Patents

Literature

838 results about "Dye uptake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

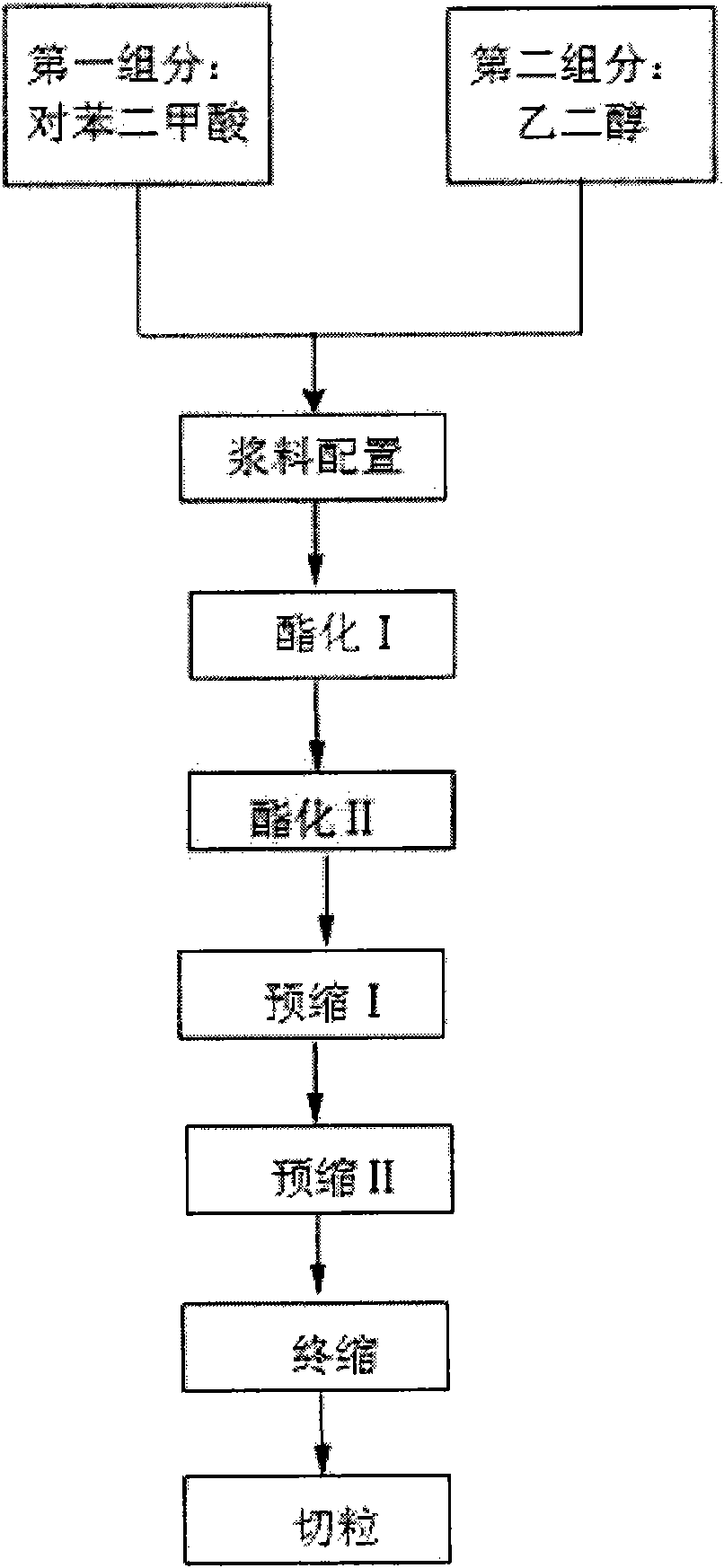

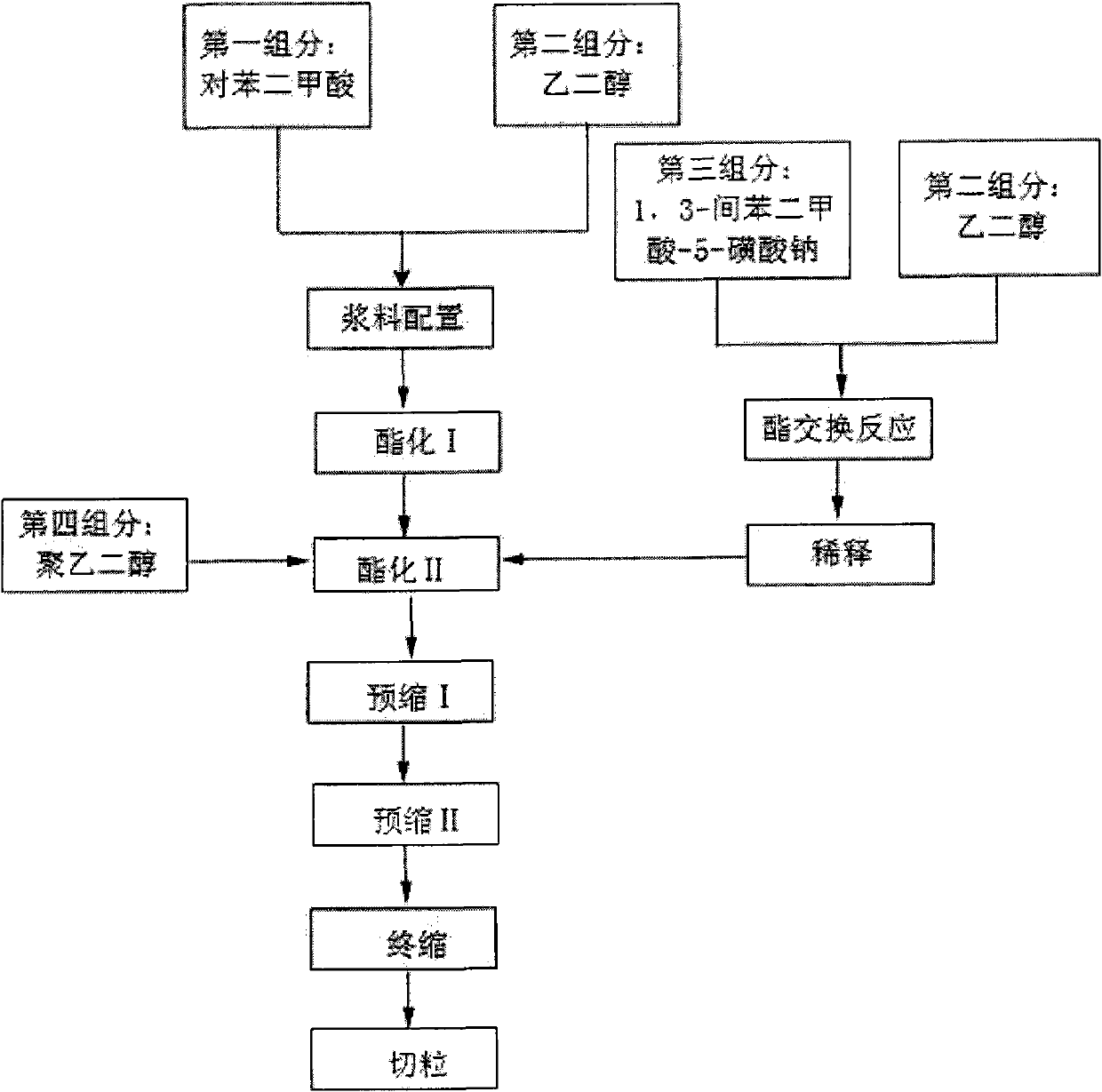

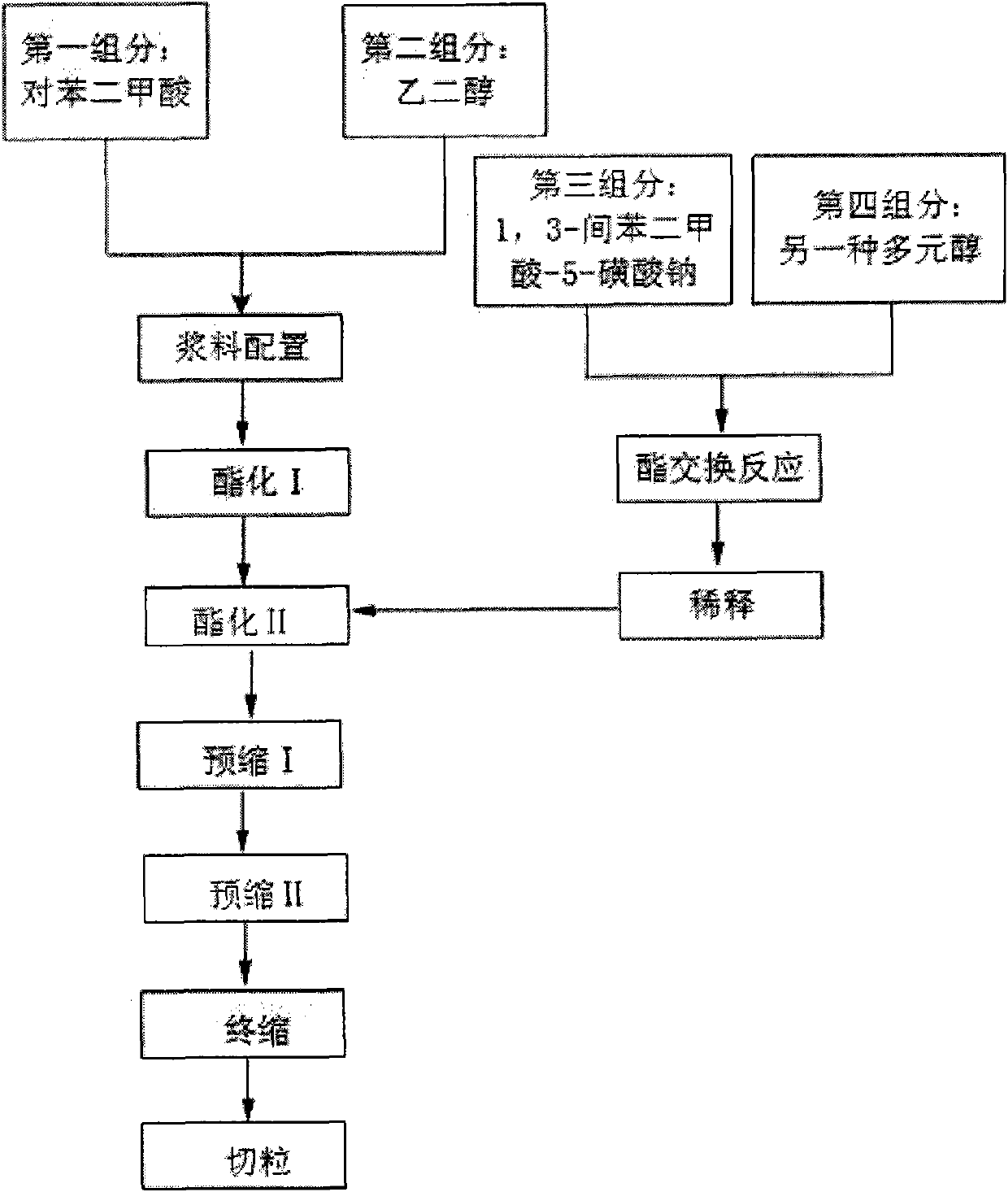

Preparation method of polyol copolyester

InactiveCN102086261AIncrease the chances of participating in a responseAchieve mass ratioDyeing processSlurryPhotochemistry

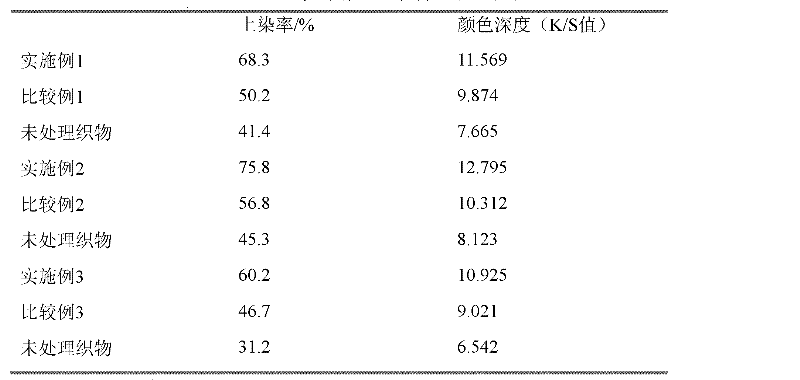

The invention discloses a preparation method of polyol copolyester. The preparation method comprises the following steps of carrying out slurry preparation, esterifying I, esterifying II, pre-condensing I, pre-condensing II, final condensing and pelletizing on terephthalic acid and glycol. The preparation method also comprises: carrying out ester exchange reaction on 1,3-isophthalic acid-5-sodium sulfonate and another polyol; diluting with the glycol, and then performing the esterifying II. In the preparation method, 1,3-isophthalic acid-5-sodium sulfonate and another polyol react in advance, thereby increasing the reaction probability of another polyol and ensuring that another poyol can reach the required mole ratio in a finished product. The preparation method is mainly applied to production of dye modified polyester by using various dihydric alcohols at normal temperature and normal pressure. The modified polyester is dyed by mainly using anode pigment, the used dye chromatograph is more than that of common polyester, dye-uptake rate can reach above 99%, colour fastness reaches 4-5 grade of European standard, and the color is more flamboyance and beautiful. When filament yarns are subjected to spinning, full-package rate is up to 95%-100%.

Owner:SHANGHAI DEFULUN CHEM FIBER

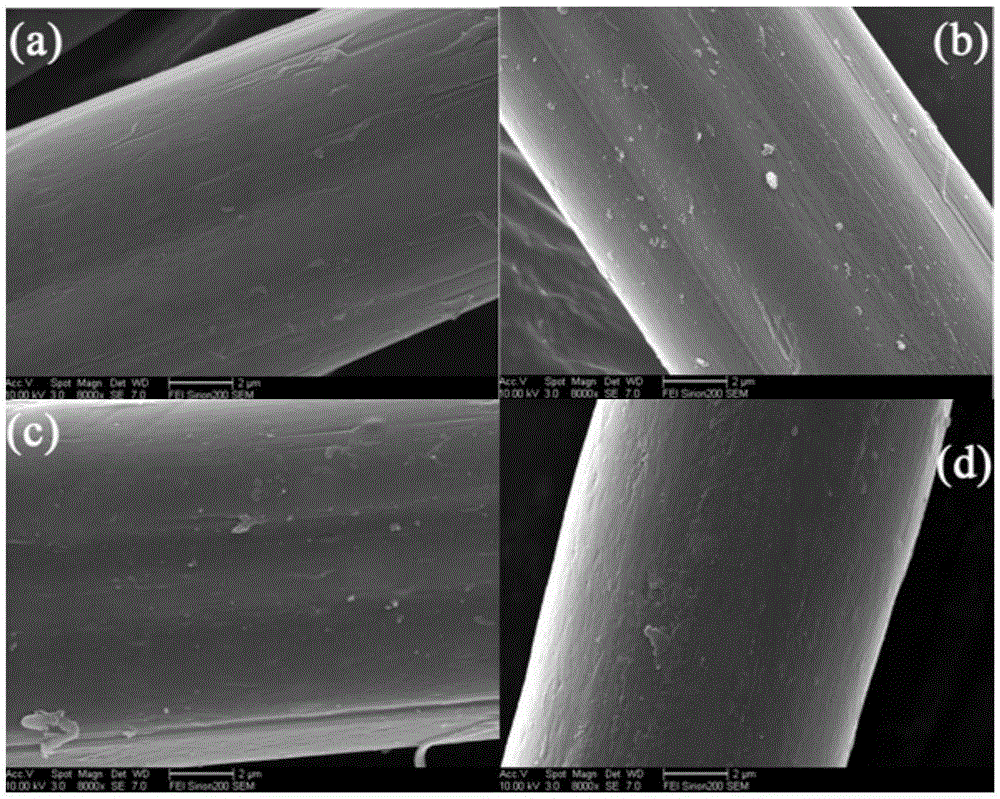

A method for improving the dyeing depth of cellulose fiber fabrics with chitosan

ActiveCN102268823AImprove accessibilityImprove responseDyeing processVegetal fibresEpoxyCooking & baking

The invention relates to a method for improving the dye depth of cellulose fiber fabrics by using chitosan. In the method, a polycarboxylic acid solution is used as a solvent and a cross-linking agent of chitosan and epoxy chloropropane is used as a cross-linking agent, and chitosan is covalently grafted to the surface of the cellulose fiber fabrics through padding, preliminary drying and baking at a high temperature. The combining strength of chitosan and the cellulose fiber fabrics is increased greatly, the electrostatic repulsion between the cellulose fiber fabrics and anionic dyes is reduced, the dye-uptake of dyes and the color depth of the fabrics are improved obviously, and the crease resistance of the cellulose fiber fabrics processed by using the method is improved obviously.

Owner:CHANGZHOU UNIV

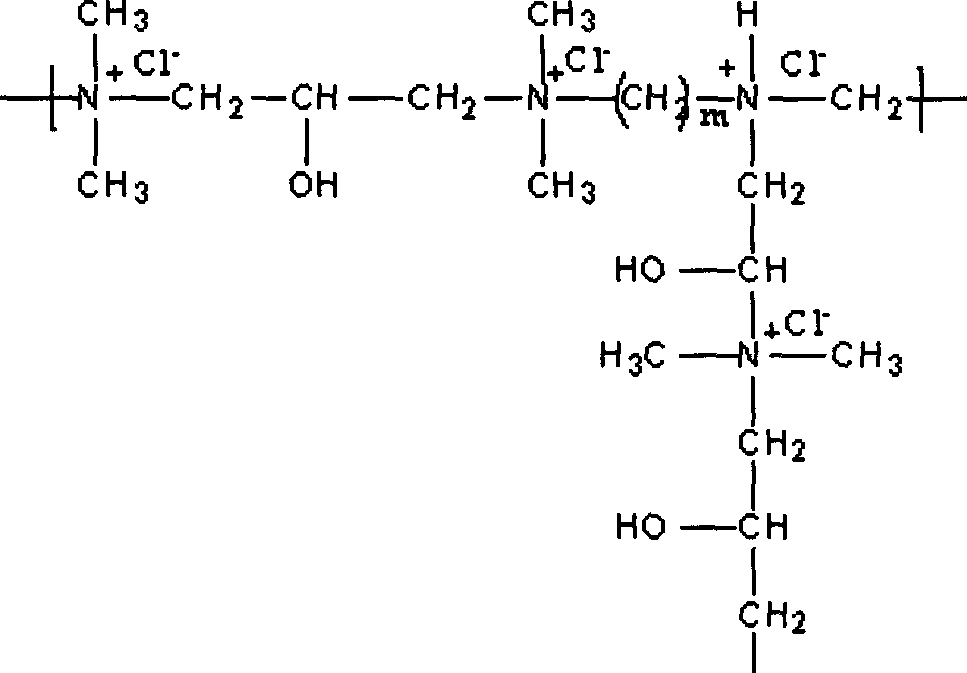

Ecological low-salt dyeing and finishing agent for reactive dyes and preparation method and applications thereof

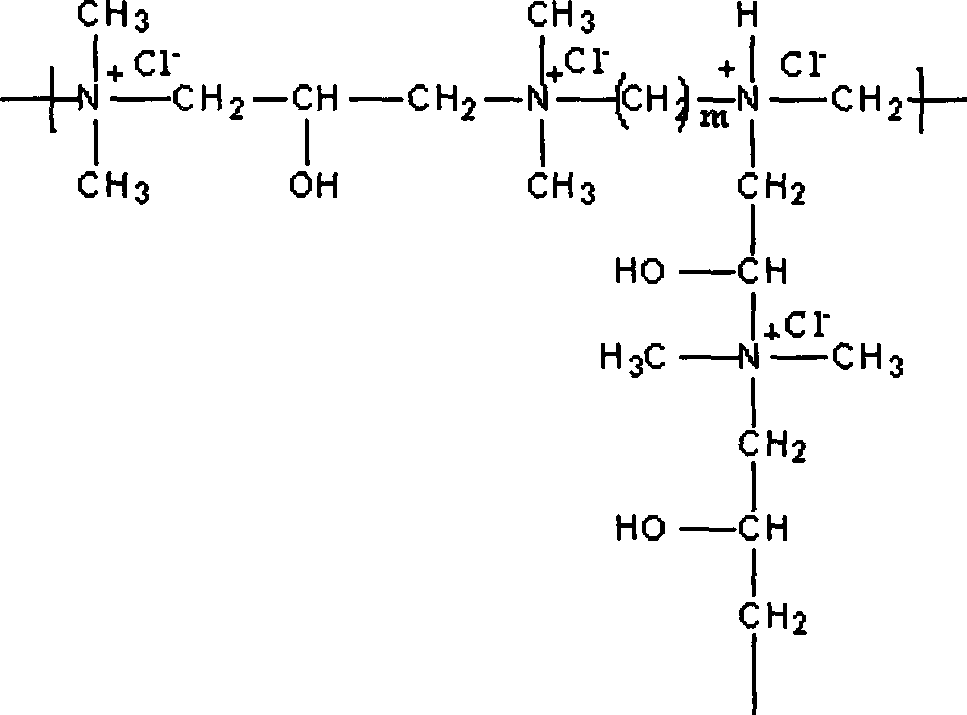

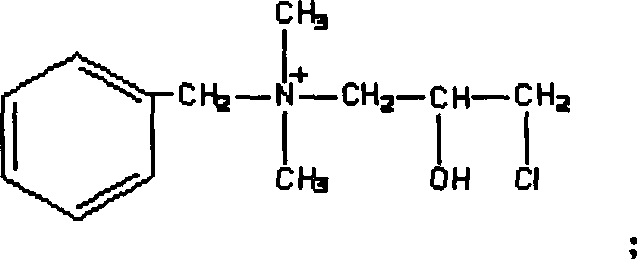

The invention discloses an ecological low-salt dyeing and finishing agent for reactive dyes, which comprises a crosslinking cationic modifier A and a branched cationic modifier B, wherein the weight ratio of the crosslinking cationic modifier A to the branched cationic modifier B is (30-50): 50. The ecological low-salt dyeing and finishing agent for reactive dyes disclosed by the invention has the advantages that in the process of treating cotton fibers by using the crosslinking cationic modifier and the branched cationic modifier, the inner portions and surfaces of the fibers can be modified through cationization, therefore, the utilization rate of reactive dyes can be improved, and the dye-uptake rate and fixation rate of cotton fabrics are significantly higher than those in conventional dyeing; salt-free low-alkali dyeing even salt-free alkali-free dyeing can be achieved, and dyeing wastewater can be recycled for secondary utilization; and the color fastness to washing and the color fastness to rubbing are consistent with those of conventional cotton fabrics.

Owner:南通曙光染织有限公司

Ecological dyeing method for dyeing cotton fabric with mulberry red natural dye

InactiveCN101851868AImprove protectionNo allergic reactionDyeing processVegetal fibresEngineeringNatural dye

The invention relates to an ecological dyeing method for dyeing a cotton fabric with mulberry red natural dye, comprising the following steps: preprocessing the cotton fabric and then dyeing the preprocessed cotton fabric with the mulberry red natural dye; adding metal salt for fixation; and soaping the fabric after fixation and then fixing colors to obtain the dyed fabric with even color, wherein washing fastness can reach 3-4degrees. The ecological dyeing method has simple dyeing process, high dye-uptake, good pigment stability and wide market prospect.

Owner:CHANGZHOU GOLDEN SPRING TEXTILE +1

Liquid ammonia modified method of cotton fibriia and yarn

InactiveCN101413213AGood flexibilityImprove curling effectLiquid/gas/vapor removal by centrifugal forceTextile treatment by pouringYarnVegetable fibers

The invention provides a method for modifying cotton and long vegetable fiber or yarn by ammonia liquid, which comprises the following steps: firstly, drying pre-treatment of raw materials; secondly, ammonia leaching of the raw materials in a hermetical treatment tank; thirdly, spin-drying of the raw materials subjected to ammonia leaching when a creel is twirled; fourthly, drying of the raw materials subjected to spin-drying by ammonia flow when the creel rotates slowly; fifthly, flushing of the raw materials which are dried by the ammonia flow by airflow when the creel rotates slowly; and so on. The method keeps the inherent advantages of the cotton, the long vegetable fiber and the yarn, overcomes the defects of the cotton, the long vegetable fiber and the yarn, increases softness, crimp tendency and fluffiness of the cotton, the long vegetable fiber and the yarn, improves the dye-uptake rate, the leveling property and the showy dye level, and further solves the problems of energy conservation, efficiency improvement and environmental protection.

Owner:上海业安纺织科技有限责任公司

Composite environmental protection type grey disperse dyes

An environmental protection type composite disperse gray dye with high dye uptake, fastness, reproducibility and sublimation fastness contains proportionally dye monomers A, B and C and assistant.

Owner:ZHEJIANG RUNTU

Preparation method of hydrolysis-resistant modified polylactic acid fibers

InactiveCN102660797AFeel goodGood flexibilityMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterHydrolysis

The invention relates to a preparation method of hydrolysis-resistant modified polylactic acid fibers. The preparation method comprises the following steps of uniformly mixing 70 to 98.9 parts by weight of polylactic acid, 1 to 30 parts by weight of one or more low-molecular weight polyesters and 0.1 to 5.0 parts by weight of multifunctional polycarbodiimides, carrying out melt blending granulation of the mixture to obtain master batches, carrying out vacuum drying of the master batches, carrying out melt spinning and winding to obtain winded wires, and carrying out drafting to obtain the hydrolysis-resistant modified polylactic acid fibers. The preparation method is simple, has a low cost and is suitable for large-scale production. The hydrolysis-resistant modified polylactic acid fibers have excellent handle and softness, realize low temperature dying, have high dye-uptake in high temperature dying and have good hydrolysis resistance so that the problem of mechanical property degradation produced in high temperature treatment is avoided.

Owner:DONGHUA UNIV

Method for dyeing textile by dye liquor prepared by mutually dissolving organic solvent and water

The invention relates to a method for dyeing textile by dye liquor prepared by mutually dissolving organic solvent and water and belongs to the technical field of textile printing and dyeing processing. The dye liquor applies organic solvent soluble in water and lower than water in boiling point, and dye is soluble in water and insoluble in organic solvent, so that effective liquor ratio is lowered, distribution coefficient of dye on fiber is changed, and dye uptake is of dye is increased. Adding the organic solvent allows boiling point of the dye liquor to reduce, energy is saved, water consumption in dyeing process is greatly reduced, the organic solvent can be recycled and reused, and discharge of waste liquor is reduced. The dyeing process includes performing twice-soaking and twice-rolling accelerant solution to textile, and solid accelerant is prevented from being precipitated out at a great amount by being added in dyeing process. The method is low in water consumption, utilization rate of dye is increased, energy consumption is low, the organic solvent can be recycled and reused, and cleaning and dyeing are achieved simultaneously.

Owner:WUHAN TEXTILE UNIV

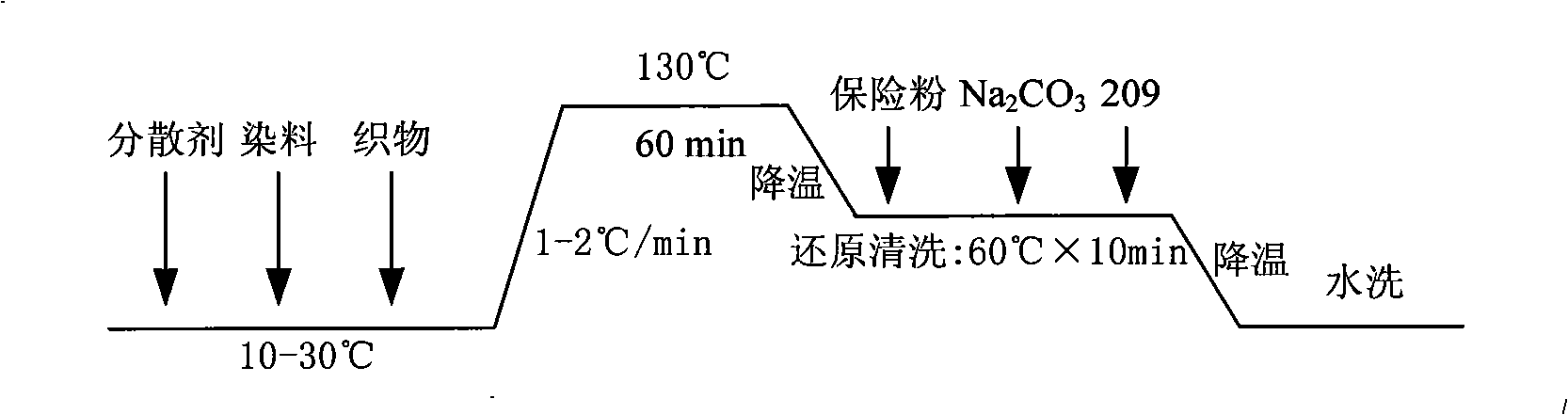

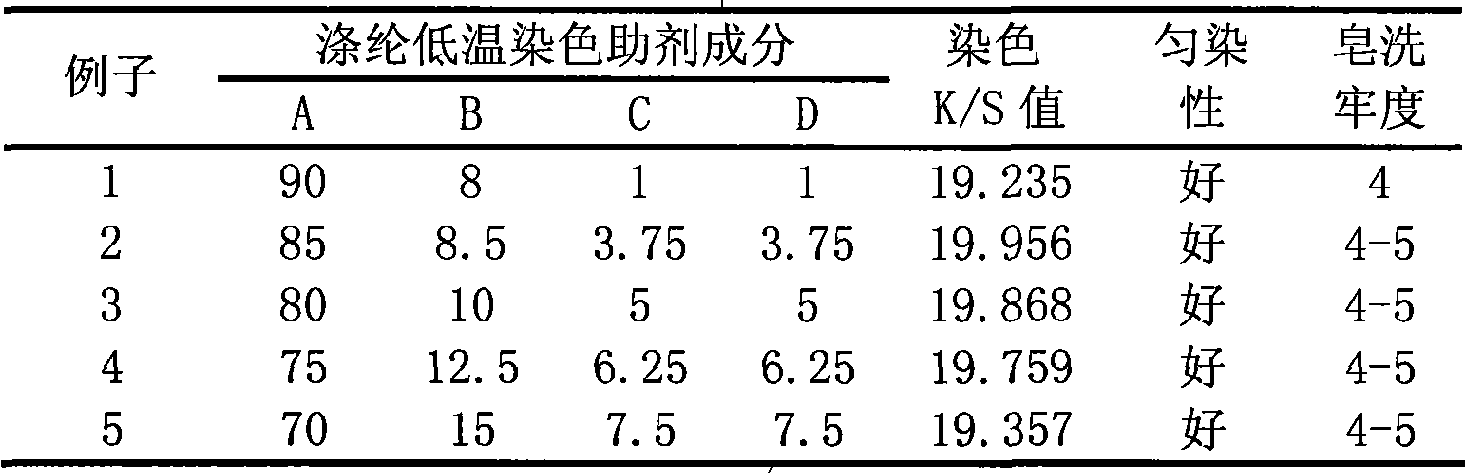

Environment-friendly type terylene low temperature dyeing assistant with alkyl phthalic imide as vector and preparation thereof

The invention discloses an environment-friendly terylen low-temperature dyeing auxiliary agent taking alkyl phthalimide as a carrier and a preparation method thereof. The compositions in percentage by weight of the dyeing auxiliary agent are: 70 to 90 percent of alkyl phthalimide compound, 8 to 15 percent of concentrated emulsion 8206, 1 to 7.5 percent of castor oil polyoxyethylene ether sulphonated matter and 1 to 7.5 percent of alkyl phenol polyoxyethylene ether, wherein the alkyl phthalimide is takes as the carrier; and the concentrated emulsion 8206, the castor oil polyoxyethylene ether sulphonated matter and the alkyl phenol polyoxyethylene ether are takes as an emulsifying agent. The environment-friendly terylen low-temperature dyeing auxiliary agent is used in low-temperature dyeing of terylen and terylen-containing textile fabrics; moreover, the dyeing auxiliary agent not only has the characteristics of nontoxicity, tastelessness, environmental protection and low cost, etc., but also has the advantages of high dye uptake, excellent level dyeing property, high dyeing fastness and wide application range, etc., thereby meeting the requirements of low-temperature dyeing production of terylen-containing textile fabrics.

Owner:ZHEJIANG SCI-TECH UNIV +1

Method for dyeing modified cellulose fiber fabric on rhubarb and curcuma longa dyes

InactiveCN101349020AHigh fixation rateStable color fastnessDyeing processVegetal fibresHigh rateCellulose fiber

The invention provides a method for dyeing a modified cellulose fiber textile by a rhubarb and turmeric dye. The method comprises the following: 1. a step of modifying a quaternary ammonium group of the cellulose fiber textile, in which a modifying agent with a concentration of 50 to 60 g / l and sodium hydrate with a concentration of 12 to 18g / l react for 40 to 60 minutes at a temperature of between 64 and 75 DEG C, the bath ratio is 1:30; in the post treatment after the modification, the fiber textile is washed by hot water at a temperature of between 40 and 50 DEG C for 10 minutes, is washed by cold water, is prickled by HAC with a concentration of 2 to 3g / l for 2 minutes, is washed by water to be neutral and is dried; 2. a step of preparing the dye solution by the sodium hydrate extracting agent with a concentration of 15 to 45g / l; and 3. a step in which the modified cellulose fiber textile is dyed, washed by water and dried directly by the dyeing technique and is washed by soap, washed by water and dried. The technique is simple and easy to implement, does not need the mordanting and the fixation processes and the like, has high rate of dye-uptake, good dye quality and the friction resisting color fastness and the colorfastness to washing up to more than three grades, is nontoxic, does not pollute the environment, and has low cost, and remarkable economic benefits and environmental benefits.

Owner:DALIAN POLYTECHNIC UNIVERSITY

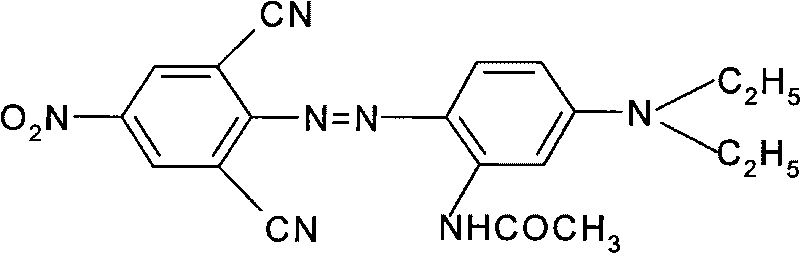

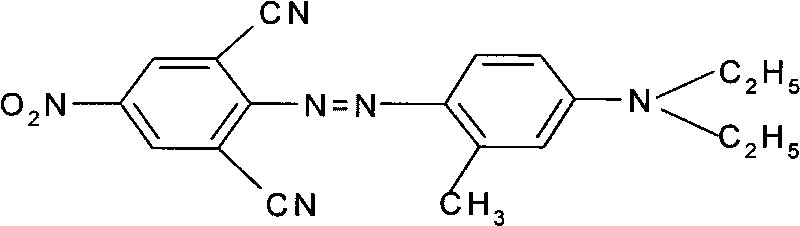

Blue disperse dye mixture

ActiveCN101705020AImprove performanceImprove dye uptakeMonoazo dyesDyeing processDisperse dyePhotochemistry

The invention discloses a blue disperse dye mixture for printing and dyeing polyester materials, which is characterized by comprising the following components in percentage by weight: 5 to 20 percent of dye A, 3 to 28 percent of dye B, 12 to 30 percent of dye C, 0 to 25 percent of dye D, and 45 to 70 percent of dispersant. The blue disperse dye mixture has the characteristics of high dye uptake, good dyeing reproducibility, good leveling property, good fastness and the like, and particularly has excellent dye uptake and wet fastness, and wide dyeing pH range.

Owner:烟台澳土复合材料有限公司

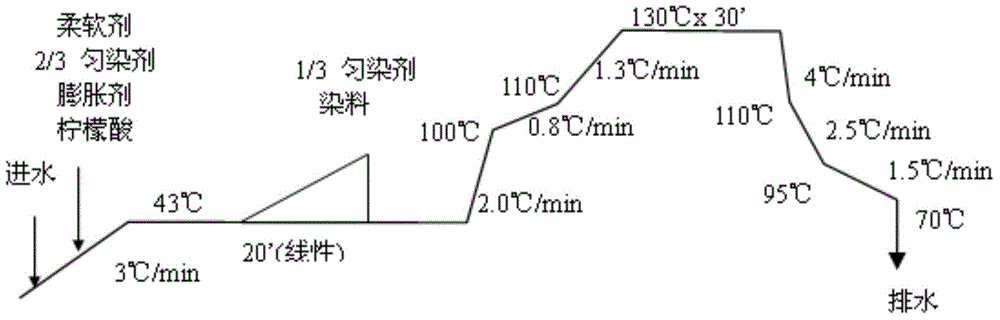

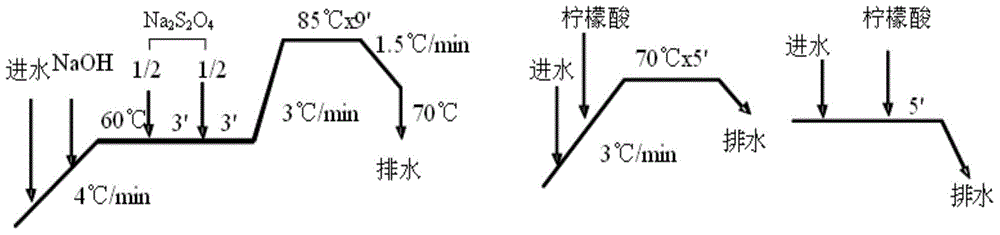

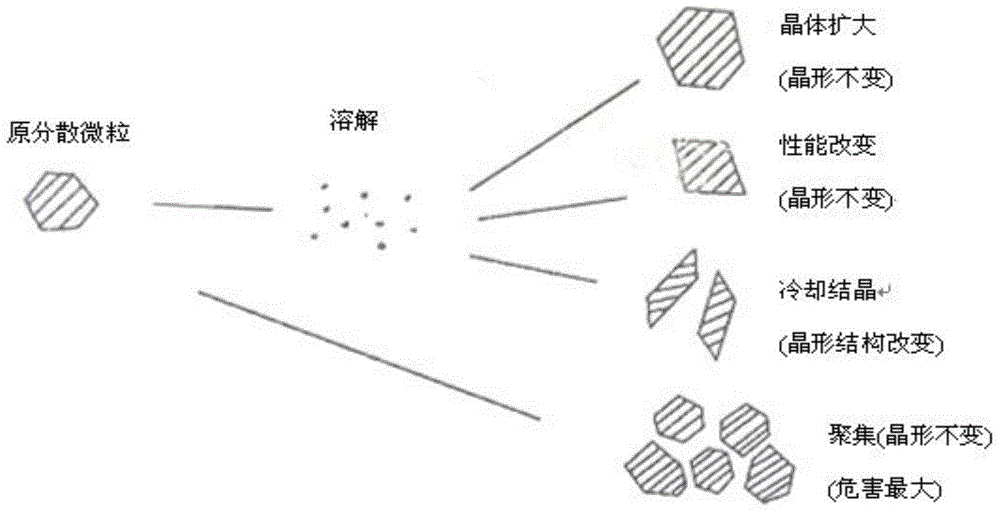

Method for dyeing superfine terylene fabric

ActiveCN104878618AGuaranteed color fastnessImprove dye uptakeDyeing processDisperse dyeColour fastness

The invention discloses a method for dyeing a superfine terylene fabric. The method comprises the following dyeing steps: adding a softening agent, part of a leveling agent, and an expansive agent into the soppy superfine terylene fabric to prepare a working solution; adding a pH regulator to regulate the pH value of the working solution to 3.5-4.0; heating the working solution with the adjusted pH value to 43 DEG C, and adding disperse dye and the residual leveling agent to prepare a dye liquor; carrying out heating and dyeing. The method aims at dyeing of a brightly colored superfine terylene fabric, and has the advantages the softening agent, the leveling agent and the expansive agent are added simultaneously, and the pH value of the dye liquor is regulated to 3.5-4.0, so that poor leveling property, uneven dyeing and other quality problems existing in a low-bath-ratio dyeing process can be solved; moreover, the dye-uptake rate of the disperse dye can be improved, secondary aggregation of the disperse dye in a high-temperature descending process is prevented, all color fastness indices of the superfine terylene fabric exceed 4-level, the dyeing property is improved, and the dyeing effect is ideal; the method further has the advantages of being environment-friendly and low in energy consumption.

Owner:PACIFIC (PANYU) TEXTILES LTD

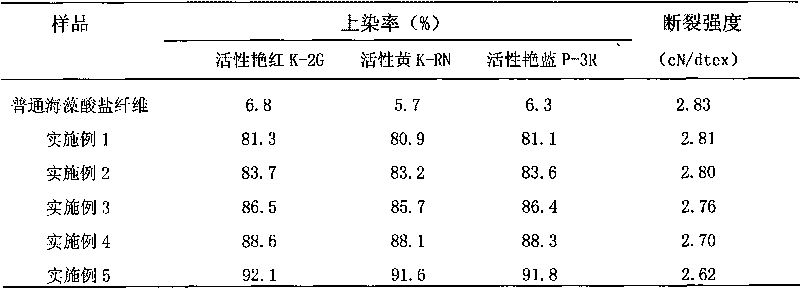

Manufacturing method of stainable alginate fibers

ActiveCN101736440AAchieve dyeingMeet diverse needsAlginate artificial filamentsWet spinning methodsColour fastnessState of art

The invention disclose a manufacturing method of stainable alginate fibers, which comprises the following steps of: adding a water-soluble dendrimers compound into a alginate fiber spinning solution, and solidifying, drafting, water washing and post-processing by adopting wet spinning equipment and technology to obtain the alginate fibers with excellent staining property, wherein the content of dendrimers in the alginate fibers is 1-10 percent. Compared with a traditional alginate fiber production technology, the invention has the advantages that the prepared alginate fibers can be applied to direct dyes and active dyes under a salt-free condition to realize staining and have higher dye uptake rate which generally reaches above 80 percent and is 10-15 times that of the alginate fibers produced by the traditional technology. In addition, the alginate fibers prepared by the invention has better color fastness and particularly excellent wet-processing fastness which reaches above grade 4.

Owner:QINGDAO TIANYI GROUP

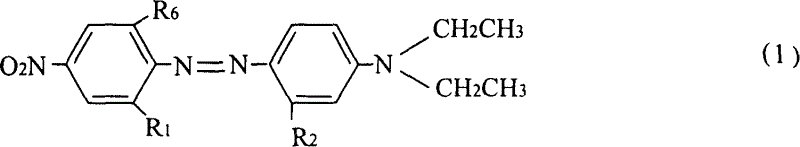

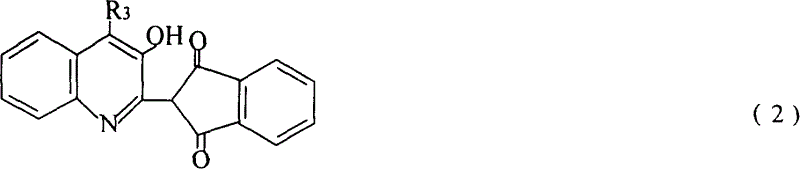

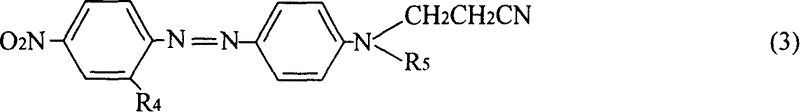

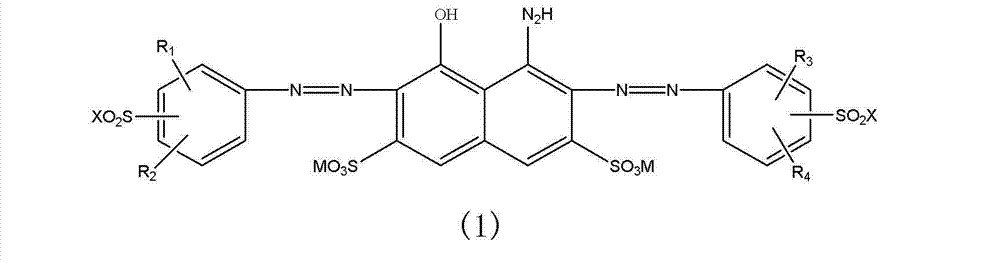

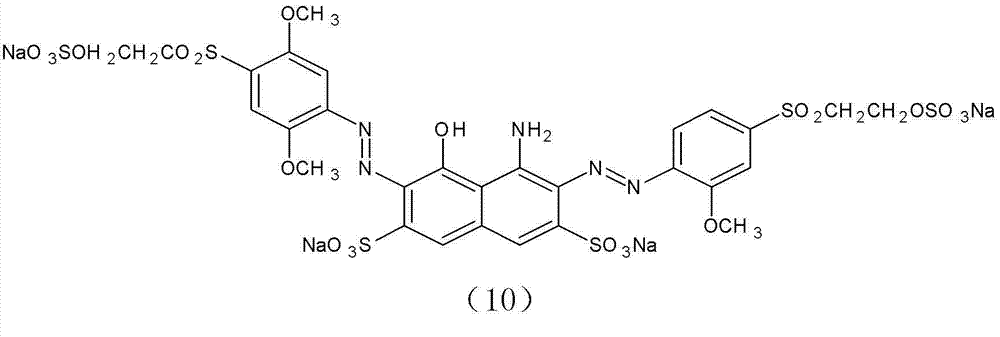

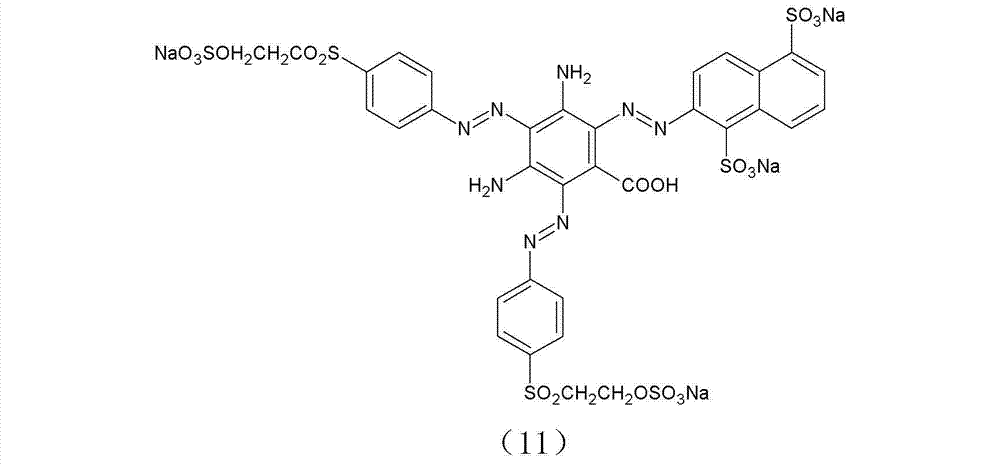

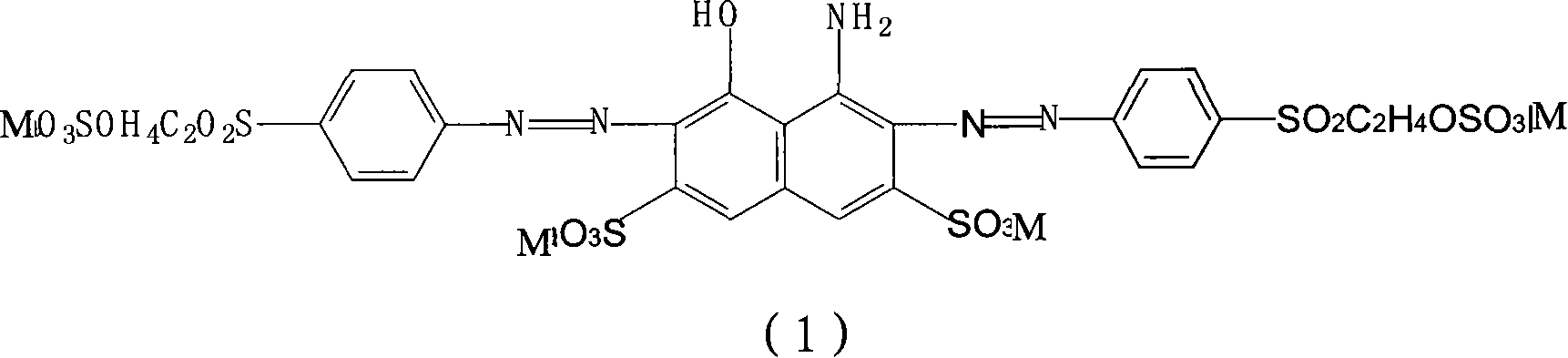

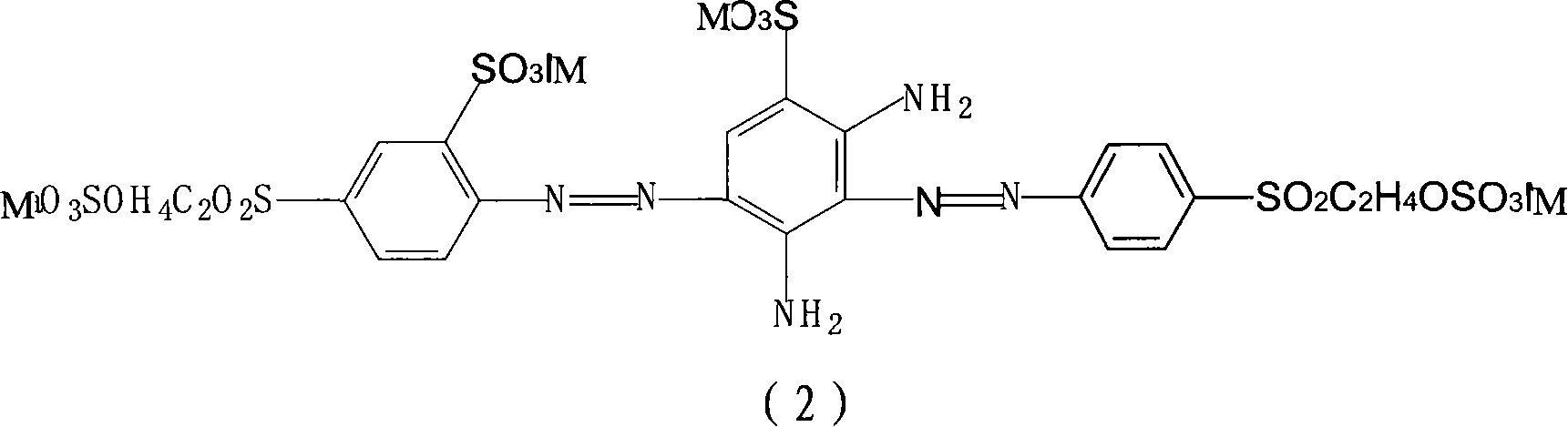

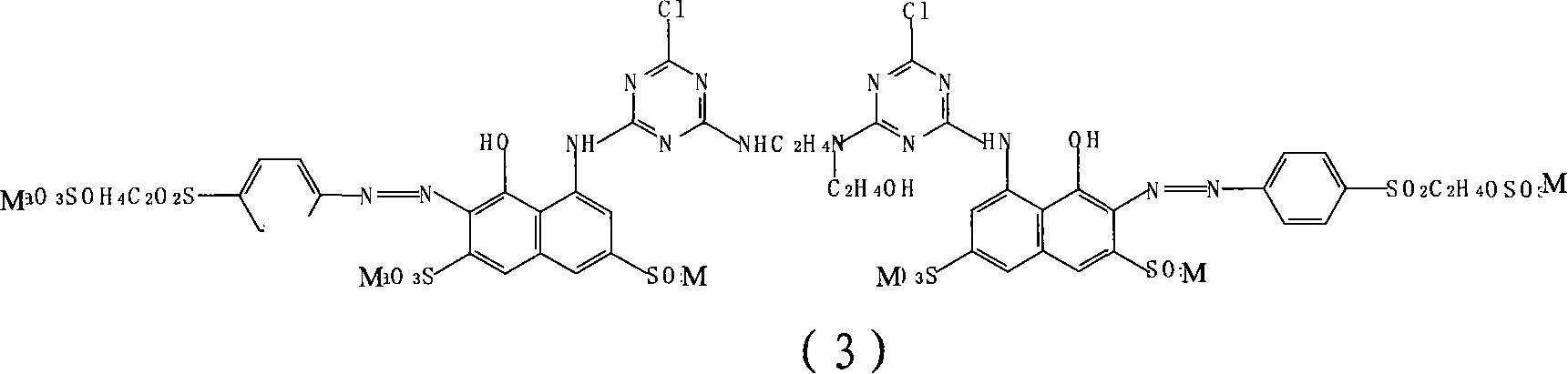

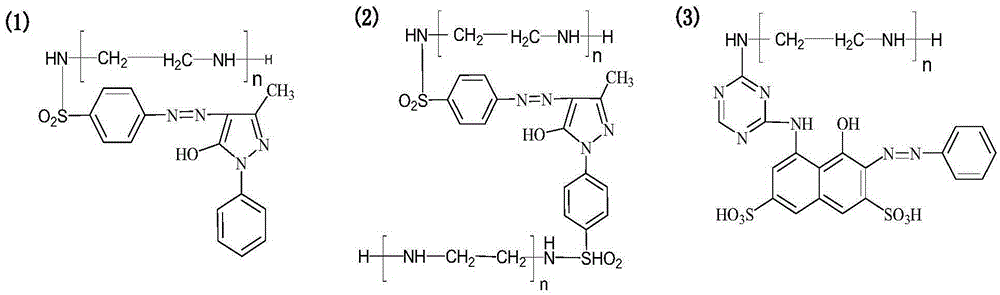

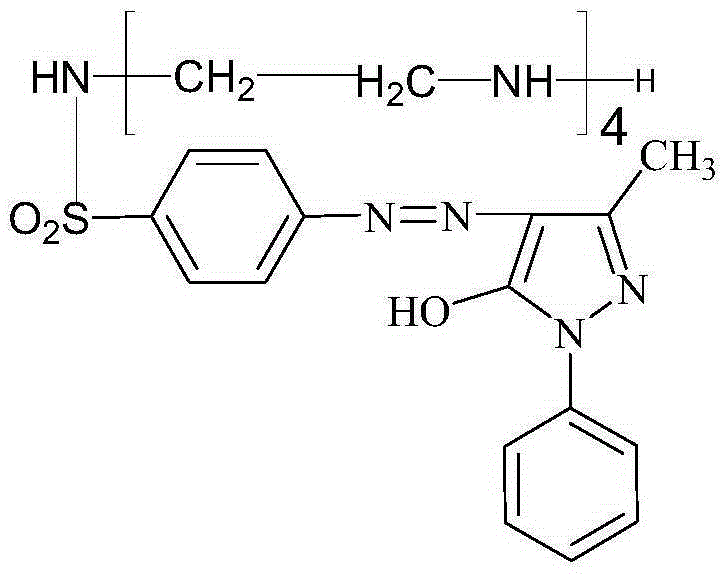

Composite dark black reactive dye

InactiveCN102898869AWide applicabilityHigh dyeing rateOrganic dyesDyeing processCellulose fiberProtein fiber

The invention discloses a composite dark black reactive dye. The dye is mixed by, by mass, reactive dyes of A, B and C, wherein the mass percent of the three dyes is 50-80% of A, 10-40% of B, 5-30% of C and the balance assistants, and the structural general formulas of A, B and C are presented in (1), (2) and (3). The composite dark black reactive dye is high in dye-uptake, fixation degree, alkali resistance and lifting power, low in substantivity, good in compatibility, easy to wash and wide in application; colors are guaranteed to be consistent before and after pad dyeing; and the dye is particularly suitable for dyeing of cellulosic fibers, protein fibers and polyamide fiber due to good leveling property.

Owner:ZHEJIANG YIDE CHEM

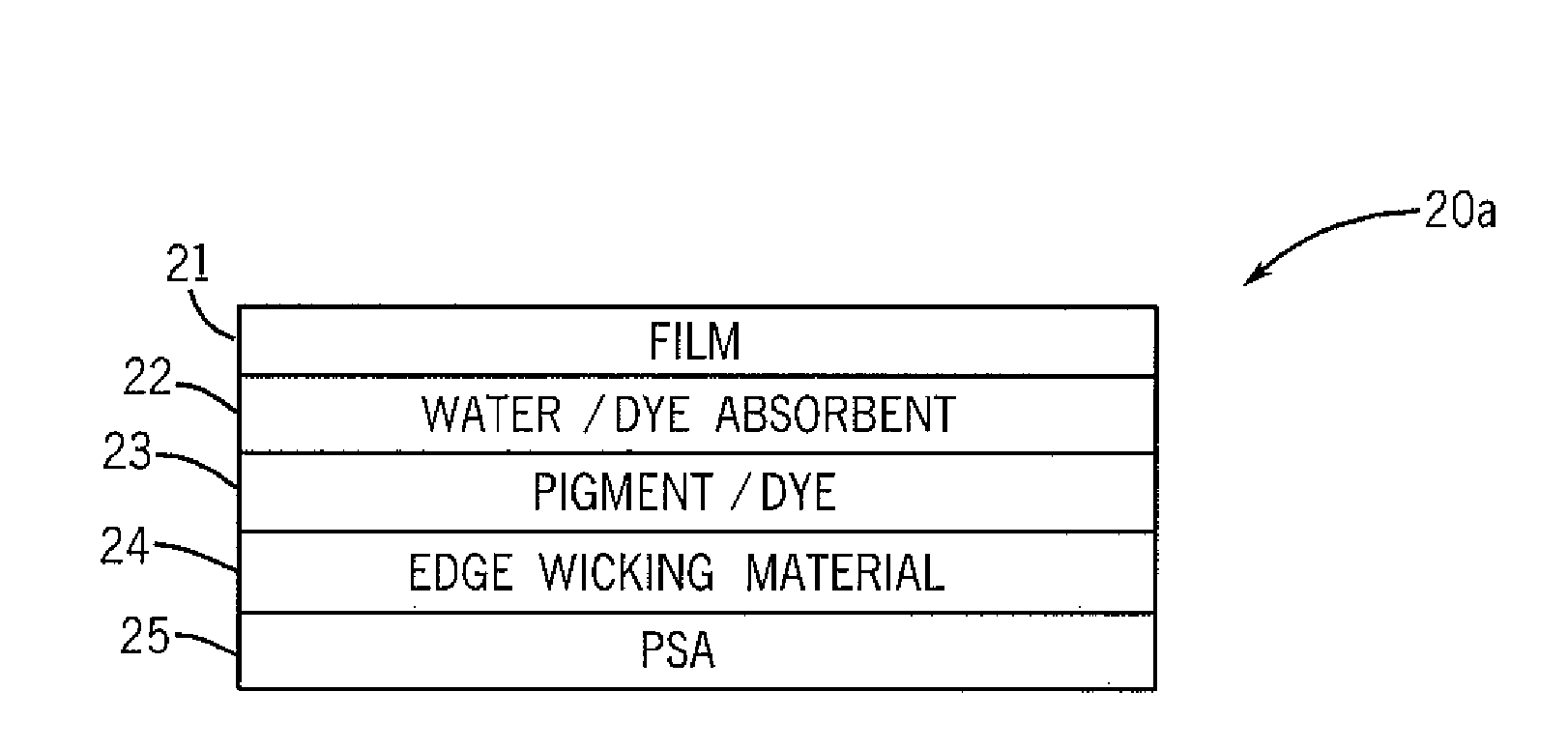

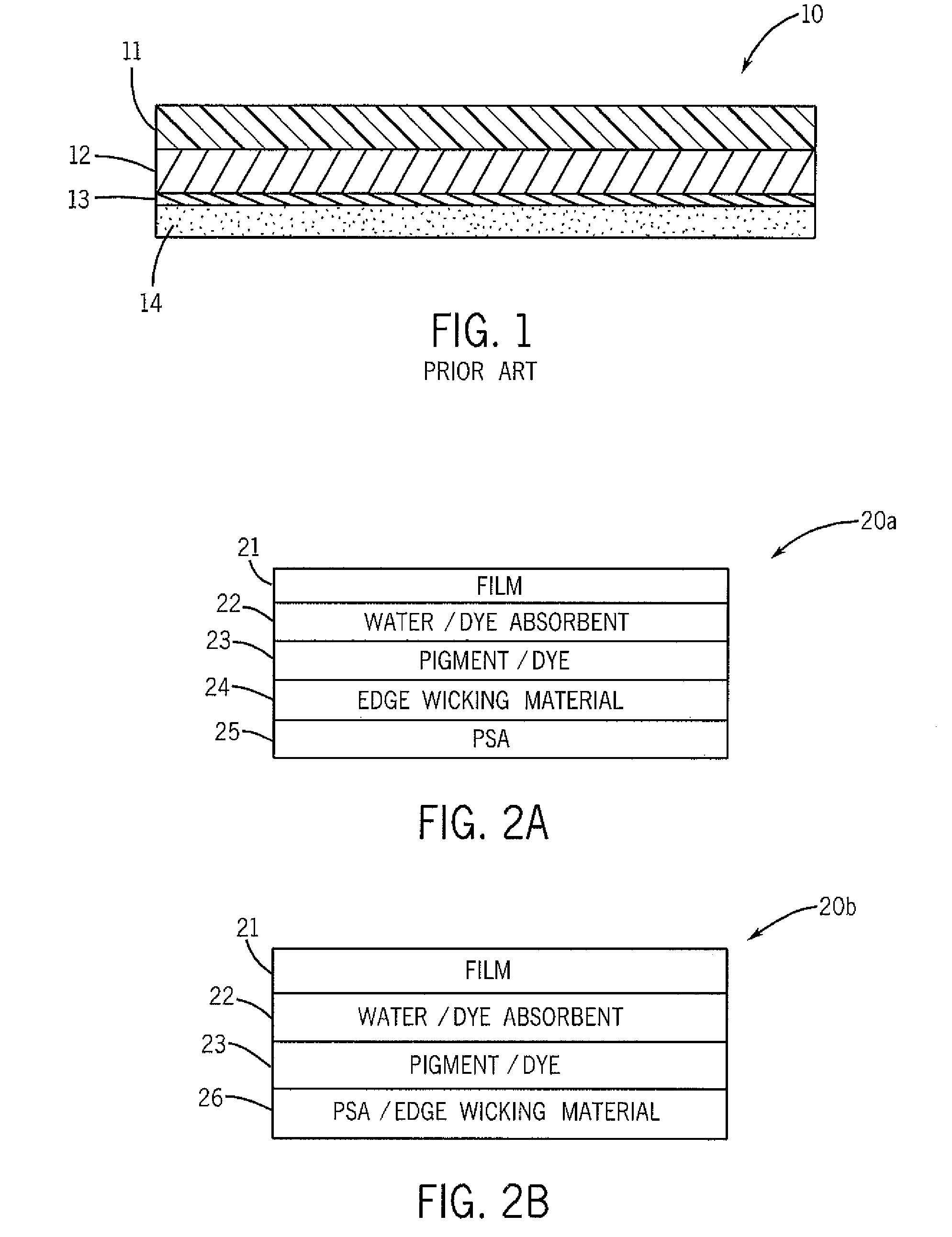

Tamper Indicating Labels with Edge Ingress Solvent-Indicating Feature

Multi-layer, edge ingress, tamper- and solvent-indicating labels comprise a top film layer coated over a solvent, e.g., water, hydrocarbon, etc., and dye absorbing layer. The solvent and dye absorbing layer can be on top of a porous layer comprising a binder, pigment and particles of a solvent-soluble dye. The porous layer can be on top of an edge-wicking layer which itself is on top of a pressure-sensitive adhesive (PSA) layer. The edge-wicking layer both absorbs and transports solvent thus serving as a means for transporting solvent to the solvent-soluble dye.

Owner:BRADY WORLDWIDE INC

Cotton fibre rapid staining process

ActiveCN101260623AReduce consumptionLow process temperatureDry-cleaning apparatus for textilesDyeing processElectricityStaining

The invention relates to the dyeing and finishing project technical field in the printing and dyeing industry production and discloses a cotton loose fiber rapid dyeing technique, comprising the dyeing of the cotton loose fiber, the post treatment and the drying, wherein, in the dyeing technique, the apposition scouring and the dyeing technique are adopted. The prior cotton loose fiber dyeing adopts the high temperature boiling-off or the low temperature pre-treatment, angle water should be discharged after the processes, otherwise, the dye uptake is low and the dye use level is increased. The apposition scouring rapid dyeing technique can short the production flow time by 20 percent, decrease the energy such as water, electricity and air consumption by more than 20 percent; moreover, the ability of fiber is increased due to the shortened fiber processing time, the tactility and the spinnability are improved, the production cost is lower and the environment is protected.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

Washing-free continuous dyeing method of terylene fabric with disperse dyes

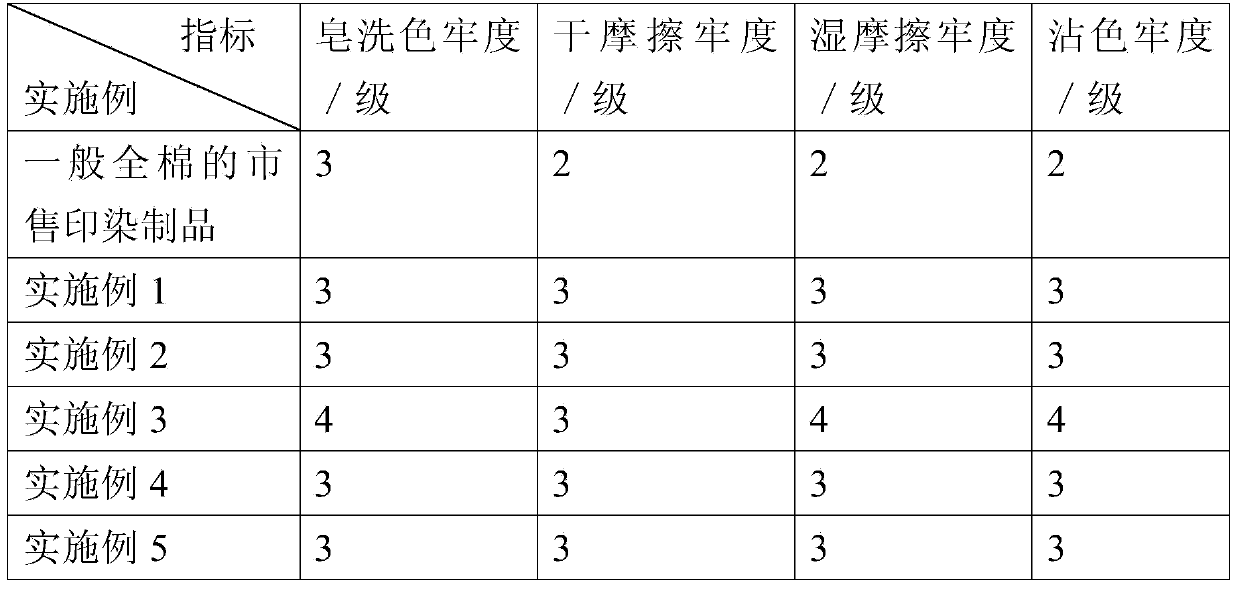

The invention relates to a washing-free continuous dyeing method for polyester fabrics with disperse dyes. The invention mixes disperse dyes, surfactants and water and grinds them uniformly to obtain disperse dye slurry; then dilutes with water, and adds emulsified paste and Thickening agent to obtain liquid disperse dyes; add water to obtain disperse dye dyeing baths, padding polyester fabrics for dyeing, then drying, and then baking to fix the color, and finally drop the cloth to cool, and the dyeing is completed. The dyeing process of the invention is simple, the chemicals used are ecological and environment-friendly, the production efficiency is high, no dyeing waste water is discharged, energy is saved, and the invention has important practical significance for energy saving and emission reduction. The dye uptake rate of the dyed product obtained by the present invention is higher than 95%, the chemical content on the fabric is not more than 3%, the dyed fabric does not need to be washed, and the dry and wet rubbing fastness and staining fastness can reach 4-5 grades. The color fastness to fading is grade 5, meeting the quality requirements for textile dyeing.

Owner:DONGHUA UNIV

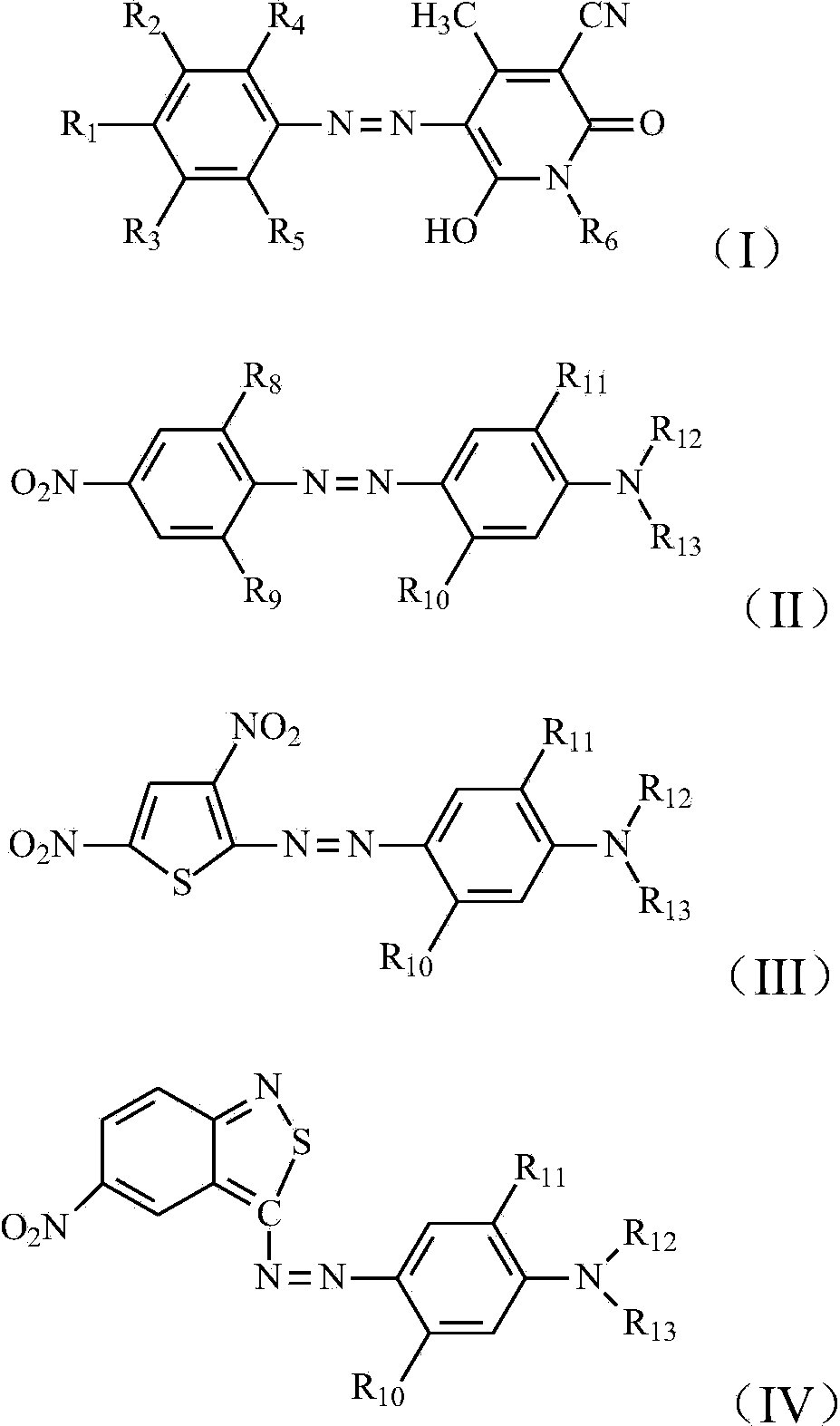

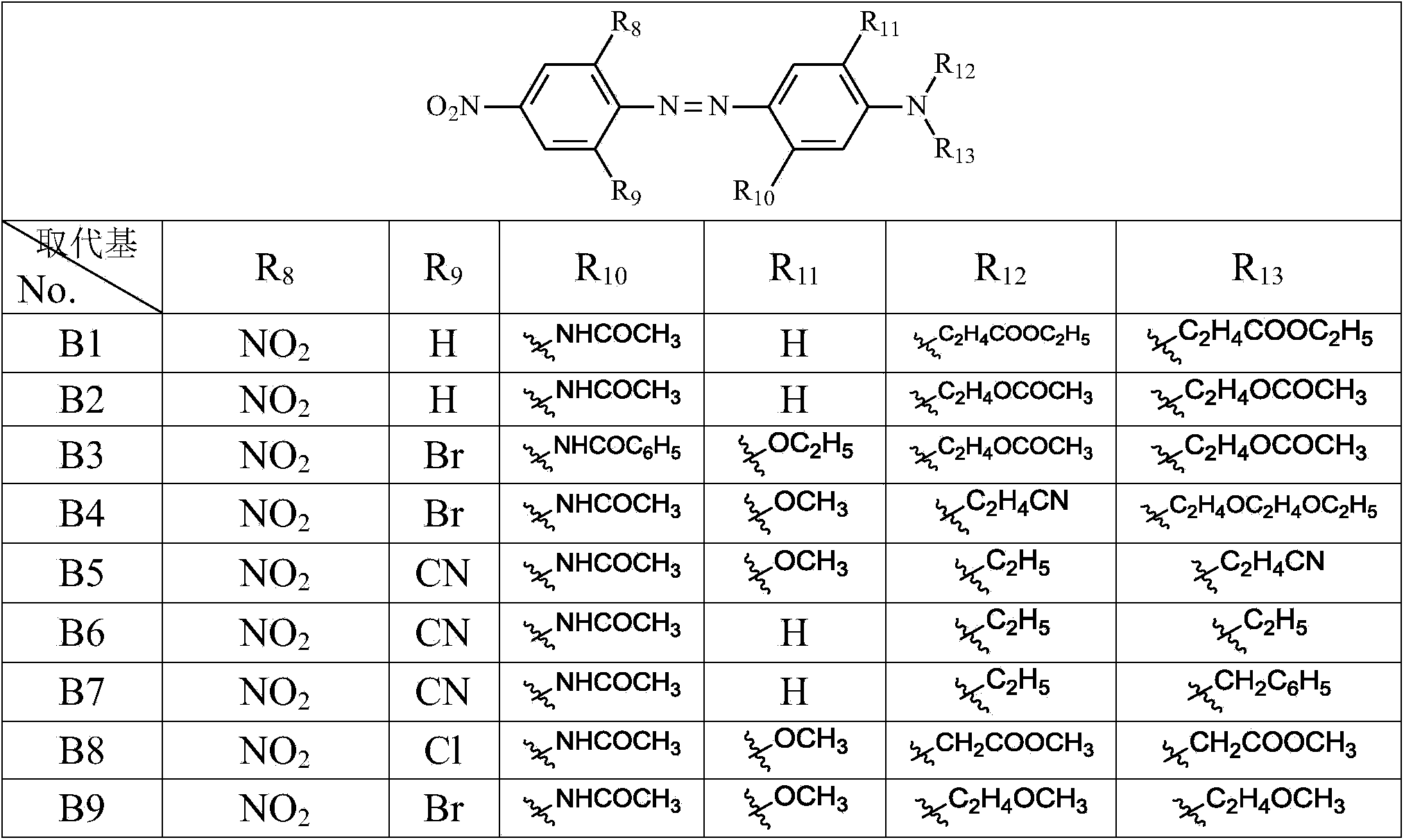

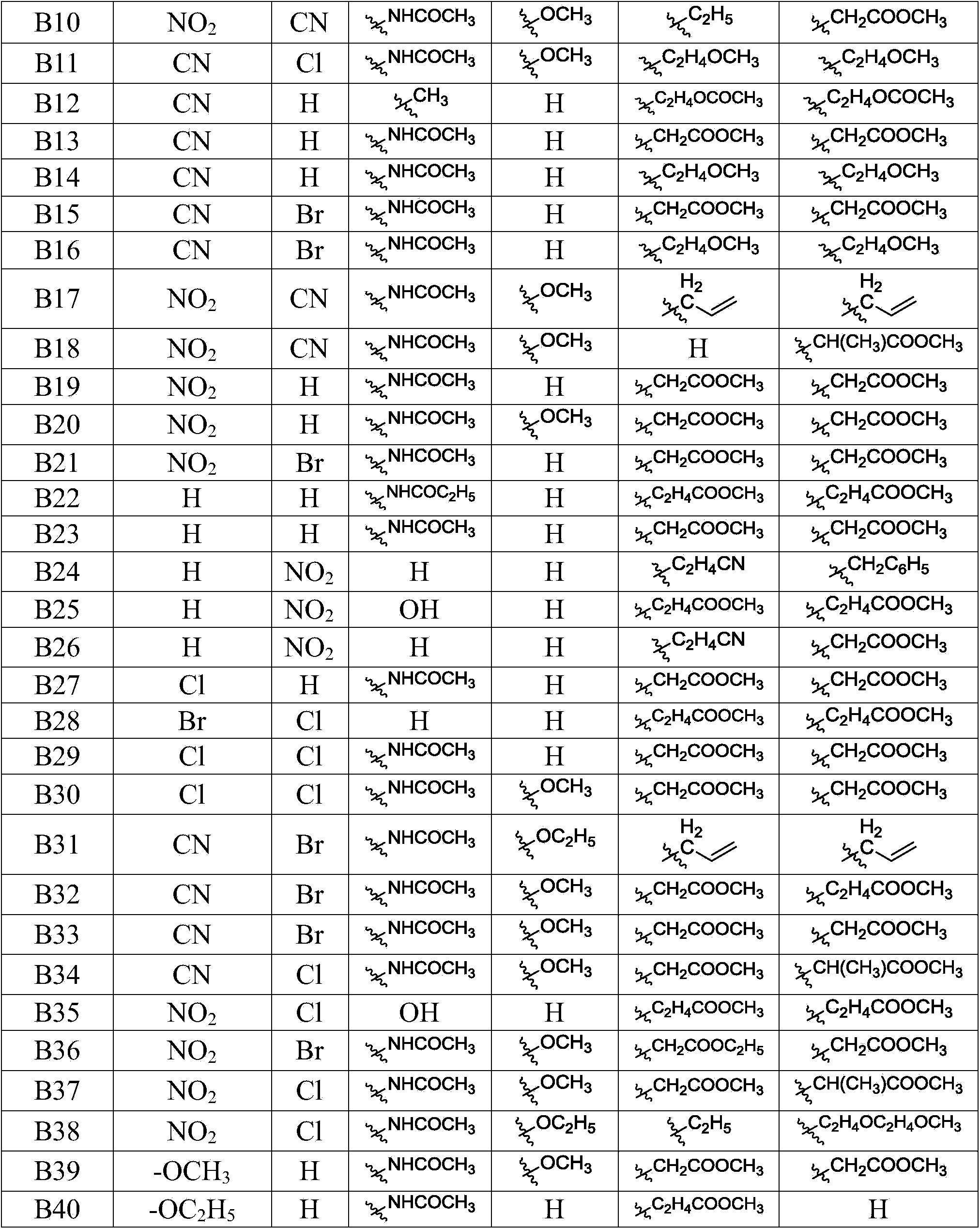

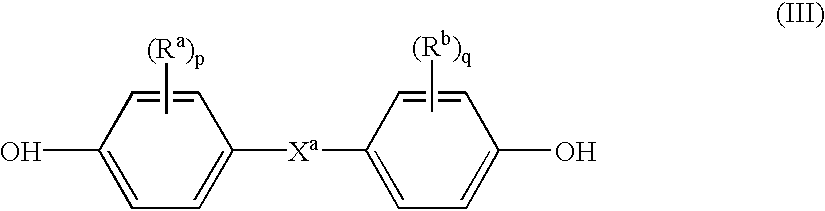

Navy blue or black disperse dye

ActiveCN104087015AProtect the environmentImprove dye uptakeOrganic dyesDyeing processDisperse dyePhotochemistry

The invention discloses a navy blue or black disperse dye. The navy blue or black disperse dye contains a navy blue or black disperse dye composition and an additives. The navy blue or black disperse dye composition comprises one or more of dye A shown as formula (I), one or more of dye B shown as formula (II), one or more of dye C shown as formula (III), and one or more of dye D shown as formula (IV). The navy blue or black dye provided by the invention has the advantages of high dye-uptake, good deep dyeing property, excellent elevating power, excellent color fastness, and good level dyeing property. (formula (I), formula (II), formula (III), formula (IV)).

Owner:SHANGHAI ANOKY GRP

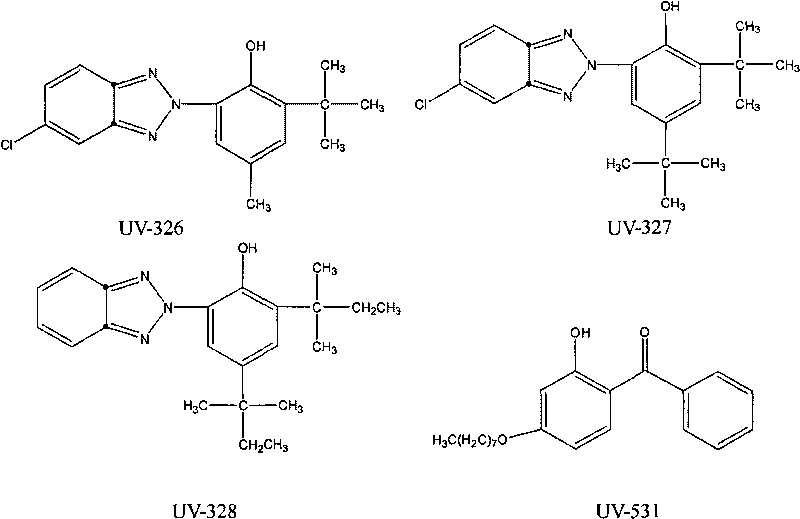

Wideband, uvioresistant and highly lightfast finishing agent as well as preparation method and application thereof

InactiveCN101696548AImproved color fastness to sunlightImproves UV protectionFibre treatmentDyeing processFiberUltraviolet

Owner:ZHEJIANG SCI-TECH UNIV +1

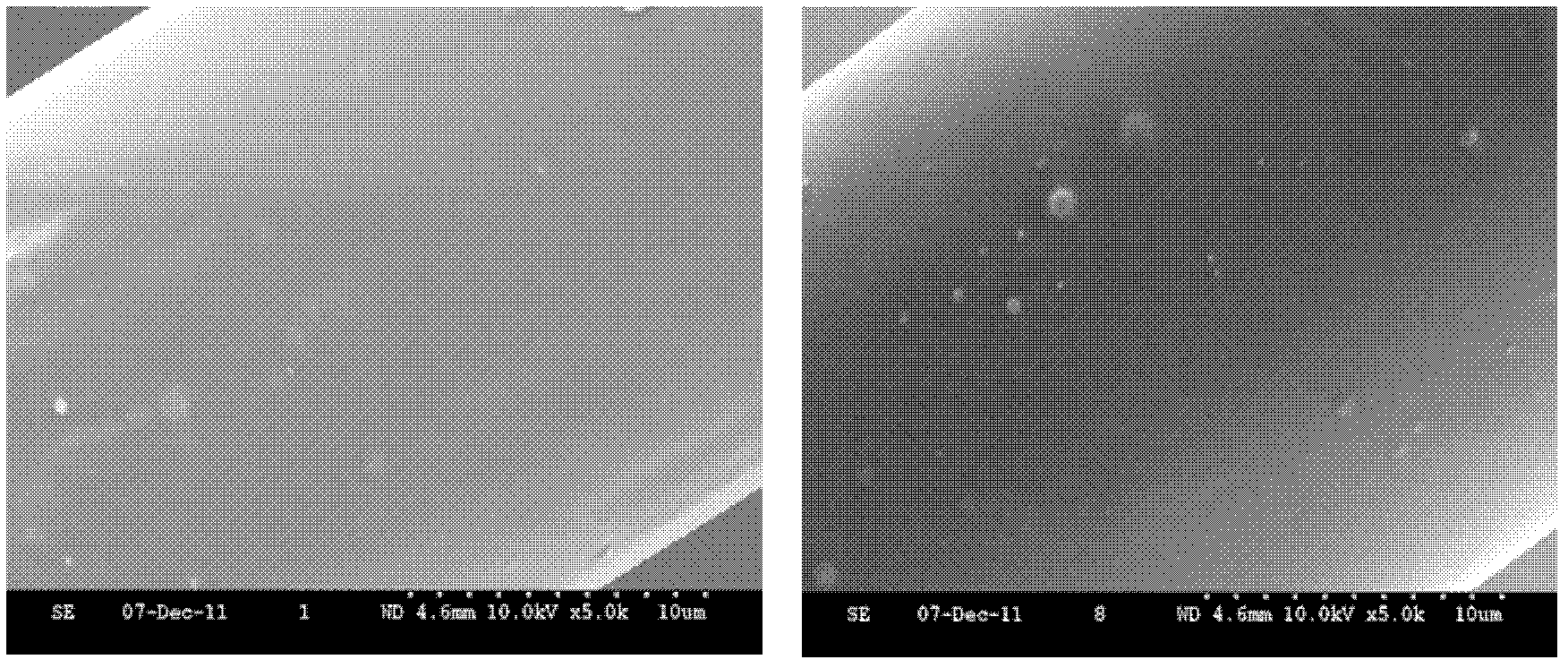

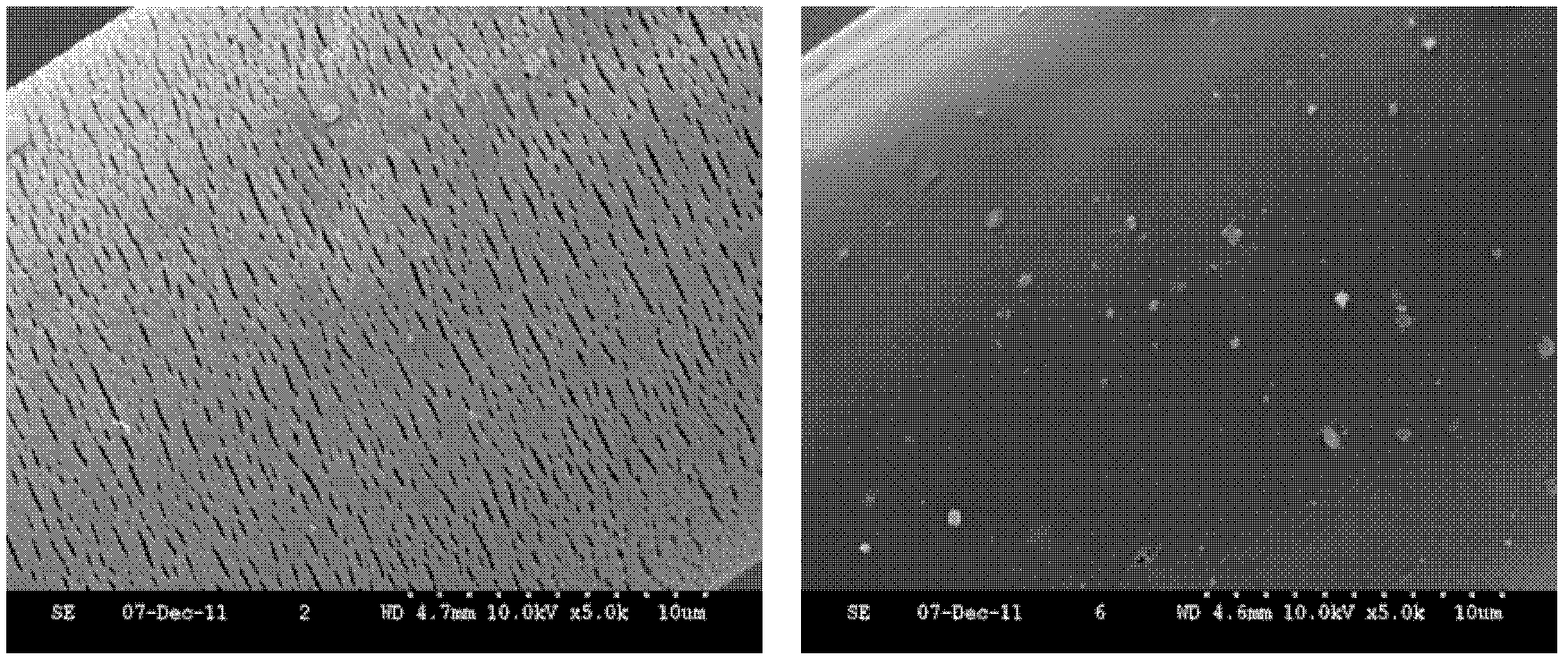

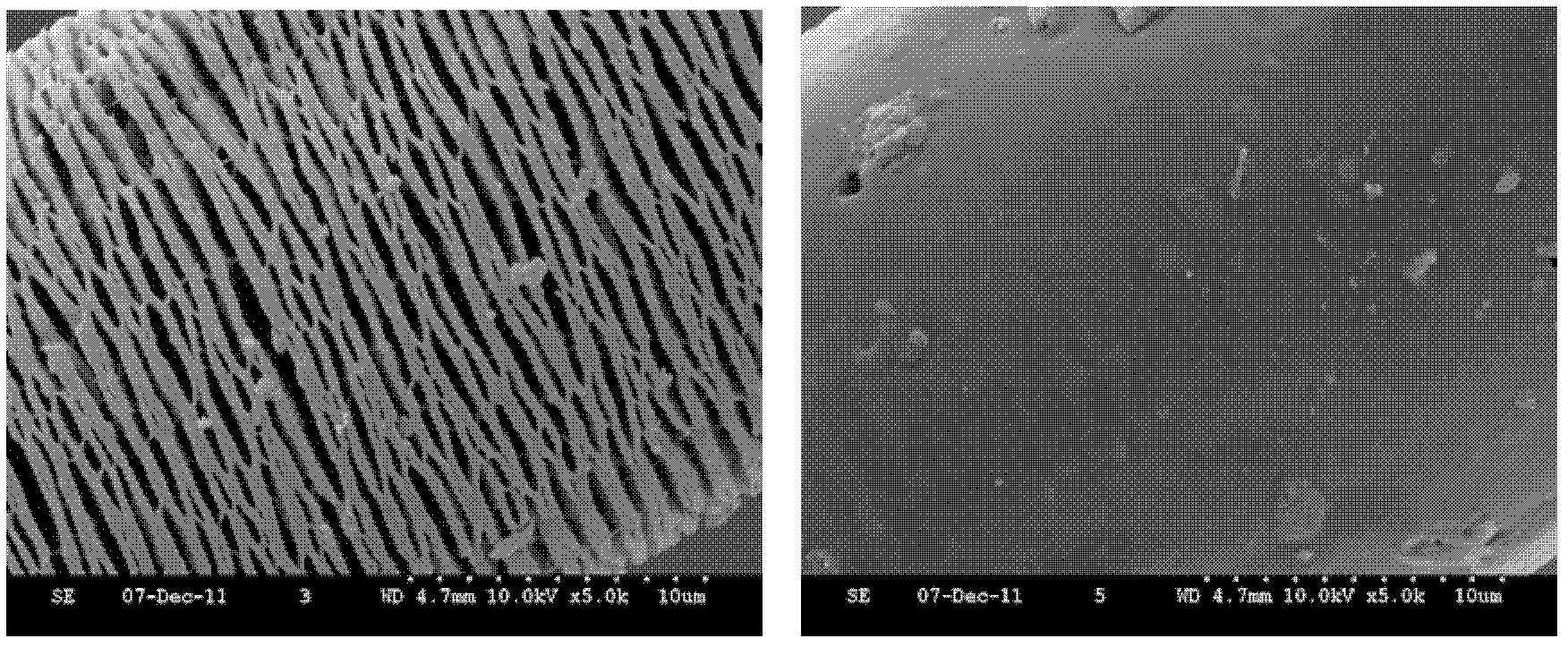

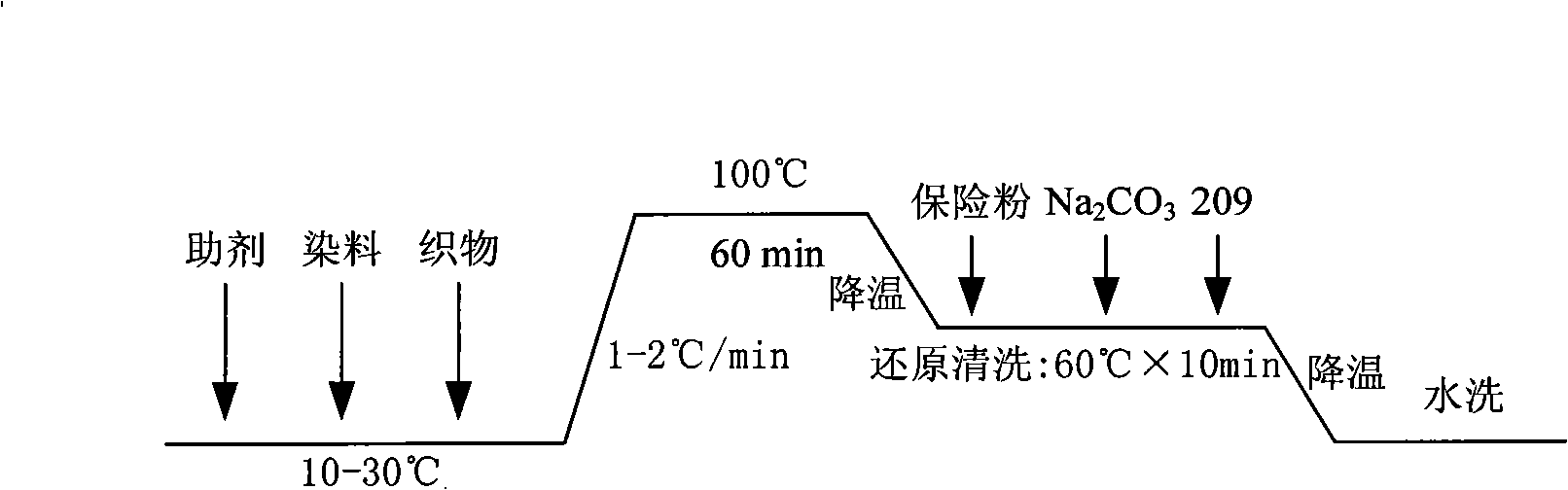

Reactive dye cosolvent staining method for cellulose fabric

The invention relates to a reactive dye cosolvent staining method for a cellulose fabric. The method comprises the following steps of: adding a solvent into an aqueous solution of a reactive dye, thus obtaining a cosolvent solution of the dye; soaking the cellulose fabric in the dyeing solution under room temperature, and raising the temperature to the dyeing temperature of 40-100 DEG C; and adding the solvent and sodium carbonate, raising the temperature to the fixation temperature of 40-100 DEG C, keeping the temperature for 30-60 minutes, taking the fabric out, and washing, soaping and washing to obtain the product. The method is simple, is easily industrialized, can obtain higher dye-uptake and higher fixation rate compared with the traditional reactive dye staining process, and has high leveling property.

Owner:DONGHUA UNIV

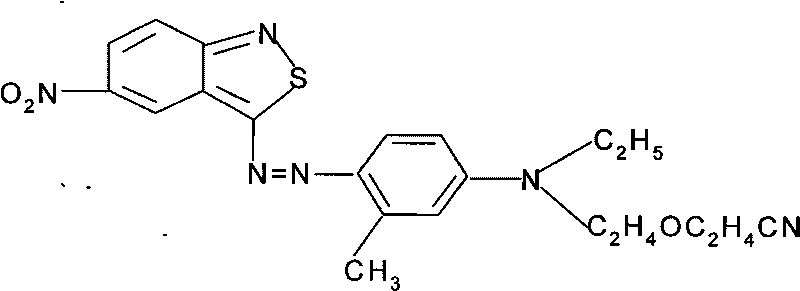

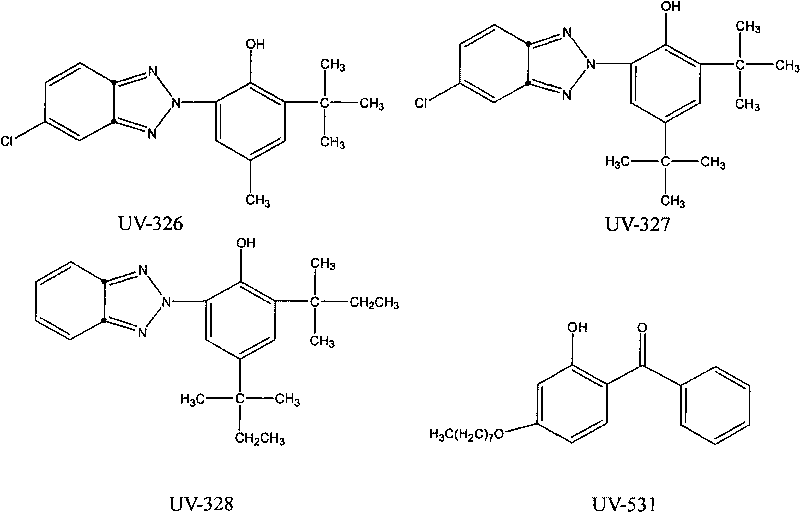

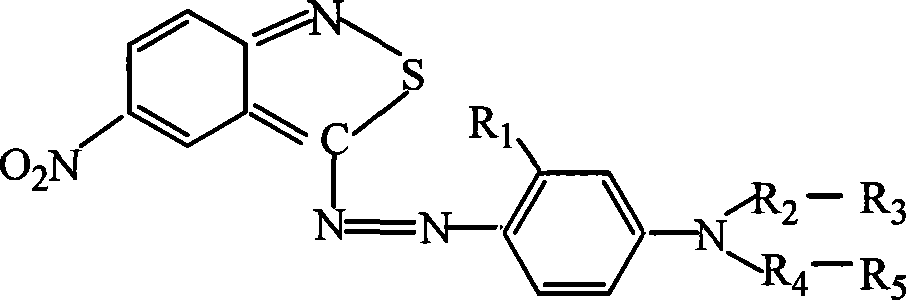

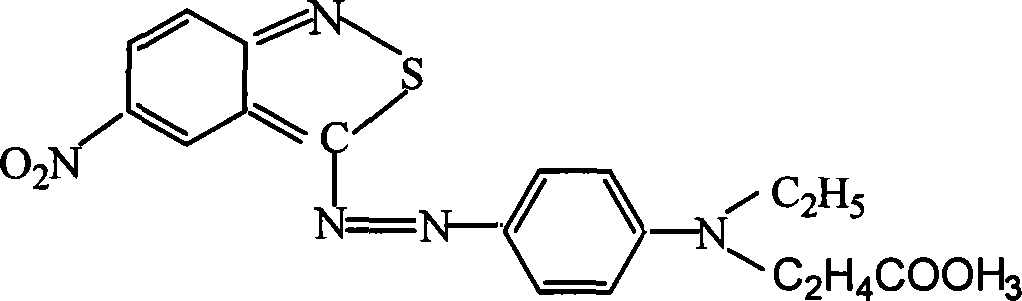

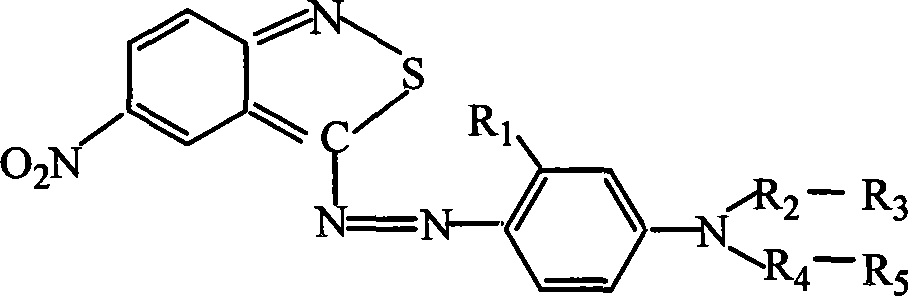

Azo type heterocyclic blue dispersion dyes

The invention provides a class of heterocyclic blue disperse dye and mixed dyes thereof, wherein the general formula of the dye is the formula at right, in the general formula: R1 is hydrogen, C1-4alkyl or C1-4alkoxy; R2, R4 is C1-4 saturated linear or branched alkane; R2 and R4 are the same or different; R3 is hydrogen, hydroxy, C1-4 alkoxy, or phenoxy; R5 is hydrogen, C1-4alkoxy, cyanoethyl or phenoxy; R3 and R5 are the same or different. The preparation of the dye includes that heterocyclic diazo component is diazotized, followed by reaction with different coupling components to get brilliant blue disperse dye. The dye can have a single structure, and also be the dye with mixed structure directly prepared. The class of dyes can give rich and deep color and has high lifting force, and good dye-uptake property, which has the same results of brilliant color light for polyester cellulose dying in acid or basic dye bath. The invention also can dye polyamide, polyurethane and cellulose acetate, and ultra-fine and blended fabric thereof.

Owner:ZHEJIANG HUIDELONG CHEM

Silicon based non-aqueous medium dyeing method suitable for cheese

ActiveCN107794788AGood dyeing effectMedia is easy to recycleDyeing processPulp and paper industryDyeing wastewater

The invention discloses a silicon based non-aqueous medium dyeing method suitable for cheese, and belongs to the technical field of textile dyeing and finishing. The dyeing method comprises the following steps: (1) preparing a dye solution; (2) dyeing cheese: soaking cheese in a silicon based non-aqueous medium, and adding the dye solution to carry out dyeing in a cheese dyeing facility; and (3) after dyeing, carrying out dehydration, soap washing, water washing, and drying to obtain a finished product. The method has the advantages that only a little amount of water and alkali is needed, other dyeing aids are not needed; the water for dyeing and dyeing wastewater are largely reduced, and dye uptake and fixation rate of cheese dyeing are improved effectively. After dyeing, the silicon based non-aqueous medium can be separated from water and is capable of being used repeatedly. The ecological dyeing of cheese is realized. The shortages of conventional water bath cheese dyeing such as much wastewater, difficulty in wastewater treatment, low dye uptake and fixation rate, and the like, are overcome.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

Limited-play optical media with improved shelf-life and playability

InactiveUS20040022986A1Complicated to manufactureIncrease costPhotosensitive materialsLayered productsMetal alloyReflective layer

Limited-play optical medium with improved shelf stability are formed from a plurality of layers, including in sequence: (a) a first substrate layer; (b) a data layer; (c) a reflective layer; (d) a reactive layer comprising a dye having a reduced state and an oxidized state and further comprising an oxidized form of a reducing agent effective to convert the dye from the oxidized state to the reduced state, and (e) a second substrate layer. The dye in the reduced state is substantially transparent to light of wavelengths used to read the optical medium, and the dye in the oxidized state absorbs light of wavelengths used to read the optical medium. The reflective metal layer is formed from a metal or metal alloy that is not significantly oxidized by the oxidized form of the reducing agent. For example, the reflective metal layer is suitably formed from silver or gold.

Owner:GENERAL ELECTRIC CO

Active black dye

InactiveCN101130643ASolve the problem of easy black spelling and dyeingSolve cylinder differenceOrganic dyesDyeing processCelluloseAdjuvant

The invention discloses a black active dye, which comprises the following parts: 15-90wt% black KN-B, 5-35wt% compound gold, 3-25wt% compound red and 0-35wt% adjuvant. The invention is fit for dyeing the cellulose or protein fiber, which has good lifting power, level-dyeing property, dyeing repeatability and dye-uptake.

Owner:ZHEJIANG RUIHUA CHEM

Technology for dyeing and finishing real silk/corn fabric

ActiveCN101736616AGuaranteed high color fastnessGuaranteed strongBiochemical fibre treatmentDyeing processDisperse dyeEngineering

The invention relates to technology for dyeing and finishing real silk / corn fabric. In order to solve the technical problem, the invention provides the provided technology for dyeing and finishing which can effectively improve the dye uptake of the corn fiber and the color fastness of the fabric, and maximize the strength of the corn fiber and the fabric. The technical scheme of invention is that: the technology for dyeing and finishing the real silk / corn fabric comprises the processes of bleaching, dyeing and heat shaping in turn. The technology for dyeing and finishing the real silk / corn fabric is characterized in that: 1) the bleaching (refining) process comprises steps of pretreating, enzyme scouring, and second scouring; 2) the dyeing process comprises steps of dyeing, reduction clearing, and water washing, wherein staining solution comprises a disperse dye and a reactive dye, or the dyeing process comprises steps of disperse dye dyeing, reduction clearing, water washing, reactive dye dyeing, soap boiling and water washing; and 3) the heat shaping process comprises steps of padding soft solution and heat shaping, wherein the enzyme scouring in the bleaching process adopts neutral enzyme scouring or alkaline enzyme scouring; the staining solution of the disperse dye comprises 0 to 2 g / L of darkening agent DL-6; and the fabric dyed by the disperse dye needs to be washed by adopting acid reduction technology.

Owner:HIGH FASHION CHINA CO LTD

Dyeing method for calcium alginate fibers

The invention belongs to the technical field of fiber dyeing, and particularly relates to a dyeing method for calcium alginate fibers. According to the dyeing method for the calcium alginate fibers, dye containing polyethylene polyamine framework structures is adopted to dye the calcium alginate fibers; the defect that the fibers are damaged due to the fact that inorganic salt needs to be added for dyeing accelerating in the dyeing process of traditional dye is fundamentally overcome, and the strength loss of the fibers after dyeing is small; meanwhile, compared with the weaker intermolecular force and hydrogen-bond interaction between general direct dye and the fibers, the acting force between molecules of the dye and the fibers is higher, and then the advantages of being higher in dye-uptake rate and soaping fastness and the like are achieved; the dyed fibers are uniform and bright in color and meet the dyeing requirements of the calcium alginate fibers, and the dyeing method is economical in energy and environmentally friendly.

Owner:SHANDONG UNIV OF TECH

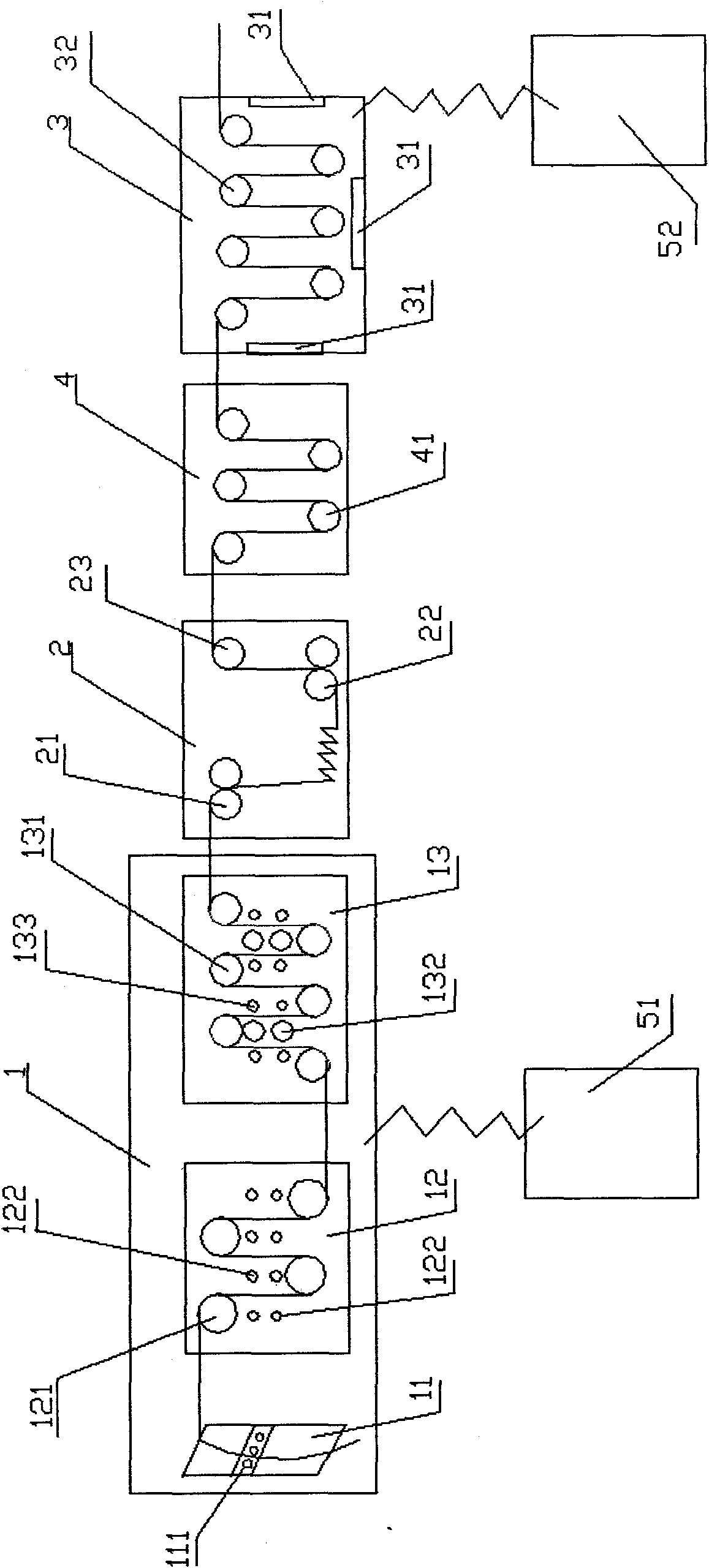

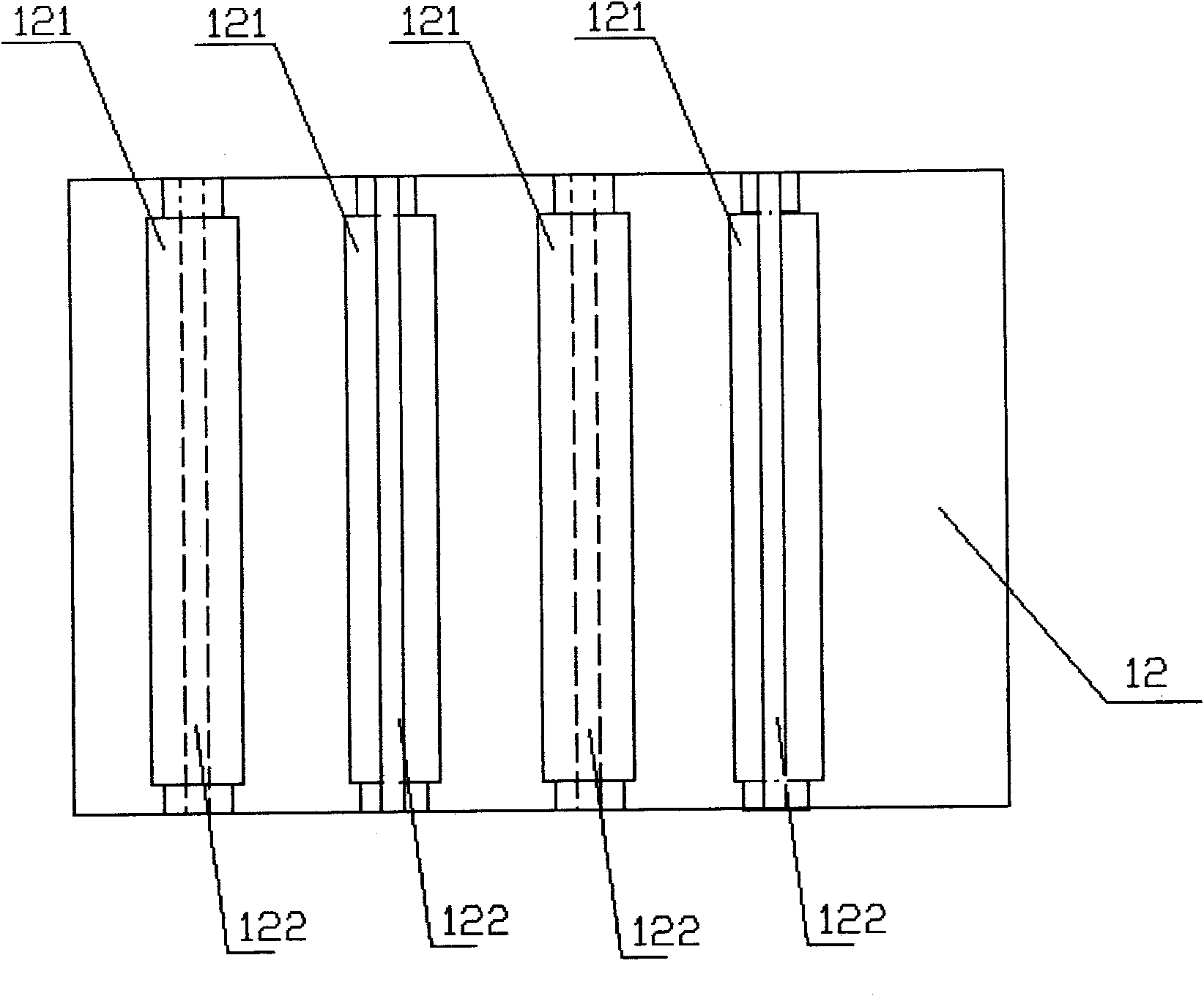

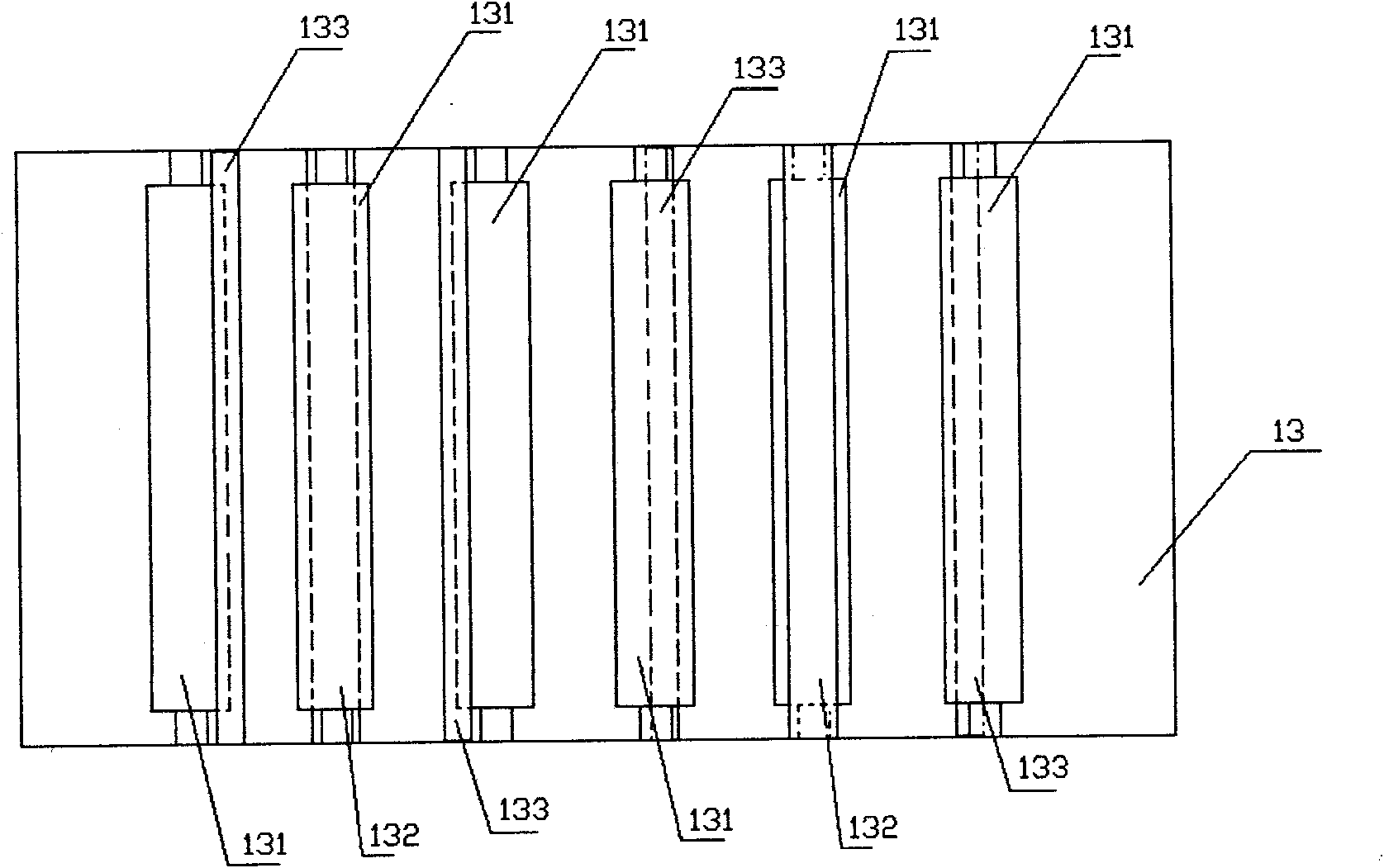

Process for dyeing fabrics by combining with plasma and ultrasonic and special device thereof

InactiveCN101880960AImprove dye uptakeReduce dosageDry-cleaning apparatus for textilesUltrasonic/sonic fibre treatmentControl systemGraft reaction

The invention relates to the field of fabrics dyeing and finishing processes, in particular to a process for dyeing fabrics by combining with plasma and ultrasonic and a special device thereof. The special device comprises low-temperature normal-pressure plasma equipment, grafting reaction equipment, ultrasonic dyeing equipment, a rinsing bath and two groups of control systems, wherein the low-temperature normal-pressure plasma equipment, the grafting reaction equipment, the rinsing bath and the ultrasonic dyeing equipment are sequentially connected, one group of control systems is connected with the low-temperature normal-pressure plasma equipment, and the other group of control systems is connected with the ultrasonic dyeing equipment. The invention organically combines the low-temperature normal-pressure plasma equipment and the ultrasonic dyeing equipment, solves the problem that the dye uptake and the dyeing quality can not improved in a process of dyeing fabrics in a high crystalline region or solves the problem of high energy consumption and high pollution in the dyeing process, and can effectively realize that the dye uptake and the dyeing quality can be improved while realizing environmental-friendly production with low energy consumption and low pollution.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

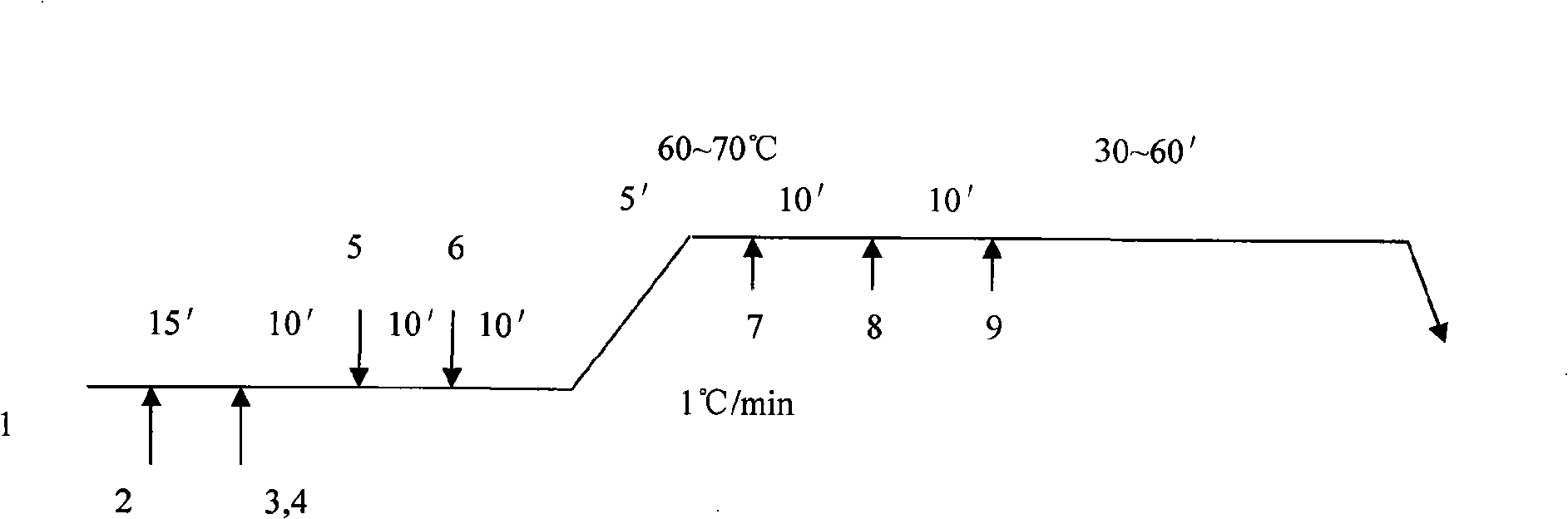

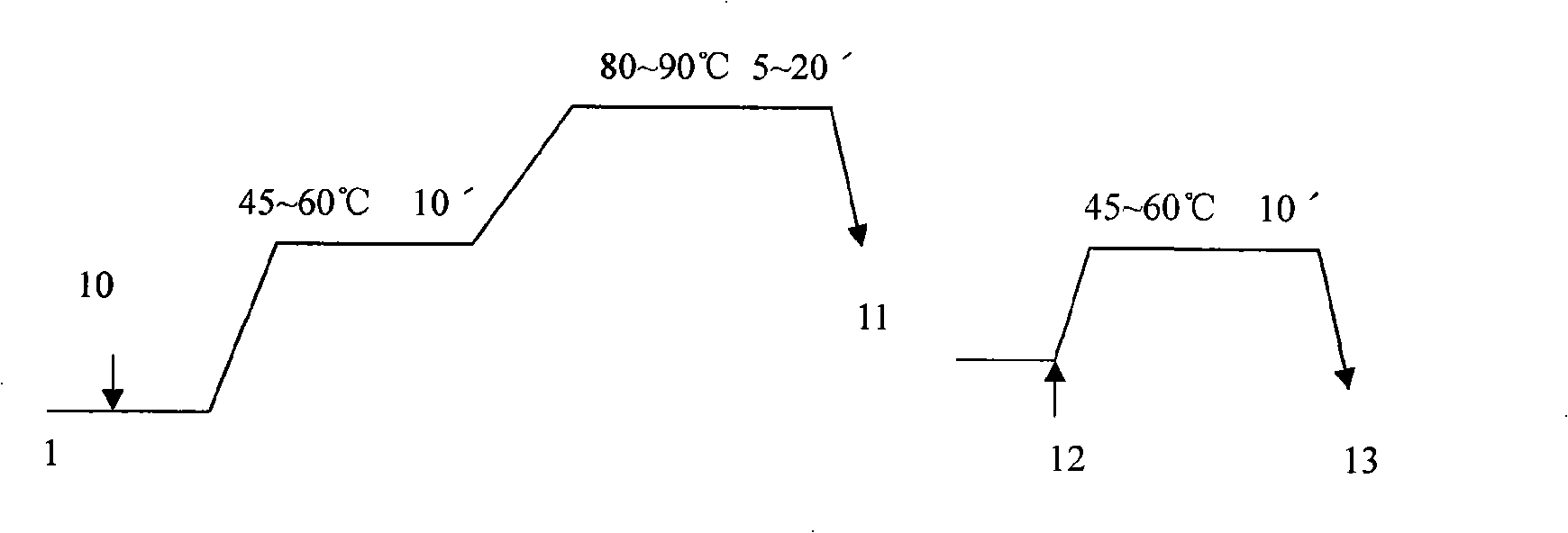

Printing and dyeing process

ActiveCN103628336ASimple printing and dyeing processEasy to implementLiquid/gas/vapor removalDyeing processEconomic benefitsChloride sodium

The invention discloses a printing and dyeing process which comprises the following steps: (1) preprocessing; (2) dyeing, namely putting a preprocessed fabric into a dyeing solution, heating the dyeing solution to 45-55 DEG C at speed of 1-2 DEG C / min, and keeping the temperature for 20-40 minutes; adding sodium chloride, heating to 60-70 DEG C at the speed of 1-2 DEG C / min, and keeping the temperature for 20-40 minutes; adding sodium carbonate, heating to 80-90 DEG C at speed of 0.2-1 DEG C / min, and keeping the temperature for 20-40 minutes; finally cooling at the speed of 1-2 DEG C / min to finish the dyeing process; (3) post-processing. According to the printing and dyeing process, the dye-uptake rate and the dye-uptake process are adjusted to be optimal through controlling temperature ranges in the dyeing process, so that a printed and dyed product is good in dyeing uniformity and high in color fastness. The printing and dyeing process is simple, can realize large-scale industrialization production and bring good economic benefits to enterprises, and has a wide prospect.

Owner:杭州开源风云信息技术有限公司

Method for carrying out salt-free dyeing on un-scoured and unbleached cotton textile by reactive dyes

The invention relates to a method for carrying out salt-free dyeing on an un-scoured and unbleached cotton textile by reactive dyes and belongs to the technical field of textile printing, dyeing and finishing. According to the method, the un-scoured and unbleached cotton textile is pre-swelled in a pre-swelling liquid which is formed by mixing a high-proportion alcohol-type organic solvent and a small amount of water, and the pre-swelled cotton textile is dyed by a dyeing liquid which is formed by mixing a high-proportion alcohol-type organic solvent, water and dyes, the wettability and the dyeability of the un-scoured and unbleached cotton textile can be effectively enhanced, and the pre-treating work processes of scouring and bleaching the cotton textile are reduced. The method can effectively enhance the dye-uptake rate, the color fixation rate, the dyeing effect and the color fastness of the reactive dyes onto the un-scoured and unbleached cotton textile, can completely meet production requirements, does not need salt, and is simple in technology, high in feasibility and easy for industrialization; the use amount of water is reduced greatly; besides, the alcohol-type organic solvents can be recycled, so that the method is little in pollution, low in cost, clean, energy-saving, safe and environment-friendly.

Owner:WUHAN TEXTILE UNIV +1

Reactive dye salt-free dyeing method

The invention relates to a reactive dye salt-free dyeing method which comprises the following steps of: soaking pre-swelled cotton fabric into reactive dye liquor, heating up to a primary dyeing temperature of 40-100 DEG C and keeping the temperature for 0-20 minutes, adding an organic solvent, heating up to a dyeing temperature of 60-100 DEG C and keeping the temperature for 0-20 minutes, adding soda ash, heating up to a fixation temperature of 40-100 DEG C and keeping the temperature for 30-60 minutes, cooling to room temperature, and carrying out washing, soaping and washing on the cotton fabric. The method is simple and easy to industrialize, is capable of obtaining dye-uptake and fixation rate higher than a traditional reactive dye dyeing process, has relatively good leveling property and is capable of realizing salt-free low-alkaline dyeing.

Owner:DONGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com