Double-component polyurethane water-based paint

A two-component polyurethane and water-based coating technology, applied in the field of polyurethane, can solve the problems of reducing coating performance, reducing matting effect, uneven dispersion of matting powder, etc., to increase roughness and unevenness, and overcome uneven storage stability Good, the effect of reducing the gloss of the coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

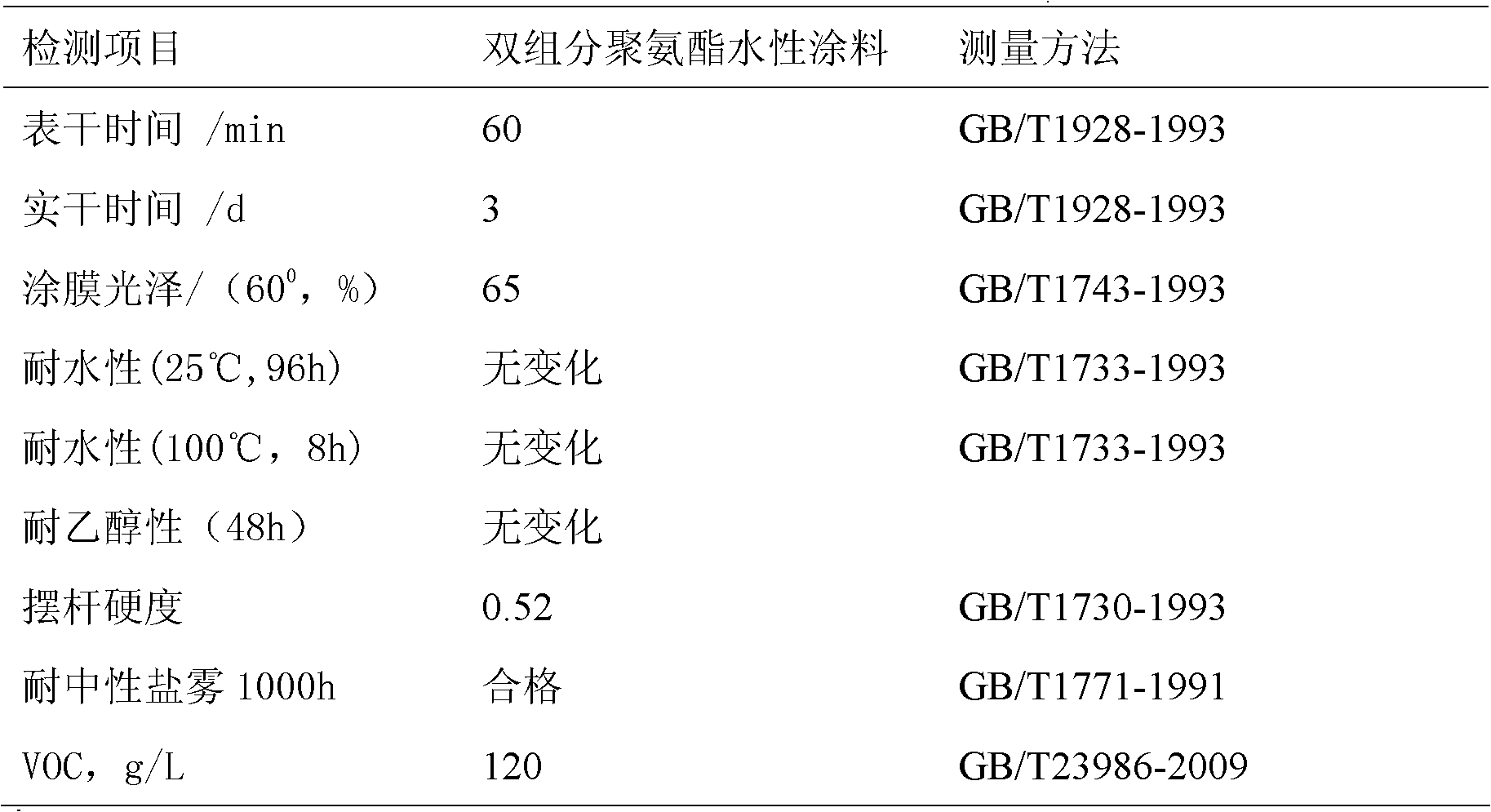

Embodiment 1

[0027] (a) Two-component polyurethane water-based coating

[0028] (1) Formula

[0029] (I) Component A

[0030] Polymer aqueous dispersion: 40g polyacrylate aqueous dispersion Bayhydrol XP2651;

[0031] Polymer emulsion: 20g polyacrylate emulsion AC-261, 40g polyacrylate emulsion (Bayhydrol XP2546);

[0032] Water: 15g

[0033] (II) Component B

[0034] Isocyanate curing agent: 10g of XP2655 from Bayer Corporation of Germany, 5g of N3390 from Bayer Corporation of Germany.

[0035] The molar ratio of polymer OH group in component A to isocyanate curing agent NCO group in component B is 1:1.6.

[0036] (b) Preparation of two-component polyurethane water-based coating

[0037] Disperse the aqueous polymer dispersion and polymer emulsion at 800 RPM for 15 minutes to obtain component A; mix XP2655 and N3390 uniformly to obtain component B. Stir and mix component A and component B evenly, and cure at room temperature for 7 days.

[0038] (c) prepare two-component polyuretha...

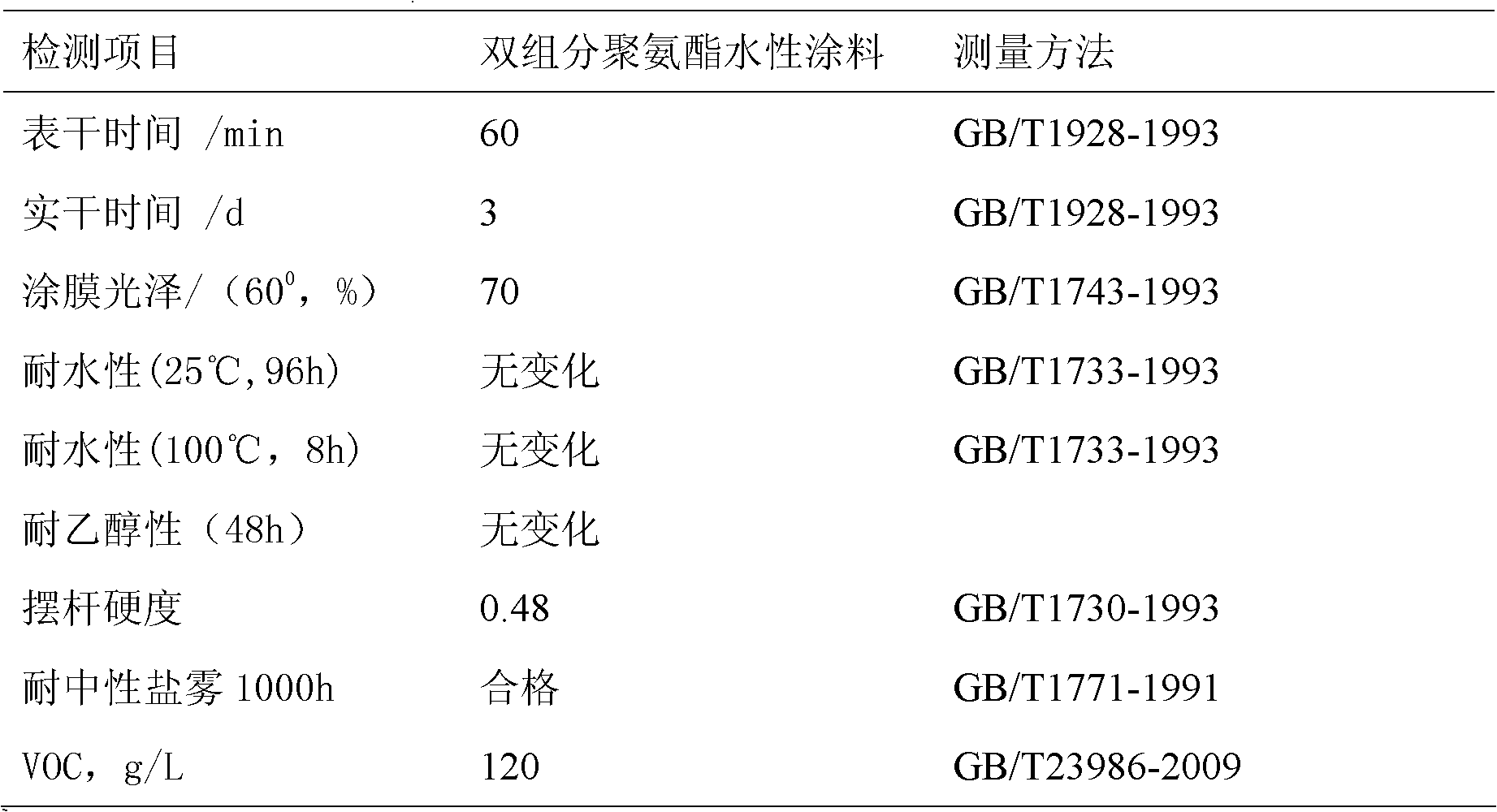

Embodiment 2

[0043] (a) Two-component polyurethane water-based coating

[0044] (1) Formula

[0045] (I) Component A

[0046] Polymer aqueous dispersion: 15g polyacrylate aqueous dispersion Bayhydrol XP2651;

[0047] Polymer emulsion: 90g polyacrylate emulsion AC-261;

[0048] Water: 25g

[0049] (I) Component B

[0050] Isocyanate curing agent: 5g hexamethylene diisocyanate trimer, 5g hexamethylene diisocyanate biuret, 5g trimer of isophorone diisocyanate.

[0051] The molar ratio of polymer OH group in component A to isocyanate curing agent NCO group in component B is 1:1.3.

[0052] (b) Preparation of two-component polyurethane water-based coating

[0053] Disperse the aqueous polymer dispersion and polymer emulsion at 800RPM for 15 minutes to obtain Component A; mix the trimer of hexamethylene diisocyanate, hexamethylene diisocyanate biuret and isophorone diisocyanate evenly to obtain Component B. Stir and mix component A and component B evenly, and cure at room temperature for 7...

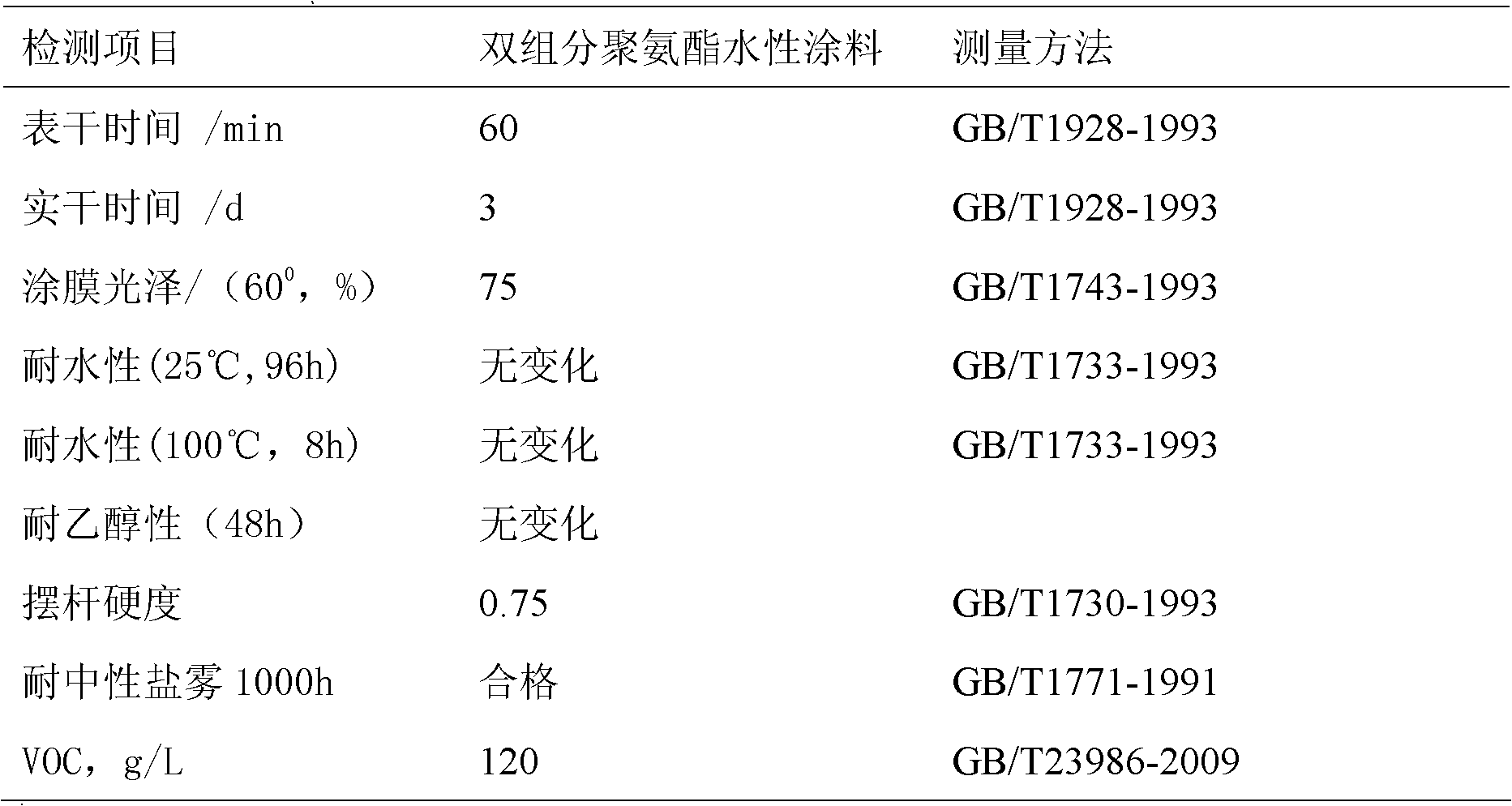

Embodiment 3

[0059] (a) Two-component polyurethane water-based coating

[0060] (1) Formula

[0061] (I) Component A

[0062] Polymer aqueous dispersion: 70g Bayer's polyacrylate aqueous dispersion Bayhydrol XP2651, 10g Bayer's polyurethane aqueous dispersion VPLS 2303;

[0063] Polymer emulsion: 8g polyacrylate emulsion AC-261, 2g alkyd resin emulsion YF155 from Guangzhou Yifu Chemical Co., Ltd.;

[0064] Matting powder: 0.5g OK607 from Degussa Company;

[0065] Film-forming aids: 2.5g dipropylene glycol methyl ether, 1.0g propylene glycol butyl ether;

[0066] Wetting agent: 0.5g TEGO-245;

[0067] Defoamer: 0.2g TEGO-805, 0.3g TEGO-815;

[0068] Thickener: 0.2g SN-612;

[0069] Water: 4.8g

[0070] (I) Component B

[0071] Isocyanate curing agent: 15g XP2655 of German Bayer Company, 5g of N3390 of German Bayer Company.

[0072] The molar ratio of polymer OH group in component A to isocyanate curing agent NCO group in component B is 1:2.2.

[0073] (b) Preparation of two-comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com