Extruding dyeing method of thin wood plate

A dyeing method and technology for wood, applied in wood treatment, wood processing equipment, wood treatment details, etc., can solve the problems of large amount of waste water, high energy consumption of thermal diffusion dyeing, and unsuitable for environmental protection requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

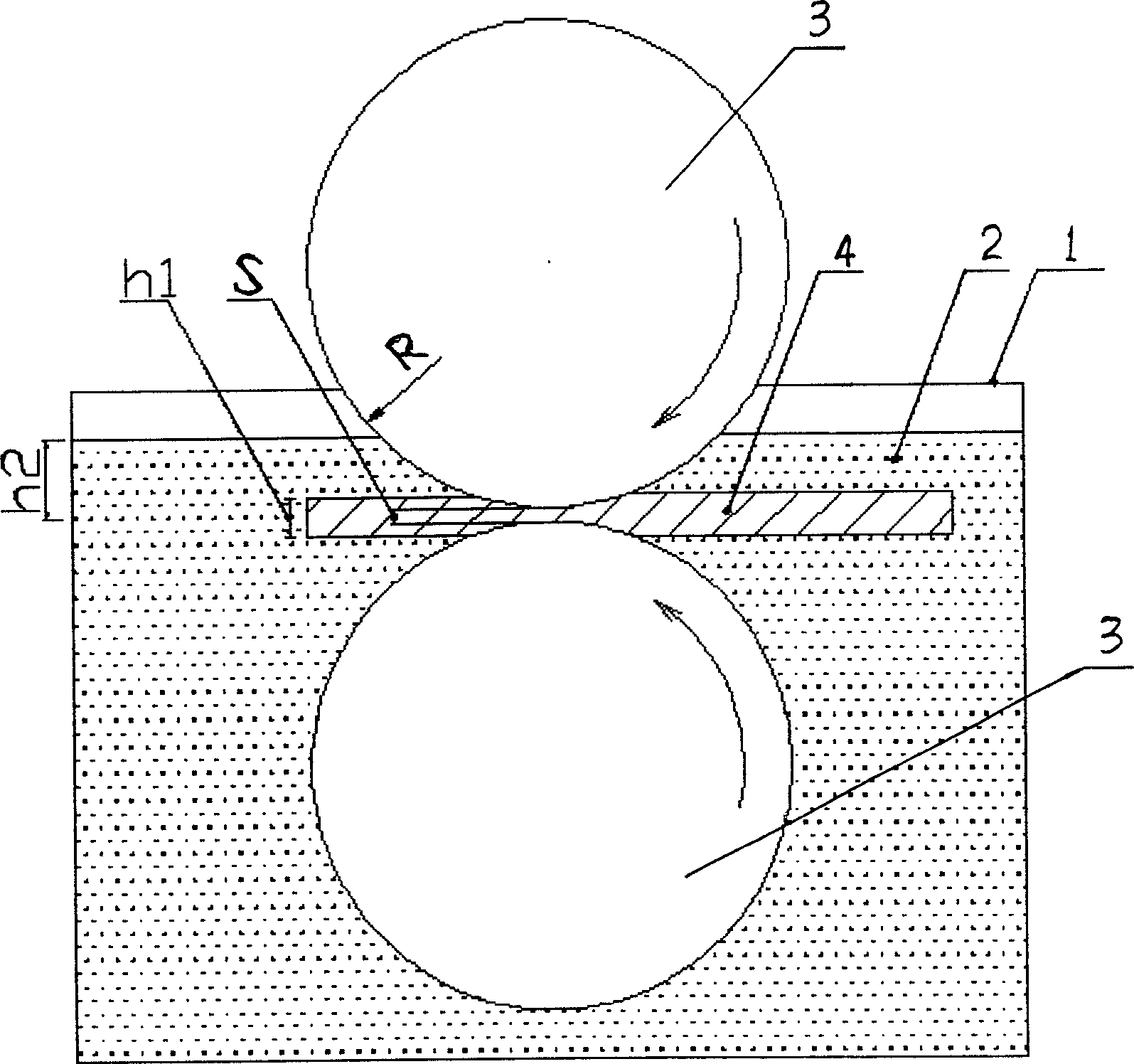

[0019] The invention discloses a wood veneer extrusion dyeing method, which combines figure 1 as shown in

[0020] The specific operation process is described as follows:

[0021] (1) Preparation of dyeing solution: prepare a suitable wood dyeing solution according to the target color, the coloring agent includes chemical coloring agent or chemical dyestuff, and auxiliary agent corresponding to the coloring agent, and the concentration of the solution is 0.0001% to 5%. The concentration depends on the species of wood to be dyed, the depth of dyeing, the type of dye and other factors. For example, for poplar veneer coloring, dye coloring, use acid dyes, direct dyes, reactive dyes, etc., and use corresponding penetrating agents and color fixing agents as auxiliary agents; when chemical coloring, use pyrogallic acid, catechol etc. as a chromogenic agent, and ferric chloride is used as an auxiliary agent, and the concentration is preferably 0.1% to 0.5%. The dyeing solution can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com