Patents

Literature

60results about How to "Achieve dyeing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dyeing method for multilevel-color jean yarns

The invention relates to a dyeing method for multilevel-color jean yarns. The dyeing method comprises the following steps: carrying out modification treatment on yarns by adopting a cationic modifying agent; padding 1-2 paths of pigment printing paste on the treated yarns at a room temperature and drying; then carrying out continuous rolling and dyeing by indigo blue and sulfur dyestuff or overdyeing of the indigo blue and the sulfur dyestuff. The jean yarns produced by the dyeing method are bright in color and luster, good in color fastness, pure in colored light and low in room-temperature dyeing power consumption; the quantity of indigo blue dyeing grooves is reduced by priming a high-fastness pigment; a process flow is shortened, the pollution discharge is reduced and the production cost is reduced.

Owner:SHANDONG DAIYIN TEXTILE GROUP SHARE CO LTD

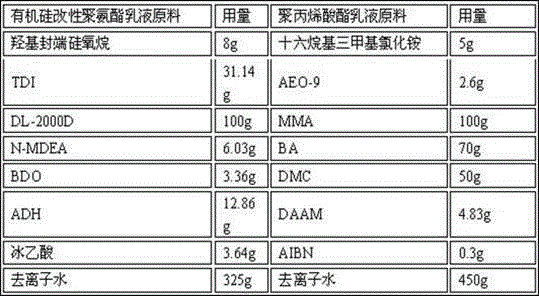

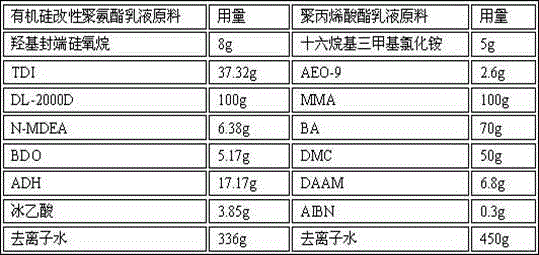

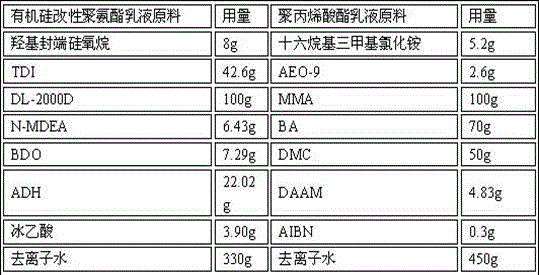

Cationic organosilicon modified waterborne PUA fabric coating adhesive with self crosslinking structure and preparation method thereof

InactiveCN106149381AImprove mechanical propertiesImprove water resistanceFibre treatmentPolyesterDiacetonamine

The present invention discloses a preparation method of a cationic organosilicon modified waterborne PUA fabric coating adhesive with a self crosslinking structure, the method is as follows:(1)using polyisocyanate and hydroxyl-terminated polysiloxane for synthesis of an-NCO-group-terminated prepolymer;(2)adding polyether or polyester glycol for reaction;(3)reacting with a cationic hydrophilic chain extender for a period of time, and further reacting with adipic dihydrazide(ADH)to obtain a hydrazine-terminated cationic waterborne polyurethane emulsion;(4)using acrylate monomers and diacetone acrylamide(DAAM)for preparing a hydrazide-group-containing polyacrylate emulsion; and(5)mixing the hydrazine-terminated cationic waterborne polyurethane emulsion and the hydrazide-group-containing polyacrylate emulsion in a certain proportion to obtain the self-crosslinking cationic organosilicon modified waterborne PUA fabric coating adhesive. The self-crosslinking cationic organosilicon modified waterborne PUA fabric coating adhesive avoids the use of a harmful crosslinking agent, has the advantages of being environmental-friendly, high in water pressure resistance, good in mechanical properties, low in cost, and dyeable and the like, and can be used for coating finishing of nylon fabrics.

Owner:WUYI UNIV

Method of natural embossing trentment on natural wood surface

A method for making the surface of natural wood material have relief effect includes such steps as smoothing the wooden surface, coating the saturated solution of 3-valence Fe salt (iron chloride, iron sulfate or iron nitrate), hot pressing at 80-140 deg.C under 0.5-4 MPa for 80-180 s, and natural cooling and drying.

Owner:汤大中

Super-hydrophobic anti-ultraviolet flame-retardant silk fabric and preparation method thereof

The invention provides a preparation method of a super-hydrophobic anti-ultraviolet flame-retardant silk fabric. The preparation method comprises the following steps: soaking the silk fabric in an acidic buffer solution; adding natural polyphenol and a laccase catalyst into the solution; carrying out a reaction for a period of time in an oxygen condition; taking out the silk fabric out and washingand drying the same; then transferring the silk fabric to a salt solution containing 10-100 mmol / L Fe<2+> and Fe<3+> to react for a period of time; taking out the silk fabric and washing the same andslowly drying the silk fabric at a low temperature; then drying the silk fabric at a high temperature to obtain the super-hydrophobic anti-ultraviolet flame-retardant silk fabric. The invention alsodiscloses the super-hydrophobic anti-ultraviolet flame-retardant silk fabric prepared by the preparation method. The preparation method is simple, environment-friendly and mild in reaction condition,and the super-hydrophobic anti-ultraviolet flame-retardant silk fabric prepared has stable super-hydrophobic, anti-ultraviolet and flame-retardant abilities in various environments.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

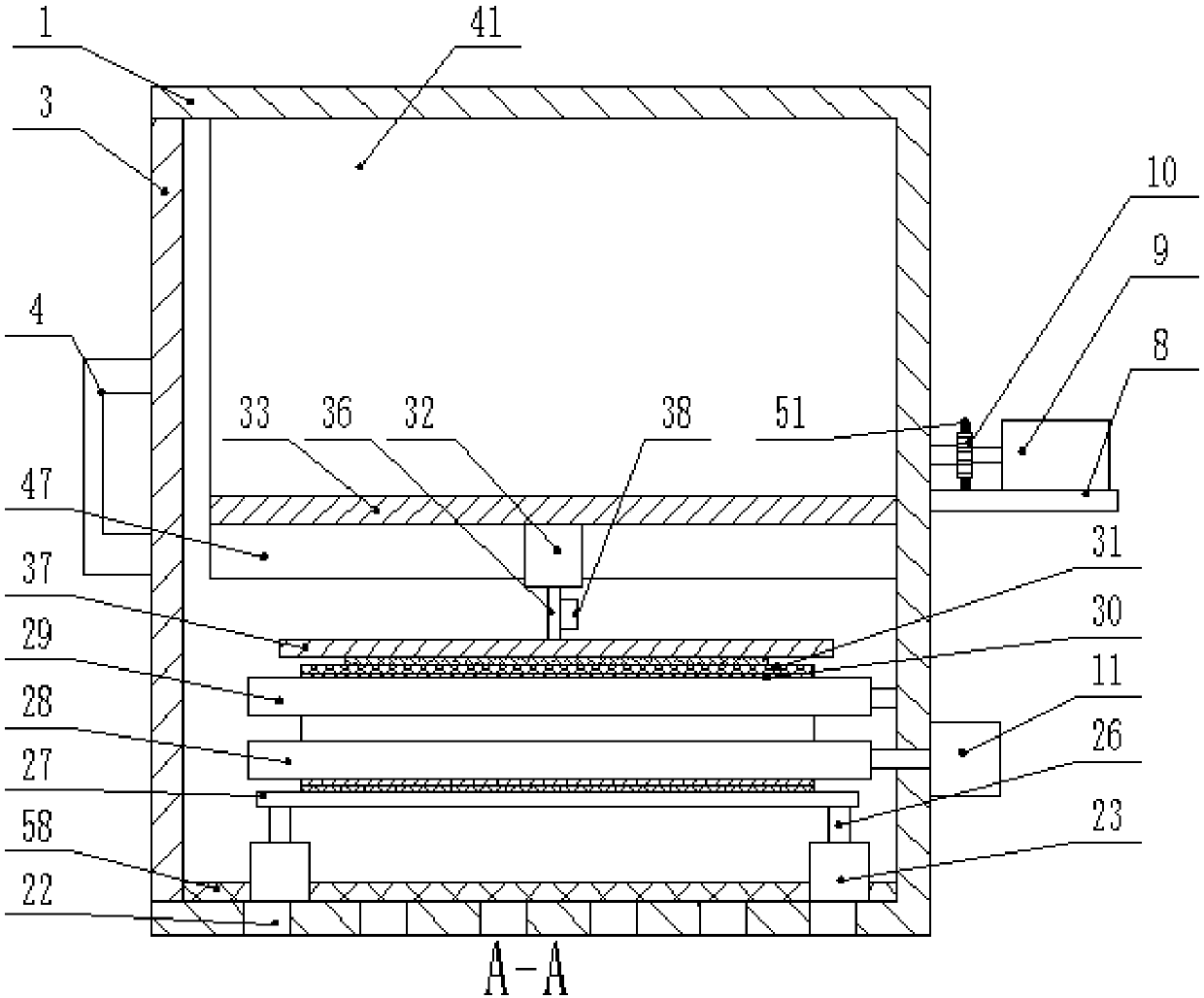

Cotton cloth dyeing device

InactiveCN109097927AImprove dyeing effectSolve wasteTextile treatment machine partsLiquid/gas/vapor removal by suctionCotton clothEngineering

The invention discloses a cotton cloth dyeing device which comprises a box. A supporting rod is fixed at each of four corners at the bottom end of the box, a box door is hinged on one side of the box,a handle is fixedly arranged on the box door, and an exhaust pipe is fixed at the top end of the box and communicated with the inside of the box. Pigment is sprayed to two sides of cloth from nozzleson a first pigment spraying box and a second pigment spraying box through a pigment supply pump, then two pigment brushing rollers are rotated through a motor, in this way, hairbrushes on the pigmentbrushing rollers can uniformly brush the pigment sprayed on the cloth to be flat, so that cloth dyeing effect is improved effectively; surplus pigment on the surface of the cloth is absorbed througha water absorbing sponge layer on a belt, so that the problem of pigment waste is solved effectively; the two sides of the cloth are dried from through holes in a first air box and a second air box through a hot air blower, so that a function of integrating dyeing with drying is realized effectively.

Owner:开平顺丰纺织有限公司

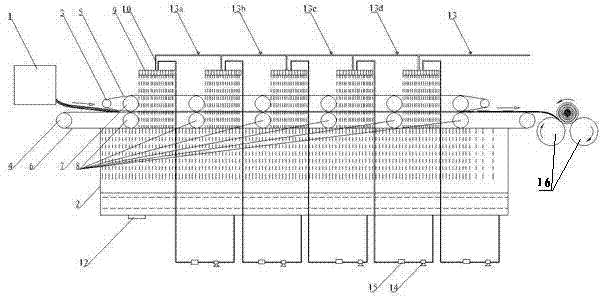

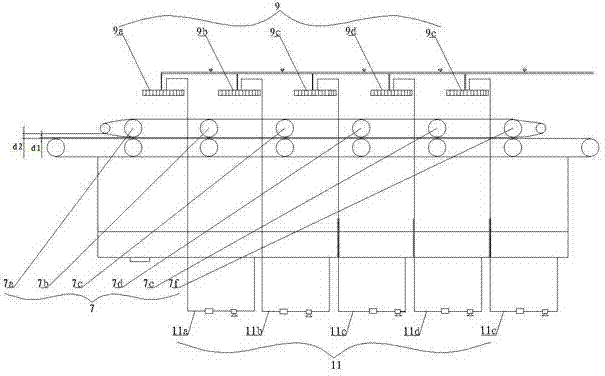

Spray-rolling type loose fiber dyeing machine

ActiveCN103774360AFast absorptionFacilitated DiffusionLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsFiberMechanical engineering

The invention relates to a spray-rolling type loose fiber dyeing machine, and belongs to the technical field of loose fiber dyeing. The spray-rolling type loose fiber dyeing machine comprises a transmission component and a spray component. The transmission component comprises a pair of upper drive rollers and a pair of lower drive rollers. The upper drive rollers and the lower drive rollers are sleeved with an upper guide belt and a lower guide belt respectively to be used in a cooperative mode. The upper guide belt is provided with a first leak hole, the upper guide belt and the lower guide belt operate synchronously, a plurality of upper rollers are arranged in an upper guide belt loop, and a plurality of lower rollers matched with the upper rollers to be used are arranged in a lower guide belt loop. The upper guide belt and the lower guide belt are matched with the upper rollers and the lower rollers to achieve synchronous clamping transportation of the loose fibers. The spray component comprises a dyeing liquid pipe and sprayer heads. One end of the dyeing liquid pipe is communicated with dyeing liquid, the other end of the dyeing liquid pipe is connected with the sprayer heads, the sprayer heads are located above the upper guide belt between adjacent upper rollers, and the dyeing liquid in the dyeing liquid pipe is sprayed downwards onto the loose fibers through the sprayer heads. By means of the spray-rolling type loose fiber dyeing machine, continuous production can be carried out, cost can be lowered to 1 / 3-1 / 5 of that in the prior art.

Owner:SHAOXING JINYU TEXITLE NEW TECH CO LTD

Preparing process of alginate fiber fleece type fabric

InactiveCN108342817AAchieve dyeingHigh color fastnessWeft knittingAlginate artificial filamentsCardingEngineering

Owner:三问家居股份有限公司

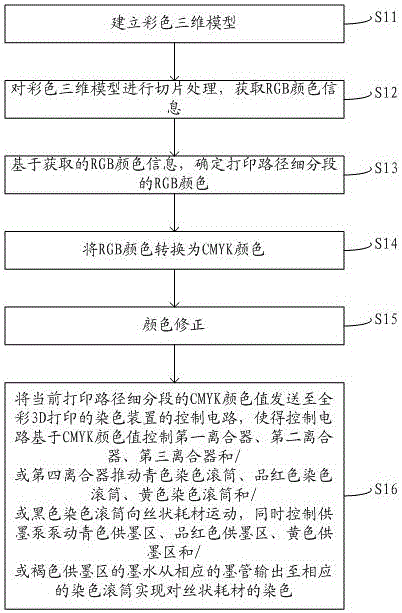

Dyeing device used for full-color 3D printing and full-color 3D printing method

The invention discloses a dyeing device used for full-color 3D printing and a full-color 3D printing method, and aims to solve the technical problem that an existing FDM printer cannot realize full-color printing. The dyeing device comprises an ink box, an ink supply pump, ink tubes, dyeing rollers, clutches, a bracket and a control circuit; the ink box comprises a cyan ink supply region, a magenta ink supply region, a yellow ink supply region and a black ink supply region; the bracket is used for bearing threadlike consumable items output by a 3D printer; the control circuit is connected to the clutches for controlling movement of the clutches; and the ink supply pump is connected to the ink box and is used for controlling the ink supply pump to pump ink in the cyan ink supply region, the magenta ink supply region, the yellow ink supply region and / or the black ink supply region to output to the corresponding dyeing rollers through the corresponding ink tubes to realize dyeing of the threadlike consumable items when the control circuit controls the clutches for pushing the dyeing rollers to move towards the threadlike consumable items. The dyed threadlike consumable items enter a printing spray head of the 3D printer for printing, so that full-color 3D printing of the FDM printer is realized with low cost.

Owner:广州尤尼智康生物科技有限公司

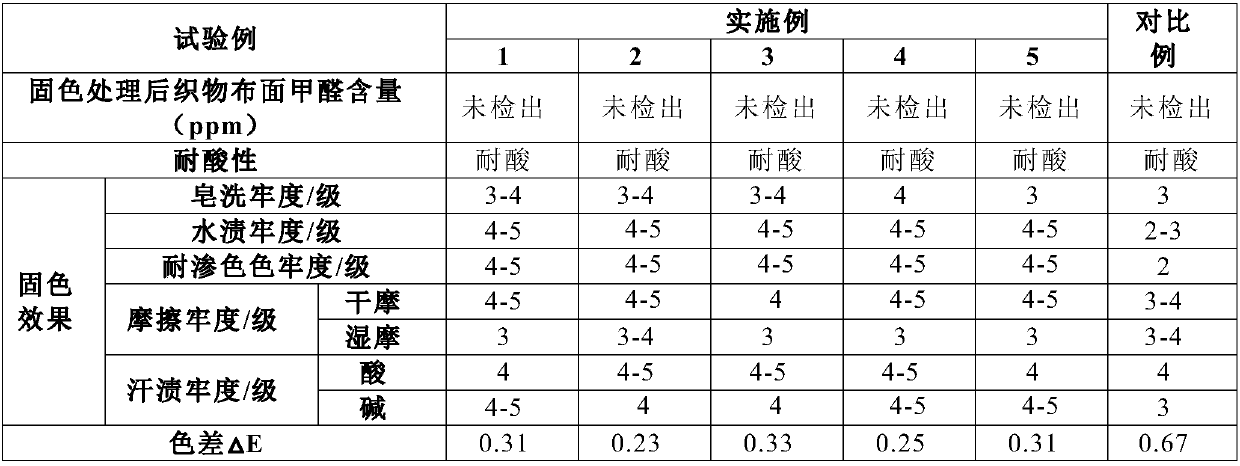

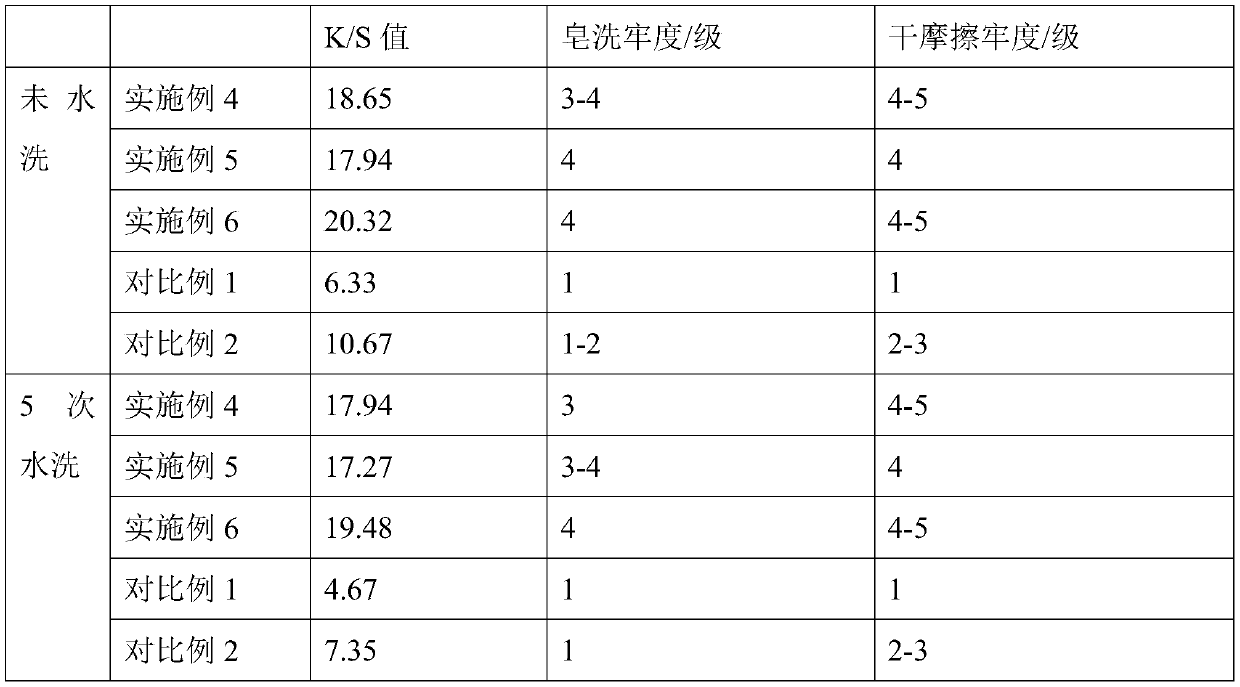

Dyeing method of chinlon

The invention belongs to the technical field of textile dyeing, and particularly relates to a dyeing method of chinlon. According to the method, final cleaning is performed through high-molecular polymer, so that dyeing of chinlon is realized. The dyeing method is stable in technology, the flow is easy to control, and dyed fabric does not have defects, such as dyeing defects and color spots, and is high in bleeding resistance color fastness, high in washing color fastness and rubbing color fastness are high, and good in quality.

Owner:FUJIAN LONGYAN XIQUE TEXTILE

Extraction method of microbial pigment and method for dyeing lyocell fibers by adopting same

ActiveCN111471316AGood compatibilityEffective approachNatural dyesDyeing processBiotechnologyMicrobiology

The invention discloses an extraction method of a microbial pigment and a method for dyeing lyocell fibers by using the same. The extraction method of the microbial pigment comprises the following steps: inoculating bacteria into a seed culture solution, culturing on a shaking table, inoculating the bacterium seed solution into a fermentation culture solution, culturing on the shaking table; afterthe fermentation is finished, centrifuging the fermentation solution, extracting the centrifugal product by using ethyl acetate; and finally, concentrating and drying the extract to obtain the microbial pigment powder. When the pigment is used for dyeing the lyocell fibers; lyocell fibers are added into a water solution containing the microbial pigment at the room temperature; dyeing is carried out for 20 to 40 minutes, the bath ratio is 1: (20-30), then alum is added, the temperature is raised to 80 DEG C, then triethanolamine is added, the temperature is maintained for dyeing for 20-40 minutes, finally a color fixing agent is added, cooling is conducted after the color fixing treatment is finished, and the fibers are taken out, washed with cold water, soaped, washed with water, and dried to obtain dyed lyocell fibers. The dyeing of the microbial pigment on the surface of the lyocell fibers is realized.

Owner:当阳市鸿阳新材料科技有限公司

Method for preparing colored nanometer cellulose/polylactic acid composite film

The invention provides a method for preparing a colored nanometer cellulose / polylactic acid composite film. The method is characterized by comprising the following steps that 1, dyed nanometer cellulose emulsion is prepared; 2, polylactic acid is dissolved in an organic solvent; the dyed nanometer cellulose emulsion is used as a water phase; an oil phase dissolved with the polylactic acid is added; homogenizing is performed; pickering emulsion is prepared; 3, an organic solvent in the pickering emulsion is volatilized; filtering and drying are performed to obtain colored composite microspheres; the colored composite microspheres are subjected to hot pressing; the colored nanometer cellulose / polylactic acid composite film is obtained through preparation. By the pickering emulsion method, the colored nanometer cellulose is uniformly dispersed into a polylactic acid matrix; the performance of the composition material can be enhanced; the rich color can also be given to the composite material; the application field of the composite material can be greatly expanded. The method is simple; the energy is saved; the environment is protected; the dyeing of the reactive dyes on the polylacticacid is indirectly realized.

Owner:DONGHUA UNIV

Polyamide-cotton mixed fabric catalyzing and printing technology in same sizing agent

InactiveCN104562749AAchieve dyeingStaining does not affectDry-cleaning apparatus for textilesDyeing processPolyamideEngineering

The invention discloses a polyamide-cotton mixed fabric catalyzing and printing technology in the same sizing agent. The technological process comprises the following steps in sequence: printing, drying, steaming, washing with hot water, soaping, washing with water, and drying. The technology of utilizing an activated dye / a neutral dye to be combined with dicyandiamide to catalyze and fix the color can obviously improve the printing color depth, reduces the dosage of an alkaline agent, realizes dyeing of the activated dye to the cotton in the fabric under the alkalescent condition, meanwhile cannot influence the dyeing of the neutral dye to polyamide, so as to achieve a good printing effect; the fastness to wet rubbing of the printed fabric can be up to level 4.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

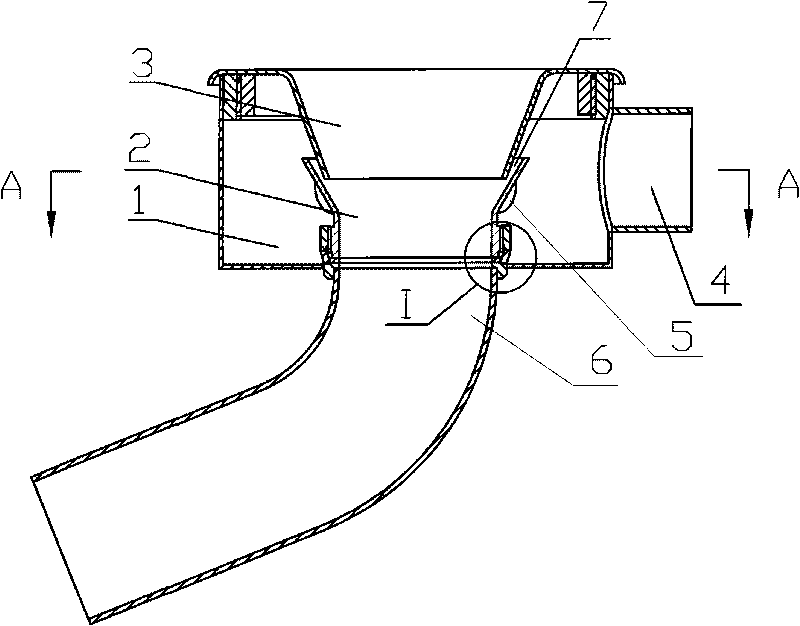

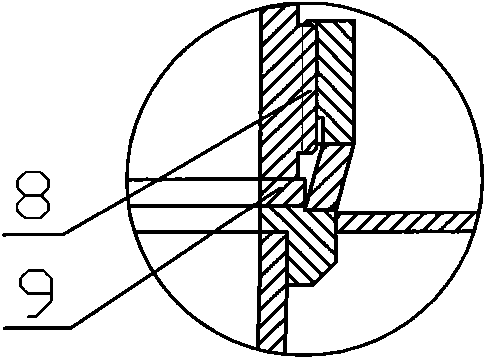

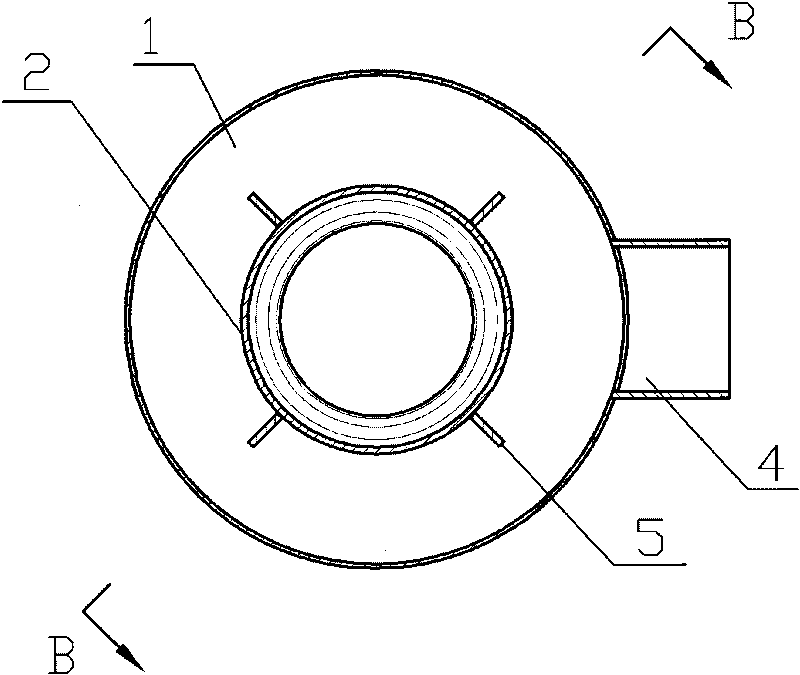

Jet overflow dyeing machine nozzle

InactiveCN101698970AReduce the speed of high speed into the nozzlePrevent backflowTextile treatment machine partsTextile treatment with treating outlet contectEngineeringScrew thread

The invention discloses a jet overflow dyeing machine nozzle, comprising a nozzle carrier and a nozzle core carrier and a nozzle cover which are arranged in the nozzle carrier; wherein the nozzle core carrier and the nozzle cover are in funnel shape, the lower end of the nozzle cover is inserted into the nozzle core carrier, an annular gap is arranged between the nozzle core carrier and the nozzle cover, the annular gap is a dye liquor injecting port, the nozzle carrier is provided with a nozzle fluid pipe, the lower end of the nozzle core carrier is connected with the nozzle carrier by screw thread, a spacer is arranged between the lower end face of the nozzle core carrier and the nozzle carrier, and the outer wall of the nozzle core carrier is provided with a plurality of watertight shutters separated each other. The invention can prevent reflow from being produced in curved pipe of nozzle and reduce textile kinking and 'tympany'. When installing the nozzle, the thickness of the spacer between the nozzle carrier and the nozzle core carrier is adjusted to regulate the size of the dye liquor injecting port and the angle between the watertight shutter on the nozzle core carrier and the nozzle fluid pipe, thus realizing regulation of liquid flow jet speed and pressure.

Owner:济南元首针织股份有限公司 +1

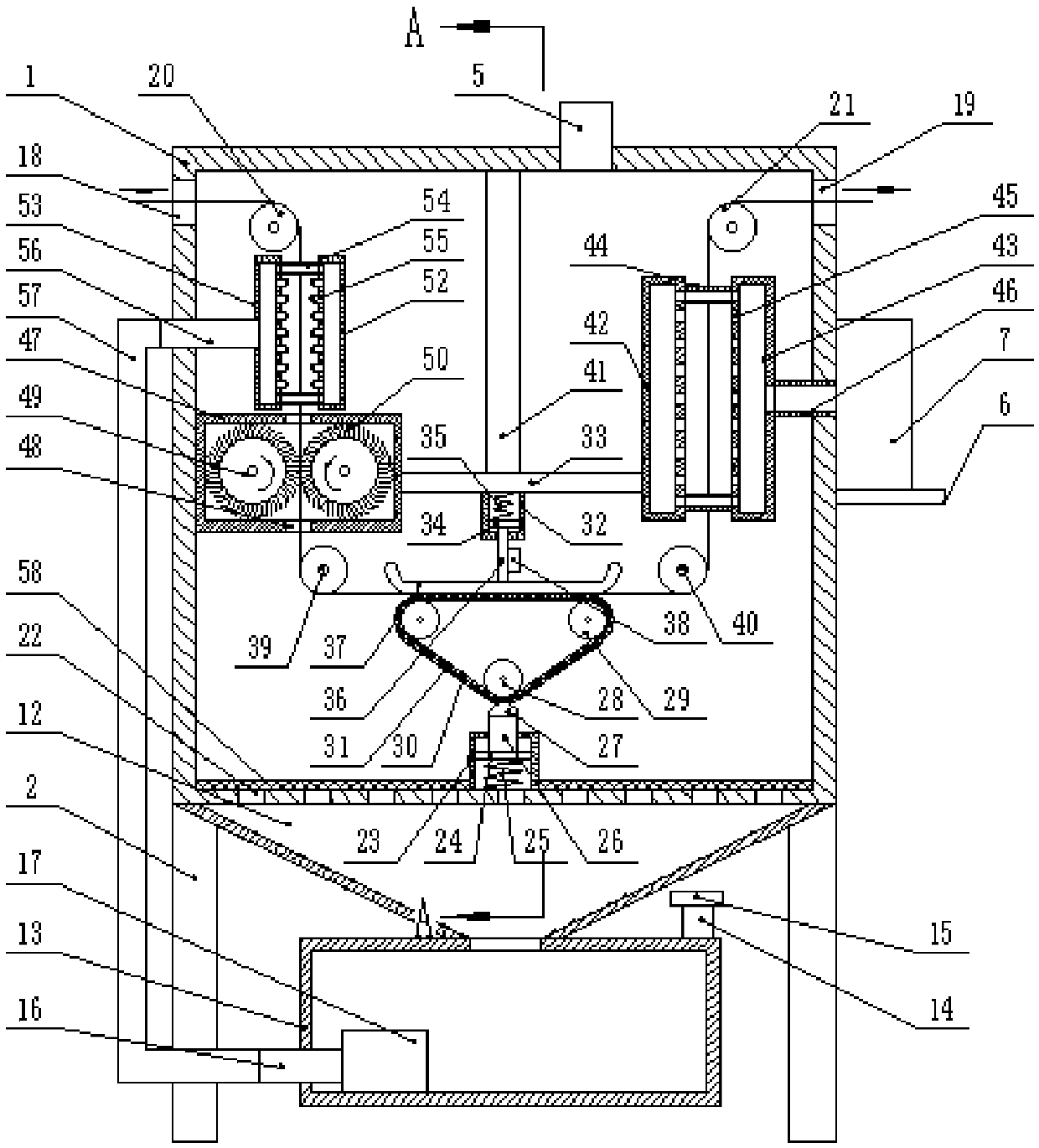

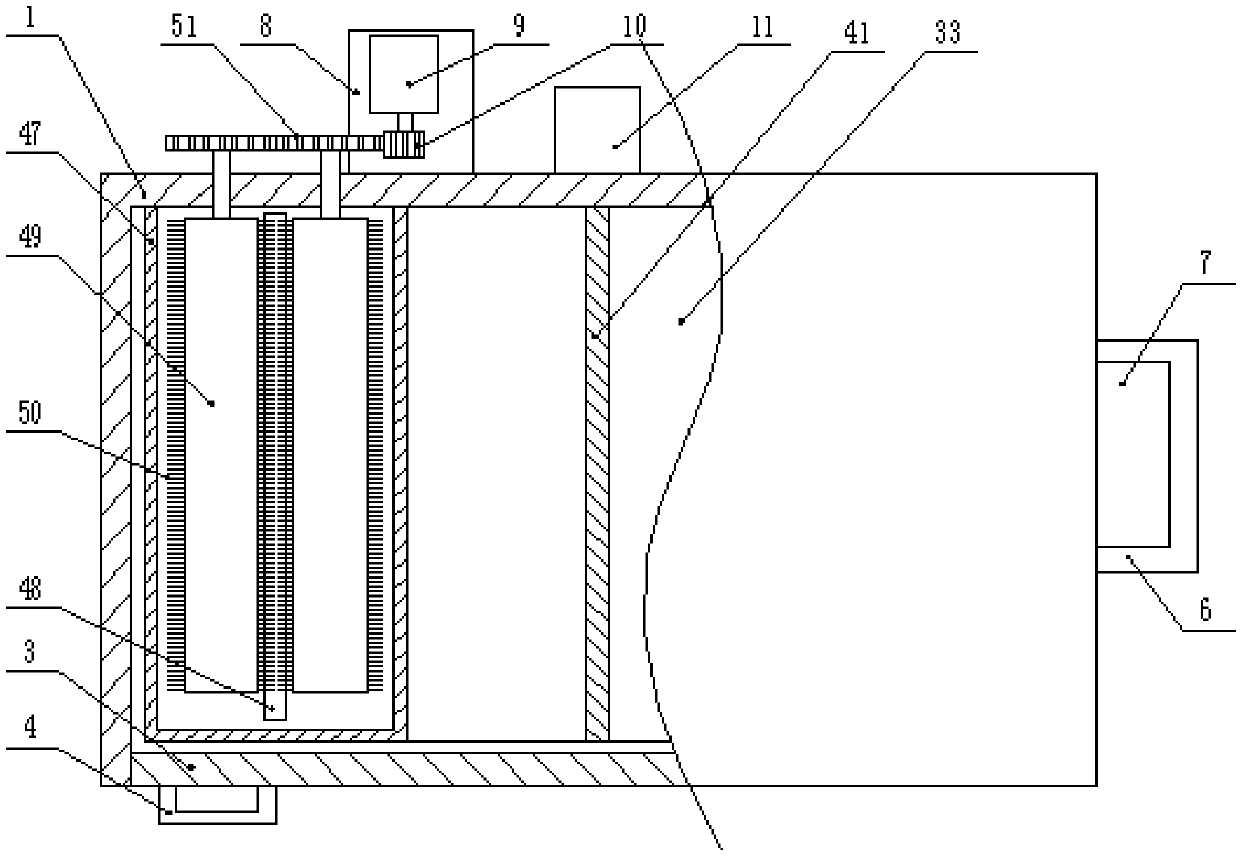

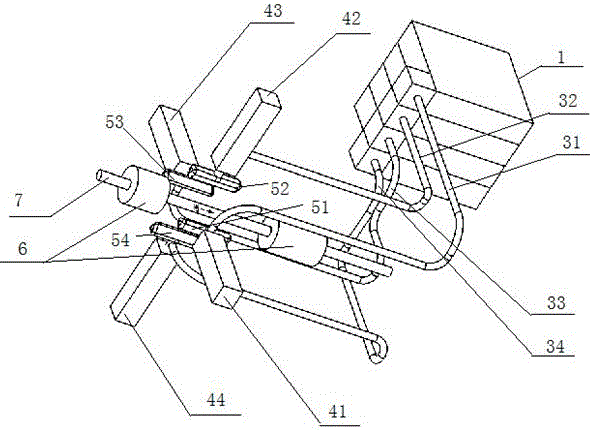

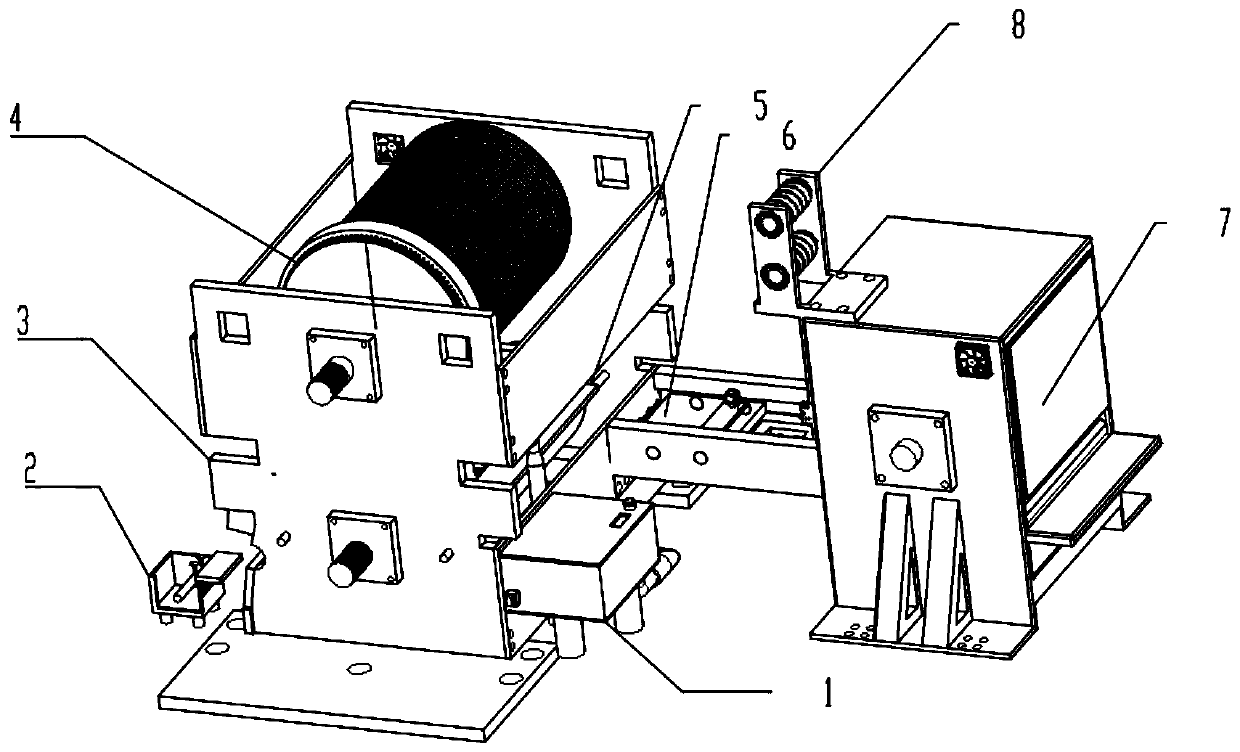

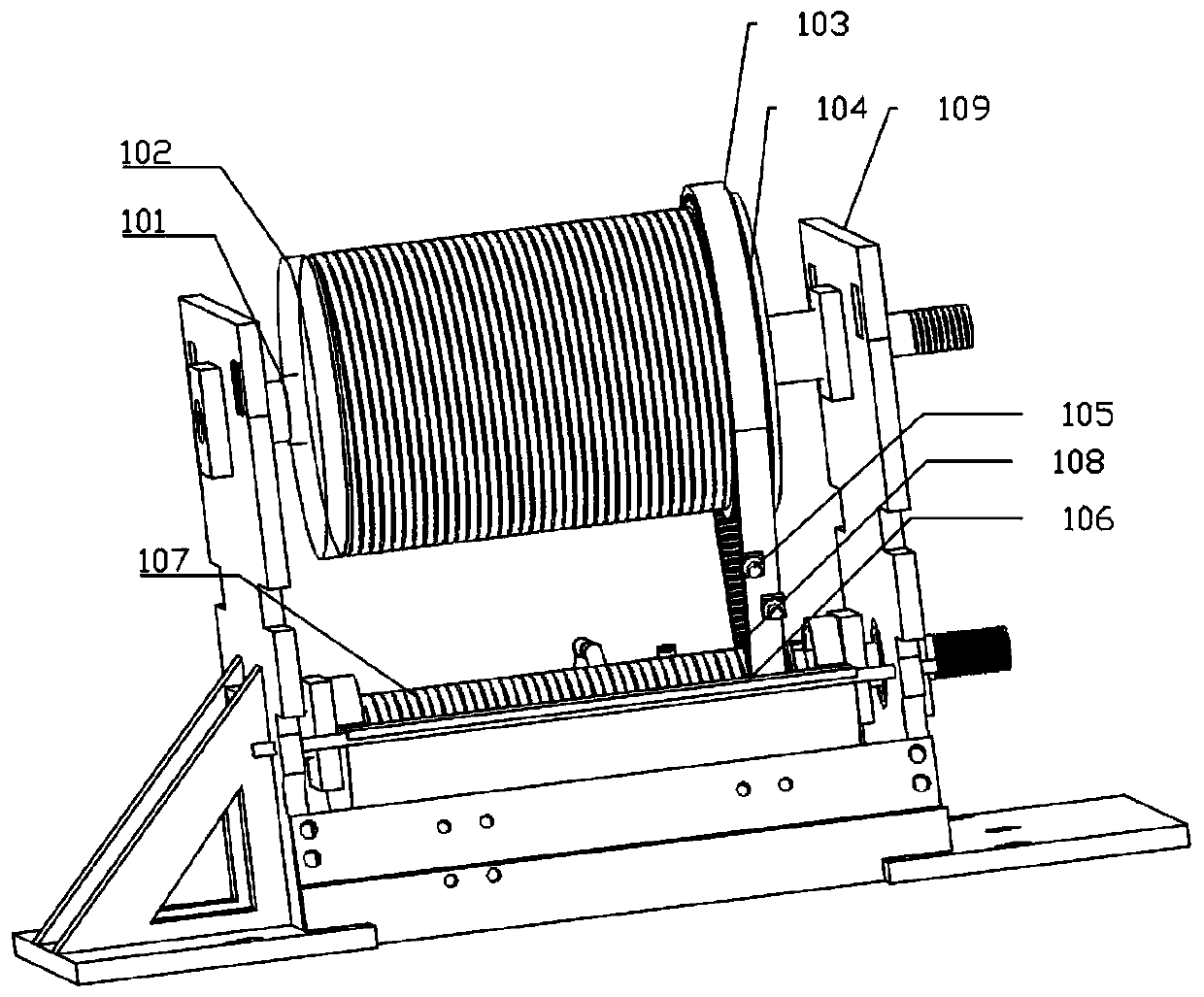

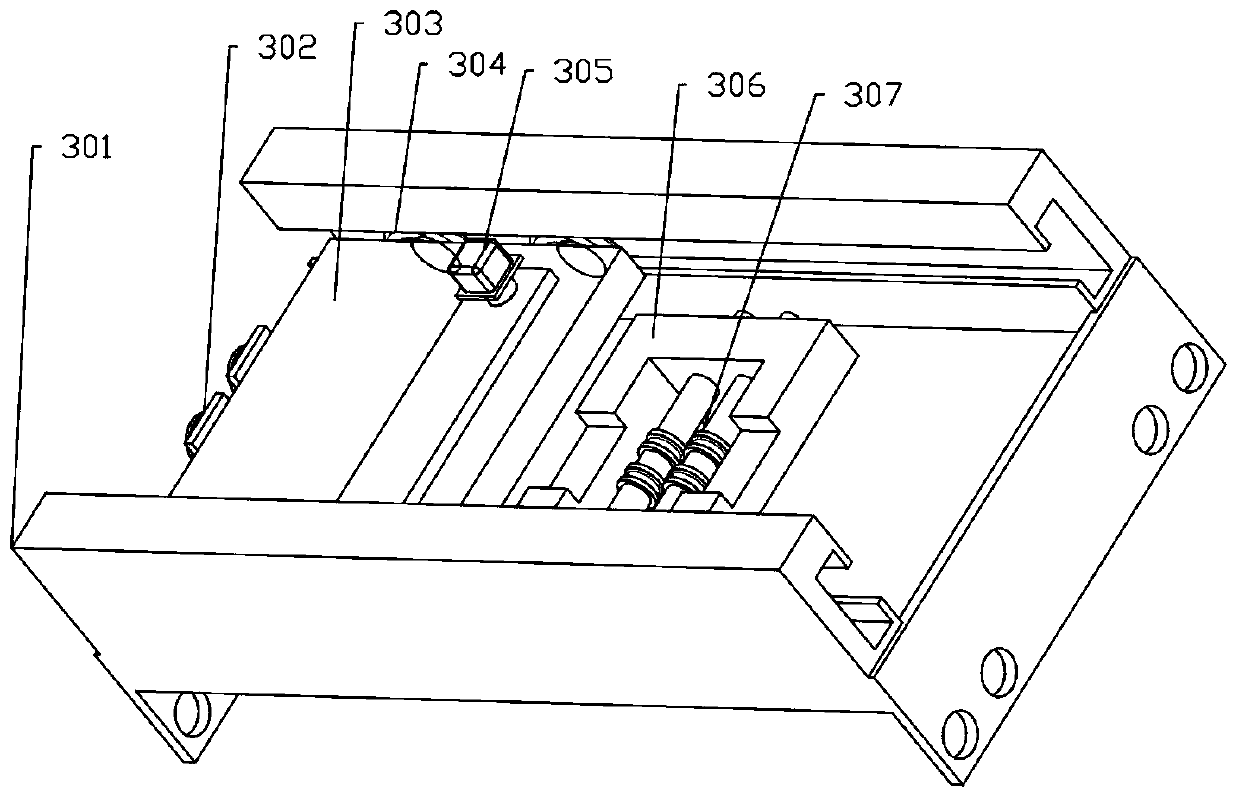

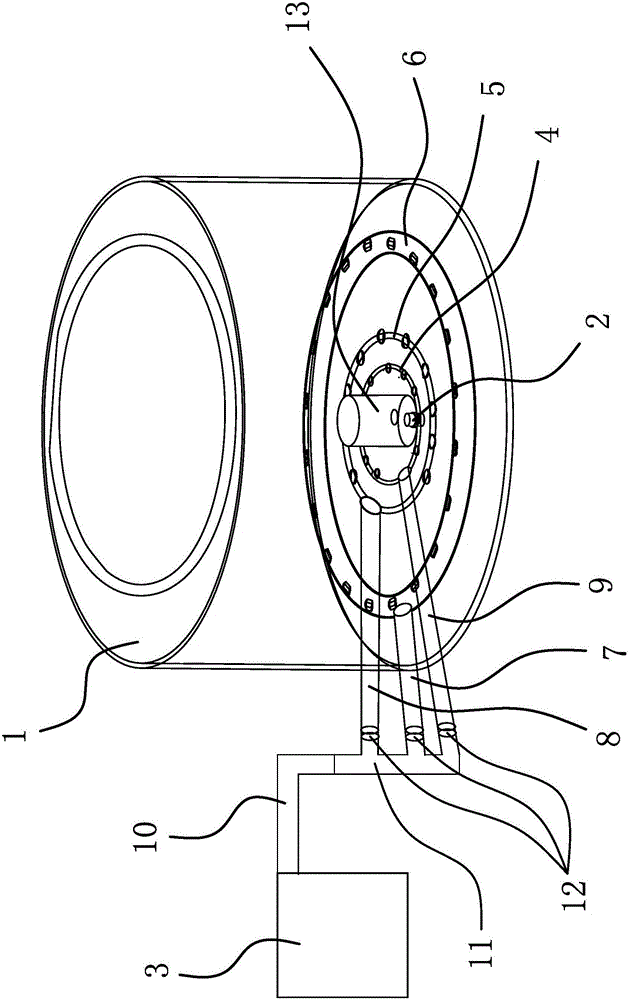

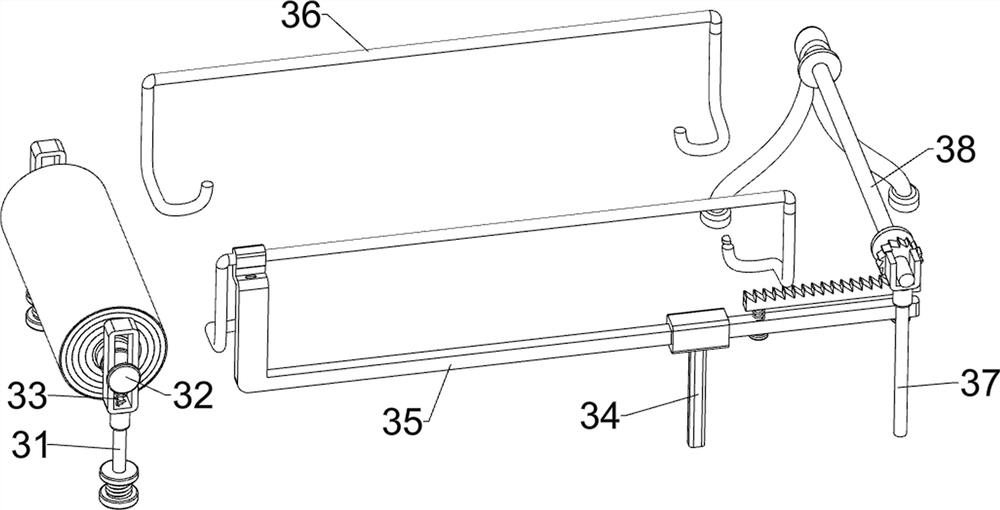

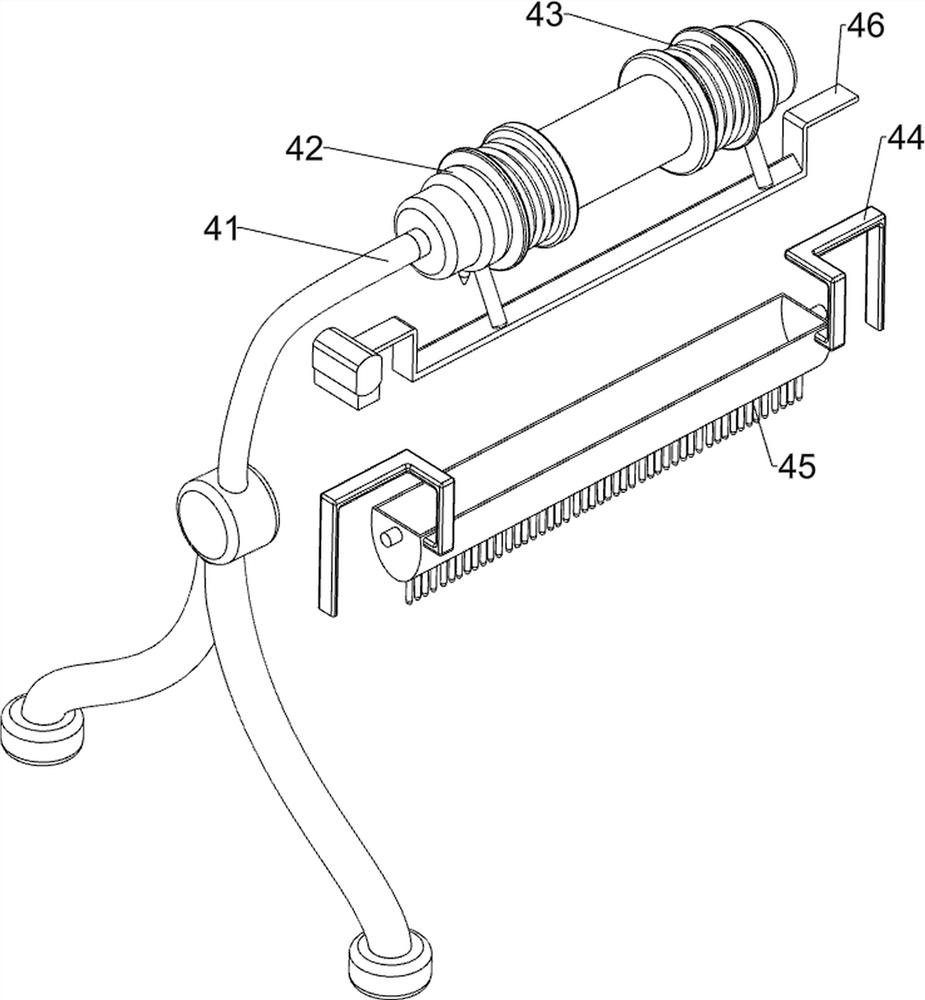

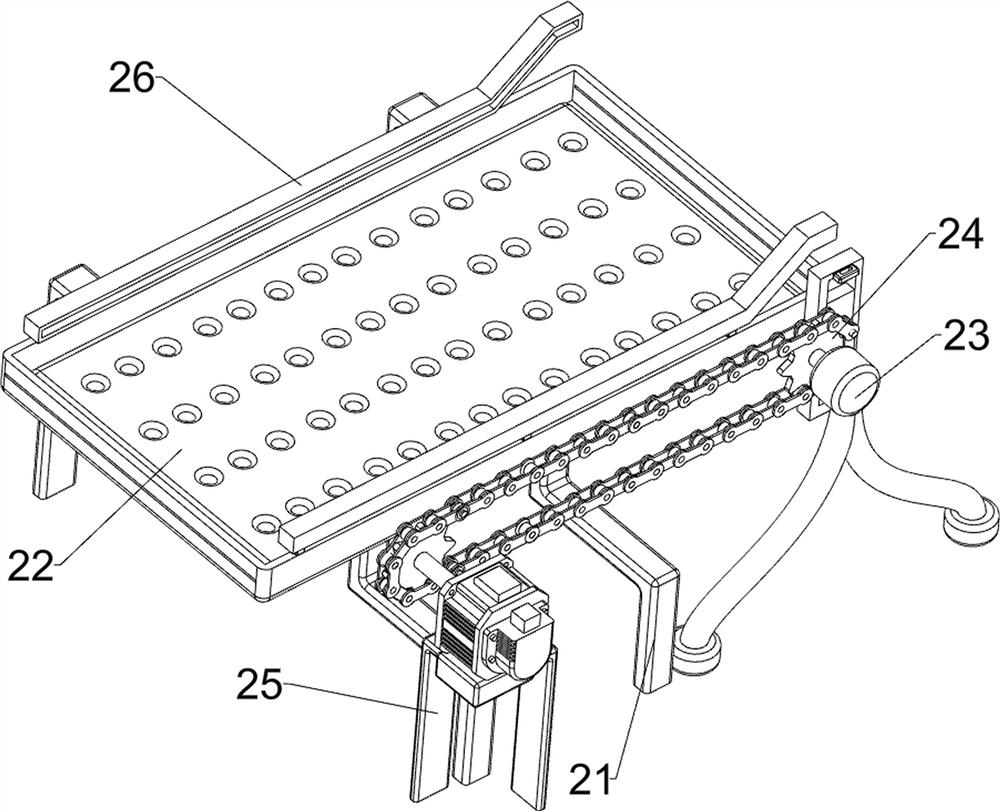

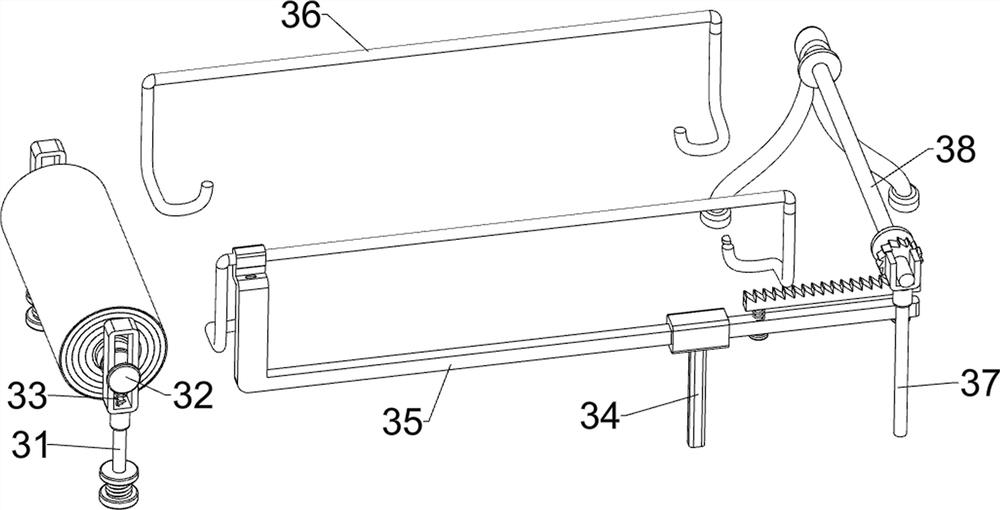

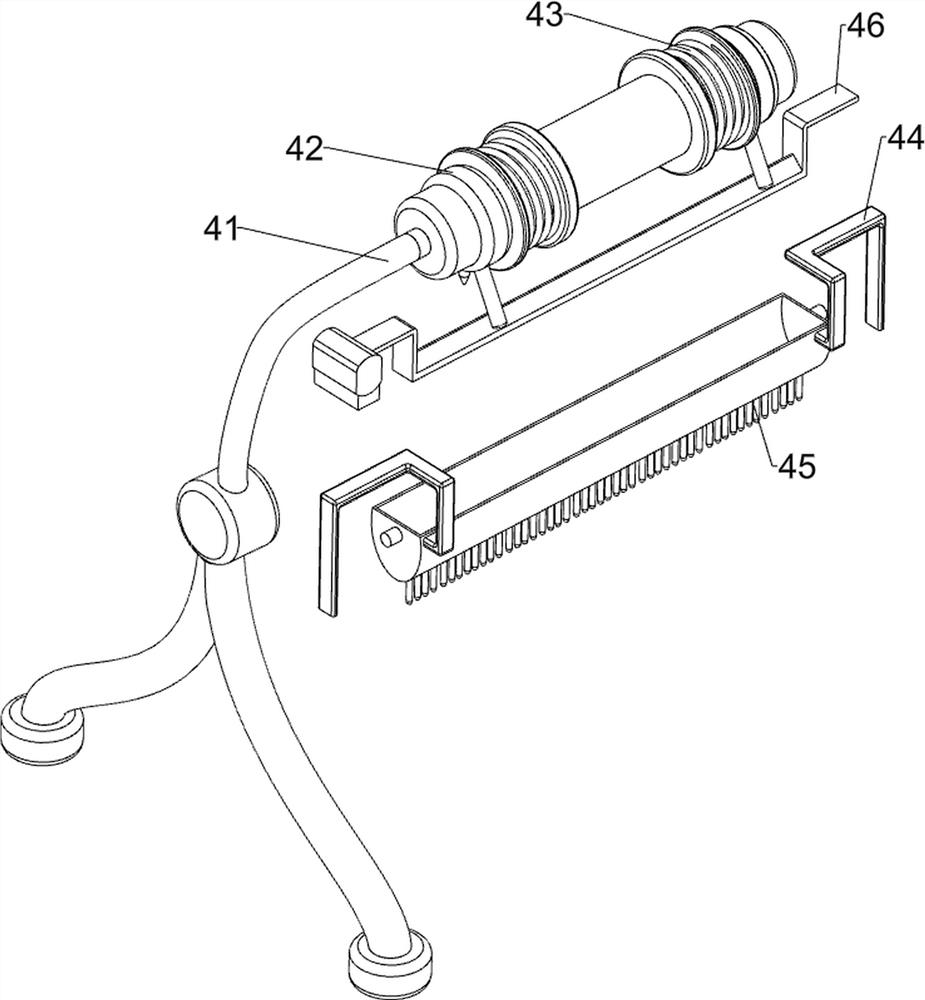

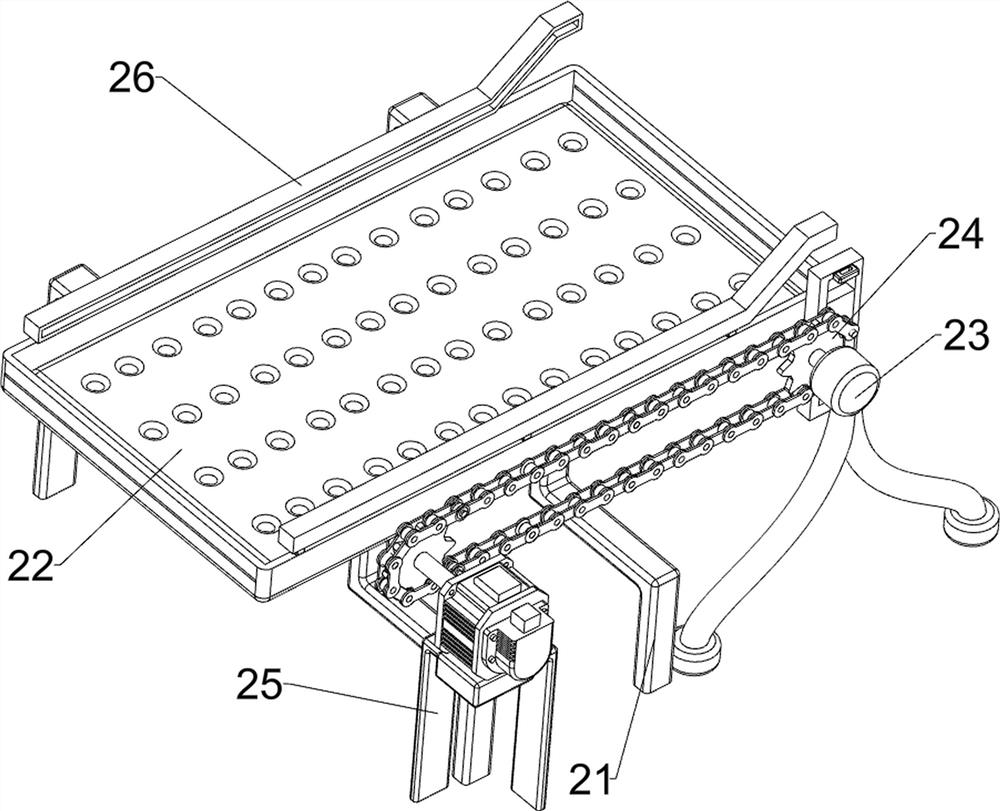

Intelligent equipment for dyeing and sizing plurality of single yarns or plied yarns

ActiveCN111519366AAchieve dyeingEasy to controlTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsProcess engineeringYarn tension

The invention discloses intelligent equipment for dyeing and sizing a plurality of single yarns or plied yarns. The intelligent equipment comprises a dye liquor distributing and heating cylinder, a yarn feeder, a yarn tension pretensioner, an automatic dyeing and yarn arranging mechanism, an automatic dye vat adjusting mechanism, an automatic sizing mechanism and an automatic drying and yarn arranging mechanism, the dye liquor distributing and heating cylinder is used for storing dye liquor and can be used for heating the dye liquor and detecting the concentration of the dye liquor; the yarn feeder is used for fixing the initial position of the yarn and guiding the yarn; the yarn tension pretensioner is used for tensioning and guiding yarns; the automatic dyeing and yarn arranging mechanism can be used for automatically arranging yarns; the automatic sizing mechanism is used for automatically sizing yarns; and the automatic drying and yarn arranging mechanism can be used for drying andarranging sized yarns. According to the intelligent equipment, the technical problem of size dyeing of a plurality of single yarns or plied yarns in a short process is solved, the size dyeing processrequirements of different yarns are met by adjusting the rotating speed of the automatic yarn arranging mechanism for yarn dyeing and the number of thread turns of the lead screw, and the problems ofhigh cost and serious waste in the sample making stage of yarn products are solved.

Owner:HUNAN INSTITUTE OF ENGINEERING

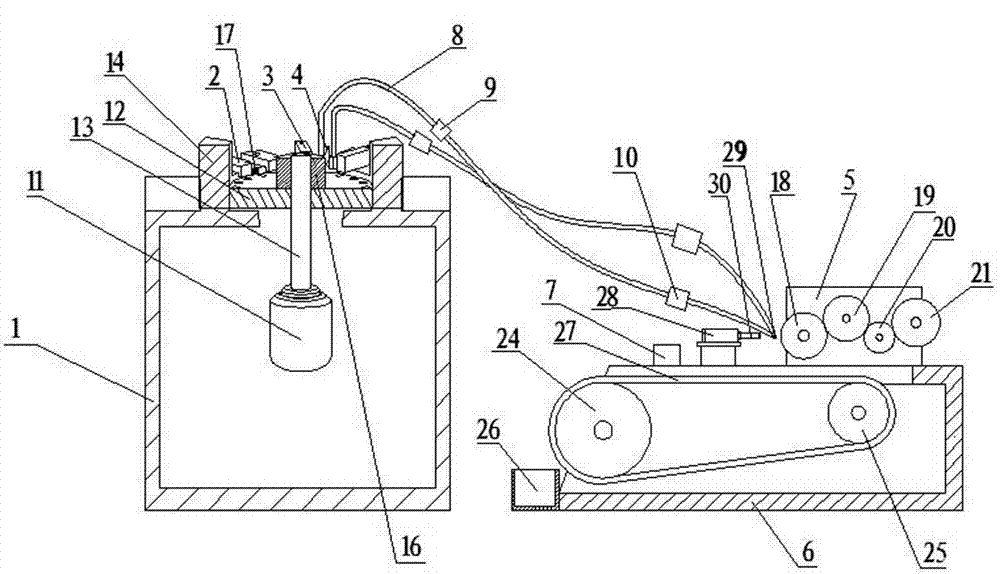

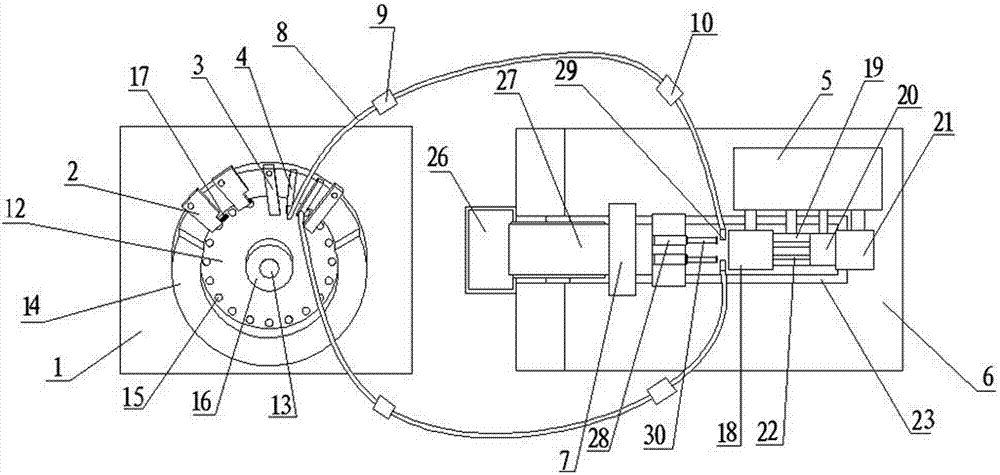

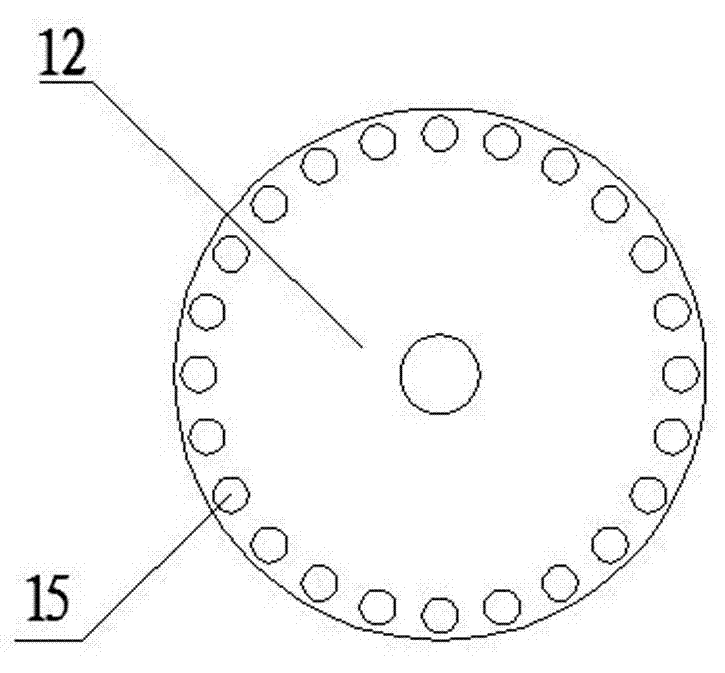

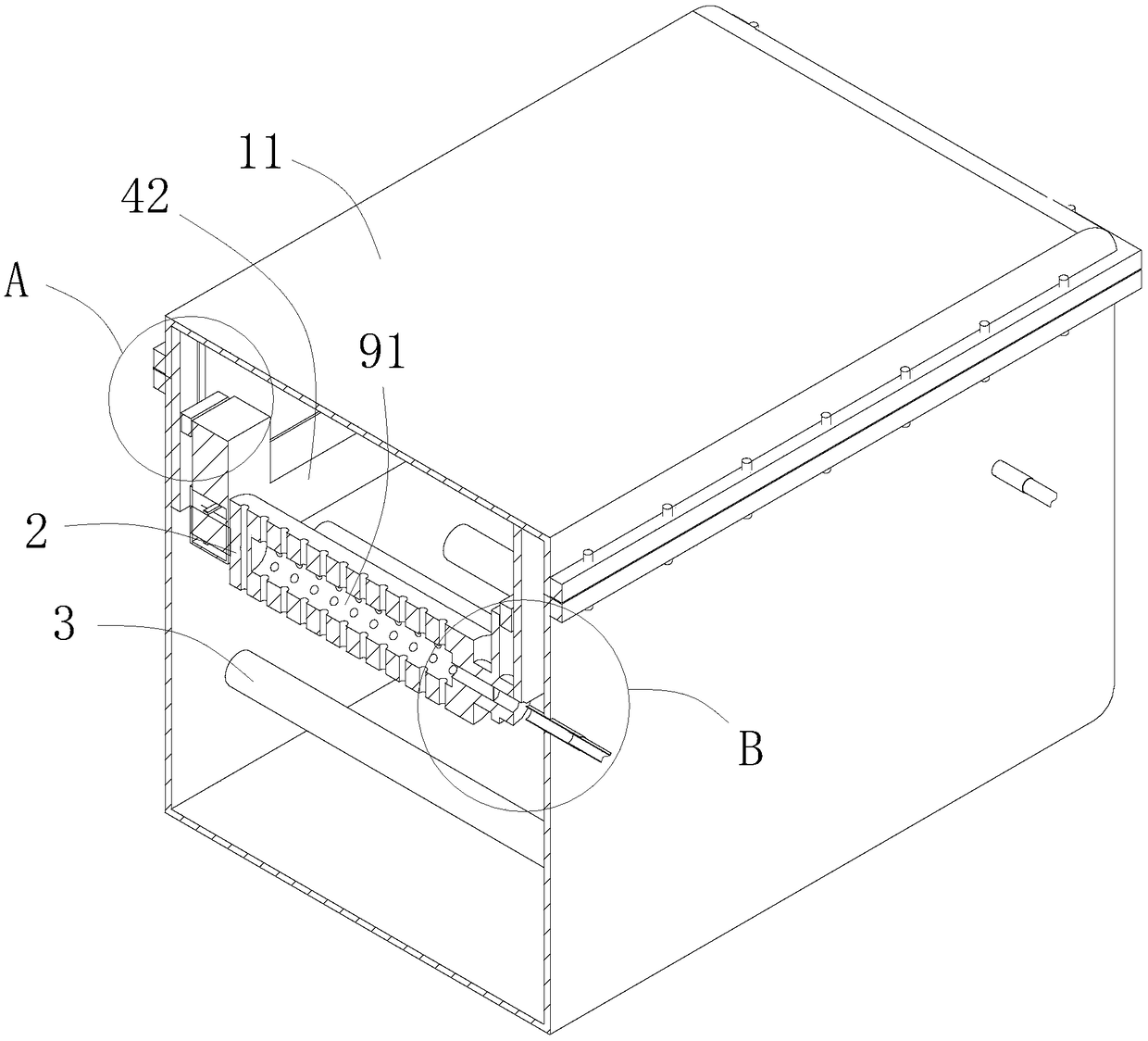

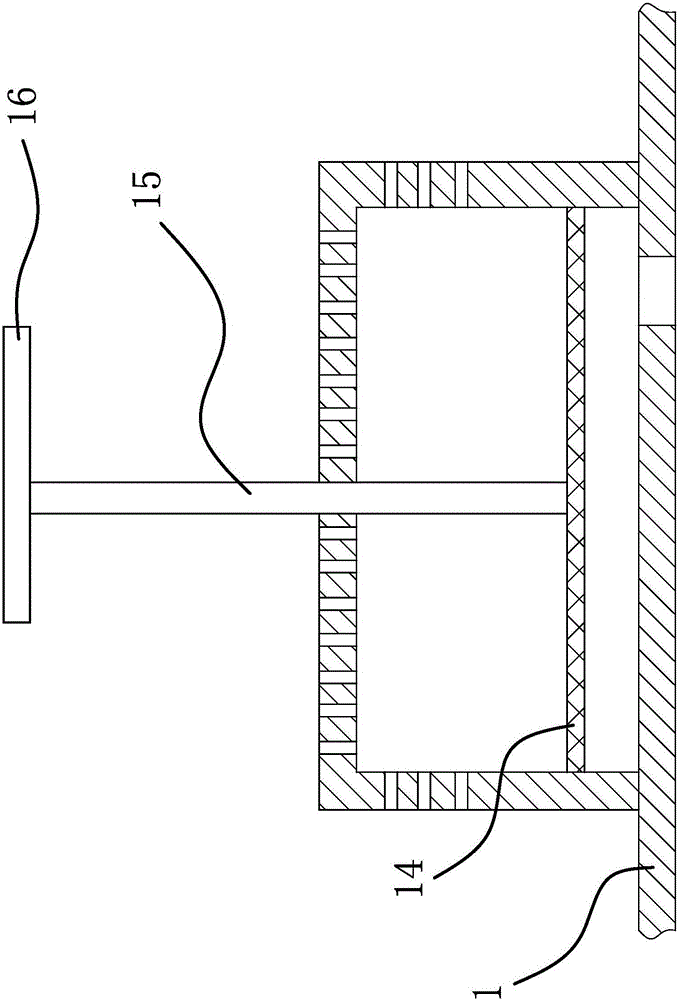

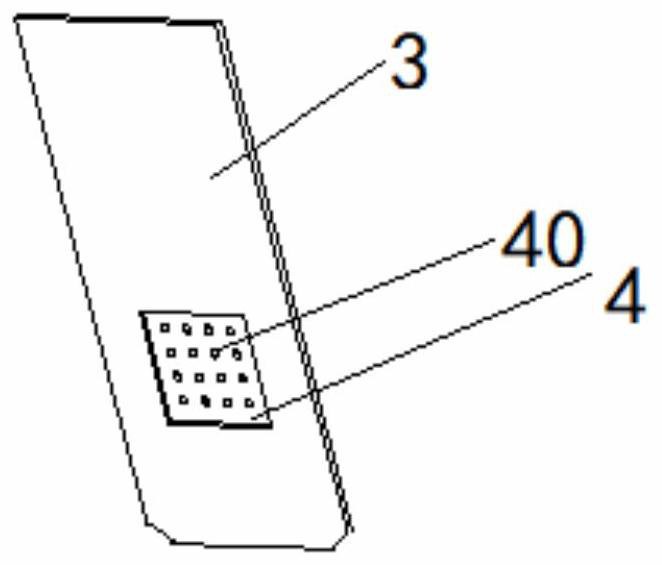

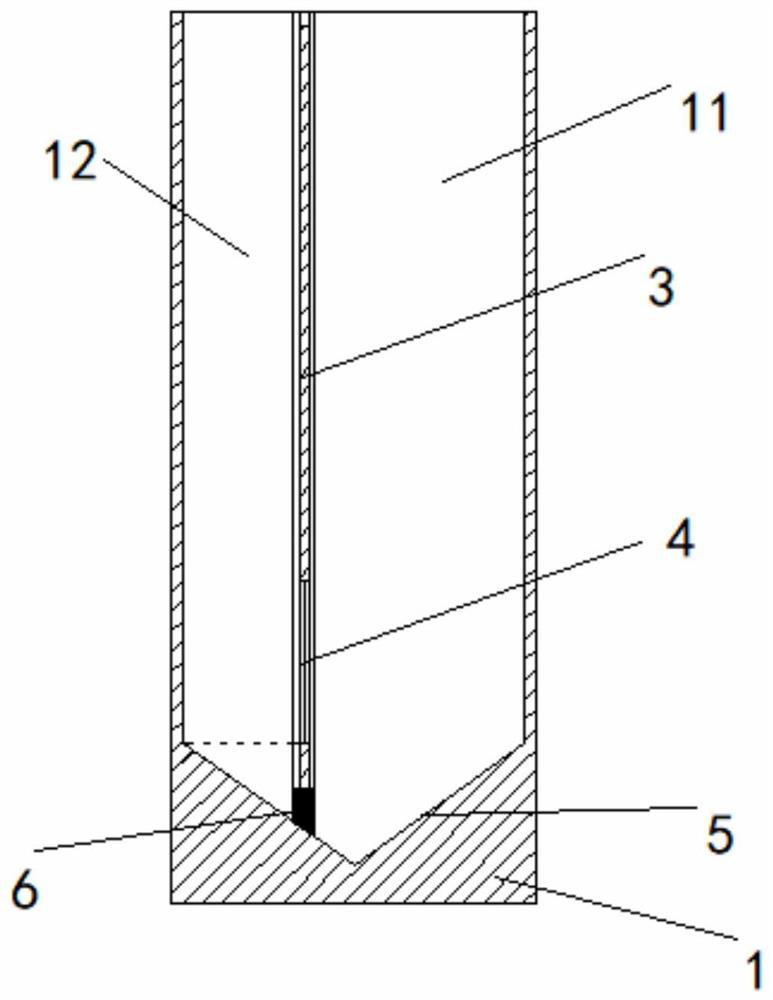

Glass-packaged diode detecting and labeling device

ActiveCN103499945AHigh degree of automationAchieve dyeingSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingProgrammable logic controllerEnergy consumption

The invention discloses a glass-packaged diode detecting and labeling device. The glass-packaged diode detecting and labeling device comprises a PLC (Programmable Logic Controller) cabinet (1), detection devices (2), reject product eliminating devices (3), qualified product discharging devices (4), a case (5), a working platform (6), a drying oven (7), feeding pipes (8), an upper sensor (9) and a lower sensor (10), wherein the detection devices (2) and the qualified product discharging devices (4) are arranged on the PLC cabinet, the feeding pipe (8) is arranged on the qualified product discharging device (4), a discharge outlet (29) of the feeding pipe (8) is arranged between a piston rod (30) and a printing-dyeing roller (18) of a single-acting cylinder (28), the case (5) is arranged on the working platform (6), and a large belt pulley (24) and a small belt pulley (25) are arranged in the working platform (6). The glass-packaged diode detecting and labeling device has the beneficial effects of being high in production efficiency, capable of reducing energy consumption, high in automation degree, simple in structure and the like.

Owner:SICHUAN BLUE COLOR ELECTRONICS TECH

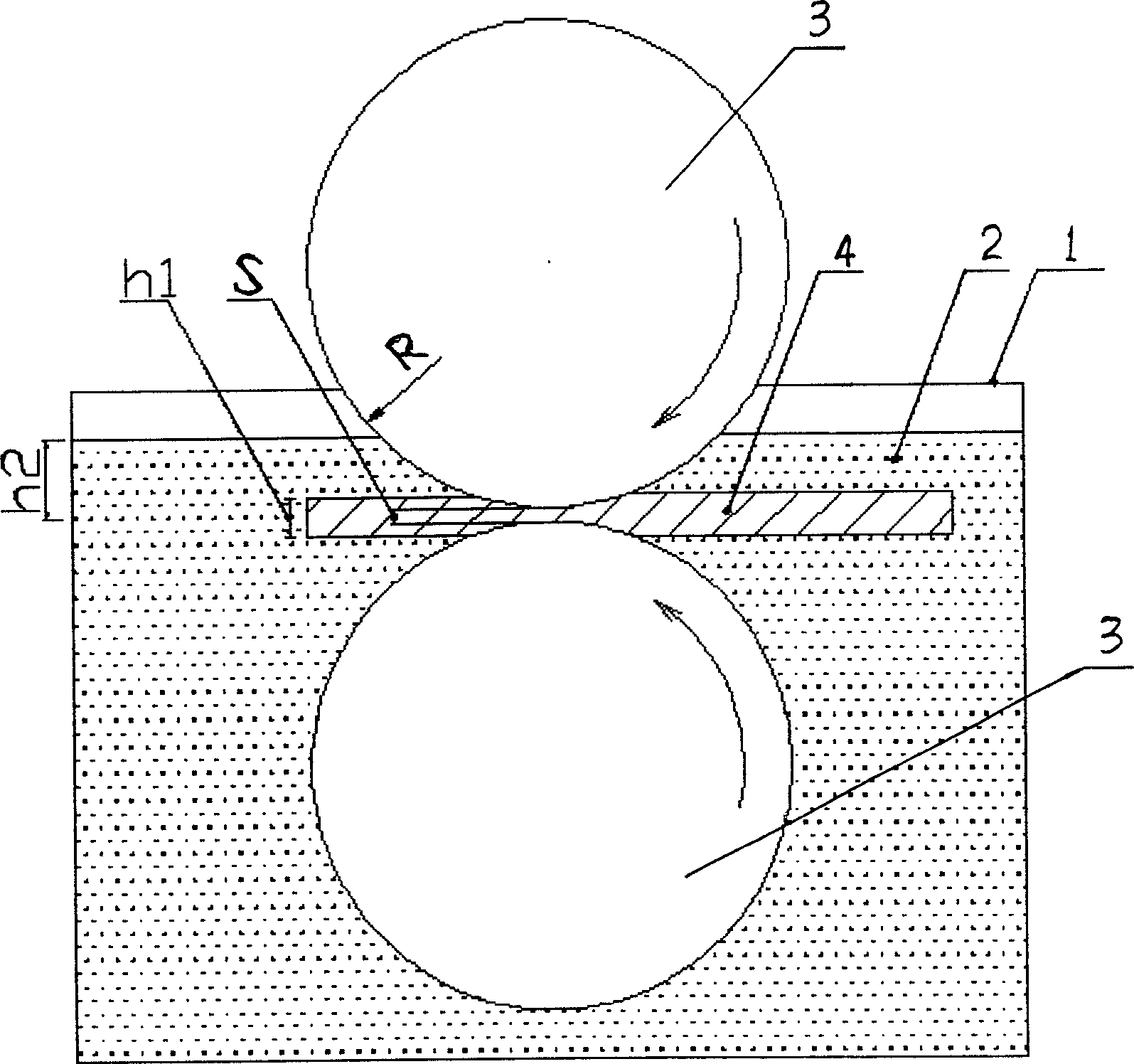

A dyeing and water squeezing integrated device for cloth printing and dyeing

ActiveCN108914450AAchieve dyeingSimple and fast operationTextile treatment containersLiquid/gas/vapor removal by squeezing rollersEngineeringMechanical engineering

The invention provides a dyeing and water squeezing integrated device for cloth printing and dyeing. The device comprises a dip dyeing chamber, a moving driving component, and a water squeezing component; a top cover in close fit with the dip dyeing chamber is arranged on the dip dyeing chamber; two dip dyeing cloth winding rollers are arranged in the dip dyeing chamber in a way of being capable of rotating forward and reversely; the two dip dyeing cloth winding rollers have a first position and a second position relative to the top cover and the moving driving component is used for driving the two dip dyeing cloth winding rollers to move between the first position and the second position; the water squeezing component is used for squeezing water from cloth on the two dip dyeing cloth winding rollers. When the two dip dyeing cloth winding rollers are at the first position, the two dip dyeing cloth winding rollers are submerged in dye liquor; when at the second position, the two dip dyeing cloth winding rollers cooperate with the water squeezing component. The operation of cloth dyeing and cloth water squeezing can be completed only by controlling the two dip dyeing cloth winding rollers to move between the first position and the second position, so that the operation is simple, time and labor can be saved and the working efficiency is high.

Owner:SHAOXING UNIVERSITY

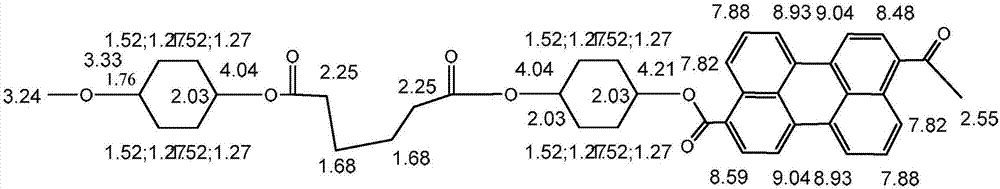

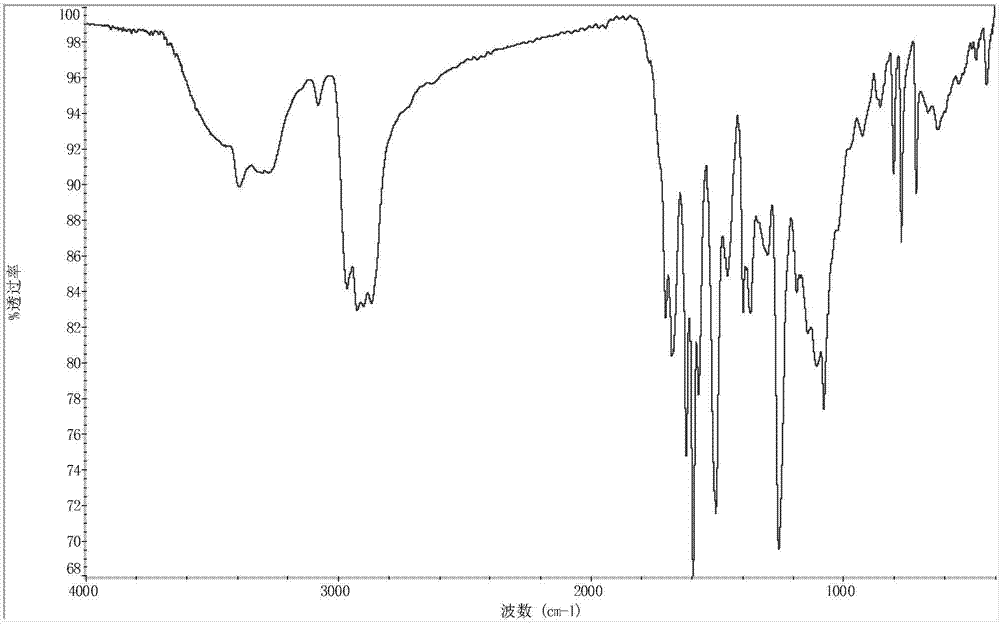

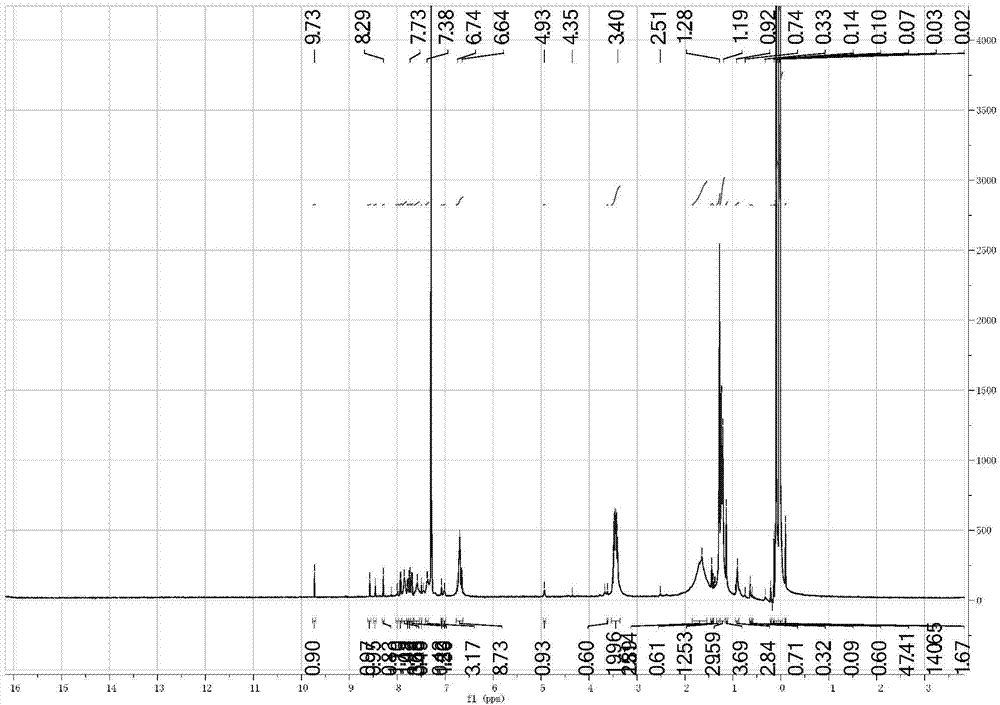

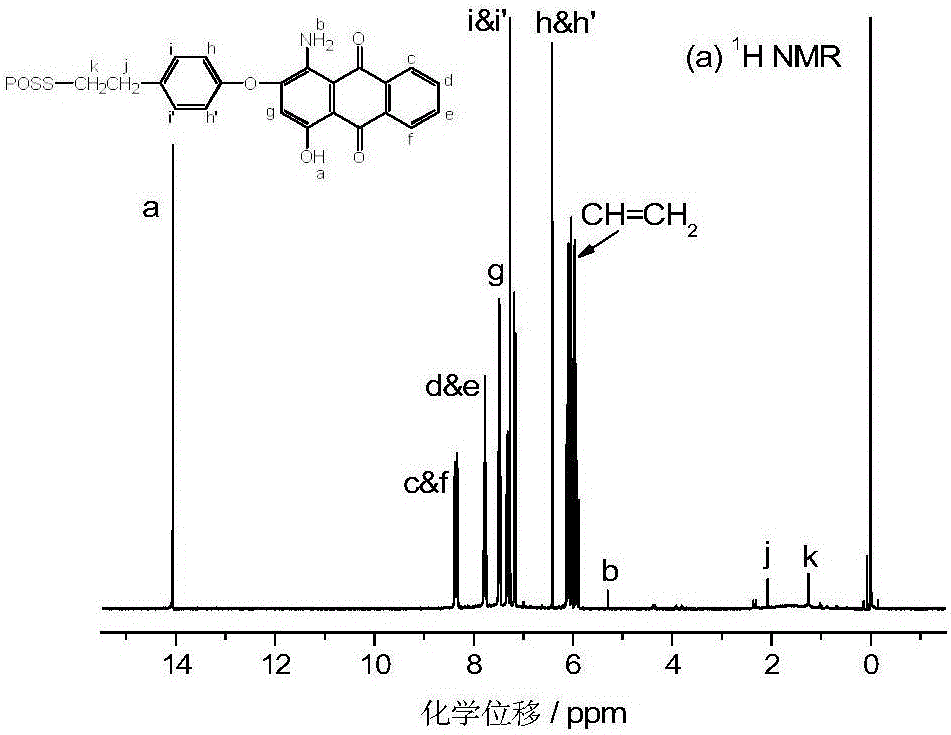

Alicyclic polyester type polymer dye for polypropylene plastic dyeing and preparation method thereof

ActiveCN107022066AGood chemical stabilityImprove migration resistanceOrganic dyesPolyesterPolymer science

The invention discloses an alicyclic polyester type polymer dye for polypropylene plastic dyeing and a preparation method thereof, and the method is as follows: a carboxylic acid or anhydride type organic small molecular is combined with a polyester backbone of a dicarboxylic acid alicyclic diol by two-step esterification to prepare the alicyclic polyester type polymer dye, and the dye content in the polymer is 1%-30%. The prepared alicyclic polyester type polymer dye prepared by the method is well compatible with polypropylene plastics after addition of a compatibilizing agent, has the advantages of even and full dyeing and excellent migration resistance performance, and can meet the application of the colored polypropylene plastics in the textile, food packaging and other fields.

Owner:宁波龙欣精细化工有限公司

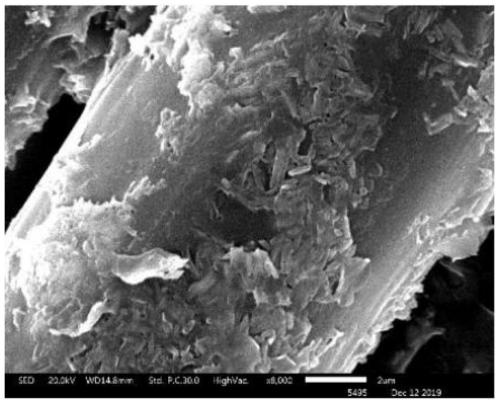

Black inorganic fiber and plasma preparation method thereof

The invention relates to a black inorganic fiber and a plasma preparation method thereof, and particularly discloses a black inorganic fiber. The black inorganic fiber comprises a fiber matrix and carbonized sugar attached to the fiber matrix, wherein the fiber matrix is an inorganic fiber capable of tolerating heat at the temperature of 500 DEG C, such as a basalt fiber, a ceramic fiber, a quartzfiber and a sepiolite fiber. The carbonized sugar attached to the fiber matrix is obtained by the following method: 1) pretreatment: carrying out surface modification on the fiber matrix by using wetplasma to obtain activated fibers, and soaking the activated fibers in a sugar aqueous solution under the action of tension; and 2) carbonization dyeing: carbonizing the soaked fibers obtained in thestep (1) at a high temperature to obtain the inorganic fibers with carbonized sugar attached to the fiber matrix after dyeing. The black inorganic fiber is novel and unique, simple in preparation method, environment-friendly and pollution-free.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

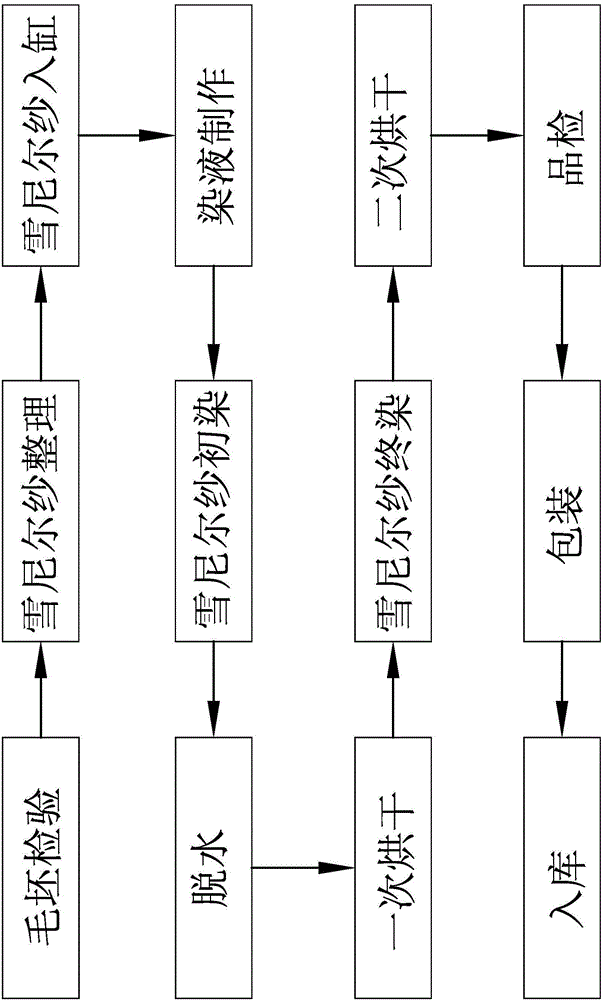

Cloud dyeing method for chenille yarn

InactiveCN105714498AAchieve preparationImprove uniformitySucessive textile treatmentsTextile treatment machine arrangementsProduct inspectionYarn

The invention provides a cloud dyeing method for a chenille yarn, belongs to the technical field of dyeing, and solves the problem of poor three-dimensional effect after the chenille yarn is dyed in the prior art. The cloud dyeing method for the chenille yarn comprises the following steps: A, inspecting blank; B, tidying the chenille yarn; C, placing the chenille yarn into a dyeing vat; D, preparing a dye liquor; E, performing primary dyeing on the chenille yarn, namely, conveying the dyeing liquor into the dyeing vat of primary dyeing equipment, and primarily dyeing the chenille yarn through the dyeing vat, wherein the dyeing time is 150 to 200 minutes; F, dewatering; G, performing primary drying; H, performing final dyeing on the chenille yarn, namely conveying the dyeing liquor into final dyeing equipment, and finally dyeing the chenille yarn through a dyeing gun in the final dyeing equipment, wherein the dyeing time is 100 to 120 minutes; I, performing secondary drying; J, performing product inspection; K, packaging; L, warehousing. The cloud dyeing method for the chenille yarn has the advantages of good there-dimensional effect.

Owner:HAINING SAURER YARN

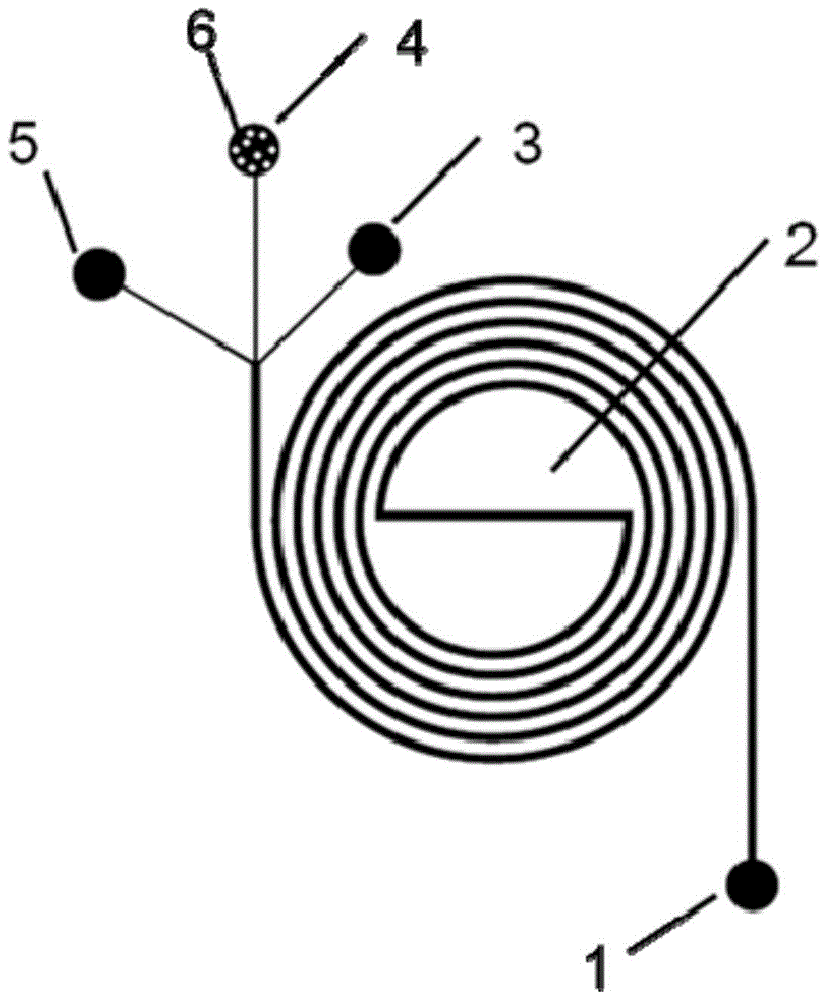

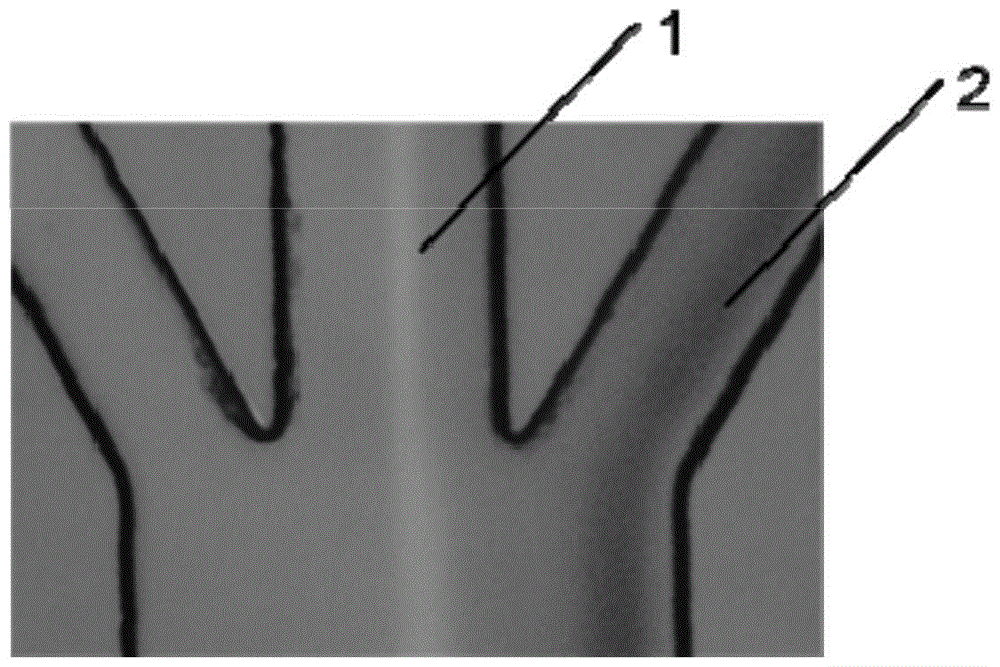

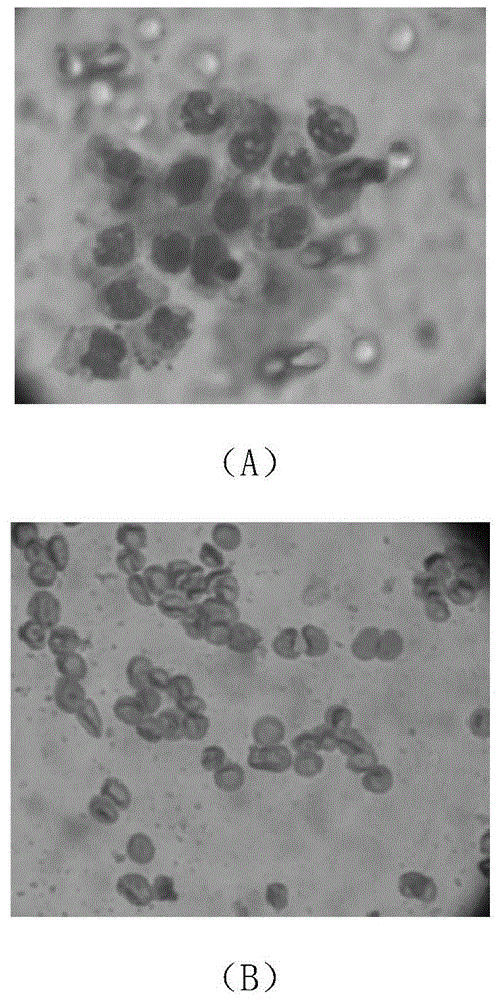

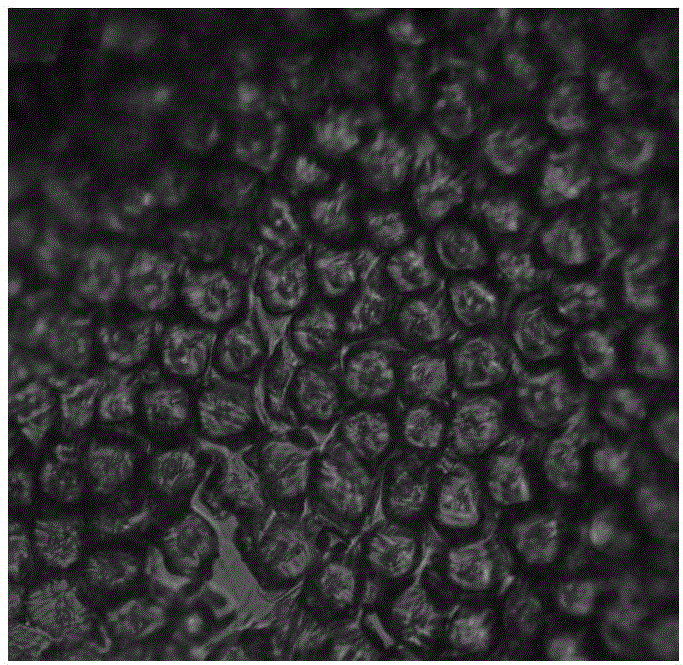

A double helix microfluidic chip

ActiveCN104111190BHigh enrichment rateEasy to shapePreparing sample for investigationLaboratory glasswaresWhite blood cellDisease patient

The invention relates to a double-helix microfluidic chip, which includes a chip inlet, a double-helix chip, a red blood cell outlet, a white blood cell outlet, a fluid outlet and a cell filter membrane, wherein the chip is composed of a double-helix channel, and the double-helix channels are respectively Open holes along the tangent direction of two parallel chips to form two parallel and opposite openings, one opening is connected with the chip inlet, and the other opening is connected with the red blood cell outlet, the white blood cell outlet and the fluid outlet respectively. The double-helix microfluidic chip can automatically load samples, stain and wash samples, and can separate and enrich white blood cells of leukemia patients' blood or / and pleural effusion with high throughput and automation, which greatly improves the accuracy of diagnosis. Accuracy and precision, it can also be used for the separation of diseased white blood cells in patients, and has a therapeutic effect.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

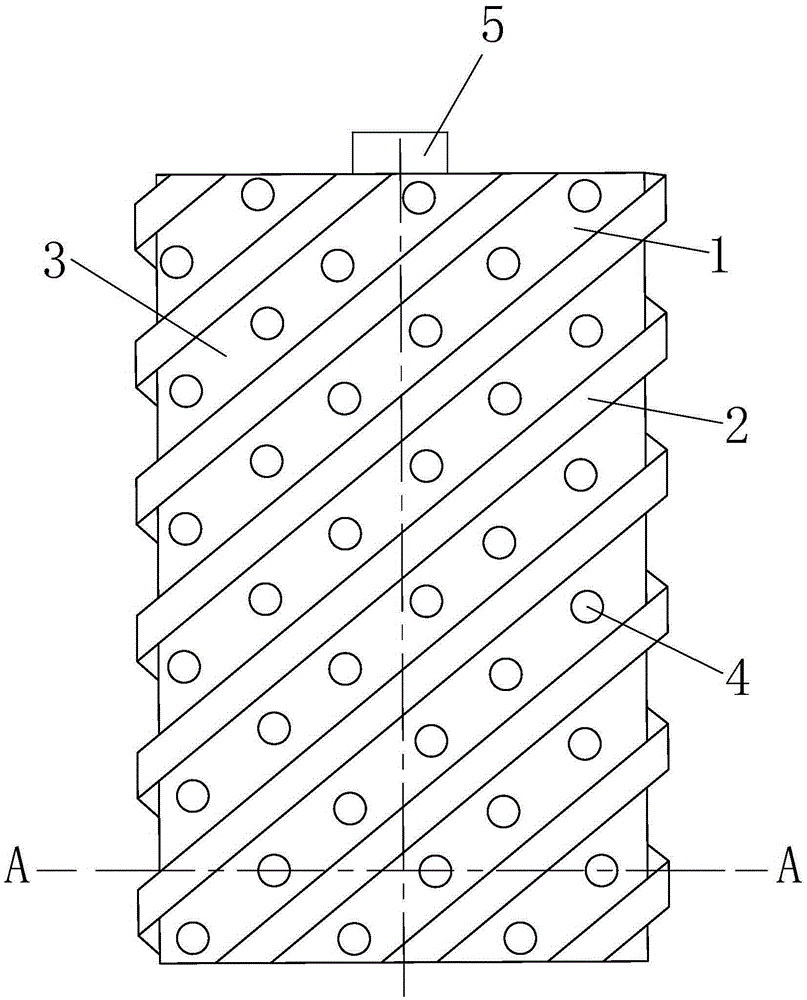

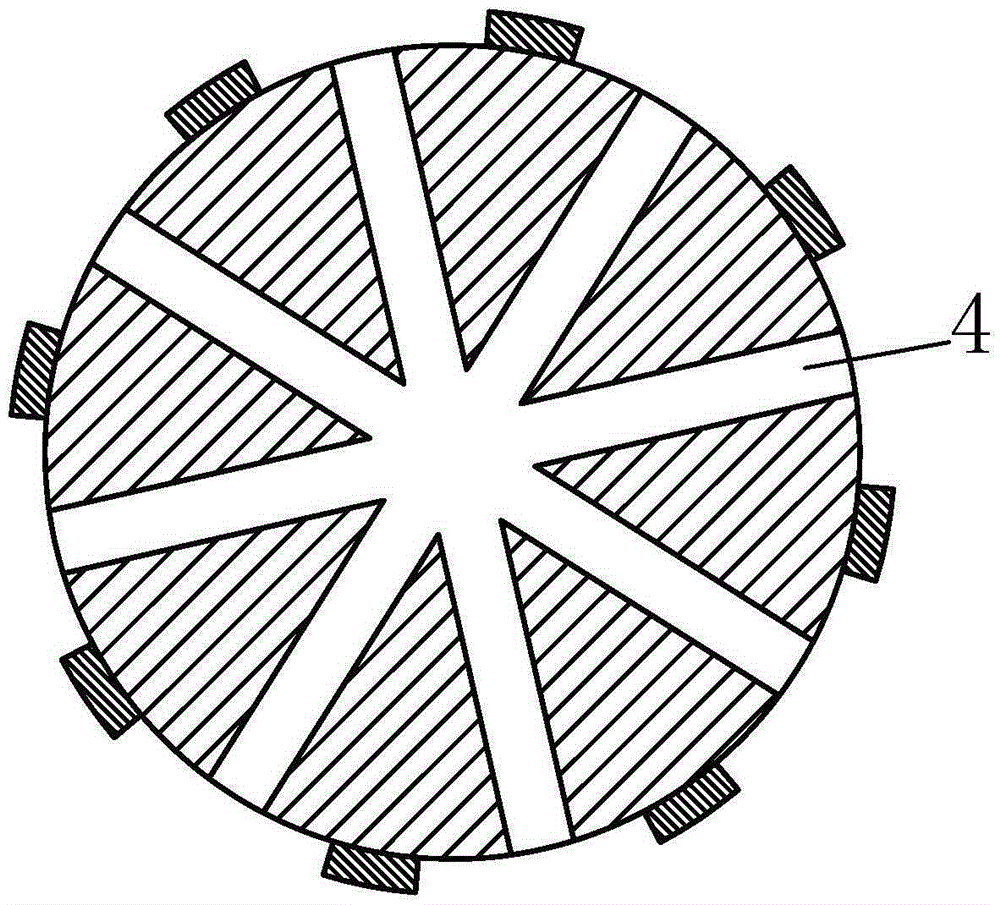

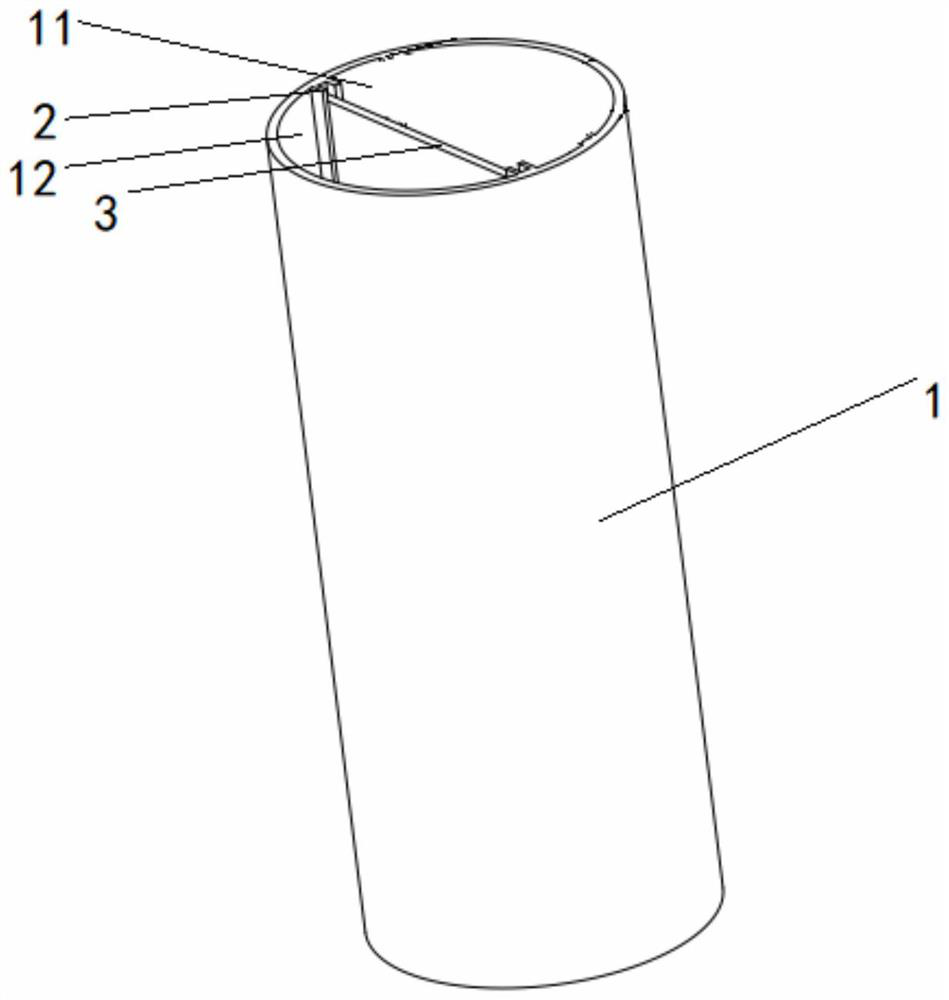

Dyeing wheel for shuttlecock coloring machine

InactiveCN105344073AImprove aestheticsGuaranteed stained areaBall sportsMechanical engineeringFeather

The invention relates to a dyeing wheel for a shuttlecock coloring machine. The dyeing wheel comprises a wheel body which is of a cylindrical structure, spiral limiting protrusions are arranged on the wheel body 1, spiral dyeing grooves are formed among the spiral limiting protrusions, material permeating holes distributed radially are uniformly formed in each spiral dyeing groove, and the upper end face of the wheel body is provided with a feeding port which is communicated with the material permeating holes respectively. The dyeing wheel has the advantages of reasonable structure design and low production cost, dyeing of feathers of shuttlecocks can be realized, and dyeing area and dyeing quality of the shuttlecocks are guaranteed while attractiveness of the shuttlecocks is improved.

Owner:安徽省无为县奥宇体育用品有限公司

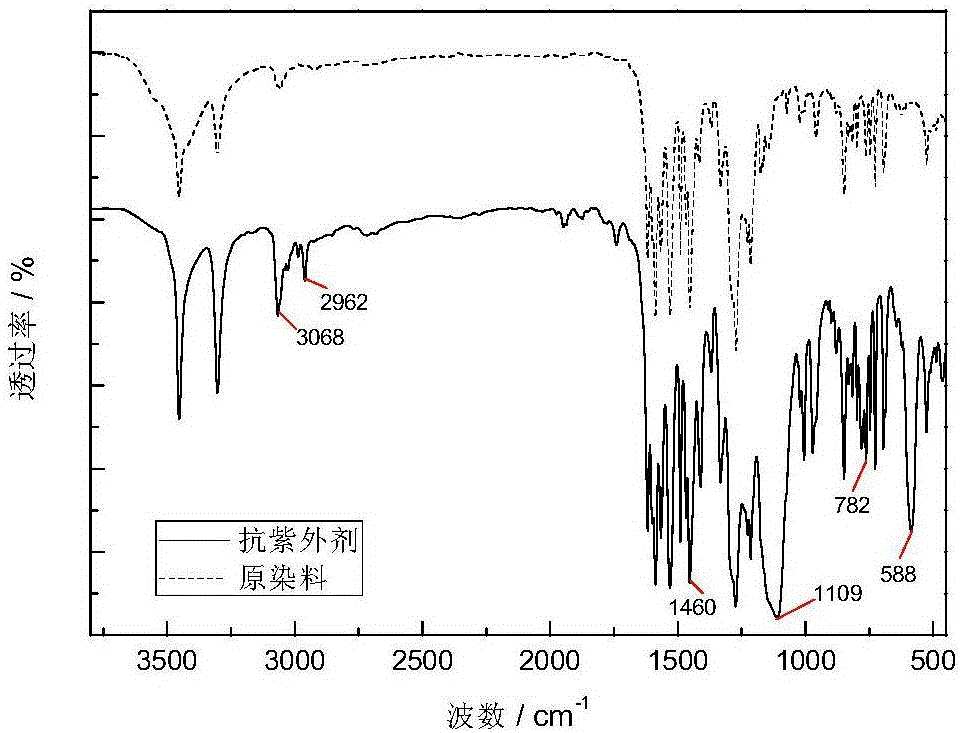

Treatment method of ultraviolet-resistant aromatic high-performance fiber

ActiveCN106436311AAchieve dyeingLong-lasting anti-ultraviolet functionLight resistant fibresDyeing processFiberHigh pressure

The invention discloses a treatment method of an ultraviolet-resistant aromatic high-performance fiber. The method comprises the steps that an ultraviolet-resistant treating agent is prepared into a treating solution with the bath ratio of 15-50 to 1 according to the fiber weight of 1.5-5%, even stirring is performed, the pH of the ultraviolet-resistant treating agent is regulated to be 5-7, then the aromatic high-performance fiber is put in the ultraviolet-resistant treating agent, and treatment is performed according to the steps and conditions of a conventional high temperature and high pressure dyeing process (shown in the description). By the adoption of the treatment method, the aromatic high-performance fiber can play a lasting ultraviolet-resistant function, can also synchronously achieve corresponding fiber dyeing, the strength retention rate of the fiber subjected to ultraviolet irradiation is effectively improved, an operation process is simple, and the conditions are easy to control. The method is suitable for industrialized production.

Owner:CHENGDU TEXTILE COLLEGE

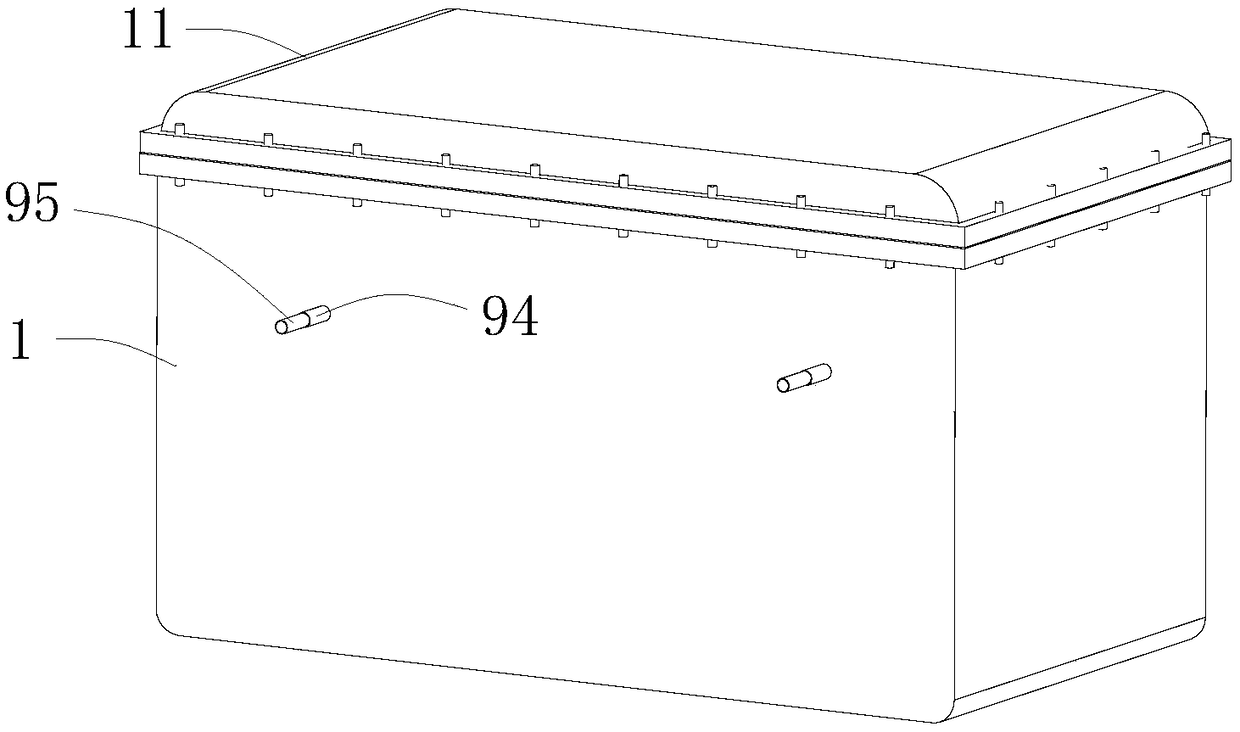

Industrial fireproof heat-insulation fiber cloth pasting and dyeing device

ActiveCN113445227AAchieve dyeingEasy to collectLiquid/gas/vapor removal by scrapingTextile treatment carriersPolymer chemistryDyeing

The invention relates to a dyeing device, in particular to an industrial fireproof heat-insulation fiber cloth pasting and dyeing device. The invention mainly provides the industrial fireproof heat-insulation fiber cloth pasting and dyeing device which can dye and roll fiber cloth at the same time by means of a machine, so that efficiency is improved. The industrial fireproof heat-insulation fiber cloth pasting and dyeing device comprises a base, wherein a driving mechanism and a rolling mechanism are arranged at the top of the base; and the driving mechanism is located on the inner side of the rolling mechanism. By arranging the driving mechanism, the rolling mechanism and a feeding mechanism, the cloth is driven to be drawn out and tightened and is in contact with sponge with pigment at the same time, so that dyeing of the cloth is achieved.

Owner:钟丹敏

Pretreatment tube and pretreatment method for liquid-based cell sample

PendingCN112834308AAchieve dilutionAchieve enrichmentPreparing sample for investigationStainingPretreatment method

The invention relates to the technical field of medical treatment, in particular to a pretreatment tube and a pretreatment method for a liquid-based cell sample.The pretreatment pipe comprises a pipe body; a pair of slots which are formed in the inner wall of the pipe body; an inserting plate, the width of the inserting plate is matched with the spacing distance of the pair of inserting grooves, and the inserting plate is used for being embedded into the pair of inserting grooves so as to divide the pipe body into a first cavity and a second cavity which are closed with each other; a filter membrane is arranged on the insertion plate and is provided with a plurality of filter holes, and the size of the filter holes is smaller than that of the cells to be treated. According to the technical scheme, the pretreatment tube has the beneficial effects that the insertion plate is arranged in the tube body of the pretreatment tube to divide the tube body into the first cavity and the second cavity, and the insertion plate is provided with the filter membrane with the filter holes, so that the tube body is not only used for storing cell samples, but also can realize other reaction functions such as dilution, enrichment and dyeing in the tube body.

Owner:南京九川科学技术有限公司

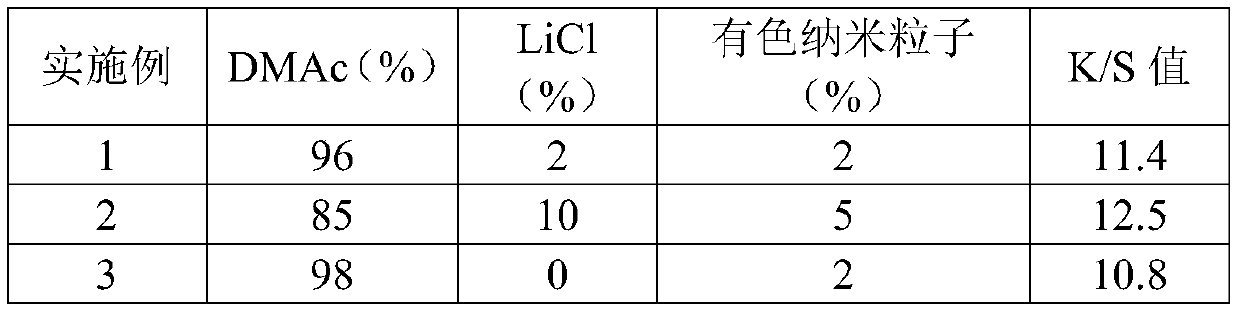

Method for dyeing high-performance fiber with liquid membrane in seconds

The invention discloses a method for dyeing a high-performance fiber with a liquid membrane in seconds. Firstly, the high-performance fiber is immersed in a dye solution configured by N,N-dimethylacetamide, LiCl and colored nanoparticles; a pretreated high-performance fiber is subjected to a high-temperature oil bath treatment; through the smaller molecular structures of N,N-dimethylacetamide andthe strong electronegativity of the amide carbonyl group, the fiber surface roughness and porosity in the high-performance fiber can be effectively increased, and more colored particles can be easilyabsorbed; at the same time, the high-temperature and high-pressure steam in an oil bath dyeing process can produce a certain internal and external pressure difference in pores of the high-performancefiber surface; and the interaction of N,N-dimethylacetamide and LiCl further inhaled into the inner layer of high-performance fiber, so as to realize fast dyeing of high-performance fiber. The printing and dyeing efficiency and fixing rate of the high-performance fiber are effectively improved, and the application of the high-performance fiber is easily expanded.

Owner:WUHAN TEXTILE UNIV

A paste dyeing device for industrial fire-proof and heat-insulating fiber cloth

ActiveCN113445227BAchieve dyeingEasy to collectLiquid/gas/vapor removal by scrapingTextile treatment carriersFiberProcess engineering

The invention relates to a dyeing device, in particular to a pasting dyeing device for industrial fire-proof and heat-insulating fiber cloth. The main purpose is to provide an industrial fire-proof and heat-insulating fiber cloth pasting and dyeing device that relies on the machine to dye and wind the fiber cloth while improving the efficiency. An industrial fire-proof and heat-insulating fiber cloth pasting and dyeing device includes: a base, a driving mechanism and a rolling mechanism are arranged on the top of the base, and the driving mechanism is located inside the rolling mechanism. By setting a driving mechanism, a rolling mechanism and a feeding mechanism, the cloth is driven to be pulled out and tightened while being in contact with the sponge with pigments, thereby realizing the dyeing of the cloth.

Owner:钟丹敏

A kind of dyeing method of nylon

ActiveCN108049213BAchieve dyeingHigh color fastness to bleedingDyeing processPolymer scienceTextile dyeing

The invention belongs to the technical field of textile dyeing, and particularly relates to a dyeing method of chinlon. According to the method, final cleaning is performed through high-molecular polymer, so that dyeing of chinlon is realized. The dyeing method is stable in technology, the flow is easy to control, and dyed fabric does not have defects, such as dyeing defects and color spots, and is high in bleeding resistance color fastness, high in washing color fastness and rubbing color fastness are high, and good in quality.

Owner:FUJIAN LONGYAN XIQUE TEXTILE

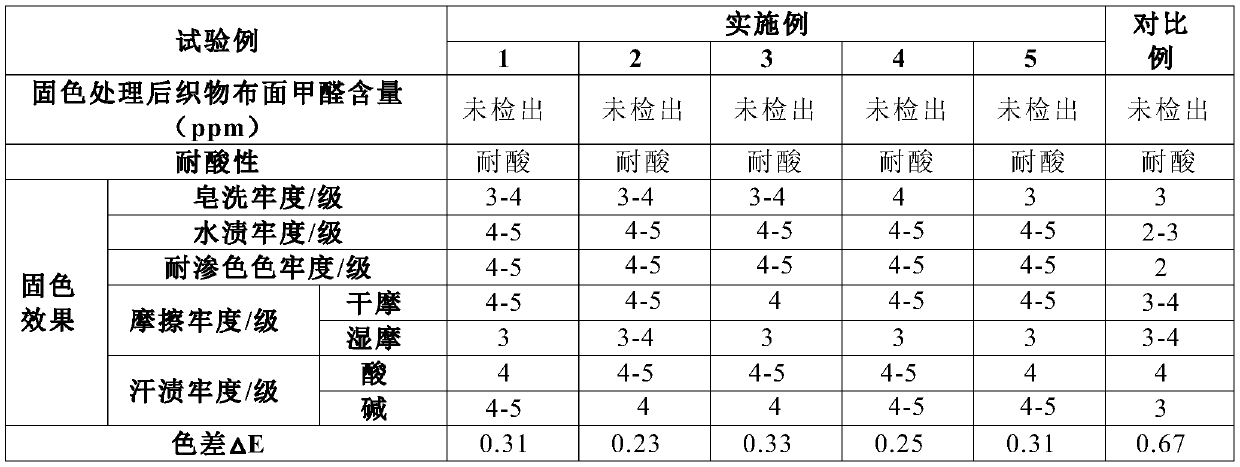

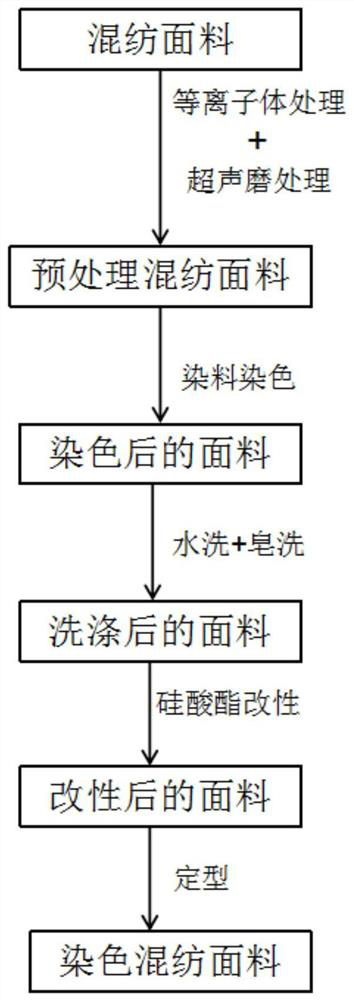

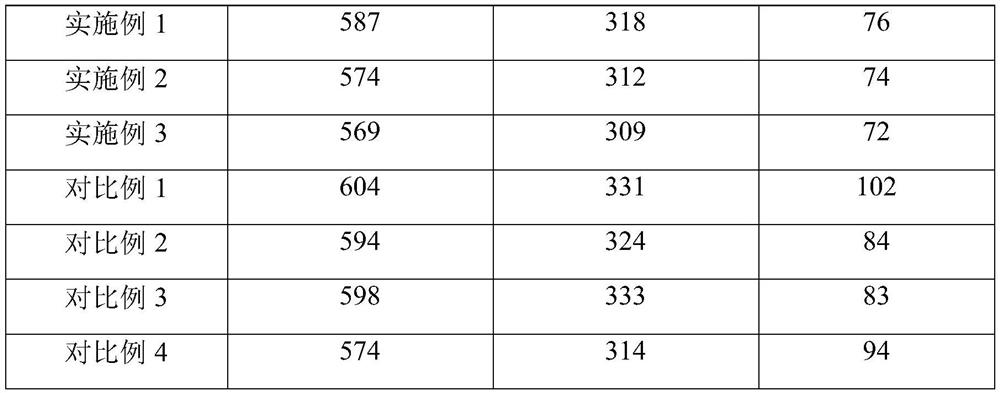

Dyeing process of blended fabric

ActiveCN114855474AImprove hydrophilicityImprove loftLight resistant fibresUltrasonic/sonic fibre treatmentColour fastnessFiber

The invention relates to a dyeing process of a blended fabric. The dyeing process sequentially comprises the following steps of pretreatment, dyeing, water washing and soaping, modification treatment and sizing. According to the method, the hydrophilicity and the bulkiness of the fabric can be improved through plasma treatment and ultrasonic treatment, so that the fabric can react with dye more easily, the blended fabric is dyed, and the dyeing uniformity and the color fastness are improved. After dyeing, water washing and soaping are completed, the blended fabric is further subjected to silicate ester modification, Si-O bonds can be generated on the fiber surface through silicate ester modification to form a three-dimensional network film, the dyeing color fastness can be further improved, and the hydrophilicity of the blended fabric is further improved. The natural plant dye is adopted to dye the blended fabric, and the natural plant dye has degradability, so that the dyeing method is healthier and more environmentally friendly.

Owner:JIANGSU DINGXIN PRINTING & DYEING

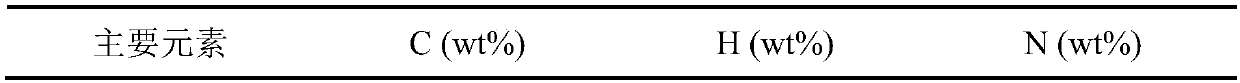

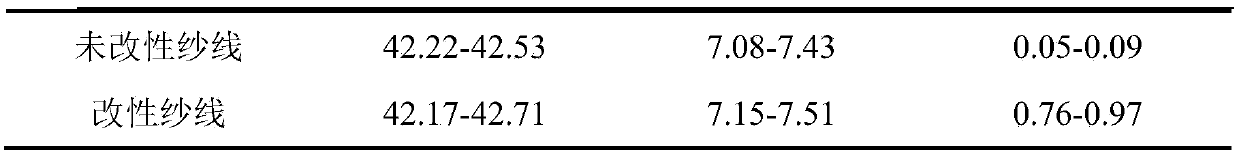

A method of ammonification modification of ramie fiber and its application method in liquid ammonia solvent dyeing

The invention relates to an ammoniation modification method of ramine fibers and an application method thereof in liquid ammonia solvent dyeing, and belongs to the technical field of textile chemistry. The ammoniation modification method comprises the following steps: pretreatment of the ramine fibers: selecting ramine yarns from the ramine fibers, placing the ramine yarns in a 200 mL of NaOH solution of which the concentration is 15%, heating to the temperature of 50 DEG C, insulating for 4 hours, and cleaning with running water until pH of eluate is 7-8 to obtain pretreated yarns; modification to the pretreated yarns: adding 10-15 mL of formaldehyde, 1-2 mL of boracic acid and 150 mL of deionized water in a three-necked flask with the volume of 250 ml, stirring uniformly, adding the pretreated ramine yarns, heating the reaction temperature to be 40 DEG C, feeding ammonia, refluxing, stirring and reacting for 3 hours, taking out the yarns after reaction is finished, washing with the deionized water, and drying the yarns after pH of the eluate is 6-7 to obtain the ammoniation modified ramine yarns. The ammoniation modification method of the ramine fibers is used in ramine fiber liquid ammonia solvent dyeing, and dyeing uniformity of the ramine fibers can be improved obviously.

Owner:博森纺织科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com