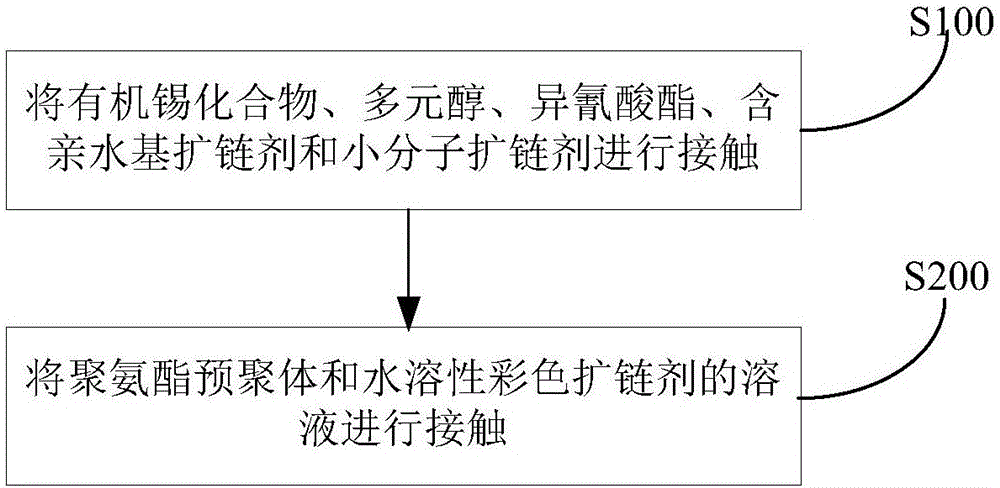

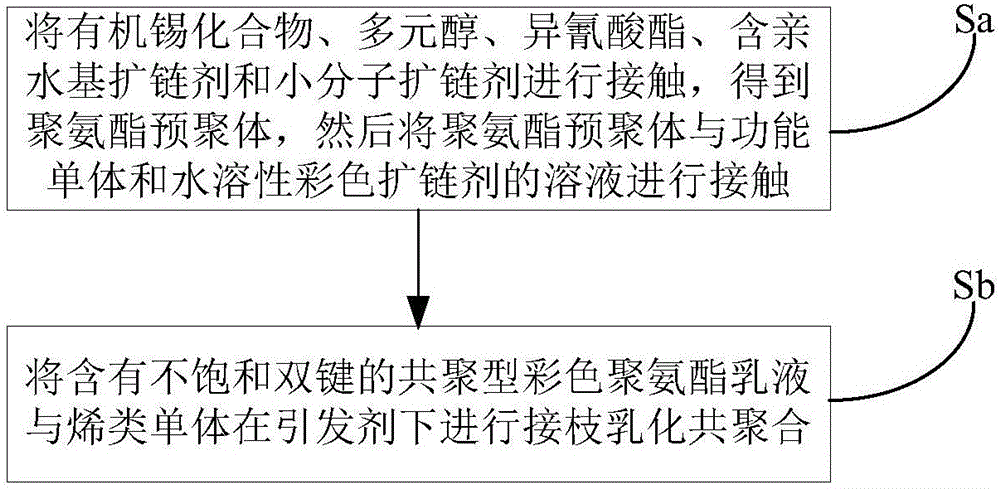

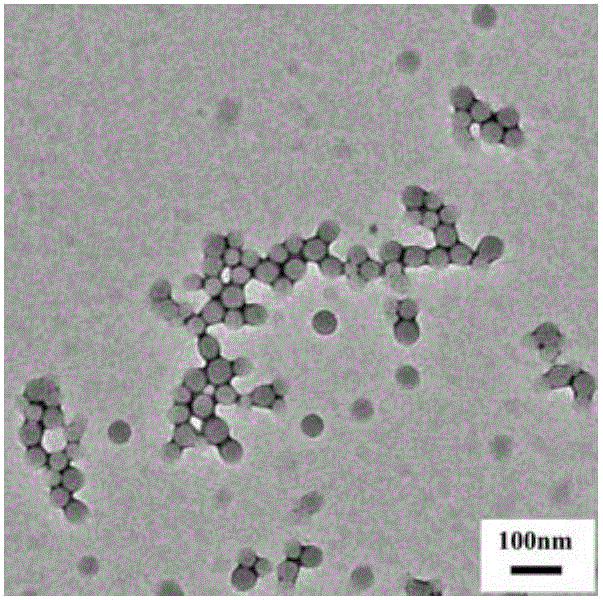

Water-soluble color chain extender, copolymerization type colored polyurethane emulsion and colored polyurethane-acrylic ester copolymer emulsion, and preparation methods thereof

The invention discloses a water-soluble color chain extender, copolymerization type colored polyurethane emulsion and colored polyurethane-acrylic ester copolymer emulsion, and preparation methods thereof, wherein at least one chromophoric group and at least two amino groups are contained in the water-soluble color chain extender. The water-soluble color chain extender can have various colors including red, yellow, blue, green, purple, brown, black and the like; in addition, the production process is simple; the production cost is low; the production efficiency is high; the green and environment-friendly effects are achieved; meanwhile, when the water-soluble color chain extender is used as a chain extender, the copolymerization type colored polyurethane emulsion and the copolymerization type colored polyurethane-acrylic ester copolymer emulsion with rich colors can be obtained through preparation; the water-soluble color chain extender can be widely used for industrial production.

Owner:TSINGHUA UNIV

Sizing-dyeing method and sizing-dyeing equipment assembly for color yarn production by paint spraying

InactiveCN105986388AHigh color fixing rateAvoid residueSucessive textile treatmentsTextile treatment by spraying/projectingYarnProcess engineering

The invention discloses a sizing-dyeing method and a sizing-dyeing equipment assembly for color yarn production by paint spraying. The sizing-dyeing equipment assembly comprises a multi-unit constant-tension winding and unwinding system, an ultrasonic cation modification system, a drying system, a plasma treatment system, a paint spraying system, an infrared constant-temperature pretreatment and shortened wet steaming system, a fixation drying system, a sizing system, an intelligent constant-tension yarn storage rack, a lease system and a winding system. By adoption of the paint spraying system for paint spraying of yarns, a traditional dip dyeing procedure is replaced, pollution is avoided, residue of paints in dip dyeing bath is avoided, sewage discharging burden after dyeing is relieved, total dyeing cost is reduced, and ecological environment is improved. Colorful patterns are formed on the yarns to meet market demands and customer aesthetic variations, and the technical problem of pattern diversification on a current dyeing market is solved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

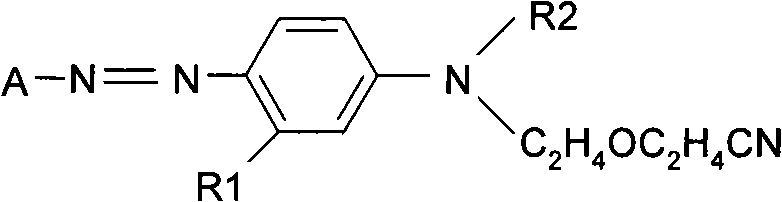

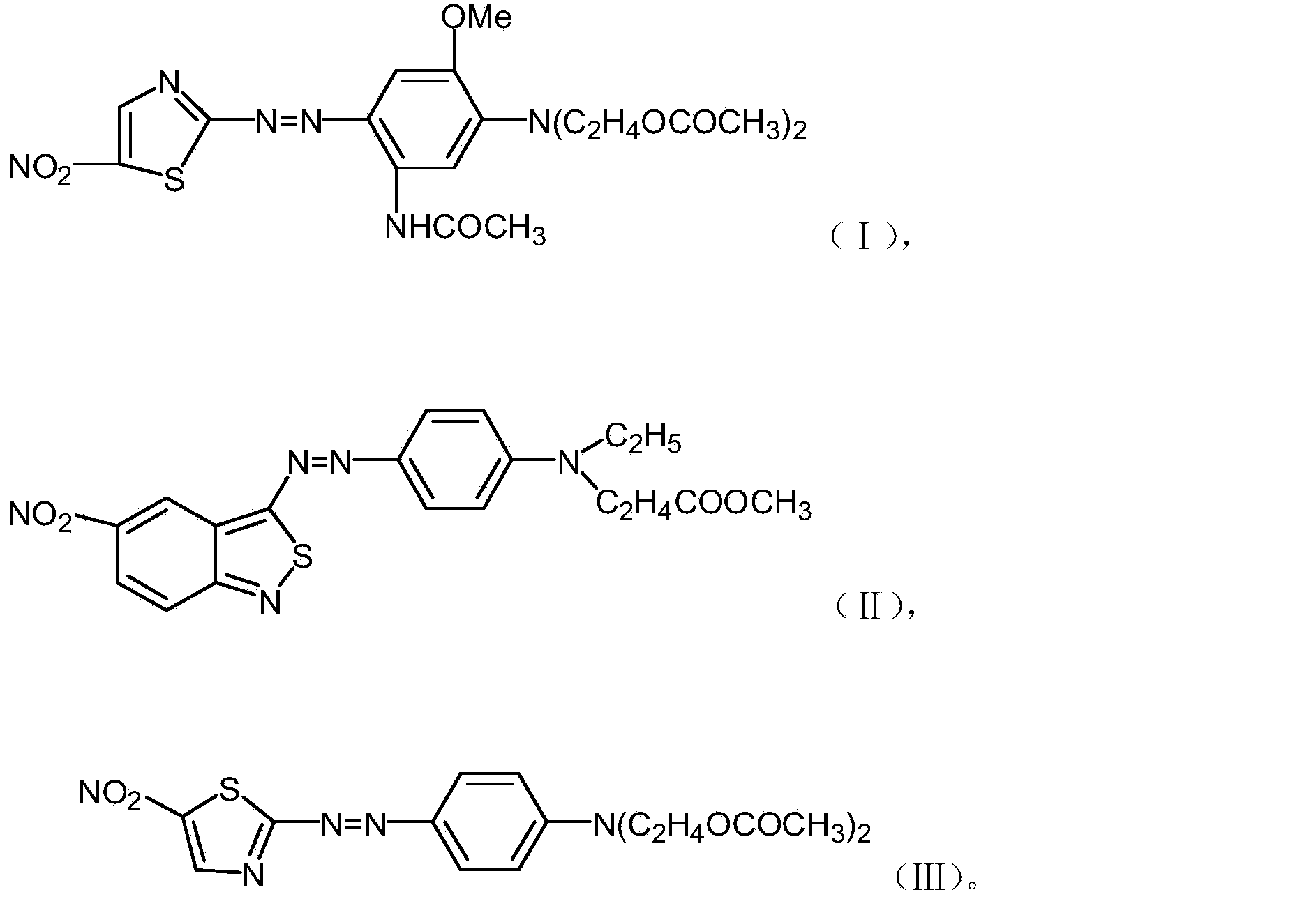

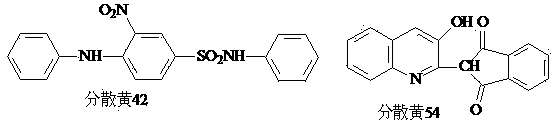

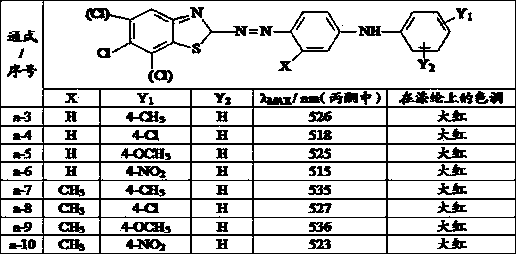

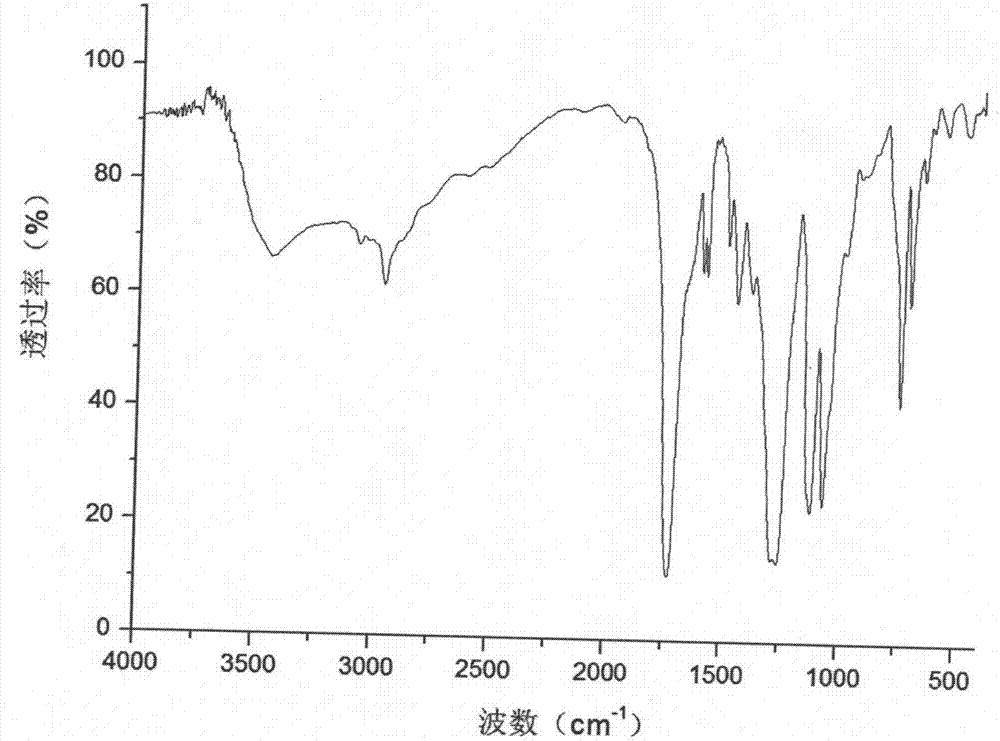

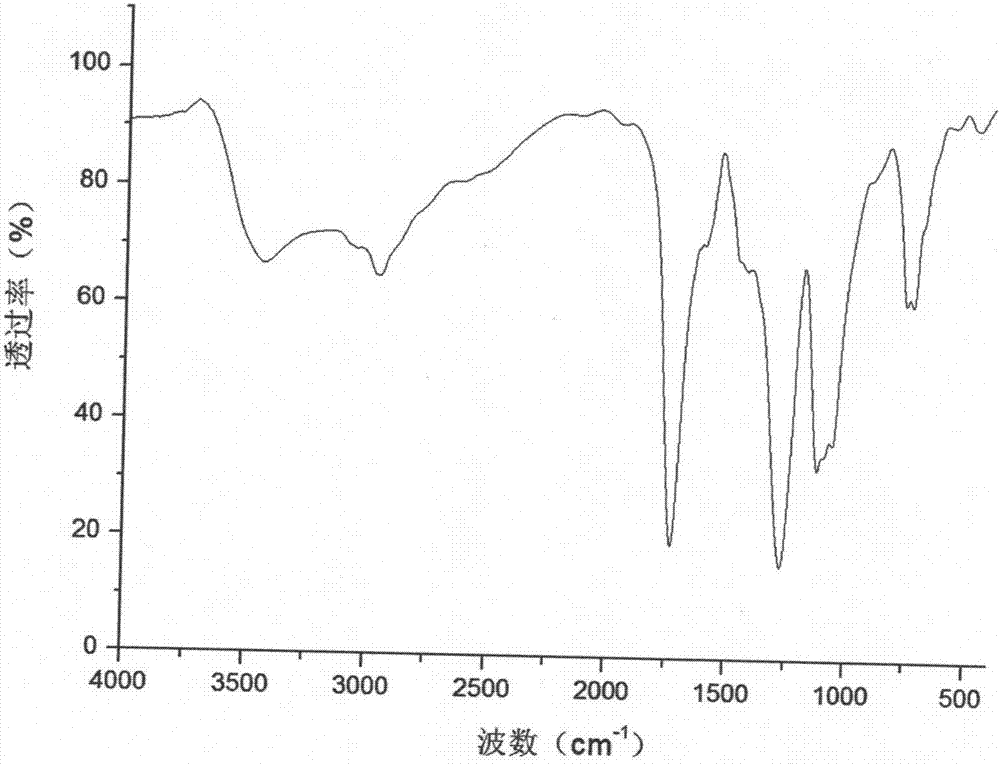

Diaminoazobenzene type disperse dye and application thereof

ActiveCN103525121AChromatography is completeImprove dye uptakeOrganic dyesDyeing processDisperse dyeCellulose fiber

The invention discloses a diaminoazobenzene type disperse dye with a general formula (1) as shown in the specification. The diaminoazobenzene type disperse dye has the characteristics of bright shade, excellent dyeing performance and fastnesses and wide pH range. The diaminoazobenzene type disperse dye can be used for performing pretreatment and one-step one-bath dyeing on polyester, polyester superfine fibers and a blend fabric of polyester and cellulose fibers in a strong alkaline bath, performing same-pulp printing on a disperse / active dye of the blend fabric of polyester fibers and cellulose fibers, and performing one-step method alkaline burn-out printing on double-sided plush, non-inverted velvet and super-soft short floss type polyester fabrics.

Owner:JIANGSU YABANG DYE

Imidazolium-based anionic dye-dyeable modified copolyester masterbatch and its preparation and application

Owner:DONGHUA UNIV

Imidazole-based anionic dye dyeable modified copolyester masterbatch, and preparation and application thereof

ActiveCN106008942ADemonstrates anionic dyeing propertiesDemonstrates dye leakage prevention performanceMasterbatchCopolyester

The invention provides an imidazole-based anionic dye dyeable modified copolyester masterbatch, and preparation and application thereof. The imidazole-based anionic dye dyeable modified copolyester masterbatch is characterized in that a comonomer of the imidazole-based anionic dye dyeable modified copolyester masterbatch comprises terephthalic acid, glycol, N-2-(3,5-dicarboxyl phenyl) ethyl-N'-methylimidazole chlorine salt and 2-methyl-1,4-butanediol according to the molar ratio of 1:1.2-2.5:0.1-0.4:0.03-0.25. The imidazole-based anionic dye dyeable modified copolyester masterbatch prepared by the invention is blended with unmodified PET polyester to obtain a polyester product which has good anionic dye dyeability, the polyester product can be dyed at normal temperature and under normal pressure or can be subjected to boiling dyeing under normal pressure, the dye-uptake can be above 85%, dye cannot leak easily, and the imidazole-based anionic dye dyeable modified copolyester masterbatch can be applied to the field of garment, home textile, agriculture, industry and the like.

Owner:DONGHUA UNIV

Azo dye composition and application thereof

ActiveCN101265369BChromatography is completeBright shadeOrganic dyesDyeing processAlkalinityDisperse dye

The invention relates to an azo dye compound and the application thereof. The compound is the combination of at least two dyes with A in the general formula (I) selected from any structure of (a), (b)or (c); any combination with A to be at least one from (a), at least one from (b) or at least one from (c); or the combination of at least one dye shown by the general formula (1) and at least one general disperse dye, or / and a dye as shown by the formula (2). Each substituent is shown as the claim of right. The compound can dye polyester and blended fabric thereof under the condition of strong alkalinity with pH more than or equal to 11 and less than or equal to 14; the alkalinity condition can effectively remove slurry and oil on the fabric, and overcomes the defect that decomposition products can be separated out in an acid bath, and cause dyeing defect. The cloth and the fabric adopting the azo dye compound are neat and have excellent styles. In addition, the polyester fiber and the blended fabric thereof can be pretreated with alkalinity and be dyed in a bath and at one step, thus improving the efficiency, and reducing the manufacturing cost and the waste water from dyeing.

Owner:浙江昱泰染化科技有限公司

Size-dyeing equipment assembly with a jet cationic modification fiber system and size-dyeing method of size-dyeing equipment assembly

InactiveCN104928868AHigh color fixing rateHigh bonding strengthSucessive textile treatmentsLiquid/gas/vapor removalInfraredFiber

The invention discloses a size-dyeing equipment assembly with a jet cationic modification fiber system. The size-dyeing equipment assembly comprises a constant-tension multi-unit reeling and unreeling system, a plasma processing system, the jet cationic modification system, a drying system, an ultrasonic pigment dyeing system, an infrared constant-temperature pretreatment and wet short steaming system, an intelligent color fixing and drying system, a sizing system, a constant-tension warp storage system, a leasing system and a multi-head reeling system which are all connected in sequence. Warps are subjected to modification treatment through a cationic modifying agent, patterns with design and colors are formed on the warps through an ultrasonic generator, priority is given to coulombian force from dependence on intermolecular force after graft modification, dye-uptake efficiency and color fixing rate of dye are increased, and bonding strength and bonding depth between the cationic modifying agent and the warps are further enhanced; the warps are subjected to jet modification by jetting the modifying agent, different modifying areas are formed as required, dip dyeing process is replaced by the ultrasonic pigment dyeing system, and no pollution is caused.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com