Method for dyeing high-performance fiber with liquid membrane in seconds

A high-performance fiber and liquid film technology, which is applied in the field of textile printing and dyeing, can solve the problems of weak interface fastness, easy peeling off of color paste film, and difficulty in dyeing bright colors of high-performance fabrics, etc., to achieve increased roughness and increased porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for dyeing high-performance fibers in seconds with a liquid film, comprising the following steps:

[0039] S1, pretreatment of high-performance fibers: soak meta-aramid high-performance fibers in N, N-dimethylacetamide (DMAc), 3% LiCl, and 3% pigments by mass ratio: 96% Red 101 colored nano-particles in the dye solution for 75s, then take it out, dry it with filter paper, and control the liquid-carrying rate of the high-performance fiber after treatment to 100%;

[0040] S2. High-temperature oil bath dyeing: place the high-performance fiber pretreated in step S1 in methyl silicone oil at 200°C, perform high-temperature treatment for 15 seconds, take it out, cool it, and wash it with ethanol, detergent, and water in sequence, and then use Ultrasonic washing with 50% ethanol aqueous solution for 10 minutes, finally rinsing with running water, and drying at 80°C to obtain the meta-aramid fiber dyed by the liquid film in seconds.

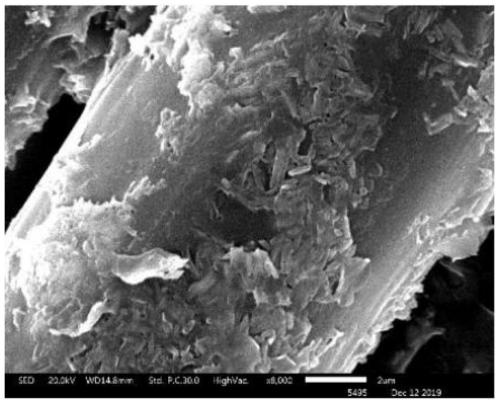

[0041] figure 1 It is the scann...

Embodiment 2-3

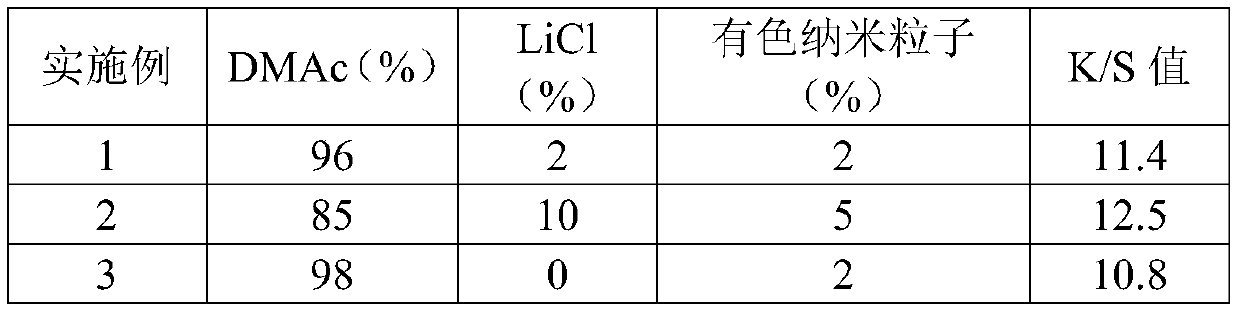

[0043] Embodiment 2-3 provides a method for dyeing high-performance fibers in seconds with a liquid film. Compared with Embodiment 1, the difference is that the mass ratio of each component in the dyeing solution described in step S1 is changed, except for the above differences , other operations are the same, and will not be repeated here; the specific experimental conditions, parameters and test results are shown in the table below.

[0044]

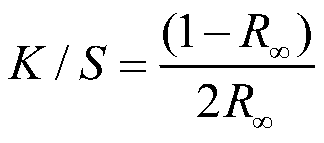

[0045] Comparing the results of Examples 1 to 3, it can be seen that changing the dosage ratio of each component in the dyeing solution in the pretreatment process of high-performance fibers will have a significant impact on the dyeing depth of high-performance fibers. Comparing Examples 1-2 and Example 3 The results show that the present invention achieves rapid dyeing of high-performance fibers through the action of high-temperature and high-pressure steam in the process of high-temperature oil bath treatment and cooperates with Li...

Embodiment 4-10

[0047] Embodiment 4-10 provides a method for liquid film instant dyeing of high-performance fibers. Compared with Embodiment 1, the difference is that the high-temperature oil bath treatment temperature and frying time in step S2 are changed. In addition to the above differences, other The operations are the same and will not be repeated here; the specific experimental conditions, parameters and test results are shown in the table below.

[0048] Example temperature(℃) time(s) K / S value 4 150 15 10.5 5 165 15 13.2 6 250 15 9.8 7 260 15 7.5 8 200 1 5.6 9 200 30 10.3 10 200 35 10.6

[0049] Comparing the results of Example 1 and Examples 4-7, it can be seen that with the increase of the high temperature oil bath treatment temperature in step S2, the dyeing depth of high-performance fibers first increases and then decreases.

[0050] Comparing the results of Example 1 and Examples 8-10, it can be seen that with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com