Imidazolium-based anionic dye-dyeable modified copolyester masterbatch and its preparation and application

An anionic dye and imidazole-based technology, which is applied in the field of copolyester masterbatch and its preparation, can solve the problems of few reports on imidazole-based comonomer research, and achieve convenient and efficient processing, simple synthesis, and good reaction controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

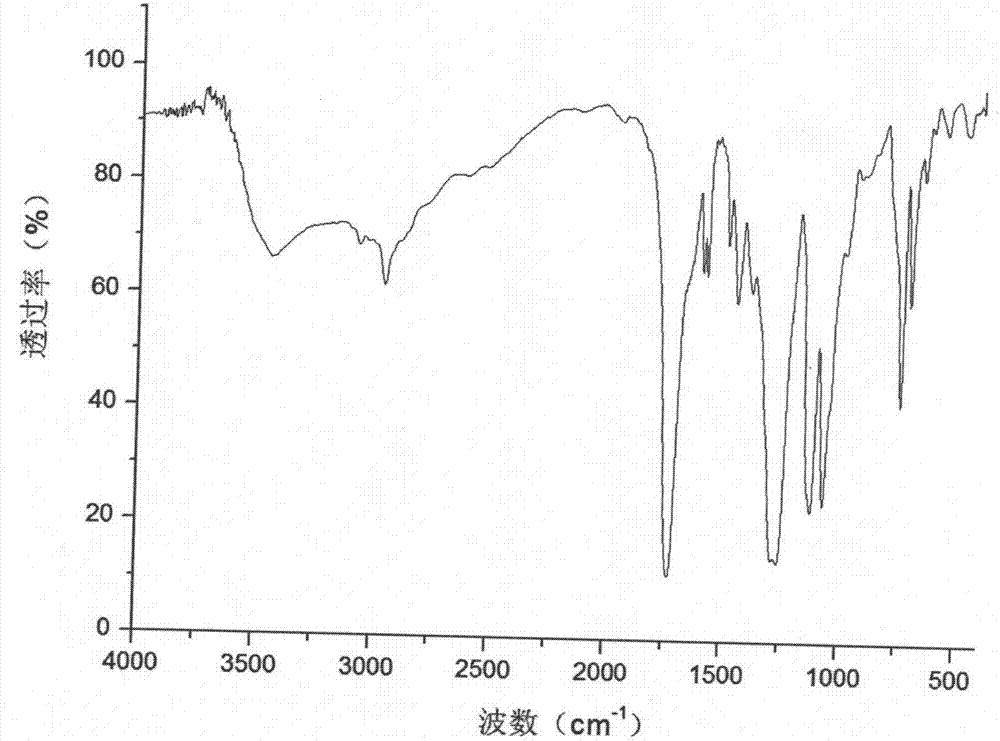

Embodiment 1

[0034] A kind of imidazolyl anionic dye-dyeable modified copolyester masterbatch, its structure is formula (I), and its comonomer comprises terephthalic acid, ethylene glycol, N-2-(3,5-dicarboxyphenyl)ethyl-N'-methylimidazolium chloride and 2-methyl-1,4-butanediol.

[0035] Adopt continuous polymerization equipment (comprising: first esterification tank, second esterification tank and polycondensation tank) to synthesize described imidazolyl anionic dye-dyeable type modified copolyester masterbatch, preparation method is:

[0036] Step a: Add 500 grams of terephthalic acid and 300 grams of ethylene glycol into the first esterification kettle, add 0.2 grams of triphenyl phosphate and 0.3 grams of antimony trioxide to carry out esterification reaction, and the reaction temperature is 250 ° C , the reaction time is 3h;

[0037] Step b: Then, the material obtained from the esterification reaction in step a enters the second esterification tank, and 2-methyl-1,4-butanediol equival...

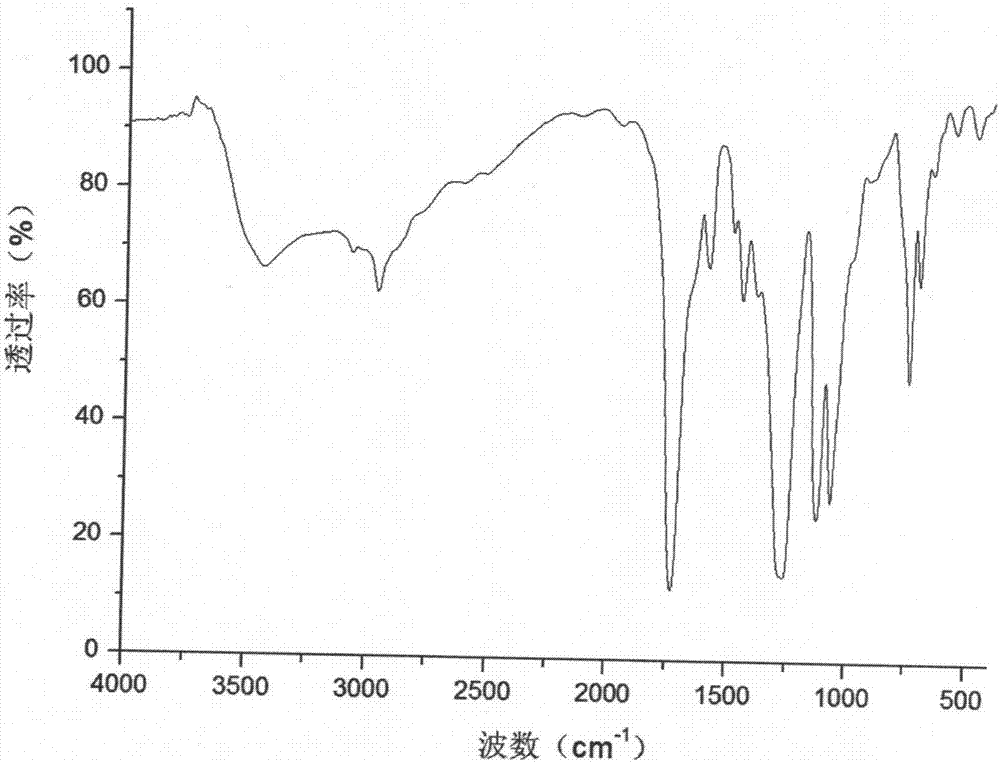

Embodiment 2

[0043] A kind of imidazolyl anionic dye-dyeable modified copolyester masterbatch, its structure is formula (I), and its comonomer comprises terephthalic acid, ethylene glycol, N-2-(3,5-dicarboxyphenyl)ethyl-N'-methylimidazolium chloride and 2-methyl-1,4-butanediol.

[0044] Adopt continuous polymerization equipment (comprising: first esterification tank, second esterification tank and polycondensation tank) to synthesize described imidazolyl anionic dye-dyeable type modified copolyester masterbatch, preparation method is:

[0045] Step a: Add 400 grams of terephthalic acid and 240 grams of ethylene glycol into the first esterification kettle, add 0.15 grams of triphenyl phosphate and 0.2 grams of antimony trioxide to carry out esterification reaction, and the reaction temperature is 255 ° C , the reaction time is 3h;

[0046] Step b: Then, the material obtained from the esterification reaction in step a enters the second esterification tank, and 2-methyl-1,4-butanediol equiva...

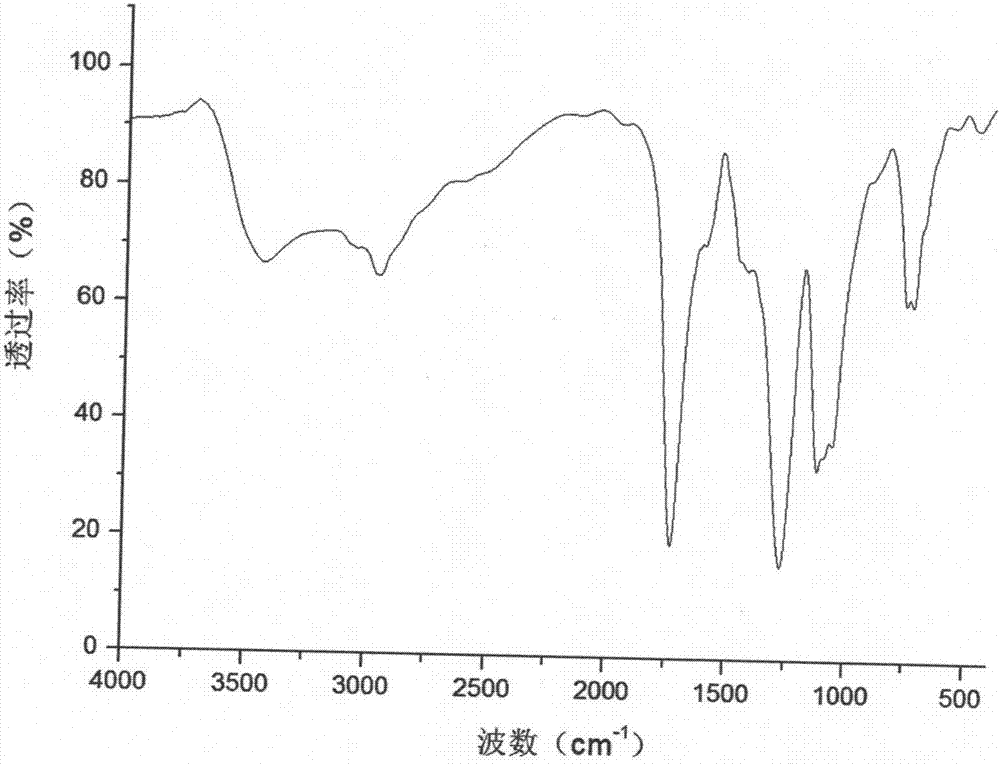

Embodiment 3

[0053] A kind of imidazolyl anionic dye-dyeable modified copolyester masterbatch, its structure is formula (I), and its comonomer comprises terephthalic acid, ethylene glycol, N-2-(3,5-dicarboxyphenyl)ethyl-N'-methylimidazolium chloride and 2-methyl-1,4-butanediol.

[0054] Adopt continuous polymerization equipment (comprising: first esterification tank, second esterification tank and polycondensation tank) to synthesize described imidazolyl anionic dye-dyeable type modified copolyester masterbatch, preparation method is:

[0055] Step a: Add 600 grams of terephthalic acid and 400 grams of ethylene glycol into the first esterification kettle, add 0.3 grams of triphenyl phosphate and 0.3 grams of antimony trioxide to carry out esterification reaction, and the reaction temperature is 252 ° C , the reaction time is 2.5h;

[0056] Step b: Then, the material obtained from the esterification reaction in step a is entered into the second esterification tank, and 2-methyl-1,4-butaned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com